Page 1

G Series

(Model B)

Convector Heater for

Hazardous Locations

GENERAL

Type G-Series Convection Heaters are designed for use in

Class I, Div. I hazardous environments. Units without control

options are suitable for areas classified as Groups B, C & D.

Units with built-in controls can be supplied for Groups C and

D or B, C and D. Refer to classification stamped on heater

nameplate.

WARNING:

this heater should not be installed in areas where vapors or

gases having an ignition temperature less than 280˚C

(536˚F)(T2A) at 1.8kW, 3.6kW, 4.5kW, 7.2kW, 9.0kW or

180˚C (356˚F)(T3A) at 1.6kW, 3.2kW, 4.0kW are present.

WARNING:

temperatures exceeding 40˚C (104˚F).

NOTE:

lines requirements for installation of electrical equipment in

hazardous (Classified) locations.

To prevent ignition of hazardous atmospheres,

These heaters must not be operated in ambient

Article 500 of the National Electric Code (NEC) out-

SAVE THESE INSTRUCTIONS

!

1. Only connect heaters to the same line voltage as on

heater nameplate.

2. All controls such as thermostat and contactor, when

required, must have the same explosion-proof rating as

heater.

3. Do not install one unit above the other.

4. Units must be mounted a minimum of 8” above the floor.

5. Heaters must be mounted on wall in a horizontal position

with terminal end at right only.

wall.

6. All unit electrical installation fittings, conduit, wiring, and

seals must meet NEC and local codes for hazardous locations. External line fusing or circuit breaker protection is

required.

7. Hazard of Shock. Heater must be effectively grounded in

accordance with the National Electrical Code.

8. Failure to understand and follow these installation instructions and the “WARNING” notes contained therein may

result in severe personal injury, death, or substantial

property damage.

Never

recess heater into

INSTALLATION

WARNING:

before installing heater.

NOTE:

Heaters can be mounted directly on any type of surface

(masonry, concrete, block, plastered walls, metal framework,

etc.) using appropriate hardware

1. Remove front panel by removing threaded bolts.

2. Locate desired heater position on wall.

3. Locate mounting holes for rear panel. Rear panel must be

a minimum of 8” from the floor.

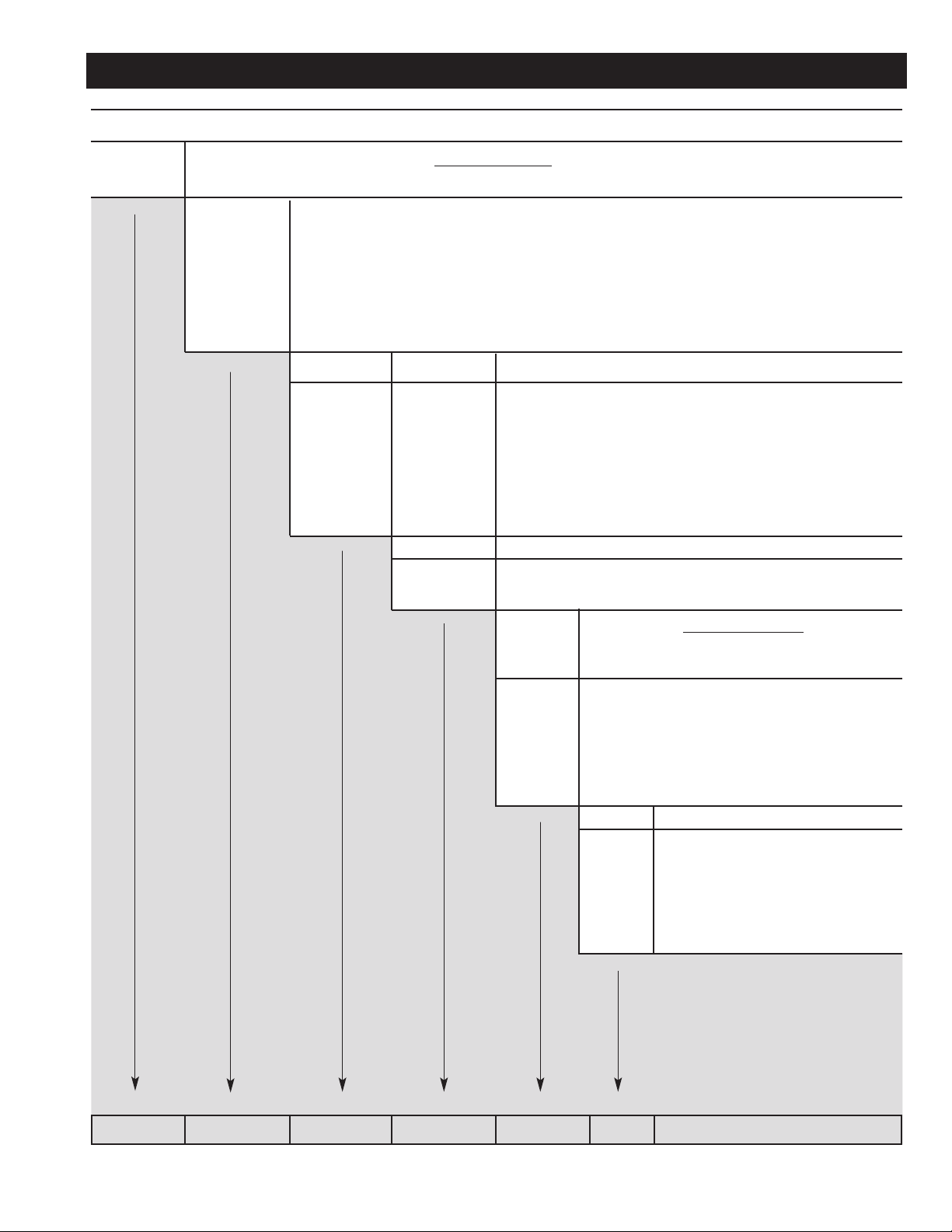

4. Refer to Figure 1A, 1B, or 1C for mounting hole layout for

each cabinet size.

Hazard of electric shock. Disconnect all power

Heaters can be mounted individually end to end.

5. Drill a pilot hole in wall mounting surface at each mounting

hole location. Use a convenient small size drill.

6. Drill the mounting holes in accordance with size in Table 1.

Insert anchors where applicable.

7. Fasten rear panel to wall with screws noted in Table 1.

WARNING:

across heating elements requires the front panel in place.

Injury from hot heating element possible with front cover

removed.

Never operate heater with front panel off. Air flow

1

Page 2

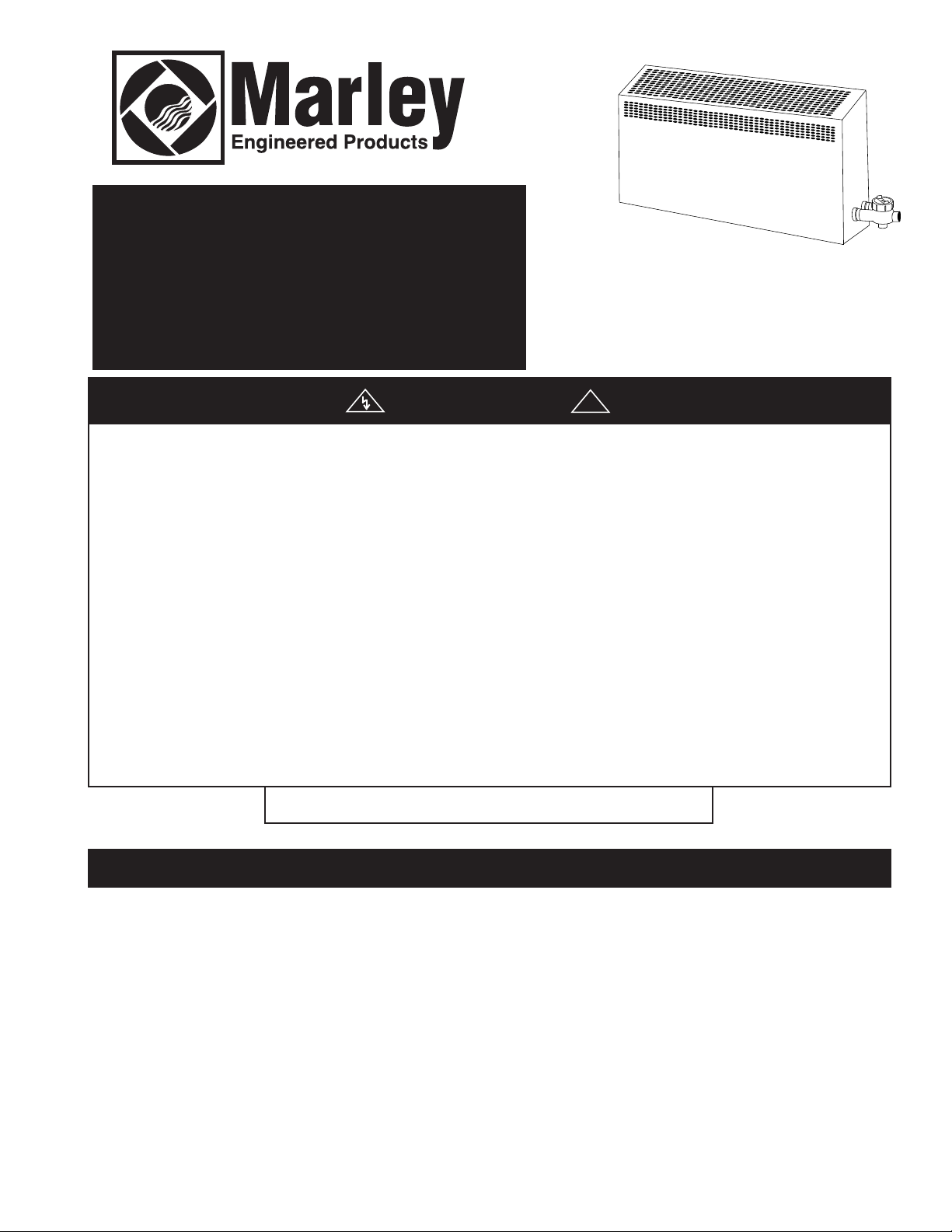

INSTALLATION

1/2

7/8

5/16

3

/4" Conduit Entrance

7

D

S

ee Detail "A"

8-15/16

D

C

C

B

19

20-1/16

A

2-3/8

5-1/16

3

-3/8

1" Conduit Entrance

8-7/8

D

See Detail "A"

C

C

D

19

20-1/16

8-15/16

A

B

Feet are Optional

P

rimarily Used to Protect

Thermowell During Shipping

and Installation

3/4" Conduit Entrance

7

D

See Detai "A"

C

C

D

19

20-1/16

8-15/16

5-1/16

3-3/8

A

2-3/8

G SERIES MODELS WITHOUT CONTROLS — GROUPS B, C AND D

Dimensions (In.)

kW ABCD

.6

1

1.8 34 20 7

.6

3

.2

3

7.6

.0

4

4.5 70 48 24 11

.0

9

G SERIES MODELS WITH BUILT-IN CONTROLS — GROUPS B, C AND D

Dimensions (In.)

kW ABCD

1.6

1.8 34 20 7

3.6

3.2

7.6

4.0

4.5 72 48 24 11

9.0

Figure 1A

N/A

58 32 16 13

Figure 1B

N/A

58 32 16 13

G SERIES MODELS WITH THERMOSTAT ONLY — GROUPS C AND D

Table 1 — Suggested Heater Mounting Screws — Types and Sizes

Type of Mounting ** Accessory Screw Size to Fit

Surface Hardware Screw Type Drill Size and Type Mtg Hole Size

Concrete Block

Masonry

Wood Studs — — Wood or Metal (Self Tapping) — — † # 1/4” x.................lg

Plaster wall Hollow or

Similar Type

* Metal Beam, Nuts

Channel, etc. Washers

*If clearance permits use washer, lock washer and nut; otherwise drill and tap to these lengths, add thickness of beam, washers, nut, etc.

**If mounting structure permits. Except plastered hollow walls explosive type anchors can be used. Suggested size noted in Table and/or

sketches should be used to determine size of anchors.

†Select overall length of screw to provide a minimum penetration of 1 inch into base wall material.

2

Ackerman Rd. Hd. Mach. Steel 1/2” Masonry † 1/4” x 20 x ............lg

Rd. Hd. Mach Steel or Pan Hd.

Metal (Self Tapping)

Rd. Hd. Mach. Steel #7 Twist † 1/4” x 20 x ............lg

5/16” Masonry † # 1/4” x .................lg

Lead Anchor

— — Toggle Bolt #7 Twist † # 1/4” x .................lg

Figure 1C

Dimensions (In.)

kW ABCD

1.6

1.8 34 20 7

3.6

3.2

58 32 16 13

7.6

4.0

4.5 70 48 24 11

9.0

N/A

7/8

Mounting Hole

Detail “A”

Page 3

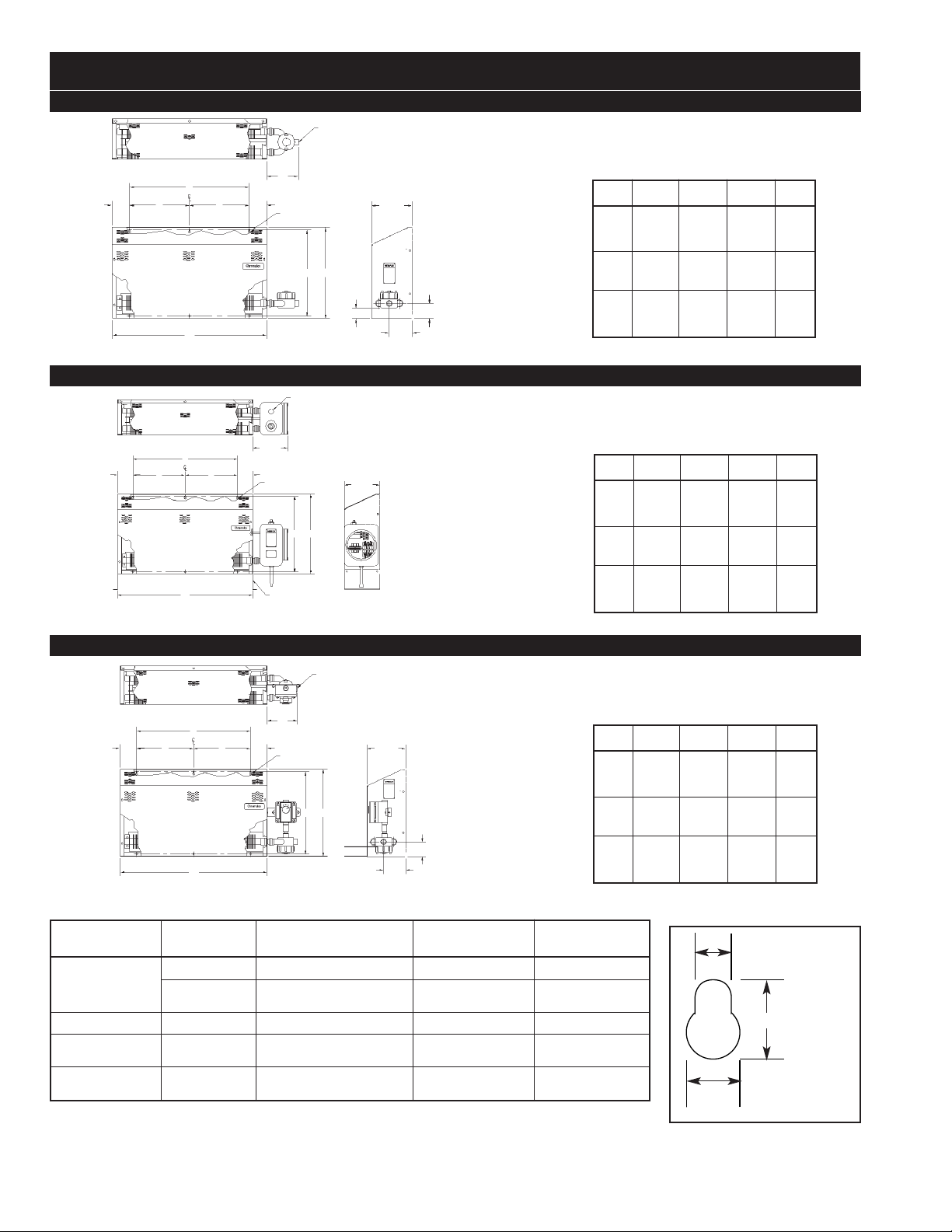

WIRING

Elements

Optional Thermostat

Built-In or Ext. Supplied

Single Phase — No Controls, 120-277V

& Heater Amps < 22A

Elements

Optional Thermostat

Built-In or Ext. Supplied

Single Phase — No Controls, Volts > 277V

& 120–277V When Heater Amps > 22A

External

Contactor

480V 1PH

Double

Element

Heaters

Control

Voltage

Elements

Optional Thermostat

Built-In or Ext. Supplied

External

Contactor

Control

Voltage

Three Phase – No Controls

Optional Thermostat

Built-In or Ext. Supplied

Contactor

Transformer

Element Wiring

1 PH or 3 PH

Single or Double

Element

Single or Three Phase

With Controls — Contactor & Transformer

Optional Thermostat

Built-In or Ext. Supplied

Contactor

Line

Voltage

Control

Voltage

Element Wiring

1 PH or 3 PH

Single or Double

Element

Single or Three Phase

With Controls — Contactor & Line Voltage Control

Optional Thermostat

Built-In or Ext. Supplied

Contactor

Element Wiring

1 PH or 3 PH

Single or Double

Element

Single or Three Phase With Controls —

Contactor & External Supplied Control Voltage

Terminal

Block

External

Supplied

Control

Voltage

WARNING:

heaters must be effectively grounded in accordance with the

National Electrical Code.

1. All wiring must be done in accordance with local codes and

the National Electrical Code by a qualified person as

defined in the NEC.

WARNING:

2. Rough-in-line-wiring to unit in manner approved for hazardous locations. (See warning below.)

3. Wire per diagrams 1 through 6 based on the rating and control options listed in table 2. Refer to table 3 for amperage

specifications.

Hazard of Shock. Any installation involving electric

Use copper conductors only.

4. Remove cover of conduit box for connections. Use either

opening and plug the other with the plug provided.

5. In single phase units (except 480 V) the heaters must be

wired in parallel, combining L1 to L1, L2 to L2 and for 3

phase unit, L3 to L3. On 480V single phase units the elements must be wired in series.

6. Re-assemble cover with a minimum of 7 turns.

WARNING:

(Group B atmospheres) To prevent ignition of

Group B atmospheres, conduit runs must not exceed 3/4” in

size and all conduit runs 1/2” size and larger must have a sealing fitting connected within 2”, 6” or 18” of the terminal enclosure depending on the exact model. For correct placement,

refer to data located on the enclosure label.

Diagram 1

Diagram 3

L2 or N

L1

L3

L2

L1

Diagram 2

Diagram 4

L2

or N

L1

L2

L1

L3

L2

L1

L3

L2

L1

Diagram 5

CAUTION:

devices with their electric heating equipment. Where the consequences of failure may be severe, back-up controls are essential. The safety of the installation is the responsibility of the

user.

Users should install adequate controls and safety

L3

L2

L1

Diagram 6

OPERATION

1. Do not operate heater at voltages in excess of that stamped

on the heater since excess voltage will shorten heater life

and cause high element temperatures which may exceed

allowable temperatures of operation in a hazardous

atmosphere.

3

Page 4

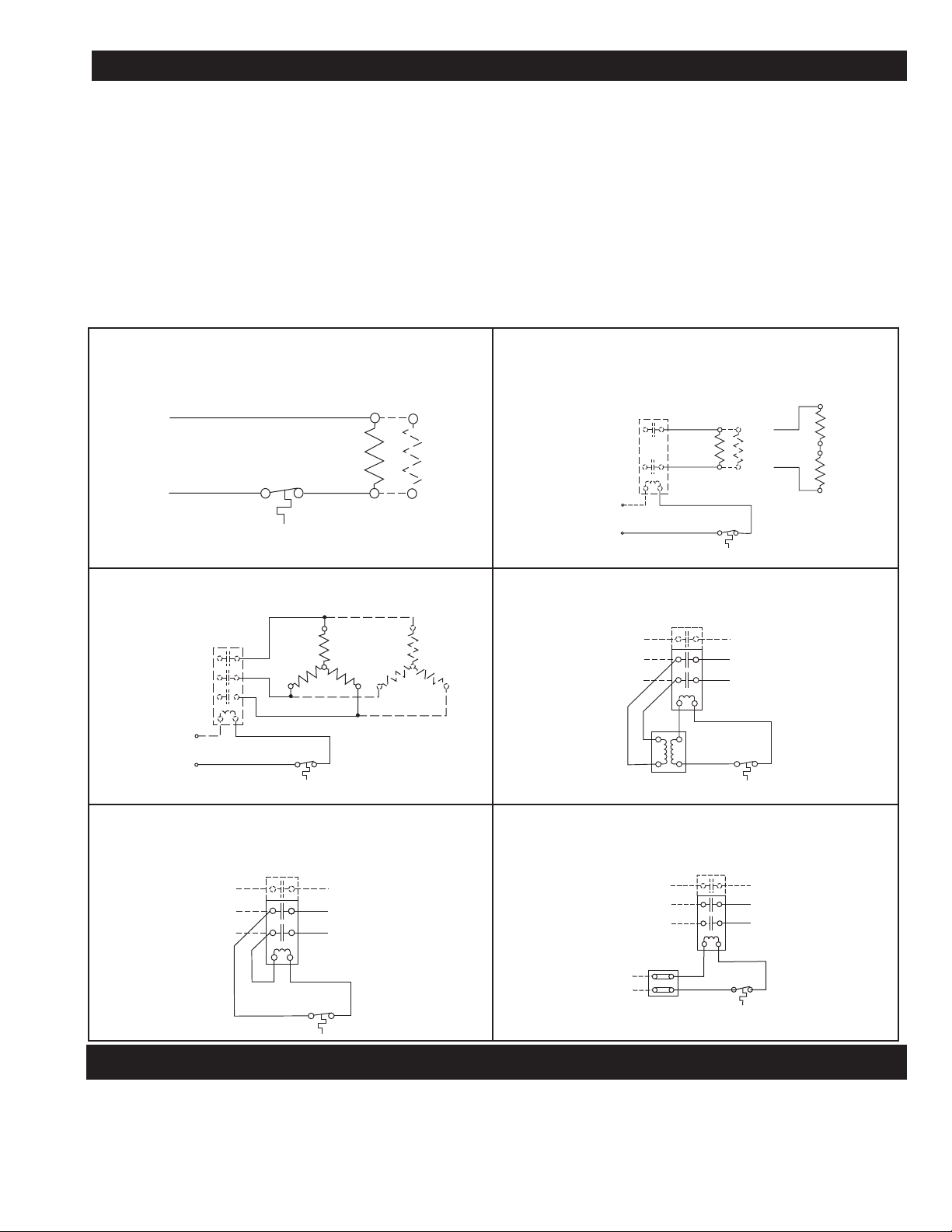

MAINTENANCE

WARNING:

before servicing or replacing heaters.

1. Before activating for next heating season, vacuum or use

compressed air to remove accumulated dust or lint, which

otherwise may restrict proper air flow.

Hazard of Shock. Disconnect all power to heater

2. Periodically check all electrical connections and retighten

to avoid electrical wiring difficulties.

3. Check to ensure terminal cover is tightly closed before

energizing.

Sealed, Heavy duty Finned

Element assembly.

Explosion Proof

Junction Box

for Field wiring

Mounting Holes

4

Page 5

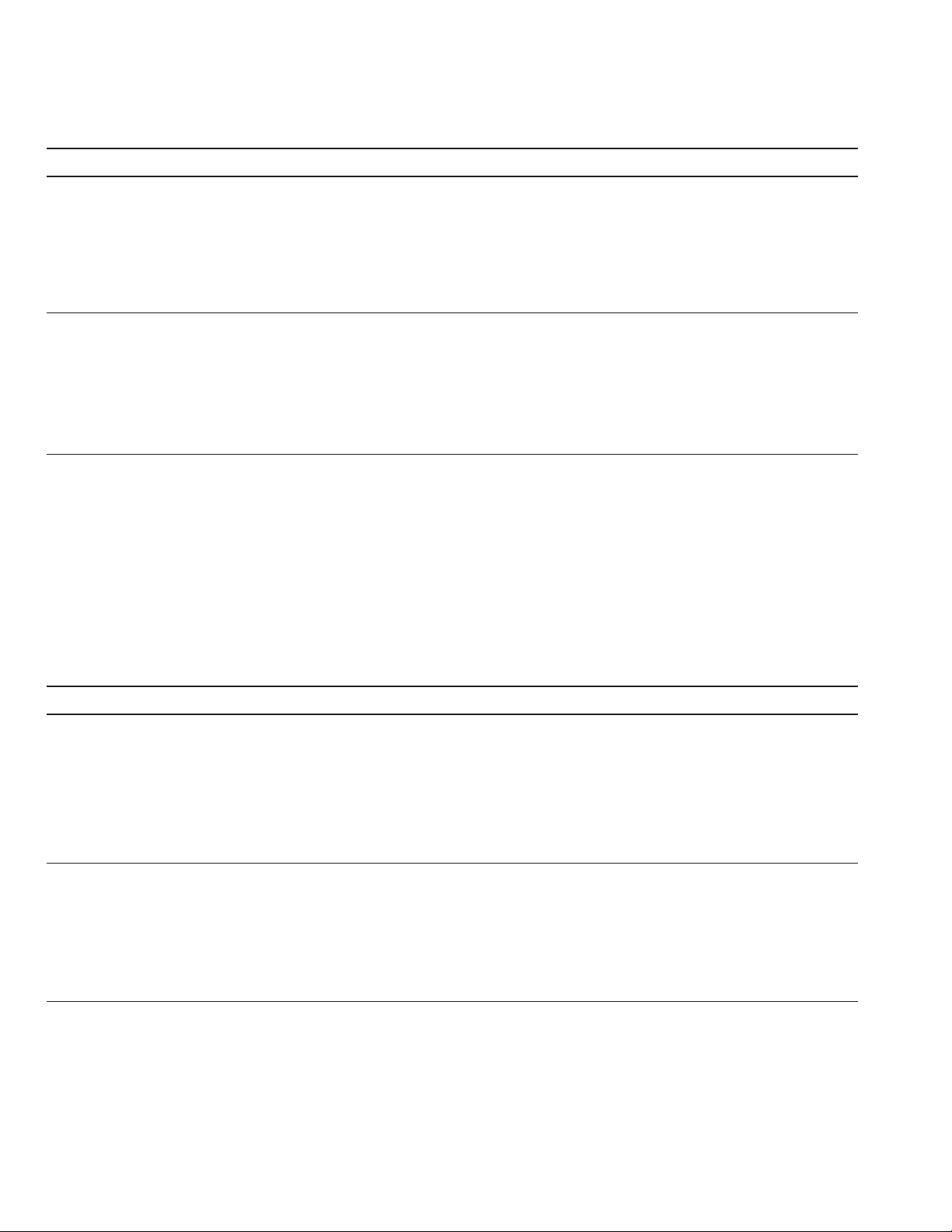

MODEL NUMBER BREAKDOWN

Model

G-Series Explosion Proof Convection Heater

Temperature Rating

G Code kW ID Number ˚F ˚C (BTU)

160 1.6 T3A 356 180 5,500

180 1.8 T2A 536 280 6,150

320 3.2 T3A 356 180 11,000

360 3.6 T2A 536 280 12,300

400 4.0 T3A 356 180 13,600

450 4.5 T2A 536 280 15,350

760 7.6 T2A 536 280 25,930

900 9.0 T2A 536 280 30,700

Code Voltage Maximum kW Allowable

0 120 1.8

4 240 9.0

38 380 9.0

48 480 9.0

6 600 9.0

7 277 9.0

8 208 9.0

Code Phase

1 1Ø

3 3Ø (Not available in 120, 277V)

Control Combination

Code Contactor Transformer

Coil Secondary

None None

CX 24 Volt 24 Volt

CX* 120 Volt 120 Volt

Code Temperature Control

TB Thermostat 40 - 90˚F

T Thermostat Group C & D

None

Group B, C & D

50 - 90˚F

G 760 48 3 CX T

Note: Letter “B” will appear after phase code to indicate engineering version.

5

Page 6

TABLE 2 — TEMPERATURE SPECIFICATIONS

DIMENSIONS REPLACEMENTS ELEMENTS REQUIREMENTS

Temperature Rating T3A 356˚F (180˚C) Common To Units W & W/O Suffix B

kW BTU Volts Phase Amps Model Width A Height B Depth C Wt. (Lbs.) Element P/N Qty.

1.6 5,500 208 1 7.7 CVEP-C-16-81 34” 20” 9” 58 003-304650-002 2

1.6 5,500 208 3 4.4 CVEP-C-16-83 34” 20” 9” 58 003-304650-005 2

1.6 5,500 240 1 6.7 CVEP-C-16-21 34” 20” 9” 58 003-304650-096 2

1.6 5,500 240 3 3.8 CVEP-C-16-23 34” 20” 9” 58 003-304650-006 2

1.6 5,500 277 1 5.8 CVEP-C-16-71 34” 20” 9” 58 003-304650-004 2

1.6 5,500 480 1 3.3 CVEP-C-16-41 34” 20” 9” 58 003-304650-003 2

1.6 5,500 480 3 1.9 CVEP-C-16-43 34” 20” 9” 58 003-304650-009 2

1.6 5,500 575 3 1.6 CVEP-C-16-63 34” 20” 9” 58 003-304650-010 2

3.2 11,000 208 1 15.4 CVEP-C-32-81 58” 20” 9” 94 003-304650-023 2

3.2 11,000 208 3 8.9 CVEP-C-32-83 58” 20” 9” 94 003-304650-026 2

3.2 11,000 240 1 13.3 CVEP-C-32-21 58” 20” 9” 94 003-304650-093 2

3.2 11,000 240 3 7.7 CVEP-C-32-23 58” 20” 9” 94 003-304650-027 2

3.2 11,000 277 1 11.6 CVEP-C-32-71 58” 20” 9” 94 003-304650-025 2

3.2 11,000 480 1 6.7 CVEP-C-32-41 58” 20” 9” 94 003-304650-093 2

3.2 11,000 480 3 3.8 CVEP-C-32-43 58” 20” 9” 94 003-304650-030 2

3.2 11,000 575 3 3.2 CVEP-C-32-63 58” 20” 9” 94 003-304650-031 2

4.0 13,600 208 1 19.2 CVEP-C-40-81 70” 20” 9” 112 003-304650-045 2

4.0 13,600 208 3 11.1 CVEP-C-40-83 70” 20” 9” 112 003-304650-048 2

4.0 13,600 240 1 16.7 CVEP-C-40-21 70” 20” 9” 112 003-304650-046 2

4.0 13,600 240 3 9.6 CVEP-C-40-23 70” 20” 9” 112 003-304650-049 2

4.0 13,600 277 1 14.4 CVEP-C-40-71 70” 20” 9” 112 003-304650-047 2

4.0 13,600 480 1 8.3 CVEP-C-40-41 70” 20” 9” 112 003-304650-046 2

4.0 13,600 480 3 4.8 CVEP-C-40-43 70” 20” 9” 112 003-304650-052 2

4.0 13,600 575 3 7.0 CVEP-C-40-63 70” 20” 9” 112 003-304650-053 2

G16081

G16083

G16041

G16043

G16071

G160481

G160483

G16063

G32081

G32083

G32041

G32043

G32071

G320481

G320483

G32063

G40081

G40083

G40041

G40043

G40071

G400481

G400483

G40063

Temperature Rating T2A 536˚F (280˚C)

kW BTU Volts Phase Amps Model Width A Height B Depth C Wt. (Lbs.) Element P/N Qty.

1.8/3.6 6,150/12,300 208 1 8.7/17.3 CVEP-C-18/36-81 34” 20” 9” 46/58 003-304650-034

1.8/3.6 6,150/12,300 208 3 5.0/10.0 CVEP-C-18/36-83 34” 20” 9” 46/58 003-304650-038

1.8/3.6 6,150/12,300 240 1 7.5/15.0 CVEP-C-18/36-21 34” 20” 9” 46/58 003-304650-098

1.8/3.6 6,150/12,300 240 3 4.3/8.7 CVEP-C-18/36-23 34” 20” 9” 46/58 003-304650-039

1.8/3.6 6,150/12,300 277 1 6.5/13.0 CVEP-C-18/36-71 34” 20” 9” 46/58 003-304650-036

1.8/3.6 6,150/12,300 480 1 3.8/7.5 CVEP-C-18/36-41 34” 20” 9” 46/58 003-304650-037/-098

1.8/3.6 6,150/12,300 480 3 2.2/4.3 CVEP-C-18/36-43 34” 20” 9” 46/58 003-304650-042

1.8/3.6 6,150/12,300 575 3 1.8/3.6 CVEP-C-18/36-63 34” 20” 9” 46/58 003-304650-043

7.6 25,930 208 1 36.5 CVEP-C-76-81 58” 20” 9” 94 003-304650-055 2

7.6 25,930 208 3 21.1 CVEP-C-76-83 58” 20” 9” 94 003-304650-058 2

7.6 25,930 240 1 31.7 CVEP-C-76-21 58” 20” 9” 94 003-304650-099 2

7.6 25,930 240 3 18.3 CVEP-C-76-23 58” 20” 9” 94 003-304650-059 2

7.6 25,930 277 1 27.4 CVEP-C-76-71 58” 20” 9” 94 003-304650-057 2

7.6 25,930 480 1 15.8 CVEP-C-76-41 58” 20” 9” 94 003-304650-056 2

7.6 25,930 480 3 9.1 CVEP-C-76-43 58” 20” 9” 94 003-304650-062 2

7.6 25,930 575 3 7.6 CVEP-C-76-63 58” 20” 9” 94 003-304650-063 2

4.5/9.0 15,350/30,700 208 1 21.6/43.3 CVEP-C-45/90-81 70” 20” 9” 87/112 003-304650-065

4.5/9.0 15,350/30,700 208 3 12.5/25.0 CVEP-C-45/90-83 70” 20” 9” 87/112 003-304650-069

4.5/9.0 15,350/30,700 240 1 18.8/37.5 CVEP-C-45/90-21 70” 20” 9” 87/112 003-304650-100

4.5/9.0 15,350/30,700 240 3 10.8/21.7 CVEP-C-45/90-23 70” 20” 9” 87/112 003-304650-070

4.5/9.0 15,350/30,700 277 1 16.2/32.5 CVEP-C-45/90-71 70” 20” 9” 87/112 003-304650-067

4.5/9.0 15,350/30,700 480 1 9.4/18.8 CVEP-C-45/90-41 70” 20” 9” 87/112 003-304650-068/-070

4.5/9.0 15,350/30,700 480 3 5.4/10.8 CVEP-C-45/90-43 70” 20” 9” 87/112 003-304650-073

4.5/9.0 15,350/30,700 575 3 4.5/9.0 CVEP-C-45/90-63 70” 20” 9” 87/112 003-304650-074

G(180)36081

G(180)36083

G(180)36041

G(180)36043

G(180)36071

G(180)360481

G(180)360483

G(180)36063

G76081

G76083

G76041

G76043

G76071

G760481

G760483

G76063

G(450)90081

G(450)90083

G(450)90041

G(450)90043

G(450)90071

G(450)900481

G(450)900483

G(450)90063

1 or 2

1 or 2

1 or 2

1 or 2

1 or 2

1 or 2

1 or 2

1 or 2

1 or 2

1 or 2

1 or 2

1 or 2

1 or 2

1 or 2

1 or 2

1 or 2

6

Page 7

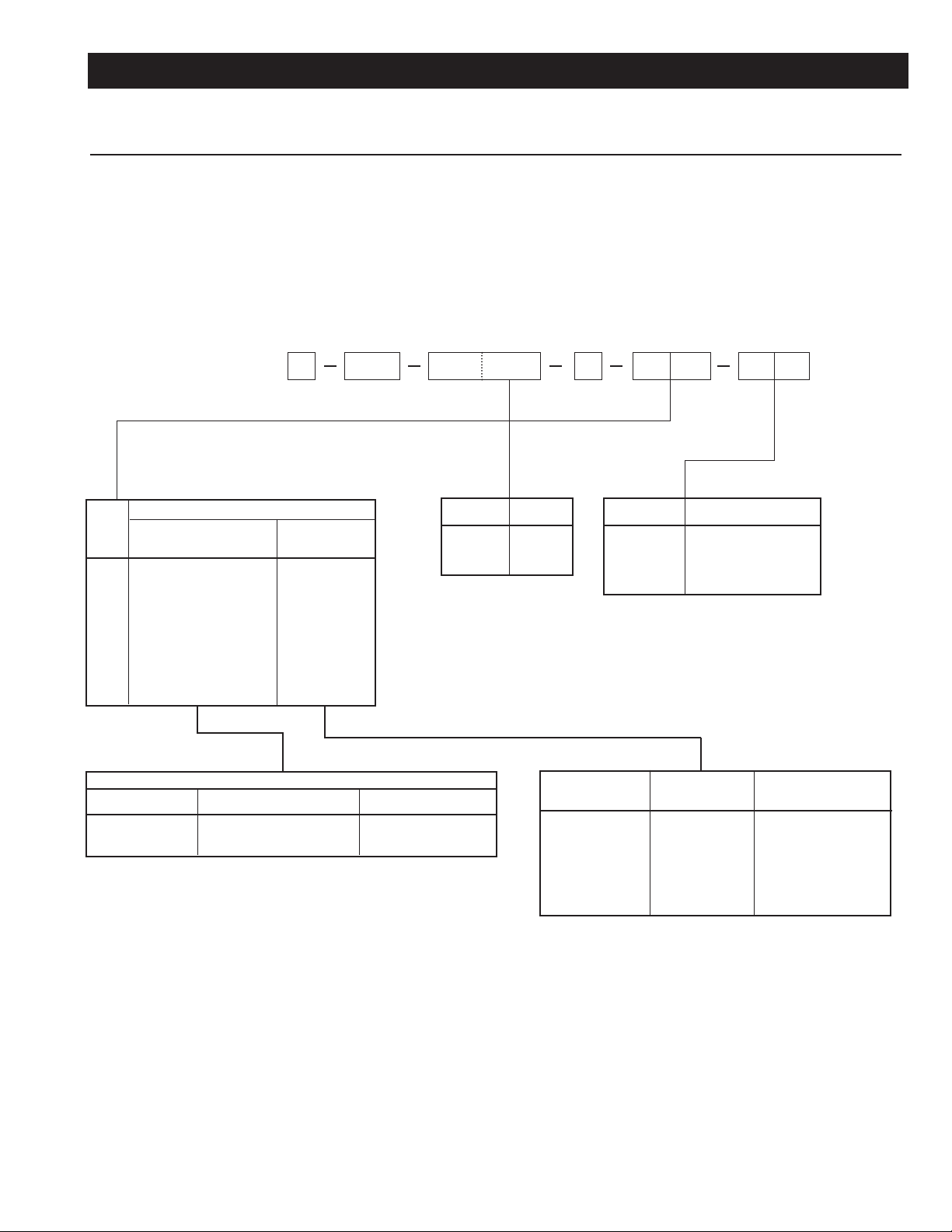

REPLACEMENT PARTS

Model Front Rear Right Left Element

Any Voltage Cover Assembly Cover Assembly Side Panel Side Panel Support Bracket

1.6, 1.8, 3.6 KW 207-304644-101 207-304644-001 207-304644-201 304-304644-301 027-304646-001

3.2, 7.6 KW 207-304644-102 207-304644-002 207-304644-201 304-304644-301 027-304646-001

4.0, 4.5, 9.0 KW 207-304644-103 207-304644-003 207-304644-201 304-304644-301 027-304646-001

kW Volts Phase Control Stat

G

Control Combination

Code Contactor Transformer

Coil Secondary

None None

CX 24 Volt 24 Volt

CX* 120 Volt 120 Volt

Contactor

Coil Voltage 30 Amp 50 Amp

24V 072-304551-001 072-303180-002

120V 072-303180-007 072-304551-008

Code Phase

1 1Ø

3 3Ø

B

Code Thermostat

None

TB 300-049197-003

T 300-113075-002

Primary Secondary

Voltage Voltage

208/240/480 24 315-304252-002

208/240/480 120 315-304252-001

277 24 315-304252-004

575 24 315-304252-005

277/575 120 315-304252-003

Transformer

7

Page 8

LIMITED WARRANTY

All products manufactured by Marley Engineered Products are warranted against defects in workmanship and materials for one year

from date of installation, except heating elements which are warranted against defects in workmanship and materials for five years

from date of installation. This warranty does not apply to damage from accident, misuse, or alteration; nor where the connected voltage is more than 5% above the nameplate voltage; nor to equipment improperly installed or wired or maintained in violation of the

product’s installation instructions. All claims for warranty work must be accompanied by proof of the date of installation.

The customer shall be responsible for all costs incurred in the removal or reinstallation of products, including labor costs, and shipping costs incurred to return products to Marley Engineered Products Service Center.Within the limitations of this warranty, inoperative units should be returned to the nearest Marley authorized service center or the Marley Engineered Products Service Center,

and we will repair or replace, at our option, at no charge to you with return freight paid by Marley. It is agreed that such repair or

replacement is the exclusive remedy available from Marley Engineered Products.

THE ABOVE WARRANTIES ARE IN LIEU OF ALL OTHER WARRANTIES EXPRESSED OR IMPLIED. AND ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE WHICH EXCEED THE AFORESAID

EXPRESSED WARRANTIES ARE HEREBY DISCLAIMED AND EXCLUDED FROM THIS AGREEMENT. MARLEY ENGINEERED

PRODUCTS SHALL NOT BE LIABLE FOR CONSEQUENTIAL DAMAGES ARISING WITH RESPECT TO THE PRODUCT,

WHETHER BASED UPON NEGLIGENCE, TORT, STRICT LIABILITY, OR CONTRACT.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above exclusion or limitation may

not apply to you. This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

For the address of your nearest authorized service center, contact Marley Engineered Products in Bennettsville, SC, at 1-800-642-

4328. Merchandise returned to the factory must be accompanied by a return authorization and service identification tag, both available from Marley Engineered Products. When requesting return authorization, include all catalog numbers shown on the products.

HOW TO OBTAIN WARRANTY SERVICE AND

WARRANTY PARTS PLUS GENERAL INFORMATION

1. Warranty Service or Parts

2. Purchase Replacement Parts

3. General Product Information

Note:

When obtaining service always have the following:

1. Model number of the product

2. Date of manufacture

3. Part number or description

1-800-642-4328

1-800-654-3545

www.marleymep.com

8

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

5200-2472-002

ECR 39003

02/11

Page 9

Calentador a convección

para ubicaciones riesgosas

Serie G

(Modelo B)

GENERAL

Los calentadores a convección de tipo Serie G están diseñados para usar en ambientes riesgosos de Clase I, Div. I. Las

unidades sin opciones de control son adecuados para áreas

clasificadas como Grupos B, C y D. Las unidades con controles integrados pueden proveerse para los grupos C y D o

B, C y D. Referirse a la clasificación estampada en la placa

de especificaciones del calentador.

ADVERTENCIA:

riesgosas, este calentador no debe instalarse en áreas

donde los vapores o gases estén presentes con una temperatura de combustión menores de 280°C (536°F) (T2A) a

1.8kV, 3.6kV, 4.5kV, 7.2kV, 9.0kV R 180°C (356°F)(T3A) a

1.6kV, 3.2kV y 4.0k.

ADVERTENCIA:

temperaturas ambiente que excedan los 40°C (104°F).

NOTA:

define los requerimientos para la instalación de equipo eléctrico en ubicaciones riesgosas (Clasificadas)

El Articulo 500 del Código Eléctrico Nacional (NEC)

Para prevenir la combustión en atmósferas

Estos calentadores no deben operarse en

GUARDAR ESTAS INSTRUCCIONES

!

1. Conectar los calentadores sólo al mismo voltaje de línea que en

la placa de especificaciones del calentador.

2.

Todos los controles tales como el termostato y el contactor, cuando es requerido, deben tener la misma clasificación nominal de la

característica a prueba de explosión que el calentador.

3.

No instalar una unidad sobre la otra.

4.

Las unidades deben montarse a un mínimo de 8" sobre el piso.

5.

Los calentadores deben montarse sobre la pared en una posición

horizontal con el extremo terminal a la derecha solamente. No

empotrar

6.

Todos los adaptadores de instalación eléctrica de la unidad, conductos, cableado y sellos deben cumplir con los códigos NEC y

locales para ubicaciones riesgosas. Se requiere protección de

fusible o de interruptor de circuito de la línea externa.

7. Riesgo de choque eléctrico. El calentador debe conectarse efectivamente a tierra de acuerdo con el Código Eléctrico Nacional

8.

El no entender y observar estas instrucciones de instalación y las

notas de "ADVERTENCIA" contenidas aquí, puede resultar en

lesiones personales graves, muerte o daños substanciales a la

propiedad.

nunca

el calentador en una pared.

.

INSTALACION

ADVERTENCIA:

toda la electricidad antes de instalar el calentador.

Nota:

Los calentadores pueden montarse individualmente de

extremo a extremo. Los calentadores pueden montarse directamente sobre cualquier tipo de superficie (mampostería, concreto, bloque, paredes enyesadas, marco de trabajo de metal,

etc.) usando el herraje apropiado.

1. Extraer el panel delantero extrayendo los pernos roscados.

2. Ubicar la posición deseada del calentador en la pared.

3. Ubicar los orificios de montaje para el panel posterior. El

panel posterior debe estar a un mínimo de 8" desde

el piso.

4. Referirse a la Figura 1A, 1B, ó 1C para la disposición de

los orificios de montaje para cada tamaño del armazón.

Riesgo de choque eléctrico. Desconectar

5. Taladrar un orificio piloto en la superficie de montaje de la

pared en cada ubicación del orificio de montaje. Usar un

taladro de tamaño pequeño conveniente.

6. Taladrar los orificios de montaje de acuerdo con el tamaño

en la Tabla 1. Insertar los anclas donde sea aplicable.

7. Fijar el panel posterior a la pared con los tornillos notados

en la Tabla 1.

ADVERTENCIA:

panel delantero. El flujo de aire a través de los elementos térmicos requiere que el panel delantero esté en su lugar. Es

posible sufrir lesiones del elemento térmico caliente con la

cubierta delantera extraída.

No se debe operar nunca el calentador sin el

9

Page 10

INSTALACION

3/4" Conduit Entrance

7

D

See Detail "A"

8

-15/16

D

C

C

B

19

2

0-1/16

A

2

-3/8

5

-1/16

3-3/8

1

" Conduit Entrance

8-7/8

D

See Detail "A"

C

C

D

1

9

20-1/16

8-15/16

A

B

Feet are Optional

Primarily Used to Protect

T

hermowell During Shipping

and Installation

3/4" Conduit Entrance

7

D

See Detai "A"

C

C

D

19

20-1/16

8-15/16

5-1/16

3-3/8

A

2-3/8

1/2

7/8

5/16

MODELOS DE SERIE G SIN CONTROLES - GRUPOS B, C Y D

Entrada del conducto de 3/4"

Dimensiones (Pulg.)

KW ABCD

Ver el detalle "A"

MODELOS DE SERIE G CON CONTROLES INTEGRADOS - GRUPOS B, C Y D

Entrada del conducto de 1"

.6

1

1.8 34 20 7

.6

3

3.2

58 32 16 13

.6

7

.0

4

4.5 70 48 24 11

9.0

Dimensiones (Pulg.)

Figura 1A

N/A

Figura 1B

Ver el detalle "A"

El soporte es opcional usado primordialmente para proteger la

pared térmica durante el transporte y la instalación

1.6

1.8 34 20 7

3.6

3.2

7.6

4.0

4.5 72 48 24 11

9.0

MODELOS DE SERIE G CON TERMOSTATO SOLAMENTE - GRUPOS C Y D

kW ABCD

Entrada del conducto de 3/4"

Dimensiones (Pulg.)

kW ABCD

Ver el detalle "A"

1.6

1.8 34 20 7

3.6

3.2

7.6

4.0

4.5 70 48 24 11

9.0

Tabla 1 - Tornillos de montaje sugeridos del calentador - Tipos y Tamaños

Tipo de superficie ** Ferretería de Tamaño d/torn.p/adap.

de montaje accesorios Tipo de tornillo Tamaño y tipo del taladro al tam. d/orif. d/mont.

N/A

58 32 16 13

Figura 1C

N/A

58 32 16 13

Bloque de concreto

Mampostería

Montantes de madera — — Madera o Metal (autoroscante) — — † # 1/4" x..................lg

Pared de yeso hueca o

de tipo similar

* Columna de metal, Tuercas

* Si la distancia lo permite usar arandela, arandela y tuerca de seguridad; de otra manera taladrar y roscar a esos largos, agregar el espesor de la columna, aran-

delas, tuerca, etc.

** Si la estructura de montaje lo permite. Excepto para paredes huecas de sello pueden usarse anclas de tipo explosivo. Debe usarse el tamaño sugerido indicado

en la Tabla y/o esquemas, para determinar el tamaño de los anclas.

† Seleccionar el largo total del tornillo para proporcionar un mínimo de 5 pulgadas dentro del material de base de la pared

canal, etc. Arandelas

Ackerman Acer. d/máq. d/cab. red. Mampostería de 1/2" † 1/4" x 20 x.............lg

Acer. d/máq. d/cab. red. o de

cab. pan de metal (autoroscante)

Acer. d/máq. d/cab. red. Giro no. 7 † 1/4" x 20 x.............lg

Mampostería de 5/16" † # 1/4" x..................lg

Ancla de plomo

— — Perno oscil. Giro no. 7 † # 1/4" x..................lg

10

7/8

Orificio de montaje

Detalle "A"

Page 11

CABLEADO

Elements

Single Phase — No Controls, 120-277V

& Heater Amps < 22A

Elements

Optional Thermostat

Built-In or Ext. Supplied

External

Contactor

480V 1PH

Double

Element

Heaters

Elements

Optional Thermostat

Built-In or Ext. Supplied

External

Contactor

Optional Thermostat

Contactor

Element Wiring

1 PH or 3 PH

Single or Double

Element

Optional Thermostat

Built-In or Ext. Supplied

Contactor

Element Wiring

1 PH or 3 PH

Single or Double

Element

Optional Thermostat

Contactor

Element Wiring

1 PH or 3 PH

Single or Double

Element

ADVERTENCIA:

que incluya calentadores eléctricos debe conectarse a tierra de

acuerdo con el Código Eléctrico Nacional.

1. Todo el cableado debe efectuarse de acuerdo con los

códigos locales y el Código Eléctrico Nacional por una persona calificada según definido en el NEC.

ADVERTENCIA:

2. Cablear a la unidad desde la línea de una manera aprobada

para ubicaciones riesgosas. (Ver la advertencia de abajo).

3. Cablear según los diagramas 1 a 6 basado en la clasificación

nominal y las opciones de control listadas en la tabla 2. Para

las especificaciones de amperaje referirse a la Tabla 3.

Riesgo de choque eléctrico. Toda instalación

Usar conductores de cobre solamente.

4. Extraer la cubierta de la caja de conducto para las conexiones. Usar cualquiera de las aberturas y taponar la otra

con el tapón provisto.

5. En las unidades monofásicas (excepto de 480V) los calentadores deben cablearse en paralelo, combinando L1 a L1,

L2 a L2 y para una unidad trifásica, L3 a L3. En las

unidades monofásicas de 480V los elementos deben

cablearse en serie.

6. Reensamblar la cubierta con un mínimo de 7 vueltas.

ADVERTENCIA:

(Atmósferas de Grupo B) Para prevenir la

combustión en atmósferas de Grupo B, las longitudes de los

conductos no deben exceder 3/4" en tamaño y todos los largos

de conducto de tamaño de 1/2" y mayores deben tener un

adaptador sellador conectado dentro de 2", 6" ó 18" del

armazón del terminal dependiendo del modelo exacto.

Referirse a los datos ubicados en el rótulo del armazón.

Monofásico - Sin controles, 120-277V

y amp. del calentador < 22A

L2 ó N

L1

Diagrama 1

Trifásico - Sin controles

Contactor

externo

Voltaje de

control

Diagrama 3

L3

L2

L1

Elementos

Termostato opcional integrado

o provisto externamente

Elementos

Termostato opcional integra-

do o provisto externamente

Monofásico - Sin controles, Voltios > 277V

y 120-277 cuando los amp. del calentador > 22A

Contactor externo

L2

ó N

L1

Voltaje de con-

trol

Diagrama 2

Mono o trifásico

con controles - Contactor y Transformador

Contactor

Diagrama 4

Transformador

Elementos

Termostato opcional integrado o provisto externamente

L3

Cableado del elemento

L2

1 ó 3 fases

Elemento simple o doble

L1

Termostato opcional integrado o provisto externamente

L2

L1

Calentadores

de doble elemento

de 480V

1 Fase

Mono o trifásico

con controles - Control de contactor y de voltaje de línea

Voltaje de

línea

Voltaje de

control

Diagrama 5

PRECAUCION:

mecanismos de seguridad con su equipo calentador eléctrico.

Donde las consecuencias de una falla pueden ser graves, son esenciales los controles auxiliares. La seguridad de la instalación es la

responsabilidad del usuario.

Los usuarios deben instalar controles adecuados y

Contactor

L3

Cableado del elemento

1 ó 3 fases

L2

Elemento simple o doble

L1

Termostato opcional integrado o provisto externamente

Mono o Trifásico con controles Contactor y voltaje de control provisto externamente

control provisto

externamente

Diagrama 6

OPERACION

1. No operar el calentador a voltajes en exceso del estampado

en el calentador dado que el exceso de voltaje acortará la

duración del calentador y causará temperaturas elevadas

del elemento las que pueden exceder las temperaturas

permisibles de operación en una atmósfera riesgosa

Voltaje de

Bloque ter-

minal

Contactor

Cableado del elemento

L3

1 ó 3 fases

L2

Elemento simple o doble

L1

Termostato opcional integrado o

provisto externamente

11

Page 12

MANTENIMIENTO

ADVERTENCIA:

tricidad entrante al calentador antes de prestar servicio o

reemplazar los calentadores.

1. Antes de activar para la próxima temporada de calefacción, aspirar o usar aire comprimido para eliminar el polvo

o pelusa acumulada, lo que de otra manera puede

restringir el flujo apropiado de aire.

Riesgo de choque. Desconectar toda la elec-

2. Inspeccionar periódicamente las conexiones eléctricas y

reajustar para evitar dificultades en el cableado eléctrico.

3. Inspeccionar para asegurar que la cubierta del terminal

esté bien cerrada antes de activar.

Conjunto del elemento con aletas,

sellado y de servicio pesado.

Caja de empalme a prueba de

explosión para el cableado de

campo.

12

Orificios de montaje

Page 13

DETALLE DEL NUMERO DE MODELO

odelo

M

Serie G Calentador a convección a prueba de explosión

Clasificación nominal de temperatura

G Código kV Número de ident. ˚F ˚C (BTU)

60 1.6 T3A 356 180 5,500

1

180 1.8 T2A 536 280 6,150

320 3.2 T3A 356 180 11,000

360 3.6 T2A 536 280 12,300

400 4.0 T3A 356 180 13,600

50 4.5 T2A 536 280 15,350

4

760 7.6 T2A 536 280 25,930

900 9.0 T2A 536 280 30,700

Código Voltaje kV máx. permisible

0 120 1.8

4 240 9.0

38 380 9.0

48 480 9.0

6 600 9.0

7 277 9.0

8 208 9.0

Código Fase

1 1Ø

3 3Ø (No está disponible en 120, 277V)

Combinación de control

Código Combinación Secundario de

CX 24 Voltios 24 Voltios

CX* 120 Voltios 120 Voltios

de control transformador

Ninguno Ninguno

Código Control de temperatura

Ninguno

TB Termostato 40 - 90°F

Grupo B, C y D

T Termostato de Grupos C y D

50 - 90°F

G 760 48 3 CX T

Nota: La letra "B" aparecerá después del código de fase para indicar la versión de ingeniería.

13

Page 14

TABLA 2 - ESPECIFICACIONES DE TEMPERATURA

DIMENSIONES REPUESTOS REQUERIMIENTO DE ELEMENTOS

Clasificación nominal de temperatura T3A 356°F (180°C) Común a las unidades con o sin sufijo B

kV BTU Voltios Fases Amps Modelo Ancho A Altura B Largo C Peso (Lbs.) N/P d/elem. cant.

1.6 5,500 208 1 7.7 CVEP-C-16-81 34” 20” 9” 58 003-304650-002 2

1.6 5,500 208 3 4.4 CVEP-C-16-83 34” 20” 9” 58 003-304650-005 2

1.6 5,500 240 1 6.7 CVEP-C-16-21 34” 20” 9” 58 003-304650-096 2

1.6 5,500 240 3 3.8 CVEP-C-16-23 34” 20” 9” 58 003-304650-006 2

1.6 5,500 277 1 5.8 CVEP-C-16-71 34” 20” 9” 58 003-304650-004 2

1.6 5,500 480 1 3.3 CVEP-C-16-41 34” 20” 9” 58 003-304650-003 2

1.6 5,500 480 3 1.9 CVEP-C-16-43 34” 20” 9” 58 003-304650-009 2

1.6 5,500 575 3 1.6 CVEP-C-16-63 34” 20” 9” 58 003-304650-010 2

3.2 11,000 208 1 15.4 CVEP-C-32-81 58” 20” 9” 94 003-304650-023 2

3.2 11,000 208 3 8.9 CVEP-C-32-83 58” 20” 9” 94 003-304650-026 2

3.2 11,000 240 1 13.3 CVEP-C-32-21 58” 20” 9” 94 003-304650-093 2

3.2 11,000 240 3 7.7 CVEP-C-32-23 58” 20” 9” 94 003-304650-027 2

3.2 11,000 277 1 11.6 CVEP-C-32-71 58” 20” 9” 94 003-304650-025 2

3.2 11,000 480 1 6.7 CVEP-C-32-41 58” 20” 9” 94 003-304650-093 2

3.2 11,000 480 3 3.8 CVEP-C-32-43 58” 20” 9” 94 003-304650-030 2

3.2 11,000 575 3 3.2 CVEP-C-32-63 58” 20” 9” 94 003-304650-031 2

4.0 13,600 208 1 19.2 CVEP-C-40-81 70” 20” 9” 112 003-304650-045 2

4.0 13,600 208 3 11.1 CVEP-C-40-83 70” 20” 9” 112 003-304650-048 2

4.0 13,600 240 1 16.7 CVEP-C-40-21 70” 20” 9” 112 003-304650-046 2

4.0 13,600 240 3 9.6 CVEP-C-40-23 70” 20” 9” 112 003-304650-049 2

4.0 13,600 277 1 14.4 CVEP-C-40-71 70” 20” 9” 112 003-304650-047 2

4.0 13,600 480 1 8.3 CVEP-C-40-41 70” 20” 9” 112 003-304650-046 2

4.0 13,600 480 3 4.8 CVEP-C-40-43 70” 20” 9” 112 003-304650-052 2

4.0 13,600 575 3 7.0 CVEP-C-40-63 70” 20” 9” 112 003-304650-053 2

G16081

G16083

G16041

G16043

G16071

G160481

G160483

G16063

G32081

G32083

G32041

G32043

G32071

G320481

G320483

G32063

G40081

G40083

G40041

G40043

G40071

G400481

G400483

G40063

Clasificación nominal de temperatura T2A 536˚F (280˚C)

kV BTU Voltios Fases Amps Modelo Ancho A Altura B Largo C Peso (Lbs.) N/P d/elem. cant.

1.8/3.6 6,150/12,300 208 1 8.7/17.3 CVEP-C-18/36-81 34” 20” 9” 46/58 003-304650-034

1.8/3.6 6,150/12,300 208 3 5.0/10.0 CVEP-C-18/36-83 34” 20” 9” 46/58 003-304650-038

1.8/3.6 6,150/12,300 240 1 7.5/15.0 CVEP-C-18/36-21 34” 20” 9” 46/58 003-304650-098

1.8/3.6 6,150/12,300 240 3 4.3/8.7 CVEP-C-18/36-23 34” 20” 9” 46/58 003-304650-039

1.8/3.6 6,150/12,300 277 1 6.5/13.0 CVEP-C-18/36-71 34” 20” 9” 46/58 003-304650-036

1.8/3.6 6,150/12,300 480 1 3.8/7.5 CVEP-C-18/36-41 34” 20” 9” 46/58 003-304650-037/-098

1.8/3.6 6,150/12,300 480 3 2.2/4.3 CVEP-C-18/36-43 34” 20” 9” 46/58 003-304650-042

1.8/3.6 6,150/12,300 575 3 1.8/3.6 CVEP-C-18/36-63 34” 20” 9” 46/58 003-304650-043

7.6 25,930 208 1 36.5 CVEP-C-76-81 58” 20” 9” 94 003-304650-055 2

7.6 25,930 208 3 21.1 CVEP-C-76-83 58” 20” 9” 94 003-304650-058 2

7.6 25,930 240 1 31.7 CVEP-C-76-21 58” 20” 9” 94 003-304650-099 2

7.6 25,930 240 3 18.3 CVEP-C-76-23 58” 20” 9” 94 003-304650-059 2

7.6 25,930 277 1 27.4 CVEP-C-76-71 58” 20” 9” 94 003-304650-057 2

7.6 25,930 480 1 15.8 CVEP-C-76-41 58” 20” 9” 94 003-304650-056 2

7.6 25,930 480 3 9.1 CVEP-C-76-43 58” 20” 9” 94 003-304650-062 2

7.6 25,930 575 3 7.6 CVEP-C-76-63 58” 20” 9” 94 003-304650-063 2

4.5/9.0 15,350/30,700 208 1 21.6/43.3 CVEP-C-45/90-81 70” 20” 9” 87/112 003-304650-065

4.5/9.0 15,350/30,700 208 3 12.5/25.0 CVEP-C-45/90-83 70” 20” 9” 87/112 003-304650-069

4.5/9.0 15,350/30,700 240 1 18.8/37.5 CVEP-C-45/90-21 70” 20” 9” 87/112 003-304650-100

4.5/9.0 15,350/30,700 240 3 10.8/21.7 CVEP-C-45/90-23 70” 20” 9” 87/112 003-304650-070

4.5/9.0 15,350/30,700 277 1 16.2/32.5 CVEP-C-45/90-71 70” 20” 9” 87/112 003-304650-067

4.5/9.0 15,350/30,700 480 1 9.4/18.8 CVEP-C-45/90-41 70” 20” 9” 87/112 003-304650-068/-070

4.5/9.0 15,350/30,700 480 3 5.4/10.8 CVEP-C-45/90-43 70” 20” 9” 87/112 003-304650-073

4.5/9.0 15,350/30,700 575 3 4.5/9.0 CVEP-C-45/90-63 70” 20” 9” 87/112 003-304650-074

G(180)36081

G(180)36083

G(180)36041

G(180)36043

G(180)36071

G(180)360481

G(180)360483

G(180)36063

G76081

G76083

G76041

G76043

G76071

G760481

G760483

G76063

G(450)90081

G(450)90083

G(450)90041

G(450)90043

G(450)90071

G(450)900481

G(450)900483

G(450)90063

1 or 2

1 or 2

1 or 2

1 or 2

1 or 2

1 or 2

1 or 2

1 or 2

1 or 2

1 or 2

1 or 2

1 or 2

1 or 2

1 or 2

1 or 2

1 or 2

14

Page 15

PIEZAS DE REPUESTO

Modelo Conj. de la Conj. de la Panel del Panel del Brazo d/soporte

Cualquier voltaje cubierta del. cubierta post. lado der. lado izq. d/elemento

1.6, 1.8, 3.6 KW 207-304644-101 207-304644-001 207-304644-201 304-304644-301 027-304646-001

3.2, 7.6 KW 207-304644-102 207-304644-002 207-304644-201 304-304644-301 027-304646-001

4.0, 4.5, 9.0 KW 207-304644-103 207-304644-003 207-304644-201 304-304644-301 027-304646-001

kV Voltios Fase Control Estat

G

Combinación de control

Código Bobina del Secundario de

contactor transformador

Ninguno Ninguno

CX 24 Voltios 24 Voltios

CX* 120 Voltios 120 Voltios

Contactor

Voltaje de la bobina 30 Amp 50 Amp

24 Voltios 072-304551-001 072-303180-002

120 Voltios 072-303180-007 072-304551-008

Código Fase

1 1Ø

3 3Ø

B

Código Termostato

Ninguno

TB 300-049197-003

T 300-113075-002

Voltaje Voltaje

primario secundario

208/240/480 24 315-304252-002

208/240/480 120 315-304252-001

277 24 315-304252-004

575 24 315-304252-005

277/575 120 315-304252-003

Transformador

15

Page 16

T

GARANTÍA LIMITADA

odos los productos fabricados por Marley Engineered Products están garantizados contra defectos de mano de obra o materiales durante un año, a

partir de la fecha de instalación. Esta garantía no se aplica a daños que resulten de accidentes, mal uso o alteraciones, ni a casos en los cuales el voltaje de alimentación sea más del 5% mayor que el voltaje especificado en la placa del producto. La garantía tampoco se aplica a equipo mal instalado o

alambrado o cuyo mantenimiento se haya efectuado sin seguir las instrucciones de instalación del producto. Toda solicitud de trabajo amparado por la

garantía deberá ir acompañada por un comprobante de la fecha de instalación.

El cliente será responsable de todos los costos incurridos por la remoción o reinstalación de los productos, incluyendo costos de mano de obra y transporte incurridos en la devolución de los productos al Centro de Servicio de Marley Engineered Products. Dentro de las limitaciones de esta garantía, la

unidades inoperantes deberán devolverse al centro de servicio autorizado por Marley más cercano o al Centro de Servicio de Marley Engineered

Products. Nosotros repararemos o reemplazaremos la unidad, a discreción nuestra y sin costo para el cliente, con el flete de retorno pagado por Marley.

El cliente acepta que esta reparación o reemplazo será el único remedio que podrá exigir a Marley Engineered Products.

LAS GARANTÍAS ANTERIORES SUSTITUYEN A CUALQUIER OTRA GARANTÍA, YA SEA EXPLÍCITA O IMPLÍCITA. TODA GARANTÍA IMPLÍCITA

DE COMERCIABILIDAD O IDONEIDAD PARA UN PROPÓSITO ESPECÍFICO QUE EXCEDA A LAS GARANTÍAS ANTERIORES QUEDARÁ EXCLUIDA DE ESTE ACUERDO. MARLEY ENGINEERED PRODUCTS NO SERÁ RESPONSABLE DE DAÑOS CONSECUENTES RELACIONADOS CON

EL PRODUCTO, YA SEA QUE ESTÉN BASADOS EN NEGLIGENCIA, AGRAVIO, RESPONSABILIDAD ESTRICTA O CONTRATO.

A

lgunos estados no permiten la exclusión o limitación de los daños incidentales o consecuentes, por lo cual es posible que la exclusión o limitación anterior no sea aplicable en su caso. Esta garantía le otorga derechos legales específicos y usted podrá tener otros derechos que varíen de un estado al

otro.

Si desea conocer la dirección del centro de servicio autorizado más cercano a usted, comuníquese con Marley Engineered Products en Bennettsville,

C

arolina del Sur, llamando al 1-800-642-4328. La mercancía devuelta a la fábrica deberá ir acompañada por una autorización de devolución y un mar-

b

ete de identificación de servicio, los cuales pueden obtenerse de Marley Engineered Products. Al solicitar la autorización de devolución, por favor incluya

todos los números de catálogo que aparecen en los productos.

COMO OBTENER SERVICIO EN GARANTIA,

PIEZAS DE REPUESTO E INFORMACION GENERAL

1. Servicio o repuestos, en garantía:

2. Compra de piezas de repuesto:

3. Información general sobre productos:

Nota:

Cuando solicite servicio, siempre dé la información que sigue:

1. Número de modelo del producto

2. Fecha de fabricación

3. Número de parte o descripción

1-800-642-4328

1-800-654-3545

www.marleymep.com

16

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

5200-2472-002

ECR

39003

02/11

Page 17

Série G

(Modèle B)

Radiateur à convection pour

les endroits dangereux

GÉNÉRALITÉS

Les radiateurs à convection de la série G sont conçus pour

être utilisés dans les endroits dangereux Classe I, Div. I. Les

unités sans les contrôles optionnels peuvent être utilisées

dans les endroits classés Groupe B, C & D. Les unités avec

contrôles incorporés peuvent être utilisées dans les endroits

classés C & D ou B, C & D. Référez-vous à la classification

imprimée sur la plaque signalétique du radiateur.

AVERTISSEMENT :

mables ne prennent feu, ce radiateur ne doit pas être installé

où les vapeurs et les gaz ont une température d’allumage

inférieure à 280 °C (536 °F) (T2A) à 1,8 kW, 3,6 kW, 4,5 kW,

7,2 kWet 9,0 kW ou bien 180 °C (356 °F) (T2A) à 1,6 kW,

3,2 kW et 4,0 kW.

AVERTISSEMENT :

ner dans une température ambiante supérieure à 40 °C (104

°F).

NOTE:

indique les conditions d’installation du matériel électrique

dans les endroits classés dangereux

L’article 400 du Code national électrique (NEC)

Pour éviter que les atmosphères inflam-

Ces radiateurs ne doivent pas fonction-

!

1. Ne connectez les radiateurs qu’à une alimentation correspondant à celle indiquée sur la plaque signalétique.

2. Tous les contrôles comme le thermostat et les contacteurs, le cas échéant, doivent avoir la même résistance

aux explosions que le radiateur.

3. N’installez pas les unités les unes au-dessus des autres.

4. Les unités doivent être montées à au moins 8 pouces du

sol.

5. Les radiateurs doivent être montés sur un mur dans une

position horizontale avec le terminal sur le côté droit

uniquement. N’encastrez jamais le radiateur dans le mur.

6. Toutes les connexions, les conduites, les câbles et les

joints de l’installation électrique doivent respecter les

normes NEC et les codes locaux concernant les endroits

dangereux. Les lignes extérieures doivent être protégées

par des fusibles ou un disjoncteur.

7. Danger d’électrocution. Le radiateur doit être effectivement mis à la terre en respect du Code électrique national.

8. Si vous ne comprenez pas ou ne respectez pas les

instructions d’installation et les "AVERTISSEMENTS" contenu dans ce manuel, vous risquez des blessures graves

ou même la mort et des dégâts matériels.

CONSERVEZ CES INSTRUCTIONS

INSTALLATION

AVERTISSEMENT:

mentation avant d’installer le radiateur.

NOTE

: Les radiateurs peuvent être montés individuellement bout

à bout. Les radiateurs peuvent être montés directement sur tout

type de surface (maçonnerie, murs en plâtre, charpente

métallique, etc.) avec les vis appropriées.

1. Retirez la panneau avant en retirant les boulons filetés.

2. Identifiez la position désirée du radiateur sur le mur.

3. Positionnez les trous de montage du panneau arrière.

4. Référez-vous à la Figure 1A, 1B, ou 1C pour l’emplace-

ment des trous de montage en fonction de la taille du

radiateur.

Danger d’électrocution. Débranchez l’ali-

5. Percez un pré-trou dans la surface de montage du mur

pour chaque trou. Utilisez un petit foret.

6. Percez les trous de montage selon les dimensions du

Tableau 1. Insérez des chevilles si nécessaire.

7. Fixez le panneau arrière avec les vis indiquées dans le

Tableau 1.

AVERTISSEMENT:

neau avant. Le flux d’air sur les éléments chauffants nécessite

que le panneau avant soit en place. Vous risquez des

blessures lorsque le panneau avant n’est pas en place.

N’utilisez jamais le radiateur sans le pan-

17

Page 18

INSTALLATION

3

/4" Conduit Entrance

7

D

S

ee Detail "A"

8-15/16

D

C

C

B

1

9

20-1/16

A

2-3/8

5-1/16

3-3/8

1" Conduit Entrance

8

-7/8

D

See Detail "A"

C

C

D

19

20-1/16

8

-15/16

A

B

Feet are Optional

Primarily Used to Protect

Thermowell During Shipping

and Installation

3/4" Conduit Entrance

7

D

See Detai "A"

C

C

D

19

20-1/16

8-15/16

5-1/16

3-3/8

A

2-3/8

1/2

7/8

5/16

MODÈLES SÉRIE G SANS LES CONTRÔLES – GROUPES B, C ET D

Entrée de la conduite de 3/4 pouce

Dimensions (pouces)

KW ABCD

oir détail "A"

V

MODÈLES SÉRIE G AVEC LES CONTRÔLES INCORPORÉS – GROUPES B, C ET D

Entrée de la conduite de 1 pouce

.6

1

1.8 34 20 7

.6

3

3.2

58 32 16 13

.6

7

.0

4

4.5 70 48 24 11

9.0

Dimensions (pouces)

Figure 1A

N/A

Figure 1B

Voir détail "A"

Les pieds sont optionnels et sont utilisés essentiellement pour protéger

le mur thermique pendant le transport et l’installation

MODÈLES SÉRIE G AVEC THERMOSTAT UNIQUEMENT – GROUPES C ET D

Entrée de la conduite de 3/4 pouce

Voir détail "A"

Tableau 1 – Vis de montage suggérées – types et tailles

Type de surface ** Quincaillerie

de montage accessoire Type de vis Type et taille du foret Dimensions de la vis

kW ABCD

1.6

1.8 34 20 7

3.6

3.2

58 32 16 13

7.6

N/A

4.0

4.5 72 48 24 11

9.0

Figure 1C

Dimensions (pouces)

kW ABCD

1.6

1.8 34 20 7

3.6

3.2

58 32 16 13

7.6

4.0

4.5 70 48 24 11

9.0

N/A

Maçonnerie

en parpaing

Poteaux en bois — — Bois ou métal auto-taraudeuse — — † 1/4 pouce x lg

Mur creux avec

plâtre ou similaire

* Poutre ou U Écrous

métallique, etc. rondelles

* Si vous avez la place, utilisez une rondelle, un rondelle de verrouillage et un écrou. Dans le cas contraire, percez en utilisant ces dimensions et ajoutez l’épais-

seur de la poutre, des rondelles, de l’écrou, etc.

** Si la structure de montage le permet. Vous pouvez utiliser les chevilles de type explosif sauf pour les murs creux plâtrés. Utilisez les dimensions notées dans le

Tableau et/ou sur les diagrammes pour vous aider à déterminer lea taille des chevilles.

† Sélectionnez la tailel des vis pour obtenir une pénétration d’au moins 1 pouce dans le matériau de base du mur.

Ackerman Tête ronde, vis à métal en acier 1/2 pouce, maçonnerie † 1/4 pouce x 20 x lg

Tête ronde, vis à métal ou

ête plate auto-taraudeuse

Vis tête ronde en acier n° 7 normal † 1/4 pouce x 20 x lg

5/16 pouce, maçonnerie † 1/4 pouce x lg

Cheville

— — boulon n° 7 normal † 1/4 pouce x lg

18

7/8

Détail "A" du trou

de montage

Page 19

CÂBLAGE

Elements

Single Phase — No Controls, 120-277V

& Heater Amps < 22A

Elements

Optional Thermostat

Built-In or Ext. Supplied

External

Contactor

480V 1PH

Double

Element

Heaters

Elements

Optional Thermostat

Built-In or Ext. Supplied

External

Contactor

Optional Thermostat

Contactor

Element Wiring

1 PH or 3 PH

Single or Double

Element

Optional Thermostat

Built-In or Ext. Supplied

Contactor

Element Wiring

1 PH or 3 PH

Single or Double

Element

Optional Thermostat

Contactor

Element Wiring

1 PH or 3 PH

Single or Double

Element

AVERTISSEMENT :

teurs électriques doit être effectivement mise à la terre en respect du

Code électrique national.

1. Tout le câblage doit être fait en accord avec les codes locaux et le

Code électrique national par une personne qualifiée selon la définition NEC.

AVERTISSEMENT :

2. Préparez l’arrivée électrique vers l’unité de manière approuvée

pour les endroits dangereux (voir l’avertissement ci-dessous).

3. Câblez selon les diagrammes 1 à 6 en fonction de la puissance et

des options de contrôle listées dans le tableau 2. Référez-vous au

tableau 3 pour les caractéristiques d’ampérage.

Danger d’électrocution. Toute installation de radia-

N’utilisez que des conducteurs en cuivre.

4. Retirez le couvercle du boîtier pour accéder aux connexions.

Utilisez une des deux ouvertures et bouchez l’autre avec le bouchon fourni.

5. Pour les unités monophasées (sauf 480 V), les radiateurs doivent

être câblés en parallèle, en connectant L1 à L1 et L2 à L2 et pour

les unités triphasées L3 à L3. Sur les unités monophasées de 480

V, les éléments doivent être connectés en série.

6. Remontez le couvercle avec au moins 7 tours.

AVERTISSEMENT :

des atmosphères de groupe B, les tronçons de conduites ne doivent

pas faire plus de 3/4 pouce et toutes les conduites de 1/2 pouce ou

plus doivent être munies d’un connecteur hermétique à 2, 6 ou 18

pouces du placard de terminal selon le modèle exact. Pour connaître le

placement exact, référez-vous aux données sur l’étiquette du boîtier.

(atmosphères groupe B) Pour éviter l’allumage

Monophasé - pas de contrôles, 120 à 277 V &

radiateur < 22 A

L2 ou N

L1

Diagramme 1

Triphasé - pas de contrôles

Contacts

extérieurs

L3

L2

L1

Tension de

contrôle

Diagramme 3

Éléments

Thermostat optionnel incorporé

ou de source externe

Éléments

Thermostat optionnel incor-

poré ou de source externe

Monophasé - pas de contrôles, > 277 V et 120 à 277 V

lorsque radiateur > 22 A

Contacts

extérieurs

L2

Éléments

ou N

L1

Tension de con-

trôle

Diagramme 2

Monophasé ou triphasé avec contrôles contacts et transformateur

Contacts

L3

Câblage de l’élément

L2

Monophasé ou triphasé

L1

Élément simple ou double

Diagramme 4

Transformateur

L2

L1

Thermostat optionnel incorporé ou de source externe

Thermostat optionnel incorporé

ou de source externe

Radiateurs à

doubles éléments 480 V

monophasé

Monophasé ou triphasé avec contrôles contacts et tension de contrôle extérieure

Tension de

ligne

Tension de

contrôle

Diagramme 5

ATTENTION

sécurité adéquats avec les radiateurs électriques. Si les conséquences

d’une panne risquent d’être sévères, il est essentiel que vous installiez

des contrôles redondants. La sécurité de l’installation est la responsabilité de l’utilisateur.

: Vous devez installer des contrôles et des systèmes de

Contacts

L3

Câblage de l’élément

L2

Monophasé ou triphasé

L1

Élément simple ou double

Thermostat optionnel

incorporé ou de source

externe

Monophasé ou triphasé avec contrôles contacts et tension de contrôle extérieure

Tension de con-

trôle extérieure

Diagramme 6

UTILISATION

1. N’utilisez pas le radiateur à des tensions supérieures à celles

indiquées sur l’étiquette car une surtension diminuerait la durée de

vie du radiateur et pourrait entraîner des températures d’élément

trop élevées qui pourraient dépasser les températures de fonctionnement autorisées dans un endroit dangereux

Bloc de

terminal

Contacts

Câblage de l’élément

L3

L2

Monophasé ou triphasé

L1

Élément simple ou double

Thermostat optionnel incorporé

ou de source externe

19

Page 20

ENTRETIEN

AVERTISSEMENT :

électrique du radiateur avant de réparer ou de remplacer l’unité.

1. Nettoyez le radiateur à l’aspirateur ou au jet d’eau (à la pression

du robinet) avant de le metrre en marche pour la prochaine saison

froide pour retirer la poussière et les saletés accumulées qui pourraient gêner le flot d’air.

Danger d’électrocution. Débranchez l’alimentation

2. Vérifiez périodiquement toutes les connexions électriques et

resserez-les pour éviter les difficultés de câblage.

3. Vérifiez que le couvercle de terminal est bien fermé avant de mettre le radiateur en route.

Ensemble de l’élément à ailettes

scellé de qualité industrielle

Boîtier de connexion résistant

aux explosions pour le

câblage sur le site

20

Trous de montage

Page 21

DÉCODAGE DU NUMÉRO DE MODÈLE

Modèle

Série G Radiateur à convection résistant aux explosions

Température maximum

G Code kW Numéro identifiant ˚F ˚C (BTU)

160 1.6 T3A 356 180 5,500

180 1.8 T2A 536 280 6,150

320 3.2 T3A 356 180 11,000

360 3.6 T2A 536 280 12,300

400 4.0 T3A 356 180 13,600

450 4.5 T2A 536 280 15,350

760 7.6 T2A 536 280 25,930

900 9.0 T2A 536 280 30,700

Code Tension Puissance maximum kW

0 120 1.8

4 240 9.0

38 380 9.0

48 480 9.0

6 600 9.0

7 277 9.0

8 208 9.0

Code Phase

1 1Ø

3 3Ø (Non disponible en 120 et 277 V)

Différentes combinaisons

Code Bobine de Secondaire du

contact transformateur

Aucun Aucun

CX 24 V 24 V

CX* 120 V 120 V

Code Contrôle de température

Aucun

TB Thermostat 40 à 90 °F

Groupe B, C & D

T Thermostat groupe C & D

50 à 90 °F

G 760 48 3 CX T

N.B. : La lettre "B" apparaît après chaque code de phase pour indiquer la version d’ingénierie.

21

Page 22

TABLEAU 2 - CARACTÉRISTIQUES DE TEMPÉRATURE

DIMENSIONS PIÈCES DE RECHANGE CARACTÉRISTIQUES DES ÉLÉMENTS

Température maximum T3A 356 °F (180°C) Commun aux unités avec et sans suffixe B

oids

kV BTU V Phases AMP Modèle Largeur A Hauteur B Profondeur C Qté.

1.6 5,500 208 1 7.7 CVEP-C-16-81 34” 20” 9” 58 003-304650-002 2

1.6 5,500 208 3 4.4 CVEP-C-16-83 34” 20” 9” 58 003-304650-005 2

1.6 5,500 240 1 6.7 CVEP-C-16-21 34” 20” 9” 58 003-304650-096 2

1.6 5,500 240 3 3.8 CVEP-C-16-23 34” 20” 9” 58 003-304650-006 2

1.6 5,500 277 1 5.8 CVEP-C-16-71 34” 20” 9” 58 003-304650-004 2

1.6 5,500 480 1 3.3 CVEP-C-16-41 34” 20” 9” 58 003-304650-003 2

1.6 5,500 480 3 1.9 CVEP-C-16-43 34” 20” 9” 58 003-304650-009 2

1.6 5,500 575 3 1.6 CVEP-C-16-63 34” 20” 9” 58 003-304650-010 2

G16081

G16083

G16041

G16043

G16071

G160481

G160483

G16063

P

livres)

(

N° de pièce

de l’élément

3.2 11,000 208 1 15.4 CVEP-C-32-81 58” 20” 9” 94 003-304650-023 2

3.2 11,000 208 3 8.9 CVEP-C-32-83 58” 20” 9” 94 003-304650-026 2

3.2 11,000 240 1 13.3 CVEP-C-32-21 58” 20” 9” 94 003-304650-093 2

3.2 11,000 240 3 7.7 CVEP-C-32-23 58” 20” 9” 94 003-304650-027 2

3.2 11,000 277 1 11.6 CVEP-C-32-71 58” 20” 9” 94 003-304650-025 2

3.2 11,000 480 1 6.7 CVEP-C-32-41 58” 20” 9” 94 003-304650-093 2

3.2 11,000 480 3 3.8 CVEP-C-32-43 58” 20” 9” 94 003-304650-030 2

3.2 11,000 575 3 3.2 CVEP-C-32-63 58” 20” 9” 94 003-304650-031 2

4.0 13,600 208 1 19.2 CVEP-C-40-81 70” 20” 9” 112 003-304650-045 2

4.0 13,600 208 3 11.1 CVEP-C-40-83 70” 20” 9” 112 003-304650-048 2

4.0 13,600 240 1 16.7 CVEP-C-40-21 70” 20” 9” 112 003-304650-046 2

4.0 13,600 240 3 9.6 CVEP-C-40-23 70” 20” 9” 112 003-304650-049 2

4.0 13,600 277 1 14.4 CVEP-C-40-71 70” 20” 9” 112 003-304650-047 2

4.0 13,600 480 1 8.3 CVEP-C-40-41 70” 20” 9” 112 003-304650-046 2

4.0 13,600 480 3 4.8 CVEP-C-40-43 70” 20” 9” 112 003-304650-052 2

4.0 13,600 575 3 7.0 CVEP-C-40-63 70” 20” 9” 112 003-304650-053 2

G32081

G32083

G32041

G32043

G32071

G320481

G320483

G32063

G40081

G40083

G40041

G40043

G40071

G400481

G400483

G40063

Température maximum T2A 536 °F (280 °C

kV

1.8/3.6 6,150/12,300 208 1 8.7/17.3 CVEP-C-18/36-81 34” 20” 9” 46/58 003-304650-034

1.8/3.6 6,150/12,300 208 3 5.0/10.0 CVEP-C-18/36-83 34” 20” 9” 46/58 003-304650-038

1.8/3.6 6,150/12,300 240 1 7.5/15.0 CVEP-C-18/36-21 34” 20” 9” 46/58 003-304650-098

1.8/3.6 6,150/12,300 240 3 4.3/8.7 CVEP-C-18/36-23 34” 20” 9” 46/58 003-304650-039

1.8/3.6 6,150/12,300 277 1 6.5/13.0 CVEP-C-18/36-71 34” 20” 9” 46/58 003-304650-036

1.8/3.6 6,150/12,300 480 1 3.8/7.5 CVEP-C-18/36-41 34” 20” 9” 46/58 003-304650-037/-098

1.8/3.6 6,150/12,300 480 3 2.2/4.3 CVEP-C-18/36-43 34” 20” 9” 46/58 003-304650-042

1.8/3.6 6,150/12,300 575 3 1.8/3.6 CVEP-C-18/36-63 34” 20” 9” 46/58 003-304650-043

BTU

V Phases AMP Modèle Largeur A Hauteur B Profondeur C Qté.

G(180)36081

G(180)36083

G(180)36041

G(180)36043

G(180)36071

G(180)360481

G(180)360483

G(180)36063

Poids

(livres)

N° de pièce

de l’élément

1 or 2

1 or 2

1 or 2

1 or 2

1 or 2

1 or 2

1 or 2

1 or 2

7.6 25,930 208 1 36.5 CVEP-C-76-81 58” 20” 9” 94 003-304650-055 2

7.6 25,930 208 3 21.1 CVEP-C-76-83 58” 20” 9” 94 003-304650-058 2

7.6 25,930 240 1 31.7 CVEP-C-76-21 58” 20” 9” 94 003-304650-099 2

7.6 25,930 240 3 18.3 CVEP-C-76-23 58” 20” 9” 94 003-304650-059 2

7.6 25,930 277 1 27.4 CVEP-C-76-71 58” 20” 9” 94 003-304650-057 2

7.6 25,930 480 1 15.8 CVEP-C-76-41 58” 20” 9” 94 003-304650-056 2

7.6 25,930 480 3 9.1 CVEP-C-76-43 58” 20” 9” 94 003-304650-062 2

7.6 25,930 575 3 7.6 CVEP-C-76-63 58” 20” 9” 94 003-304650-063 2

4.5/9.0 15,350/30,700 208 1 21.6/43.3 CVEP-C-45/90-81 70” 20” 9” 87/112 003-304650-065

4.5/9.0 15,350/30,700 208 3 12.5/25.0 CVEP-C-45/90-83 70” 20” 9” 87/112 003-304650-069

4.5/9.0 15,350/30,700 240 1 18.8/37.5 CVEP-C-45/90-21 70” 20” 9” 87/112 003-304650-100

4.5/9.0 15,350/30,700 240 3 10.8/21.7 CVEP-C-45/90-23 70” 20” 9” 87/112 003-304650-070

4.5/9.0 15,350/30,700 277 1 16.2/32.5 CVEP-C-45/90-71 70” 20” 9” 87/112 003-304650-067

4.5/9.0 15,350/30,700 480 1 9.4/18.8 CVEP-C-45/90-41 70” 20” 9” 87/112 003-304650-068/-070

4.5/9.0 15,350/30,700 480 3 5.4/10.8 CVEP-C-45/90-43 70” 20” 9” 87/112 003-304650-073

4.5/9.0 15,350/30,700 575 3 4.5/9.0 CVEP-C-45/90-63 70” 20” 9” 87/112 003-304650-074

G76081

G76083

G76041

G76043

G76071

G760481

G760483

G76063

G(450)90081

G(450)90083

G(450)90041

G(450)90043

G(450)90071

G(450)900481

G(450)900483

G(450)90063

22

1 or 2

1 or 2

1 or 2

1 or 2

1 or 2

1 or 2

1 or 2

1 or 2

Page 23

PIÈCES DE RECHANGE

Modèle Ensemble du Ensemble du Panneau latéral Panneau latéral Support de

Toutes tensions couvercle avant couvercle arrière droit gauche l’élément

1.6, 1.8, 3.6 KW 207-304644-101 207-304644-001 207-304644-201 304-304644-301 027-304646-001

3.2, 7.6 KW 207-304644-102 207-304644-002 207-304644-201 304-304644-301 027-304646-001

4.0, 4.5, 9.0 KW 207-304644-103 207-304644-003 207-304644-201 304-304644-301 027-304646-001

kW V Phase Contrôle Stat

G

Différentes combinaisons

Code Bobine de Transformateur

contact secondaire

Aucun Aucun

CX 24 V 24 V

CX* 120 V 120 V

Contacts

Tension de la bobine 30 A 50 A

24 V 072-304551-001 072-303180-002

120 V 072-303180-007 072-304551-008

Code Phases

1 1Ø

3 3Ø

B

Code Thermostat

Aucun

TB 300-049197-003

T 300-113075-002

Tension Tension

primaire secondaire

208/240/480 24 315-304252-002

208/240/480 120 315-304252-001

277 24 315-304252-004

575 24 315-304252-005

277/575 120 315-304252-003

Transformateur

23

Page 24

Tous les produits fabriqués par Marley Engineered Products sont garantis contre les défauts de main d'oeuvre et de matériaux pendant un an à compter

GARANTIE LIMITÉE

de la date de l'installation. Cette garantie ne s'applique pas aux dégâts provenant d'accident, de mauvais emploi ou de modification ; ni là où la tension

branchée est supérieure de 5 % à la tension de la plaque signalétique ; ni à un matériel incorrectement installé ou câblé ou entretenu en infraction aux

instructions d'installation du produit. Toutes les réclamations relatives à la main d'oeuvre de garantie doivent être accompagnées de la preuve de la date

d'installation.

Le client sera responsable de tous les frais encourus par la dépose ou la réinstallation des produits, y compris les frais de main d'oeuvre et les frais d'expédition encourus pour renvoyer les produits au Marley Engineered Products Service Center. Dans le cadre des limites de la présente garantie, les

appareils défectueux devraient être retournés au centre de service après-vente autorisé le plus proche ou au Centre Marley Engineered Products, et nous

les réparerons ou les remplacerons, à notre choix, gratuitement, les frais d'expédition de retour étant payés par Marley. Il est convenu qu'une telle réparation ou un tel remplacement sont les seuls recours pouvant être obtenus auprès de Marley Engineered Products.

LES GARANTIES CI-DESSUS REMPLACENT TOUTES LES AUTRES GARANTIES EXPLICITES OU IMPLICITES ET TOUTES LES GARANTIES

IMPLICITES DE COMMERCIABILITÉ ET D'ADAPTATION À UN USAGE PARTICULIER QUI DÉPASSENT LES GARANTIES EXPLICITES DÉCRITES

CI-DESSUS SONT RÉPUDIÉES PAR LA PRÉSENTE ET EXCLUES DE CET ACCORD. MARLEY ENGINEERED PRODUCTS NE SERA PAS RESPONSABLE DES DOMMAGES INDIRECTS SE RAPPORTANT AU PRODUIT, QUE CE SOIT PAR NÉGLIGENCE, DÉLIT, RESPONSABILITÉ STRICTE OU

CONTRAT.

Certaines provinces n'autorisent pas l'exclusion ou la limitation de dommages-intérêts fortuits ou indirects, de sorte que l'exclusion ou la limitation cidessus peut ne pas s'appliquer à vous. La présente garantie vous donne des droits légaux spécifiques et vous pouvez aussi avoir d'autres droits qui

varient d'une province à l'autre.

Pour l'adresse de votre centre d'entretien autorisé le plus proche, veuillez prendre contact avec Marley Engineered Products à Bennettsville, Caroline du

Sud, au 1-800-642-4328. La marchandise renvoyée à l'usine doit être accompagnée d'une autorisation de renvoi et d'une étiquette d'identification de

service, les deux sont à votre disposition auprès de Marley Engineered Products. Lors de la demande d'autorisation de renvoi, inclure tous les numéros

de catalogue qui figurent sur les produits.

COMMENT OBTENIR DES INFORMATIONS GÉNÉRALES ET

DEMANDER UNE RÉPARATION OU DES PICES SOUS GARANTIE

1. Réparations et piéces sous garantie

2. Achat de piéces de rechange

3. Informations générales sur les produits

Remarque :

Lorsque vous demandez de l'assistance, ayez toujours en main

1. Le numéro de modéle du produit

2. La date de fabrication

3. Numéro ou description de la piéce

1-800-642-4328

1-800-654-3545

www.marleymep.com

24

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

5200-2472-002

ECR

39003

02/11

Loading...

Loading...