QT QTLP670C-2, QTLP670C-3, QTLP670C-4, QTLP670C-7 Datasheet

PACKAGE DIMENSIONS DESCRIPTION

The QT Optoelectronics surface mount lamps are

designed with a flat top and sides for automatic

placement equipment. They are compatible with convective IR and vapor phase reflow soldering and conductive epoxy attachment process.

The package size and configuration conform to the

EIA–535 BAAC standard specification for case 3528

tantalum capacitor.

■ Non-diffused package for backlighting and

coupling to light pipe

■ Low package profile

■ Low power dissipation

■ Wide viewing angle

FEATURES

SMT LED LAMP

PLCC–2 PACKAGE

HIGH EFFICIENCY RED QTLP670C–2 GREEN QTLP670C–4

YELLOW QTLP670C–3 AlGaAs RED QTLP670C–7

HER Yellow Green AlGaAs Red

QTLP 670C–2 670C–3 670C–4 670C–7 Units

DC forward current, I

F

30 20 30 30 mA

Operating temperature range –40° C to +85° C

Storage temperature range –40° C to +100° C

Lead soldering time 5 seconds @ 260° C

Peak forward current1, I

F

160 160 160 200 mA

Power dissipation Pd (mW) 100 100 100 100 mW

Reversed Voltage (VR)5555V

ABSOLUTE MAXIMUM RATINGS (TA = 25° C Unless otherwise specified)

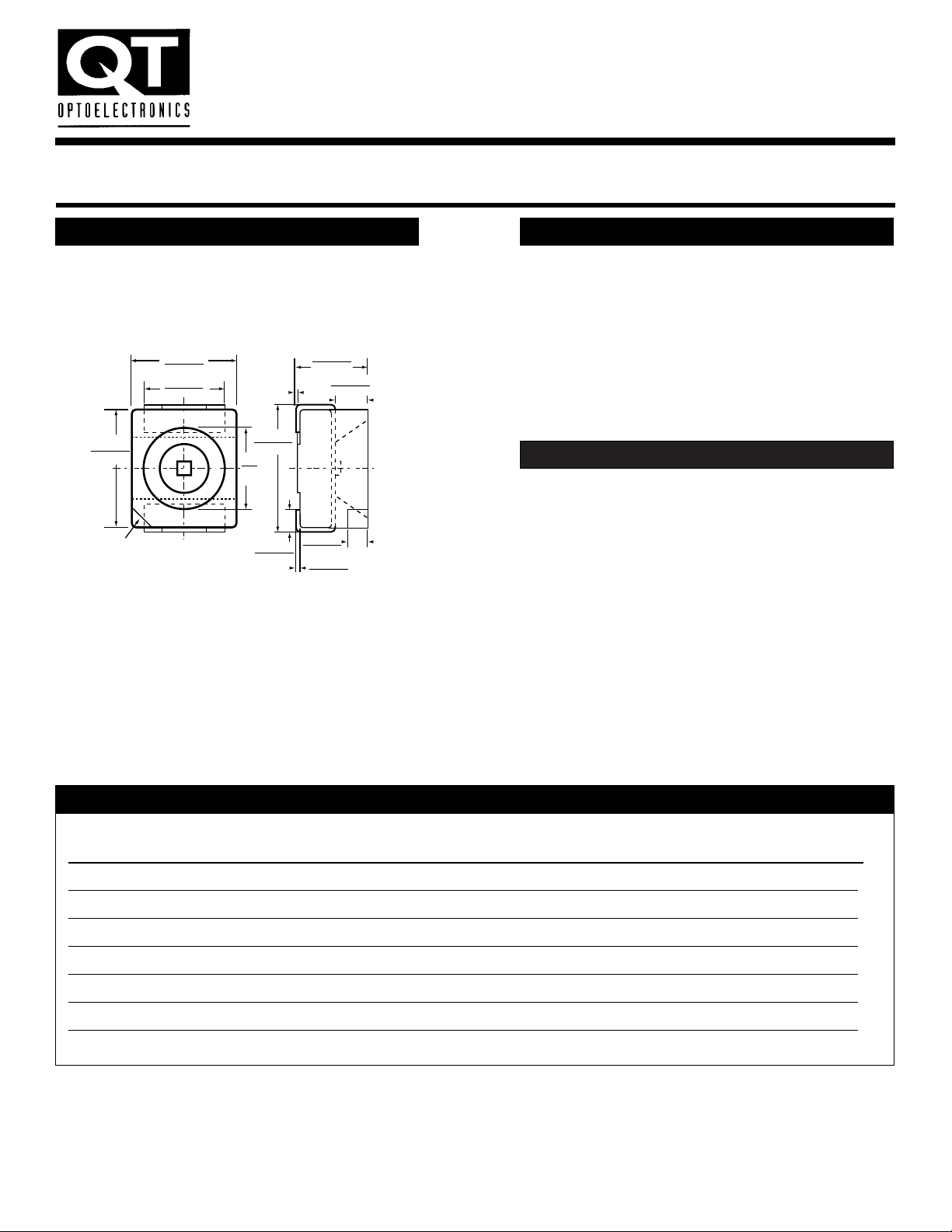

NOTE: ALL DIMENSIONS ARE IN INCHES (mm)

.118 (3.0)

.102 (2.6)

.091 (2.3)

.083 (2.1)

.134 (3.4)

.118 (3.0)

.094

(2.4)

CATHODE

ANODE FOR QTLP670C–7

.083 (2.1)

.067 (1.7)

Ø .04

(.1)

.142 (3.6)

.126 (3.2)

.043 (1.1)

.020 (.5)

.007 (.18)

.005 (.12)

.024 (.6)

.016 (.4)

.035 (.9)

.028 (.7)

Notes:

1. Measured @ f=1.0 kHz, Duty factor = 1/10

HER = High Efficiency Red

SMT LED LAMP

PLCC–2 PACKAGE

AlGaAs

HER YELLOW GREEN RED TEST

QTLP 670C–2 670C–3 670C–4 670C–7 UNITS CONDITIONS

LUMINOUS INTENSITY

minimum 6 6 15 25 mcd I

F

= 20 mA

typical 10 10 25 40 mcd

FORWARD VOLTAGE

minimum 1.7 1.7 1.7 1.5 V I

F

= 20 mA

typical 2.0 2.0 2.1 1.7 V

maximum 2.8 2.8 2.8 2.4 V

PEAK WAVELENGTH 635 585 570 660 nm I

F

= 20 mA

SPECTRAL LINE HALF WIDTH 45 35 30 20 nm

VIEWING ANGLE 120° 120° 120° 120°

ELECTRO-OPTICAL CHARACTERISTICS (TA = 25° C Unless otherwise specified)

INDIVIDUAL COMPONENT CHARACTERISTICS

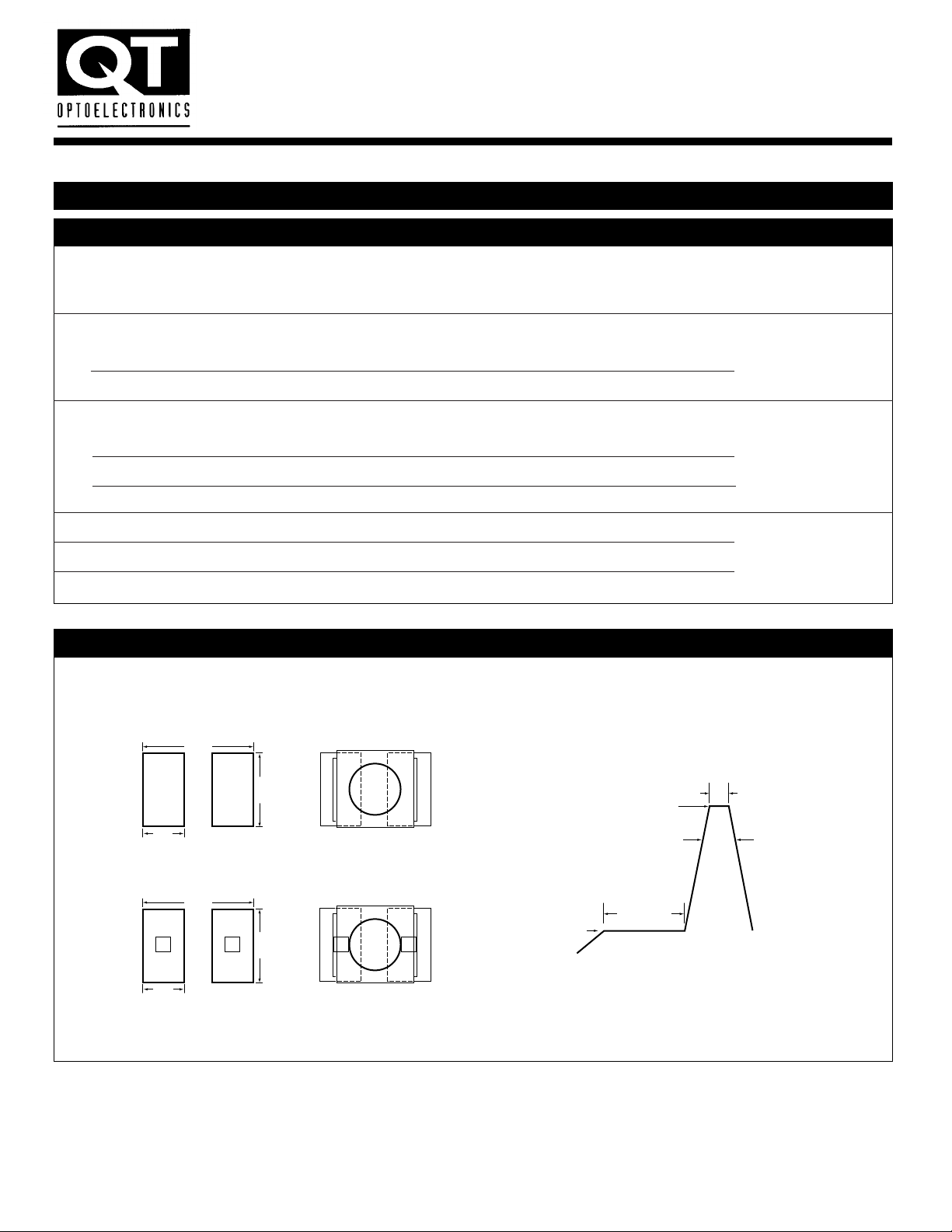

SOLDERING

FIG. 1 - Recommended Solder Pad Patterns

FIG. 2 - Recommended IR Reflow Soldering Profile

INFRARED VAPOR PHASE

REFLOW SOLDERING

4.45

(.175)

1.65

(.065)

4.45

(.175)

1.65

(.065)

0.64 (.025) SQ.

CENTERED HOLE

COMPONENT LOCATION

ON PAD

COMPONENT LOCATION

ON PAD

2.41

(.095)

2.41

(.095)

240° MAX

5 s MAX

soldering time

60 – 120 sec

Preheating

+5° C/s MAX –5° C/s MAX

120 – 150° C MAX

Notes:

All dimensions are in millimeters (inches).

HER = High Efficiency Red

Loading...

Loading...