Page 1

HTSS Series

Smart Series™ Wall Heater

IMPORTANT INSTRUCTIONS

READ CAREFULLY

tion should be directed to the warnings provided below which identify certain precautions and special instructions for safe and efficient installation and use. Studying these instructions first may save you considerable time and money later and keep your installation time to a minimum. If you are not familiar with electricity or feel uncomfortable in working with electricity, refer the installation of

this product to a licensed electrician or qualified person.

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK OR

INJURY TO PERSONS:

READ ALL INSTRUCTIONS

1.

heater.

ELECTRICAL SHOCK HAZARD:

2.

power coming to heater at circuit breaker box or main

disconnect switch and lock in OFF position before wiring.

All wiring must be in accordance with The National Electrical

Code and applicable local codes and ordinances.

The heater must be properly connected to an effective

building ground.

3. Verify the supply voltage coming to heater is the same as

shown on the heater nameplate before energizing.

Energizing at a voltage in excess of nameplate voltage will

damage heater and void warranty.

4. This heater has hot and arcing or sparking parts inside.

Do not install or use in areas where gasoline, paint, or flammable liquids are used or stored.

5. Do not install this heater upside down, sideways, in ceiling,

or floor. Install only as shown in this manual. Refer to

Mounting Clearances

must be maintained.

6. The heater assembly must be installed in the back box provided. Do not operate the heater without the grille installed.

7. This heater is not approved for use in corrosive

atmospheres such as marine, green house or chemical

storage areas.

- This manual provides instructions for the correct installation, safe use, and care of this product. Special atten-

WARNING

before installing or using the

Disconnect all electrical

, page 2 for minimum clearances that

8. Do not use outdoors.

9. Extreme caution is necessary when any heater is used by or

near children or invalids and whenever the heater is left

operating or unattended.

10. This heater is hot when in use. To avoid burns, do not let

bare skin touch hot surfaces. Keep combustible materials,

such as furniture, pillows, bedding, papers, clothes, and

curtains away from heater. Do not block air intakes or

exhaust in any manner. For efficient and safe operation, we

recommend keeping all items at least 3 feet from front of

heater.

11. Do not insert or allow foreign objects to enter any ventilation

or exhaust opening as this may cause an electric shock or

fire, or damage the heater.

12. Should the heater become blocked or otherwise overheat, it

is provided with a manual-reset thermal safety switch and

alarm light that will activate to alert that the heater has

cycled off. If warning light is on, check to see if the reason

for the overheating can be identified. Remove any

blockage, allow heater to cool, then press Reset button.

Heater should return to normal operation. Do not continue

to use heater if it repeatedly cycles off. Have it inspected

and repaired by a qualified repair person.

11. Use this heater only as described in this manual. Any other

use not recommended by the manufacturer may cause fire,

electric shock, or injury to persons.

!

SAVE THESE INSTRUCTIONS

Page 2

SPECIFICATIONS

MODEL WIRE

NUMBER VOLTS AMPS WATTS BTUHR SIZE

HT2024SS 240 1.0 - 8.3 250 - 2000 853 - 6826 14AWG

HT1502SS 120 1.6 - 12.5 200 - 1500 682 - 5120 12AWG

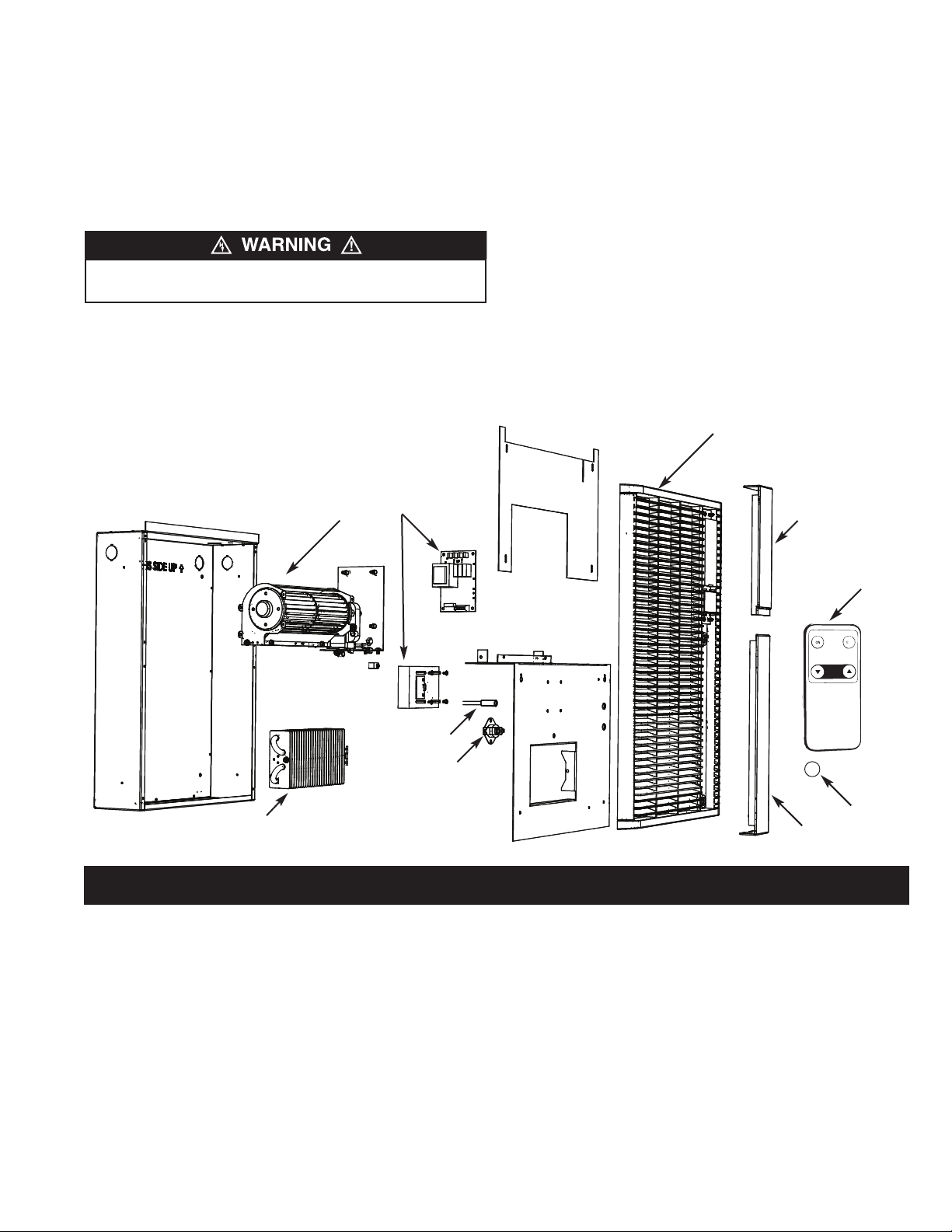

UNPACKING

The carton contains the following:

• Remote control

• Bottom bezel

• Grille with installed electronics

• Heater assembly

• Installation Instructions and User’s Manual

INSTALLATION

The heater is designed for recessed installation in 2” x 4” (50

mm x 101 mm) stud or larger wall sections using the back box

provided. The heater may be wired with standard building wire

(60°C). Refer to “Specifications” and heater nameplate for

correct supply voltage and wire size.

NOTE:

(450 to 600 mm) from floor to bottom of back box. DO NOT

install closer than 12” (305 mm) from the floor.

Mounting Clearances

The optimum mounting height for this heater is 18” to 24”

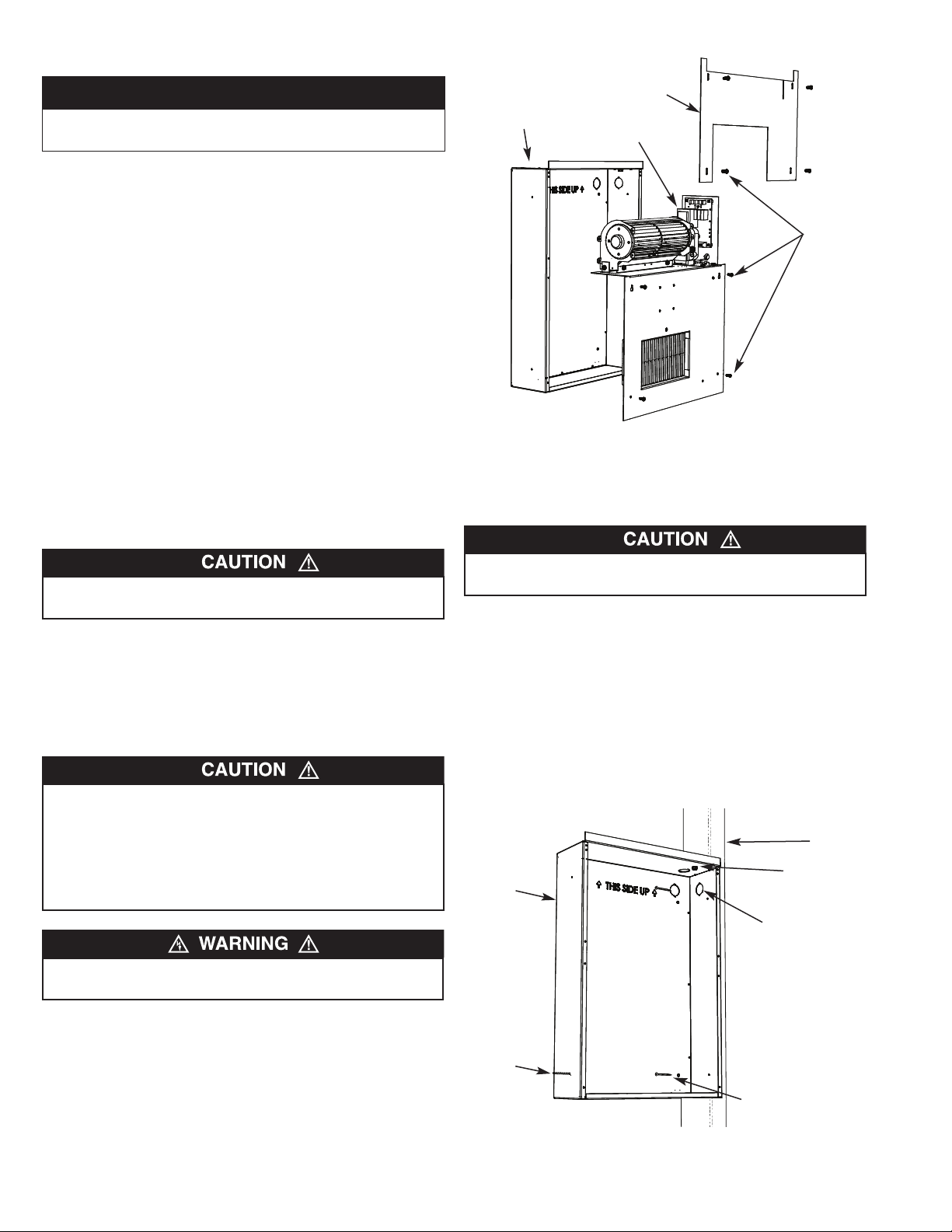

Junction Box

Cover

Back Box

Heater Assembly

Screws

(8) Total

Figure 1- Removing Heater Assembly From Back Box

Figure 1).

2. Remove one of the knockouts in the side of the back box

and install appropriate cable clamp (not supplied).

TO PROVIDE FOR SAFE OPERATION, THE FOLLOWING

CLEARANCES MUST BE MAINTAINED.

Wall Mounting Only:

a. Minimum twelve (12) inches (305 mm) to floor;

b. Minimum twelve (12) inches

(305 mm) to adjacent walls;

c. Minimum thirty six (36) inches

(915 mm) to ceiling.

THE HEATER IS HOT WHEN IN USE. DO NOT INSTALL THE

HEATER BEHIND DOOR, BEHIND TOWEL RACK, IN

CLOSET, WHERE CURTAINS OR DRAPES COULD TOUCH

OR BECOME SCORCHED BY HEATER, OR WHERE

AIRFLOW TO HEATER MAY BE OBSTRUCTED.

KEEP ELECTRICAL CORDS, BEDDING, FURNITURE AND

OTHER COMBUSTIBLES AWAY FROM HEATER.

TO PREVENT HAZARD OF FIRE OR ELECTRICAL SHOCK,

DO NOT INSTALL WITHOUT BACK BOX.

TO PREVENT POSSIBLE DAMAGE TO POWER WIRING,

USE ONLY THE KNOCKOUTS PROVIDED IN BACK BOX.

Installation of Back Box in New Construction

NOTE:

tions for “Installation of Back Box in Finished Wall”.

1. In new construction without the finished wall in place, posi-

2. Run power supply cable through cable clamp (previously

If the finished wall surface is already up, follow instruc-

tion the back box against the side of stud allowing the side to

extend beyond the stud so it will be flush with the finished

wall surface. (You must know the thickness of the finished

wall when installing) Secure the box to the stud using two

screws (not included) as shown in Figure 2.

installed) leaving approximately 6 inches (152 mm) of wire

Stud

Ground Screw

Back

Box

Knock Out

Preparing Heater For Installation

1. Remove the junction box cover / heater assembly from the

back box by removing 8 screws. Set the screws aside since

they will be used to reattach the heater assembly to the back

box later.

NOTE:

parts. The upper part is referred to as the junction box cover.

The lower part is referred to as the heater assembly. (See

The junction box cover / heater assembly consists of two

Hole with

Support Screw

(To Adjacent Stud

Where Possible)

Nails or Screws (2)

Figure 2 - Attaching Backbox to Stud

NOTE: The back box must be installed so the front edge will be

flush with the finished surface.

2

Page 3

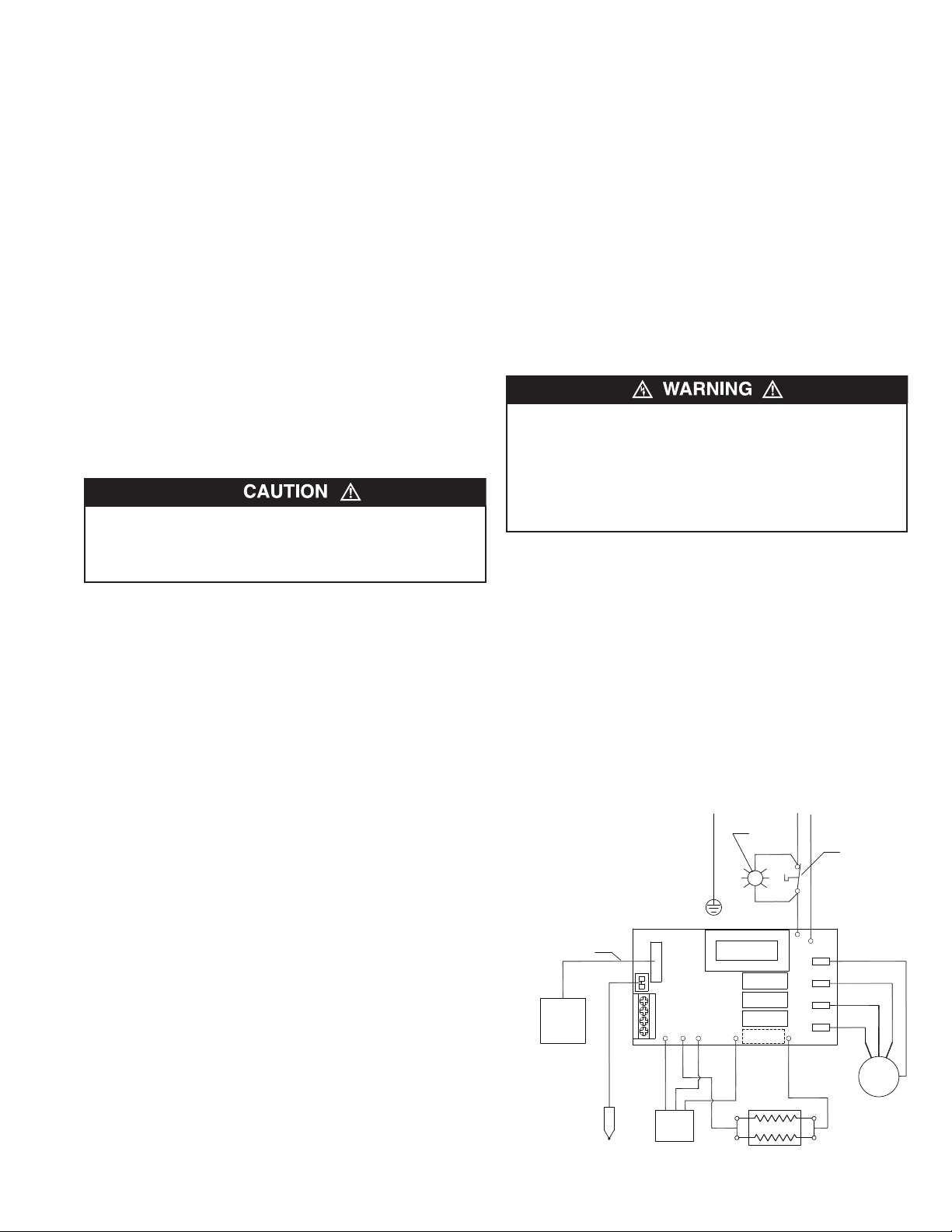

Element

Triac

Sensor

Control - Display Screen

Ribbon Cable

Green Ground

Manual Reset

White - 120 V

Red - 240 V

Pilot

Light

BlackBlack

White

Motor

Black

Blue

Red

White

Black

Blue

Yellow

Red

Control-Power Board

GL/L1N/L2

N

FANH

FANM

FANL

inside box for connections to heater pigtails. Tighten clamp.

3. Attach power supply ground wire to green ground pigtail lead

using appropriate Listed wire nuts or approved connectors.

Push the wires into upper corner of box out of way.

NOTE:

If power supply is provided by standard non-metallic

sheathed cable (Romex) and the supply voltage is 240 volts

(two power wires), the white wire color must be changed using

black electrical tape to comply with the NEC. White is only

allowed for a Neutral conductor.

4. To secure sides of back box not attached to stud, we recom-

mend one of the following methods:

a. When possible, install an additional long screw (such as a

3” wood screw) through the lower side mounting hole into

the nearest stud (see Figure 2). Use care and do not overtighten the screw as this will deform the backbox and

make installation of the heater assembly difficult or impossible. Screw should only be tightened enough to keep

screw in place.

b. Drill a small hole in back box flush with the inside surface

of the finished wall and install a screw (length not critical,

but should be at least 1 inch) see Figure 2.

Installation of Back Box in Finished Wall

AN ELECTRICAL SHOCK, FIRE OR WATER DAMAGE

COULD RESULT IF WIRING OR PIPING IS DAMAGED

DURING CUTTING. MAKE SURE ALL WIRING AND PIPING

ARE CLEAR OF AREA BEFORE CUTTING.

1. Locate a stud and carefully mark and cut a hole measuring

12-1/2” (318 mm) wide by 17-3/4” (451 mm) high so one side

of hole is along the edge of a stud – see Figure 2.

2. Run power supply cable through cable clamp (previously

installed) leaving approximately 6 inches (152 mm) of wire

inside box for connections to heater pigtails. Tighten clamp.

3. Fit back box into opening aligning sides of box flush with fin-

ished wall surface and secure box to stud using two screws

(not included) as shown in Figure 2.

NOTE:

TIP:

1/8” thick spacer can be used such as a metal yard stick or 1/8”

thick piece of wood, prior to final attachment of the back box to

the stud. This allows enough space for the grille to fit properly

over the back box flanges. Once back box is secured to the stud

the spacer can be removed.

4. Attach power supply ground wire to green ground pigtail lead

NOTE:

cable (Romex) and the supply voltage is 240 volts (two power

wires), the white wire color must be changed using black electrical tape to comply with the NEC. White is only allowed for a

Neutral conductor.

5. Insert one #8, three inch long wood screw (not provided)

Top flange must extend out from finished wall surface

approximately 1/8 inch (3.2 mm) to allow grill to attach.

For proper spacing behind the back box upper flange, a

using appropriate Listed wire nuts or approved connectors.

Push the wires into upper corner of box out of way.

If power supply is provided by standard non-metallic

through the free side of the back box not mounted to the

stud and secure in the lower ounting hole. This will prevent

the baack box from pull out on the unsupported side when

installing the heater assembly. Be careful not to drive the

wood screw more than 3/8” into the stud. Too much would

cause the back box to pull out of alignment. See Figure 2.

Installation of Heater Assembly

NOTE:

Use the screws provided by the factory, removed in

step 1 to install heater assembly to the back box.

1. Carefully position the heater assembly, with fan on top, and

element on bottom into the back box. Guide the flange

through the slot openings in the back box. This will help

guide the heater assembly into position.

NOTE:

The heater assembly must be carefully positioned to

ensure the ribbon connector is not trapped behind the circuit

board.

2. The heater assembly (lower portion) can now be attached to

the back box with 4 screws set aside in step 1

Wiring of Heater

Refer to wiring diagram Figure 3

POWER SUPPLY VOLTAGE MUST BE THE SAME AS

HEATER VOLTAGE RATING SHOWN ON HEATER NAMEPLATE. CONNECTING TO A VOLTAGE IN EXCESS OF

NAMEPLATE RATING WILL DAMAGE HEATER AND VOID

WARRANTY.

ALL CONNECTIONS MUST BE WITH APPROPRIATELY

SIZED LISTED WIRE CONNECTORS.

FOR HEATERS RATED 120 VOLTS:

1. Connect the black (L1) heater pigtail to the black power lead.

2. Connect the white (N) heater pigtail to the white neutral lead.

3. If not already done, connect green heater pigtail to equip-

ment ground wire coming into heater.

4. Push wires up into right hand corner of box out of way.

FOR HEATERS RATED 240 VOLTS:

1. Connect the black (L1) heater pigtail to the black power lead.

2. Connect the red (L2) heater pigtail to the other black power

lead.

NOTE:

sheathed cable (Romex) and the supply voltage is 240 volts

(two power wires), the white wire color must be changed using

Figure 3- Wiring Diagram

3

If power supply is provided by standard non-metallic

Page 4

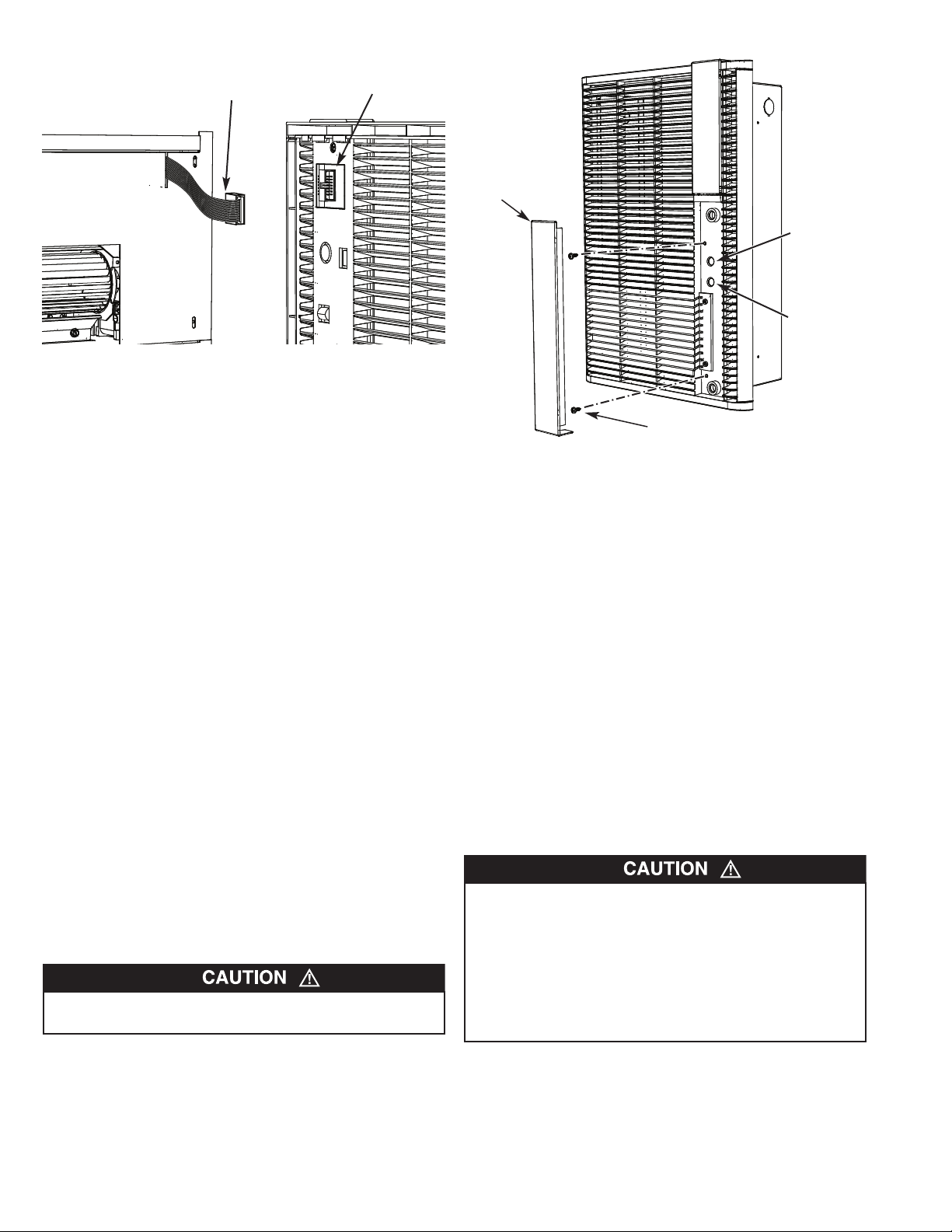

Receptacle in

Ribbon Connector

back of grille

Figure 4- Ribbon Connector

black electrical tape to comply with the NEC. White is only

allowed for a Neutral conductor.

3. If not already done, connect green (G) heater pigtail to

equipment ground wire coming into heater.

4. Push wires up into right hand corner of box out of way.

ALL HEATERS:

Position junction box cover in place making sure flat ribbon

cable is fitted into elongated slot in cover as shown in Figure 4.

Secure cover in place using the 4 screws provided.

NOTE:

Approximately 3-1/2 inches (89 mm) of ribbon cable

should be extending through the slot for connection to electronics in grille. Orientation of connector must be as shown in

Figure 4.

Installation of Grille and Ribbon Connector

1. While holding the right side grille in your right hand, extend

the ribbon connector with the free hand and fit the black connector into the black slot located on the back of the electronic control, behind the grille. The connectors are keyed so it

will fit only one way (Figure 4).

NOTE:

2. Once connected, position the grille over heater back box

3. Reach behind the grille and push excess ribbon back into the

4. There are two holes in the bottom bezel area of the grille that

5. Place the lower bezel in position over the grille and snap

Press the connector gently and firmly, but do not force.

assembly aligning top of grille with the flanges along top of

back box.

slot in the junction box cover to avoid unnecessary bends in

the ribbon. Lower top of grille so the grille flanges catch the

back box flange and hold it in place.

align with two holes in the heater assembly. Insert the two

screws in these holes and tighten (Figure 5).

USE CARE AND DO NOT OVER TIGHTEN THE MOUNTING

SCREWS FOR THIS MAY DAMAGE THE GRILLE.

tabs into the corresponding holes making sure it is seated

securely.

Bottom Bezel

Red Warning

Light

Manual Reset

Safety Limit

Screw (2)

Figure 5- Grille Screw Locations

OPERATION

Initial Setup Instructions (Performed by Installer)

NOTE:

ing procedures to ensure proper operation of the heater.

Programming of the heater controls can be performed by the

user. (See OPERATION MANUAL included with the heater for

programming the heater controls)

1. After heater is completely assembled, turn power to heater

2. Press “Power ON” Icon located in the lower left corner of the

Operational Notice

This heater is equipped with a manual-reset safety limit control

that will automatically turn off the heater if it overheats to prevent a fire. A red warning light will illuminate to alert that this

control had activated. See Figure 5 for the location of these

devices.

TO RESET SAFETY LIMIT (SEE FIGURE 5)

The manual reset button is located behind the bottom bezel just

below the red warning light. To access the button, gently pull out

on the bottom tab of the bottom bezel and snap off. Do not use

a tool to remove the bezel, it may get damaged. Once the

heater has cooled, push the reset button. The heater should

return to normal operation. Replace the bezel.

4

After installation, the installer should perform the follow-

on at the main switch panel. The “Power” button on the front

of the heater should illuminate an orange color.

display. The Icon will illuminate a bright blue color, indicating

the heater is ON.

THE ACTIVATION OF THE SAFETY LIMIT CONTROL AND

RED WARNING LIGHT OCCURS WHEN THE HEATER

OVERHEATS. CHECK HEATER TO MAKE SURE IT IS NOT

BLOCKED – IF SO, REMOVE THE BLOCKAGE. IF THERE IS

NO BLOCKAGE, IT IS RECOMMENDED THAT THE HEATER

BE INSPECTED BY A REPUTABLE ELECTRICIAN OR

REPAIR SERVICE TO ENSURE THE HEATER IS NOT

DAMAGED. DO NOT CONTINUE TO USE HEATER IF IT

REPEATEDLY CYCLES OFF ON THIS SAFETY LIMIT.

Page 5

MAINTENANCE

Your heater is designed for years of trouble-free operation and

requires no special maintenance other than occasional cleaning.

The motor is permanently lubricated.

Cleaning

Once each year, the heater should be cleaned to remove dust

and other foreign material which has collected during the heating season, as follows:

ALL OTHER SERVICING SHOULD BE PERFORMED BY AN

ELECTRICIAN OR QUALIFIED PERSON

1. Turn power off at main switch.

2. Remove bottom bezel and the two screws that hold the grille.

3. Use vacuum cleaner with brush attachment to remove dust

and dirt that has accumulated in heater (especially around

element and blower blade). Do not use water or any cleaners

to clean heater components.

4. Replace grille and bottom bezel.

5. Wipe grille clean with a damp cloth. DO NOT use waxes or

any cleaners that leave a residue since these may discolor

during heater operation.

6. Turn the main line switch on at the switch panel to restore

power to heater. The heater is now ready for another season

of operation.

REPAIR PARTS

3

5

8

6

7

1

2

4

Repair Parts List

Ref Part Number

No. Description 120V 240V

1. Grille panel only 2501-11003-000 2501-11003-000

2. Electronic Assembly 1016-11035-001 1016-11035-001

with top bezel

3. Motherboard, triac/heat sink, ribbon connector, 1414-11007-000 1414-11007-001

and sensor assembly (in one box):

4. Bottom bezel 1219-11004-000 1219-11004-000

5. Motor assembly 1225-11001-000 1225-11001-001

6. Manual Reset 4520-11005-000 4520-11005-000

7. Heating Element 302023802 302023805

8. Red lamp 3510-2017-000 3510-2017-001

9. Remote Control 1414-11017-000 1414-11017-000

10 Battery 1218-11003-000 1218-11003-000

9

10

5

Page 6

All products manufactured by Marley Engineered Products are warranted against defects in workmanship and materials for one year from date of installation, except

LIMITED WARRANTY

heating elements which are warranted against defects in workmanship and materials for five years from date of installation. This warranty does not apply to damage from

accident, misuse, or alteration; nor where the connected voltage is more than 5% above the nameplate voltage; nor to equipment improperly installed or wired or

maintained in violation of the product’s installation instructions. All claims for warranty work must be accompanied by proof of the date of installation.

The customer shall be responsible for all costs incurred in the removal or reinstallation of products, including labor costs, and shipping costs incurred to return products

to Marley Engineered Products Service Center. Within the limitations of this warranty, inoperative units should be returned to the nearest Marley authorized service center or the Marley Engineered Products Service Center, and we will repair or replace, at our option, at no charge to you with return freight paid by Marley. It is agreed that

such repair or replacement is the exclusive remedy available from Marley Engineered Products.

THE ABOVE WARRANTIES ARE IN LIEU OF ALL OTHER WARRANTIES EXPRESSED OR IMPLIED, AND ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE WHICH EXCEED THE AFORESAID EXPRESSED WARRANTIES ARE HEREBY DISCLAIMED AND EXCLUDED FROM

THIS AGREEMENT. MARLEY ENGINEERED PRODUCTS SHALL NOT BE LIABLE FOR CONSEQUENTIAL DAMAGES ARISING WITH RESPECT TO THE

PRODUCT, WHETHER BASED UPON NEGLIGENCE, TORT, STRICT LIABILITY, OR CONTRACT.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above exclusion or limitation may not apply to you. This warranty gives

you specific legal rights, and you may also have other rights which vary from state to state.

For the address of your nearest authorized service center, contact Marley Engineered Products in Bennettsville, SC, at 1-800-642-4328. Merchandise returned to the factory must be accompanied by a return authorization and service identification tag, both available from Marley Engineered Products. When requesting return authorization,

include all catalog numbers shown on the products.

HOW TO OBTAIN WARRANTY SERVICE AND

WARRANTY PARTS PLUS GENERAL INFORMATION

1. Warranty Service or Parts

2. Purchase Replacement Parts

3. General Product Information

Note:

When obtaining service always have the following:

1. Model number of the product

2. Date of manufacture

3. Part number or description

1-800-642-4328

1-800-654-3545

www.marleymep.com

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

Part No. 5200-11046-001

ECR 38932

10/10

Page 7

Calefactor de montaje en pared

Smart Series™

Serie HTSS

INSTRUCCIONES IMPORTANTES

LEA CUIDADOSAMENTE Debe darse atención especial a las advertencias presentadas abajo que identifican ciertas precauciones e instrucciones especiales

para la instalación y uso seguros y eficientes. Estudiar estas instrucciones por primera vez podría ahorrarle posteriormente tiempo y

dinero considerables, y reducir su tiempo de instalación. Si usted no está familiarizado con la electricidad o se siente incómodo al

trabajar con electricidad, solicite la instalación de este producto a un electricista con licencia o persona calificada.

PARA REDUCIR EL RIESGO DE INCENDIO, DESCARGA ELÉCTRICA O LESIONES A PERSONAS:

LEA TODAS LAS INSTRUCCIONES

1.

el calefactor.

PELIGRO DE DESCARGA ELÉCTRICA:

2.

cables, desconecte toda la energía eléctrica que llega al calefactor, en la caja de interruptores automáticos (breakers) o el

interruptor de desconexión principal, y asegure con llave en la

posición de APAGADO (OFF). Todo el cableado debe

realizarse de acuerdo con el Código Eléctrico Nacional y las

normas y códigos locales aplicables. El calefactor debe conectarse apropiadamente con una conexión a tierra efectiva de la

edificación.

3. Antes de aplicar energía, verifique que el voltaje de alimentación que llega al calefactor es igual al mostrado en la

placa de datos del calefactor. Aplicar energía con voltaje superior al voltaje indicado en la placa de datos dañará el calefactor

y anulará la garantía.

4. Este calefactor tiene en su interior piezas calientes, piezas que

forman arcos eléctricos o piezas que producen chispa. No

instale ni utilice en áreas donde se utiliza o almacena gasolina,

pintura, o líquidos inflamables.

5. No instale este calefactor en posición invertida (boca abajo), de

manera lateral, dentro de cielo raso o piso. Instale únicamente

según se muestra en este manual. Consulte

montaje

deben mantenerse.

6. El calefactor debe instalarse en la caja de respaldo suministrada. No ponga en funcionamiento el calefactor sin tener la rejilla instalada.

, pág. 2, para conocer los espacios libres mínimos que

Este manual suministra instrucciones para la instalación correcta, uso seguro y cuidado este producto.

ADVERTENCIA

antes de instalar o utilizar

Antes de conectar los

Espacios libres de

7. Este calefactor no está aprobado para uso en atmósferas corrosivas tales como áreas marinas, invernaderos o áreas de

almacenamiento de químicos.

8. No utilice en exteriores.

9. Debe tenerse extrema precaución cuando el calefactor se utiliza cerca de niños o personas discapacitadas y cuando el calefactor se deja en funcionamiento sin supervisión.

10. Este calefactor está caliente cuando está en uso. Para evitar

quemaduras, no permita que la piel desnuda haga contacto con

las superficies calientes. Mantenga alejados del calefactor los

materiales combustibles tales como muebles, almohadas, ropa

de cama, papeles, ropa y cortinas. No obstruya de ninguna

manera las entradas o escape de aire. Para una operación eficiente y segura, recomendamos mantener todo artículo a una

distancia mínima de 3 pies (91 cm) del calefactor.

11. No inserte ni permita que objetos extraños ingresen a las aberturas de ventilación o de escape, ya que esto podría causar

una descarga eléctrica, incendio, o podría dañar el calefactor.

12. Si el calefactor se obstruye o se sobrecalienta de algún otro

modo, éste está equipado con un interruptor de seguridad térmico de reinicio manual y una bombilla de alarma que se activará para avisar que el calefactor se ha apagado. Si la bombilla de advertencia está encendida, revise para ver si puede

identificarse el motivo del sobrecalentamiento. Retire cualquier

obstrucción, permita que el calefactor se enfríe, luego presione

el botón Reset (Reiniciar). El calefactor debe regresar a la

operación normal. No continúe utilizando el calefactor si este

se apaga repetidamente. Solicite a una persona de reparación

calificada que lo inspeccione y repare.

13. Sólo utilice este calefactor según se describe en este manual.

Cualquier otro uso no recomendado por el fabricante podría

causar un incendio, descarga eléctrica, o lesiones a personas.

!

GUARDE ESTAS INSTRUCCIONES

Page 8

ESPECIFICACIONES

NÚMERO DE TAMAÑO

MODELO VOLTIOS AMPERIOS WATTS BTUHR DE ALAMBRE

HT2024SS 240 1,0 - 8,3 250 - 2000 853 - 6826 14AWG

HT1502SS 120 1,6 - 12,5 200 - 1500 682 - 5120 12AWG

DESEMPAQUE

La caja de cartón contiene lo siguiente:

• Control remoto

• Bisel inferior

• Rejilla con sistema electrónico instalado

• Conjunto calefactor

• Instrucciones de instalación y manual del usuario

INSTALACIÓN

El calefactor está diseñado para instalación empotrada en secciones de

pared con columna de 2” x 4” (50 mm x 101 mm) o superiores, utilizando la caja de respaldo suministrada. El calefactor puede cablearse con

alambre normal de edificaciones (60°C). Consulte “Especificaciones” y

la placa de datos del calefactor para obtener el tamaño de alambre y

voltaje de suministro correctos.

NOTA:

La altura de montaje óptima para este calefactor es de 18” a 24”

(450 a 600 mm) desde el piso a la parte inferior de la caja de respaldo.

NO instale a una distancia menor de 12” (305 mm) del piso.

Espacios libres de montaje

PARA PROPORCIONAR UNA OPERACIÓN SEGURA, DEBEN MANTENERSE LOS SIGUIENTES ESPACIOS LIBRES.

Cubierta de la caja

Caja de

respaldo

Figura 1- Remoción del conjunto calefactor fuera de la caja de respaldo

PARA EVITAR POSIBLE DAÑO DE LOS CABLES DE ENERGÍA,

SÓLO UTILICE LOS RECORTES CIRCULARES REMOVIBLES SUMINISTRADOS EN LA CAJA DE RESPALDO.

de conexiones

Conjunto calefactor

Tornillos

(8) Total

Sólo montaje en pared:

a. Mínimo: Doce (12) pulgadas (305 mm) del piso;

b. Mínimo: Doce (12) pulgadas (305 mm) de paredes

adyacentes;

c. Mínimo: Treinta y seis (36) pulgadas (915 mm) del

cielo raso.

EL CALEFACTOR SE CALIENTA CUANDO ESTÁ EN FUNCIONAMIENTO. NO INSTALE EL CALEFACTOR DETRÁS DE PUERTAS, DETRÁS DEL COLGADOR DE TOALLAS, DENTRO DE

ARMARIOS, EN LUGARES DONDE LAS CORTINAS PUDIERAN

HACER CONTACTO O SER QUEMADAS POR EL CALEFACTOR, O

DONDE PUDIERA OBSTRUIRSE EL FLUJO DE AIRE HACIA EL

CALEFACTOR. MANTENGA ALEJADOS DEL CALEFACTOR LOS

CABLES ELÉCTRICOS, ROPA DE CAMA, MUEBLES Y OTROS

MATERIALES COMBUSTIBLES.

PARA EVITAR EL PELIGRO DE INCENDIO O DESCARGA ELÉCTRICA, NO INSTALE SIN LA CAJA DE RESPALDO.

Preparación del calefactor para instalación

1. Remueva el conjunto calefactor / cubierta de la caja de conexiones

fuera de la caja de respaldo removiendo 8 tornillos. Coloque aparte

los tornillos ya que estos se utilizarán posteriormente para sujetar

nuevamente el conjunto calefactor a la caja de respaldo.

NOTA:

El conjunto calefactor / cubierta de la caja de conexiones consta

de dos partes. La parte superior es la cubierta de la caja de conexiones.

La parte inferior es el conjunto calefactor. (Vea la Figura 1).

2. Remueva uno de los recortes circulares removibles ubicados en el

lado de la caja de respaldo e instale la abrazadera de cables apropiada (no se suministra).

Instalación de la caja de respaldo en construcción nueva

NOTA:

Si la superficie de pared ya está terminada, siga las instruc-

ciones para “Instalación de caja de respaldo en pared terminada”.

1. En construcción nueva sin pared terminada, coloque la caja de

respaldo contra el lado de la columna permitiendo que el lado se

extienda más allá de la columna de modo que la caja quedará a ras

con la superficie de pared terminada. (Durante la instalación, usted

debe conocer el espesor de la pared terminada). Asegure la caja a

la columna utilizando dos tornillos (no incluidos) según se muestra

en la Figura 2.

2. Instale el cable de suministro de energía a través de la abrazadera

de cables (previamente instalado) dejando aproximadamente 6 pulgadas (152 mm) de alambre dentro de la caja para conexiones con

los cables flexibles de conexión del calefactor. Apriete la

abrazadera.

Columna

Tornillo de

Caja de

respaldo

Orificio con

tornillo de

soporte

(A columna

adyacente donde

sea posible)

Figura 2 - Sujeción de la caja de respaldo a la columna

NOTA: La caja de respaldo debe instalarse de modo que el borde

delantero quedará a ras con la superficie terminada.

8

conexión a tierra

Recorte circular

removible

Clavos o tornillos (2)

Page 9

3. Conecte el alambre de conexión a tierra con el cable flexible verde

Element

Triac

Sensor

Control - Display Screen

Ribbon Cable

Green Ground

Manual Reset

White - 120 V

Red - 240 V

Pilot

Light

BlackBlack

White

Motor

Black

Blue

Red

White

Black

Blue

Yellow

Red

Control-Power Board

GL/L1N/L2

N

FANH

FANM

FANL

de conexión a tierra utilizando los capuchones registrados apropiados o conectores aprobados. Empuje los alambres hacia el interior

de la esquina superior de la caja para despejar el área.

NOTA:

Si la alimentación de energía es suministrada mediante cable

con forro no-metálico estándar (Romex) y el voltaje de suministro es de

240 voltios (dos alambres de energía), el alambre de color blanco debe

cambiarse utilizando cinta eléctrica negra para cumplir con el NEC. El

color blanco sólo se permite para el alambre neutro.

4. Para asegurar los lados de la caja de respaldo no sujetados a

columna, recomendamos uno de los siguientes métodos:

a. Cuando sea posible, instale un tornillo largo adicional (tal como

un tornillo para madera de 3”) a través del orificio de montaje

inferior y dentro de la columna más cercana (vea la Figura 2).

Tenga cuidado y no apriete en exceso el tornillo ya que esto

deformará la caja de respaldo y dificultará o hará imposible la

instalación del conjunto calefactor. El tornillo sólo debe apretarse

lo suficiente para mantener el tornillo en su sitio.

b. Taladre un orificio pequeño en la caja de respaldo a ras con la

superficie interior de la pared terminada e instale un tornillo (la

longitud no es decisiva, pero debe ser de 1 pulgada como mínimo), vea la Figura 2.

Instalación de la caja de respaldo en pared terminada

Instalación del conjunto calefactor

NOTA:

Utilice los tornillos suministrados por la fábrica, removidos en el

paso 1, para instalar el conjunto calefactor en la caja de respaldo.

1. Coloque cuidadosamente el conjunto calefactor, con el ventilador en

la parte superior, y el elemento calefactor en la parte inferior, dentro

de la caja de respaldo. Guíe el reborde a través de las aberturas

tipo ranura en la caja de respaldo. Esto ayudará a guiar el conjunto

calefactor hacia su posición.

NOTA:

El conjunto calefactor debe posicionarse cuidadosamente para

garantizar que el conector tipo cinta no quede atrapado detrás de la tarjeta de circuitos.

2. El conjunto calefactor (parte inferior) ahora puede sujetarse a la caja

de respaldo mediante los 4 tornillos colocados aparte en el paso 1.

Conexión de cables del calefactor

Consulte el diagrama de cableado, Figura 3

EL VOLTAJE DE SUMINISTRO DE ENERGÍA DEBE SER IGUAL A LA

CAPACIDAD DE VOLTAJE DEL CALEFACTOR MOSTRADA EN LA

PLACA DE DATOS DEL CALEFACTOR. LA CONEXIÓN A UN

VOLTAJE SUPERIOR A LA CAPACIDAD INDICADA EN LA PLACA

DE DATOS DAÑARÁ EL CALEFACTOR Y ANULARÁ LA GARANTÍA.

TODAS LAS CONEXIONES DEBEN REALIZARSE CON CONECTORES REGISTRADOS DE TAMAÑO APROPIADO.

PODRÍA PRODUCIRSE UNA DESCARGA ELÉCTRICA, INCENDIO O

DAÑO POR AGUA SI LOS CABLES O TUBOS SE DAÑAN DURANTE

EL CORTE. ANTES DEL CORTE, VERIFIQUE QUE TODOS LOS

ALAMBRES Y TUBOS ESTÁN FUERA DEL ÁREA.

1. Ubique una columna, marque cuidadosamente y corte una abertura

que mida 12-1/2” (318 mm) de ancho por 17-3/4” (451 mm) de alto,

de modo que un lado de la abertura quede a lo largo del borde de

una columna – vea la Figura 2.

2. Instale el cable de suministro de energía a través de la abrazadera

de cables (previamente instalado) dejando aproximadamente 6 pulgadas (152 mm) de alambre dentro de la caja para conexiones con

los cables flexibles de conexión del calefactor. Apriete la

abrazadera.

3. Encaje la caja de respaldo dentro de la abertura alineando los lados

de la caja a ras con la superficie de la pared terminada y asegure la

caja a la columna utilizando dos tornillos (no incluidos) según se

muestra en la Figura 2.

NOTA:

El reborde superior debe extenderse por fuera de la superficie

de la pared terminada aproximadamente 1/8 pulg. (3.2 mm) para permitir sujetar la rejilla.

RECOMENDACIÓN:

Para el espaciado apropiado detrás del reborde

superior de la caja de respaldo, puede utilizarse un espaciador con

espesor de 1/8” tal como una varilla metálica o pieza de madera con

espesor de 1/8”, antes de la sujeción final de la caja de respaldo a la

columna. Esto deja suficiente espacio para que la rejilla encaje apropiadamente sobre los rebordes de la caja de respaldo. Una vez que la

caja de respaldo está asegurada a la columna, el espaciador puede retirarse.

4. Conecte el alambre de conexión a tierra con el cable flexible verde

de conexión a tierra utilizando los capuchones registrados apropiados o conectores aprobados. Empuje los alambres hacia el interior

de la esquina superior de la caja para despejar el área.

NOTA:

Si la alimentación de energía es suministrada mediante cable

con forro no-metálico estándar (Romex) y el voltaje de suministro es de

240 voltios (dos alambres de energía), el alambre de color blanco debe

cambiarse utilizando cinta eléctrica negra para cumplir con el NEC. El

color blanco sólo se permite para el alambre neutro.

5. Inserte un tornillo para madera #8, de tres pulgadas de longitud (no

suministrado) a través del lado libre de la caja de respaldo no montado en la columna, y asegure en el orificio de montaje inferior. Esto

evitará que la caja de respaldo sea extraída del lado no-soportado al

instalar el conjunto calefactor. Tenga cuidado de no atornillar el

tornillo para madera más de 3/8” dentro de la columna. Un atornillado excesivo causaría que la caja de respaldo se desalinee. Vea la

Figura 2.

PARA CALEFACTORES CON CAPACIDAD DE 120 VOLTIOS:

1. Conecte el cable flexible de conexión negro (L1) del calefactor con

el alambre negro de energía.

2. Conecte el cable flexible de conexión blanco (N) del calefactor con

el alambre blanco neutro.

3. Si la conexión no está todavía, conecte el cable flexible de conexión

verde del calefactor con el alambre de tierra del equipo que ingresa

al calefactor.

4. Empuje los alambres hacia arriba dentro de la esquina derecha de

la caja para despejar el área.

PARA CALEFACTORES CON CAPACIDAD DE 240 VOLTIOS:

1. Conecte el cable flexible de conexión negro (L1) del calefactor con

el alambre negro de energía.

2. Conecte el cable flexible de conexión rojo (L2) del calefactor con el

otro alambre negro de energía.

NOTA:

Si la alimentación de energía es suministrada mediante cable

con forro no-metálico estándar (Romex) y el voltaje de suministro es de

240 voltios (dos alambres de energía), el alambre de color blanco debe

cambiarse utilizando cinta eléctrica negra para cumplir con el NEC. El

color blanco sólo se permite para el alambre neutro.

Bombilla

piloto

Tierra, verde

Cable tipo cinta

energía-control

Pantalla - Control

Amarillo

Figura 3- Diagrama de cableado

Tarjeta de

Azul

Negro

Negro

Rojo

Blanco

Elemento calefactor

Reset (Reinicio)

manual

Blanco - 120 V

Rojo - 240 V

Blanco

Negro

Azul

Rojo

9

Page 10

Receptáculo en la parte

Conector tipo cinta

Figura 4- Conector tipo cinta

3. Si la conexión no está todavía, conecte el cable flexible de conexión

verde (G) del calefactor con el alambre de tierra del equipo que

ingresa al calefactor.

4. Empuje los alambres hacia arriba dentro de la esquina derecha de

la caja para despejar el área.

TODOS LOS CALEFACTORES:

Coloque la cubierta de la caja de conexiones verificando que el cable

tipo cinta plana está encajado dentro de la ranura alargada de la cubierta según se muestra en la Figura 4. Asegure la cubierta utilizando los

cuatro tornillos suministrados.

NOTA:

Aproximadamente 3-1/2 pulgadas (89 mm) del cable tipo cinta

debe extenderse a través de la ranura para la conexión con el sistema

electrónico en la rejilla. La orientación del conector debe ser tal como se

muestra en la Figura 4.

trasera de la rejilla

Instalación de la rejilla y del conector tipo cinta

1. Mientras se sostiene el lado derecho de la rejilla en su mano

derecha, extienda el conector tipo cinta con la mano libre y encaje el

conector negro en la ranura negra ubicada en el dorso del control

electrónico, detrás de la rejilla. Los conectores tienen chaveta de

modo que sólo encajarán de una manera (Figura 4).

NOTA:

Presione con cuidado y firmemente el conector, pero sin forzarlo.

2. Una vez conectado, coloque la rejilla sobre la caja de respaldo del

calefactor alineando la parte superior de la rejilla con los rebordes a

lo largo de la parte superior de la caja de respaldo.

3. Extiéndase detrás de la rejilla y empuje la cinta sobrante de regreso

dentro de la ranura en la cubierta de la caja de conexiones para evitar pliegues innecesarios en la cinta. Baje la parte superior de la

rejilla de modo que los rebordes de la rejilla enganchen el reborde

de la caja de respaldo y la sostengan en su sitio.

4. Hay dos orificios en el área de bisel inferior de la rejilla que se alin-

ean con dos orificios del conjunto calefactor. Inserte los dos tornillos

en estos dos orificios y apriete (Figura 5).

TENGA CUIDADO Y NO APRIETE EXCESIVAMENTE LOS TORNILLOS DE MONTAJE YA QUE ESTO PODRÍA DAÑAR LA REJILLA.

5. Coloque el bisel inferior sobre la rejilla y sujete a presión las pes-

tañas dentro de los orificios correspondientes verificando que quede

asentado firmemente.

Bisel inferior

Bombilla roja

de advertencia

Límite de

seguridad de

reinicio (reset)

manual

Tornillo (2)

Figura 5- Ubicaciones de tornillos de rejilla

OPERACIÓN

Instrucciones de configuración inicial (realizada por instalador)

NOTA:

Después de la instalación, el instalador debe realizar los siguientes procedimientos para garantizar el funcionamiento apropiado del

calefactor.

La programación de los controles del calefactor puede ser realizada por

el usuario. (Vea el MANUAL DE OPERACIÓN incluido con el calefactor

para la programación de los controles del calefactor)

1. Después que el calefactor está completamente ensamblado, encien-

da la energía hacia el calefactor desde el panel de interruptores

principal. El botón “Power” (“Energía”) en la parte delantera del calefactor debe iluminarse en color naranja.

2. Oprima el icono “Power ON” (“Encender”) ubicado en la esquina

inferior izquierda de la pantalla. El icono se iluminará en color azul

claro, indicando que el calefactor está ENCENDIDO.

Aviso de funcionamiento

Este calefactor está equipado con un control de límite de seguridad de

reinicio manual que apagará automáticamente el calefactor si éste se

sobrecalienta, para evitar un incendio. Se encenderá una bombilla roja

de advertencia para avisar que este control se ha activado. Vea la

Figura 5 para conocer la ubicación de estos dispositivos.

LA ACTIVACIÓN DEL CONTROL DE LÍMITE DE SEGURIDAD Y DE LA

BOMBILLA ROJA DE ADVERTENCIA OCURRE CUANDO EL CALEFACTOR SE SOBRECALIENTA. REVISE EL CALEFACTOR PARA

VERIFICAR QUE NO ESTÁ OBSTRUIDO – SÍ LO ESTÁ, RETIRE LA

OBSTRUCCIÓN. SI NO HAY LA OBSTRUCCIÓN, SE RECOMIENDA

QUE EL CALEFACTOR SEA INSPECCIONADO POR UN ELECTRICISTA DE BUENA REPUTACIÓN O UN SERVICIO DE

REPARACIÓN PARA GARANTIZAR QUE EL CALEFACTOR NO ESTÁ

DAÑADO. NO CONTINÚE UTILIZANDO EL CALEFACTOR SI ÉSTE SE

APAGA REPETIDAMENTE EN ESTE LÍMITE DE SEGURIDAD.

PARA REINICIAR EL LÍMITE DE SEGURIDAD (VEA LA FIGURA 5)

El botón de reinicio (reset) manual está ubicado detrás del bisel inferior

justo debajo de la bombilla roja de advertencia. Para lograr acceso al

botón, jale suavemente hacia afuera la lengüeta inferior del bisel inferior

y remueva a presión. No utilice herramienta para remover el bisel ya

que éste podría dañarse. Una vez que el calefactor se ha enfriado, presione el botón de reinicio (reset). El calefactor debe regresar a la

operación normal. Coloque nuevamente el bisel.

10

Page 11

MANTENIMIENTO

Su calefactor está diseñado para años de funcionamiento sin problemas

y no requiere mantenimiento especial diferente a una limpieza ocasional. El motor está lubricado permanentemente.

Limpieza

Una vez al año, el calefactor debe limpiarse para remover el polvo y

material extraño que se haya acumulado durante la temporada de calefacción, de la siguiente manera:

TODOS LOS DEMÁS PROCEDIMIENTOS DE MANTENIMIENTO

DEBEN SER REALIZADOS POR UN ELECTRICISTA O PERSONA

CALIFICADA

1. Apague la energía en el interruptor de línea principal.

2. Remueva el bisel inferior y los dos tornillos que sostienen la rejilla.

3. Utilice una aspiradora con accesorio de cepillo para remover el

polvo y suciedad que se ha acumulado dentro del calefactor (especialmente alrededor del elemento calefactor y aspas del ventilador).

No utilice agua ni ningún limpiador para limpiar los componentes del

calefactor.

4. Coloque nuevamente la rejilla y el bisel inferior.

5. Limpie frotando la rejilla con un trapo húmedo. NO utilice ceras ni

ningún limpiador que dejen un residuo ya que éstos pueden decolorar durante la operación del calefactor.

6. Encienda el interruptor de línea principal en el panel de interruptores

para restaurar la energía hacia el calefactor. El calefactor ahora está

listo para otra temporada de operación.

REPUESTOS

1

3

5

8

6

7

2

9

4

10

Lista de repuestos

Ref Número de pieza

No. Descripción 120 V 240 V

1. Rejilla sólo 2501-11003-000 2501-11003-000

2. Conjunto electrónico con 1016-11035-001 1016-11035-001

bisel superior

3. Tarjeta principal, triac/disipador de calor, conector tipo cinta, 1414-11007-000 1414-11007-001

y sensor (en 1 caja ):

4. Bisel inferior 1219-11004-000 1219-11004-000

5. Motor 1225-11001-000 1225-11001-001

6. Reinicio (Reset) manual 4520-11005-000 4520-11005-000

7. Elemento calefactor 302023802 302023805

8. Bombilla roja 3510-2017-000 3510-2017-001

9. Control remoto

1414-11017-000 1414-11017-000

10 Batería 1218-11003-000 1218-11003-000

11

Page 12

Todos los productos fabricados por Marley Engineered Products están garantizados contra defectos en manufactura y materiales durante un (1) año a partir de la fecha

GARANTÍA LIMITADA

instalación, excepto los elementos calefactores los cuales están garantizados contra defectos en manufactura y materiales durante cinco años a partir de la fecha de

instalación. Esta garantía no aplica a daño por accidente, uso incorrecto, o alteración; ni donde el voltaje conectado sea superior en 5% al voltaje indicado en la placa

de datos; ni se aplica a equipo instalado o cableado o mantenido de manera inapropiada en violación de las instrucciones de instalación del producto. Todas las reclamaciones de trabajo de garantía deben incluir un documento que compruebe la fecha de instalación.

El cliente será responsable de todos los costos incurridos en la remoción o reinstalación de productos, incluyendo los costos de mano de obra, y los costos de envío

incurridos para devolver los productos al Centro de Servicio de Marley Engineered Products. Dentro de las limitantes de esta garantía, las unidades inoperantes deben

devolverse al centro de servicio autorizado Marley más cercano o al Centro de Servicio de Marley Engineered Products, y nosotros repararemos o reemplazaremos,

según nuestra elección, sin costo para usted, con el costo de envío de regreso pagado por Marley. Se acuerda que dicha reparación o reemplazo es el remedio exclusivo disponible de parte de Marley Engineered Products.

LAS ANTERIORES GARANTÍAS REEMPLAZAN CUALQUIER OTRA GARANTÍA EXPRESA O IMPLÍCITA, Y TODAS LAS GARANTÍAS IMPLÍCITAS DE MERCADEABILIDAD Y ADECUADIBILIDAD PARA UN PROPÓSITO EN PARTICULAR QUE EXCEDEN LAS GARANTÍAS EXPRESAS MENCIONADAS SON DENEGADAS MEDIANTE ESTE DOCUMENTO Y EXCLUIDAS DE ESTE ACUERDO. MARLEY ENGINEERED PRODUCTS NO SERÁ RESPONSABLE POR DAÑOS CONSECUENCIALES QUE SURJAN CON RESPECTO AL PRODUCTO, ESTÉN O NO BASADOS EN NEGLIGENCIA, INFRACCIÓN, RESPONSABILIDAD ESTRICTA, O CONTRATO.

Algunos estados no permiten la exclusión o la limitación de los daños resultantes o adicionales, de modo que la anterior exclusión o limitación podría no aplicarse a usted.

Esta garantía le otorga derechos legales específicos, y además, usted podría tener otros derechos que varían de un estado a otro.

Para obtener la dirección de su centro de servicio autorizado más cercano, comuníquese con Marley Engineered Products en Bennettsville, SC, en el teléfono:

1-800-642-4328. La mercancía devuelta a la fábrica debe incluir una autorización de devolución y la etiqueta de identificación de servicio, las cuales pueden conseguirse

en Marley Engineered Products. Al solicitar la autorización de devolución, incluya todos los números de catálogo mostrados en los productos.

CÓMO OBTENER EL SERVICIO DE GARANTÍA Y LAS PIEZAS

DE GARANTÍA, Y ADEMÁS, INFORMACIÓN GENERAL

1. Servicio o Piezas de Garantía

2. Compra de Piezas de Repuesto

3. Información General de Productos

Nota:

Al solicitar servicio, siempre tenga a mano lo siguiente:

1. Número de modelo del producto

2. Fecha de fabricación

3. Número o descripción de la pieza

1-800-642-4328

1-800-654-3545

www.marleymep.com

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

Pieza No. 5200-11046-001

ECR 38932

10/10

Page 13

Série HTSS

Radiateur mural

Smart Series

TM

INSTRUCTIONS IMPORTANTES

À LIRE ATTENTIVEMENT –

nécessaire. Vous devez prêter une attention particulière aux mises en garde données ci-dessous, elles identifient certaines précautions et des instructions spéciales pour une installation et un fonctionnement sans risques avec efficacité. En commençant par

analyser ces instructions vous pourrez gagner un temps considérable et économiser plus tard de l'argent, et réduire la durée d'installation à un minimum. Si vous n'y connaissez rien en électricité ou ne vous sentez pas à l'aise pour ces travaux, confiez l'installation de ce produit à un électricien agréé ou à une personne qualifiée.

POUR RÉDUIRE LES RISQUES DE DÉPART D'INCENDIE,

D'ÉLECTROCUTION OU DE BLESSURES AUX

PERSONNES :

LISEZ TOUTES LES INSTRUCTIONS

1.

d'utiliser le radiateur.

RISQUE D'ÉLECTROCUTION :

2.

électrique du radiateur en amont au niveau du disjoncteur ou

de l'interrupteur général, et verrouillez cette coupure, avant

de procéder au câblage. Tout le câblage doit être conforme à

la norme électrique américaine et aux normes et réglementations locales applicables. Le radiateur doit être correctement

relié à une bonne terre électrique.

3. Vérifiez que la tension secteur alimentant le radiateur correspond à la spécification mentionnée sur sa plaque signalétique avant de le mettre sous tension. Une mise sous tension

de valeur excessive par rapport à la spécification peut

endommager le radiateur et annuler sa garantie.

4. Ce radiateur comporte à l'intérieur des parties qui sont

brûlantes, out produisent des arcs électriques ou des étincelles. Ne l'installez pas et ne l'utilisez pas dans des locaux

où sont utilisés ou entreposés de l'essence, de la peinture ou

d'autres liquides inflammables.

5. N'installez pas ce radiateur à l'envers, sur le côté, au plafond

ou au sol. Ne l'installez que comme c'est montré dans ce

manuel. Référez-vous aux espacements de montage, page 2,

pour les distances de sécurité minimales à garder autour.

6. L'ensemble de radiateur doit être monté dans le boîtier arrière

fourni. Ne le faites pas fonctionner sans que sa grille soit

mise.

7. Ce radiateur n'est pas approuvé pour une utilisation en atmosphère corrosive, comme dans des zones marines, des ser-

Ce manuel fournit des instructions sur l'installation correcte et l'utilisation sûre ce produit, et l'entretien

AVERTISSEMENT

avant d'installer ou

Coupez toute l'alimentation

res, et là où sont entreposés des produits chimiques.

8. N'utilisez pas ce radiateur à l'extérieur.

9. Il faut faire très attention quand un radiateur de chauffage est

utilisé par des enfants des personnes invalides, ou près

d'eux, ou quand il est laissé en fonctionnement sans surveillance.

10. Ce radiateur est très chaud en fonctionnement. Pour éviter

les brûlures, évitez le contact de la peau nue sur les surfaces

chaudes. Gardez les matières combustibles, comme les

meubles, oreillers, literies, papiers, vêtements et rideaux, à

distance du radiateur. Ne bloquez pas les prises d'air ou les

sorties de soufflage d'une quelconque manière. Pour un fonctionnement efficace et sûr, nous recommandons de maintenir

tous ces objets à au moins 90 cm de l'avant du radiateur.

11. N'insérez pas d'objet étranger et n'en laissez pas entrer dans

les ouvertures de ventilation ou de soufflage car il y a risque

d'électrocution, incendie et dégâts pour le radiateur.

12. Au cas où le radiateur serait obstrué ou passerait en surchauffe pour une quelconque raison, il comporte un interrupteur thermique qui peut se restaurer manuellement, et une

alarme visuelle s'active pour prévenir de la coupure automatique du radiateur. Si ce voyant d'alerte est allumé, cherchez

à trouver la raison de cette surchauffe. Dégagez tout blocage

éventuel, laissez le radiateur refroidir, puis actionnez le bouton de restauration. Le radiateur doit revenir en fonctionnement normal. Ne poursuivez pas son utilisation s'il continue de disjoncter. Faites-le inspecter et réparer par une personne qualifiée.

13. N'utilisez ce radiateur que comme décrit dans ce fascicule.

Toute autre utilisation non recommandée par le constructeur

peut provoquer incendie, électrocution ou blessures.

!

CONSERVEZ CES INSTRUCTIONS

Page 14

SPÉCIFICATIONS

N° DE TAILLE

MODÈLE VOLTS AMPÈRES WATTS BTUHR DE FILS

HT2024SS 240 1,0 - 8,3 250 - 2 000 853 - 6 826 14AWG

HT1502SS 120 1,6 - 12,5 200 - 1 500 682 - 5 120 12AWG

DÉBALLAGE

Contenu du carton :

Télécommande

•

• Enjoliveur inférieur

• Grille avec électronique intégrée

• Ensemble de radiateur

• Instructions d'installation et manuel d'utilisation

INSTALLATION

Le radiateur est conçu pour une installation encastrée dans des sections de mur avec des poteaux muraux de 2 x 4” (50 x 101 mm) ou

plus, en utilisant le boîtier arrière fourni. Le radiateur peut se câbler

avec des fils standard pour bâtiments (supportant 60 °C). Référezvous aux “Spécifications” et à la plaque signalétique du radiateur pour

contrôler la tension secteur correcte et le calibre de fils recommandé.

REMARQUE :

de 18” à 24” (45 à 60 cm), du plancher au bas du boîtier arrière. Ne

l'installez PAS à moins de 12” (30,5 cm) du plancher.

Espacements au montage

POUR PERMETTRE UN FONCTIONNEMENT SÛR, LES ESPACEMENTS QUI SUIVENT DOIVENT ÊTRE RESPECTÉS.

Montage mural uniquement :

a. Au minimum 12" (30,5 cm) par rapport au plancher

b. Au minimum 12" (30,5 cm) par rapport à des cloisons

adjacentes

c. Au minimum 36" (91,5 cm) par rapport au plafond

LE RADIATEUR EN FONCTIONNEMENT EST TRÈS CHAUD. NE

L'INSTALLEZ PAS DERRIÈRE UNE PORTE OU UN PORTESERVIETTES, DANS UN PLACARD, ET À UN ENDROIT OÙ IL

POURRAIT TOUCHER OU ROUSSIR DES RIDEAUX OU

DRAPERIES, OÙ SON ÉCOULEMENT D'AIR POURRAIT ÊTRE

OBSTRUÉ. MAINTENEZ LES CORDONS ÉLECTRIQUES, LA

LITERIE, LE MOBILIER ET D'AUTRES OBJETS COMBUSTIBLES À

DISTANCE DU RADIATEUR.

La hauteur de montage optimale pour ce radiateur va

Couvercle de boîtier

e raccordement

Boîtier

arrière

Figure 1 – Démontage de l'ensemble de radiateur du boîtier arrière

POUR ÉVITER DES DOMMAGES POSSIBLES AU CÂBLAGE DU

SECTEUR, UTILISEZ SEULEMENT LES TROUS À DÉFONCER

PRÉVUS SUR LE BOÎTIER ARRIÈRE.

d

Ensemble de

radiateur

Vis

(8 au total)

Installation du boîtier arrière dans une construction neuve

REMARQUE :

suivez les instructions pour “Installation du boîtier arrière dans une

construction ancienne".

1. Dans une construction neuve sans finition de mur en place, positionnez le boîtier arrière contre le côté d'un poteau mural, en le

laissant dépasser légèrement du poteau pour arriver de niveau

avec la surface de mur finie (Il vous faut connaître l'épaisseur de

la future finition murale avant l'installation). Fixez le boîtier au

poteau en utilisant deux vis (non fournies) comme montré en

Figure 2.

2. Faites passer le câble d'alimentation secteur au travers du serrecâble (précédemment installé, en laissant environ 6" (152 mm) de

mou à l'intérieur du boîtier pour la connexion sur les raccords en

queue de cochon du radiateur. Resserrez bien sur le câble.

Si la surface du mur a déjà a déjà reçu une finition,

Poteau

POUR ÉVITER UN RISQUE DE DÉPART D'INCENDIE OU

D'ÉLECTROCUTION, NE FAITES PAS D'INSTALLATION SANS LE

BOÎTIER ARRIÈRE.

Préparation du radiateur pour son installation

1. Retirez du boîtier arrière couvercle de boîtier de raccordement /

ensemble de radiateur en ôtant 8 vis. Mettez de côté ces vis qui

resserviront plus tard pour fixer l'ensemble de radiateur au boîtier

arrière.

REMARQUE :

radiateur est en deux parties. La partie supérieure est nommée couvercle de boîtier de raccordement, la partie inférieure est nommée

radiateur (Voir la Figure 1).

2. Dégagez l'une des pastilles à défoncer sur le côté du boîtier de

raccordement, et installez-y un serre-câble approprié (non fourni).

Couvercle de boîtier de raccordement / ensemble de

Vis de terre

Boîtier

arrière

Pastille à

défoncer

Trou pour

vis de

support

(Sur poteau si

c'est possible)

Figure 2. Fixation du boîtier au poteau

REMARQUE : Le boîtier arrière doit être installé de façon à ce que

son bord avant soit de niveau avec la surface une fois finie.

14

Clous ou vis (2)

Page 15

. Attachez le fil de terre de l'alimentation électrique au fil vert de

Element

Triac

Sensor

Control - Display Screen

Ribbon Cable

Green Ground

Manual Reset

White - 120 V

Red - 240 V

Pilot

Light

BlackBlack

White

Motor

Black

Blue

Red

White

Black

Blue

Yellow

Red

Control-Power Board

GL/L1N/L2

N

FANH

FANM

FANL

3

terre avec queue de cochon en utilisant des capuchons de raccordement ou des connecteurs approuvés. Dégagez l'excédent de

fils dans l'angle supérieur du boîtier, hors du passage.

REMARQUE :

Si l'alimentation électrique est amenée par câble standard à gaine non métallique (Romex) et qu'il s'agit de 240 V (deux fils

de phase), la couleur du fil blanc doit être changée (en y enroulant de

la bande adhésive noire) pour être en conformité avec NEC, le blanc

n'étant permis que pour le neutre du secteur.

. Pour fixer le côté du boîtier arrière non relié à un poteau, nous

4

recommandons une des méthodes suivantes :

a. Si c'est possible, installez une vis longue additionnelle (comme

ne vis à bois de 3”) au travers du trou de montage du bas,

u

pour aller jusqu'au Poteau le plus proche (Voir la Figure 2).

Veillez à ne pas serrer cette vis avec excès pour ne pas

déformer le boîtier arrière, ce qui rendrait l'insertion de l'ensemble de radiateur difficile ou impossible. Cette vis ne devra être

serrée que juste assez pour tenir en place.

b. Percez un petit trou dans le boîtier arrière, de niveau avec la

surface intérieure du mur fini, et installez-y une vis (sa longueur

n'est pas critique, mais elle doit faire au moins 1" ou 2,5 cm).

oir la Figure 2.

V

Installation du boîtier arrière sur un mur déjà fini

Installation de l'ensemble de radiateur

REMARQUE :

Utilisez les vis fournies par l'usine que vous aviez

retirées à l'étape 1, afin de fixer l'ensemble de radiateur sur le boîtier

rrière.

a

. Positionnez soigneusement l'ensemble de radiateur dans le boîti-

1

er, son ventilateur vers le haut et son élément chauffant vers le

bas. Guidez le rebord dans les fentes d'ouverture du boîtier

arrière. Cela vous aidera à bien mettre l'ensemble de radiateur en

place.

REMARQUE :

L'ensemble de radiateur doit être placé soigneusement

en évitant de coincer le connecteur ruban derrière la carte de circuit.

2. La partie inférieure de l'ensemble de radiateur peut maintenant

être fixée sur le boîtier arrière avec 4 vis mises de côté à l'étape 1.

Câblage du radiateur

Référez-vous au schéma de câblage de la Figure 3.

A TENSION SECTEUR ALIMENTANT LE RADIATEUR DOIT

L

ÊTRE LA MÊME QUE CELLE MENTIONNÉE SUR SA PLAQUE

SIGNALÉTIQUE. UNE MISE SOUS TENSION DE VALEUR EXCESSIVE PAR RAPPORT À LA SPÉCIFICATION PEUT ENDOMMAGER LE RADIATEUR ET ANNULER SA GARANTIE. TOUTES

LES CONNEXIONS DOIVENT SE FAIRE AVEC DES FILS LISTÉS

DE CALIBRE APPROPRIÉ.

UNE COMMOTION ÉLECTRIQUE, UN DÉPART D'INCENDIE OU

DES DÉGÂTS DES EAUX PEUVENT ARRIVER SI DU CÂBLAGE

OU DE LA TUYAUTERIE SONT ENDOMMAGÉS DURANT LA

DÉCOUPE. ASSUREZ-VOUS QU'IL N'Y EN A PAS DANS LA ZONE

AVANT DE COUPER.

1. Localisez un poteau et marquez soigneusement le mur avant de

découper un trou mesurant 12-1/2” (31,8 cm) de large sur 17-3/4”

(45,1 cm) de haut, de façon à ce qu'un côté de cette découpe

suive le bord du poteau (Voir la Figure 2).

2. Faites passer le câble d'alimentation secteur au travers du serrecâble (précédemment installé, en laissant environ 6" (152 mm) de

mou à l'intérieur du boîtier pour la connexion sur les raccords en

queue de cochon du radiateur. Resserrez bien sur le câble.

3. Insérez le boîtier arrière dans l'ouverture, en alignant ses côtés

pour arriver de niveau avec la surface de mur fini, et fixez le boîtier au poteau en utilisant deux vis (non fournies) comme montré en

Figure 2.

REMARQUE :

Le rebord du haut doit dépasser de la surface de mur

fini d'environ 1/8" (3,2 mm) pour permettre la fixation de la grille.

CONSEIL :

Pour avoir un bon espacement derrière le rebord

supérieur du boîtier, une cale d'épaisseur 1/8” peut s'utiliser, comme

une lame étalon ou un morceau de bois de cette épaisseur, avant de

finaliser la fixation du boîtier arrière sur le poteau. Cela laisse à la

grille suffisamment de place pour s'adapter comme il faut sur les

rebords du boîtier arrière. Une fois que le boîtier est tenu en place,

cette cale peut être retirée.

4. Attachez le fil de terre de l'alimentation électrique au fil vert de

terre avec queue de cochon en utilisant des capuchons de raccordement ou des connecteurs approuvés. Dégagez l'excédent de

fils dans l'angle supérieur du boîtier, hors du passage.

REMARQUE :

dard à gaine non métallique (Romex) et qu'il s'agit de 240 V (deux fils

Si l'alimentation électrique est amenée par câble stan-

de phase), la couleur du fil blanc doit être changée (en y enroulant de

la bande adhésive noire) pour être en conformité avec NEC, le blanc

n'étant permis que pour le neutre du secteur.

5. Insérez une vis à bois #8 de trois pouces de long (non fournie) au

travers du côté libre du boîtier arrière qui n'est pas fixé au poteau,

et fixez dans le trou de montage du bas. Cela empêchera le boîtier arrière de pouvoir être tiré du côté non supporté au moment de

l'installation dedans de l'ensemble de radiateur. Faites attention de

ne pas faire mordre la vis à bois de plus de 3/8” dans le poteau.

Trop d'enfoncement entraînerait la sortie du boîtier arrière de son

alignement (Voir la Figure 2).

RADIATEURS PRÉVUS POUR 120 VOLTS :

1. Branchez le fil noir en queue de cochon (L1) du radiateur avec le

fil noir d'arrivée de phase du secteur.

2. Branchez le fil blanc en queue de cochon (N) du radiateur avec le

fil blanc d'arrivée de neutre du secteur.

3. Si ce n'est pas déjà fait, branchez le fil vert en queue de cochon

du radiateur au fil vert d'arrivée pour mise à la terre.

4. Dégagez l'excédent de fils dans l'angle supérieur du boîtier, hors

du passage.

RADIATEURS PRÉVUS POUR 240 VOLTS :

1. Branchez le fil noir en queue de cochon (L1) du radiateur avec le

fil noir d'arrivée de phase du secteur.

2. Branchez le fil noir en queue de cochon (L2) du radiateur avec

l'autre fil noir d'arrivée de phase du secteur.

REMARQUE :

Si l'alimentation électrique est amenée par câble standard à gaine non métallique (Romex) et qu'il s'agit de 240 V (deux fils

de phase), la couleur du fil blanc doit être changée (en y enroulant de

la bande adhésive noire) pour être en conformité avec NEC, le blanc

n'étant permis que pour le neutre du secteur.

Voyant

témoin

Câble ruban

Écran de

contrôle/affichage

Détecteur

Vert (terre)

Carte de commande

de puissance

Noir

Bleu

Jaune

Noir

Noir

Blanc

Rouge

Élément chauffant

Restauration

manuelle

Blanc – 120 V

Rouge – 240 V

Blanc

Noir

Bleu

Rouge

Moteur

Figure 3 – Schéma de câblage

15

Page 16

Prise à l'arrière

Connecteur ruban

Figure 4 – Ruban connecteur

3. Si ce n'est pas déjà fait, branchez le fil vert en queue de cochon

du radiateur au fil vert d'arrivée pour mise à la terre.

4. Dégagez l'excédent de fils dans l'angle supérieur du boîtier, hors

du passage.

de la grille

Enjoliveur inférieur

Vis (2)

Figure 5 – Emplacements des vis de grille

Voyant rouge

d'alerte

Restauration

anuelle

m

de limite de

sécurité

TOUS LES RADIATEURS :

Mettez en place le couvercle du boîtier de raccordement en vous

assurant que le câble en ruban plat est passé dans la fente allongée

dans la couvercle, comme montré en Figure 4.

Fixez le couvercle en utilisant les 4 vis fournies.

REMARQUE :

fente pour la connexion sur l'électronique de la grille. L'orientation du

connecteur doit être comme montré en Figure 4.

Environ 3-1/2" (89 mm) de câble ruban doit sortir de la

Installation de la grille et du ruban connecteur

1. Tout en maintenant le côté droit de la grille avec votre main droite,

étendez le ruban connecteur avec l'autre main et enfichez le connecteur noir dans la prise noire située au dos du contrôle électronique, derrière la grille. Connecteur et prise ont un détrompeur, la

liaison ne peut donc se faire que d'une façon (Figure 4).

REMARQUE :

mais sans forcer.

2. Une fois la connexion faite, positionnez la grille par-dessus

l'ensemble de boîtier arrière et de radiateur, en alignant le haut de

la grille avec les rebords sur le dessus du boîtier arrière.

3. Allez derrière la grille et repoussez l'excédent de ruban dans la

fente du couvercle du boîtier de raccordement, pour éviter qu'il ne

subisse des pliures inutiles. Abaissez le dessus de la grille de

façon à ce que ses brides attrapent le rebord du boîtier arrière et

maintiennent la grille en place.

4. Il y a deux trous dans la zone de l'enjoliveur inférieur de la grille,

qui s'alignent avec deux trous dans l'ensemble de radiateur.

Insérez deux vis dans ces trous et serrez (Figure 5).

FAITES ATTENTION DE NE PAS SERRER AVEC EXCÈS LES VIS

DE MONTAGE CAR VOUS POURRIEZ ENDOMMAGER LA

GRILLE.

5. Mettez l'enjoliveur inférieur en position par-dessus la grille et

enfichez ses taquets dans les trous correspondants en vérifiant

qu'il tient bien en place.

Appuyez sur le connecteur doucement et fermement,

FONCTIONNEMENT

Instructions de mise en œuvre initiale (par l'installateur)

REMARQUE :

dures pour s'assurer du bon fonctionnement du radiateur.

La programmation du radiateur peut être faite par l'utilisateur

(Consultez le MANUEL D'UTILISATION livré avec le radiateur pour la

programmation de ses contrôles).

1. Une fois le radiateur complètement assemblé, établissez son alimentation secteur au niveau de l'interrupteur général en amont. Le

bouton “Power” sur l'avant du radiateur doit s'allumer en orange.

2. Appuyez sur l'icône “Power ON” situé dans l'angle inférieur

gauche de l'affichage. Cette icône va s'éclairer brillamment en

bleu, indiquant ainsi que le radiateur est en marche (ON).

Avis sur le fonctionnement

Ce radiateur est équipé d'un contrôle de limite de sécurité à restauration manuelle, qui va automatiquement couper le radiateur en cas de

surchauffe pour éviter un départ d'incendie. Un voyant rouge d'alerte

va s'allumer pour prévenir que la coupure de sécurité a été

déclenchée. La Figure 5 indique l'emplacement de ces éléments.

L'ACTIVATION DU CONTRÔLE DE LIMITE DE SÉCURITÉ ET

L'ALLUMAGE DU VOYANT ROUGE SE PRODUISENT QUAND LE

RADIATEUR CHAUFFE TROP. VÉRIFIEZ-LE POUR VOUS

ASSURER QU'IL N'A PAS DE D'OBSTRUCTION, ET DÉGAGEZ-LA

S'IL Y EN A UNE. SINON IL EST RECOMMANDÉ QUE LE

RADIATEUR SOIT INSPECTÉ PAR UN BON ÉLECTRICIEN OU UN

SERVICE DE RÉPARATIONS, POUR VÉRIFIER S'IL N'EST PAS

ENDOMMAGÉ. NE POURSUIVEZ PAS L'UTILISATION D'UN RADIATEUR SI SON CONTRÔLE DE SÉCURITÉ LE FAIT DISJONCTER

DE FAÇON RÉPÉTITIVE.

RESTAURATION DE LA LIMITE DE SÉCURITÉ (SEE FIGURE 5)

Le bouton de restauration manuelle est situé derrière l'enjoliveur

inférieur, juste sous le voyant rouge d'alerte. Pour accéder à ce bouton, tirez doucement sur l'enjoliveur inférieur pour qu'il se désolidarise.

N'utilisez pas d'outil pour l'enlever, vous pourriez l'abîmer. Une fois

que le radiateur aura refroidi, actionnez le bouton de restauration. Le

radiateur doit reprendre son fonctionnement normal. Remettez alors

l'enjoliveur en place.

Après l'installation, l'installateur doit suivre ces procé-

16

Page 17

ENTRETIEN

Votre radiateur est conçu pour vous fournir des années de fonctionnement sans soucis, il ne nécessite pas d'entretien particulier en

dehors d'un nettoyage occasionnel. Son moteur est lubrifié à vie.

Nettoyage

Chaque année, le radiateur doit être nettoyé pour éliminer la poussière et les autres matières étrangères collectées durant la saison de

chauffage, de la façon suivante :

TOUTES LES AUTRES INTERVENTIONS DE SERVICE DOIVENT

ÊTRE MENÉES PAR UN ÉLECTRICIEN OU UNE PERSONNE

UALIFIÉE.

Q

1. Coupez l'alimentation électrique à l'interrupteur général en amont.

2. Enlevez l'enjoliveur inférieur et les deux vis qui maintiennent la

rille.

g

. Utilisez un aspirateur avec une brosse comme accessoire pour

3

enlever la poussière et les matières étrangères qui se sont accumulées dans le radiateur (particulièrement autour de l'élément

chauffant et des pales de soufflante). N'utilisez ni eau ni produit

nettoyant pour nettoyer les composants du radiateur.

4. Après le nettoyage repassez l'interrupteur interne en position de

marche (ON) et remettez la grille en place.

5. Essuyez bien la grille avec un chiffon humide. N'utilisez PAS de

cire ou d'autres produits nettoyante qui laissent un résidu, car cela

provoquerait une décoloration pendant le fonctionnement du radiateur.

6. Rétablissez l'envoi du secteur en amont pour alimenter le radiateur. Il est maintenant prêt pour une nouvelle saison de chauffage.

PIÈCES DE RECHANGE

7

1

3

5

8

6

2

9

4

10

Liste de pièces de rechange

N° N° de pièce N° de pièce

référence Description (120 V) (240 V)

1. Grille seulement 2501-11003-000 2501-11003-000

2. Ensemble électronique avec 1016-11035-001 1016-11035-001

enjoliveur supérieur

3. Carte mère, triac/dissipateur, connecteur ruban, 1414-11007-000 1414-11007-001

ensemble de détection (en un même boîtier)

4. Enjoliveur inférieur 1219-11004-000 1219-11004-000

5. Ensemble de moteur 1225-11001-000 1225-11001-001

6. Restauration manuelle 4520-11005-000 4520-11005-000

7. Élément chauffant 302023802 302023805

8. Voyant rouge 3510-2017-000 3510-2017-001

9. Télécommande 1414-11017-000 1414-11017-000

10 Batterie 1218-11003-000 1218-11003-000

17

Page 18

GARANTIE LIMITÉE

Tous les produits fabriqués par Marley Engineered Products sont garantis contre les défauts dus à la main-d'oeuvre et aux matériaux pendant un an à compter de leur

date d'installation, à l'exception des éléments chauffants qui eux portent une garantie dans les mêmes conditions de cinq ans. Cette garantie ne s'applique pas pour des

dommages résultant d'accident, de mésusage ou d'altération ; ni si l'appareil a été branché sur un secteur faisant 5 % de plus que la tension de sa plaque signalétique ;

ni si l'appareil a été mal installé ou mal câblé ou mal entretenu, en ne respectant pas les instructions d'installation et d'entretien. Toutes les demandes portant sur du travail dans le cadre de la garantie doivent être accompagnées d'une preuve de la date d'installation.

Le client gardera à sa charge tous les coûts encourus pour le démontage et la réinstallation des produits, incluant les coûts de main-d'oeuvre et les coûts de transport

pour envoyer les produits au centre de service de Marley Engineered Products. Compte tenu des limitations de cette garantie, les unités présentant un dysfonctionnement

doivent être retournées au centre de service Marley agréé le plus proche, ou directement au centre de service de Marley Engineered Products, et nous le réparerons ou

le remplacerons, à notre choix, sans frais, et nous vous renverrons un appareil en port prépayé par Marley. Vous devez convenir que cette réparation ou ce remplacement sera le seul remède fourni par Marley Engineered Products.

LES GARANTIES QUI PRÉCÈDENT TIENNENT LIEU DE TOUTES AUTRES FORMES DE GARANTIES, EXPLICITES OU IMPLICITES, INCLUANT CELLES DE

VALEUR MARCHANDE OU D'ADÉQUATION À UNE FINALITÉ PARTICULIÈRE. TOUT CE QUI EXCÈDERAIT LES GARANTIES ÉNONCÉES PLUS HAUT EST ICI

REJETÉ ET EXCLU DE CE CONTRAT. MARLEY ENGINEERED PRODUCTS NE SERA PAS TENU POUR RESPONSABLE DE DOMMAGES CONSÉCUTIFS SURVENANT EN RELATION AVEC CE PRODUIT, QU'ILS VIENNENT DE NÉGLIGENCE, DE TORT, DE RESPONSABILITÉ ABSOLUE OU CONTRACTUELLE.

Certains États ne permettent pas l'exclusion ou la limitation des dommages accessoires ou consécutifs, de ce fait l'exclusion ou la limitation qui précède peut ne pas s'appliquer dans votre cas. Cette garantie vous donne des droits légaux spécifiques, et vous pouvez également avoir d'autres droits qui varient d'un État à l'autre.

Pour obtenir l'adresse du centre de service agréé le plus proche de chez vous, contactez Marley Engineered Products à Bennettsville, SC, au 1-800-642-4328. Les

marchandises retournées à l'usine doivent être accompagnées par une autorisation de renvoi et une étiquette d'identification de service, toutes deux fournies par Marley

Engineered Products. Quand vous demandez une autorisation de renvoi, incluez tous les numéros d'identification relevés sur les produits concernés.

POUR OBTENIR UN SERVICE DANS LE CADRE DE LA GARANTIE,

DES PIÈCES DE RECHANGE OU DES INFORMATIONS GÉNÉRALES :

1. Service ou pièces sous garantie

2. Achat de pièces de rechange

3. Informations générales sur les produits

Remarque :

1. Référence de modèle du produit

2. Date de fabrication

3. Numéro ou description de la pièce

Pour obtenir du service, préparez toujours à l'avance :

1-800-642-4328

1-800-654-3545

www.marleymep.com

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

Document N° 5200-11046-001

ECR 38932

10/10

Page 19

NOTES / NOTAS / NOTES

Page 20

NOTES / NOTAS / NOTES

Loading...

Loading...