Page 1

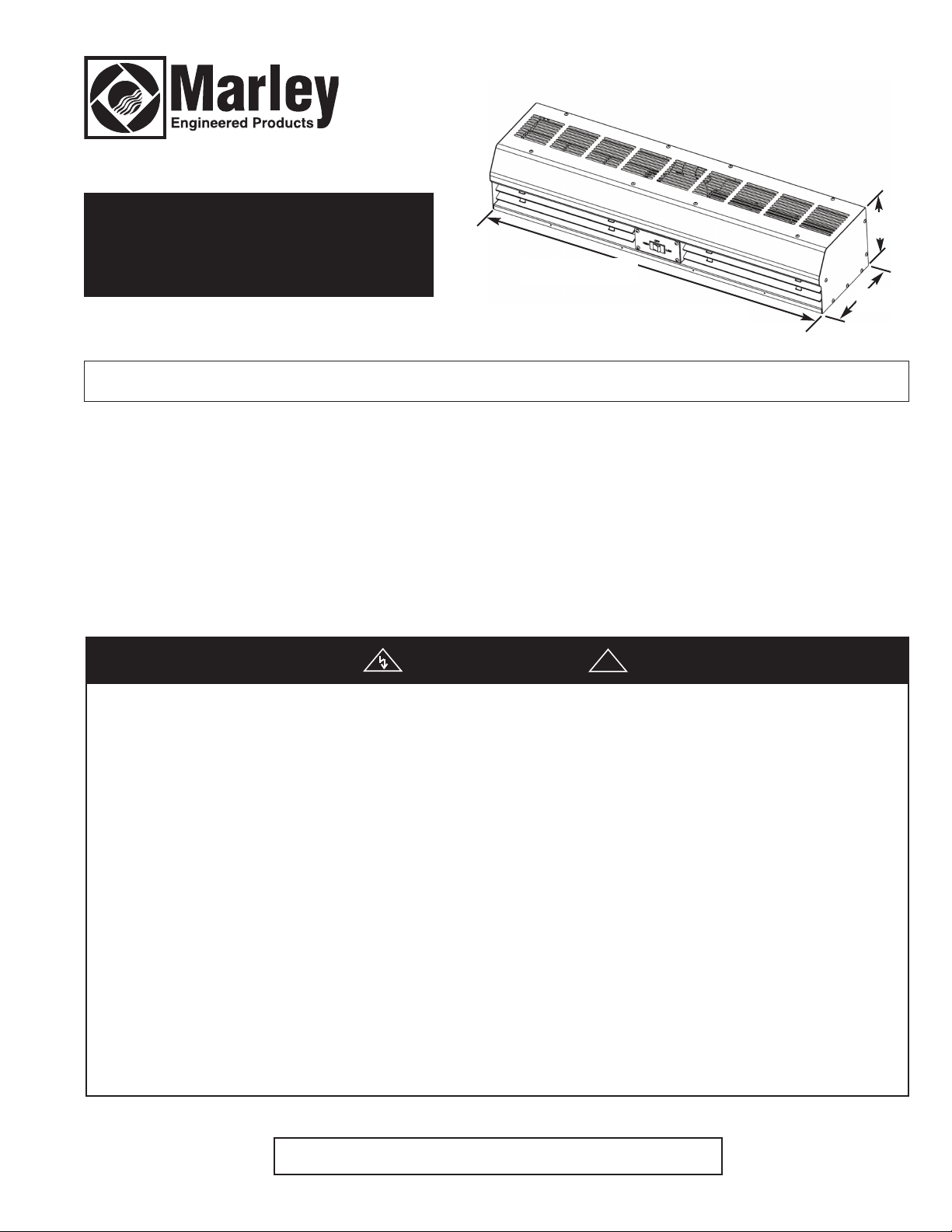

LP Series

”

7

178 mm

Low Profile Air Curtains

Refer to Specifications

imension “A”, page 2

D

Note – All dimensions are the same for all low-profile

series air curtains. Model number indicates width of

unit. (Example LP4800 indicates 48” wide unit.)

7

8

/8”

223 mm

Installation, Operation & Maintenance Instructions

GENERAL

Marley air curtains produce a wall of continuously flowing air that acts as a thermal barrier against outside air and flying insects.

These air curtains maintain interior conditioned temperature and prevent heated or cooled air from escaping through open doorways. They reduce humidity and loss of cold air when used over freezer and cooler doors. High traffic area doors can be left open,

eliminating wear and nuisance of opening and closing automatic and manual doors used over service entrances, access doors, etc.

Air curtains provide protection against insects, dust, odor, fumes and other contaminants.

WARNING

Read Carefully - These instructions are written to help you

prevent difficulties that might arise during installation of the unit.

Studying the instructions first may save you considerable time

and money later. Observe the following procedures, and cut

your installation time to a minimum.

CAUTION - TO REDUCE RISK OF FIRE AND ELECTRIC

SHOCK OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended by the manufacturer. If you have questions contact the manufacturer.

2. Before servicing or cleaning the unit, switch power off at

service panel and lock service panel to prevent power from

being switched on accidentally.

3. Installation work and electrical wiring must be done by qualified persons in accordance with all applicable codes and

standards, including fire rated construction.

4. When cutting or drilling into wall or ceiling, do not damage

electrical wiring or other hidden utilities.

5. Make certain that the power source conforms to the electrical requirements of the unit (check nameplate). Disconnect

power before installing or servicing. Lock it in the open position and tag it to prevent unexpected application of power.

Failure to do so could result in fatal electric shock.

6. All wiring should be done by a qualified electrician, using

copper wire only and in accordance with the National

Electric Code (NEC), all applicable local codes, and ordinances, and all sections of this manual. Any variance voids

the warranty and may create unsafe conditions.

7. Special attention must be given to any grounding information pertaining to this product. To prevent the risk of electrocution, the unit must be securely and accurately

grounded. This should be accomplished by connecting a

grounded conductor between the service panel and the

grounding lug provided in the wiring compartment.

To ensure proper ground, the grounding means must be

tested by a qualified electrician.

8. Do not insert fingers or foreign objects into the air curtain.

Do not block or tamper with in any matter while in operation.

Do not touch it while in operation or just after it has been

turned off, as some parts may be hot enough to cause

injury.

9 This product must NOT be used in potentially dangerous

areas such as hazardous locations, flammable, explosive,

chemical-laden, or wet atmospheres are present.

10. To reduce the risk of fire or electric shock, do not use this

air curtain with any solid state speed control devices.

!

SAVE THESE INSTRUCTIONS

Page 2

Specifications

AIR DELIVERY

Dim. Avg. FPM CFM Total Max

Model No. “A” at Nozzle at Nozzle HP Amps Volts

LP36001115 37.0 1800/1350 1295/971 1/15 1.3A 120

LP42001110 42.0 1800/1350 1470/1103 1/10 1.6A 120

LP48001108 48.0 1800/1350 1681/1260 1/8 2.1A 120

LP60001108 60.0 1800/1350 2102/1576 1/8 2.1A 120

LP36001208 37.0 1800/1350 1295/971 1/8 0.7A 240

LP42001208 42.0 1800/1350 1470/1103 1/8 0.7A 240

LP48001206 48.0 1800/1350 1681/1260 1/6 1.0A 240

LP60001206 60.0 1800/1350 2102/1576 1/6 1.0A 240

DO NOT DEPEND UPON A THERMOSTAT OR OTHER

SWITCH AS THE SOLE MEANS OF DISCONNECTING

POWER WHEN INSTALLING OR SERVICING THE UNIT.

ALWAYS DISCONNECT AND LOCK OUT POWER AT THE

MAIN CIRCUIT BREAKER AS DESCRIBED ABOVE.

FAILURE TO DO SO COULD RESULT IN FATAL ELECTRIC

SHOCK.

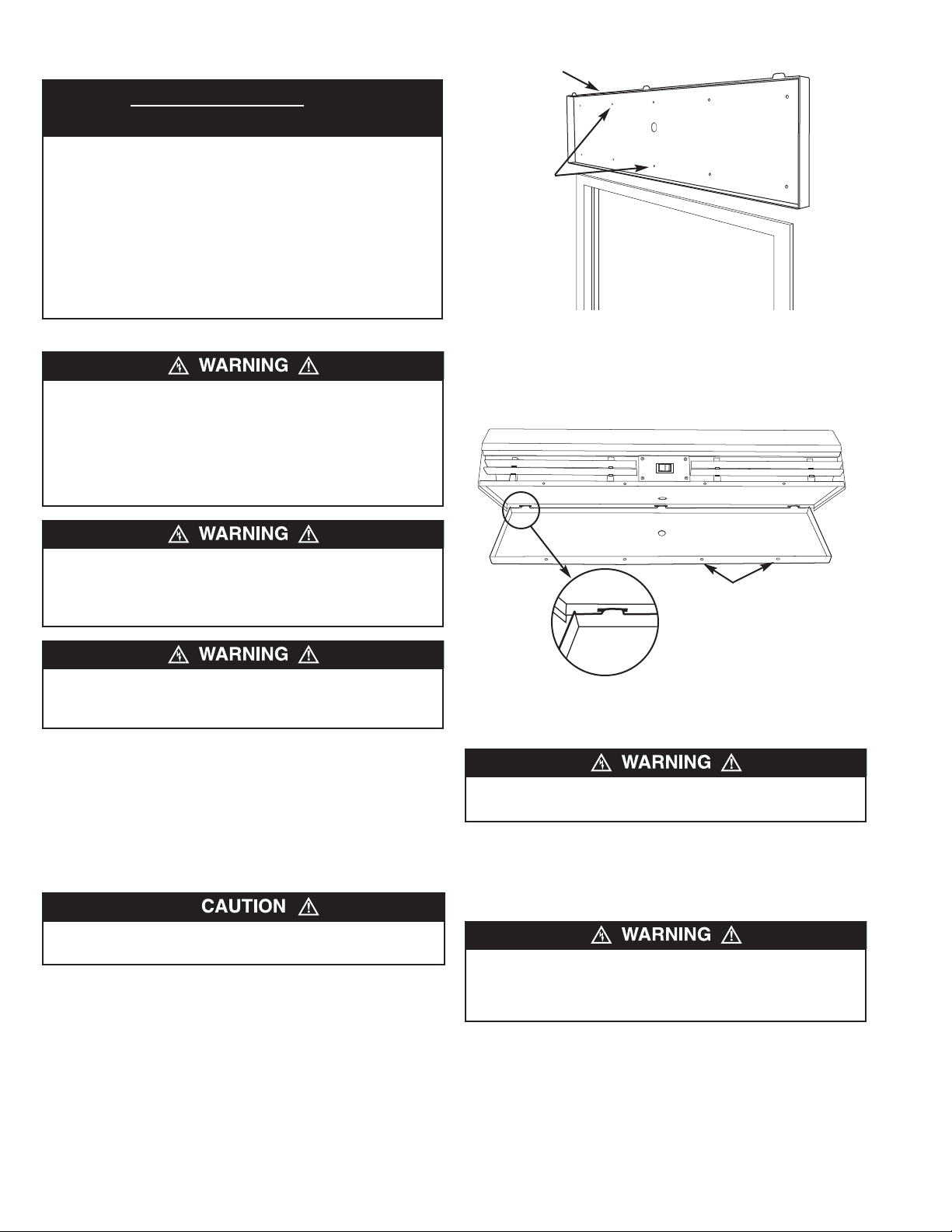

Mounting bracket

Mounting holes

(10 total)

Figure 1

2. Mount air curtain cabinet assembly by simply “hanging” unit

onto unit mounting bracket by aligning vertical tabs with air

curtain cabinet assembly slots (Figure 2). Secure air curtain

to mounting bracket by four (4) phillips screws.

THIS PRODUCT MUST NOT BE USED IN POTENTIALLY

DANGEROUS AREAS SUCH AS HAZARDOUS LOCATIONS,

FLAMMABLE, EXPLOSIVE, CHEMICAL-LADEN, OR WET

ATMOSPHERES ARE PRESENT.

TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK, DO

NOT USE THIS AIR CURTAIN WITH ANY SOLID STATE

SPEED CONTROL DEVICES.

UNPACKING

1. With packaged unit on floor, carton arrows should point

upward.

2. Carefully remove staples from top of carton and fold back

sides.

3. Carefully remove cabinet by lifting out unit and place on work

surface.

DO NOT ATTEMPT TO LIFT THIS AIR CURTAIN BY ITS

LOUVER OR DAMAGE MAY RESULT.

4. Remove four (4) phillips screws securing mounting bracket

and remove unit mounting bracket.

Screw holes (4)

Fit tab of mounting bracket into

slot on back of unit as shown

Figure 2

ELECTRICAL CONNECTIONS

ALL AIR CURTAINS SHOULD BE INSTALLED BY QUALIFIED

PERSONNEL.

Cord Connected

1. Connect power per nameplate to correct power supply.

2. Install all wiring, protection, and grounding in accordance

with the National Electrical Code (NEC) and all requirements.

THIS FAN HAS AN INTERNAL SELF-RESETTING THERMAL

OVERLOAD PROTECTOR. ALWAYS DISCONNECT FROM

POWER SUPPLY BEFORE SERVICING.

INSTALLATION

1. Determine mounting location utilizing unit mounting bracket

and attach unit mounting bracket using appropriate mounting

hardware (not included).

IMPORTANT: The hardware and the supporting structure must

be capable of supporting a minimum 150 lb. load.

NOTE: All installation should be done to meet local building

codes.

3. Unit is ready for operation.

4. Confirm unit is operating within all electrical and performance

specifications.

NOTE: Air curtain has high/low selector switch that is factory

wired

2

Page 3

MAKE SURE AMP RATING OF ANY ON/OFF SWITCH

EXCEEDS NAMEPLATE AMP RATING OF MOTOR.

Hard Wire Connection

NOTE: Unit is factory wired for cord connection and may be field

wired for hard wire connection.

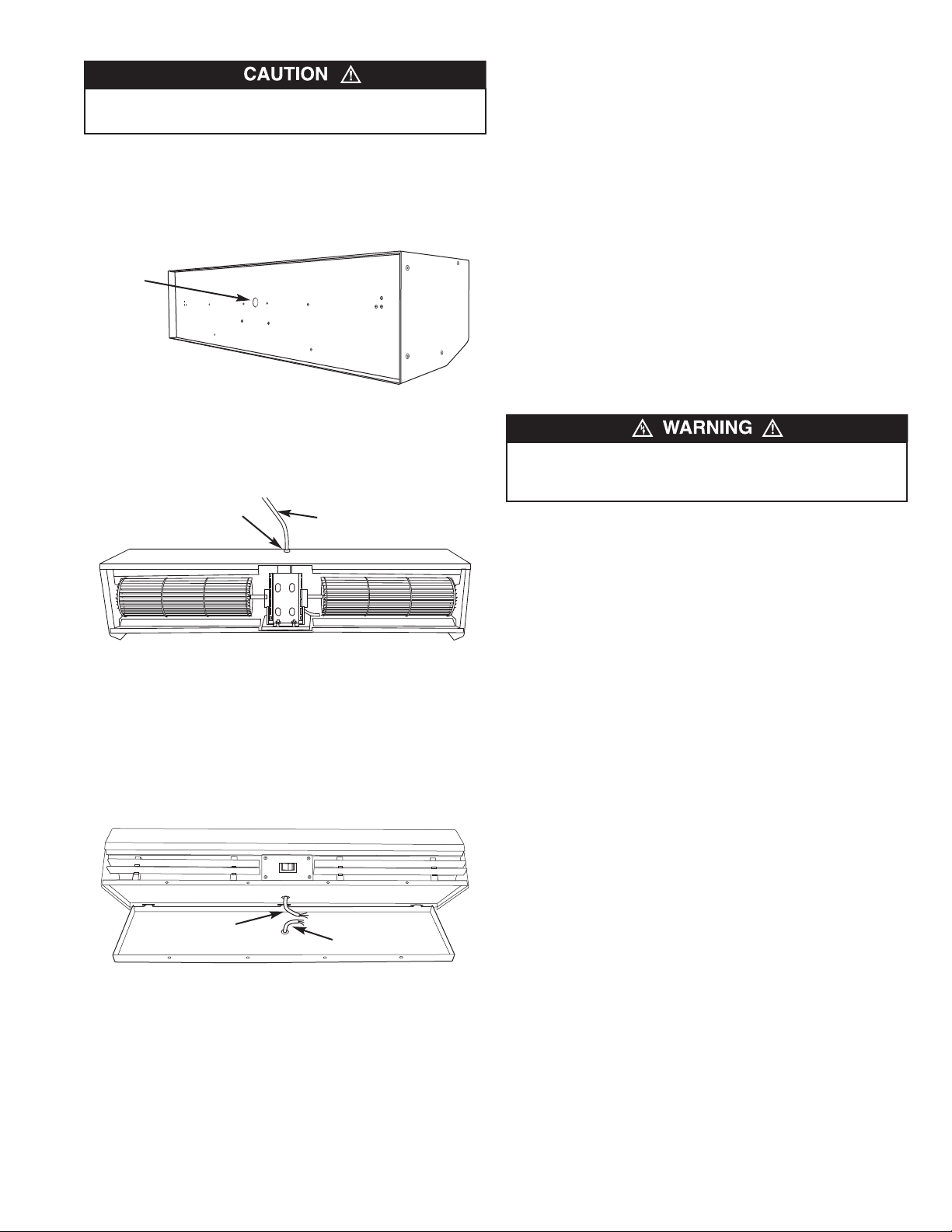

1. Remove knockout from back of unit cabinet (see Figure 3).

Knockout

Figure 3

2. Remove front inlet grille from unit.

3 Cut plug from end of supply cord and remove strain relief

bushing.

OPERATION

1. After power has been connected to unit, fans will start in

either preset (high/low) speed selection.

2. Air velocity is controlled by selection of high or low speed

indicator. This feature allows the setting of air velocity to

individual desired performance and energy efficiency.

3. Air direction at outlet can be controlled by adjustable vanes

at nozzle which compensates for possible draft conditions.

IMPORTANT: In freezer applications, unit is always mounted on

outside (warm side) of freezer or cooler.

NOTE: Cold air will try to escape near floor level. Warm air will

try to penetrate curtain near top of doorway. Air flow can be

controlled by direction of nozzle louvers and by high/low settings.

NOTE: For best operation, the interior space must have an

equalized pressure to the exterior space.

MAINTANCE

TO REDUCE THE RISK FOR ELECTRIC SHOCK ALWAYS

DISCONNECT AND LOCK OUT POWER SUPPLY BEFORE

SERVICING.

Strain relief bushing

Figure 4

4. Route cut cord end into air curtain cabinet and out through

knockout hole in back. Replace strain relief bushing.

5. Route hard field wire into center of mounting bracket.

6. Connect power per nameplate to correct power supply in

space between air curtain cabinet and mounting bracket.

Use adequate size wire for all branch and feeder runs.

Cabinet wiring

Cord

Field supply wiring

Lubrication

Sleeve bearings are permanently lubricated and require no

further lubrication.

Cleaning

1. The air curtain cabinet may be wiped off with a damp cloth.

Do not allow motor to get wet. Do not use solvents or harsh

detergents.

NOTE: Keep air intake louvers clear of dirt and dust

accumulation which could affect performance.

2. Check blower wheels for accumulated dirt twice a year and

clean.

Figure 5

7. Install all wiring, protection, and grounding in accordance

with the National Electrical Code (NEC) and all requirements.

8. Replace front grille.

9. Unit is ready for operation.

10.Confirm unit is operating within all electrical and performance

specifications.

3

Page 4

All products manufactured by Marley Engineered Products are warranted against defects in workmanship and materials for one year from date of installation, except

LIMITED WARRANTY

heating elements which are warranted against defects in workmanship and materials for five years from date of installation. This warranty does not apply to damage from

accident, misuse, or alteration; nor where the connected voltage is more than 5% above the nameplate voltage; nor to equipment improperly installed or wired or

maintained in violation of the product’s installation instructions. All claims for warranty work must be accompanied by proof of the date of installation.

The customer shall be responsible for all costs incurred in the removal or reinstallation of products, including labor costs, and shipping costs incurred to return products

to Marley Engineered Products Service Center. Within the limitations of this warranty, inoperative units should be returned to the nearest Marley authorized service center or the Marley Engineered Products Service Center, and we will repair or replace, at our option, at no charge to you with return freight paid by Marley. It is agreed that

such repair or replacement is the exclusive remedy available from Marley Engineered Products.

THE ABOVE WARRANTIES ARE IN LIEU OF ALL OTHER WARRANTIES EXPRESSED OR IMPLIED, AND ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE WHICH EXCEED THE AFORESAID EXPRESSED WARRANTIES ARE HEREBY DISCLAIMED AND EXCLUDED FROM

THIS AGREEMENT. MARLEY ENGINEERED PRODUCTS SHALL NOT BE LIABLE FOR CONSEQUENTIAL DAMAGES ARISING WITH RESPECT TO THE

PRODUCT, WHETHER BASED UPON NEGLIGENCE, TORT, STRICT LIABILITY, OR CONTRACT.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above exclusion or limitation may not apply to you. This warranty gives

you specific legal rights, and you may also have other rights which vary from state to state.

For the address of your nearest authorized service center, contact Marley Engineered Products in Bennettsville, SC, at 1-800-642-4328. Merchandise returned to the factory must be accompanied by a return authorization and service identification tag, both available from Marley Engineered Products. When requesting return authorization,

include all catalog numbers shown on the products.

HOW TO OBTAIN WARRANTY SERVICE AND

WARRANTY PARTS PLUS GENERAL INFORMATION

1. Warranty Service or Parts 1-800-642-4328

2. Purchase Replacement Parts 1-800-654-3545

3. General Product Information www.marleymep.com

Note: When obtaining service always have the following:

1. Model number of the product

2. Date of manufacture

3. Part number or description

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

Part No. 5200-2835-001

ECR39232

09/11

Page 5

Cortinas de aire de perfil bajo

”

7

178 mm

Serie LP

Consulte las especificaciones

imensión “A”, página 2

D

Nota – Todas las dimensiones son iguales para todas

as cortinas de aire de la serie de perfil bajo. El número

l

de modelo indica el ancho de la unidad. (Ejemplo:

LP4800 indica una unidad con ancho de 48”).

7

8

/8”

223 mm

Instrucciones de instalación, operación y mantenimiento

GENERALIDADES

Las cortinas de aire Marley producen una pared de aire que fluye continuamente que actúa como una barrera térmica contra el

aire exterior y los insectos voladores. Estas cortinas de aire mantienen la temperatura acondicionada interior y evitan que el aire

calentado o enfriado escape a través de las puertas abiertas. Éstas reducen la humedad y pérdida de aire frío cuando se utilizan

sobre puertas de congeladores y enfriadores. Las puertas de áreas de alto tráfico pueden dejarse abiertas, eliminando el uso e

incomodidad de la apertura y cierre de puertas automáticas y manuales utilizadas sobre las entradas de servicio, puertas de acceso, etc. Las cortinas de aire proporcionan protección contra insectos, polvo, olores, humos y otros contaminantes.

ADVERTENCIA

Lea Cuidadosamente - Estas instrucciones están escritas para

ayudarlo a solucionar las dificultades que pudieran surgir durante la

instalación de la unidad. El estudio previo de estas instrucciones le

ahorrará considerable tiempo y dinero en el futuro. Realice los siguientes procedimientos y reducirá a un mínimo el tiempo de instalación.

PRECAUCIÓN - PARA REDUCIR EL RIESGO DE INCENDIO Y

DESCARGA ELÉCTRICA, CUMPLA LO SIGUIENTE:

1. Utilice esta unidad sólo de la manera prevista por el fabricante. Si

tiene preguntas, comuníquese con el fabricante.

2. Antes de suministrar servicio de mantenimiento o antes de limpiar

la unidad, coloque en la posición Apagado (Off) el interruptor de

energía ubicado en el panel de servicio y coloque candado al panel

de servicio para evitar que la energía sea activada involuntariamente.

3. El trabajo de instalación y cableado eléctrico deben ser realizados

por personas calificadas de acuerdo con todos los códigos y normas aplicables, incluyendo la construcción con capacidad contra

incendio.

4. Al cortar o taladrar en paredes o cielos rasos, tenga cuidado de no

dañar los cables eléctricos u otras instalaciones ocultas.

5. Verifique que la fuente de energía cumple los requisitos eléctricos

de la unidad (consulte la placa de datos). Desconecte la energía

ante de instalar o suministrar servicio de mantenimiento a la

unidad. Colóquele candado en la posición abierta y etiquétela para

evitar la aplicación inesperada de la energía. No hacerlo así podría

resultar en descarga eléctrica mortal.

6. Todo el cableado debe ser realizado por un electricista calificado,

utilizando únicamente cable de cobre y de acuerdo con el Código

Eléctrico Nacional (NEC), todos los códigos locales aplicables y

ordenanzas, y todas las secciones de este manual. Cualquier

variación anula la garantía y podría crear condiciones inseguras.

7. Debe prestarse atención especial a cualquier información sobre

conexión a tierra relacionada con este producto. Para evitar el riesgo de electrocución, la unidad debe conectarse a tierra de manera

segura y precisa. Esto debe realizarse conectando un conductor

conectado a tierra entre el panel de servicio y la oreja de conexión

a tierra suministrada en el compartimiento de conexión de cables.

Para garantizar una conexión a tierra apropiada, los elementos de

conexión a tierra deben ser probados por un electricista calificado.

8. No inserte los dedos u objetos extraños en la cortina de aire. No

obstruya ni manipule inapropiadamente la unidad mientras está en

funcionamiento. No la toque mientras está en funcionamiento o

justo después de haberse apagado, ya que algunas piezas podrían

estar lo suficientemente calientes para causar lesiones.

9. Este producto NO debe utilizarse en áreas potencialmente peligrosas donde existan atmósferas inflamables, explosivas, cargadas con sustancias químicas o mojadas.

10. Para reducir el riesgo de incendio o descarga eléctrica, no utilice

esta cortina de aire con ningún dispositivo de control de velocidad

del tipo de estado sólido.

!

GUARDE ESTAS INSTRUCCIONES

Page 6

Especificaciones

SUMINISTRO DE AIRE

im. Pies/min prom Pie

odelo No. “A” en boquilla en boquilla total Máx Voltios

M

LP36001115 37.0 1800/1350 1295/971 1/15 1.3 A 120

LP42001110 42.0 1800/1350 1470/1103 1/10 1.6 A 120

LP48001108 48.0 1800/1350 1681/1260 1/8 2.1 A 120

LP60001108 60.0 1800/1350 2102/1576 1/8 2.1 A 120

LP36001208 37.0 1800/1350 1295/971 1/8 0.7 A 240

LP42001208 42.0 1800/1350 1470/1103 1/8 0.7 A 240

LP48001206 48.0 1800/1350 1681/1260 1/6 1.0 A 240

LP60001206 60.0 1800/1350 2102/1576 1/6 1.0 A 240

AL INSTALAR O SUMINISTRAR SERVICIO DE MANTENIMIENTO O

REPARACIÓN A LA UNIDAD, NO DEPENDA DE UN TERMOSTATO

U OTRO INTERRUPTOR COMO ÚNICO MEDIO DE DESCONEXIÓN

DE LA ENERGÍA. SIEMPRE DESCONECTE Y ASEGURE CON CANDADO LA ENERGÍA EN EL INTERRUPTOR AUTOMÁTICO PRINCIPAL SEGÚN SE DESCRIBIÓ ANTERIORMENTE. NO HACERLO ASÍ

PODRÍA RESULTAR EN DESCARGA ELÉCTRICA MORTAL.

D

3

min HP Amps

/

Soporte de

Montaje

Orificios de

montaje

(10 total)

Figura 1

2. Monte la carcasa de la cortina de aire simplemente “colgando” la unidad sobre el soporte de montaje de la unidad alineando las lengüetas verticales con las ranuras de la carcasa

de la cortina de aire (Figura 2). Asegure la cortina de aire al

soporte de montaje mediante los cuatro (4) tornillos cruciformes.

ESTE PRODUCTO NO DEBE UTILIZARSE EN ÁREAS POTENCIALMENTE PELIGROSAS DONDE EXISTAN ATMÓSFERAS INFLAMABLES, EXPLOSIVAS, CARGADAS CON SUSTANCIAS QUÍMICAS

O MOJADAS.

PARA REDUCIR EL RIESGO DE INCENDIO O DESCARGA ELÉCTRICA, NO UTILICE ESTA CORTINA DE AIRE CON NINGÚN DISPOSITIVO DE CONTROL DE VELOCIDAD DEL TIPO DE ESTADO

SÓLIDO.

DESEMBALAJE/DESEMPAQUE

1. Con la unidad empacada sobre el piso, las flechas de la caja

de cartón deben estar dirigidas hacia arriba.

2. Remueva cuidadosamente las grapas de la parte superior de

la caja de cartón y doble hacia atrás los lados.

3. Saque cuidadosamente la unidad y coloque sobre una

superficie de trabajo.

NO INTENTE LEVANTAR ESTA CORTINA DE AIRE POR SU REJILLA O PODRÍA PRODUCIRSE UN DAÑO.

4. Remueva los cuatro (4) tornillos cruciformes que aseguran

el soporte de montaje y remueva el soporte de montaje de

la unidad.

INSTALACIÓN

1. Determine mounting location utilizing unit mounting bracket

and attach unit mounting bracket using appropriate mounting

hardware (not included).

IMPORTANTE: Los herrajes y la estructura de soporte deben

ser capaces de soportar una carga mínima de 150 lb.

NOTA: Toda instalación debe realizarse de tal modo que se

cumplan los códigos de construcción locales.

Orificios para tornillo (4)

Encaje la lengüeta del soporte de

montaje dentro de la ranura ubicada

en la parte trasera de la unidad,

Figura 2

según se muestra.

CONEXIONES ELÉCTRICAS

TODAS LAS CORTINAS DE AIRE DEBEN SER INSTALADAS POR

PERSONAL CALIFICADO.

Cable de alimentación conectado

1. Conecte, según la placa de datos, con la fuente de energía

correcta.

2. Instale todos los cables, protección y conexiones a tierra, de

acuerdo con el Código Eléctrico Nacional (NEC) y todos los

requisitos.

ESTE VENTILADOR TIENE UN PROTECTOR CONTRA SOBRECARGA TÉRMICA INTERNO DE AUTO-REPOSICIONAMIENTO. ANTES

DE SUMINISTRAR UN SERVICIO DE MANTENIMIENTO O

REPARACIÓN, SIEMPRE DESCONECTE DE LA FUENTE DE

ENERGÍA

3. La unidad está lista por operación.

4. Confirme que la unidad está funcionando dentro de todas las

especificaciones eléctricas y de funcionamiento.

NOTA: La cortina de aire tiene un interruptor selector alto/bajo

que viene cableado de fábrica

6

Page 7

VERIFIQUE QUE LA CAPACIDAD DE AMPERIOS DE CUALQUIER

INTERRUPTOR DE ENCENDIDO/APAGADO EXCEDE LA CAPACIDAD DE AMPERIOS DEL MOTOR INDICADA EN LA PLACA DE

DATOS.

Conexión con cables existentes

NOTA: La unidad viene cableada de fábrica para conexión

mediante el cable de alimentación de energía y puede

cablearse en campo para conexión con cables existentes.

1. Remueva las tapas precortadas removibles de la parte

trasera de la carcasa de la unidad (vea la Figura 3).

Tapa

precortada

removible

Figure 3

2. Retire la rejilla de entrada delantera de la unidad.

3. Corte el enchufe del extremo del cable de alimentación de

energía y retire el buje de alivio de esfuerzo mecánico.

Buje de alivio de

esfuerzo mecánico

Cable de alimentación de energía

MANEJO

1. Después de haber conectado la energía hacia la unidad, los

ventiladores arrancarán en la selección de velocidad preajustada (alta/baja).

2. La velocidad del aire es controlada por la selección del indicador de velocidad alta o baja. Esta característica permite el

ajuste de la velocidad del aire para lograr la eficiencia de

energía y funcionamiento deseados individuales.

3. La dirección del aire en la salida puede controlarse mediante

persianas ajustables en la boquilla, lo cual compensa posibles condiciones de corriente de aire.

IMPORTANTE: En las aplicaciones con congeladores, la unidad

siempre se monta en el lado exterior (lado caliente) del congelador o enfriador.

NOTA: El aire frío tratará de escapar cerca del nivel del piso. El

aire caliente tratará de penetrar la cortina cerca de la parte

superior del marco de puerta. El flujo del aire puede controlarse

mediante la dirección de las persianas de la boquilla y mediante

los valores alto/bajo.

NOTA: Para lograr el mejor funcionamiento, el espacio interior

debe tener una presión igualada con el espacio exterior.

MANTENIMIENTO

PARA REDUCIR EL RIESGO DE DESCARGA ELÉCTRICA,

SIEMPRE DESCONECTE Y ASEGURE CON CANDADO LA

FUENTE DE ENERGÍA ANTES DE SUMINISTRAR SERVICIO DE

MANTENIMIENTO.

Figura 4

4. Inserte el extremo cortado del cable de alimentación de

energía dentro de la carcasa de la cortina de aire y sáquelo

a través del orificio de la tapa precortada removible en la

parte trasera. Coloque nuevamente el buje de alivio de

esfuerzo mecánico.

5. Inserte, el cable de suministro de energía existente en

campo, en el centro del soporte de montaje.

6. Conecte la energía según la placa de datos con la fuente de

energía correcta en el espacio entre la carcasa de la cortina

de aire y el soporte de montaje. Utilice el alambre de tamaño

apropiado para todos los tramos de derivación y de suministro de energía.

Cable de la carcasa

Cable de suministro

existente en campo

Figura 5

7. Instale todos los cables, protección y conexiones a tierra, de

acuerdo con el Código Eléctrico Nacional (NEC) y todos los

requisitos.

8. Coloque nuevamente la rejilla delantera.

9. La unidad está lista por operación.

10.Confirme que la unidad está funcionando dentro de todas las

especificaciones eléctricas y de funcionamiento.

Lubricación

Los cojinetes tipo buje están lubricados de manera permanente

y no requieren lubricación adicional.

Limpieza

1. La carcasa de la cortina de aire puede limpiarse con un

trapo húmedo. No permita que el motor se moje. No utilice

solventes o detergentes agresivos.

NOTA: Mantenga limpias las persianas de entrada del aire y sin

acumulación de polvo que pudiera afectar el funcionamiento.

2. Revise dos veces por año las ruedas de aspas del ventilador

en cuanto a suciedad acumulada, y limpie.

7

Page 8

Todos los productos fabricados por Marley Engineered Products están garantizados contra defectos de fabricación y de materiales por 1 año desde la fecha de

instalación,

instalación.

nominal -indicada en la placa de características- en más de 5 %, ni a equipos que hayan sido instalados o cableados incorrectamente, o mantenidos en forma

que no cumpla lo indicado en las instrucciones de instalación del producto. Todo reclamo por trabajos en garantía debe acompañarse con una prueba de la fecha

de instalación.

El cliente será responsable de todos los costos incurridos en el retiro o reinstalación de productos, incluyendo los costos de mano de obra y los costos de envío

incurridos para regresar productos a un Centro de Servicio de Marley Engineered Products. Dentro de las limitaciones de esta garantía, las unidades que no

funcionan deben regresarse al centro de servicio autorizado Marley más cercano, o al Centro de Servicio de Marley Engineered Products, y nosotros lo

repararemos o reemplazaremos, a nuestra opción, sin cargo para usted, con el flete de retorno pagado por Marley. Se acuerda que tal reparación o reemplazo

es el único recurso que Marley Engineered Products pone a su disposición.

LAS GARANTÍAS EXPUESTAS MÁS ARRIBA TOMAN EL LUGAR DE TODA OTRA GARANTÍA, EXPRESA O IMPLÍCITA, Y POR LA PRESENTE SE

DECLINA Y EXCLUYE DE ESTE ACUERDO TODA GARANTÍA IMPLÍCITA DE COMERCIABILIDAD Y ADECUACIÓN A UN PROPÓSITO PARTICULAR QUE

EXCEDA LAS GARANTÍAS EXPRESAS ANTEDICHAS. MARLEY ENGINEERED PRODUCTS NO SE HARÁ RESPONSABLE POR DAÑOS CONSIGUIENTES

QUE SE PRODUZCAN CON RESPECTO AL PRODUCTO, EN BASE YA SEA A NEGLIGENCIA, AGRAVIO, RESPONSABILIDAD ESTRICTA, O CONTRATO.

Algunos estados o jurisdicciones no permiten la exclusión o limitación de daños incidentales o consiguientes, de modo que la exclusión o limitación expresada

más arriba puede no aplicarse a su caso. Esta garantía le da derechos legales específicos, y usted puede tener también otros derechos, que varían de un estado o jurisdicción a otro.

Para obtener la dirección de su centro de servicio autorizado más cercano comuníquese con Marley Engineered Products en Bennettsville, SC, Estados Unidos,

llamando al 1-800-642-4328. Toda mercadería regresada a la fábrica debe ser acompañada por una autorización de retorno y una etiqueta de identificación de

servicio, disponibles ambas en Marley Engineered Products. Cuando solicite la autorización de retorno, incluya todos los números de catálogo mostrados en los

productos.

CÓMO OBTENER SERVICIO EN GARANTÍA, PIEZAS DE

REPUESTO E INFORMACIÓN GENERAL

1. Servicio o repuestos en garantía 1-800-642-4328

2. Compra de repuestos 1-800-654-3545

3. Información general sobre productos www.marleymep.com

Nota: cuando solicite servicio, siempre dé la información que sigue:

1. Número de modelo del producto

2. Fecha de fabricación

3. Número de parte o descripción

excepto los elementos calefactores los cuales están garantizados contra defectos en manufactura y materiales durante cinco años a partir de la fecha de

Esta garantía no se aplica a daños debidos a accidente, mal uso o alteración, ni a los casos en que la tensión eléctrica conectada supere a la tensión

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

GARANTÍA LIMITADA

Número de parte 5200-2835-001

ECR39232

09/11

Page 9

Série LP

”

7

178 mm

Rideaux d’air à profil mince

éférez-vous aux spécifications

R

Dimension “A”, page 2

emarque – Toutes les dimensions sont les mêmes

R

our tous les rideaux d’air à profil mince. La référence

p

de modèle indique la largeur de l’appareil. (Par exemple

LP4800 indique un rideau de largeur 48”.)

7

8

/8”

223 mm

Instructions d’installation, d’utilisation et d’entretien

GÉNÉRALITÉS

Les rideaux d’air de Marley produisent un mur d’air continuellement en circulation qui agit comme une barrière thermique contre

l’effet de l’air ambiant extérieur et les insectes volants. Ces rideaux d’air conservent la température intérieure régulée et évitent que

l’air réchauffé ou refroidi ne s’échappe par les voies d’accès ouvertes. Ils réduisent l’humidité et la perte d’air froid en cas d’utilisation au-dessus des portes de congélateurs ou de réfrigérateurs. Les portes de zones à trafic intense peuvent être laissées

ouvertes, ce qui élimine l’usure et l’inconvénient des ouvertures et fermetures automatiques et manuelles de portes pour les

entrées de service, les accès, etc. Les rideaux d’air fournissent une protection contre les insectes, la poussière, les odeurs, les

fumées et d’autres contaminants.

AVERTISSEMENT

À lire attentivement - Ces instructions sont écrites pour vous aider

à surmonter les difficultés qui peuvent survenir pendant l’installation de

ces appareils. L’étude de ces instructions peut vous faire gagner un

temps considérable au départ et de l’argent ensuite. Observez les

procédures qui suivent, vous ramènerez la durée d’installation à un minimum.

ATTENTION – POUR RÉDUIRE LE RISQUE D’INCENDIE ET DE

COMMOTION ÉLECTRIQUE, RESPECTEZ CE QUI SUIT :

1. N’utilisez cet appareil que de la manière prévue par son constructeur. Si vous avez des questions, contactez le constructeur.

2. Avant d’intervenir pour du service ou du nettoyage sur l’appareil,

coupez son alimentation au tableau électrique en amont et verrouillez cette coupure pour éviter une remise sous tension accidentelle.

3. Le travail d’installation et le câblage électrique doivent être effectués par des personnes qualifiées, en conformité avec l'ensemble

des normes et réglementations applicables, y compris celles de

construction pour la résistance au feu.

4. Quand vous coupez ou percez dans des cloisons ou plafonds, n’endommagez pas de câblage électrique ou d’autres alimentations

cachées.

5. Assurez-vous que la source secteur est conforme aux besoins

électriques de l’appareil (vérifiez sur sa plaque signalétique).

Débranchez le secteur avant d’installer ou de dépanner. Verrouillez

la coupure du secteur et apposez une étiquette pour éviter une

remise sous tension inattendue. Si vous ne le faites pas vous

risquez une électrocution mortelle.

6. Tous le câblage doit être réalisé par un électricien qualifié, en utilisant des fils de cuivre, en conformité avec la norme électrique

américaine (NEC), toutes les législations et réglementations locales

applicables, et toutes les sections du présent manuel. Toute

déviance annulerait la garantie et pourrait causer des conditions

dangereuses.

7. Une attention particulière doit être apportée à toutes informations

de mise à la terre relatives à ce produit. Pour éviter le risque d’électrocution, l’appareil doit être bien relié à la terre dans les normes.

Cela doit être réalisé en branchant un conducteur relié à la terre

entre le panneau de service et la cosse de mise à la terre dans le

compartiment de câblage. Pour assurer que la mise à la terre est

correcte, la liaison doit être testée par un électricien qualifié.

8. N’insérez pas vos doigts ou des objets étrangers dans le rideau

d’air. Ne bloquez pas ou n’altérez pas d’une quelconque façon l’appareil en fonctionnement. Ne le touchez pas quand il est en marche

ou juste après sa coupure, certaines de ses parties peuvent être

assez chaudes pour causer des brûlures.

9. Ce produit ne doit PAS être utilisé dans des zones potentiellement

dangereuses, telles que celles contenant des produits inflammables, explosifs, des produits chimiques nocifs, ou dans des atmosphères fortement humides.

10. Pour réduire le risque de départ d’incendie ou de commotion électrique, n’utilisez pas ce rideau d’air branché sur un quelconque variateur de tension à semi-conducteurs.

!

CONSERVEZ CES INSTRUCTIONS

Page 10

Spécifications

° de Dimension FPM moyen CFM Total Courant

N

modèle. “A” à la buse à la buse en CV max. Tension

LP36001115 37,0 1800/1350 1295/971 1/15 1,3 A 120 V

LP42001110 42,0 1800/1350 1470/1103 1/10 1,6 A 120 V

LP48001108 48,0 1800/1350 1681/1260 1/8 2,1 A 120 V

LP60001108 60,0 1800/1350 2102/1576 1/8 2,1 A 120 V

LP36001208 37,0 1800/1350 1295/971 1/8 0,7 A 240 V

LP42001208 42,0 1800/1350 1470/1103 1/8 0,7 A 240 V

LP48001206 48,0 1800/1350 1681/1260 1/6 1,0 A 240 V

LP60001206 60,0 1800/1350 2102/1576 1/6 1,0 A 240 V

NE COMPTEZ PAS SUR SEULEMENT UN THERMOSTAT OU UN

AUTRE COMMUTATEUR COMME MOYEN UNIQUE DE COUPER

L’ALIMENTATION ÉLECTRIQUE DURANT L’INSTALLATION DE

L’APPAREIL OU UNE INTERVENTION DE SERVICE. COUPEZ TOUJOURS ET VERROUILLEZ LA COUPURE À L’INTERRUPTEUR

PRINCIPAL COMME C’EST DÉCRIT PLUS HAUT. SI VOUS NE LE

FAITES PAS VOUS RISQUEZ UNE ÉLECTROCUTION MORTELLE.

FOURNITURE D’AIR

Support de

montage

Trous de montage

(10 en tout)

Figure 1

2. Montez l’ensemble de coffret de rideau d’air en le suspendant

simplement sur son support de montage, en alignant les taquets

verticaux avec les fentes d’assemblage du coffret de rideau d’air

(Figure 2). Fixez le coffret de rideau d’air sur son support avec les

quatre (4) vis à tête Phillips.

CE PRODUIT NE DOIT PAS ÊTRE UTILISÉ DANS DES ZONES

POTENTIELLEMENT DANGEREUSES, TELLES QUE CELLES CONTENANT DES PRODUITS INFLAMMABLES, EXPLOSIFS, DES PRODUITS CHIMIQUES NOCIFS, OU DANS DES ATMOSPHÈRES

FORTEMENT HUMIDES.

POUR RÉDUIRE LE RISQUE DE DÉPART D’INCENDIE OU DE COMMOTION ÉLECTRIQUE, N’UTILISEZ PAS CE RIDEAU D’AIR

BRANCHÉ SUR UN QUELCONQUE VARIATEUR DE TENSION À

SEMI-CONDUCTEURS.

DÉBALLAGE

1. L’appareil emballé étant posé sur le plancher, les flèches sur son

carton doivent être dirigées vers le haut.

2. Enlevez soigneusement les agrafes du haut du carton et rabattez

ses côtés.

3. Sortez avec précautions le carter de l’appareil en le soulevant, puis

posez-le sur une surface de travail.

N’ESSAYEZ PAS DE SOULEVER CET APPAREIL À

RIDEAU D’AIR PAR SES VOLETS, VOUS POURRIEZ

L’ENDOMMAGER.

4. Ôtez les quatre (4) vis à tête Phillips qui tiennent le support de montage, et séparez l’appareil de ce support.

INSTALLATION

1. Déterminez l’emplacement de montage en utilisant le support de

montage de l’appareil, et fixez-le en place à l’aide de la visserie de

maintien appropriée (non incluse).

IMPORTANT: La visserie et la structure de support doivent pouvoir supporter une charge d’au moins 68 kg.

REMARQUE: Toute l’installation doit être réalisée pour être conforme

aux normes de construction locales.

Trous de vis (4)

Insérez le taquet du support de

montage dans la fente du bas de

l’appareil comme c’est indiqué

Figure 2

BRANCHEMENTS ÉLECTRIQUES

TOUS LES RIDEAUX D’AIR DOIVENT ÊTRE INSTALLÉS PAR DU

PERSONNEL QUALIFIÉ.

Branchement du cordon

1. Branchez l’alimentation sur du secteur de valeur correspondant aux

indications de la plaque signalétique.

2. Réalisez tout le câblage, la protection et la liaison à la terre en conformité avec la norme électrique américaine (NEC) et toutes les exigences applicables.

CET APPAREIL COMPORTE UNE PROTECTION THERMIQUE

INTERNE CONTRE LES SURCHARGES, À RESTAURATION

AUTOMATIQUE. COUPEZ TOUJOURS L’ALIMENTATION SECTEUR

AVANT D’INTERVENIR SUR L’APPAREIL.

3. L’appareil est prêt à fonctionner.

4. Confirmez que l’appareil fonctionne bien selon les spécifications

électriques et de performance.

REMARQUE: L’appareil à rideau d’air comporte un commutateur de

sélection rapide/lent qui est câblé en usine.

10

Page 11

ASSUREZ-VOUS QUE L’AMPÉRAGE NOMINAL DE TOUT INTERRUPTEUR M/A DÉPASSE LES VALEURS DE COURANT DE

MOTEUR SPÉCIFIÉES SUR LA PLAQUE SIGNALÉTIQUE.

Branchement fixe

Branchement fixe: L’appareil est câblé en usine pour une alimentation

par cordon, mais il peut être relié en fixe au secteur sur place.

1. Enlevez l'ouverture à enfoncer à l’arrière du coffret de l’appareil (Voir

la Figure 3).

Ouverture

à enfoncer

Figure 3

FONCTIONNEMENT

1. Une fois que l’alimentation secteur a été branchée, les ventilateurs

vont commencer à tourner à la vitesse sélectionnée antérieurement

(rapide/lent).

2. La vitesse d’écoulement d’air est contrôlée par le choix de vitesse

lente ou rapide. Cela permet d’adapter la vitesse de l’air à la performance individuelle ou aux économies d’énergie souhaitées.

3. La direction de l’air en sortie peut être contrôlée par des lames

réglables à la buse, qui compensent des conditions possibles de

dérive.

IMPORTANT: Dans des applications pour congélateur, l’appareil est

toujours monté à l’extérieur (côté chaud) du congélateur ou réfrigérateur.

REMARQUE: L’air froid a tendance à s’échapper en restant près du

niveau du plancher. De l’air chaud essayera de pénétrer le rideau près

du haut de l’accès. Le flux d’air peut être contrôlé par l’orientation des

volets de la buse et le réglage rapide/lent.

REMARQUE: Pour un fonctionnement optimal, l’espace intérieur doit

avoir une pression égale à celle de l’espace extérieur.

ENTRETIEN

2. Ôtez la grille d’entrée frontale de l’appareil.

3. Coupez la fiche de l’extrémité du cordon d’alimentation, et enlevez la

bague de serrage.

Bague de serrage

Cordon

Figure 4

4. Faites rentrer l’extrémité coupée du cordon dans le coffret de l’appareil et ressortez-la par le trou enfoncé à l’arrière. Remettez en

place la bague de serrage.

5. Faites passer le câble d’alimentation fixe au milieu du support de

montage.

6. Branchez le câble sur du secteur de valeur correspondant aux spécifications de la plaque signalétique entre le coffret et le support de

montage. Utilisez du câble de calibre adéquat pour amener le

secteur.

POUR RÉDUIRE LE RISQUE DE COMMOTION ÉLECTRIQUE,

COUPEZ TOUJOURS L’ALIMENTATION SECTEUR ET

VERROUILLEZ LA COUPURE AVANT TOUTE INTERVENTION

SUR L’APPAREIL.

Lubrification

Les paliers à coussinets sont lubrifiés à vie et ne nécessitent pas d’intervention supplémentaire.

Nettoyage

1. Le coffret de rideau d’air peut être frotté avec un chiffon humide. Ne

permettez pas que le moteur soit mouillé. N’utilisez ni solvants ni

détergents puissants.

REMARQUE: Maintenez les volets d’admission d’air exempts de

toute accumulation de poussière ou de saleté qui pourrait affecter

la performance.

2. Vérifiez les rotors de soufflantes pour les nettoyer de la saleté

accumulée deux fois par an.

Câblage du

coffret

Câblage du

secteur local

Figure 5

7. Réalisez tout le câblage, la protection et la liaison à la terre en conformité avec la norme électrique américaine (NEC) et toutes les exigences applicables.

8. Remettez la grille frontale en place.

9. L’appareil est prêt à fonctionner.

10. Confirmez que l’appareil fonctionne bien selon les spécifications

électriques et de performance.

11

Page 12

Tous les produits fabriqués par Marley Engineered Products sont garantis contre des défauts dus à la main d’œuvre et aux matériaux pendant un an à partir de la date

GARANTIE LIMITÉE

d’installation, saufs les éléments de chauffe qui sont garantis de la même façon pendant cinq ans. Cette garantie ne s’applique pas pour des dommages résultant d’accident, de mésusage ou d’altération ; ni si la tension secteur envoyée fait 5 % ou plus au-dessus de la tension nominale de la plaque signalétique ; ni sur l’équipement

est incorrectement installé ou câble, en violation avec les instructions d’installation. Toutes les demandes d’exercice de la garantie devront être accompagnées de la

preuve de date d’installation.

Le client doit être responsable de tous les coûts occasionnés pour le démontage ou la réinstallation des produits, incluant les coûts de main-d’œuvre, et les coûts d’expédition pour renvoyer les produits au centre de service de Marley Engineered Products. Dans le cadre des limitations de cette garantie, les unités ne fonctionnant pas

doivent être renvoyées au centre de service agréé Marley le plus proche, ou directe au centre de service de Marley Engineered Products, où ils seront réparés ou remplacés, à notre choix, sans frais pour vous avec le port de retour payé par Marley. Il est convenu que cette réparation ou ce remplacement sera le seul remède à attendre de Marley Engineered Products.

LES GARANTIES QUI PRÉCÈDENT TIENNENT LIEU DE TOUTES LES AUTRES GARANTIES, EXPLICITES OU IMPLICITES, ET TOUTES LES GARANTIES

IMPLICITES DE VALEUR MARCHANDE ET D’ADÉQUATION POUR UNE FINALITÉ SPÉCIFIQUE QUI EXCÉDERAIENT LES DISPOSITIONS DE GARANTIE

PRÉCÉDEMMENT ÉNONCÉES SONT ICI REJETÉES ET EXCLUES DE CET ACCORD. MARLEY ENGINEERED PRODUCTS NE SERA PAS TENU POUR RESPONSABLE DES DOMMAGES CONSÉCUTIFS SURVENANT EN RELATION AVEC LE PRODUIT, QU’ILS SOIENT À BASE DE NÉGLIGENCE, TORT, RESPONSABILITÉ

PURE OU CONTRACTUELLE.

Certaines provinces ne permettent pas l’exclusion ou la limitation des dommages consécutifs ou annexes, de ce fait l’exclusion ou la limitation qui précède peut ne pas

s’appliquer à votre cas. Cette garantie vous donne des droits légaux spécifiques, qui varient d’une province à l’autre.

Pour obtenir l’adresse de votre centre de service agréé le plus proche, contactez Marley Engineered Products à Bennettsville, SC, USA, au 1-800-642-4328. Toute

marchandise retournée à l’usine doit être accompagnée d’une autorisation de renvoi et d’une étiquette d’identification pour le service, ces deux documents étant

disponibles auprès de Marley Engineered Products. En demandant une autorisation de retour, fournissez tous les numéros de catalogue indiqués sur les produits.

COMMENT OBTENIR DU SERVICE ET DES PIÈCES DANS LE

CADRE DE LA GARANTIE ET DES INFORMATIONS GÉNÉRALES

1. Service et pièces sous garantie 1-800-642-4328

2. Pièces détachées à acheter 1-800-654-3545

3. Informations générales sur les produits www.marleymep.com

Remarque : Pour obtenir le service sous garantie vous devez toujours

avoir préparé :

1. Référence de modèle du produit

2. Date de fabrication

3. Numéro ou description de pièce

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

N° de document 5200-2835-001

ECR39232

09/11

Loading...

Loading...