LQ QT60040

Creates 4 ‘touch buttons’ through any dielectric

Only 1 inexpensive capacitor required

Simple 4x1 matrix key geometry

100% drift compensation for lifetime reliability

'2' key rollover: senses any 2 keys at same time

Back-lit keys possible with ITO electrodes

Simple direct 'per key' active-high drive outputs

Auto recalibration after 10 or 60 seconds of touch

2.5 - 5.5V single power supply operation

CMOS design - very low power consumption

14-pin SOIC package

E604 Evaluation reference design board available

4-KEY C

OPT1

OPT2

HARGE-TRANSFER

14

13

12

11

10

X2

X3

X4

Y

CS

9

8

X1

1

2

3

4

5

6

7

VDD GND

Q1

Q2

Q3 Q4

IC

APPLICATIONS -

Security keypanels

Industrial keyboards

The QT60040 digital charge-transfer (“QT”) QMatrix™ IC is designed to detect touch on up to 4 keys in a scanned 4x1 matrix.

It will project the keys through almost any dielectric, like glass, plastic, stone, ceramic, and even most kinds of wood, up to

thicknesses of 6mm. The touch areas are defined as simple 2-part interdigitated electrodes of conductive material, like

copper, Indium-Tin-Oxide (ITO), or screened silver or carbon deposited on the rear of a control panel. Alternatively the keys

can be implemented on a stick-on flex circuit that can be adhered to the rear of most panels.

The IC is designed specifically for domestic appliances, computer and peripheral control buttons, ATM machines, security

panels, portable instruments, machine tools, or similar products that are subject to environmental challenges or physical

attack. It permits the construction of 100% sealed, watertight keypanels that are immune to environmental factors such as

humidity and condensation, temperature, dirt accumulation, or the physical deterioration of the panel surface from abrasion,

chemicals, or abuse. The QT60040 contains Quantum-pioneered self-calibration, drift compensation, and digital filtering

algorithms that make its sensing function extremely robust and survivable.

The device can easily control keys over graphical LCD panels or LEDs when used with clear, conductive ITO electrodes. It

does not require 'chip on glass' or other exotic fabrication techniques, thus allowing the OEM to source the keymatrix from

multiple vendors.

External circuitry consists only of a single, inexpensive capacitor. The sensitivity of the keys can be set by simply changing

the value of this capacitor. The device has 4 outputs which indicate detection on the keys; up to 2 keys can be sensed at any

one time.

The QT60040 features automatic recalibration timeouts which will cause the device to recalibrate keys on an individual basis

when they are 'stuck on' for intervals of either 10s or 60s, depending on a jumper option.

QT60040 technology makes use of an important new variant of charge-transfer sensing, transverse charge-transfer, in an XY

format that minimizes the number of required scan lines and external components. Unlike older technologies it does not

require one IC per key, and is cost competitive even with some rubber membrane technologies. A distinct advantage is an

accelerated time to market due to the fact that custom molded membranes are not required; the entire system can be

designed using common PCB materials.

The E604 board available from Quantum is a reference design that permits full evaluation of the QT60040

Appliance controls

Vandal-proof keypads

ATM machines

Touch-screens

Automotive controls

PC / peripheral controls

lQ

A

0

C to +700C

AVAILABLE OPTIONS

QT60040-IS-400C to +850C

DIPSOICT

QT60040-D-0

-

Copyright © 2000 Quantum Research Group Ltd

QT60040 / R1.04 / 0303

©Quantum Research Group Ltd.

r

r

1 - OVERVIEW

The QT60040 is a CMOS charge-transfer (QT) sensor designed

specifically for matrix touch controls; it includes all signal

processing functions necessary to provide stable sensing under a

wide variety of changing conditions. Only one low cost external

capacitor is required for operation.

The QT60040 uses burst-mode charge transfer methods

pioneered and patented by Quantum. This revolutionary new

technology allows the construction of entirely new forms of

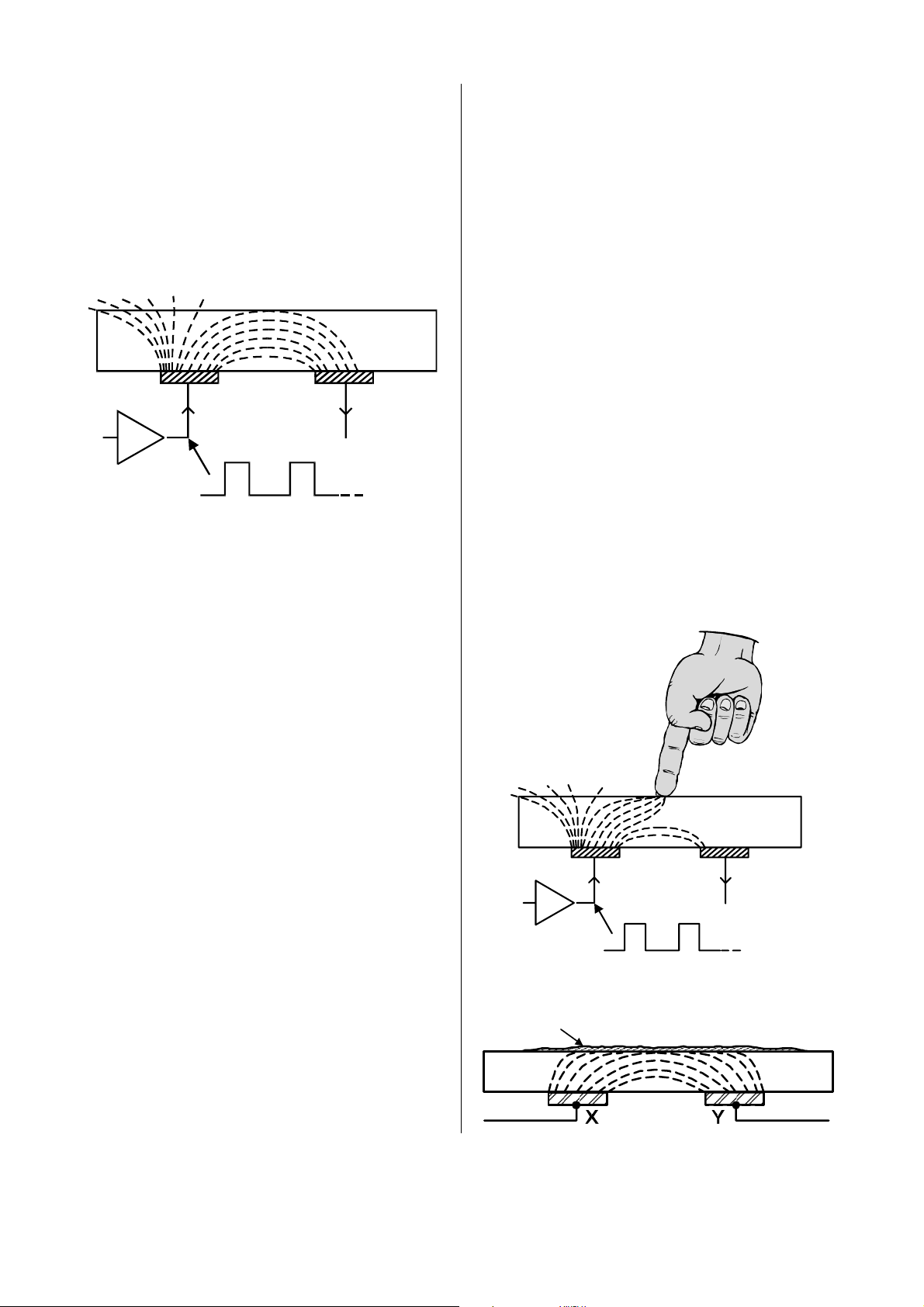

Figure 1-1 Field flow between X and Y elements

overlying panel

X

element

cmos

d

ive

keypanels which can include back-illumination, arbitrary shapes

of keys, 'morphed' keys wrapped onto complex surfaces, and

keys having unique textures and feel, all at very low cost.

The QT60040 uses a 4x1 matrix, having 4 'X' drive lines and 1 'Y'

receive line. This configuration reduces interconnect

requirements and also lowers the external component count to

one charge sampling capacitor which is sequentially shared by

the four keys.

The QT60040 has four simple active-high CMOS outputs that go

high when the corresponding key is touched. Up to 2 keys can be

touched at the same time; three or more keys touched will limit to

the first two touch outputs. An option pin allows this to be

restricted to only one key if desired.

The device operates on a 2.5 to 5.5 regulated power supply

which can be from a common 78L05-type IC regulator or a simple

2-stage zener regulator supply.

Y

element

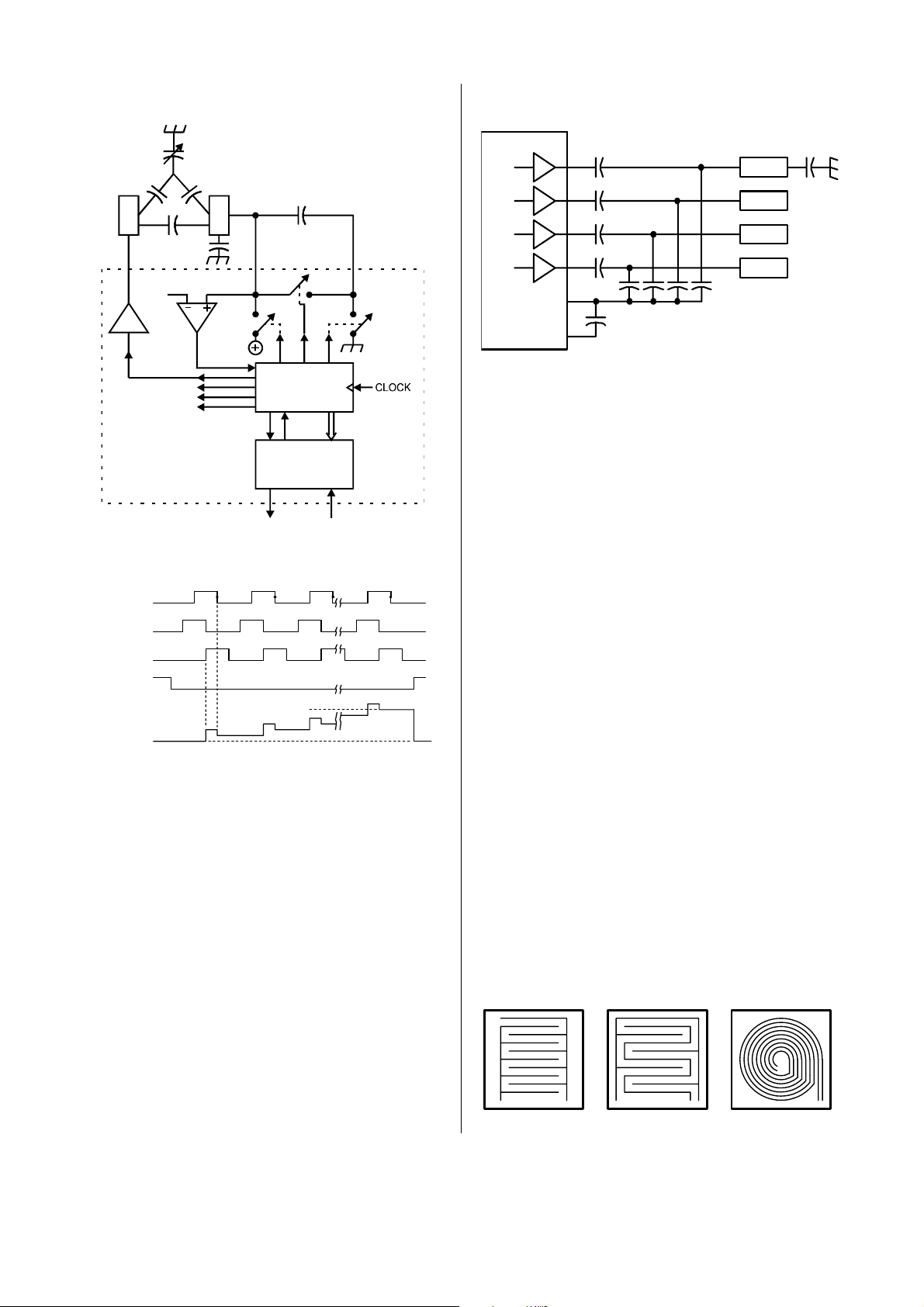

1.2 CIRCUIT MODEL

An electrical circuit model is shown in Figure 1-4. The coupling

capacitance across the X and Y electrodes and from each to a

finger is represented by Cx1, Cx2a, and Cx2b. The sampling

capacitor Cs is used to accumulate charge during the course of a

burst. An important parasitic capacitance from the Y line to

ground, Cx3, is also shown.

QT switch timing action is shown in Figure 1-5.

Initially, switch S3 is closed to reset Cs then re-opened. After S3

is opened, S1 is closed to charge the capacitances associated

with the Y-line, including all Y-to-X capacitances. After S1 is

closed, one of the four X lines is raised high, so that there is then

a zero differential potential from the selected X line to the Y line.

Then, S1 is opened and S2 is closed, causing charge to flow

from the Cx capacitances into Cs; Cs charges up slightly with the

polarity shown. Then the selected X line is driven low, causing a

step-function decrease in charge on Cs whose magnitude is

proportionate to the amount of coupling from X to Y.

The final charge accumulated on Cs per QT cycle is thus a direct

function of Cx3 minus the small amount of charge subtracted via

the Cx1 / Cx2a / Cx2b / Cfinger network. Since the charge from

the Cx2a / Cx2b network is highly dependent on Cfinger, which

effectively forms a capacitive divider, the total charge absorbed

by Cs is dependent on touch: a touch nets more charge

transferred into Cs per QT cycle because less charge is

transferred out of Cs per QT cycle.

The acquisition process is controlled by a state machine which

continues the acquisition cycle as a burst, which finally

terminates when the voltage across Cs reaches the predefined

level Vref. This burst takes hundreds or even thousands of cycles

Figure 1-2 Field Flows When Touched

overlying panel

1.1 FIELD FLOWS

Figure 1-1 shows how charge is transferred across an electrode

set to permeate the overlying panel material; this charge flow

exhibits a rapid dQ/dt during the edge transitions of the X drive

pulse. The charge emitted by the X electrode is partly received

onto the Y electrode which is then captured by the Cs capacitor

and processed.

The QT60040 matrix uses 4 'X' edge-driven rows and 1 'Y' sense

column to detect 4 keys. The X drive occurs as a burst of pulses

on each key.

The charge flows set into motion by the X drive signals are

partially absorbed by the touch of a human finger (Figure 1-2)

resulting in a decrease in coupling from X to Y; coupled charge

increases in the presence of a conductive film like water (Figure

1-3) which acts to bridge the two elements. Increasing signals

due to water films are quite easy to discern and are not detected

by the QT60040.

lQ

X

element

cmos

driver

Y

element

Figure 1-3 Fields With a Conductive Film

Wa te r fil m

- 2 - QT60040 / R1.04 / 0303

©Quantum Research Group Ltd.

O

UTO

S

Figure 1-4 QT60040 Circuit Model

C

FINGER

C

X2A

X

n

DRIVE

Vref

1 OF 4

C

X2B

C

X1

C

X3

S1

C

CHARGE

DONE START RESULT

C

S

+-

S3

RESET

STATE

MACHINE

POST

PROCESSOR

PTION

S2

TRANSFER

Figure 1-5 Circuit Switch Timings

X DRIVE X

CHARGE S 1

TRANSFER S 2

to complete; the burst length depends on the value of Cs, the Cx

capacitances, and Cfinger. Increasing Cs increases the burst

length, increasing Cx3 decreases burst length, and increasing

Cx1 and Cx2 increase burst length. Increasing Cfinger decreases

the burst length. The value of the burst length is thus a variable

that is dependent on these capacitances; the burst length is used

to create an internal reference signal level during a calibration

cycle, and to determine the presence of touch by virtue of a

change in the burst length relative to the reference level.

Because the Cs capacitor is shared among all four channels it is

important that the four interdigitated key designs be reasonably

well matched. It is also important to keep Cx1 and Cx3 to a

minimum while maximizing the values of Cx2a and Cx2b through

good key design methods. These requirements also dictate that

the IC be placed close to the keys to achieve good sensitivity

levels; long Y traces also increase the risk of susceptibility to

interference, as well as low gain. To reduce Cx3, the Y line

should not be run close to other unrelated traces or over or near

ground planes.

RESET S3

∆

V

n

V

REF

CS

Cycle 1

Cycle 'm '

Figure 1-6 Conversion to Single Electrodes

QT60040

X1

X2

X3

X4

C

X2A

C

Y

C

S

X2B

capacitances, possibly by using intentional mutual capacitive

coupling of tracks on a PCB; traces from the intersections of

these capacitors are led to solid touch pads which are

implemented as metallizations on the rear of a control panel.

Touching the front of the panel has the same absorptive effect on

signal strength as an interdigitated electrode set.

The values of Cx2a and Cx2b should be consistent among all

keys to preserve signal balance, which is required for proper

operation. The surface area and geometry of this type of

electrode should be adjusted to suit the desired activation area.

Typical values of Cx2a and Cx2b range from 5pF to 10pF. The

traces leading from the junctions of these capacitors to the solid

touch pads should not see a load of more than 10pF, thus the

traces to these pads should be thin and short and not

accompanied by a ground plane or other traces.

C

FINGE R

1.4 INTERDIGITATED ELECTRODES

Key electrodes can be made using interdigitated sets of fingers,

serpentines, spirals or similar patterns (Figure 1-7). One element

of each key must be connected to an X line, with the other

connected to the common Y line. The pattern surface area should

be similar from key to key to preserve relative key sensitivities.

It is important to prevent substantial capacitive coupling from a

‘bare’ Y line to a finger. A transient increase in Cx3 will cause a

sudden disturbance common to all keys that can create

unintentional detections. The connecting Y trace running between

the keys should be as thin as possible, on a side of the flex circuit

or pcb away from the user panel, and where possible run closely

in parallel with a segment of a nearby X trace so as to suppress

this effect. The problem of a bare Y line can be demonstrated by

touching the Cs capacitor (which is connected to Y), which will

cause one or two random keys to activate with each touch.

In cases where it is not possible to have both the X and Y traces

on the same plane, the X traces should be run on the ‘finger’ side

of the board. In all cases where the X and Y lines run on opposite

planes, the substrate (a flex circuit, or a pcb) should be as thin as

Figure 1-7 Sample Electrode Geometries

1.3 SINGLE ELECTRODE OPERATION

An alternative mode of operation is shown in Figure 1-6.

Capacitances Cx2a and Cx2b are implemented as discrete

lQ

PARALLEL LINES SERPENTINE SPIRAL

- 3 - QT60040 / R1.04 / 0303

Loading...

Loading...