Page 1

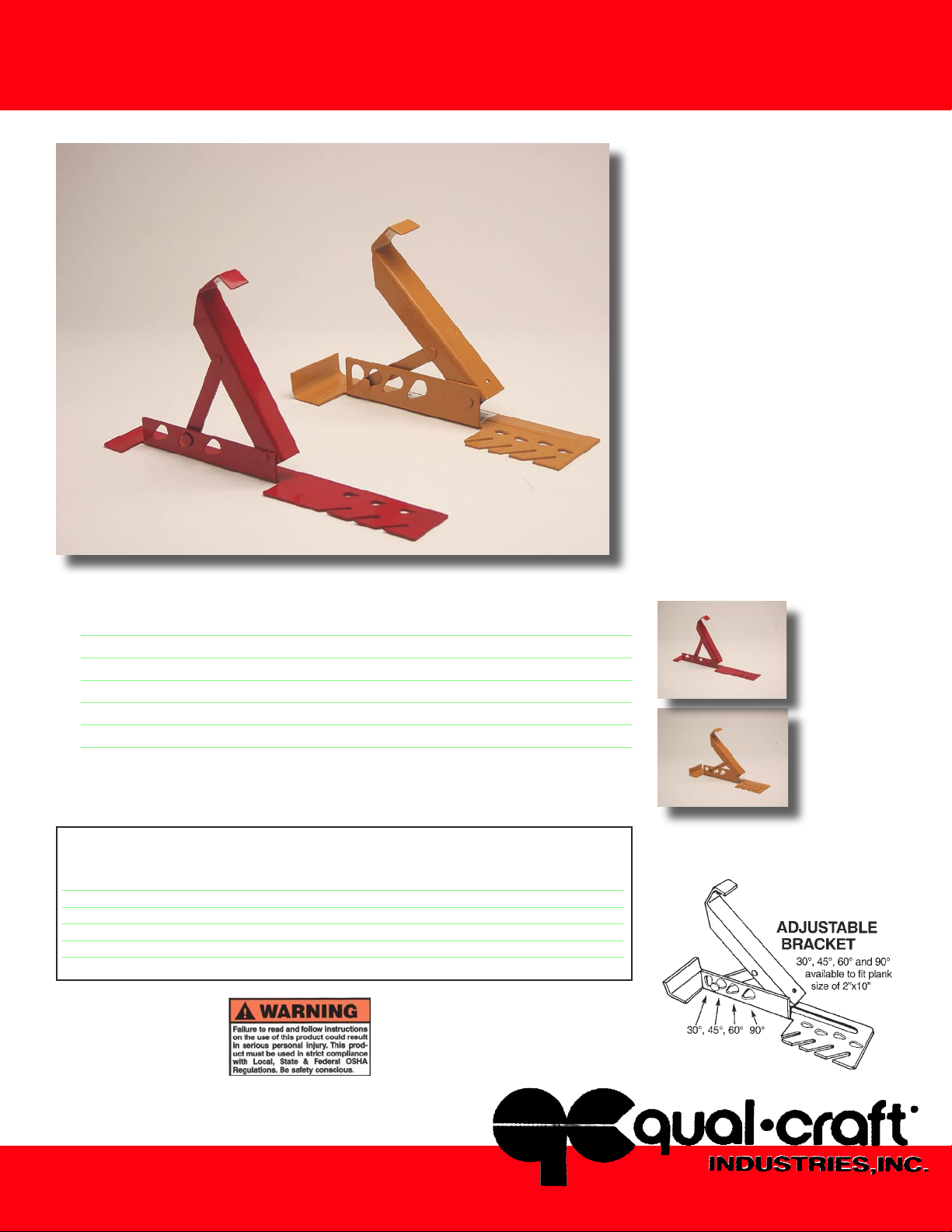

STEEL • ADJUSTABLE ROOFING BRACKETS

Model #3500

Model #2500

ROOFING

PRODUCTS

Adjustable Steel

Roof Brackets

Heavy Duty Model #2500

PRO-line Model #3500

Durable heavy duty steel construction. Designed to hold a 10”

platform. Easy installation and removal without damaging shingles.

Adjustable three or four position

platform, dependent on model line.

Additional safety features include a

platform retainer and unique locking

mechanism Capacity: 1 worker per

8’ staging plus 40 lbs. Maximum 8’

spacing between brackets.

Easy to set up, operate, reposition

and take down without damage to

shingles. Folds at for compact

storage.

For use on VARIABLE PITCH ROOFS AND PROJECTS

HEAVY DUTY - Model #2500 10" x [ 30º, 45º, or 60º ]

PRO-LINE - Model #3500 10" x [ 30º, 45º, 60º, or 90º ]

Product Specications

Model # 2500 3500

Description: 10” Adjustable 10” Adjustable Welded w/Gusset

Unit Pack: 10 / Carton 12 / Carton

Weight per Pack: 24 Pounds / Carton 45 Pounds

Cu. Ft. per Pack: .52 cu. ft. 1.28 cu. ft.

Model #2500

Model #3500

© Copyright 2003 • Qual-Craft® Industries • 1551 Central Street

Customer Support and Ordering Information

PO Box 559 • Stoughton, MA 02072

781-344-1000 • www.qualcraft.com

Page 2

ROOFING

PRODUCTS

Model #2500

STEEL • ADJUSTABLE ROOFING BRACKETS

Model #2500

INSTRUCTIONS FOR INSTALLATION AND USE OF THE MODEL #2500 & #3500 10” ADJUSTABLE

ROOFING BRACKET: CAPACITY: One worker per 8 feet of scaffolding plus 40 pounds of materials.

GENERAL REQUIREMENTS: When installed, the platform support arm must be set to match the pitch

of the roof, allowing for the installation of a fully decked and level walk surface. MOUNTING THE

ROOF BRACKET: 1) All brackets shall be attached to the roof with 20-penny nails. Use all teardrop

holes on left or all slots on right side of mounting plate as desired. 2) Position bracket so that all nails

penetrate both the roof’s surface and the rafter below. 3) Spacing between brackets shall not exceed

8 feet. INSTALLING PLATFORM: 1) wood platforms shall not be less than 2 inches nominal thickness and shall extend beyond the support arm not less than 6 inches and not more than 12 inches.

2) Always use clear, straight-grained wood free from knots or defects. 3) If extended length platforms

are required, use additional Roof Brackets every 8 feet. 4) Secure to bracket by nailing the platform

to the bracket using the hole provided in the platform retainer. INSTRUCTIONS FOR USE: 1) No more

than one person shall occupy any given 8 feet of a Roong Bracket Scaffold. 2) Always use OSHA

compliant fall arrest system, guardrails, catch platforms or other safety equipment as required by Local, State or Federal OSHA Regulations. 3) Roof Brackets are intended for use by the experienced

tradesman. 4) OSHA Regulations require that employers provide training in the use and care of this

product. CARE AND MAINTENANCE: 1) Inspect all Roong Brackets before each use to be sure that

there is no damage or deformation, or deterioration from rusting. Discard if necessary. 2) Do not throw

or drop from a building or onto a truck. 3) Do not use if exposed to extreme heat or cold. Discard at

once. 4) Do not use if wet or frozen.

© Copyright 2003 • Qual-Craft® Industries • 1551 Central Street

PO Box 559 • Stoughton, MA 02072

Customer Support and Ordering Information

781-344-1000 • www.qualcraft.com

Loading...

Loading...