Page 1

“K” Series

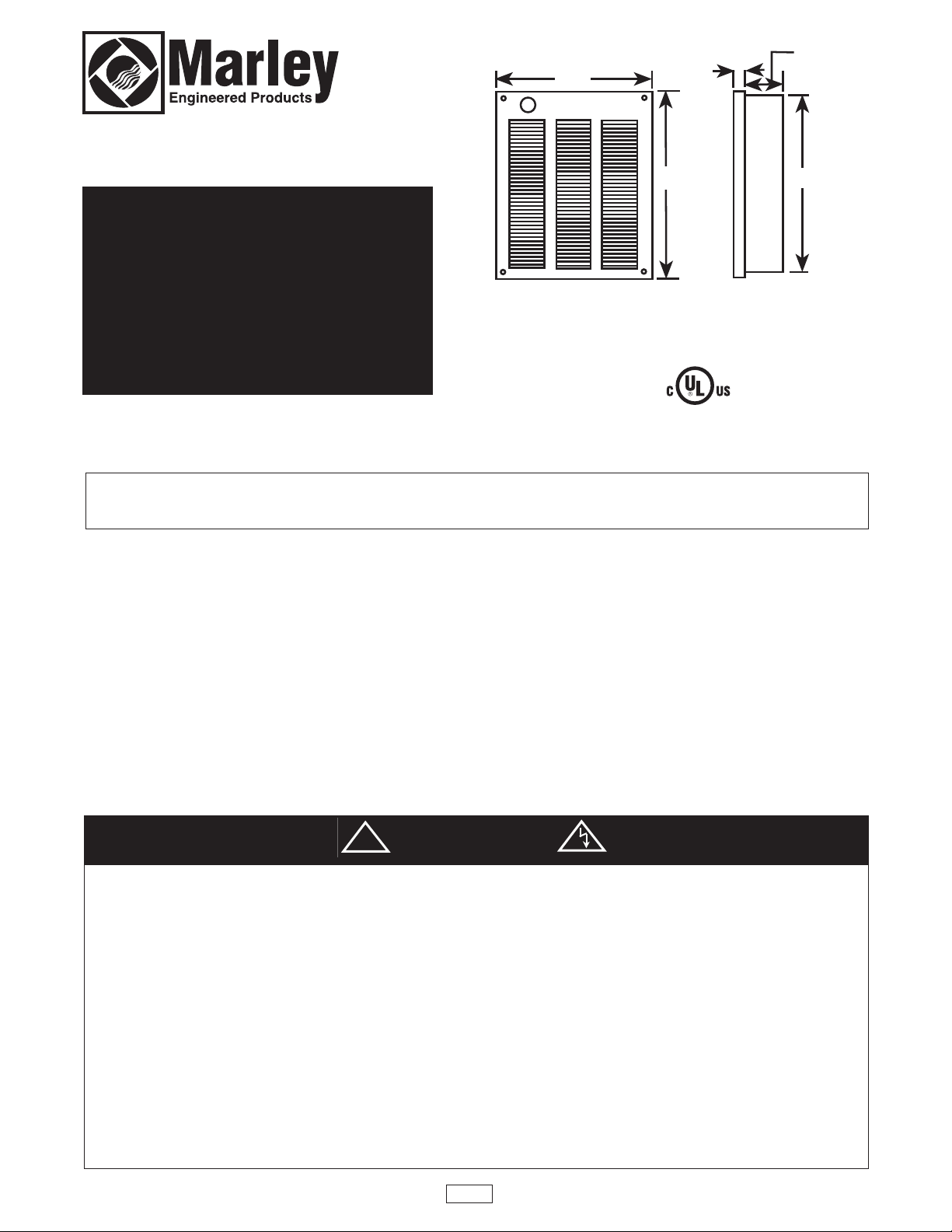

!

(

400mm)

15-3/4"

(485mm)

19-1/8"

(35mm)

1

-3/8"

(95mm)

3

-3/4"

(463mm)

18-1/4"

(Model A)

Fan Forced

Wall Heaters

FILE #E21609

Installation & Maintenance Instructions

Dear Owner,

Congratulations! Thank you for purchasing this new heater manufactured by Marley Engineered

Products. You have made a wise investment selecting the highest quality product in the heating industry. Please carefully read the installation and maintenance directions shown in this manual. You should

enjoy years of efficient heating comfort with this product from Marley Engineered Products... the industry’s leader in design, manufacturing, quality and service.

WARNING

Read Carefully - These instructions are written to help you

prevent difficulties that might arise during installation of

heaters. Studying the instructions first may save you considerable time and money later. Observe the following procedures and cut your installation time to a minimum.

To reduce risk of fire or electric shock:

1. To prevent electrical shock, disconnect all power coming

to heater at main service panel before wiring or servicing.

2. All wiring must be in accordance with the National and

Local Electrical Codes and the heater must be grounded

as a precaution against possible electric shock.

3. Verify the power supply voltage coming to heater matches the ratings printed on the heater nameplate before

energizing.

4. This heater is hot when in use. To avoid burns, do not let

bare skin touch hot surfaces.

SAVE THESE INSTRUCTIONS

... The Employees of

Marley Engineered Products

5. Do not insert or allow foreign objects to enter any ventilation or exhaust opening as this may cause an electric

shock, fire, or damage to the heater.

6. To prevent a possible fire, do not block air intakes or

exhaust in any manner. Keep combustible materials, such

as crates, drapes, etc., away from heater. Do not install

behind doors, furniture, towels, or boxes.

7. A heater has hot and arcing (sparking) parts inside. Do

not use it in areas where gasoline, paint, or flammable

liquids are used or stored.

8. Use this heater only as described in this manual. Any

other use not recommended by the manufacturer may

cause fire, electric shock, or injury to persons.

9. This heater is not approved for use in corrosive atmospheres such as marine, green house, or chemical storage

areas.

1

Page 2

IMPORTANT

!!!

IN. 36” (915mm)

M

o ceiling

t

WARNING

DO NOT INSTALL HEATER UPSIDE DOWN OR SIDE-

AYS.

W

DO NOT USE HEATER WITHOUT GRILLE.

CAUTION

FOR WALL MOUNTING ONLY. DO NOT INSTALL HEATER

CLOSER THAN 8" (203 mm) TO THE FLOOR OR ANY

ADJACENT WALL SURFACE. DO NOT INSTALL CLOSER

THAN 36" (915 mm) TO THE CEILING.

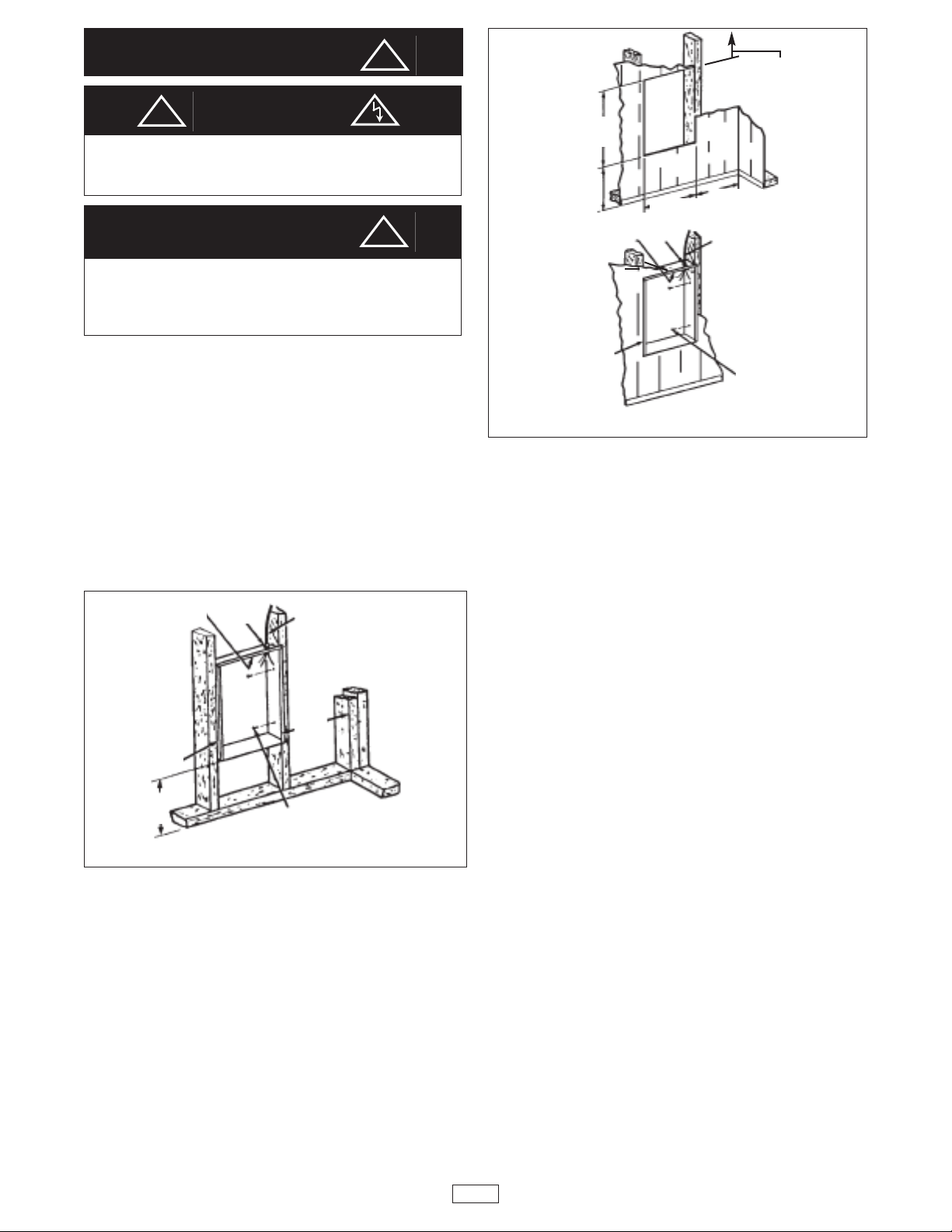

Installation of Recessed Back Box

1. Mounting Back Box (See Figure 1).

a. Place the back box between two 16" (406mm)

center-to-center wall studs at the desired mounting

height but no closer than 8" (203mm) to adjacent wall

or floor.

Note: If wall studs are spaced greater than 16” on center,

additional framing supports may be necessary.

b. Align back box such that the bottom and sides will be

flush with finished wall surface (top flange of back box

should protrude approximately 1/2" (13mm) from fin-

ished wall surface).

c. Secure the back box in position with wood screws or

nails as shown in Figure 1.

GROUND

SCREW

BACK BOX

in New Construction

CABLE

CLAMP

POWER SUPPLY CABLE

8” MIN.

(203mm)

18-1/2” MIN.

470mm)

(

8” MIN.

203mm)

(

CABLE CLAMP

ROUND SCREW

G

BACK BOX

4-1/2” MIN.

1

(362mm)

” MIN.

8

(203mm)

OWER SUPPLY CABLE

P

NAIL OR SCREW

2 EACH SIDE)

(

Fig. 2: Locating Recessed Back Box in Existing Construction

Installation of Recessed

Back box in Exisiting Construction

1. Provide a wall opening 14-1/2" (362mm)wide x 18-1/2"

(470mm) high at the desired mounting height, but no

closer than 8" (203mm) to any adjacent wall or floor and

36” (915mm) to ceiling. (See Figure 2.)

NOTE: Locate so at least one side of the opening is at stud.

2. Power Supply Wiring

NOTE: (Wiring Compartment Volume - 119in3(1950cm3).

a. Run a power supply cable into the area above the top

of the wall opening.

b. Install a cable clamp in the knockout in the top of

back box.

c. Insert power supply cable through cable clamp, allow-

ing at least 6" (152mm) of cable length to remain

inside the back box to facilitate connections.

d. Ground the back box by connecting the supply ground

leadwire to the green ground screw located in the

inside top of the back box.

8” MIN.

(203mm)

NAIL OR SCREW

(2 EACH SIDE)

Fig. 1: Locating Recessed Back Box in New Construction

3. Mounting Back Box

a. Place the back box into wall opening flush with fin-

ished wall surface on bottom and sides of box. (Top

flange of back box should protrude approximately 1/2"

(13mm) from finished wall surface).

b. Secure the back box in place with wood screws or nails.

2. Power Supply Wiring (See Figure 1).

NOTE: Wire Compartment Volume - 119in3(1950cm3).

a. Run a power supply cable into the knockout area in

the upper right hand corner of the back box. Refer to

NOTE: For correct wire sizing, please refer to the

National Electrical Code, Section 310. Only use copper

wire rated at least 75° C Do not use alluminum wire with

this unit.

Figure 1.

b. Install a cable clamp in the “knockout” in the top of

the back box.

c. Insert power supply cable through cable clamp, allow-

ing at least 6" (152mm) of leads to extend inside the

back box.

d. Ground the back box by connecting the supply ground

leadwire to the green ground screw located in the

inside top of the back box.

2

Page 3

3-13/16"

!

(97mm)

OWER

P

LEADS

HERMOSTAT

T

MOUNT BACK BOX TO

WALL USING REAR

OUNTING HOLES.

M

HANG FRAME

N BACK BOX

O

5-5/32"

1

385mm)

(

19"

(482mm)

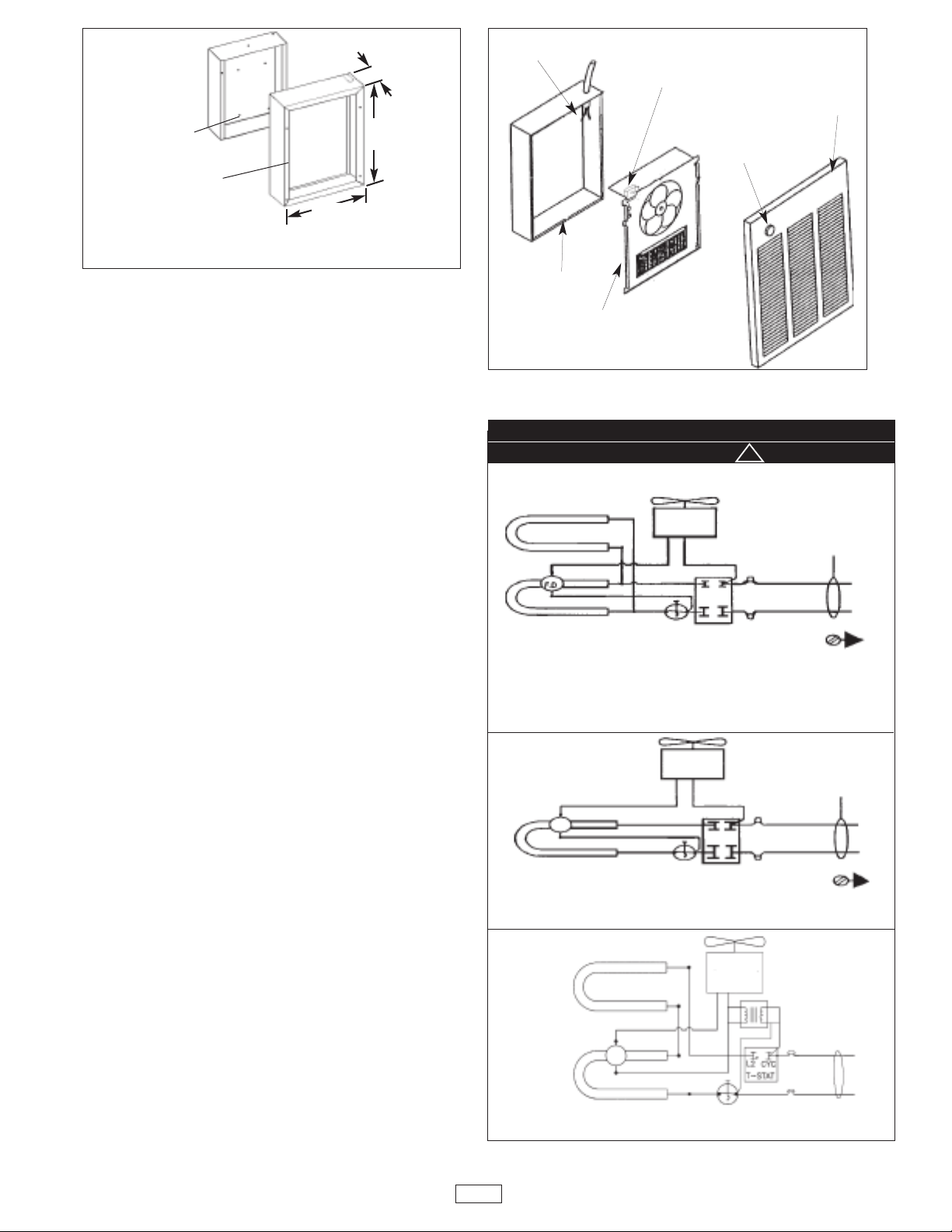

Fig. 3: Surface Mounting Installation

Installation of Back Box With Optional

Surface-Mounting Frame (See Figure 3).

1. Secure back box to wall (with knockouts in upper right

hand corner) using screws and anchors.

2. Hang the surface-mounting frame on the back box.

Ensure that the back edge of the surface-mounting

frame is flush against the wall.

NOTE: If heater is located in a high traffic area where it may

be subjected to vandalism or abuse, take extreme care to see

that the back box is firmly attached to the wall.

3. Power Supply Wiring

NOTE: Wiring Compartment Volume - 119in3(1950cm3).

a. Run a power supply cable into the area of the upper

right corner of the mounting frame.

GRILLE

NOB

K

RECESS BACK

OX

B

HEATER

SSEMBLY

A

Fig. 4

WIRING DIAGRAMS (SINGLE PHASE)

CAUTION

To assure proper operation of fan, thermostat must not cycle fan

on and off. Follow wiring diagram exactly.

an Motor

Red

F

Field

Wiring

Element

NOTE: If the wiring is to run through the wall, cut a hole in the

area of the top of the back box. Run the supply wire through

this hole. Then remove the knockout from the top of the box

and proceed to step c.

b. Remove the knockout on the top side of the frame.

c. Feed the power supply cable through the frame allow-

ing 6" (152mm) of lead to remain inside the frame

d. Secure the power supply cable to the back box

(using cable clamps, connector, or other suitable strain

relief) allowing 6”(152mm) of lead to remain inside the

back box.

e. Ground the back box by connecting the supply ground

leadwire to the green ground screw located in the

inside top of the back box.

Installation of Heater Assembly and Grille

After back box is competely installed and no further construction dirt is expected, clean debris from back box, remove

heater assembly from its carton, then refer to Figure 4 and

proceed as follows:

1. Insert the heater assembly into back box, placing

the four mounting holes (with key-hole slots) over the

screws in the back box. Tighten all screws securely.

2. If surface-mounting frame is used, ensure that the

frame is even with all four heater assembly tabs before

tightening screws.

3. Connect the power lead wires (field wiring) to the lead

wires from the heater assembly. See wiring diagram

in next column.

4. Turn thermostat to the extreme counterclockwise

position.

5. Mount the grille using four (4) long screws provided.

The screws thread into holes located in the side

flanges of the back box.

6. Push thermostat knob onto thermostat shaft.

TʼStat

Element

Manual

Reset

Limit

GND

1500, 4800, 4000, & 3000 WATT HEATERS

120V, 208V, 240V, OR 277V (Full wattage heaters can be converted to half

wattage

by removing the red jumper wire connecting the top and bottom element terminals.)

NOTE: Conversion not applicable on K151.

F.D.

Element

Manual

Reset

Limit

Fan Motor

TʼStat

GND

Field

Wiring

2000 & 1500 WATT HEATERS

208V, 240V, OR 277V

Fan Motor

Element

F.D.

Element

4800, 4000, & 3000 WATT HEATERS

347V, 600V

Manual

Reset

Limit

3

Page 4

peration

!

!

O

1. Turn power to heater on at main switch panel. Rotate the

thermostat knob fully clockwise. This should energize the

heating elements and the fan, causing air to flow from the

air discharge at the openings in the bottom of the grille.

2. After the discharge air has become warm, rotate the

thermostat knob to the desired postion to obtain room

comfort.

NOTE: For best results, the heater should be left ON con-

tantly during the heating season since the thermostat, when

s

properly set, will maintain the desired temperature.

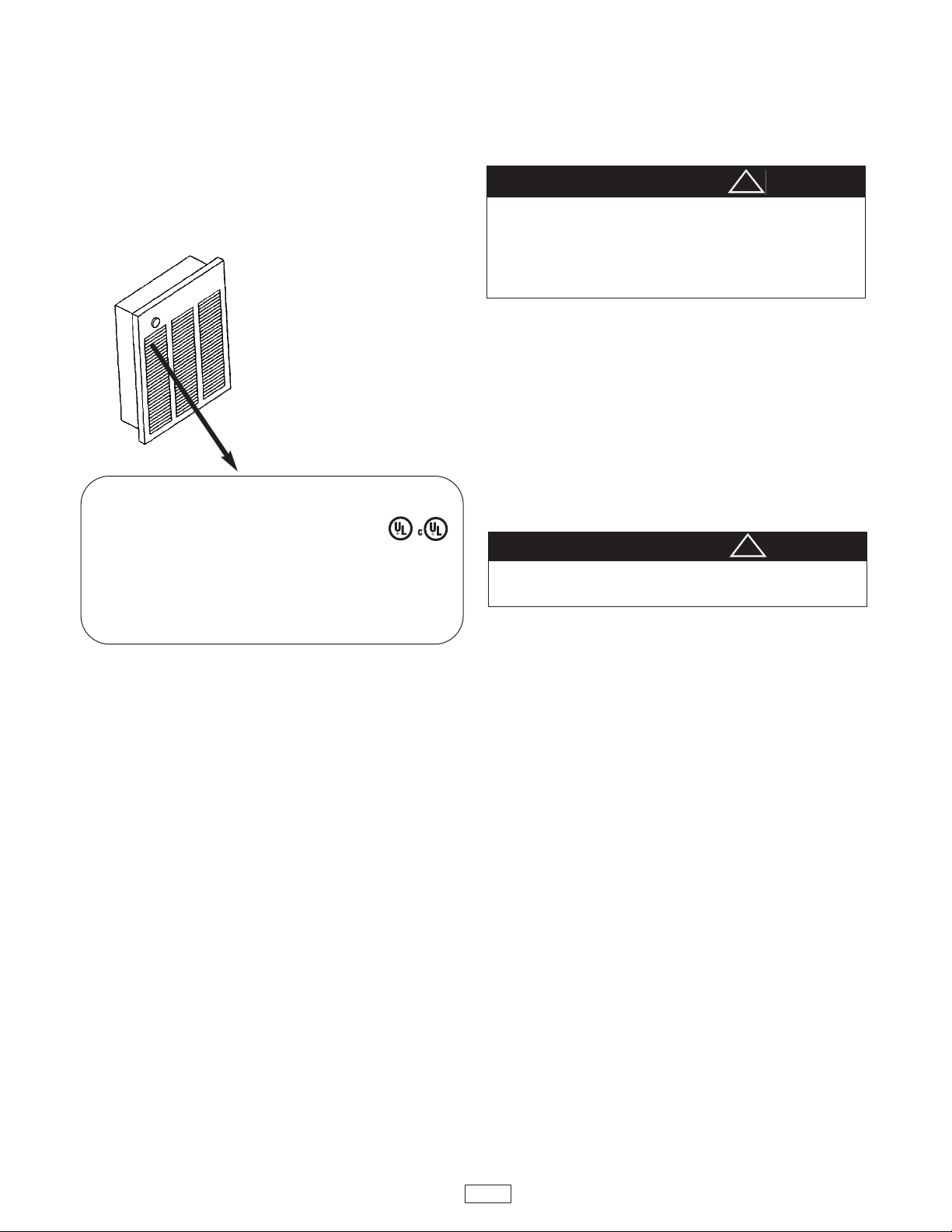

IMPORTANT INFORMATION

MODEL NO. K404A DATE CODE: 0595

AN FORCED WALL HEATER

F

APPAREIL DE CHAUFFAGE MURAL À AIR PLUSÉ

VOLTS AC 60HZ WATTS PHASE

240/208 4000/3000 1

MUST BE USED WITH BACK BOX

DO NOT OPERATE WITHOUT FRONT COVER IN

PLACE.

DOIT ÉTRE UTILISÉ AVEC BOÎTIER ARRIÈRE AWH-BB

NE PAS UTILISER SI LE COUVERCLE AVANT NʼEST PAS EN PLACE.

MARLEY ENGINEERED PRODUCTS

BENNETTSVILLE, SC 29512 4104-2093-028

EXAMPLE

774G LISTED

ROOM HEATER

aintenance

M

TO RESET MANUAL RESET LIMIT

Your heater is equipped with a manual reset safety thermal

limit control that will automatically turn the heater off to prevent a fire if the heater overheats. This control is located on

the fan panel assembly between the element and fan blade

and marked “reset”. The red reset button can be seen

through the front grille when the heater is installed. To reset,

CAUTION

OPERATION OF THE MANUALRESET SAFETY THERMAL LIMIT

CONTROL IS AN INDICATION THAT THE HEATER HAS BEEN

SUBJECTED TO SOME ABNORMAL CONDITION. IT IS RECOMMENDED THAT THE HEATER BE CHECKED BY A REPUTABLE

ELECTRICIAN OR REPAIR SERVICE TO ENSURE THE HEATER

HAS NOT BEEN DAMAGED.

llow the heater to cool, then push the red button that is vis-

a

ible through the hole in the fan panel. The heater should

immediately return to normal operation.

The heater should be cleaned annually to remove dust and

other foreign material which has collected during the heating

season. This is a simple operation when performed as follows:

1. Turn off the electric power at main line switch (or

remove all fuses) to disconnect electric power from the

heater. THIS IS IMPORTANT.

2. Remove the grille (Fig. 4).

3. With a vacuum cleaner nozzle or dust cloth, remove

dust and other foreign material.

4. After cleaning reinstall the grille.

CAUTION

DO NOT USE WATER OR DAMP CLOTH FOR CLEANING

AND DO NOT DISTURB THE HEATING ELEMENT.

5. Turn on the main line switch (or replace fuses) to

restore power to the heater. The heater is now ready

for another season of operation.

4

Page 5

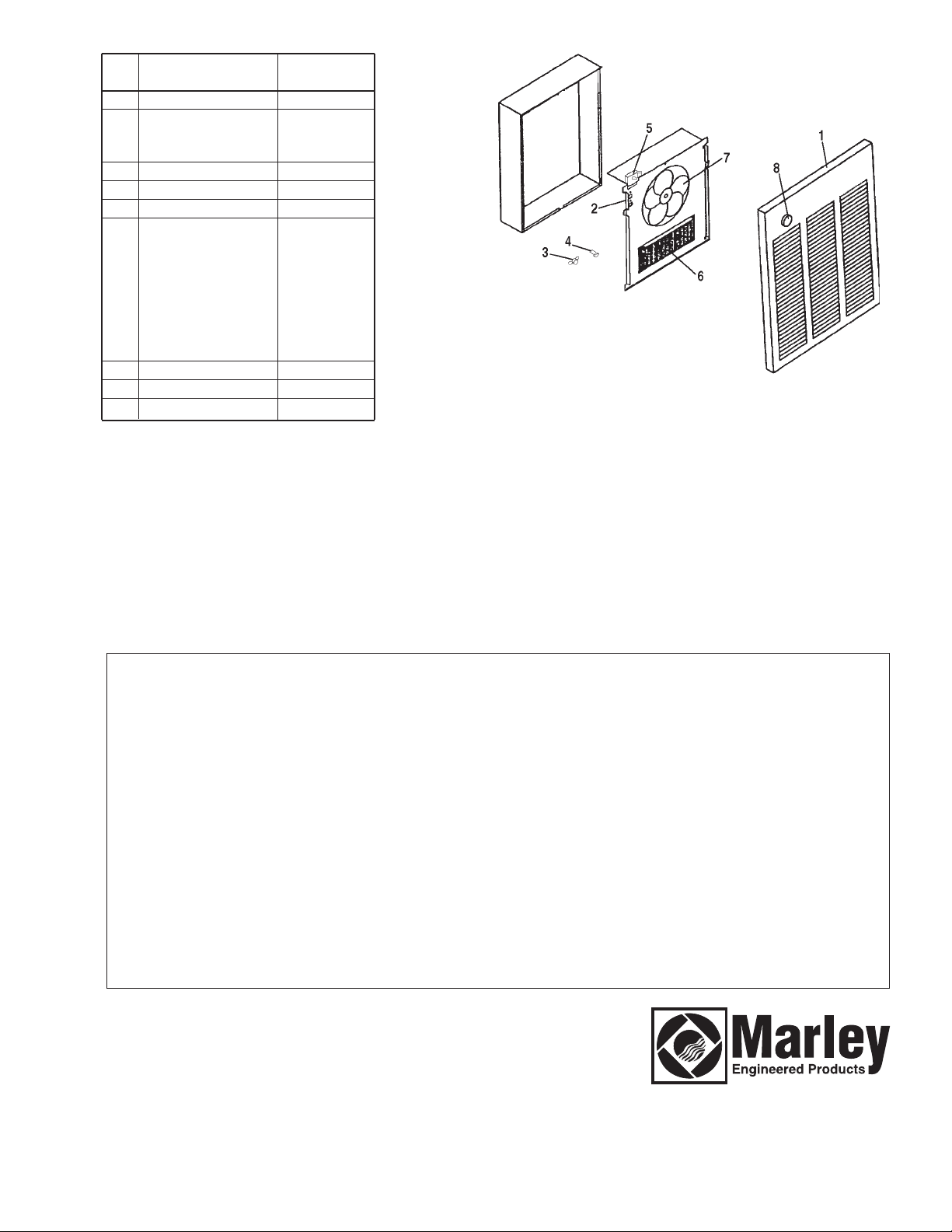

eplacement Parts

R

Key

o. Description

N

Part Number

1 Front Cover 1402-2239-000

2 Motor: 208V 3900-2010-000

240V 3900-2010-000

120V 3900-2010-003

3 Manual Limit 4520-2013-000

4 Fan Delay 410074000

5 Thermostat 5813-2027-000

6 Element: 208V/2000W 302015001

240V/2000W 302015002

277V/2000W 302015003

277V/3000W 302012006

208V/4000W 302012007

40V/4000W 302012008

2

240V/3000W 302012009

240V/4800W 302012010

277V/4800W 302012011

120V/1500W 302012827

7 Fan Blade 490030103

8 Parts Bag 1205-2070-001

All products manufactured by Marley Engineered Products are warranted against defects in workmanship and materials for one year from date of

LIMITED WARRANTY

installation, except heating elements which are warranted against defects in workmanship and materials for five years from date of installation. This

warranty does not apply to damage from accident, misuse, or alteration; nor where the connected voltage is more than 5% above the nameplate voltage; nor to equipment improperly installed or wired or maintained in violation of the productʼs installation instructions. All claims for warranty work must

be accompanied by proof of the date of installation.

The customer shall be responsible for all costs incurred in the removal or reinstallation of products, including labor costs, and shipping costs incurred

to return products to Marley Engineered Products Service Center. Within the limitations of this warranty, inoperative units should be returned to the

nearest Marley authorized service center or the Marley Engineered Products Center, and we will repair or replace, at our option, at no charge to you

with return freight paid by Marley. It is agreed that such repair or replacement is the exclusive remedy available from Marley Engineered Products.

THE ABOVE WARRANTIES ARE IN LIEU OF ALL OTHER WARRANTIES EXPRESSED OR IMPLIED. AND ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE WHICH EXCEED THE AFORESAID EXPRESSED WARRANTIES ARE HEREBY

DISCLAIMED AND EXCLUDED FROM THIS AGREEMENT. MARLEY ENGINEERED PRODUCTS SHALL NOT BE LIABLE FOR CONSEQUENTIAL

DAMAGES ARISING WITH RESPECT TO THE PRODUCT, WHETHER BASED UPON NEGLIGENCE, TORT, STRICT LIABILITY, OR CONTRACT.

Some states do allow the exclusion or limitation of incidental or consequential damages, so the above exclusion or limitation may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

For the address of your nearest authorized service center, contact Marley Engineered Products in Bennettsville, SC, at 1-800-642-4328. Merchandise

returned to the factory must be accompanied by a return authorization and service identification tag, both available from Marley Engineered Products.

When requesting return authorization, include all catalog numbers shown on the products.

HOW TO OBTAIN WARRANTY SERVICE AND

WARRANTY PARTS PLUS GENERAL INFORMATION

1. Warranty Service or Parts 1-800-642-4328

2. Purchase Replacement Parts 1-800-654-3545

3. General Product Information www.marleymep.com

Note: When obtaining service always have the following:

1. Model number of the product

2. Date of manufacture

3. Part number or description

Part No. 5200-2267-007

ECR 38696

04/10

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

Page 6

Calentador de

(

400mm)

1

5-3/4"

(485mm)

19-1/8"

(35mm)

1-3/8"

(95mm)

3-3/4"

(463mm)

18-1/4"

Pared de Tiro

Forzado

de Serie “K”

Modelo A

EXPEDIENTE NO E21609

Instrucciones de Instalación y Mantenimiento

Estimado propietario:

¡Felicitaciones! Gracias por comprar este nuevo calentador fabricado por una división de Marley Engineered

Products. Usted ha efectuado una sabia inversión al seleccionar el producto de la más alta calidad en la

industria de calefacción. Por favor lea cuidadosamente las instrucciones de instalación y mantenimiento

indicadas en este manual. Usted debería gozar de años de calefacción eficiente con este producto de Marley

Engineered Products...el líder de la industria en diseño, fabricación, calidad y servicio.

!

ADVERTENCIA

Lea cuidadosamente - Estas instrucciones están escritas para ayudarle a

prevenir dificultades que podrían surgir durante la instalación de los calentadores. El estudiar primero las instrucciones puede ahorrarle un tiempo considerable y dinero después. Observe los procedimientos siguientes, y reduzca a un mínimo su tiempo de instalación.

Para reducir el riesgo de chogue eléctrico:

1. Antes de cablear o prestar servicio y para prevenir el choque eléctrico,

desconecte la potencia entrante al calentador por el panel principal de

servicio.

2. Todo el cableado debe conformar con los códigos eléctricos nacionales

y locales y el calentador debe estar conectado a tierra como precaución contra un choque eléctrico posible.

3. Antes de activar, verifique que el voltaje del suministro de potencia

entrante al calentador corresponda a las clasificaciones principales

impresas en la placa de nombre.

4. Este calentador está caliente durante el uso. Para evitar quemaduras,

no permita que la piel expuesta toque las superficies calientes.

GUARDE ESTA INSTRUCCIONES

… Los empleados de

Marley Engineered Products

5. No inserte ni permita que objetos extraños entren a ninguna apertura

de ventilación o escape ya que esto puede causar un choque eléctrico,

incendio o daños al calentador.

6. No bloquee de ninguna manera las tomas de aire o los escapes, para

prevenir un posible incendio. Mantenga los materiales combustibles,

tales como cajas de madera, cortinas, etc, alejados del calentador. No

instale detrás de puertas, muebles, tohalleros, o cajas.

7. Un calentador tiene adentro piezas calientes y productoras de arcos

eléctricos o de chispas. No use en áreas donde estén almacenados

gasolina, pintura o líquidos inflamables.

8. Use este calentador sólo de la manera descrita en este manual.

Cualquier otro uso no recomendado por el fabricante puede causar

incendio, choque eléctrico, o lesiones a las personas.

9. Este calentador no está aprobado para usar en atmósferas corrosivas

tales como de mar, invernaderos o áreas de almacenamiento de productos químicos.

1

Page 7

IMPORTANTE

!

ADVERTENCIA

NO INSTALE EL CALENTADOR INVERTIDO O DE COSTADO.

NO USE EL CALENTADOR SIN LA REJILLA.

PRECAUCION

PARA MONTAJE DE PARED SOLAMENTE. NO INSTALE EL

CALENTADOR MAS CERCA QUE 8” (203 mm) DEL PISO O DE

CUALQUIER SUPERFICIE ADYACENTE A LA PARED. NO

INSTALE MAS CERCA QUE 36” (915mm) DEL TEHCO.

!

!

Instalación de la caja posterior empotrada

en nueva construcción

1. Montaje de la caja posterior (Vea la Figura 1).

a. Coloque la caja posterior entre dos pernos prisioneros de

pared a 16” (406 MM) entre centros a la altura deseada de

montaje pero no más cercanos que 8” (203mm) a la pared

adyacente o al piso.

Nota: Si los travesaños de la pared están espaciados a más de

406 mm (16”) entre centros, puede que se necesiten soportes de

armazón adicionales.

b. Alinee la caja posterior de tal manera que el fondo y los

lados estarán al ras con la superficie acabada de la pared

(la brida superior de la caja posterior debe sobresalir 1/2”

aproximadamente (13mm) de la superficie acabada de la

pared).

c. Asegure la caja posterior en posición con tornillos o clavos

de madera según se muestra en la Figura 1.

TORNILLO DE

CONEXION A

TIERRA

SUJETADOR

DE

CABLE

CABLE DE SUMINISTRO

DE POTENCIA

CUALQUIER PARED

ADYACENTE Ó 36”

(915MM) AL CIELORASO

18-1/2” MIN.

470mm)

(

8” MIN.

203mm)

(

SUJETADOR DE CABLE

TORNILLO DE

CONEXION A TIERRA

CAJA

POSTERIOR

Fig.2: Ubicación de la caja empotrada posterior en construcción existente

2. Cableado de suministro de potencia

NOTA: Volumen del compartimiento de conductores - 119

pulg.3 (1950 cm3).

a. Tienda un cable de suministro de potencia dentro del área

sobre el tope de la abertura de la pared.

b. Instale un sujetador de cable en el orificio ciego en el tope

de la caja posterior.

c. Inserte el cable de suministro de potencia a través del suje-

tador del cable, permitiendo por lo menos 6” (152mm) de

guías permaneciendo dentro de la caja posterior para facilitar las conexiones.

d. Conecte a tierra la caja posterior conectando el conductor

guíade suministro a tierra al tornillo verde de conexión a tierra ubicado en el tope interior de la caja posterior.

4-1/2” MIN.

1

(362mm)

” MIN.

8

(203mm)

CABLE DE

SUMINISTRO DE

POTENCIA

CLAVO O TORNILLO

(2 DE CADA LADO)

8” MIN.

(203mm)

CAJA

POSTERIOR

8” MIN.

(203 mm)

Fig.1: Ubicación de la caja empotrada posterior en nueva construcción

2. Cableado de suministro de potencia (Vea la Figura 1)

NOTA: Volumen del compartimiento de conductores - 119pulg.3

(1950cm3).

a. Tienda un cable de suministro de potencia dentro del área

del orificio ciego en la esquina superior derecha de la caja

posterior.

b. Instale un sujetador de cable en el “orificio ciego” en el tope

de la caja posterior.

c. Inserte el cable de suministro de potencia a través del suje-

tador del cable, permitiendo que por lo menos 6” (152mm)

de guías se extendiendan dentro de la caja posterior.

d. Conecte a tierra la caja posterior conectando el conductor

guía de suministro a tierra al tornillo verde de conexión a

tierra ubicado en el tope interior de la caja posterior.

CLAVO O TORNILLO

(2 DE CADA LADO)

Instalación de la caja empotrada

posterior en construcción existente

1. Provea una abertura de pared de 14-1/2” (362mm) de ancho

por 18-1/2” (470mm) de alto a la altura deseada de montaje,

pero no más cerca que 8” (203mm) a cualquier pared adya-

cente ó piso y 36” (915mm) al cieloraso. (Vea la Figura 2)

Nota: Elija la ubicación de modo que al menos un lado de la abertura coincida con un travesaño de la pared.

3. Montaje de la caja posterior

a. Coloque la caja posterior dentro de la abertura de pared al

ras con la superficie acabada de pared y con los lados de la

caja. (La brida superior de la caja posterior debe sobresalir

1/2”(13mm) aproximadamente desde la superficie acabada

de la pared).

b. Asegure la caja posterior en su lugar con tornillos o clavos

para madera.

NOTA: Para el apresto correcto del alambre, refiera por favor al

código eléctrico nacional, sección 310. Solamente el uso por

lo menos 75° clasificado el alambre de cobre C no utiliza el

alambre del alluminum con esta unidad.

Instalación de la caja posterior con

marco de montaje de superficie

(Vea la Figura 3).

1. Asegure la caja posterior a la pared (con los orificios ciegos en

la esquina superior derecha) usando tornillos y anclas.

2. Cuelgue el marco de montaje de superficie en la caja posterior.

Asegúrese que el borde posterior del marco de montaje de

superficie esté al ras contra la pared.

NOTA: Si el calentador está ubicado en un área de tráfico intenso,

donde puede estar sujeto a vandalismo o abuso, sea muy precavido

en verificar que la caja esté firmemente fijada a la pared.

3. Cableado de suministro de potencia

NOTA: Volumen del compartimiento de cableado - 119pulg.3

(1950cm3).

a. Tienda un cable de suministro de potencia dentro del área

de la esquina superior derecha del marco de montaje.

NOTA: Si el cableado debe tenderse a través de la pared, corte un

orificio en el área del tope de la caja de pared. Tienda el conductor

de suministro a través de este orificio. A continuación extraiga la

cobertura del orificio ciego del tope de la caja y proceda al paso C.

2

Page 8

b. Extraiga la cubierta del orificio ciego en el lado tope del

marco.

c. Alimente el cable de suministro de potencia a través del

marco permitiendo que 6” (152mm) permanezcan dentro del

armazón.

-13/16"

3

(97mm)

MONTE LA CAJA

OSTERIOR A LA

P

PARED USANDO LOS

SOPORTES POSTERI-

RES DE MONTAJE

O

UELGUE EL

C

MARCO DE LA

CAJA POSTERIOR

15-5/32"

385mm)

(

19"

(482mm)

Fig.3: Instalación de montaje de superficie

d. Inserte el cable de suministro de potencia a través del sujeta-

dor de cable, permitiendo que por lo menos 6” (152mm) de

guías se extiendan dentro de la caja posterior. Conecte los

conductores azules de guía del interruptor desconectador a

las guías de los conductores de suministro, usando conectores de conductor (Vea el diagrama de cableado, pág. 3).

e. Conecte a tierra la caja posterior conectando el conductor guía

de suministro a tierra al tornillo verde de conexión a tierra ubicado en el tope interior de la caja posterior.

Instalación del conjunto del calentador y de la rejilla

Después que se haya instalado completamente la caja posterior y no

se anticipan más desechos de construcción, limpie los desechos de

la caja posterior, extraiga el conjunto del calentador de su caja, a

continuación, refiérase a la Figura 4 y proceda como sigue:

1. Inserte el conjunto del calentador dentro de la caja posterior,

colocando los cuatro orificios de montaje (con las chaveteras)

sobre los tornillos en la caja posterior. Ajuste seguramente

todos los tornillos.

2. Si se usa un marco de montaje de superficie, asegúrese que el

marco esté alineado con todas las aletas de ensamblado del

calentador antes de ajustar los tornillos.

3. Conecte los conductores del cable de alimentación a los con-

ductores de la conjunto del calentador. (Vea el Diagrama de

Cableado). Después de conectar, empuje los conductores dentro de la abertura.

4. Gire el termostato a la posición extrema contraria a las agujas

del reloj.

5. Monte la rejilla usando los cuatro (4) tornillos grandes provis-

tos. Los tornillos se enroscan dentro de los orificios ubicados

en las bridas laterales de la caja posterior.

6. Empuje la perilla del termostato dentro del eje del termostato.

GUIAS DE

POTENCIA

ERMOSTATO

T

REJILLA

ERILLA

P

CAJA POSTERIOR

EMPOTRADA

CONJUNTO DEL

CALENTADOR

Fig. 4

DIAGRAMAS DE CABLEADO (FASE UNO)

Para asegurar una operación adecuada del ventilador, el

termostato no debe ciciar el ventilador a prendido y apagado.

Siga exactamente el diagrama de cableado.

ELEMENTOS

ELEMENTOS

CALENTADORES DE 4800, 4000 y 3000 VATIOS

208V, 240V O 277V (Los calentadores de vataje completo pueden convertirse a

medio vataje extrayendo el conector rojo puente que conecta los terminales de

los elementos superior e inferior.

PRECAUCION

MOTOR DEL

ENTILADOR

V

ROJO

REPOSICION

MANUAL

MOTOR DEL

VENTILADOR

TERMOSTATO

TERMOSTATO

CABLEADO

DE CAMPO

CABLEADO

DE CAMPO

ELEMENTOS

REPOSICION

MANUAL

CALENTADORES DE 2000 y 1500 VATIOS

208V, 240V, O 277V

ELEMENTOS

ELEMENTOS

CALENTADORES DE 4800, 4000, y 3000 VATIOS

347V, 600V

3

MOTOR DEL

VENTILADOR

REPOSICION

MANUAL

CABLEADO

DE CAMPO

Page 9

NFORMACION IMPORTANTE Mantenimiento

I

REPOSICION DE LA REPOSICION MANUAL DE LIMITE

Su calentador está equipado con un control de reposición térmica

manual de límite que automáticamente apagará el calentador para

prevenir un incendio si el calentador se calienta excesivamente. Este

control está ubicado en el conjunto del panel del ventilador entre el

elemento y la hélice del ventilador y está marcado “reset”. El botón

rojo de reposición puede verse a través de la rejilla delantera, al

instalarse el calentador. Para reposicionar, permita que el calentador

y se enfríe, va continuación, presione el botón rojo que es visible a

través del orificio en el panel del ventilador. El calentador debe

retornar inmediatamente a la operación normal.

NO. MODELO K404A CODIGO DE FECHA: 0595

CALENTADOR DE PARED DE TIRO FORZADO

PPAREIL DE CHAUFFAGE MURAL À AIR PLUSÉ

A

VOLTS AC 60HZ VATIOS FASE

40/208 4000/3000 1

2

SE DEBE USAR CON CASA POSTERIOR

O OPERE SIN LA CUBIERTA FRONTAL EN SU

N

LUGAR.

OIT ÉTRE UTILISÉ AVEC BOÎTIER ARRIÈRE AWH-BB

D

NE PAS UTILISER SI LE COUVERCLE AVANT NʼEST PAS EN PLACE.

ARLEY ENGINEERED PRODUCTS

M

BENNETTSVILLE, SC 29512 4104-2093-028

EJEMPL

O

774G LISTED

CALENTADOR

E CUARTO

D

PRECAUCION

LA OPERACION DEL CONTROL DE REPOSICION TERMICA

MANUAL DE LIMITE ES UNA INDICACION QUE EL CALENTADOR HA ESTADO SUJETO A ALGUNA CONDICION ANORMAL.

SE RECOMIENDA QUE EL CALENTADOR SEA INSPECCIONADO POR UN ELECTRICISTA O SERVICIO DE REPARACIONES

DE BUENA REPUTACION PARAASEGURAR QUE EL CALENTADOR NO HAYA SIDO AVERIADO.

El calentador debe limpiarse una vez por año para eliminar polvo y

otras materias extrañas que se hayan acumulado durante la temporada de calefacción. Esta es una operación sencilla cuando se efectúa como sigue:

1. Corte la potencia eléctrica en el interruptor principal de línea

(o extraiga todos los fusibles) para desconectar la potencia

eléctrica del calentador. ESTO ES IMPORTANTE.

2. Extraiga la rejilla (Figura 4).

3. Con una boquilla de aspiradora o trapo para polvo, elimine

el polvo y otros materiales extraños.

PRECAUCION

NO USE AGUA NI UN TRAPO HUMEDO PARA LIMPIAR Y NO

MUEVA EL ELEMENTO TERMICO.

4. Después de limpiar, cambie el interruptor desconectador a la

posición ENCENDIDO y vuelva a instalar la rejilla.

5. Conecte el interruptor principal de línea (o vuelva a colocar los

fusibles) para restaurar la potencia al calentador. El calentador

está ahora listo para otra temporada de operación.

!

!

4

Page 10

iezas de repuesto

P

Nº

clave Descripción

Número

de parte

1 Cubierta frontal 1402-2239-000

Motor: 208V 3900-2010-000

2

240V 3900-2010-000

120V 3900-2010-003

3 Manual Limit 4520-2013-000

4 Fan Delay 410074000

5 Thermostat 5813-2027-000

6 Elemento:208V/2000W 302015001

240V/2000W 302015002

77V/2000W 302015003

2

277V/3000W 302012006

208V/4000W 302012007

240V/4000W 302012008

240V/3000W 302012009

240V/4800W 302012010

277V/4800W 302012011

120V/1500W 302012827

7 Paleta del ventilador 490030103

8 Bolso De las Piezas 1205-2070-001

Todos los productos fabricados por Marley Engineered Products están garantizados contra defectos de mano de obra y materiales durante un año a

GARANTIA LIMITADA

partir de la fecha de instalación, excepto los elementos calefactores que están garantizados contra defectos de mano de obra y materiales durante

cinco años a partir de la fecha de instalación. Esta garantía no se aplica por daños ocurridos por accidente, mal uso, o alteración, ni cuando el voltaje conectado sea 5% mayor que el indicado en la placa de nombre; ni al equipo instalado o cableado indebidamente, o mantenido en violación de

esta hoja de instrucciones. Todos los reclamos de trabajo de garantía deben estar acompañados por prueba de la fecha de instalación.

El cliente será responsable por todos los costos incurridos en la extracción o reinstalación de los productos, incluyendo costos de mano de obra, y

costos de transporte incurridos al retornar los productos a Marley Engineered Products Service Center y nosotros las repararemos o reemplazaremos, a nuestra opción, sin cargo para usted, con transporte de regreso pagado por Marley. Se acuerda mutuamente que tal reparación o reemplazo es el remedio exclusivo disponible de Marley Engineered Products.

LAS GARANTIAS INDICADAS ARRIBA SON A CAMBIO DE CUALQUIER OTRA GARANTIA EXPRESA O IMPLICITA Y SE DESCONOCEN Y

EXCLUYENDE ESTEACUERDOTODAS LAS GARANTIASIMPLICITAS DE COMERCIALIZACIONYAPTITUDPARAUN FIN PARTICULAR QUE

EXCEDAN LAS GARANTIAS PREVIAMENTE EXPRESADAS. MARLEY ENGINEERED PRODUCTS NO SERA RESPONSABLE POR DAÑOS

CONSECUENTES ORIGINADOS POR EL PRODUCTO, YA SEAN QUE ESTEN BASADOS EN NEGLIGENCIA, LITIGACION, RESPONSABILIDAD ESTRICTA O CONTRATO.

Algunos estados no permiten la exclusión o limitación de los daños incidentales o consecuentes, de manera que la exclusión o limitación indicada

arriba puede no aplicarse a usted. Esta garantía le otorga derechos legales específicos, y usted puede tener también otros derechos que varían de

estado a estado.

Llame a Marley Engineered Products en Bennettsville, SC al 1-800-642-4328 para la dirección de su centro autorizado de servicio más cercano. La

mercancía retornada a la fábrica debe estar acompañada por una autorización de retorno y una etiqueta de identificación de servicio, ambas

disponibles de la ubicación indicada. Incluya todos los números de catálogo mostrados en el producto, al requerir autorización de retorno.

COMO OBTENER SERVICIO EN GARANTIA,

PIEZAS DE REPUESTO E INFORMACION GENERAL

1. Servicio o repuestos, en garantía: 1-800-642-4328

2. Compra de piezas de repuesto: 1-800-654-3545

3. Información general sobre productos: www.marleymep.com

Nota: Cuando solicite servicio, siempre dé la información que sigue:

1. Número de modelo del producto

2. Fecha de fabricación

3. Número de parte o descripción

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

No. de Pieza 5200-2267-007

ECR 38696

04/10

Page 11

Radiateurs muraux

!

(400mm)

15-3/4"

(485mm)

1

9-1/8"

(35mm)

1

-3/8"

(95mm)

3-3/4"

(463mm)

18-1/4"

à air pulsé

Série “K”

Model A

DOSSIER Nº E21609

Instructions dʼinstallation et dʼentretien

Cher utilisateur,

Félicitations ! Nous vous remercions d'avoir fait l'acquisition de ce nouveau radiateur fabriqué par une

division de Marley Engineered Products. Vous avez fait un bon investissement en choisissant un appareil

de qualité imbattable. Veuillez lire attentivement et suivre scrupuleusement les consignes de ce manuel

concernant l'installation et l'entretien. Nous sommes sûrs que vous bénéficierez de nombreuses années de

confort grâce à cet appareil de chauffage efficace de Marley Engineered Products... le numéro 1 du

secteur du chauffage en matière de conception, fabrication, qualité et service.

... Les employés de

Marley Engineered Products

AVERTISSEMENT

À lire attentivement - Ces instructions sont écrites pour vous aider

à éviter des difficultés qui peuvent survenir pendant lʼinstallation des

radiateurs. Étudier les instructions au préalable peut vous faire

économiser beaucoup de temps et dʼargent plus tard. Observer les

procédures suivantes pour réduire le temps dʼinstallation à un minimum.

Pour réduire le risque dʼincendie et dʼélectrocution

1. Pour éviter les électrocutions, couper le courant venant au radiateur au tableau dʼalimentation principale avant de câbler ou

dʼeffectuer un entretien.

2. Tout le câblage doit être conforme au code électrique local et

national et le radiateur doit être mis à la terre à titre de précaution

contre les électrocutions.

3. Avant de mettre sous tension, vérifier que la tension dʼalimentation venant au radiateur corresponde à la tension nominale

indiquée sur la plaque signalétique du radiateur.

4. Ce radiateur est chaud lorsquʼil fonctionne. Pour éviter les brûlures, ne pas laisser la peau nue toucher les surfaces chaudes.

CONSERVER CES INSTRUCTIONS

5. Ne pas insérer ni laisser des corps étrangers entrer par les ouvertures de ventilation ou de sortie dʼair car cela peut causer une

électrocution, un incendie ou une détérioration du radiateur.

6. Pour éviter un incendie, ne pas boucher les prises dʼair ou les

sorties dʼair. Garder les matériaux combustibles, comme les

cageots, les rideaux, etc... éloignés du radiateur. Ne pas installer

le radiateur derrière des portes, des meubles, des serviettes ou

des caisses. Ne pas installer dans le plafond.

7. Un radiateur contient des pièces chaudes et produisant des arcs

électriques (étincelles). Ne pas lʼutiliser dans des zones de remisage dʼessence, de peinture ou de liquides inflammables.

8. Utiliser ce radiateur uniquement selon les instructions de ce manuel. Toute autre utilisation non recommandée par le fabricant

peut causer un incendie, une électrocution ou des blessures corporelles.

9. Ce radiateur nʼest pas approuvé pour utilisation dans des atmosphères corrosives, comme les zones de remisage de produits

chimiques, les serres ou les zones maritimes.

1

Page 12

IMPORTANT

!!!

AVERTISSEMENT

NE PAS INSTALLER LE RADIATEUR TÊTE EN BAS OU

DE CÔTÉ.

NE PAS UTILISER LE RADIATEUR SANS LA GRILLE.

Installation du boîtier mural encastré dans

ne construction existante

1. Faire une ouverture murale de 362 mm de large par

470 mm de haut à la hauteur de fixation désirée, mais

pas à moins de 203 mm des murs adjacents ou le

plancher et à plus de 915 mm du plafond. (Voir la figure

2.)

2. Câblage de lʼalimentation électrique

u

ATTENTION

POUR FIXATION MURALE UNIQUEMENT. NE PAS INSTALLER LE RADIATEUR À MOINS DE 203 mm DU SOL

U DʼUN MUR ADJACENT. NE PAS INSTALLER LE RA-

O

DIATEUR À MOINS DE 915 mm DU PLAFOND.

Installation de boîtier mural encastré dans

1. Fixation du boîtier mural (voir la figure 1)

a. Placer le boîtier mural entre deux poutres murales

espacées de 460 mm centre à centre à la hauteur de

fixation désirée mais pas à moins de 203 mm du sol

ou du mur adjacent.

b. Aligner le boîtier mural pour que le bas et les côtés

soient au ras de la surface finie du mur (le bord

supérieur du boîtier mural doit dépasser dʼenviron

13 mm de la surface finie du mur).

VIS DE MISE

À LA TERRE

BOÎTIER

8” MIN.

(203 mm)

Fig. 1 : Positionnement du boîtier encastré dans une construction neuve

c. Bloquer le boîtier en position avec des vis à bois ou

des clous conformément à la figure 1.

2. Câblage de lʼalimentation électrique (voir la figure 1)

REMARQUE : Volume du compartiment de câblage –

1950 cm

a. Passer un câble dʼalimentation dans la découpe du

coin supérieur droit du boîtier.

b. Installer un collier de câble dans la découpe en haut

du boîtier mural.

c. Insérer le câble dʼalimentation dans le collier de câ

ble, en laissant au moins 152 mm de fils de connexion dépasser à lʼintérieur du boîtier. Connecter les

fils de connexion bleus de lʼinterrupteur de mise horscircuit sur les fils dʼalimentation avec des connecteurs

de fil (voir le schéma de câblage page 3).

d. Mettre le boîtier à la terre avec la vis verte située sur

le bord supérieur intérieur du boîtier.

une construction neuve

COLLIER

DE CÂBLE

3

.

CÂBLE D’ALIMENTATION

ÉLECTRIQUE

8” MIN.

)

(203mm

CLOU OU VIS (2 DE

CHAQUE CÔTÉ)

8-1/2” MIN.

1

(470mm)

8” MIN.

203mm)

(

VIS DE MISE

LA TERRE

À

BOÎTIER

Fig. 2 : Positionnement du boîtier encastré dans une construction existante

14-1/2” MIN.

362mm)

(

OLLIER

C

DE CÂBLE

8” MIN.

203mm)

(

ÂBLE D’ALIMENTATION ÉLECTRIQUE

C

CLOU OU VIS

2 DE CHAQUE CÔTÉ)

(

REMARQUE : Volume du compartiment de câblage – 1950 cm3.

a. Passer un câble dʼalimentation dans la zone au-dessus

du haut de lʼouverture murale.

b. Installer un collier de câble dans la découpe en haut du

boîtier mural.

c.Insérer le câble dʼalimentation dans le collier de câble,

en laissant au moins 152 mm de longueur de câble à

lʼintérieur du boîtier. Connecter les fils dʼalimentation

électrique aux fils bleus de lʼinterrupteur de mise horscircuit avec des connecteurs de fil (voir le schéma de

câblage de la page 3)

d. Mettre le boîtier à la terre avec la vis verte située sur

le bord supérieur intérieur du boîtier.

3. Fixation du boîtier mural

a. Placer le boîtier mural dans lʼouverture murale au ras

de la surface murale finie sur le bas et les côtés du

boîtier. (le bord supérieur du boîtier mural doit dépasser

dʼenviron 13 mm de la surface murale finie).

b. Bloquer le boîtier mural en place avec des vis à bois ou

des clous.

REMARQUE : Pour le classement par taille correct de fil,

référez vous svp au code électrique national, la section 310.

Seulement l'utilisation au moins 75° évalué par fil de cuivre C

n'emploient pas le fil d'alluminum avec cette unité.

Installation du boîtier avec cadre

de fixation en surface

(voir figure 3).

1. Bloquer le boîtier arrière au mur (avec les découpes dans

le coin supérieur droit) en utilisant des vis et des chevilles.

2. Accrocher le cadre de fixation en surface sur le boîtier ar-

rière. Sʼassurer que le bord arrière du cadre de fixation en

surface soit au ras contre le mur.

REMARQUE : Si le radiateur se trouve dans une zone de

grand passage, où il peut être soumis à du vandalisme ou à

des abus, veiller soigneusement à ce que le boîtier soit fermement fixé au mur.

2

Page 13

FIXER LE BOÎTIER

!

ARRIÈRE AU MUR AVEC

ES TROUS DE FIXATION

L

ARRIÈRE

ACCROCHER LE CADRE

UR LE BOÎTIER ARRIÈRE

S

5-5/32"

1

385mm)

(

3-13/16"

97mm)

(

19"

(482mm)

BOÎTIER

MURAL

ENCASTRÉ

FILS DʼALIMENTATION

EMPLACEMENT DU THERMOSTAT

ig. 3 : Installation de fixation en surface

F

3. Câblage de lʼalimentation électrique

REMARQUE : Volume du compartiment de câblage - 1950 cm

. Passer un câble dʼalimentation dans la zone du coin

a

droit supérieur du cadre de fixation.

REMARQUE : Si le câblage doit passer dans le mur, couper un

trou dans la zone du haut du boîtier mural. Passer le fil dʼalimentation dans ce trou. Puis enlever la découpe du haut du

boîtier et aller à lʼétape C.

b. Enlever la découpe sur le dessus du cadre.

c. Passer le câble dʼalimentation dans le cadre, en laissant

152 mm de fil de connexion à lʼintérieur du boîtier intérieur.

d. Insérer le câble dʼalimentation dans le collier de câble,

en laissant au moins 152 mm de fil dépasser dans le boîtier. Connecter les fils dʼalimentation aux fils bleus de

lʼinterrupteur de mise hors-circuit avec des connecteurs

de fil (voir le schéma de câblage page 3).

e. Mettre le boîtier à la terre en connectant le fil de terre de

lʼalimentation à la vis verte de mise à la terre située en

haut à lʼintérieur du boîtier.

Installation du radiateur et de sa grille

Lorsque le boîtier mural est complètement installé et quʼaucune autre saleté de construction nʼest supposée être produite,

nettoyer les débris du boîtier mural, sortir le radiateur de son

carton puis consulter la figure 4 et procéder de la manière suivante :

Fig. 4

3

.

Schémas de câblage (Phase1)

RADIATEUR

ATTENTION

OUR ASSURER UN FONCTIONNEMENT CORRECT DU VENTILATEUR,

P

LETHERMOSTAT NE DOIT PAS METTRE EN MARCHE ET ARRÊTER EN PER-

ANENCE LE VENTILATEUR. SUIVRE PRÉCISÉMENT LE SCHÉMA DE

M

CÂBLAGE.

MOTEUR DE

ÉLÉMENTS

ÉLÉMENTS

4800, 4000, & 3000 WATT RADIATEURS

208V, 240V, OR 277V (Les radiateurs à puissance complète peuvent être convertis à demi-puissance en fetirant le fil jarretièr rouge reliant les bornes éléments

supérieurs et inférieurs.)

VENTILATEUR

ROUGE

RÉINITIALISATION

MANUELLE

MOTEUR DE

VENTILATEUR

L2

CYC

L1

FF

O

CÂBLAGE DE

HAMP

C

TERRE

CÂBLAGE DE

CHAMP

1. Insérer le radiateur dans le boîtier mural, plaçant les

quatre trous de fixation (avec les fentes en trou de serrure) sur les vis dans le boîtier. Serrer fermement toutes

les vis.

2. En cas dʼutilisation de cadre de fixation en surface, sʼassurer que le cadre soit àniveau avec les quatre languettes de radiateur avant de serrer les vis.

3. Connecter les fils de un câble dʼalimentation jusquʼaux

fils de connexion de la radiateur. Voir le schéma de

câblage de la colonne suivante.

4. Tourner le thermostat à fond dans le sens inverse des

aiguilles dʼune montre.

5. Fixer la grille avec les quatre (4) longues vis fournies.

Les vis se vissent dans les trous sur les parois latérales

du boîtier arrière.

6. Pousser le bouton de thermostat sur lʼarbre de thermos

tat.

Utilisation

1. Tourner le bouton du thermostat à fond dans le sens des aiguilles dʼune montre. Ceci doit activer les éléments chauffants et le ventilateur, faisant sortir de lʼair chaud des ouvertures en bas de la grille.

2. Après vérification du fonctionnement, tourner le bouton du

thermostat à la position désirée pour obtenir un confort

ambiant.

REMARQUE : Pour obtenir de meilleurs résultats, le radiateur

doit être laissé sur la position MARCHE en permanence pendant la saison de chauffage parce que le thermostat, lorsquʼil

est bien réglé, maintient la température désirée.

L2

ÉLÉMENTS

RÉINITIALISATION

MANUELLE

L1

2000 & 1500 WATT RADIATEURS

208V, 240V, OR 277V

VENTILATEUR

ÉLÉMENTS

ÉLÉMENTS

4800, 4000, & 3000 WATT RADIATEURS

347V, 600V

CYC

OFF

MOTEUR DE

RÉINITIALISATION

MANUELLE

TERRE

3

Page 14

POUR RÉINITIALISER LE DISJONCTEUR DE SÉCURITÉ À

!

!

Entretien

RÉINITIALISATION MANUELLE

ʼappareil de chauffage est équipé dʼun disjoncteur thermique de

L

sécurité à réinitialisation manuelle qui coupe automatiquement le

radiateur pour empêcher un incendie si le radiateur surchauffe. Ce

contrôle est situé sur le tableau du ventilateur entre lʼélément et la

pale de ventilateur et est marqué "reset" (réinitialisation). Le bouton

rouge de réinitialisation peut être vu par la grille avant lorsque lʼappareil de chauffage est installé. Pour réinitialiser le disjoncteur de sécurité, laisser le radiateur refroidir, puis appuyer sur le bouton rouge qui

est visible par le trou du panneau du ventilateur. Le radiateur doit

immédiatement retourner au fonctionnement normal.

MODEL NO. K404A DATE CODE: 0595

FAN FORCED WALL HEATER

PPAREIL DE CHAUFFAGE MURAL À AIR PLUSÉ

A

VOLTS AC 60HZ WATTS PHASE

40/208 4000/3000 1

2

MUST BE USED WITH AWH-BB BACK BOX

DO NOT OPERATE WITHOUT FRONT COVER IN

PLACE.

DOIT ÉTRE UTILISÉ AVEC BOÎTIER ARRIÈRE

NE PAS UTILISER SI LE COUVERCLE AVANT NʼEST PAS EN PLACE.

MARLEY ENGINEERED PRODUCTS

BENNETTSVILLE, SC 29512 4104-2093-028

EXEMPLE

774G LISTED

OOM HEATER

R

ATTENTION

LE FONCTIONNEMENT DU DISJONCTEUR THERMIQUE DE

SÉCURITÉ À RÉINITIALISATION MANUELLE INDIQUE QUE

E RADIATEUR A ÉTÉ SOUMIS À UNE CONDITION ANOR-

L

MALE. IL EST RECOMMANDÉ DE FAIRE VÉRIFIER LE RADIATEUR PAR UN ÉLECTRICIEN RÉPUTÉ OU PAR UN BON

SERVICE DE DÉPANNAGE POUR SʼASSURER QUE LE RADIATEUR NʼAIT PAS ÉTÉ DÉTÉRIORÉ.

Une fois par an, le radiateur doit être nettoyé pour en retirer la poussière et les autres corps étrangers qui se sont accumulés pendant la

saison de chauffage. Cʼest une opération simple lorsquʼelle est effectuée de la manière suivante :

1. Couper le courant au commutateur principal (ou enlever tous les

fusibles) pour débrancher le courant électrique du radiateur.

CʼEST IMPORTANT.

2. Enlever la grille (figure 4) et mettrelʼinterrupteur de mise hors-circuit en position dʼarrêt.

3. Avec un suceur dʼaspirateur ou un chiffon à poussière, enlever la

poussière et les autres corps étrangers.

. Lorsque le nettoyage est terminé, mettre le commutateur demise

4

hors-circuit sur la position de marche et réinstaller la grille.

ATTENTION

NE PAS UTILISER DʼEAU OU DE CHIFFON HUMIDE POUR

NETTOYER ET NE PAS DÉPLACER LʼÉLÉMENT CHAUFFANT.

5. Remettre le commutateur principal sur marche (ou remettre les

fusibles en place) pour rétablir le courant au radiateur. Le radiateur est désormais prêt pour une autre saison de fonctionnement.

4

Page 15

Identification des pièces de replacement

o

N

réf. Descripction

o

N

de pièce

1 Couvercle avant 1402-2239-000

Moteur:208V 3900-2010-000

2

240V 3900-2010-000

120V 3900-2010-003

3 Restauration manuelle 4520-2013-000

4 Retard à la ventilation 410074000

5 Thermostat 5813-2027-000

6 Elemento:208V/2000W 302015001

240V/2000W 302015002

77V/2000W 302015003

2

277V/3000W 302012006

208V/4000W 302012007

240V/4000W 302012008

240V/3000W 302012009

240V/4800W 302012010

277V/4800W 302012011

120V/1500W 302012827

7 Pale de ventilateur 490030103

8 Sac De Pièces 1205-2070-001

GARANTIE LIMITÉE

Tous les produits fabriqués par Marley Engineered Products sont garantis contre les défauts de fabrication et de matériau pendant un an à compter

de la date dʼinstallation, sauf les éléments chauffants qui sont garantis contre les défauts de fabrication et de matériau pendant cinq ans à partir de

la date dʼinstallation. Cette garantie ne sʼapplique pas aux détériorations consécutives à un accident, à une mauvaise utilisation ou à une modification; ni si la tension dʼalimentation est supérieure de plus de 5% à la tension de la plaque signalétique; ni à un équipement incorrectement installé ou

câblé ou entretenu en violation des instructions dʼinstallation du produit. Toutes les réclamations pour du travail sous garantie doivent être accompagnées par une preuve de la date dʼinstallation.

Le client sera responsable de tous les frais causés par lʼenlèvement ou la réinstallation des produits, y compris les frais de main dʼoeuvre et les frais

dʼexpédition pour renvoyer les produits au centre dʼentretien Marley Engineered Products. Dans le cadre des limites de cette garantie, les appareils

défaillants doivent être renvoyés au centre de service après-vente agréé Marley le plus proche ou au centre Marley Engineered Products et nous les

réparerons ou remplacerons, à notre choix, gratuitement pour vous avec les frais de retour payés par Marley. Il est entendu quʼune telle réparation ou

un tel remplacement sont les seuls recours pouvant être obtenus de Marley Engineered Products.

LES GARANTIES CI-DESSUS REMPLACENT TOUTES LES AUTRES GARANTIES EXPLICITES OU IMPLICITES ET TOUTES LES GARANTIES

IMPLICITES DE COMMERCIABILITÉ ET DʼADAPTATION À UN USAGE PARTICULIER QUI DÉPASSENT LES GARANTIES EXPLICITES DÉCRITES CI-DESSUS SONT RÉFUTÉES PAR LA PRÉSENTE ET EXCLUES DE CET ACCORD. MARLEY ENGINEERED PRODUCTS NE SERA PAS

RESPONSABLE DES DOMMAGES CIRCONSTANCIELS CAUSÉS PAR LE PRODUIT, QUE CE SOIT PAR NÉGLIGENCE, DÉLIT,

RESPONSABILITÉ STRICTE, OU CONTRAT.

Certaines provinces nʼautorisent pas lʼexclusion ou la limitation des dommages circonstanciels ou fortuits, lʼexclusion ou la limitation ci-dessus peuvent donc ne pas vous concerner. Cette garantie vous donne des droits légaux spécifiques et vous pouvez aussi avoir dʼautres droits qui varient dʼune

province à lʼautre.

Pour lʼadresse de notre centre dʼentretien autorisé le plus proche, contacter Marley Engineered Products à Bennettsville, Caroline du Sud, États-Unis

dʼAmérique au 1-800-642-4328. La marchandise renvoyée en usine doit être accompagnée dʼétiquettes dʼidentification dʼautorisation de renvoi et de

service, disponibles chez Marley Engineered Products. Lors de la demande dʼautorisation de renvoi, inclure tous les numéros de catalogue apparaissant sur les produits.

COMMENT OBTENIR DES INFORMATIONS GÉNÉRALES ET

DEMANDER UNE RÉPARATION OU DES PIťCES SOUS GARANTIE

1. Réparations et piŹces sous garantie 1-800-642-4328

2. Achat de piŹces de rechange 1-800-654-3545

3. Informations générales sur les produits www.marleymep.com

Remarque : Lorsque vous demandez de l'assistance, ayez toujours en main

1. Le numéro de modŹle du produit

2. La date de fabrication

3. Numéro ou description de la piŹce

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

ECR 38696

Part No. 5200-2267-007 04/10

Loading...

Loading...