Quadra-Fire VOYAGEUR GRAND INSERT GRAND-MBK-AU Owner's Manual

R

VOYAGEUR GRAND INSERT

Automatic Combustion Control (ACC)

OWNER’S MANUAL

Installation and Operations

Model:

GRAND-MBK-AU

INSTALLATIONS TO COMPLY WITH AS/NZS2918:2001

AND WILL REQUIRE A BUILDING CONSENT

IMPORTANT: Read all instructions carefully before starting installation. Failure to follow these

instructions may result in a re hazard and will void the warranty.

• Fig. 3,4,5,6, 7 and Table 1,2,3,4 relate to installations with tested ue systems; as per AS/NZS

2918:2001 - Appendix F, with a ceiling angle between 0° - 30° inclusive.

• For installations with a ceiling angle greater than 30°, refer to Fig. 18.1, 21.1 & 21.2 and AS/NZS

2918:2001 4.6.3(b)

• Ceiling Plate may vary in size depending on ceiling angle. Please specify ceiling pitch prior to

ordering the ceiling plate.

• Quadra-Fire Voyageur Grand ACC wood burner’s are tested and approved to the N.Z. National

Environmental Standards;

GRAND-MBK-AU Voyageur Grand Insert Hardwood Certied

Particulate Emissions = 2.0 g/kg Space Heating Efciency = 62.8%

Page 1

7075-205

April 29, 2013

R

Voyageur Grand

Hearth & Home Technologies welcomes you to our tradition

of excellence! In choosing a Quadra-Fire appliance, you

have our assurance of commitment to quality, durability, and

performance.

This commitment begins with our research of the market,

including ‘Voice of the Customer’ contacts, ensuring we

make products that will satisfy your needs. Our Research

and Development facility then employs the world’s most

advanced technology to achieve the optimum operation of

VOYAGEUR GRAND

OVERALL AVERAGE EFFICIENCY BURNING HARD-

(WHEN TESTED IN ACCORDANCE TO AS/NZS 4012)

AVERAGE PARTICULATE EMISSION FACTOR BURN-

ING HARDWOOD

(WHEN TESTED IN ACCORDANCE TO AS/NZS 4013)

MAXIMUM AVERAGE HEAT OUTPUT BURNING

HARDWOOD

our stoves, inserts and replaces. And yet we are old-fashioned when it comes to craftsmanship. Each unit is meticulously fabricated and surfaces are hand-nished for lasting

beauty and enjoyment. Our pledge to quality is completed

as each model undergoes a quality control inspection.

We wish you and your family many years of enjoyment in

the warmth and comfort of your hearth appliance. Thank

you for choosing Quadra-Fire.

WOOD

62.8%

2.0 g/kg

9.3 kw

BURN ONLY HARDWOOD WITH A MOISTURE CON-

APPROVED FUEL

TENT LESS THAN 25% (dry basis).

WETBACK - ALL MODELS

MANUFACTURED BY

Wetbacks are NOT an approved option and must

not be tted.

NOTE: Performance may vary from test values

depending on actual operating conditions.

INSTALLATION DATE

VOYAGEUR GRAND INSERT

This appliance has been TESTED TO AS/NZS4013 for

Serial No.

007057

Mfg by:

U.S. ENVIRONMENTAL PROTECTION AGENCY - Export stove. May not be operated within the United States

JAN FEB MAR APR MAY JUN JUL AUG SEP OCT NOV DEC

2013

Hardwood by VIPAC LTD.

Report # 30A-13-0025-TRP-331382-0

Date tested: March 2013

1445 N. Highway, Colville, WA 99114 www.quadrafire.com

2014 2015

DO NOT REMOVE THIS LABEL

Made in U.S.A. of US and

imported parts.

7075-206

R

Page 2

7075-205

April 29, 2013

R

Voyageur Grand

Safety Alert Key:

• DANGER! Indicates a hazardous situation which, if not avoided will result in death or serious injury.

• WARNING! Indicates a hazardous situation which, if not avoided may result in death or serious injury.

• CAUTION! Indicates a hazardous situation which, if not avoided, may result in minor or moderate injury.

• NOTICE: Indicates practices which may cause damage to the appliance or to property.

TABLE OF CONTENTS

Congratulations ...............................................................2

Serial Number Label ........................................................2

User’s Guide

Section 1: Operating Instructions

A. Quick Start Guide ..............................................4

B. Automatic Combustion Control (ACC) ..............5

C. Air Controls .......................................................5

D. Burn Rates and Operating Efciency ................5

E. Blower Control Box Snap Disc Operations .......5

F. Blower Operating Instructions ........................... 5

Section 2: Maintenance & Service

A. Disposal of Ashes .............................................7

B. Chimney and Chimney Connector

Inspection/Cleaning...........................................7

C. Appliance Inspection - Routine .........................7

D. Cleaning Plated Services ..................................7

E. Glass Cleaning ..................................................8

F. Inspect Firebrick & Replacement Instructions ... 8

G. Quick Reference Maitenance Guide .................9

H. Trouble Shoot Guide .........................................10

Section 3: Service Parts Replacement

A. Glass Replacement ...........................................11

B. Snap Disc Replacement....................................11

C. Wiring Diagram .................................................11

D. Blower Replacement .........................................12

E. Door Handle Assembly .....................................13

F. Bafe & Ceramic Blanket Removal ................... 13

G. Tube Channel Assembly Replacement .............14

Installer’s Guide

Section 4: Getting Started

A. Tools and Supplies Needed ..............................15

B. Fire Safety .........................................................15

C. Inspect Appliance and Components

and Pre-Burn Checklist .....................................15

Section 5: Dimensions and Clearances

A. Appliance Dimensions.......................................16

B. Clearances to Combustibles (UL and ULC)

and Hearth Protection Requirements ................ 17

C. Alternate Floor Protection Calculation...............18

Section 6: Chimney Systems

A. Venting Systems ...............................................19

B. Inspections ........................................................19

C. Larger Chimneys ............................................... 19

D. Masonry Chimney ............................................. 19

E. Prefabricated Metal Chimney ............................19

F. Installation into a Masonry Fireplace.................20

G. Installation into a Factory Built Fireplace ..........20

Section 7: Appliance Set-up

A. Outside Air Installation ......................................22

B. Optional Elbow Flue Adapter Installation ..........23

C. Securing Stove Pipe/Liner to Flue Collar .......... 23

D. Leveling Legs .................................................... 23

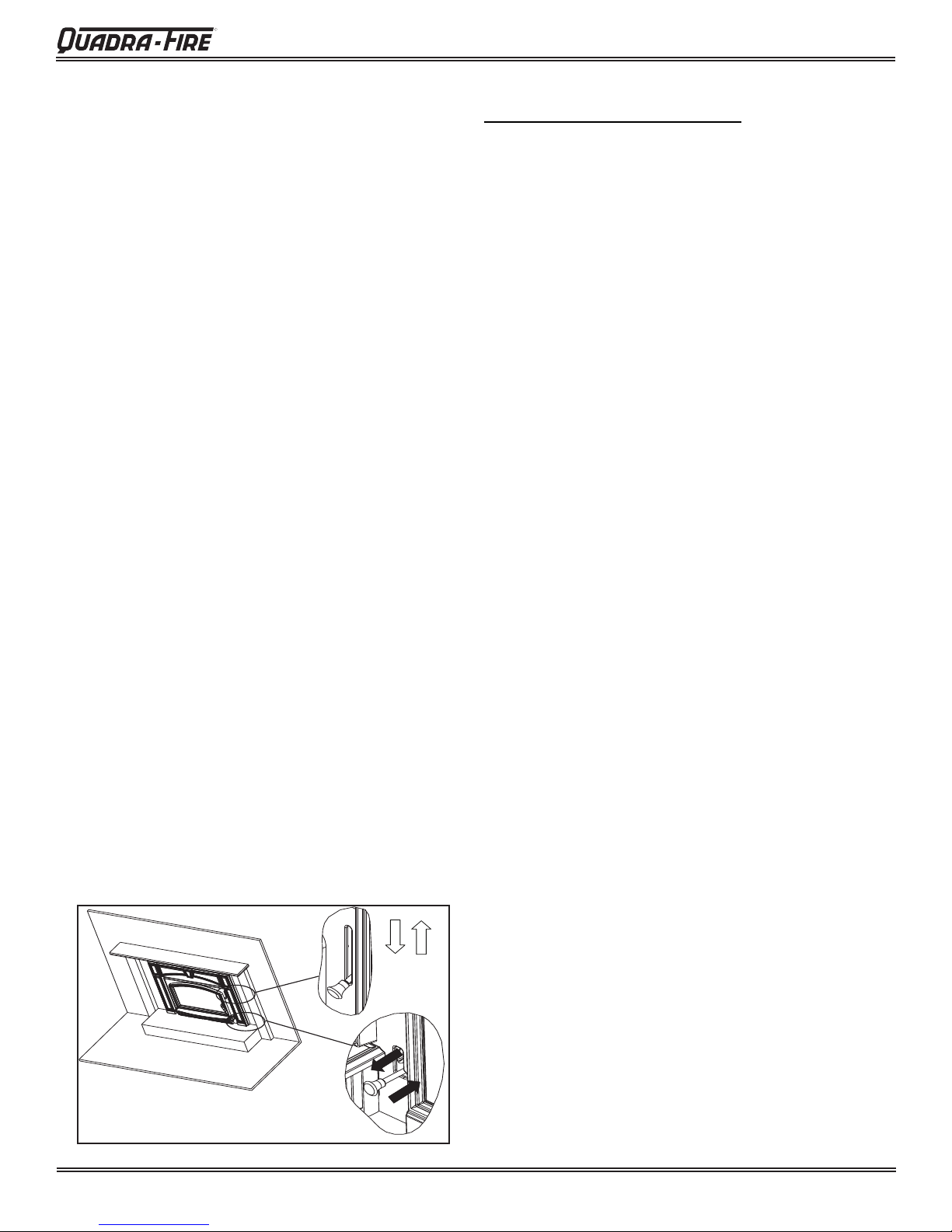

E. Securing Appliance to Stove Pipe/Liner ............24

F. Standard Surround & Trim Installation .............. 24

G. Standard Surround & Cast Trim, .......................25

H. All Cast Surround .............................................. 26

I. Blower Cord Installation - Left Side ...................26

Section 8: Reference Materials

A. Warnings ...........................................................29

B. Warranty Policy .................................................30

C. Contact Information ........................................... 32

April 29, 2013

7075-205

Page 3

R

Voyageur Grand

Operating Instructions

1

User’s Guide

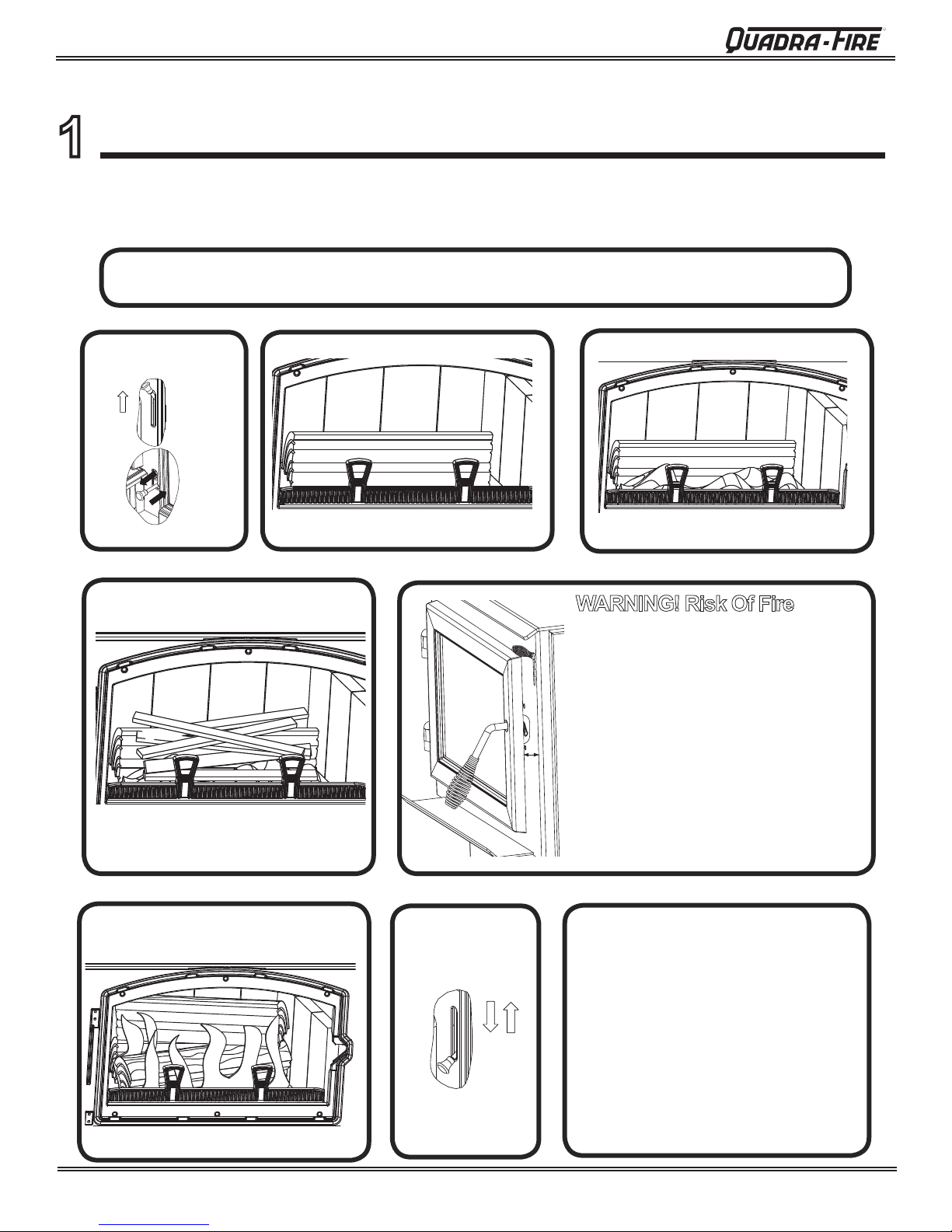

A. Quick Start Guide

FIRST FIRE ITEMS NEEDED:

OPEN AIR

CONTROLS

HIGH

LOW

START-UP

AIR

Push In and then Pull Out

BURN

RATE

Upper

right

corner

Lower

right

corner

1

ADD KINDLING

LIGHT THE PAPER

Note: Thesearegenericdrawingsandmaynotrepresent

yourspecicmodel.

10 Pieces of Newspaper, 10-20 Pieces of Dry Kindling

and a Few Pieces of Dry Split Wood.

LOAD WOOD

ADD NEWSPAPER

2

WARNING! Risk Of Fire

DO NOT LEAVE UNATTENDED

During startup, if additional draft is needed,

allow the door to remain open approximately1/2 inch. Once the draft is established,

close and securely latch the door to prevent:

• Spillage of smoke, ame and carbon

monoxide

• Spillage of sparks, coals and logs

• Over-ring

DO NOT leave the stove unattended with the door open

4

3

5

ADD MORE WOOD &

SECURELY LATCH THE DOOR

Page 4

6

REDUCE AIR

CONTROL

Set to desired heat

output

HIGH

LOW

BURN RATE CONTROL

Upper Right Corner

7

7075-205

The stove is ready for

normal operation.

April 29, 2013

R

Voyageur Grand

Burn Rate Control

ACC Start-up

Air Control

HIGH

LOW

To activate: Push back until it stops

and then pull forward until it stops

B. Automatic Combustion Control (ACC)

Typically, when you build a re, you open the air controls fully

and monitor the re to prevent it from going into an overre

situation and/or burning your wood up too quickly before you

shut down the air controls to the desired burn rate.

When using the Automatic Combustion Control (ACC) system,

you do not have to continually monitor the re. Once you

set the ACC system it will control the re for you. Follow the

instructions below to learn how to operate your stove with

ease.

C. Air Controls

1. Start-Up Air Control

The function of the Start-Up Air Control is to activate the

Automatic Combustion Control system (ACC).

• Push the Start-Up Air Control all the way back until it stops

and then pull forward to the front of the appliance until it

stops. Figure 5.1.

• The air channel opens and allows air to enter the front of

the appliance for approximately 20-25 minutes.

• The air channel gradually shuts down until it is completely

closed at the end of the 20-25 minutes.

• The re is now controlled by the air supplied by the Burn

Rate Air Control. Figure 5.1.

• This function should be performed each time you reload

the appliance.

2. Burn Rate Air Control

• The air supply enters at the upper front of the rebox,

near the top of the glass door.

• This preheated air supplies the necessary fresh oxygen

to mix with the unburned gases, helping to create the

second, third and fourth combustion process.

• This air is regulated by the Burn Rate Air Control.

• There are four settings High, Medium-High, Medium-Low

and Low.

• When the control is raised all the way up it is on the High

setting and when pushed all the down it is on the Low

setting.

D. Burn Rates and Operating Efciency

For maximum operating efciency

1. Burn dry, well-seasoned wood.

2. Follow these burn rate instructions below and refer to

Figure 5.1.

*NOTE:

These are guidelines. Actual settings may vary with

type of wood, chimney draft, altitude and other variables.

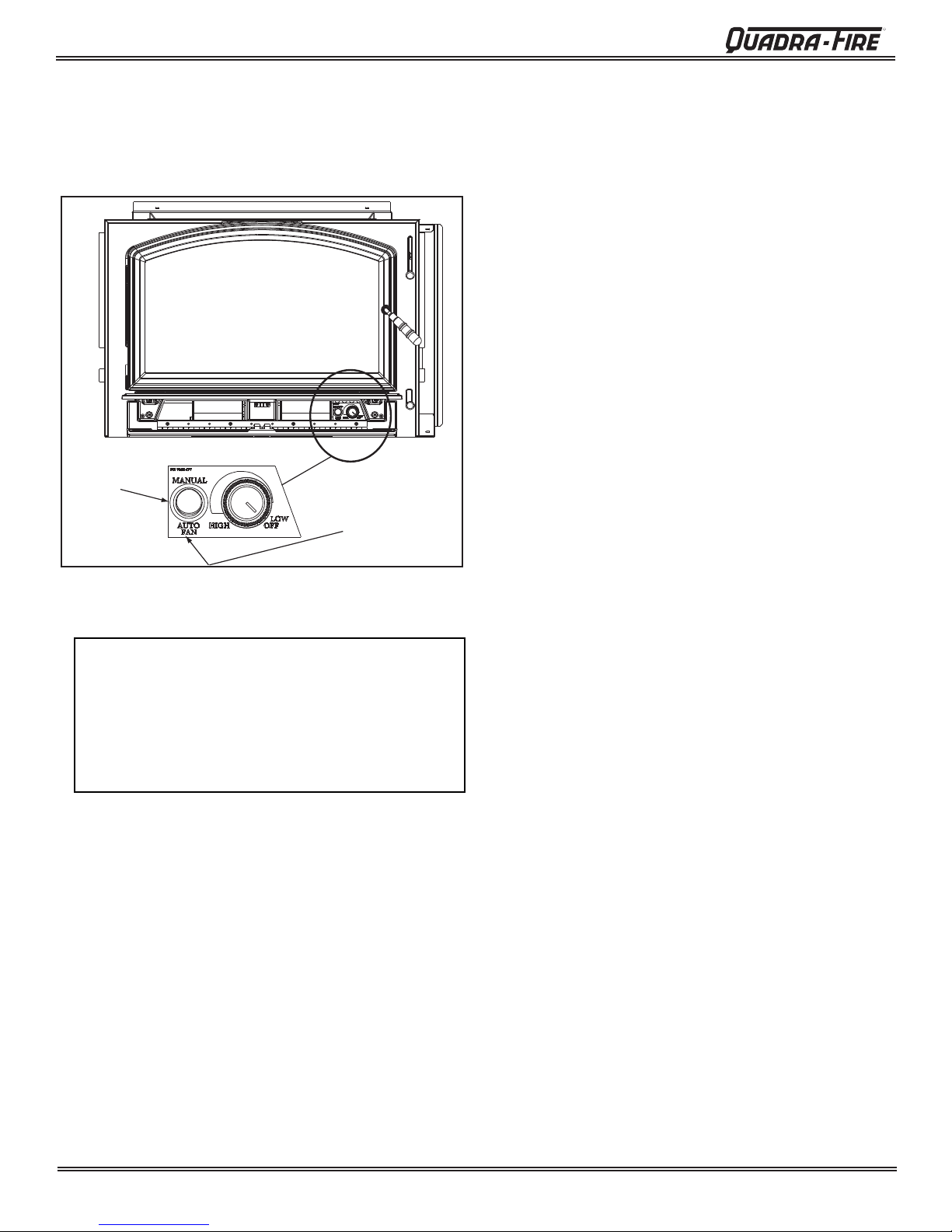

E. Blower Control Box & Snap Disc

Operating Instructions

1. The blower will turn on/off automatically when set to

AUTO. Figure 6.1 on page 6.

2. When set to MANUAL, the fan will turn on/off only when

you turn it on or off. This setting over-rides the internal

snap disc.

3. Swing the grille downward to expose the blower controls.

Adjust the speed of the fan by turning the HIGH/LOW

knob to the desired setting.

F. Blower Operating Instructions

1. Initial (cold) startup: Open both controls fully by raising

the Burn Rate Air Control all the way up until it stops and

PUSH the Start-up Air Control back until it stops.

blower tends to cool the appliance. Leave the blower off

until the burn is well established, i.e., 30 minutes.

2. High Burn Setting: Both controls are open. Burn Rate

Air Control is pulled up and the Start-up Air Control is fully

pushed in. Blower may remain on.

3. Medium-High Burn Setting*: Burn Rate Air Control

is closed then opened to 1 inch to fully open (pull up).

Blower may remain on.

4. Medium-Low Burn Setting*: Burn Rate Air Control

is closed then opened to 1/4 inch to 1/2 inch (pull up).

Leave the blower off until the burn is well established, i.e.,

30 minutes.

5. Low Burn Setting*: Burn Rate Air Control is closed

(down position).

Leave the blower off until the burn is well

established, i.e., 30 minutes.

*NOTE: For burn settings 3 to 5 the Start-up Air Control

needs to be pushed in (Open) then pulled forward to activate the Automatic Combustion Control (ACC).

NOTE: For maximum efciency and lowest emissions,

when operating the blower in either the automatic or

manual setting for the low and medium low burn settings

leave the blower off until the burn is well established, i.e.,

30 minutes.

The

Figure 5.1 Start-up and Burn Rate Air Controls

April 29, 2013

7075-205

Page 5

R

Voyageur Grand

Blower Controls Under Ash Lip

MANUAL: overrides the internal

snap disc

AUTO: Fan with turn ON/OFF

automatically and is controlled

by the internal Snap Disc

6. The blower is equipped with a rheostat (speed control).

The highest blower speed is obtained by turning the

rheostat on, then adjusting back towards “OFF” as far as

possible without turning the blower off. For a low blower

speed, turn the control knob clockwise as far as possible

Figure 15.1

Figure 6.1

NOTICE!

Do NOT operate a circulating fan within close proximity, approximately 4 ft (1.2m), of appliance

• Can reverse air ow, blowing hot air into appliance

cavity.

• Can damage appliance blower due to overheating.

Page 6

7075-205

April 29, 2013

R

Maitenance & Service

2

A. Disposal of Ashes

• Frequency: When ash reaches the top of the brick

covers (should not spill over covers). Leave 1/4 inch

(6mm) of ash in the bottom of the firebox.

• By: Homeowner

WARNING! Risk of Fire! Ashescouldcontainhotembers.

• Place ashes in a metal container with a tight-tting lid.

• The closed container should be placed on a noncombustible

oor or on the ground, well away from all combustible

materials, pending nal disposal.

• If the ashes are disposed of by burial in soil or otherwise

locally dispersed, they should be retained in the closed

container until all cinders have thoroughly cooled

Voyageur Grand

Creosote - Formation and Need for Removal

• When wood is burned slowly, it produces tar and other

organic vapors, which combine with expelled moisture

to form creosote.

• The creosote vapors condense in the relatively cool

chimney ue of a slow-burning re.

• As a result, creosote residue accumulates on the ue

lining. When ignited this creosote makes an extremely

hot re.

• The chimney and chimney connector shall be inspected

every two months during the heating season to

determine when a creosote buildup has occurred.

• When creosote has accumulated it shall be removed to

reduce the risk of a chimney re.

B. Chimney and Chimney Connector

Inspection/Cleaning

• Frequency: Every 2 months during heating season or

as recommended by a certied chimney sweep; more

frequently if chimney exceeds or is under 14-16 feet (4.3

to 4.8m) measured from bottom of appliance.

• By: Certied chimney sweep

• Remove all ash from the rebox and extinguish all hot

embers before disposal.

• Allow the appliance to cool completely.

• If your type of installation involves a full reline of the

chimney, it will be necessary to either remove the bafe

from the insert, or remove the insert from the replace

and disconnect the vent prior to cleaning the chimney.

Refer to page 23 in this manual for instructions on Bafe

Removal.

• If your type of installation is direct connect within a masonry

chimney, the insert will need to be pulled out from the

replace and disconnected from the ue prior to cleaning

the chimney.

• The creosote or soot should be removed with a brush

specically designed for the type of chimney in use.

• Clean out fallen ashes from the rebox.

• It is also recommended that before each heating season

the entire system be professionally inspected, cleaned

and repaired if necessary.

WARNING! Risk of Fire!

Donotusechimneycleanersoramecolorantsinyour

appliance.Itwillcorrodeyourpipe.

C. Appliance Inspection - Routine

• Frequency: Every 2 months at the same time the

chimney and chimney connector are inspected.

• By: Homeowner

Check for:

• Cracks in glass

• Door handle - smooth cam operation

• Bafe and ceramic blanket correct placement

• Bafe for warpage

• Firebrick for cracks, broken or crumbly

• Door gasket. (Dollar bill test). Place a dollar bill between the stove and the door and then shut the door. If

you can pull the dollar bill out, replace the door gasket.

• Glass frame for loose screws

D. Cleaning Plated Surfaces

• Frequency: As desired

• By: Homeowner

• Clean all the ngerprints and oils from plated surfaces

BEFORE ring the appliance for the rst time.

• If not cleaned properly before lighting your rst re, the

oils can cause permanent markings on the plating.

• After the plating is cured, the oils will not affect the nish

and little maintenance is required.

• Wipe clean as needed.

CAUTION! Do not use polishes with abrasives. Itwill

scratchplatedsurfaces.

April 29, 2013

7075-205

Page 7

R

Voyageur Grand

E. Glass Cleaning

• Frequency: As desired

• By: Homeowner

• Clean glass with a non-abrasive glass cleaner. Abrasive

cleaners may scratch and cause glass to crack.

• If the deposits on the glass are not very heavy, normal

glass cleaners work well. Heavier deposits may be

removed by using a damp cloth dipped in wood ashes or

by using a commercially available oven cleaner.

• After using an oven cleaner, it is advisable to remove any

residue with a glass cleaner or soap and water. Oven

cleaner left on during the next ring can permanently stain

the glass and damage the nish on plated metal surfaces.

• A portion of the combustion air entering the rebox is de-

ected down over the inside of the door glass.

• This air ow “washes” the glass, helping to keep smoke

from adhering to its surface.

• When operated at a low burn rate, less air will be owing

over the glass and the smoky, relatively cool condition of

a low re will cause the glass to become coated.

• Operating the appliance with the Burn Rate Air Control

and Start-Up Air Control all the way open for 15-20 minutes should remove the built up coating.

CAUTION! Handle glass assembly with care. Glass is

breakable.

• Avoidstriking,scratchingorslammingglass

• Avoidabrasivecleaners

• Donotcleanglasswhileitishot

F. Inspect Firebrick & Replacement

Instructions

• Frequency: After each ash removal

• By: Homeowner

Replace the rebrick if they become crumbly and/or if

there is a 1/4 inch (6.35mm) gap between the bricks.

The rebox is lined with rebrick, which has exceptional

insulating properties. Do not use a grate; simply build

a re on the rebox oor. Do not operate appliance

without rebrick.

1. After the coals have completely cooled, remove all

old brick and ash from unit and vacuum rebox.

2. Remove new brick set from box and lay out to the

diagram shown in the instructions that come with

the replacement brick set.

3. Lay bottom bricks in unit.

4.

Install rear bricks on the top of the bottom bricks.

5. Install side bricks. Slide top of brick under clips

on side of rebox and push the bottom of the brick

until it is ush with the side of the unit.

Use Part 832-0550 when ordering individual brick. Provide

brick dimension or copy the page in the service parts list, mark

the desired brick and take it to your authorized dealer.

Page 8

7075-205

April 29, 2013

R

Voyageur Grand

Baffle

Blanket

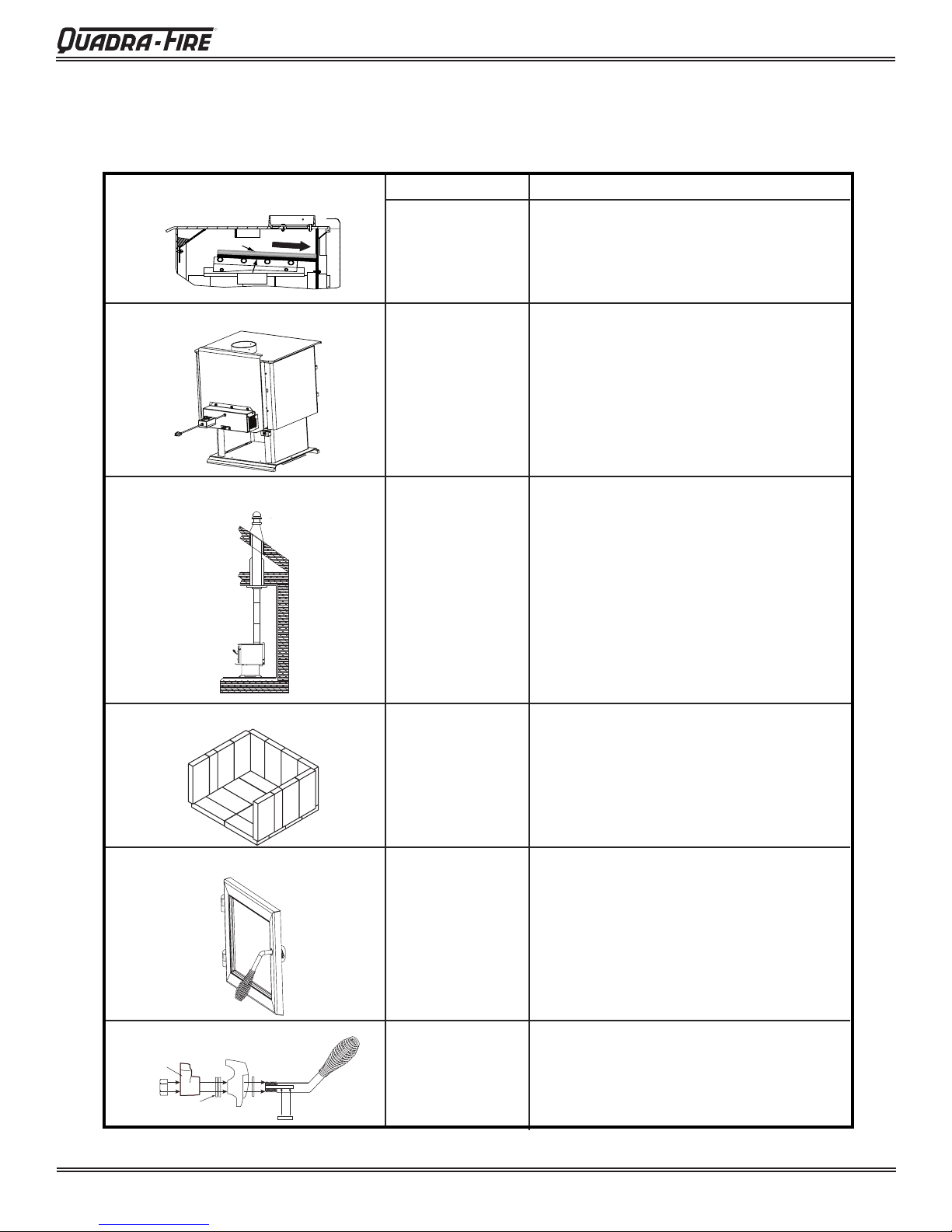

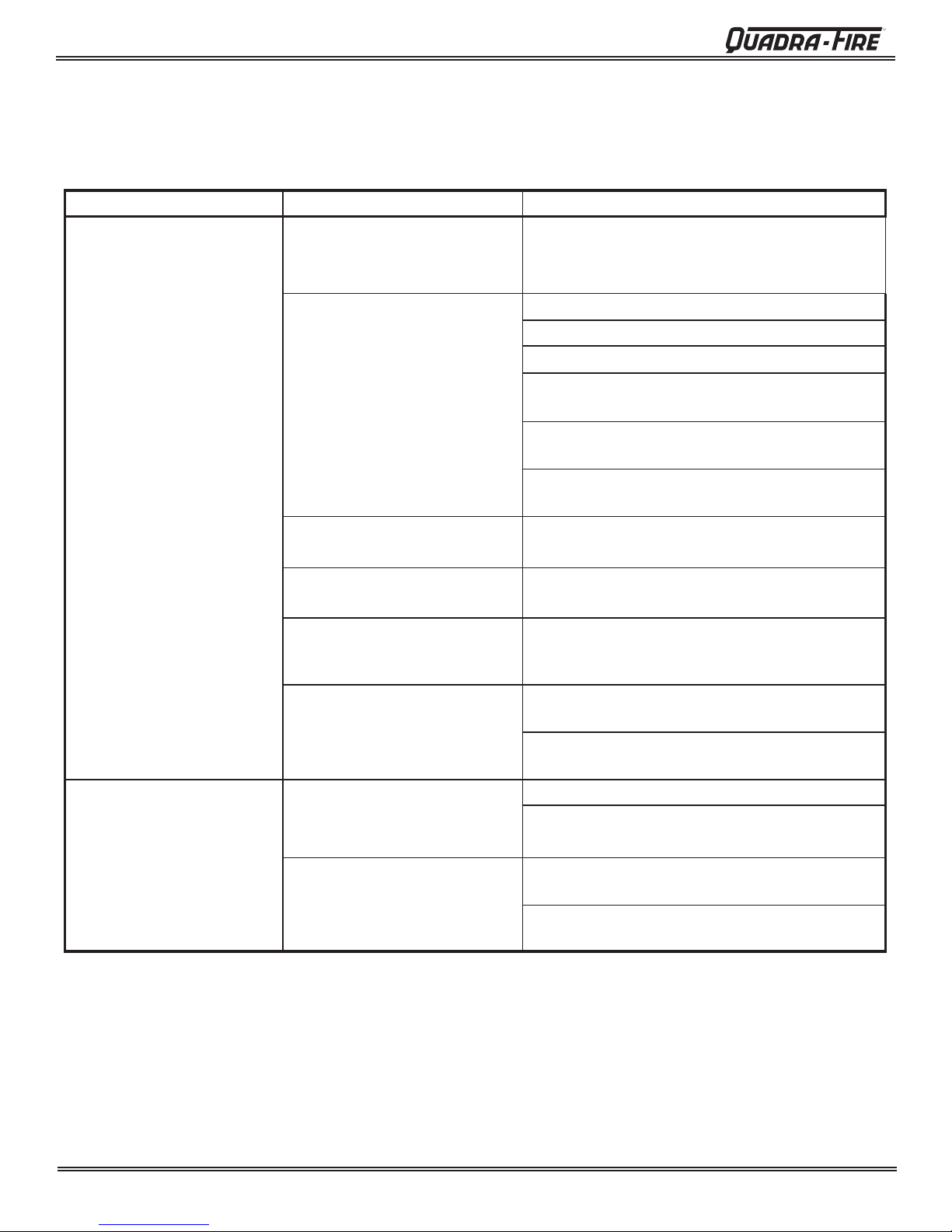

G. Quick Reference Maintenance Guide

CAUTION! Allow the appliance to completely cool

down before performing any cleaning or maintenance.

Bafe & Blanket

Optional Blower

Chimney System

Frequency

MONTHLY

or

After Every

Cord of Wood

YEARLY

or

After Every

4 Cords of

Wood

EVERY 2

MONTHS

or

After Every

4 Cords of

Wood

Start the rst inspection after the rst 2 months of use,

or if performance changes, and adjust your schedule

accordingly. Maintenance is required for safe operation

and must be performed to maintain your warranty.

Task

Bafe and blanket placement is critical to

heat output, efciency and overall life of the

unit. Make sure the bafe is pushed all of the

way to the back of the rebox and the blanket

is laying at. Inspect bafe for cracks.

Vacuum the blower impellers.

T

he chimney and chimney cap must be inspected for soot and creosote every two

months during the burn season or more frequency if chimney exceeds or is under 14-16 ft

(4.3m-4.8m) measured from bottom of appli-

ance.

This will prevent pipe blockage, poor draft,

and chimney res.

Always burn dry wood to help prevent cap

blockage and creosote build-up.

Firebrick & Ash Removal

Door & Glass Assemblies

Door Handle

Latch Cam

Spacing Washers

Note: These are generic drawings and may not represent your specic model.

April 29, 2013

WEEKLY

or

After Every

25 Loads of

Wood

WEEKLY

or

After Every

25 Loads of

Wood

WEEKLY

or

After Every 25

Loads of Wood

7075-205

Ashes must be cool before you can dispose

of the ashes in a non-combustible container.

Firebrick is designed to protect your rebox.

After ashes are removed, inspect the rebrick and replace rebricks that are crumbling, cracked or broken.

Keep door and glass gasket in good shape to

maintain good burn times on a low burn setting.

To test: place a dollar bill between the stove

and door and then shut the door. If you can

pull the dollar out, remove one washer from

door handle behind latch cam and try again. If

you can still pull it out, replace the door gasket.

Check the glass frame for loose screws to

prevent air leakage. Check glass for cracks.

Check the door latch for proper adjustment.

This is very important especially after the door

rope has formed to the stove face.

Check door handle for smooth cam operation.

Page 9

R

Voyageur Grand

H. Troubleshooting Guide

With proper installation, operation, and maintenance your woodstove will provide years of trouble-free service. If you do

experience a problem, this troubleshooting guide will assist you or a qualied service person in the diagnosis of a problem

and the corrective action to be taken.

Start Fire Problems Possible Cause Solution

Can not get re started

Excessive smoke or spillage

Burns too slowly

Not enough heat output

Not enough kindling/paper or no

kindling/paper

Not enough air for re to ignite

Use dry kindling, more paper. Arrange kindling &

wood for air movement.

Check for restricted termination cap

Check for blockage of outside air kit (if installed).

Check for ue blockage.

Pre-warm ue before starting re (refer to Building

a Fire Section).

Check for adequate vent height (refer to Chimney

Height Section).

Open window below the appliance towards the

wind.

Fire burns too fast

Wood condition is too wet, too

large

Bed of coals not established

before adding wood

Flue blockage such as birds’

nests or leaves in termination

cap

Down draft or negative pressure

Competition with exhaust

devices

Extremely dry or soft wood

Overdrafting

Use dry, seasoned wood (refer to Seasoned Wood

Section).

Start with paper & kindling to establish bed of

coals (refer to Building a Fire Section).

Have chimney inspected for creosote and cleaned

by a certied chimney sweep.

Do not use exhaust fans during start-up (refer to

Negative Pressure Section).

Open window below the appliance towards the

wind.

Mix in hardwood.

Mix in less seasoned wood after re is established

(refer to Wood Fuel Section).

Check for correct vent height; too much vertical

height creates overdrafting.

Check location of vent termination (refer to

Chimney Termination Requirement Section).

Page 10

7075-205

April 29, 2013

Loading...

Loading...