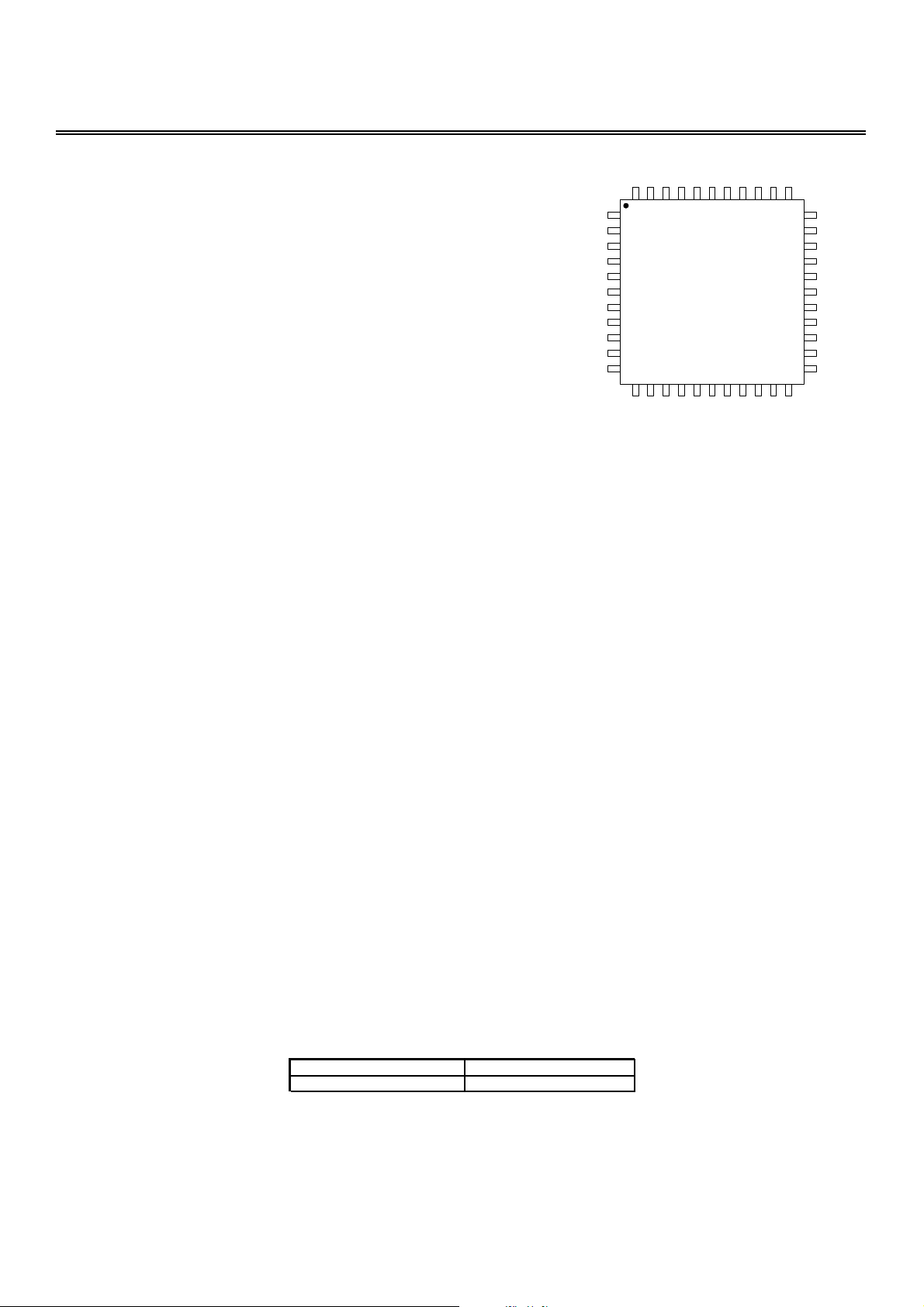

LQ QT60161B

16 KEY QMatrix™ K

Advanced second generation QMatrix controller

16 touch keys through any dielectric

100% autocal for life - no adjustments required

SPI Slave or Master/Slave interface to a host controller

Parallel scan interface for electromechanical compatibility

Keys individually adjustable for sensitivity, response time,

and many other critical parameters

Sleep mode with wake pin

Synchronous noise suppression

Mix and match key sizes & shapes in one panel

Adjacent key suppression feature

Panel thicknesses to 5 cm or more

Low overhead communications protocol

MOSI

MISO

SCK

RST

Vdd

Vss

XTO

XTI

RX

TX

WS

EYPANEL SENSOR

DRDY

VREF

SO

SS

43 42

44

2

3

4

5

6

7

8

9

10

11 23

12

41 40393837363435

QT60161B

TQFP-44

13

1615

14 22

SMP

X0OPA

X1OPBX2X3

CS0A

CS1A

CS0B

LED

Vdd

Vss

17

Vdd

Vss

CS1B

21192018

XS0

XS1

XS2

XS3

IC

CS2A1

33

CS2B

32

CS3A

31

CS3B

30

Aref

29

AGnd

28

AVd d

27

YS3

26

YS2

25

YS1

24

YS0

44-pin TQFP package

APPLICATIONS -

Security keypanels

Industrial keyboards

Appliance controls

Outdoor keypads

ATM machines

Touch-screens

The QT60161B digital charge-transfer (“QT”) QMatrix™ IC is designed to detect human touch on up 16 keys when used in

conjunction with a scanned, passive X-Y matrix. It will project the keys through almost any dielectric, e.g. glass, plastic, stone,

ceramic, and even wood, up to thicknesses of 5 cm or more. The touch areas are defined as simple 2-part interdigitated

electrodes of conductive material, like copper or screened silver or carbon deposited on the rear of a control panel. Key sizes,

shapes and placement are almost entirely arbitrary; sizes and shapes of keys can be mixed within a single panel of keys and can

vary by a factor of 20:1 in surface area. The sensitivity of each key can be set individually via simple functions over the SPI or

UART port, for example via Quantum’s QmBtn program, or from a host microcontroller. Key setups are stored in an onboard

eeprom and do not need to be reloaded with each powerup.

The device is designed specifically for appliances, electronic kiosks, security panels, portable instruments, machine tools, or

similar products that are subject to environmental influences or even vandalism. It can permit the construction of 100% sealed,

watertight control panels that are immune to humidity, temperature, dirt accumulation, or the physical deterioration of the panel

surface from abrasion, chemicals, or abuse. To this end the device contains Quantum-pioneered adaptive auto self-calibration,

drift compensation, and digital filtering algorithms that make the sensing function robust and survivable.

The part can scan matrix touch keys over LCD panels or other displays when used with clear ITO electrodes arranged in a matrix.

It does not require 'chip on glass' or other exotic fabrication techniques, thus allowing the OEM to source the matrix from multiple

vendors. Materials such as such common PCB materials or flex circuits can be used.

External circuitry consists of a resonator and a few capacitors and resistors, all of which can fit into a footprint of less than 6 sq. cm

(1 sq. in). Control and data transfer is via either a SPI or UART port; a parallel scan port provides backwards compatibility with

scanned electromechanical keys.

The QT60161B makes use of an important new variant of charge-transfer sensing, transverse charge-transfer, in a matrix format

that minimizes the number of required scan lines. Unlike some older technologies it does not require one sensing IC per key.

The QT60161B is identical to earlier QT60161 in all respects except that the device exhibits lower signal noise. This

device replaces QT60161 parts directly. After December 2003 the QT60161 will no longer be sold.

Automotive panels

Machine tools

lQ

AVAILABLE OPTIONS

A

TQFP Part NumberT

QT60161B-AS-400C to +1050C

Copyright © 2001 Quantum Research Group Ltd

Pat Pend. R1.03/04.03

Contents

1 Overview

2 Signal Processing

3 Circuit Operation

4 Communications Interfaces

5 Commands & Functions

............................................

.......................................

..................................

..................................

....................................

................................

.................................

.......................................

................................

................................

.................................

.....................................

......................................

3.3.1 RFI From X Lines

3.3.2 Noise Coupling Into X lines

3.4.1 RFI From Y Lines

3.4.2 Noise Coupling Into Y Lines

................................

..................................

....................................

..................................

................................

....................................

................................

.....................................

.......................................

..............................

..............................

.................................

...............................

..............................

.............................

g 0x67 - Get Command

p 0x70 - Put Command

s 0x73 - Specific Key Scope

S 0x53 - All Keys Scope

x 0x78 - Row Keys Scope

y 0x79 - Column Keys Scope

..............................

..............................

..............................

..............................

.............................

©Quantum Research Group Ltd.

........................

.........................

...........................

....................

.........................

.............................

............................

............................

...........................

..........................

...........................

.........................

.................

.....................

......................

..........................

..........................

...........................

............................

..........................

..................

.....................

...........................

...........................

4

41.1 Field Flows

41.2 Circuit Overview

41.3 Communications

5

52.1 Negative Threshold

52.2 Positive Threshold

52.3 Hysteresis

52.4 Drift Compensation

62.5 Negative Recalibration Delay

62.6 Detection Integrator

62.7 Positive Recalibration Delay

62.8 Reference Guardbanding

62.9 Adjacent Key Suppression (‘AKS’)

72.10 Full Recalibration

72.11 Device Status & Reporting

7

73.1 Matrix Scan Sequence

73.2 Signal Path

83.3 'X' Electrode Drives

8

8

83.4 'Y' Gate Drives

8

8

83.5 Burst Length & Sensitivity

83.6 Burst Acquisition Duration

93.7 Intra-Burst Spacing

93.8 Burst Spacing

93.9 Sample Capacitors

93.10 Water Film Suppression

93.11 Reset Input

93.12 Oscillator

93.13 Startup / Calibration Times

93.14 Sleep_Wake / Noise Sync Pin (WS)

103.15 LED / Alert Output

113.16 Oscilloscope Sync

113.17 Power Supply & PCB Layout

113.18 ESD / Noise Considerations

11

114.1 Serial Protocol Overview

124.2 SPI Port Specifications

124.3 SPI Slave-Only Mode

134.4 SPI Master-Slave Mode

144.5 UART Interface

154.6 Sensor Echo and Data Response

154.7 Parallel Scan Port

164.8 Eeprom Corruption

17

175.1 Put / Get Direction Commands

17

17

185.2 Scope Commands

18

18

18

18

0 0x30 - Signal for Single Key

1 0x31 - Delta Signal for Single Key

2 0x32 - Reference Value

5 0x35 - Detection Integrator Counts

6 0x36 - Eeprom Checksum

7 0x37 - General Device Status

<sp> 0x20 - Signal Levels for Group

! 0x21 - Delta Signals for Group

" 0x22 - Reference Levels for Group

% 0x25 - Detect Integrator Counts for Group

e 0x65 - Error Code for Selected Key

E 0x45 - Error Codes for Group

k 0x6B - Reporting of First Touched Key

^A 0x01 - Negative Detect Threshold

^B 0x02 - Positive Detect Threshold

^C 0x03 - Negative Threshold Hysteresis

^D 0x04 - Positive Threshold Hysteresis

^F 0x06 - Burst Length

^G 0x07 - Burst Spacing

^H 0x08 - Negative Drift Compensation Rate5

^I 0x09 - Positive Drift Compensation Rate

^J 0x0A - Negative Detect Integrator Limit

^K 0x0B - Positive Recalibration Delay

^L 0x0C - Negative Recalibration Delay

^M 0x0D - Intra-Burst Pulse Spacing

^N 0x0E - Positive Reference Error Band

^O 0x0F - Negative Reference Error Band

^P 0x10 - Adjacent Key Suppression (‘AKS’)

6 0x36 - Eeprom Checksum

L 0x4C - Lock Reference Levels

b 0x62 - Recalibrate Keys

l 0x6C - Return Last Command Character

r 0x72 - Reset Device

V 0x56 - Return Part Version

W 0x57 - Return Part Signature

Z 0x5A - Enter Sleep

^Q 0x11 - Data Rate Selection

^R 0x12 - Oscilloscope Sync

^W 0x17 - Noise Sync

6 Electrical Specifications

7 Mechanical

8 Index

.............................................

...............................

..........................

.......................

.............................

......................

...........................

..........................

.......................

.........................

......................

.................

......................

.........................

....................

..............................

.......................

.......................

....................

.....................

...............................

..............................

.................

..................

...................

.....................

.....................

.......................

....................

...................

..................

....................

...........................

.........................

.............................

...................

...............................

...........................

.........................

................................

..........................

...........................

...............................

.........................

..............................

.................................

............................

..................

................

...............................

.................................

..................

........................................

....................................

.......................................

185.3 Status Commands

18

18

18

18

18

19

19

19

19

19

19

20

20

215.4 Setup Commands

21

21

21

21

21

22

22

22

22

23

23

23

23

23

24

245.5 Supervisory / System Functions

24

24

24

25

25

25

25

25

25

26

26

275.6 Function Summary Table

305.7 Timing Limitations

305.8 Erratta / Notes

31

316.1 Absolute Maximum Specifications

316.2 Recommended operating conditions

316.3 DC Specifications

316.4 Protocol Timing

326.5 Maximum Drdy Response Delays

33

337.1 Dimensions

337.2 Marking

34

lQ

ii

www.qprox.com QT60161B / R1.03

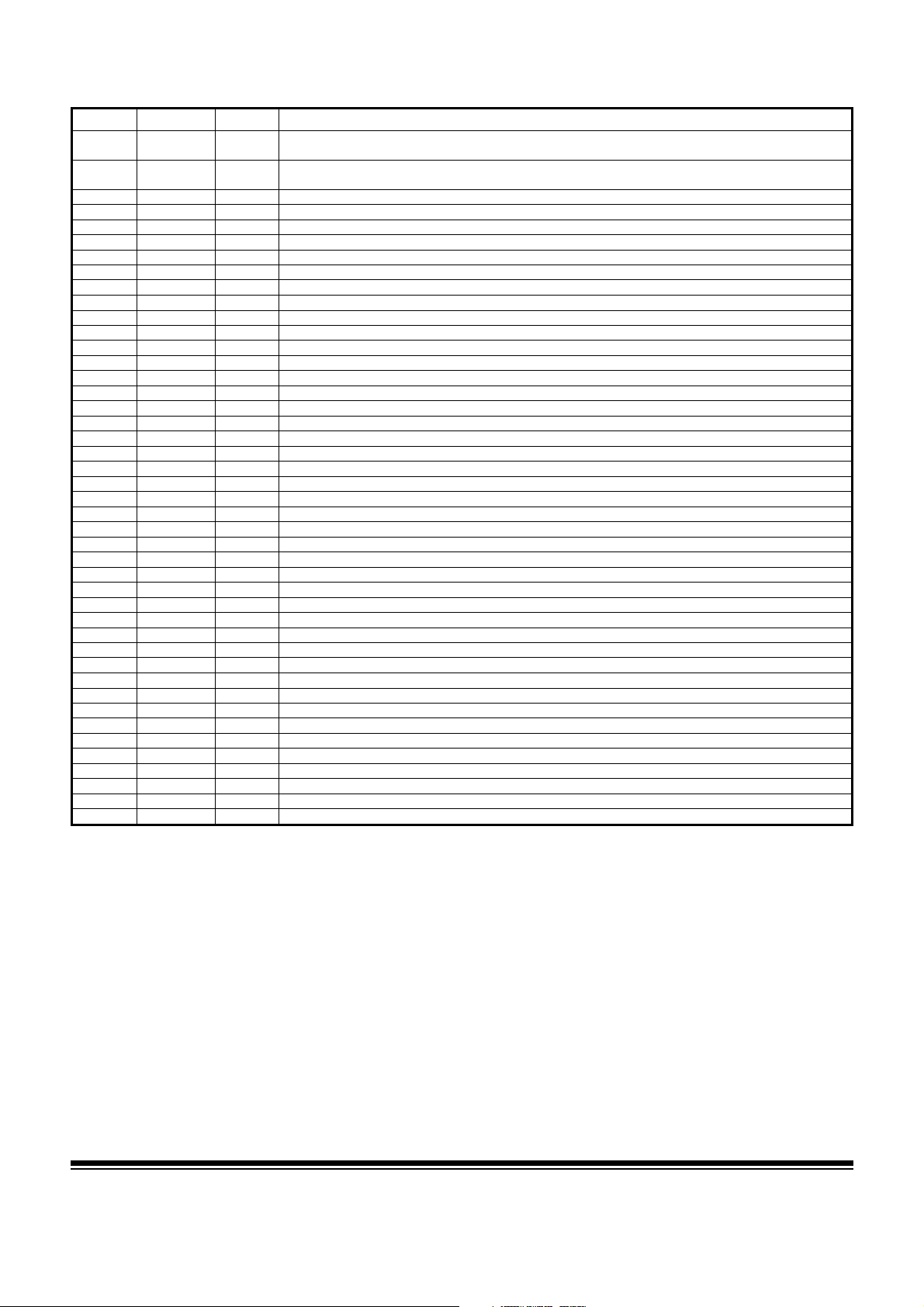

Table 1.1 Device Pin Lis

t

I/O PPMOSI1

I/O PPMISO2

I/O: I = Input

O = Output

Pwr = Power pin

I/O = Bidirectional line

PP = Push Pull output drive

OD = Open drain output drive

©Quantum Research Group Ltd.

DescriptionTypeNamePin

Master-Out / Slave In SPI line. In Master/Slave SPI mode is used for both communication directions.

In Slave SPI mode is the data input (in only).

Master-In / Slave Out SPI line. Not used in Master/Slave SPI mode.

In Slave mode outputs data to host (out only).

SPI Clock. In Master mode is an output; in Slave mode is an inputI/O PPSCK3

Reset input, active low resetIRST4

+5V supplyPwrVdd5

GroundPwrVss6

Oscillator drive output. Connect to resonator or crystal.plyO PPXTO7

Oscillator drive input. Connect to resonator or crystal, or external clock source.IXTI8

UART receive inputIRX9

UART transmit outputO PPTX10

Wake from Sleep / Sync to noise sourceIWS11

Sample output controlO PPSMP12

X0 Drive matrix scan / Communications option A inputI/O PPX0OPA13

X1 Drive matrix scan / Communications option B inputI/O PPX1OPB14

X2 Drive matrix scanO PPX215

X3 Drive matrix scanO PPX316

+5V supplyPwrVdd17

GroundPwrVss18

XS0 Scan input lineIXS019

XS1 Scan input lineIXS120

XS2 Scan input lineIXS221

XS3 Scan input lineIXS322

YS0 Scan output lineO PPYS023

YS1 Scan output lineO PPYS124

YS2 Scan output lineO PPYS225

YS3 Scan output lineO PPYS326

+5 supply for analog sectionsPwrAVdd27

Analog groundPwrAGnd28

+5 supply for analog sectionsPwrAref29

Cs3 control BI/O PPCS3B30

Cs3 control AI/O PPCS3A31

Cs2 control BI/O PPCS2B32

Cs2 control AI/O PPCS2A33

Cs1 control BI/O PPCS1B34

Cs1 control AI/O PPCS1A35

Cs0 control BI/O PPCS0B36

Cs0 control AI/O PPCS0A37

+5 supplyPwrVdd38

GroundPwrVss39

Active low LED status drive / Activity indicatorO PPLED40

Data ready output for Slave SPI mode; active lowO ODDRDY41

Vref input for conversion referenceIVref42

Oscilloscope sync outputO PPSO43

Slave select for SPI direction control; active lowI/O ODSS44

lQ

iii

www.qprox.com QT60161B / R1.03

©Quantum Research Group Ltd.

1 Overview

QMatrix devices are digital burst mode charge-transfer (QT)

sensors designed specifically for matrix geometry touch

controls; they include all signal processing functions

necessary to provide stable sensing under a wide variety of

changing conditions. Only a few low cost external parts are

required for operation. The entire circuit can be built in under

6 square centimeters of PCB area.

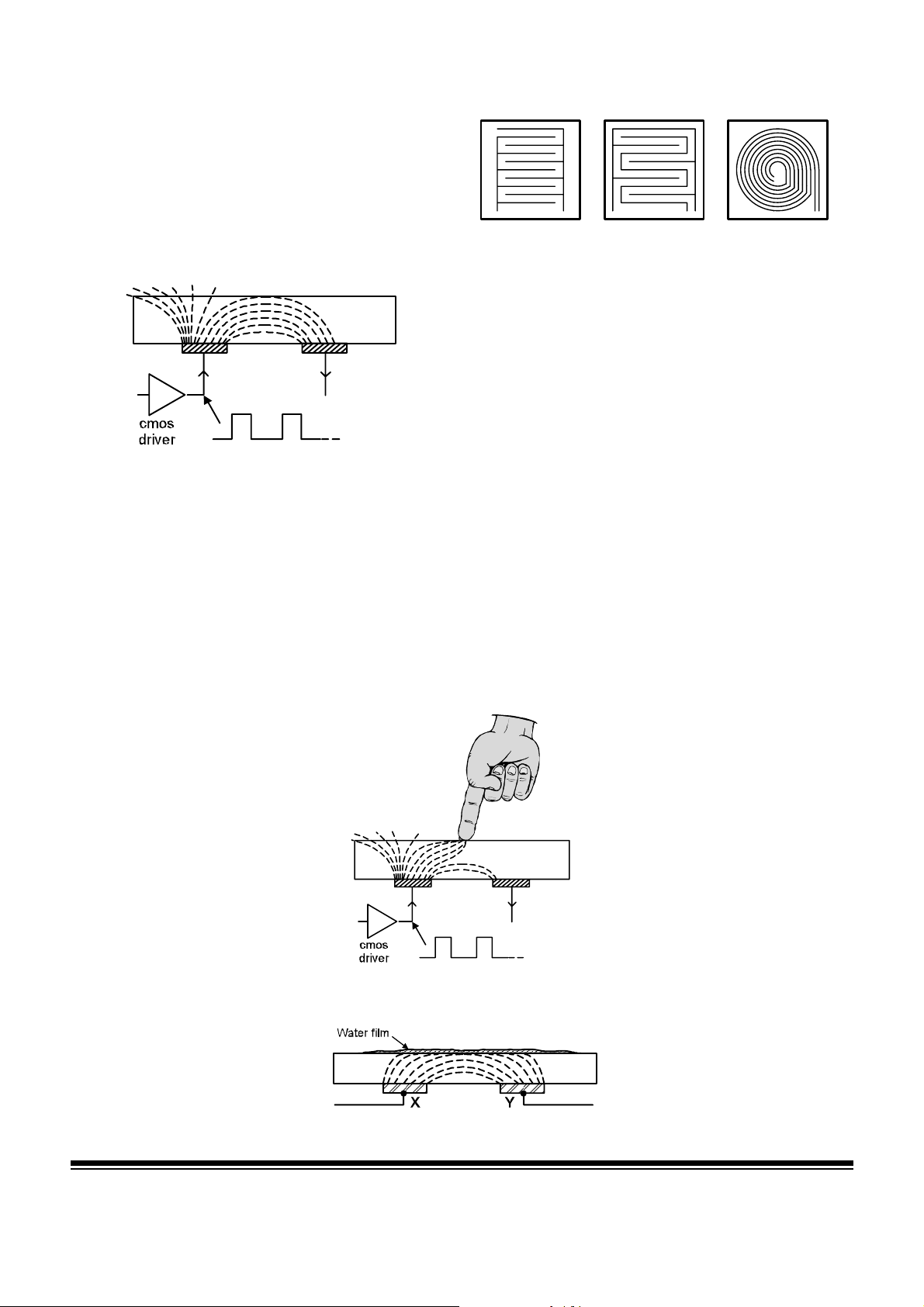

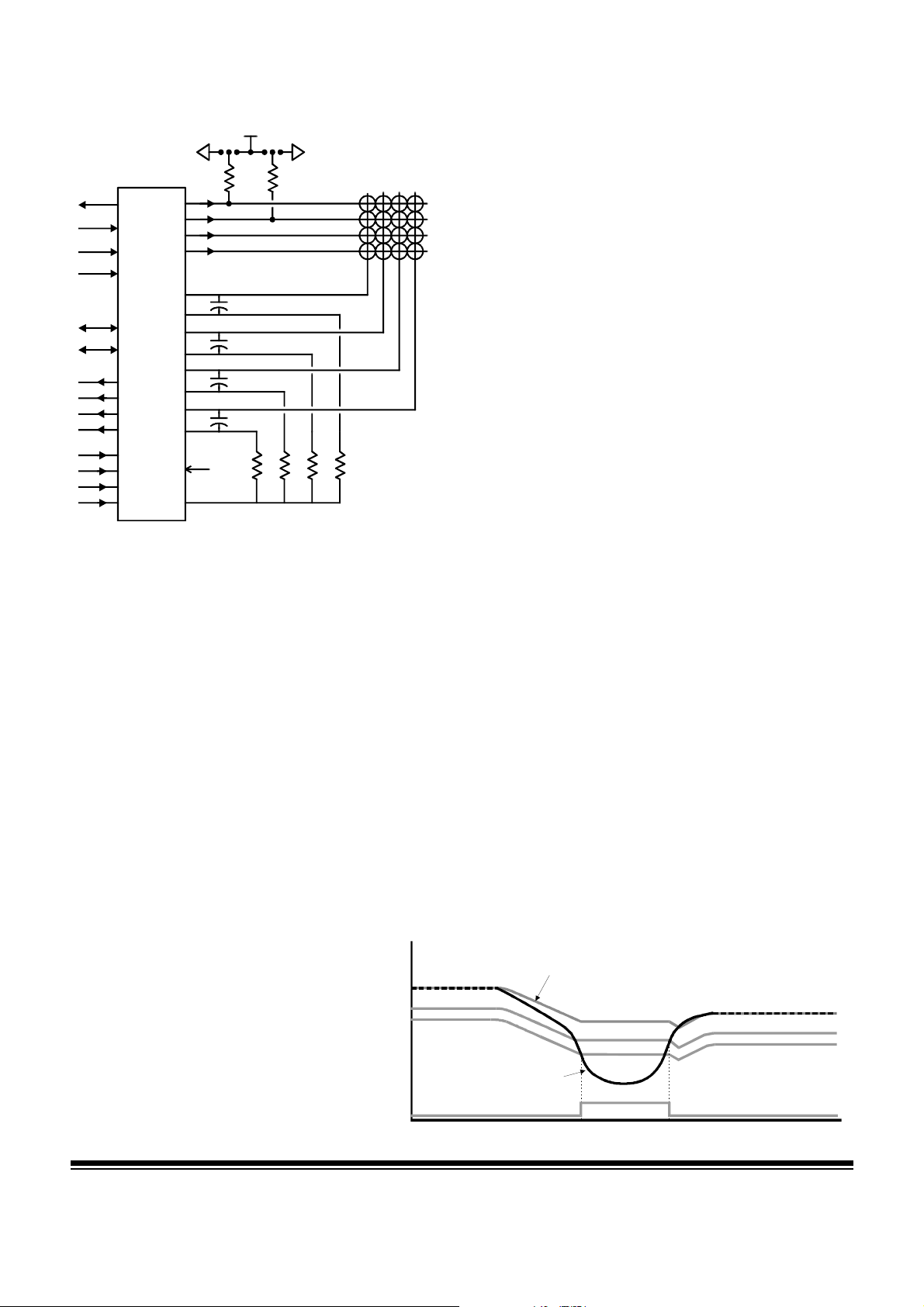

Figure 1-1 Field flow between X and Y elements

overlying panel

X

element

The device has a wide dynamic range that allows for a wide

variety of key sizes and shapes to be mixed together in a

single touch panel. These features permit new types of

keypad features such as touch-sliders, back-illuminated keys,

and complex warped panels.

The devices use an SPI interface running at up to 3MHz rates

to allow key data to be extracted and to permit individual key

parameter setup, or, a UART port which can run at rates to

57.6 Kbaud. The serial interface protocol uses simple

commands; the command structure is designed to minimize

the amount of data traffic while maximizing the amount of

information conveyed.

In addition to normal operating and

setup functions the device can also

report back actual signal strengths

and error codes over the serial

interfaces.

QmBtn software for the PC can be

used to program the IC as well as

read back key status and signal

levels in real time.

A parallel scan port is also provided

that can be used to directly replace

membrane type keypads.

QMatrix technology employs

transverse charge-transfer ('QT')

sensing, a new technology that

senses the changes in an electrical

charge forced across an electrode

set.

Figure 1-3 Fields With a Conductive Film

1.1 Field Flows

Figure 1-1 shows how charge is

transferred across an electrode set

to permeate the overlying panel

material; this charge flow exhibits a

high dQ/dt during the edge

transitions of the X drive pulse. The

Y

elem ent

Figure 1-2 Field Flows When Touched

X

element

Figure 1-4 Sample Electrode Geometries

PARALLEL LINES SERPENTINE SPIRAL

charge driven by the X electrode is partly received onto the

corresponding Y electrode which is then processed. The part

uses 4 'X' edge-driven rows and 4 'Y' sense columns to sense

up to 16 keys.

The charge flows are absorbed by the touch of a human

finger (Figure 1-1) resulting in a decrease in coupling from X

to Y. Thus, received signals decrease or go negative with

respect to the reference level during a touch.

As shown in Figure 1-3, water films cause the coupled fields

to increase slightly, making them easy to distinguish from

touch.

1.2 Circuit Overview

A basic circuit diagram is shown in Figure 1-5. The ‘X’ drives

are sequentially pulsed in groupings of bursts. At the

intersection of each ‘X’ and ‘Y’ line in the matrix itself, where

a key is desired, should be an interdigitated electrode set

similar to those shown in Figure 1-4. See Quantum App Note

AN-KD01, or consult Quantum for application assistance.

The device uses fixed external capacitors to acquire charge

from the matrix during a burst of charge-transfer cycles; the

burst length can be varied to permit digitally variable key

signal gains. The charge is converted to digital using a

single-slope conversion process.

Burst mode operation permits the

use of a passive matrix, reduces RF

emissions, and provides excellent

response times.

Refer to Section 3 for more details

on circuit operation.

1.3 Communications

The device uses two variants of SPI

overlying panel

Y

element

communications, Slave-only and

Master-Slave, a UART interface,

plus a parallel scan interface. Over

the serial interfaces are used a

command and data transfer

structure designed for high levels of

flexibility using minimal numbers of

bytes. For more information see

Sections 4 and 5.

The parallel scan port permits the

replacement of electromechanical

keypads that would be scanned by

a microcontroller; the scan interface

mimics an electromechanical

keyboard’s response.

lQ

4

www.qprox.com QT60161B / R1.03

©Quantum Research Group Ltd.

V

Figure 1-5 Circuit Block Diagram

cc

Opt B

Opt A

QT60161

LED

Scope

Sync

Reset

Wake /

Sync

CS0A

CS0B

SPI

to Host

CS1A

UART

CS1B

to Host

CS2A

CS2B

CS3A

CS3B

Scan Output

VREF

Scan Input

Sample

X0

X1

X2

X3

Sample caps

CS0

CS1

CS2

CS3

Y0 Y1 Y2 Y3

X0

X1

X2

X3

2 Signal Processing

The device calibrates and processes signals using a number

of algorithms specifically designed to provide for high

survivability in the face of adverse environmental challenges.

The QT60161B provides a large number of processing

options which can be user-selected to implement very

flexible, robust keypanel solutions.

2.1 Negative Threshold

See also command ^A, page 21

The negative threshold value is established relative to a key’s

signal reference value. The threshold is used to determine

key touch when crossed by a negative-going signal swing

after having been filtered by the detection integrator (Section

2.6). Larger absolute values of threshold desensitize keys

since the signal must travel farther in order to cross the

threshold level. Conversely, lower thresholds make keys

more sensitive.

As Cx and Cs drift, the reference point drift-compensates for

these changes at a user-settable rate (Section 2.4); the

threshold level is recomputed whenever the

reference point moves, and thus it also is drift

compensated.

The threshold is user-programmed on a per-key

basis using the setup process (Section 5).

The threshold is user-programmed using the setup process

described in Section 5 on a per-key basis.

2.3 Hysteresis

See also command ^C and ^D, page 21

Refer to Figure 1-6. The QT60161B employs programmable

hysteresis levels of 12.5%, 25%, or 50% of the delta between

the reference and threshold levels. There are different

hysteresis settings for positive and negative thresholds which

can be set by the user. The percentage refers to the distance

KEYMATRIX

between the reference level and the threshold at which the

detection will drop out. A percentage of 12.5% is less

hysteresis than 25%, and the 12.5% hysteresis point is closer

to the threshold level than to the reference level.

The hysteresis levels are set for all keys only; it is not

possible to set the hysteresis differently from key to key on

either the positive or negative hysteresis levels.

2.4 Drift Compensation

See also commands ^H, ^I, page 22

Signal levels can drift because of changes in Cx and Cs over

time. It is crucial that such drift be compensated, else false

detections, non- detections, and sensitivity shifts will follow.

The QT60161B can compensate for drift using two setups, ^H

and ^I.

Drift compensation is performed by making the reference

level track the raw signal at a slow rate, but only while there is

no detection in effect. The rate of adjustment must be

performed slowly, otherwise legitimate detections could be

ignored. The devices drift compensate using a slew-rate

limited change to the reference level; the threshold and

hysteresis values are slaved to this reference.

When a finger is sensed, the signal falls since the human

body acts to absorb charge from the cross-coupling between

X and Y lines. An isolated, untouched foreign object (a coin,

or a water film) will cause the signal to rise very slightly due to

the enhanced coupling thus created. These effects are

contrary to the way most capacitive sensors operate.

Once a finger is sensed, the drift compensation mechanism

ceases since the signal is legitimately detecting an object.

Drift compensation only works when the key signal in

question has not crossed the negative threshold level

(Section 2.1).

The drift compensation mechanism can be made asymmetric

if desired; the drift-compensation can be made to occur in

one direction faster than it does in the other simply by setting

^H and ^I to different settings.

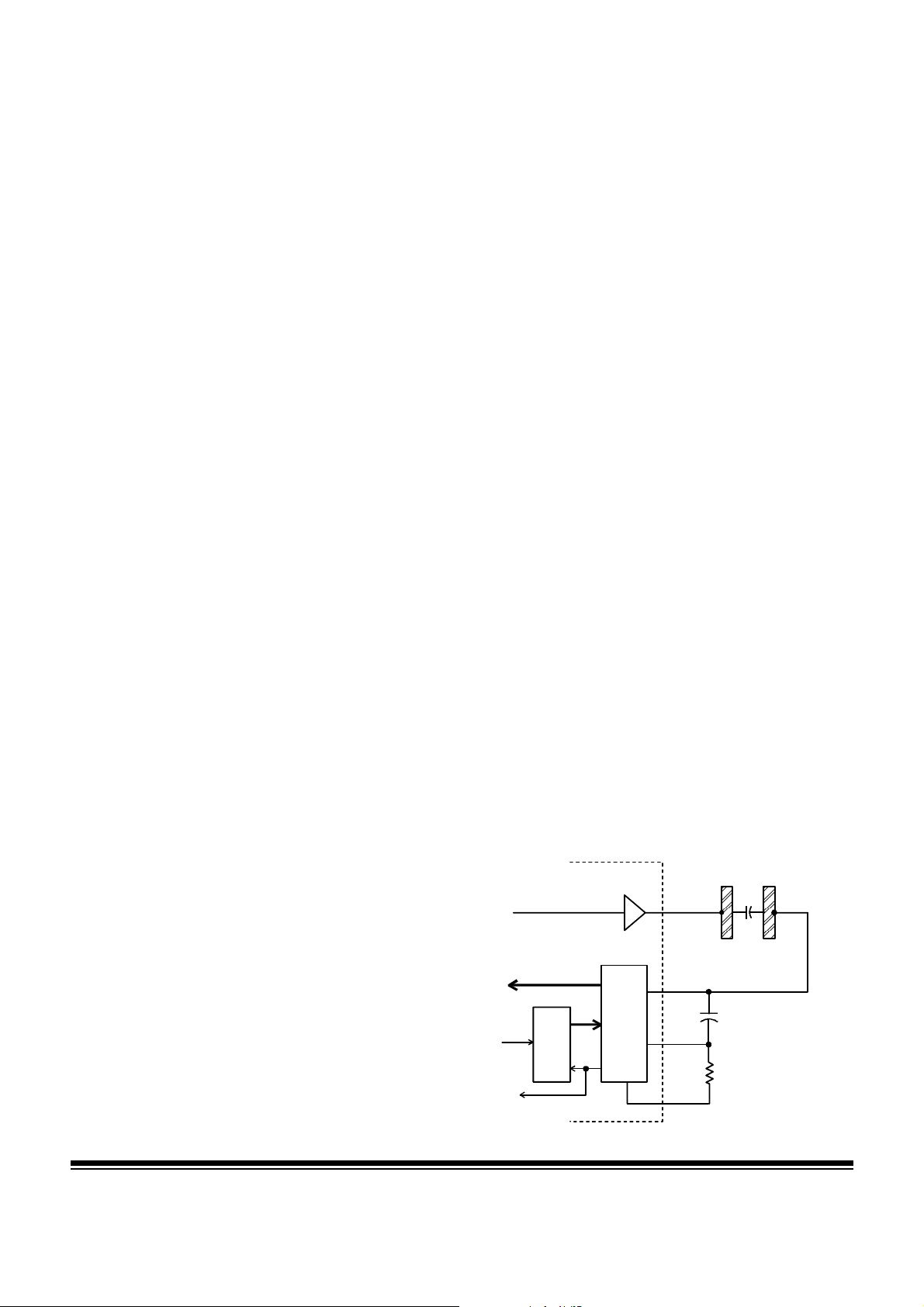

Figure 1-6 Detection and Drift Compensation

Reference

2.2 Positive Threshold

See also command ^B, page 21

Hysteresis

Threshold

The positive threshold is used to provide a

mechanism for recalibration of the reference point

when a key's signal moves abruptly to the positive.

These transitions are described more fully in

Section 2.7.

lQ

Output

5

Signal

www.qprox.com QT60161B / R1.03

©Quantum Research Group Ltd.

Drift compensation should usually be set to compensate

faster for increasing signals than for decreasing signals.

Decreasing signals should not be compensated quickly, since

an approaching finger could be compensated for partially or

entirely before even touching the touch pad. However, an

obstruction over the sense pad, for which the sensor has

already made full allowance for, could suddenly be removed

leaving the sensor with an artificially suppressed reference

level and thus become insensitive to touch. In this case, the

sensor should compensate for the object's removal by raising

the reference level quickly.

The drift compensation rate can be set for each key

individually, and can also be disabled completely if desired on

a per-key basis.

Drift compensation and the detection time-outs (Section 2.5)

work together to provide for robust, adaptive sensing. The

time-outs provide abrupt changes in reference location

depending on the duration of the signal 'event'.

2.5 Negative Recalibration Delay

See also command ^L, page 23

If a foreign object contacts a key the key's signal may change

enough in the negative direction, the same as a normal

touch, to create an unintended detection. When this happens

it is usually desirable to cause the key to be recalibrated in

order to restore its function after a time delay of some

seconds.

The Negative Recal Delay timer monitors this detection

duration; if a detection event exceeds the timer's setting, the

key will be recalibrated so that it can function thereafter. The

^L function can be altered on a key by key basis. It can be

disabled if desired by setting the ^L parameter to zero, so that

it will never recalibrate automatically.

2.6 Detection Integrator

See also command ^J, page 22

To suppress false detections caused by spurious events like

electrical noise, the QT60161B incorporates a 'detection

integrator' counter that increments with each detection

sample until a user-defined limit is reached, at which point a

detection is confirmed. If no detection is sensed on any of the

samples prior to the final count, the counter is reset

immediately to zero, forcing the process to restart.

When an active key is released, the counter must count down

to zero before the key state is set to 'off'. Setting a key’s

detection integrator target value to zero disables that key

although the bursts for that key continue normally.

The detection integrator is extremely effective at reducing

false detections at the expense of slower reaction times. In

some applications a slow reaction time is desirable; the

detection integrator can be used to intentionally slow down

touch response in order to require the user to touch longer to

operate the key.

There are 16 possible values for this function.

2.7 Positive Recalibration Delay

See also command ^K, page 23

A recalibration can occur automatically if the signal swings

more positive than the positive threshold level. This condition

can occur if there is positive drift but insufficient positive drift

compensation, or if the reference moved negative due to a

recalibration, and thereafter the signal returned to normal.

As an example of the latter, if a foreign object or a finger

contacts a key for period longer than the Negative Recal

Delay, the key is recalibrated to a new lower reference level.

Then, when the condition causing the negative swing ceases

to exist (e.g. the object is removed) the signal can suddenly

swing back positive to near its normal reference.

It is almost always desirable in these cases to cause the key

to recalibrate to the new signal level so as to restore normal

touch operation. The device accomplishes this by simply

setting Reference = Signal.

The time required to detect this condition before recalibrating

is governed by the Positive Recalibration Delay command. In

order for this feature to operate, the signal must rise through

the positive threshold level (Section 2.2) for the proscribed

interval determined by Setup ^K.

After the Positive Recal Delay interval has expired and the

fast-recalibration has taken place, the affected key will once

again function normally. This interval can be set on a per-key

basis; it can also be disabled by setting ^K to zero.

2.8 Reference Guardbanding

See also commands ^N, ^O, page 23; ‘L’, page 24

The QT60161B provides for a method of self-checking that

allows the host to ascertain whether one or more key

reference levels are 'out of spec'. This feature can be used to

determine if an X or Y line has broken, the matrix panel has

delaminated from the control panel, or there is a circuit fault.

Reference guardbanding alerts the host when the reference

level of a key falls outside of user-defined levels. The

reference guardband is determined as a percent deviation

from the 'locked' reference level for each individual key.

These reference levels can be stored into internal eeprom via

the Lock command 'L' during production; deviations in

reference levels that fall outside the guardbands centered on

these locked reference levels are then reported as key errors.

The amount of guardbanding can be set differently for each

signal direction relative to the stored and locked levels. The

possible settings are from 0.1% to 25.5% of signal reference

in steps of 0.1% as set by commands ^N (positive swings)

and ^O (negative swings). A setting of 0 (zero) disables the

corresponding guardband direction.

Once the L command has recorded all values of signal

reference into eeprom, and if guardbanding is enabled, the

part will compare the actual reference level of each key to its

corresponding guardbands to see if it falls outside of these

limits. If so, either of bits 2 and 3 of command 'e' will be set

for that key. The error will also appear in a bitfield reported

via command 'E'.

lQ

2.9 Adjacent Key Suppression (‘AKS’)

See also command ^P, page 24

The QT60161B incorporates adjacent key suppression

(‘AKS’) that can be enabled on a per-key basis. AKS permits

6

www.qprox.com QT60161B / R1.03

©Quantum Research Group Ltd.

the suppression of multiple key presses based on relative

signal strengths. AKS assists in solving the problem of

surface water which can bridge a key touch to an adjacent

key, causing multiple key presses, causing multiple key

presses even though only one key was touched. This feature

is also useful for panels with tightly spaced keys, where a

fingertip can partially overlap an adjacent key.

AKS works for keys that are AKS-enabled anywhere in the

matrix and is not restricted to physically adjacent keys; the

device has no knowledge of which keys are physically

adjacent. When enabled for a key, adjacent key suppression

causes detections on that key to be suppressed if any other

AKS-enabled key in the panel has a more negative signal

deviation from its reference.

This feature does not account for varying key gains (burst

length) but ignores the actual negative detection threshold

setting for the key. If AKS-enabled keys in a panel have

different sizes, it may be necessary to reduce the gains of

larger keys relative to smaller ones to equalize the effects of

AKS. The signal threshold of the larger keys can be altered to

compensate for this without causing problems with key

suppression.

AKS works to augment the natural moisture suppression

capabilities of the device (Section 3.10), creating a more

robust touch panel.

2.10 Full Recalibration

See also command ‘b’, page 24

The part fully recalibrates one or more keys after the ‘b’

command has been issued to it, depending on the current

scope of the ‘b’ command. The device recalibrates all keys on

powerup, after a hard reset via the RST pin or on power up,

or via a reset using the ‘r’ command. Since the circuit

tolerates a very wide dynamic signal range, it is capable of

adapting to a wide mix of key sizes and shapes having widely

varying Cx coupling capacitances.

If a false calibration occurs due to a key touch or foreign

object on the keys during powerup, the affected key will

recalibrate again when the object is removed depending on

the settings of Positive Threshold and Positive Recal Delay

(Sections 2.2 and 2.7).

Calibration requires 9 full burst cycles to complete, and so the

time it takes is dependent on the burst spacing parameter

(Section 3.8 also, ^G, page 22.

2.11 Device Status & Reporting

See also commands ‘7’, page 19; ‘e’, page 19; ‘E’, page 20;

‘k’, page 20, ‘K’, page 20

The device can report on the general device status or specific

key states including touches and error conditions, depending

on the command used.

Usually it is most efficient to periodically request the general

device status using command ‘7’ first, as the response to this

command is a single byte which reports back on behalf of all

keys. ‘7’ indicates if there are any keys detecting, calibrating,

or in error.

If command ‘7’ reports a condition requiring further

investigation, the host device can then use commands ‘e’, ‘E’,

‘k’ or ‘K’ to provide further details of the event(s) in progress.

This hierarchical approach provides for a concise information

flow using minimal data transfers and low host software

overhead.

3 Circuit Operation

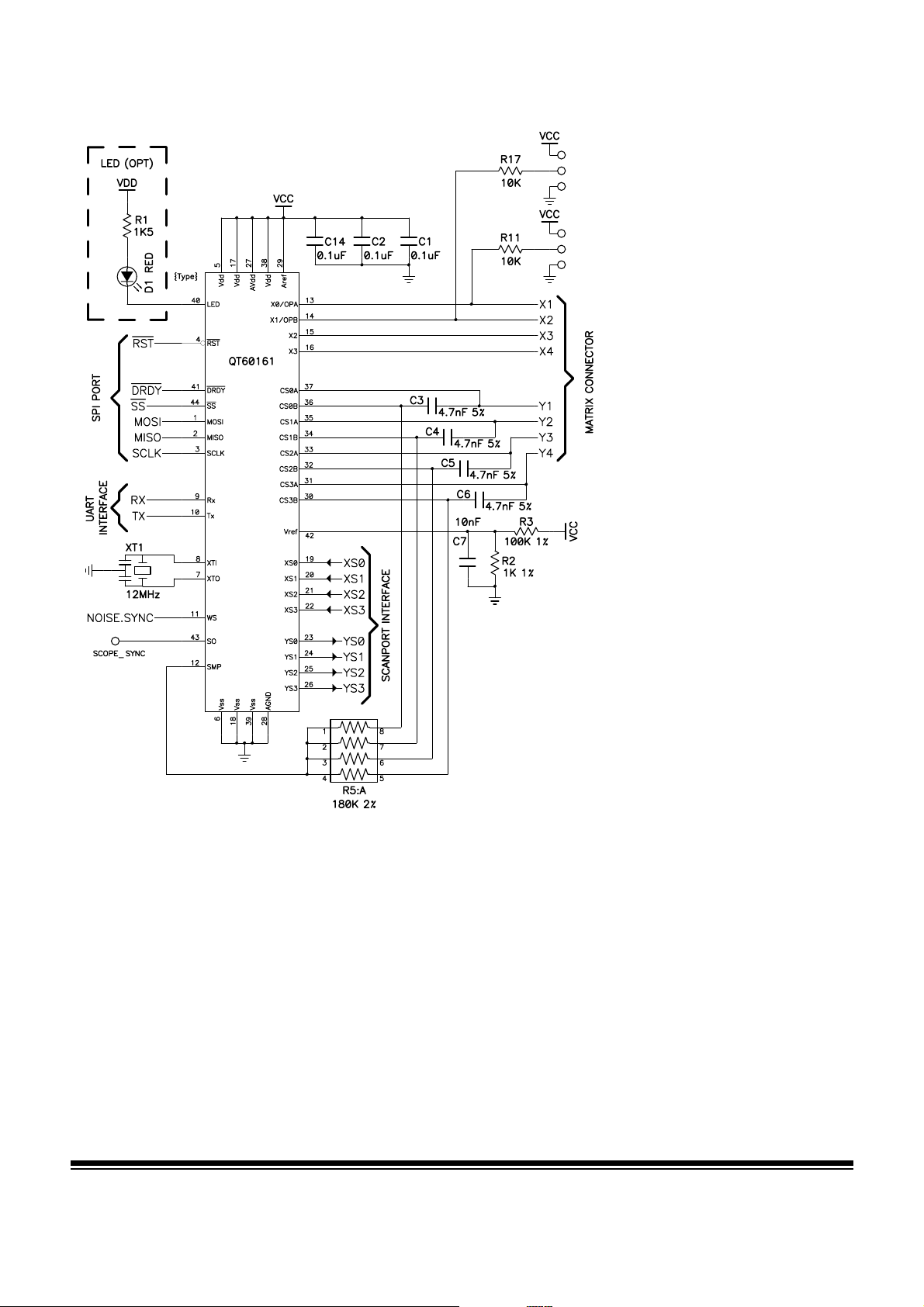

A QT60161B reference circuit is shown in Figure 2-1.

3.1 Matrix Scan Sequence

The circuit operates by scanning each key sequentially, key

by key. Key scanning begins with location X=0 / Y=0. X axis

keys are known as rows while Y axis keys are referred to as

columns. Keys are scanned sequentially by row, for example

the sequence Y0X0 Y0X1 Y0X2 Y0X3 Y1X0 etc.

Each key is sampled from 1 to 64 times in a burst whose

length is determined by Setup ^F. A burst is completed

entirely before the next key is sampled; at the end of each

burst the resulting analog signal is converted to digital using a

single-slope conversion process. The length of the burst

directly impacts on the gain of the key; each key can have a

unique burst length in order to allow tailoring of key sensitivity

on a key by key basis.

3.2 Signal Path

Refer to Figures 1-5, 3-1, and 3-2.

X-Drives. The X drives are push-pull CMOS lines which drive

charge through the matrix keys on the positive and negative

edges of X. Only the positive edge of X is used for signal

purposes, however the negative edge must cause the charge

across the keys to neutralize prior to the next positive edge,

else the sampling mechanism will cease after one pulse. The

part accomplishes this by holding all Y lines to ground during

the falling edge of X.

Charge gate. Only one X row is pulsed during a burst.

Charge is coupled across a key's Cx capacitance from the X

row to all Y columns. A particular key is chosen by gating the

charge from a single Y column into a single one of four

possible sampler capacitors. The other three X and three Y

lines are clamped to ground during this process.

Dwell time. The dwell time is determined internally and is

the same as one oscillator period, i.e. 83.3ns with a 12MHz

resonator. The dwell time is set via internal switching action

Figure 3-1 QT60161B Circuit Model

X drive

Start

Result

(1 of 4)

X

electrode

CSA

14 bit ADC

CSB

Done

Single-slope

SMP

Burst

Control

Cx

X

Y line (1 of 4)

Cs (1 of 4)

Rs (1 of 4)

Y

electrode

lQ

7

www.qprox.com QT60161B / R1.03

©Quantum Research Group Ltd.

which limits the interval during which charge can be accepted

by a Cs capacitor after the rise of an X drive line.

Dwell time has a dramatic effect on the suppression of

moisture films as described in Section 3.10.

Cs Charge Integrator capacitor. The Cs capacitors

integrate charge arriving through the matrix keys' Cx

capacitances, correspondent with the rise of X; to do this a

switching arrangement on the Cs control pins permits the

charge to accumulate so that the B side of the Cs capacitors

becomes negative when the A side is clamped to ground.

Charge conversion. At the end of each burst the voltage on

Cs is converted to digital by means of a single-slope

conversion process, using one of the external resistors to

ramp up the capacitor towards a reference voltage. The

elapsed time required to reach the comparison voltage is the

digital result. The time required to perform the conversion

depends on Cs, Cx, Rs, Aref, and the burst length.

3.3 'X' Electrode Drives

The 'X' lines are directly connected to the matrix without

buffering. The positive edges of these signals are used to

create the transient field flows used to scan the keys. Only

one X line is actively driving the matrix for scanning purposes

at a time, and it will pulse repetitively for a ‘burst length’ for

each key as determined by the 'Burst Length' Setups

parameter (see command ^F, page 21 and Section 3.5).

3.3.1 RFI F

X drive lines will radiate a small amount of RFI. This can be

attenuated if required by using series resistor in-line with

each X trace; the resistor should be placed near to the

QT60161B. Typical values can range from 100 to 500 ohms.

Excessive amounts of R will cause a counterproductive drop

in signal strength. RC networks can also be used as shown in

Figure 4-6.

Resistance in the X lines also have the positive effect of

limiting ESD discharge currents (Section 3.18).

3.3.2 N

External noise, sometimes caused by ground bounce due to

injected line noise, can couple into the X lines and cause

signal interference in extreme cases. Such noise can be

readily suppressed by the use of series resistors as

described above. Adding a small capacitor to the matrix line

on the QT60161B side of the R, for example 100pF to ground

near the QT60161B, will greatly help to reduce such effects.

ROM

X L

INES

OISE COUPLING INTO

X

LINES

3.4 'Y' Gate Drives

There are 4 'Y' gate drive pairs (CS0A,B..CS3A,B); only one

pair of these lines is used during a burst for a particular key.

The magnitude of the voltages accumulated on the Cs

capacitors should never exceed 0.25V.

3.4.1 RFI F

Y lines are nearly 'virtual grounds' and are negligible radiators

of RFI; in fact, they act as ‘sinks’ for RFI emitted by the X

lines. Resistors are not required in the Y lines for RFI

suppression, and in fact can introduce cross-talk among keys

if large enough. However, small resistance values can be

beneficial to limit ESD transients and make the circuit more

resistant to external RF fields (Section 3.18).

3.4.2 N

External noise, sometimes caused by ground bounce due to

power line noise, can couple into the Y lines and cause signal

ROM

Y L

INES

OISE COUPLING INTO

Y L

INES

interference in extreme cases. Such noise can be readily

suppressed by adding a 22pF capacitor from each Y line to

ground near the QT60161B.

3.5 Burst Length & Sensitivity

See also Command ^F, page 21

The signal gain in volts / pF of Cx for each key is controlled

by circuit parameters as well as the burst length.

The burst length is simply the number of times the

charge-transfer (‘QT’) process is performed on a given key.

Each QT process is simply the pulsing of an X line once, with

a corresponding Y line gated so as to capture the resulting

charge passed through the key’s capacitance Cx.

QT60161B devices use a finite number of QT cycles which

are executed in a short burst. There can be from 1 to 64 QT

cycles in a burst, in accordance with the list of permissible

values shown on page 21. If a key's burst length is set to

zero, that burst is disabled but its time slot in the scanning

sequence of all keys is preserved so as to maintain scan

timing.

Increasing burst length directly affects key sensitivity. This

occurs because the accumulation of charge on Cs is directly

linked to the burst length. The burst length of each key can be

set individually, allowing for direct digital control over the

signal gains of each key, indivudally.

Apparent touch sensitivity is also controlled by the Negative

Threshold setting (Section 2.1). Burst length and negative

threshold interact; normally burst lengths should be kept as

short as possible to limit RF emissions, but the threshold

setting should normally be kept above a setting of 6 to limit

false detections. The detection integrator can also prevent

false detections at the expense of slower reaction times

(Section 2.6).

The value of Rs also affects sensitivity. Higher values of Rs

will lead to larger values of ADC result and higher conversion

gains. The side effect of this is that the conversion will take

longer and timing conflicts can occur (Section 3.6).

Cs does not significantly affect gain. Smaller values of Cs will

have higher delta signal voltages but this gain increase is

offset by the decrease in gain caused by a steeper ADC

conversion slope. However smaller values of Cs lead to faster

conversion times for a given value of Rs, which in turn allows

for more relaxed burst timings. Smaller values of Cs also

reduce the dynamic range of the system, meaning that the

acquisition becomes less tolerant of high values of Cx, due to

earlier saturation of the voltage across Cs.

3.6 Burst Acquisition Duration

The total time required to acquire a key's signal depends on

the burst length for that key plus the time required to convert

the voltage on the corresponding Cs capacitor to digital. The

conversion is performed via a single-slope ADC process

using one of the external Rs resistors.

If the total time required for the acquisition, i.e. the burst

length plus ADC times plus the signal processing and serial

interface command handler times exceed the burst spacing

setup parameter (Section 3.8), significant timing errors and

communications problems can occur.

The time taken by the burst itself is straightforward to

quantify, but the time required to do the ADC step is not. The

ADC step depends on the value of Vref (pin 42), Cs, Rs, and

lQ

8

www.qprox.com QT60161B / R1.03

©Quantum Research Group Ltd.

Cx. Therefore it is vital that the circuit be checked with an

oscilloscope to make sure that burst spacings are unaffected

during normal operation.

3.7 Intra-Burst Spacing

See also Command ^M, page 23

The time between X drive pulses during a burst is the

intra-burst pulse QT spacing. This timing has no noticeable

effect on performance of the circuit, but can have an impact

on the nature of RF spectral emissions from the matrix panel.

The setting of this function can be from 1µs to 10µs, loosely

corresponding to fundamental emission frequencies of from

1MHz to 100kHz respectively.

Longer spacings require more time to execute and can limit

the operational settings of burst length and/or burst spacing

(Section 5.7).

The intra-burst QT spacing has no effect on sensitivity or

water film suppression and is not particularly important to the

sensing function other than described above.

3.8 Burst Spacing

See also Command ^G, page 22

The interval of time from the start of one burst to the start of

the next is known as the burst spacing. This is an alterable

parameter which affects all keys.

Shorter spacings result in faster response time, but due to

increasing timing restrictions at shorter spacings burst

lengths or the conversion resolution may be restricted,

limiting the amount of gain that can be obtained; see Sections

3.6 and 5.7. Conversely longer spacings permit higher burst

lengths but slow down response time.

Three settings of burst spacing are possible: 500µs, 1ms, and

2ms.

3.9 Sample Capacitors

Charge sampler capacitors Cs should be either ceramic NPO,

X7R 5%, or PPS film for stability reasons.

The values of capacitance should not be altered from that

shown in the schematic of Figure 3-2 without good reason.

Changes in Cs have only a limited effect on signal gain.

3.10 Water Film Suppression

Water films on the user surface can cause problems with

false detection under certain conditions. Water films on their

own will not normally cause false detections. The most

common problem occurs when surface water bridges over 2

or more keys, and a user touches one of the keys and the

water film causing an adjacent key to also trigger. Essentially,

the water film transports the touch contact to adjacent keys.

The circuit suppresses water coupling by having a short dwell

time, equal to one oscillator period or 83ns. A short dwell time

reduces the amount of charge collected via resistive water

films, i.e. it suppresses charge from areas adjacent to the

scanned key. This effect has nothing to do with the frequency

of the burst itself.

Very short dwell times can cause excess suppression of

human touch as well. If series resistors are used in line with

the X and Y matrix lines for noise and ESD suppression

(Section 3.18), a short dwell time can seriously affect signal

gain.

Mechanical measures can also be used to suppress key

cross-coupling, for example one can use raised plastic

barriers between keys, or placing keys in shallow wells to

lengthen the electrical path from key to key.

3.11 Reset Input

The RST’ pin can be used to reset the device to simulate a

power down cycle, in order to bring the part up into a known

state should communications with the part be lost. The pin is

active low, and a low pulse lasting at least 10µs must be

applied to this pin to cause a reset.

To provide for proper operation during power transitions the

devices have an internal brown-out detector set to 4 volts.

A reset command, ‘r’, is also provided which generates an

equivalent hardware reset (page 25).

3.12 Oscillator

The oscillator can use either a quartz crystal or a ceramic

resonator. In either case, the XTI and XTO must both be

loaded with 22pF capacitors to ground. 3-terminal resonators

having onboard ceramic capacitors are commonly available

and are recommended. An external TTL-compatible

frequency source can also be connected to XTI; XTO should

be left unconnected.

The frequency of oscillation should be 12MHz +/-2%.

3.13 Startup / Calibration Times

The QT60161B requires initialization times as follows:

1. From very first powerup to ability to communicate:

2,000ms (One time event to initialize all of eeprom)

2. Normal cold start to ability to communicate:

70ms (Normal initialization from any reset)

3. Calibration time per key vs. burst spacings:

spacing = 500µs: 100ms

spacing = 1ms: 150ms

spacing = 2ms: 300ms

To the above, add 2,000ms or 70ms from (1) or (2) for

the total elapsed time from reset to ability to report key

detections.

Keys that cannot calibrate for some reason require 5

calibration cycles before they report as errors. However, the

device can report back during this interval that the key(s)

affected are still in calibration via status function bits.

3.14 Sleep_Wake / Noise Sync Pin (WS)

The Sleep_wake and Noise sync features use input pin WS.

The Sleep and Sync features can be used simultaneously;

the part can be put into Sleep mode, but awakened by a

noise sync signal which is gated in at the time desired.

Sleep mode: See also command ‘Z’, page 25. The device

can be put into an ultra low-power sleep mode using the ‘Z’

command. When this command is received, the WS pin must

be placed immediately thereafter into a logic-high state. The

part will complete an ongoing burst before entering Sleep.

The part can be awakened by a low transition on the WS pin

lasting at least 5µs. One convenient way to wake the part is

to connect WS to MOSI, and have the host send a null

lQ

9

www.qprox.com QT60161B / R1.03

©Quantum Research Group Ltd.

Figure 3-2 Recommended Circuit Diagram

command to the device. The part will wake and the null

command will not be processed. The MOSI line in turn

requires a pullup resistor to prevent the line from floating low

and causing an unintentional wake from sleep.

During Sleep the oscillator is shut down, and the part

hibernates with microamp levels of current drain. When the

part wakes, the part resumes normal functionality from the

point where it left off. It will not recalibrate keys or engage in

other unwarranted behavior.

Just before going to sleep the part will respond with a

response of 'Z'. In slave-only SPI mode (see Section 4.3), the

SS line must be floated high by the host as soon as it

receives this response; if SS does not float high, sleep will fail

and the device will instead completely reset after about 2

seconds. Upon waking the part will issue another 'Z' byte

back to the host.

Noise sync: See also command ^W,

page 26. External fields can cause

interference leading to false

detections or sensitivity shifts. The

strongest external fields usually

come from AC power. RF noise

sources are heavily suppressed by

the low impedance nature of the QT

circuitry itself.

External noise only becomes a

problem if the noise is uncorrelated

with signal sampling; uncorrelated

noise can cause aliasing and beat

effects in the key signals. To

suppress this problem the devices

feature a noise sync input which

allows bursts to synchronize to the

noise source. This same input can

also be used to wake the part from a

low-power Sleep state.

The device’s bursts can be

synchronized to an external source

of repetitive electrical signal, such as

50Hz or 60Hz, or possibly a video

display vertical sync line, using the

Sleep_wake / Noise sync line. The

noise sync operating mode is set by

command ^W. This feature allows

dominant external noise signals to

be heavily suppressed, since the

system and the noise become

synchronized and no longer beat or

alias with respect to each other. The

sync occurs only at the burst for key

0 (X0Y0); the device waits for the

sync signal for up to 100ms after the

end of a preceding full matrix scan

(after key #15), then when a negative

sync edge is received, the matrix is

scanned in its entirety again.

The sync signal drive should be a

buffered logic signal, or perhaps a

diode-clamped signal, but never a

raw AC signal from the mains.

Since Noise sync is highly effective

yet simple and inexpensive to implement, it is strongly

advised to take advantage of it anywhere there is a possibility

of encountering electric fields. Quantum’s QmBtn software

can show signal noise caused by nearby AC electric fields

and will hence assist in determining the need to make use of

this feature.

If the sync feature is enabled but no sync signal exists, the

sensor will continue to operate but with a delay of 100ms

from the end of one scan to the start of the next, and hence

will have a slow response time.

3.15 LED / Alert Output

Pin 40 is designed to drive a low-current LED, 5mA

maximum, in an active-low configuration. Higher currents can

cause significant level shifts on the die and are not advised.

The LED will glow brightly (i.e. pin 40 will be solid low) during

calibration of one or more keys, for example at startup. When

a key is detected, the LED will pulse low for the duration of

lQ

10

www.qprox.com QT60161B / R1.03

©Quantum Research Group Ltd.

the burst during which the key is being sensed, i.e. with a

very low duty cycle. Each additional key being detected will

also create a low pulse for that key’s burst. During all other

times, the LED pin will be off (high).

This pin can be used to alert the host that there is key activity,

in order to further limit the amount of communication between

the device and the host. The LED / Alert line should ideally be

connected to an interrupt pin on the host that can detect a

negative edge, following which the host can proceed to poll

the device for keys.

This line also pulls low if there is a key error of any kind.

Note that in sleep mode if the LED was on prior to sleep, it

will remain on during sleep.

3.16 Oscilloscope Sync

See also Command ^R, page 26

The ‘SO’ pin can output an oscilloscope sync signal which is

a positive pulse that brackets the burst of a selected key. This

feature is controlled by the ^R command. More than one burst

can output a sync pulse, for example if the scope of the

command when set is a row or column, or is all keys. The ^R

command is volatile and does not survive a reset or power

down.

This feature is invaluable for diagnostics; without it, observing

signals clearly on an oscilloscope for a particular burst is

nearly impossible.

This function is supported in QmBtn PC software via a

checkbox.

3.17 Power Supply & PCB Layout

Vdd should be 5.0 volts +/- 5%. This can be provided by a

common 78L05 3-terminal regulator. LDO type regulators are

often fine but can suffer from poor transient load response

which may cause erratic signal behavior.

If the power supply is shared with another electronic system,

care should be taken to assure that the supply is free of

low-level spikes, sags, and surges which can adversely affect

the circuit. The devices can track slow changes in Vcc

depending on the settings of drift compensation, but signals

can be adversely affected by rapid voltage steps and impulse

noise on the supply rail.

Supply bypass capacitors of 0.1uF to a ground plane should

be used near every supply pin of every active component in

the circuit.

PCB layout: The PCB layout should incorporate a ground

plane under the entire circuit; this is easily possible with a

2-layer design. The ground plane should be broken up as

little as possible. Internal nodes of the circuit can be quite

sensitive to external noise and the circuit should be kept

away from stray magnetic and electric fields, for example

those emanating from mains power components such as

transformers and power capacitors. If proximity to such

components is unavoidable, an electrostatic shield may be

required.

The use of the Sync feature (Section 3.14) can be invaluable

in reducing these types of noise sources, but only up to a

point.

3.18 ESD / Noise Considerations

In general the QT60161B will be well protected from static

discharge during use by the overlying panel. However, even

with a dielectric panel transients currents can still flow into

scan lines via induction or in extreme cases, dielectric

breakdown. Porous or cracked materials may allow a spark to

tunnel through the panel. In all cases, testing is required to

reveal any potential problems. The IC has diode protected

pins which can absorb and protect the device from most

induced discharges, up to 5mA.

The X lines are not usually at risk during operation, since they

are low-resistance output drives. Diode clamps can be used

on the X and Y matrix lines if desired. The diodes should be

high speed / high current types such as BAV99 dual diodes,

connected from Vdd to Vss with the diode junction connected

to the matrix pin. Diode arrays can also be used.

Capacitors placed on the X and Y matrix lines can also help

to a limited degree by absorbing ESD transients and lowering

induced voltages. Values up to 100pF on the X lines and

22pF on the Y lines can be used.

The circuit can be further protected by inserting series

resistors into the X and/or Y lines to limit peak transient

current. RC networks as shown in Figures 4-6 and 4-7 can

provide enhanced protection against ESD while also limiting

the effects of external EMI should this be a problem.

External field interference can occur in some cases; these

problems are highly dependent on the interfering frequency

and the manner of coupling into the circuit. PCB layout

(Section 3.17) and external wiring should be carefully

designed to reduce the probability of these effects occurring.

SPI / UART data noise: In some applications it is necessary

to have the host MCU at a distance from the sensor, perhaps

with the interface coupled via ribbon cable. The SPI link is

particularly vulnerable to noise injection on these lines;

corrupted or false commands can be induced from transients

on the power supply or ground wiring. Bypass capacitors and

series resistors can be used to prevent these effects as

shown in Figures 4-6 and 4-7.

4 Communications Interfaces

The QT60161B uses parallel, UART, and SPI interfaces to

communicate with a host MCU. The serial interfaces use a

protocol described in Section 5. Only one interface can be

used at a time; the interface type is selected by

resistor-coupled jumpers connected to pins X0OPA (pin 13)

and X0OPB (pin 14) shown in Table 4-1. See also Figure 3-2.

Further specific information on each interface type is

contained in the following sections:

SPI Slave-Only Mode: Section 4.3

SPI Master-Slave Mode: Section 4.4

UART Interface: Section 4.5

Parallel Interface: Section 4.7

4.1 Serial Protocol Overview

The SPI and UART interface protocols are based entirely on

polled data transmission, that is, the part will not send data to

the host of its own volition but will do so only in response to

specific commands from a host.

lQ

11

www.qprox.com QT60161B / R1.03

©Quantum Research Group Ltd.

Run-time data responses, such as key detection or error

information, requires simple single-byte functions to evoke a

response from the part.

Setup mode interactions mostly use 2-byte functions from the

host to cause the part to alter its behavior; these functions

also cause writes to the internal eeprom.

The concept of 'scope' is used to allow functions to operate

on individual keys or groupings of keys. The scope of

subsequent functions can be altered by short initial scope

instructions.

See Section 5 for protocol details.

4.2 SPI Port Specifications

The part has an SPI synchronous serial interface with the

following specifications at 12MHz oscillator frequency:

Max clock rate, Fck 3MHz

Data length 8 bits

Host command space, Tcm m 50µs

Response delay to host, Tdr1 Table 4-1, also, Sec. 6

Drdy delay from response, Tdr2 1µs to 1ms

Multi-byte return spacing, Tdr3 10µs to 2ms

The host can clock the SPI with the part in Slave mode at any

rate up to and including the maximum clock rate Fck. The

maximum clock rate of the part in Master mode is determined

by Setup ^Q (page 25).

The part can operate in either master-slave mode or

slave-only mode, and is thus compatible with virtually all

SPI-capable microcontrollers.

The SPI interface should not be used over long distances due

to problems with signal ringing and introduced noise etc.

unless suitably buffered or filtered with RC networks as

shown in Figures 4-6 and 4-7. Slower data rates with longer

RC timeconstants will provide enhanced resistance to noise

and ringing problems.

4.3 SPI Slave-Only Mode

Refer to Figures 4-1, 4-3 and 4-2. In Slave-only mode the

host must always be in Master mode, as it controls all SPI

activity including the clocking of the interface in both

directions. Unlike hardware SPI slaves, the QT60161B needs

processing time to respond to functions. DRDY’ is used to let

the host know when data is ready for collection; it indicates to

the host when data is ready in response to a command so

that the host can clock over the data.

This mode requires 5 signals to operate:

MOSI - Master out / Slave in data pin; used as an input for

data from

connected to the MOSI pin of the host device.

MISO - Master in / Slave out data pin; used as an output for

data to

to the MISO pin of the host device.

SCK - SPI clock - input only clock pin from host. The host

must shift out data on the falling edge of SCK; the

QT60161B clocks data in on the rising edge of SCK.

Important note: SCK must idle low just before and after

SS’ transitions either up or down, or the transmission will

fail; between bytes SCK should idle low.

SS’ - Slave select - input only; this pin acts as a framing

signal to the sensor from the host. This line must go low

the host at all times. This pin should be

the host at all times. This pin should be connected

just before and during reception of data from the host. It

must not go high again until the SCK line has returned low;

during data or echo response it must not go high until after

the host has sensed that DRDY’ has gone high from the

device. This pin must idle high. The SS’ pin has an internal

pullup resistor inside.

DRDY’ - Data Ready - active-low - indicates to the host that

the part is ready to send data back subsequent to a

command from the host. This pin idles high. The DRDY’

pin has an internal pullup resistor inside.

Internal pullup resistors note: The internal pullup resistors

can range from 35k to 120k ohms. If RC filtering is used on

the SPI lines per Figure 4-6, this resistance may not be low

enough to ensure adequate signal risetime and may need to

be augmented with external 10k pullups.

The host must wait until DRDY’ goes low before an SPI

transfer to retrieve data. For multi-byte responses, the host

must observe DRDY' to see when it goes high again after

each data byte, then low again, before executing another

transfer to get the next data byte. The host should send null

bytes (0x00) to retrieve data.

If the DRDY’ line does not go low after a command, the

command was not properly received or it was inappropriate.

The delay to DRDY’ low depends on the command and how

many bytes of data are being stored into eeprom; Table 4-1

shows the maximum delays encountered in most cases.

Absolute worst case delays are found in Section 6-5; these

timings occur only rarely, for example if the device happens

to be busy with adjacent key suppression calculations, which

occurs only at the moment when a key is first detected.

A typical Slave-only function sequence is as follows:

1) The host pulls SS’ low, then transfers a command to the

sensor. The host then releases SS’ to float high. DRDY’ is

unaffected in this step.

2) For 2-byte functions, (1) is repeated with a m50us delay.

3) When the sensor has the command echo or requested

data ready to send back to the host, it loads it into its SPI

register and pulls DRDY’ low.

4) The host detects that the sensor has pulled DRDY’ low

and in turn the host pulls SS’ low.

5) The host obtains the byte from the sensor by transmitting

a dummy byte (0x00) to the sensor.

6) The sensor releases DRDY’ to float high.

7) After the host detects that DRDY' has floated high the

host must allow SS’ to also float high.

8) For multi-byte responses, steps (3) through (7) are

repeated until the return data is completely sent.

Note that the host must release the SS’ line in step (7) even

between multiple byte responses because the QT60161B

waits for the SS’ line to return high before signalling that the

next byte is ready for collection.

Note also that the host should check the DRDY’ line and wait

for it to go high before transmitting another byte. Until the

DRDY’ line is released the sensor is still processing a data

return, even if the complete response data has been fully

transferred; the sensor may still be busy when the host

finishes the byte transfer and may not be able to digest a new

command immediately.

lQ

12

www.qprox.com QT60161B / R1.03

©Quantum Research Group Ltd.

Q

x

x

x

x

V

See Section 3.15, page 10, for a description of the Alert pin

which can be used to reduce communication traffic.

4.4 SPI Master-Slave Mode

Refer to Figures 4-1, 4-2, and 4-4. In Master-Slave mode the

host and the sensor take turns being Master, with the host

always leading off in Master mode during an exchange. The

current Master always controls all 3 signal lines. The sensor

takes a variable amount of time to respond to the host,

depending on the nature of the function and its current and

pending tasks. The host, like the sensor, must idle in slave

mode when not sending a command.

Master/Slave requires 3 signals to operate:

MOSI - Master out / Slave in data pin - bidirectional - an input

pin while the host is transmitting data; an output when the

sensor is transmitting data. The MOSI of the host and

slave should be tied together. The MISO lines are not used

on either part and should be left open.

SCK - SPI clock - bidirectional - an input pin when receiving

data; an output pin when sending. The host must shift out

data on the falling edge of SCK; the QT60161B clocks data

in on the rising edge of SCK. Important note: SCK from

the host must be low before asserting SS’ low or high at

either end of a byte or the transmission will fail. SCK

should idle low; if in doubt, a 10K pulldown resistor should

be used. When the sensor returns data it becomes the

Master; data is shifted out by it on the falling edge of SCK

and should be clocked in by the host on the rising edge.

SS’ - Slave select - bidirectional framing control. When the

sensor is in slave mode, this pin accepts the SS’ control

signal from the host. In either data direction, SS' must go

low before and any during data transfer; it should not go

high again until SCK has returned low at the end of a byte.

In Master mode the sensor asserts control over this line, to

make the host a slave and to frame the data. This line

must idle high; the part includes an internal pullup resistor

and should be floated during idle times.

Internal pullup resistor note: The internal pullup resistor on

SS’ can range from 35k to 120k ohms. If RC filtering is used

on the SPI lines per Figure 4-7, this pullup resistance may not

be low enough to ensure adequate signal risetime and may

need to be augmented with external 10k pullups.

A command may consist of one or two bytes with a m50us

delay between command bytes. At the end of a full command,

the Master must go into Slave mode to await a response from

the sensor.

The sensor may take some time to process the host

command and respond. When it does so, it asserts SS’ low

and begins clocking its data. For multi-byte responses, the

bytes will be sent at intervals which may be somewhat

irregular depending on the request and the processing

load of the sensor. The host must be prepared to accept

the sensor data as it comes or there can be a data

overrun in the host. If the data returns too fast for the host

to accept it, the SPI clock rate should be lowered.

A typical Master-Slave function sequence is as follows:

1) Host enters Master mode. The sensor is already in

Slave mode.

Figure 4-1 Communications Option Jumpers

cc

Opt B

10K10K

To M a t ri x

X0

X1

Opt A

L H H L

13

14

Interface TypeX0OPB (Pin 14)X0OPA (Pin 13)

SPI, Slave onlyLowLow

UARTHighLow

SPI, Master/SlaveLowHigh

ParallelHighHigh

2) The host pulls SS’ low, then transfers one byte of

command to the sensor via MOSI, then releases SS’ to

float high again.

3) For 2-byte functions, (2) is repeated with m50us spacings

between bytes.

4) The host immediately places its SPI port into Slave mode,

floating SCK and MOSI’; SS’ stays floating.

5) When the sensor has a command echo or data to send

back, it puts its SPI register in Master mode, taking control

over MOSI and SCK. SS' remains floating.

6) The sensor pulls SS’ low, then clocks out its response

byte to the host, then floats SS’ high again.

7) The sensor repeats (6) as necessary for multiple byte

responses.

8) The sensor returns to slave mode.

After the transmission sequence, the SPI lines float high or

are left to float in an indeterminate state (MOSI) until the next

transmission sequence is initiated by the host. The host

should wait for >1ms after a sequence before initiating

another transmission sequence.

See Section 3.15, page 10, for a description of the Alert pin

which can be used to reduce communication traffic.

Figure 4-2 SPI Connections

Slave-Only Master-Slave

Host MCU

P_IN

P_OUT

SCK SCK

MOSI MOSI

SS

Vdd

T60

DRDY

SS

MISOMISO

5

Host MCU QT60

SS

SCK SCK

MOSI MOSI

DRDY

SS

MISOMISO

5

lQ

13

www.qprox.com QT60161B / R1.03

©Quantum Research Group Ltd.

T

DRDY

{from sensor}

SS

{from host}

SCK

{from host}

MOSI

{from host}

MISO

{from sensor}

SS

SCK

MOSI

Figure 4-3 SPI Slave-Only Mode Timing

dr3

T

cm

7 6543210

7 6543210 7 6543210

Invalid Data

7 6543210

T

dr1

Optional Byte 2Host Command Byte 1 Null Dummy Data Null Dummy Data

7 6543210 7 6543210

Invalid Data Response Data or Echo Nth Response Data

T

dr2

Figure 4-4 SPI Master/Slave Mode Timing

T

cm

7 6543210 7 6543210 7 6543210 7 6543210

Command Byte 1

from Host to sensor

Optional Byte 2

from host to sensor

T

dr1

Response Byte or Echo

from sensor to host

{N = command dependent}

T

dr3

Nth Byte from sensor

{N = command dependent}

SS, SCK, MOSI originate from Host SS, SCK, MOSI originate from sensor

Floating

Figure 4-5 UART Timing

T

dr1

RX

{from host}

TX

{from sensor}

T

cm

Command Byte 1

from host to sensor

76543210S

Optional Byte 2

from host to sensor

4.5 UART Interface

Refer to Figures 4-1 and 4-5.

UART communications requires only 2 wires, TX and RX to

communicate with a host device. All communications must be

Table 4-1 Typical Tdr1 Response Delays (100µs sample ramp)

Setup - Put (affect 1 key)

Setup - Put (affect 8 keys)

Setup - Put (affect 16 keys)

Lock reference Level (L)

Calibrate command (all keys)

Get key errors (E)

Get keys pushed (K)

All other commands

T

dr3

76543210S

76543210S

Response Byte or Echo

from sensor to host

Nth Byte from sensor

{N = command dependent}

76543210S

initiated by the host. The baud rate is determined by Setup

^Q (page 25); the maximum baud rate with a 12MHz oscillator

is 57.6K. UART communications uses the following settings:

Burst Spacing

2ms1ms500µsFunction Type

10ms10ms10ms

20ms20ms20ms

65ms65ms65ms

65ms65ms65ms

500µs500µs500µs

450µs450µs450µs

350µs350µs350µs

350µs350µs350µs

lQ

14

www.qprox.com QT60161B / R1.03

©Quantum Research Group Ltd.

5

5

Baud rate 9,600 - 57,600

Data length 8 bits

Parity None

Stop bits 1

Host command space, Tcm m 50µs

Response delay to host, Tdr1 Table 4-1,

also, Sec. 6

Multi-byte return spacing, Tdr3 10µs to 2ms

The actual baud rate is determined by Setup ^Q (page 25).

A UART command may consist of one or two bytes with a

m50us delay between command bytes. At the end of a full

command, the host must await a response from the sensor.

The sensor may take some time to process the host

command and respond. When it does so, it sends back its

data. For multi-byte responses, the bytes will be sent at

intervals which may be somewhat irregular depending on the

request and the processing load of the sensor. The host must

be prepared to accept the sensor data as it comes or there

can be a data overrun in the host. If the data returns

too quickly for the host to accept it, the baud rate

should be lowered.

A typical UART communication sequence is as follows:

1) Host sends a byte to the sensor.

2) For 2-byte functions, a m50us delay is inserted by

the host and then the second byte is sent.

3) If the sensor has a command echo or data to send

back, it does so. The delay from step 2 to step 3 is

shown in Table 4-1. The delay between successive

response bytes (if they occur) is parameter Tdr3

noted above.

4) The sensor repeats (3) as necessary for multiple

byte responses.

5) The sensor waits for the next command.

The host should wait for >1ms after a sequence before

initiating another transmission sequence to be sure

that the sensor has completed any residual activities

from the prior command. Commands that are sent to

the host prematurely will be ignored.

4.6 Sensor Echo and Data Response

Xn

The devices respond to each and every valid

command from the host with at least one return byte.

In the case of functions that do not send data back to

the host, the part returns the command itself as an

echo, but only after the function has been processed to

completion; this also holds for 2-byte functions where

the second byte is an operand: in these cases the

Yn

return byte is an echo of the command, not the

operand.

One important exception to this is the recalibration

command ‘b’ which returns an acknowledgment

immediately rather than prior to the actual

recalibration.

Commands that return data do not send back a

command echo. If desired, the command byte can be

verified via the 'l' (lowercase L) function; see page 25.

The host should not transmit a new command until the

last command has been processed and responded to

completion, plus 1ms.

Commands that are not recognized are ignored, and the host

should monitor for timeouts to detect these conditions. If this

occurs a new command should not be sent until the specified

timeout condition has expired.

The maximum timings shown in Table 4-1 and Section 6-5

are guaranteed provided that the part is operating within its