Page 1

PRH Series

Plenum Heaters

Installation & Maintenance Instructions

Dear Owner,

Congratulations! Thank you for purchasing this new heater manufactured by Marley Engineered Products. You have made a wise

investment selecting the highest quality product in the heating industry. Please carefully read the installation and maintenance

instructions shown in this manual. You should enjoy years of efficient heating comfort with this product from Marley Engineered

Products... the industry’s leader in design, manufacturing, quality and service.

... The Employees of Marley Engineered Products

WARNING

!

Read Carefully - These instructions are written to help

you prevent difficulties that might arise during installation of heaters. Studying the instructions first may save

you considerable time and money later. Observe the

following procedures and cut your installation time to a

minimum.

TO REDUCE RISK OF FIRE OR ELECTRIC SHOCK:

1. Disconnect all power coming to the heater at main service

panel before wiring or servicing.

Note: More than one disconnect may be required.

2. All wiring must be in accordance with national and local

electric codes and the heater must be grounded.

3. Verify the power supply voltage coming to heater matches

the ratings printed on the heater nameplate before energizing.

SAVE THESE INSTRUCTIONS

4. This heater is hot when in use. To avoid burns, do not let

bare skin touch hot surfaces.

5. Do not insert or allow foreign objects to enter any ventilation or exhaust opening as this may cause electric shock,

fire, or damage to heater.

6. Do not block air intakes or exhaust in any manner.

7. A heater has hot and arcing (sparking) parts inside. Do not

use in areas where gasoline, paint, or flammable liquids

are used or stored.

8. Use this heater only as described in this manual. Any other

use not recommended by the manufacturer may cause fire,

electric shock, or injury.

9. This heater is not approved for use in corrosive atmospheres such as marine, green house, or chemical storage

areas.

10. FOR DUCT CONNECTED HEATERS, rated at 0.20”

external static pressure.

Page 2

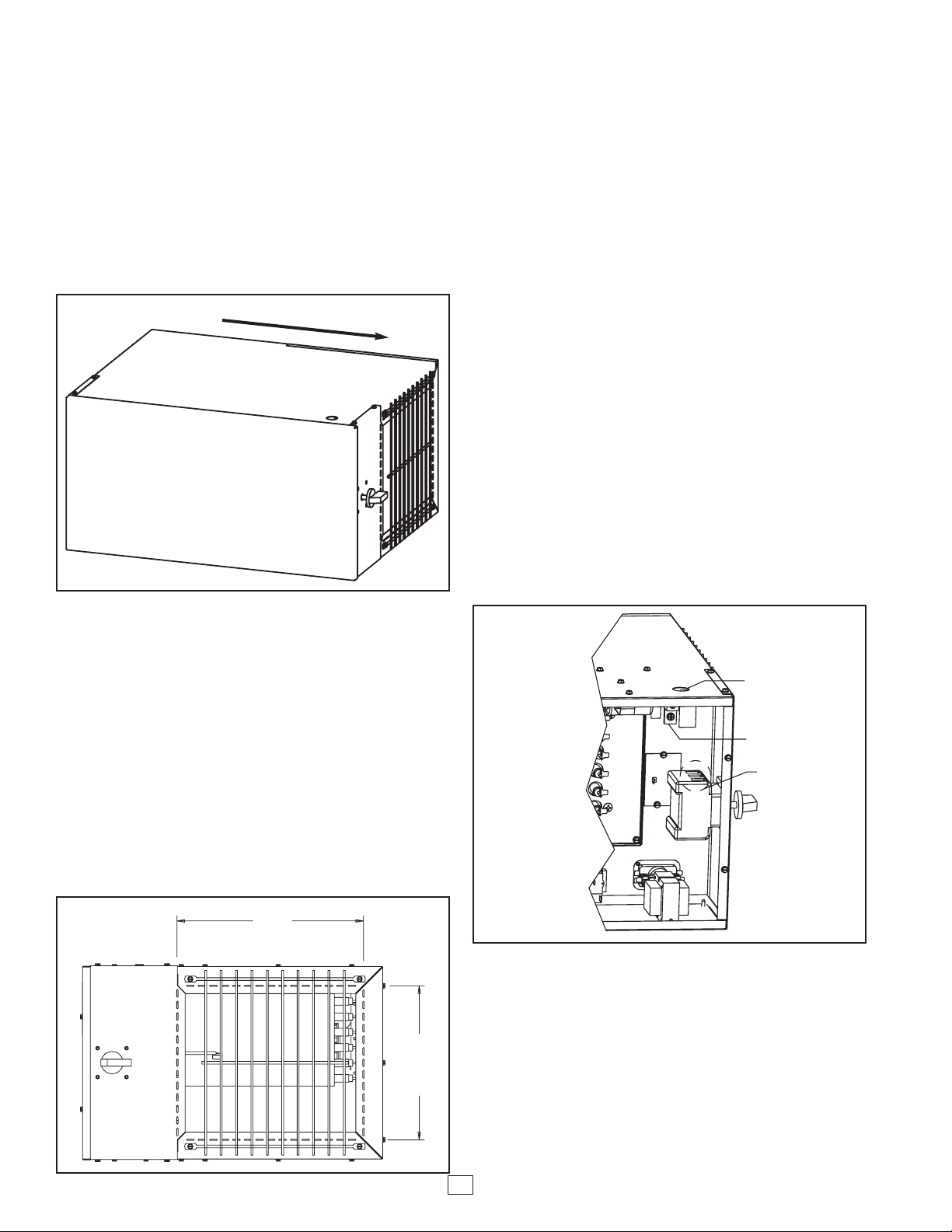

ENERAL INFORMATION:

12” Small

11.64” Large

10”

Small

15.32”

Large

Electrical

Knocknot

Ground

Connection

Power

Connection

G

The PRH Series plenum heaters are design certified by ETL to

Standard for Heating and Cooling Equipment ANSI / UL 1995,

CAN/CSA C22.2 No. 236-05, third edition. The PRH Series

plenum heaters are unique application heaters approved for

installation in a concealed space, an area between a finished

ceiling and drop ceiling, a plenum space or inside a plenum.

These series of heaters may be installed in areas that are not

eadily accessible and may be installed with a duct system or

r

installed for free-air discharge. Always install units to operate

within the intended temperature rise, intended external static

pressure range and in the intended installation position (see

Figure 2 horizontal-right).

Figure 2

AIRFLOW DIRECTION

MOUNTING:

The PRH Series plenum heaters are intended to be mounted

in the horizontal-right installation position (see Figure 2) and in

a suspended manner. The unit can be rotated on its axis in

any position needed (can not be mounted vertically). Suspend

the unit from the building structure in a horizontal plane. Units

must be independently supported. Support channels or straps

are intended to be permanently attached to unit frame/housing.

Be careful not to obstruct access to control panel with support

channels or straps. DUCT CONNECTIONS / DUCTING:

The PRH Series plenum heaters may either be installed for

free-air discharge or with a duct system. The proper sizing of

warm air ducts is essential in providing satisfactory heating

operation. Ductwork should be in accordance with the latest

editions of NFPA-90B (Warm Air Heating and Air Conditioning

ystems) or Canadian equivalent. Every PRH model is

S

equipped with an inlet and outlet grille for free-air discharge.

Both grilles are intended to be removed when connecting to a

duct system. The inlet and outlet ends of the unit are

equipped with perforated flanges to aid in forming both inlet

and outlet duct flanges (see Figure 3).

These perforations will aid in forming a rectangular inlet and

outlet duct flange if they are desired for connection to the duct

ystem. The unit is designed for a rectangular flange duct con-

s

necting and the clear area around the flange is intended for

screw penetration. This feature aids in attaching the duct work

to the unit so that the ductwork may be fastened and sealed to

the unit.

CONTROL ACCESS:

The front door allows access to all the controls and components within the unit. The unit is design certified for 0” clearances however, while installing the unit, be careful not to

obstruct access to this control panel. This panel allows access

to the unit for making the power connection, the thermostat

connection and is intended to allow access to all the internal

components that make up the unit.

ELECTRICAL CONNECTIONS:

All field wiring must comply with NEC and local codes.

NNOOTTEE:: SSEEEE PPAAGGEE 33 && 44 FFOORR WWIIRRIINNGG DDIIAAGGRRAAMMSS

All units are designed for a single point connection to supply

power to the fan and electric heater. The PRH series plenum

heaters are shipped standard with a 80 amp 3-pole disconnect

switch. Field power connections are made to the line side of

this disconnect switch (see Figure 4).

Each unit is equipped with a grounding lug for ground connec-

Figure 4

Figure 3

tion. The unit must be properly grounded to comply with NEC

and local codes. Before making the power connection, insure

that the line voltage to the unit matches the ratings located on

the nameplate of the unit. All units should have copper wire

sized for 125% of nameplate amperage. Disconnect the power

supply before wiring the unit and insure the disconnect switch

is in the OFF position while making power connections or servicing the unit. The unit cabinet has a 7/8” electrical knockout

for routing power supply to the disconnect switch (see

Specifications section for knockout location). Should the unit

require a larger electrical conduit connection, this electrical

knockout is intended to serve as the pilot hole in order to field

convert to larger electrical connections.

2

Page 3

ONTROL CONNECTIONS:

C

The PRH Series plenum heaters are designed to operate from

a 24VAC thermostat. Model TH5220D1003 24V 2 stage thermostat is recommended to be used with the PRH Series

heaters. Thermostat connections are made to the thermostat

board located inside the unit. The thermostat label indicates

which connections are (RGCW) for making these thermostat

connections. The unit cabinet has a 3/8” knockout for routing

hermostat wiring to the units thermostat board (see

t

Specifications section for knockout location). Instructions for

wiring the thermostat are packed with the thermostat. The unit

is intended to operate with heat (W) and fan (G). If the unit is

intended for cooling signals from the thermostat, make the Y

connection from the thermostat to the G connection on the

unitʼs thermostat board.

UNIT OPERATION:

The PRH Series plenum heaters are intended to be operated

from a 24V thermostat. (Model TH5220D1003)

HEATING OPERATION

When there is a demand for heat, the thermostat sends a signal to the unit for this demand for heat. The unitʼs thermostat

board will send power to the unit controls to initiate the heating

operation. The call for heat makes the connection on the thermostat board by powering “W” with “R”. Upon this demand for

heat, the heating element starts heating and the fan on delay

will power the fan within 60 seconds from the call for heat.

The fan delay ensures that there will not be a cold blast of air

to ensure comfort heating. When the heat demand has been

met, the thermostat will send the signal back to the unitʼs thermostat board to stop the heating operation. This breaks the

power connection between “R” to “W” and the heating element

tops heating immediately. The fan off delay allows the fan to

s

continue running to remove all residual heat from the heating

element and will turn the fan off within 60 seconds. Should

there be any abnormal conditions to cause the units limit to

open during the call for heat, the units heat will turn off immediately but the fan will go through its normal off delay. During

this open limit period, the power to the thermostat will be interrupted until the limit closes. This helps in determining abnormalities during heating operation by way of interrupting power

o the thermostat.

t

FAN OPERATION

When there is a demand for fan, the thermostat sends a signal

to the unit for this demand for fan. The unitʼs thermostat will

send power to the unit controls to initiate the fan operation.

The call for fan makes the connection on the thermostat board

by powering “G” with “R”. The fan will immediately come on

and continue to run until the demand for fan has ended. When

the fans demand has been met, the fan will immediately turn

off. This breaks the power connection between “R” to “G”.

HEATING OPERATION + FAN OPERATION

When there is a demand for both heat and fan at the same

time, the heating element will come on immediately as well as

the fan. The fan on delay will be bypassed. Upon completion

of the demand for both heat and fan, the heating element will

turn off immediately. However, the off delay will work the same

as during the heating operation.

COOLING OPERATION

Should the unit be used for cooling, the “Y” connection from

the thermostat should be connected to the “G” on the thermostat board. The cooling operation will operate like the fan

operation above.

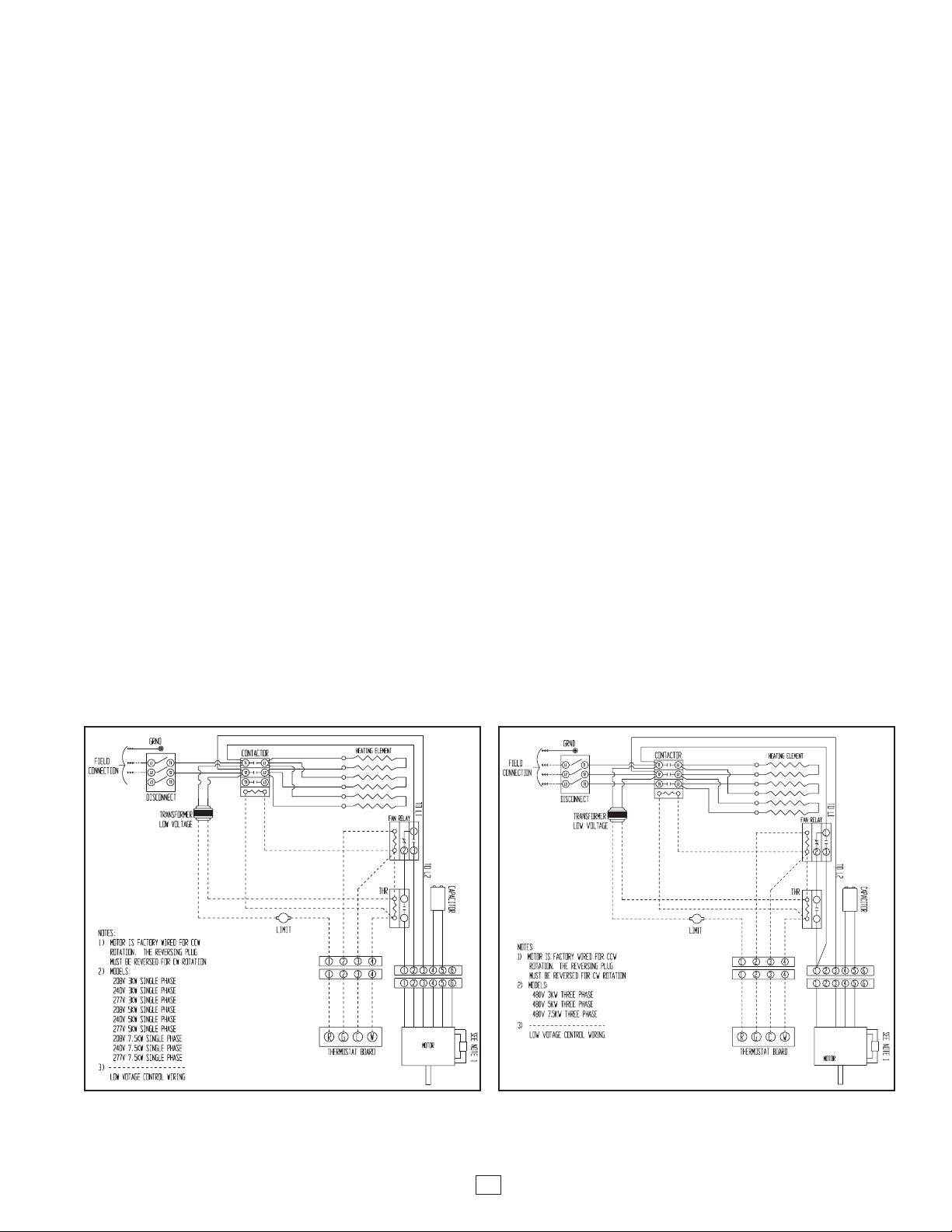

WIRING DIAGRAMS

Single Phase - Single Element

Three Phase - Single Element 480V

3

Page 4

WIRING DIAGRAMS Cont.

Three Phase - Single Element

Three Phase - Dual Element 480V

Single Phase - Dual Element

Three Phase - Dual Element

4

Page 5

WIRING DIAGRAMS Cont.

ingle Phase - 2 Stage Heat

S

Three Phase - 2 Stage Heat 208V, 240V

Three Phase - 2 Stage Heat 480V

5

Page 6

9

1

6

10

2

11

3

4

8

7

5

Replacement Parts

KEY DESCRIPTION 3KW 5KW 7.5KW 10KW 15KW QTY

1 Blower Assembly 1225-2022-000 1225-2022-000 1225-10158-000 1225-10158-000 1225-10158-000 1

2 Contactor / relay 5018-0005-004 5018-0005-004 5018-0005-004 5018-0005-004 5018-0005-004 1

3 Time Delay Relay 410171001 410171001 410171001 410171001 410171001 1

4 Fan Relay 5018-2024-000 5018-2024-000 5018-2024-000 5018-2024-000 5018-2024-000 1

5 Element

6 Motor

7 Motor Plug 6109-8090 6109-8090 6109-8090 6109-8090 6109-8090 1

8 Primary Limit Control 1414-2040-000 1414-2040-000 1414-2040-001 1414-2040-001 1414-2040-001 1

9 Capacitor 1432-0002-001 1432-0002-001 1432-0002-VAR 1432-0002-VAR 1432-0002-VAR 1

10 Disconnect Switch 5216-2039-000 5216-2039-000 5216-2039-000 5216-2039-000 5216-2039-000 1

11 Transformer

Note: Use capacitor P/N 1432-0002-002 with motor P/N 3900-10160-002. All other motors will use capacitor P/N 1432-0002-001.

208V 302006850 302006804 302006809 302006804 302006809 1

240V 302006851 302006852 854 302006852 854 1

277V 302006838 302006840 855 302006840 855 1

480V 302006853 302006807 302006810 302006807 302006810 1

208V 3900-2094-000 3900-2094-000 3900-10160-002 3900-10160-002 3900-10160-002 1

240V 3900-2094-000 3900-2094-000 3900-10160-002 3900-10160-002 3900-10160-002 1

277V 3900-2095-000 3900-2095-000 3900-10162-000 3900-10162-000 3900-10162-000 1

480V 3900-10164-000 3900-10164-000 3900-10164-000 3900-10164-000 3900-10164-000 1

208-240V 5814-0003-000 5814-0003-000 5814-0003-000 5814-0003-000 5814-0003-000 1

277-480V 5814-0003-001 5814-0003-001 5814-0003-001 5814-0003-001 5814-0003-001 1

480V 5814-0003-002 5814-0003-002 5814-0003-002 5814-0003-002 5814-0003-002 1

6

Page 7

DIMENSIONS - SMALL CABINET

DIMENSIONS - LARGE CABINET

IMPORTANT INFORMATION

LOW SPEED** HIGH SPEED** WT.

CATALOG NUMBER PHASE KW VOLTAGE AMPS* CFM RISE CFM RISE LBS H X W X L

PRH138124 208 15.32

PRH132124 13240 13.4

PRH137124 277 11.63

PRH138324 208 9.23

PRH132324 33240 8.12

PRH134324 480 4.11

PRH158124 208 24.94

PRH152124 15240 21.73

PRH157124 277 18.85

PRH158324 208 14.78

PRH152324 35240 12.93

PRH154324 480 6.51

PRH158124L 208 24.94

PRH152124L 15240 21.73

PRH157124L 277 18.85

PRH158324L 208 14.78

PRH152324L 35240 12.93

PRH154324L 480 6.51

PRH1758124 208 38.12

PRH1752124 1 7.5 240 33.31

PRH1757124 277 28.91

PRH1758324 208 22.88

PRH1752324 3 7.5 240 20.1

PRH1754324 480 10.16

PRH1102124 1 10 240 43.73

PRH1107124 277 37.93

PRH2102124 1 10 240 43.73

PRH2107124 277 37.93

PRH1108324 208 29.82

PRH1102324 3 10 240 26.12 37ºF 31ºF

PRH1104324 480 13.17

PRH2108324 208 29.82

PRH2102324 3 10 240 26.12 850 37º / 20ºF 1000 31º / 16ºF

PRH2104324 480 13.17

PRH1158324 208 43.9

PRH1152324 3 15 240 38.14 850 56ºF 1000 47ºFº

PRH1154324 480 19.18

PRH2152324 3 15 240 38.14

PRH2154324 480 19.18

*Total Amps including Resistive and Inductive loads.

**Low speed fan operation not available on 480V models.

Low and High speed fan operation is determined during installation of thermostat set up

† Tested @0.2” S.P.

350 27ºF 400 24ºF 49 12.5”x19.5”x24”

350 45ºF 400 39ºF 49 12.5”x19.5”x24”

850 20ºF 1000 16ºF 49 18”x18”x35.5”

850 28ºF 1000 24ºF 69 18”x18”x35.5”

37ºF 31ºF

850 37º / 20ºF 1000 31º / 16ºF

69 18”x18”x35.5”

850 56º / 28ºF 1000 47º / 24ºF

7

Page 8

AINTENANCE & REPAIR

M

Note: Periodic maintenance and repair should be performed by qualified personnel only.

1. Periodically inspect all electrical connections and terminals to avoid electrical wiring difficulties. Inspect all wiring for frayed or

worn insulation.

2. Periodically and before each heating season, clean the steel finned elements and fan inlet with compressed air, vacuum, or

feather brush. Be sure all electrical covers are tightly closed.

3. If heat output seems to be low, check amperage draw on each element leg. Compare measured values to the correct cur-

rents as listed on the unit nameplate.

4. The thermally protected fan motor is permanently lubricated and sealed. No field servicing is required unless needed.

eplace only with a factory supplied identical motor or blower.

R

5. Check blower rotation to be sure that no is inside blower housing.

TROUBLE SHOOTING

Problem Potential Cause Solution

1. Motor does not operate. > Fan delay not operating and /or connected. > Check connections

> Disconnect switch is open > Energize circuit

> Blower motor damaged > Verify and relace if necessary

> No power supply > Verify and energize circuit

> Blocked blower wheel > Verify and unblock wheel for proper rotation

2. Heat not working. > Heating elements are not energized > Check connections and operation

> Electical components may be open > Check disconnect, fuses, and circuit breaker

> Fan delay not connected. > Check connections

> Safety thermal limits opened > Check, verify and replace if necessary

> Incorrect wattage or voltage of element > Verify and replace if necessary

> Thermostat setting too low > Rotate dial clockwise to a higher setting

3. Airflow is insufficient. > Air filters restriction airflow > Check, clean, and or replace filters

> Blocked blower wheel > Verify and unblock wheel for proper rotation.

LIMITED WARRANTY

All products manufactured by Marley Engineered Products are warranted against defects in workmanship and materials for one

year from date of installation, except heating elements which are warranted against defects in workmanship and materials for five

years from date of installation. This warranty does not apply to damage from accident, misuse, or alteration; nor where the connected voltage is more than 5% above the nameplate voltage; nor to equipment improperly installed or wired or maintained in violation of the productʼs installation instructions. All claims for warranty work must be accompanied by proof of the date of installation.

The customer shall be responsible for all costs incurred in the removal or reinstallation of products, including labor costs, and shipping costs incurred to return products to Marley Engineered Products Service Center.Within the limitations of this warranty, inoperative units should be returned to the nearest Marley authorized service center or the Marley Engineered Products Service

Center, and we will repair or replace, at our option, at no charge to you with return freight paid by Marley. It is agreed that such

repair or replacement is the exclusive remedy available from Marley Engineered Products.

THE ABOVE WARRANTIES ARE IN LIEU OF ALL OTHER WARRANTIES EXPRESSED OR IMPLIED, AND ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE WHICH EXCEED THE AFORESAID

EXPRESSED WARRANTIES ARE HEREBY DISCLAIMED AND EXCLUDED FROM THIS AGREEMENT. MARLEY ENGINEERED PRODUCTS SHALL NOT BE LIABLE FOR CONSEQUENTIAL DAMAGES ARISING WITH RESPECT TO THE PRODUCT, WHETHER BASED UPON NEGLIGENCE, TORT, STRICT LIABILITY, OR CONTRACT.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above exclusion or limitation

may not apply to you. This warranty gives you specific legal rights, and you may also have other rights which vary from state to

state.

For the address of your nearest authorized service center, contact Marley Engineered Products in Bennettsville, SC, at 1-800-642-

4328. Merchandise returned to the factory must be accompanied by a return authorization and service identification tag, both available from Marley Engineered Products. When requesting return authorization, include all catalog numbers shown on the products.

470 Beauty Spot Rd. East

Part No. 5200-2834-004

ECR 38777

07/10

8

Bennettsville, SC 29512 USA

Loading...

Loading...