lQ

L

Q

4

Completely independent QT touch circuits

Individual logic outputs per channel (open drain)

Projects prox fields through any dielectric

Only one external capacitor required per channel

Sensitivity easily adjusted on a per-channel basis

100% autocal for life - no adjustments required

3~5.5V, 5mA single supply operation

Toggle mode for on/off control (strap option)

10s, 60s, infinite auto-recal timeout (strap options)

AKS™ Adjacent Key Suppression (pin option)

Sync pin for multi-chip sync or line sync

Less expensive per key than many mechanical switches

Eval board with backlighting - p/n E160

APPLICATIONS

QProx™ QT140 / QT150

AND

5 KEY QT

SSOP

Vss

Vss

Vdd

Vdd

SNS1A

SNS1B

SNS2A

SNS2B

SNS3A

SNS3B

SNS4A

SNS4B

SNS5A

Vss

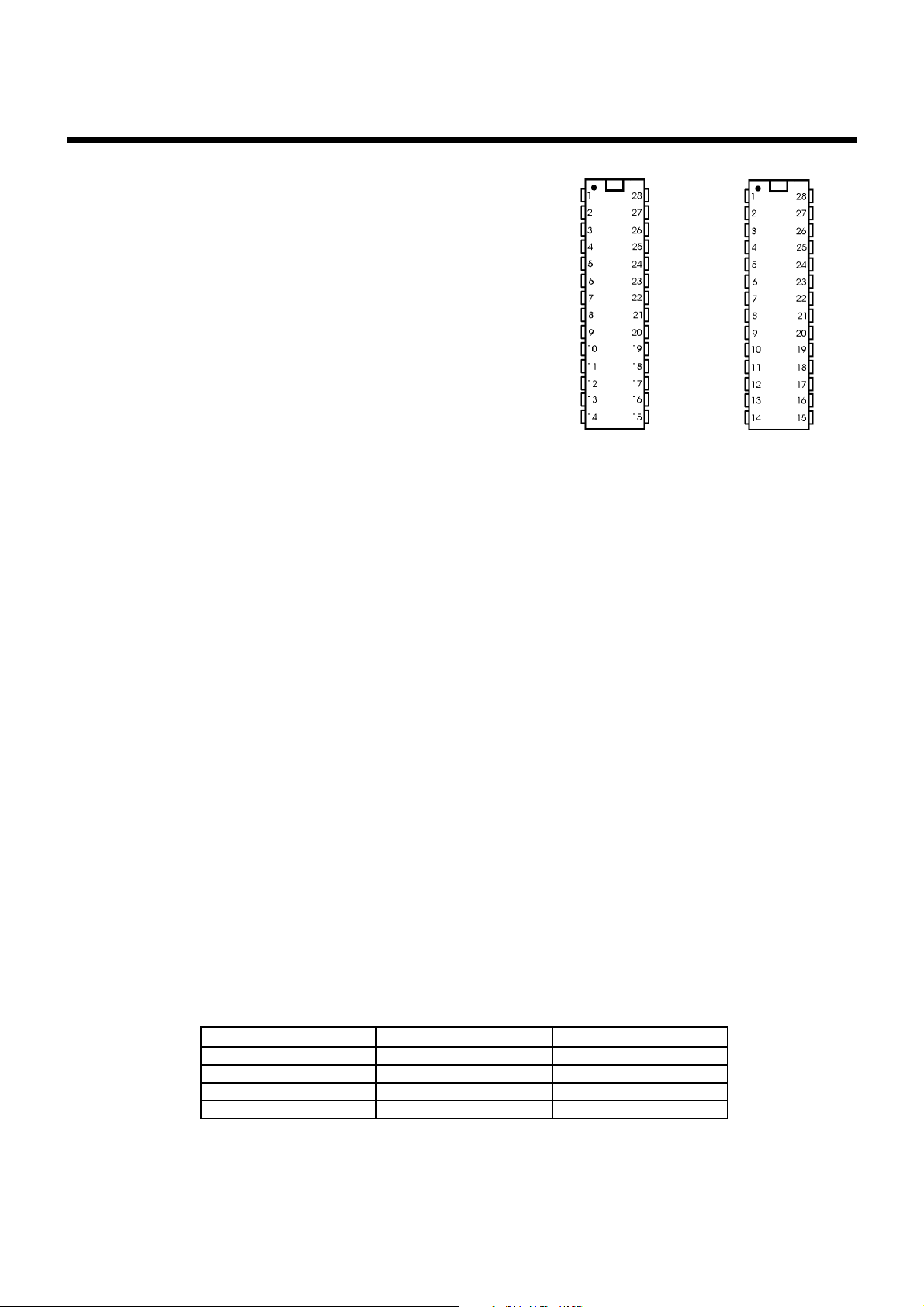

QT150 shown - NOTE: Pinouts are not the same!

OUCH

/RST

OSC_I

OSC_O

OPT2

OPT1

SYNC

OUT5

OUT4

OUT3

OUT2

OUT1

AKS

OC

SNS5B

™ S

Vdd

Vdd

Vss

Vss

Vss

SNS1A

SNS1B

SNS2A

SNS2B

SNS3A

SNS3B

SNS4A

SNS4B

SNS5A

ENSOR

DIP

IC

/RST

OSC_I

OSC_O

OPT2

OPT1

SYNC

OUT5

OUT4

OUT3

OUT2

OUT1

AKS

OC

SNS5B

s

PC Peripherals

Backlighted buttons

Appliance controls

Security systems

Access systems

Pointing devices

Instrument panels

Gaming machines

QT140 / QT150 charge-transfer (“QT’”) QTouch ICs are self-contained digital controllers capable of detecting near-proximity or

touch on 4 or 5 electrodes. They allow electrodes to project independent sense fields through any dielectric like glass, plastic,

stone, ceramic, and wood. They can also turn metal-bearing objects into intrinsic sensors, making them responsive to proximity

or touch. This capability coupled with their continuous self-calibration feature can lead to entirely new product concepts, adding

high value to product designs.

Each of the channels operates independently of the others, and each can be tuned for a unique sensitivity level by simply

changing its sample capacitor value.

The devices are designed specifically for human interfaces, like control panels, appliances, gaming devices, lighting controls,

or anywhere a mechanical switch or button may be found; they may also be used for some material sensing and control

applications.

These devices require only a common inexpensive capacitor per sensing channel in order to function. They also offer patent

pending AKS™ Adjacent Key Suppression which suppresses touch from weaker responding keys and allows only a dominant

key to detect, for example to solve the problem of large fingers on tightly spaced keys.

These devices also have a SYNC I/O pin which allows for synchronization with additional similar parts and/or to an external to

suppress interference.

The RISC core of these devices use signal processing techniques pioneered by Quantum which are designed to survive

numerous real-world challenges, such as ‘stuck sensor’ conditions, component ageing, moisture films, and signal drift.

By using the charge transfer principle, these devices deliver a level of performance clearly superior to older technologies yet

are highly cost-effective.

A

0

C to +700C

0

C to +1050C

0

C to +700C

0

C to +1050C

AVAILABLE OPTIONS

QT140-AS-40

QT150-AS-40

DIP-28SSOP-28T

QT140-D-0

-

QT150-D-0

-

Copyright © 2002 QRG Ltd

QT140/150 1.01/1102

4

4

/

/

/

4

4

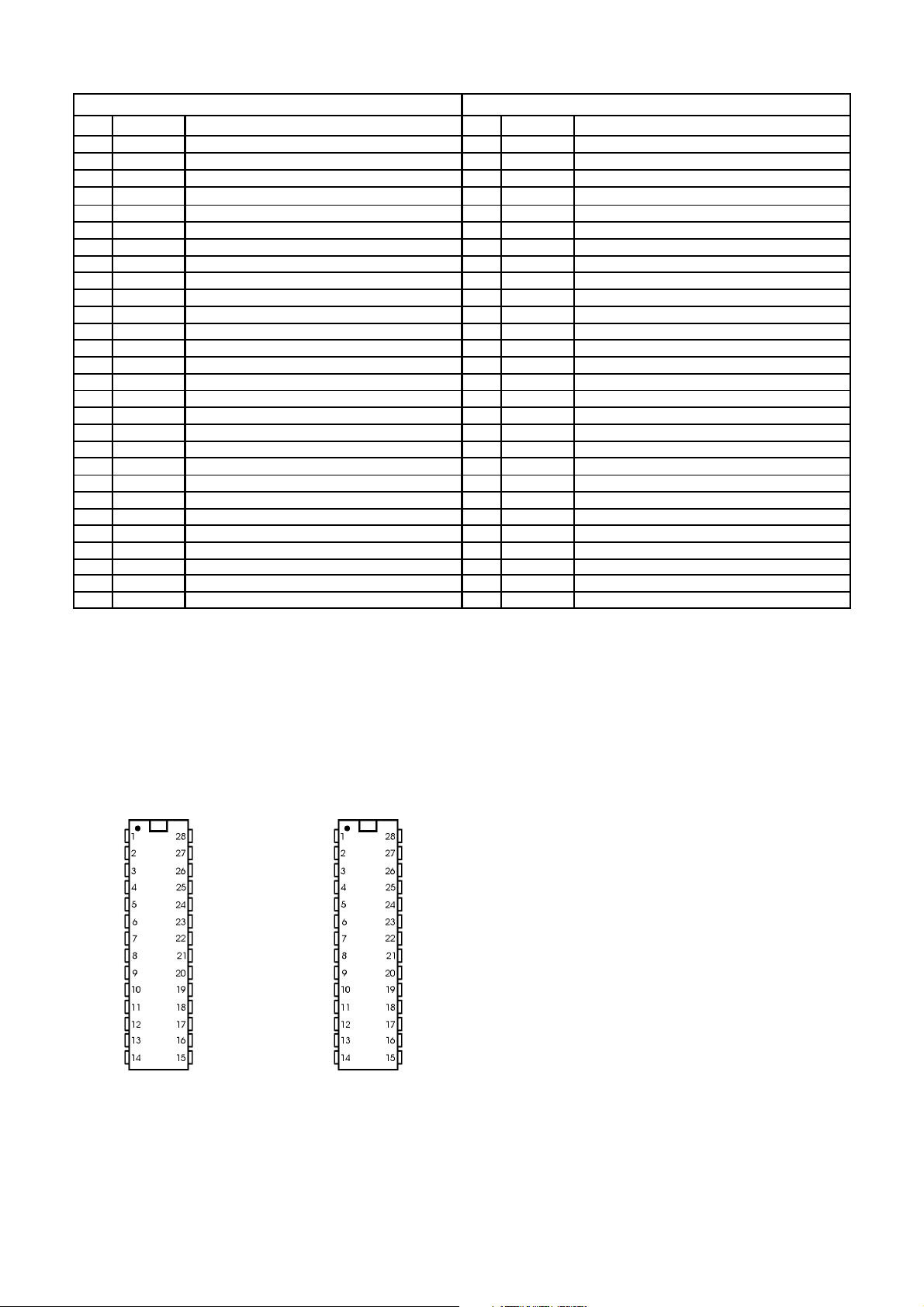

Table 1-1 Pin Listing

Supply negative rail (ground)Vss1

Option Mode (Input pin - see Table 2-1)OPT12

QT140 / QT150 DIP-28QT140 / QT150 SSOP-28

DescriptionNamePinDescriptionNamePin

Positive powerVdd1Negative power (Ground)Vss1

Positive powerVdd2Negative power (Ground)Vss2

Negative power (Ground)Vss3Positive powerVdd3

Negative power (Ground)Vss4Positive powerVdd4

Negative power (Ground)Vss5Sense pin (to Cs1, electrode)SNS1A 5

Sense pin (to Cs1, electrode)SNS1A6Sense pin (to Cs1)SNS1B 6

Sense pin (to Cs1)SNS1B7Sense pin (to Cs2, electrode)SNS2A7

Sense pin (to Cs2, electrode)SNS2A8Sense pin (to Cs2)SNS2B8

Sense pin (to Cs2)SNS2B9Sense pin (to Cs3, electrode)SNS3A9

Sense pin (to Cs3, electrode)SNS3A10Sense pin (to Cs3)SNS3B10

Sense pin (to Cs3)SNS3B11Sense pin (to Cs4, electrode) SNS4A11

Sense pin (to Cs4, electrode) SNS4A12Sense pin (to Cs4)SNS4B12

Sense pin (to Cs4)SNS4B13Sense pin (to Cs5, electrode) n/c on QT140NC/SNS5A13

SNS5A1

SNS5B15Sense pin (to Cs5) n/c on QT140NC/SNS5B15

OUT522Channel 5 output, o-d or p-p (n/c on QT140)NC/OUT522

Sense pin (to Cs5, electrode) n/c on QT140NC

Sense pin (to Cs5) n/c on QT140NC

Output Option (input pin; 1= open drain)OC16Output Option (input pin; 1= open drain)OC16

Adjacent Key Suppression Opt. (input ; 1=AKS)AKS17Adjacent Key Suppression Opt. (input; 1=AKS)AKS17

Channel 1 output, o-d or p-pOUT118Channel 1 output, o-d or p-pOUT118

Channel 2 output, o-d or p-pOUT219Channel 2 output, o-d or p-pOUT219

Channel 3 output, o-d or p-pOUT320Channel 3 output, o-d or p-pOUT320

Channel 4 output, o-d or p-pOUT421Channel 4 output, o-d or p-pOUT421

Channel 5 output, o-d or p-p (n/c on QT140)NC

Synchronization pin (I/O pin - pull high with 10K)SYNC23Synchronization pin (I/O pin - pull high with 10K)SYNC23

Option Mode (Input pin - see Table 2-1)OPT12

Option Mode (Input pin - see Table 2-1)OPT225Option Mode (Input pin - see Table 2-1)OPT225

Oscillator outputOSC_O26Oscillator outputOSC_O26

Oscillator inputOSC_I27Oscillator inputOSC_I27

Reset pin (active low input)/RST28Reset pin (active low input)/RST28

1 - OVERVIEW

QT140/150 devices are burst mode digital charge-transfer

(QT) sensor ICs designed specifically for touch controls; they

include all hardware and signal processing functions

necessary to provide stable sensing under a wide variety of

conditions. Only a single low cost capacitor per channel is

required for operation.

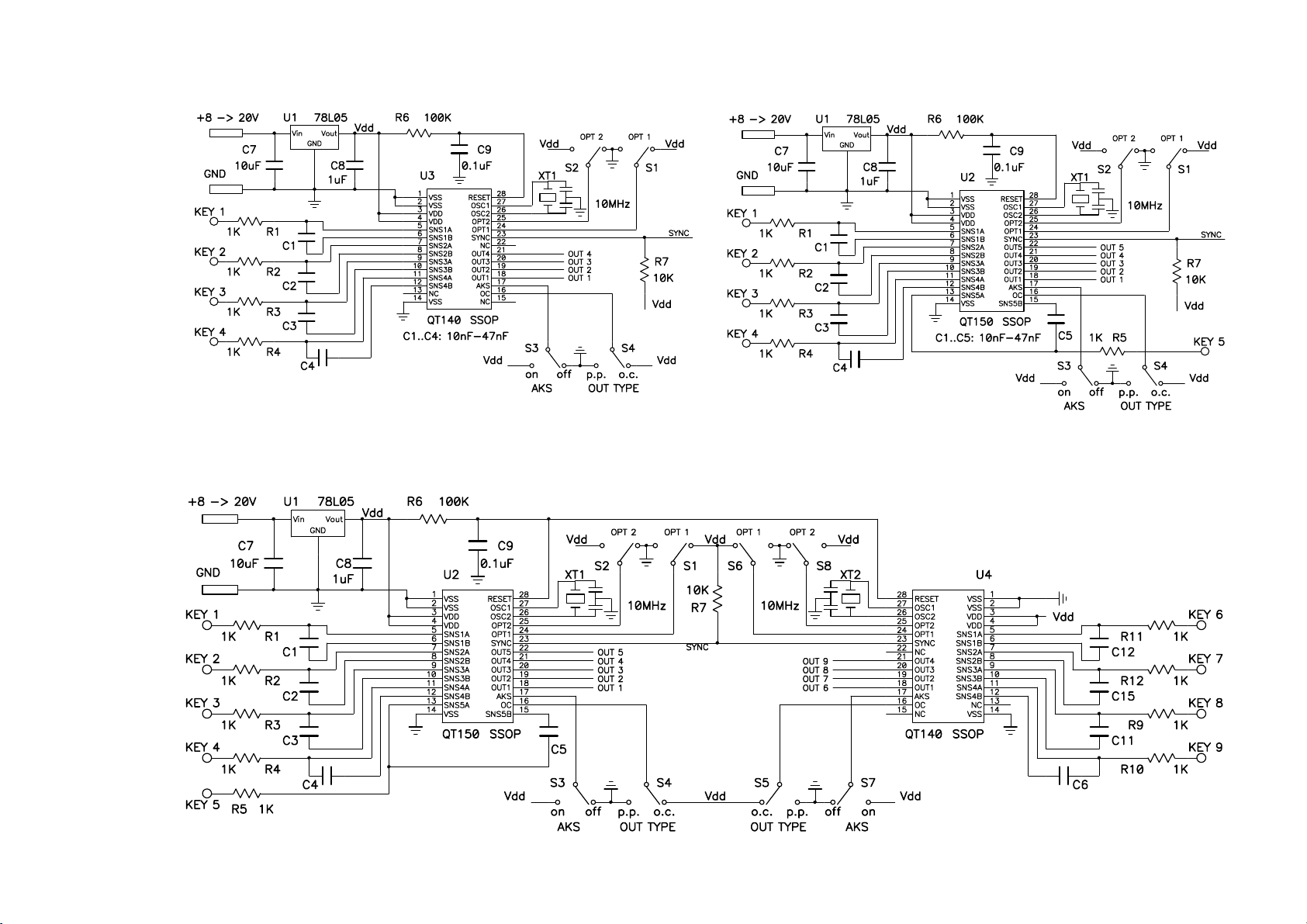

Figures 1-6 and 1-7 show basic circuits for these devices.

See Table 1-1 for device pin listings.

SSOP

Vss

Vss

Vdd

Vdd

SNS1A

SNS1B

SNS2A

SNS2B

SNS3A

SNS3B

SNS4A

SNS4B

NC

Vss

/RST

OSC_I

OSC_O

OPT2

OPT1

SYNC

NC

OUT4

OUT3

OUT2

OUT1

AKS

OC

NC

Fig 1-1 QT140 Pinouts

NOTE: SSOP / DIP Pinouts are not the same!

Vdd

Vdd

Vss

Vss

Vss

SNS1A

SNS1B

SNS2A

SNS2B

SNS3A

SNS3B

SNS4A

SNS4B

NC

DIP

/RST

OSC_I

OSC_O

OPT2

OPT1

SYNC

NC

OUT4

OUT3

OUT2

OUT1

AKS

OC

NC

The DIP and SOIC pinouts are not the same and serious

damage can occur if a part is miswired.

1.1 BASIC OPERATION

The devices employ bursts of charge-transfer cycles to

acquire signals. Burst mode permits low power operation,

dramatically reduces RF emissions, lowers susceptibility to

RF fields, and yet permits excellent speed. Internally, signals

are digitally processed to reject impulse noise using a

'consensus' filter that requires three consecutive

confirmations of detection. Each channel is measured in

sequence starting with Channel 1.

The QT switches and charge measurement hardware

functions are all internal to the device. A single-slope

switched capacitor ADC includes the QT charge and transfer

switches in a configuration that provides direct ADC

conversion; an external Cs capacitor accumulates the charge

from sense-plate Cx, which is then measured.

Larger values of Cx cause the charge transferred into Cs to

rise more rapidly, reducing available resolution; as a

minimum resolution is required for proper operation, this can

result in dramatically reduced gain. Conversely, larger values

of Cs reduce the rise of differential voltage across it,

increasing available resolution by permitting longer QT

bursts. The value of Cs can thus be increased to allow larger

values of Cx to be tolerated. The IC is responsive to both Cx

and Cs, and changes in Cs can result in substantial changes

in sensor gain.

lQ

2 QT140/150 1.01/1102

Unused channels: If a channel is not used, a dummy sense

capacitor (nominal value: 1nF) of any type must be

connected between the unused SNSnA / SNSnB pins ensure

correct operation.

Unused pins: Unused device pins labeled NC should

remain unconnected.

1.2 ELECTRODE DRIVE

These devices have completely independent sensing

channels. The internal ADC treats Cs on each channel as a

floating transfer capacitor; as a direct result, sense

electrodes can be connected to either SNSnA or SNSnB and

the sensitivity and basic function will be the same; however

there is an advantage in connecting electrodes to SNSnA

lines to reduce EMI susceptibility.

The PCB traces, wiring, and any components associated

with or in contact with SNSnA and SNSnB will become touch

sensitive and should be treated with caution to limit the touch

area to the desired location.

Multiple touch electrodes connected to SNSnA can be used,

for example to create control surfaces on both sides of an

object.

It is important to limit the amount of stray capacitance on the

SNSnA and SNSnB terminals, for example by minimizing

trace lengths and widths to allow for higher gains and lower

values of Cs.

1.3 KEY DESIGN

1.3.1 K

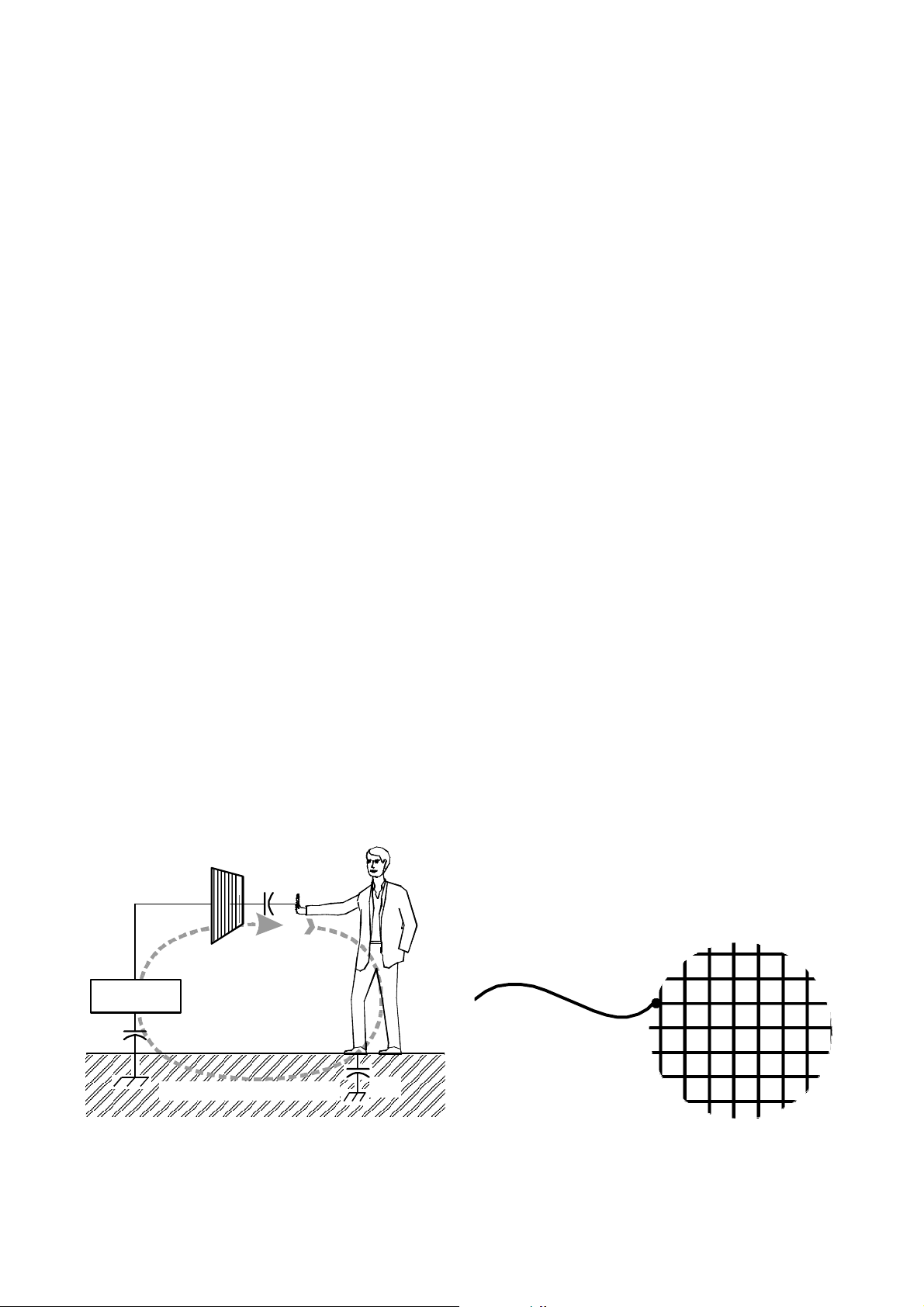

Like all capacitance sensors, these parts rely on Kirchoff’s

Current Law (Figure 1-2) to detect the change in capacitance

of the electrode. This law as applied to capacitive sensing

requires that the sensor’s field current must complete a loop,

returning back to its source in order for capacitance to be

sensed. Although most designers relate to Kirchoff’s law with

regard to hardwired circuits, it applies equally to capacitive

field flows. By implication it requires that the signal ground

and the target object must both be coupled together in some

manner for a capacitive sensor to operate properly. Note that

there is no need to provide actual galvanic ground

connections; capacitive coupling to ground (Cx1) is always

IRCHOFF’S CURRENT LAW

Figure 1-2 Kirchoff's Current Law

C

X2

sufficient, even if the coupling might seem very tenuous. For

example, powering the sensor via an isolated transformer will

provide ample ground coupling, since there is capacitance

between the windings and/or the transformer core, and from

the power wiring itself directly to 'local earth'. Even when

battery powered, just the physical size of the PCB and the

object into which the electronics is embedded will generally

be enough to couple a few picofarads back to local earth.

1.3.2 KEY G

EOMETRY

, S

IZE, AND LOCATION

There is no restriction on the shape of the key electrode; in

most cases common sense and a little experimentation can

result in a good electrode design. The devices will operate

with long thin electrodes, round or square ones, or keys with

odd shapes. Electrodes can also be on 3-dimensional

surfaces. Sensitivity is related to the amount of electrode

surface area, overlying panel material and thickness, and the

ground return coupling quality of the circuit.

If a relatively large touch area is desired, and if tests show

that the electrode has more capacitance than the part can

tolerate, the electrode can be made into a sparse mesh

(Figure 1-3) having lower Cx than a solid plane.

Since the channels acquire their signals in time-sequence,

any of the electrodes can be placed in direct proximity to

each other if desired without cross-interference.

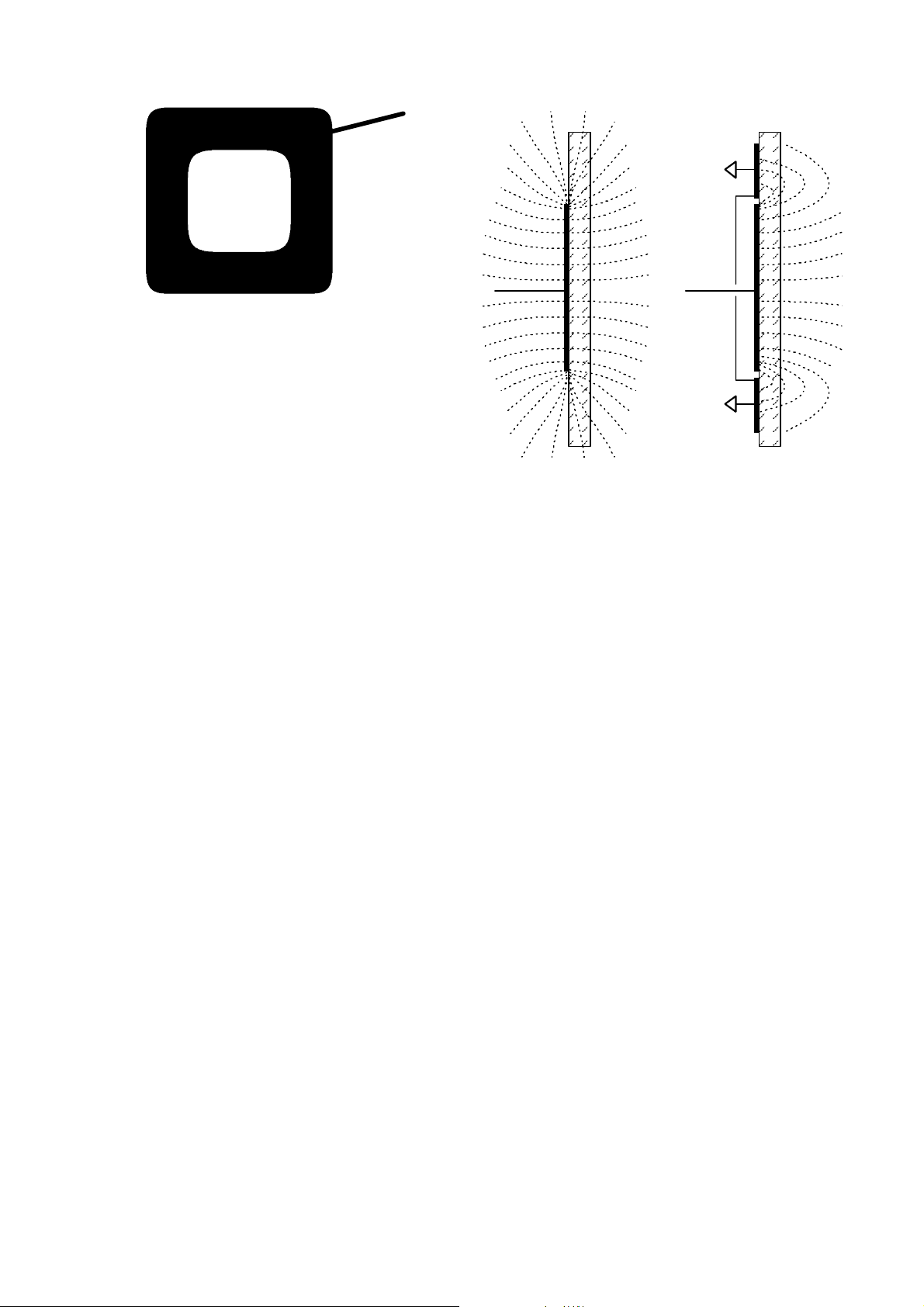

1.3.3 B

ACKLIGHTING KEYS

Touch pads can be back-illuminated quite readily using

electrodes with a sparse mesh (Figure 1-3) or a hole in the

middle (Figure 1-4). The holes can be as large as 4 cm in

diameter provided that the ring of metal is at least twice as

wide as the thickness of the overlying panel, and the panel is

greater than 1/8 as thick as the diameter of the hole. Thin

panels do not work well with this method as they do not

propagate fields laterally very well, and will have poor

sensitivity in the middle. Experimentation is required.

A good example of backlighting can be found in the E160

evaluation board.

1.3.4 V

IRTUAL CAPACITIVE GROUNDS

When detecting human contact (e.g. a fingertip), grounding

of the person is never required. The human body naturally

has several hundred picofarads of ‘free space’ capacitance

to the local environment (Cx3 in Figure 1-2), which is more

than two orders of magnitude greater than that required to

create a detection. The sensor’s PCB however may be

physically small, so there may be little ‘free space’ coupling

(Cx1 in Figure 1-2) between it and the environment to

Figure 1-3 Mesh Electrode Geometry

Sense Electrode

SENSOR

C

X1

Surrounding environment

lQ

C

X3

3 QT140/150 1.01/1102

Figure 1-4 Open Electrode for Back-Illumination

Figure 1-5 Shielding Against Fringe Fields

complete the return path. If the circuit ground cannot be

earth grounded by wire, for example via the supply

connections, then a ‘virtual capacitive ground’ may be

required to increase return coupling.

A ‘virtual capacitive ground’ can be created by connecting

the IC's circuit ground to:

(1) A nearby piece of metal or metallized housing;

(2) A floating conductive ground plane;

(3) A larger electronic device (to which its output might be

connected anyway).

Free-floating ground planes such as metal foils should

maximize exposed surface area in a flat plane if possible. A

square of metal foil will have little effect if it is rolled up or

crumpled into a ball. Virtual ground planes are more effective

and can be made smaller if they are physically bonded to

other surfaces, for example a wall or floor.

1.3.5 F

The electrode can be prevented from sensing in undesired

directions with the assistance of metal shielding connected

to circuit ground (Figure 1-5). For example, on flat surfaces,

the field can spread laterally and create a larger touch area

than desired. To stop field spreading, it is only necessary to

surround the touch electrode on all sides with a ring of metal

connected to circuit ground. The ring will stop field spreading

from that point outwards.

If one side of the panel to which the electrode is fixed has

moving traffic near it, these objects can cause inadvertent

detections. This is called ‘walk-by’ and is caused by the fact

that the fields radiate from either surface of the electrode

equally well. Again, shielding in the form of a metal sheet or

foil connected to circuit ground will prevent walk-by; putting

an air gap between the grounded shield and the electrode

will help to keep the value of Cx low.

1.3.6 S

Sensitivity can be altered to suit various applications and

situations on a channel-by-channel basis. The easiest and

IELD SHAPING

ENSITIVITY

Sense

wire

most direct way to impact sensitivity is to alter the value of

Cs; more Cs yields higher sensitivity.

1.3.6.1 Alternative Ways to Increase Sensitivity

Sensitivity can also be increased by using bigger electrodes,

reducing panel thickness, or altering panel composition.

Increasing electrode size can have diminishing returns, as

high values of Cx counteract sensor gain; however, Cs can

be increased to combat this up to the rated device limit. Also,

increasing the electrode's surface area will not substantially

increase touch sensitivity if its diameter is already much

larger in surface area than fingertip contact area.

The panel or other intervening material can be made thinner,

but again there are diminishing rewards for doing so. Panel

material can also be changed to one having a higher

dielectric constant, which will help propagate the field

through to the front. Locally adding some conductive material

to the panel (conductive materials essentially have an infinite

dielectric constant) will also help; for example, adding carbon

or metal fibers to a plastic panel will greatly increase frontal

field strength, even if the fiber density is too low to make the

plastic bulk-conductive.

1.3.6.2 Decreasing Sensitivity

In some cases the circuit may be too sensitive. Gain can be

lowered further by a number of strategies: a) making the

electrode smaller, b) making the electrode into a sparse

mesh using a high space-to-conductor ratio (Figure 1-3), or

c) by decreasing the Cs capacitors.

Sense

wire

lQ

4 QT140/150 1.01/1102

l

Q

2

Figure 1-6 Basic Circuit (QT140, SSOP Package)

Figure 1-7 Basic Circuit (QT150, SSOP Package)

5 QT140/150 1.01/110

Figure 1-8 Synchronized QT140, QT150 Circuits

2 - QT140/QT150 SPECIFICS

Figure 2-1 Drift Compensation

2.1 SIGNAL PROCESSING

These devices process all signals using 16 bit

math, using a number of algorithms pioneered by

Quantum. These algorithms are specifically

designed to provide for high survivability in the face

of adverse environmental changes.

2.1.1 D

Signal drift can occur because of changes in Cx,

Cs, and Vdd over time. If a low grade Cs capacitor

is chosen, the signal can drift greatly with

temperature. If keys are subject to extremes of

temperature or humidity, the signal can also drift. It

is crucial that drift be compensated, else false detections,

non-detections, and sensitivity shifts will follow.

Drift compensation (Figure 2-1) is a method that makes the

reference level track the raw signal at a slow rate, only while

no detection is in effect. The rate of reference adjustment

must be performed slowly else legitimate detections can also

be ignored. The IC drift compensates each channel

independently using a slew-rate limited change to the

reference level; the threshold and hysteresis values are

slaved to this reference.

Once an object is sensed, the drift compensation mechanism

ceases since the signal is legitimately high, and therefore

should not cause the reference level to change.

The signal drift compensation is 'asymmetric'; the reference

level drift-compensates in one direction faster than it does in

the other. Specifically, it compensates faster for decreasing

signals than for increasing signals. Increasing signals should

not be compensated for quickly, since an approaching finger

could be compensated for partially or entirely before even

approaching the sense electrode. However, an obstruction

over the sense pad, for which the sensor has already made

full allowance for, could suddenly be removed leaving the

sensor with an artificially elevated reference level and thus

become insensitive to touch. In this latter case, the sensor

will compensate for the object's removal very quickly, usually

in only a few seconds.

With large values of Cs and small values of Cx, drift

compensation will appear to operate more slowly than with

the converse.

2.1.2 T

The internal threshold level is fixed at 6 counts for all

channels. These IC's employ a fixed hysteresis of 2 counts

below the threshold (33%).

2.1.3 MAX ON-D

If a sufficiently large object contacts a key for a prolonged

duration, the signal will trigger a detection output preventing

further normal operation. To cure such ‘stuck key’ conditions,

the sensor includes a timer on each channel to monitor

detection duration. If a detection exceeds the maximum timer

setting, the timer causes the sensor to perform a full

recalibration (if not set for infinite). This is known as the Max

On-Duration feature.

After the Max On-Duration interval, the sensor channel will

once again function normally, even if partially or fully

obstructed, to the best of its ability given electrode

RIFT COMPENSATION

HRESHOLD CALCULATION

URATION

Threshold

Out pu t

Signal

Reference

conditions. There are three timeout durations available via

strap option: 10s, 60s, and infinite (Table 2-1).

Max On-Duration works independently per channel; a

timeout on one channel has no effect on another channel

except when the AKS feature is impacted on an adjacent

key. Note also that the timings in Table 2-1 are dependent on

the oscillator frequency: Doubling the recommended

frequency will halve the timeouts.

Infinite timeout is useful in applications where a prolonged

detection can occur and where the output must reflect the

detection no matter how long. In infinite timeout mode, the

designer should take care to be sure that drift in Cs, Cx, and

Vdd do not cause the device to ‘stick on’ inadvertently even

when the target object is removed from the sense field.

The delay timings for Max On-Duration depend directly on

resonator frequency. Also, if the acquisition burst on one or

more channels lasts longer than 5.5ms per channel, the

specified timings may be longer.

2.1.4 D

It is desirable to suppress false detections due to electrical

noise or from quick brushes with an object. To this end,

these devices incorporate a per-key ‘Detection Integrator’

counter that increments with each signal detection exceeding

the signal threshold (Figure 2-1) until a limit count is

reached, after which an Out pin becomes active. If a ‘no

detect’ is sensed prior to the limit, this counter is reset to

zero. The required limit count is 3.

The Detection Integrator can also be viewed as a

'consensus' vote requiring a detection in three successive

samples to trigger an active output.

2.1.5 F

Pin 28 is a Reset pin, active-low, which in cases where

power is clean can be simply tied to Vdd. On power-up, the

device will automatically recalibrate all channels of sensing.

Pin 28 can also be controlled by logic or a microcontroller to

force the chip to recalibrate, by toggling it low for 5µs then

raising it high again.

2.1.6 R

Response time is fixed at 99ms at a 10MHz clock. Response

time can be altered by changing the clock frequency;

doubling the frequency to 20MHz will cut the response time

to 49ms.

ETECTION INTEGRATOR

ORCED SENSOR RECALIBRATION

ESPONSE TIME

Hysteresis

lQ

6 QT140/150 1.01/1102

2.2 OUTPUT FEATURES

These devices are designed for maximum flexibility and can

accommodate most popular sensing requirements via option

pins.

OPT1 and OPT2 inputs control the output mode and Max

On-Duration settings;

OC controls the output drive type;

AKS controls the use of Adjacent Key Suppression.

All option pins are read by the IC once each complete

acquisition cycle and can be changed during operation.

OPT1 and OPT2 modes are shown in Table 2-1. These OPT

pins affect all sensing channels.

2.2.1 DC M

Outputs can respond in a DC mode, where they are active

upon a confirmed detection. An output will remain active for

the duration of the detection, or until the ‘Max On-Duration’

expires (if not infinite), whichever occurs first. If a Max

On-Duration timeout occurs first, the sensor performs a full

recalibration and the output becomes inactive until the next

detection.

2.2.2 T

This mode makes the sensor respond in an on/off flip-flop

mode. It is useful for controlling power loads, for example in

kitchen appliances, power tools, light switches, etc. or

wherever a ‘touch-on / touch-off’ effect is required.

Max On-Duration in Toggle mode is fixed at 10 seconds.

When a timeout occurs, the sensor recalibrates but leaves

the output state unchanged.

2.2.3 O

The OC pin controls the output drive type.

OC=0: When tied low, the output is ‘push-pull’, i.e. ‘normal’.

In this mode, the OUT pins are active-high and can source

1mA and sink 5mA of non-inductive current.

OC=1: When tied high, the output is ‘open drain’ or ‘open

collector’, i.e. There is no internal pullup device in this mode;

OUT pins are active-low and can sink 5mA of non-inductive

current.

If inductive loads are used, such as small relays, the

inductances should be diode clamped to prevent damage.

When set to operate in a proximity mode (at high gain)

output pin currents should be limited to 1mA to prevent gain

shifting side effects from occurring, which happens when the

load current creates voltage drops on the die and bonding

wires; these small shifts can materially influence the signal

level to cause detection instability as described below.

Care should be taken when the IC and the loads are both

powered from the same supply, and the supply is minimally

regulated. These devices derive their internal references

from the power supply, and sensitivity shifts can occur with

changes in Vdd, as happens when loads are switched on.

This can induce detection ‘cycling’, whereby an object is

detected, the load is turned on, the supply sags, the

detection is no longer sensed, the load is turned off, the

supply rises and the object is reacquired, ad infinitum. To

prevent this occurrence, the Out pins should only be lightly

loaded if the device is operated from an unregulated supply,

ODE OUTPUTS

OGGLE MODE OUTPUTS

UTPUT DRIVE

; OC O

PTION PIN

Table 2-1 OPT Strap Options

Max On-DurationOPT2OPT1

DC Out

DC Out

Toggle

DC Out

10sVddGnd

60sGndVdd

10sVddVdd

infiniteGndGnd

e.g. batteries. Detection ‘stiction’, the opposite effect, can

occur if a load is shed when an Out pin is active.

2.3 AKS™ - ADJACENT KEY SUPPRESSION

These devices feature patent-pending Adjacent Key

Suppression for use in applications where keys are tightly

spaced. If keys are very close and a large finger touches one

key, adjacent keys might also activate. AKS stops such false

detections by comparing relative signal levels among

channels and choosing the channel with the largest signal.

The AKS feature can be disabled via the AKS pin:

AKS=0: Disabled; AKS=1: Enabled

The AKS in these parts is a ‘global’ in nature, meaning that

the signal of each key is compared with all other keys, and

only the key with the strongest signal among all keys will

survive initial detection. The word ‘Adjacent’ therefore should

be taken liberally, as a particular key number can be

physically near any other key number and the AKS feature

will operate correctly.

When a touch is detected on a key, but just before the

corresponding OUT pin is activated, a check is made for a

pending or current detection on the other keys. If any other

key is active, or if a signal of greater strength is found on any

other key, the key detection is suppressed. Once the active

key(s) are released, a pending key is free to detect.

Drift compensation also ceases for any key which has been

suppressed, provided its signal exceeds its threshold level

(Figure 2-1).

AKS is also very effective on water films which bridge over

adjacent keys. When touching one key a water film will

‘transport’ the touch to the adjacent keys covered by the

same film. These side keys will receive less signal strength

than the key actually being touched, and so they will be

suppressed even if the signal they are detecting is large

enough to otherwise cause an output.

The downside of ‘global’ AKS is that it is not possible to have

more than one key active at a time.

When two or more devices are synchronized together and all

are using AKS mode, the AKS feature does not extend

beyond each chip. Therefore, in multi-chip configurations it is

possible to use AKS on all keys but still permit 2 or more

keys to detect at the same time.

2.4 SYNCHRONIZATION

Adjacent capacitive sensors that operate independently can

cross-interfere with each other in ways that will create

sensitivity shifts and spurious detections. Because

Quantum’s QT devices operate in burst mode as opposed to

continuous mode, the opportunity exists to solve this problem

by using time-sequencing of the sensing channels so that

physically adjacent channels do not sense within the same

lQ

7 QT140/150 1.01/1102

time-slot. Within these ICs the sensing channels already

operate in time-sequence, so it is not possible for a given

IC’s channels to cross interfere with each other even if the

electrodes are directly adjacent to one another.

However the use of 2 or more chips can create a problem,

because if they are not somehow synchronized to each other

the cross-interference problem will occur between adjacent

channels of the different chips.

2.4.1 M

A bidrectional, open-drain SYNC pin has been provided to

allow 2 or more QT140’s or QT150’s in various combinations

to synchronize to each other (Figure 1-8). All the chips in a

system, whether 1 or 20, should connect to this common line

with a single 10K pullup resistor.

A single QT140 or QT150 must also use a pullup resistor.

SYNC floats high during the Channel 1 sensing burst. When

the IC completes Channel 1 sensing, it pulls down SYNC.

SYNC will continue to be pulled low until the last sensing

channel has completed, when it is unclamped. The IC waits

until SYNC rises high before it will start Channel 1 sensing

again.

If two or more chips are tied into SYNC, all chips must

release SYNC before it actually floats high. Thus, all chips

that us a common SYNC connection will synchronize on

Channel 1.

This mechanism forces all like sensing channels to be

time-aligned among all chips. Thus, all Channel 1’s acquire

at the same time, then all Channel 2’s etc. This means that

when designing a PCB and electrode array, it is important to

not place like channel numbers next to each other or they will

cross interfere. However this leaves a tremendous latitude

for placing channels from different chips having different

channel numbers next to each other.

For example Channel 1 of chip ‘A’ can be routed and

physically placed adjacent to Channel 2 of chip ‘B’, or

Channel 4 of chip ‘F’ and so on. But it is not good to place

Channel 3 of chip ‘A’ next to Channel 3 of chip ‘B’.

ULTI-CHIP SYNC

3 - CIRCUIT GUIDELINES

3.1 SAMPLE CAPACITOR

Charge sampler caps Cs can be virtually any plastic film or

low to medium-K ceramic capacitor. The acceptable Cs

range is from 1nF to 200nF depending on the sensitivity

required; larger values of Cs demand higher stability to

ensure reliable sensing. Acceptable capacitor types include

plastic film (especially PPS film), NP0 / C0G ceramic. X7R

ceramic can also be used but these are less stable over

temperature.

3.2 OPTION STRAPPING

The option pins OC, AKS, OPT1 and OPT2 should never be

left floating. If they are floated, the device can draw excess

power and the options will not be properly read. See Section

2.2 and 2.3 for options.

3.3 POWER SUPPLY, PCB LAYOUT

The power supply can range from 3 to 5.5 volts. If this

fluctuates slowly with temperature, the device will track and

compensate for these changes automatically with only minor

changes in sensitivity. If the supply voltage drifts or shift

quickly, the drift compensation mechanism will not be able to

keep up, causing sensitivity anomalies or false detections.

The devices will track slow changes in Vdd, but can be

seriously affected by rapid voltage steps.

If the supply is shared with another electronic system, care

should be taken to assure that the supply is free of digital

spikes, sags, and surges which can cause adverse effects.

The supply is best locally regulated using a conventional

78L05 type regulator, or almost any 3-terminal LDO device

from 3V to 5V.

For proper operation a 0.1µF or greater bypass capacitor

must be used between Vdd and Vss; the bypass cap should

be placed very close to the device Vss and Vdd pins.

The PCB should if possible include a copper pour under and

around the IC, but not extensively under the SNS lines.

2.4.2 N

The effects of external noise sources can be heavily

suppressed by synchronizing these devices to the noise

source itself. External noise creates an ‘aliasing’ or ‘beat’

frequency effect between the sampling rate of the QT part

and the external noise frequency.

In many cases, especially with repetitive noise like 50/60Hz

AC fields, the noise effects will vanish if the device is

synchronized to the external field. This can take the form of a

simple AC zero-crossing detector feeding the pullup resistor

on SYNC instead of tying the SYNC resistor to Vdd. Multiple

devices tied to SYNC can be synchronized to the mains

frequency in this fashion.

In the case of noise from sources such as backlight inverters

etc, it is sometimes best to synchronize by disabling the

inverter for a brief moment while the QT device acquires.

OISE SYNC

lQ

3.4 OSCILLATOR

The oscillator should be a 10MHz resonator with ceramic

capacitors to ground on each side. 3-pin resonators with

built-in capacitors designed for the purpose are inexpensive

and commonly found. Manufacturers include AVX, Murata,

Panasonic, etc.

Alternatively an external clock source can be used in lieu of a

resonator. The OSC_I pin should be connected to the

external clock, and OSC_O should be left unconnected.

These ICs are fully synchronous devices that are slaved to

the OSC_I clock frequency. If the frequency of OSC_I is

changed, all timings will also change in direct proportion,

from the charge and transfer times to the detection response

times and the Max On-duration timings.

3.5 UNUSED CHANNELS

Unused SNS pins should not be left open. They should have

a small value non-critical dummy Cs capacitor connected to

their SNS pins to allow the internal circuit to continue to

function properly. A nominal value of 1nF (1,000pF) X7R

ceramic will suffice.

8 QT140/150 1.01/1102

Unused channels should not have sense traces or

electrodes connected to them.

3.6 ESD PROTECTION

In cases where the electrode is placed behind a dielectric

panel, the IC will be protected from direct static discharge.

However even with a panel, transients can still flow into the

electrodes via induction, or in extreme cases via dielectric

breakdown. Porous materials may allow a spark to tunnel

right through the material. Testing is required to reveal any

problems. The device does have diode protection on its SNS

pins which absorb and protect the device from most induced

discharges, up to 20mA; the usefulness of the internal

clamping will depending on the dielectric properties, panel

thickness, and rise time of the ESD transients.

In extreme cases ESD dissipation can be aided further by

adding 1K series resistors in series with the electrodes as

shown in Figures 1-6 through 1-8. Because the charge time

is 1.2µs, the circuit can tolerate large values of series-R, up

to 20k ohms in cases where electrode Cx load is below

10pF. Extra diode protection at the electrodes can also be

used, but this often leads to additional RFI problems as the

diodes will rectify RF signals into DC which will disturb the

signals.

If the series-R is too large, sensitivity will drop off.

Directly placing semiconductor transient protection devices

or MOV's on the sense leads is not advised; these devices

have extremely large amounts of nonlinear parasitic C which

will swamp the capacitance of the electrode and cause

strange sensing problems.

Series-R’s should be low enough to permit at least 6 RC

time-constants to occur during the charge and transfer

phases, where R is the added series-R and C is the load Cx.

If the device is connected to an external control circuit via a

cable or long twisted pair, it is possible for ground-bounce to

cause damage to the Out pins and/or interfere with key

sensing. Noise current injection into the power supply is best

dealt with by shunting the noise aside to chassis ground with

capacitors, and further limited using resistors or ferrites.

3.7 RFI PROTECTION

PCB layout, grounding, and the structure of the input circuitry

have a great bearing on the success of a design that can

withstand strong RF interference.

The circuit is remarkably immune to RFI provided that certain

design rules are adhered to:

1. Use SMT components to minimize lead lengths.

2. Connect electrodes to SNSnA, not SNSnB pins.

3. Use a ground plane under and around the circuit and

along the sense lines, that is as unbroken as possible

except for relief under and beside the sense lines to

reduce total Cx. Relieved rear ground planes along the

SNS lines should be ‘mended’ by bridging over them at

1cm intervals with 0.5mm ‘rungs’ like a ladder.

4. Ground planes and traces should be connected only to a

common point near the Vss pins of the IC.

5. Route sense traces away from other traces or wires that

are connected to other circuits.

6. Sense electrodes should be kept away from other

circuits and grounds which are not directly connected to

the sensor’s own circuit ground; other grounds will

appear to float at high frequencies and couple RF

currents into the sense lines.

7. Keep the Cs sampling capacitors and all series-R

components close to the IC.

8. Use a 0.1µF minimum ceramic bypass cap very close to

the Vss / Vdd supply pins.

9. Use series-R’s in the sense lines, of as large a value as

the circuit can tolerate without degrading sensitivity

appreciably.

10.Bypass input power to chassis ground and again at

circuit ground to reduce line-injected noise effects.

Ferrites over the power wiring may be required to

attenuate line injected noise.

Achieving RF immunity requires diligence and a good

working knowledge of grounding, shielding, and layout

techniques. Very few projects involving these devices will fail

EMC tests once properly constructed.

lQ

9 QT140/150 1.01/1102

4.1 ABSOLUTE MAXIMUM SPECIFICATIONS

A

A

V

V

V

V

Operating temp................................................................................ as designated by suffix

Storage temp....................................................................................... -55

DD

.................................................................................................... -0.5 to +7.0V

V

Max continuous pin current, any control or drive pin..............................................................±20mA

Short circuit duration to ground, any pin......................................................................... infinite

DD

Short circuit duration to V

, any pin............................................................................ infinite

Voltage forced onto any pin...................................................................-0.6V to (Vdd + 0.6) Volts

O

C to +125OC

4.2 RECOMMENDED OPERATING CONDITIONS

VDD.....................................................................................................+3.0 to 5.5V

Operating temperature range, 4.5V - 5.5V (QT140-AS, QT150-AS)........................................... -40 - +105C

Operating temperature range, 3.0V - 4.5V (QT140-AS, QT150-AS)............................................ -40 - +85C

Operating temperature range, all voltages (QT140-D, QT150-D).................................................0 - +70C

Operating frequency, 4.5V - 5.5V........................................................................... 4 - 20MHz

Operating frequency, 3.0V - 5.5V........................................................................... 4 - 10MHz

Short-term supply ripple+noise................................................................................ ±5mV/s

Long-term supply stability.................................................................................... ±100mV

Cs value............................................................................................... 1nF to 200nF

Cx value..................................................................................................0 to 100pF

4.3 AC SPECIFICATIONS

RC

PC

PT

AC

BL

BL

BLMR

R

cquisition time, all channelsT

llowable burst duration rangeT

Vdd = 5.0, Ta = recommended, Cx = 5pF, Cs = 39nF, Fosc = 10MHz

ms330Recalibration timeT

µs1.2Charge durationT

µs1.6Transfer durationT

ms33

ms3Burst duration, each channelT

counts1,000Burst length, each channelN

Before all timings degradems5.50.1

Including detection integratorms99Response timeT

4.4 DC SPECIFICATIONS

Vdd = 5.0V, Cs = 39nF, Cx = 5pF, Fosc = 10MHz, Ta = recommended range, unless otherwise noted

DD

DDS

HL

OL

OH

IL

IL

Vdd-0.7High output voltage

R

0.7Low input logic level

mA82.5Supply currentI

Req’d for startup, w/o reset circuitV/s100Supply turn-on slopeV

OPT1, OPT2, OC, AKS, SYNC

OPT1, OPT2 , OC, AKS, SYNCV2High input logic levelV

OUTn, SYNC, @ 4mA sinkV0.6Low output voltageV

OUTn, 1mA source

OPT1, OPT2, OC, AKSµA±1Input leakage currentI

bits1410Acquisition resolutionA

NotesUnitsMaxTypMinDescriptionParameter

NotesUnitsMaxTypMinDescriptionParameter

lQ

10 QT140/150 1.01/1102

4.5 SIGNAL PROCESSING

V

alueDescription

samples3Consensus filter length (Detection integrator)

ms/level990Positive drift compensation rate

ms/level231Negative drift compensation rate

All curves at Vdd = 5.0V

NotesUnits

From signal referencecounts6Threshold differential

From thresholdcounts2Hysteresis

Option pin selectedsecs10, 60, infinitePost-detection recalibration timer duration

Burst Duration vs. Cs, Cx

18000

16000

14000

12000

10000

8000

6000

4000

Burst Duration, Microseconds

2000

0

01020304050

Cx

Figure 4-1 Figure 4-2

18000

16000

14000

Cs = 220nF

Cs = 100nF

Cs = 47nF

Cs = 39nF

Cs = 22nF

Cs = 10nF

Burst Duration cs. Cs, Cx

Burst Dura tion v s . Cs, Cx

4000

3500

3000

2500

2000

1500

1000

Burst Duration, Microseconds

500

0

0 1020 304050

Cx

Cs = 47nF

Cs = 39nF

Cs = 22nF

Cs = 10nF

12000

10000

8000

6000

4000

Burst Duration, Microseconds

2000

0

0 50 100 150 200 250

Cs, nF

Cx = 5pF

Cx = 10pF

Cx = 15pF

Cx = 22pF

Cx = 33pF

Cx = 47pF

Figure 4-3

lQ

11 QT140/150 1.01/1102

5 - PACKAGE OUTLINES

SYMBOL

Package type: 28-Pin Dual-In-Line

L

D

InchesMillimeters

NotesMaxMinNotesMaxMin

0.2950.287.4937.112a

0.330.318.3827.874A

1.3951.38535.17934.163M

0.0480.0231.220.584Q

0.0220.0160.5590.406P

0.140.1253.5563.175R

-0.015-0.381r

0.1450.1253.6833.175S

0.180.1433.6323.632S1

0.310.317.8747.874Aa

0.390.329.9068.128x

BSC1.31.3BSC33.0233.02m

4 places0.020.0084 places0.5080.203L

Typical0.0650.04Typical1.6511.016L1

BSC0.10.1BSC2.542.54F

Typical0.0130.008Typical0.2030.203Y

SYMBOL

Seating level

2a

W

e

ø

M

Base level

H

h

E

Package type: 28-pin SSOP

InchesMillimeters

NotesMaxMinNotesMaxMin

0.4070.39610.3310.070M

0.3110.3017.97.650W

0.2120.2055.385.2002a

0.0260.0260.650.650D

0.0150.0100.380.250L

0.0370.0220.950.550E

0.0090.0050.220.130e

8º0º8º0ºØ

0.0780.0681.991.730H

0.0080.0020.210.050h

lQ

12 QT140/150 1.01/1102

8 - ORDERING INFORMATION

MARKINGPACKAGETEMP RANGEPART

QT140PDIP-280 - 70CQT140-D

QT140-ASSOP-28-40 - 105CQT140-AS

QT150PDIP-280 - 70CQT150-D

QT150-ASSOP-28-40 - 105CQT150-AS

lQ

13 QT140/150 1.01/1102

lQ

Copyright © 2002 QRG Ltd. All rights reserved.

Patented and patents pending

Corporate Headquarters

Ensign Way, Hamble SO31 4RF

Tel: +44 (0)23 8056 5600 Fax: +44 (0)23 8045 3939

1 Mitchell Point

Great Britain

admin@qprox.com

www.qprox.com

North America

651 Holiday Drive Bldg. 5 / 300

Pittsburgh, PA 15220 USA

Tel: 412-391-7367 Fax: 412-291-1015

The specifications set out in this document are subject to change without notice. All products sold and services supplied by QRG are subject

to our Terms and Conditions of sale and supply of services which are available online at www.qprox.com and are supplied with every order

acknowledgement. QProx, QTouch, QMatrix, QLevel, and QSlide are trademarks of QRG. QRG products are not suitable for medical

(including life-saving equipment), safety or mission critical applications or other similar purposes. Except as expressly set out in QRG's

Terms and Conditions, no licenses to patents or other intellectual property of QRG (express or implied) are granted by QRG in connection

with the sale of QRG products or provision of QRG services. QRG will not be liable for customer product design and customers are entirely

responsible for their products and applications which incorporate QRG's products.

Loading...

Loading...