Quadra-Fire GB40I, GRAND BAY 40 Installation & Operating Instructions Manual

CONGRATULATIONS!

You are now the proud

owner of one of the finest

gas inserts on the market -

the QUADRA-FIRE

GB40I

INSTALLATION, OPERA TION, VENTING AND MAINTENANCE

North America’s Best

GRAND BAY 40 GAS INSERT

This Manual contains instructions for

WARNING

If the information in this manual is not followed exactly, a

fire or explosion may result causing property damage,

personal injury, or death.

FOR YOUR SAFETY:

• Extinguish any open flame.

• Open windows.

• Do not try to light any appliance.

• Do not touch any electric switch.

• Do not use any telephone in your building.

DO NOT store or use gasolive or other flammable vapors and

liquids in the vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Immediately call your gas supplier from a

neighbor’s phone.

• Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier,

call the fire department.

WARNING

Improper installation, adjustment, alteration, service or maintenance can cause injury or

property damage. Refer to this manual for corr ect installation and operational procedur es. for

assistance or additional information consult a qualified installer, service agency, or the gas

supplier.

401 N. Wynne Street

Colville, WA 99114

SAVE THESE INSTRUCTIONS

(Revised March 2000) Part #250-2641 #842-1270

www.aladdinhearth.com

aladdin@aladdinhearth.com

GB 40 I - FIREPLACE INSERT

Welcome

Aladdin Hearth Products welcomes you to our tradition of excellence! In choosing a

Quadra-Fire appliance, you have our assurance of commitment to quality , durability,

and performance.

This commitment begins with our research of the market, including ‘Voice of the Cus-

tomer’ contacts, ensuring we make products that will satisfy your needs. Our Research

and Development facility then employs the world’s most advanced technology to

achieve the optim um operation of our stoves, inserts and fireplaces. And yet we are

old-fashioned when it comes to craftsmanship . During manufacturing each unit is

meticulously fabricated and gold surfaces are hand-finished for lasting beauty and

enjoyment. Our pledge to quality is completed as each model undergoes a quality

control inspection. Additionally, we feel it is important to offer you several finishing

options and accessories to compliment your home’s décor, individualize the use of

your appliance, and provide financial options in acquiring a quality hearth appliance.

Ask your Quadra-Fire Dealer f or inf ormation on these options. From design, to fabrication, to shipping: Our guar antee of quality is more than a word, it’s Quadra-Fire

tradition, and we proudly back this tradition with a Lifetime W arranty .

Prior to installation, we ask you to take a few moments to read this manual. It has

been our experience that your overall enjoyment of your new appliance will be greatly

enhanced by becoming familiar with its’ installation, operation and maintenance requirements. We wish you and y our family many years of enjoyment in the warmth and

comfort of your hearth appliance. Thank y ou f or choosing Quadra-Fire.

With warm regards,

President V .P. Research & Development

Controller Operations Manager V .P. Sales & Marketing

Western Sales Manager Central Sales Manager Eastern Sales Manager

Manufacturing Eng. Mgr. Sr . Purchasing Agent T echnical Support Manager

WELCOME

Customer Support Manager Human Resources Supervisor

Page 2

GB40-I with gold-plated H-channel door

March 2000

GB 40 I - FIREPLACE INSERT

NOTES

MODEL PURCHASED

SERIAL NUMBER

DATE PURCHASED

DEALERSHIP WHERE PURCHASED:

DEALER PHONE NUMBER

ADDITIONAL INFORMATION :

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

GB40-I

NOTES

A TT ACH YOUR SALES RECEIPT AND WARRANTY STUB HERE:

March 2000

Page 3

GB 40 I - FIREPLACE INSERT

T ABLE OF CONTENTS

Welcome ................................................................................................................................................... 2

Notes......................................................................................................................................................... 3

Safety Label.............................................................................................................................................. 5

Safety Notices .......................................................................................................................................... 6

Specifications ............................................................................................................................................ 7

Gas Line Connection................................................................................................................................. 7

Pressure Testing ....................................................................................................................................... 7

Safety Listings .......................................................................................................................................... 7

Dimensions................................................................................................................................................ 8

Minimum Fireplace Clearances ................................................................................................................ 9

Clearances to Combustibles...................................................................................................................... 10

High Altitude Operation ............................................................................................................................ 11

Installation

Panel & T rim Installation..................................................................................................................... 12

Brick Installation.................................................................................................................................. 13

Log Set Installation .............................................................................................................................. 14

Door Installation ................................................................................................................................... 15

Thermostat Installation ........................................................................................................................ 16

Blower Power Cord ......................................................................................................... ................... 17

Gas Connections.................................................................................................................................. 18

Vent Attachment to Flue Collar ........................................................................................................... 19

Flue Clamp Instructions....................................................................................................................... 20

V enting Requirements

Terminations ....................................................................................................................................... 21

Exhaust Spillage and Testing Procedure ............................................................................................ 23

Lighting Instructions.................................................................................................................................. 24

First Fire.................................................................................................................................................... 25

Maintenance

Cleaning and Inspection ...................................................................................................................... 26

Burner Tube Cleaning ......................................................................................................................... 26

Glass Cleaning ...................................................................................................................................... 26

Glass Replacement .............................................................................................................................. 27

Schematics................................................................................................................................................ 28

Blower & Snap Disc Replacement .......................................................................................................... 29

Conversion to Alternate Fuel .................................................................................................................... 30

Troubleshooting ......................................................................................................................................... 32

Zero Clearance Fireplace Kit ................................................................................................................... 33

Offset Adapter Kit .................................................................................................................................... 33

CONTENTS

Accessories & ServiceParts ..................................................................................................................... 34

Warranty ................................................................................................................................................... 35

Warranty Card Insert

Page 4

March 2000

GB 40 I - FIREPLACE INSERT

SAFETY LABEL

(As found on chain in lower front grill.)

MANUFACTURED BY:

GB40 -I NG

GB40-I LP

GAS-FIRED VENTED ROOM HEATER

SERIAL NO.

CAN 1-2.1-M86 / ANSI 21.11.1a-1993

Report #061-S-07-4

GB40-I (NG) GB40-I (NG) GB40-I (LP) GB40-I (LP)

For use with Natural Gas For use with Natural Gas For use with Propane For use with Propane

Altitude 0-2000' 2000-4500' 0-2000' 2000-4500'

Input High 46,000 BTUH 40,000 BTUH 40,000 BTUH 36,000 BTUH

Input Low 31,000 BTUH 29,000 BTUH 32,000 BTUH 25,000 BTUH

Output Blower off 33,600 BTUH 29,200 BTUH 30,000 BTUH 27,000 BTUH

Output Blower on 35,420 BTUH 31,000 BTUH 32,000 BTUH 28,440 BTUH

Manifold Pressure 3.5" WC 3.5" WC 10.0" WC 10.0" WC

Reduced Manifold Pressure 1.5" WC 1.5" WC 5.8" WC 5.8" WC

Min. Supply Pressure 4.5" WC 4.5" WC 11.0" WC 11.0" WC

Orifice Size (DMS)

Front burner #53 #54 #66 #67

Middle Burner #52 #53 #63 #64

Rear Burner #38 #37 #53 #54

401 N. Wynne

Colville, WA 99114

SAFETY LABEL

ATTENTION

This appliance must be installed in acordance with local codes, if any; if not,

follow current ANSI Z223.1/CAN 1-B149.

ELECTRICAL SUPPL Y: 120 V olts, 1.2 Amps, 60 Hz.

Install and use only in accordance with manufacturer’s installation and operating instructions.

For direct discharge without duct connections.

Not for use with solid fuel.

Keep burner and control compartment clean.

Due to high surface temperatures, keep children, clothing and furniture away.

MINIMUM CLEARANCES TO COMBUSTIBLES

SIDEWALL A 10" (255mm)

MANTEL C 12.5" (320mm)

MANTEL WIDTH G 1" (25mm)

NOTE: FOR EVERY 1" (25mm) OF MANTEL WIDTH ADD 1" (25mm)

TO CLEARANCE “C”. EX: MANTEL WIDTH 6" (150mm) -

CLEARANCE “C” MUST BE 17.5" (445mm)

NON-COMBUSTIBLE HEARTH EXTENSION

HEARTH HEIGHT (H) 0" (0mm) 2" (51mm) 4" (100mm)

HEARTH DEPTH (I) 24" (610mm) 22" (560mm) 0" (0mm)

HEARTH WIDTH J 30" (760mm)

DO NOT REMOVE THIS LABEL

MANUF ACTURED AS A:

GB40-I (NG)

GB40-I (LP)

FROM HEATER

March 2000

Page 5

GB 40 I - FIREPLACE INSERT

SAFETY NOTICES

This appliance should only be installed by a qualified installer . It is approved for installation in a bedroom.

Bedroom installation in Canada requires that the stove be connected to a thermostat. The appliance must

be electrically grounded in accordance with local codes, or the latest edition of the National Electric Code.

If no local codes exist, this appliance should be installed following the current codes:

CAN/CGA-B149.1 ........................................................................ Natural Gas Installation Code

CSA-C22.1 ....................................................................................Canadian Electrical Code

ANSI Z223.1 ................................................................................. National Fuel Gas Code

ANSI NFP A-70............................................................................. National Electrical Code

The control compartment, burner, and circulating air passageways MUST be kept clean and clear to allow

for adequate combustion and proper operation. Provide adequate clearances around air openings and adequate

accessibility clearance for service and operation. NEVER obstruct the openings of the appliance or the vent

termination on the exterior of the building. NEVER vent the appliance to other rooms or buildings; this

appliance must be vented ONLY to the outside, with a vertical termination. During installation, be sure to

maintain minimum clearances to combustibles, as shown on page 9. Always contact your local building

department or fire department prior to installing this appliance. If required, obtain a permit before installing,

and have the completed installation inspected. Failure to do this could jeopardize your homeowner’s insurance.

The area around the appliance MUST be kept free from combustible materials, gasoline and other

flammable vapors and liquids.

This appliance is hot during operation, and should be located out of heavy traffic areas and away from

furniture and draperies. Clothing or other flammable material should not be placed on or near the appliance.

Children and adults should be alerted to the hazards of high surface temperatures and should stay away to

avoid burns or clothing ignition. Children should not be left unsupervised in the room when this appliance is in

operation.

If any part of this appliance has been under water, DO NOT USE it!! Immediately call a qualified service

technician to inspect the appliance, and to replace any part of the control system or any gas control which

has been under water.

This appliance should NOT be modified under any circumstances. Any parts removed for servicing must be

replaced before operating this appliance. Installation and repair should only be done by a qualified service

technician. The appliance and its venting system should be inspected and cleaned annually by a qualified

service technician. More frequent cleaning may be necessary due to excess lint and dust from carpeting,

bedding material, etc. Be sure to turn off gas valve and pilot before cleaning this appliance.

Install at least one smoke detector on each floor of your home to ensure your safety . They should be located

away from the gas appliance and close to the sleeping areas. Follow the smoke detector manufacturer’s

placement and installation instructions, and be sure to maintain regularly. Your local fire department may

provide assistance in selecting smoke detectors, or contact the Consumer Product Safety Commission,

W ashington, D.C. 20207.

SAFETY NOTICES

Warning: Do not operate appliance with the glass front removed, cracked or broken.

Replacement of the glass should be done by a licensed or qualified service person.

Page 6

March 2000

GB 40 I - FIREPLACE INSERT

SPECIFICATIONS

Manifold pressure 3.5” WC 10.0” WC

Minimum inlet gas supply pressure 4.5” WC 11 0” WC

Maximum inlet gas supply pressure 7.0” WC 14.0” WC

BTU input rating (high) 46,000 40,000

BTU input rating (low) 31,000 32,000

Efficiency with blower (steady state) 77% 79%

Efficiency without blower (steady state) 73% 75%

A.F.U.E. 65% 66%

GAS LINE CONNECTION

Gas line connection can be made near the lower rear of the appliance (3/8” gas hookup). You must

supply a shutoff valve installed in a visible location within 3’ of the insert.

CAUTION

IN SOME AREAS, GAS LINE PRESSURE MAY BE MORE THAN 1/2 PSIG (14” WC). IF YOU

BELIEVE THAT THIS MIGHT BE THE CASE IN YOUR LOCALITY, CONTACT YOUR GAS

SUPPLIER OR LOCAL UTILITY COMPANY. LINE PRESSURE GREATER THAN 1/2 PSIG

WILL DAMAGE THE APPLIANCE VALVE. YOU MUST INSTALL A REGULATOR UPSTREAM

FROM THE APPLIANCE IF LINE PRESSURE IS GREATER THAN 1/2 PSIG.

SPECIFICATIONS

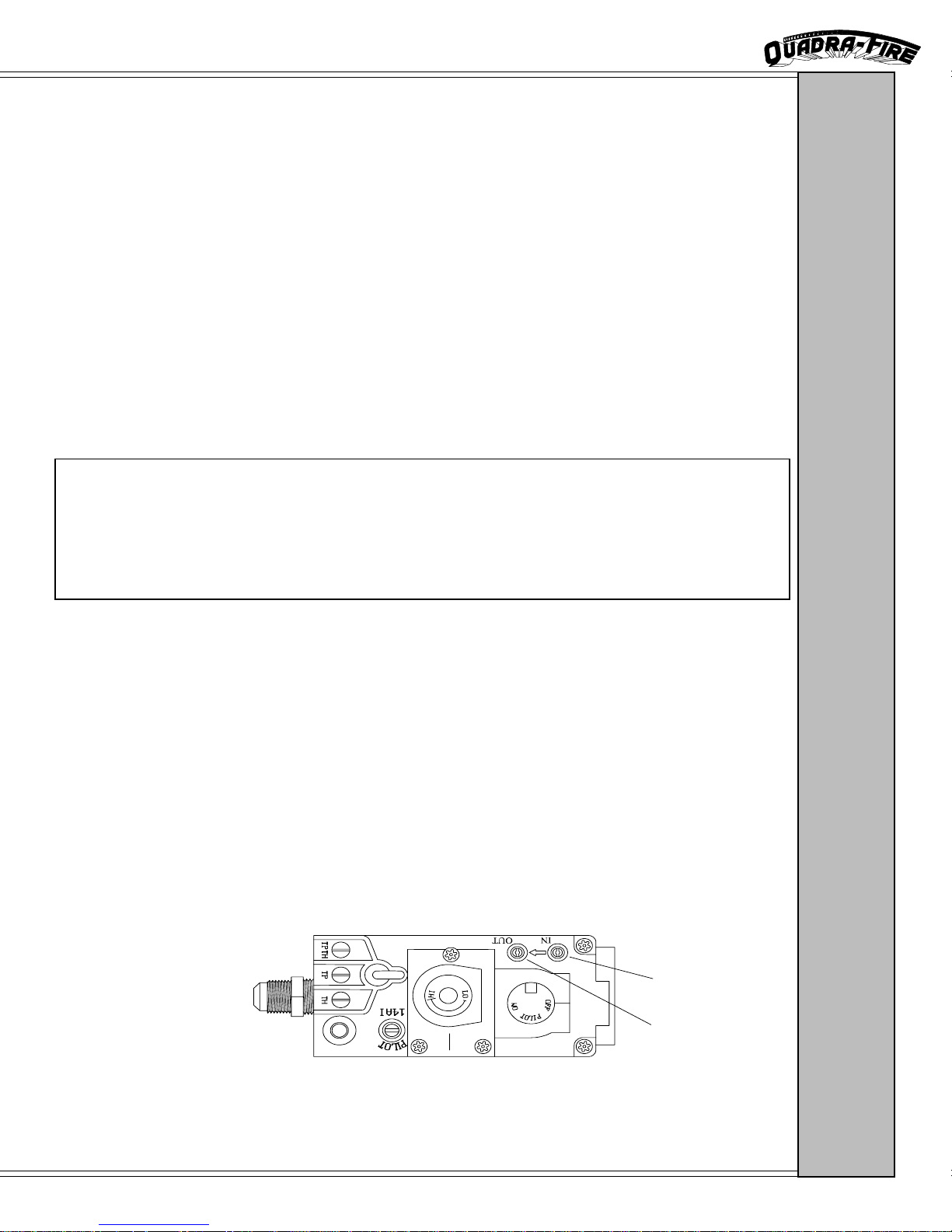

PRESSURE TESTING

During any pressure testing of the gas supply piping system that exceeds test pressures of 1/2 PSIG, this

appliance and its individual shutoff valve must be disconnected from the piping system. If test pressure is

less than or equal to 1/2 PSIG, then this appliance must be isolated from the piping system by closing its

individual shutoff valve. The gas valve is supplied with pressure test ports for checking input and output

pressures. These are located just below the on/off knob and can be found inside the hinged lower access

grill. The port on the left is for output pressure and the port on the right for input. Pressure can be

checked by turning the captured screw counterclockwise two or three turns and then placing the

manometer tubing over the test port. BE SURE TO CLOSE CAPTURED SCREWS AFTER TESTING

BY TURNING THEM CLOCKWISE. DO NOT OVERTIGHTEN SCREWS.

NOTE: To make flame and heat output adjustments, turn the HI-LO knob located on the center of the

valve (as seen below). Turn clockwise for a higher flame and counterclockwise for a lower flame

INPUT SIDE

TEST VALVE

OUTPUT SIDE

TEST VALVE

.

The Quadra-Fire GB40-I is listed to ANSI Z21.11.1 and CAN1-2.1 by OMNI-Test Laboratories, Inc.

March 2000

LISTINGS

Page 7

20 1/4” (514mm)

GB 40 I - FIREPLACE INSERT

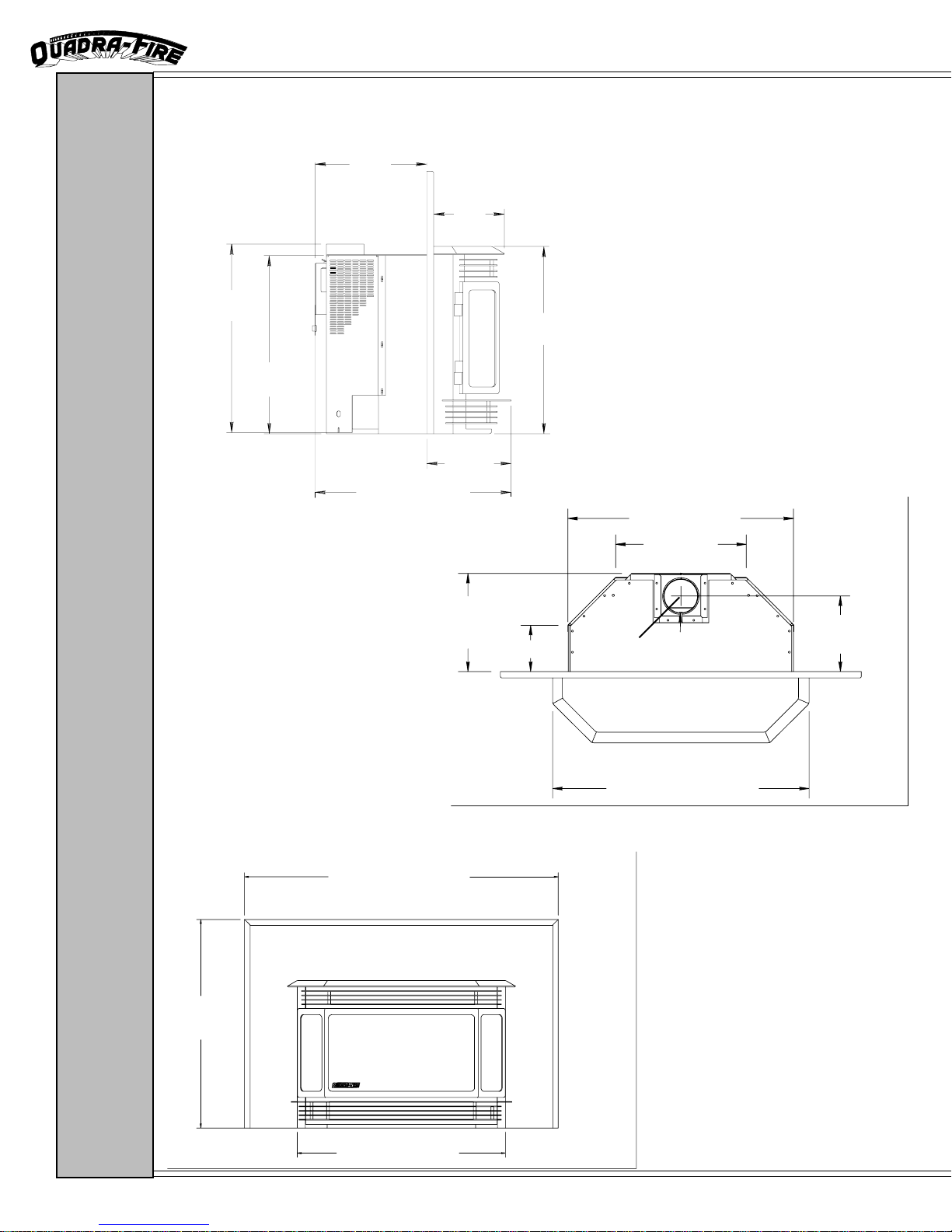

DIMENSIONS

11 7/8”

(302mm)

7 1/2”

(190mm)

20” (507mm)

19 1/8”

(485mm)

9”

(229mm)

21” (533mm)

26 1/4” (668mm)

15 1/4”

(387mm)

11 3/8”

42 1/2” (1080mm)

(289mm)

5 3/8” (136mm)

4” flue

29 7/8” (758m)

8/3/4”

(223mm)

DIMENSIONS

28 1/4”

(718mm)

Page 8

28 1/4” (718mm)

March 2000

GB 40 I - FIREPLACE INSERT

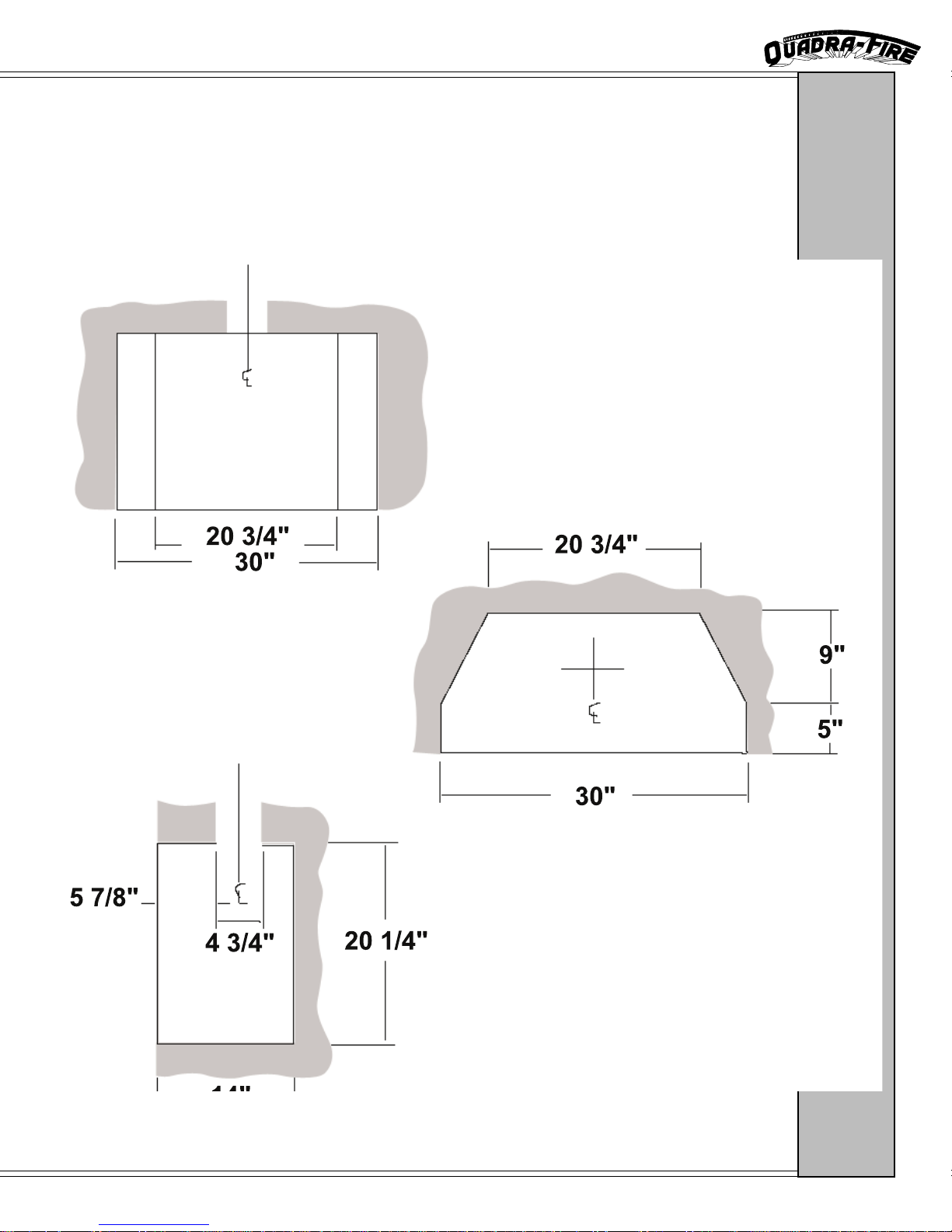

MINIMUM FIREPLACE CLEARANCES

The following diagrams show the minimum fireplace dimensions that are required for installation of the

Quadra-Fire GB40-I gas fireplace insert.

CLEARANCES

March 2000

Page 9

GB 40 I - FIREPLACE INSERT

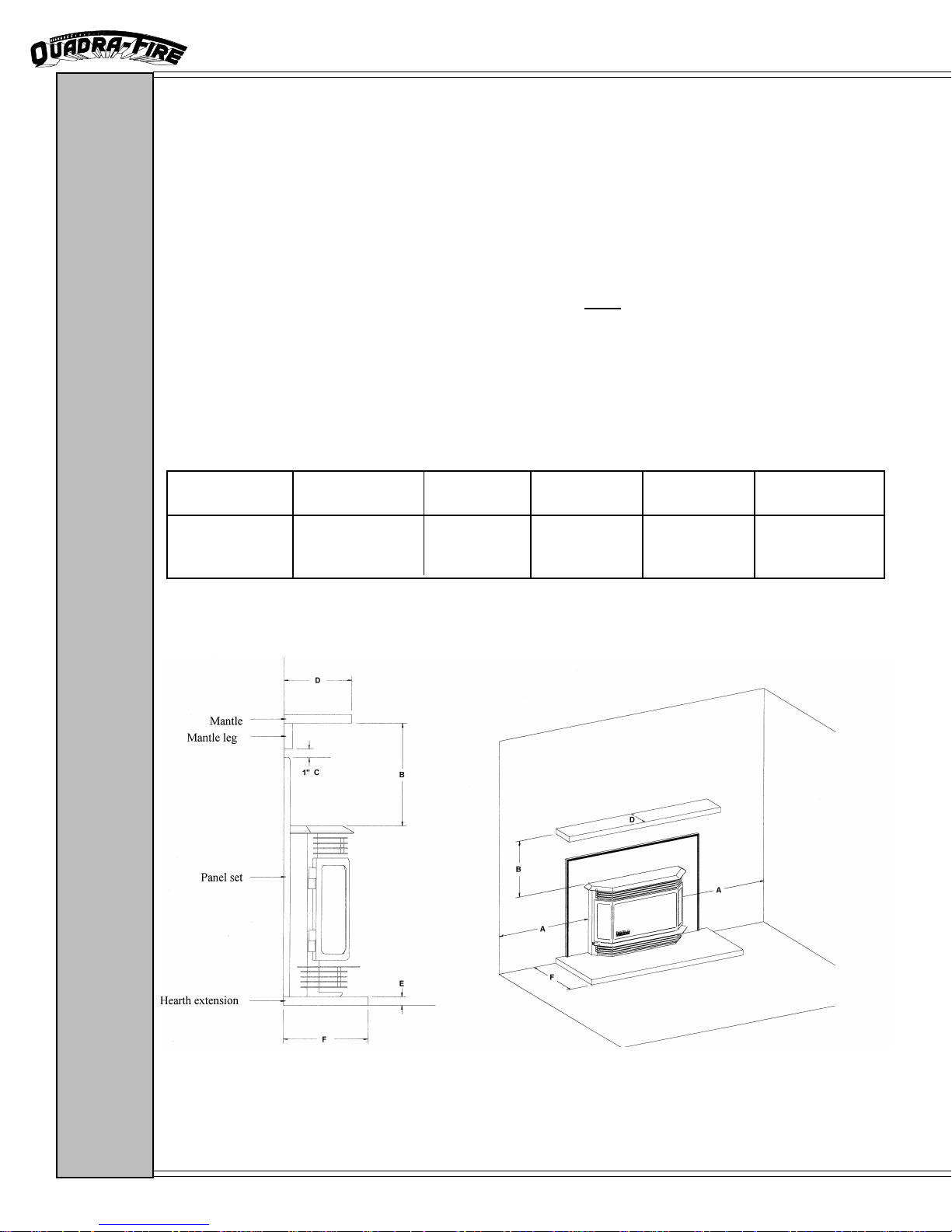

CLEARANCES TO COMBUSTIBLES

Minimum clearances to combustible materials

From HEATER TO: SIDEWALL A 10” (255mm)

From HEATER TO: MANTEL B 12.5” (320mm) *

From PANEL TOP TO: MANTEL LEG C 1” (25mm)

MANTEL WIDTH D 1” (25mm)

* NOTE: For every 1” (25mm) of MANTEL WIDTH, ADD 1” (25mm) to Clearance “C”.

Example: Mantel Width is 6” (150mm) - Clearance “C” must be 17.5” (445mm).

HEAR TH REQUIREMENTS: A minimum 3/8” (10mm) non-combustible material is required under

the appliance. The depth of the hearth extension is variable depending on the height of the non-combustible

hearth material. Follow the hearth extension clearance requirements noted below for compliance to this

requirement:

Height (E) 3/8”(10mm) 1” (25mm) 2” (51mm) 3” (76mm) 4” (102mm)

Depth (F) 24” 23” 22” 15” 0”

(610mm) (585mm) (560mm) (380mm) (0mm)

CLEARANCES

Page 10

March 2000

GB 40 I - FIREPLACE INSERT

HIGH ALTITUDE OPERATION

For installations in the United States and at altitudes above 2000 feet, the appliance input shall be adjusted

in accordance with local codes or, in the absence of any, follow the current ANSI Z223.1, National Fuel

Gas Code. For installation in Canada for altitudes up to 4500 feet, for altitudes above 4500 feet, contact

the authority having jurisdiction, or the manufacturer . Follow local codes or CAN 1 B-149.

NOTE: In the United States, input ratings of this unit are based on sea level operation, and shall not be

changed for operation at elevations up to 2000 feet (600m). For operation at elevations above

2000 feet, this appliance shall be reduced at the rate of 4% for each 1000 feet above sea level.

Exception: As permitted by the authority having jurisdiction.

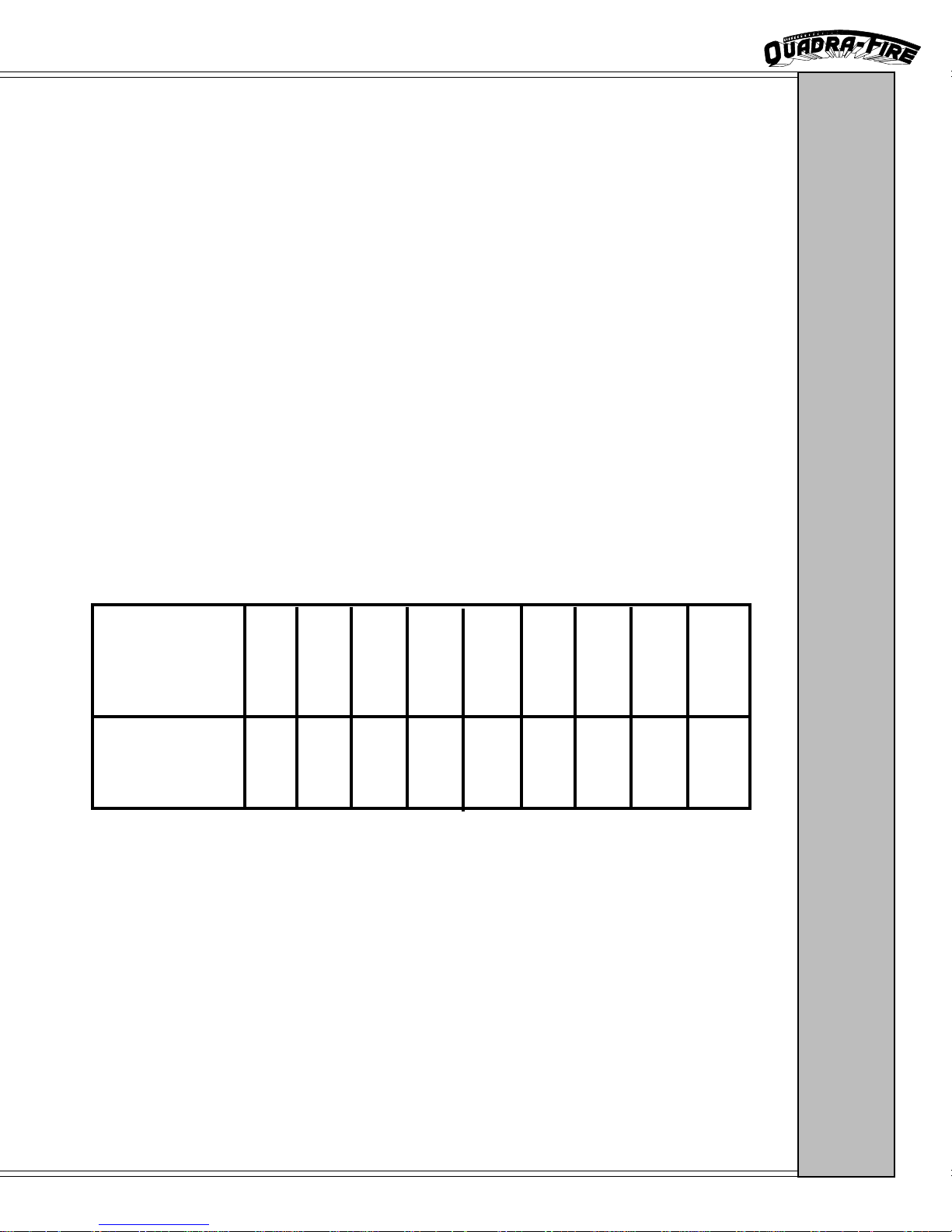

EQUIVALENT ORIFICE SIZES A T HIGH AL TITUDES

(INCLUDES 4% INPUT REDUCTION FOR EACH 1000 FEET)

Orifice at sea level 2000 3000 4000 5000 6000 7000 8000 9000 10000

Natural Gas

Front 53 54 54 54 54 54 54 55 55 55

Middle 52 52 53 53 53 53 53 54 54 54

Rear 38 39 40 41 41 42 42 43 43 44

Propane

Front 66 67 67 68 68 68 69 69 69 70

Middle 63 64 64 65 65 65 66 66 67 68

Rear 53 54 54 54 54 54 54 55 55 55

HIGH ALTITUDE

March 2000

Page 11

Loading...

Loading...