QSC ADS-282-H Owners manual

High-power Two-way Multi-Use Loudspeaker

• two 8-inch (203mm) neodymium magnet low-frequency drivers

• 1-inch throat compression high-frequency driver

• yoke mount

I-282H Speakon® input, pole cup, and floor-mount swivel feet. Bi-amp capable, 8 ohm

AD-S282H bi-amp capable, 8 ohm

AD-S282HT 70V/100V transformer equipped, bypassable to 8 ohm

*TD-000148-00*

TD-000148-00 rev.B

IMPORTANT SAFETY PRECAUTIONS

& EXPLANATION OF SYMBOLS

1- Read these instructions.

2- Keep these instructions.

3- Heed all warnings.

4- Follow all instructions.

5- Clean only with a dry cloth.

6- Install in accordance with QSC Audio Product’s instructions and a licensed, professional engineer.

7- Do not install near any heat sources such as radiators, heat registers, stoves, or other apparatus (including ampli-

fiers) that produce heat.

8- Only use attachments/accessories from QSC Audio Products, Inc.

9- Use only with mounts or brackets specified by QSC Audio Products.

10- Refer all servicing to qualified personnel. Servicing is required when the apparatus has been damaged in any

way.

The exclamation point within an equilateral triangle is intended to alert the user to the presence of

important operating and maintenance (servicing) instructions in this manual.

WARNING! Before placing, installing, rigging, or suspending any speaker product, inspect all hardware,

suspension, cabinets, transducers, brackets and associated equipment for damage. Any missing, corroded, deformed or non-load rated component could significantly reduce the strength of the installation,

placement, or array. Any such condition severely reduces the safety of the installation and should be

immediately corrected. Use only hardware which is rated for the loading conditions of the installation

and any possible short-term unexpected overloading. Never exceed the rating of the hardware or equipment. Consult a licensed, professional engineer when any doubt or questions arise regarding a physical

equipment installation.

Warranty (USA only; other countries, see your dealer or distributor)

Disclaimer

QSC Audio Products, Inc. is not liable for any damage to amplifiers, or any other equipment that is caused by negligence or

improper installation and/or use of this loudspeaker product.

QSC Audio Products 3 Year Limited Warranty

QSC Audio Products, Inc. (“QSC”) guarantees its products to be free from defective material and / or workmanship for a period of

three (3) years from date of sale, and will replace defective parts and repair malfunctioning products under this warranty when the

defect occurs under normal installation and use - provided the unit is returned to our factory or one of our authorized service stations via pre-paid transportation with a copy of proof of purchase (i.e., sales receipt). This warranty provides that the examination

of the return product must indicate, in our judgment, a manufacturing defect. This warranty does not extend to any product which

has been subjected to misuse, neglect, accident, improper installation, or where the date code has been removed or defaced. QSC

shall not be liable for incidental and/or consequential damages. This warranty gives you specific legal rights. This limited warranty

is freely transferable during the term of the warranty period.

Customer may have additional rights, which vary from state to state.

In the event that this product was manufactured for export and sale outside of the United States or its territories, then this limited

warranty shall not apply. Removal of the serial number on this product, or purchase of this product from an unauthorized dealer,

will void this limited warranty.

Periodically, this warranty is updated. To obtain the most recent version of QSC’s warranty statement, please visit www.qscaudio.com.

Contact us at 800-854-4079 or visit our website at www.qscaudio.com.

© Copyright 2004, 2006 QSC Audio Products, Inc.

QSC® is a registered trademark of QSC Audio Products, Inc.

“QSC” and the QSC logo are registered with the U.S. Patent and Trademark Office

Speakon

2

® is a registered trademark of Neutrik AG, OmniMount® is a registered trademark of OmniMount Systems, Phoenix, AZ, USA

Introduction

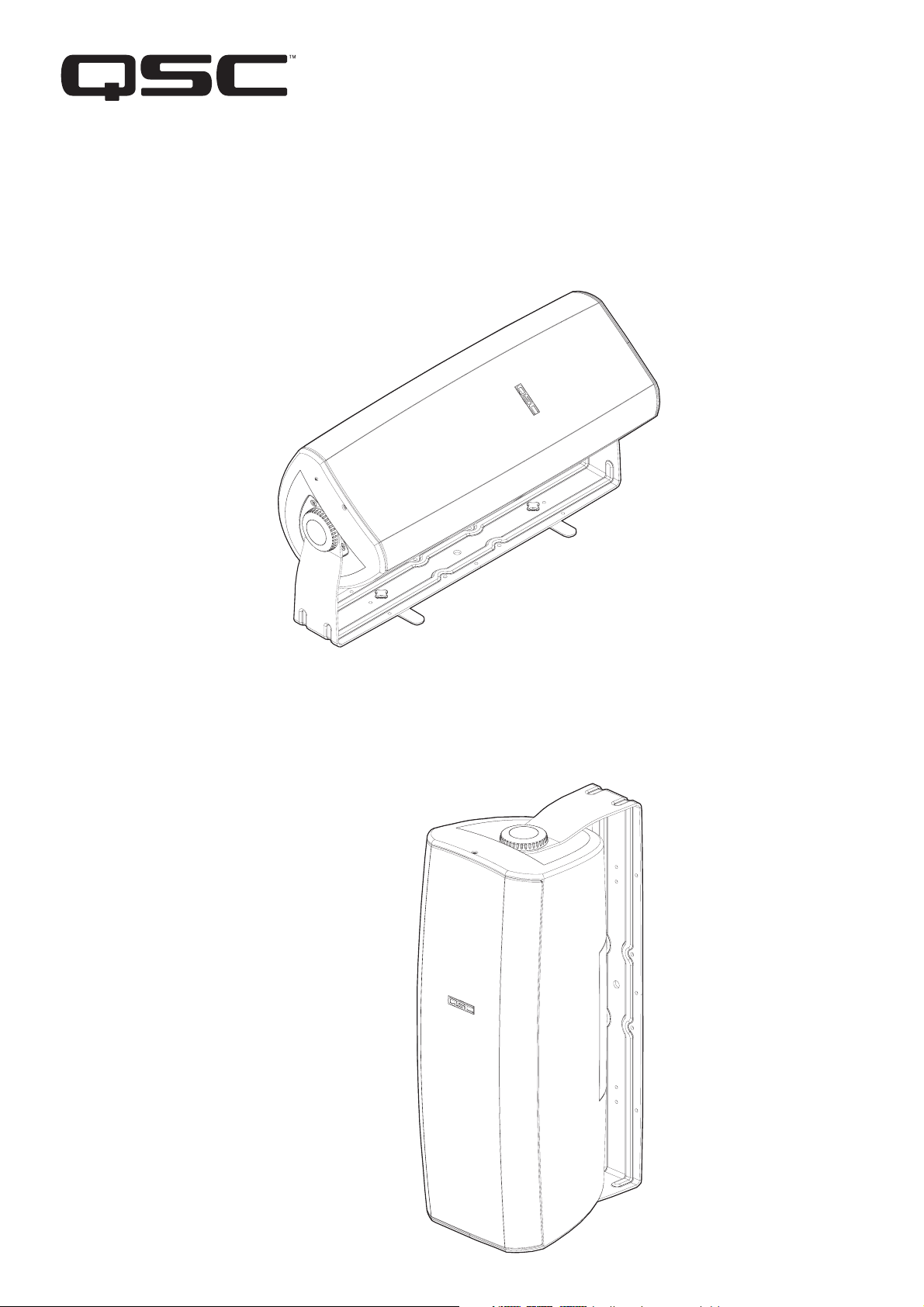

Thank you and congratulations on your purchase of the I-282H, AD-S282H, or AD-S282HT

multi-use, weather resistant loudspeakers. These products represent the state-of-the-art

in lightweight sound reinforcement loudspeaker systems. To get the most from your

investment, we encourage you to review this manual carefully.

These loudspeaker systems are full range, high output, two-way designs delivering superior sound quality and high SPL in a weather resistant enclosure. The low frequency drivers feature neodymium magnets, while the high frequency driver features a ferrite

magnet. The included yoke mount provides secure and versatile installation. These loudspeakers make an excellent choice for a wide variety of applications. All models include

an adapter plate for users who desire to use OmniMount

ing options.

®’s suitable loudspeaker mount-

The I-282H features two Speakon

tion and easy parallel connection of multiple loudspeakers. The Speakon connectors are

wired for passive or bi-amp use and have a selector switch for bypassing the crossover

when used in bi-amp applications. Additionally, the I-282H includes two swivel “outrigger” feet for converting the yoke mount to a floor monitor application.

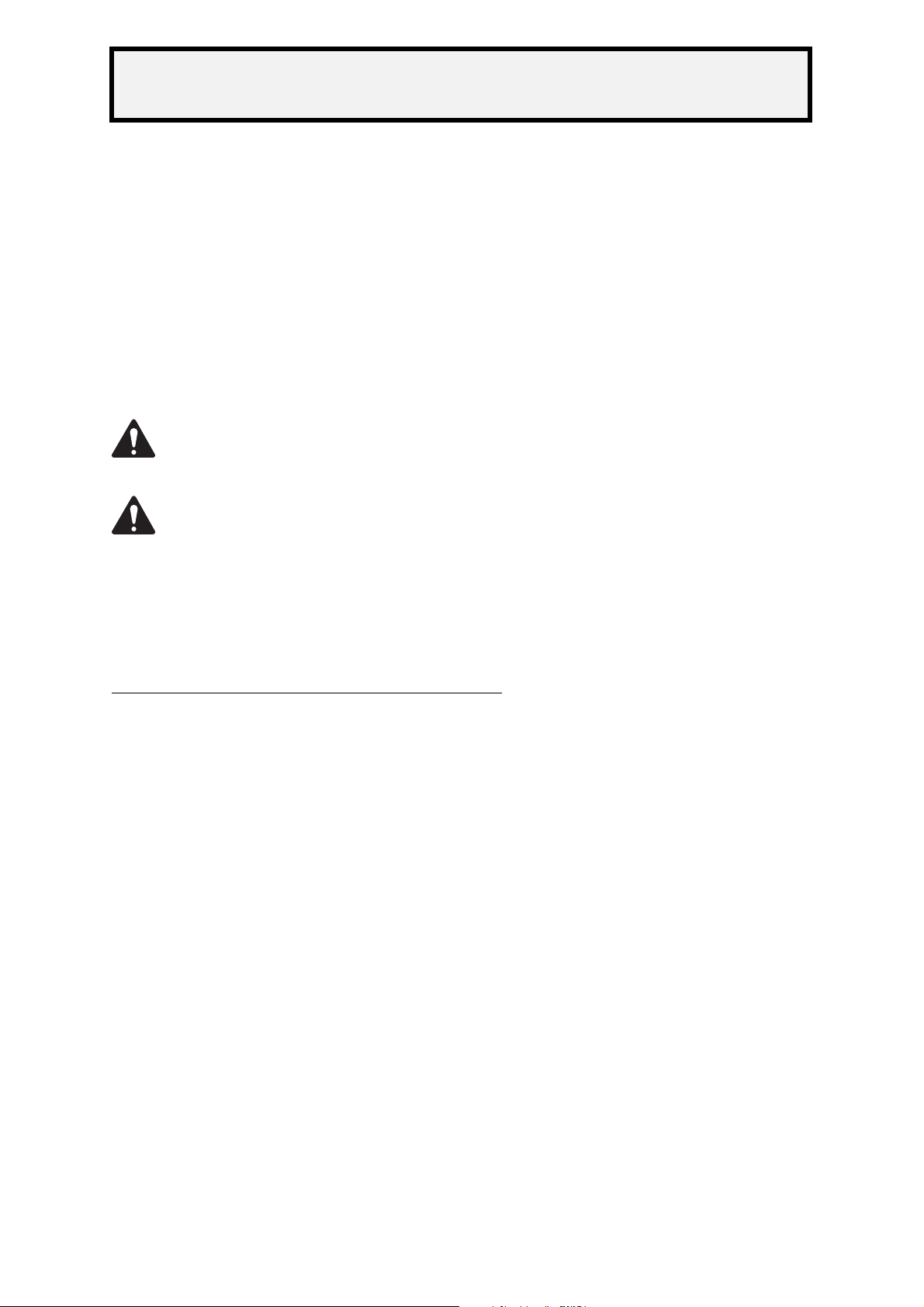

The AD-S282H and AD-S282HT models feature weather resistant input wiring covers and

wiring strain relief bushings. They also include socket head screws for applications where

enhanced mounting security may be desired (used in place of the yoke mount retaining

knobs).

The AD-S282H model is bi-amp capable and features a crossover bypass switch.

The AD-S282HT is 70V/100V matching transformer equipped complete with an integral

power-tap selector switch. The transformer may be bypassed for low impedance (8 ohm)

application versatility. Two sets of parallel-connected input wiring barrier-strip terminals

are provided for connecting multiple loudspeakers.

® connectors wired in parallel for fast, reliable connec-

What’s Included

I-282H

•I-282H loudspeaker (1 each)

•Yoke mount (1 each)

•Yoke mount retaining knobs (2 each)

•M10 x 1.0 x 23mm socket head screws, with flat and lock washers for security-enhanced yoke mounting (2 each)

•Yoke mount insert plugs for non-yoke mount applications (2 each)

•Swivel feet and retaining knobs for floor monitor applications (2 each)

•Self-adhesive rubber feet for swivels (4 each)

•Omni-Mount adapter plate and M4 self-tapping retaining screw (1 each)

•This User Manual

AD-S282H and AD-S282HT

•AD-S-282H or AD-S282HT loudspeaker (1 each)

•Yoke mount (1 each)

•Yoke mount retaining knobs (2 each)

•M10 x 1.0 x 23mm socket head screws, with flat and lock washers for security-enhanced yoke mounting (2 each)

•Yoke mount insert plugs for non-yoke mount applications (2 each)

•Input wiring cover and gasket (1 each)

•Input wiring cover retaining screws, M4 x 1.4 x 15 mm (2 each)

•Input wiring strain relief bushing with wire hole (2 each, may be part of cover)

•Input wiring strain relief bushing, no wire hole (1 each)

•Strain relief bushing retaining nut with wire hole (2 each)

•Strain relief bushing retaining nut, no wire hole (1 each)

•Omni-Mount adapter plate and M4 self-tapping retaining screw (1 each)

•This User Manual

3

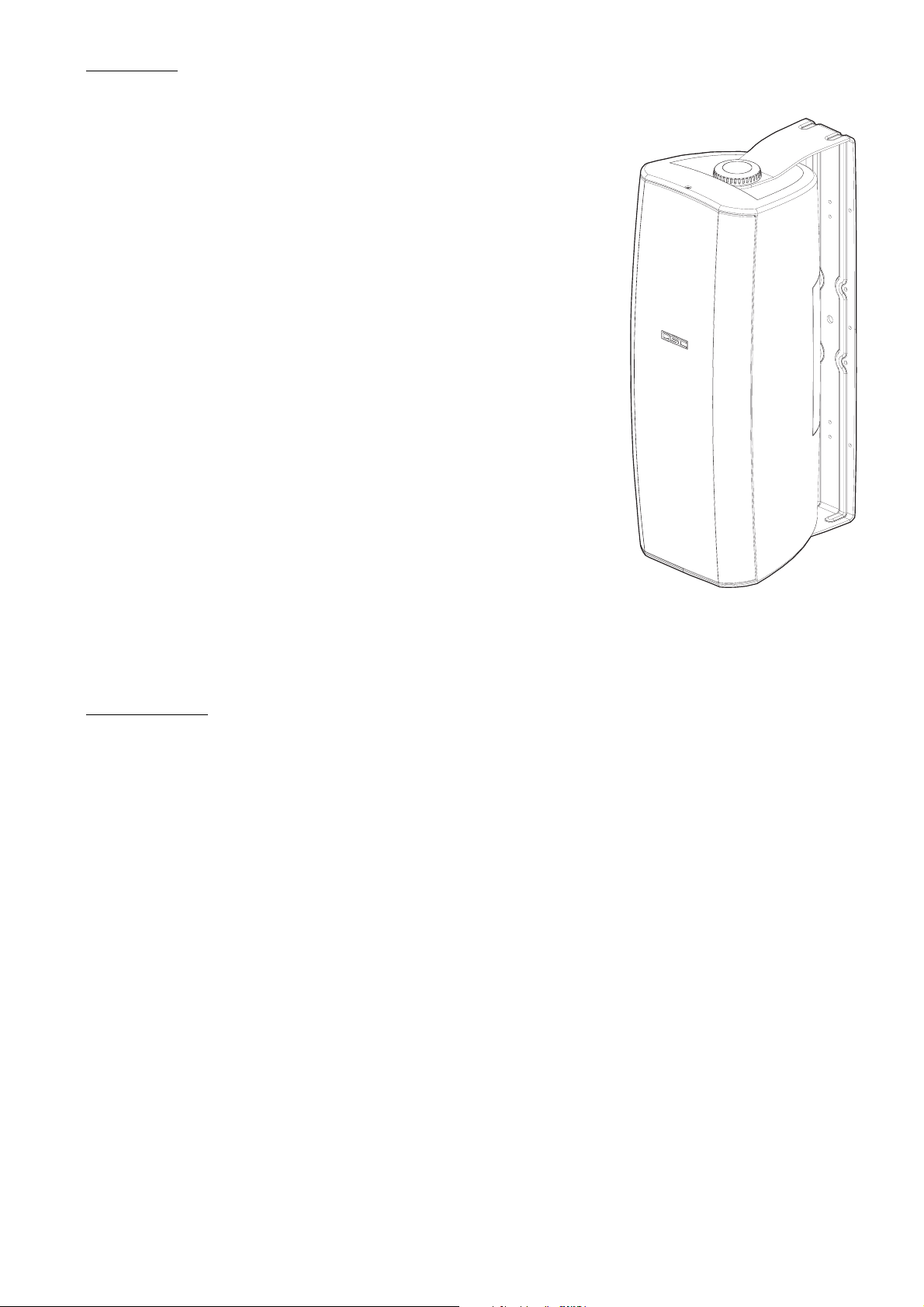

Grill Removal

If it is necessary to remove the protective grill, do so with care as to avoid

bending or distorting the grill. The grill is held in place by two retaining

screws, one at the front edge of the top of the cabinet and one at the front

edge of the bottom.

Removing the Grill

1- Using a #2 Phillips-head screwdriver, remove the two grill retaining

screws.

2- Carefully pry the grill from its retaining groove using a plastic flat-blade

tool such as a plastic putty knife. Gently and evenly work the grill out of its

retaining groove to avoid bending the grill.

Coverage Angles

Before mounting the loudspeaker, determine the mounting orientation and desired coverage

angles. As supplied from the factory, the loudspeaker’s coverage angles are 90° (horizontal) x 60°

(vertical) with the cabinet oriented vertically. The waveguide can be rotated to interchange the

coverage angles.

Rotating the Waveguide to Alter HF Coverage Pattern

1- Remove the grill as outlined, above.

2- Remove the eight waveguide retaining screws. A #2-size Phillips screwdriver is recommended.

3- Reach into the waveguide’s port and pull gently to remove the waveguide. Be careful not to

damage the connections, wiring, or the gasket between the waveguide and the cabinet.

4- Rotate the horn 90° clockwise or counter clockwise and set it back in place. Make certain the

wiring is not stressed or pulled loose from its connections.

5- Before reinstalling the waveguide screws, lift the assembly a small distance and make sure

that the gasket is properly in place. Reposition it, if required. Set the waveguide in place and

reinstall the screws. Do not overtighten.

6- Replace the grill and install the upper and lower grill retaining screws.

4

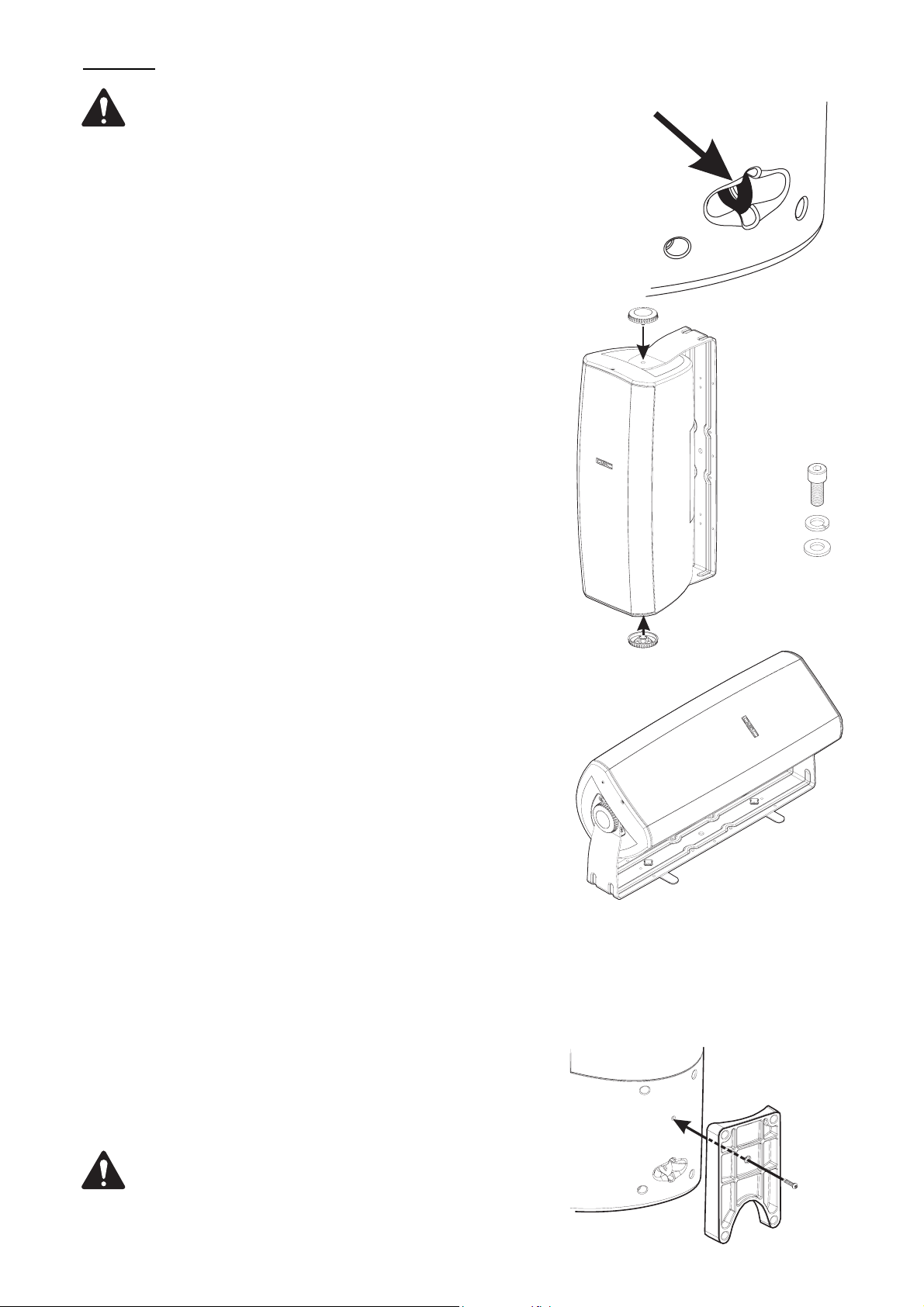

Mounting

IMPORTANT! ENSURE THAT THE LOUDSPEAKER IS

MOUNTED PROPERLY AND A SAFETY CABLE IS INSTALLED

TO RETAIN THE LOUDSPEAKER IN THE EVENT OF A MOUNTING FAILURE. CONSULT A LICENSED, PROFESSIONAL ENGINEER WHEN ANY DOUBT OR QUESTIONS ARISE REGARDING

A PHYSICAL EQUIPMENT INSTALLATION.

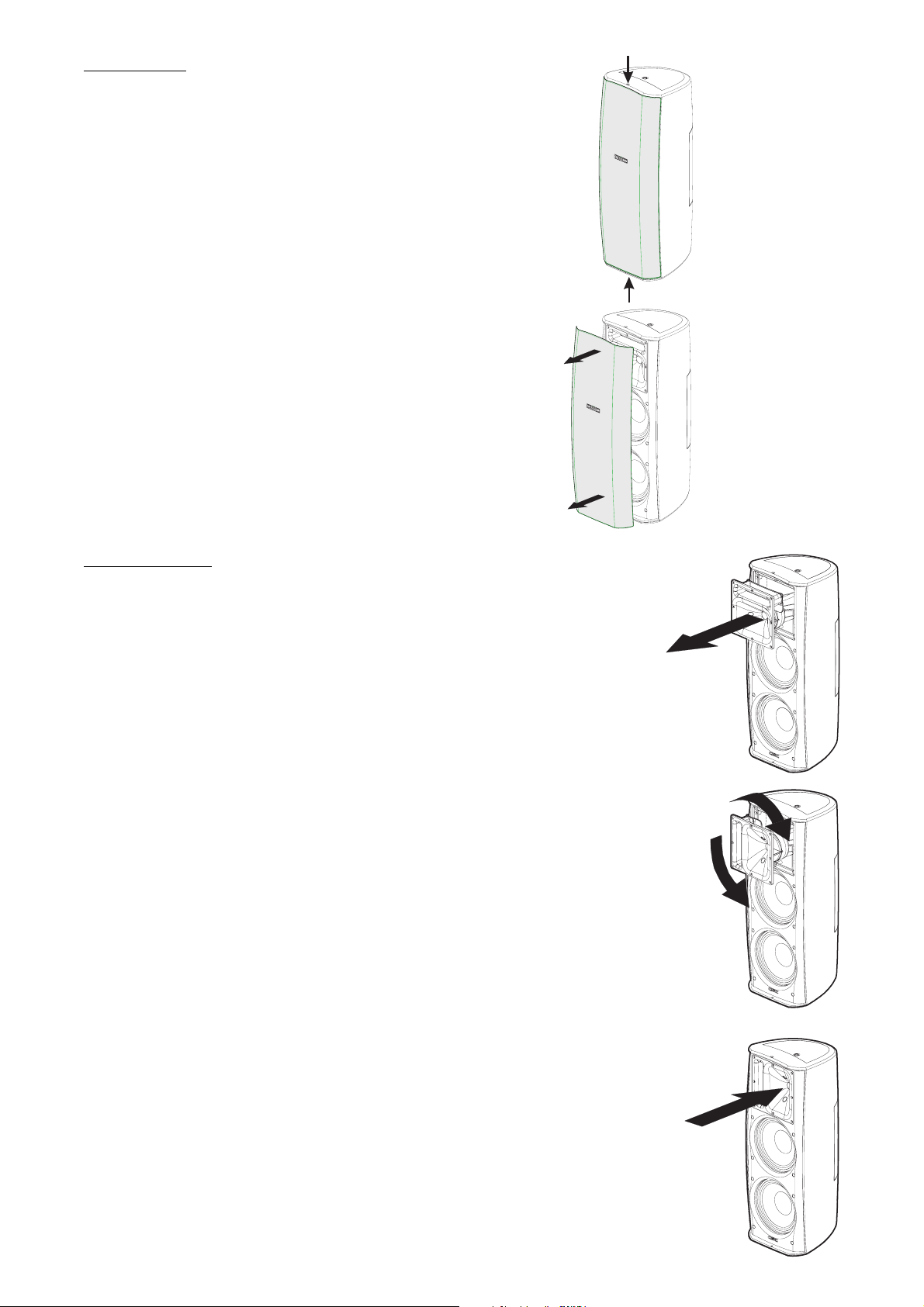

Safety Cable Attachment (all models)

On the back of the loudspeaker, near the bottom, is a safety cable attachment

point. Install a safety cable strong enough to support several times the

weight of the loudspeaker assembly in the event it may fall. The cable must

be secured to a secondary support point which is also strong enough to support several times the loudspeaker’s weight.

Yoke Mount (all models)

The included yoke mount handles most surface mounting applications. It is

constructed of light, strong alloy and pre-drilled for ease of use. Integral

bushings at the cabinet contact points ensure ease of positioning. A large

center-hole is provided on the mounting surface side for wiring pass-through.

Mount the yoke to a surface strong enough to support the weight of the loudspeaker assembly using suitable hardware (not included). If any doubt exists

as to the suitability or strength of the mounting surface, consult a qualified

professional engineer. After securing the yoke to the mounting surface, have

an assistant hold the loudspeaker in place while installing either the retaining knobs or socket head screws with flat and lock washers (AD-S282H and

AD-S282HT only). Once the loudspeaker has been positioned for desired

acoustic coverage, tighten the hardware securely.

Attach safety

cable here

For enhanced security,

use the included M10

socket head screws to

secure the loudspeaker

to the yoke mount.

Floor Monitor (I-282H only)

The I-282H yoke mount comes with two swivel feet, four self-adhesive rubber feet, and retaining knobs. Attach the two of the rubber feet to each of

the two swivel outrigger bars, one at each end. Press firmly in place to

ensure adhesion. Then attach each of the two swivel outrigger bars to the

yoke mount using the two small retaining knobs included. The rubber feet

should be oriented away from the yoke mount. Swivel the outrigger bars perpendicular to the long axis of the yoke and tighten the retaining knobs. Set

the completed yoke assembly on the floor, resting on the rubber feet. Place

the loudspeaker into the yoke and secure using the two large retaining knobs

provided. Position the loudspeaker for desire acoustic coverage and tighten

the retaining knobs securely.

Pole Mounting (I-282H only)

On the bottom of the I-282H is a pole cup that accepts 1.375” or 1.500” (35

mm or 38 mm) pole diameters. For pole mounting, lift the loudspeaker into

position over the pole end and set it onto the pole. Ensure the pole is fully

and firmly seated into the pole cup of the loudspeaker.

OmniMount (all models)

For applications requiring the use of OmniMount’s Pro 60.0 mount, there is an

adapter plate included. The adapter plate is used between the OmniMount

bracket and the loudspeaker cabinet. Orient the plate with it’s curved side

toward the loudspeaker and its safety cable access cut-out toward the bottom of the loudspeaker. Attach to cabinet using the provided M4 x 18mm

self-tapping screw. Consult OmniMount’s literature and installation recommendations for proper and safe application of their product.

OmniMount adapter plateAttach to cabinet using provided M4 x 18mm

self tapping screw, then attach OmniMount

following manufacturer’s recommendations.

We recommend the use of M8 x 1.25 x 50mm bolts with a flat

washer 1.8mm thick and a split-lock washer 1.9mm thick for

securing the OmniMount bracket to the loudspeaker cabinet.

5

Loading...

Loading...