Quadro WM-1042 LCD, WM-1242 LCD Service Manual

SERVICE MANUAL

White goods

Electronic washing machines

MODEL:

WM-1042 LCD

WM-1242 LCD

DISASSEMBLY

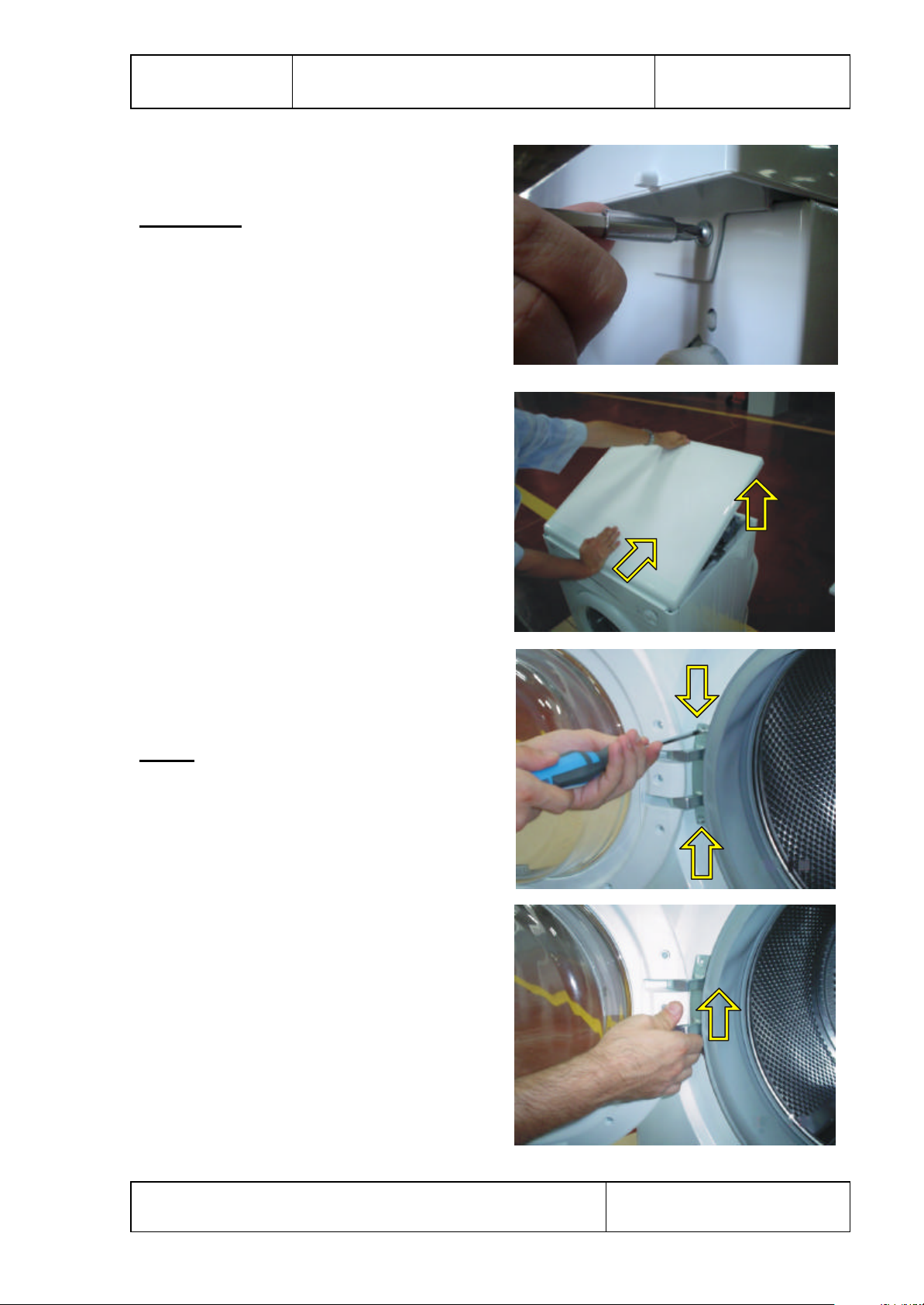

TOP PLATE

Remove two screws that fix the top-plate at

the back.

Push the top-plate back and pull it up.

DOOR

Remove two screws that fix the door.

Pull the door up.

1

Issue Date:01.08.2003 Documentation Number:

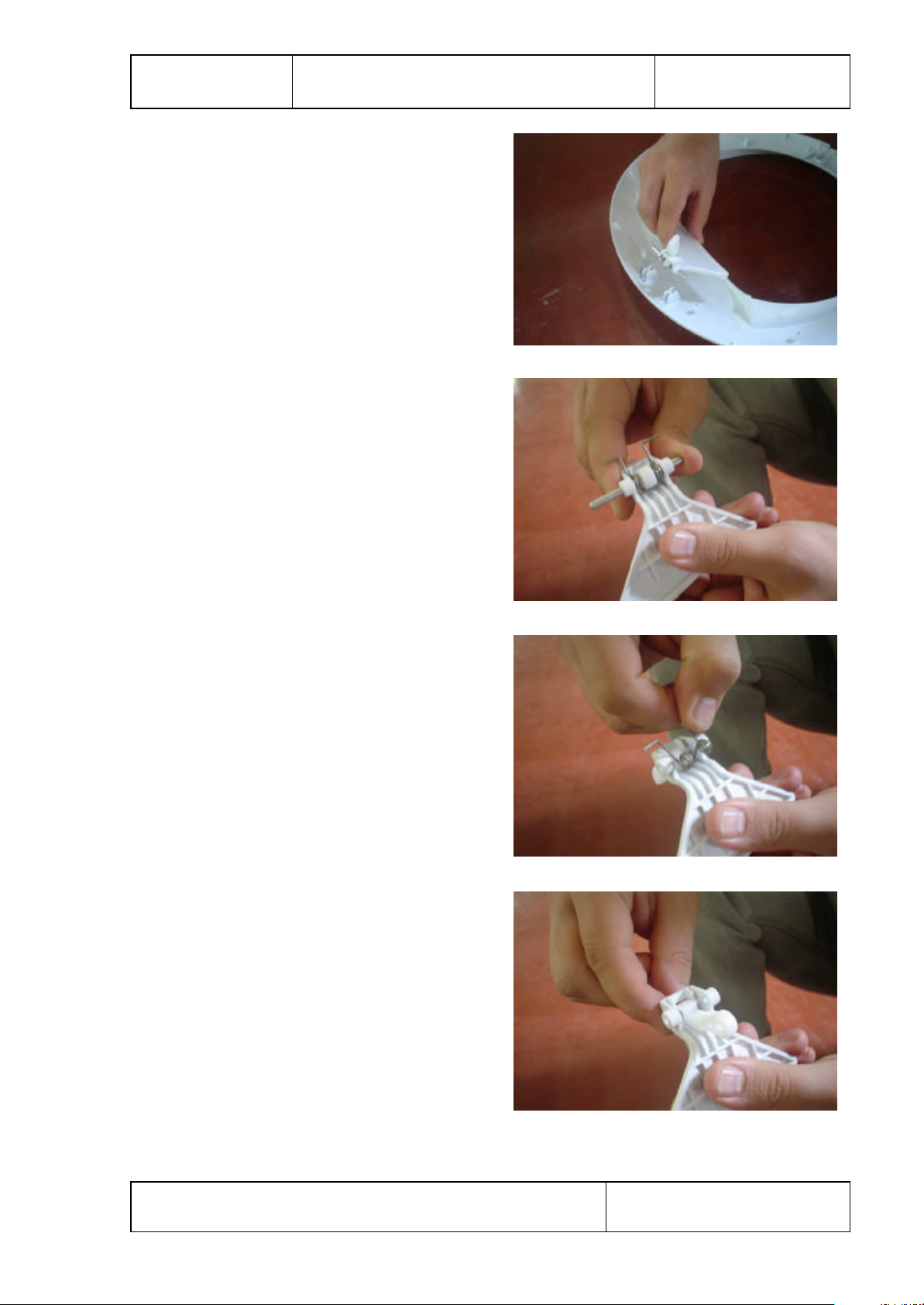

Remove nine screws that fix the door group.

Remove the door inside plastic as it is showing

the picture.

Remove the door hinge as it is showing

the picture.

Remove the door glass as it is showing

the picture.

2

Issue Date:01.08.2003 Documentation Number:

Remove the door handle as it is showing

the picture.

Remove the door handle pim as it is showing

the picture.

Remove the door handle spring as it is showing

the picture.

Remove the door lock tongue as it is showing

the picture.

3

Issue Date:01.08.2003 Documentation Number:

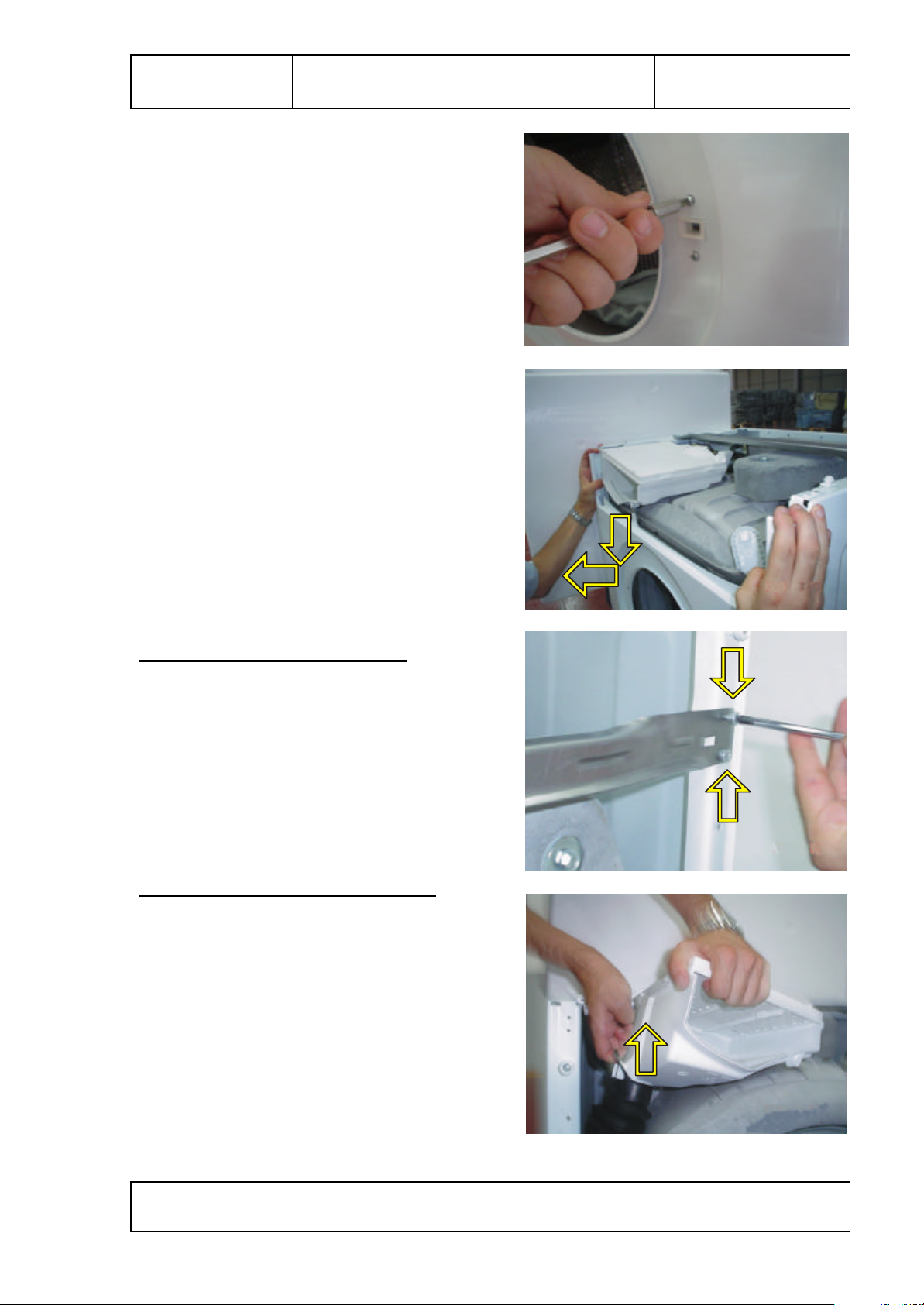

GASKET

Pull the gasket as it is showing in the picture.

Remove the gasket-body fixing string.

DETERGENT DRAWER

Remove the detergent drawer and pull it up

carefully.

CONTROL PANEL

Remove four screws which fix the control

panel to the front panel.

4

Issue Date:01.08.2003 Documentation Number:

Remove two screws fixing the control panel.

Remove one screws fixing the detergent box

group.

Pull the control panel up.

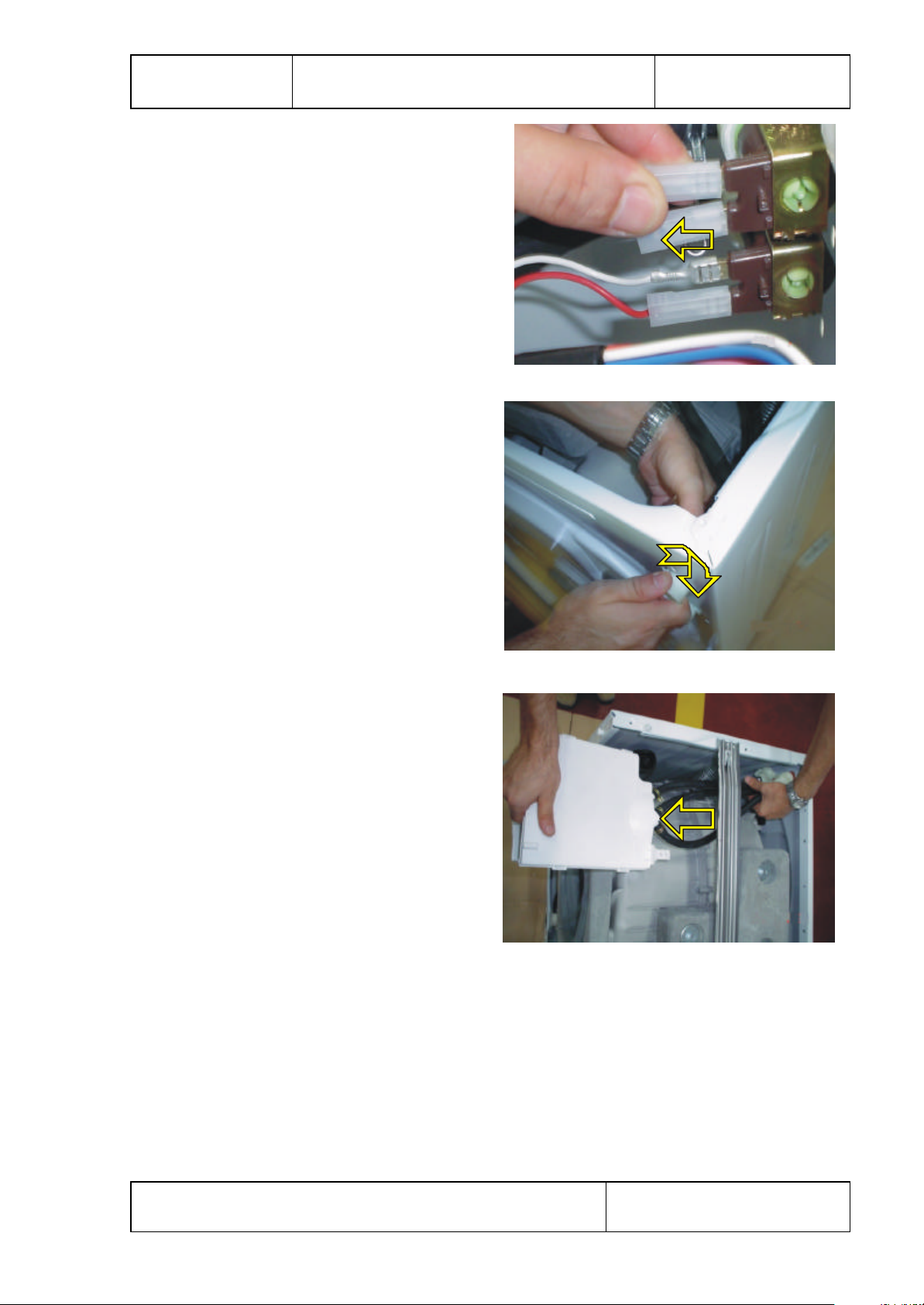

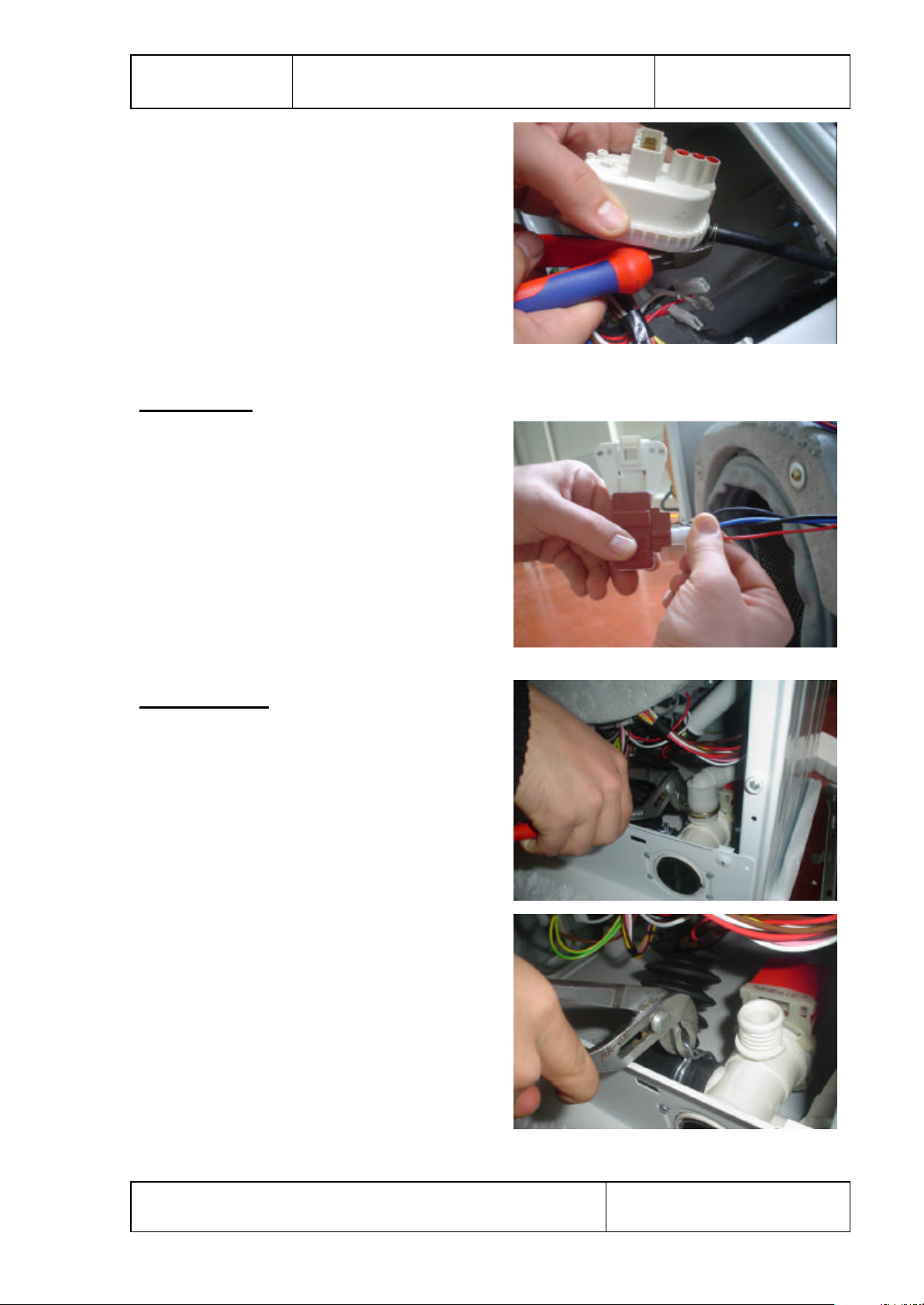

Remove wires as it is showing in the picture.

5

Issue Date:01.08.2003 Documentation Number:

Remove four screws fixing the electronic card.

Remove the electronic card as it is showing

the picture.

KICKPLATE

Remove the kickplate as it is showing

the picture.

FRONT PANEL

Remove two screws fixing the front panel

at the bottom.

6

Issue Date:01.08.2003 Documentation Number:

Remove two screws fixing the door lock.

Push it down and remove the front panel.

MEDIUM SUPPORT BRACKET

Remove four screws fixing the panel.

DETERGENT DRAWER HOUSING

Remove the tub seal connector, which is

attached to the detergent drawer housing.

7

Issue Date:01.08.2003 Documentation Number:

Remove the wire that is connected to

the valve.

Remove the valve connection.

Remove the detergent drawer housing

assembly.

8

Issue Date:01.08.2003 Documentation Number:

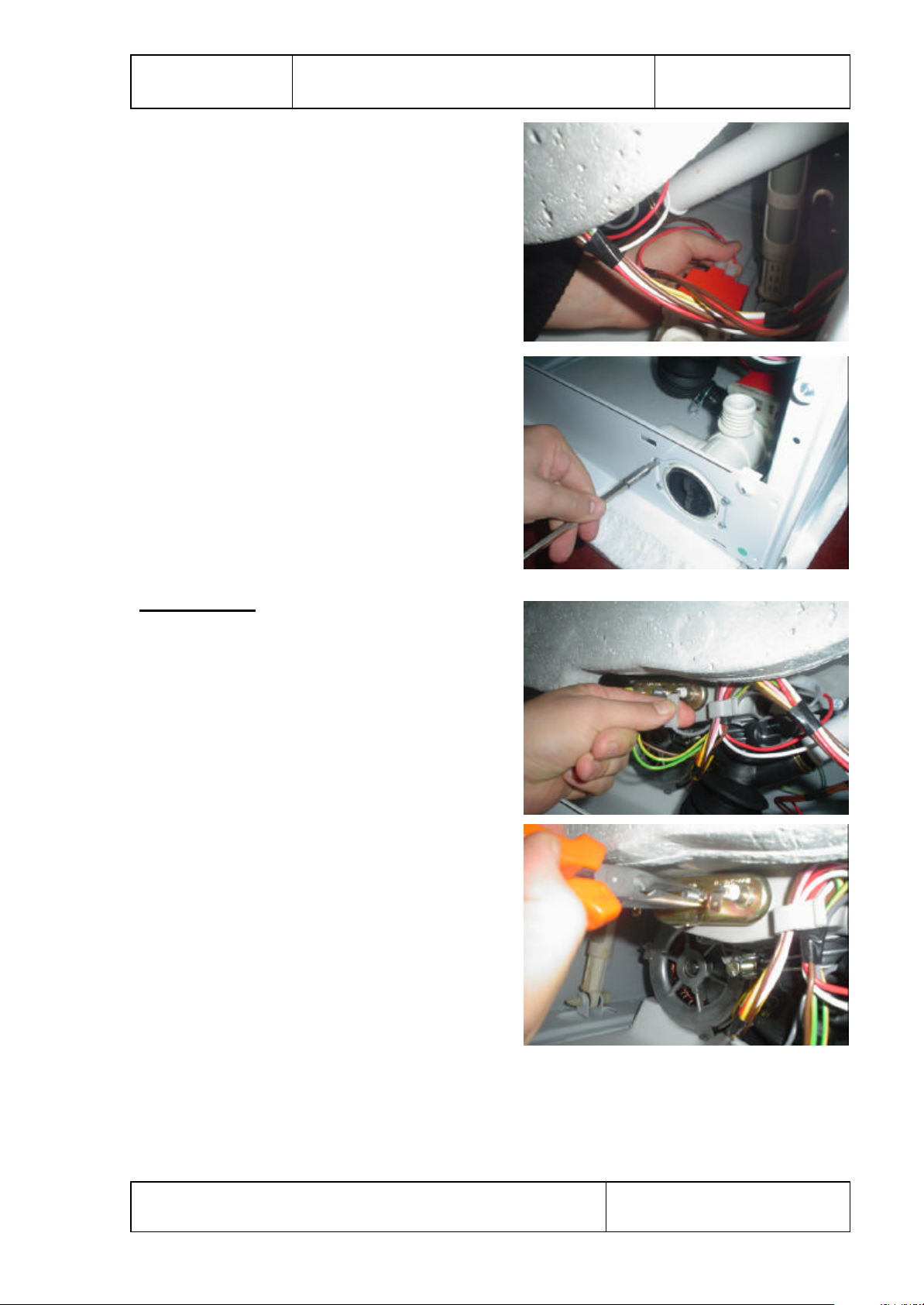

POWER CABLE GROUP AND PARASITE FILTER

Remove the wire that is connected to

the parasite filter.

Remove two screws fixing the parasite filter.

Remove the power cable group as it is showing

the picture.

PRESSURE SWITCH

Remove the wire that is connected to

the pressure switch.

Remove the pressure switch as it is showing

the picture.

9

Issue Date:01.08.2003 Documentation Number:

Remove the pressure switch hose handcuffs and

pressure switch hose as it is showing

the picture.

DOOR LOCK

Remove the wire that is connected to

the door lock.

PUMP MOTOR

Remove pipe clip that fixes the drain hose.

Remove pipe clip fixing the tub outlet hose.

10

Issue Date:01.08.2003 Documentation Number:

Remove the wire that is connected to

the pump motor.

Remove four screws fixing the pump motor.

RESISTANCE

Remove the wire that is connected to

the resistance.

Remove one nut fixing the resistance.

11

Issue Date:01.08.2003 Documentation Number:

FRONT COUNTERWEIGHT

Remove four screws fixing the front

counterweight on the front and pull it up.

Hold the gasket and gasket-body fixing spring

together, and pull them up.

SHOCK ABSORBER PIM

Remove two pim fixing the shock absorber.

TUB

Remove four screws fixing the spring hanger

sheet iron.

12

Issue Date:01.08.2003 Documentation Number:

Remove the washing group as it is showing

the picture.

UPPER COUNTERWEIGHT

Remove three screws fixing the upper

counterweight.

BELT

Remove the belt as it is showing

the picture.

DRIVEN PULLEY

Remove one screws fixing driven pulley.

13

Issue Date:01.08.2003 Documentation Number:

MOTOR

Lay down the machine with an angel of 45°

to the floor. Disconnect wires and remove

two screws fastening the motor under the tub.

Pull the motor up for disassembly.

TUB

Remove seventeen screws fixing tub.

14

Issue Date:01.08.2003 Documentation Number:

FAILURE PROBABLE CAUSE

The spining process is

not done or starts with

delay .

No failure. The

unbalanced load

control may works in

that way.

METHODS OF

ELIMINATION

The unbalanced load

control system will try

to distribute your

clothes in a

homogenous manner.

After your clothes are

distributed, passage to

spining process will be

realized.In the next

washing process,place

your clothes into the

machine in a wellbalanced manner.

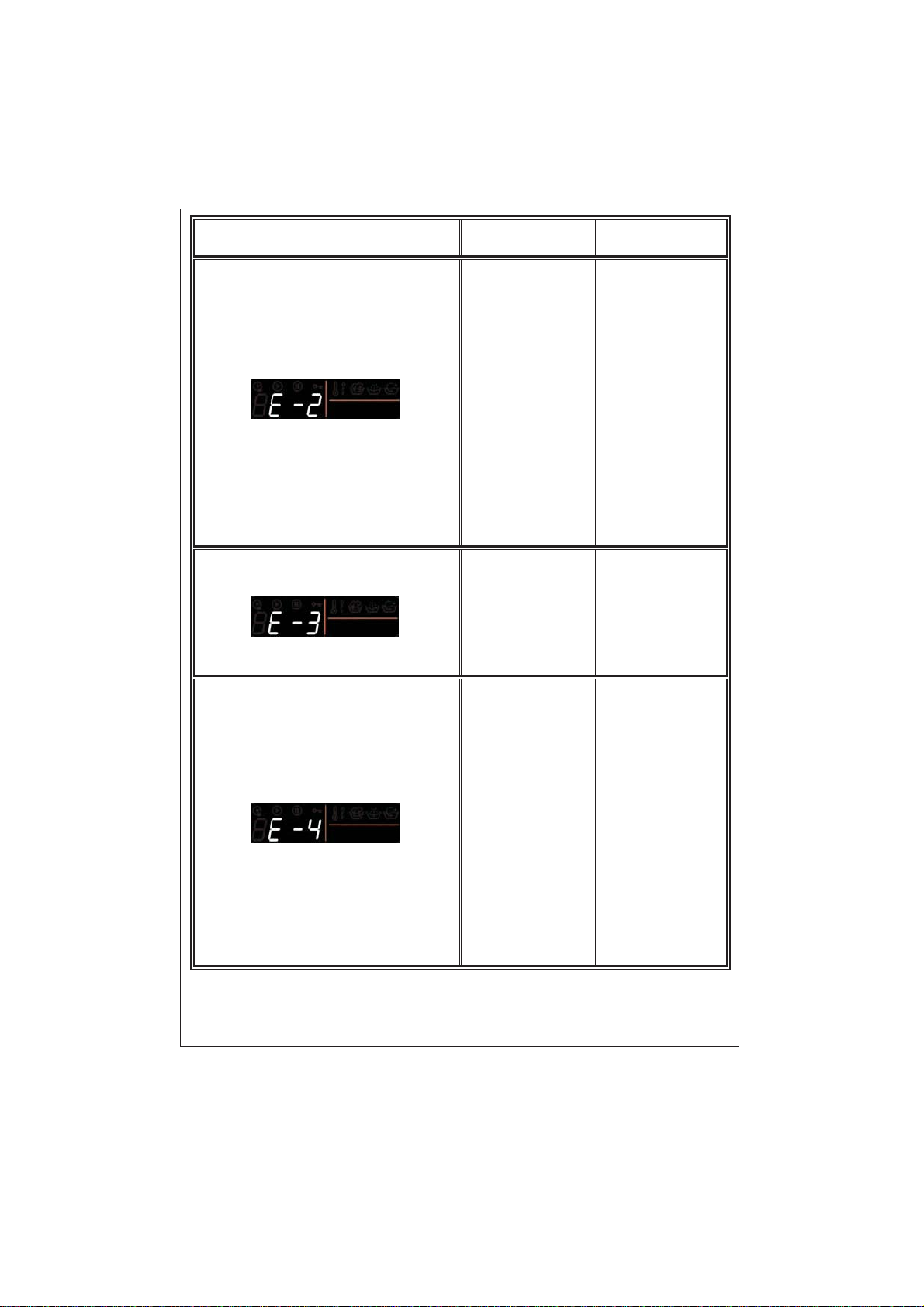

SECTION 9: AUTOMATIC FAILURE DETECTION SYSTEM

Your machine is equipped with systems which will both takethe necessary

precautions and warn you in case of any failure by controlling it self constantly

during the washing processes.

FAILURE CODE

PROBABLE

FAILURE

The door is not

shut properly.

30

THE PROCESS

TO BE DONE

Shut the door

properly so that

you hear the

click. If the

problem

persists, turn off

the machine

unplug and

apply to the

nearest

authorized

service

immediately.

FAILURE CODE

PROBABLE

FAILURE

The water level

in your machine

is below heater.

The pressure of

your water

supply may be

low or locking.

Thepumphas

failed or the

pump filter is

obstructed.

There is an

excessive

amount of water

in your machine.

THE PROCESS

TO BE DONE

Turn on the tap

to the end.Water

may be cut,

check it.If the

problem is still

continuing,your

machine will

automatically

stop after a

while.Unplug

your machine,

turn off the tap

and apply to the

nearest

authorized

service.

Clean the pump

filter.If the

problem

persists,apply to

the nearest

authorized

service.(*)

Your machine

will automatically

drain the water.

After your

machine has

completed the

draining

process,shut

down your

machine and

unplug. Close

the tap and

apply to the

nearest

authorized

service.

(*) See the section regarding the maintenance and cleaning of your machine.

31

Loading...

Loading...