Page 1

POWERLIGHT 2A

User Manual

Manuel de l’utilisateur

Bedienhandbuch

Manual del Usario

*TD-000089-00*

TD-000089-00

rev.A

PL2A Audio Power Amplifiers

with Analog Signal Processing

• PL218A

• PL224A

• PL230A

• PL236A

Page 2

EXPLANATION OF GRAPHICAL SYMBOLS

The lightning flash with arrowhead symbol within an equilateral triangle is intended to alert the user to the presence of uninsulated “dangerous” voltage within the

product’s enclosure that may be of sufficient magnitude to constitute a risk of electric shock to humans.

The exclamation point within an equilateral triangle is intended to alert the user to the presence of important operating and maintenance (servicing) instructions in the

literature accompanying the product.

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

CAUTION: To reduce the risk of electric shock, do not remove the cover. No user-serviceable parts inside.

Refer servicing to qualified personnel.

WARNING: To prevent fire or electric shock, do not expose this equipment to rain or moisture.

FCC INTERFERENCE STATEMENT

NOTE: This equipment has been tested and found to comply with the limits for a class B digital device, pursuant to part 15 of the FCC rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation. This equipment generates, uses, and can radiate radio frequency energy and if not installed and used in

accordance to the instructions , may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation. If

this equipment does cause harmful interference to radio or television reception, which can be determined by switching the equipment off & on, the user is encouraged to try to correct

the interference by one or more of the following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and the receiver.

- Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

- Consult the dealer or an experienced radio or TV technician for help.

© Copyright 2000, QSC Audio Products, Inc.

QSC® is a registered trademark of QSC Audio Products, Inc.

PowerWave™ is a trademark of QSC Audio Products, Inc.

“QSC” and the QSC logo are registered with the U.S. Patent and Trademark Office

All trademarks are the property of their respective owners.

2

Page 3

TABLE OF CONTENTS

Explanation of Graphical Symbols.......................................................2

FCC Interference Statement....................................................................2

INTRODUCTION:

PL2A Series Overview.................................................4

Front Panel...................................................................4

Rear Panel....................................................................5

Side Panel....................................................................5

FEATURES & SETUP:

Rear Panel Switches-

INPUT CONFIGURATION..............................................6

MODE...........................................................................7

DATAPORT INPUT SIGNAL..........................................8

GAIN-SENSITIVITY SELECT.........................................9

Side Panel Switches and SIP networks-

Subaudio Filter & Subaudio Frequency....................10

Lo Frequency Delay and HF ATTEN..................................11

HORN BOOST.............................................................12

POWER LIMITER........................................................13

CLIP LIMITER..............................................................15

Crossover & Delay SIP Networks.............................16

CONNECTIONS:

Inputs................................................................................21

Outputs............................................................................22

SECURITY PANEL USE & INSTALLATION...................................................24

OPERATION:

Gain Controls................................................................25

AC Power Switch...............................................................25

Front Panel LED Indicators.................................................25

Normal operating levels......................................................25

TROUBLESHOOTING.......................................................................................26

TECHNICAL OVERVIEW & BLOCK DIAGRAM............................................28

SPECIFICATIONS..............................................................................................30

WARRANTY INFORMATION..........................................................................32

HOW TO CONTACT QSC AUDIO PRODUCTS..............................................32

BLANK SETUP SHEETS...................................................................................33

DataPort, Front Panel LEDs, Gain Controls-

INSTALLATION:

Basic Overview...........................................................18

Rack mounting & Mounting Dimensions.................19

Fan Cooling & AC Mains..........................................20

3

Page 4

INTRODUCTION: PL2A OVERVIEW

Thank you for the purchase of your new POWERLIGHT 2A amplifier. To get the most

out of your amplifier, review this manual carefully. The installation and operation

sections provide proper connection and operation guidelines.

The POWERLIGHT 2A expands upon the features of the POWERLIGHT 2. The

flexibility, user-friendliness and reliability of this amplifier will make it a valuable

part of your system for years to come.

The POWERLIGHT 2A was designed to fit your system. You can adjust the input

sensitivity to match the output capability of your mixing board. DataPort input

signals can be summed before or after internal processing so that conflicts with

external processing are avoided. The 4th order Linkwitz-Riley crossover has

independent adjustment of crossover frequency and defeatable low-pass delay

time. The high-pass side of the crossover includes separate binary adjustments for

trim and driver EQ. The precision limiters provide separate adjustment of limiter

threshold, peak mode and attack/release times. You can adjust the limiter

threshold between 100% and 3% of available power. The limiters have a gentle

limiting knee which preserves a sense of signal dynamics. In bi-amplified systems,

a slower attack/release time can be used on the low frequency channel. The

limiters can also be connected together to maintain stereo balance in full range

mode or frequency balance in bi-amplified mode. A peak limiting mode with a fast

attack time provides protection for fragile high frequency drivers.

The POWERLIGHT 2A is easy to use. All operating mode switches are grouped

together on the rear panel. These critical switches have color-coded LED’s to

positively confirm switch position. A brilliant blue LED on the front clearly

indicates when the amplifier is in bi-amp mode. Limiter threshold, high-pass trim

(HF ATTEN) and high-pass EQ (HORN BOOST) levels use combinations of two

position switches for easy adjustment. These less used switches are located on

the side panel.

The POWERLIGHT 2A is built for the long haul. Rubber-isolated XLR input

connectors reduce stress on the contact pins and provide a tight, noise-free

connection. All signal processing is done in side loops and then returned to the

main signal path. This maintains high signal fidelity and provides a more robust

system in the unlikely event a processor ceases to function.

Your new POWERLIGHT 2A amplifier will give you many years of great sound. The

POWERLIGHT 2A is the most flexible, durable and best performing amplifier you

can buy.

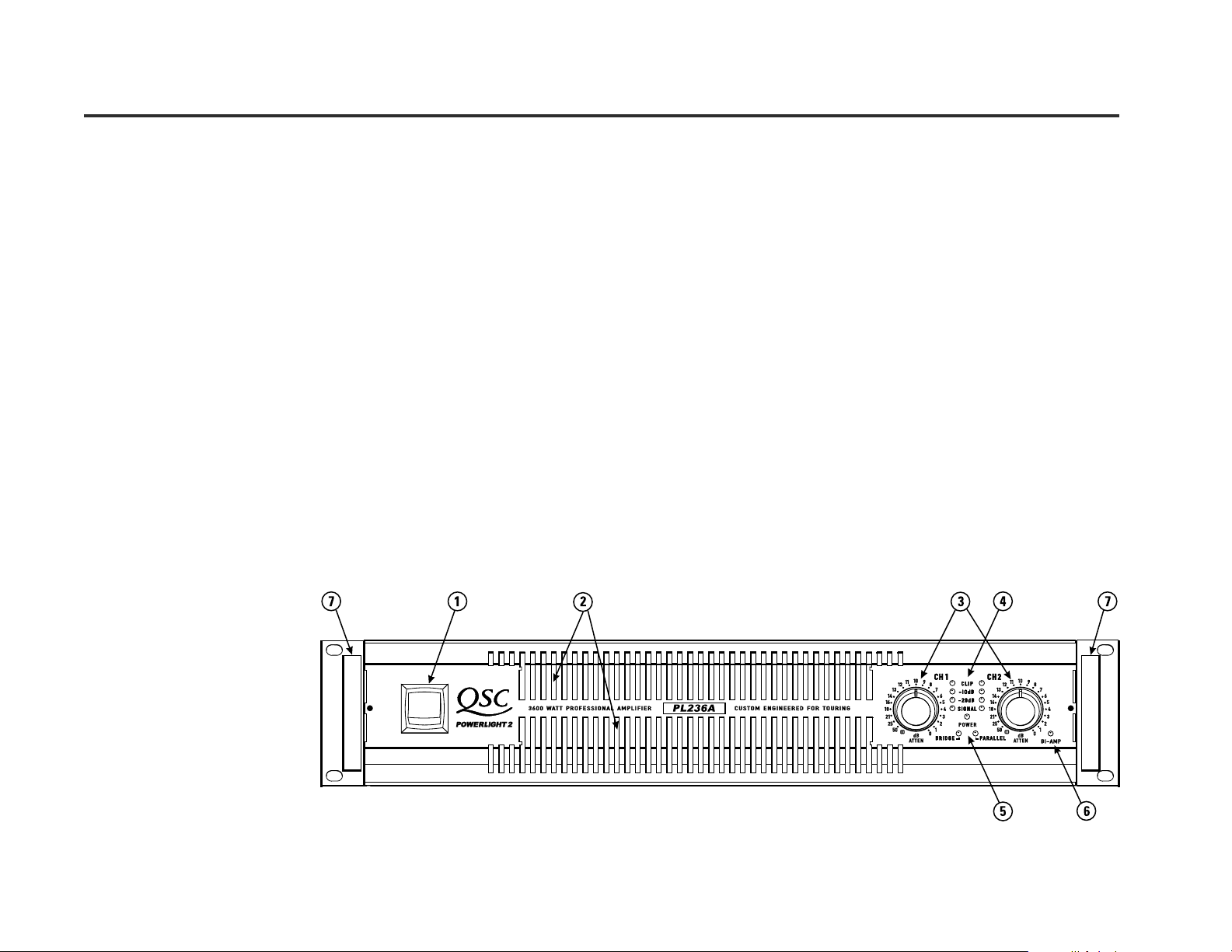

FRONT PANEL

1. Power switch

2. Cooling vents

3. Gain control (1 per

channel)

4. CLIP, -10 dB, -20 dB and

SIGNAL indicator LEDs, 1

per channel

5. POWER, BRIDGE, and

PARALLEL indicator LEDs

6. BI-AMP indicator LED

7. Handles

4

Page 5

INTRODUCTION: PL2A OVERVIEW

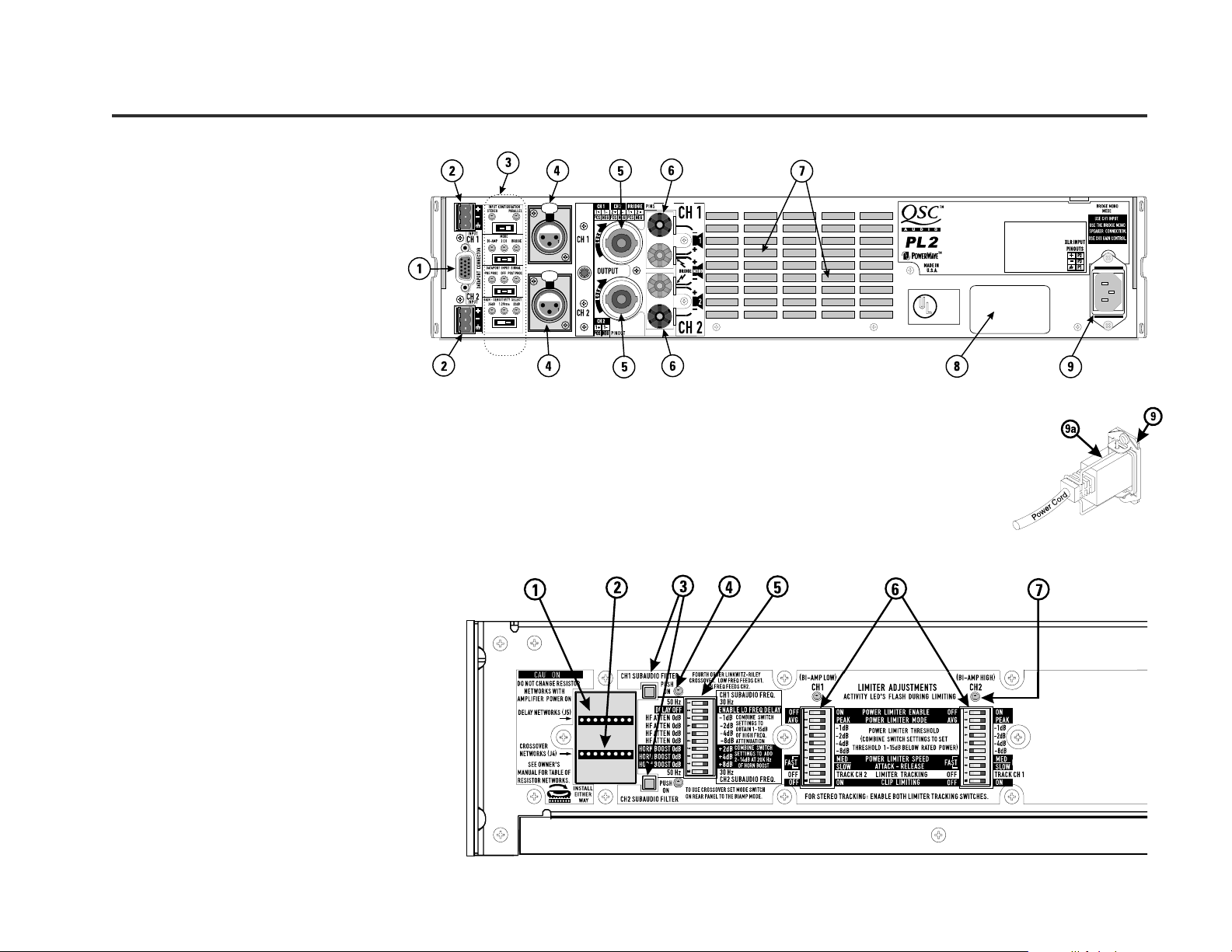

REAR PANEL

1. DataPort

2. Terminal block inputs

3. Configuration switches

4. XLR inputs

5. Speakon outputs

6. Binding post outputs

7. Cooling air inlet vents

8. Serial number label

9. IEC connector for AC power cord

9a. Power cord retaining clip (install on item 8)

SIDE PANEL

1. Low pass delay network SIP* socket (J5)

2. Crossover frequency network SIP socket (J4)

3. Subaudio filter push-button switches (1 per

channel)

4. Subaudio filter “on” indicator LEDs (1 per channel)

5. DIP** switch for subaudio filter frequency select,

low frequency delay enable, HF attenuation

and horn boost

6. DIP switches for power limiting adjustments

and clip limiting enable

7. Activity LEDs for indication of power limiter

activity (1 per channel)

*SIP is the abbreviation for Single-In-line Package

**DIP is the abbreviation for Dual-In-line Package

Side cover plate removed for this illustration

5

Page 6

FEATURES & SETUP- REAR PANEL SWITCHES: INPUT CONFIGURATION

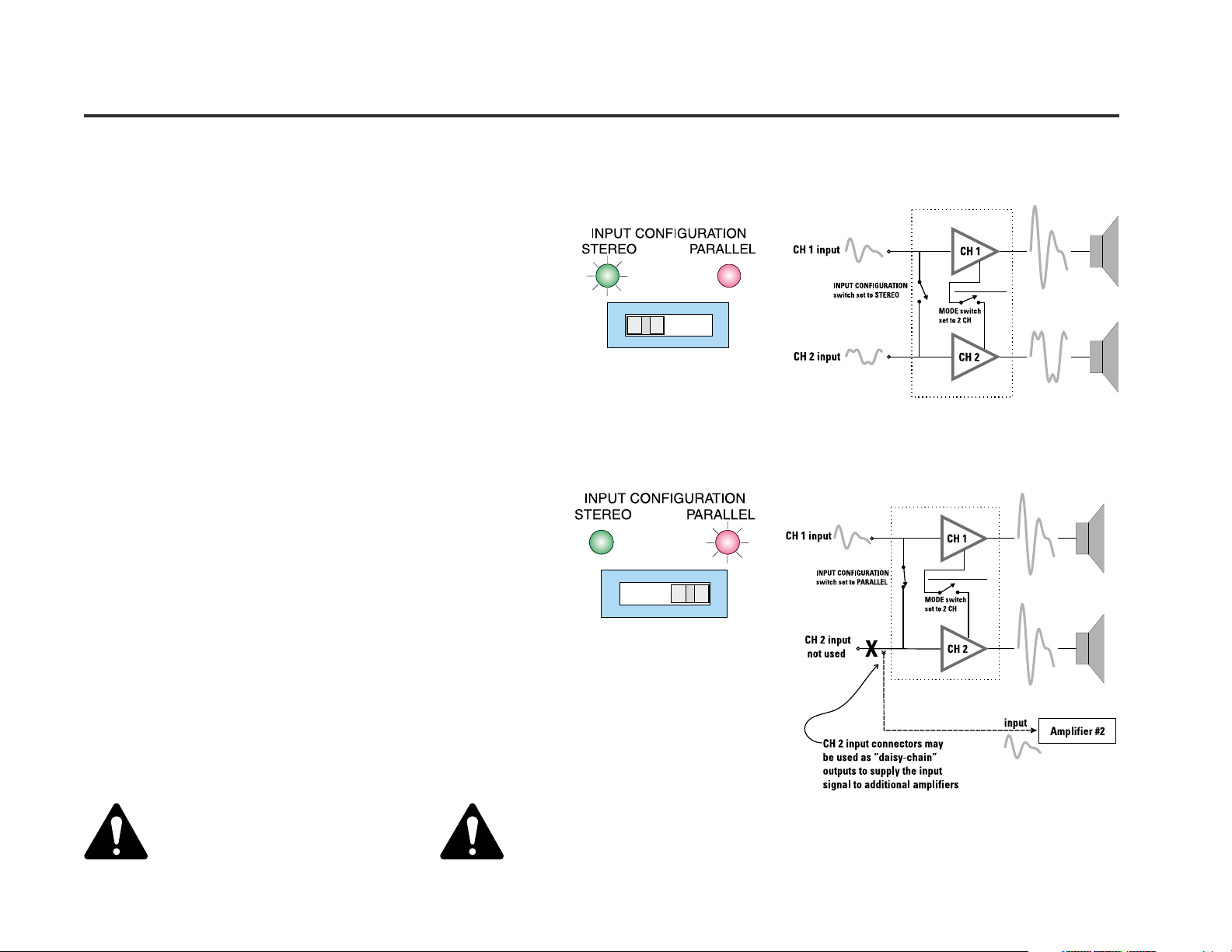

INPUT CONFIGURATION- This switch selects between STEREO or PARALLEL

input configuration. The indicator LED’s above the switch confirm the switch setting.

STEREO: Each input is sent to its respective channel. Each channel has

independent subaudio filtering, clip limiting, gain control, and outputs. In

STEREO mode, a full-frequency signal may be presented to each channel.

When to use STEREO input configuration: Use STEREO for stereo

sources (L-R inputs) and any other situation that requires each channel to

be completely separate from the other.

PARALLEL: The CH 1 and CH 2 inputs are connected together, applying a

single input signal

input jack will drive both channels. Each channel's subaudio filtering, clip

limiting, and gain control still function independently. Each channel feeds

its own speaker load.

to both channels of the amplifier. A signal into any

You can patch the input signal on to additional amplifiers (“daisy-chain”)

by using any of the remaining input jacks. This feature eliminates the

need for “Y” cables.

The orange PARALLEL LED on the front panel clearly indicates when the

amplifier in configured for PARALLEL input.

When to use PARALLEL input configuration: Use PARALLEL when

you need one signal to drive both channels.

NOTE: Ensure that the INPUT CONFIGURATION

switch is set to STEREO when feeding two

separate signals to the two channels.

6

NOTE: The “normal” position of the MODE

switch is 2 CH when operating in STEREO or

PARALLEL input for the operating conditions

shown above. See the following section for

more information regarding the MODE switch.

Page 7

FEATURES & SETUP- REAR PANEL SWITCHES: MODE

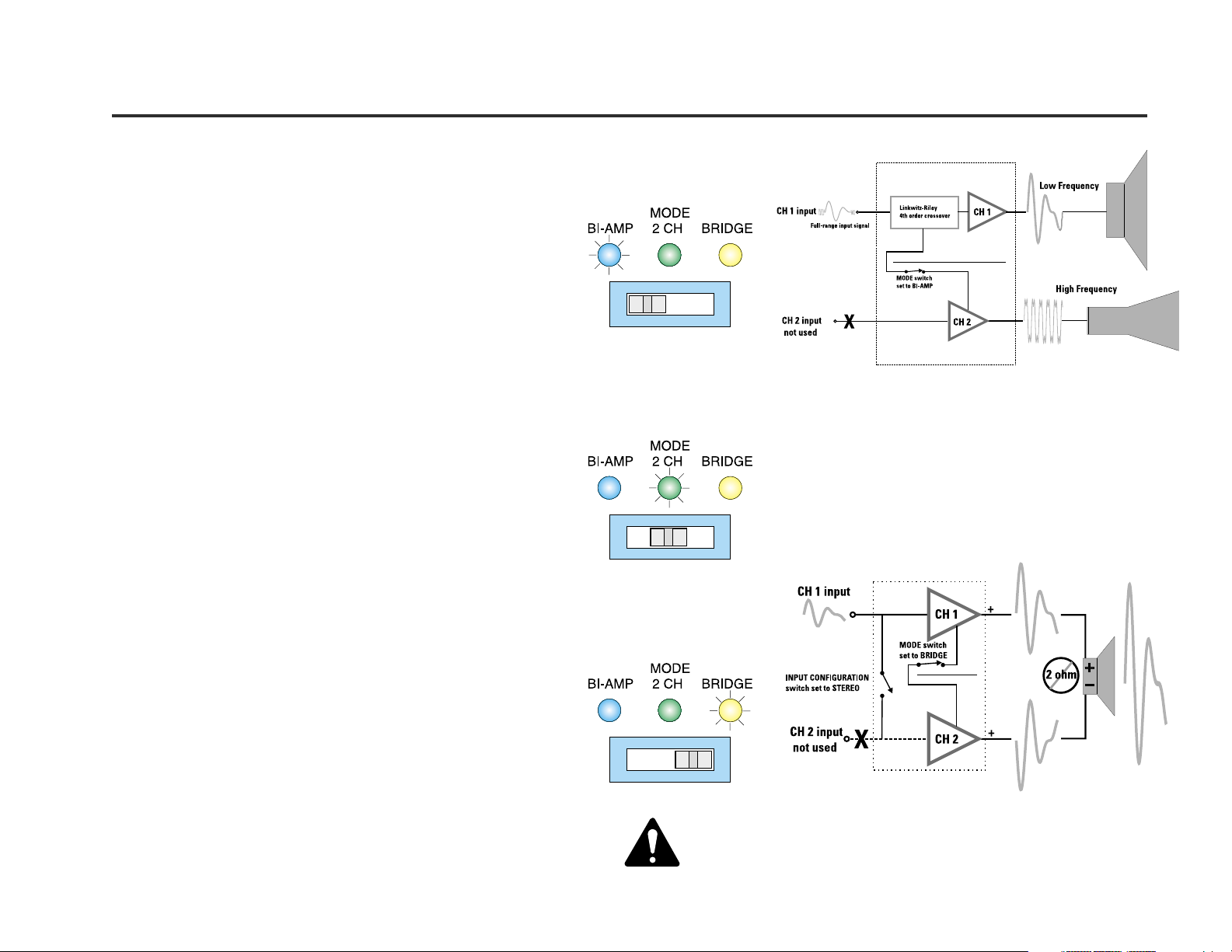

MODE-

The indicator LED’s above the switch confirm the selection.

This switch selects between BI-AMP, 2 CH, or BRIDGE modes of operation.

BI-AMP: This puts the amplifier into a “crossover” mode. CH 1 receives

the low frequencies and CH 2 is receives the high frequencies. The

crossover is a 4th order Linkwitz-Riley. The crossover frequency and lowfrequency alignment delay are “programmed” with SIP (single in-line

package) resistor networks . These small plug-in networks are installed

from the side of the amplifier and plug into J4 and J5. WARNING: Do not

insert or remove networks with the power turned on. See the SIP Network

Selection and Installation section for more information. The HF ATTEN,

HORN BOOST, and SUBAUDIO FILTER controls are active in BI-AMP

mode. The blue BI-AMP LED on the front panel indicates when the amp

is in bi-amp mode.

When to use BI-AMP mode: Use BI-AMP when you need to split the

high frequency and low frequency signals to power separate driver types.

2 CH: This is the “normal” mode used for stereo and parallel input

configuration. Each channel carries full-frequency signals (no crossover)

and is independently controlled (gain, processing, output connection).

BRIDGE: This mode combines both output channels into one output. This

mode is for driving a single, high-powered load with twice the “normal”

voltage swing. This results in about 4 times the peak power and about

three times the sustained power of a single channel. This mode uses the

input, gain control, subaudio filter, and clip limiter of CH 1; CH 2's filter

and clip limiter have no effect. The yellow BRIDGE LED on the front panel

indicates when the amp is in BRIDGE mode.

When to use BRIDGE mode: Use BRIDGE mode when you need to

deliver the power of two channels to a single 8 or 4 ohm load, such as a

subwoofer. Do not use less than 4 ohm loads in BRIDGE mode.

BRIDGE MODE OUTPUT CONNECTION-

Note that speaker connection for bridge mono mode is different than other modes.

See section on Connections: Outputs for proper bridge mode output connections.

7

Page 8

FEATURES & SETUP- REAR PANEL SWITCHES: DATAPORT INPUT SIGNAL

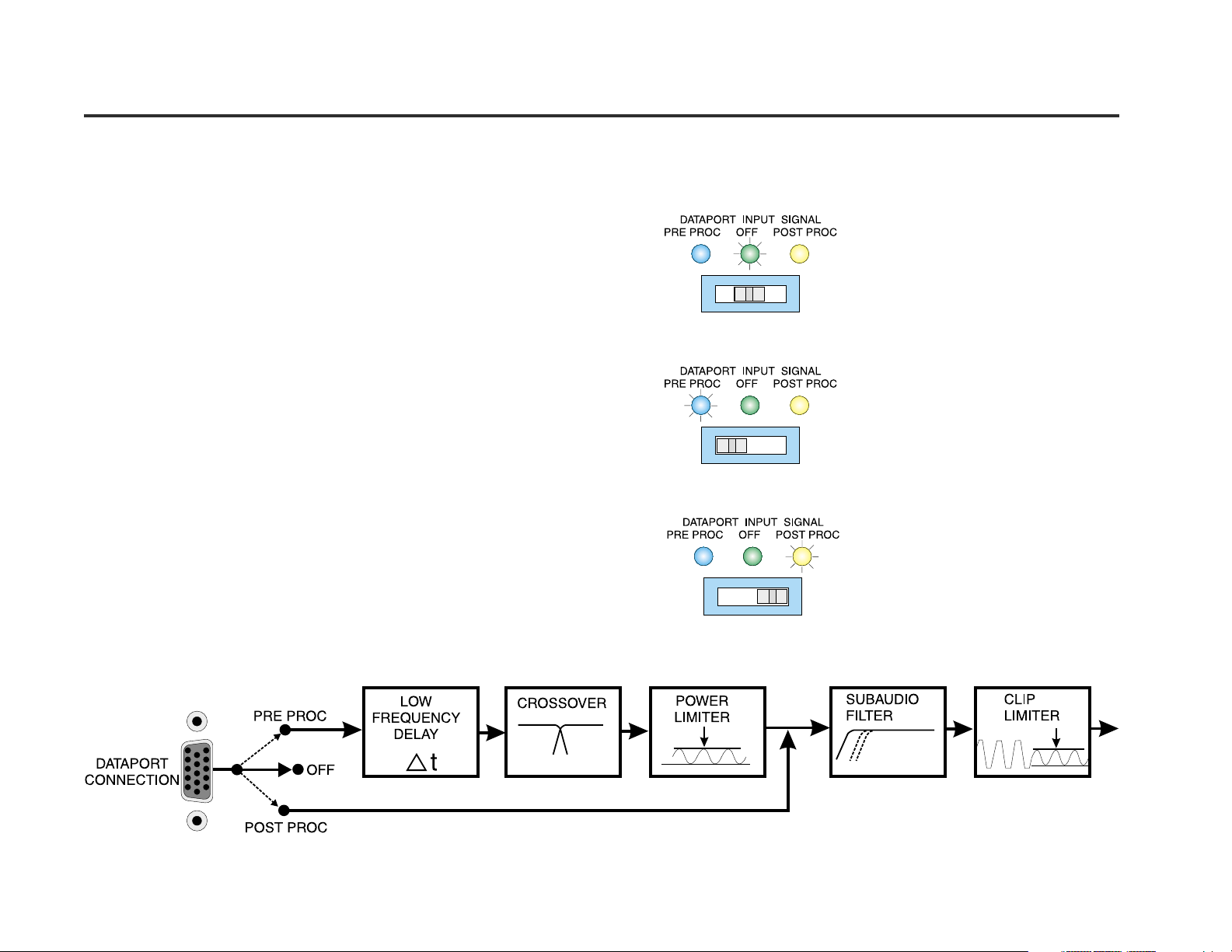

DATAPORT INPUT SIGNAL- This switch selects the regular inputs or the

DataPort inputs, and allows the DataPort to enter before or after the analog

processing. WARNING: There is no DataPort “flag” for this setting, so the appropriate

setting must be confirmed manually.

OFF: If the DATAPORT CONNECTION is not being used, set to the OFF position. The

DataPort MONITOR SIGNALS and STANDBY are still active, but the DataPort input signals

will not reach the amplifier.

PRE PROC: This setting will insert the DATAPORT signals ahead of the amplifier’s signal

processor. If you are using external processing on the DATAPORT input signal, be aware that

additional internal processing will be added to the signal. This may cause unexpected overall

results.

POST PROC: This selection inserts the DATAPORT signals after the amplifier’s processor.

The subaudio filters and clip limiting remain functional,

bypassed. See the Block Diagram for more detailed signal flow information.

DATAPORT signal routing options using the

but all other processing is

8

DATAPORT INPUT SIGNAL

switch

Page 9

FEATURES & SETUP- REAR PANEL SWITCHES: GAIN-SENSITIVITY SELECT

GAIN-SENSITIVITY SELECT- This switch selects the gain structure of the amplifier. Each channel

runs through a gain buffer which allows all models to have either a uniform 1.2 Vrms input sensitivity or

a uniform 26 or 32 dB of voltage gain (all measured with the GAIN controls at maximum). The internal

signal leaving this stage is approximately +4 dB, leaving about 16 dB of headroom for the rest of the

signal processing. NOTE: The GAIN-SENSITIVITY SELECT setting does not effect DataPort gain in any

mode.

1.2 Vrms: This selection sets the input sensitivity to approximately 1.2 Vrms.

This is the input voltage required to drive the amplifier to rated output power

into an 8 ohm load.

26 dB: This selection sets the maximum voltage gain of the amplifier to

approximately 26 dB.

32 dB: This selection sets the maximum voltage gain of the amplifier to

approximately 32 dB

9

Page 10

FEATURES & SETUP- SIDE PANEL SWITCHES: SUBAUDIO FILTER and SUBAUDIO FREQUENCY

The side panel cover plate must be removed to access the side panel switches.

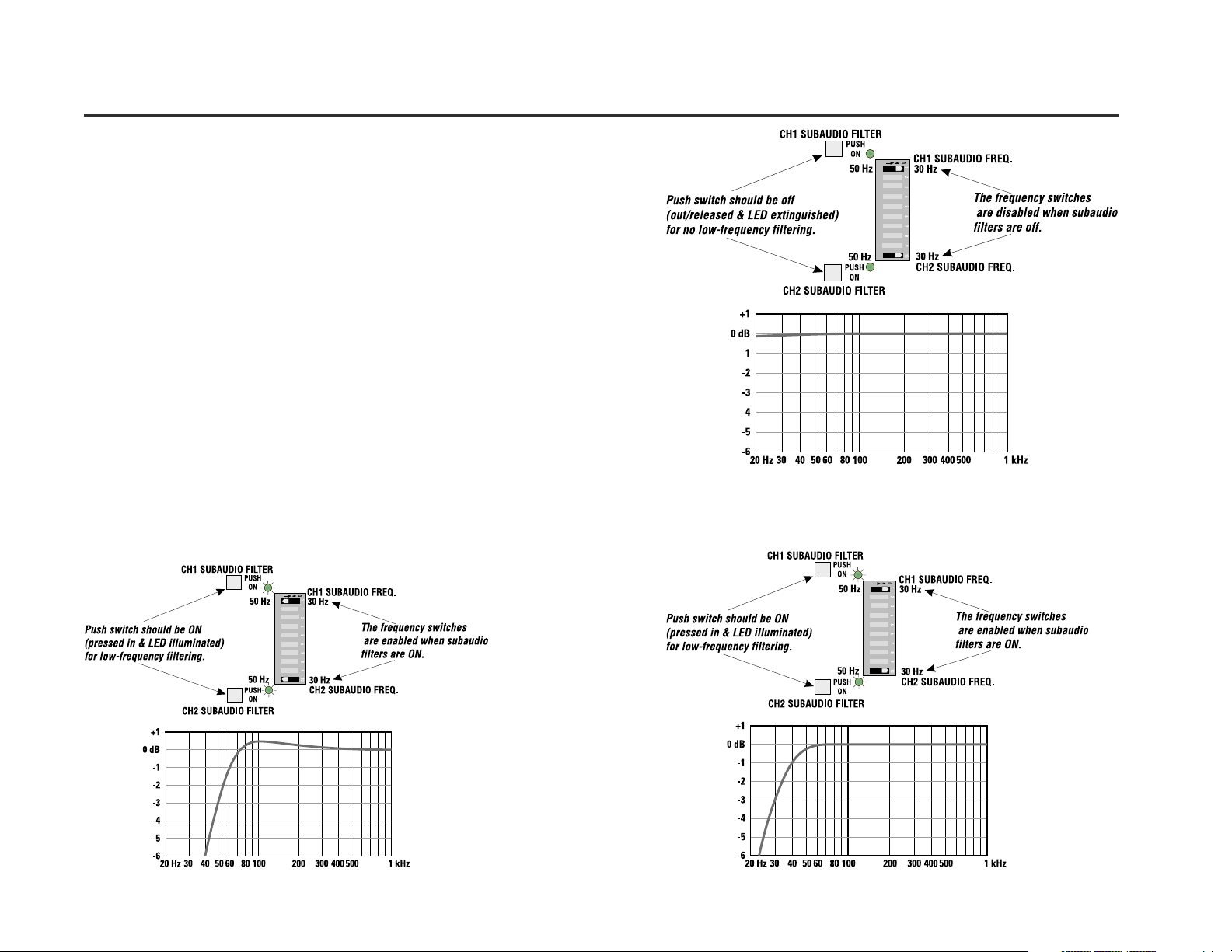

CH1 SUBAUDIO FILTER, CH2 SUBAUDIO FILTER-

to turn on or off the SUBAUDIO FILTER for each channel.

LED illuminates when the filter is ON. Push in and allow the switch to release for

LED extinguishes when the filter is OFF.

The filter’s roll-off frequency is determined by each channel’s SUBAUDIO FREQUENCY switch.

When the filter is switched OFF, a 5 hertz roll-off frequency protects the load against DC or deep

subaudio output from the amplifier.

use the

SUBAUDIO FILTER

frequencies below the speaker’s limits.

systems with rated frequency response below 30 hertz or if low frequency filtering is provided by

other devices.

Unless you already have filtering upstream of the amplifier,

to protect your speakers from cone over-excursion caused by

The OFF position should be used only for subwoofer

These push-button switches are used

Press the switch in for ON; the green

OFF

; the green

CH1 SUBAUDIO FREQUENCY, CH2 SUBAUDIO FREQUENCY- These switches

determine the low frequency roll-off of the SUBAUDIO FILTER. Generally, match the frequency

selection to your speaker’s low frequency capability. This improves speaker performance by

limiting subaudio cone movement, making more power available for the speaker’s rated

frequency range. 30 Hz and 50 Hz are the available settings. If the SUBAUDIO FILTER switches

are OFF, these settings will have no effect. These switches are located on sections 1 and 10 of

the left-most DIP switch.

Subaudio filter frequency response- filter off

Subaudio filter frequency response- filter on, 50 hertz selected Subaudio filter frequency response- filter on, 30 hertz selected

10

Page 11

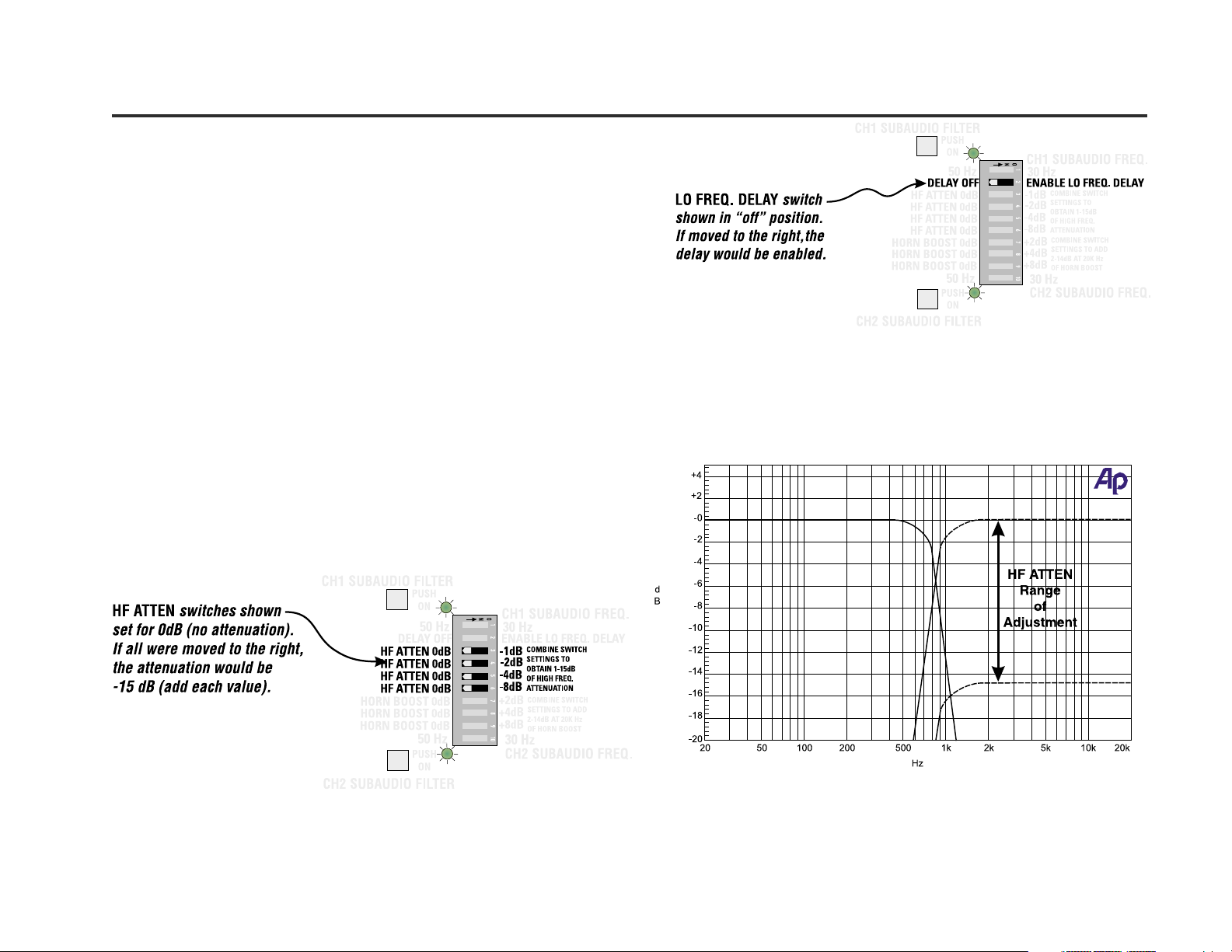

FEATURES & SETUP- SIDE PANEL SWITCHES: LO FREQ DELAY and HF ATTEN

LO FREQ DELAY-

switch controls an additional analog delay which adds to the inherent delay of the low

frequency filter. The amount of delay is determined by the SIP programming network installed

in the DELAY NETWORK socket (J5). DELAY OFF disables the delay. ENABLE LO FREQ

DELAY activates the delay. Refer to the SIP network value selection chart for more

information.

This switch is active only when the amplifier is in BI-AMP mode. This

HF ATTEN- These switches are active only when the amplifier is in BI-AMP mode.

These four switches (section 3, 4, 5, and 6 of the left-most DIP switch) work in

combination to control the amount of high-frequency attenuation. The amount of

attenuation can be selected in 1dB steps from 0 to 15 dB. Add the selected switch values

for the total attenuation. EXAMPLE: Setting -1 dB and -4 dB results in -5 dB of high

frequency attenuation.

Typical crossover frequency response curve showing

the range of adjustment of the

Crossover frequency is programmable.

HF ATTEN

switches.

11

Page 12

FEATURES & SETUP- SIDE PANEL SWITCHES: HORN BOOST

HORN BOOST- These switches are only active when the amplifier is in BI-AMP

mode. These switches work in combination to control the amount of high-frequency horn

boost. The horn boost is adjustable from 0 to 14dB in 2dB steps as measured at 20 kHz.

Add the values of the selected switches for the total boost.

12

Page 13

FEATURES & SETUP- SIDE PANEL SWITCHES: POWER LIMITER

POWER LIMITER: Each channel has its own limiter with independently adjustable threshold and time con-

stants. A ten-section switch for each channel controls the limiter settings.

LIMITER ACTIVITY LED’s: Just below the CH 1 and CH 2 labels you will note a clear circle which has a yellow

LED behind it. Each LED illuminates only when its limiter is reducing gain. Therefore, the LED activity tells you

how hard the limiter is working and shows the limiter time constant (see SPEED).

POWER LIMITER ENABLE: Set this switch to ON to activate the limiter for each channel. NOTE: The Limiter

Activity LED does not illuminate until the output power reaches the limiter threshold.

POWER LIMITER MODE:

AVG mode tracks the program level with moderate attack and release rates (SPEED is set

below). This setting does not respond strongly to isolated peaks and therefore gives the

smoothest results.

PEAK mode causes limiting to increase abruptly, even on short peaks. It provides faster

protection, but causes more audible “ducking” of the program level.

POWER LIMITER THRESHOLD: These four switches control the threshold where limiting begins in 1 dB steps

relative to the amplifier’s rated power. The limiting characteristic has a soft knee which begins several dB below

the threshold. The threshold is reached at 6 dB of limiting. Slope is 8:1 on AVG mode, and 15:1 on PEAK mode.

To enter the desired power, find the amplifier’s rated power at your load impedance (see Specification

section), determine the desired percentage of power and consult the table at right to convert this to the nearest

dB setting. Then combine switch settings to obtain the desired setting.

EXAMPLE:

which is rated for 900 watts into 4 ohms. Therefore, you want to limit at 11% of this power. This falls between 9 dB and -10 dB on the table (below). We enter -10 dB by setting the -8 dB and -2 dB switches.

POWER LIMITER SPEED, ATTACK-RELEASE: Three overall response times or “speeds” are available.

Although it may seem desirable to have rapid response in all cases, a limiter should not change gain appreciably

during an individual cycle of audio, as this causes intermodulation (IM) distortion. Therefore the speed must be

slow enough to pass the lowest frequency intended, without unwanted modulation. Otherwise the low frequency tones cause “garbling” of the highs. The speed settings adjust the release time which governs how much

the limiter can change from one cycle to the next. The AVG mode (described above) has a 25% attack time

relative to this release time, so the gain changes gradually in both directions. The PEAK mode has a 1 to 2%

attack time and therefore gain reduction can occur quickly for more protection. However, gain increase is still

controlled by the overall SPEED setting, and therefore, the same frequency range applies.

NOTE: The time constants for each setting are determined by internal capacitor values which can be

changed by a qualified service technician. Consult QSC Technical Services for more information.

You want limiting to occur at 100 watts, using a 4 ohm load. You are using a PL230A

Limiter adjustment DIP switches.

Settings shown are for example only.

Power limiter switch settings for all possible combinations

13

Page 14

FEATURES & SETUP- SIDE PANEL SWITCHES: POWER LIMITER (continued from previous page)

FAST- Set both POWER LIMITER SPEED switches to FAST. This setting produces 20 milliseconds (0.020 seconds) of release time. The AVG mode will produce 8 milliseconds of

attack time, and PEAK mode will produce less than 1 millisecond of attack time. This setting will have low distortion down to about 1 kHz. It is suitable for high frequency protection,

but will cause a distinctly “muddy” effect when used on full range material.

MED- Set the upper POWER LIMITER SPEED switch to MED and the lower switch to FAST. This setting produces 200 milliseconds of release time. The AVG mode produces 80

milliseconds of attack time and the PEAK mode produces 10 milliseconds of attack time. This setting is the fastest possible setting for full range material and may still produce some

IM distortion for extremely low frequencies.

SLOW- Set the lower POWER LIMITER SPEED switch to SLOW and the upper switch to FAST. This setting provides 4 seconds of release time. The AVG mode produces 1.6

second of attack time and the PEAK mode produces 180 milliseconds of attack time. This setting will change the gain very gradually in the AVG mode, and sudden peaks may clip for

1 to 2 seconds. The PEAK mode will push overloads down quickly, but recovery time will still take many seconds.

POWER LIMITER TRACKING- Each channel’s power limiter operates independently, with its own threshold and time constants.

Four tracking modes are available for your use:

1- No Tracking-- switch section 9 of

2- CH 1 tracks the limiter activity of CH 2-- switch section 9 of channel 1’s limiter adjustment DIPs should be set to TRACK CH 2 and switch section 9 of channel 2’s limiter

adjustment DIPs should be set to OFF. This tracking mode is not often used, but is applied to paging environments with high ambient noise levels. Limiting on channel 2 will cause

limiting to occur on channel 1. Channel 2 is set up for a vocal-range horn and carries the voice page; its limiter is set for MED speed and PEAK mode with a power threshold and

gain setting that produces proper paging level. Channel 1 is set up for a full-range music speaker with its level set for comfortable listening against the ambient noise. When a

page drives channel 2 into limiting, channel 1 is driven “down” also, making the page more audible against the background noise. Some experimentation with channel 2’s gain and

threshold will be required for best performance with a range of paging voices & levels.

3- CH 2 tracks the limiter activity of CH 1 (

channel 1’s limiter adjustment DIPs should be set to OFF. This tracking mode is useful for high frequency bi-amping , using fast protection on the horn without “ducking” the low

frequencies. When used carefully, this mode can protect each driver in a two-way system , while preserving musical dynamics and balance.

We offer the following suggestions as a starting point for bi-amp tracking:

TWO-WAY SPEAKER WITH A FAIRLY HIGH CROSSOVER FREQUENCY-

driver. The limiting is tailored for each driver; higher power threshold and slower limiter speed for the low frequency driver and a lower power threshold and faster limiter speed for

the high frequency driver.

The low frequency driver can handle short time overloads, so its limiter can be set to the slower responding AVG (average) mode with MED to SLOW overall limiting times. Short

peaks may clip, but the overall limiting will be smooth and gradual with no low frequency distortion and a minimum of “ducking”. If there is too much clipping, try the CLIP

LIMITER or use the PEAK mode and MED speed.

both

limiter adjustment DIPs should be set to OFF. This is the “usual” mode where neither channel’s limiting effects the other.

bi-amp tracking

) -- switch section 9 of channel 2’s limiter adjustment DIPs should be set to TRACK CH 1 and switch section 9 of

Most of these systems have a large cone low frequency driver and a comparatively delicate high frequency

14

Page 15

FEATURES & SETUP- SIDE PANEL SWITCHES: CLIP LIMITER

POWER LIMITER TRACKING- continued

The high frequency driver requires a lower power threshold and fast limiting response. Try the FAST setting and the PEAK mode. Short peaks will be limited aggressively, but signals

will return to normal almost instantly. This response (fast with low threshold) would have too much “ducking” and low frequency distortion for use with full range material.

Once each driver has optimal protection, you need to make them work properly together. When only one channel is limiting, the frequency balance will be upset. This may not be a

problem with some material, but testing is required. The different tracking “modes” offer different solutions. For example, if the crossover frequency is low, both drivers may have

similar power capacities and protection speed requirements. For this type of bi-amping, you may find that “mode” 4 (stereo tracking, below) offers the best sound performance.

Experimentation with the actual speakers is needed.

4- Each channel tracks the other (stereo tracking)-- switch section 9 of both channel’s limiter adjustment DIP switches should be set to the right (TRACKS CH 2 and TRACKS

CH 1). Stereo playback usually uses matched speakers and thus if one channel limits, it will effect the image and placement of the instruments. When each channel tracks the other,

any limiting on one channel causes limiting on the other, preserving the overall “balance” while protecting the speakers. The power threshold and speed settings for each channel

should be matched.

CLIP LIMITER: The PL2A amplifier also has separate limiters which respond only to amplifier clipping. These

may be used with or without the adjustable Power Limiters.

When the audio signal drives the amp's output circuit beyond its power capability, the amp clips and flattens the

peaks of the waveform. The clip limiter detects this and quickly reduces the gain to minimize the amount of

overdrive. To preserve as much of the program dynamics as possible, limiting occurs only during actual clipping.

Each channel has its own clip limiter that can be switched on or off independently, as shown at right.

When to use it-

When driving full-range speakers, clip limiting reduces high frequency distortion caused by bass overloads. It

also protects high frequency drivers from excess overdrive and harsh clipping harmonics.

We recommend using the clip limiters in all applications.

NOTE: After all side panel switches have been set and SIP resistor networks installed, verify your

setup and reinstall the side cover plate to keep dirt, dust, and foreign objects from entering the

chassis.

CAUTION: Clip limiting reduces extreme overdrive peaks, allowing a

higher average signal level without audible distortion. However,

increasing the gain with the clip limiter engaged, until clipping is again

audible, can double the average output power. Be careful not to exceed

the power rating of your speakers.

Clip limiter switches are at the bottom of each

LIMITER ADJUSTMENT DIP switch (1 per channel)

15

Page 16

FEATURES & SETUP- SIDE PANEL: CROSSOVER & DELAY NETWORK SELECTION & INSTALLATION

SIP RESISTOR NETWORK INSTALLATION GUIDELINES AND SELECTION

INFORMATION

Your PL2A amplifier is shipped configured to order with SIP networks installed. If

the factory set up is not applicable for your application,then you will need to

know your desired crossover frequency and low frequency delay time in order to

select the corresponding SIP resistor network values. Refer to the selection

chart, below, for nominal crossover frequency and delay values.

A general guideline would be to

that used for the crossover

selection chart, locate the plastic bag containing the SIP networks and locate

the desired value.

never use a larger value of delay SIP than

. After choosing the desired values from the

DECODING SIP NETWORK RESISTANCE VALUES

(see note below decoding chart)

16

NOTE: Due to the number of manufacturers of SIP resistor networks, we can not

possibly provide examples of all the various part number marking schemes. We have

provided the three most common marking schemes, above. If the SIP networks you have

received do not conform to one of the above schemes, QSC’s Technical Services

Department will be glad to assist you in determining the resistance value of your SIPs.

Alternatively, you could measure the resistance value with a multimeter; simply set you

meter to the proper resistance range and connect your multimeter’s leads to the first two

pins of either end to obtain the value.

Page 17

FEATURES & SETUP- SIDE PANEL: CROSSOVER & DELAY NETWORK SELECTION & INSTALLATION

Turn the power to the amplifier off before removing or installing SIPs!

The SIPs may be installed “either way”. The

SIPs are symmetrical and thus perform

identically no matter which end points to the

left or right. This completely eliminates

“polarity” errors that might otherwise arise.

The side cover plate must be removed to access

the SIP sockets. Be sure to reinstall the side

cover plate after installing the SIPs.

Before installing the SIP (as shown right) ensure

that the pins are straight. This will ease

insertion into the jack and help to avoid

damaging the pins due to misaligned insertion.

NOTE: Reinstall the side

cover plate after SIP

installation to keep dust, dirt,

and foreign objects from

entering the internal

circuitry of the amplifier.

Failure to do so could result

in damage to the amplifier

should any such material

enter the chassis.

17

Page 18

FEATURES & SETUP: DATAPORT, FRONT PANEL LED INDICATORS, GAIN CONTROLS

DATAPORT CONNECTOR

The PL2A amplifier features a QSC DataPort connector which connects to accessory products to enhance your amplifier application.

The CM16a Amplifier Network Monitor can remotely control and monitor your PL2A amplifier. The DSP-3 digital signal processor can

mount directly to the rear of your PL2A amplifier, adding an incredible amount of processing power in a small, powerful module at a

very competitive price.

WARNING: The PL2A amplifiers use a rear panel switch (

signal from the DataPort. When using a DataPort-connected accessory, be sure to set this switch to

(blue confirmation LED illuminated) or

must be in the

OTHER ACCESSORIES-

Accessories for the PL2A amplifiers are available through your local distributor or directly from QSC. For accessory information,

contact QSC's Technical Services Department or your QSC representative. Check QSC’s web page for the latest product information.

FRONT PANEL LED INDICATORS

At full brightness, the green POWER LED indicates that the amplifier is operating. Half brightness indicates the

amp is in its start-up sequence or that the amplifier is in STANDBY mode.

As the input signal strength increases, the green SIGNAL, -20dB, and amber -10dB LED indicators light

respectively at 0.1%, 1% and 10% of full power. The red CLIP LED indicator flashes during overload (clipping). A

bright, steady glow indicates protective muting. If this occurs during use, see the Troubleshooting section. The

yellow BRIDGE LED illuminates when the amp is in BRIDGE mode. The blue BI-AMP LED illuminates when the

amplifier is in BI-AMP mode. The orange PARALLEL LED illuminates when the amp is in PARALLEL input mode.

GAIN CONTROLS

The gain controls are detented (21 steps) for repeatable adjustment. Surrounding the gain control knob, the

attenuation level is shown in dB. Maximum gain depends on the model and the GAIN-SENSITIVITY SELECT

switch setting. For full details, see the specification section.

OFF

position (green confirmation LED illuminated) to use the regular inputs.

POST PROC

DATAPORT INPUT SIGNAL switch

(yellow confirmation LED illuminated) as desired. This switch

) to control the input

PRE PROC

Front panel: gain controls and indicator LED’s for

signal level, clip indication, power status indication,

and operating mode (bridge, parallel, bi-amp)

DataPort connector location

18

Page 19

INSTALLATION: RACK MOUNTING AND MOUNTING DIMENSIONS

Before installing into equipment rack: ensure that all side-access DIP

switches and crossover SIPs are setup as desired. They will be

impossible (or extremely difficult) to change after the amplifier is

installed in the rack. The side cover plate should be installed to keep

dust and foreign material out of the chassis.

Securing the Front Ears to the Rack Rails

Use four screws and washers when mounting the PL2A amplifier to the front rails.

Support the weight of the amplifier while securing it to the rails to avoid bending or

distorting the front rack mount ears.

Supporting the Rear of the Amplifier

Supporting the amplifier at the rear is important, especially for mobile and touring

use. Rear rack mounting ear kits are an accessory item and are available from QSC’s

Technical Services Department or from your dealer or distributor.

The rear rack mounting ear kit may be installed in two

different ways.

Method 1- The amplifier is first installed from the front

of the rack and then the ears are secured directly to the

amplifier with two machine screws as shown, left. Then

the ears are secured to the rails using ordinary rail

hardware.

PL2 A rack mounting installation and major

dimensions

Method 2- The amplifier is first installed from the front

of the rack. Then, the accessory rear ears are positioned

on the rear rack rails and secured. The pin installation

position can now be selected. Install the pin so that it fits

well into the slot provided on the amplifier's rear

mounting tab.

PL2 A dimensional details

19

Page 20

INSTALLATION: FAN COOLING & AC MAINS

FAN COOLING

The fan varies speed automatically to maintain safe internal temperatures and minimize noise. Keep the front

and rear vents clear to allow full air flow.

Hot air exhausts out the front of the amp so it does not heat the interior of the rack. Make sure that plenty of

cool air can enter the rack, especially if there are other units which exhaust hot air into it.

Keep the front and rear vents clear to allow full air flow. Make sure that plenty of cool

air can enter the rack, especially if there are other units which exhaust hot air into it.

Air flow in QSC amplifiers

OPERATING VOLTAGE (AC mains)

The correct AC line voltage is shown on the serial number label. Connecting to the wrong line voltage is dangerous and may damage the amplifier. The power cord attaches to the IEC

connector on the rear panel. Use the cord supplied with the amplifier, or an equivalent. Insure that the wire gauge of the cord is #14AWG. Use of smaller wire gauges can reduce the

line voltage available to the amplifier. A power cord retaining clip is provided with the amplifier. We recommend you install and use the retaining clip to prevent accidental power cord

disconnection.

Use the best possible connection to the AC power source. Avoid extension cords as they will cause some voltage drop between the AC source and you amplifier. If the use of an

extension cord is required, ensure that it is the largest wire size available (smaller gauge number means larger wire size). Ensure that all grounding connections are maintained.

The correct AC line voltage is shown on the serial number label.

Connecting to the wrong line voltage is dangerous and may damage the amplifier.

20

Page 21

CONNECTIONS: INPUTS

INPUTS

Each channel has active balanced "Euro-style" terminal block and XLR jacks wired in parallel. The input impedance is 12 kOhm balanced or 6 kOhm unbalanced. Each channel's input

jacks are wired in parallel. Unused input jacks may be daisy-chained to additional amplifiers if desired.

Balanced connection is recommended. Balanced signals are less prone to AC hum, but unbalanced signals can be suitable for short cable runs. The signal source's output impedance

should be less than 600 Ohms to avoid high frequency loss in long cables.

shield

Balanced inputs: Use the XLR or

the detachable terminal blocks.

Proper connection for balanced input

options are shown at right.

XLR connection•Balanced•Symétrique•Symmetrisch•Balanceado

Terminal block balanced • bloc

détachable symêtrique • symetrische

Anschlußstecker • Entrada de bloque

balanceado

Unbalanced inputs: Connect the

unused side of the balanced input to

ground, as shown in the illustrations

for unbalanced connections, right.

jumper 1 to 3

XLR unbalanced • XLR asymêtrique •

unsymetrische XLR • XLR no

balanceado

shield

jumper

Terminal block unbalanced • bloc

détachable asymêtrique • unsymetrische

Anschlußstecker • Entrada de bloque no

balanceado

21

Page 22

CONNECTIONS: OUTPUTS

OUTPUTS: PL2A amplifiers offer a choice of output connections; Neutrik NL4MD Speakon jacks and "touch-proof" binding post outputs.

SPEAKER CABLING: Always use the largest wire size and shortest length of wire practical for any given installation. Larger wire sizes and shorter lengths minimize power loss and

degradation of damping factor.

Speakon™ Outputs: The Speakon connector is designed specially for high-power speaker connections. It locks in place, prevents shock hazard, and assures the correct polarity. For

easier insertion, use the newer-style NL4FC Speakon connectors with quick lock thumb latches.

The upper Speakon jack (CH1) has both Channel 1 and Channel 2 outputs, so it is especially useful for parallel, bi-amp, or bridged mono operation. The other Speakon carries only

Channel 2’s output. See the illustrations below.

Do not place speaker cables next to input wiring.

BRIDGED-MONO PRECAUTIONS:

Do Not Use 2 Ohm Loads in Bridge Mono Mode! 4 Ohms is the minimum impedance for bridge mono operation!

This mode puts a high demand on the amplifier and speaker. Excessive clipping may cause protective muting or speaker damage.

Ensure the speaker has a sufficient power rating.

Output voltages greater than 100 volts rms are available between the amplifier's bridged terminals. CLASS 3 wiring methods, as

specified in accordance with national (NEC) and local codes, must be used to connect the speaker. To prevent electric shock, do

not operate the amplifier with any conductors of the speaker cable exposed.

2 channels/canaux/Kanäle/canales & 2 Speakons

(Stereo, bi-amp, or parallel mode; Modes stéreo, bi-amp ou

parallèle; Stereo-, Bi-amp- oder Parallelbetrieb; Modos estéreo,

bi-amp o paralelo)

22

2 channels/canaux/Kanäle/canales & 1 Speakon

(Stereo, bi-amp, or parallel mode; Modes stéreo, bi-amp ou

parallèle; Stereo-, Bi-Amp- oder Parallelbetrieb; Modos estéreo,

bi-amp o paralelo)

Bridged mono • Mono ponté • Monobrückenbetrieb •

Mono puente

Page 23

CONNECTIONS: OUTPUTS

Binding post outputs

Three connection methods may be used to connect to the binding post output terminals:

• wire inserted from the side then the retaining nut is tightened

• spade terminal inserted from the side then the knurled retaining nut is tightened

• banana plug inserted into the post

Banana plug capability is provided on

non-European

models ONLY!

Binding Post strip length, spade terminal size and

connection methods

Stereo, bi-amp, or parallel mode

Modes stéreo, bi-amp ou parallèle

Stereo-, Bi-amp- oder Parallelbetrieb

Modos estéreo, bi-amp o paralelo

Bridged mono • Mono ponté •

Monobrückenbetrieb • Mono puente

23

Page 24

SECURITY PANEL USE & INSTALLATION

Right: a POWERLIGHT 2A amplifier with security panel installed

A droite: le panneau avant avec plaquette protectrice installée

Rechts: ein POWERLIGHT 2A-Verstärker mit Sicherheitsabdeckung

Derecha: un amplificador PL2 Acon el panel de seguridad instalado

SECURITY PANEL

After setting the gain controls, you can install the security panel to prevent tampering and accidental misadjustment. After the knobs have been removed and the gain setting checked,

install the security panel as shown in the general illustration to the left and on next page.

NOTE: The PL2A security panel has a viewing hole for the blue BI-AMP LED. DO NOT USE the PL2

security panel as it has no BI-AMP LED hole. The use of the incorrect security panel may result in

damage to the BI-AMP LED. Ensure PL2A security panels are used with PL2A amplifiers.

INSTALLING THE SECURITY PANEL

1. Remove the gain control knobs. Do not pry on the knob as damage to the gain control could result.

2. Use a 9/64" or 3.5 mm hex key to loosen the screw.

3. Slide the right end of the security panel under the screw head.

4. Insert the tabs into the keyed portion of the ventilation slots, then slide the panel to the right so it locks in the slot.

5. Align the right end of the security panel with the chassis openings; tighten the screw to secure the panel. Do not over tighten.

Step 1

REMOVING THE SECURITY PANEL

1. Use an angle 9/64" or 3.5 mm hex key to loosen the screw.

2. Use a small flat screwdriver to lift the right end of the security panel so that its tabs are free of the slots in the front panel.

3. Slide the security panel to the left until you can lift the left end free; slide the panel to the left to remove it from behind the screw.

4. Reinstall the gain control knobs by aligning the flat spot on the control shaft with the flat spot on the knob's shaft opening and pushing the knob firmly onto the shaft.

Step 2

Step 3

Step 4

24

Step 5

Page 25

OPERATION

GAIN CONTROLS

Turn down the gain controls before applying power. The gain controls are detented 21 steps for repeatable adjustment. Surrounding the gain control knob, the attenuation level is shown

in dB. The gain structure may be selected on the PL2A. On the rear panel you will find a switch labeled

or 26 dB of voltage gain.

AC POWER SWITCH

Before applying power, check all connections and turn down the gain controls. The "soft start" sequence starts with the

LED at half brightness. A few seconds later the fan starts, the

The

CLIP

LEDs will glow bright red. When the

CLIP

LEDs go out, the amplifier is ready.

POWER

indicator fully illuminates and the amplifier mutes for two seconds.

FRONT PANEL LED INDICATORS

At full brightness, the green POWER LED indicates that the amplifier is operating. Half brightness indicates the

amp is in its start-up sequence or

As the input signal strength increases, the green SIGNAL, -20dB, and amber -10dB LED indicators light

respectively at 0.1%, 1% and 10% of full power.

STANDBY

mode.

GAIN-SENSITIVITY SELECT

POWER

indicator

; you may select from +4 dB input sensitivity, 32 dB

The red CLIP LED indicator flashes during overload (clipping). A bright, steady glow indicates protective muting;

if this occurs during use, see Troubleshooting.

The yellow BRIDGE LED illuminates when the MODE switch is set to BRIDGE.

The blue BI-AMP LED illuminates when the MODE switch is set to BI-AMP.

The orange PARALLEL LED illuminates when the INPUT CONFIGURATION switch is set to PARALLEL.

Front panel: gain controls and indicator LED’s for

signal level, clip indication, power status indication,

and operating mode (bridge, parallel, bi-amp)

NORMAL OPERATING LEVELS

The amp's protective muting system guards against excessive internal temperatures. With normal ventilation and 4 to 8 ohm loads, the amplifier will handle any signal level including

overdrive. Lower load impedances and higher signal levels produce more internal heating. When using 2 ohm loads, frequent or prolonged clipping may trigger power cutback or

protective muting.

BRIDGE mode doubles the output impedance of the amp; 4 ohms is the minimum load impedance. Heavy clipping may cause muting. If this happens, see Troubleshooting section.

25

Page 26

TROUBLESHOOTING: NO SOUND

Problem:

• INDICATION:

• Check the AC plug.

• Confirm that the AC outlet works by plugging in another device. If too many amplifiers are used on one outlet, the

building's circuit breaker may trip and shut off power.

• An overload in

POWER LED, followed by a normal restart cycle. Check the load impedance (4 ohms minimum), or reduce signal

level.

• An amplifier which keeps shutting off may have a serious internal fault. Turn it off, remove AC power, and have the

amplifier serviced by a qualified technician.

•

INDICATION:

• Ensure that the DATAPORT INPUT SIGNAL switch is in the proper position. If you are using the XLR or terminal

block inputs, it should be in the OFF position. If you are using the DATAPORT for your input signal, the switch should

be set to PRE PROC or POST PROC.

• If the green POWER indicator LED is at full brightness, yet the signal LEDs indicate no signal, check the input.

Make sure the signal source is operating and try another input cable. Connect the source to another channel or

amplifier to confirm its operation.

•

INDICATION:

• If the green SIGNAL, -20 dB, and -10 dB indicators are lighting normally, the fault is somewhere between the amp

and the speaker. Check the speaker wiring for breaks. Try another speaker and cable.

NO SOUND

POWER INDICATOR NOT LIT

bridge

mode may cause the amplifier to click off for three seconds, indicated by the half-bright

SIGNAL LED NOT LIT

SIGNAL LEDS RESPONDING TO SIGNAL LEVEL

•

INDICATION:

The amplifier is in protective muting.

• One second of muting is normal when the amp is turned on or off.

• Overheating will cause protective muting. The fan will be running at full speed and the chassis will be hot to the

touch; sound should resume within a minute as the amplifier cools to a safe operating temperature. Check for

proper ventilation. If the fan isn't running at all, the amplifier requires servicing.

•

INDICATION:

• If the red CLIP indicator flashes when signal is applied, the amplifier output may be shorted. Check the speaker

wiring for stray strands or breaks in the insulation.

CLIP LEDS BRIGHT AND STEADY

CLIP LED FLASHING

26

Page 27

TROUBLESHOOTING: DISTORTION, NO CHANNEL SEPARATION, HUM, HISS, FEEDBACK

PROBLEM:

•

INDICATION:

• If the red

shorted. Unplug each speaker one-by-one

cable, that cable or speaker is shorted. Try another cable and speaker to locate the fault.

•

INDICATION:

• This could be caused by a faulty speaker or loose connection. Check the wiring and try another speaker.

• The signal source may be clipping. Keep the amplifier gain controls at least halfway up so that the source does

not have to be overdriven.

PROBLEM:

• Check the yellow PARALLEL or orange BRIDGE MONO LEDs on the front panel, which indicate the switch settings

on the back of the amplifier. Neither should be lit in dual-channel, bi-amp, or stereo use where different signals go to

each channel. Make sure the "Parallel Input" and "Bridge Mode" switches are

• Make sure other equipment in the signal path, such as mixers, preamps, etc., is set for stereo, not mono.

PROBLEM:

• Check that the BI-AMP LED on the front panel is not illuminated. If it is, the MODE switch on the rear panel is in the

BI-AMP position. Move the MODE switch to the 2 CH position. This assumes you do not want to be in BI-AMP mode

and that you are operating in a 2 channel mode.

PROBLEM:

• Unplug the amplifier input to confirm that the hiss is coming from the source or a device upstream; erratic or popping

noises indicate an electronic fault in the offending unit.

• To keep the normal noise floor low, operate the primary signal source at full level, without clipping, and avoid boosting

the signal further between the source and the amplifier.

DISTORTED SOUND

CLIP LED FLASHING

CLIP

indicator flashes before all three signal indicators do, the load impedance is abnormally low or

at the amplifier.

CLIP INDICATOR NOT FLASHING

If the

CLIP

LED goes out when you disconnect a

NO CHANNEL SEPARATION

OFF

.

CH 1 IS ALL LOW FREQUENCY MATERIAL & CH 2 IS ALL HIGH FREQUENCY MATERIAL

HISS

PROBLEM:

• Microphone feedback should be controlled with mixer controls. If noise continues to build up with zero mic gain, there

is a serious fault in the signal processors or cables. Working in succession from the signal source towards the

amplifier, check each device in the signal path by reducing its gain or unplugging it.

PROBLEM:

• The PowerWave

Move cabling and signal sources to identify "hot spots" in the system; then avoid those spots. Cables with faulty

shielding are a common entry point for hum. Use top quality cabling.

SQUEALS AND FEEDBACK

HUM

TM

supply eliminates internal hum fields, but transformers in other magnetic devices may cause hum.

Magnetic field from power supplies in equipment can

induce hum into cabling that is located in the field. If

hum is a problem, try relocating cabling so that is

away from power supplies, transformers and other

magnetic field producing devices.

27

Page 28

TECHNICAL OVERVIEW: BLOCK DIAGRAM & OPERATIONAL DETAILS

An impressive amount of

technology is packed "under the

hood" of a PL2A amplifier.

Thousands of watts of power

flow inches away from stateof-the-art low noise inputs.

Precise circuit layout and

thorough protection assure

that all of this activity occurs

smoothly and safely. So, what

actually happens when you

turn on the power switch?

Soft Start Sequence. The

first task is to charge the

primary energy reservoir

without drawing a large surge

current. A special inrush limiter

allows just enough current to

charge the energy bank in

three seconds. Meanwhile, a

low-power switching supply

provides power to start up the

main supply. After three

seconds, a relay bypasses the

inrush limiting and full power

operation is enabled. The

audio circuitry mutes for one

second to eliminate start-up

thumps. When the red

lights go out, the amplifier is

ready for action.

CLIP

PowerWave™ Technology. High current switching devices draw over 10,000 watts of peak power from the main energy reservoir, which is

replenished directly from the AC line for maximum stiffness. Conventional amplifiers must isolate the energy bank with a large AC transformer,

which weakens the flow of current, allows greater sag under load, and produces hum. The PowerWave supply performs voltage conversion at

a very high frequency, allowing better coupling through a much smaller isolation transformer.

Block diagram of audio path in a PL2A amplifier

28

Page 29

TECHNICAL OVERVIEW: BLOCK DIAGRAM & OPERATIONAL DETAILS

High Performance Audio. High speed power transistors convert this DC power into the full range audio output which drives the speakers. High-current design and special dual-sense

output feedback corrects errors on both sides of the speaker terminals, improving damping and control of speaker motion. The power devices are directly mounted to isolated heat sinks,

which form a short, wide air tunnel in front of the fan for optimum cooling.

Each channel has a thermal sensor embedded in its heat sink for accurate temperature monitoring. The sensor controls fan speed, bias tracking and thermal shutdown. It also reports

temperature readings to the DataPort (for remote monitoring with QSC's CM16a Processor).

The output circuitry is actively clamped during clipping for smooth and very fast recovery. The clamp also feeds a proportional clip limiter, which actually senses the depth of clipping and

responds accordingly.

The balanced inputs use premium 0.1% precision resistors for very high noise rejection. The precision components used in the input filters and all other circuitry ensure accurate

performance.

Shutdown. The amplifier mutes as soon as power is

shut off, preventing turn-off noises. Serious faults

trigger a shutdown of the power supply; the high

switching frequency allows the power supply to shut

down within microseconds to limit damage.

Basic functional block diagram

of PowerWave™ power supply

29

Page 30

SPECIFICATIONS

PL218A PL224A PL230A PL236A

OUTPUT POWER

FTC:

EIA: 1 kHz

@1% THD

Bridged Mono:

DYNAMIC HEADROOM (all models) less than 2 dB at 4 ohms

DISTORTION (all models)

FREQUENCY RESPONSE (all models) 20 Hz to 20 kHz, ±0.2 dB

DAMPING FACTOR (all models) Greater than 500

SIGNAL to NOISE (unweighted, 20-20k Hz.) -103 dB -103 dB -103 dB -103 dB

VOLTAGE GAIN Selectable from 26dB or 32 dB voltage gain (or a 1.2 Vrms input sensitivity) by the GAIN-SENSITIVITY SELECT switch

in watts

8 ohms per channel (20-20k Hz., 0.05% THD) 310 440 575 725

4 ohms per channel (20-20k Hz., 0.07% THD) 525 715 900 1100

8 ohms per channel 350 475 625 800

4 ohms per channel 600 825 1050 1300

2 ohms per channel 900 1200 1500 1850

16 ohms, 20–20k Hz, 0.1% THD 650 900 1200 1500

8 ohms, 20–20k Hz, 0.1% THD 1100 1500 2000 2400

4 ohms, 1 kHz, 1% THD 1800 2400 3000 3600

SMPTE-IM Less than 0.01%

Typical, 10 dB below rated power, 20-20k Hz. <0.025%

Typical, full rated power, 1k Hz. and below <0.025%

(at 10 dB below rated output power) -3 dB points: 8 Hz and 65 kHz

INPUT SENSITIVITY, V RMS switch position 26dB 1.2Vrms 32dB 26dB 1.2Vrms 32dB 26dB 1.2Vrms 32dB 26dB 1.2Vrms 32dB

for rated power into 8 ohms 2.57 1.28 1.28 3.05 1.20 1.53 3.84 1.22 1.93 3.95 1.24 1.98

for rated power into 4 ohms 2.37 1.18 1.18 2.97 1.10 1.39 3.41 1.08 1.71 3.45 1.09 1.73

INPUT CLIPPING, Vrms (all models) +22dBu

INPUT IMPEDANCE (all models) 6k ohms unbalanced

CONTROLS (all models) Front: AC switch, CH 1 and CH 2 gain knobs

12k ohms balanced

Back: Slide switches with LED confirmation for: Input Configuration, Mode, DataPort Input Signal assignment and Gain-Sensitivity Select

Side: SIP networks for crossover frequency and low frequency delay; push-button toggle switch for Subaudio Filter; DIP switches for Subaudio Frequency select,

Lo Frequency delay enable/off, HF Attenuation 0 to -15 db adjust, Horn Boost 0 to +14 dB adjust. “Per Channel” switches: Power Limiter enable/off,

Power Limiter Mode peak/average, Power Limiter Threshold 0 to -15dB adjust, Power Limiter attack & release time fast-medium-slow, Power Limiter

tracking none/bi-amp (CH 2 tracks CH 1)/”reverse” bi-amp (CH 1 tracks CH 2)/stereo (each channel tracks the other), and Clip Limiting on/off

30

Page 31

SPECIFICATIONS

PL218A PL224A PL230A PL236A

INDICATORS (all models) Front: POWER: Green LED, STANDBY: POWER LED 1/2 brightness, BRIDGED: Yellow LED, PARALLEL: Orange LED, BI-AMP: Blue LED, CLIP/Protect: Red LED,

CONNECTORS (all models) Input: 3-pin rubber-isolated XLR (pin 1, earth; pin 2, +; pin 3, -) and 3-pin detachable terminal block (pin out labeled)

COOLING (all models) Continuously variable speed fan, back-to-front air flow, provision for optional air filter

AMPLIFIER PROTECTION (all models) Full short circuit, open circuit, thermal, ultrasonic, and RF protection

LOAD PROTECTION (all models) Turn-on/turn-off muting, DC-fault power supply shutdown, clip limiting, power limiting

OUTPUT CIRCUIT TYPE AB 2-step Class H 2-step Class-H 2-step Class-H

POWER REQUIREMENTS (all models) 120 Volts AC, 50/60 Hz

POWER CONSUMPTION

(both channels driven)

@ 120 VAC, typical

1 per channel, Level -10 dB: Orange LED, 1 per channel, Level -20 dB: Green LED, 1 per channel, SIGNAL -35dB: Green LED, 1 per channel

Back: STEREO: Green LED, PARALLEL: Orange LED, BI-AMP: Blue LED, 2 CH: Green LED, BRIDGE: Yellow LED, DATAPORT PRE PROC: Blue LED,

DATAPORT OFF: Green LED, DATAPORT POST PROC: Yellow LED, GAIN-SENSITIVITY SELECT: 26dB Orange LED, 1.2Vrms Green LED, 32dB Yellow LED

Side: SUBAUDIO FILTER: Green LED is on when filter is engaged (1 per channel),

POWER LIMITER ACTIVITY LED: Yellow LED flashes when limiter is active (1 per channel)

Output: “Touch-Proof” binding posts and Neutrik® Speakon connectors; Speakon for CH 1 can be used for one or both channels and for bridged mono

Stable into reactive or mismatched loads

Idle 1 A 1 A 1 A 1 A

1/8 power, 8 ohms* 5 A 5 A 6 A 7 A

1/8 power, 4 ohms* 8 A 8 A 9 A 10 A

1/8 power, 2 ohms* 12 A 11 A 13 A 17 A

NOTE: 1/8 power is representative of current draw with typical music program material with occasional clipping. *Pink noise

DIMENSIONS (all models) 19.0" (48.3 cm) wide, 3.5" (8.9 cm) tall (2 rack spaces)

14.0" (35.6 cm) deep (from front mounting rails) including rear support ears

WEIGHT (all models) Shipping: 27 lb. (12.3 kg) Net: 21 lb. (9.5 kg)

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE

US Patent Number 5767744

31

Page 32

WARRANTY INFORMATION & HOW TO CONTACT QSC AUDIO PRODUCTS

WARRANTY

(USA only; other countries, see

your dealer or distributor)

Disclaimer

QSC Audio Products, Inc. is not

liable for any damage to speakers,

amplifiers, or any other equipment

that is caused by negligence or

improper installation and/or use of

the PL2A amplifier.

Product Warranty

QSC guarantees the PL2A to be free

from defective material and/or

workmanship for a period of three

years from the date of sale, and will

replace defective parts and repair

malfunctioning products under this

warranty when the defect occurs

under normal installation and use—

provided the unit is returned to our

factory via prepaid transportation

with a copy of the proof of purchase,

i.e., sales receipt. This warranty

provides that examination of the

returned product must indicate, in

our judgment, a manufacturing

defect. This warranty does not

extend to any product which has

been subjected to misuse, neglect,

accident, improper installation, or

where the date code has been

removed or defaced.

HOW TO CONTACT QSC AUDIO PRODUCTS

Mailing address / Adresse postale / Postanschrift / Dirección postal: QSC Audio Products, Inc.

1675 MacArthur Boulevard

Costa Mesa, CA 92626-1468 USA

Telephone Numbers / Numéros de téléphone / Telefonnummern / Números de teléfono:

Main Number / Numéro principal / Hauptnummer / Número principal +(714) 754-6175

Sales Direct Line / Ligne directe ventes / Verkauf-Direkt / Línea directo ventas +(714) 957-7100

Sales & Marketing / Ventes & marketing / Verkauf u. Marketing / Ventas y marketing (800) 854-4079

Customer Service / Service à la clientèle / Kundendienst / Servicio a la clientela +(714) 957-7150

(800) 772-2834

Facsimile Numbers / Numéros de télécopieur / Telefaxnummern / Número de FAX:

Sales & Marketing FAX / Télécopie ventes & marketing / Telefax der Verkauf u. Marketing / FAX ventas y marketing

+(714) 754-6174

Customer Service FAX / Télécopie service à la clientèle / Kundendienst-Telefax / FAX servicio a la clientela

+(714) 754-6173

World Wide Web: www.qscaudio.com

E-mail: info@qscaudio.com

service@qscaudio.com

(toll-free in U.S.A. only)

(sans frais aux É-U seulement)

(zollfrei nur beim USA)

(sin costo en EE. UU. solamente)

(toll-free in U.S.A. only)

(sans frais aux É-U seulement)

(zollfrei nur beim USA)

(sin costo en EE. UU. solamente)

32

Page 33

SETUP SHEET FOR PL2A AMPLIFIERS

Use these handy sheets to mark your switch positions for various setups. Each switch position has been “blanked” out so that you may place an “X” or a checkmark to indicate the setting of each switch for future reference.

Copy these blanks so that you have several copies.

NOTES:______________________

___________________________

___________________________

____________________________

___________________________

___________________________

___________________________

___________________________

____________________________

___________________________

___________________________

___________________________

___________________________

____________________________

___________________________

___________________________

___________________________

___________________________

____________________________

___________________________

___________________________

___________________________

___________________________

____________________________

___________________________

___________________________

33

Page 34

SETUP SHEET FOR PL2A AMPLIFIERS

Use these handy sheets to mark your switch positions for various setups. Each switch position has been “blanked” out so that you may place an “X” or a checkmark to indicate the setting of each switch for future reference.

Copy these blanks so that you have several copies.

NOTES:______________________

___________________________

___________________________

____________________________

___________________________

___________________________

___________________________

___________________________

____________________________

___________________________

___________________________

___________________________

___________________________

____________________________

___________________________

___________________________

___________________________

___________________________

____________________________

___________________________

___________________________

___________________________

___________________________

____________________________

___________________________

___________________________

34

Page 35

Page 36

QSC Audio Products, Inc. 1675 MacArthur Boulevard Costa Mesa, California 92626 USA

“QSC” and the QSC logo are registered with the U.S. Patent and Trademark Office.

©2000 QSC Audio Products, Inc.

Loading...

Loading...