Page 1

Specifications – Table 1

Electrical Data (50 Hz) Dimensions (In)

Model

Volts kW Phase Amps BTU Height Width Depth

SDH3043 480 30 3 37.2 102,360 38.5 26 44

SDH3093 600 30 3 30.0 102,360 38.5 26 44

SDH4843 480 48 3 58.9 163,776 38.5 30-1/4 44

SDH4893 600 48 3 47.3 163,776 38.5 30-1/4 44

SDH6043 480 60 3 73.3 204,720 38.5 30-1/4 44

SDH6093 600 60 3 58.9 204,720 38.5 30-1/4 44

Portable High

Temperature

Blower Heater

Dear Owner,

Congratulations! Thank you for purchasing this new heater by Marley Engineered Products. You have made a wise investment

selecting the highest quality product in the heating industry. Please carefully read the installation and maintenance instructions

shown in this manual. You should enjoy years of efficient heating comfort with this product from Marley Engineered Products...

the industry’s leader in design, manufacturing, quality and service.

... The Employees of

Marley Engineered Products

Installation & Maintenance Instructions

Attention: Do not operate this heater in

explosive areas.

Page 2

2

WARNING - IMPORTANT SAFTY INSTRUCTIONS

When using electrical appliances, basic precautions should always be

followed to reduce the risk of fire, electric shock and injury to persons, including the following:

1. Read all instructions before using this heater.

2. This heater is hot when in use. To avoid burns, do not let bare skin

touch hot surfaces. If provided, use handles when moving this

heater. Keep combustible materials, such as furniture, pillows,

bedding, papers, clothes, and curtains at least 3 feet (0.9m) from

the front of the heater and keep them away from the sides and rear.

3. Extreme caution is necessary when any heater is used by or near

children or handicapped individuals and whenever the heater is

left operating and unattended.

4. Always disconnect heater when not in use.

5. Do not operate any heater with a damaged cable or plug or after

the heater malfunctions, has been dropped or damaged in any

manner. Return heater to authorized service facility for examination, electrical or mechanical adjustments, or repair.

6. Do not use outdoors.

7. This heater is not intended for use in bathrooms, laundry areas and

similar indoor locations. Never locate heater where it may fall into

a bathtub or other water container.

8. Do not run cord under carpeting. Do not cover cord with throw

rugs, runners or the like. Arrange cord away from traffic area and

where it will not be tripped over.

9. To disconnect heater, turn thermostat off, then remove plug from

outlet.

10. Connect to properly grounded outlets only.

11. Do not insert or allow foreign objects to enter any ventilation or

exhaust opening as this may cause an electric shock, fire or damage the heater.

12. To prevent a possible fire, do not block air intakes or exhaust in

any manner. Do not use on soft surfaces, like a bed, where opening may become blocked.

13. A heater has hot and arcing or sparking parts inside.Do not use it

in areas where gasoline, paint, flammable liquids are used or

stored.

14. Use this heater only as described in this manual. Any other use not

recommended by the manufacturer may cause fire, electric shock

or injury to persons.

15. This heater is not intended for use with an extension cord.

16. Do not use as a residential or household heater.

17.

SAVE THESE INSTRUCTIONS.

WIRING

ELECTRIC SHOCK HAZARD. Disconnect all power before installing or

servicing heater. Failure to do so could result in personal injury or

property damage. Heater must be effectively grounded in accordance with the National Electrical Code, NFPA 70.

1. Use heater only on the voltage and frequency specified on the

nameplate.

2. All wiring should be done in accordance with local codes and the

National Electrical Code by a qualified person.

3. Branch circuit wire for connection to heater must be at least

90˚C wire.

4. The top access panel is secured by 4 screws that must be loosened

to gain access.

5. A ground terminal is provided near the power terminal board.

The ground wire should be connected before other connections

are made.

6. Refer to Table A for proper size “SO” grade of cable.

7. A proper strain relief must be used with “SO” grade cable.

8. Heaters are factory pre-wired for 3-phase delta operation. Some

units can be converted to single phase operation by changing the

wiring. The appropriate wiring diagram is also located on the back

of the wiring compartment cover.

Cord Preparation for Portable Heaters

1. Determine the gage and number of conductors from the tabulation

below using amps and phase from the heater nameplate. It is not

recommended that cord exceed 50 feet in length.

Model Number Volts kW Phase Amps Min Wire Size

SDH3043 480 30 3 37.2 6 Ga

SDH3063 600 30 3 30.0 8 Ga

SDH4843 480 48 3 58.9 4 Ga

SDH4863 600 48 3 47.3 4 Ga

SDH6043 480 60 3 73.3 2 Ga

SDH6063 600 60 3 58.9 4 Ga

SET-UP AND OPERATION

Heaters in the heat mode should not be operated in room tempera-

tures above 130˚F. Fan motor is not designed to operate in ambients

below -10˚F. The SDH is designed to be used with 20” diameter flexible duct. A feature of the heater is that the fan speed can be easily

adjusted from 1500 to 2300rpm, (SDH heaters are shipped from the

factory with the fan speed set at 1800 rpm). The maximum external

static load for the blower is .38” H

2

O, regardless of the fan speed

selected. The outlet temperature is controlled by a built-in thermostatic control; the maximum outlet temperature is a function of the kW rating and the amount of air (cfm) flowing through the heater. The addition of flexible duct will provide additional static load, resulting in a

lower cfm, the lower air flow will reaise maximum outlet temperature

until the static load reaches .38”H

2

O. Exceeding the maximum static

load will result in the tripping of the overtemperature control. The performance range of the SDH units is as shown in table B.

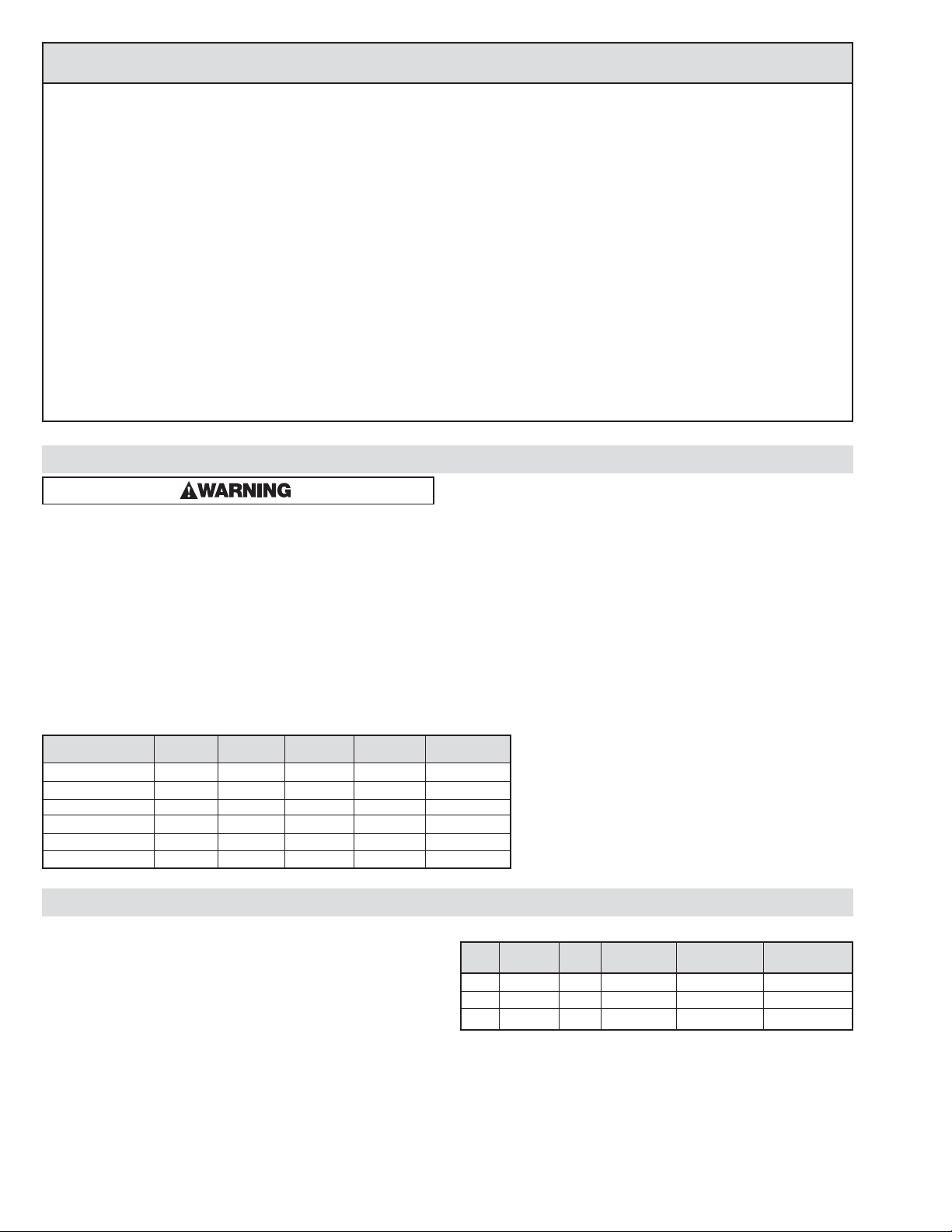

The motor and fan have variable pitch pulleys for changing the air

flow and the ∆T. Graphs 1, 2 and 3 provide the performance data for

each size heater at the recommended minimum, medium and maximum fan speeds. The curves end at the point where the .38” H

2

O static load has been reached. The temperature rise is based on using

Marley 20” diameter SDHFX20 flexible duct. The performance curves

were determined by actual testing; therefore using flexible duct not

supplied by Marley may vary the results. The introduction of bends in

the ducting will add static load equivalent to adding 15 feet of duct

length for each 90˚ bend and 25 feet of duct length for each 180˚ bend.

∆ T Max. ∆T at Max.

kW Fan RPM CFM No Load Static Load Static Load

30 1800 2200 42˚F .38” H2O86˚F

48 1800 2200 68˚F .38” H2O 144˚F

60 1800 2200 88˚F .38” H2O 170˚F

Table A

Table B

Page 3

3

WIRING (cont’d.)

ACCESSORIES

Temperature Rise vs Duct Length

60 kW

100

60

40

20

0

0

100

75

50

25

125

150

175

Duct Length in Feet

Temperature Rise ˚F

120

140

160

1800

RPM

2200

RPM

1500

RPM

80

180

200

SDH heaters can be easily field if modified to vary the fan speed.

There may be some circumstances where the use of short lengths of

duct may not create sufficient pressure drop to achieve the desired temperature rise. This may also be the case of using the unit without a duct.

This insufficient static pressure drop may result in high air flow, with

the maximum temperature rise below the desired level, (even after the

fan speed has been reduced to the minimum rpm). An accessory

SDHAD, adjustable damper, is available and can be attached to the

heater to produce a static load, ranging from .1” to .19” H

2

O which will

act to reduce the amount of air flow.

The “Friction Loss” Graph 4 provides the actual test data on the

friction loss for the ADHAD damper attachment. The losses are stated

as the equivalent length in feet of 20” duct.

The SDH Dragon includes 2 thermostats. The thermostat on the air

inlet end of the unit is for the minimum air temperature desired. The

thermostat on the discharge end of the heater is for the maximum air

temperature desired. The two thermostats are wired in series with the

heating element contactor coil. The temperature range of both thermostats is 60 - 180˚F.

Adjustable Damper and Duct Adaptor

Rear of

Heater

Front of

Heater

Adjustable

Damper

1/4-20 Wing nut

Provided with

SDHAD

Duct

Adapter

100

75

50

25

Temperature Rise ˚F

0

0

25

Temperature Rise vs Duct Length

160

140

120

100

80

60

40

Temperature Rise ˚F

20

0

0

1500

RPM

25

Temperature Rise vs Duct Length

30 kW

1500

RPM

50

75

Duct Length in Feet

48 kW

75

50

Duct Length in Feet

2200

RPM

100

100

2200

RPM

1800

RPM

1800

RPM

125 150

125

150

175

175

Friction Loss SDHAD Damper

90

80

70

60

50

40

30

20

Equivalent Duct Length FT

10

0

1400

Damper Full Open

1600

Damper Full Closed

1800

2000

Fan RPM

2200

2400

Page 4

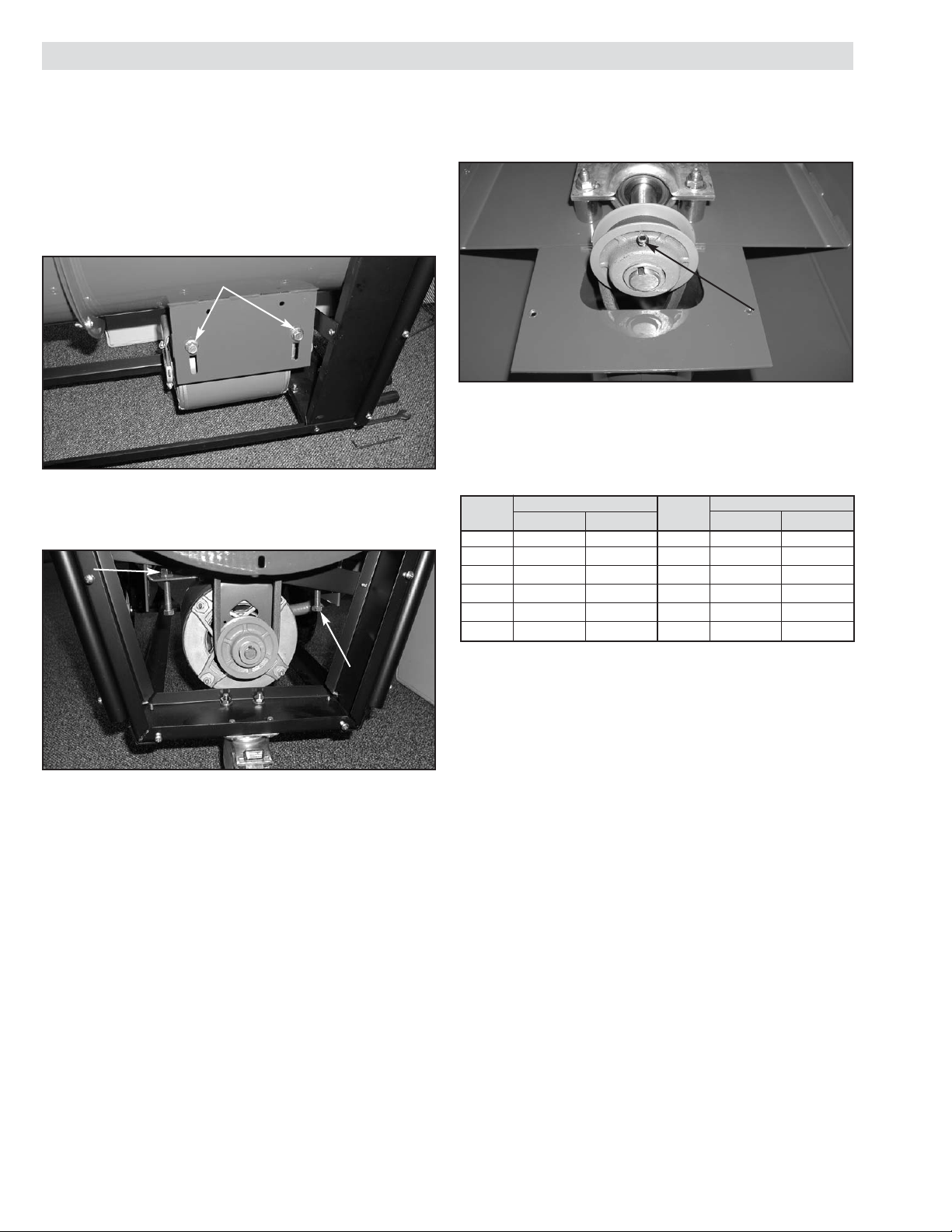

FAN SPEED ADJUSTMENTS

Changing the Pitch Diameter of the Sheaves:

1. Tools required: 5/32” allen wrench, 3/8” nut driver, 9/16” box

wrench and a medium size phillips screwdriver.

2. Remove the lower belt cover by removing the (5) sheet metal

screws.

3. Remove the rear grille by removing the (4) 1/4” bolts and nuts.

4. Remove the belt cover inside the blower by removing the (4) sheet

metal screws.

5. Loosen the (4) bolts, (2) on each side. See Fig. 1.

6. Loosen the (2) motor tension lock nuts and the fan belt tension

adjusting bolts. See Fig.2

7. Loosen the set screw on the fan pulley or motor pulley. Fig. 3

shows the construction of the fan pulley, the motor pulley is the

same construction.

8. Rotate the front half of the pulley clockwise until it bottoms, then

rotate counter clockwise until the set screw aligns with the flat in

the threaded half of the pulley. The pulley is now in position for

adjustment. See Table 1 for the number of turns out. Tip: Leave

allen wrench in set screw and use free hand to hold fan blade.

9. Retighten set screw, use of thread locking compound is recom-

mended.

10. Adjust fan belt tension, see Fig. 2. A 1/2” of belt deflection is rec-

ommended. Tighten lock nuts.

11. Tighten the 3/8” bolts, see Fig. 1

12. Rotate fan blade to make sure the fan belt does not rub.

13. Reinstall top belt cover, grille and lower belt cover. Tip: Installing

the grille before installing the lower cover makes it easier to access

the two lower grille bolts.

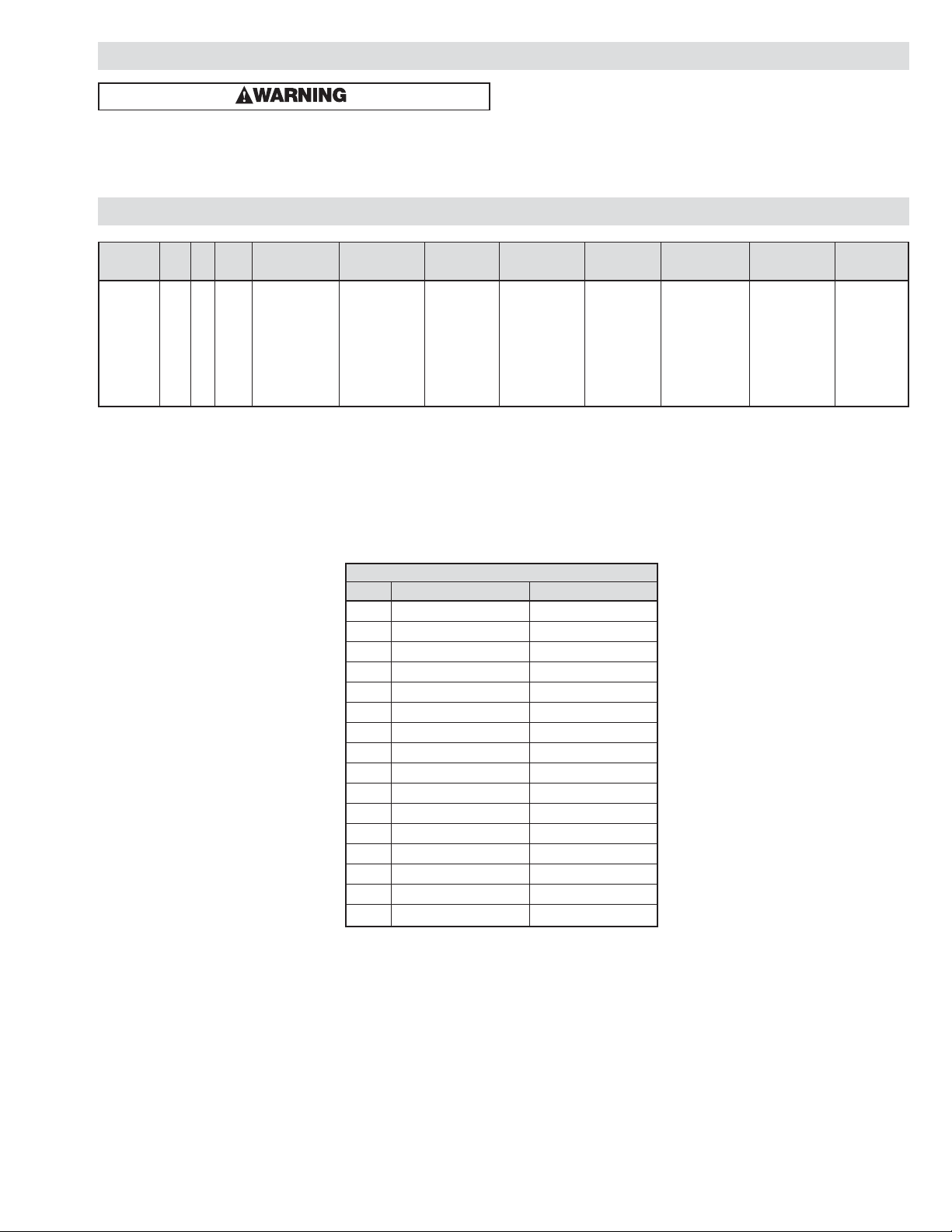

Table 1

Fan

No. of turns from full closed

Fan

No. of turns from full closed

RPM Motor Pulley Fan Pulley RPM Motor Pulley Fan Pulley

1500 3 1-1/2 1950 1-1/2 3

1600 2-1/2 1-1/2 2000 1-1/2 3-1/2

1650 2 1-1/2 2100 1-1/2 4

1725 1-1/2 1-1/2 2200 1-1/2 4-1/2

1800 1 1-1/2 2300 1 4-1/2

1850 1/2 1-1/2

4

Figure 1

Figure 2

Figure 3

3/8” Bolts

Lock Nuts

Fan belt tension

adjusting bolts

3/8” Bolts

Fan belt tension

adjusting bolts

Page 5

5

WIRING DIAGRAMS

SDH 30kW, 480V, 3PH

SDH 48kW, 480V, 3PH

SDH 60kW, 480V, 3PH

r

r

P4

P5

P6

T1

T2

Motor

T3

T6

T9

T4

T7

T5

T8

Inlet

Thermostat

Outlet

Thermostat

Cutout

Attach all Wires on this

Side of Contactor to

Auxillary Terminals

Run these Wires

Through 1/2"

Conduit

Motor

Relay

L1

L2

L3

P4

P5

P6

T6

T4

T5

Blk/Red

or Grey

Blk

T1

T2

Motor

T3

T9

T7

T8

30 Amp Fusing

45 Amp

Fusing

Toggle Switch

Motor Relay

L1

L2

L3

Blk

Transformer

Control Enclosure

Green Pilot Light

Wht

Transformer

Contactor

Contactor

Contactor

Wht

Amber Pilot Light

Blk

Toggle

Switch

Run these Wires

Through 1" Conduit

4

Inlet Thermostat

4

Heater Terminal Box

Outlet Thermostat

10

12

Front of

1

Heater

10

Cutout

14

13

1

15

12

18

Front

17

of

Heate

1

Run these Wires

Through 1/2"

Conduit

Motor

Relay

L1

L2

L3

Control Enclosure

P4

P5

P6

T1

T2

T3

T6

T9

T4

T7

T8

50 Amp Fusing

50 Amp Fusing

Control Enclosure

T5

Motor

Green Pilot Light

Wht

Transformer

Contactor

Contactor

Run these Wires

through 1/4" Conduit

One end attached

to screw in terminal box

and other end attached to

screw on sub panel.

Amber Pilot Light

Toggle

Switch

Blk

Run these Wires

through 1/4" Conduit

One end attached

to screw in terminal box

and other end attached to

screw on sub panel.

Inlet Thermostat

4

Heater Terminal Box

Outlet Thermostat

12

1

14

10

Heater Terminal Box

Cutout

20

1

15

13

1

17

18

24

23

Front

of

2

Heate

22

Page 6

6

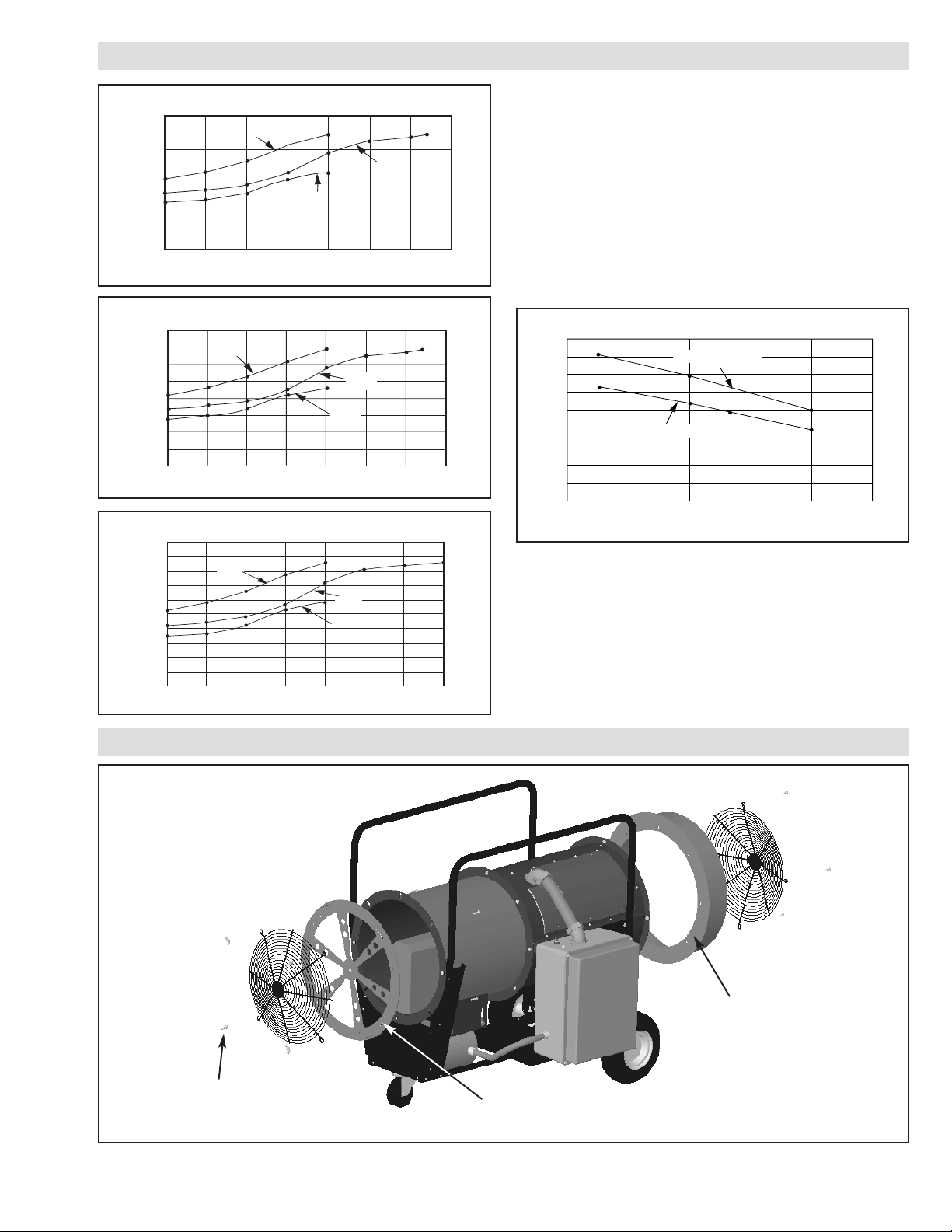

PARTS LOCATION

19

12

11

11

12

12

11

19

12

11

12

12

12

11

11

12

12

Front of

Heater

View Showing Element Placement

and Routing of Thermostat Capillary

and Mounting of Bulb

19

12

11

11

11

12

12

12

11

11

11

12

12

Front of

Heater

View Showing Element Placement

and Routing of Thermostat Capillary

and Mounting of Bulb

(30-1/4)

Twist Wire

(20-1/2)

38

37

(44)

(38-1/2)

16

84

36

45

80

81

20

21

18

32

21

Back of

Heater

Side View Detail Showing Pulley

and Belt Installation

Motor Pulley

Fan Pulley

77

79

78

23

Element Assembly 30kW

Element Assembly 60kW

Front View with Grille Removed (All Sizes)

Element Assembly 48kW

Side View shown with Heater and Control Terminal Box Covers Removed

All Sizes

Page 7

7

MAINTENANCE

ELECTRIC SHOCK HAZARD. Disconnect heater from power supply

before servicing and/or inspecting the heater; failure to do so may

result in electrical shock.

Replace or repair damaged cords or plugs immediately. Check tightness of all electrical connections prior to energizing heater. Blow out

or vacuum away any dirt or debris that may have accumulated around

the control enclosure fan motor or heating elements.

RENEWAL PARTS IDENTIFICATION

PARTS COMMON TO ALL UNITS

Item Description Part No.

18 Temperature Control 300-019560-002

19 Hi-Limit Cut-out 300-049200-004

23 Toggle Switch 292-046123-001

32 Blower Assembly 021-304823-009

33 Inlet & Outlet Grille 134-304780-002(2)

36 Caster / Locking 375-122535-007

37 Handle - Right Side 139-304779-003

38 Handle - Left Side 139-304779-004

45 Semipneumatic Wheel 333-557518-004(2)

77 Pulley Var. Pitch 7/8” 225-305091-004

78 Pulley Var. Pitch 5/8” 225-305091-003

79 Pulley Belt 017-049702-009

86 Pilot Light - Green 213-122066-043

87 Pilot Light - Amber 213-122066-042

94 Thermostat Knob 169-017949-004

95 Thermostat Label 220-019122-010

Element (11) Element (12) Motor (16) Contactor (20) Transformer (21) Fuse Block (80) Fuse (81) Term. Block (84)

Model No. Volts kW Phase Part No. Part No. Part No. Part No. Part No. Part No. Part No. Part No.

SDH3043 480 30 3 118-304793-011(3) 118-304793-013(3) 193-121843-232 072-304551-008 315-304252-001 N/A N/A N/A*

SDH3093 600 30 3 118-304793-012(3) 118-304793-014(3) 193-121843-233 072-304551-008 315-304252-003 N/A N/A N/A*

SDH4843 480 48 3 118-304793-011(3) 118-304793-013(6) 193-121843-232 072-304551-008(2) 315-304252-001 129-025643-001 128-026510-005(3) 303-047468-004

SDH4893 600 48 3 118-304793-012(3) 118-304793-014(6) 193-121843-233 072-304551-008(2) 315-304252-003 129-025643-001 128-026510-005(3) 303-047468-004

SDH6043 480 60 3 118-304793-011(6) 118-304793-013(6) 193-121843-232 072-304551-008(2) 315-304252-001 129-025643-001(2) 128-026510-006(6) 303-047468-004

SDH6093 600 60 3 118-304793-012(6) 118-304793-014(6) 193-121843-233 072-304551-008(2) 315-304252-003 129-025643-001(2) 128-026510-006(6) 303-047468-004

* Wired directly to contactor.

All units contain two sets of elements. The ratings of the elements on the discharge end have a lower wattage than the elements on the inlet end of heater.

The ends of the elements are color coded, the lower wattage are color coded yellow and the higher wattage are color coded blue.

a. Lower wattage elements, discharge end, yellow coded

b. Higher wattage elements, fan end, blue coded

Page 8

ECR

36513

3/05

5200-2691-000

How to order repair parts:

In order to obtain any needed repair or replacement

parts, warranty service or technical information,

please contact the Marley Engineered Products

Service Center toll-free by calling 1-800-642-HEAT.

When ordering replacement parts, always give the

information listed as follows:

1. The Part Number

2. The Model Number

3. The Part Description

4. Date of Manufacture

LIMITED WARRANTY

All products manufactured by Marley Engineered Products are warranted against defects in workmanship and materials for one year from date of installation, except

heating elements which are warranted against defects in workmanship and materials for five years from date of installation. This warranty does not apply to damage

from accident, misuse, or alteration; nor where the connected voltage is more than 5% above the nameplate voltage; nor to equipment improperly installed or wired or

maintained in violation of the product’s installation instructions. All claims for warranty work must be accompanied by proof of the date of installation.

The customer shall be responsible for all costs incurred in the removal or reinstallation of products, including labor costs, and shipping costs incurred to return products to Marley Engineered Products Service Center. Within the limitations of this warranty, inoperative units should be returned to the nearest Marley authorized service center or the Marley Engineered Products Service Center, and we will repair or replace, at our option, at no charge to you with return freight paid by Marley. It is

agreed that such repair or replacement is the exclusive remedy available from Marley Engineered Products.

THE ABOVE WARRANTIES ARE IN LIEU OF ALL OTHER WARRANTIES EXPRESSED OR IMPLIED, AND ALL IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE WHICH EXCEED THE AFORESAID EXPRESSED WARRANTIES ARE HEREBY DISCLAIMED AND EXCLUDED

FROM THIS AGREEMENT. MARLEY ENGINEERED PRODUCTS SHALL NOT BE LIABLE FOR CONSEQUENTIAL DAMAGES ARISING WITH RESPECT TO THE

PRODUCT, WHETHER BASED UPON NEGLIGENCE, TORT, STRICT LIABILITY, OR CONTRACT.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above exclusion or limitation may not apply to you. This warranty

gives you specific legal rights, and you may also have other rights which vary from state to state.

For the address of your nearest authorized service center, contact Marley Engineered Products in Bennettsville, SC, at 1-800-642-4328. Merchandise returned to the

factory must be accompanied by a return authorization and service identification tag, both available from Marley Engineered Products. When requesting return authorization, include all catalog numbers shown on the products.

161-304812-003

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

Loading...

Loading...