Page 1

MUH Series

Modular Unit Heaters

FILE #E21609

Installation, Operation & Maintenance Instructions

Dear Owner,

Congratulations! Thank you for purchasing this new heater manufactured by Marley Engineered Products.

You have made a wise investment selecting the highest quality product in the heating industry.

Please carefully read the installation and maintenance instructions shown in this manual. You should enjoy

years of efficient heating comfort with this product from Marley Engineered Products... the industry’s leader in

design, manufacturing, quality and service.

... The Employees of

Marley Engineered Products

WARNING

Read Carefully

prevent difficulties that might arise during installation of heaters.

Studying the instructions first may save you considerable time

and money later. Observe the following procedures, and cut

your mounting time to a minimum.

To reduce risk of fire or electric shock:

1. To prevent electrical shock, disconnect all power coming to

heater at main service panel before wiring or servicing.

2. All wiring must be in accordance with the National and

Local Electrical Codes and the heater must be grounded as

a pre-caution against possible electric shock.

3. Verify the power supply voltage coming to heater matches

the ratings printed on the heater name plate before energizing.

4. This heater is hot when in use. To avoid burns, do not let

bare skin touch hot surfaces.

- These instructions are written to help you

!

5. Do not insert or allow foreign objects to enter any ventilation

or exhaust opening as this may cause an electric shock,

fire,or damage to the heater.

6. To prevent a possible fire, do not block air intakes or

exhaust in any manner. Keep combustible materials, such

as crates, drapes, etc., away from heater. Do not install

behind door, furniture, towels, or boxes.

7. A heater has hot and arcing or sparking parts inside. Do not

use it in areas where gasoline, paint or flammable liquids

are stored.

8. Use this heater only as described in this manual. Any other

use not recommended by the manufacturer may cause fire,

electric shock, or injury to persons.

9. This heater is not approved for use in corrosive atmospheres such as marine, green house or chemical storage

areas.

SAVE THESE INSTRUCTIONS

Page 2

THE HEATER MUST BE MOUNTED AT LEAST 7' (2134MM)

A

B

C

D

ABOVE THE FLOOR TO PREVENT ACCIDENTAL CONTACT

WITH THE FAN BLADE WHICH COULD CAUSE INJURY.

THE CEILING MOUNTING STRUCTURE AND THE ANCHORING PROVISIONS MUST BE OF SUFFICIENT STRENGTH

TO SUPPORT THE COMBINED WEIGHT OF THE HEATER

AND MOUNTING BRACKET. (SEE TABLE 4).

ALL BUILT-IN THERMOSTATS: IF THE HEATER IS USED TO

PREVENT PIPING OR LIQUIDS FROM FREEZING, AND IF

THE THERMOSTAT IS SET BELOW 45° F (7°C), THE FAN

MUST RUN CONTINUOUSLY.

TO PREVENT POSSIBLE OVERHEATING OR DAMAGE DUE

TO OVERHEATING, KEEP AT LEAST 5' (1524MM) CLEARANCE IN FRONT OF HEATER. REFER TO TABLE 1 FOR

SIDE, TOP, AND BACK CLEARANCE REQUIREMENTS.

DO NOT MOUNT MERCURY TYPE THERMOSTAT DIRECTLY

ON UNIT. VIBRATION COULD CAUSE HEATER TO

MALFUNCTION.

MANUAL RESET LIMIT

(FACTORY INSTALLED OPTION

ONLY.) THE LIMIT SWITCH IS LOCATED INTERNALLY ON

THE REAR OF THE HEATER. ON THE 3KW AND 5KW

MODELS, THE ACCESS TO THE RESET BUTTON IS ON THE

RIGHT SIDE (WHEN FACING REAR OF HEATER); ON ALL

OTHER MODELS IT IS NEAR THE TOP REAR OF THE

HEATER.

THE MANUAL RESET LIMIT IS IN SERIES WITH THE AUTOMATIC RECYCLING PROTECTOR (LIMIT). THE MANUAL

RESET LIMIT WILL NOT RESET UNTIL THE HEATER HAS

COOLED AND THE BUTTON IS PUSHED IN.

HEATER LOCATION INSTRUCTIONS

Arrange units so their discharge air streams:

a.

are subjected to a minimum of interference from columns,

machinery and partitions;

b.

wipe exposed walls without blowing directly at them;

c.

are directed away from room occupants in comfort heating;

d.

are directed along the windward side when installed in a

building exposed to a prevailing wind.

Locate thermostats approximately 5' (1524mm) above the floor

on interior partition walls or post away from cold drafts, internal

heat sources and away from heater discharge air streams.

Small rooms can be heated by one unit heater.

Large rooms require multi-unit installations. Number and capaci-

ty of units will be determined by volume of building and square

feet of floor area to be heated. Arrange units to provide perimeter air circulation where each unit supports the air stream from

another.

MOUNTING THE HEATER - GENERAL

The heater may be mounted to discharge the heated air either

horizontally or vertically. When the heater is mounted for vertical

discharge, it is recommended that the heater be positioned so

that the access door will open away from the wall to provide

greater access to the wiring and control compartment. If the

heater is to be mounted with the access door facing a wall, the

heater must be mounted far enough from that wall to allow full

opening of the access door (a distance approximately equal to

the width of the heater ... check clearance before installing).

Refer to Table 1 for wall and ceiling clearances before mounting

heater.

The heater may be mounted for either vertical or horizontal discharge by the use of threaded rods. (Refer to Table 2 for threaded rod sizes required.) Observe the detailed procedures in the

following installation instructions.

The heater may also be suspended from the wall or ceiling by

means of an optional mounting bracket (type MMB or MCMB)

which permits horizontal pivoting of the heater.

After the heater is installed, the louvers may be positioned to

direct the heated air in the desired direction. When the heater is

installed for horizontal discharge, the louvers should direct the

air either straight ahead or downward. Directing the air upward

may cause the heated air to remain in the ceiling area and

waste energy.

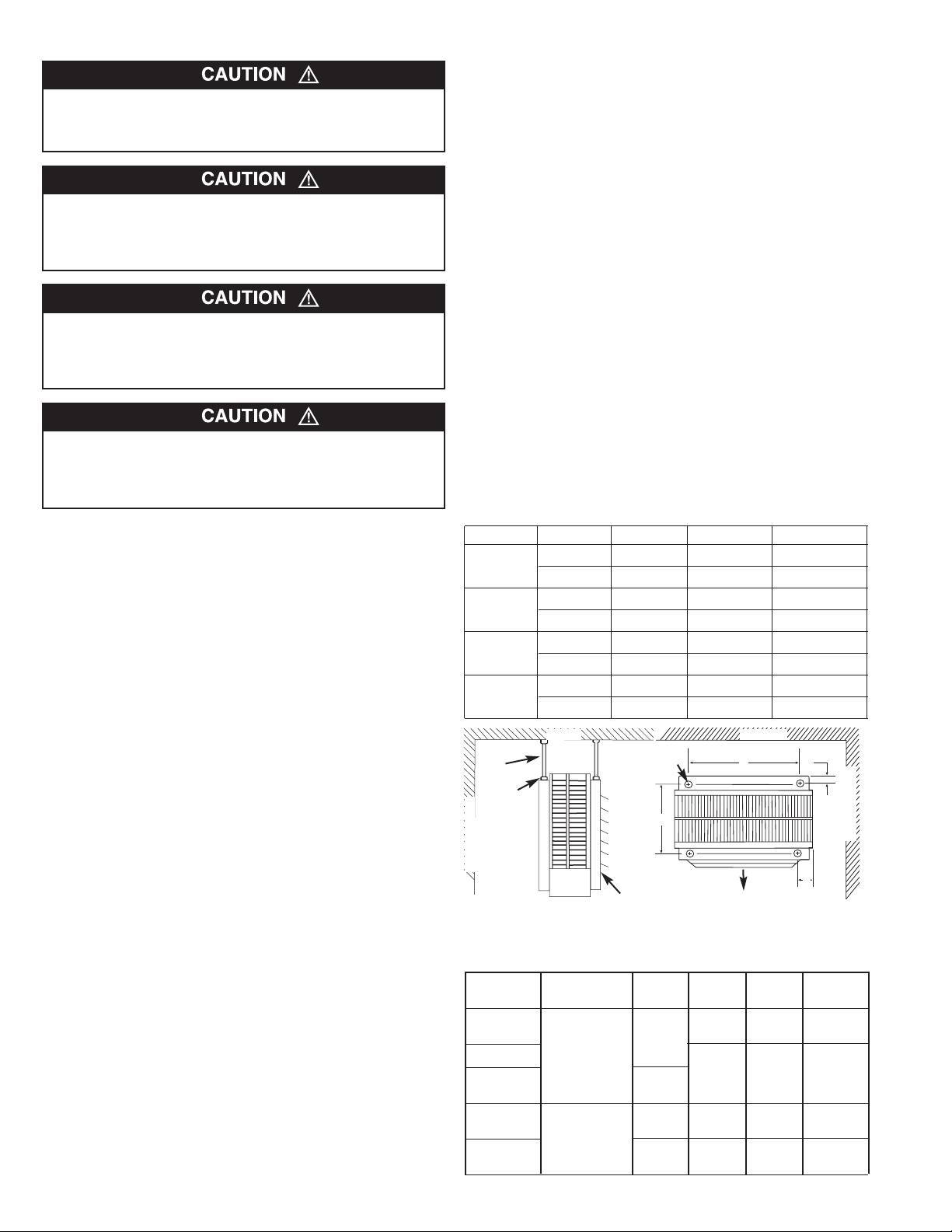

Table 1. Wall and Ceiling Clearance, inches (mm)

Unit Discharge Ceiling Side Wall Back Wall

3 & 5 kW

7.5 to 10 kW

15 to 10 kW

25 to 50 kW

MOUNTING

ROD

LOCK NUT

B

A

C

K

W

A

L

L

Figure 1. Horizontal Discharge Mounting and Spacing.

Table 2. Rod Thread and Spacing Dimensions, inches (mm)

for Horizontal Discharge

Unit Type A B C D

3 - 5 kW

7.5 - 10 kW

15 - 20 kW

25 - 30 kW

40 - 50 kW

2

Horiz. 2 (50.8) 6 (152.4) 9 (228.6)

Vert. 6 (152.4) 18 (457.2) 18 (457.2)

Horiz. 6 (152.4) 6 (152.4) 13 (330.2)

Vert. 6 (152.4) 24 (609.6) 24 (609.6)

Horiz. 6 (152.4) 9 (228.6) 12

Vert 6 (152.4) 24 (609.6) 24 (609.6)

Horiz. 16 (406.4) 12 (304.8) 18

Vert. 12 (304.8) 39 (914.4) 39 (914.4)

CEILING

UNIT HEATER

THREADED

MOUNTING

OLES

H

A

BACK WALL

B

(TOP VIEW)

1

/2(317.5)

1

/2(470.0)

D

C

Rod Thread

3

3

8

5

5

5

/16- 18

3

/8- 16

51/

1

/

16

16

16

64

61/

(153.9)

11

(289.0)

10

(268.2) (368.3) (157.2) (16.0)

1515/1614 - 12 63/

(404.9) (368.3) (157.2) (16.0)

(152.4) (103.1) (19.0)

16

87/

3

/

8

9

/

16

8

(225.6) (130.3) (19.0)

14 - 12 63/

/

4

/

4

/

8

/

8

S

I

D

E

W

A

L

L

Page 3

Horizontal Discharge (Rod-mount from Ceiling)

1. Install four threaded mounting rods in the threaded holes and

secure in place using lock nuts. (See Table 2).

2. Securely attach the four mounting rods to the ceiling. (Refer

to Table 1 for wall and ceiling clearances, and Table 2 for

mounting rod spacing).

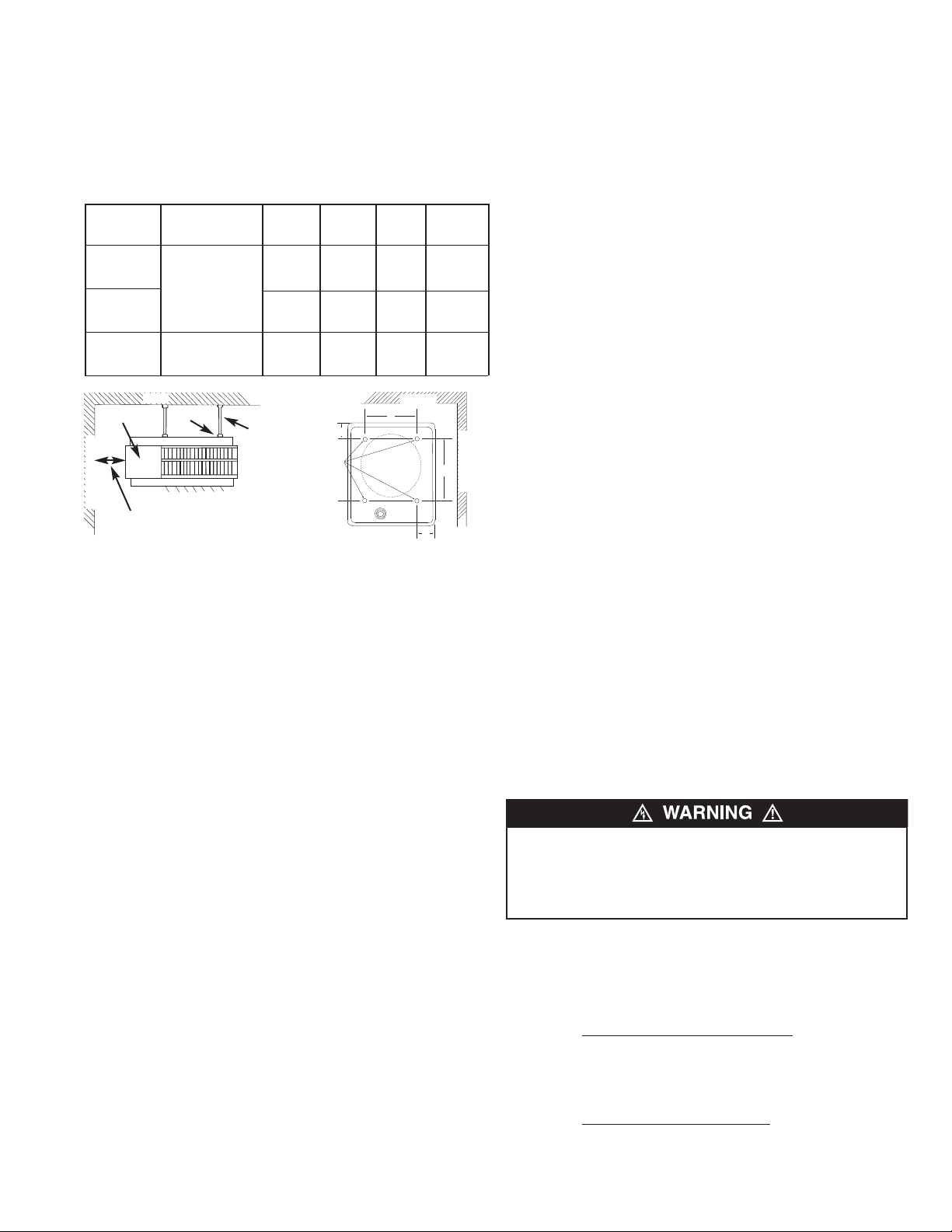

Table 3. Rod Thread and Spacing Dimensions, inches (mm)

for Vertical Discharge

Rod Thread

Unit Type E F G H

3 - 5 kW

7.5 - 20 kW

25 - 30 kW

ACCESS

DOOR

B

A

C

K

W

A

L

L

CLEARANCE EQUAL TO W IDTH

OF HEAT ER TO PERMIT FULL

OPENING OF THE ACCESS DOOR

CEILING

LOCK NUT

5

/16- 18

3

/8- 16

THREADED

MOUNTING

HOLES

3

/

4

145/

8

211/

4

G

(TOP VIEW)

24

25

23/

E

69

152.4) 247.7) (50.8) (103.1)

(

7

8

/

8

225.6) (371.6) (50.8) (130.3)

(

1

14

/

2

368.3) (539.8) (56.0) (157.2)

(

MOUNTING

ROD (4)

16

BACK WALL

1

/

6

1

1

/

8

63/

16

S

I

D

E

W

F

A

L

L

H

Figure 2. Vertical Discharge Mounting and Rod Spacing

Vertical Discharge (Rod-Mount from Ceiling)

1. Remove bolts from the threaded holes in the back of the

heater.

2. Install four threaded mounting rods in the threaded holes and

and secure in place using lock nuts.

3. Securely attach the four mounting rods to the ceiling. (Refer

to Table 1 for wall and ceiling clearances, and Table 3 for

mounting rod spacing dimensions.)

WIRING

Branch Circuit (Power)

1. Connect heater only to the voltage, amperage and frequency

specified on the nameplate.

2. Field wiring must be properly sized to carry the amperage in

accordance with the NEC.

3. The access door is hinged. There are either one or two

screws accessible from the side that must be loosened to

gain access. These screws are the captive type; do not try

to remove them.

4. A knockout is provided in the back of the heater close to the

power terminal block and the control terminal board. The

control terminal board knockout is 1/2 inch (12.7 mm) conduit

size. The power terminal block knockout is multiple diameter. Use the diameter that fits the required conduit size.

5. A ground terminal is provided near the power terminal board.

The ground wire should be connected before other connections are made.

6. The power terminal block is equipped with box terminals sized

to accept the correct size power supply wire. Branch circuit

wire rated min 600V, 60° C is acceptable for heaters rated up

to 80 amps. For heaters rated more than 80 amps, branch

circuit wire must be rated at least 75°C. Either aluminum or

copper wire is satisfactory for connection to the heater power

terminal block box terminal. Copper wire is recommended

and must be used with built-in disconnect switch.

7. Each heater has a wiring diagram affixed to the inside of the

access door. Consult this diagram before making any field

connections.

Important Note - Installation Screw Lug Torque:

During transportation it is possible screw lug connections can

loosen. After installation, before power is turned on to the

heater, check all screw lug connections for tightness to a recommended minimum torque of 35 in-lbs. (3.9 N-m).

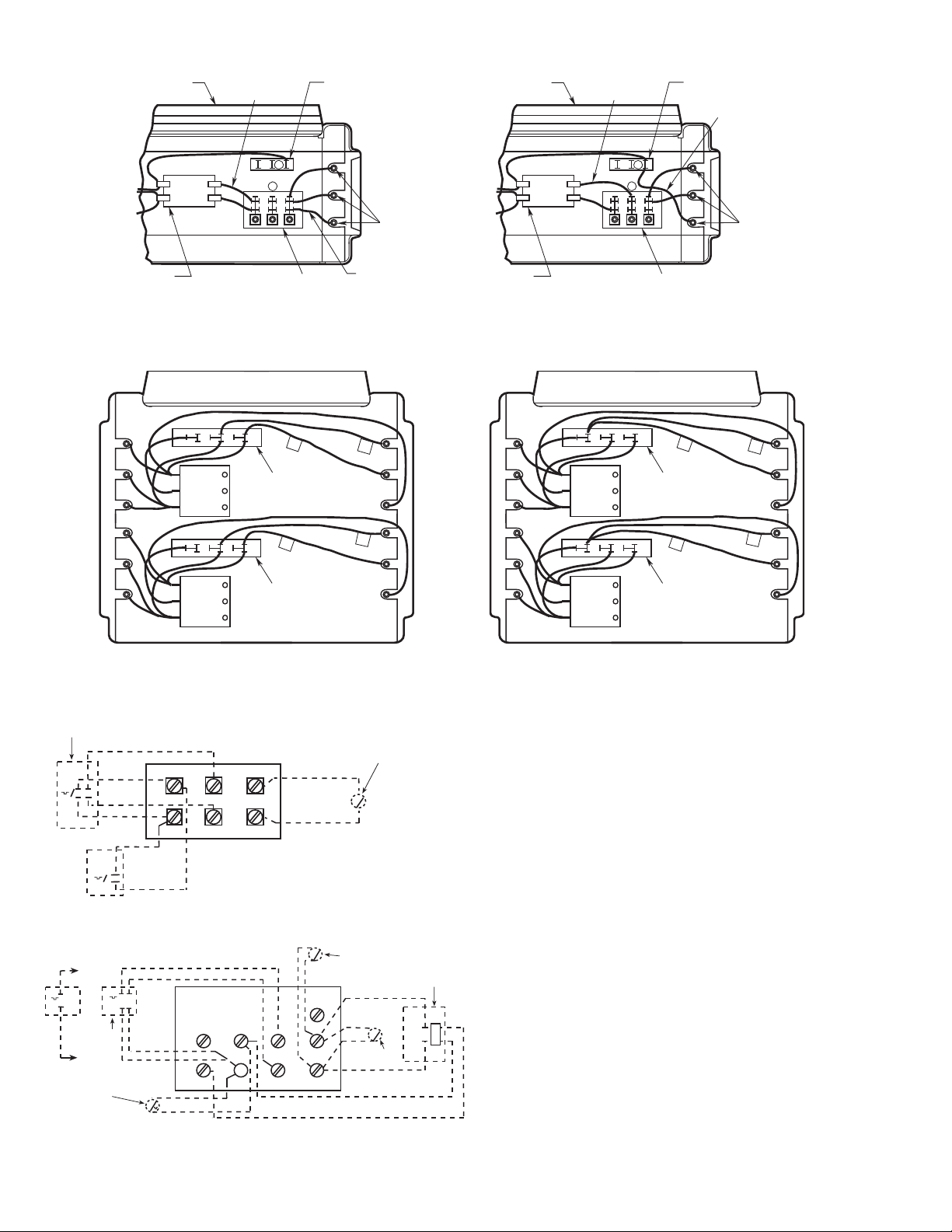

8. Single or three-phase power connections may be used with

heater models MUH0521, MUH0581, MUH072, MUH078,

MUH102, MUH108, and MUH158. These units are factory

wired for single-phase operation. If these heaters are for

use with three-phased power, reconnect the wires as indicated in the wiring diagram attached to the heater.

Additional information can be found by looking at the wiring

illustrations in Figures 3a and 3b and following the directions

shown below.

On models MUH0521,MUH0581, MUH072, MUH078, MUH102,

and MUH108 (Figure 3a), move only the two wires marked “A1”

and marked “B1”; do not move or change any other wiring. The

element lead wire marked “B1” which is factory connected to the

power terminal block (terminal located closest to the elements)

must be moved to terminal “B” on the three-phase terminal

block.

The relay (contactor) lead wire “A1” must be moved from the

end terminal of the power terminal block (terminal closest to the

contactor or control terminal board) to the “A” terminal of the

lower terminal block (center terminal).

Model MUH158 (Figure 3b) has two three-phase terminal blocks

located adjacent to the relays (contactors). Move only the two

wires marked “C1” and “D1” on each of these two three-phase

terminal blocks to terminal “B”. Do not move or change any

other wires.

9. Electrical Accessories, either kits or factory-installed

options, are shown connected by a dash line on the heater

wiring diagram.

208/240 VOLT HEATER:

10.

The heaters are wired for 240V

from factory. When heater is to be connected to 208V supply, the transformer leads have to be interchanged. For units

rated 30/40kW or higher, interchange ORANGE and RED

primary leads. The black colored lead is the COMMON for

the transformer (50VA) provided with the high wattage units.

For lower kW rated heaters, interchange BLACK and RED

primary leads. The WHITE colored lead is the COMMON for

the control transformer provided with these heaters. Always

refer to the wiring diagram on the cover of the heater before

making this reconnection of tranformer primary leads.

Control Wiring

LINE VOLTAGE IS PRESENT ON SOME OF THE TERMINALS ON THE CONTROL TERMINAL BOARD. ALWAYS

DISCONNECT THE POWER FROM THE HEATER BEFORE

MAKING ANY CONNECTIONS TO THE CONTROL BOARD

TO PREVENT ELECTRIC SHOCK HAZARD.

1. Use min. 600 volts, NEC Class 1 insulated wire for all control

circuit wiring.

2. Use a crimp-on type fork terminal on the wire ends that attach

to the control terminal board if more than one connection is to

be made under the terminal screw.

3. On units not provided with internal contactor (3 & 5 KW), refer

to Figure 4 for wiring diagram.

Note:

Thermostat and control circuit wiring must be suitable to

handle the full load of the heater (example MUH0581 is rated 24

amps)

4. On units provided with internal contactor

higher) refer to Figure 5 for wiring diagram. Control wiring

must be rated minimum 18 AWG.

3

(units rated 7 KW and

Page 4

A

B

LEAD WIRE

"B1"

ELEMENTS

CONTACTOR

(OR P2)

POWER TERMINAL BLOCK

HEATER FRONT

LEAD WIRE

"A1"

3 PHASE BLOCK

TO ELEMENTS

A

B

L

EAD WIRE

"B1"

ELEMENTS

CONTACTOR

(OR P2)

POWER TERMINAL BLOCK

HEATER FRONT

LEAD WIRE

"A1"

3 PHASE BLOCK

TO ELEMENTS

FACTORY-WIRED FOR SINGLE-PHASE POWER FIELD-WIRED FOR THREE-PHASE POWER

Figure 3a. Wiring Connections for Single-Phase and Three -Phase Power(MUH0521, MUH0581, MUH072, MUH078, MUH102 and MUH108)

B

3 PHASE BLOCK

FACTORY-WIRED FOR SINGLE-PHASE POWER

C

1

D

1

D

1

C

1

C

D

B

C

D

3 PHASE BLOCK

B

3 PHASE BLOCK

FIELD-WIRED FOR THREE-PHASE POWER

C

1

D

1

D

1

C

1

C

D

B

C

D

3 PHASE BLOCK

BLACK

RED

RED

BLACK

C

RW1

W2

F 2

F 1

G

T R

T

S

S

REMOTE SUMMER FAN

SWITCH (MRFS-1)

FAN RELAY

(FOR MRFS-2 AMD MHRT)

SUMMER

FAN

SWITCH

MT-1

MT-2

2-STAGE

INTERNAL

THERMOSTAT

BLACK

RED

RED

BLACK

P2

H2

F 1

F 2

S

REMOTE SUMMER

FAN SWITCH (MRFS-1)

OR SUMMER FAN

SWITCH MCFS (MANUAL)

P1

H1

T

T

MT-1

MT-2

BLACK TO W1

RED TO R

2-STAGE

INTERNAL

THERMOSTAT

MHRT HEAT RECOVERY

THERMOSTAT OR

REMOTE FAN

SWITCH (MRFS-2)

BLACK

RED

RED

BLACK

C

RW1

W2

F 2

F 1

G

T R

T

S

S

REMOTE SUMMER FAN

SWITCH (MRFS-1)

FAN RELAY

(FOR MRFS-2 AMD MHRT)

SUMMER

FAN

SWITCH

Figure 3b. Wiring Connections for Single-Phase and Three -Phase Power (MUH158)

NOTES:

1. THIS STYLE CONTROL TERMINAL BOARD USED WITH MODELS

MUH0321, MUH0371, MUH0381, MUH0521, MUH0571, AND

MUH0581.

2. WHEN UNIT IS WIRED FOR SINGLE-PHASE, JUMPER H1 TO H2.

IF SINGLE-POLE THERMOSTAT IS USED WITH SINGLE-PHASE

UNIT, CONNECT THERMOSTAT LEADS TO P1 AND H1.

3. EXTERNAL LINE VOLTAGE THERMOSTATS SHOULD BE

TREATED AS SINGLE STAGE ONLY.

Figure 4. Control Terminal Board (for Heaters Without Contactors)

Figure 5. Control Terminal Board (for Heaters With Contactors)

4

NOTES:

1. THIS STYLE CONTROL TERMINAL BOARD USED

WITH MODELS EXCEPT MUH0321, MUH0371,

MUH0381, MUH0521, MUH0571, AND MUH0581.

2. REMOVE JUMPER W1 TO W2 WHEN 2-STAGE THERMOSTAT IS USED.

3. *ONLY ONE OF THESE ACCESSORIES MAY BE

4. EXTERNAL LINE VOLTAGE THERMOSTATS

INSTALLED IN A SINGLE HEATER.

SHOULD BE TREATED AS SINGLE STAGE ONLY.

Page 5

Table 4. Specifications

Basic Model Height Width Depth Weight Compartment

No. in (mm) in. (mm) in. (mm) lbs. (kg) Volume

MUH0381 27 (12.2)

UH0321 27 (12.2)

M

UH0371 27 (12.2)

M

MUH0341 30 (13.6)

MUH0581 27 (12.2)

UH0521

M

MUH0571

6 14 7

1

406.4) (355.6) (190.5)

(

MUH0541 30 (13.6)

UH0331 30 (13.6)

M

MUH0361 30 (13.6)

MUH0531 30 (13.6)

MUH0561 30 (13.6)

UH078 38 (17.2)

M

MUH072 38 (17.2)

MUH077 38 (17.2)

UH074 38 (17.2)

M

MUH108

MUH102

3

21

/

19 71/

4

(552.5) (482.6) (190.5)

MUH107 38 (17.2)

MUH104 38 (17.2)

MUH073 38 (17.2)

UH076 38 (17.2)

M

MUH103 38 (17.2)

MUH106 38 (17.2)

MUH158 54 (24.5)

MUH152 50 (22.7)

MUH154 50 (22.7)

MUH208

MUH202

3

21

/

19 123/

4

(552.5) (482.6) (323.9)

MUH204 55 (24.9)

MUH156 55 (24.9)

MUH206 55 (24.9)

MUH252 89 (40.4)

MUH254 89 (40.4)

MUH308

MUH302

MUH304 89 (40.4)

30 26

(76.2) 676.4) (298.5)

5

/

113/

8

MUH256 89 (40.4)

MUH306 89 (40.4)

MUH402 119 (54.0)

MUH404 119 (54.0)

MUH508

MUH502

MUH504 119 (54.0)

30 26

(76.2) 676.4) (435.1)

5

/

171/

8

MUH406 119 (54.0)

MUH506 119 (54.0)

Mounting Wiring

1

/

7 (12.2)

2

2

27 (12.2)

38 (17.2) 100 in

2

38 (17.2)

60 (27.2)

4

55 (24.9)

89 (40.4)

4

89 (40.4)

119 (54.0)

4

119 (54.0)

0 in

9

14.70 cm

(

(1639 cm

140 in

(2295 cm

504 in

(8260 cm

648 in

(10620 cm

3

3

)

3

3

)

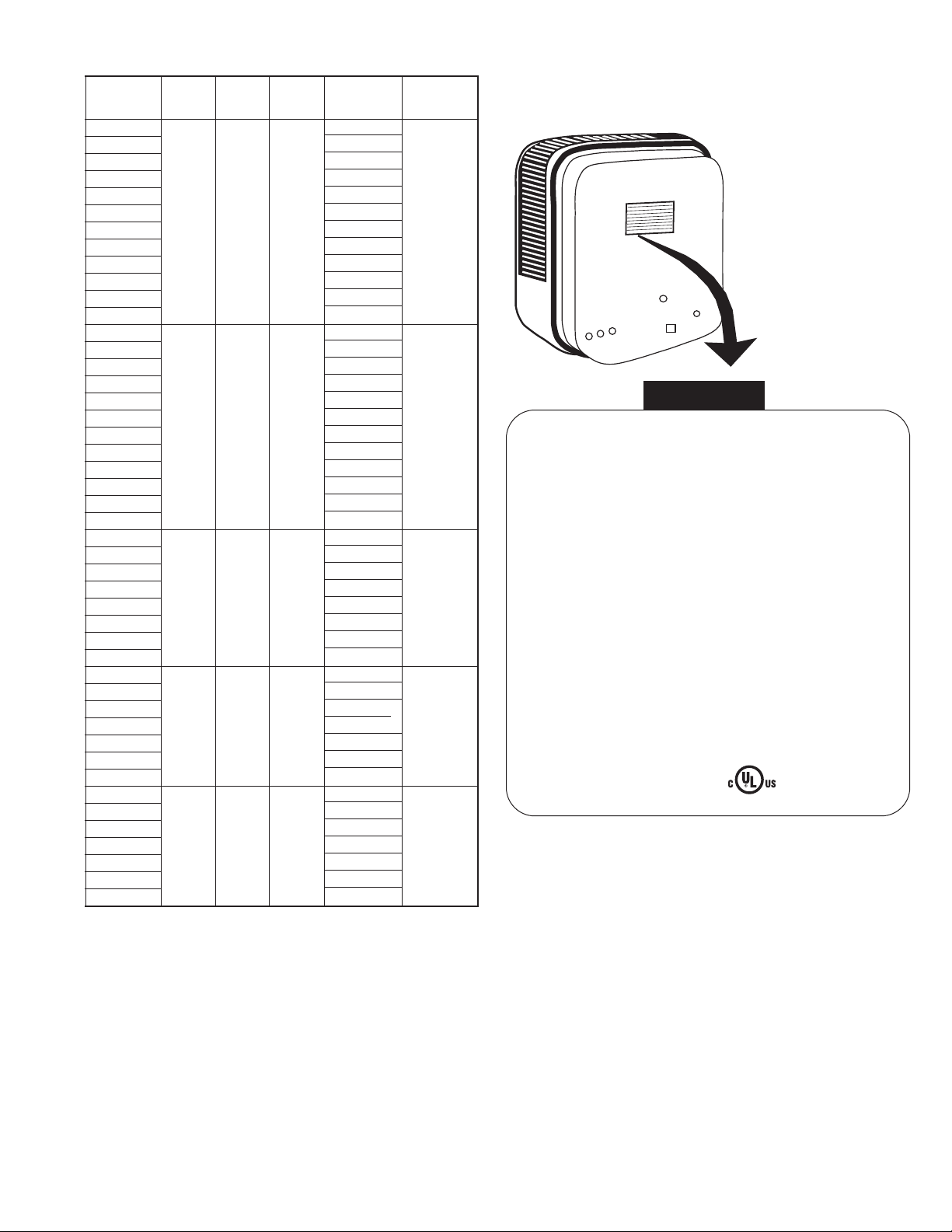

MODEL NO.

MFG. NO.

NAMEPLATE

MUH0321

DATE CODE

0395

VOLTS AC KILOWATTS PHASE MIN. SUPPLY

60 HZ CIR. AMPACITY

208 / 240 2.2 /3 1

MAX. FUSE MOTOR CONTROLS CUSTOMER NO

VAC AMP VAC

208/240 .25 208/240

3

3

)

AIR MINIMUM MOUNTING CLEARANCE

FLOW SIDE BACK CEILING FLOOR

HORIZ. 6" 9.5" 2" 7'

VERT. 18" 18" 6" 7'

WARNING:

DISCONNECT POWER BEFORE SERVICING. IF EXTERNAL CONTROL IS

USED, ALSO DISCONNECT EXTERNAL POWER SUPPLY.

NE PAS RELEVER LES LAMES AU-DEL

3

3

)

L'APPAREIL. METTRE HORS TENSION AVANT DE PROCEDER A

L'ENTRETIEN. SI UNE COMMANDE EXTERNE EST UTILISEE, COUPER

AUSSE L'ALIMENTATION EXTERNE. ASSURER UN DEGAGEMENT D'AU

MOINS 6 PI ENTRE L'APPAREIL DE CHAUFFAGE ET LEPLANCHER.

MARLEY ENGINEERED PRODUCTS

BENNETTSVILLE, SC 29512 4104-0275-036

3

3

)

DO NOT TURN LOUVERS ABOVE LEVEL OF THE UNIT.

`

A DU NIVEAU PREVU DE

774G LISTED

AIR HEATER

IMPORTANT INFORMATION

5

Page 6

All products manufactured by Marley Engineered Products are warranted against defects in workmanship and materials for one year from date of installation, except

LIMITED WARRANTY

heating elements which are warranted against defects in workmanship and materials for five years from date of installation. This warranty does not apply to damage from

accident, misuse, or alteration; nor where the connected voltage is more than 5% above the nameplate voltage; nor to equipment improperly installed or wired or

maintained in violation of the product’s installation instructions. All claims for warranty work must be accompanied by proof of the date of installation.

The customer shall be responsible for all costs incurred in the removal or reinstallation of products, including labor costs, and shipping costs incurred to return products

to Marley Engineered Products Service Center. Within the limitations of this warranty, inoperative units should be returned to the nearest Marley authorized service center or the Marley Engineered Products Service Center, and we will repair or replace, at our option, at no charge to you with return freight paid by Marley. It is agreed that

such repair or replacement is the exclusive remedy available from Marley Engineered Products.

THE ABOVE WARRANTIES ARE IN LIEU OF ALL OTHER WARRANTIES EXPRESSED OR IMPLIED, AND ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE WHICH EXCEED THE AFORESAID EXPRESSED WARRANTIES ARE HEREBY DISCLAIMED AND EXCLUDED FROM

THIS AGREEMENT. MARLEY ENGINEERED PRODUCTS SHALL NOT BE LIABLE FOR CONSEQUENTIAL DAMAGES ARISING WITH RESPECT TO THE

PRODUCT, WHETHER BASED UPON NEGLIGENCE, TORT, STRICT LIABILITY, OR CONTRACT.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above exclusion or limitation may not apply to you. This warranty gives

you specific legal rights, and you may also have other rights which vary from state to state.

For the address of your nearest authorized service center, contact Marley Engineered Products in Bennettsville, SC, at 1-800-642-4328. Merchandise returned to the factory must be accompanied by a return authorization and service identification tag, both available from Marley Engineered Products. When requesting return authorization,

include all catalog numbers shown on the products.

HOW TO OBTAIN WARRANTY SERVICE AND

WARRANTY PARTS PLUS GENERAL INFORMATION

1. Warranty Service or Parts

2. Purchase Replacement Parts

3. General Product Information

Note:

When obtaining service always have the following:

1. Model number of the product

2. Date of manufacture

3. Part number or description

1-800-642-4328

1-800-654-3545

www.marleymep.com

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

Part No. 5200-0722-013

ECR 38995

03/11

Page 7

Serie MUH

Unidades de Calentadores

Modulares

EXPEDIENTE No. E21609

Instrucciones de instalación, operación y mantenimiento

Estimado propietario:

¡Felicitaciones! Gracias por comprar este nuevo calefactor fabricado por Marley Engineered Products.

Al seleccionar el producto de más alta calidad de la industria de calefacción, usted ha hecho una sabia inversión. Por favor,

lea cuidadosamente las instrucciones de instalación y mantenimiento incluídas en este manual. Así podrá disfrutar de años

de calefacción confortable y eficiente con este producto de Marley Engineered Products... el líder de la industria en diseño, fabricación, calidad y servicio.

... Los empleados de

Marley Engineered Products

ADVERTENCIA

Lea cuidadosamente ayudarle a prevenir dificultades que podrían surgir durante la

instalación de los calentadores. El estudiar primero las instrucciones puede ahorrarle un tiempo considerable y dinero

después. Observe los procedimientos siguientes, y reduzca a

un mínimo su tiempo de instalación.

Para reducir el riesgo de incendio o choque eléctrico:

1. Antes de cablear o prestar servicio y para prevenir el

choque eléctrico, desconecte la potencia entrante al calentador por el panel principal de servicio.

2. Todo el cableado debe conformar con los códigos eléctricos

nacionales y locales, y el calentador debe estar conectado

a tierra como precaución contra un choque eléctrico posible.

3. Antes de activar, verifique que el voltaje del suministro de

potencia entrante al calentador corresponda a las

clasificaciones principales impresas en la placa de nombre.

4. Este calentador está caliente durante el uso. Para evitar

quemaduras, no permita que la piel expuesta toque las

superficies calientes.

Estas instrucciones están escritas para

!

5. No inserte ni permita que objetos extraños entren a ninguna apertura de ventilación o escape ya que esto puede

causar un choque eléctrico, incendio o daños al calentador.

6. No bloquee de ninguna manera las tomas de aire o los

escapes, para prevenir un posible incendio. Mantenga los

materiales combustibles, tales como cajas de madera,

cortinas, etc. alejados del calentador. No instale detrás de

puertas, muebles, toallas, o cajas.

7. Un calentador tiene adentro piezas calientes y productoras

de arcos eléctricos o de chispas. No use en áreas donde

estén almacenados gasolina, pintura o líquidos inflamables.

8. Use este calentador solo de la manera descrita en este

manual. Cualquier otro uso no recomendado por el fabricante puede causar incendio, choque eléctrico, o lesiones a

las personas.

9. Este calentador no está aprobado para usar en atmósferas

corrosivas tales como de mar, invernaderos o áreas de

almacenamiento de productos químicos.

CONSERVE ESTAS INSTRUCCIONES

Page 8

la corriente de aire de otra unidad.

A

B

C

D

EL CALENTADOR DEBE SER INSTALADO POR LO MENOS

7’(2134 MM) SOBRE EL PISO PARA PREVENIR QUE EL

CONTACTO ACCIDENTAL CON LAS HOJAS DEL ABANICO

PUEDA CAUSAR LESIONES.

LA ESTRUCTURA DE MONTAJE EN EL TECHO Y LAS PROVISIONES PARA SU ASEGURAMIENTO DEBEN SER LO

SUFICIENTEMENTE FUERTES PARA SOPORTAR EL PESO

COMBINADO DEL CALENTADOR Y DEL SOPORTE DE

MONTAJE. (VEA TABLA 4).

TODOS LOS TERMOSTATOS INCORPORADOS: SI EL

CALENTADOR ES UTILIZADO PARA PREVENIR QUE TUBERIAS O LIQUIDOS SE CONGELEN, Y SI EL

TERMOSTATO SE AJUSTA A MENOS DE 45°F (7°C), EL

ABANICO DEBE DE FUNCIONAR CONTINUAMENTE.

PARA PREVENIR POSIBLE SOBRECALENTAMIENTO O DAÑOS

POR SOBRECALENTAMIENTO, MANTENGA UN ESPACIO MINIMO DE 5’ (1524 MM) EN LA PARTE FRONTAL DEL CALENTADOR. REFIERASE A LA TABLA 1 PARA LOS REQUERIMIENTOS

DE ESPACIO A LOS LADOS, ARRIBA Y ABAJO.

NO INSTALE TERMOSTATOS DE MERCURIO DIRECTAMENTE EN

LA UNIDAD. LA VIBRACION PUEDE CAUSAR FALLAS EN EL

CALENTADOR.

LIMITE DE REPOSICIONAMIENTO MANUAL

(OPCION INSTALADA

EN LA FABRICA SOLAMENTE.) EL INTERRUPTOR DE LIMITE ESTA

COLOCADO INTERNAMENTE EN LA PARTE TRASERA DEL CALENTADOR. EN LOS MODELOS MUH03 Y MUH05, EL ACCESO AL

BOTON DE REPOSICIONAMIENTO ESTA A LA DERECHA (OBSERVANDO AL CALENTADOR DESDE ATRAS); EN TODOS LOS DEMAS

MODELOS, EL BOTON ESTA CERCA DE LA PARTE SUPERIOR

TRASERA DEL CALENTADOR.

EL LIMITE DE REPOSICIONAMIENTO MANUAL ESTA EN SERIE

CON EL PROTECTOR DE RECICLAJE AUTOMATICO (LIMITE). EL

LIMITE DE REPOSICIONAMIENTO MANUAL NO VA A REPOSICIONAR HASTA QUE EL CALENTADOR SE HAYA ENFRIADO Y EL

BOTON SEA PRESIONADO.

INSTRUCCIONES PARA UBICAR

EL CALENTADOR

Coloque las unidades de manera tal que las corrientes de aire de

descarga:

a.

sean sujetas a un mínimo de interferencia por columnas,

maquinaria y particiones;

b.

contacten las paredes expuestas sin soplar directamente a ellas;

c.

no se dirijan directamente a los ocupantes de un cuarto en calor

confortable;

d.

estén dirigidas barlovento cuando son instaladas en edificios

expuestos a vientos imperantes.

Ubique los termostatos aproximadamente a 5’ (1524 mm) sobre el

piso, en paredes de división interior o postes lejos de corrientes de

aire frías, fuentes internas de calor y lejos de corrientes de aire de

descarga de calentadores.

Cuartos pequeños pueden ser calentados por un solo calentador.

Cuartos grandes requieren de la instalación de varias unidades. El

número y la capacidad de las unidades serán determinados con base

en el volumen del edificio y la dimensión, en pies cuadrados, del área

de piso que va a ser calentada. Coloque las unidades de manera tal

que el aire circule en forma circular cuando cada unidad coopera con

COMO INSTALAR EL CALENTADOR

GENERAL

El calentador puede ser instalado para que descargue el aire

caliente vertical u horizontalmente. Cuando el calentador es instalado para que descargue verticalmente, se recomienda que el calentador sea ubicado de manera tal que la puerta de acceso abra

hacia el lado contrario de la pared, para permitir mayor acceso al

compartimiento de control y cableado. Si el calentador va a ser

instalado con la puerta de acceso mirando hacia la pared, el calentador debe ser instalado con suficiente espacio, que permita que la

puerta de acceso pueda abrirse en su totalidad (una distancia

aproximadamente igual al ancho del calentador … confirme el espacio antes de la instalación). Refiérase a la Tabla 1 para los espacios en el techo y la pared antes de instalar el calentador.

El calentador puede ser instalado para descarga vertical u horizontal

mediante el uso de varillas con rosca. (Refiérase a la Tabla 2 para los

tamaños de varilla con rosca requeridos). Observe los procedimientos

en forma detallada en las siguientes instrucciones para la instalación.

El calentador también puede ser suspendido desde la pared o techo

con la ayuda de un soporte de montaje opcional (tipo MMB o

MCMB), el cual permite que el calentador gire horizontalmente.

Luego de que el calentador ha sido instalado, las persianas pueden

ser colocadas para dirigir el aire caliente en la dirección deseada.

Cuando el calentador ha sido instalado para descarga horizontal,

las persianas deben dirigir el aire ya sea hacia el frente o hacia

abajo. Dirigir el aire hacia arriba puede causar que el aire caliente

se quede en el área del techo, lo que es un desperdicio de energía.

Descarga Horizontal

Tabla 1. Espacios de pared y techo, en pulgadas (mm)

Unidad Descarga Techo Pared Lateral Pared Trasera

3 & 5 kW

7.5 to 10 kW

15 to 10 kW

25 to 50 kW

VARILLA

DE

MONTAJE

P

TUERCA

A

DE

R

SEGURIDAD

E

D

T

R

A

S

E

R

A

Figura 1. Instalación y espaciamiento para descarga horizontal

(Instalado con varillas desde el techo)

1. Instale cuatro varillas de montaje con rosca en los huecos con

rosca y asegure utilizando tuercas de seguridad. (Vea Tabla 2).

2. Pegue firmemente las cuatro varillas de montaje al techo.

(Refiérase a la Tabla 1 para los espacios de las paredes y el

techo y a la Tabla 2 para la separación entre varillas de montaje).

Descarga Vertical

(Instalado con varilla desde el techo)

1. Remueva los tornillos de los huecos con rosca en la parte

trasera del calentador.

Español 2

Horiz. 2 (50.8) 6 (152.4) 9 (228.6)

Vert. 6 (152.4) 18 (457.2) 18 (457.2)

Horiz. 6 (152.4) 6 (152.4) 13 (330.2)

Vert. 6 (152.4) 24 (609.6) 24 (609.6)

Horiz. 6 (152.4) 9 (228.6) 12

Vert 6 (152.4) 24 (609.6) 24 (609.6)

Horiz. 16 (406.4) 12 (304.8) 18

Vert. 12 (304.8) 39 (914.4) 39 (914.4)

TECHO PARED TRASERA

UECOS

H

UNIDAD

CALENTADOR

CON ROSCA

PARA

ONTAJE

M

A

DE

(VISTA SUPERIOR)

B

1

/2(317.5)

1

/2(470.0)

D

C

P

A

R

E

D

L

A

T

E

R

A

L

Page 9

Tabla 2. Rosca de varilla y dimensiones de espaciamiento,

en pulgadas (mm), para descarga horizontal

Tipo de rosca

Unidad de varilla A B C D

8

6

ARED TRASERA

P

3

/

4

3

/

4

5

/

8

5

/

8

P

A

R

E

D

L

A

F

T

E

R

A

L

H

3 - 5 kW

7.5 - 10 kW

15 - 20 kW

25 - 30 kW

40 - 50 kW

ECHO

T

PUERTA DE

ACCESO

P

A

R

E

D

T

R

A

S

E

R

DISTANCIA IGUAL AL ANCHO DEL

A

CALENTADOR PARA PERMITIR APERTURA TOTAL DE LA PUERTA DE ACCESO

5

/16- 18

3

/8- 16

TUERCA DE

SEGURIDAD

51/

1

/

16

3

/

16

1

E

64

152.4) (103.1) (19.0)

(

16

61/

(153.9)

87/

3

1

/

1

8

(289.0)

9

0

1

/

16

(268.2) (368.3) (157.2) (16.0)

1515/

6

1

404.9) (368.3) (157.2) (16.0)

(

VARILLA DE

MONTAJE (4)

8

225.6) (130.3) (19.0)

(

4 - 12 6

1

14 - 12 63/

G

HUECOS

CON

ROSCA

PARA

MONTAJE

(VISTA SUPERIOR)

Figura 2. Vertical Discharge Mounting and Rod Spacing

Tabla 3. Tipos de rosca de varilla y dimensiones de

espaciamiento, en pulgadas (mm), para descarga vertical

Tipo de rosca

Unidad de varilla E F G H

3 - 5 kW

7.5 - 20 kW

25 - 30 kW

5

/16- 18

3

/8- 16

145/

211/

3

/

4

8

4

24

25

23/

69

(152.4) 247.7) (50.8) (103.1)

7

8

/

8

(225.6) (371.6) (50.8) (130.3)

1

14

/

2

(368.3) (539.8) (56.0) (157.2)

1

/

16

1

/

8

63/

16

16

2. Instale cuatro varillas de montaje con rosca en los huecos con

rosca y asegure utilizando tuercas de seguridad.

3. Pegue firmemente las cuatro varillas de montaje al techo.

(Refiérase a la Tabla 1 para los espacios de las paredes y el

techo y a la Tabla 3 para la separación entre varillas de montaje).

CABLEADO

Circuito Derivado (Alimentacion)

1. Conecte el calentador solo al voltaje, amperaje y frecuencia

especificadas en la placa del fabricante.

2. El tamaño del cableado de campo debe ser el apropiado para el

amperaje que se va a movilizar, de acuerdo al NEC.

3. La puerta de acceso tiene bisagras. Existen uno o dos tornillos,

accesibles desde el lado, que deben de ser aflojados para accesar. Estos tornillos son cautivos, no trate de sacarlos totalmente.

4. Se provee un agujero en la parte de atrás del calentador, cerca del

bloque de terminales de alimentación y de la tarjeta de terminales de

control. El agujero de la tarjeta de terminales de control es del tamaño

de una tubería eléctrica de 1/2 pulgada (12.7 mm). El agujero del

bloque de terminales de alimentación sirve para varios diámetros.

Utilice el diámetro que calza con el tamaño de la tubería eléctrica.

5. Se provee de una terminal tierra cerca de la tarjeta de terminales de alimentación. El cable tierra debe ser conectado antes

de que cualquier otra conexión se lleve a cabo.

6. El bloque de terminales de la energía se equipa de los terminales de la caja clasificados para aceptar el alambre correcto de

la fuente de alimentación del tamaño. El circuito minuto clasificado alambre 600V, 60° C del rama es aceptable para los calentadores clasificados hasta 80 amperios. Para los calentadores

clasificados más de 80 amperios, ramifica el alambre del circuito

debe ser por lo menos 75°C clasificado. El aluminio o el alambre

del cobre es satisfactorio para la conexión al terminal de la caja

del bloque de terminales de la energía del calentador. El alambre de cobre se recomienda y se debe utilizar con el interruptor

incorporado de la desconexión.

Español 3

7. Cada calentador tiene un diagrama de cableado pegado en la

parte interior de la puerta de acceso. Consulte este diagrama

antes de hacer cualquier conexión de campo.

Nota importante - Par de instalación de los terminales a tornillo:

durante el transporte es posible que las conexiones de los terminales a tornillo se aflojen. Después de la instalación, antes de

aplicar la alimentación eléctrica al calefactor, verifique que todas las

conexiones de terminales a tornillo estén apretadas con un par de

3.9 N·m (35 lb·pulg.) como mínimo recomendado.

8. Para los calentadores modelo MUH0521, MUH0581, MUH072,

MUH078, MUH102, MUH108 y MUH158 se pueden utilizar

conexiones de alimentación tri-fásicas o mono-fásicas. Estas

unidades son cableadas de fabrica para operación mono-fásica.

Si los calentadores se van a utilizar con alimentación tri-fásica,

reconecte los cables tal y como es indicado en el diagrama de

cableado pegado al calentador. Información adicional puede ser

encontrada en las ilustraciones de cableado en las Figuras 3a y

3b y siguiendo las indicaciones presentadas a continuación.

En los modelos MUH0521, MUH0581, MUH072, MUH078, MUH102

y MUH108 (Figura 3a) mueva solamente los dos cables marcados

con “A1” y “B1”, no mueva o cambie ningún otro cable. El cable del

elemento marcado “B1”, el cual es el cable conectado de fabrica, al

bloque de terminales de alimentación (terminal localizada más cerca

de los elementos) debe ser movido a la terminal “B” en el bloque de

terminales tri-fásico.

El cable relé (contactor) “A1” debe ser movido de la terminal final del

bloque de terminales de alimentación (terminal más cercana al contactor o tarjeta de terminales de control) a la terminal “A” del bloque

de terminales inferior (terminal central).

El modelo MUH158 (Figura 3b) tiene dos bloques de terminales tri-fásicos colocados a la par de los relés (contactores). Mueva solamente los

dos cables marcados “C1” y “D1” en cada uno de esos bloques de terminales tri-fásicos a la terminal “B”. No mueva o cambie ningún otro cable.

9. Accesorios eléctricos, ya sea juegos u opciones instaladas de

fábrica, se presentan conectados por una línea de rayas en el

diagrama de cableado del calentador.

CALENTADOR DE 208/240 VOLTIOS

10.

. los calentadores están

cableados de fábrica para 240 V. Cuando conecte el calentador a una fuente de alimentación de 208 V debe intercambiar

los cables de conexión del transformador. Para unidades con

una especificación de 30/40 kW o mayor, intercambie los

cables de conexión NARANJA y ROJO del primario. El cable

de conexión de color NEGRO es el COMÚN (retorno) del

transformador (50 VA) suministrado con las unidades de alta

potencia (watts). Para calentadores con una especificación

más baja de potencia (kW), intercambie los cables de conexión

NEGRO y ROJO del primario. El cable de conexión de color

BLANCO es el COMÚN (retorno) del transformador de control

suministrado con estos calentadores. Antes de realizar esta

reconexión de los cables de conexión del primario del transformador, consulte siempre el diagrama de conexionado en la

cubierta del calentador.

Cableado de Control

ALGUNAS DE LAS TERMINALES EN LA TARJETA DE TERMINALES DE CONTROL PUEDEN PRESENTAR VOLTAJE

DE LINEA. SIEMPRE DESCONECTE LA ALIMENTACION

DEL CALENTADOR ANTES DE HACER CUALQUIER

CONEXION A LA TARJETA DE CONTROL PARA PREVENIR

EL PELIGRO DE CHOQUES ELECTRICOS.

1. Utilize alambre insulado de 600 voltios minimo, Clase 1 NEC

para todos los ciruitos de control.

2. Use una terminal de horquilla en el extremo del cable que se

pega a la tarjeta de terminales de control MUH si se debe hacer

más de una conexión en el tornillo de la terminal.

3. las unidades que no incluyen contactor interno (3 & 5 kW),

refiere a la figura 4 para el diagrama electrico.

Nota:

los alambres del termostato y el circuito de control deben ser

capaz demantener la corriente del calentador (Ejemplo MUH0581

24 amperos)

4. En las unidades que si incluyen contactor interno (7 kW y mas)

refiere a la figura 5 para el diagrama electrico. El alambre del

circuito de control deber ser minimo 18 AWG.

Page 10

A

B

LEAD WIRE

"B1"

ELEMENTS

CONTACTOR

(OR P2)

POWER TERMINAL BLOCK

HEATER FRONT

LEAD WIRE

"A1"

3 PHASE BLOCK

TO ELEMENTS

A

B

LEAD WIRE

"B1"

ELEMENTS

CONTACTOR

(OR P2)

POWER TERMINAL BLOCK

HEATER FRONT

LEAD WIRE

"A1"

3 PHASE BLOCK

TO ELEMENTS

FACTORY-WIRED FOR SINGLE-PHASE POWER FIELD-WIRED FOR THREE-PHASE POWER

RENTE DEL

B

3 PHASE BLOCK

FACTORY-WIRED FOR SINGLE-PHASE POWER

C

1

D

1

D

1

C

1

C

D

B

C

D

3 PHASE BLOCK

B

3 PHASE BLOCK

FIELD-WIRED FOR THREE-PHASE POWER

C

1

D

1

D

1

C

1

C

D

B

C

D

3 PHASE BLOCK

BLACK

RED

RED

BLACK

C

RW1

W2

F 2

F 1

G

T R

T

S

S

REMOTE SUMMER FAN

SWITCH (MRFS-1)

FAN RELAY

(FOR MRFS-2 AMD MHRT)

SUMMER

FAN

SWITCH

MT-1

MT-2

2-STAGE

INTERNAL

THERMOSTAT

BLACK

RED

RED

BLACK

P2

H2

F 1

F 2

S

REMOTE SUMMER

FAN SWITCH (MRFS-1)

OR SUMMER FAN

SWITCH MCFS (MANUAL)

P1

H1

T

T

MT-1

MT-2

BLACK TO W1

RED TO R

2-STAGE

INTERNAL

THERMOSTAT

MHRT HEAT RECOVERY

THERMOSTAT OR

REMOTE FAN

SWITCH (MRFS-2)

BLACK

RED

RED

BLACK

C

RW1

W2

F 2

F 1

G

T R

T

S

S

REMOTE SUMMER FAN

SWITCH (MRFS-1)

FAN RELAY

(FOR MRFS-2 AMD MHRT)

SUMMER

FAN

SWITCH

F

CALENTADOR

CABLE

“A1”

BLOQUE TRI-FASICO

RENTE DEL

F

CALENTADOR

CABLE

“A1”

LOQUE TRI-FASICO

B

CABLE

“B1”

ABLE

C

“B1”

ELEMENTOS

A LOS ELEMENTOS

ONTACTOR

C

(O P2)

BLOQUE DE TERMINALES

DE ALIMENTACION

CABLEADO DE FABRICA PARA ALIMENTACION MONO-FASICA

CABLE

B1”

“

LEMENTOS

E

A LOS ELEMENTOS

ONTACTOR

C

(O P2)

BLOQUE DE TERMINALES

E ALIMENTACION

D

CABLEADO DE CAMPO PARA ALIMENTACION TRI-FASICA

Figura 3a. Conexión de cables para alimentación mono-fásica y tri-fásica (MUH0521, MUH0581, MUH072, MUH078, MUH102 y MUH108)

LOQUE TRI-FASICO

B

BLOQUE TRI-FASICO

INTERRUPTOR DE ABANICO DE

VERANO REMOTO (MRFS-1) O

INTERRUPTOR DE ABANICO DE

VERANO (MANUAL)

NOTAS:

1. ESTE ESTILO DE TARJETA DE TERMINALES DE

2. CU ANDO LA UNIDAD ESTA CABLEADA

3. TERMOSTATOS DE LINEAS DE VOLTAJE EXTER-

CABLEADO DE FABRICA PARA ALIMENTACION MONO-FASICA

Figura 3b. Conexiones de cableado para alimentaciones mono-fásicas y tri-fásicas

TERMOSTATO

INTERNO DE

DOS FASES

NEGRO

ROJO

NEGRO

ROJO

CABLEADO DE CAMPO PARA ALIMENTACION TRI-FASICA

CONTROL ES UT ILIZADO CO N LOS MODELOS

MUH0321, MUH0371, MUH0381, MUH0521, MUH0571

Y MUH0581.

MONO-FASICA, EMPALME H1 CON H2. SI UN TERMOSTATO DE UN BORNE ES UTILIZADO CON UNA

UNIDAD MONO-FASICA, CONECTE LOS CABLES

DEL TERMOSTATO A P1 Y H1.

NAS DEBEN SER TRATADOS SOLAMENTE COMO

DE UNA SOLA FASE.

BLOQUE TRI-FASICO

BLOQUE TRI-FASICO

Figura 4. Tarjeta de Terminales de Control (para Calentadores sin Interruptor)

INTERRUPTOR DE ABANICO DE

VERANO REMOTO (MRF8-1)

INTERRUPTOR

PARA ABANICO

DE VERANO

RELE DEL ABANICO

(PARA MRFS-2 Y MHRT)

Español 4

ROJO

NEGRO

DE VUELTA

A W1

ROJO A R

TERMOSTATO PARA LA

RECUPERACION DE

CALOR MHRT O INTERRUPTOR

REMOTO DEL ABANICO (MRFS-2)

Figura 5. Tarjeta de Terminales de Control (para Calentadores con Contactor).

TERMOSTATO

INTERNO DE

DOS FASES

NEGRO

ROJO

NOTAS:

1. ESTE ESTILO DE TARJETA DE TERMINALES DE CONTROL

NO ES UTILIZADO CON LOS MODELOS MUH0321, MUH0371,

MUH0381, MUH0521, MUH0571 Y MUH0581.

2. REMUEVA EL EMPALME DE W1 A W2 CUANDO SE UTILICE UN

TERMOSTATO DE DOS FASES.

3. *SOLAMENTE UNO DE ESTOS ACCESORIOS PUEDE SER

CONECTADO A UN CALENTADOR INDIVIDUAL.

4. TERMOSTATOS DE LINEAS DE VOLTAJE EXTERNAS DEBEN

SER TRATADOS SOLAMENTE COMO DE UNA SOLA FASE.

Page 11

Tabla 4. Especificaciones

Modelo pulgadas pulgadas pulgadas Instalación Compartimiento

Altura Ancho

Profundidad

Básico Nº (mm) (mm) (mm) lbs. (kg) de Cableado

MUH0381 27 (12.2)

UH0321 27 (12.2)

M

UH0371 27 (12.2)

M

MUH0341 30 (13.6)

MUH0581 27 (12.2)

UH0521

M

MUH0571

6 14 7

1

406.4) (355.6) (190.5)

(

MUH0541 30 (13.6)

UH0331 30 (13.6)

M

MUH0361 30 (13.6)

MUH0531 30 (13.6)

MUH0561 30 (13.6)

UH078 38 (17.2)

M

MUH072 38 (17.2)

MUH077 38 (17.2)

UH074 38 (17.2)

M

MUH108

MUH102

3

21

/

19 71/

4

(552.5) (482.6) (190.5)

MUH107 38 (17.2)

MUH104 38 (17.2)

MUH073 38 (17.2)

UH076 38 (17.2)

M

MUH103 38 (17.2)

MUH106 38 (17.2)

MUH158 54 (24.5)

MUH152 50 (22.7)

MUH154 50 (22.7)

MUH208

MUH202

3

21

/

19 123/

4

(552.5) (482.6) (323.9)

MUH204 55 (24.9)

MUH156 55 (24.9)

MUH206 55 (24.9)

MUH252 89 (40.4)

MUH254 89 (40.4)

MUH308

MUH302

MUH304 89 (40.4)

30 26

(76.2) 676.4) (298.5)

5

/

113/

8

MUH256 89 (40.4)

MUH306 89 (40.4)

MUH402 119 (54.0)

MUH404 119 (54.0)

MUH508

MUH502

MUH504 119 (54.0)

30 26

(76.2) 676.4) (435.1)

5

/

171/

8

MUH406 119 (54.0)

MUH506 119 (54.0)

Peso de Volumen del

1

7 (12.2)

2

/

2

27 (12.2)

38 (17.2) 100 in

2

38 (17.2)

60 (27.2)

4

55 (24.9)

89 (40.4)

4

89 (40.4)

119 (54.0)

4

119 (54.0)

0 in

9

14.70 cm

(

(1639 cm

140 in

(2295 cm

504 in

(8260 cm

648 in

(10620 cm

INFORMACION IMPORTANTE

3

3

)

PLACA DEL FABRICANTE

3

3

)

MODELO NO.

MFG. NO.

MUH321

VOLTS AC KILOWATTS FASE AMPACIDAD MIN. DE

60 HZ ALIMENTACION DE CIR.

208 / 240 2.2 /3 1

MAX. FUSIBLE MOTOR CONTROLES CLIENTE Nº

VAC AMP VAC

208/240 .25 208/240

FLUJO DE ESPACIO MINIMO DE INSTALACION

3

3

)

3

3

)

3

3

)

AIRE LADO ATRAS TECHO PISO

HORIZ. 6" 9.5" 2" 7'

VERT. 18" 18" 6" 7'

¡ADVERTENCIA!

UNIDAD. DESCONECTE ANTES DE REPARAR. SI SE UTILIZA CONTROL EXTERNO,

TAMBIEN SE DEBE DESCONECTAR LA FUENTE DE ALIMENTACION EXTERNA.

NE PAS RELEVER LES LAMES AU-DEL`A DU NIVEAU PREVU DE

L'APPAREIL. METTRE HORS TENSION AVANT DE PROCEDER A

L'ENTRETIEN. SI UNE COMMANDE EXTERNE EST UTILISEE, COUPER AUSSE

L'ALIMENTATION EXTERNE. ASSURER UN DEGAGEMENT D'AU MOINS 6 PI

ENTRE L'APPAREIL DE CHAUFFAGE ET LEPLANCHER.

MARLEY ENGINEERED PRODUCTS

BENNETTSVILLE, SC 29512 4104-0275-036

NO VOLTEE LAS PERSIANAS POR ENCIMA DEL NIVEL DE LA

ODIGO DE FECHA

C

CALENTADOR DE

AIRE LISTADO 774G

0395

Español #Español 5

Page 12

Todos los productos fabricados por Marley Engineered Products están garantizados contra defectos de fabricación y de materiales por 1 año desde la fecha de

GARANTÍA LIMITADA

instalación. Esta garantía no se aplica a daños debidos a accidente, mal uso o alteración, ni a los casos en que la tensión eléctrica conectada supere a la tensión nominal -indicada en la placa de características- en más de 5 %, ni a equipos que hayan sido instalados o cableados incorrectamente, o mantenidos en

forma que no cumpla lo indicado en las instrucciones de instalación del producto. Todo reclamo por trabajos en garantía debe acompañarse con una prueba de

la fecha de instalación.

El cliente será responsable de todos los costos incurridos en el retiro o reinstalación de productos, incluyendo los costos de mano de obra y los costos de envío

incurridos para regresar productos a un Centro de Servicio de Marley Engineered Products. Dentro de las limitaciones de esta garantía, las unidades que no

funcionan deben regresarse al centro de servicio autorizado Marley más cercano, o al Centro de Servicio de Marley Engineered Products, y nosotros lo

repararemos o reemplazaremos, a nuestra opción, sin cargo para usted, con el flete de retorno pagado por Marley. Se acuerda que tal reparación o reemplazo

es el único recurso que Marley Engineered Products pone a su disposición.

LAS GARANTÍAS EXPUESTAS MÁS ARRIBA TOMAN EL LUGAR DE TODA OTRA GARANTÍA, EXPRESA O IMPLÍCITA, Y POR LA PRESENTE SE

DECLINA Y EXCLUYE DE ESTE ACUERDO TODA GARANTÍA IMPLÍCITA DE COMERCIABILIDAD Y ADECUACIÓN A UN PROPÓSITO PARTICULAR QUE

EXCEDA LAS GARANTÍAS EXPRESAS ANTEDICHAS. MARLEY ENGINEERED PRODUCTS NO SE HARÁ RESPONSABLE POR DAÑOS CONSIGUIENTES

QUE SE PRODUZCAN CON RESPECTO AL PRODUCTO, EN BASE YA SEA A NEGLIGENCIA, AGRAVIO, RESPONSABILIDAD ESTRICTA, O CONTRATO.

Algunos estados o jurisdicciones no permiten la exclusión o limitación de daños incidentales o consiguientes, de modo que la exclusión o limitación expresada

más arriba puede no aplicarse a su caso. Esta garantía le da derechos legales específicos, y usted puede tener también otros derechos, que varían de un estado o jurisdicción a otro.

Para obtener la dirección de su centro de servicio autorizado más cercano comuníquese con Marley Engineered Products en Bennettsville, SC, Estados Unidos,

llamando al 1-800-642-4328. Toda mercadería regresada a la fábrica debe ser acompañada por una autorización de retorno y una etiqueta de identificación de

servicio, disponibles ambas en Marley Engineered Products. Cuando solicite la autorización de retorno, incluya todos los números de catálogo mostrados en los

productos.

CÓMO OBTENER SERVICIO EN GARANTÍA, PIEZAS DE

REPUESTO E INFORMACIÓN GENERAL

1. Servicio o repuestos en garantía

2. Compra de repuestos

3. Información general sobre productos

Nota:

cuando solicite servicio, siempre dé la información que sigue:

1. Número de modelo del producto

2. Fecha de fabricación

3. Número de parte o descripción

1-800-642-4328

1-800-654-3545

www.marleymep.com

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

Número de parte 5200-0722-013

ECR 38995

03/11

Page 13

Série MUH

Radiateurs modulaires

Homologués U.L.

Instructions d'installation, d’utilisation et d'entretien

Cher propriétaire,

Félicitations! Merci pour l’achat de cet appareil de chauffage fabriqué par Marley Engineered Products. Vous avez fait un

investissement judicieux en choisissant un produit de la meilleure qualité qui soit. Veuillez lire attentivement les instructions d’installation et d’entretien figurant dans ce manuel. Vous allez désormais profiter d'une chaleur confortable pendant

plusieurs années, grâce à ce produit fabriqué par Marley Engineered Products... une entreprise jouissant d'une excellente

réputation au niveau de la conception technique, de la fabrication, de la qualité et du service.

... Les employés de

Marley Engineered Products

AVERTISSEMENT

À lire attentivement : Cette notice a pour objet de vous aider à

éviter les difficultés qui pourraient surgir lors de l'installation

des radiateurs. Vous économisez beaucoup de temps, et

réaliserez des économies plus tard en prenant connaissance

de cette notice. Procédez de la façon indiquée ci- dessous et

abrégez le temps nécessaire à l'installation.

Pour Réduire les risques d’incendie ou d’électrocution

1. Pour empêcher tout risque possible d'électrocution, couper

le courant arrivant au radiateur au niveau du tableau de distribution principal avant d'entreprendre un câblage ou une

réparation.

2. Tout câblage doit être conforme aux codes électriques

national et local en vigueur et le radiateur doit être raccordé

à la terre, mesures préventives contre les risques d'électrocution.

3. Vérifier que la tension d'alimentation vers l'appareil et la tension du circuit de commande arrivant au radiateur et aux

accessoires correspondent aux valeurs nominales

indiquées sur la plaque signalétique du radiateur et des

accessoires avant de les mettre sous tension.

4. La surface de ce radiateur est chaude pendant son utilisation. Pour éviter de se brûler, ne pas laisser la peau nue

entrer en contact avec la surface chaude.

!

5. Ne pas introduire ou ne pas laisser pénétrer de corps

étrangers dans les ouvertures de ventilation ou d'échappement, cela pouvant provoquer électrocution, incendie ou

dommages au radiateur.

6. Pour empêcher tout risque d'incendie, ne pas obstruer les

prises d'air ni les orifices d'échappement de quelque façon

que ce soit. Éloigner les matériaux combustibles tels que

caisses, tentures, etc. du radiateur. Ne pas installer cet

appareil de chauffage derrière une porte, un meuble, un

porte-serviettes ou des cartons.

7. Un radiateur comporte des pièces internes chaudes dans

lesquelles se produisent des arcs ou des étincelles. Ne pas

s'en servir dans des lieux dans lesquels on utilise ou entrepose de l'essence, de la peinture ou des liquides inflammables.

8. N'utiliser ce radiateur que de la façon décrite dans cet

ouvrage. Toute autre utilisation non conseillée par le manufacturier risque de provoquer incendie, électrocution ou

blessures.

9. Ce radiateur n'est pas agréé pour une utilisation dans une

atmosphère corrosive telle que celle d'un bateau, d'une

serre ou d'un entrepôt de produits chimiques.

CONSERVER CES INSTRUCTIONS

Page 14

d'air d'un autre appareil.

A

B

C

D

MONTER LE RADIATEUR À 213.4CM (7 PIEDS) MINIMUM

AU-DESSUS DU SOL AFIN D'EMPÊCHER TOUT CONTACT

ACCIDENTEL AVEC LES PALES DU VENTILATEUR, CE QUI

POURRAIT PROVOQUER DES BLESSURES.

L FAUT QUE LA STRUCTURE DE MONTAGE AU PLAFOND

ET QUE LES DISPOSITIFS D'ANCRAGE SOIENT SUFFISAMMENT RÉSISTANTS POUR POUVOIR SUPPORTER LE

POIDS DU RADIATEUR ET DU SUPPORT DE MONTAGE.

(VOIR LE TABLEAU 4).

POUR TOUS LES APPAREILS À THERMOSTATS INTÉGRÉS

: SI LE RADIATEUR SERT À EMPÊCHER DES TUYAUX OU

DES LIQUIDES DE GELER, ET SI LE THERMOSTAT EST

RÉGLÉ À MOINS DE 7˚C (45˚F), IL FAUT QUE LE VENTILATEUR TOURNE EN PERMANENCE.

POUR EMPÊCHER TOUT RISQUE POSSIBLE DE SURCHAUFFE OU DE DOMMAGES PROVOQUÉS PAR UNE

SURCHAUFFE, LAISSER UNE DISTANCE DE 152.4CM (5

PIEDS) MINIMUM À L'AVANT ET CONSULTER LE TABLEAU

1 POUR CONNAÎTRE LES DISTANCES MINIMALES SUR

LES CÔTÉS ET À L'ARRIÈRE.

NE JAMAIS MONTER DE THERMOSTAT À MERCURE DIRECTEMENT SUR L'APPAREIL. LES VIBRATIONS POURRAIENT PROVOQUER UN MAUVAIS FONCTIONNEMENT DU RADIATEUR.

INTERRUPTEUR MANUEL DE REMISE EN MARCHE

INSTALLÉE EN USINE UNIQUEMENT). L'INTERRUPTEUR MANUEL

DE REMISE EN MARCHE EST SITUÉ À L'INTÉRIEUR DU RADIATEUR, À LA PARTIE ARRIÈRE. SUR LES MODÈLES MUH03 ET

MUH05, L'ACCÈS AU BOUTON MANUEL DE REMISE EN MARCHE

EST SITUÉ SUR LE CÔTÉ DROIT (LORSQU'ON SE PLACE À L'ARRIÈRE DE L'APPAREIL); SUR TOUS LES AUTRES MODÈLES IL EST

SITUÉ PRÈSDE LA PARTIE SUPÉRIEURE ARRIÈRE DU RADIATEUR.

L'INTERRUPTEUR MANUEL DE REMISE EN MARCHE EST MONTÉ

EN SÉRIE AVEC LE PROTECTEUR DE RECYCLAGE AUTOMATIQUE (LIMITE). L'APPAREIL NE REFONCTIONNERA PAS TANT

QUE L'ON N'AURA PAS APPUYÉ SUR CE BOUTON.

CONSEILS POUR L'EMPLACEMENT DU

RADIATEUR

Disposer les radiateurs pour que le flux d'air chaud :

a.

rencontre un minimum d'obstacles tels que colonnes, machines

ou cloisons;

b.

balaie les murs exposés sans souffler directement sur eux;

c.

soit dirigé à l'opposé des occupants de la pièce dans le cas d'un

chauffage de confort;

d.

soit dirigé du côté venté lorsque les radiateurs sont installés

dans un bâtiment exposé à un vent prédominant.

Placer les thermostats à 1524 mm (5 pieds) du sol sur des cloisons

intérieures, ou sur des colonnes à l'abri de courants d'air froid, de sources

de chaleur internes et de flux d'air chaud provenant de radiateurs.

Les petites pièces peuvent être chauffées par un seul appareil de

chauffage.

Les plus grandes pièces nécessitent plusieurs appareils. Le nombre

et la puissance des appareils dépendra du volume des locaux et de

la superficie à chauffer. Disposer les appareils pour fournir un

périmètre de circulation d'air où chaque appareil favorise le courant

(OPTION

Français 2

MONTAGE DU RADIATEUR - GÉNÉRALITÉS

Le radiateur peut être monté de façon à décharger l'air chaud soit horizontalement, soit verticalement. Lorsque le radiateur est monté pour

une décharge verticale, il est conseillé de le disposer de façon à ce

que la porte d'accès se trouve ailleurs que face à un mur afin de

faciliter l'accès au compartiment de câblage et de commande. Si le

radiateur est monté de façon à ce que la porte d'accès se trouve face

au mur, laisser une distance au mur suffisante pour permettre la pleine

ouverture de la porte d'accès (la distance doit être environ égale à la

largeur du radiateur... vérifier qu'il existe un espace suffisant avant l'installation). Avant de monter le radiateur, se reporter au tableau 1 qui

indique les distances à respecter par rapport au mur et au plafond.

Le radiateur peut se monter pour une décharge verticale ou horizontale

à l'aide de tiges filetées. (Se reporter au tableau 2 pour connaître les

dimensions des tiges filetées requises). Suivre les méthodes détaillées

dans les instructions d'installation suivantes.

Le radiateur peut aussi se suspendre au mur ou au plafond à l'aide

d'un support en option (de type MMB ou MCMB) qui permet le pivotement horizontal du radiateur.

Une fois le radiateur installé, on peut orienter les persiennes de

manière à diriger le flux d'air chaud de la façon souhaitée.

Lorsque le radiateur est installé pour une décharge horizontale, les

persiennes doivent diriger l'air tout droit ou vers le bas. L'air dirigé vers

le haut peut rester dans la zone du plafond, ce qui gaspille de l'énergie.

Décharge horizontale

(Montage sur tige au plafond)

1. Monter quatre tiges filetées de fixation dans les trous filetés et les bloquer en place à l'aide de contre-écrous (Voir tableau 2).

2. Fixer fermement les quatre tiges filetées au plafond. (Se reporter au

tableau 1 indiquant les distances à respecter par rapport aux murs et au

plafond et au tableau 2 qui indique l'espacement des tiges de fixation).

Décharge verticale (Tige montée au plafond)

1. Enlever les boulons des tiges filetées à l'arrière du radiateur.

2. Monter quatre tiges de fixation filetées dans les trous filetés et

fixer en place à l'aide de contre-écrous.

3. Fixer solidement les quatre tiges filetées au plafond. (Se reporter

au tableau 1 où figurent les distances à respecter par rapport au

mur et au plafond et au tableau 3 indiquant les dimensions pour

l'espacement des tiges de fixation).

Tableau 1. Distances par rapport aux murs et au plafond en mm (pouces )

Appareil Dégagement Plafond Mur Latéral Mur Arrière

3 & 5 kW

7.5 to 10 kW

15 to 10 kW

25 to 50 kW

TIGE DE

FIXATION

M

CONTRE-

U

ÉCROU

R

A

R

R

I

È

R

E

Figure 1. Décharge horizontale, montage et espacements.

Horiz. 2 (50.8) 6 (152.4) 9 (228.6)

Vert. 6 (152.4) 18 (457.2) 18 (457.2)

Horiz. 6 (152.4) 6 (152.4) 13 (330.2)

Vert. 6 (152.4) 24 (609.6) 24 (609.6)

Horiz. 6 (152.4) 9 (228.6) 12

Vert 6 (152.4) 24 (609.6) 24 (609.6)

Horiz. 16 (406.4) 12 (304.8) 18

Vert. 12 (304.8) 39 (914.4) 39 (914.4)

PLAFOND

RADIATEUR

TROUS DE

MONTAGE

FILETÉS

A

(VUE DE DESSUS)

MUR ARRIÈRE

B

1

/2(317.5)

1

/2(470.0)

D

C

M

U

R

L

A

T

É

R

A

L

Page 15

Tableau 2. Filetage de la tige et dimensions de l’espacement en mm

(po) pur décharge horizontale

Appareil de la tige

3 - 5 kW

7.5 - 10 kW

15 - 20 kW

25 - 30 kW

40 - 50 kW

PORT

D’ACCÈS

M

U

R

A

R

R

I

È

R

E

Type de filetage

5

/16- 18

3

/8- 16

PLAFOND

CONTREÉCROU

DISTANCE AU MUR ÉGALE À LA

LARGEUR DU RADIATEUR POUR

PERMETTRE L’OUVERTURE DE

LA PORTE D’ACCÈS

A B C D

64

152.4) (103.1) (19.0)

6

1

3

1

/

8

9

0

/

16

6

1

(

87/

8

225.6) (130.3) (19.0)

(

4 - 12 6

1

14 - 12 63/

G

TROUS DE

MONTAGE

FILETÉS

(VUE DE DESSUS)

61/

(153.9)

1

(289.0)

1

(268.2) (368.3) (157.2) (16.0)

1515/

404.9) (368.3) (157.2) (16.0)

(

TIGE DE

MONTAGE (4)

1

51/

3

E

/

16

8

/

16

6

1

MUR ARRIÈRE

H

3

/

4

3

/

4

5

/

8

5

/

8

M

U

R

L

A

T

F

É

R

A

L

Figure 2. Montage pour déchargement vertical et espacement des tiges

Tableau 3. Type de tiges filetées et dimensions de l’espacement des

tiges en mm (po) pour une décharge verticale

Appareil de la tige

Type de filetage

3 - 5 kW

5

/16- 18

7.5 - 20 kW

25 - 30 kW

3

/8- 16

E F G H

145/

211/

3

/

4

8

4

24

25

23/

69

(152.4) 247.7) (50.8) (103.1)

7

8

/

8

(225.6) (371.6) (50.8) (130.3)

1

14

/

2

(368.3) (539.8) (56.0) (157.2)

1

/

16

1

/

8

63/

6

1

1

6

CÂBLAGE

Circuit d’alimentation (puissance)

1. Brancher le radiateur uniquement à la tension, au courant et à la

fréquence spécifiés sur la plaque de firme.

2. La taille des fils de câblage sur site doit être convenablement

choisie pour transporter l'ampérage en conformité avec le NEC.

3. La porte d'accès est munie de charnières. Il faut desserrer une

ou deux vis accessibles par les côtés pour y accéder. Il s'agit de

vis prisonnières : ne pas essayer de les retirer.

4. Une pastille défonçable est fournie à l'arrière du radiateur près

du bornier secteur et de la plaque à bornes de commande. La

partie défonçable du bornier de commande est pour un conduit

de 12,7 mm (1/2 po). La pastille défonçable pour bornier de

puissance est de diamètre multiple. Utiliser le diamètre correspondant à la taille requise du conduit.

5. Une borne de masse est fournie près de la plaque à bornes de

puissance. Le fil de masse doit être branché avant d'effectuer

tout autre raccordement.

6. Le TB de puissance est équipé des bornes de boîte classées

pour accepter le fil correct d'alimentation d'énergie de taille. Le

circuit la minute évaluée par fil 600V, 60° C de branche est

acceptable pour des réchauffeurs évalués jusqu'à 80 ampères.

Pour des réchauffeurs évalués plus de 80 ampères,

s'embranchent le fil de circuit doit être au moins 75°C évalué.

L'aluminium ou le fil de en cuivre est satisfaisant pour le

raccordement à la borne de boîte de TB de puissance de

réchauffeur. Le fil de cuivre est recommandé et doit être

employé avec le commutateur intégré de débranchement.

7. Un schéma de câblage est collé sur la face interne de la porte

d'accès. Se reporter au schéma avant d'effectuer un quelconque

raccordement sur le site.

Français 3

Note importante – Couple des bornes à vis à l’installation :

Durant le

transport il est possible que des connexions par bornes à vis se

soient desserrées. Après l’installation, avant de mettre sous tension

l’appareil de chauffage, vérifiez toutes les connexions par borne à

vis, leur serrage doit être à un couple d’au moins 35 in-lbs. (3,9 Nm).

8. Un raccordement sur secteur monophasé ou triphasé peut être

utilisé sur les radiateurs modèles MUH0521, MUH0581,

MUH072, MUH078, MUH102, MUH108, et MUH158. Ces unités

sont câblées en usine pour un fonctionnement en monophasé.

Si ces radiateurs doivent être utilisés sur une alimentation en

triphasé, rebrancher les fils comme l'indique le schéma de

câblage livré avec le radiateur. Les figures 3a et 3b illustrant le

câblage ainsi que les consignes ci-dessous apportent des renseignements supplémentaires.

Sur les modèles MUH0521, MUH0581, MUH072, MUH078,

MUH102, et MUH108 (figure 3a), déplacer uniquement les deux fils

marqués "A1" et "B1"; ne déplacer et ne changer aucun autre fil. Le

fil principal de l'élément marqué "B1" qui est branché en usine sur le

bornier de puissance (le bornier le plus proche des éléments) doit

être déplacé sur la borne marquée "B" du bornier triphasé.

Le fil du relais (contacteur) "A1" doit être déplacé de la borne d'extrémité du bornier de puissance (borne la plus proche du contacteur

ou de la plaque à bornes de commande) vers la borne "A" du

bornier inférieur (borne centrale).

Le modèle MUH158 (figure 3b) est doté de deux blocs de borniers

de triphasé situés tout près des relais (contacteurs). Déplacer

uniquement les deux fils marqués "C1" et "D1" de chacun de ces

blocs de borniers de triphasé vers le bornier "B". Ne déplacer et ne

changer aucun autre fil.

9. Les accessoires électriques, kits ou options installés en usine,

sont indiqués par un trait en pointillé sur le schéma de câblage

du radiateur.

RADIATEUR DE 208/240 V

10.

. Les appareils de chauffage sont

câblés en usine pour du secteur 240 volts. Quand l'appareil

est branché sur 208 volts, ses fils de transformateur ont à être

déplacés. Pour les unités de puissance nominale 30/40 kW ou

plus, intervertissez les fils de primaire ORANGE et ROUGE. Le

fil de couleur noire est le COMMUN pour le transformateur (50

VA) fourni avec les unités à forte puissance. Pour les appareils

de chauffage à puissance nominale en kW plus faible, intervertissez les fils de primaire NOIR et ROUGE. Le fil de couleur

BLANCHE est le COMMUN pour le transformateur de commande fourni avec ces appareils de chauffage. Référez-vous

toujours au schéma de câblage sur le couvercle de l'appareil

avant d'effectuer ce branchement différent des fils du primaire

de transformateur.

Câblage de commande

LA TENSION SECTEUR EST PRÉSENTE SUR CERTAINES DES

BORNES DE LA PLAQUE À BORNES DE COMMANDE. TOUJOURS

DÉBRANCHER L'ALIMENTATION DU RADIATEUR AVANT DE

PROCÉDER À UN RACCORDEMENT SUR LA PLAQUE DE COMMANDE AFIN D'ÉVITER TOUT RISQUE D'ÉLECTROCUTION.

1. Utilisez les fils Class 1 de NEC isole pour 600V minimum pour le

tout le câblage de circuit de commande.

2. Utiliser une cosse à sertir en forme de fourche sur les extrémités

des fils qui se fixent sur la plaque à bornes de commande du

MUH si plus d'un raccordement doit être effectué sous la borne

à vis.

3. Pour l’ unités non-equipées de contacteur intégrale (3 et 5 kW),

referez vous au Schema 4 pour le diagramme de filage.

Note:

Le thermostat et les conducteurs de circuit de commande

doivent supporter le courant de plein charge du radiateur (example:

MUH0581 l est evalues à 24 amperes).

4. Pour l’ unités equipées de contacteur intégrale (7kW et plus),

referez vous au Schema 5 pour le diagramme de filage. Le

grosseur minimum pour le câblage de circuit de commande est

18AWG

Page 16

A

B

LEAD WIRE

"B1"

ELEMENTS

CONTACTOR

(OR P2)

POWER TERMINAL BLOCK

HEATER FRONT

LEAD WIRE

"A1"

3 PHASE BLOCK

TO ELEMENTS

A

B

LEAD WIRE

"B1"

ELEMENTS

CONTACTOR

(OR P2)

POWER TERMINAL BLOCK

HEATER FRONT

LEAD WIRE

"A1"

3 PHASE BLOCK

TO ELEMENTS

FACTORY-WIRED FOR SINGLE-PHASE POWER FIELD-WIRED FOR THREE-PHASE POWER

RENTE DEL

B

3 PHASE BLOCK

FACTORY-WIRED FOR SINGLE-PHASE POWER

C

1

D

1

D

1

C

1

C

D

B

C

D

3 PHASE BLOCK

B

3 PHASE BLOCK

FIELD-WIRED FOR THREE-PHASE POWER

C

1

D

1

D

1

C

1

C

D

B

C

D

3 PHASE BLOCK

BLACK

RED

RED

BLACK

C

RW1

W2

F 2

F 1

G

T R

T

S

S

REMOTE SUMMER FAN

SWITCH (MRFS-1)

FAN RELAY

(FOR MRFS-2 AMD MHRT)

SUMMER

FAN

SWITCH

MT-1

MT-2

2-STAGE

INTERNAL

THERMOSTAT

BLACK

RED

RED

BLACK

P2

H2

F 1

F 2

S

REMOTE SUMMER

FAN SWITCH (MRFS-1)

OR SUMMER FAN

SWITCH MCFS (MANUAL)

P1

H1

T

T

MT-1

MT-2

BLACK TO W1

RED TO R

2-STAGE

INTERNAL

THERMOSTAT

MHRT HEAT RECOVERY

THERMOSTAT OR

REMOTE FAN

SWITCH (MRFS-2)

BLACK

RED

RED

BLACK

C

RW1

W2

F 2

F 1

G

T R

T

S

S

REMOTE SUMMER FAN

SWITCH (MRFS-1)

FAN RELAY

(FOR MRFS-2 AMD MHRT)

SUMMER

FAN

SWITCH

F

CALENTADOR

CABLE

“A1”

BLOQUE TRI-FASICO

RENTE DEL

F

CALENTADOR

CABLE

“A1”

LOQUE TRI-FASICO

B

CABLE

“B1”

LEMENTOS

CABLE

B1”

“

E

A LOS ELEMENTOS

ABLE

ONTACTOR

C

(O P2)

BLOQUE DE TERMINALES

E ALIMENTACION

D

C

“B1”

CABLEADO DE CAMPO PARA ALIMENTACION TRI-FASICA

A LOS ELEMENTOS

ONTACTOR

C

(O P2)

BLOQUE DE TERMINALES

DE ALIMENTACION

CABLEADO DE FABRICA PARA ALIMENTACION MONO-FASICA

Figura 3a. Conexión de cables para alimentación mono-fásica y tri-fásica (MUH0521, MUH0581, MUH072, MUH078, MUH102 y MUH108)

LOQUE TRI-FASICO

B

BLOQUE TRI-FASICO

BLOQUE TRI-FASICO

BLOQUE TRI-FASICO

ELEMENTOS

CABLEADO DE FABRICA PARA ALIMENTACION MONO-FASICA

Figura 3b. Conexiones de cableado para alimentaciones mono-fásicas y tri-fásicas

TERMOSTATO

INTERNO DE

DOS FASES

NEGRO

ROJO

NEGRO

ROJO

INTERRUPTOR DE ABANICO DE

VERANO REMOTO (MRFS-1) O

INTERRUPTOR DE ABANICO DE

VERANO (MANUAL)

NOTAS:

1. ESTE ESTILO DE TARJETA DE TERMINALES DE

CONTROL ES UTILIZA DO CON LOS MODELO S

MUH0321, MUH0371, MUH0381, MUH0521, MUH0571

Y MUH0581.

2. CU ANDO LA UNIDAD ESTA CABLEADA

MONO-FASICA, EMPALME H1 CON H2. SI UN TERMOSTATO DE UN BORNE ES UTILIZADO CON UNA

UNIDAD MONO-FASICA, CONECTE LOS CABLES

DEL TERMOSTATO A P1 Y H1.

3. TERMOSTATOS DE LINEAS DE VOLTAJE EXTERNAS DEBEN SER TRATADOS SOLAMENTE COMO

DE UNA SOLA FASE.

CABLEADO DE CAMPO PARA ALIMENTACION TRI-FASICA

Figura 4. Tarjeta de Terminales de Control (para Calentadores sin Interruptor)

INTERRUPTOR DE ABANICO DE

VERANO REMOTO (MRF8-1)

INTERRUPTOR

PARA ABANICO

DE VERANO

RELE DEL ABANICO

(PARA MRFS-2 Y MHRT)

Français 4

ROJO

NEGRO

DE VUELTA

ROJO A R

TERMOSTATO PARA LA

RECUPERACION DE

CALOR MHRT O INTERRUPTOR

REMOTO DEL ABANICO (MRFS-2)

Figura 5. Tarjeta de Terminales de Control (para Calentadores con Contactor).

A W1

TERMOSTATO

INTERNO DE

DOS FASES

NOTAS:

1. ESTE ESTILO DE TARJETA DE TERMINALES DE CONTROL

NO ES UTILIZADO CON LOS MODELOS MUH0321, MUH0371,

MUH0381, MUH0521, MUH0571 Y MUH0581.

2. REMUEVA EL EMPALME DE W1 A W2 CUANDO SE UTILICE UN

TERMOSTATO DE DOS FASES.

3. *SOLAMENTE UNO DE ESTOS ACCESORIOS PUEDE SER

CONECTADO A UN CALENTADOR INDIVIDUAL.

4. TERMOSTATOS DE LINEAS DE VOLTAJE EXTERNAS DEBEN

SER TRATADOS SOLAMENTE COMO DE UNA SOLA FASE.

Page 17

Tabla 4. Especificaciones

Modelo pulgadas pulgadas pulgadas Instalación Compartimiento

Altura Ancho

Profundidad

Básico Nº (mm) (mm) (mm) lbs. (kg) de Cableado

MUH0381 27 (12.2)

UH0321 27 (12.2)

M

UH0371 27 (12.2)

M

MUH0341 30 (13.6)

MUH0581 27 (12.2)

UH0521

M

MUH0571

6 14 7

1

406.4) (355.6) (190.5)

(

MUH0541 30 (13.6)

UH0331 30 (13.6)

M

MUH0361 30 (13.6)

MUH0531 30 (13.6)

MUH0561 30 (13.6)

UH078 38 (17.2)

M

MUH072 38 (17.2)

MUH077 38 (17.2)

UH074 38 (17.2)

M

MUH108

MUH102

3

21

/

19 71/

4

(552.5) (482.6) (190.5)

MUH107 38 (17.2)

MUH104 38 (17.2)

MUH073 38 (17.2)

UH076 38 (17.2)

M

MUH103 38 (17.2)

MUH106 38 (17.2)

MUH158 54 (24.5)

MUH152 50 (22.7)

MUH154 50 (22.7)

MUH208

MUH202

3

21

/

19 123/

4

(552.5) (482.6) (323.9)

MUH204 55 (24.9)

MUH156 55 (24.9)

MUH206 55 (24.9)

MUH252 89 (40.4)

MUH254 89 (40.4)

MUH308

MUH302

MUH304 89 (40.4)

30 26

(76.2) 676.4) (298.5)

5

/

113/

8

MUH256 89 (40.4)

MUH306 89 (40.4)

MUH402 119 (54.0)

MUH404 119 (54.0)

MUH508

MUH502

MUH504 119 (54.0)

30 26

(76.2) 676.4) (435.1)

5

/

171/

8