Page 1

SANITARY DIRECT MOUNT BALL VALVES

The next generation ball valves are live loaded with selfadjusting packing and a design that is specifically manufactured

for high cycle applications. Tru-Flo products reduce the

worries of routine maintenance expenses while lowering

actuation costs by eliminating custom brackets and couplers.

Double o-ring protection provides additional defense against

leaking through stem and lower operating torque.

Features & Benefits

»

Designed for high cycle automated applications

»

Highly polished internals and end caps with 8-12 Ra nish

»

All materials comply with FDA, USDA, & 3A requirements

»

Investment cast body and end caps

»

ASTM 316 stainless steel

»

Standard with Tri-clamp® ends; other end congurations available

»

100% tested and inspected prior to shipping

»

Full traceability of all components

»

SST x PTFE steam seats available for high temperature applications

»

Standard seats are TFM-1600

»

Cavity llers are virgin PTFE

Available in STANDARD

or CAVITY FILLED seats

#1614

www.tru-o.com

Pyram id al Stem &

Anti- St atic De vi ce

(Opti on al)

e

r

P

r

u

s

s

m

e

T

-

e

P

P

a

g

p

e

r

T

e

1

a

t

u

r

e

C

h

a

r

t

9

Page 2

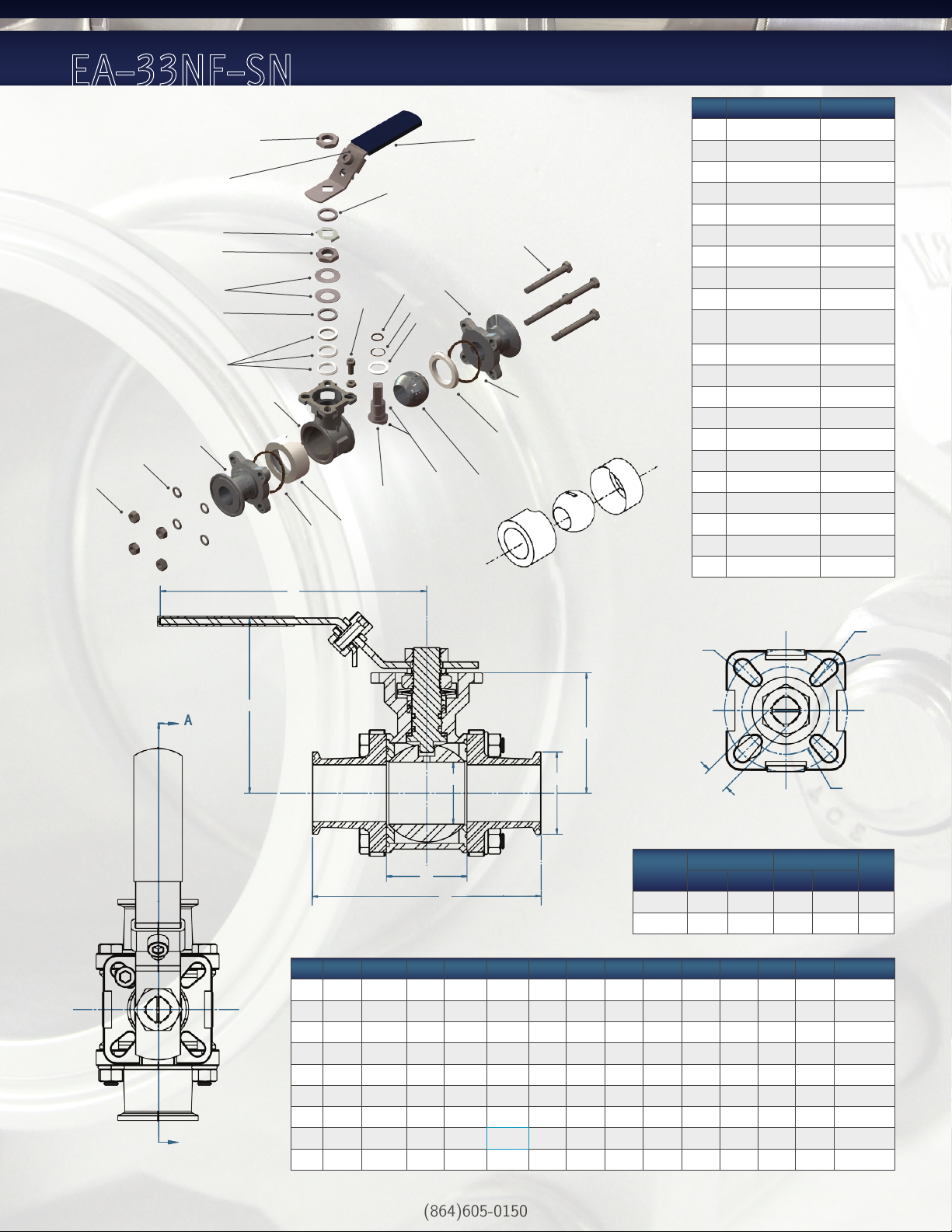

EA–33NF–SN

11

19

12

11

10

9

8

1

2

17

16

Item Part (Qty) Material

13

9

15

2

18

21

14

7

6

3

20

4

5

3*

6

1 Body CF8M/316

2 End Caps

3* Seats

4 Ball SUS 316

5 Stem SUS 316

6 Body Seal

7 Stem Gasket PTFE

8 Stem Seals (3) PTFE

9 Gland Ring

Belleville Spring

10

11 Lever Nut SUS 304

12 Locking Tab SUS 304

13 Handle SUS 304

14 O ring SUS 304

15 Bolts

16 Bolts Nut

17 Washer

18 Stop Screw PVC

19 Locking Device SUS 304

20 Static Device

21 O ring VITON

(2) CF8M/316

(2) PTFE

(2) PTFE

(2) SUS 301

(2)

Washer

(4) SUS 304

(4) SUS 304

(4) SUS 304

(2) SUS 316

SUS 304

D

d1

ØJ1

d2

C

A

H

ØA

G

B

Size A B C D E G H L J J1 d1 d2 SW ISO5211

½” 0.37 3.50 2.79 4.33 1.00 0.99 1.67 0.32 1.42 1.65 0.24 0.24 0.35 F03/F04

¾” 0.63 4.00 2.89 4.33 1.00 1.09 1.76 0.32 1.42 1.65 0.24 0.24 0.35 F03/F04

1” 0.87 4.50 3.31 5.32 1.98 1.30 2.13 0.39 1.65 1.97 0.24 0.28 0.43 F04/F05

1½” 1.37 5.50 4.31 6.50 1.98 1.94 2.89 0.58 1.97 2.76 0.28 0.35 0.55 F05/F07

2” 1.87 6.25 4.68 6.50 2.52 2.50 3.26 0.58 1.97 2.76 0.28 0.35 0.55 F05/F07

2½” 2.37 7.00 5.25 9.06 3.05 2.76 4.21 0.67 2.76 4.02 0.35 0.43 0.67 F07/F10

3” 2.88 9.00 6.30 11.81 3.58 4.02 4.62 0.67 2.76 4.02 0.35 0.43 0.67 F07/F10

A

4” 3.84 9.50 6.90 11.81 8.90 4.02 5.21 0.67 2.76 4.02 0.35 0.43 0.67 F07/F10

6” 5.78 15.50 8.51 19.68 6.57 7.42 8.50 1.06 4.02 4.92 0.47 0.55 1.06 F10/F12

ØE

SW

*Option: Cavity Filled

Standard

Grit

240g 14–18 .34–.46 15–20 .38–.51 B

320g 8–10 .21–.25 9–11 .23–.28 A

Ra RMS

µin µ µin µ

ØJ

Class

(864)605-0150

Loading...

Loading...