Page 1

MCARWH Series

Mechanical Artisan

Heavy-Duty Architectural

Wall Heater

Installation, Operation & Maintenance Instructions

Table 1. Specifications

MIN. SUPPLY

MODEL VOLTS PHASE WATTS AMPS WIRE GAUGE

MCARWH1802 120 1 1800 15 12

MCARWH4808 208 1 4000 / 2000 19.2 / 9.6 10

MCARWH4804 240 1 4800 / 2400 20.0 / 10.0 10

MCARWH4807 277 1 4800 / 2400 17.3 / 8.7 12

NOTE: The model numbers shown are Northern White color. Add suffix to the model number for the following colors:

AL = Aluminum, BZ = Bronze, W = Navajo White.

IMPORTANT INSTRUCTIONS

WARNING

WHEN USING ELECTRIC APPLIANCES, BASIC PRECAUTIONS SHOULD ALWAYS BE FOLLOWED TO REDUCE THE

RISK OF FIRE, ELECTRIC SHOCK, AND INJURY TO PERSONS, INCLUDING THE FOLLOWING:

1. Read all instructions before installing or using this heater.

2. This heater is hot when in use. To avoid burns, do not let

bare skin touch hot surfaces. Keep combustible materials,

such as furniture, pillows, bedding, papers, clothes, etc. and

curtains at least 3 feet (0.9 m) from the front of the heater.

3. Extreme caution is necessary when any heater is used by or

near children or invalids and whenever the heater is left

operating and unattended.

4. Do not operate any heater after it malfunctions. Disconnect

power at service panel and have heater inspected by a reputable electrician before using.

5. Do not use outdoors.

6. To disconnect heater, turn controls to OFF, and turn OFF

power to heater circuit at main disconnect panel.

7. Do not insert or allow foreign objects to enter any ventilation

or exhaust opening as this may cause an electric shock, fire,

or damage to the heater.

8. To prevent a possible fire, do not block air intake or exhaust

in any manner.

!

9. A heater has hot and arcing or sparking parts inside. Do not

use it in areas where gasoline, paint, or flammable liquids

are used or stored.

10. Use this heater only as described in this manual. Any other

use not recommended by the manufacturer may cause fire,

electric shock, or injury to persons.

11. This heater is provided with a red alarm light that will illuminate only if the heater has turned off as a result of overheating. Should the sensor register an overheat condition,

the heater will stop generating heat, the fan will turn off, and

the red alarm light will turn ON. DO NOT OPERATE THE

HEATER WITH THE ALARM LIGHT ILLUMINATED. See

“TO RESET MANUAL RESET LIMIT” in OPERATING

INSTRUCTION section.

12. This heater is intended for comfort heating applications and

not intended for use in special environments. Do not use in

damp or wet locations such as marine or greenhouse or in

areas where corrosive or chemical agents are present.

13. When installing, see INSTALLATION INSTRUCTIONS for

additional warnings and precautions.

14. For safe and efficient operation, and to extend the life of your

heater, keep your heater clean - See MAINTENANCE

INSTRUCTIONS.

SAVE THESE INSTRUCTIONS

PPD 39696 4/14 5200-11204-000

Page 2

INSTALLATION

INSTRUCTIONS

To prevent a possible fire, injury to persons or damage to the

heater, adhere to the following:

1. Disconnect all power coming to heater at main service

panel before wiring or servicing.

2. All wiring procedures and connections must be in accordance with the National and Local Codes having jurisdiction

and the heater must be grounded.

3. Verify the power supply voltage coming to heater matches

the ratings as shown on the heater nameplate.

CAUTION: ENERGIZING HEATER AT A VOLTAGE GREATER

THAN THE VOLTAGE PRINTED ON THE NAMEPLATE WILL

DAMAGE THE HEATER AND VOID THE WARRANTY AND

COULD CAUSE A FIRE.

4. CAUTION - High temperature, risk of fire, keep electrical

cords, drapery, furnishings, and other combustibles at least

3 feet (0.9 m) from front of heater. Do not install heater

behind doors, below towel racks, or in an area where it is

subject to being blocked by furniture, curtains or storage

materials. Hot air from the heater may damage certain fabrics and plastics.

5. To reduce the risk of fire, do not store or use gasoline or

other flammable vapors and liquids in the vicinity of the

heater.

6. For wall mounting only with air discharge downward. Do

NOT install in floor, ceiling, upside down (air discharge

upward), or sideways.

7. The following minimum clearances must be maintained:

Bottom of heater to floor - 12” (305 mm).

Sides of heater to adjacent wall - 12” (305 mm).

Top of heater to ceiling - 36” (915 mm).

8. Do not operate the heater without the back box.

9. Do not use this heater for dry out purposes as the paint,

plaster, sawdust and drywall sanding dust will permanently

damage the heater and must be kept out of the heater.

10. Remove motor shipping bracket and yellow tag prior to operating this heater.

The heater is designed for recessed installation in 2” x 4”

(50 mm x 101 mm) studs or larger wall sections using the back

box provided. The heater may be wired with standard building

wire (60°C). Refer to “Specifications” and heater nameplate for

correct supply voltage and wire size.

NOTE: The optimum mounting height for this heater is 18” to 24”

(450 mm to 600 mm) from floor to bottom of back box. DO NOT

install closer than 12” (305 mm) from the floor.

Ground screw

Back Box

12” Min.

(305 mm)

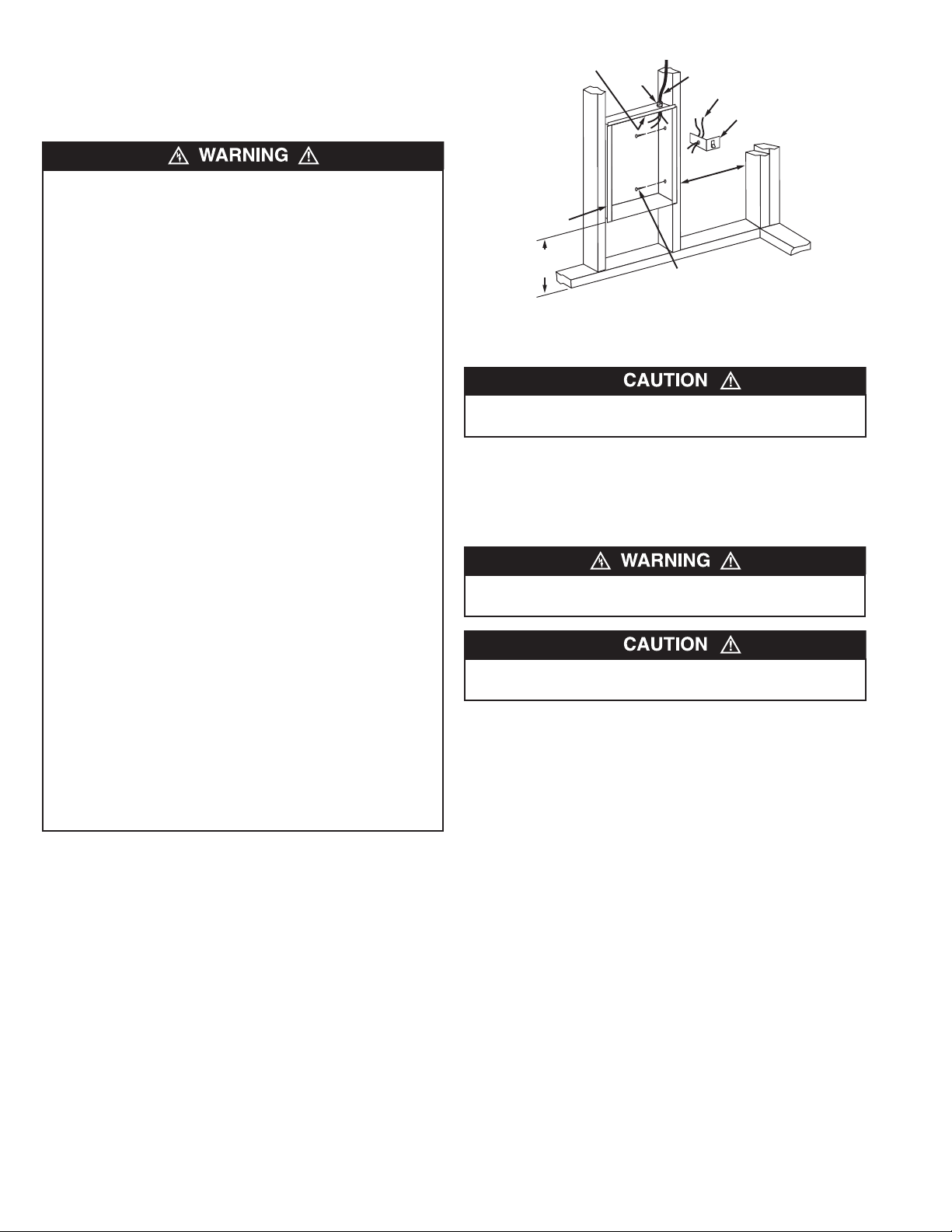

Figure 1: Locating Back Box in New Construction

Cable

clamp

Power supply cable

Lead wires (Blue)

12” Min.

(305 mm)

Nail or screw

(2 each side)

Disconnect switch

bracket with switch and

leads

(No disconnect

switch on

208V models)

Mounting Clearances

TO PROVIDE FOR SAFE OPERATION, THE FOLLOWING

CLEARANCES MUST BE MAINTAINED.

Wall Mounting Only:

a. Minimum twelve (12) inches (305 mm) to floor;

b. Minimum twelve (12) inches (305 mm) to adjacent walls;

c. Minimum thirty six (36) inches (915 mm) to ceiling.

TO PREVENT HAZARD OF FIRE OR ELECTRICAL SHOCK,

DO NOT INSTALL WITHOUT BACK BOX.

TO PREVENT POSSIBLE DAMAGE TO POWER WIRING,

USE ONLY THE KNOCKOUTS PROVIDED IN BACK BOX.

Installation of Back Box in New Construction

(See Figure 1).

NOTE: If the finished wall surface is already up, follow instruc-

tions for “Installation of Back Box in Existing Construction”.

1. Place the back box between two 16" (406 mm) center-tocenter wall studs at the desired mounting height but no closer than 12" (305 mm) to adjacent wall or floor.

NOTE: If wall studs are spaced greater than 16” (407 mm) on

center, additional framing supports may be necessary.

2. Align back box such that the bottom and sides will be flush

with finished wall surface (top flange of back box should protrude approximately 1/2" (12.7 mm) from finished wall surface

(You must know the thickness of the finished wall when

installing).

3. Secure the back box in position with wood screws or nails as

shown in Figure 1.

4. Run a power supply cable into the knockout area in the upper

right hand corner of the back box (see Figure 1). All wiring

must be in accordance with National and Local Electrical

Codes. Refer to Specifications for correct wire size.

5. Remove disconnect switch bracket by loosening two screws

on the right side.

6. Install a cable clamp in the knockout in the top of the back

box.

2

Page 3

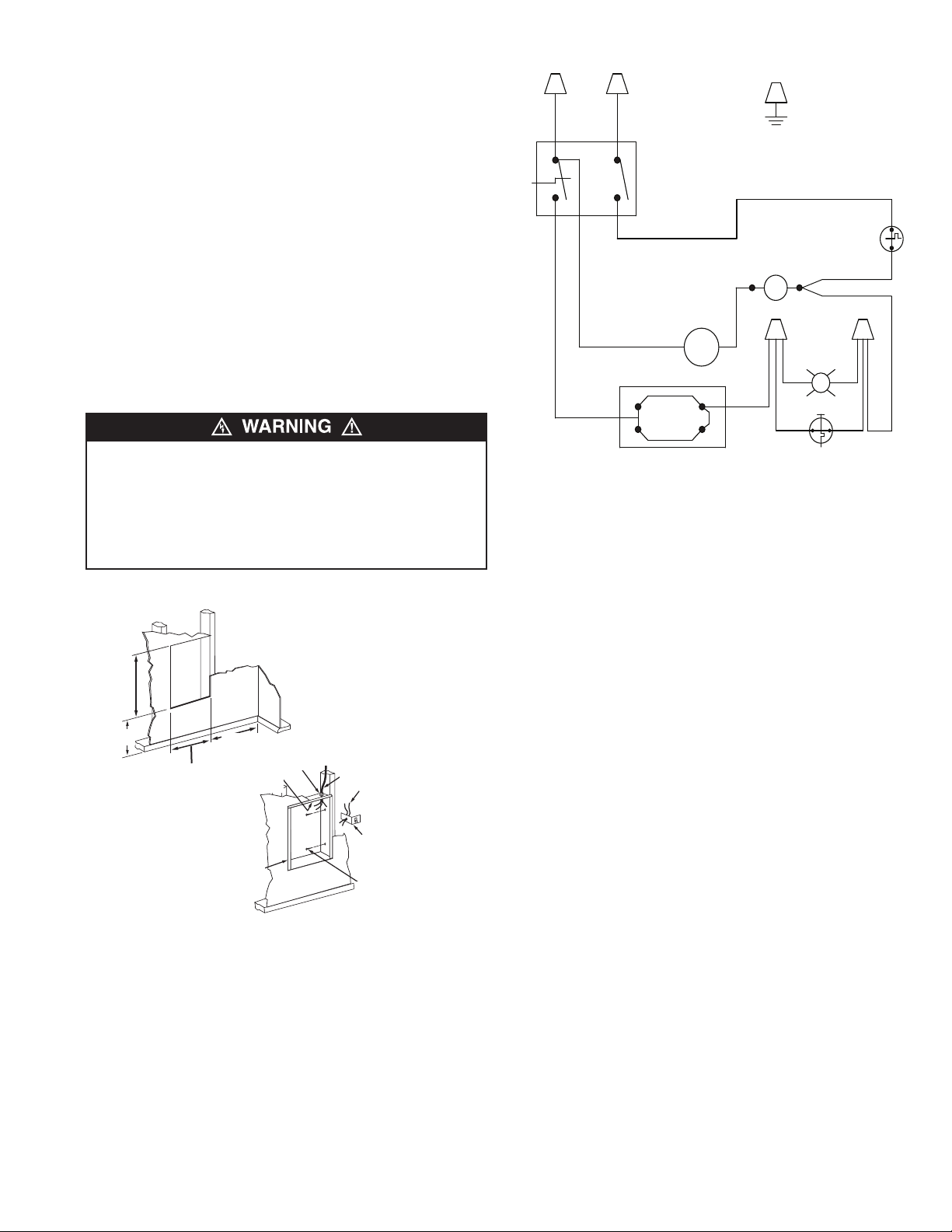

GND

TO

DISCONNECT

SWITCH

L1

L2

PL

F.D

THERMOSTAT

L1

OFF

L2

CYC

MOTOR

MOTOR

E1

E2

JUMPER

BLK

MANUAL RESET

LIMIT

EOL

ELEMENTS

MOTOR

7. Insert power supply cable through cable clamp, allowing at

least 6" (152 mm) of leads to extend inside the back box.

Connect the blue lead wires of disconnect switch to the supply wire leads using wire connectors (see Figure 3, Wiring

Diagram).

NOTE: If power supply is provided by standard non-metallic

sheathed cable (Romex) and the supply voltage is 240 or 208

volts (two power wires), the white wire color must be changed

using black electrical tape to comply with the NEC. White is only

allowed for a Neutral conductor.

8. Connect building ground conductor to the back box using the

green pigtail lead located in the inside top of the back box

and secure second green pigtail lead to back box green pigtail.

9. Feed remaining 2 wires from disconnect switch through hole

in switch bracket and secure disconnect switch bracket in

place by tightening screws.

10. Secure disconnect switch bracket in place by tightening

screws.

POWER SUPPLY VOLTAGE MUST BE THE SAME AS

HEATER VOLTAGE RATING SHOWN ON HEATER NAMEPLATE. CONNECTING TO A VOLTAGE IN EXCESS OF

Figure 3: Wiring Diagram

NAMEPLATE RATING WILL DAMAGE HEATER AND VOID

WARRANTY.

ALL CONNECTIONS MUST BE MADE WITH APPROPRIATELY

SIZED LISTED WIRE CONNECTORS.

Installation of Recessed Back Box in

Existing Construction

1. Provide a wall opening 14-3/4" (375 mm) wide by 18-1/2"

(470 mm) high at the desired mounting height, but no closer

than 12" (305 mm) from floor. (See Figure 2.) Locate so at

least one side of opening is at wall stud.

2. Run a power supply cable into the knockout area in the upper

right hand corner of the wall opening (see Figure 2). All

wiring must be in accordance with National and Local

Electrical Codes. Refer to Specifications for correct wire size.

3. Remove disconnect switch bracket by loosening two screws

on the right side.

12” Min.

(305 mm)

Figure 2: Locating Back Box in Existing Construction

14 1/2” Min.

(362 mm)

12” Min.

(305 mm)

Back Box

Ground

screw

Cable

clamp

Power supply cable

Lead wires (Blue)

Disconnect switch

bracket with switch

and leads. (No disconnect switch on 208V

models)

Nail or screw

(2 each side)

4. Install a cable clamp in the knockout in the top of the back

box.

5. Insert power supply cable through cable clamp, allowing at

least 6" (152 mm) of leads to extend inside the back box.

Connect the blue lead wires of disconnect switch to the supply wire leads using wire connectors (see Figure 4, Wiring

Diagram).

NOTE: If power supply is provided by standard non-metallic

sheathed cable (Romex) and the supply voltage is 240 or 208

volts (two power wires), the white wire color must be changed

using black electrical tape to comply with the NEC. White is only

allowed for a Neutral conductor.

6. Connect building ground conductor to the back box using the

green screw located in the inside top of the back box.

9. Feed remaining 2 wires from disconnect switch through hole

in switch bracket and secure disconnect switch bracket in

place by tightening screws.

8. Insert back box in wall opening being careful not to damage

the supply wiring. Secure the back box in place with wood

screws or nails.

3

Page 4

Building Management Systems (BMS)

To utilize BMS capabilities of this unit, there are two (optional)

accessories available. Model WHR2A which has a 24 volt holding coil can switch the heaters ON/OFF from remote source.

Model WHR12A which has a 120 volt holing coil can switch the

heaters ON/OFF from remote source.

Refer to the control installation manual when installing.

Installation of Back Box with Optional

Surface-Mounting Frame HTWHSM (See Figure 4)

1. Secure back box to wall with knockouts in upper right hand

corner using screws and anchors.

2. Hang the surface-mounting frame on the back box. Ensure

that the back edge of the surface-mounting frame is flush

against the wall.

NOTE: If heater is located in a high traffic area, where it may be

subjected to vandalism or abuse, take extreme care to see that

the back box is firmly attached to the wall.

3. Power Supply Wiring

NOTE: Wiring Compartment Volume - 119in3 (1950cm3).

a. Run a power supply cable into the area to the right of the

mounting frame. Arrangement of wiring to this point must

be in accordance with National and Local codes. Refer to

Table 1 on page 1 for proper wire size.

MOUNT BACK BOX

TO WALL USING

REAR MOUNTING

HOLES.

HANG FRAME

ON BACK BOX.

15-5/32 "

Figure 4 - Surface Mounting Installation

(385mm)

NOTE: If the wiring is to run through the wall, cut a hole I in the

area of the top right corner of the back box. Run the supply wire

through this hole. Then remove the “knockout” from the top of the

box and proceed to step C.

c. Remove disconnect switch bracket by loosening the two

screws on the right side.

d. Feed the power supply cable through the frame allowing

6in (152mm) of lead to remain inside the back box (using a

cable clamp, connector, or other suitable strain relief)

e. Secure the power supply cable to the back box (using

cable clamp, connector, or other suitable strain relief)

allowing 6in (152mm) of lead to remain inside the back

box.

f. Connect supply wires to blue wires of disconnect switch

using wiring connectors (see wiring diagram 3, Page 3).

g. Ground the back box by connecting the supply ground

lead wire to the green ground screw located in the inside

top of the back box.

h. Feed remaining 2 wires from disconnect switch through

hole in the switch bracket and secure disconnect switch

bracket in place.

3-13/16"

(97mm)

19"

(482mm)

Installation of Heater / Grille into Back Box

Note to Installer: Converting heater to half wattage

(Not applicable to MCARWH1802 120 Volt Models)

The MCARWH Series wall heaters are manufactured and

shipped at the higher rated wattage. Full wattage heaters can be

converted to half wattage by doing the following steps.

1. Remove the red jumper wire as shown in Figure 5 and discard.

2. To permanently make the heater half wattage, cut the male

terminal spade, carefully not to damage the cold pin and discard.

3. Mark the wattage of the heater on the white label inside the

back box.

After back box is completely installed and no further construction

dirt is expected, clean debris from back box and remove heater

assembly from its carton.

1. Lift and rotate the grille assembly into the back box carefully

to ensure the wiring is not trapped between the grille assembly and back box. Position the grille assembly in front of the

back box and insert Control Shelf into the notches on either

side of the back box. At the same time hooking the tabs on

the bottom corners of the grille assembly over the bottom

flange of the back box. Refer to figures 6 and 7..

2. With the top of the grille assembly leaning forward, supported

by the first notch in control shelf, extend the lead wires from

the back of the top of the heater grille assembly to the (2)

power wires of the disconnect switch assembly and connect

according to Wiring Diagram shown in Figure 3 (page 3)

3. If a surface mounting frame is used, ensure that the frame is

even with all four sides of the heater.

4. Connect the two disconnected switch wires to the heater

wires using wire nuts (provided). After the connection, carefully push wires back into the opening.

5. Turn thermostat to the extreme counterclockwise position in

OFF position.

6. Push disconnect switch to ON position.

7. Tighten top cover screws down to hold grille in place.

See Figure 8.

THE HEATER ASSEMBLY MUST BE CAREFULLY POSITIONED TO ENSURE THE CONTROL WIRES ARE NOT

TRAPPED BETWEEN THE HEATER ASSEMBLY AND THE

BACK BOX.

Male terminal spade

Red jumper wire

Figure 5- Jumper Wire Location

4

Page 5

Control

Shelf

Figure 6- Installation of Heater/Grille Assembly

Back Box

Notch

Tab

Notches

OPERATION

INSTRUCTIONS

1. Heater must be properly installed before operation.

2. Turn power supply ON at the service panel for this heater.

3. Rotate the thermostat fully clockwise. This should energize

the heating elements and cause warm air to flow from the hot

air discharge at the openings in the bottom front part of the

grille. This may take a minute or two for the fan delay to operate the fan.

4. After the operation check, rotate the thermostat counterclockwise to the desired position to obtain room comfort.

Note: For best results, the heater should be left “ON” constantly

during the heating season because the thermostat, when

properly set, will maintain the desired temperature.

THE ACTIVATION OF THE THERMAL LIMIT CONTROL AND

RED WARNING LIGHT OCCURS IF THE HEATER OVERHEATS. CHECK HEATER TO MAKE SURE IT IS NOT

BLOCKED – IF SO, REMOVE THE BLOCKAGE. IF THERE IS

NO BLOCKAGE, IT IS RECOMMENDED THAT THE HEATER

BE INSPECTED BY A REPUTABLE ELECTRICIAN OR

REPAIR SERVICE TO ENSURE THE HEATER IS NOT

DAMAGED. DO NOT CONTINUE TO USE HEATER IF IT

REPEATEDLY CYCLES OFF ON THIS THERMAL LIMIT.

Control

Shelf

Figure 7- Heater / Grille Assembly Detail, Grille Supported for Wiring

Figure 8- Securing Bezel

Flange

TO RESET THERMAL LIMIT CONTROL

Your heater is equipped with a manual reset safety thermal limit

control that will automatically turn the heater OFF to prevent a

fire if the heater overheats. This control is mounted inside the

heater (top left). On the top cover of the grille assembly it is

marked “Reset Button.” REMOVE the plug button that covers the

hole. To reset, allow the heater to cool, then push the red button

that is visible through the hole downward (you may have to use

a pencil- blunt side) to reach the button. The heater should

immediately return to normal operation.

DO NOT TAMPER WITH OR BYPASS ANY THERMAL LIMITS

INSIDE HEATER.

NOTE: The unit is provided with an End of Life “oneshot” protective device. This serves as a back up protector in extreme conditions if the overheat protector fails to maintain safe temperatures

during an overheat condition. If the end of life control activates,

the heater must be checked by a reputable repairman.

Figure 9- Top Panel Layout

5

Page 6

MAINTENANCE

INSTRUCTIONS

It is important to keep this heater clean. Your heater will give you

years of service and comfort with only minimum care. To assure

efficient operation follow the simple instructions below.

ALL SERVICING BEYOND SIMPLE CLEANING THAT

REQUIRES DISASSEMBLY SHOULD BE PERFORMED BY

QUALIFIED SERVICE PERSONNEL.

TO REDUCE RISK OF FIRE AND ELECTRIC SHOCK OR

INJURY, DISCONNECT ALL POWER COMING TO HEATER

AT MAIN SERVICE PANEL AND CHECK THAT THE ELEMENT

IS COOL BEFORE SERVICING OR PERFORMING

MAINTENANCE.

User Cleaning Instructions:

1. After the heater has cooled, a vacuum cleaner with brush

attachment may be used to remove dust and lint from exterior

surfaces of the heater including the grille openings.

2. With a damp cloth, wipe dust and lint from grille and exterior

surfaces.

3. Return power to heater and check to make sure it is operating properly.

Maintenance Cleaning Instructions:

(To be performed only by Qualified Service Personnel)

At least annually, the heater should be cleaned and serviced by

a qualified service person to assure safe and efficient operation.

This should include the removal of the heater grille assembly

from the back box to clean residue from the unit. After completing the cleaning and servicing, the heater should be fully

reassembled and checked for proper operation.

6

Page 7

REPAIR PARTS

16

12

11

4

10

13

8

9

7

6

3

15

17

1

5

14

2

Repair Parts List

Ref Part Number

No Description MCARWH4804 MCARWH4808 MCARWH4807 MCARWH1802

1 Grille 2501-11023-VAR* 2501-11023-VAR* 2501-11023-VAR* 2501-11023-VAR*

2 Cover Bracket Lower Left 1215-11070-000 1215-11070-000 1215-11070-000 1215-11070-000

3 Cover Bracket Lower Left 1215-11070-001 1215-11070-001 1215-11070-001 1215-11070-001

4 Motor Mount Bracket 1215-2235-002 1215-2235-002 1215-2235-002 1215-2235-002

5 Fan Blade 490030103 490030103 490030103 490030103

6 Thermal Cutout 4520-2030-000 4520-2030-000 4520-2030-000 4520-2030-000

7 Element Retention Bracket 1215-11090-000 1215-11090-000 1215-11090-000 1215-11090-000

8 Fan Delay 410074000 410074000 410074000 1414-2039-000

9 Clip-limit Capillary 402040001 402040001 402040001 402040001

10 Bracket - Limit 1215-11101-000 1215-11101-000 1215-11101-000 1215-11101-000

11 Protect or Manual Reset 4520-11019-000 4520-11019-000 4520-11019-000 4520-11019-000

12 Thermostat 2-Pole 5813-2027-000 5813-2027-000 5813-2027-000 5813-2027-000

13 Motor 3900-2010-000 3900-2010-000 3900-2010-001 3900-2010-003

14 Element 302012810 302012807 302012811 302012828

15 Bezel 4503-11015-000 4503-11015-000 4503-11015-000 4503-11015-000

16 Control Knob 3301-11013-000 3301-11013-000 3301-11013-000 3301-11013-000

17. Light (Alarm) 3510-2010-000 3510-2010-000 3510-2010-000 3510-2010-000

*NOTE: The standard color is Northern White. Add suffix to the model number for the following colors:

AL = Aluminum, BZ = Bronze, W = Navajo White. Call Factory for part number.

7

Page 8

All products manufactured by Marley Engineered Products are warranted against defects in workmanship and materials for one year from date of installation, except

LIMITED WARRANTY

heating elements which are warranted against defects in workmanship and materials for five years from date of installation. This warranty does not apply to damage from

accident, misuse, or alteration; nor where the connected voltage is more than 5% above the nameplate voltage; nor to equipment improperly installed or wired or

maintained in violation of the product’s installation instructions. All claims for warranty work must be accompanied by proof of the date of installation.

The customer shall be responsible for all costs incurred in the removal or reinstallation of products, including labor costs, and shipping costs incurred to return products to

Marley Engineered Products Service Center. Within the limitations of this warranty, inoperative units should be returned to the nearest Marley authorized service center

or the Marley Engineered Products Service Center, and we will repair or replace, at our option, at no charge to you with return freight paid by Marley. It is agreed that such

repair or replacement is the exclusive remedy available from Marley Engineered Products.

THE ABOVE WARRANTIES ARE IN LIEU OF ALL OTHER WARRANTIES EXPRESSED OR IMPLIED, AND ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE WHICH EXCEED THE AFORESAID EXPRESSED WARRANTIES ARE HEREBY DISCLAIMED AND EXCLUDED FROM THIS

AGREEMENT. MARLEY ENGINEERED PRODUCTS SHALL NOT BE LIABLE FOR CONSEQUENTIAL DAMAGES ARISING WITH RESPECT TO THE

PRODUCT, WHETHER BASED UPON NEGLIGENCE, TORT, STRICT LIABILITY, OR CONTRACT.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above exclusion or limitation may not apply to you. This warranty gives

you specific legal rights, and you may also have other rights which vary from state to state.

For the address of your nearest authorized service center, contact Marley Engineered Products in Bennettsville, SC, at 1-800-642-4328. Merchandise returned to the factory must be accompanied by a return authorization and service identification tag, both available from Marley Engineered Products. When requesting return authorization,

include all catalog numbers shown on the products.

HOW TO OBTAIN WARRANTY SERVICE AND

WARRANTY PARTS PLUS GENERAL INFORMATION

1. Warranty Service or Parts 1-800-642-4328

2. Purchase Replacement Parts 1-800-654-3545

3. General Product Information www.marleymep.com

Note: When obtaining service always have the following:

1. Model number of the product

2. Date of manufacture

3. Part number or description

Note: Do not return to manufacturer.

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

Loading...

Loading...