LQ QT300

C

APACITANCE TO

Capacitance to Digital Converter (CDC) IC

Direct-to-digital conversion, 16 bits

Log response: Wide dynamic range

Outputs raw data to a host device

Single wire UART interface

Master or Slave mode SPI interface

Programmable clock speed

Turns objects into intrinsic touch sensors

One external sample capacitor to control gain

Multiple QT300’s possible on one SPI bus

The QT300 charge-transfer (“QT’”) IC is a self-contained Capacitance-toDigital-Converter (CDC) capable of detecting femotofarad level changes in

capacitance. While designed primarily for instrumentation applications, it can be used

also for touch control applications where signal processing is best handled by a host

MCU.

Primary applications include fluid level sensors, distance sensors, transducer

‘amplifiers’ for pressure and humidity sensing functions, material detectors, and other

uses requiring quantified capacitance data.

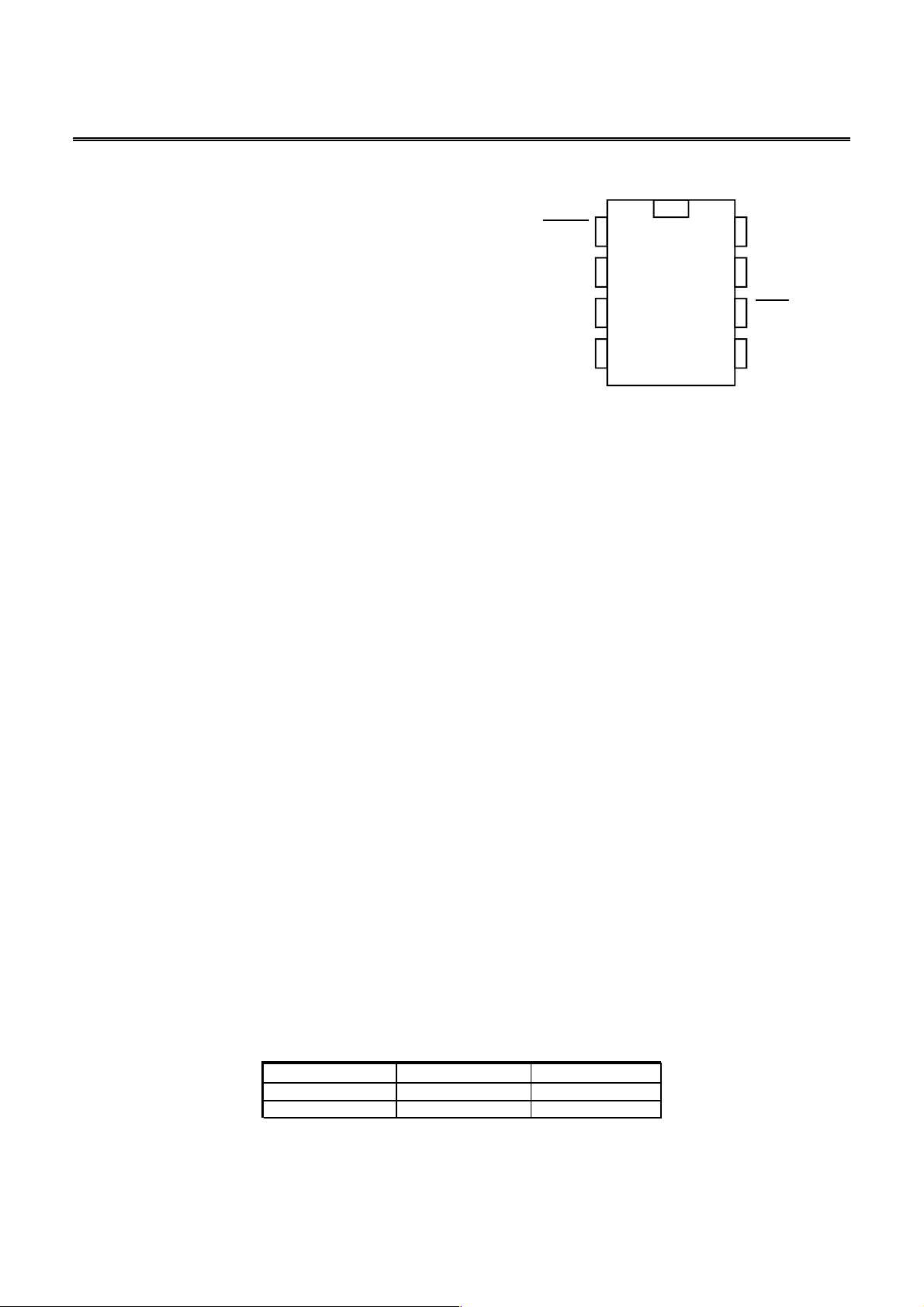

DRDY 1

SCK

SNS1

D

IGITAL

C

ONVERTER

8

Vdd

QT300

7

6

SDO

REQ / 1W

SNS2Vss

2

3

45

APPLICATIONS

Fluid level sensors

Prox sensors

Moisture detection

Position sensing

Transducer driver

Material sensors

Unlike other Quantum products, the QT300 does not process its acquired data. Its only result is raw, unprocessed binary

data which can be transmitted to a host via either a bidirectional SPI interface or a simple polled single wire UART type

interface. This allows the designer to treat the device as a capacitance-to-digital-converter (CDC) for measurement

applications. It is ideal for situations where there are unique signal processing requirements.

The device requires only a single sampling capacitor to function. The value of this capacitor controls the gain of the sensor,

and it can be adjusted over 2½ decades of range from 1nF to 500nF. No external switches, opamps, or other components

are required.

The device operates on demand, and can be synchronized to allow several QT300’s to operate near each other without

cross-interference.

AVAILABLE OPTIONS

A

0

C to +700C

8-PIN DIPSOICT

QT300-D-0

-QT300-IS-400C to +850C

LQ

Copyright © 2002 QRG Ltd QT300 R1.01 21/09/03

Table 1-1 SPI Mode Pin Description

FunctionNamePin

Data Ready/DRDY1

Serial data clockSCK2

Sense 1 lineSNS13

Negative supply (ground)VSS4

Sense 2 lineSNS25

Request input/REQ6

Serial data outSDO7

Positive supplyVDD8

Table 1-2 1W UART Mode Pin Description

FunctionNamePin

Connect to Vdd or Vss-1

Connect to Vdd or Vss-2

Sense 1 lineSNS13

Negative supply (ground)VSS4

Sense 2 lineSNS25

1W UART Line1W6

Connect to Vdd or Vss-7

Positive supplyVDD8

Table 1-3 Alternate Cloning Pin Functions

FunctionNamePin

Serial clone data clockSCK2

Serial clone data inSDI6

Serial clone data outSDO7

1 - OVERVIEW

The QT300 is a digital burst mode charge-transfer (QT)

capacitance-to-digital converter (CDC) designed for

applications requiring raw signal information such as fluid

level sensing and distance gauging; it outputs raw digital

signal data over a serial interface. The output data is in a

16-bit format; signal levels depend on load (Cx) and the

sampling capacitor value (Cs).

1.1 Basic Operation

The QT300 does no internal signal processing; data is simply

returned via one of two serial port types.

There are two basic types of serial interface: 4-wire SPI and

a simple single wire (‘1W’) UART. The SPI interface allows

multiple devices to be connected on one SPI bus, while

the1W UART requires that the controller have one dedicated

pin for each QT300. There are two types of SPI mode,

master and slave.

The type of serial port and its mode can be selected via the

cloning process using a QTM300CA programming adapter.

The QT300 operates only on request from a host device.

After initiation via a trigger signal, the QT300 generates an

acquisition burst and sends the resulting raw signal data

back via one of the serial modes.

Vdd

SCK

SDO

8

Vcc

GND

4

SNS 1

SNS 2

100nF

3

SENSOR

5

CS

DRDY

SCK

Host Micro

REQ REQ

SDI

QT 300

1

2

6

7

DRDY

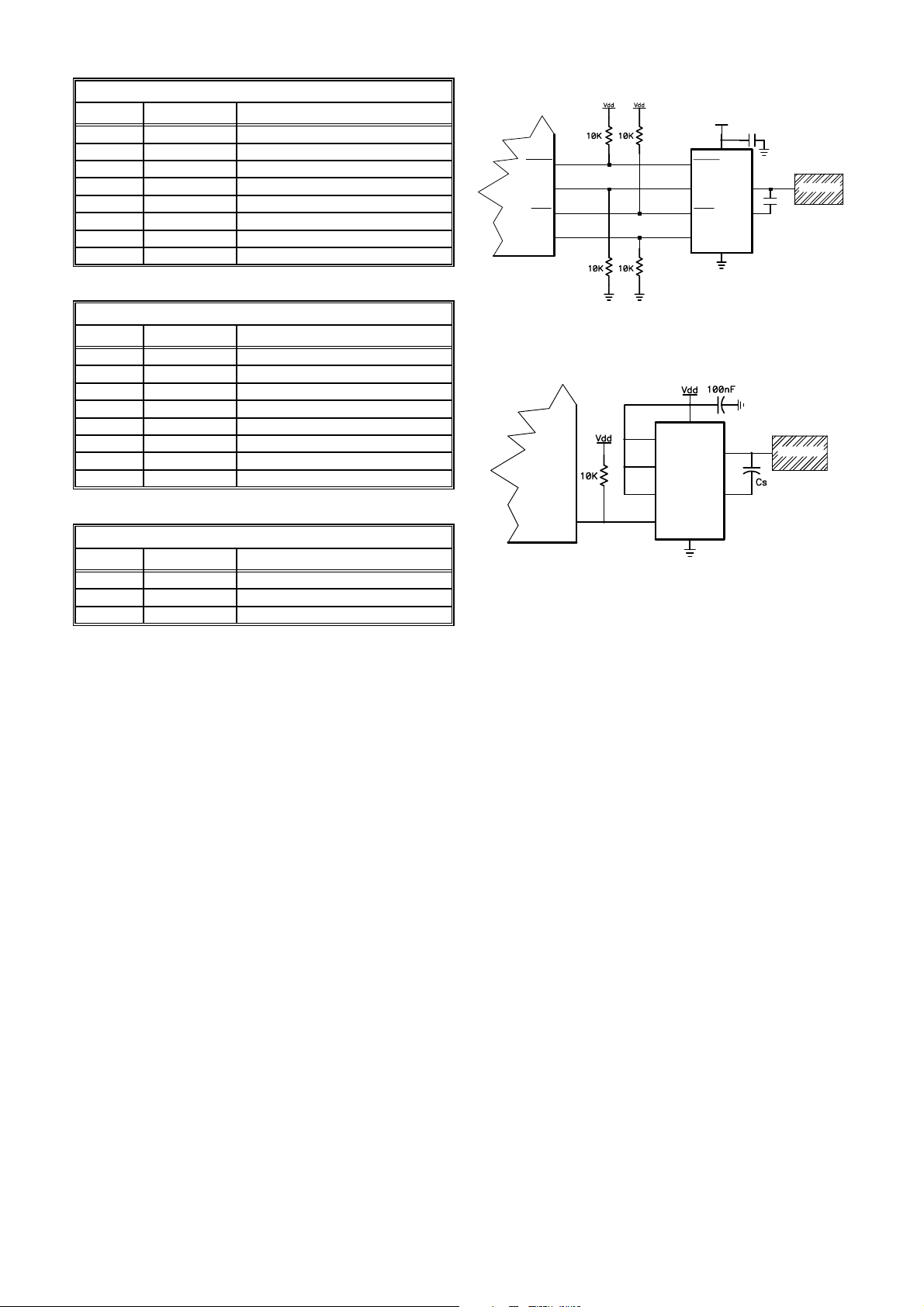

Figure 1-1 Basic QT300 Circuit in SPI mode.

QT300

8

Vdd

Host Micro

(1W UART)

1

2

7

Rx

6

1W

Vss

4

SNS1

SNS2

3

5

Electrode

Figure 1-2 Basic QT300 Circuit in UART mode.

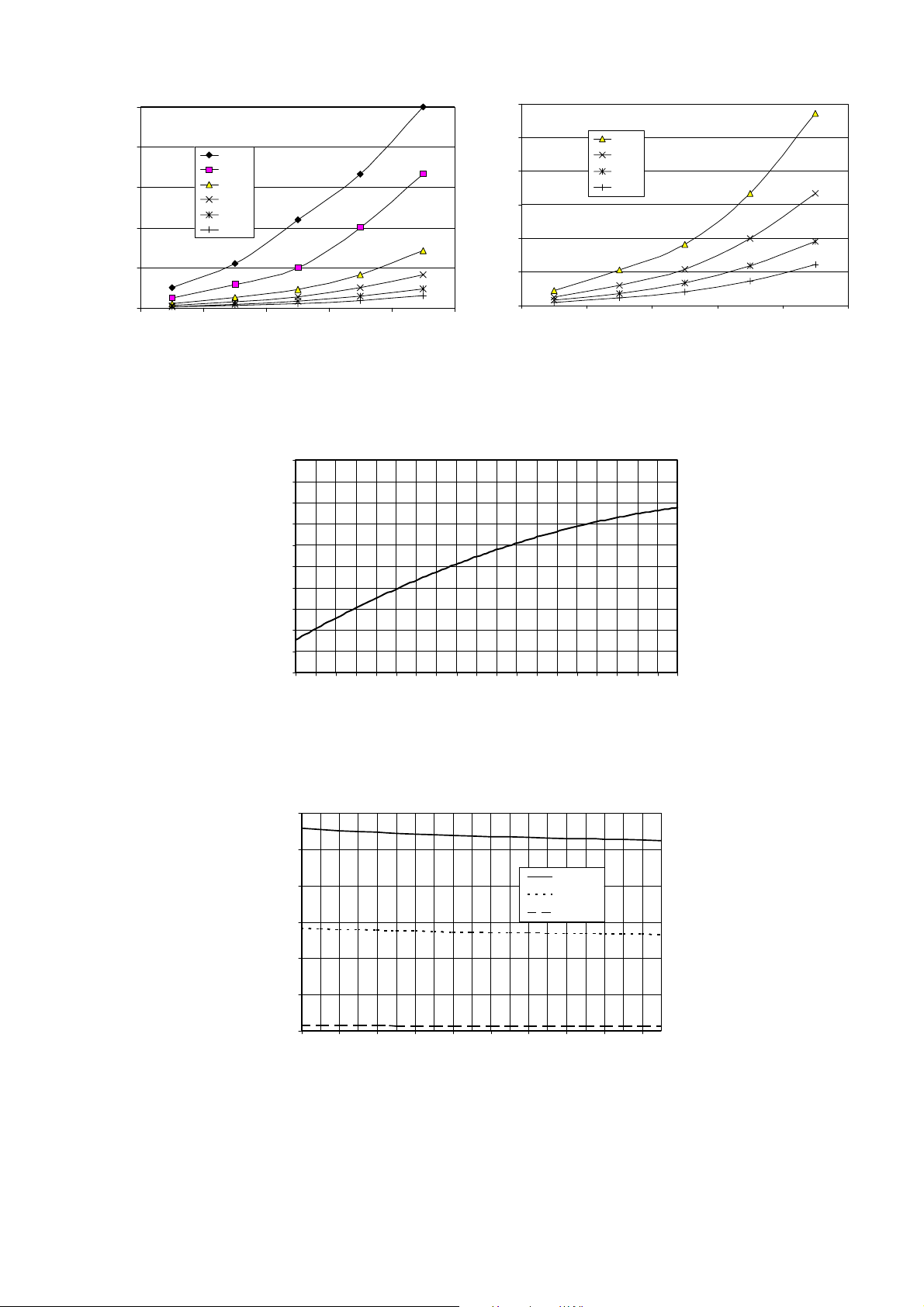

1.2 CS / CX Dependency

The value returned is a direct function of Cs, the fixed sample

capacitor and Cx, the unknown or variable capacitance.

These two values influence device sensitivity and response

time, making them very important parameters.

Sensitivity is also a function of electrode size, shape,

orientation, the composition and aspect of the object being

sensed, the thickness and composition of any dielectric

overlaying the electrode, and the degree of mutual coupling

between the electrode and the object being sensed.

The response follows a logarithmic curve (Figures 7-4, 7-5,

Page 10); each doubling of Cs increases the signal level and

differential sensitivity by a factor of 2. Likewise, doubling Cx

reduces the signal level and differential sensitivity by a factor

of 2.

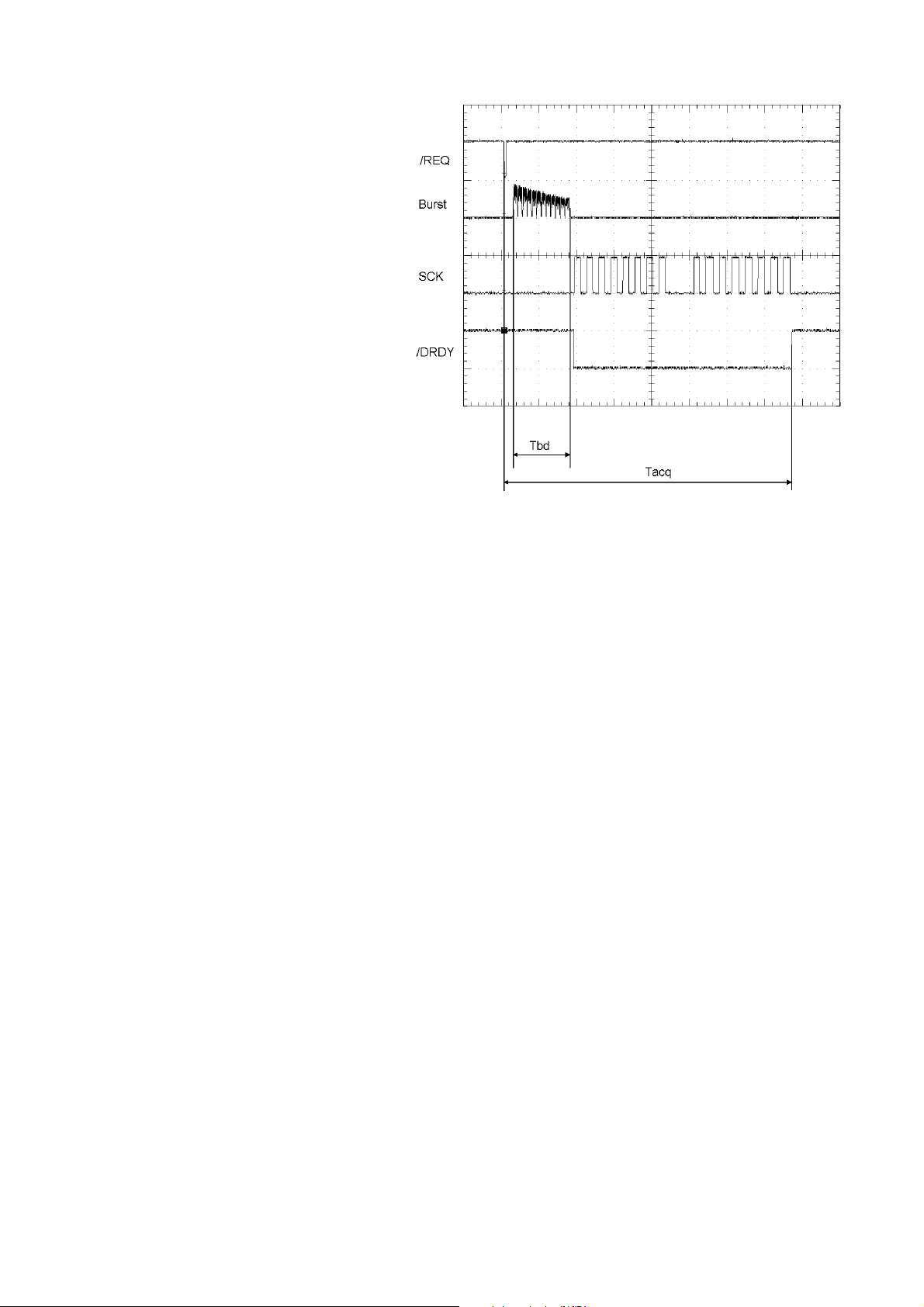

2 - Timing

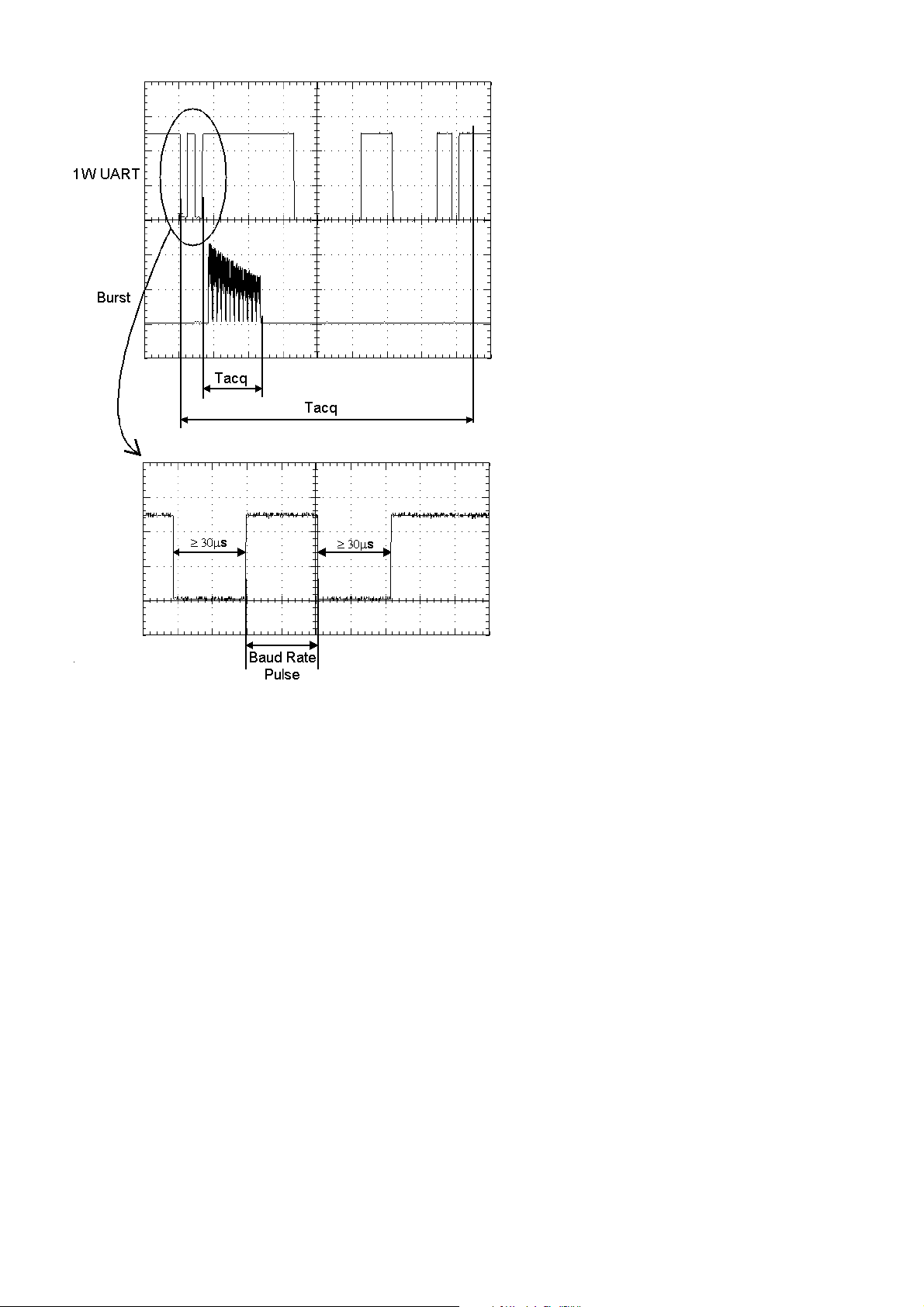

Figure 2-1 shows the basic QT300 acquisition timing

parameters. The basic timing parameters are:

Tbd Burst duration (2.1)

Tacq Acquire response time (2.2)

Tbs Burst Spacing (2.3)

2.1 Tbd - Burst duration

The burst duration depends on the values of Cs and Cx and

to a lesser extent, Vdd. The burst is composed of

charge-transfer cycles operating at about 240kHz.

LQ

2

QT300 R1.01 21/09/03

The length of this burst is an important

parameter as it is directly related to the signal

value. The burst duration also affects the

response time of the sensor; the larger Cs is, the

longer the burst, the slower the possible

acquisition rate.

2.2 Tacq - Acquire Response Time

The time from the /REQ or 1W line going low

until the completion of data transmission is

Tacq. Tacq depends on the acquisition burst

length as well as the serial transmission time.

SPI Mode: In SPI mode Tacq depends in part on

the serial clock speed and the space between

the returned high and low bytes. In SPI slave

mode the clock speed and the inter-byte spacing

time Tbdly is determine by the host. In SPI

Master mode these timings are set by Setup

parameters SCD and MLS.

1W mode: Tacq depends in part on the Baud

rate as well as the inter-byte spacing. The Baud

rate is auto-set by the trigger pulse width; the

inter-byte spacing is set by the MLS parameter.

See Section 4.

2.3 Tbs - Burst Spacing

Burst spacing is the time from the start of one

acquisition burst to the start of the next burst. It

depends on the host’s trigger rate on the /REQ or 1W pin.

The QT300 only acquires when the host requests it.

While waiting for a new request the part is in a low power

mode.

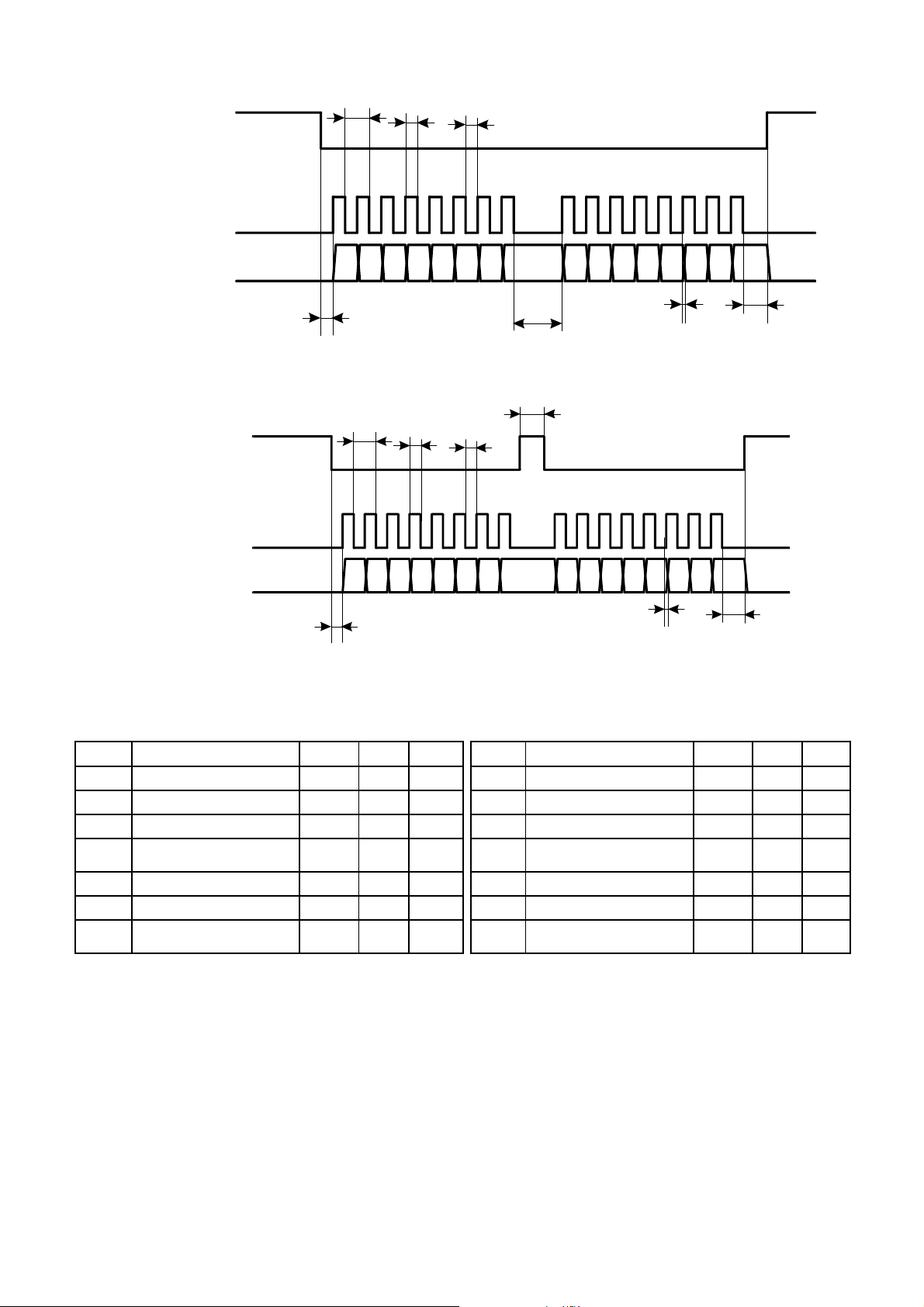

3 - SPI Port

3.1 SPI Specifications

The QT300 can operate in master or slave mode, and thus is

compatible with virtually all SPI-capable microcontrollers. The

SPI interface has the following specifications:

Max clock rate, Fckm 40KHz (master mode)

Max clock rate, Fcks 40KHz (slave mode)

Data length 2 bytes (16 bits total)

Inter-byte delay ≥8µs (master mode)*

≥12µs (slave mode)

Clock idle logic level Low or High*

Clock edge Data out on rising or falling edge*

Data sequence High byte first, MSB first

*Determined by Setups

The host can clock the SPI at any rate up to and including

the maximum. The maximum clock rate of the part in Master

mode is determined in Setups via cloning.

3.2 Protocol Overview

The QT300 only transmits data on request, after an

acquisition burst. The host requests an acquire by setting the

/REQ line low for at least 30µs; the device then acquires.

When finished, the DRDY line is pulled low by the QT300 to

indicate it is ready to send data. (Figure 2-1). The transfer is

done as two bytes, with the highest byte transferred first.

Figure 2-1 Signal Acquisition - Slave SPI Mode

In master mode, /DRDY goes high between bytes for the

period determined by Setup parameter MLS; this is a multiple

of 6µs.

When not communicating, all SPI lines float to allow multiple

chips to connect over the same SPI lines. A pullup or

pulldown resistor is required on SCK depending on the

selected clock phase, determined by Setups. A pullup

resistor is required on /DRDY. /REQ may require a pullup if

the host ever allows this line to float.

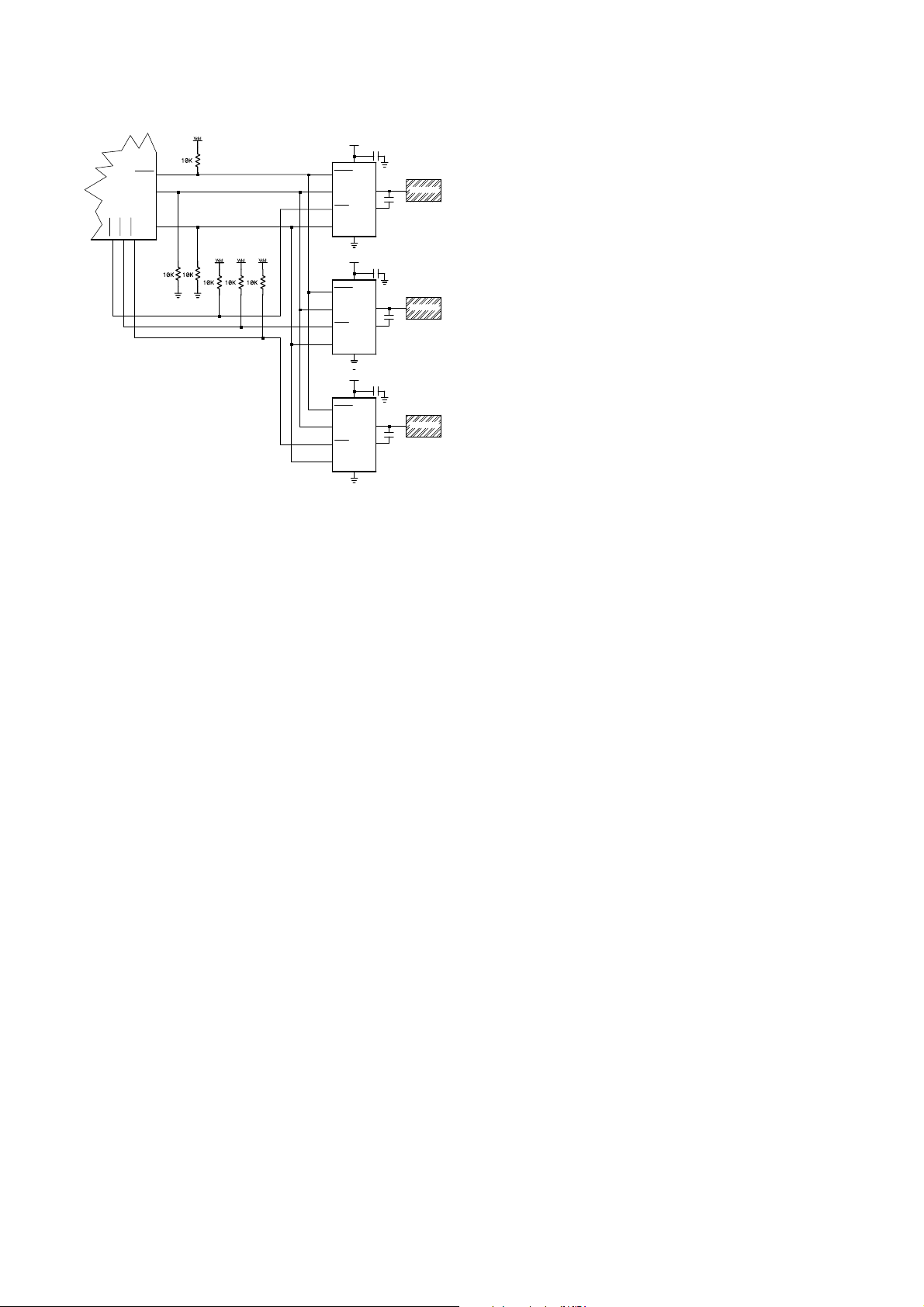

3.3 SPI Bus Sharing

All SPI float transfers making it possible to have several

QT300 devices (or other unrelated devices) share the SPI

control signals (Figure 3-1).

Each part needs an individual /REQ line, but /DRDY, SCK

and SDO can be connected together.

3.4 SPI Slave Mode

Refer to Figure 7-1 and Table 7-1, page 8.

In SPI Slave mode, /DRDY is used to let the host know when

data is ready for collection in response to a request so that

the host can clock over the data.

SPI Slave mode uses 4 signals:

/REQ - Request Acquisition Input; Active low input-only.

When /REQ is pulled low, the QT300 wakes and starts an

acquire. The IC will transmit the resulting data only when

the acquire has finished.

/REQ should return high before the end of the burst. If

/REQ is still low at the end of the burst the part will go into

Setup mode. The minimum duration of /REQ is 30µs.

LQ

3

QT300 R1.01 21/09/03

Figure 3-1 Multiple QT300's on the same SPI port

Vdd

100nF

8

QT 300

Vcc

1

QT 300

QT 300

DRDY

SCK

REQ

SDO

DRDY

SCK

REQ

SDO

DRDY

SCK

REQ

SDO

3

100nF

100nF

SENSOR

5

CS

3

SENSOR

5

CS

3

SENSOR

5

CS

SNS 1

SNS 2

GND

4

Vdd

8

Vcc

SNS 1

SNS 2

GND

4

Vdd

8

Vcc

SNS 1

SNS 2

GND

4

2

6

7

1

2

6

7

1

2

6

7

Host Micro

REQ1

REQ2

DRDY

REQ3

SCK

SDI

SDO - Serial Data Output; Output-only. This is the data

output to the host during an SPI transfer. When not in use,

this pin floats. This pin should be connected to the SDI

input pin of the host device.

SCK - SPI clock; Idle high or idle low; input-only SPI clock

from the host. The idle state is determined in Setups by

the serial mode (SM) parameter.

If SM is set for idle-low SCK: Data is shifted out of the

QT300 on the rising edge of SCK and should be shifted

into the host on the falling edge of SCK.

If SM is set for idle-high SCK: Data is shifted out of the

QT300 on the falling edge of SCK and should be shifted

into the host on the rising edge of SCK.

The maximum clock speed is 40kHz, and the timings

should obey the parameters Tskh and Tskl in Table 7-1.

/DRDY - Data Ready; active low output only. This indicates to

the host that the device is ready to send data back to the

host. During idle times this pin floats and therefore must

be connected to a pullup resistor. The host must wait until

/DRDY goes low before starting an SPI transfer.

Between the high and low byte clockings, the host should

observe a delay of ≥12µs.

A typical SPI slave mode communication sequence is:

1) Host pulses /REQ low for ≥30µs to initiate an acquire.

2) QT300 acquires a signal in response to /REQ.

3) QT300 pulls /DRDY low when ready to send data back.

4) Host detects /DRDY is low.

5) Host clocks out the high byte of data from the QT300.

6) Host waits for ≥12µs.

7) Host clocks out the low byte of data from the QT300.

8) QT300 releases /DRDY to float high.

3.5 SPI Master Mode

Refer to Figure 7-2 and Table 7-2, page 8.

In master SPI mode the QT300 generates the clock signal

after an acquire initiated from the host via the /REQ line. The

clock speed and the spacing between the two bytes is set via

the Setup process (Section 6).

SCD setup parameter determines the master-mode clock

rate. The default value is 55 (resulting in a 2.55KHz rate).

The relationship is:

Fscd = 1200/(30+ (SCD x 8)) in Khz

Where SCD = 0..255

MLS setup parameter determines the spacing between the

two return bytes; this can be important to allow a slow host

device to recover from receiving the first byte to prevent an

overrun. The default value is 148 (resulting in a 500µs gap).

The relationship is:

Tmls (in µs) = (10 + MLS x 4) / 1.2

Where MLS = 0..255 (from user setup MLS)

Master SPI mode requires at least 3 signals to operate:

/REQ - Request Acquisition Input; Active low input-only.

When /REQ is pulled low, the QT300 wakes and starts an

acquire. The IC will transmit the resulting data only when

the acquire has finished.

/REQ must return high before the end of the burst. If

/REQ is still low at the end of the burst the part goes into

Setup mode. The minimum duration of /REQ is 30µs.

SDO - Serial Data Output; Idle low output-only. This is the

data output to the host during an SPI transfer. When not in

use, this pin floats. This pin should be connected to the

SDI input pin of the host device.

SCK - SPI clock; Idle high or idle low, output-only. The idle

state is determined in Setups by the serial mode (SM)

parameter.

If SM is set for idle-low SCK: Data is shifted out of the

QT300 on the rising edge of SCK and should be shifted

into the host on the falling edge of SCK.

LQ

If SM is set for idle-high SCK: Data is shifted out of the

QT300 on the falling edge of SCK and should be shifted

into the host on the rising edge of SCK.

The maximum clock speed is 40kHz, and the timings

should obey the parameters Tskh and Tskl in Table 7-2.

/DRDY - Data Ready (Optional); active low output only. This

indicates to the host that the device is ready to send data

4

QT300 R1.01 21/09/03

4 Single-Wire (1W) UART

Interface

The single wire ('1W') UART option allows all

communications to take place over a single

bidirectional line with a 10K pullup resistor. The host

device triggers the QT300 to acquire by means of a

pulse sent to the QT300 over the wire. The Baud rate

is established by the width of this pulse; the pulse

width establishes the bit rate of the UART

transmission to follow. The QT300 then acquires, and

responds by sending two bytes of data back over the

1W line with a delay between the bytes as determined

by parameter MLS.

1W operation permits a device to be controlled from a

single pin on a host controller, using either a hardware

or software UART. Several QT300’s can coexist on a

single host pin, provided there is some logic steering.

This mode is set via the cloning process using

parameter SM (see Section 6).

4.1 1W UART Specifications

The QT300 operates in 1W UART mode with the

following specifications:

Baud rate range 4,800 to 9,600 bits/sec

Data length 2 bytes (16 bits total)

Stop bit 1 (each byte)

Parity None

Idle state High

The 1W line must have a pullup resistor on it (i.e.

10K), or 1W communications will not function.

Figure 4-1 UART and Trigger Pulse Signal.

back to the host. During idle times this pin floats and

therefore must be connected to a pullup resistor.

The DRDY line can be used as a Slave Select line (SS).

The host does not need this line to operate in many cases.

DRDY can be used to 'frame' byte transmissions.

Between bytes /DRDY will go high for a period determined

by the MLS setup parameter; the minimum period is 8.3µs.

A typical Master mode SPI sequence is:

1) Host pulses /REQ low for ≥30µs.

2) QT300 acquires a signal in response to /REQ.

3) QT300 pulls /DRDY low when ready to send data.

4) Host detects /DRDY low and prepares to receive data.

5) QT300 clocks out first byte of data (MSB).

6) QT300 sets /DRDY high for a duration determined by

Setup parameter MLS.

7) QT300 pulls /DRDY low.

8) QT300 clocks out the low byte (LSB).

9) QT300 releases /DRDY to float high.

4.2 UART 1W Protocol

The QT300 acquires and transmits only on request.

The sequence is:

1) The host generates a pulse on the 1W pin; the

pulse width must match the Baud rate (bit width)

of the expected return Baud rate from the QT300.

This pulse actually sets the Baud rate each time,

and so it can vary from one acquire to another. See

Section 4.3 and Figure 4-1.

2) The 1W pulse width is measured by the QT300 to

determine the Baud rate.

3) The host floats 1W high.

4) The QT300 acquires the signal to completion.

5) QT300 returns data in the following UART format:

start bit (low)

8 bits, high byte

stop bit (high)

delay (determined by MLS setup)

start bit (low)

8 bits, low byte

stop bit (high)

6) The QT300 floats the 1W line and enters idle mode.

LQ

5

QT300 R1.01 21/09/03

4.3 Trigger pulse description

The part wakes from low power mode when the first negative

edge is detected on the 1W pin (Figure 4-1, bottom). The

negative pulse must be at least 30µs wide.

The host then generates the positive pulse that actually sets

the Baud rate. The QT300 measure this pulse and uses its

length to set the Baud bit (shift out) rate. 30µs (or more) of

logic-low must follow this pulse.

The host must then float the 1W line to allow the QT300 to

start the signal acquisition.

5.3 PCB LAYOUT

5.3.1 G

The use of ground planes around the device is encouraged

for noise reasons, but ground or power should not be

coupled too close to the sense pins in order to reduce Cx

load. Likewise, the traces leading from the sense pins to the

electrode should not be placed directly over a ground plane;

rather, the ground plane should be relieved by at least 3

times the width of the sense traces directly under it, with

periodic thin bridges over the gap to provide ground

continuity.

ROUND PLANES

5 Circuit Guidelines

5.1 Sample capacitors

Cs capacitors can be virtually any plastic film or low to

medium-K ceramic capacitor. The normal usable Cs range is

from 1nF ~ 500nF depending on the sensitivity required;

larger values of Cs require higher stability to ensure low drift.

Acceptable capacitor types include NP0 or C0G ceramic,

PPS film, and Y5E and X7R ceramics in that order.

5.2 Power Supply

5.2.1 S

The QT300 makes use of the power supply as a reference

voltage. The acquired signal will shift slightly with changes in

Vdd; Vdd fluctuations often happen when additional loads

are switched on or off such as LEDs etc.

If the power supply is shared with another electronic system,

care should be taken to assure that the supply is free of

spikes, sags, and surges. It is best practice to use a

regulator just for the QT300 (or one for a set of QT300's).

5.2.2 S

Vdd can range from 2 to 5 volts nominal. Current drain will

vary depending on Vdd. During writing of the internal

EEPROM, Vdd must be at least 2.2 volts.

If desired, the supply can be regulated using a conventional

regulator, for example CMOS LDO regulators, or standard

78Lxx-series 3-terminal devices.

For proper operation a 100nF (0.1uF) ceramic bypass

capacitor must

cap should be placed very close to the Vdd and Vss pins.

TABILITY

UPPLY REQUIREMENTS

be used between Vdd and Vss; the bypass

5.3.2 N

OISE SYNCHRONIZATION

External fields can cause interference leading to a noisy and

unstable signal. The most common external fields usually are

from AC mains power.

The /REQ line of the QT300 can be used to synchronize the

acquisition to a repetitive external source of interference

such as the power line frequency in order to dramatically

reduce signal noise.

If line frequency is present near the sensors, this feature

should be used.

6 Parameter Setups Cloning

A special interface is provided to allow user-defined Setups

to be loaded into internal eeprom or read back out for

development and production purposes.

The QTM300CA cloning board in conjunction with QT3View

software simplifies the Setups cloning process greatly. The

E3A eval board has been designed with a connector to

facilitate direct connection with the QTM300CA. The

QTM300CA in turn connects to any PC with a serial port

which can run QT3View software (included with the

QTM300CA and available free on Quantum’s web site).

The connections required for cloning are shown in Figure

6-1. Further information on the cloning process can be found

in the QTM300CA instruction guide. The parameters which

can be altered are shown in Table 7-4.

The internal eeprom has a life expectancy of 100,000

erase/write cycles and the minimum voltage for a write cycle

is 2.2 Volts.

A serial interface specification for the device can be obtained

by contacting Quantum.

LQ

Cloning Signal

Vdd

SCK

REQ

SDO

8

Vcc

GND

4

100nF

SNS 1SCK

SNS 2

3

5

SENSOR

CS

DRDY

REQ

SDI

SDO

SDI

SCK

GND

QT 300

1

DRDY

2

6

7

Figure 6-1 Clone interface wiring

6

QT300 R1.01 21/09/03

7 Electrical specifications

V

V

V

V

7.1 ABSOLUTE MAXIMUM SPECIFICATIONS

Operating temp................................................................................ as designated by suffix

Storage temp....................................................................................... -65

V

DD

...................................................................................................... -0.5 to +6V

Max continuous pin current, any control or drive pin..............................................................±40mA

Short circuit duration to ground, any pin......................................................................... infinite

Short circuit duration to V

DD

, any pin............................................................................ infinite

Voltage forced onto any pin.................................................................... -1V to (Vdd + 0.5) Volts

7.2 RECOMMENDED OPERATING CONDITIONS

VDD........................................................................................................ +2 to 5V

V

DD

min required to reprogram eeprom Setups................................................................... +2.2V

Short-term supply ripple+noise..................................................................................±5mV

Long-term supply stability.................................................................................... ±100mV

Cs value................................................................................................. 1 to 500nF

Cx value..................................................................................................0 to 100pF

7.3 AC SPECIFICATIONS

Vdd = 3.0, Ta = recommended operating range, Cs=100nF unless noted

NotesUnitsMaxTypMinDescriptionParameter

PC

BL

RQP

ns830Charge/transfer durationT

Cs = 4.7nF to 200nF; Cx = 0ms250.5Burst lengthT

µs30Request pulseT

O

C to +125OC

7.4 DC specifications

Vdd = 3.0V, Cs = 10nF, Cx = 5pF, Ta = recommended range, unless otherwise noted

V5.52Supply voltageV

V0.4Low output voltageV

VVdd-0.6High output voltageV

bits16Acquisition resolutionA

DD

DD

OL

OH

IL

IH

R

0.6 VddInput high voltage

NotesUnitsMaxTypMinDescriptionParameter

Dependent on duty cycleµA1,50060Supply currentI

Vdd = 2.5 to 5.0VV0.3 VddInput low voltageV

dd = 2.5 to 5.0

Figs 7-4, 7-5fF71,000Resolution per bitS

LQ

7

QT300 R1.01 21/09/03

{from QT300}

T

DRDY

SCK

{from host}

SDO

{from QT300}

DRDY

{from QT300}

Tskd

D15

D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

Tds

Ts kh

Ts kl

Tmls

Ts o s h

Figure 7-1 SPI Slave Mode

mls

Tskd

Tsk h

Ts kl

Thso

T

SKD

SKH

SKL

SOSH

HSO

MLS

T

DS

{from QT300}

SCK

SDO

{from QT300}

SCK High To SDO Ready

Setup Time

DRDY Low To SCK High

Delay

Table 7-1 Slave SPI Timing

D15

D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

Tds

Ts osh

Figure 7-2 SPI Master Mode

UnitsmaxminParameterSymbol

-25Clock DurationT

-13SCK High DurationT

-12SCK Low DurationT

10-

-7SDO Hold TimeT

1,00012MSB-LSB SpacingT

1,00012

µs

µs

µs

µs

µs

µs

µs

SKD

SKH

SKL

SCK High To SDO Ready

T

SOSH

HSO

MLS

T

DS

Setup Time

DRDY Low To SCK High

Delay

Table 7-2 Master SPI Timing

Thso

1,72525Clock DurationT

862.512.5SCK High DurationT

862.512.5SCK Low DurationT

1,7088.3MSB-LSB SpacingT

UnitsmaxminParameterSymbol

µs

µs

µs

74

µs

--12.5SDO Hold TimeT

µs

--12.5

LQ

8

QT300 R1.01 21/09/03

1W UART

Twu

Tbr

Ts b

Tacq

Ts t a r t

Figure 7-3 1W UART Mode

8 x Tbr-MSB

8 x Tbr-LSB

Table 7-3 1W UART Timing

8bits MSB 8bits LSB

Tmls

Tstop

-5,00030Wake levelTwu

-210104Baud set pulseTbr

-5,00030Baud end levelTsb

-9,6004,800Baud rate range

-TbrStart pulseTstart

-TbrStop pulseTstop

-8508MSB-LSB spacingTmls

8 bits data, LSB first

UnitsNotesmaxminParameterSymbol

µs

µs

µs

%-2Baud rate match accuracy

msDepends on Cs and Cx 400-Acquisition timeTacq

µs

µs

µs

Clock Speed

MSB-LSB

Spacing

UnitCalculation / NotesDefaultValid ValuesSymbolDescription

1W UART0

Master Clock

1

SMMode

2

3

4

Idle Low

Master Clock

Idle High

Slave Clock

Idle Low

Slave Clock

Idle High

Table 7-4 Setups summary chart

3

Slave Clock

Idle Low

-

Tscd = (30 + (SCD x 8))/1.2550 - 255SCD

Tmls = (10 + (MLS x 4))/1.21480 - 255MLS

-

µs

µs

LQ

9

QT300 R1.01 21/09/03

500

400

300

200

Resolution Per Count (fF)

100

Cs

9nF

19nF

43nF

74nF

124nF

200nF

150

125

100

75

50

Resolution Per Count (fF)

25

Cs

43nF

74nF

124nF

200nF

0

011213448

Cx Load

Figure 7-4 Typical resolution vs Cx & Cs;

Vdd = 3.0 Volts

5.00%

4.00%

3.00%

2.00%

1.00%

0.00%

-1.0 0%

% Deviation

-2.0 0%

-3.0 0%

-4.0 0%

-5.0 0%

-10-5 0 5 1015202530354045 5055606570 758085

Figure 7-6 Typical Signal Deviation vs. Temperature

Vdd = 5.0 Volts, Cx = 10pF, Cs = 5~200nF PPS Film

0

0 11213448

Cx Load

Figure 7-5 Typical resolution vs Cx & Cs;

Vdd = 3.0 Volts

Temperature, C

LQ

6000

5000

4000

3000

Signal, Counts

2000

1000

0

-10 0 10 20 30 40 50 60 70 80

Temperature, °C

200nF PPS

100nF PPS

4.7nF PPS

Figure 7-7 Typical Signal Vs. Cs & Temp

Vdd = 5.0 Volts, Cx = 10pF, PPS film capacitors

10

QT300 R1.01 21/09/03

Pin 1

M

SYMBOL

F

A

S1

a

A

r

S

L2

x

m

Q

L1 L

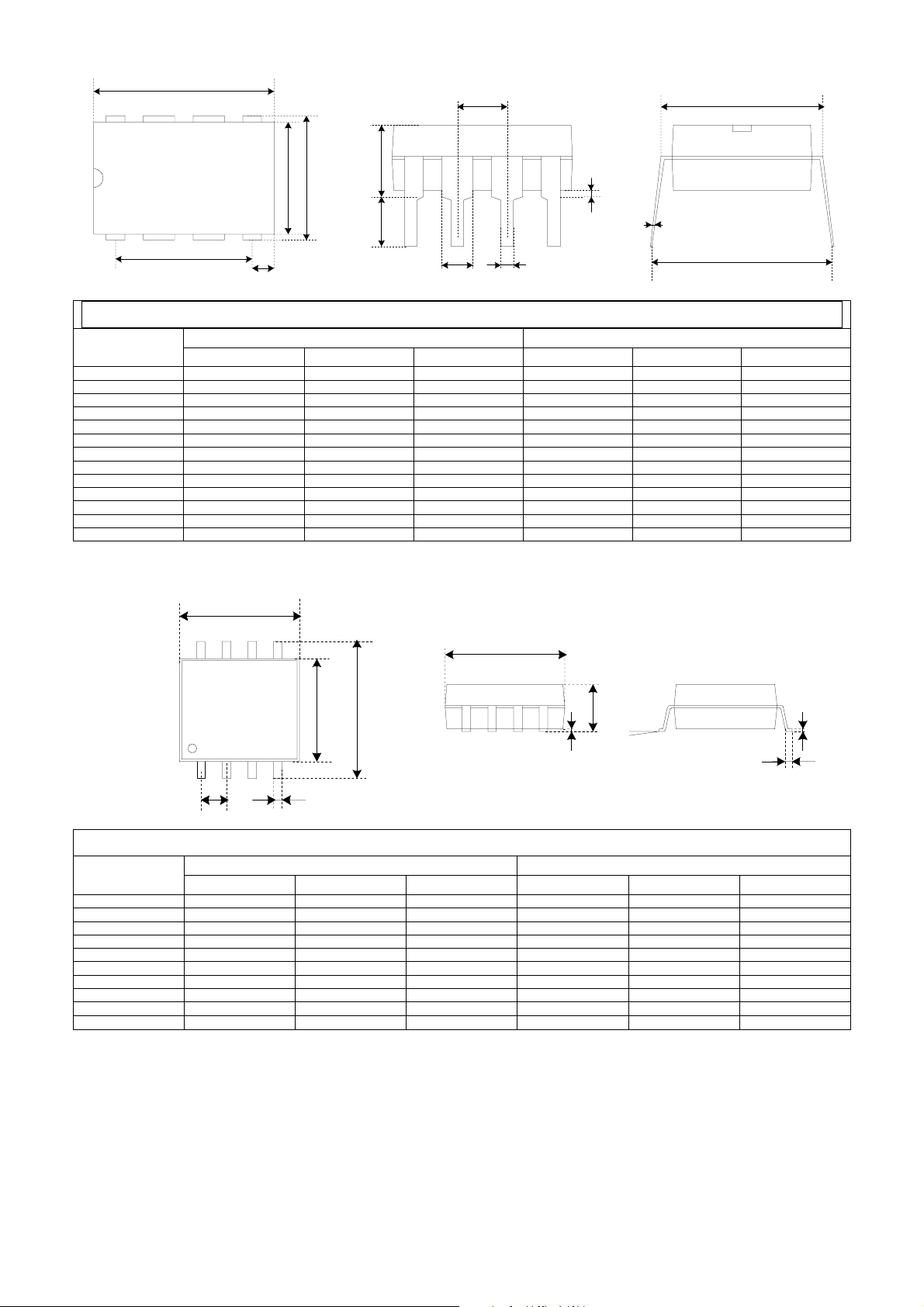

Package type: 8-pin Dual-In-Line

InchesMillimeters

0.280.247.116.1a

0.3250.38.267.62A

0.40.35510.169.02M

0.0370.0270.940.69Q

0.0220.0140.5590.356L

0.070.0451.781.14L1

0.0120.0080.3050.203L2

-0.015-0.38r

0.150.1153.812.92S

0.21-5.33-S1

0.4310.9x

NotesMaxMinNotesMaxMin

Typical-0.3Typical-7.62m

BSC-0.1BSC-2.54F

Pin 1

SYMBOL

φ

M

M

a

A

H

φ

h

e

E

Package type: 8-pin Wide SOIC

InchesMillimeters

0.2130.2055.415.21a

0.330.38.387.62A

0.2120.2035.385.16M

0.020.0120.5080.305L

0.0130.0040.330.102h

0.080.072.031.78H

0.010.0070.2540.178e

0.0350.020.8890.508E

o

0

o

8

o

0

o

8

NotesMaxMinNotesMaxMin

BSC0.05BSC1.27F

LQ

11

QT300 R1.01 21/09/03

lQ

Copyright © 2002 QRG Ltd. All rights reserved.

Patented and patents pending

Corporate Headquarters

1 Mitchell Point

Ensign Way, Hamble SO31 4RF

Great Britain

Tel: +44 (0)23 8056 5600 Fax: +44 (0)23 8045 3939

admin@qprox.com

www.qprox.com

North America

651 Holiday Drive Bldg. 5 / 300

Pittsburgh, PA 15220 USA

Tel: 412-391-7367 Fax: 412-291-1015

The specifications set out in this document are subject to change without notice. All products sold and services supplied by QRG are subject

to our Terms and Conditions of sale and supply of services which are available online at www.qprox.com and are supplied with every order

acknowledgement. QProx, QTouch, QMatrix, QLevel, and QSlide are trademarks of QRG. QRG products are not suitable for medical

(including life-saving equipment), safety or mission critical applications or other similar purposes. Except as expressly set out in QRG's

Terms and Conditions, no licenses to patents or other intellectual property of QRG (express or implied) are granted by QRG in connection

with the sale of QRG products or provision of QRG services. QRG will not be liable for customer product design and customers are entirely

responsible for their products and applications which incorporate QRG's products.

Loading...

Loading...