Page 1

J Series (Model B)

Institutional Convector

Dear Owner,

Congratulations! Thank you for purchasing this new heater manufactured by a division of Marley

Engineered Products. You have made a wise investment selecting the highest quality product in the heating industry. Please carefully read and follow the installation and maintenance directions shown in this

manual. You should enjoy years of efficient heating comfort with this product from Marley Engineered

Products... the industry’s leader in design, manufacturing, quality and service.

... The Employees of

Marley Engineered Products

Read Carefully - These instructions are written to help

you prevent difficulties that might arise during installation

of heaters. Studying the instructions first may save you

considerable time and money later. Observe the following

procedures, and cut your mounting time to a minimum.

1. To prevent electrical shock, disconnect all power coming to

heater at main service panel before wiring or servicing.

2. All wiring must be in accordance with the National and Local

Electrical Codes and the heater must be grounded as a precaution against possible electric shock.

3. Verify the power supply voltage coming to heater matches

the ratings printed on the heater nameplate before energizing.

4. Do not insert or allow foreign objects to enter any ventilation

or exhaust opening as this may cause an electric shock,

fire, or damage to the heater.

5. To prevent a possible fire, do not block air intakes or exhaust

in any manner. Keep combustible materials, such as boxes,

crates, drapes, etc., away from heater.

6. A heater has hot and arcing or sparking parts inside. Do not

use it in areas where gasoline, paint or flammable liquids are

used or stored.

7. Use this heater only as described in this manual. Any other

use not recommended by the manufacturer may cause fire,

electric shock, or injury to persons.

8. This heater is not approved for use in hazardous atmospheres

or corrosive atmospheres such as marine, green house

or chemical storage areas.

Installation & Maintenance Instructions

FILE #E21609

1

SA VE THESE INSTRUCTIONS

WARNING

!

Page 2

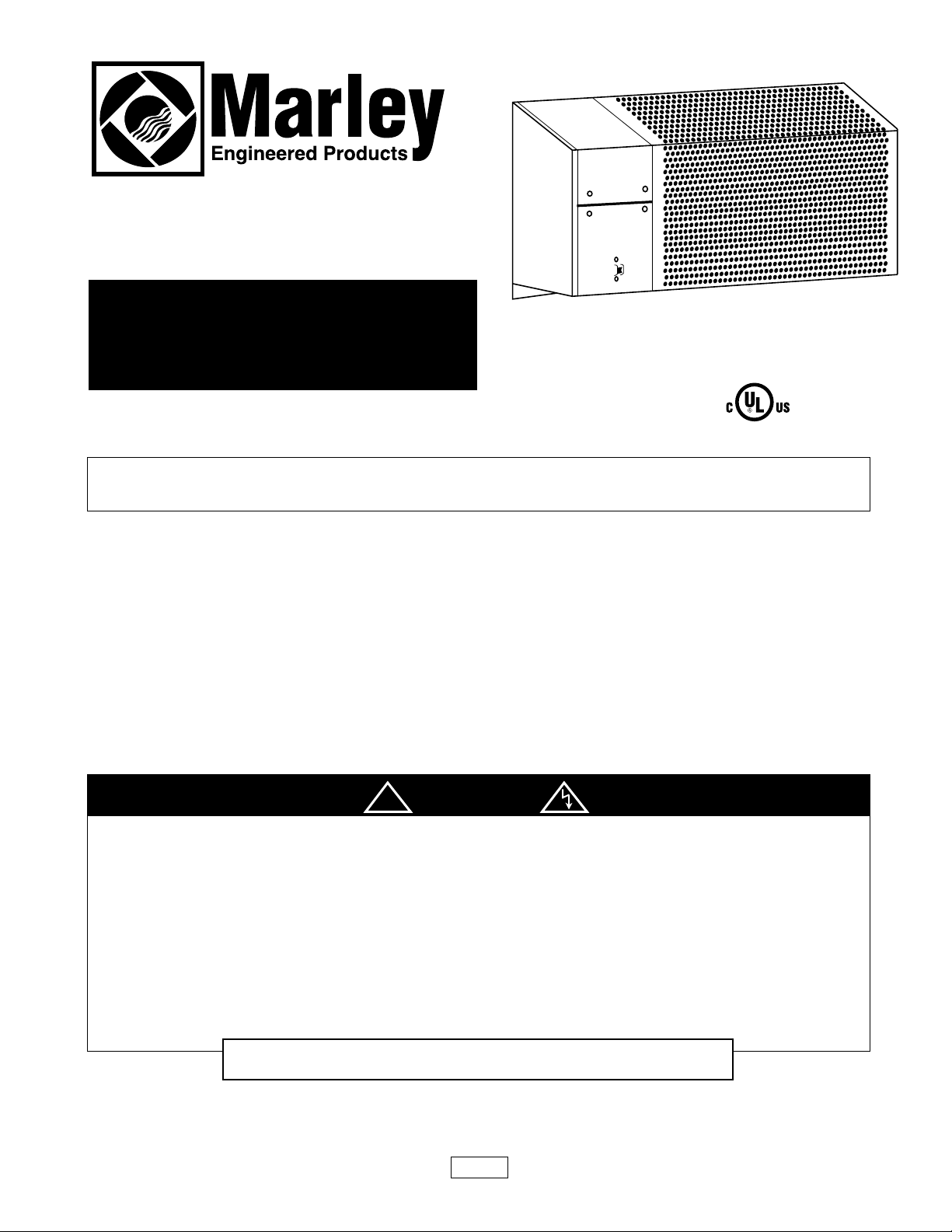

MOUNTING AND WIRING

NOTE: Electrical wiring is to be sized in accordance with National

Electric Code and local codes using at least 75°C type RH, THW

or equivalent insulated wire. See chart located on page 3 for

amp. loads.

1. Locate on vertical wall with length of heater positioned

horizontally.

2. When selecting a mounting location, the following minimum

distances must be observed to insure proper operation.

a. Six (6") inches (152mm) from bottom of heater to floor.

b. One (1.5") inch (38mm) from wall or other obstruction to

the right or left side of heater.

3. Do not mount heater in a recess, since such mounting

interferes with free air circulation, increases temperature and

prevents proper thermostat operation.

NOTE: Unit is shipped with non-tamper resistant screws securing

front cover. Remove screws and discard.

4. Mount the rear panel assembly of the heater to the wall using

the 11/32" (8.7mm) diameter holes (bolts and wall anchors to be

supplied by customer).

5. Install the perforated cover by hooking the top edge of the

cover over the top edge of rear panel.

6. Attach the bottom lip of the perforated cover to the wall using

the 1/4 - 20 x 1" tamper proof screws provided (Wall anchors

to be supplied by customer).

7. Electrical wiring must be brought into heater through 1-3/32"

(27.8mm) diameter hole located in the rear panel.

8. Grounding conductor must be connected to the green pigtail

lead.

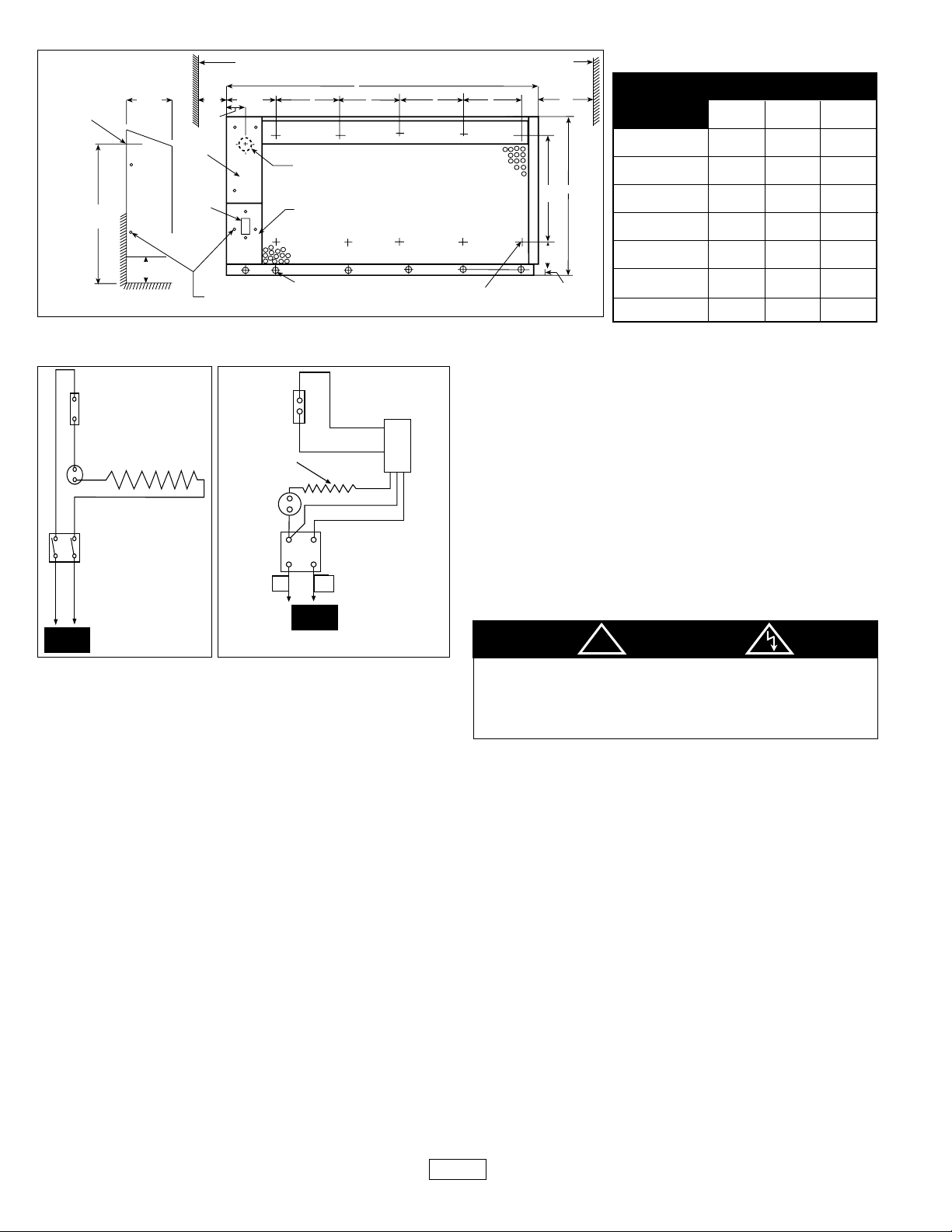

9. Make the proper connections following the wiring diagram.

Install disconnect switch cover assembly with (2) #8 x 5/8"

tamper proof screws (provided).

10. Adjust thermostat to the desired setting. Install top access

cover with (4) #8 x 5/8" tamper proof screws (provided).

OPERATION AND MAINTENANCE

To assure efficient operation, follow the simple instructions listed

below.

TO CLEAN HEATER

Because of the convection heating principle which depends upon

a circulation of air through the finned element, dust particles will

periodically be deposited between the fins, and should be

removed occasionally for maximum efficiency of the heater. With

front cover removed, a vacuum cleaner with proper attachments

can easily be worked along the top and bottom of the finned element to clear it of dust deposits.

TO REPAINT, IF DESIRED

The baked enamel finish was chosen to blend with interior decors.

If you wish to repaint the heaters, use high quality household

enamel. No primer is necessary. Do not use rubber base paint.

Paint heater front cover only. Do not paint heating element.

HAZARD OF ELECTRIC SHOCK. DISCONNECT ALL

POWER BEFORE A TTEMPTING TO SERVICE THE

HEA TERS.

WATTAGE

DIMENSIONS

A

24"

608mm

28"

709mm

36"

912mm

48"

1216mm

60"

1520mm

72"

1824mm

96"

2432mm

18"

456mm

18.25"

462mm

B

19.1”

485 mm

11.5"

291mm

15.0"

380mm

14.3"

362mm

13.75"

348mm

16.75"

424mm

C

-

11.5"

291mm

16"

405mm

14.3"

362mm

13.75"

348mm

16.75"

424mm

400

500

750

1000

1250

1500

2000

2

other obstruction

TO POWER

CIRCUIT

!

DANGER

(1000W thru 2000W)

(1250W thru 2000W)

120V thru

277V ONLY

347V and

600V ONLY

(347V) N

(600V)L2

TO POWER

CIRCUIT

Wiring Diagrams

L1

N

A

B

C

(all models)

(1000W, 1 250W, 1 500W)

center line of

1-3/32" dia. hole

in rear panel

for customer entry.

19"

Min.

(481mm)

5"

(127mm)

6" to floor Min.

(152mm)

(25mm)

Top

Access

Cover

Disconnect

Switch

1"

3"

(76mm)

Min.

1 3/4"

(25mm)

Tamper Proof

Screws 10 - 32 x 1/2"

Conduit Entrance

Disconnect Switch Cover

Mounting holes 11/32" (8.7mm) dia. for mtg.

front cover to wall by using 1/4 - 20 x 1"

tamper proof screws supplied.

Thermostat

Element

High

Limit

L1

N

Disconnect

Switch

L1

Thermostat

Limit

Disconnect

Switch

L2 or N

Element

Transformer

Relay

Red

White

Red

Blue

Black

or other obstruction

C

C

(1250W & 1500W o nly)

Mounting holes 11/32" (8.7mm)

dia. for mtg. rear panel to wall

(25mm)

10" 16"

(253mm)

3 7/16"

(87mm)

(6.3mm)

1/4"

Min.

1"

(405mm)

Page 3

IMPORTANT INFORMATION

MODEL NO.

J400B

J408B

J404B

J407B

120

208

240

277

400

400

400

400

3.3

1.9

1.7

1.4

40

40

40

40

J750B

J758B

J754B

J757B

J753B

J1000B

J1008B

J1004B

J1007B

J1003B

J1006B

J1250B

J1258B

J1254B

J1257B

J1253B

J1256B

J1500B

J1508B

J1504B

J1507B

J1503B

J1506B

J2008B

J2004B

J2007B

J2003B

J2006B

208

240

277

347

600

2000

2000

2000

2000

2000

9.6

8.3

7.2

5.8

3.3

130

130

130

130

130

120

208

240

277

347

120

208

240

277

347

120

208

240

277

347

600

120

208

240

277

347

600

120

208

240

277

347

600

500

500

500

500

500

750

750

750

750

750

1000

1000

1000

1000

1000

1000

1250

1250

1250

1250

1250

1250

1500

1500

1500

1500

1500

1500

4.2

2.4

2.1

1.8

1.4

6.3

3.6

3.1

2.7

2.2

8.3

4.8

4.4

3.6

2.9

1.7

10.4

6.0

5.2

4.5

3.6

2.1

12.5

7.2

6.3

5.4

4.3

2.5

45

45

45

45

45

55

55

55

55

55

65

65

65

65

65

65

80

80

80

80

80

80

95

95

95

95

95

95

HEATER

VOLTS

WATTS

AMPS

SHIPS

WT.(lbs.)

3

MODEL NO. J757B DATECODE 0295

ROOM HEATER

APPAREIL DE CHAUFFAGE

277 750 2.7

VOLTS WATTS AMPS.

774G LISTED

ROOM HEATER

MARLEY ENGINEERED PRODUCTS

BENNETTSVILLE, SC 29512 4104-2150-010

NAMEPLATE

J500B

J508B

J504B

J507B

J503B

Page 4

HOW TO ORDER REPAIR PARTS

In order to obtain any needed repair or replacement

parts, warranty service or technical information, please

contact Marley Engineered Products toll-free by calling 1800-642-HEAT.

When ordering repair parts, always give the information

listed as follows:

1. The Part Number

2. The Model Number

3. The Part Description

4. Date of Manufacture

LIMITED W ARRANTY

All products manufactured by Marley Engineered Products are warranted against defects in workmanship and materials for one year

from date of installation, except heating elements which are warranted against defects in workmanship and materials for five years

from date of installation. This warranty does not apply to damage from accident, misuse, or alteration; nor where the connected voltage is more than 5% above the nameplate voltage; nor to equipment improperly installed or wired or maintained in violation of the

product’s installation instructions. All claims for warranty work must be accompanied by proof of the date of installation.

The customer shall be responsible for all costs incurred in the removal or reinstallation of products, including labor costs, and shipping costs incurred to return products to Marley Engineered Products Service Center.Within the limitations of this warranty, inoperative units should be returned to the nearest Marley authorized service center or the Marley Engineered Products Service Center,

and we will repair or replace, at our option, at no charge to you with return freight paid by Marley. It is agreed that such repair or

replacement is the exclusive remedy available from Marley Engineered Products.

THE ABOVE WARRANTIES ARE IN LIEU OF ALL OTHER WARRANTIES EXPRESSED OR IMPLIED. AND ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE WHICH EXCEED THE AFORESAID

EXPRESSED WARRANTIES ARE HEREBY DISCLAIMED AND EXCLUDED FROM THIS AGREEMENT. MARLEY ENGINEERED

PRODUCTS SHALL NOT BE LIABLE FOR CONSEQUENTIAL DAMAGES ARISING WITH RESPECT TO THE PRODUCT,

WHETHER BASED UPON NEGLIGENCE, TORT, STRICT LIABILITY, OR CONTRACT.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above exclusion or limitation may

not apply to you. This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

For the address of your nearest authorized service center, contact Marley Engineered Products in Bennettsville, SC, at 1-800-642-

4328. Merchandise returned to the factory must be accompanied by a return authorization and service identification tag, both available from Marley Engineered Products. When requesting return authorization, include all catalog numbers shown on the products.

Part No. 5200-2251-003

4

ECR 33823

05/98

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

Loading...

Loading...