Page 1

LADDER JACKS

Two Rung Short Body

Three Rung Long Body

Model #2420, #2430, #2400

LADDER

ACCESSORIES

Aluminum

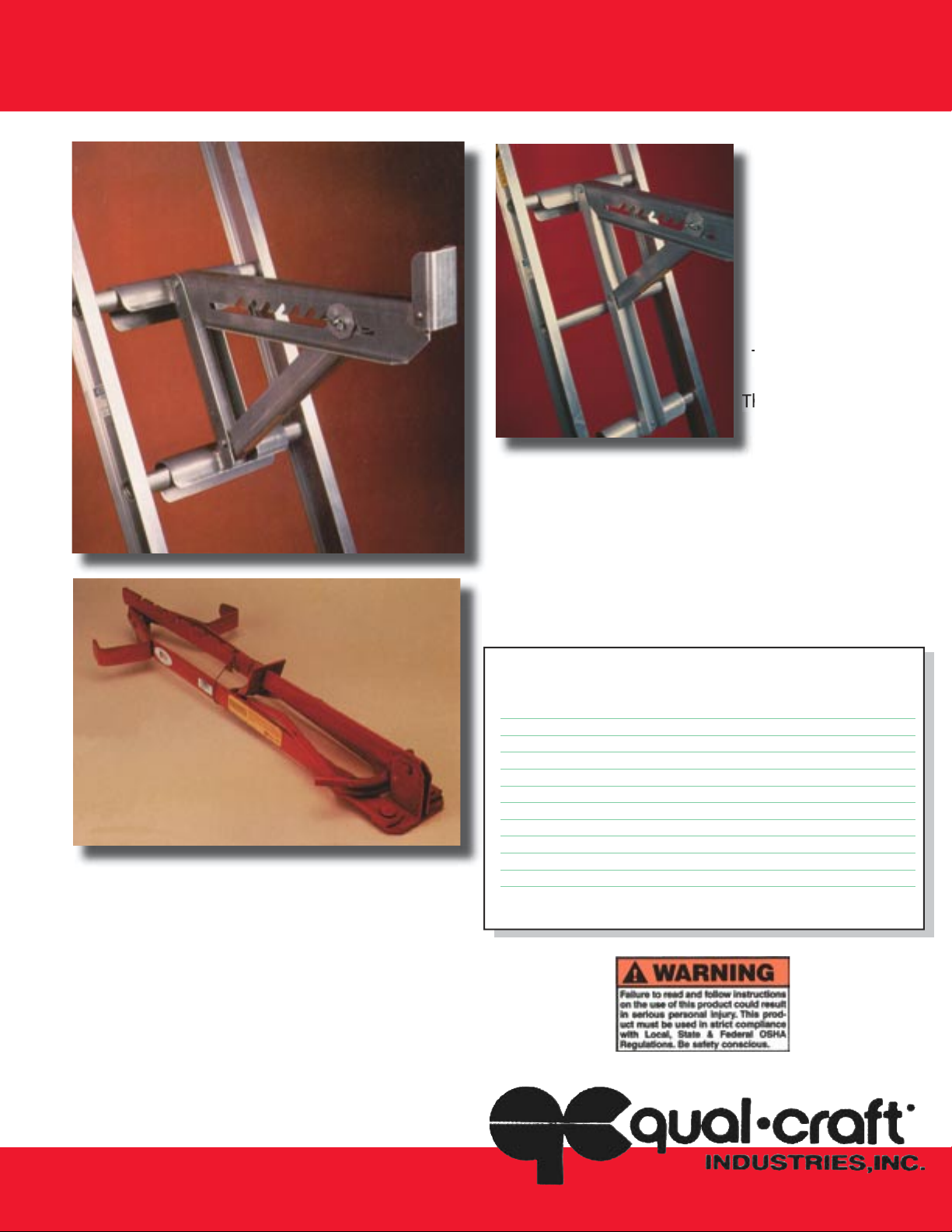

Ladder Jacks

Model # 2420

Model # 2430

MIG welded and riv et ed con struc tion for strength

and du ra bil i ty. This high quality aluminum ladder

jack will work on ei ther the in side or the outside of

the ladder's face, and will ac com mo date up to an

18” wide plank, and is ad just able to t round or

“D” rung lad ders.

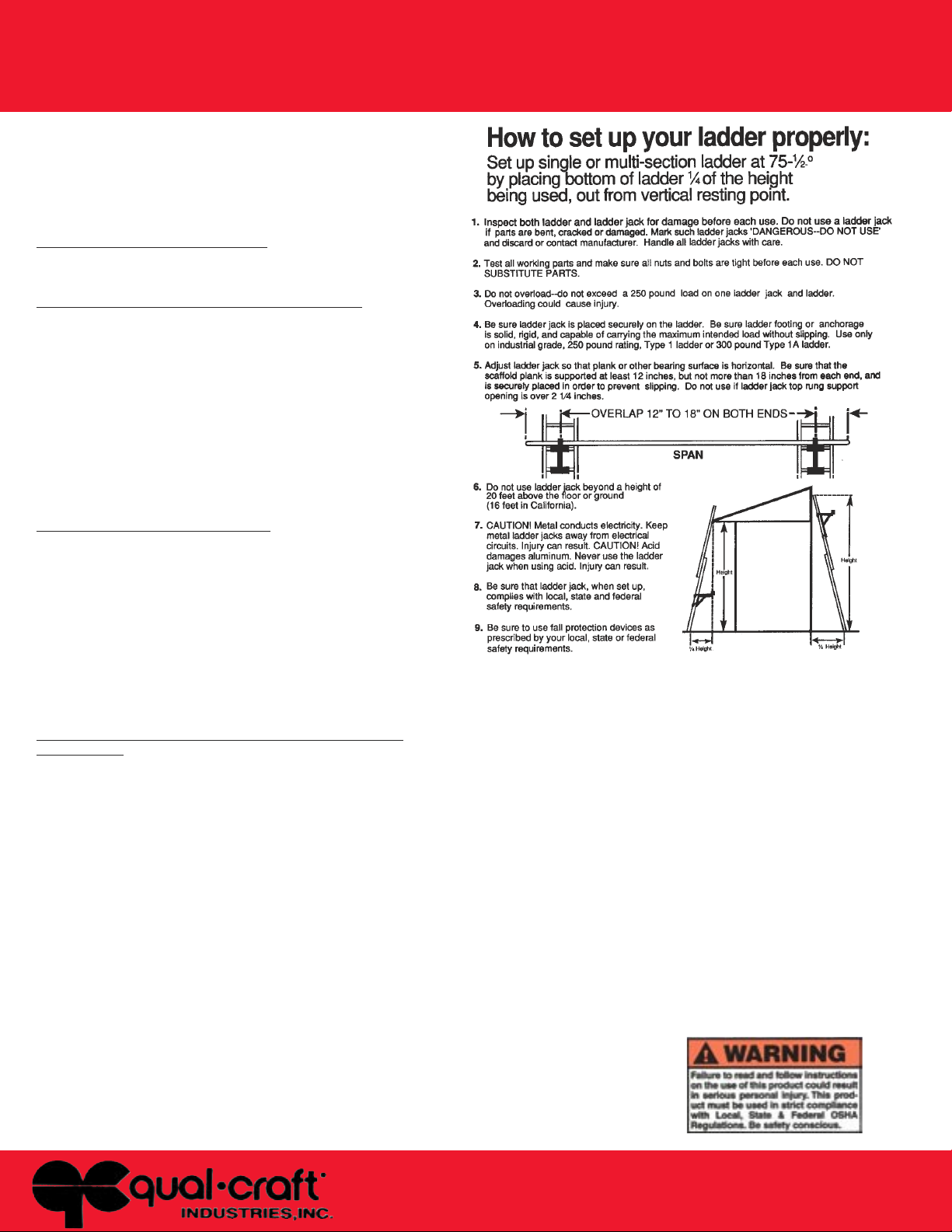

Side Rail Ladder Jack

Model #2400

These all steel con struct ed jacks fea ture capacity

for a 20” work platform, and t single or double

side rail ladders. Works in side or outside lad der,

and adjusts to t any pitch. Capacity is two work ers plus 75lbs. per staging, with no more than 8

feet spac ing be tween jacks. Plat form must be fully

decked with 2” thick planks, and is limited for use

to 20 feet above ground. Folds for convenient

stor age and trans port.

Product Speci cations

Model # 2400 2420 2430

Description: Side Rail Two Rung Three Rung

Steel Short Body Long Body

Unit Pack: 1 1 1

Weight per Pack: 11.6 Pounds 4.5 Pounds 5.5 Pounds

Cu. Ft. per Pack: .79 1.15 cu. ft. 1.77 cu. ft.

Customer Support and Ordering In for ma tion

781-344-1000 • www.qualcraft.com

Page 2

LADDER

ACCESSORIES

INSTRUCTIONS FOR THE INSTALLATION AND

USE OF LADDER JACK SCAFFOLD BRACKETS

– MODEL #2400, #2420 & #2430

Capacity: Two men per staging plus 75 pounds.

Ladder requirements:

Model #2400 Side Rail Steel Ladder Jack - Use on Industrial grade,

250 pound rated Type 1 or 300 pound rated Type 1A ladder

aluminum or wood ladders. Do Not Use with Fiberglass Ladders. This

style ladder jack should be used only with wooden walk planks.

Model #2420 & #2430 Aluminum Rung Style Ladder Jack - Use on

Industrial grade, 250 pound rated Type 1 or 300 pound rated Type

1A ladder aluminum or Fiberglass ladders. Do Not Use with Wood

Ladders.

Setting the Ladder:

Insure that both feet are secured rmly at ground level. The top

section of both ladders should rest at against the building. The

feet of each ladder should be set into the ground 3” to 4” when

an earthen base is available. If working on a solid base the ladder

should be equipped with proper cleats. The top of the ladder

should then be tied down to prevent slipping. The ladder must be

erected at a pitch of 75 degrees, in accordance with ladder safety

standards, so that the distance between the ladder base and the

vertical wall is one-quarter the working length of the ladder.

Attaching Ladder Jacks:

Model #2400 Side Rail Steel Ladder Jack: This ladder jack can

be installed both on the inside or the outer side of the ladder

depending on the distance between the ladder and the work wall.

The rectangular bars of the ladder jack attach to the ladder by

capturing each of the side-rails of the ladder as well as resting on

one of the ladder’s rungs. Be sure that the rectangular bars are

placed fully into the ladder’s opening and down onto the rung so

as to fully engage the rung. The round hook shaped bars of the

ladder jack should then be placed around the side-rails of the ladder,

resting above the rectangular bars. Adjust the gusset plate, which is

attached to the base of the round bars so that the rectangular bars,

which become the support arms for the platform, are parallel to

the ground creating a level platform. Secure gusset plate by sliding

rmly into the appropriate notch in the center bar.

Model #2420 & #2430 Aluminum 2-Rung and 3-Rung

Ladder Jack: This ladder jack can be installed both on the inside

or the outer side of the ladder depending on the distance between

the ladder and the work wall. Inspect all scaffold components for

damage before each use. Test all working parts and make sure all

nuts & bolts are tight before each use. Do not substitute parts.

Install ladder jack so that the rung support arms seat fully onto the

ladder rungs. Do not use if ladder jack top rung support opening is

over 2-1/4 inches. Adjust support arm so the arm is parallel to the

ground creating a level platform. Securely tighten the wing nut to

prevent slippage during use. Do not use ladder jack if parts are bent,

cracked, or damaged. Mark such ladder jacks “DANGEROUS – DO

NOT USE” and discard or contact manufacturer.

Setting the platform:

Adjust ladder jack so that walk plank is horizontal. Be sure that the

scaffold plank is supported at least 12 inches, but not more than

18 inches from each end and is securely placed in order to prevent

slipping. (Do not use extension planks on ladder jack scaffolds) Do

not use ladder jack scaffolding beyond a height of 20 feet (16 feet in

California) above the oor or ground. Failure to do so could cause

injury. Be sure that the ladder jack scaffold complies with local,

state and federal safety requirements. When using wooden walk

planks the distance between ladders should not exceed 8 feet. The

maximum plank length is 10 feet. Use clear straight-grained scaffold

grade lumber. Planking should not be less than 2” x 10” nominal

thickness. Always use two planks to fully deck the platform arms

(18” minimum width).

LADDER JACKS

Model #2420, #2430, #2400

Instructions for use:

No more than 2 people shall occupy any ladder jack scaffold. Only one set

of ladder jacks can be used between any two ladders. Do not install more

than one ladder jack per ladder. Do not overload – do not exceed 250

pound load on one ladder jack or ladder. Overloading could cause injury.

Do not step or stand on plank retaining tab (Model #2420 & 2430) .State

and Federal OSHA regulations require the use of an OSHA compliant fall

arrest system when working height exceeds 6 feet above the ground

Care and Maintenance:

Inspect ladder jack scaffold before and after each use, be sure that

there is no damage, deformation or rusting and that all nuts & bolts are

tight before each use. Discard if necessary. Do not throw or drop from

building or onto a truck. Always handle with care. Do not use if ladder

jack has been exposed to extreme heat or cold, discard at once. Do not

use if scaffold is wet or frozen. Federal Regulations require the user

have knowledge of all regulations that apply to the use and care of this

product and that the employer provide training.

CAUTION! Metal conducts electricity. Keep metal ladder and ladder

jacks away from electrical circuits. Injury can result.

CAUTION! Acid damages aluminum. Never use a ladder when using

acid. Injury can result.

© Copyright 2001-2003

Qual-Craft Industries, Inc.,

Stoughton, MA 02072

Customer Support and Ordering Information

781-344-1000 • www.qualcraft.com

Loading...

Loading...