LQ

2-C

HANNEL PROGAMMABLE ADVANCED SENSOR

Two channel digital advanced capacitive sensor IC

Projects two ‘touch buttons’ through any dielectric

Cloning for user-defined sensing behavior

100% autocal - no adjustments required

Only one external capacitor per channel

User-defined drift compensation, threshold levels

Variable gain via Cs capacitor change

Selectable output polarities

Toggle mode / normal mode outputs

HeartBeat™ health indicator on outputs (can be disabled)

1.8 ~ 5V supply, 60µA

APPLICATIONS

QP

ROX

™

QT320

IC

Light switches

Industrial panels

The QT320 charge-transfer (“QT’”) touch sensor chip is a self-contained digital IC capable of detecting near-proximity or

touch on two sensing channels. It will project sense fields through almost any dielectric, like glass, plastic, stone, ceramic,

and most kinds of wood. It can also turn small metal-bearing objects into intrinsic sensors, making them respond to proximity

or touch. This capability coupled with its ability to self calibrate continuously can lead to entirely new product concepts.

It is designed specifically for human interfaces, like control panels, appliances, security systems, lighting controls, or

anywhere a mechanical switch or button may be found; it may also be used for some material sensing and control

applications provided that the presence duration of objects does not exceed the recalibration time-out interval.

The IC requires only a common inexpensive capacitor per channel in order to function.

Power consumption and speed can be traded off depending on the application; drain can be as low as 60µA, allowing

operation from batteries.

The IC’s RISC core employs signal processing techniques pioneered by Quantum; these are specifically designed to make

the device survive real-world challenges, such as ‘stuck sensor’ conditions and signal drift. Even sensitivity is digitally

determined. All key operating parameters can be set by the designer via the onboard eeprom which can be configured to alter

sensitivity, drift compensation rate, max on-duration, output polarity, and toggle mode independently on each channel.

No external switches, opamps, or other analog components aside from Cs are usually required.

The Quantum-pioneered HeartBeat™ signal is also included, allowing a host controller to monitor the health of the QT320

continuously if desired; this feature can be disabled via the cloning process.

By using the charge transfer principle, the IC delivers a level of performance clearly superior to older technologies in a highly

cost-effective package.

Appliance control

Security systems

Access systems

Pointing devices

Computer peripherals

Entertainment devices

LQ

A

0

C to +700C

AVAILABLE OPTIONS

8-PIN DIPSOICT

QT320-D-0

-QT320-IS-400C to +850C

Copyright © 2002 QRG Ltd QT320/R1.03 08/02

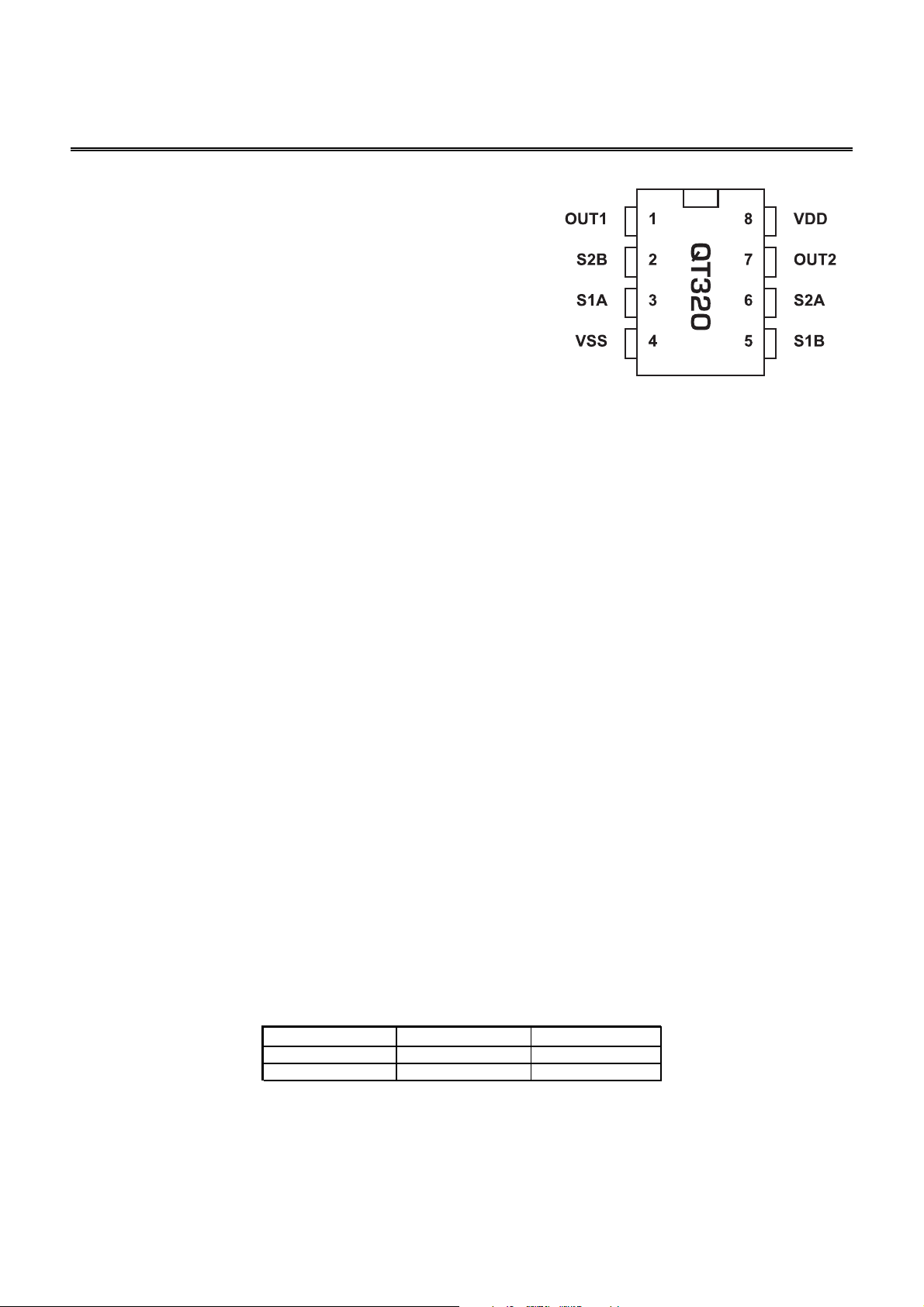

Table 1-1 Pin Descriptions

FunctionNamePin

Detection output, Ch. 1OUT11

Sense Ch 2 pin BS2B2

Sense Ch 1 pin AS1A3

Negative supply (ground)VSS4

Sense Ch 1 pin BS1B5

Sense Ch 2 pin AS2A6

Detection output, Ch. 2OUT27

Positive supplyVDD8

Alternate Pin Functions for Cloning

Serial clone data clockSCK3

Serial clone data outSDO6

Serial clone data inSDI7

1 - OVERVIEW

The QT320 is a 2 channel digital burst mode charge-transfer

(QT) sensor designed specifically for touch controls; it

includes all hardware and signal processing functions

necessary to provide stable sensing under a wide variety of

changing conditions. Only two low-cost, non-critical capacitors

are required for operation.

A unique aspect of the QT320 is the ability of the designer to

‘clone’ a wide range of user-defined setups into the part’s

eeprom during development and in production. Cloned setups

can dramatically alter the behavior of each channel,

independently. For production, the parts can be cloned

in-circuit or can be procured from Quantum pre-cloned.

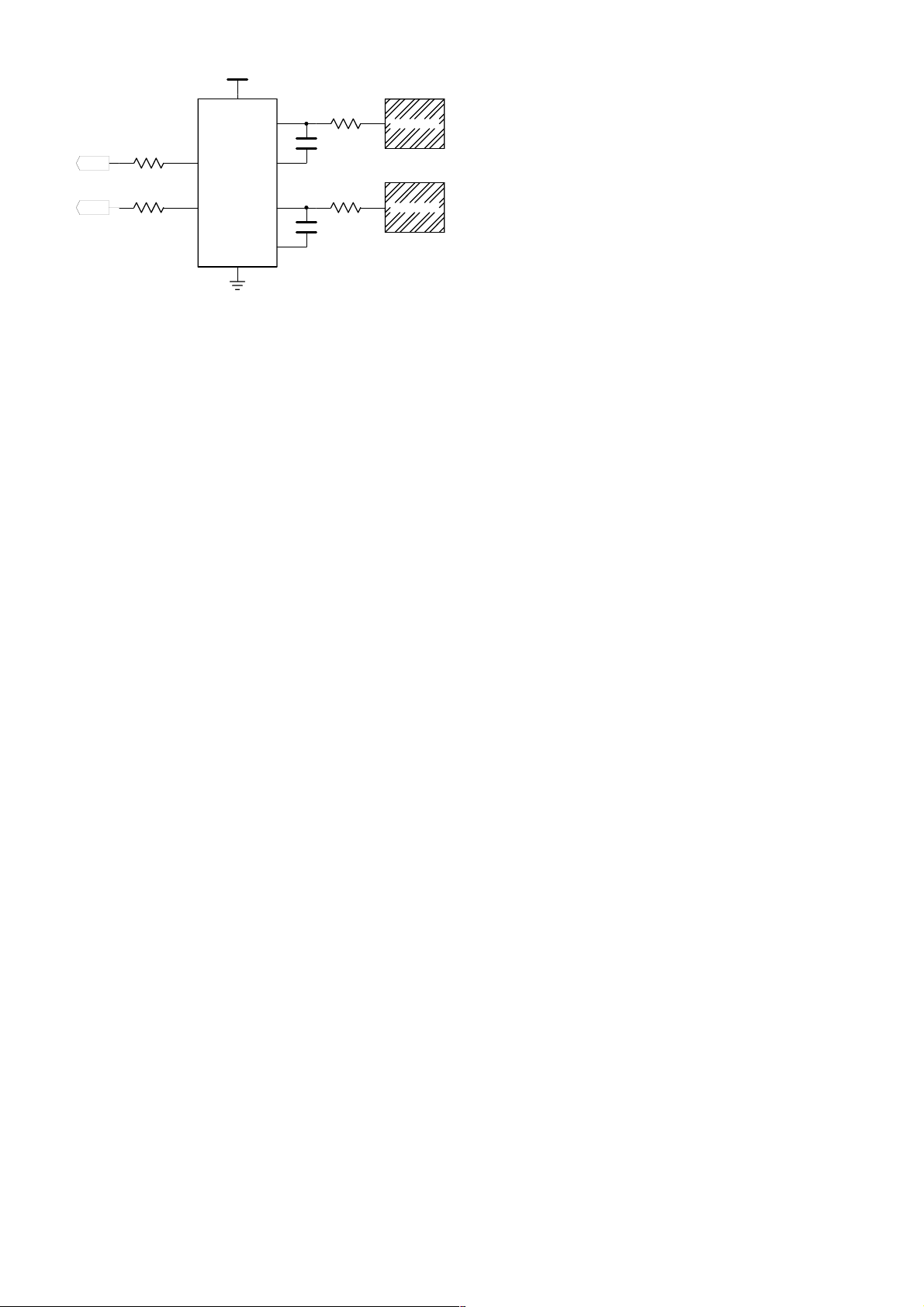

Figure 1-1 shows the basic QT320 circuit using the device,

with a conventional output drive and power supply

connections.

1.1 BASIC OPERATION

The QT320 employs bursts of variable-length charge-transfer

cycles to acquire its signal. Burst mode permits power

consumption in the microamp range, dramatically reduces RF

emissions, lowers susceptibility to EMI, and yet permits

excellent response time. Internally the signals are digitally

processed to reject impulse noise using a 'consensus' filter

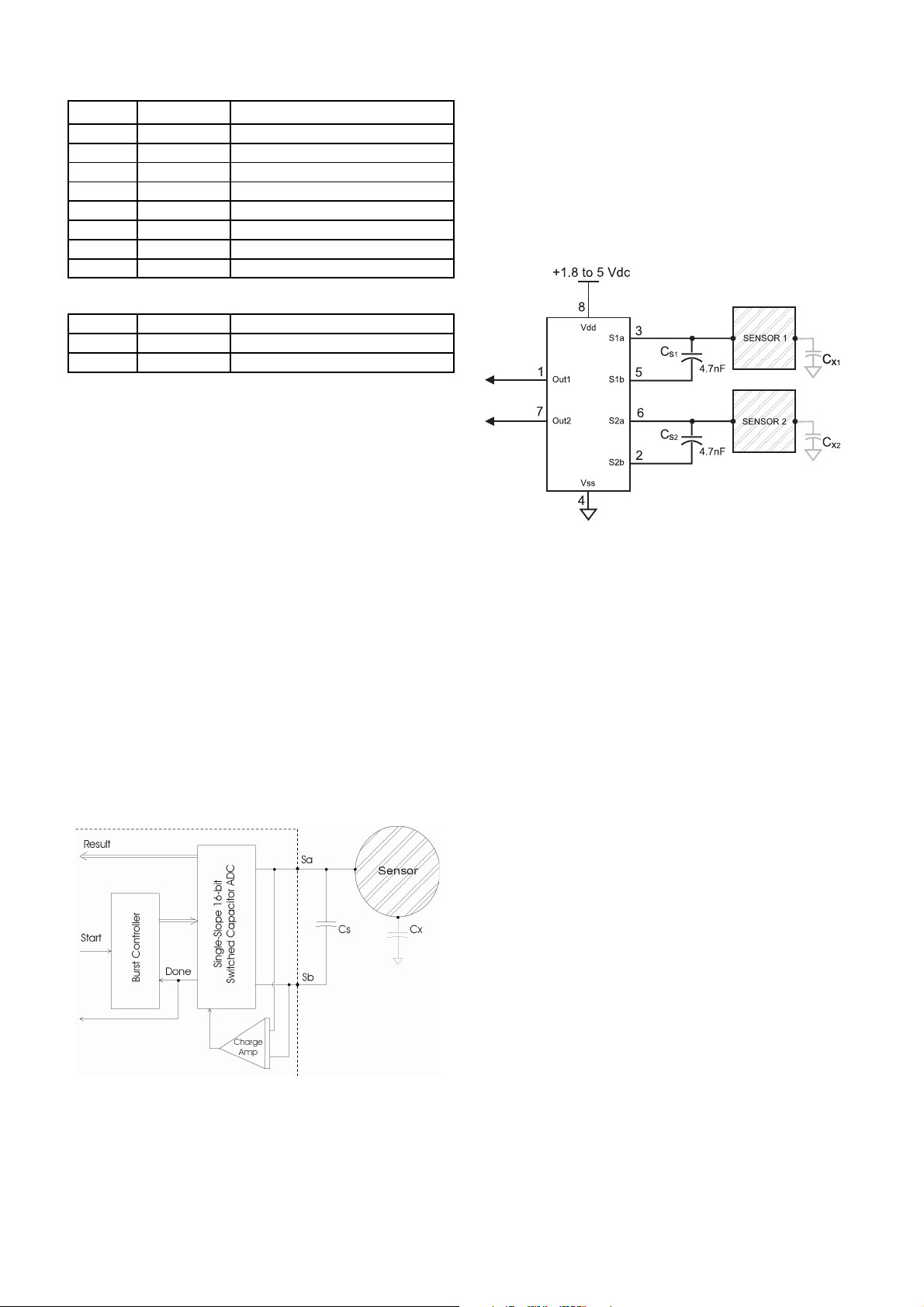

Figure 1-2 Internal Switching

which requires several consecutive confirmations of a

detection before an output is activated.

The two channels of sensing operate in a completely

independent fashion. A unique cloning process allows the

internal eeprom of the device to be programmed for each

channel, to permit unique combinations of sensing and

processing functions for each.

The two sensing channels operate in interleaved

time-sequence and thus cannot interfere with each other.

Figure 1-1 Basic QT320 circuit

1.2 ELECTRODE DRIVE

1.2.1 S

The IC implements two channels of direct-to-digital

capacitance acquisition using the charge-transfer method, in

a process that is better understood as a capacitanceto-digital converter (CDC). The QT switches and charge

measurement functions are all internal to the IC (Figure 1-2).

The CDC treats sampling capacitor Cs as a floating store of

accumulated charge which is switched between the sense

pins; as a result, the sense electrode can be connected to

either pin with no performance difference. In both cases the

rule Cs >> Cx must be observed for proper operation. The

polarity of the charge build-up across Cs during a burst is the

same in either case. Typical values of Cs range from 2nF to

100nF for touch operation.

Larger values of Cx cause charge to be transferred into Cs

more rapidly, reducing available resolution and resulting in

lower gain. Conversely, larger values of Cs reduce the rise of

differential voltage across it, increasing available resolution

and raising gain. The value of Cs can thus be increased to

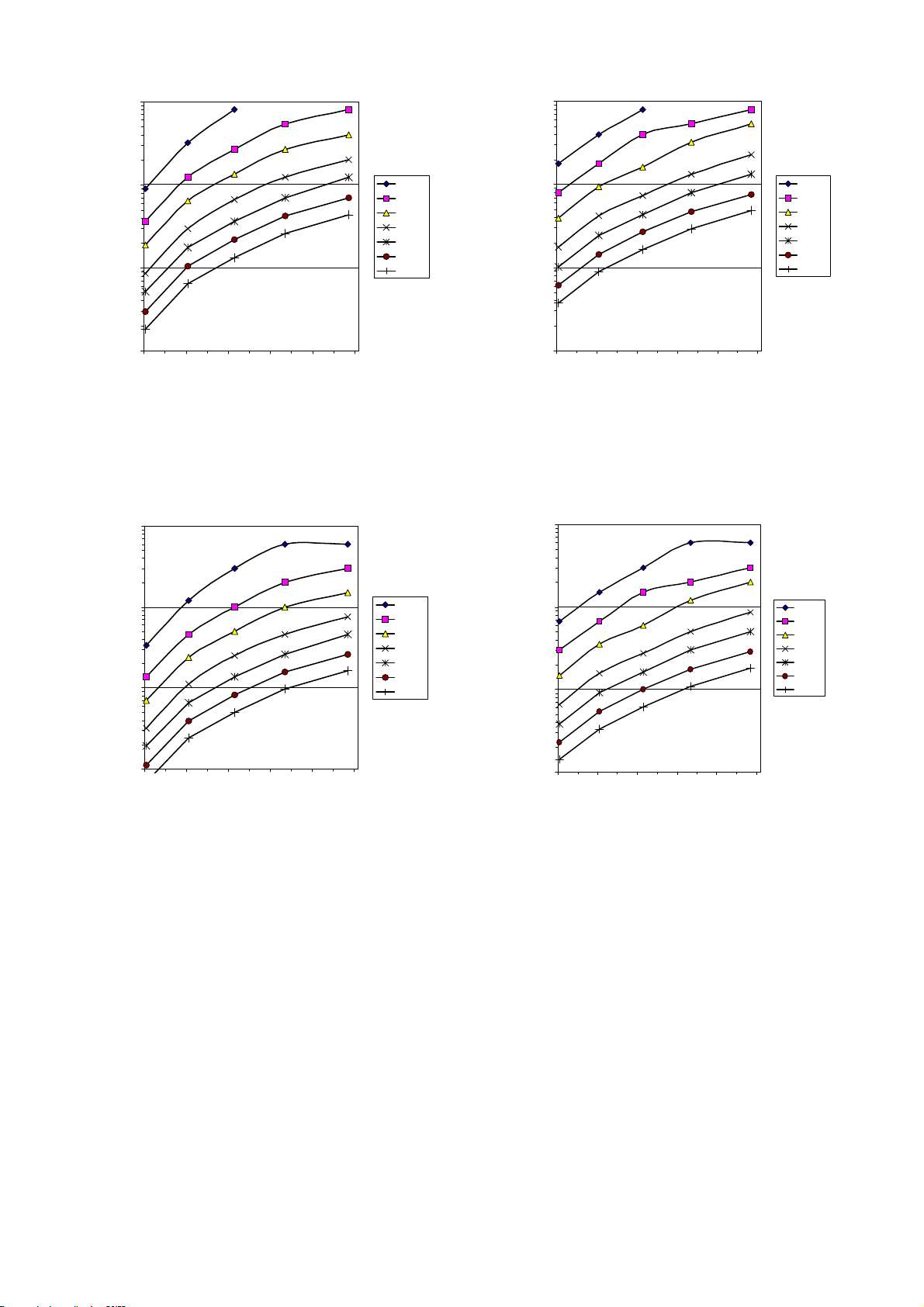

allow larger values of Cx to be tolerated (Figures 5-1 to 5-4).

As Cx increases, the length of the burst decreases resulting in

lower signal numbers.

It is possible to connect separate Cx and Cx’ loads to Sa and

Sb simultaneously, although the result is no different than if

the loads were connected together at Sa (or Sb). It is

important to limit the amount of stray Cx capacitance on both

terminals, especially if the load Cx is already large. This can

be accomplished by minimising trace lengths and widths.

WITCHING OPERATION

lQ

2 QT320/R1.03 08/02

1.2.2 C

f

f

The PCB traces, wiring, and any components associated with

or in contact with Sa and Sb of either channel will become

touch sensitive and should be treated with caution to limit the

touch area to the desired location.

Multiple touch electrodes can be connected to one sensing

channel, for example to create a control button on both sides

of an object, however it is impossible for the sensor to

distinguish between the two connected touch areas.

ONNECTION TO ELECTRODES

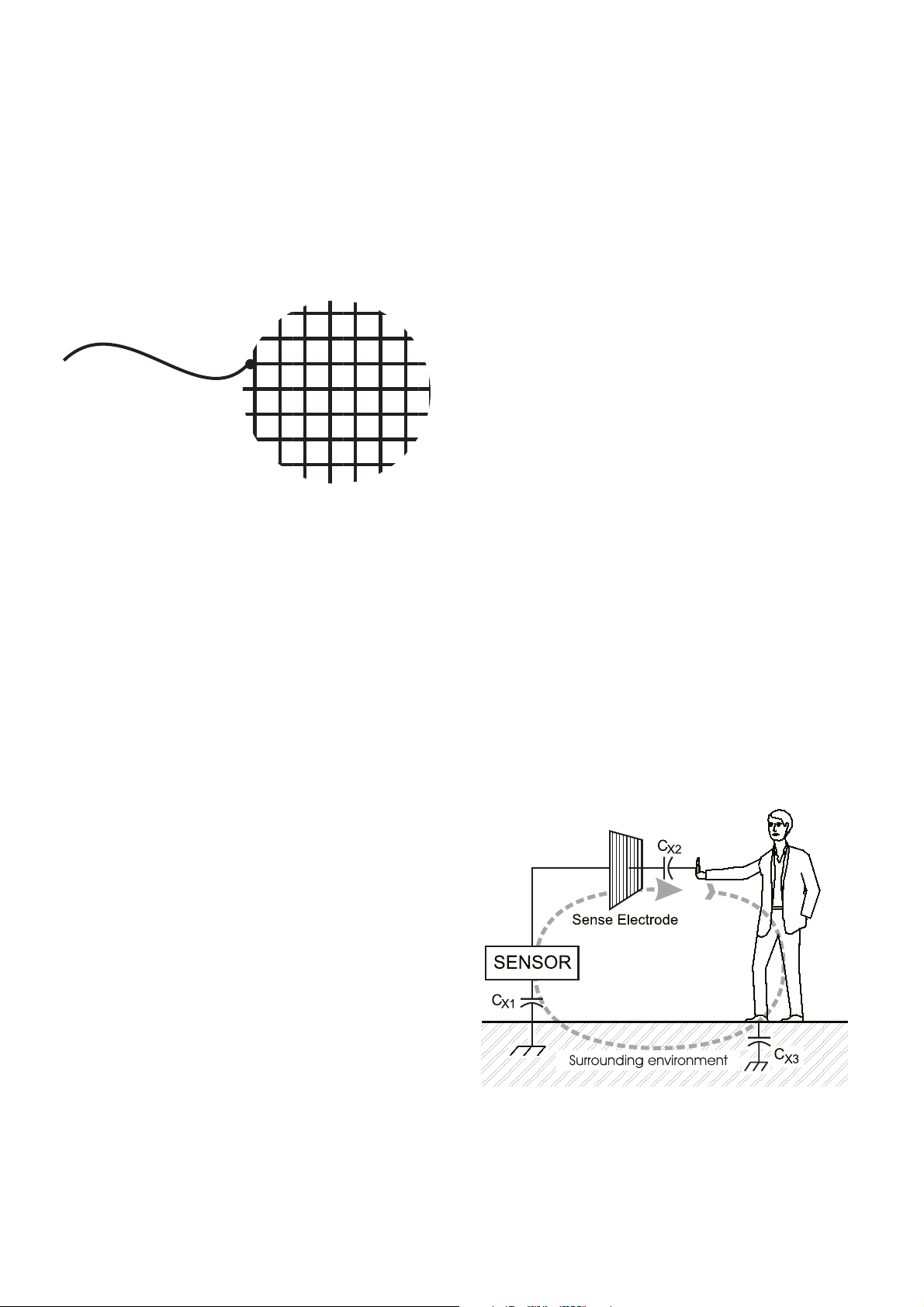

Figure 1-3 Mesh Electrode Geometry

1.3.2 K

Like all capacitance sensors, the QT320 relies on Kirchoff’s

Current Law (Figure 1-4) to detect the change in capacitance

of the electrode. This law as applied to capacitive sensing

requires that the sensor’s field current must complete a loop,

returning back to its source in order for capacitance to be

sensed. Although most designers relate to Kirchoff’s law with

regard to hardwired circuits, it applies equally to capacitive

field flows. By implication it requires that the signal ground

and the target object must both be coupled together in some

manner in order for the sensor to operate properly. Note that

there is no need to provide an actual hardwired ground

connection; capacitive coupling to ground (Cx1) often is

sufficient, even if the coupling might seem very tenuous. For

example, powering the sensor via an isolated transformer will

almost always provide ample ground coupling, since there is

plenty of capacitance between the primary and secondary

windings via the transformer core and from there to the power

wiring itself directly to 'local earth'. Even when battery

powered, just the physical size of the PCB and the object into

which the electronics is embedded is often enough to couple

enough back to local earth.

The implications of Kirchoff’s law can be most visibly

demonstrated by observing the E3B eval board’s sensitivity

change between laying the board on a table versus holding

the board in your hand by it’s batteries. The effect can also be

observed by holding the board only by one electrode, letting it

recalibrate, then touching the battery end; the board will work

quite well in this mode.

IRCHOFF’S CURRENT LAW

1.2.3 B

The acquisition process occurs in bursts (Figure 1-7) of

variable length, in accordance with the single-slope CDC

method. The burst length depends on the values of Cs and

Cx. Longer burst lengths result in higher gains and more

sensitivity for a given threshold setting, but consume more

average power and are slower.

Burst mode operation acts to lower average power while

providing a great deal of signal averaging inherent in the CDC

process, making the signal acquisition process more robust.

The QT method is a very low impedance method of sensing

as it loads Cx directly into a very large capacitor (Cs). This

results in very low levels of RF susceptibility.

URST MODE OPERATION

1.3 ELECTRODE DESIGN

1.3.1 E

There is no restriction on the shape of the electrodes; in most

cases common sense and a little experimentation can result

in a good electrode design. The QT320 will operate equally

well with long, thin electrodes as with round or square ones;

even random shapes are acceptable. The electrode can also

be a 3-dimensional surface or object. Sensitivity is related to

electrode surface area, orientation with respect to the object

being sensed, object composition, and the ground coupling

quality of both the sensor circuit and the sensed object.

Smaller electrodes will have less sensitivity than large ones.

If a relatively large electrode surfaces are desired, and if tests

show that an electrode has a high Cx capacitance that

reduces the sensitivity or prevents proper operation, the

electrode can be made into a mesh (Figure 1-3) which will

have a lower Cx than a solid electrode area.

LECTRODE GEOMETRY AND SIZE

1.3.3 V

When detecting human contact (e.g. a fingertip), grounding of

the person is never required, nor is it necessary to touch an

exposed metal electrode. The human body naturally has

several hundred picofarads of ‘free space’ capacitance to the

local environment (Cx3 in Figure 1-4), which is more than two

orders of magnitude greater than that required to create a

return path to the QT320 via earth. The QT320's PCB

however can be physically quite small, so there may be little

‘free space’ coupling (Cx1 in Figure 1-4) between it and the

environment to complete the return path. If the QT320 circuit

ground cannot be grounded via the supply connections, then

IRTUAL CAPACITIVE GROUNDS

Figure 1-4 Kircho

’s Current Law

lQ

3 QT320/R1.03 08/02

Sen se

wire

Unshielded

Electrode

Sense

wire

Shielded

Electro de

Figure 1-5 Field Shielding & Shaping

a ‘virtual capacitive ground’ may be required to increase

return coupling.

A ‘virtual capacitive ground’ can be created by connecting the

QT320’s own circuit ground to:

(1) A nearby piece of metal or metallized housing;

(2) A floating conductive ground plane;

(3) A fastener to a supporting structure;

(4) A larger electronic device (to which its output might be

connected anyway).

Because the QT320 operates at a relatively low frequency,

about 500kHz, even long inductive wiring back to ground will

usually work fine.

Free-floating ground planes such as metal foils should

maximise exposed surface area in a flat plane if possible. A

square of metal foil will have little effect if it is rolled up or

crumpled into a ball. Virtual ground planes are more effective

and can be made smaller if they are physically bonded to

other surfaces, for example a wall or floor.

1.3.4 F

IELD SHIELDING AND SHAPING

The electrode can be prevented from sensing in undesired

directions with the assistance of metal shielding connected to

circuit ground (Figure 1-5). For example, on flat surfaces, the

field can spread laterally and create a larger touch area than

desired. To stop field spreading, it is only necessary to

surround the touch electrode on all sides with a ring of metal

connected to circuit ground; the ring can be on the same or

opposite side from the electrode. The ring will kill field

spreading from that point outwards.

If one side of the panel to which the electrode is fixed has

moving traffic near it, these objects can cause inadvertent

detections. This is called ‘walk-by’ and is caused by the fact

that the fields radiate from either surface of the electrode

equally well. Again, shielding in the form of a metal sheet or

foil connected to circuit ground will prevent walk-by; putting a

small air gap between the grounded shield and the electrode

will keep the value of Cx lower and is encouraged. In the case

of the QT320, sensitivity can be high enough (depending on

Cx and Cs) that 'walk-by' signals are a concern; if this is a

problem, then some form of rear shielding may be required.

1.4 SENSITIVITY ADJUSTMENTS

There are three variables which influence sensitivity

independently for each channel:

1. Cs (sampling capacitor)

2. Cx (unknown capacitance)

3. Signal threshold value

There is also a sensitivity dependence of the whole device on

Vdd. Cs and Cx effects are covered in Section 1.2.1.

The threshold setting can be adjusted independently for each

channel from 1 to 16 counts of signal swing (Section 2.2).

Note that sensitivity is also a function of other things like

electrode size, shape, and orientation, the composition and

aspect of the object to be sensed, the thickness and

composition of any overlaying panel material, and the degree

of mutual coupling of the sensor circuit and the object (usually

via the local environment, or an actual galvanic connection).

It is advisable to set the sensitivity to the approximate desired

result by changing Cx and Cs first using a signal threshold

fixed at 10. Use the threshold value thereafter to fine-tune

sensitivity.

1.4.1 I

In some cases it may be desirable to greatly increase

sensitivity, for example when using the sensor with very thick

panels having a low dielectric constant, or when sensing low

capacitance objects.

Sensitivity can be increased by using a bigger electrode,

reducing panel thickness, or altering panel composition.

Increasing electrode size can have diminishing returns, as

high values of Cx load will also reduce sensor gain (Figures

5-1 to 5-4). The value of Cs also has a dramatic effect on

sensitivity, and this can be increased in value up to a limit.

Increasing electrode surface area will not substantially

increase sensitivity if its area is already larger than the object

to be detected. The panel or other intervening material can be

made thinner, but again there are diminishing rewards for

doing so. Panel material can also be changed to one having a

higher dielectric constant, which will help propagate the field.

Locally adding some conductive material to the panel

(conductive materials essentially have an infinite dielectric

constant) will also help; for example, adding carbon or metal

fibers to a plastic panel will greatly increase frontal field

NCREASING SENSITIVITY

Figure 1-6 Circuit with Csx gain equalization capacitor

lQ

4 QT320/R1.03 08/02

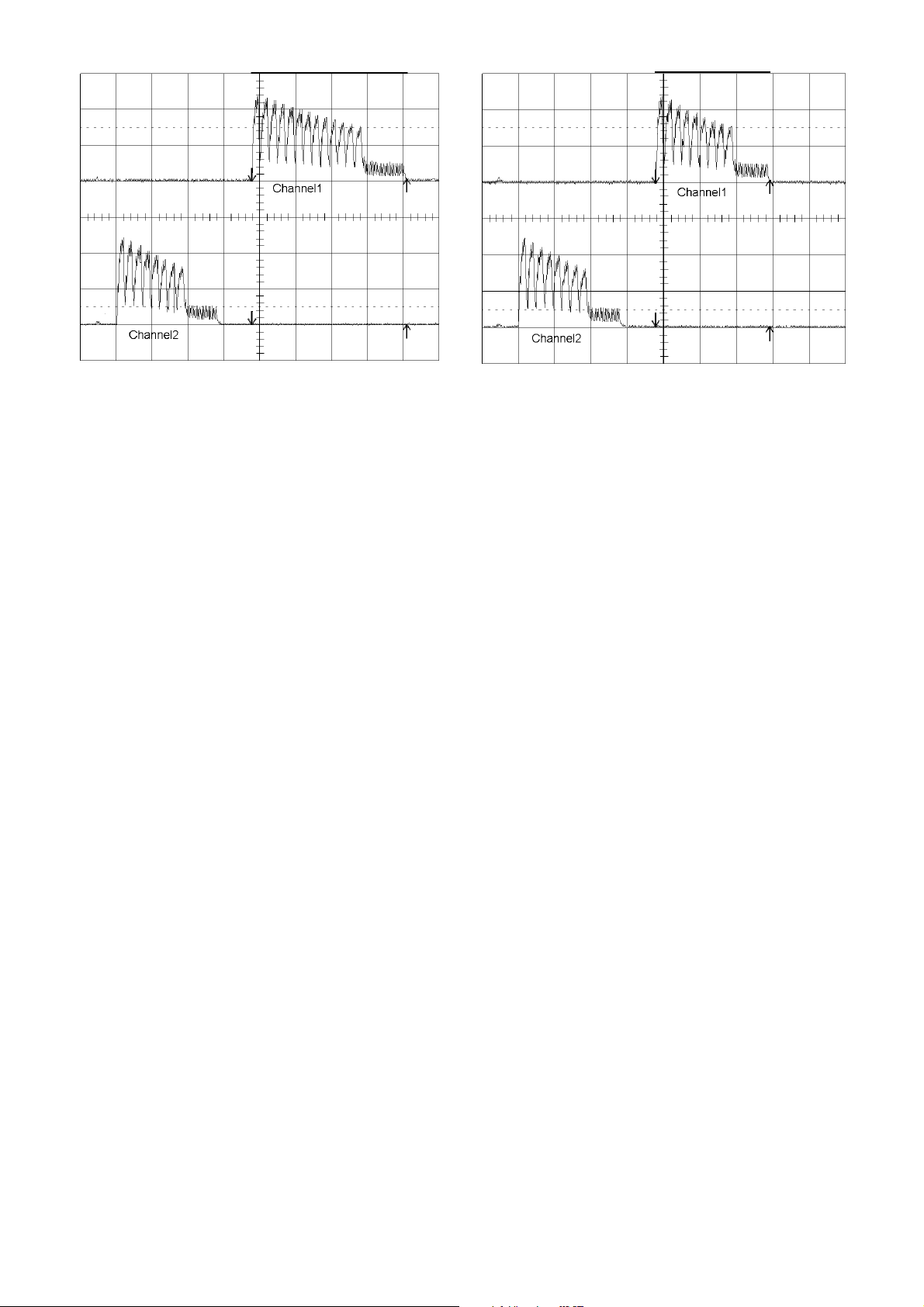

Figure 1-7 Burst lengths without Csx installed

(observed using a 750K resistor in series with probe)

Figure 1-8 Burst lengths with Csx installed

(observed using a 750K resistor in series with probe)

strength, even if the fiber density is too low to make the

plastic electrically conductive.

1.4.2 D

In some cases the circuit may be too sensitive, even with high

signal threshold values. In this case gain can be lowered by

making the electrode smaller, using sparse mesh with a high

space-to-conductor ratio (Figure 1-3), and most importantly by

decreasing Cs. Adding Cx capacitance will also decrease

sensitivity.

It is also possible to reduce sensitivity by making a capacitive

divider with Cx by adding a low-value capacitor in series with

the electrode wire.

1.4.3 H

Hysteresis is required to prevent chattering of the output lines

with weak, noisy, or slow-moving signals.

The hysteresis can be set independently per channel.

Hysteresis is a reference-based number; thus, a threshold of

10 with a hysteresis of 2 will yield 2 counts of hysteresis

(20%); the channel will become active when the signal equals

or exceeds a count of 10, and go inactive when the count falls

to 7 or lower.

Hysteresis can also be set to zero (0), in which case the

sensor will go inactive when the count falls to 9 or lower in the

above example.

Threshold levels of under 4 counts are hard to deal with as

the hysteresis level is difficult to set properly.

1.4.4 C

Channel 1 has less internal Cx than Channel 2, which makes

it more sensitive than Channel 2 given equal Cx loads and Cs

ECREASING SENSITIVITY

YSTERESIS

HANNEL BALANCE

capacitors. This can be useful in some designs where one

more sensitive channel is desired, but if equal sensitivity is

required a few basic rules should be followed:

1. Use a symmetrical PCB layout for both channels: Place

the IC half way between the two electrodes to match Cx

loading. Avoid routing ground plane (or other traces) close

to either sense line or the electrodes; allow 4-5 mm

clearance from any ground or other signal line to the

electrodes or their wiring. Where ground plane is required

(for example, under and around the QT320 itself) the

sense wires should have minimized adjacency to ground.

2. Connect a small capacitor (~5pF) between S1a or S1b

(either Channel 1 pin) and circuit ground (Csx in Figure

1-6), this will increase the load capacitance of Channel 1,

thus balancing the sensitivity of the two channels (see

Figures 1-7, 1-8).

3. Adjust Cs and/or the internal threshold of the two channels

until the sensitivities of the two channels are

indistinguishable from each other.

Since the actual burst length is proportional to sensitivity, you

can use an oscilloscope to balance the two channels with

more accuracy than by empirical methods (See Figures 1-7

and 1-8). Connect one scope probe to Channel 1 and the

other to Channel 2, via large resistors (750K ohms) to avoid

disturbing the measurement too much, or, use a low-C FET

probe. The Csx balance capacitor should be adjusted so that

the burst lengths of Channels 1 and 2 look nearly the same.

With some diligence the PCB can also be designed to include

some ground plane nearer to Channel 1 traces to induce

about 5pF of Csx load without requiring an actual discrete

capacitor.

lQ

5 QT320/R1.03 08/02

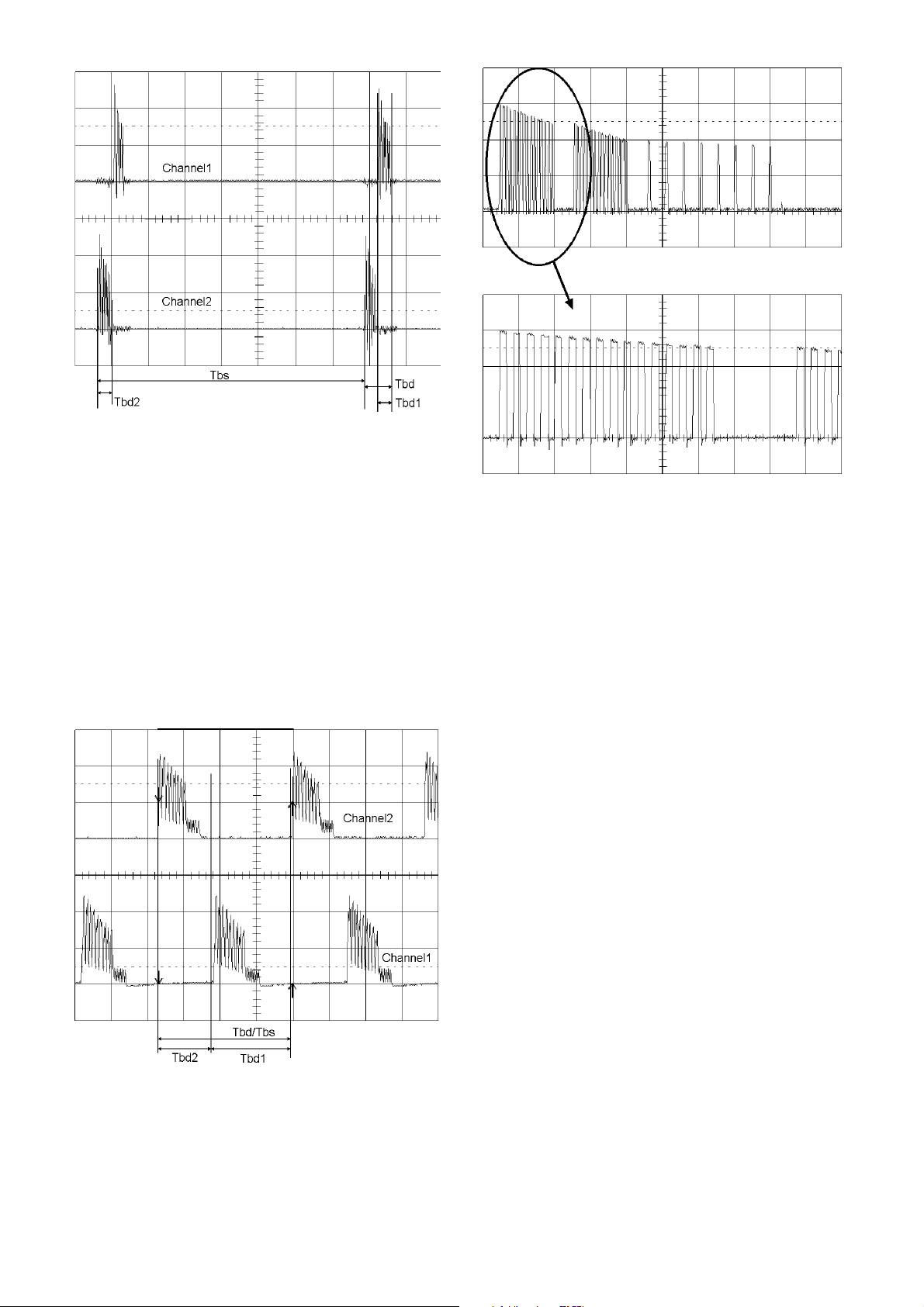

Figure 1-9 Bursts when SC > 0

1.5 TIMING

The QT320 runs two sensing bursts, one per channel, each

acquisition cycle (Figure 1-9). The bursts are successive in

time, with Channel 2 firing first.

The basic QT320 timing parameters are:

Ti Basic timing interval (1.5.1)

Tbs Burst spacing (1.5.1)

Tbd1 Burst duration, Channel 1 (1.5.2)

Tbd2 Burst duration, Channel 2 (1.5.2)

Tbd Burst duration, Ch1 + Ch2 (1.5.2)

Tmod Max On-Duration (1.5.3)

Tdet Detection response time (1.5.4)

Figure 1-11 Burst detail

1.5.1 B

Between acquisition bursts, the device can go into a low

power sleep mode. The percentage of time spent in sleep

depends on the burst spacing and the combined burst lengths

of both channels; if the burst lengths occupy all of the sleep

interval, no time will be spent in sleep mode and the part will

operate at maximum power drain.

The burst spacing is a multiple of the basic timing interval Ti;

Ti in turn depends heavily on Vdd (see Section 2.1 and Figure

5.7). The parameter ‘Sleep Cycles’ or SC is the user-defined

Setup value which controls how many Ti intervals there are

from the start of a burst on Channel 2 until the start of the

next such burst. The resulting timing is Tbs:

All the basic timing parameters of the QT320 such as

recalibration delay etc. are dependent on Tbs.

If SC = 0, the device never sleeps between bursts (Figure

1-10). This mode is fast but consumes maximum power; it is

also unregulated in timing from burst to burst, depending on

the combined burst lengths of both channels.

Conversely if SC >> 0, the device will spend most of its time

in sleep mode and will consume very little power, but it will be

slower to respond.

By selecting a supply voltage and a value for SC, it is possible

to fine-tune the circuit for the desired speed / power tradeoff.

URST SPACING

Tbs = SC x Ti where SC > 0.

: TI, SC, T

BS

Figure 1-10 Bursts when SC = 0

(750K resistor in series with scope probe)

lQ

1.5.2 B

The two burst durations depend entirely on the values of Cs

and Cx for the coresponding sensing channel, and to a lesser

extend, Vdd. The bursts are composed of hundreds of

charge-transfer cycles (Figure 1-11) operating at about

500kHz. Channel 2 always fires first (Tbd2) followed by

Channel 1 (Tbd1); the sum total of the time required by both

channels is parameter Tbd.

URST DURATIONS

: TBD1, TBD2, T

BD

6 QT320/R1.03 08/02

When SC=0 (no sleep cycles), the sensor operates without a

fixed timing and the acquisition spacing Tbs is the sum of the

burst durations for both channels (Figure 1-10). In this mode

of operation, Tbs and Tbd are the same value.

1.5.3 MAX ON-D

The Max On-Duration is the amount of time required for a

continuously detecting sense channel to recalibrate itself. This

parameter is user settable by changing MOD and SC (Section

2.6).

Tmod restarts if the OUT pin becomes inactive.

A recalibration of one channel has no effect on the other;

Tmod operates independently for each channel.

1.5.4 R

Response time from the onset of detection to an actual OUT

pin becoming active depends on:

Ti depends in turn on Vdd.

If the control bit DIS is normal (0), then Tdet depends on the

rate at which the bursts are acquiring, and the value of DIT. A

DIT number of bursts must confirm the detection before the

OUT line becomes active:

If DIS is set to fast, then Tdet also depends on BL:

Ti depends in turn on Vdd; Tbd depends on Cs and Cx for

both channels.

Quantum’s QT3View software calculates an estimate of

response time based on these parameters.

ESPONSE TIME

Ti Basic Timing Interval

SC Sleep Cycles (user setting)

DIT Detection Integrator Target (user setting)

DIS Detect Integration Speed (user setting)

Tbd Burst duration (if DIS is set too fast)

Tdet = SC x Ti x DIT (normal DIS)

Tdet = (SC x Ti) + (DIT-1)*Tbd (fast DIS)

URATION

, T

, T

DET

MOD

1.6 EXTERNAL RECALIBRATION

The QT320 has no recalibration pin; a forced recalibration is

accomplished only when the device is powered up. However,

supply drain is low enough that the IC can be powered from a

logic gate or I/O pin of an MCU; driving the Vdd pin low and

high again can serve as a forced recalibration. The source

resistance of many CMOS gates and MCU’s are

low enough to provide direct power without

problems. A 0.01uF minimum bypass capacitor is

required directly across Vdd to Vss.

2 - CONTROL & PROCESSING

All acquisition functions are digitally controlled and can be

altered via the cloning process.

Signals are processed using 16 bit integers, using

Quantum-pioneered algorithms specifically designed to

provide for high survivability.

2.1 SLEEP CYCLES (SC)

Range: 0..255; Default: 1

Affects speed & power of entire device.

Refer to Section 1.5.1 for more information on the effect of

Sleep Cycles.

SC changes the number of intervals Ti separating two

consecutive burst pairs (Figure 1-10). SC = 0 disables sleep

intervals and bursts are crowded together with a rep rate that

depends entirely on the burst lengths of both channels

(Section 1.5.2).

Response time, drift compensation rate, max on-duration, and

power consumption are all affected by this parameter. A high

value of SC will make the sensor very low power and very

slow.

2.2 DRIFT COMPENSATION (PDC, NDC)

Signal drift can occur because of changes in Cx, Cs, Vdd,

electrode contamination and aging effects. It is important to

compensate for drift, otherwise false detections and sensitivity

shifts can occur.

Drift compensation is performed by making the signal’s

reference level slowly track the raw signal while no detection

is in effect. The rate of adjustment must be performed slowly,

otherwise legitimate detections could be affected. The device

compensates using a slew-rate limited change to the signal

reference level; the threshold and hysteresis points are slaved

to this reference.

Once an object is detected, drift compensation stops since a

legitimate signal should not cause the reference to change.

Positive and negative drift compensation rates (PDC, NDC)

can be set to different values (Figure 2-1). This is invaluable

for permitting a more rapid reference recovery after a channel

has recalibrated while an object was present and then

removed.

lQ

Figure 2-1 Drift Compensation

7 QT320/R1.03 08/02

If SC > 0, then PDC+1 sets the number of burst spacings,

Tbs, that determines the interval of drift compensation, where:

Tbs = SC x Ti (Section 1.5.1)

Example: PDC = 9, (user setting)

Tbs = 100ms

then

Tpdc = (9+1) x 100ms = 1 sec.

If SC = 0, the result is multplied by 16, and Tbd becomes the

time basis for the compensation rate, where:

Tbd = Tbd1 + Tbd2 (Section 1.5.2)

Example: PDC = 5, (user setting)

Tbd = 31ms

then

Tpdc = (5+1) x 31ms x 16 = 2.98 sec

NDC operates in exactly the same way as PDC.

2.2.1 P

Range: 0..255; Default: 100; 255 disables

Ability to compensate for drift with increasing signals.

PDC corrects the reference when the signal is drifting up.

Every interval of time the device checks each channel for the

need to move its reference level in the positive direction in

accordance with signal drift. The resulting timing interval for

this adjustment is Tpdc.

This value should not be set too fast, since an approaching

finger could be compensated for partially or entirely before

even touching the sense electrode. Tpdc is common to both

sensing channels and cannot be independently adjusted.

2.2.2 N

Range: 0...255 Default: 2; 255 disables

Aability to compensate for drift with decreasing signals.

This corrects the reference level when the signal is

decreasing due to signal drift. This should normally be faster

than positive drift compensation in order to compensate

quickly for the removal of a touch or obstruction from the

electrode after a MOD

recalibration (Section 1.5.3).

This parameter is common to

both channels. The resulting

timing interval for this

adjustment is Tndc.

OSITIVE DRIFT COMPENSATION

EGATIVE DRIFT COMPENSATION

(PDC)

(NDC)

2.3 THRESHOLDS (THR1, THR2)

Range: 1..16; Default: 6

Affects sensitivity.

The detection threshold is set independently for each channel

via the cloning process. Threshold is measured in terms of

counts of signal deviation with respect to the reference level.

Higher threshold counts equate to less sensitivity since the

signal must travel further in order to cross the detection point.

If the signal equals or exceeds the threshold value, a

detection can occur. The detection will end only when the

signal become less than the hysteresis level.

2.4 HYSTERESIS (HYS1, HYS2)

Range: 0...16; Default: 2

Affects detection stability.

The hysteresis levels are set independently for each channel

via the cloning process. Hysteresis is measured in terms of

counts of signal deviation below the threshold level. Higher

values equate to more hysteresis. The channel will become

inactive after a detection when the signal level falls below

THRn-HYSn. Hysteresis prevents chattering of the OUT pin

when there is noise present.

If HYS1 or HYS2 are set to a value equal or greater than

THR1 or THR2 respectively, the channel may malfunction.

Hysteresis should be set to between 10% and 40% of the

threshold value for best results.

If THR1 = 10 and HYS1 = 2, the hysteresis zone will represent

20% of the threshold level. In this example the ‘hysteresis

zone’ is the region from 8 to 10 counts of signal level. Only

when the signal falls back to 7 will the OUT pin become

inactive.

lQ

Figure 2-2 Detect Integrator Filter Operation

8 QT320/R1.03 08/02

2.5 DETECT INTEGRATORS (DIA, DIB, DIS)

DIAT1, 2 Range: 1..256 Default: 10

DIBT1, 2 Range: 1..6 Default: 6

DIS Range: 0, 1 Default: 1

Affects response time Tdet.

See Figure 2-2 for operation.

It is usually desirable to suppress detections generated by

sporadic electrical noise or from quick contact with an object.

To accomplish this, the QT320 incorporates two detection

integrator (‘DI’) counters per channel that serve to confirm

detections and slow down response time. The counter pairs

operate independently for each sensing channel.

DIA / DIAT: The first counter, DIA, increments after each

burst if the signal threshold has been exceeded in that burst,

until DIA reaches its terminal count DIAT, after which the

corresponding OUT pin goes active. If the signal falls below

the threshold level prior to reaching DIAT, DIA resets.

DIA can also be viewed as a 'consensus' filter that requires

signal threshold crossings over ‘T’ successive bursts to create

an output, where ‘T’ is the terminal count (DIAT).

DIA1 / DIAT1 and DIA2 / DIAT2 are used in conjunction with

their respective channels.

DIB / DIBT: If OUT is active and the signal falls below the

hysteresis level, detect integrator DIB, counts up towards

terminal count DIBT; when DIBT is reached, OUT is

deactivated. DIBT is the same as DIAT if DIBT <= 6;

If DIAT > 6, then DIBT = 6.

DIBT cannot be adjusted separately from DIAT.

DIS: Because the DI counters count at the burst rate, slow

burst spacings can result in very long detection delays with

terminal counts above 1. To cure this problem, the burst rate

can be made faster while DIA or DIB is counting up. This

creates the effect of a gear-shifted detection process: normal

speed when there are no threshold crossings, and fast mode

when a detection is pending. The control bit for the fast DI

mode is referred to as DIS. DIS applies to both channels; it

cannot be enabled for just one channel.

DIS gear-shifts the effect of both DIA and DIB. The

gear-shifting ceases and normal speed resumes once the

detection is confirmed (DIA = DIAT) and once the detection

ceases (DIB = DIBT).

When SC=0 the device operates without any sleep cycles,

and so the timebase for the DI counters is very fast.

The MOD function can also be disabled, in which case the

channel will never recalibrate unless the part is powered down

and back up again. In infinite timeout the designer should

take care to ensure that drift in Cs, Cx, and Vdd do not cause

the device to ‘stick on’ inadvertently when the target object is

removed from the sense field.

MOD is expressed in multiples of the burst space interval,

which can be either Tbs or Tbd depending on the Sleep

Cycles setting (SC).

If SC > 0, the delay is:

Tmod = (MOD + 1) x 16 x Tbs

Example:

Tbs = 100ms,

MOD = 9;

Tmod = (9 + 1) x 16 x 100ms = 160 secs.

If SC = 0, Tmod is a function of the total combined burst

durations, Tbd. If SC = 0, the delay is:

Tmod = (MOD + 1) x 256 x Tbd

Example:

Tbd = 18ms,

MOD = 9;

Tmod = (9 + 1) x 256 x 18ms = 46 secs.

If MOD = 255, recalibration timeout = infinite (disabled)

regardless of SC.

An MOD induced recalibration will make an OUT pin inactive

except if the output is set to toggle mode (Section 2.7.2), in

which case the OUT state will be unaffected but the

underlying channel will have recalibrated.

2.7 OUTPUT FEATURES

Available output processing options accommodate most

requirements; these can be set via the clone process.

Both OUT pins are open-drain, and require pullup resistors.

2.7.1 DC M

In DC mode the OUT pins respond to detections with a

steady-state active logic level, this state will endure for the

length of time that a detection exists or until a MOD timeout

occurs (Section 2.6).

The polarity of OUT can be set via the cloning process. Each

channel can be set for this feature independently. Either

active-low or active-high can be selected.

ODE

, P

OLARITY

2.6 MAX ON-DURATION (MOD)

Range: 0..255; Default: 14; 255 disables

Affects parameter Tmod, the calibration delay time

If a stray object remains on or near the sense electrode, the

signal may rise enough to activate an OUT pin thus

preventing normal operation. To provide a way around this, a

Max On-Duration (‘MOD’) timer is provided to cause a

channel recalibration if the activation lasts longer than the

designated timeout, Tmod.

The timeout applies individually per channel. If one channel is

active for the Max On-duration interval it will recalibrate, but

the other channel will remain unaffected.

lQ

2.7.2 T

Toggle mode gives OUT pins a touch-on / touch-off flip-flop

action, so that its state changes with each detection. It is most

useful for controlling power loads, for example kitchen

appliances, power tools, light switches, etc.

MOD time-outs (Section 2.6) will recalibrate the underlying

channel but leave the OUT state unchanged.

OUT polarity (Section 2.7.1) has no effect when toggle mode

is engaged. The initial state at power-up of the OUT pins in

toggle mode is always open drain (logic high).

Each channel can be set individually for this feature.

OGGLE MODE

9 QT320/R1.03 08/02

Vdd

8

OUT1

OUT2

RE3

RE4

VDD

1

OUT1

7

OUT2 S2A

VSS

4

S1A

S1B

S2B

3

5

6

2

Figure 3-1 ESD/EMC protection resistors

CS1

CS2

RE1

RE2

SENSOR 1

SENSOR 2

3.2 POWER SUPPLY

3.2.1 S

The QT320 derives its internal references from the power

supply. Sensitivity shifts and timing changes will occur with

changes in Vdd, as often happens when additional power

supply loads are switched on or off via one of the Out pins.

These supply shifts can induce detection ‘cycling’, whereby

an object is detected, the load is turned on, the supply sags,

the detection is no longer sensed, the load is turned off, the

supply rises and the object is reacquired, ad infinitum.

Detection ‘stiction’, the opposite effect, can occur if a load is

shed when an output is active and the signal swings are

small: the Out pin can remain stuck even if the detected

object is no longer near the electrode.

TABILITY

2.7.3 H

EARTBEAT

™ O

UTPUT

Both OUT pins have HeartBeat™ ‘health’ indicator pulses

superimposed on them. Heartbeat floats both 'OUT' pins for

approximately 15µs once before Channel 2’s burst.

These pulses can be used to determine that the sensor is

operating properly. The pulses are evident on an OUT line

that is low, and appear as positive pulses.

They are not evident on an OUT pin that is high.

Heartbeat indication can be used to determine if the chip is

operating properly. The frequency of the pulses can be used

to determine if the IC is operating within desired limits.

It is not possible to disable these pulses.

Heartbeat pulses can be easily filtered by placing a suitable

capacitor from an OUT pin to Vss, to prevent the OUT line

from rising substantially within the 15µs pulse. For example,

with a 10K pullup resistor, the capacitor can be 0.015µF of

virtually any type.

2.7.4 O

UTPUT DRIVE CAPABILITY

The outputs can sink up to 2mA of non-inductive current. If an

inductive load is used, such as a small relay, the load should

be diode-clamped to prevent damage. The current must be

limited to 2mA max to prevent detection side effects from

occurring, which happens when the load current creates

voltage drops on the die and bonding wires; these small shifts

can materially influence the signal level to cause detection

instability.

3 CIRCUIT GUIDELINES

3.1 SAMPLE CAPACITORS

Cs capacitors can be virtually any plastic film or low to

medium-K ceramic capacitor. The normal usable Cs range is

from 1nF ~ 200nF depending on the sensitivity required;

larger values of Cs require higher stability to ensure reliable

sensing. Acceptable capacitor types include NPO or C0G

ceramic, PPS film, Y5E and X7R ceramic in that order.

If the design requires sensitivity matching between channels,

it is strongly advised to use tight tolerance capacitors and to

trim the relative sensitivities as described in Section 1.4.4.

3.2.2 S

UPPLY REQUIREMENTS

Vdd can range from 1.8 to 5.25 volts during operation, and

2.2 to 5.25 during eeprom Setups configuration. Current drain

will vary depending on Vdd, the chosen sleep cycles, and the

burst lengths. Increasing Cx values will decrease power drain

since increasing Cx loads decrease burst length (Figures 5-1,

5-4).

If the power supply is shared with another electronic system,

care should be taken to assure that the supply is free of

spikes, sags, and surges. The QT320 will track slow changes

in Vdd if drift compensation is enabled, but it can be adversely

affected by rapid voltage steps and spikes at the millivolt

level.

If desired, the supply can be regulated using a conventional

low current regulator, for example CMOS LDO regulators with

low quiescent currents, or standard 78Lxx-series 3-terminal

regulators.

For proper operation a 100nF (0.1uF) ceramic bypass

capacitor should be used between Vdd and Vss; the bypass

cap should be placed very close to the Vdd and Vss pins.

3.3 PCB LAYOUT

3.3.1 G

The use of ground planes around the device is encouraged

for noise reasons, but ground should not be coupled too close

to the four sense pins in order to reduce Cx load. Likewise,

the traces leading from the sense pins to the electrode should

not be placed directly over a ground plane; rather, the ground

plane should be relieved by at least 3 times the width of the

sense traces directly under it, with periodic thin bridges over

the gap to provide ground continuity.

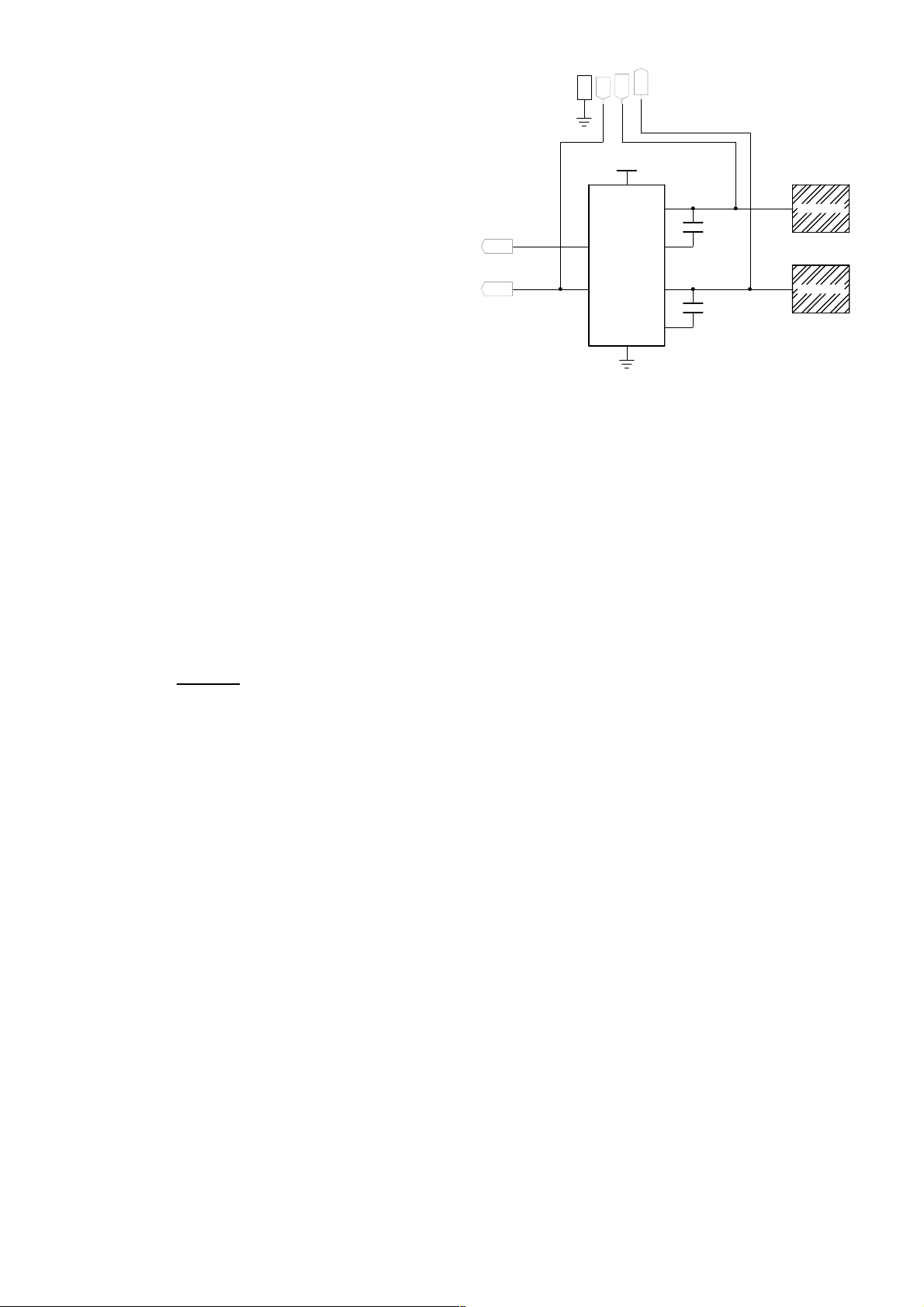

3.3.2 C

If a cloning connector is used, place this close to the QT320

(Figure 4-1). Placing the cloning connector far from the

QT320 will increase the load capacitance Cx of the sensor

and decrease sensitivity, as some of the cloning lines are

sense lines. Long distances on these lines can also make the

clone process more susceptible to communication errors from

ringing and interference.

Cloning can be designed for production by using pads (SMT

or through-hole) on the solder side which are connected to a

fixture via spring loaded ATE-style ‘pogo-pins’. This eliminates

the need for an actual connector to save cost.

ROUND PLANES

LONE PORT CONNECTOR

lQ

10 QT320/R1.03 08/02

3.4 ESD ISSUES

8

S2A

S1A

2

6

3

4

S2B

S1B

5

SCK

OUT2

VSS

7

OUT2

SENSOR 2

SENSOR 1

OUT1

OUT1

1

Vdd

VDD

CS1

GND

SDI

SDO

CS2

In cases where the electrode is placed behind a dielectric

panel, the device will usually be well protected from static

discharge. However, even with a plastic or glass panel,

transients can still flow into the electrode via induction, or in

extreme cases, via dielectric breakdown. Porous materials

may allow a spark to tunnel right through the material;

partially conducting materials like 'pink poly' static dissipative

plastics will conduct the ESD right to the electrode. Panel

seams can permit discharges through edges or cracks.

Testing is required to reveal any problems. The QT320 has

internal diode protection which can absorb and protect the

device from most induced discharges, up to 20mA; the

usefulness of the internal clamping will depend on the

dielectric properties, panel thickness, and rise time of the

ESD transients.

ESD protection can be enhanced with an added resistor as

shown in Figure 3-1. Because the charge and transfer times

of the QT320 are 1us in duration, the circuit can tolerate

values of Re which result in an RC timeconstant of about

200ns. The ‘C’ of the RC is the Cx load on the distant side

from the QT320. Thus, for a Cx load of 20pF, the maximum

Re should be 10K ohms. Larger amounts of Re will result in

an increasingly noticeable loss of sensitivity.

3.5 EMC ISSUES

Electromagnetic and electrostatic susceptibility are often a

problem with capacitive sensors. QT320 behavior under these

conditions can be improved by adding the series-R shown in

Figure 3-1, exactly as shown for ESD protection. The resistor

should be placed next to the chip.

This works because the inbound RC network formed by Re

and Cs has a very low cutoff frequency which can be

computed by the formula:

Fc =

1

2✜ Re Cs

If Re = 10K and Cs = 10nF, then Fc = 1.6kHz.

This leads to very strong suppression of external fields.

Nevertheless, it is always wise to reduce lead lengths by

placing the QT320 as close to the electrodes as possible.

Likewise, RF emissions are sharply curtailed by the use of

Re, which bandwidth limits RF emissions based on the value

of Re and Cx, the electrode capacitance.

Line conducted EMI can be reduced by making sure the

power supply is properly bypassed to chassis ground. The

OUT lines can also be paths for conducted EMI, and these

can be bypassed to circuit ground with an RC filter network.

4 PARAMETER CLONING

The cloning process allows user-defined settings to be loaded

into internal eeprom, or read back out, for development and

production purposes.

The QTM300CA cloning board in conjunction with QT3View

software simplifies the cloning process greatly. The E3B eval

Figure 4-1 Clone interface wiring

board has been designed with a connector to facilitate direct

connection with the QTM300CA. The QTM300CA in turn

connects to any PC with a serial port which can run QT3View

software (included with the QTM300CA and available on

Quantum’s web site).

The connections required for cloning are shown in Figure 4-1.

Further information on the cloning process can be found in

the QTM300CA instruction guide. Section 3.3.2 discusses

wiring issues associated with cloning.

The parameters which can be altered are shown in Table 4-1

(next page).

Parameters that can be altered for each channel

independently are:

Threshold

Hysteresis

Detect Integrator A

Detect Integrator B

Max On-Duration

Output Mode

Parameters that are common to the entire part are:

Detect Integrator Speed

Negative Drift Compensation

Positive Drift Compensation

Sleep Cycles

It is possible for an on-board host controller to read and

change the internal settings via the interface, but doing so will

inevitably disturb the sensing process even when data

transfers are not occuring. The additional capacitive loading

of the interface pins will contribute to Cx; also, noise on the

interface lines can cause erratic operation.

The internal eeprom has a life expectancy of 100,000

erase/write cycles.

A serial interface specification for the device can be obtained

by contacting Quantum.

lQ

11 QT320/R1.03 08/02

TABLE 4-1 SETUPS SUMMARY CHART

Det Integrator A

Channel 1

Specific

Channel 2

Specific

Features

Common

To Both

Channels

Note 1: Tbs is the combined (summed) burst duration of Channel1 and Channel2 (Tbd).

Note 2: Tbs is variable with the voltage, see figure 5-7. If Tbd is longer than 10ms,Tbs is Tbd plus the sleep time find on figure 5-7.

Note 5: The sleep period time is find on figure 5-7(equivalent at 1 sleep period).

Det Integrator B

Max-On Duration

Output Mode

Threshold

Hysteresis

DI Speed

Negative Drift

Compensation

Positive Drift

Compensation

Sleep Cycles

MOD1

OUT1

MOD2Max-On Duration

OUT2Output Mode

DIS

NDC

PDC

SC

Finite0 - 254

Active Low 0

Active High1

Toggle2

Finite0 - 254

Active Low 0

Active High 1

Toggle2

Slow0

Fast1

On0 - 254

14 (~10s at 3V)

14 (~10s at 3V)

1

2 (~0.13s/bit

@ 3V)

On0 - 254

No Sleep0

Sleep1 - 255

100 (~4.36s/bit

@ 3V)

1 (~47ms Tbs

@ 3V)

Value taken from DIAT1 but truncated to 66-1 - 6DIBT1

Tmod = (MOD1 + 1) x 256 x Tbs (note1)SC = 0

Tmod = (MOD1 + 1) x 16 x Tbs (note2)SC > 0Infinite255

Requires pullup resistor on OUT10

Value taken from DIAT2 but truncated to 66-1 - 6DIBT2Det Integrator B

Tmod = (MOD2 + 1) x 256 x Tbs (note1)SC = 0

Tmod = (MOD2 +1) x 16 x Tbs (note2)SC > 0Infinite255

Requires pullup resistor on OUT20

Tndc = (NDC + 1) x 16 x Tbs (note1)SC = 0

Tndc = (NDC + 1) x Tbs (note2)SC > 0Off255

Tpdc = (PDC + 1) x 16 x Tbs (note1)SC = 0

Tpdc = (PDC + 1) x Tbs (note2)SC > 0Off255

UnitCalculation / NotesDefaultValid ValuesSymbolDescription

CountsHigher = less sensitive6-1 - 16THR1Threshold

CountsHigher = more hysteresis2-0 - 16HYS1Hysteresis

Burst CyclesHigher = longer to detect, more noise immune10-1 - 256DIAT1

Seconds

-

-

-

CountsHigher = less sensitive6-1 - 16THR2

CountsHigher = more hysteresis2-0 - 16HYS2

Burst CyclesHigher = longer to detect, more noise immune10-1 - 256DIAT2Det Integrator A

Seconds

-

-

-

-

-

-

-

Seconds / bit

change

Seconds / bit

change

CountsBurst rep interval = Tbs = SC x Ti

lQ

12 QT320/R1.03 08/02

5 ELECTRICAL SPECIFICATIONS

5.1 ABSOLUTE MAXIMUM SPECIFICATIONS

Operating temp.................................................................................as designated by suffix

Storage temp........................................................................................ -65

V

DD

...................................................................................................... -0.5 to +6V

Max continuous pin current, any control or drive pin.............................................................. ±40mA

Short circuit duration to ground, any pin..........................................................................infinite

Short circuit duration to V

DD

, any pin.............................................................................infinite

Voltage forced onto any pin................................................................... -0.5V to (Vdd + 0.5) Volts

5.2 RECOMMENDED OPERATING CONDITIONS

VDD..................................................................................................... +1.8 to 5.5V

V

DD

during eeprom writes................................................................................. +2.2 to 5.5V

Short-term supply ripple+noise.................................................................................. ±5mV

Long-term supply stability..................................................................................... ±100mV

Cs value................................................................................................ 1nF to 200nF

Cx value.................................................................................................. 0 to 100pF

5.3 AC SPECIFICATIONS

Vdd = 3.0, Ta = recommended operating range, Cs=100nF unless noted

NotesUnitsMaxTypMinDescriptionSymbol

RC

PC

PT

BL

HB

µs1Charge durationT

µs1Transfer durationT

µs15Heartbeat pulse widthT

Cs, Cx dependentms150Recalibration timeT

Cs = 10nF to 200nF; Cx = 0ms250.5Burst lengthT

O

C to +150OC

5.4 SIGNAL PROCESSING

5.5 DC SPECIFICATIONS

Vdd = 3.0V, Cs = 10nF, Cx = 5pF, Ta = recommended range, unless otherwise noted

DD

DDW

DD

DDS

IL

IH

OL

X

R

V5.251.8Supply voltageV

V5.252.2Vdd during eeprom writeV

pF2000Load capacitance rangeC

bits16Acquisition resolutionA

NotesUnitsMaxTypMinDescriptionSymbol

counts161Threshold differential w.r.t. reference

counts150Hysteresis w.r.t. threshold

samples2561Consensus filter length

ms/bit-Positive drift compensation rate

ms/bit-Negative drift compensation rate

secsinfinite<1Post-detection recalibration timer duration

NotesUnitsMaxTypMinDescriptionSymbol

Depends on setting of Sleep CyclesµA1,50060060Supply currentI

Required for proper start-upV/s100Supply turn-on slopeV

Vdd = 2.5 to 5.0VV0.3 VddInput low voltageV

Vdd = 2.5 to 5.0VV0.6 VddInput high voltageV

OUT1, OUT2, 2mA sinkV0.4Low output voltageV

Threshold = 6; ref. Figure 5-3pF0.4Sensitivity range, Channel 1S1

Threshold = 6; ref. Figure 5-4pF0.6Sensitivity range, Channel 2S2

lQ

13 QT320/R1.03 08/02

10.00

10.00

1.00

0.10

Detection Threshold, pF

0.01

0 1020304050

Cx Load

Figure 5-1 Typical Ch 1 Sensitivity vs. Cx;

Threshold = 16, Vdd = 3.0

10.00

1.00

0.10

Detection Threshold, pF

4.7nF

9nF

19nF

43nF

74nF

124nF

200nF

4.7nF

9nF

19nF

43nF

74nF

124nF

200nF

1.00

0.10

Detection Threshold, pF

0.01

0 1020304050

Cx Load

Figure 5-2 Typical Ch 2 Sensitivity vs. Cx;

Threshold = 16, Vdd = 3.0

10.00

1.00

0.10

Detection Threshold, pF

4.5nF

9nF

19nF

43nF

74nF

124nF

200nF

4.7nF

9nF

19nF

43nF

74nF

124nF

200nF

0.01

0 10203040 50

Figure 5-3 Typical Ch 1 Sensitivity vs. Cx;

Threshold = 6, Vdd = 3.0

lQ

Cx Load

0.01

0 1020304050

Cx Load

Figure 5-4 Typical Ch 2 Sensitivity vs. Cx;

Threshold = 6, Vdd = 3.0

14 QT320/R1.03 08/02

25.000

25.000

20.000

15.000

10.000

Burst Length (ms)

5.000

0.000

52

118

228

507

Sampling Capacitor (nF)

884

1450

2357

Cx = 48pF

Figure 5-5 Typical Ch 1 burst length vs Cx, Cs;

Vdd = 3.0

180

160

140

120

100

80

60

Burst Spacing (ms)

40

20

0

1.5 2 2.5 3 3.5 4 4.5 5 5.5

Cx = 0pF

Cx = 21pF

Load (pf)

Power Supply (Volts)

20.000

15.000

10.000

Burst Length (ms)

5.000

0.000

52

118

228

507

884

1450

Sampling Capacitor (nF) Load (pF)

Cx = 48pF

2357

Figure 5-6 Typical Ch 2 burst length vs Cx, Cs;

Vdd = 3.0

Cx = 0pF

Cx = 21pF

lQ

Figure 5-7 Typical total burst spacing vs. Vdd;

SC = 1, Tbd < 10ms

15 QT320/R1.03 08/02

450

400

350

300

250

200

Cuurent (uA)

150

100

50

0

0 102030405060

Sampling Capacitor (nF)

Figure 5-8 Idd current vs Cs; Vdd = 2.0

900

800

700

600

500

400

Current (uA)

300

200

100

0

0 102030405060

Sampling Capacitor (nF)

Sleep Cyc les

None

One

Two

Three

Five

Sleep Cycles

None

One

Two

Three

Five

Ten

Figure 5-9 Idd current vs Cs; Vdd = 3.3

2000

1800

1600

1400

1200

1000

800

Current (uA)

600

400

200

0

0 102030405060

Sampling Cap acitor (nF)

Figure 5-10 Idd current vs Cs; Vdd = 5.0

Sleep Cycles

None

One

Two

Thre e

Five

Ten

lQ

16 QT320/R1.03 08/02

Pin 1

SYMBOL

m

M

F

A

S1

a

A

r

S

L2

x

Q

L1 L

Package type: 8-pin Dual-In-Line

InchesMillimeters

0.280.247.116.1a

0.3250.38.267.62A

0.40.35510.169.02M

0.0370.0270.940.69Q

0.0220.0140.5590.356L

0.070.0451.781.14L1

0.0120.0080.3050.203L2

-0.015-0.38r

0.150.1153.812.92S

0.21-5.33-S1

0.4310.9x

NotesMaxMinNotesMaxMin

Typical-0.3Typical-7.62m

BSC-0.1BSC-2.54F

Pin 1

SYMBOL

φ

M

M

a

A

H

φ

h

e

E

Package type: 8-pin Wide SOIC

InchesMillimeters

0.2130.2055.415.21a

0.330.38.387.62A

0.2120.2035.385.16M

0.020.0120.5080.305L

0.0130.0040.330.102h

0.080.072.031.78H

0.010.0070.2540.178e

0.0350.020.8890.508E

o

0

o

8

o

0

o

8

NotesMaxMinNotesMaxMin

BSC0.05BSC1.27F

lQ

17 QT320/R1.03 08/02

lQ

Tel: +44 (0)23 8056 5600 Fax: +44 (0)23 8045 3939

This device expressly not for use in any medical or human safety related

application without the express written consent of an officer of the company.

©2002 QRG Ltd.

Patented and patents pending

Corporate Headquarters

1 Mitchell Point

Ensign Way, Hamble SO31 4RF

Great Britain

admin@qprox.com

www.qprox.com

North America

651 Holiday Drive Bldg. 5 / 300

Pittsburgh, PA 15220 USA

Tel: 412-391-7367 Fax: 412-291-1015

Specifications subject to change.

Loading...

Loading...