Q

CHARGE-TRANSFER QLEVEL™ SENSOR IC

!!!! Limit sensing of almost any fluid or powder

!!!! 2-Tier level sensor - Hi / Low limits with one probe

!!!! Only one external part required - a 5¢ capacitor

!!!! Uses internal probes or external electrodes

!!!! Active high or active low outputs

!!!! Slosh filter averages response of moving fluids

!!!! LED drive capable on both outputs

!!!! 2.5 to 5V 20µA single supply operation

!!!! HeartBeat™ health indicator on both outputs

APPLICATIONS -

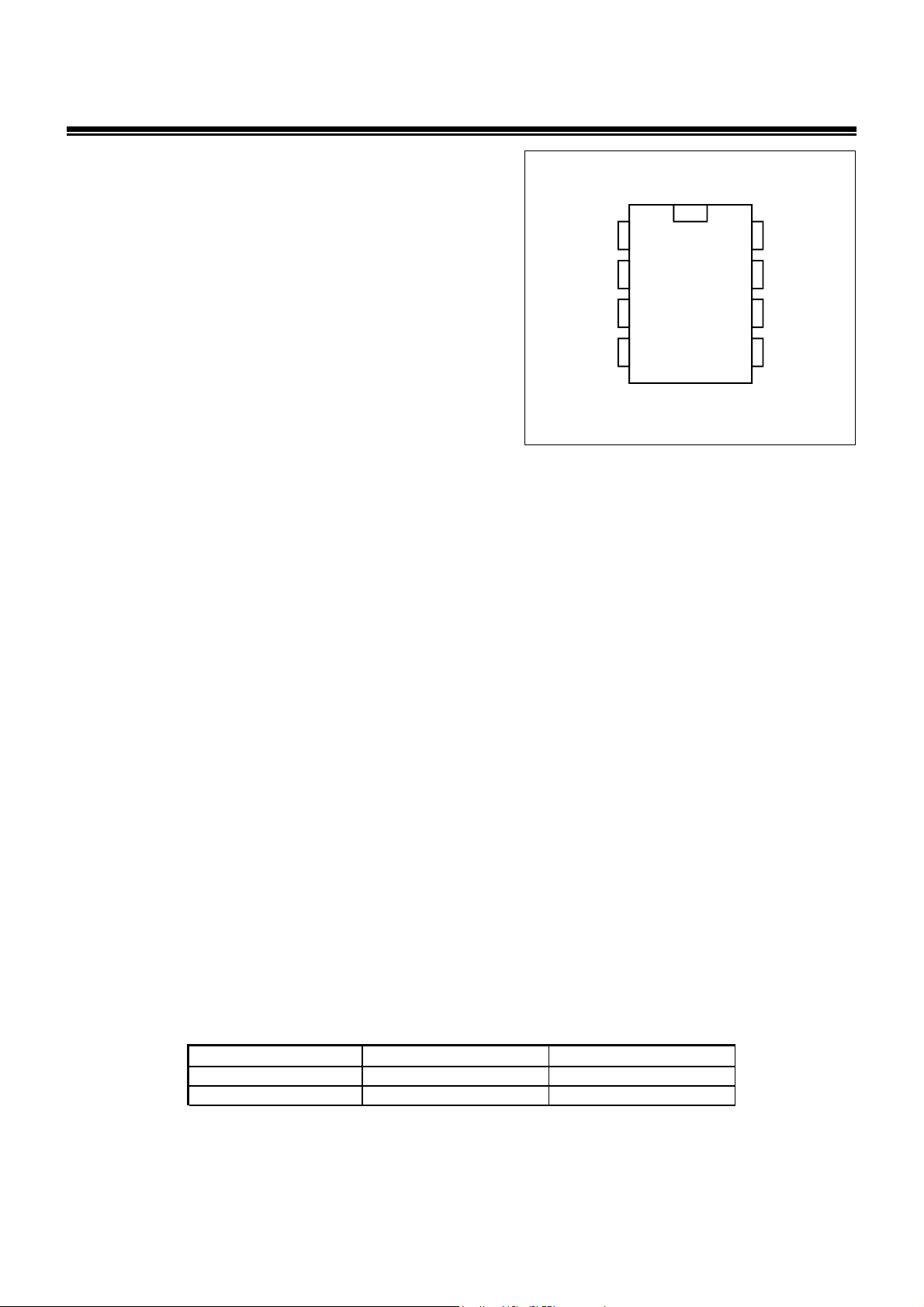

Vcc 1

Out1

Out2

QProx™ QT114

8

QT114

2

3

45

7

6

Gnd

Sns2

Sns1

PolFilt

! Process controls

! Vending machines

! Automotive fluids

! Consumer appliances

! Medical fluid sensing

! Soil moisture sensing

DESCRIPTION -

The QT114 QuickLevel™ charge-transfer (“QT”) sensor IC is specifically designed to detect point level in fluids

and powders. It will project a sense field through almost any dielectric, like glass, plastic, or ceramic, to sense

level on the inside of a vessel, from its exterior. It has the unique capability of independently sensing two trip

points when used with structured electrodes having two tiers.

The QT114 does not have sensing timeouts, drift compensation, or other functions which would interfere with

level sensing. Its threshold levels are fixed, and the amount of signal required to exceed a threshold is dependent

on circuit gain and electrode size and loading, all of which are under the control of the designer.

The QT114 requires only a single inexpensive capacitor in order to function. One or two LEDs can also be added

to provide a visual sensing indication.

Power consumption is under 20mA in most applications, allowing operation from Lithium cells for many years. In

most cases the power supply needs only minimal regulation.

The QT114 employs numerous signal acquisition and processing techniques pioneered by Quantum. No external

switches, opamps, or other analog components aside from CS are required.

A unique feature is the 'slosh filter', a detection integrator which averages detections over a rolling 15 second

interval before activating or deactivating the OUT pins. This filter allows use of the QT114 with violently moving

fluids, for example in a moving vehicle, that would otherwise cause the outputs to flicker between two states.

The device also includes selectable output polarity, allowing both output lines to be made either active-high or

active-low. It also includes the Quantum-pioneered HeartBeat™ signal, allowing a host controller to monitor the

health of the QT114 continuously if desired. By using the charge transfer principle, the IC delivers a level of

performance clearly superior to older technologies. It is specifically designed to replace electromechanical

devices like float switches, thermistors, and conductance probes.

AVAILABLE OPTIONS

A

0

C to +700C

QT114-IS-400C to +850C

8-PIN DIPSOICT

QT114-DQT114-S0

-

uantum Research Group Ltd Copyright © 1999 Quantum Research Group Ltd

R1.03

The QT114 is a digital burst mode charge-transfer (QT)

sensor designed specifically for point level sensing; it

includes all hardware and signal processing functions

necessary to provide stable level sensing under a wide

variety of changing conditions. Only a single external

capacitor is required for operation.

Figure 1-1 shows a basic QT114 circuit using the device,

with conventional OUT drives and power supply connections.

The sensing electrode can be connected to a single-tier or

2-tier electrode as required.

Calibration is done by design, through adjustment of the

electrode sizes and the Cs capacitor. Only under rare

situations do QT114 circuits require calibration on an

individual basis, and the circuit can make provision for that.

OUT 1

OUT 2

Vcc

1

2

OUT1

3

OUT2

45

FILT

8

dd Vdd

V

SNS2

SNS1

POL

Gnd

7

6

POLARITYFILTER

To 10x Scope Probe

C

s

POL: 1 = Active High

FILT: 1 = Slosh Filter

2M (optional)

Ω

To Electrode(s)

Ω

1M multi-turn

pot (optional)

1 - SIGNAL ACQUISITION

The QT114 employs a short, low duty cycle burst of

charge-transfer cycles to acquire its signal. Burst mode

permits power consumption in the low microamp range,

dramatically reduces RF emissions, lowers susceptibility to

EMI, and yet permits excellent response time. Internally the

signals are digitally processed to generate the required

output signals.

The QT switches and charge measurement hardware

functions are all internal to the QT114 (Figure 1-2). A 14-bit

single-slope switched capacitor ADC includes both the

required QT charge and transfer switches in a configuration

that provides direct ADC conversion. The burst length is

inversely proportional to the rate of charge buildup on Cs,

which in turn depends on the values of Cs, Cx, and Vcc. Vcc

is used as the charge reference voltage. Larger values of Cx

cause the charge transferred into Cs to accumulate more

rapidly. The trip points of the sensor can be changed by

altering Cs and Cx, the load capacitance. As a result, the

values of Cs, Cx, and Vcc should be fairly stable over the

expected operating temperature range.

Two fixed thresholds are used, one for low fluid level and the

other for high level; adjusting Cs and Cx to allow these to trip

at appropriate points is required by design, and if required

may be trimmed by an adjustment. Figure 1-1 shows the

optional potentiometer which can be used to fine-tune the

placement of these threshold points relative to the signal.

Figure 1-1 Standard mode options

It is not necessary to use both detection threshold points; if

only single point sensing is desired, only the lower threshold

and OUT1 can be used, while ignoring OUT2.

Two option pins allow the selection of output polarity and the

insertion of a 'slosh filter' before the OUT pins, as shown in

Figure 1-1.

1.1 ELECTRODE DRIVE

The internal ADC treats Cs as a floating transfer capacitor;

as a direct result, the sense electrode can be connected to

either SNS1 or SNS2 with no performance difference. The

polarity of the charge buildup across Cs during a burst is the

same in either case. Cs must be of within a certain range for

proper operation.

It is possible to connect separate Cx and Cx’ loads to SNS1

and SNS2 simultaneously, although the result is no different

than if the loads were connected together at SNS2 (or

SNS1). It is important to limit the amount of stray

capacitance on both terminals, especially if the load Cx is

already large, for example by minimizing trace lengths and

widths so as not to exceed the Cx load specification and to

allow for a larger sensing electrode size if so desired.

The PCB traces, wiring, and any components associated

with or in contact with SNS1 and SNS2 will become

proximity sensitive and should be treated with caution.

Result

Start

SNS2

Done

Burst Controller

Single-Slope 14-bit

Switched Capacitor ADC

Charge

Amp

SNS1

Figure 1-2 Internal Switching & Timing

ELECTRODE

C

s

- 2 -

1.2 THRESHOLD POINTS

The QT114 employs twin threshold points set at both

250 (for T1) and 150 counts (for T2) of acquisition

signal. The signal travels in an inverse direction:

increasing amounts of Cx reduce the signal level; the

baseline ('dry') signal should lie at 300 counts or

more under most conditions. Calibration details are

discussed fully in Section 3.2.

C

2 ELECTRODE DESIGN

x

The QT114 is designed to operate with a 'plateau'

sensor, having a substantial surface area at each

desired trip point, to create a capacitive 'step'.

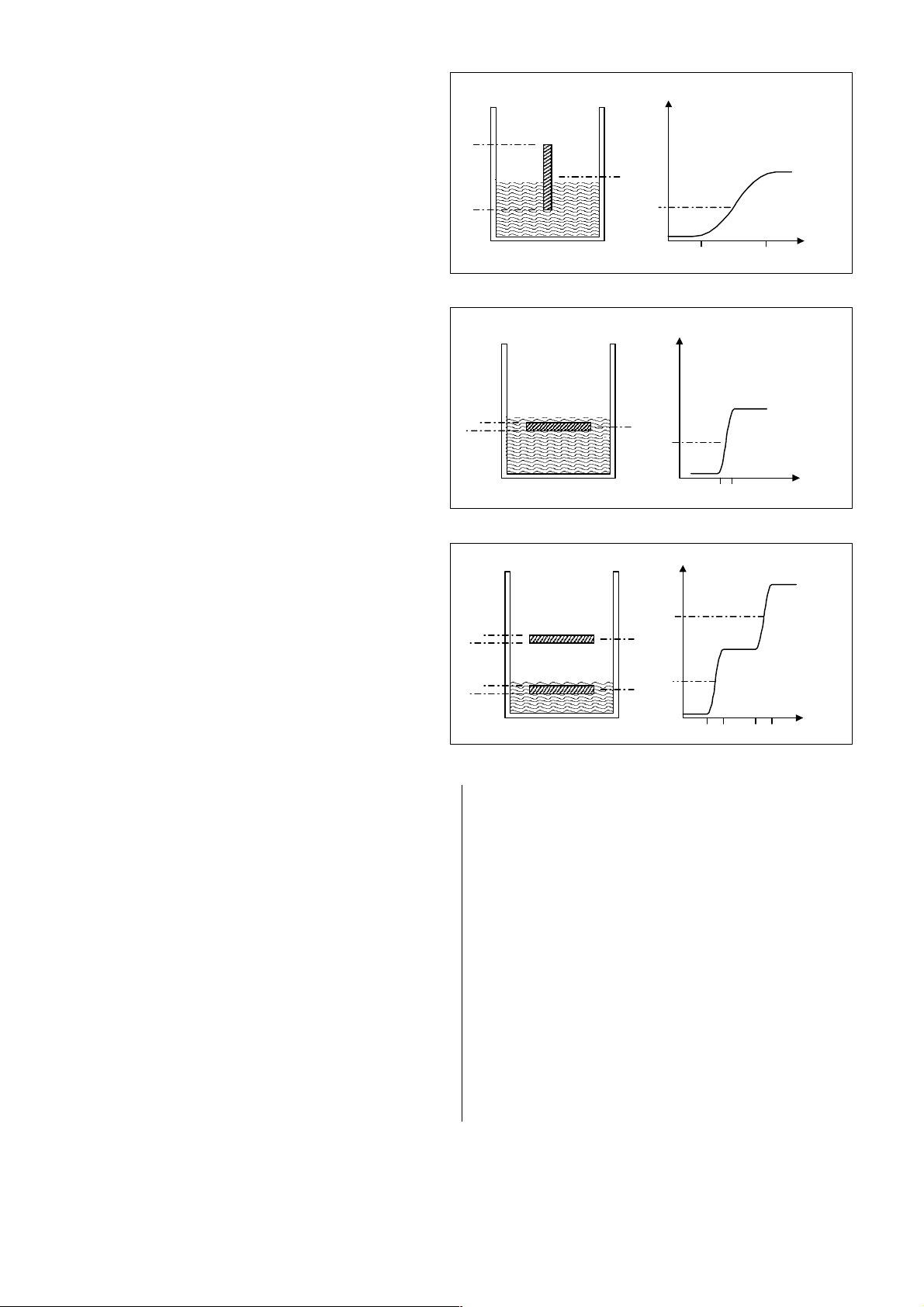

As Figure 2-1 shows, a vertical strip sensor on the

outside of a container (or a vertical, insulated rod in

the fluid) will generate a long sloping signal. The

desired trip point 'T' is subject to a great deal of

variation in location if the sensing signal drifts much,

for example due to changes in Cs or Cx over the operating

temperature range.

Figure 2-2 shows the response from a horizontal strip of

the same surface area; the signal exhibits a very rapid rise

in signal between points l1 and l2. Variations in circuit

gain or signal drift have much less of an effect on the trip

point with this orientation.

In some cases (thin walled vessels for example) it may be

sufficient to have a small round or square electrode patch

on the exterior.

Figure 2-3 shows the response from a twin-level external

electrode set. The use of two horizontal electrode planes

or tiers creates well-defined trip points that can be used to

sense both 'low' and 'high' levels. A crossing of threshold

T1 will be reflected in the OUT1 signal, while T2 will be

reflected on OUT2.

2.1 EXTERNAL ELECTRODES

External electrodes should be electrically conductive;

metal foils and conductive carbon are both possible. Care

should be taken that other objects or people near the

vessel will not touch the electrode; in some cases

shielding around the electrode with grounded metal will be

required to prevent disturbances. If used, the shield

element should be spaced apart from the electrode by an

air gap or a low-density foam to reduce Cx loading.

The required surface area of the external electrode will

depend on the amount of signal needed to bracket the

detection threshold, which in turn will depend in part on Cs

and stray Cx. External electrodes sensing through thick

walls and/or sensing low permittivity fluids will require

larger surface areas than those sensing water through thin

plastic, for example. External electrodes are more likely to

require potentiometer trimming to achieve reliable

operation (Figure 1-1, also Section 3.2).

Note that external electrodes used with conductive

solutions (i.e. aqueous liquids) do not measure the

permittivity of the fluid: they actually measure the

permittivity of the vessel wall, between 2 plates: the

electrode (plate 1) and the fluid (plate 2, effectively a

variable-area ground plate): if the fluid were to be replaced

with mercury the signal would be unchanged. A 20%

thickness variation in the vessel wall will therefore

introduce about a 20% variation in the resulting

capacitance; if the vessel wall cannot be controlled

accurately enough in production, serious sensing errors may

occur.

When external electrodes are used to sense non-aqueous

substances (like oils or gasoline), the vessel wall dielectric

becomes a lessor contributor to the overall signal, which is

then heavily dominated by the permittivity of the fluid. The

lower the permittivity of the fluid the greater its dominance.

2.2 INTERNAL PROBES

When used with aqueous fluids or other electrically

conducting liquids, internal probes should be insulated with a

plastic layer. See also Section 2.1 for a discussion of

electrodes when used with conductive fluids. Aqueous

probes should be 100% insulated, even on the cut end of a

wire probe. The slightest pinhole of exposed metal anywhere

on an immersed part of the probe will immediately convert

the probe into a bare-metal probe (see Section 2.2.5).

Numerous types of internal point-level probes are possible.

Signal

l

2

T

1

l

1

T

1

Level

l

1

l

2

Figure 2-1 Signal vs. Level for an External Vertical Strip

Signal

l

2

l

1

T

1

T

1

l

l

1

2

Level

Figure 2-2 Signal vs. Level for an External Horizontal Strip

Signal

T

2

l

4

l

3

l

2

l

1

T

2

T

1

T

1

l

l3l

l

1

2

Level

4

Figure 2-3 Signal vs. Level for Twin Horizontal Strips

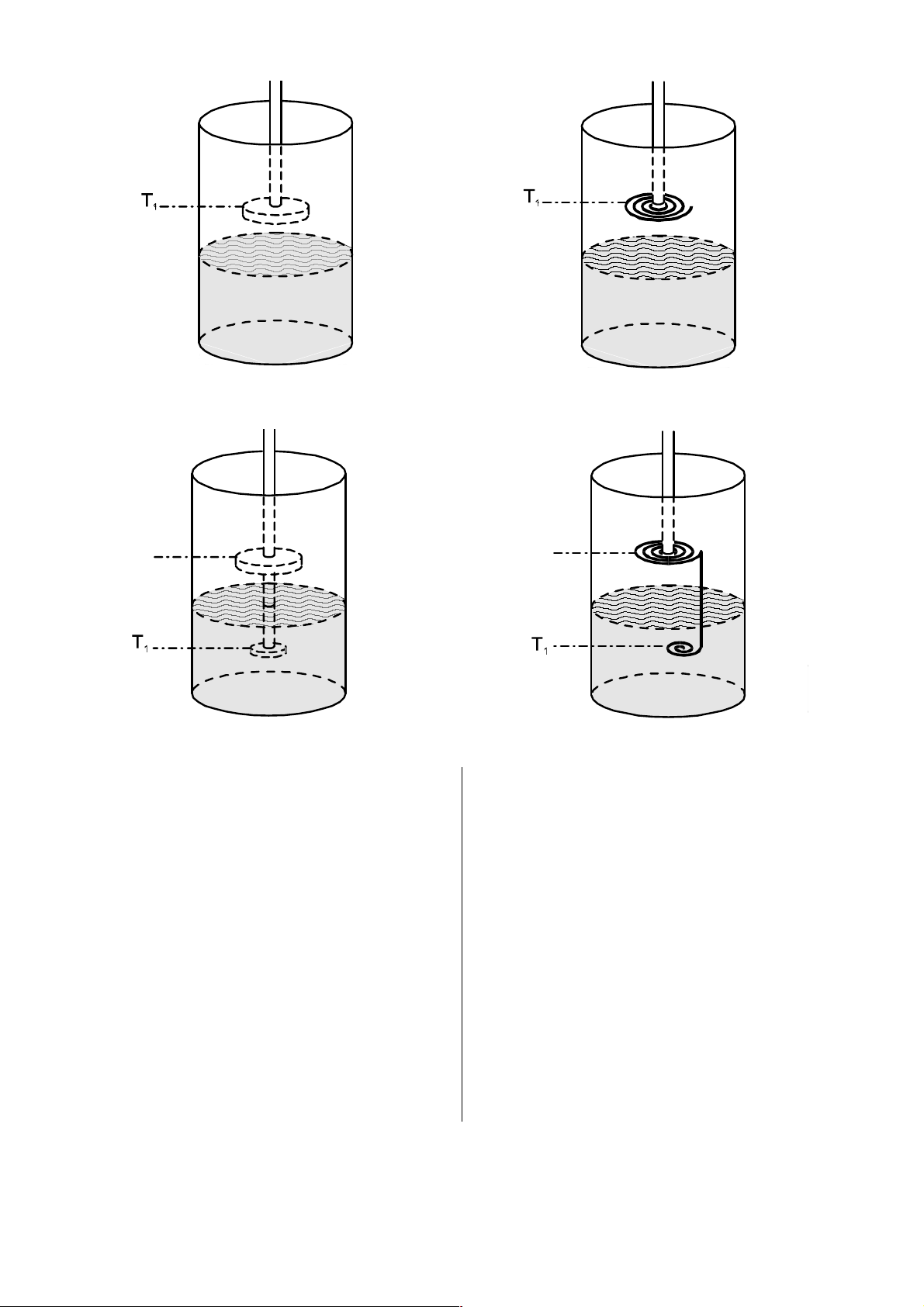

2.2.1 DISC PROBES

The simplest internal geometry is probably a disc probe

(Figure 2-4), having at least one planar surface ('tier')

parallel to the fluid surface. The sensing error can be

minimized by making the tier thin, so that the signal

transitions abruptly higher (see Figure 2-2) as the fluid

covers the tier.

A notable difficulty with disc probes is the task of insulating

them with a uniform, repeatable thickness of insulation.

2.2.2 SPIRAL WIRE PROBES

A spiral solid-wire probe is simple to construct (Figure 2-5),

and has the advantage of being pre-insulated in a wide

choice of plastics from inexpensive PVC to PTFE. These

probe types provide a large step-function of capacitance

localized at the desired trip point, and are easy to form.

Spiral wire probes are most effective in water-based fluids;

they are not as effective in oils and other nonconductive

substances.

- 3 -

Figure 2-5 Single Level Internal Spiral Wire ProbeFigure 2-4 Single Level Internal Planar Probe

T

2

Figure 2-6 Twin-Level Internal Planar Probe

Spiral wire probes have the disadvantage of not being as

rugged as a solid disc probe.

2.2.3 SIDE-ENTRY PROBES

Another type is a side-entry probe (Figure 2-8), which

requires an entry point into the vessel wall, but may have the

advantage of accessibility in certain cases. These can be

made of simple metal rod, insulated in almost any plastic if

required.

2.2.4 COAXIAL PROBES

Another type of internal probe is the coaxial probe (Figure

2-10); these are most useful with oils or similar fluids having

a low dielectric constant; the inner rod is connected to the

signal connection, and together with the outer grounded

cylinder forms a capacitor whose dielectric is either air or oil.

Keeping the gap between rod and cylinder to a minimum

increases the 'gain' of the electrode.

Coaxial probes are more expensive to make, and can have

problems with vibration if they are not constructed robustly.

The outer cylinder should be perforated at key spots to allow

T

2

Figure 2-7 Twin-Level Internal Spiral Wire Probe

fluid to fill and drain the cavity without trapping air bubbles

inside. The outer cylinder can also be made of a wire mesh.

The outer cylinder does not have to be coated in plastic,

even when used with water-based fluids. When used with

oils, the inner rod does not require insulation either.

2.2.5 BARE METAL PROBES

Bare metal internal probes can be used, for example with

nonconductive fluids like oils, without difficulty. This applies

to all probe types described above.

Bare probes can also be used with aqueous fluids, but in

these cases a 1,000pF (1nF) ceramic NPO capacitor should

be inserted between the probe and the QT114 to block DC

current flows.

A bare internal probe used with conductive fluids and an

in-line blocking capacitor will generate a huge, robust

capacitive response that will not readily permit the use of a

2-level probe due to signal saturation. Even the slightest

amount of bare metal exposed to the fluid will usually

generate an immediate, large response with aqueous fluids.

- 4 -

Loading...

Loading...