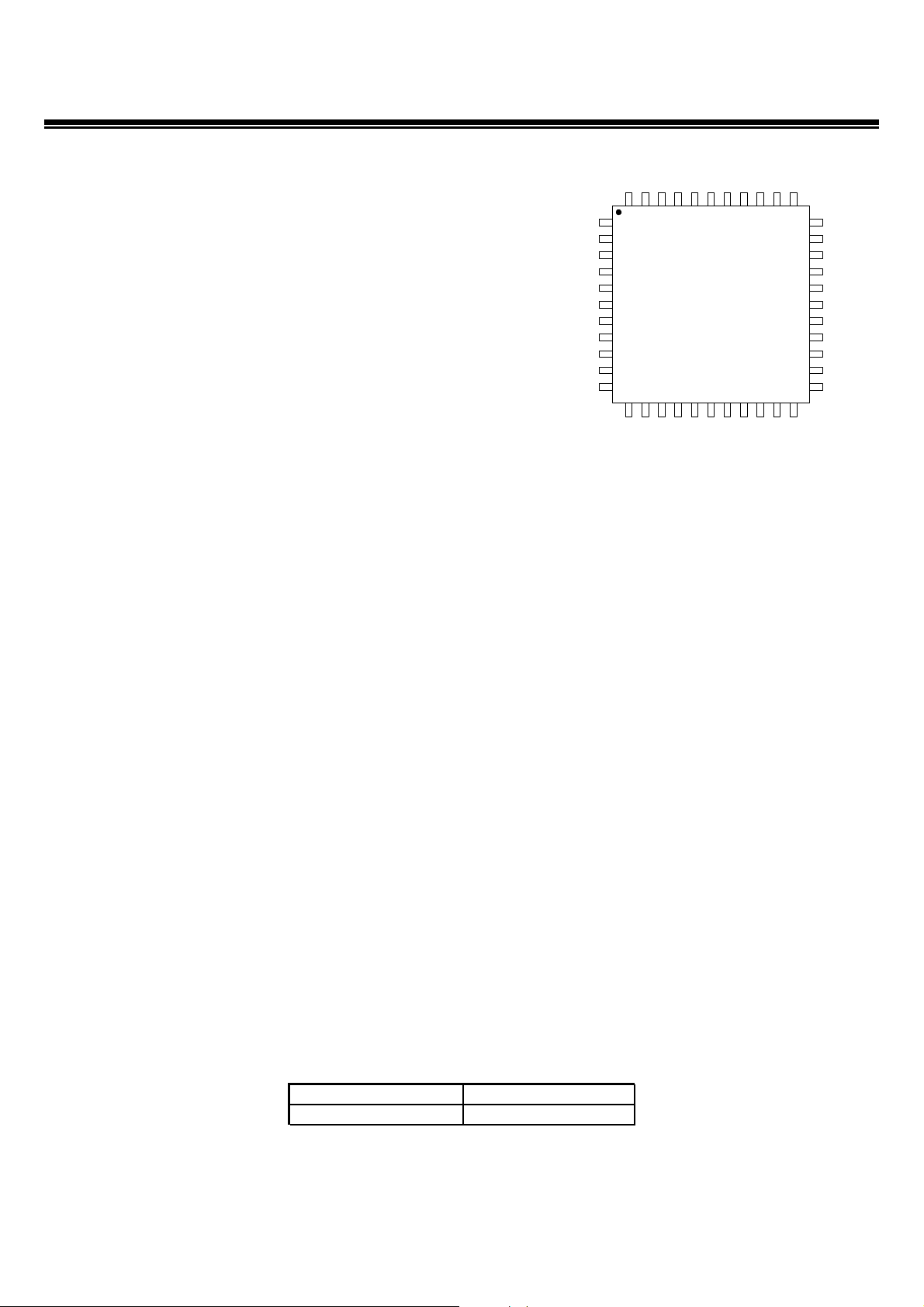

LQ QT60320C

NOT RECOMMENDED FOR NEW DESIGNS

Creates 32 ‘touch buttons’ through any dielectric

32-KEY QM

100% autocal for life - no adjustments required

'N' key rollover: senses all 32 keys in parallel

Keys individually adjustable for sensitivity

Mix 'n match key sizes & shapes in one panel

Tolerates a 20:1 variance in key sizes on a panel

Panel thicknesses to 5 cm or more

Back lit keys possible with ITO electrodes

LED status function drives

User-addressable multifunction drive pins

User-addressable internal eeprom

Simple, universal serial interface

5V single supply operation

44-pin TQFP package

One square inch (6.5 square cm) of PCB required

APPLICATIONS -

Security keypanels

Industrial keyboards

Appliance controls

Outdoor keypads

ATRIX

X6

X7

X8

RST

Vcc

Gnd

XT2

XT1

RX

TX

O1 O5

ATM machines

Touch-screens

™ C

HARGE-TRANSFER

Gnd

Vcc

X5X4X3

44 434241 403938 37 363435

2

3

4

5

6

7

8

9

10

11 23

12

O2O3O4L1L2

X2

X1

QT60320

13

1615

14 22

AIN

17

Vcc

GndY1Y2Y3Y4

Automotive panels

Machine tools

I4I3I2

21192018

IC

I11

33

CC1

32

CC2

31

CS

30

Aref

29

AGnd

28

Vcc

27

O8

26

O7

25

O6

24

The QT60320 digital charge-transfer (“QT”) QMatrix™ IC is designed to detect touch on up to 32 keys in a scanned X-Y matrix. It will

project the keys through almost any dielectric, like glass, plastic, stone, ceramic, and even most kinds of wood, up to thicknesses of

5 cm or more. The touch areas are defined as simple 2-part interdigitated electrodes of conductive material, like copper,

Indium-Tin-Oxide (ITO), or screened silver or carbon deposited on the rear of the control panel. Key sizes, shapes and placement are

almost entirely arbitrary; sizes and shapes of keys can be mixed within a single panel of keys and can vary by a factor of 20:1 or more

in area. The gain (sensitivity) and threshold of each key can be set individually via simple commands over the UART port, for example

via the freeware QmBtn program. Key setups are stored internally in an onboard eeprom and do not need to be reloaded.

The IC is designed specifically to work with appliances, ATM machines, security panels, portable instruments, machine tools, or

similar products that are subject to environmental 'challenges' or even physical attack. It permits the construction of 100% sealed,

watertight keypanels that are immune to environmental factors such as humidity and condensation, temperature, dirt accumulation, or

the physical deterioration of the panel surface from abrasion, chemicals, or abuse. To this end the QT60320 contains

Quantum-pioneered self-calibration, drift compensation, and digital filtering algorithms that make the sensing function extremely

robust and survivable.

The device can readily control keys over graphical LCD panels or LEDs when used with clear, conductive ITO electrodes. It does not

require 'chip on glass' or other exotic fabrication techniques, thus allowing the OEM to source the keymatrix from multiple vendors.

External circuitry consists of an opamp, a common PLD, and a quad fet switch, which can fit into a footprint of roughly 1 square inch

(6.5 sq. cm). The device also can control two status LEDs, and includes in addition 8 addressable output drive lines and 4 readable

spare input lines which can be used to control LEDs, LCDs, or other panel functions without requiring additional control lines from the

host CPU. It also makes available to the user 86 bytes of onboard writeable and readable eeprom via the serial interface, thus helping

to reduce system cost by eliminating extra components.

QT60320 technology makes use of an important new variant of charge-transfer sensing, transverse charge-transfer, in an XY format

that minimizes the number of required scan lines. Unlike older technologies it does not require one IC per key, and is cost competitive

even with some membrane technologies. In many cases it can also replace resistive XY sense elements commonly used in touch

screens, at a fraction of the price.

This part is not recommended for new designs. Consult Quantum for advice on alternatives.

LQ

0

-40

C to +1050C

AVAILABLE OPTIONS

A

QT60320C-AS

TQFPT

Copyright © 1999, 2001 Quantum Research Group Ltd

QT60320C R1.08/01.03

1 - OVERVIEW

The QT60320 is a digital burst mode charge-transfer (QT)

sensor designed specifically for matrix geometry touch

controls; it includes all signal processing functions necessary

to provide stable sensing under a wide variety of changing

conditions. Only a few low cost external parts are required for

operation. The entire circuit can be built within about 1

square inch of PCB area (smt).

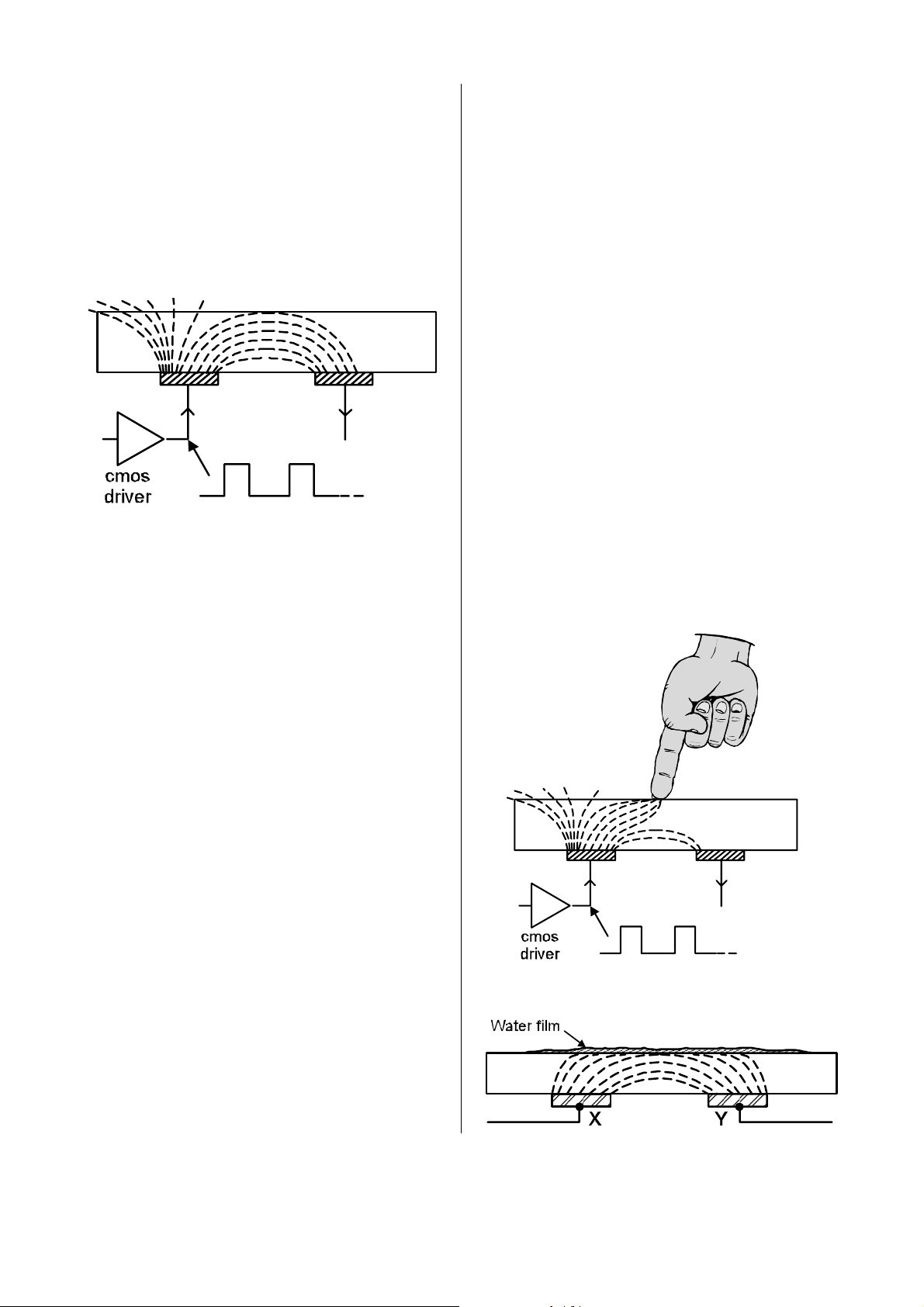

Figure 1-1 Field flow between X and Y elements

overlying panel

X

eleme nt

The 60320 uses burst-mode charge transfer methods

pioneered and patented by Quantum, including charge

cancellation methods which allow for a wide range of key

sizes and shapes to be mixed together in a single keypanel.

These features permit the construction of entirely new

classes of keypanels never before contemplated, such as

touch-sliders, back-illuminated keys, and arbitrary shape

keypanels, all at very low cost.

The QT60320 uses an asynchronous serial (uart) interface

running at 9600 baud to allow key data to be extracted and to

permit individual key parameter setup. The interface protocol

uses simple ASCII commands and responds with either

ASCII or binary results depending on the command.

In addition to normal operating and setup commands the

device can also report back actual key signal strength and

error codes. Spare eeprom memory (over 80 bytes) can also

be written to and read to save the system designer from

having to install and interface to a separate eeprom.

The IC also includes 4 readable input (I1..I4) pins and 8

settable output (O1..O4) pins which can be used in any way

desired, including to scan a secondary keypad of up to 32

contact closures. Alternatively they can be used to remotely

activate panel LEDs, buzzers, or other types of indicators.

QmBtn software for the PC can be used to program a board

containing the IC as well as read back key status and signal

levels in real time.

The QT60320 employs transverse charge-transfer ('QT')

sensing, a new technology that senses the charge forced

across an electrode set by a digital edge.

Y

element

of the X drive pulse. The charge emitted by the X electrode is

partly received onto the corresponding Y electrode which is

then processed. The QT60320 matrix uses 8 'X' edge-driven

rows and 4 'Y' sense columns to allow up to 32 keys.

The charge flows are absorbed by the touch of a human

finger (Figure 1-2) resulting in a decrease in coupling from X

to Y; coupled charge increases in the presence of a

conductive film like water (Figure 1-3) which acts to bridge

the two elements. Increasing signals due to water films are

quite easy to discern and are not detected by the IC.

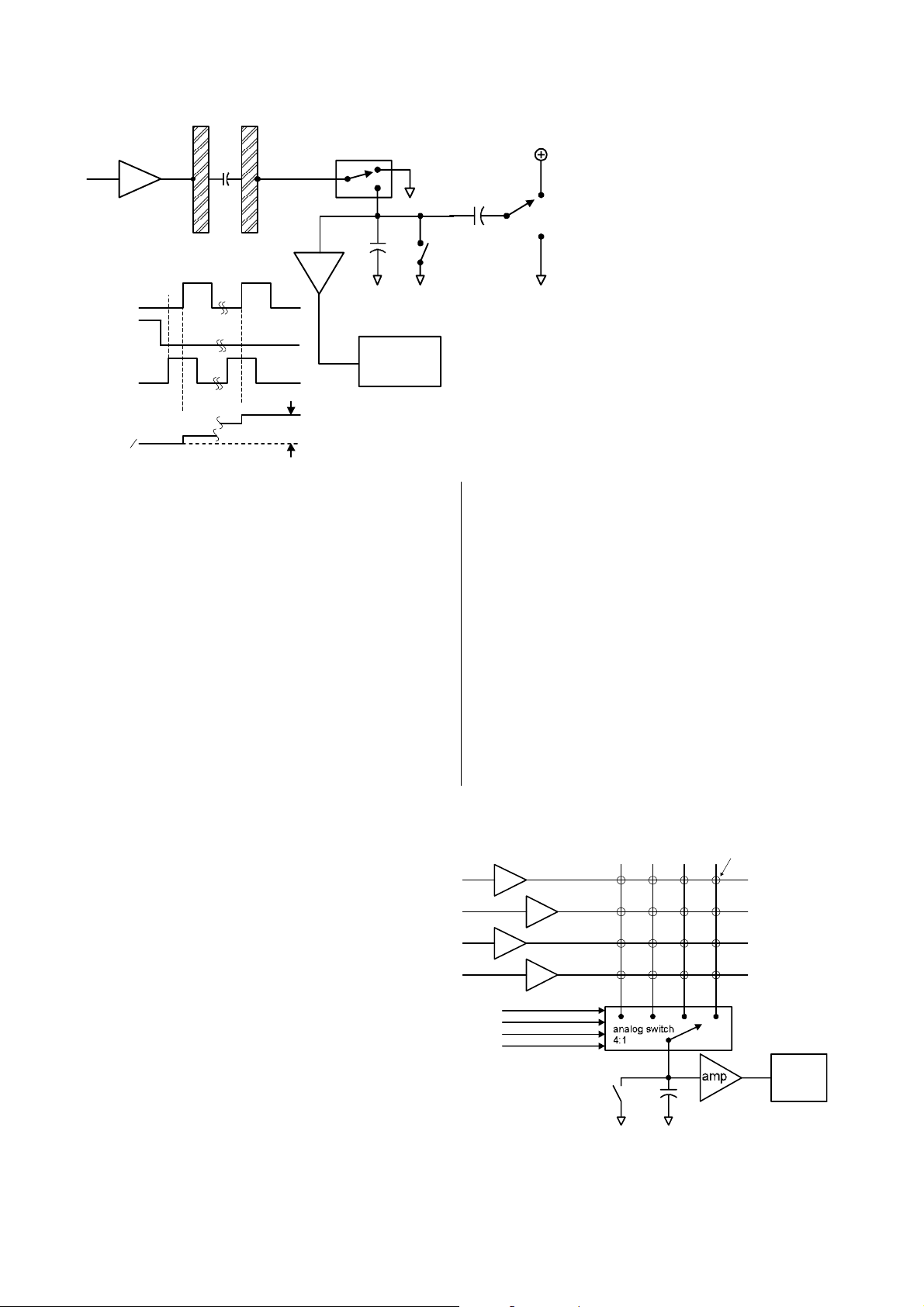

1.2 CIRCUIT MODEL

An electrical circuit model is shown in Figure 1-4. The

coupling capacitance between X and Y electrodes is

represented by Cx. While the reset switch is open, a

sampling switch is gated so that it transfers charge flows only

from the rising edge of X into the sample capacitor Cs. Cs is

a large value capacitor, typically in the range of 1 - 50nF. The

voltage rise captured on Cs after each X edge is quite small,

on the order of a millivolt, while changes due to touch are on

typically the order of 10's of microvolts. The X pulse can be

repeated in a burst consisting of up to several hundred

pulses to build up the voltage (and the change in voltage due

to touch) to a larger value. Longer bursts increase system

gain by collecting more charge; gain can thus be digitally

manipulated to achieve the required sensitivity on a

key-by-key basis during scanning.

If the voltage on Cs rises excessively it can fall outside of the

ADC's range. To reduce the voltage again without affecting

gain, one of two (or both) Cz capacitors can be switched to

Figure 1-2 Field Flows When Touched

overlying panel

X

element

Figure 1-3 Fields With a Conductive Film

Y

element

1.1 FIELD FLOWS

Figure 1-1 shows how charge is transferred across the

electrode set to permeate the overlying panel material; this

charge flow exhibits a rapid dQ/dt during the edge transitions

LQ

2 QT60320C R1.08/01.03

Figure 1-4 QT60320 Circuit Model

X1X2X3X

X

switch (1 of 4)

Amp

Sample

0

Cs

8-bit ADC

011

Reset

switch

X drive (1 of 8)

electrode

X Drive

Reset

switch

Sample

switch

Amp

out

0

Cx

X

Y

electrode

Y

receive line

(1 o f 4)

V

out

subtract charge from Cs to create a negative-going offset,

bringing the signal back to a usable level. This action occurs

during the course of the burst and is not illustrated in the

timing diagram of Figure 1-4. This mechanism has the benefit

of allowing high levels of Cx while remaining highly sensitive

to small changes in charge coupling due to touch; the circuit

permits the designer to create very large, highly interdigitated

touch keys that are very sensitive.

The large Cs capacitor creates a virtual ground termination,

making the Y lines appear as a low impedance; this

effectively eliminates cross-coupling among Y lines due to

voltage spikes, while dramatically lowering susceptibility to

EMI. The circuit is also highly tolerant of capacitive loading

on the Y lines, since stray C from Y to ground appears

merely as a parallel capacitance to a much larger value of

Cs.

The QT60320 circuit design maintains high gain levels

independent of Cx or stray coupling C to ground. It also

readily compensates for field-related issues like

electrode design or the composition of the overlying

panel, as it has individual programmable gain and

threshold settings for each key.

Short sample gate dwell times after the X edge can be

used to limit the effect of moisture spreading from key

to key by taking advantage of the RC filter-like nature

of continuous films; the shorter the dwell time, the less

time that the charge has to travel through the

impedance of the film. This effect is completely

independent of the frequency of burst repetition,

intra-burst pulse spacing, or X drive pulse width.

Burst mode operation permits reduced power

consumption and reduces RF emissions, while

permitting excellent response time.

1.3 MATRIX CONFIGURATION

The matrix scanning configuration is shown in part in

Figure 1-5. The X drives are conventional CMOS

push-pull outputs which are sequentially pulsed in

groupings of bursts; a 4-pole analog switch

acts as the sample switch for all 4 Y lines. At

the intersection of each X and Y line is an

interdigitated electrode set as shown in

Figure 1-6. Typically the outermost electrode

Cancellation

switch (1 of 2)

is connected to X and the inner electrode

connected to Y. Remaining Y lines not

being sampled are grounded.

Cz

(1 of 2 )

1.4 'X' ELECTRODE DRIVES

The 8 'X' lines can be directly connected to

the matrix without buffering. Only the X lines'

positive edges are used to create the

transient field flows used to scan the keys.

Only one X line is active at a time, and it will

pulse for a burst length determined by the

'gain' setting parameter.

If desired an external 22V10 type CMOS

PLD can be used to create the short gate

dwell times necessary to enhance moisture

suppression (Section 1.2). The PLD takes

as its input all 'X' and 'Y' lines, and with

added RC time constants creates the

required short dwell time on the Y switches.

The code for the PLD is available freely on

the Quantum web site and can also be found in Section 5.

1.5 'Y' GATE DRIVES

There are 4 'Y' gate drives (Y1..Y4) which are active-high;

only one Y line is used during a burst for a particular key. The

chosen Y line goes high just before an X line transitions high,

and goes low again just after the X line rises. It is used to

gate on an analog switch, such as a 74HC4066, to capture

charge coupled through a key to the sample capacitor Cs.

An inverted version of the Y lines can be used to gate

unselected Y lines to ground, to suppress residual cross-key

coupling that might be caused by cross-pickup from adjacent

X drive traces. See Section 2.2.

Y gate signals can be manipulated externally so that the gate

dwell time is very short to suppress the effects of surface

conductivity due to water films. See Section 2.3.

Figure 1-5 QT60320 Matrix Configuration

drives

(4 of 8 shown)

4

Y

Y2Y3Y

Reset

switch

1

Cs

Y

s1

Y

s2

Y

s3

Y

s4

Interdigitated

keys

4

ADC

LQ

3 QT60320C R1.08/01.03

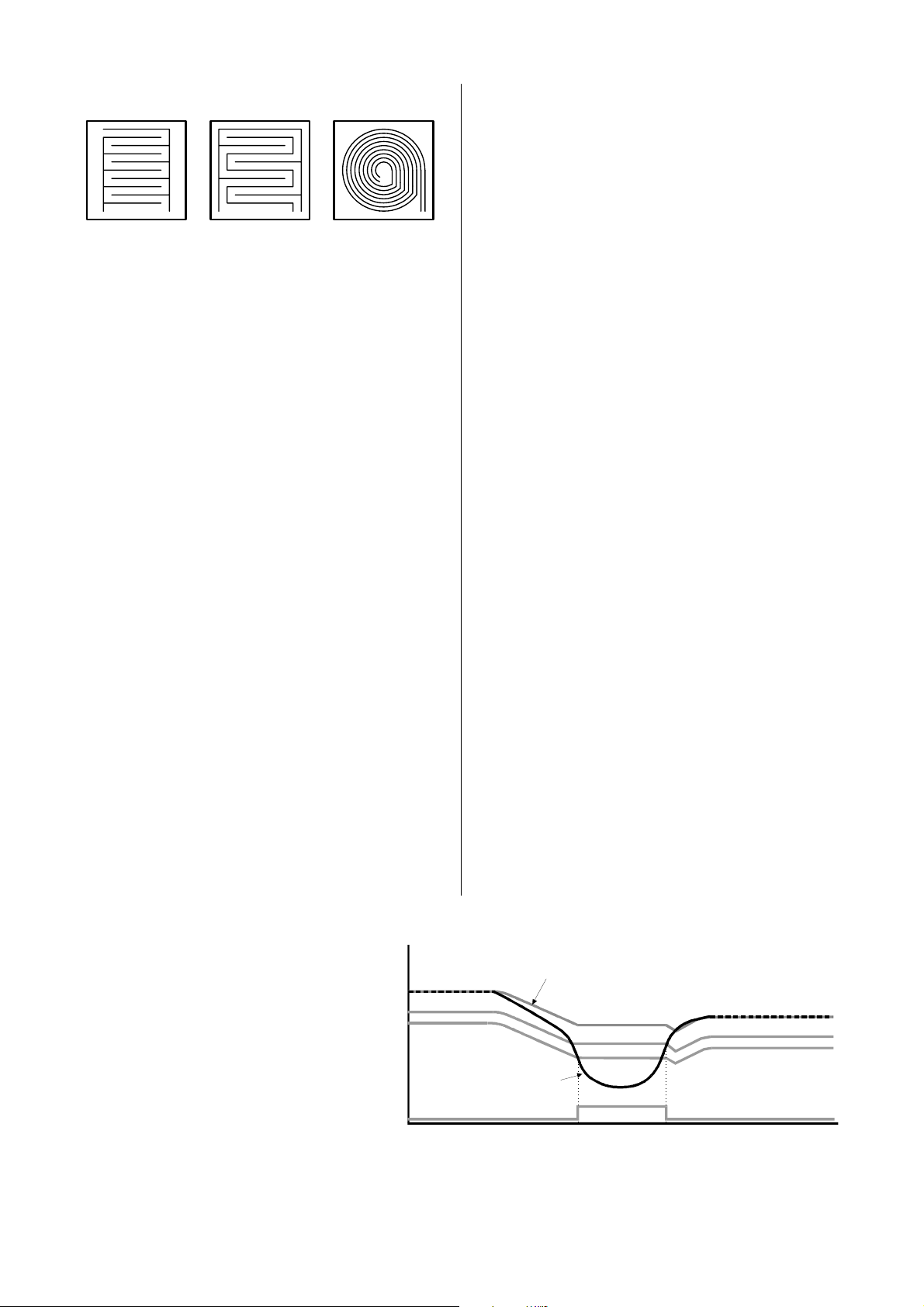

Figure 1-6 Sample Electrode Geometries

PARALLEL LINES SERPENTINE SPIRAL

1.6 SIGNAL PROCESSING

The QT60320 calibrates and processes all signals using a

number of algorithms pioneered by Quantum. These

algorithms are specifically designed to provide for high

survivability in the face of adverse environmental challenges.

1.6.1 S

The QT60320 is fully self-calibrating. On powerup the IC

scans the matrix key by key and sets appropriate calibration

points for each in accordance with setup information in its

internal eeprom, or on the fly from a host MPU. Since the

circuit can tolerate a very wide dynamic range, it is capable of

adapting to a wide mix of key sizes and shapes having wildly

varying Cx coupling capacitances. No special operator or

factory calibration or circuit tweak is required to bring keys

into operation, except for a gain and threshold batch setup

which can be performed in seconds from a file saved on a

PC. Once set, there should never be a need to readjust these

parameters.

1.6.2 D

Signal drift can occur because of changes in Cx and Cs over

time. It is crucial that drift be compensated for, otherwise

false detections, non-detections, and sensitivity shifts will

follow.

Drift compensation (Figure 1-7) is performed by making the

reference level track the raw signal at a slow rate, but only

while there is no detection in effect. The rate of adjustment

must be performed slowly, otherwise legitimate detections

could be ignored. The QT60320 drift compensates using a

slew-rate limited change to the reference level; the threshold

and hysteresis values are slaved to this reference.

When a finger is sensed, the signal falls since the human

body acts to absorb charge from the cross-coupling between

X and Y lines. An isolated, untouched foreign object (a coin,

or a water film) will cause the signal to rise slightly due to the

enhanced coupling thus created. These effects are contrary

to the way most capacitive sensors operate.

Once a finger is sensed, the drift compensation mechanism

ceases since the signal is legitimately low, and

therefore should not cause the reference level to

change.

The QT60320's drift compensation is

'asymmetric': the drift-compensation occurs in

one direction faster than it does in the other.

Specifically, it compensates faster for increasing

signals than for decreasing signals. Decreasing

signals should not be compensated for quickly,

since an approaching finger could be

compensated for partially or entirely before even

touching the sense pad. However, an obstruction

over the sense pad, for which the sensor has

already made full allowance for, could suddenly

ELF-CALIBRATION

RIFT COMPENSATION ALGORITHM

Hysteresis

Threshold

Output

be removed leaving the sensor with an artificially suppressed

reference level and thus become insensitive to touch. In this

latter case, the sensor will compensate for the object's

removal by raising the reference level quickly.

1.6.3 T

The threshold value is established as an offset to the

reference level. As Cx and Cs drift, the reference drift

compensates with the changes and the threshold level is

automatically recomputed in real time so that it is never in

error. Since key touches result in negative signal swings, the

threshold is set below the signal reference level.

The QT60320 employs a hysteresis of 25% of the delta

between the reference and threshold levels. The signal must

rise by 25% of the distance from threshold to reference

before the detection event drops out and the key registers as

untouched.

1.6.4 MAX ON-D

If a foreign object contacts a key the signal may change

enough to create a 'false' detection lasting for the duration of

the contact. To overcome this, the IC includes a timer which

monitors detection duration. If a detection exceeds the timer

setting, the timer causes the sensor to perform a full

recalibration. This is known as the Max On-Duration feature.

After the Max On-Duration interval has expired and the

recalibration has taken place, the affected key will once again

function normally even if still contacted by the foreign object,

to the best of its ability. The Max On-Duration is fixed at 10

seconds of continuous detection.

1.6.5 D

To suppress false detections caused by spurious events like

electrical noise, the QT60320 incorporates a detection

integration counter that increments with each detection

sample until a limit is reached, at which point a detection is

confirmed. If no detection is sensed on any of the samples

prior to the final count, the counter is reset immediately to

zero, forcing the process to restart. The required count is 4.

HRESHOLD AND HYSTERESIS CALCULATIONS

URATION

ETECTION INTEGRATOR

2 - CIRCUIT SPECIFICS

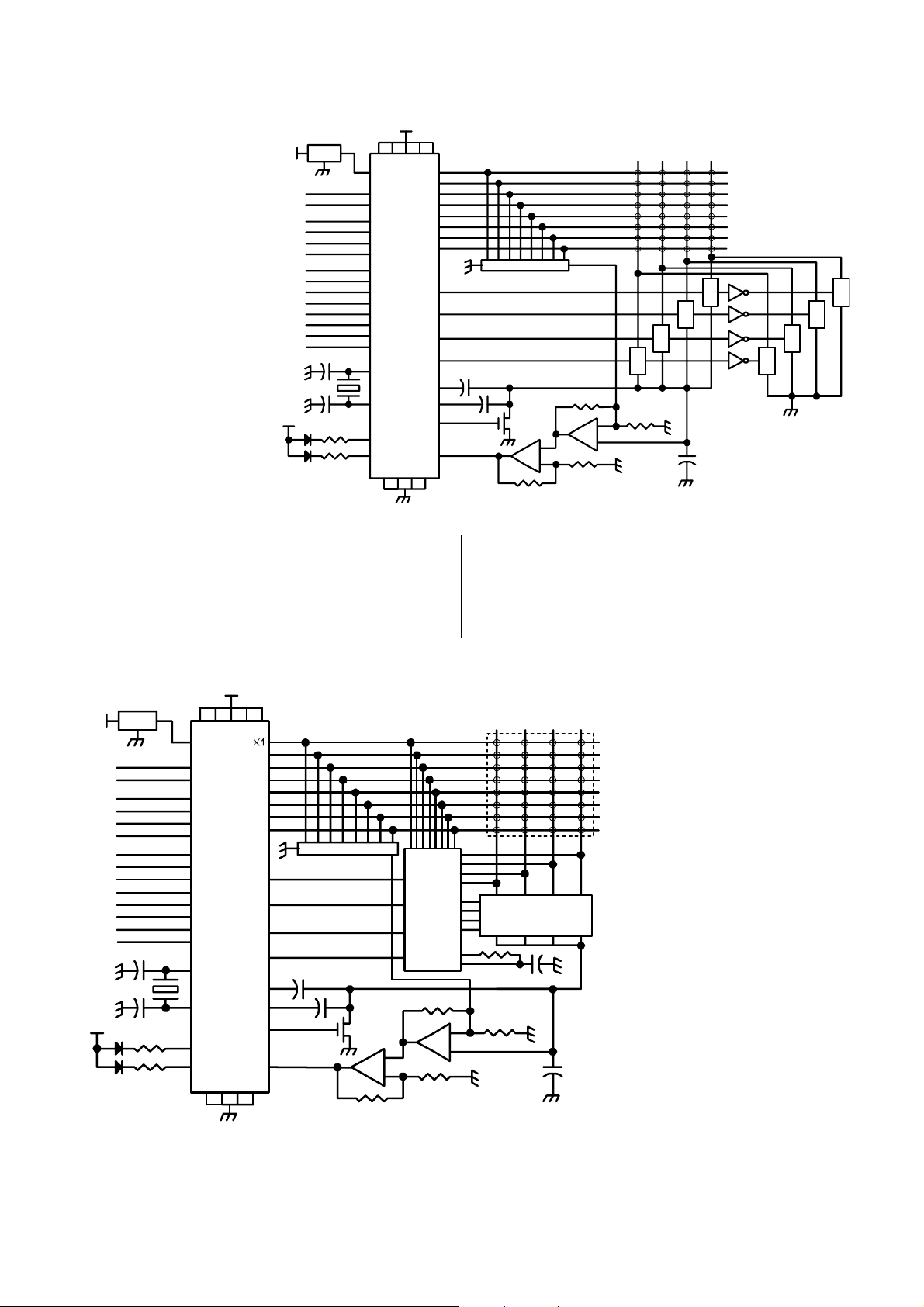

A basic QT60320 circuit is shown in Figure 2-1.

2.1 SIGNAL PATH

The QT60320 requires an external sampling capacitor, two

Cz capacitors, an amplifier, some analog switches, and an

R2R ladder DAC to operate.

The Cs capacitor performs the charge integration function by

collecting charge coupled though a selected key during the

Figure 1-7 Drift Compensation

Reference

Signal

LQ

4 QT60320C R1.08/01.03

dV/dt of the rising edge of an

Figure 2-1 Basic QT60320 Circuit

'X' scan line. The charge is

sampled 'n' times during the

course of a burst of switching

cycles of length 'n'. As the

burst progresses the charge on

Cs increases in a staircase

fashion (Figure 1-4).

At the burst's end the voltage

on Cs, which is on the order of

a few tenths of a volt, is

amplified by a gain circuit

which includes an offset

current from the R2R ladder

DAC driven by the X drive

lines. The offset current from

the R2R ladder repositions the

output of the amplifier chain to

coincide as closely as possible

with the center span of the

60320's ADC, which can

convert voltages between 0

and 5 volts. Between bursts the

Cs reset mosfet is activated to

reset the Cs capacitor to

Vcc

Vcc

UART IN

UART OUT

USE R PO RT PINS

CAL L ED

STAT LED

DS1811

8MHz

Vcc

51727 38

VVV

4

Rst

9

Rx

10

Tx

33

I1

34

I2

35

I3

36

I4

11

O1

12

O2

13

O3

14

O4

23

O5

24

O6

25

O7

26

O8

8

XT1

7

XT2

15

L1

16

L2

GGGG

618 39

29

V

V

X1

X2

X3

X4

X5

X6

X7

X8

YS1

YS2

QT6032 0

YS3

YS4

CC1

CC2

CS

AIN

28

ground.

Gain is directly controlled by

burst length 'n', amplifier gain

Av, and the values of Cs, Cz1 and Cz2. Only 'n' can be

adjusted on a key by key basis whereas Av and the

capacitances can only be adjusted for all keys. The amplifier

should typically have a total positive gain of 100 +/- 20%..

Figure 2-2 Improved Circuit to Suppress Water Films

Vcc

29

8MH z

10

33

34

35

36

11

12

13

14

23

24

25

26

15

16

51727 38

VVV

4

Rst

9

Rx

Tx

I1

I2

I3

I4

O1

O2

O3

O4

O5

O6

O7

QT60320

O8

8

XT1

7

XT2

L1

L2

GGGG

618 39

28

V

YS3

CC1

CC2

YS1

YS2

YS4

CS

AIN

V

X2

X3

X4

X5

X6

X7

X8

40

41

42

43

44

1

2

3

19

20

21

22

C6 (Cz 1) 820pF

C7 (Cz2) 820pF

32

31

30

BSN 20

37

R2R dac 100K

R4 100 K

+

_

22V10

R3 68K

TLC2272

R6 10K

USE R POR T PINS

Vcc

DS1811

Vcc

UART IN

UART OUT

CAL LED

STAT LED

Keymatrix

1/4

HC4066

R5 10K

Y3 Y2Y4 Y1

1/4

HC4066

C5 ( Cs)

15nF

1/4

HC4066

1/4

HC4066

1/4

74AC04

HC4066

40

41

42

43

44

1

2

3

19

20

21

22

C6 (Cz1) 8 20pF

C7 (Cz2) 8 20pF

32

31

30

BSN20

37

R2R dac 100K

+

_

R4 100K

R3 68 K

_

+

TLC2272

R6 10 K

If there is a large amount of coupling between X and Y lines,

and where burst length 'n' is set to a high number, charge

accumulation on Cs may reach a point where the ladder DAC

can no longer offset the signal back into the ADC's usable

range. In this case the circuit will employ one or two of the Cz

capacitors to 'knock back' or cancel the charge accumulated

on Cs; each Cz will cancel charge

in a discrete step as required.

Components shown in Figure 2-1

include:

Keymatrix

Y3 Y2Y4 Y1

An LVD reset (e.g. Dallas

DS1811) suitable for 5 volt

supplies and an active-low on

low-voltage output;

An R2R ladder network (CTS

750-107R100K or equivalent);

A >2MHz GBW CMOS rail-rail

output opamp capable of

sensing ground on the inputs;

An 8MHz crystal or resonator,

I/O I/O I/O I/O

E

E

QS31 25

E

I/O I/O I/O I/O

E

Ct

Rt

or a ceramic resonator with

built-in capacitors;

Two indicator LEDs (optional)

to show sensing state and

calibration status;

74AC04 inverters to drive the

R5 10K

_

+

C5 ( Cs)

15nF

two banks of analog switches

in opposite states;

Two 74HC4066 analog

switches;

A reset mosfet, most any

small-signal mosfet with a

guaranteed on-state at 4 volts

1/4

HC4066

1/4

HC4066

1/4

HC4066

LQ

5 QT60320C R1.08/01.03

Loading...

Loading...