Q-matic Q-36 User Manual

Q-Matic Ovens

Owners Manual

For models – Q-36, Q-36W, Q-55 & Q-80

Includes Hybrid Models

Table of Contents

Introduction

Radiant Heat Ovens

Oven Cross Section

Specifications

Installation Instructions

Delivery and Inspection

Oven Location and Installation

Oven Assembly

Conveyor Installation

Wire Belt Installation

Speed Control Wiring Diagram

Gas Piping

Piping Size Requirements

Electrical Connections

Component Locations

Oven Start-up

Temperature Control

Oven Shut Down

Guidelines for Cooking Adjustments

Cleaning and Maintenance

Troubleshooting

Electrical Wiring Diagrams

Product Test Form

Warranty

3

3

4

5

6

7

9

10

11

12

14

19

20

21

22

24

25

40

41

45

46

48

52

53

FOR YOUR SAFETY DO NOT

STORE GASOLINE OR

OTHER FLAMMABLE

VAPORS AND LIQUIDS IN

THE VICINITY OF THIS OR

ANY OTHER APPLIANCE.

Instructions to be followed in

the event that the user smells

gas must be posted in

prominent location. This

information may be obtained

by consulting your local gas

supplier.

The information contained in

this manual is important for the

proper installation, use and

maintenance of this oven.

Adherence to prescribed

procedures and instructions

will result in a satisfactory

baking results and long trouble

–free service. Please read this

manual carefully and retain it

for future reference.

Introduction

The Q-Matic Radiant Ovens

Q-Matic is an automatic piece of equipment that can hold and

control the heat applied to a product and the cooking time. Once

the cooking time and temperature has been established for a certain

type of product, i.e. pizza, the operator just turns on the switches in

the morning and off at the end of the day!

This revolutionary new equipment uses infrared heat instead

of forced convection. Infrared heat is produced by gas infrared

metal burners that can use natural gas, butane or any other

manufactured combustion gas. By using infrared heat, this oven

combines the advantages of a deck oven and a conveyor oven.

Since there is plenty of bottom heat capacity, the oven is very

easily adjustable for any type of crust you may have. Also because

of its versatility, Q-Matic is better suited for independent pizza

operations than the forced convention ovens. The noisiness of

forced convection is also eliminated since the Q-Matic ovens do not

employ any blowers to circulate air. For your convenience, the

oven has also been designed with a easy access panel at the front

of the oven for quick efficient service.

Please take the time to read the following operating

instructions carefully. They are the key to successful use of the QMatic oven.

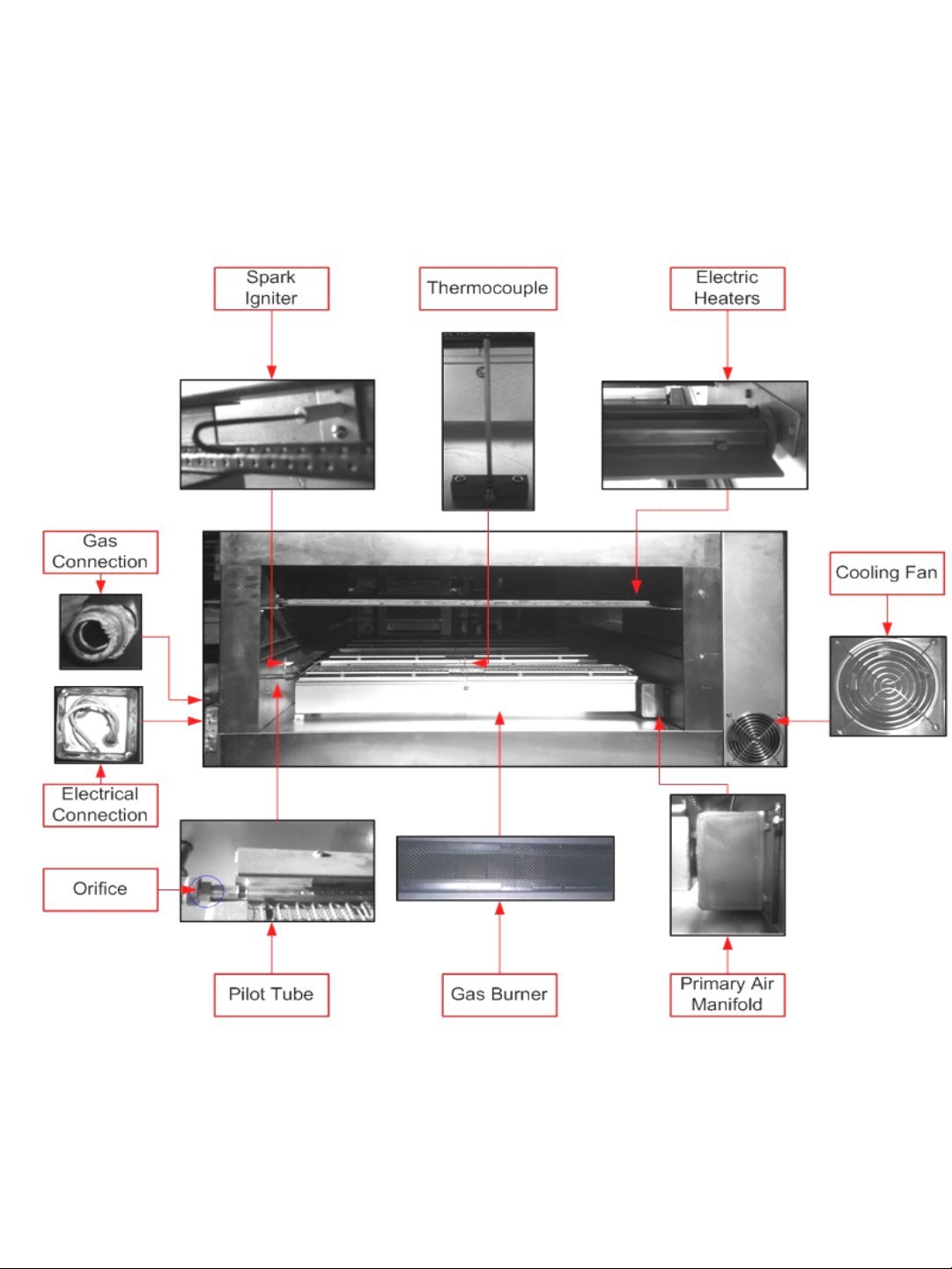

Oven Cross Section

-

-

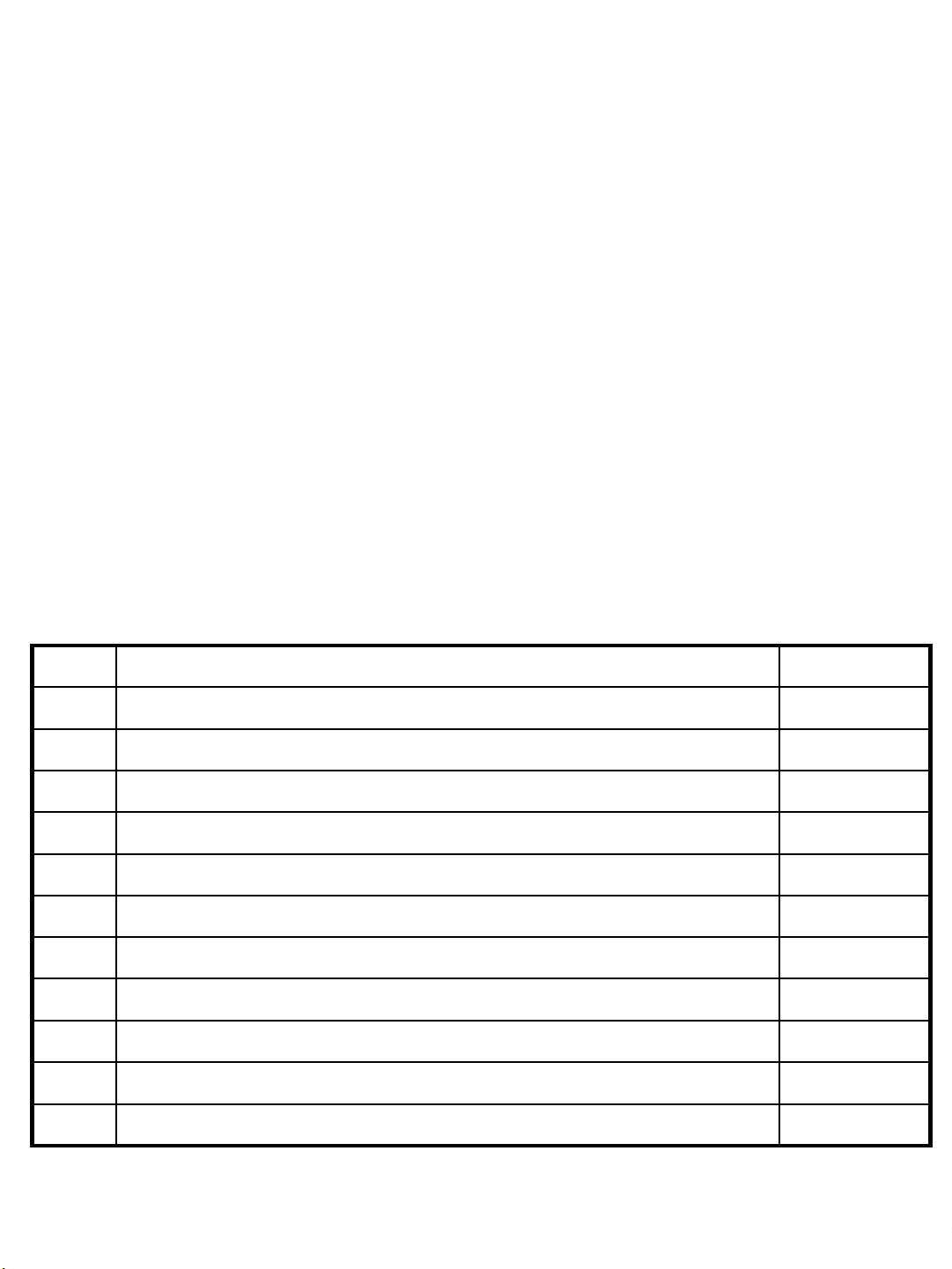

Oven Specifications

Model Q-36 Q-36H Q-36W Q-36WH Q-55 Q-80

Belt Width

Cooking Zone

Length

Cooking Area

Floor Space

Maxium

Operating

Temperature

Maxium

Energy Output

Operating

Range

24" 24" 30" 30" 32" 32"

36" 36" 36" 36" 55" 80"

5.3 Sq. Ft. 5.3 Sq. Ft. 7.5 Sq. Ft. 7.5 Sq. Ft. 12.5 Sq. Ft. 15.3 Sq. Ft.

64" x 36" 64" x 36" 64" x 42" 64" x 42" 91" x 54" 116" x 54"

550° F 550° F 550° F 550° F 550° F 550° F

90,000

BTU/HR

40,000 - 60,000

BTU/HR

90,000

BTU/HR

70,000

BTU/HR

120,000

BTU/HR

50,000 - 90,000

BTU/HR

120,000

BTU/HR

80,000

BTU/HR

160,000

BTU/HR

60,000 - 90,000

BTU/HR

240,000

BTU/HR

80,000 120,000

BTU/HR

Power

Requirements

Product

Clearance

Gas Supply

Estimated

Crated Weight

120/208 - 230/1

50-60 HZ 3

Wire, 15amp

3.5 " 3.5 " 3.5 " 3.5 " 3.5 " 3.5 "

3/4" 3/4" 3/4" 3/4" 3/4" 3/4"

410 lbs. 410 lbs. 480 lbs. 480 lbs. 520 lbs. 810 lbs.

208 - 240/3, 50

60 HZ 3 Wire,

35 amp

120/208 - 230/1

50-60 HZ 3

Wire, 25amp

208 - 240/3, 50

60 HZ 3 Wire,

35 amp

120/208 - 230/1

50-60 HZ 3

Wire, 40amp

120/208 - 230/1

Wire, 50amp

50-60 HZ 3

Installation Instructions

THE INSTALLATION INSTRUCTIONS CONTAINED

HEREIN ARE FOR THE USE OF QUALIFIED

INSTALLATION AND SERVICE PERSONNEL

ONLY. INSTALLATION OR SERVICE BY OTHER

THAN QUALIFIED PERSONNEL MAY RESULT

IN DAMAGE TO THE OVEN AND/OR TO

THE OPERATOR.

Qualified installation personnel are individuals, a firm,

A corporation, or a company which either person or

through a representative are engaged in, and are

responsible for:

The installation or replacement of gas piping or the

Connection, installation, repair or servicing of equipment,

Who are experienced with such work, familiar with all

Precautions required, and have compiled with all

Requirements of state and local authorities having

jurisdiction. Reference: National Fuel Gas Code, NFPA 541980 and ANSI Z23.1-1980

Section 1.4.

The installation of electrical wiring from the electric

Meter, main control box or service outlet to the electric

Appliance. Qualified installation personnel must be experienced

In such work, be familiar with all precautions required and have

Compiled with all requirements of state or local authorities having

Jurisdiction. Reference: National Electric Code, NFPA70-1981

Canadian installations should conform to “Installation

Codes of Gas Burning Appliance and Equipment” CAN-1-B149 and

B149.2 and/or local codes.

Delivery and Inspection

All Q-Matic Technologies ovens are shipped in containers to prevent damage. When tendered to the carrier,

each unit was carefully inspected and packed.

Upon delivery of your new oven:

Inspect the shipping container for any external damage. Any evidence of damage should be noted upon the

delivery receipt which must be signed by the driver. If any external damages are noted, unpack immediately

and check for internal damage. Carriers will accept claims for concealed damage if notified within three days

of delivery if the shipping container is retained for inspection. Q-Matic Technologies cannot assume

responsibility for damages occurred during transportation. All shipments are FOB Gurnee, Illinois. We are,

however, prepared to assist you in filing a claim if necessary.

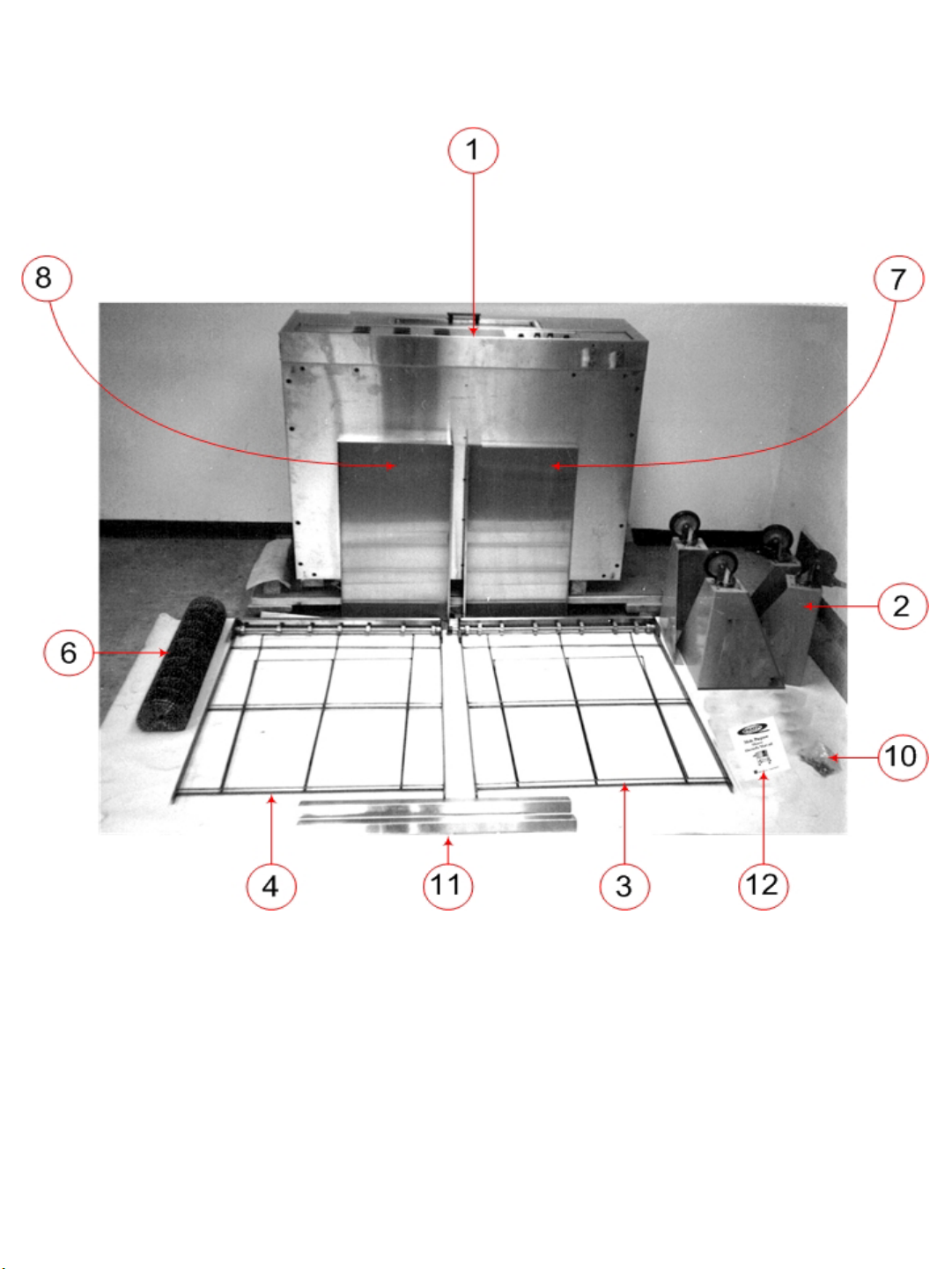

The oven can now be moved to the installation site. Check the list below with Figure 1 to be sure all items

were received.

Fig. 1 No.Part DescriptionQty.

1Main Oven Body1

2Oven Support Assembly4

3Left Conveyor Belt Support Assembly1**

4Right Conveyor Belt Support Assembly1

6Rolled Wire Belt1*

7Left Crumb Pan1

8Right Crumb Pan1

9Conveyor Drive Chain Cover1*

10Conveyor Belt Inner and Outer Master Links1

11Top End Plugs1

12Owner’s Manual1

Oven Location and

Installation

The well planned and proper placement

of the oven will result in long term operator

convenience and satisfactory performance.

It is therefore urged that adequate thought

to be given to the location of the oven prior

to its delivery and installation.

Place the oven in an area that is free of

drafts and is accessible for proper

operation and servicing. A minimum of

twenty (20) inches from the oven body

sides and eleven (11) inches from the body

oven back must be maintained from any

combustible construction. In addition, a

minimum of thirty-eight (38) inches from

oven body’s left side and twenty-eight (28)

inches from oven body back must be

available for operation and servicing.

It is also essential that provisions for an

adequate air supply to the oven be

maintained and that natural flow for

combustion and ventilation air not to be

obstructed in any way if proper operation is

to be assured. DO NOT use fans around

the oven!!! The oven tunnel is not

pressurized, therefore any drafts direct to

the tunnel will disrupt the heat pattern in the

oven, inducing inconsistent cooking.

The necessity of a properly designed and

installed ventilation system cannot be

overemphasized.

Such a system will allow the oven to

function properly while removing unwanted

vapors and products of combustion from

the operating area.

Failure to properly vent the oven can be

hazardous to the health of the operator. It

will also result in operational problems,

unsatisfactory baking, and possible

damage to the equipment. Damages

sustained as a direct result from improper

ventilation will not be covered by the

Manufacturer Warranty.

This appliance must be vented with a

properly designed mechanically driven

exhaust hood. The hood should be sized

to completely cover the equipment, plus an

overhang of at least six (6) inches in all

sides not adjacent to the wall. The

distance of the floor from the lower edge of

the hood should not exceed seven (7) feet.

The capacity of the hood should be sized

appropriately and provision should be

made for adequate makeup air. Should be

noted that Q-Matic ovens do not use

blowers and therefore the tunnel is not

pressurized, the spillage of hot air into the

kitchen is substantially reduced and

subsequently the need for powerful

exhaust. Refer to your local ventilation

codes to establish the right proportion

between exhaust and make-up air.

Oven Assembly

1. Connect the oven supports to the main body using the 3/8-16 bolts, making

sure that the casters with brakes are facing the front of the oven.

Figure 2

2. Carefully place oven onto casters. (It will be necessary to have several persons

to lift the oven off the pallet and set in on the casters.) Engage brakes on the front

casters.

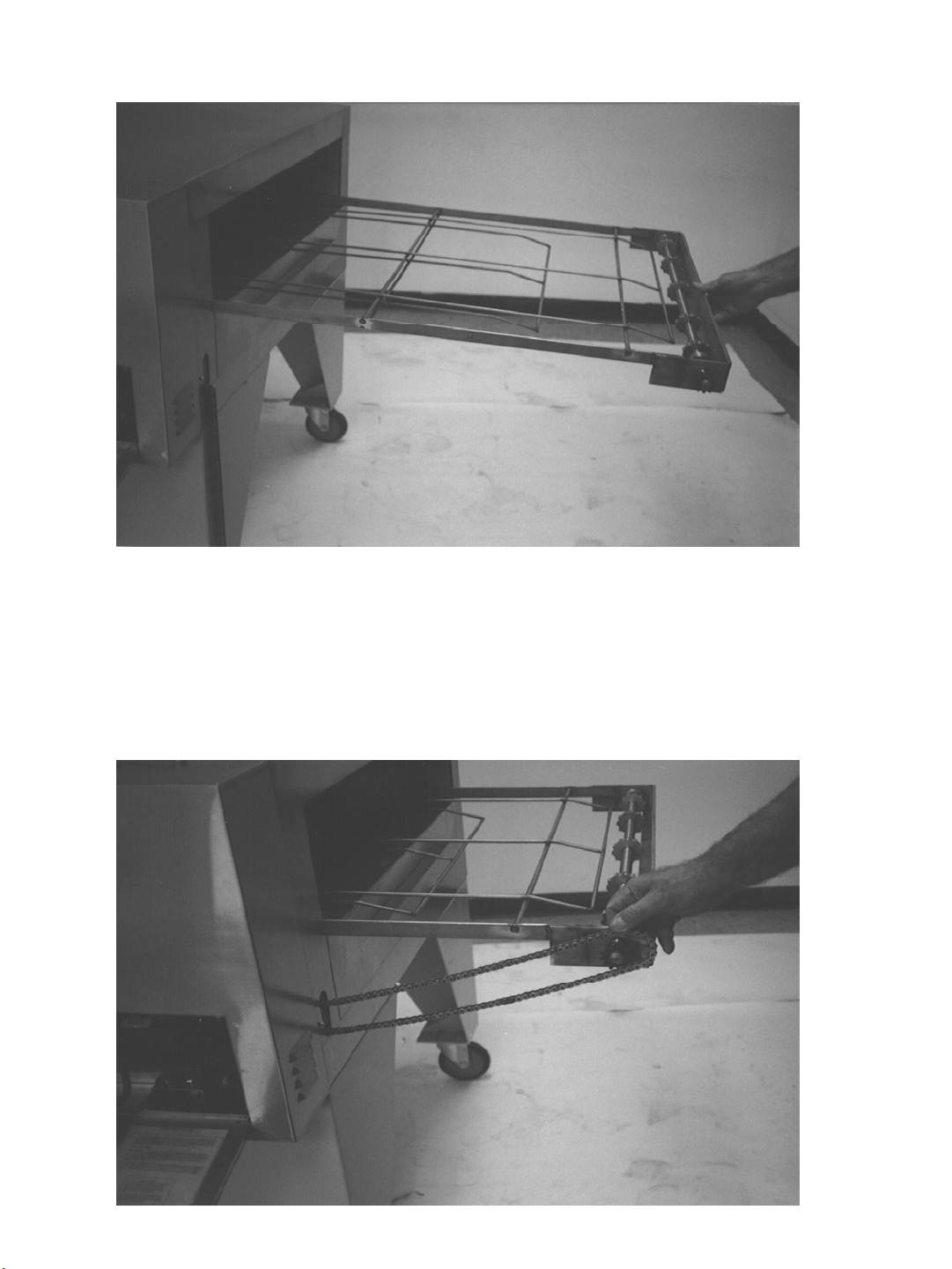

3. Slide right conveyor belt support (with sprocket on end of shaft) into

the support tracks. Sprocket must be located next to the control box

after being pushed into the ovens. Refer to Figure 3.

Figure 3

4. Cut the plastic tie holding the drive chain around the motor sprocket

through the opening in the main body and install the drive chain around

the sprocket on the conveyor belt support. Pull belt support back to

tighten chain. Refer to Figure 4. (Dual belt model will have a sprocket

and chain on both sides.)

Figure 4

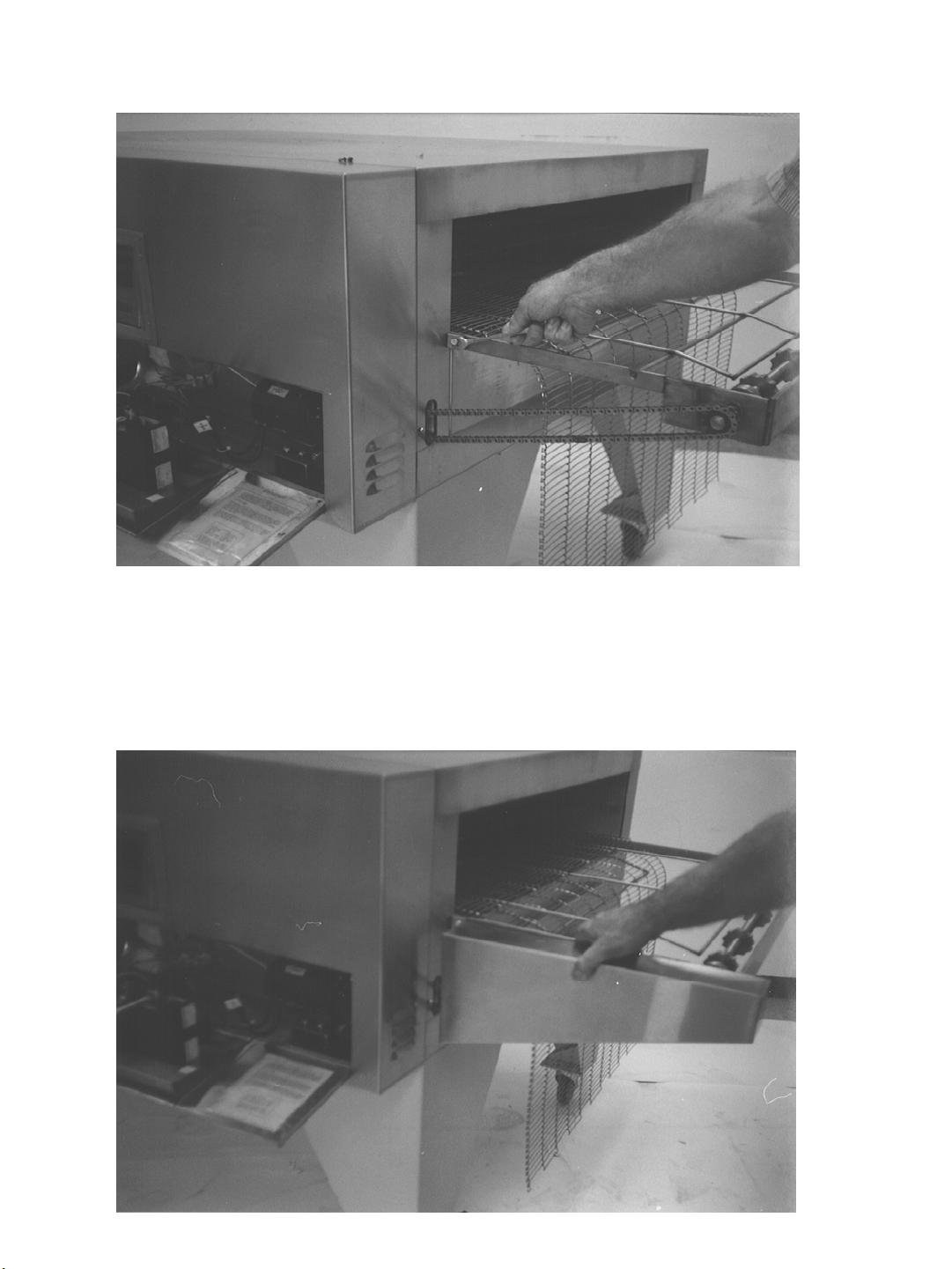

5. Install the conveyor support stop using the ¼-20 hex head screw.

Refer to Figure 5.

Figure 5

6. Install the drive chain cover to the right side and tighten screws.

Refer to Figure 6.

Figure 6

7. Slide left conveyor belt support into the support tracks until it touches the right

support.

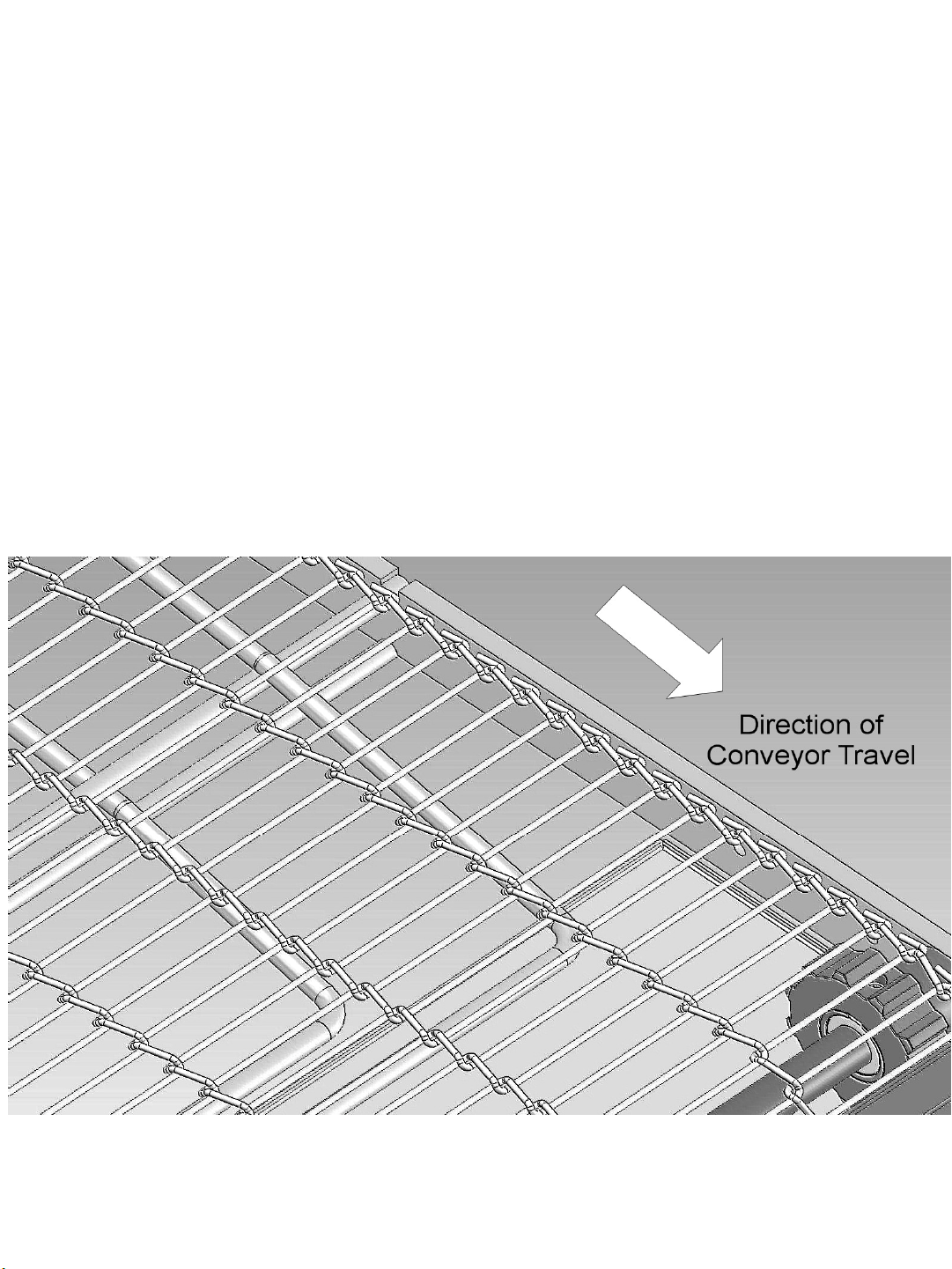

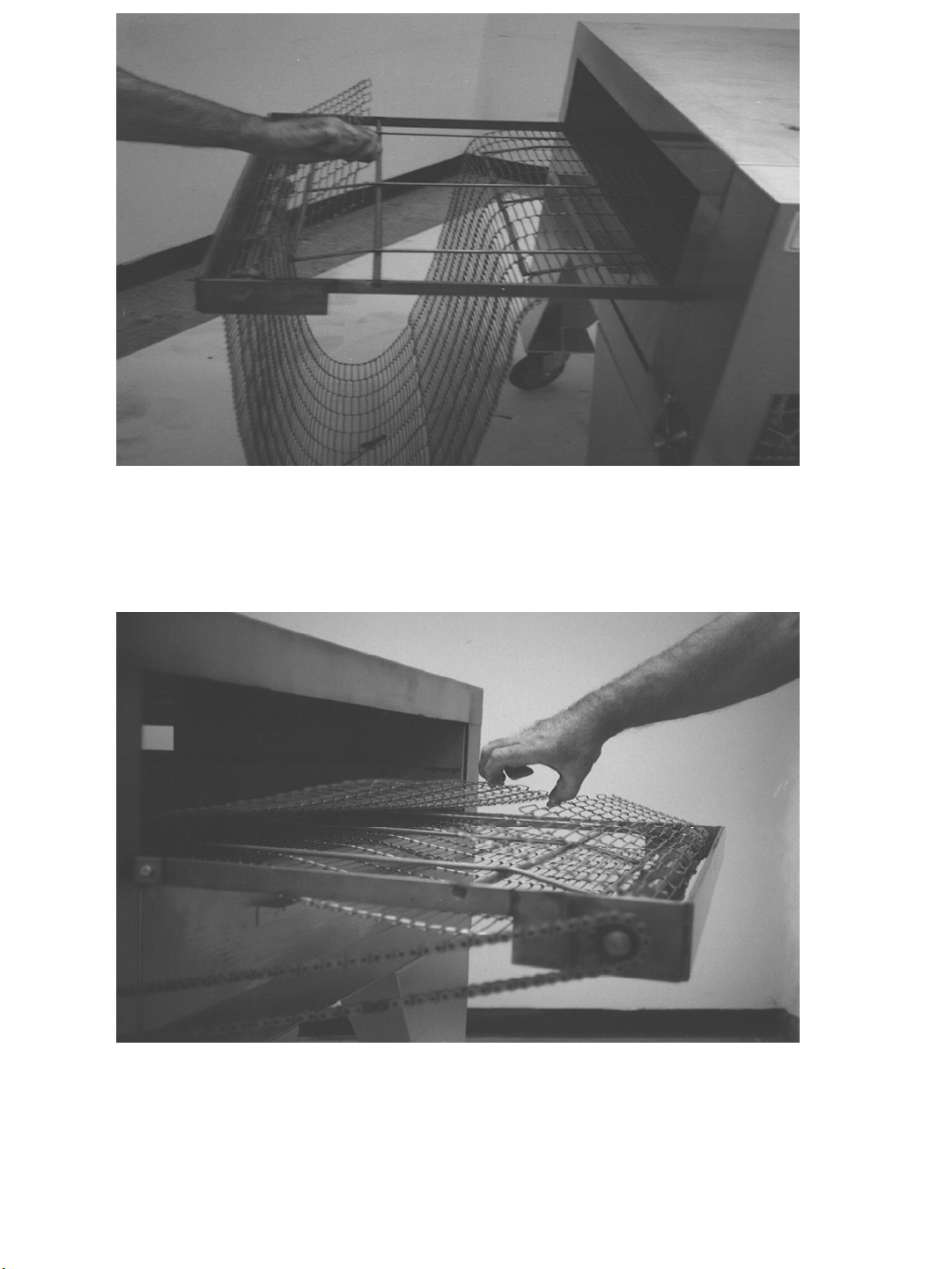

8. Installation of wire conveyor belt.

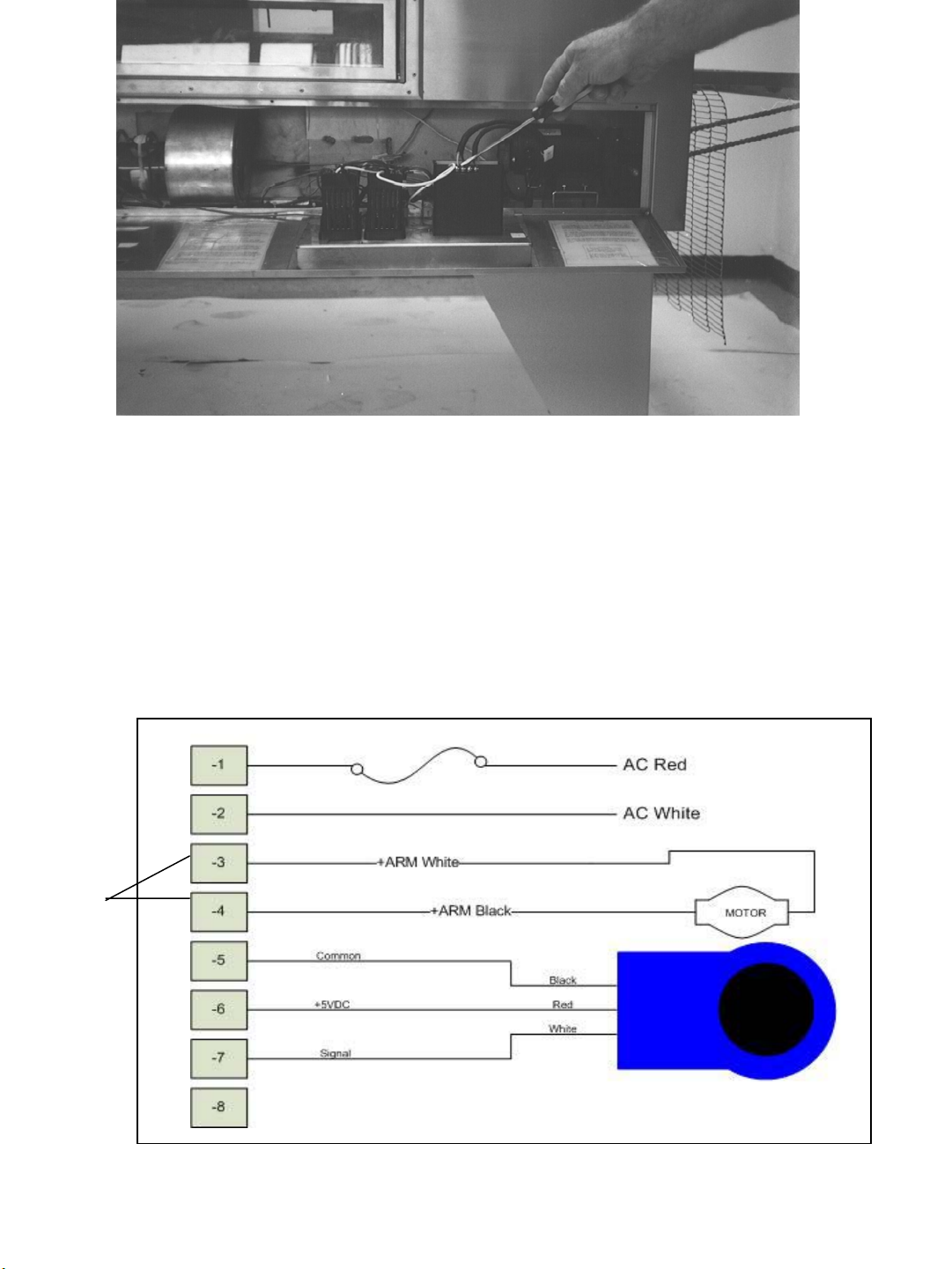

Note: Unless specified otherwise, conveyor travel is factory set for left to

right operation when facing the front of the oven. If a change of

direction is required, the polarity of the drive motor must be

reversed. Simply interchange the black and white motor leads at

the D.C. Controller located in the control panel. Refer to Figure

8,9. In addition, the conveyor belt must be installed from the right

side of the oven vs. left side.

Before threading the conveyor belt, note that the belt has loops at

both ends. These loops must ride backward on the top of the

conveyor support to avoid any catching. Also note that the belt has

a top and bottom. The bottom is always smooth.

Refer to Figure 7.

Figure 7

To change the

direction of the

conveyor, switch

leads 3 & 4

(Black & White)

Figure 8

Wiring Diagram – Speed Control

Figure 9

Thread wire belt starting from the left side of the oven, lower lever first.

After pushing belt through, on the lower level (leave about one foot

hanging out on right side), take remainder of belt looping it around left

shaft, and push through upper lever.

Refer to Figures 10, 11 and 12.

Figure 10

Figure 11

Figure 12

Loading...

Loading...