Page 1

R Series &

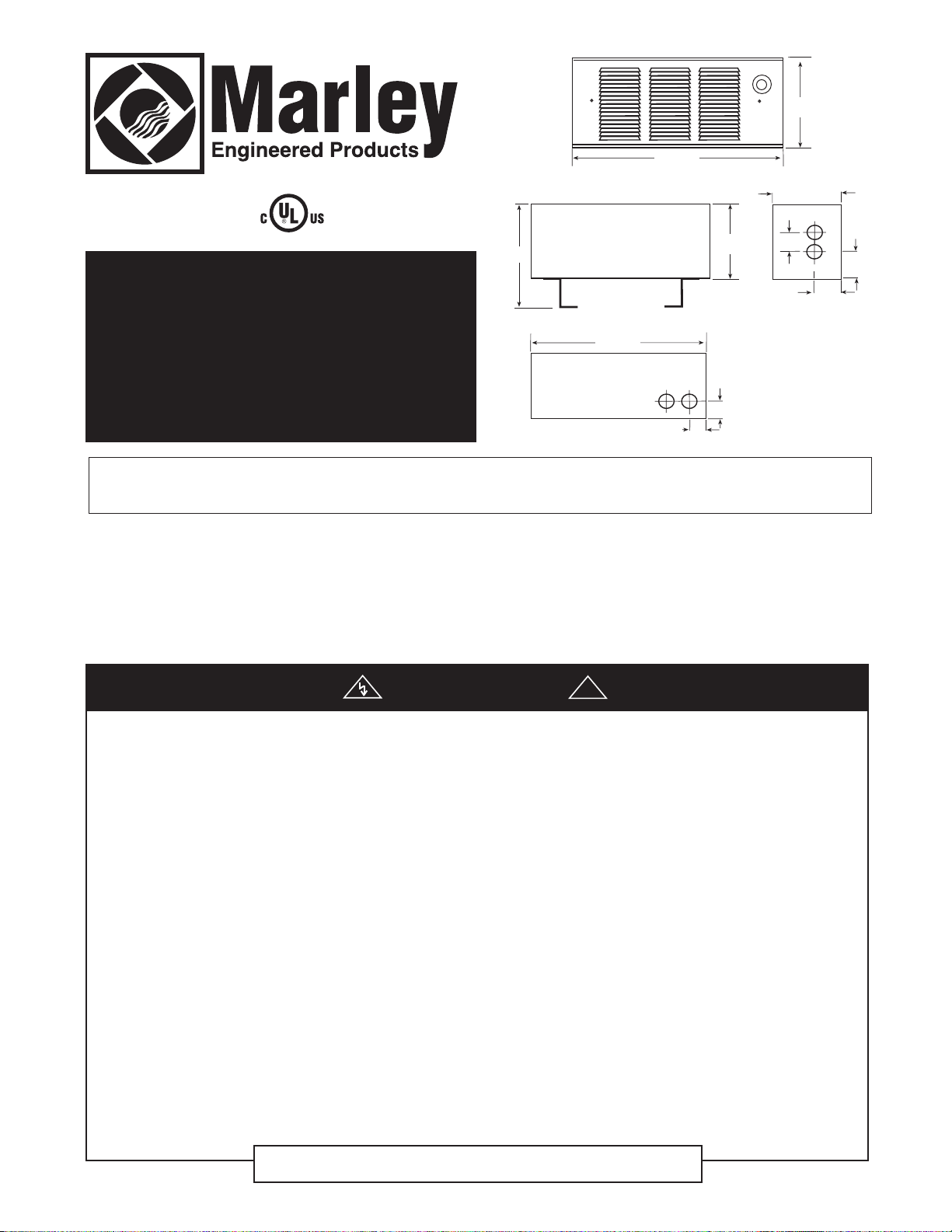

FRONT VIEW

SIDE VIEW

BOTTOM VIEW

10-5/8”

16-7/8”

6-5/8”

1-1/2”

1-1/16”

7-3/4”

4-3/8”

RT2 Series

shown

(BACK)

2-1/2”

RT2 Series

Fan Forced Wall Heaters

with new Clip ‘n’ Fit® Board

US Patent No. 6,172,343

14-3/8”

BOTTOM VIEW (BACK)

1-3/16

NOTE: Knockouts in

top - same dimensions

as bottom

7/8”

Installation & Maintenance Instructions

Dear Owner,

Congratulations! Thank you for purchasing this new heater manufactured by Marley Engineered Products. You have made a

wise investment selecting the highest quality product in the heating industry. Please carefully read the installation and

maintenance instructions shown in this manual. You should enjoy years of efficient heating comfort with this product from

Marley Engineered Products... the industry’s leader in design, manufacturing, quality and service.

... The Employees of Marley Engineered Products

WARNING

Read Carefully - These instructions are written to help you

prevent difficulties that might arise during installation of

heaters. Studying the instructions first may save you

considerable time and money later. Observe the following

procedures, and cut your installation time to a minimum.

CAUTION - TO REDUCE RISK OF FIRE AND ELECTRIC

SHOCK:

1. Disconnect all power coming to heater at main service panel

before wiring or servicing.

2. All wiring must be in accordance with the National and Local

Electrical Codes and the heater must be grounded.

3. Verify the power supply voltage coming to heater matches the

ratings printed on the heater nameplate before energizing.

4. This heater is hot when in use. To avoid burns, do not let bare

skin touch hot surfaces.

5. Do not insert or allow foreign objects to enter any ventilation or

exhaust opening as this may cause an electric shock, fire, or

damage to the heater.

6. Do not block air intakes or exhaust in any manner. Keep

combustible materials, such as crates, drapes, etc., away

from heater. Do not install behind doors, furniture, towels, or

boxes.

7. A heater has hot and arcing or sparking parts inside. Do not use

it in areas where gasoline, paint, or flammable liquids are used

or stored.

8. Use this heater only as described in this manual. Any other use

not recommended by the manufacturer may cause fire, electric

shock, or injury to persons.

9. This heater is not approved for use in corrosive atmospheres

such as marine, green house, or chemical storage areas.

10. Heater must only be installed in a horizontal direction (motor &

thermostat to right) as shown in this manual. Do not install

sideways or upside down.

11. Heater must be installed with Back Box.

12. For wall mounting only. The following minimum clearances must

be maintained: Heater to floor - 4 in. (102 mm); Heater to any

adjacent wall - 6 in. (152 mm); heater to ceiling - 36 in. (915 mm).

13. When wiring, power supply must enter through knockouts in

right end of heater. Do not use the knockouts in left end of

heater.

14. Do not operate heater without grille installed.

15. Do not use heater for dry out. Paint, plaster, sawdust and drywall sanding dust will damage heater and must be kept out of

heater.

16. Grille and discharge air are hot when in use. Do not install or

use heater in any area where the airflow from heater may be

obstructed. Hot air may damage certain fabrics and plastics.

Always keep electrical cords, bedding, furniture, and other

combustibles away from heater.

!

SAVE THESE INSTRUCTIONS

Page 2

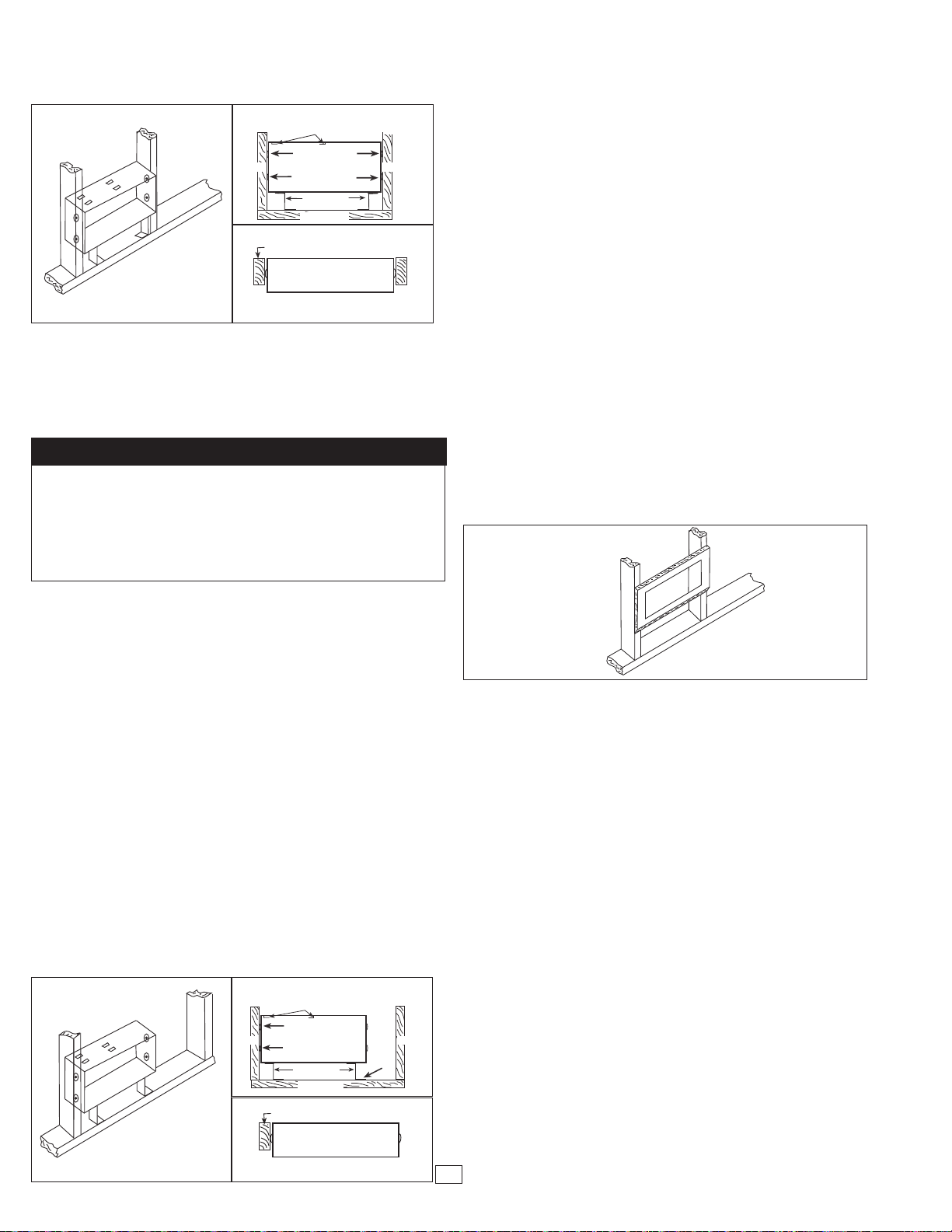

The “R” Series heaters are designed for recessed installation in

BACK BOX (FRONT VIEW)

NAIL OR SCREW

4 PLACES

BACK BOX

SUPPORT BKTS.

SOLE PLATE

STUD

STUD

MOUNTING RAILS

M

BACK BOX

TOP VIEW

INSERT FAN DECK

THIS SIDE

STUD

BACK BOX (FRONT VIEW)

NAIL OR SCREW

BACK BOX

SUPPORT BKTS.

SOLE PLATE

NAIL OR SCREW

STUD

STUD

MOUNTING RAILS

BACK BOX

TOP VIEW

INSERT FAN DECK

THIS SIDE

STUD

standard 2 x 4 (50mm X 100mm) or larger stud walls with the

back box mounted as shown in either Fig. 1, or Fig. 2.

Figure 1A

Fig. 1B

Fig. 1C

NOTE: Heater should be controlled by either built-in thermostat or

remote wall thermostat. Models with “T2” suffix are equipped with

built-in thermostat.

This heater may be wired with standard building wiring (rated

minimum 60° C). Refer to Table 2 (Page 3) for appropriate wire

size for the heater to be used.

NOTE TO INSTALLER

The “IF” models do not include a backbox. The Backbox is

ordered separately. In the parts bag for “IF” models, there is a

white label that indicates multiple wattage and must be place in

the backbox on the bottom right-hand side. When making

wattage changes, the installer must circle the wattage on the

white label before installing the heat deck.

TO INSTALL BACK BOX IN NEW CONSTRUCTION -

WALL STUDS SPACING GREATER THAN 16” OC.

(REFER TO FIG. 2)

NOTE: Fig. 2 depicts the back box installed with the left side

adjoining stud. For a box with the right side adjoining a stud,

reverse the directions shown below.

1. Locate back box and back box support brackets (2). Back box

must be installed with mounting rails to the top (see Fig. 2B)

2. Determine which side of the back box will adjoin stud and

insert back box support bracket on that side with foot tab

directed towards center of back box. On the side of the back

box that will not adjoin stud, install back box support bracket

on that side with foot tab directed towards end of box and

secure to box with 3/8” long sheet metal screw (provided).

3. Determine which knockout in back box will be used for field

wiring and remove (see back box drawing pg. 1). Install

strain relief (field supplied).

4. Fish field wiring through strain relief leaving 6” of wire inside

box.

5. Insert back box assembly into wall, aligning rear of back box

with back side of stud (see Fig. 2C). The back box support

brackets should be resting on the sole plate of the stud wall

to insure proper spacing and leveling (see Fig. 2B).

6. Use two (2) wood screws or drywall screws or two (2) nails

(field supplied) to secure the side of the back box that adjoins

a stud. Use one (1) wood screw or drywall screw or one (1)

nail (field supplied) to secure the foot tab of the back box

support bracket (that is on the end opposite the stud) to the

sole plate (see Fig. 2B).

Figure 3

TO INSTALL BACK BOX (Model RBB)

IN NEW CONSTRUCTION - WALL STUDS 16” OC.

(REFER TO FIG. 1)

1. Locate back box (model RBB) and back box support

brackets (2). Back box must be installed with mounting rails

to the top (see Fig. 1B).

2. Install back box support brackets with foot tabs directed

towards the center of the back box as shown in Fig. 1A and

1B. It may be necessary to bend up slightly the tab on the

back box support bracket to allow insertion under the mounting lances on the bottom of the back box.

3. Determine which knockout in back box will be used for field

wiring and remove (see back box drawing pg.1). Install

strain relief (field supplied). See warning No. 13.

4. Fish field wiring through strain relief leaving 6” of wire inside

box.

5. Insert back box assembly into wall, aligning rear of back box

with back side of studs (see Fig. 1C). The back box support

brackets should be resting on the sole plate of the stud wall

to insure proper spacing and leveling (see Fig. 1B).

6. Using four (4) wood screws or drywall screws or four (4) nails

(field supplied), secure back box to studs (see Fig. 1B).

Back box support brackets can now be removed. If not

removed, secure to sole plate.

Figure 2A

Fig. 2B

Fig. 2C

TO INSTALL BACK BOX IN

EXISTING CONSTRUCTION

1. Locate wall studs to be sure that entire cut-out can be made

between studs. At least one side of the cut-out must be flush

with side of the stud. Bottom of cut-out must be 4” above

finished floor minimum. Make a cut-out in wall 14-1/2” wide

X 6-3/4” high (368mm X 171mm) (see Fig. 3).

2. Determine which knockout in back box will be used for field

wiring and remove (see back box drawing, pg.1). Install

strain relief (field supplied).

3. Fish field wiring through strain relief leaving 6” of wire inside

box.

4. Insert back box into cut-out. Rear of back box should be

flush with back of stud wall.

5. Using four (4) wood screws or drywall screws (field supplied)

or four (4) nails (field supplied), secure back box to studs

(see Fig. 1B). If wall studs are greater than 16”oc., use only

2 fasteners and on the opposite end of the back box drive a

1” sheet metal screw (provided) through hole in end cap.

This will draw the back box tight with drywall when grille is

installed. (See Fig. 4.)

TO INSTALL THERMOSTAT ASSEMBLY (RT2 only)

NOTE: Thermostat assembly should not be installed until after

the drywall phase of construction is complete. Dust from drywall

installation and joint compound can be harmful if it gets inside

thermostat assembly components.

1. The thermostat must be installed in right end of the heater.

2. Position thermostat above slot in right end of back box.

2

Push tab on thermostat bracket through slot in top, right

end of back box until the bracket locks in place. See Fig. 5.

Page 3

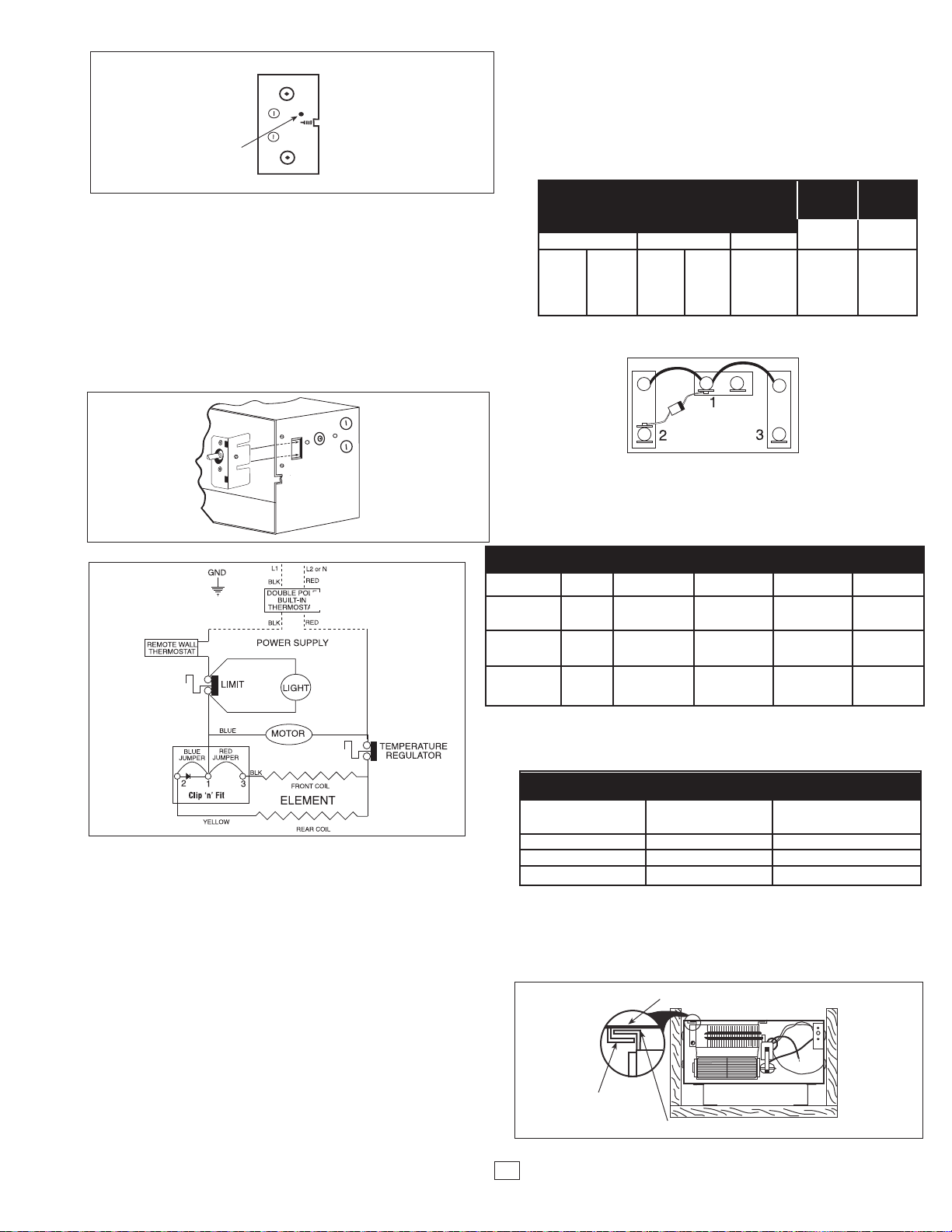

TOP OF BACK BOX

FLANGE ON FAN DECK

MOUNTING RAIL

BACK BOX

END CAP

HOLE

Figure 4

End View

3. If the thermostat is controlling more than one heater, the total

of all heater amperage ratings (Table 1) cannot exceed 25

amps at 120 volts AC thru 240 volts AC. Refer to Table

2 for correct wire, circuit breaker, or fuse sizing.

4. Connect one red and one black thermostat lead to power

wiring per wiring diagram (Fig. 6) using properly sized listed

wirenuts (provided).

5. Fold wires back into wiring compartment behind thermostat

to clear fan deck.

Figure 5

TO CHANGE WATTAGE OUTPUT

The chart shows the wattages available by model. Each heater

is factory wired for its maximum wattage. The last two columns

in the chart refer to the jumpers on the CLIP ‘n’ Fit

®

Board. To

change wattage, clip out Jumper 1 and/or Jumper 2 as shown in

the chart below. Completely remove jumpers by clipping at both

ends as close to the board as possible.

JUMPER1JUMPER

2

Blue

Jumper

Leave in

Clip out

Leave in

Clip out

Red

Jumper

Leave in

Leave in

Clip out

Clip out

R2404 &

R2404T2

@240V @208V

2400

1800

1200

600

1800

1350

900

450

WATTAGE

R2004 &

R2004T2

@240V @208V

2000

1500

1000

500

BLUE

JUMPER

1500

1125

750

375

R1500 &

R1500T2

@120V

1500

1125

750

375

RED

JUMPER

Clip ‘n’ Fit®Board

Figure 6

RT2 Series only

R Series only

®

TO INSTALL FAN DECK ASSEMBLY

NOTE: Fan deck assembly should not be installed until after the

drywall phase of construction is complete. Dust from drywall

installation and joint compound can be harmful if it gets inside fan

deck components.

1. Locate fan deck and mounting rails in top of back box.

2. Insert flanges on fan deck into mounting rails and slide back

until fan deck stops (see Fig. 7).

3. Make wiring connections, attaching one red and one black

thermostat lead to two (2) black heater leads for 240V or to

black and white heater leads for 120V with wirenuts

(provided). Connect field ground lead to bare ground wire

with wirenut (provided). See Fig. 6.

4. Remove 1/2” knockout from grille and install grille using two

oval head screws. Push thermostat knob on thermostat

shaft.

5. Reconnect power at main fuse or circuit breaker distribution

panel.

TABLE 1

MODEL

R1500

R1500T2

R2004

R2004T2

R2404

R2404T2

VOLTS

120

240

208

240

208

WATTS/AMPS

1500W/12.5A

2000W/8.3A

1500W/7.2A

2400W/10.0A

1800W/8.7A

WATTS/AMPS

1125W/9.4A

1500W/6.3A

1125W/5.4A

1800W/7.5A

1350W/6.5A

WATTS/AMPS

750W/6.3A

1000W/4.2A

750W/3.6A

1200W/5.0A

900W/4.3A

Note: “IF” Inner Frame models must be used with RBB Back

box.

TABLE 2

TOTAL AMPS

0 thru 12

12.1 thru 16

16.1 thru 24

WIRE SIZE

(COPPER)

#14

#12

#10

CIRCUIT BREAKER

OR FUSE SIZE

15 Amps

20 Amps

30 Amps

Figure 7

WATTS/AMPS

375W/3.1A

500W/2.1A

375W/1.8A

600W/2.5A

450W/2.2A

3

Page 4

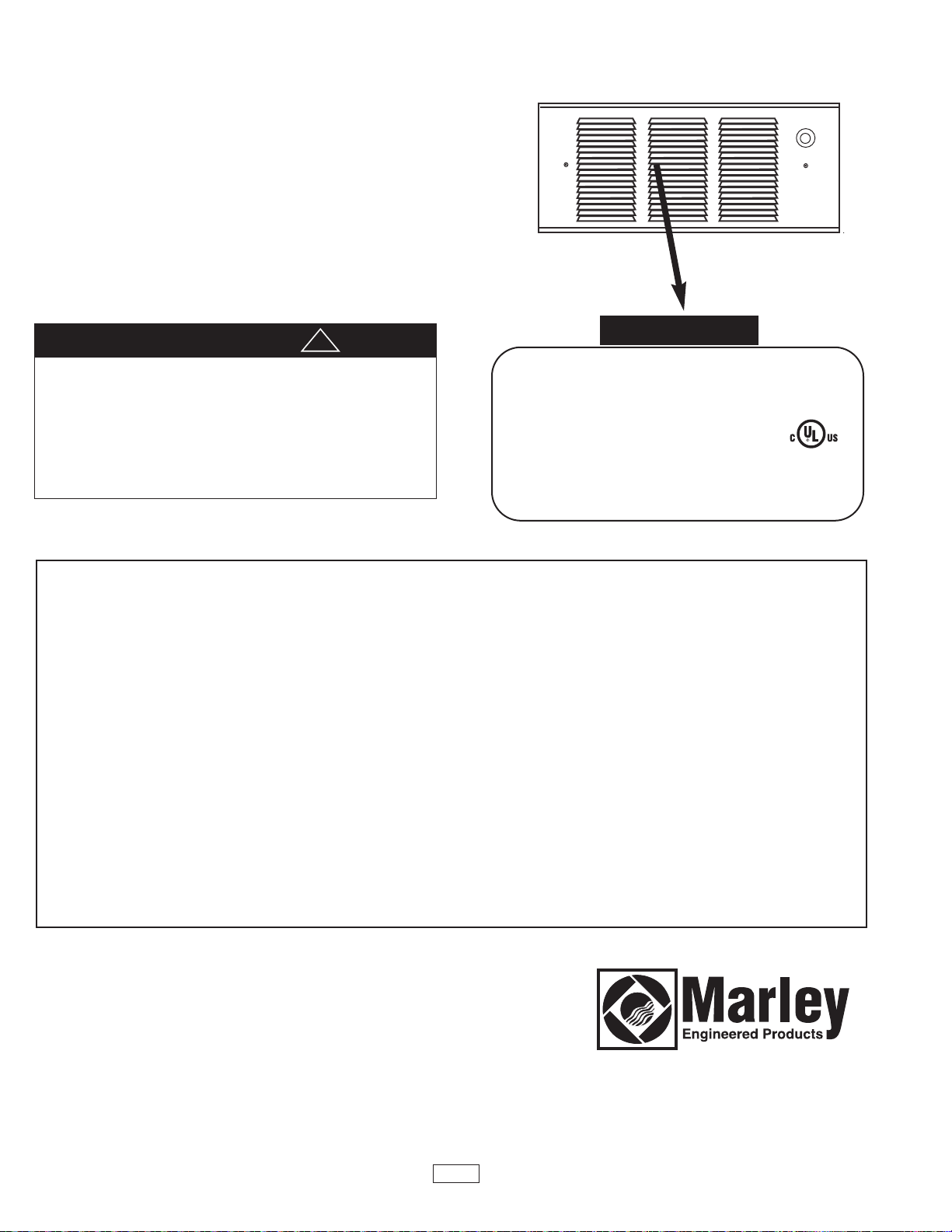

IMPORTANT INFORMATION

MAINTENANCE

TO CLEAN HEATER: The heater should be cleaned annually for

maximum efficiency or more often if used in dirty environment.

Before cleaning be sure power is off and heater is cool. First,

remove knob by pulling straight out, then remove front grille and

clean blower wheel using a vacuum cleaner with a brush

attachment. The grille may be cleaned with a slightly damp rag

if desired.

OPERATIONAL NOTICE

Your heater is equipped with an automatic reset limit control that

will automatically turn the heater OFF to prevent a fire if the

heater overheats. Should this occur, the red warning light will

Model shown is

“RT2” series with

built-in thermostat.

illuminate and will continue to shine until the limit resets.

a

CAUTION

THE ILLUMINATED RED WARNING LIGHT SIGNIFIES THE HEATER HAS

BEEN SUBJECTED TO SOME ABNORMAL CONDITION CAUSING IT TO

OVERHEAT. CHECK HEATER TO INSURE THAT IT HAS NOT BEEN

BLOCKED IN ANY MANNER (IF SO, REMOVE BLOCKAGE). IF THERE IS

NO INDICATION OF BLOCKAGE IT IS RECOMMENDED THE HEATER BE

CHECKED BY A REPUTABLE ELECTRICIAN OR REPAIR SERVICE TO

INSURE THE HEATER HAS NOT BEEN DAMAGED. DO NOT CONTINUE TO

USE HEATER IF LIGHT IS ON.

!

MODEL NO.

FAN FORCED WALL HEATER

120 1500/1125/750/375 12.5/9.4/6.3/3.1

VOLTS AC WATTS AMPS

USE ONLY WITH RBB SERIES BACK BOX. DO

NOT OPERATE WITHOUT GRILLE IN PLACE.

MARLEY ENGINEERED PRODUCTS

BENNETTSVILLE, SC 29512 4104-2159-003

R1500T2 DATE CODE 0599

NAMEPLATE

774G LISTED

ROOM HEATER

LIMITED WARRANTY

All products manufactured by Marley Engineered Products are warranted against defects in workmanship and materials for one year from date of

installation, except heating elements which are warranted against defects in workmanship and materials for five years from date of installation. This

warranty does not apply to damage from accident, misuse, or alteration; nor where the connected voltage is more than 5% above the nameplate

voltage; nor to equipment improperly installed or wired or maintained in violation of the product’s installation instructions. All claims for warranty work

must be accompanied by proof of the date of installation.

The customer shall be responsible for all costs incurred in the removal or reinstallation of products, including labor costs, and shipping costs incurred

to return products to Marley Engineered Products Service Center. Within the limitations of this warranty, inoperative units should be returned to the

nearest Marley authorized service center or the Marley Engineered Products Service Center, and we will repair or replace, at our option, at no charge

to you with return freight paid by Marley. It is agreed that such repair or replacement is the exclusive remedy available from Marley Engineered

Products.

THE ABOVE WARRANTIES ARE IN LIEU OF ALL OTHER WARRANTIES EXPRESSED OR IMPLIED AND ALL IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE WHICH EXCEED THE AFORESAID EXPRESSED WARRANTIES ARE

HEREBY DISCLAIMED AND EXCLUDED FROM THIS AGREEMENT. MARLEY ENGINEERED PRODUCTS SHALL NOT BE LIABLE FOR

CONSEQUENTIAL DAMAGES ARISING WITH RESPECT TO THE PRODUCT, WHETHER BASED UPON NEGLIGENCE, TORT, STRICT

LIABILITY, OR CONTRACT.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above exclusion or limitation may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

For the address of your nearest authorized service center, contact Marley Engineered Products in Bennettsville, SC, at 1-800-642-4328. Merchandise

returned to the factory must be accompanied by a return authorization and service identification tag, both available from Marley Engineered Products.

When requesting return authorization, include all catalog numbers shown on the products.

HOW TO OBTAIN WARRANTY SERVICE AND

WARRANTY PARTS PLUS GENERAL INFORMATION

1. Warranty Service or Parts

2. Purchase Replacement Parts

3. General Product Information

Note:

When obtaining service always have the following:

1. Model number of the product

2. Date of manufacture

3. Part number or description

5200-2367-006

1-800-642-4328

1-800-654-3545

www.marleymep.com

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

ECR 39219

09/11

4

Page 5

FRONT VIEW

SIDE VIEW

BOTTOM VIEW

16-7/8”

7-3/4”

Serie RT2

ilustrada

1-1/2”

1-1/16”

4-3/8”

PARTE

POSTERIOR

2-1/2”

VISTA

LATERAL

Serie R y RT2

Calentadores de Pared de

Tiro Forzado

con la nueva pizarra de

Clip ‘n’ Fit

®

10-5/8”

VISTA DELANTERA

14-3/8”

VISTA DEL FONDO

(PARTE POSTERIOR)

6-5/8”

NOTA: Orificios ciegos en el tope -iguales

dimensiones que en el

fondo

7/8”

1-3/16

Patente No. 6.172.343 De los E.E.U.U.

Instrucciones de Instalación y Mantenimiento

Estimado propietario:

¡Felicitaciones! Gracias por comprar este nuevo calentador fabricado por Marley Engineered Products. Usted ha efectuado

una sabia inversión al seleccionar el producto de la más alta calidad en la industria de calefacción. Por favor lea

cuidadosamente las instrucciones de instalación y mantenimiento indicadas en este manual. Usted debería gozar de años

de calefacción eficiente con este producto de Marley Engineered Products...el líder de la industria en diseño, fabricación,

calidad y servicio.

... Los empleados de Marley Engineered Products

ADVERTENCIA

Lea cuidadosamente -Estas instrucciones están escritas

para ayudarlo a prevenir dificultades que podrían surgir

durante la instalación de los calentadores. El estudiar

primero las instrucciones puede ahorrarle un tiempo considerable y dinero después. Observe los procedimientos siguientes, y reduzca a un mínimo su tiempo de instalación.

PRECAUCION - PARA REDUCIR EL RIESGO DE INCENDIOS Y CHOQUES ELECTRICOS

1. Antes de cablear o prestar servicio y para prevenir el choque eléctrico, desconecte la potencia entrante al calentador por el panel

principal de servicio.

2. Todo el cableado debe conformar con los códigos eléctricos

nacionales y locales y el calentador debe estar conectado a

tierra como precaución contra un choque eléctrico posible.

3. Antes de activar, verifique que el voltaje del suministro de potencia entrante al calentador corresponda a las clasificaciones

principales impresas en la placa de nombre.

4. Este calentador está caliente cuando está en uso. Para evitar

quemaduras, no permita que la piel expuesta toque las superficies calientes.

5. No inserte ni permita que objetos extraños entren a ninguna apertura de ventilación o escape ya que esto puede causar un choque

eléctrico, incendio o daños al calentador.

6. No bloquee de ninguna manera las tomas de aire o los escapes,

para prevenir un posible incendio. Mantenga los materiales combustibles, tales como cajas de madera, cortinas, etc, alejados del

calentador. No instale detrás de puertas, muebles, toallas o cajas.

7. Un calentador tiene adentro piezas calientes y productoras de

!

arcos eléctricos o de chispas. No use en áreas donde estén almacenados gasolina, pintura o líquidos inflamables.

8. Use este calentador sólo de la manera descrita en este manual.

Cualquier otro uso no recomendado por el fabricante puede

causar incendio, choque eléctrico o lesiones a las personas.

9. Este calentador no está aprobado para uso en atmósferas corro-

sivas, tales como marina, invernaderos o áreas de almacenamiento químico.

10. El calentador debe instalarse en dirección horizontal solamente

(motor y termostato a la derecha) según se ilustra en este

manual. No lo instale lateralmente ni invertido.

11. El calentador debe instalarse con la Caja Posterior.

12. Para montaje de pared solamente. Deben mantenerse las sepa-

raciónes mínimas siguientes: Del calentador al piso - 4 pulg.

(102mm); del calentador a cualquier pared adyacente - 6 pulg.

(152mm); del calentador al cielo raso - 36 pulg. (915mm).

13. Al conectar los cables, la alimentación debe entrar a través de los

orificios ciegos al extremo derecho del calentador. No use los orificios ciegos al extremo izquierdo del calentador.

14. No opere el calentador sin la rejilla instalada.

15. No use el calentador para secar. La pintura, el yeso, el aserrín y

el polvo de lijado de los tabiques dañarán el calentador y deben

mantenerse fuera del calentador.

16. La rejilla y el aire de descarga están calientes cuando la unidad

está en uso. No instale ni use el calentador en áreas donde

pueda obstruirse el flujo de aire del calentador. El aire caliente

puede dañar ciertas telas y plásticos. Mantenga siempre los cordones eléctricos, la ropa de cama, los muebles y otros combustibles, alejados del calentador.

GUARDE ESTAS INSTRUCCIONES

Page 6

Los calentadores de Serie "R" están diseñados para una instalación

BACK BOX (FRONT VIEW)

NAIL OR SCREW

4 PLACES

BACK BOX

SUPPORT BKTS.

SOLE PLATE

BACK BOX (FRONT VIEW)

NAIL OR SCREW

BACK BOX

SUPPORT BKTS.

NAIL OR SCREW

STUD

STUD

STUD

STUD

MOUNTING RAILS

MOUNTING RAILS

BACK BOX (FRONT VIEW)

NAIL OR SCREW

4 PLACES

BACK BOX

SUPPORT BKTS.

SOLE PLATE

BACK BOX

TOP VIEW

INSERT FAN DECK

THIS SIDE

STUD

BACK BOX (FRONT VIEW)

NAIL OR SCREW

BACK BOX

SUPPORT BKTS.

SOLE PLATE

BACK BOX

TOP VIEW

INSERT FAN DECK

THIS SIDE

STUD

NAIL OR SCREW

STUD

STUD

STUD

STUD

MOUNTING RAILS

MOUNTING RAILS

BACK BOX (FRONT VIEW)

NAIL OR SCREW

BACK BOX

SUPPORT BKTS.

SOLE PLATE

NAIL OR SCREW

STUD

STUD

MOUNTING RAILS

BACK BOX (FRONT VIEW)

NAIL OR SCREW

BACK BOX

SUPPORT BKTS.

SOLE PLATE

BACK BOX

TOP VIEW

INSERT FAN DECK

THIS SIDE

STUD

NAIL OR SCREW

STUD

STUD

MOUNTING RAILS

BACK BOX

END CAP

HOLE

TOP OF BACK BOX

FLANGE ON FAN DECK

empotrada en paredes estándar de 2" x 4" (50mm x 100mm) o paredes

más grandes con montantes con la caja posterior montada según se

muestra en la Fig.1 o en la Fig.2.

Figura 1A

NOTA: El calentador debe controlarse por un termostato integrado o un

termostato de pared. Los Modelos con el sufijo "T2" están equipados con

un termostato integrado.

Este calentador puede conectarse con el cableado estándar del edificio

(clasificación mínima nominal de 60ºC). Para el tamaño correcto de cable

para el calentador a usar, refiérase a la Tabla 2 (Página 3).

INSTALACION DE LA CAJA POSTERIOR (Modelo RBB) EN

NUEVA CONSTRUCCION - MONTANTES DE PARED A 16"

1. Ubique la caja posterior (Modelo RBB) y las ménsulas de soporte de

2. Instale las ménsulas de soporte de la caja posterior con las aletas

3. Determine cuál orificio ciego de la caja posterior se usará para el

4. Atrape el cableado de campo a través del escape de tensión dejan-

5. Inserte el conjunto de la caja posterior en la pared, alineando la

6. Usando cuatro (4) tornillos para madera o tornillos de tabique o cua-

CONSTRUCCION - MONTANTES DE PARED A UNA DISTANCIA

MAYOR QUE 16" DEL CENTRO (REFIERASE A LA FIG.2)

NOTA: La Fig.2 muestra la caja posterior instalada con el lado izquierdo

adyacente a un montante. Para una caja con el lado derecho adyacente

a un montante, revierta las direcciones mostradas abajo.

Figura 2A

1. Ubique la caja posterior y las ménsulas de soporte de la caja pos-

CAJA POSTERIOR (VISTA DELANTERA)

Fig. 1B

MONTANTE

Fig. 1C

MON-

CLAVO O TORNILLO

TANTE

MONTANTE

VISTA SUPERIOR DE LA

INSERTE LA PLATAFORMA DEL

VENTILADOR DE ESTE LADO

RIELES DE MONTAJE

4 LUGARES

MENSULAS DE SOPORTE

DE LA CAJA POSTERIOR

PLACA DE BASE

CAJA POSTERIOR

DEL CENTRO (REFIERASE A LA FIG.1)

la caja posterior (2). La caja posterior debe instalarse con los rieles

de montaje en el tope (vea la Fig.1B).

de pie dirigidas hacia el centro de la caja posterior según se muestra en la Fig.1A y 1B. Puede ser necesario doblar hacia arriba levemente la lengüeta en el soporte trasero de la caja para permitir la inserción debajo de las lanzas del montaje en el fondo de la caja trasera.

cableado de campo y abra (vea la ilustración de pág.1 de la caja

posterior). Instale el escape de tensión (provisto en el campo). Vea

la advertencia No. 13.

do 6" de cable dentro de la caja.

parte posterior de la caja con el reverso de los montantes (vea la

Fig.1C). Las ménsulas de soporte de la caja posterior deben apoyarse sobre la placa de base de la pared con montantes para asegurar una separación y nivelación apropiados (vea la Fig.1B).

tro (4) clavos (provisto en el campo), asegure la caja posterior a los

montantes (vea la Fig.1B). Pueden retirarse ahora las ménsulas de

soporte de la caja posterior. Si no lo son, asegure a la placa de base.

INSTALACION DE LA CAJA POSTERIOR EN NUEVA

CAJA POSTERIOR (VISTA DELANTERA)

RIELES DE MONTAJE

MON-

TANTE

terior (2). La caja posterior debe instalarse con los rieles de montaje en el tope (vea la Fig.2B).

CLAVO O TORNILLO

MENSULAS DE SOPORTE

DE LA CAJA POSTERIOR

PLACA DE BASE

MONTANTE

VISTA SUPERIOR DE LA

CAJA POSTERIOR

INSERTE LA PLATAFORMA DEL

VENTILADOR DE ESTE LADO

Fig. 2B

MON-

TANTE

CLAVO O TORNILLO

Fig. 2C

6

2. Determine cuál es el lado de la caja posterior que será adyacente al

montante e inserte la ménsula de soporte de la caja posterior en ese

lado con la aleta de pie dirigida hacia el centro de la caja posterior.

Instale la ménsula de soporte de la caja posterior del lado de la caja

posterior que no es adyacente al montante con la aleta de pie dirigida hacia el extremo de la caja y asegure a la caja con un tornillo

para lámina de metal de 3/8" de largo (provisto).

3. Determine cuál orificio ciego se usará para el cableado de campo y

abra (vea la ilustración de pág.1 de la caja posterior). Instale el

escape de tensión (provisto en el campo).

4. Atrape el cableado de campo a través del escape de tensión dejando 6" de cable dentro de la caja.

5. Inserte el conjunto de la caja posterior en la pared, alineando la

parte posterior de la caja con el reverso de los montantes (vea la

Fig.2C). Las ménsulas de soporte de la caja posterior deben apoyarse sobre la placa de base de la pared con montantes para asegurar una separación y nivelación apropiados (vea la Fig.2B).

6. Usando dos (2) tornillos para madera o de tabique o dos (2) clavos

(provistos en el campo), asegure el lado de la caja posterior que es

adyacente a uno los montantes. Use un (1) tornillo para madera o

de tabique o un (1) clavo (provisto en el campo) para asegurar la

aleta de pie de la ménsula de soporte de la caja posterior (que está

en el extremo opuesto del montante) a la placa de base.

INSTALACION DE LA CAJA POSTERIOR

EN UNA CONSTRUCCION EXISTENTE

1. Ubique los montantes de pared para asegurar que se pueda efectuar todo el corte entre los montantes. Uno de los lados del corte por

lo menos debe estar al ras con el lado del montante. El fondo del

corte debe estar a 4" como mínimo sobre el piso terminado. Efectúe

un corte en la pared de 14-1/2" de ancho X 6-3/4" de alto (368mm

X 171mm) (vea la Fig.3).

Figura 3

2. Determine cuál orificio ciego se usará para el cableado de campo y

abra (vea la ilustración de pág.1 de la caja posterior). Instale el

escape de tensión (provisto en el campo).

3. Atrape el cableado de campo a través del escape de tensión dejando 6" de cable dentro de la caja.

4. Inserte la caja posterior en el corte. La parte posterior de la caja

debe estar al ras con el reverso de la pared de montante.

5. Usando cuatro (4) tornillos para madera o tornillos de tabique o cuatro (provistos en el campo) o cuatro (4) clavos (provisto en el

campo), asegure la caja posterior a los montantes (vea la Fig.1B).

Si los montantes de pared son más grandes que una distancia de

16" desde el centro (oc) , use sólo 2 sujetadores y al lado opuesto

de la caja posterior inserte un tornillo para lámina metálica de 1"

(provisto) a través del orificio en la tapa del extremo. Esto afirmará

la caja posterior al tabique cuando se instale la rejilla. (Vea la Fig 4).

Figura 4

ORIFICIO

INSTALACION DEL CONJUNTO DEL TERMOSTATO

NOTA: El conjunto del termostato no debe instalarse hasta después que

se haya completado la construcción de los tabiques. El polvo proveniente

de la instalación y del compuesto de juntas de los tabiques puede ser

perjudicial si penetra en los componentes del conjunto del termostato.

1. El termostato debe instalarse en el extremo derecho del calentador.

2. Coloque el termostato en posición sobre la ranura en el extremo derecho de la caja posterior. Empuje la aleta de la ménsula del termostato

a través de la ranura del tope y al extremo derecho de la caja posterior hasta que la ménsula calce en su lugar. Vea la Fig. 5.

CAJA POSTERIOR

Vista del Extremo

(RT2 solamente)

Page 7

Figura 5

TOP OF BACK BOX

FLANGE ON FAN DECK

MOUNTING RAIL

MODELO

R1500

R1500T2

R2004

R2004T2

R2404

R2404T2

VOLTIOS

120

240

208

240

208

VATIOS/AMP.

1500W/12.5A

2000W/8.3A

1500W/7.2A

2400W/10.0A

1800W/8.7A

TABLA 1

VATIOS/AMP.

1125W/9.4A

1500W/6.3A

1125W/5.4A

1800W/7.5A

1350W/6.5A

VATIOS/AMP.

750W/6.3A

1000W/4.2A

750W/3.6A

1200W/5.0A

900W/4.3A

VATIOS/AMP.

375W/3.1A

500W/2.1A

375W/1.8A

600W/2.5A

450W/2.2A

3. Si el termostato controla más que un calentador, el total de las clasificaciones nominales de amperaje del calentador (Tabla 1) no puede

exceder 25 amperios a 120 voltios de CA hasta 240 voltios de CA.

Para los tamaños correctos de cable, interruptor de circuito o fusible,

refiérase a la Tabla 2.

4. Conecte una guía roja y una negra de termostato al cableado de potencia según el diagrama de cableado (Fig.6) usando las tuercas de cable

(provistas) de tamaño apropiado.

5. Pliegue los cables en el compartimiento de cableado detrás del termostato para despejar la plataforma del ventilador.

Figura 6

Serie R solamente

TERMOSTATO

REMOTO DE

PARED

PUENTE

TIERRA

ALIMENTACION ELECTRICA

LIMITE

AZUL

PUENTE

AZUL

ROJO

NEGRO

®

AMARILLO

NEGRO

L2 o N

ROJO

NEGRO

TERMOSTATO

INTEGRADO

DE DOS POLOS

ROJO

LUZ

MOTOR

BOBINA DELANTERA

ELEMENTO

BOBINA POSTERIOR

Serie RT2 solamente

REGULADOR

DE TEMPERATURA

PARA CAMBIAR LA SALIDA DE VATAJE

La tabla muestra los vatajes disponibles por modelo. Cada calentador está cableado de fábrica para su vataje máximo. Las dos últimas

columnas en la tabla se refieren a los puentes en el tablero CLIP-AWATT®. Para cambiar el vataje, fijar el Puente 1 y Puente 2 según

se muestra en la tabla de abajo. Anule completamente los puentes

fijando ambos extremos tan cerca al panel como sea posible.

PUENTE1PUENTE

2

Puente

azul

Dejar en

Fijar

Dejar en

Fijar

Puente

rOJO

Dejar en

Dejar en

Fijar

Fijar

R2404 Y

R2404T2

a 240V a 208V

2400

1800

1200

600

1800

1350

900

450

VATAJE

R2004 Y

R2004T2

a 240V a 208V

2000

1500

1500

1125

1000

750

500

375

PUENTE

AZUL

R1500 Y

R1500T2

a 120V

1500

1125

750

375

PUENTE

ROJO

Pizarra de Clip ‘n’ Fit ®

Nota: Los modelos de Armazón Interno "IF" deben usarse con

la caja posterior RBB.

NOTA AL INSTALADOR

Los modelos “IF” no incluyen caja posterior. La caja posterior se ordena separado. En la bolsa de piezas para los modelos “IF”, hay una etiqueta blanca que

indica vatjos multiples y que debe ser montado en la esquina derecha de abajo

de la caja posterior. Cuando se cambia el vatjo, el instalador debe marcar el

vatio en la etiqueta blanca con un circulo, antes de instalar el cojunto de la

plataforma del ventilador.

TABLA 2

AMPS. TOTALES

De 0 a 12

De 12.1 a 16

De 16.1 a 24

CALIBRE DEL

COND. (COBRE)

No. 14

No. 12

No. 10

TAMAÑO DEL INTERR.

DE CIRC. O DEL FUSIBLE

15 Amp.

20 Amp.

30 Amp.

INSTALACION DE LA PLATAFORMA

DEL VENTILADOR

NOTA: No debe instalarse el conjunto de la plataforma del venti-

lador hasta que esté lista la fase de construcción de tabiques. El

polvo proveniente de la instalación de tabiques y del compuesto de

juntas puede ser perjudicial si penetra dentro de los componentes

de la plataforma del ventilador.

Figura 7

RIEL DE MONTAJE

BRIDA EN LA PLATAFORMA DEL VENTILADOR

1. Ubique la plataforma del ventilador y los rieles de montaje en

el tope de la caja posterior.

2. Inserte las bridas de la plataforma del ventilador dentro de los

rieles de montaje y corra hacia atrás hasta que la plataforma

se detenga (vea la Fig.7).

3. Efectúe la conexión del cableado, conectando el cableado de

campo a las dos (2) guías flexibles negras para 240V o a las

guías flexibles blancas para 120V con las tuercas para cable

(provistas). Conecte la guía de conexión a tierra de campo al

cable flexible expuesto de conexión a tierra con la tuerca para

cable provista. Vea la Fig.6.

4. Corte el orificio ciego de 1/2" de la rejilla e instálela usando dos

tornillos de cabeza ovalada. Empuje la perilla del termostato

sobre el eje del termostato.

5. Reconecte la potencia en el panel maestro de fusibles o de

interruptores de circuitos.

TOPE DE LA CAJA POSTERIOR

7

Page 8

IMPORTANTE INFORMACION

MANTENIMIENTO

LIMPIEZA DEL CALENTADOR: El calentador se debe limpiar

minimo una vez al año o mas a menudo si esta instalado en

areas sucias. Antes de limpiar asegúrese que la potencia esté

desconectada y el calentador esté frío. Retire la rejilla delantera

y limpie la rueda del ventilador usando una aspiradora con un

aditamento de cepillo. La rejilla puede limpiarse con un trapo ligeramente húmedo si se desea.

AVISO OPERATIVO

Su calentador está equipado con un control de límite automático

de reposición que apagará automáticamente el calentador (OFF)

para prevenir un incendio si el calentador se calienta en exceso.

Si ocurriera esto, se iluminará la luz del indicador y continuará

brillando hasta que se reposicione el límite.

El modelo ilustrado es

de la serie "RT2" con

termostato incorporado.

PLACA DE NOMBRE

a

PRECAUCION

LA LUZ DE AVISO ROJADEL INDICADOR SIGNIFICA QUE EL CALENTADOR HA ESTADO SUJETO A ALGUNA CONDICION ANORMAL CAUSANDO QUE CALIENTE EN EXCESO. INSPECCIONE EL CALENTADOR PARA

ASEGURAR QUE NO HA SIDO BLOQUEADO DE NINGUNA MANERA (DE

HABERLO SIDO, ELIMINE EL BLOQUEO). SI NO HUBIERA INDICACION DE

BLOQUEO SE RECOMIENDA QUE EL CALENTADOR SE INSPECCIONE

POR UN ELECTRICISTA CALIFICADO O UN SERVICIO CALIFICADO DE

REPARACIONES PARA ASEGURAR QUE NO SE HA DAÑADO EL CALENTADOR. SI LA LUZ ESTA ENCENDIDA NO CONTINUE USANDO EL CALENTADOR.

!

NO. DE MODELO R1500T2CODIGO DE FECHA 0597

FAN FORCED WALL HEATER

CALENTADOR MURAL DE TIRO FORZADO POR VENTILADOR

120 1500/1125/750/375 12.5/9.4/6.3/3.1

VOLTIOS CA VATIOS AMPERIOS

USE ONLY WITH RBB SERIES BACK BOX. DO NOT

OPERATE WITHOUT GRILLE IN PLACE. USAR

SOLAMENTE CON LA CAJA POSTERIOR RBB. NO

OPERE SIN LA REJILLA EN SU LUGAR.

MARLEY ENGINEERED PRODUCTS

BENNETTSVILLE, SC 29512 4104-2159-003

774G LISTADO

ROOM HEATER

GARANTIA LIMITADA

Todos los productos cubiertos por esta hoja de instrucciones están garantizados contra defectos de mano de obra y materiales durante un año a partir de

la fecha de instalación. Esta garantía no se aplica por daños ocurridos por accidente, mal uso, o alteración, ni cuando el voltaje conectado sea 5% mayor

que el indicado en la placa de nombre; ni al equipo instalado o cableado incorrectamente, o mantenido en violación de esta hoja de instrucciones. Todos

los reclamos de trabajo de garantía deben estar acompañados por prueba de la fecha de instalación.

El cliente será responsable por todos los costos incurridos en la extracción o reinstalación de los productos, incluyendo costos de mano de obra, y costos

de transporte incurridos al devolver los productos a Marley Engineered Products Service Center. Con las limitaciones de esta garantía, las unidades

inoperantes deberían devolverse al centro autori zado de servicio más cercano de Marley o al Marley Engineered Products Service Center, y las repararemos

o reemplazaremos, a nuestra opción, sin cargo para usted, con transporte de regreso pago por Marley. Se acuerda mutuamente que tal reparación o

reemplazo es el remedio exclusivo disponible de Marley Engineered Products.

LAS GARANTIAS INDICADAS ARRIBA SON A CAMBIO DE CUALQUIER OTRA GARANTIA EXPRESA O IMPLICITA. POR LA PRESENTE SE

DESCONOCEN Y EXCLUYEN DE ESTE ACUERDO TODAS LAS GARANTIAS IMPLI CITAS DE COMERCIALIZACION Y APTITUD PARA UN FIN

PARTICULAR QUE EXCEDAN LAS GARANTIAS PREVIAMENTE EXPRESADAS. MARLEY ENGINEERED PRODUCTSNO SERA RESPONSABLE POR

DAÑOS CONSECUENTES ORIGINADOS POR EL PRODUCTO, YA SEAN QUE ESTEN BASADOS EN NEGLIGENCIA, LITIGACION,

RESPONSABILIDAD ESTRICTA O CONTRATO.

Algunos estados no permiten la exclusión o limitación de los daños incidentales o consecuentes, de manera que la exclusión o limitación indicada arriba

puede no aplicarse a usted. Esta garantía le otorga derechos legales específicos, y usted puede tener también otros derechos que varían de estado a estado.

Escriba a Marley Engineered Products a 470 Beauty Spot Road East, Bennettsville, SC 29512 EE.UU., para la dirección de su centro autorizado de servicio

más cercano. La mercancía devuelta a la fábrica debe estar acompañada por una autorización de devolución y una etiqueta de identificación de servicio,

ambas disponibles de la ubicación indicada. Incluya todos los números de catálogo mostrados en el producto al requerir autorización de devolución.

CÓMO OBTENER SERVICIO EN GARANTÍA, PIEZAS DE

REPUESTO E INFORMACIÓN GENERAL

1. Servicio o repuestos en garantía 1-800-642-4328

2. Compra de repuestos 1-800-654-3545

3. Información general sobre productos www.marleymep.com

Nota:

cuando solicite servicio, siempre dé la información que sigue:

1. Número de modelo del producto

2. Fecha de fabricación

3. Número de parte o descripción

No. de Pieza 5200-2367-006

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

ECR 39219

09/11

8

Page 9

FRONT VIEW

SIDE VIEW

BOTTOM VIEW

16-7/8”

7-3/4”

Série RT2

illustrée

4-3/8”

(DOS)

1-1/2”

2-1/2”

1-1/16”

VUE

DE CÔTÉ

Radiateurs muraux

à air pulsé

Séries R et RT2

Circuit Clip ‘n’ Fit

Numéro 6.172.343 De Brevet Des USA

®

10-5/8”

VUE DE FACE

14-3/8”

VUE DE DESSOUS

(ARRIÈRE)

6-5/8”

REMARQUE: Les

découpes du dessus sont

de la même dimension

que celles du dessous

7/8”

1-3/16

Instructions d’installation et d’entretien

Cher propriétaire,

Félicitations! Nous vous remercions d’avoir acheté ce nouveau radiateur fabriqué par Marley Engineered Products. Vous avez

fait un bon investissement en choisissant le produit de la meilleure qualité de l’industrie du chauffage. Veuillez lire soigneusement les instructions d’installation et d’entretien apparaissant dans ce manuel. Vous profiterez de nombreuses années de

confort de chauffage efficace avec ce produit de Marley Engineered Products ... le leader de l’industrie en conception, fabrication, qualité et service.

... Les employés de Marley Engineered Products

AVERTISSEMENT

À lire attentivement - Ces instructions sont écrites pour vous

permettre d’éviter des difficultés qui peuvent survenir pendant l’installation des radiateurs. Étudier les instructions au préalable peut

vous faire économiser beaucoup de temps et d’argent plus tard.

Observer les procédures suivantes pour réduire le temps d’installation à un minimum.

TRO CUTION ET D’INCENDIE:

1. Couper le courant venant au radiateur au tableau d’alimentation

principal avant de câbler ou d’effectuer un entretien.

2. Tout le câblage doit être conforme aux codes électriques en

vigueur et le radiateur doit être mis à la terre.

3. Avant de mettre sous tension, vérifier que la tension d’alimentation

venant au radiateur corresponde à la tension nominale indiquée

sur la plaque signalétique du radiateur.

4. Ce radiateur est chaud lorsqu’il fonctionne. Pour éviter les

brûlures, ne pas laisser la peau nue toucher les surfaces chaudes.

5. Ne pas insérer ni laisser des corps étrangers entrer par les ouvertures de ventilation ou de sortie d’air car cela peut causer une électrocution, un incendie ou une détérioration du radiateur.

6. Ne pas boucher les prises d’air ni les sorties d’air. Garder les

matériaux combustibles, comme les boîtes, les cageots, les

rideaux, etc... éloignés du radiateur. Ne pas installer le radiateur

derrière des portes, des meubles, des serviettes ou des boîtes.

7. Un radiateur contient des pièces chaudes et produisant des arcs

électriques ou des étincelles. Ne pas l’utiliser dans des zones

d’utilisation ou de remisage d’essence, de peinture ou de liquides

inflammables.

POUR RÉ DUIRE LE RISQUE D’ÉLEC -

!

8. Utiliser ce radiateur uniquement selon les instructions de ce

manuel. Toute autre utilisation non recommandée par le fabricant

peut causer un incendie, une électrocution ou des blessures.

9. Ce radiateur n’est pas approuvé pour utilisation dans les atmosphères corrosives, comme les zones de remisage de produits

chimiques, les serres ou les zones maritimes.

10. Le radiateur ne doit être installé que horizontalement (moteur et

thermostat à droite) comme illustré dans ce manuel. Ne pas l’installer tête en bas ou sur le côté.

11. Le radiateur doit être installé avec un boîtier arrière.

12. Pour fixation murale uniquement. Les dégagements minimum

suivants doivent être assurés: Radiateur à 102 mm du sol, à

152 mm de tout mur adjacent, à 915 mm du plafond.

13. Lors du câblage, l’alimentation doit entrer par les découpes de l’extrémité droite du radiateur. Ne pas utiliser les découpes de l’extrémité gauche.

14. Ne pas utiliser le radiateur sans que la grille ne soit installée.

15. Ne pas utiliser le radiateur pour sécher. La peinture, le plâtre, la

sciure et la poussière de placo-plâtre abîment le radiateur et

doivent en être gardés à l’écart.

16. La grille et l’air de sortie sont chauds pendant l’utilisation. Ne pas

installer ni utiliser le radiateur dans une zone où le débit d’air du

radiateur peut être bloqué. L’air chaud peut abîmer certains tissus

et plastiques. Toujours garder les fils électriques, la literie, le mobi lier et les autres combustibles à l’écart du radiateur.

CONSERVER CES INSTRUCTIONS

Page 10

Les radiateurs de la série “R” sont conçus pour être encastrés dans des

BACK BOX (FRONT VIEW)

NAIL OR SCREW

4 PLACES

BACK BOX

SUPPORT BKTS.

SOLE PLATE

BACK BOX (FRONT VIEW)

NAIL OR SCREW

BACK BOX

SUPPORT BKTS.

NAIL OR SCREW

STUD

STUD

STUD

STUD

MOUNTING RAILS

MOUNTING RAILS

BACK BOX (FRONT VIEW)

NAIL OR SCREW

4 PLACES

BACK BOX

SUPPORT BKTS.

SOLE PLATE

BACK BOX

TOP VIEW

INSERT FAN DECK

THIS SIDE

STUD

BACK BOX (FRONT VIEW)

NAIL OR SCREW

BACK BOX

SUPPORT BKTS.

SOLE PLATE

BACK BOX

TOP VIEW

INSERT FAN DECK

THIS SIDE

STUD

NAIL OR SCREW

STUD

STUD

STUD

STUD

MOUNTING RAILS

MOUNTING RAILS

BACK BOX (FRONT VIEW)

NAIL OR SCREW

BACK BOX

SUPPORT BKTS.

SOLE PLATE

NAIL OR SCREW

STUD

STUD

MOUNTING RAILS

BACK BOX (FRONT VIEW)

NAIL OR SCREW

BACK BOX

SUPPORT BKTS.

SOLE PLATE

BACK BOX

TOP VIEW

INSERT FAN DECK

THIS SIDE

STUD

NAIL OR SCREW

STUD

STUD

MOUNTING RAILS

poutres murales standard de 50 x 100 mm ou plus grosses, avec le

boîtier arrière monté comme illustré à la figure 1, ou à la figure 2.

Figure 1A

REMARQUE: Le radiateur doit être commandé par un thermostat intégré

ou un thermostat mural à distance. Les modèles avec le suffixe T2 sont

équipés d’un thermostat intégré.

Ce radiateur peut être câblé avec du câble standard de construction (température nominale minium de 60 ˚C). Voir le tableau 2 (page 3) pour connaître la dimension appropriée de fil pour le radiateur.

Le boîtier arrière n’est pas fournie avec les modéles “IF”. Il faut commander le

boîtier arrière separement. Une étiquette blanche est dans le sac des pièces

fournie avec les modéles “IF”. Cette étiquette indique les différentes puissance

de sortie en watts. Lorsque on change le wattage l’installateure doit encircler le

bon wattage sur cette étiquete. Placer l’étiquette en bas dans l’intérieur de boîte

arrière vers le côté droite avant l’installation de support de moteur.

DANS UNE CONSTRUCTION NEUVE - POUTRES MURALES À

1. Identifier l’emplacement du boîtier arrière (modèle RBB) et des sup-

2. Installer les supports du boîtier arrière avec les languettes de pied

3. Déterminer la découpe du boîtier arrière à utiliser pour le câblage

4. Passer le câble dans le dispositif de reprise des contraintes en lais-

5. Insérer le boîtier arrière dans le mur, en alignant l’arrière du boîtier

6. À l’aide de quatre vis à bois ou quatre vis à placo-plâtre, ou quatre

Figure 2A

BOÎTIER ARRIÈRE (VUE DE FACE)

Fig. 1B

POUTRE

Fig. 1C

POUTRE

RAILS DE FIXATION

CLOU OU VIS

4 EMPLACEMENTS

SUPPORTS DU

BOÎTIER ARRIÈRE

PLAQUE DE SEMELLE

POUTRE

BOÎTIER ARRIÈRE

VUE DE DESSUS

INSÉRER LE SUPPORT DE

VENTILATEUR DE CE CÔTÉ

NOTE À L’INSTALLATEUR

INSTALLATION DE BOÎTIER ARRIÈRE (Modèle RBB)

406 MM CENTRE À CENTRE (VOIR LA FIGURE 1)

ports de boîtier arrière (2). Le boîtier arrière doit être installé avec les

rails de fixation sur le dessus (voir la figure 1B).

vers le centre du boîtier arrière comme illustré aux figures 1A et 1B.

Il peut être nécessaire de replier légèrement vers le haut la bride de

fixation sur le support de boîte arrière pour permettre l'insertion sous

les lances de montage sur le fond de la boîte arrière.

sur le site et la retirer (voir le plan du boîtier arrière page 1). Installer

le dispositif de reprise des contraintes (fourni sur le site). Voir l’avertissement nº 13.

sant 152 mm de fil dans le boîtier.

arrière avec l’arrière des poutres (voir la figure 1C). Les supports du

boîtier arrière doivent reposer sur la plaque de semelle du mur pour

assurer un bon espacement et assurer que le radiateur soit bien

hori zontal (voir la figure 1B).

clous (fournis sur le site), fixer le boîtier arrière sur les poutres (voir

la figure 1B). Les supports du boîtier arrière peuvent désormais être

enlevés. S’ils ne sont pas enlevés, les fixer sur la plaque de semelle.

Fig. 2B

POUTRE

CLOU OU VIS

Fig. 2C

BOÎTIER ARRIÈRE (VUE DE FACE)

RAILS DE FIXATION

POUTRE

CLOU OU VIS

SUPPORTS DU

BOÎTIER ARRIÈRE

PLAQUE DE SEMELLE

POUTRE

INSÉRER LE SUPPORT DE

VENTILATEUR DE CE CÔTÉ

BOÎTIER ARRIÈRE

VUE DE DESSUS

10

INSTALLATION DU BOÎTIER ARRIÈRE DANS UNE

CONSTRUCTION NEUVE - ESPACEMENT DES POUTRES

SUPÉRIEUR À 406 mm (VOIR LA FIGURE 2)

REMARQUE: La figure 2 décrit le boîtier arrière installé avec le côté

gauche contre une poutre. Pour un boîtier avec le côté droit contre une

poutre, inverser les instructions ci-dessous.

1. Identifier l’emplacement du boîtier arrière et des supports de boîtier

arrière (2). Le boîtier arrière doit être installé avec les rails de fixation sur le dessus (voir la figure 2B).

2. Déterminer le côté du boîtier arrière qui doit être contre une poutre

et insérer le support de boîtier arrière de ce côté avec la languette

de pied orientée vers le centre du boîtier arrière. Sur le côté du

boîtier arrière qui n’est pas contre une poutre, installer le support de

boîtier arrière avec la languette de pied orientée vers l’extrémité du

boîtier et le bloquer sur le boîtier avec une vis à tôle longue de 9 mm

(fournie).

3. Déterminer la découpe du boîtier arrière à utiliser pour le câblage

sur le site et la retirer (voir plan du boîtier arrière page 1). Installer le

dispositif de reprise des contraintes (fourni sur le site).

4. Passer le câble dans le dispositif de reprise des contraintes en laissant 152 mm de fil dans le boîtier

5. Insérer le boîtier arrière dans le mur, en alignant l’arrière du boîtier

arrière avec l’arrière de la poutre (voir la figure 2C). Les supports du

boîtier arrière doivent reposer sur la plaque de semelle du mur pour

assurer un bon espacement et assurer que le radiateur soit bien horizontal (voir la figure 2B).

6. Utiliser deux (2) vis à bois ou vis à placo-plâtre ou deux (2) clous

(fournis sur le site) pour bloquer le côté du boîtier arrière qui est contre une poutre. Utiliser une (1) vis à bois ou vis à placo-plâtre ou un

(1) clou (fourni sur le site) pour bloquer la languette de pied du support de boîtier arrière (sur l’extrémité opposée à la poutre) sur la

plaque de semelle (voir la figure 2B).

Figure 3

INSTALLATION DU BOÎTIER ARRIÈRE DANS

UNE CONSTRUCTION EXISTANTE

1. Identifier l’emplacement des poutres murales pour s’assurer de pouvoir faire toute la découpe entre les poutres. Au moins un des côtés

de la découpe doit être au ras d’une poutre. Le bas de la découpe

doit être au moins 101 mm au-dessus du sol fini. Faire une découpe

dans le mur de 368 mm de large et de 171 mm de haut (voir la

figure 3).

2. Déterminer la découpe du boîtier arrière à utiliser pour le câblage

sur le site et la retirer (voir le plan du boîtier arrière page 1). Installer

le dispositif de reprise des contraintes (fourni sur le site).

3. Passer le câble dans le dispositif de reprise des contraintes en laissant 152 mm de fil dans le boîtier

4. Insérer le boîtier arrière dans la découpe. L’arrière du boîtier arrière

doit être au ras de l’arrière des poutres.

5. Avec quatre (4) vis à bois ou vis à placo-plâtre (fournies sur le site)

ou quatre (4) clous (fournis sur le site), bloquer le boîtier arrière sur

les poutres (voir la figure 1B). Si les poutres murales sont à plus de

406 mm de distance, n’utiliser que 2 fixations et, sur l’extrémité

opposée du boîtier arrière, visser une vis à tôle de 25 mm (fournie)

dans le trou du bouchon d’extrémité. Ceci ammène la boîtier arrière

contre le placo-plâtre lorsque la grille est installée (voir la figure 4).

REMARQUE: Le thermostat ne doit pas être installé avant la fin de la

phase de placo-plâtre de la construction. La poussière d’installation du

placo-plâtre et du mastic de joint peut être nocive si elle entre dans les

INSTALLATION DU THERMOSTAT (RT2 uniquement)

composants du thermostat.

1. Il faut installer le thermostat dans l’extrémité droite du radiateur.

2. Positionner le thermostat au-dessus de la fente dans l’extrémité

droite du boîtier arrière. Pousser la languette sur le support de thermostat dans la fente de l’extrémité supérieure droite du boîtier arrière

jusqu’à ce que le support se bloque en place. Voir la figure 5.

Page 11

TOP OF BACK BOX

FLANGE ON FAN DECK

MOUNTING RAIL

BACK BOX

END CAP

HOLE

TOP OF BACK BOX

FLANGE ON FAN DECK

Figure 4

BOÎTIER ARRIÈRE

TROU

Vue d’extrémité

3. Si le thermostat contrôle plus d’un radiateur, le total de toutes les intensités nominales des radiateurs (tableau 1) ne peut pas dépas ser 25 A

entre 120 V alt. et 240 V alt. Voir le tableau 2 pour les bonnes dimensions de fusible, de disjoncteur et de fil.

4. Brancher un fil rouge et un fil noir du thermostat sur le câblage d’ali mentation conformément au schéma de câblage (figure 6) en utili sant

les écrous de connexion de la bonne dimension (fournis).

5. Replier les fils dans le compartiment de fils derrière le thermostat pour

dégager le support de ventilateur.

Figure 5

POUR CHANGER LA PUISSANCE DE SORTIE EN WATTS

Le tableau ci-dessous indique les différentes puissances de sortie en

watts par modèle. Chaque modèle est branché en usine pour fournir

le maximum de watts. Les deux dernière colonnes se rapportent aux

cavaliers sur le circuit CLIP-A-WATT®. Pour changer les watts,

débrancher le cavalier no.1 et/ou le cavelier no.2 comme indiqué.

Débrancher complétement les cavaliers en les prenant à chaque

extrémité aussi près que possible du circuit.

R2404 &

R2404T2

@240V @208V

2400

1800

1200

600

1800

1350

900

450

WATTS

R2004 &

R2004T2

@240V @208V

2000

1500

1500

1125

1000

500

CAVALIER

BLEU

750

375

R1500 &

R1500T2

@120V

1500

1125

750

375

CAVALIER

ROUGE

CAVALIER

CAVALIER

BLEU

En place

Débran.

En place

Débran.

no. 1

CAVALIER

no. 2

CAVALIER

ROUGE

En place

En place

Débran.

Débran.

Figure 6

Série R seulement

THERMOSTAT

MURAL À DIS-

TANCE

TERRE

ALIMENTATION ÉLECTRIQUE

LIMITE

BLEU

CAVALIER

CAVALIER

BLEU

ROUGE

®

JAUNE

NOIR

NOIR

NOIR

THERMOSTAT

INTÉGRÉ BI-

POLAIRE

ECLAIRAGE

MOTEUR

BOBINE AVANT

ELEMENT

BOBINE ARRIÈRE

L2 ou neutre

ROUGE

Série RT2 seulement

ROUGE

RÉGULATEUR DE

TÉMPERATURE

INSTALLATION DU SUPPORT DE VENTILATEUR

REMARQUE: Il ne faut pas installer le support de ventilateur avant

la fin de la phase de placo-plâtre de la construction. La poussière

d’installation du placo-plâtre et du mastic de joint peut être nocive

si elle entre dans les composants du support de ventilateur.

1. Identifier le support de ventilateur et les rails de fixation dans

le haut du boîtier arrière.

2. Insérer les brides du support de ventilateur dans les rails de

fixation et les glisser vers l’arrière jusqu’à ce que le support de

ventilateur soit en butée (voir la figure 7).

3. Faire les connexions de câblage, en branchant un fil rouge et

un fil noir du thermostat sur les deux (2) fils noirs du radiateur

pour 240 V ou sur les fils noir et blanc du radiateur pour 120

V, à l’aide d’écrous de connexion (fournis). Brancher le fil de

terre dénudé sur la terre du site à l’aide d’un écrou de connexion (fourni). Voir la figure 6.

4. Retirer la découpe de 12,5 mm de la grille et installer la grille

avec deux vis à tête ovale. Pousser le bouton de thermostat

sur l’arbre de thermostat.

5. Rebrancher l’alimentation au tableau principal de fusible ou de

disjoncteur.

Circuit Clip ‘n’ Fit

®

TABLEAU 1

MODÈLE

R1500

R1500T2

R2004

R2004T2

R2404

R2404T2

VOLTS

120

240

208

240

208

WATTS/AMPÈRES

1500W/12.5A

2000W/8.3A

1500W/7.2A

2400W/10.0A

1800W/8.7A

WATTS/AMPÈRES

1125W/9.4A

1500W/6.3A

1125W/5.4A

1800W/7.5A

1350W/6.5A

WATTS/AMPÈRES

750W/6.3A

1000W/4.2A

750W/3.6A

1200W/5.0A

900W/4.3A

Remarque: Les modèles “IF” Inner Frame (À cadre interne)

doivent être utilisés avec un boîtier arrière RBB.

TABLEAU 2

AMPÈRES

TOTAUX

0 à 12

12.1 à 16

16.1 à 24

DIMENSION DU

FIL (CUIVRE)

nº 14

nº 12

nº 10

DIMENSION DU FUSIBLE

OU DU DISJONCTEUR

15 A

20 A

30 A

CHANGEMENT DE PUISSANCE DE SORTIE

Le tableau montre les puissances disponibles par modèle. Chaque radia teur est câblé en usine pour sa puissance maximum. Les nombres dans

le tableau se rapportent aux bornes DU CIRCUIT DE CONTRÔLE DE

PUISSANCE. Pour changer la puissance, déplacer le fil d’alimentation ou

le cavalier comme indiqué dans le tableau ci-dessous.

Figure 7

RAIL DE FIXATION

BRIDE SUR LE SUPPORT DE VENTILATEUR

HAUT DU BOÎTIER ARRIÈRE

WATTS/AMPÈRES

375W/3.1A

500W/2.1A

375W/1.8A

600W/2.5A

450W/2.2A

11

Page 12

INFORMATION IMPORTANTE

ENTRETIEN

NETTOYAGE DU RADIATEUR: Le réchauffeur devrait être nettoyé annuellement pour l'efficacité maximum ou plus souvent si

utilisé dans modifié l'environnement. Avant de le nettoyer, s’assurer que l’alimentation soit coupée et que le radiateur soit refroidi. Tout d’abord, retirer le bouton en le tirant bien droit, puis retirer la grille avant et nettoyer la roue de la soufflante avec un aspirateur équipé d’une brosse. La grille peut être nettoyé avec un

chiffon légèrement humide le cas échéant.

AVIS OPÉRATIONNEL

Votre radiateur est équipé d’une protection thermique avec

réarmement automatique qui coupe automatiquement le radiateur en cas de surchauffe, pour éviter un incendie. Dans ce cas,

le voyant d'alarme de rouge s’allume et continue de briller

jusqu’à ce que la protection thermique soit réarmée.

a

ATTENTION

VOYANT D'ALARME DE ROUGE ALLUMÉ SIGNIFIE QUE LE RADIATEUR A ÉTÉ SOUMIS À UNE CONDITION ANORMALE LE

FAISANT SURCHAUFFER. VÉRIFIER QUE LE RADIATEUR N’EST

PAS BOUCHÉ (RETIRER L’OBSTRUCTION LE CAS ÉCHÉANT).

S’IL NE SEMBLE PAS Y AVOIR D’OBSTRUCTION, IL EST

RECOMMANDÉ DE FAIRE VÉRIFIER LE RADIATEUR PAR UN

ÉLECTRICIEN OU UN DÉPANNEUR RÉPUTÉ POUR S’ASSURER

QUE LA RADIATEUR N’EST PAS ABÎMÉ. NE PAS CONTINUER D’UTILISER LE RADIATEUR SI LE TÉMOIN RESTE ALLUMÉ.

!

Le modèle illustré est

la série “RT2” avec

thermostat intégré.

PLAQUE SIGNÉTIQUE

MODEL NO.

FAN FORCED WALL HEATER

120 1500/1125/750/375 12.5/9.4/6.3/3.1

VOLTS AC WATTS AMPS

USE ONLY WITH RBB SERIES BACK BOX. DO

NOT OPERATE WITHOUT GRILLE IN PLACE.

MARLEY ENGINEERED PRODUCTS

BENNETTSVILLE, SC 29512 4104-2159-003

R1500T2 DATE CODE 0597

774GLISTED

ROOM HEATER

GARANTIE LIMITÉE

Tous les produits fabriqués par Marley Engineered Products sont garantis contre les défauts de fabrication et de matériau pendant un an à compter de la date d’installation,

sauf les éléments chauffants qui sont garantis contre les défauts de fabrication et de matériau pendant cinq ans à partir de la date d’installation. Cette garantie ne s’applique

pas aux détériorations consécutives à un accident, à une mauvaise utilisation ou à une modification; ni si la tension d’alimentation est supérieure de plus de 5% à la tension

de la plaque signalétique; ni à un équipement incorrectement installé ou câblé ou entretenu en violation des instructions d’installation du produit. Toutes les réclamations

pour du travail sous garantie doivent être accompagnées par une preuve de la date d’installation.

Le client sera responsable de tous les frais causés par l’enlèvement ou la réinstallation des produits, y compris les frais de main-d’oeuvre et les frais d’expédition pour renvoyer les produits au centre d’entretien Marley Engineered Products. Dans le cadre des limites de cette garantie, les appareils défaillants doivent être renvoyés au centre

de service après-vente agréé Marley le plus proche ou au centre Marley Engineered Products et nous les réparerons ou remplacerons, à notre choix, gratuitement pour vous

avec les frais de retour payés par Marley. Il est entendu qu’une telle réparation ou un tel remplacement sont les seuls recours pouvant être obtenus de Marley Engineered

Products.

LES GARANTIES CI-DESSUS REMPLACENT TOUTES LES AUTRES GARANTIES EXPLICITES OU IMPLICITES ET TOUTES LES GARANTIES IMPLICITES DE

COMMERCIABILITÉ ET D’ADAPTATION À UN USAGE PARTICULIER QUI DÉPASSENT LES GARANTIES EXPLICITES DÉCRITES CI-DESSUS SONT RÉFUTÉES PAR

LA PRÉSENTE ET EXCLUES DE CET ACCORD. MARLEY ENGINEERED PRODUCTS NE SERA PAS RESPONSABLE DES DOMMAGES CIRCONSTANCIELS

CAUSÉS PAR LE PRODUIT, QUE CE SOIT PAR NÉGLIGENCE, DÉLIT, RESPONSABILITÉ STRICTE, OU CONTRAT.

Certaines provinces n’autorisent pas l’exclusion ou la limitation des dommages circonstanciels ou fortuits, l’exclusion ou la limitation ci-dessus peuvent donc ne pas vous

concerner. Cette garantie vous donne des droits légaux spécifiques et vous pouvez aussi avoir d’autres droits qui varient d’une province à l’autre.

Pour l’adresse de notre centre d’entretien autorisé le plus proche, contacter Marley Engineered Products à Bennettsville, Caroline du Sud, États-Unis d’Amérique au

1-800-642-4328. La marchandise renvoyée en usine doit être accompagnée d’étiquettes d’identification d’autorisation de renvoi et de service, disponibles chez Marley

Engineered Products. Lors de la demande d’autorisation de renvoi, inclure tous les numéros de catalogue apparaissant sur les produits.

POUR OBTENIR UNE RÉPARATION OU DES

PIÈCES SOUS GARANTIE, DE MÊME QUE DES

INFORMATIONS GÉNÉRALES

1. Réparations et pièces sous garantie 1-800-642-4328

2. Achat de pièces de rechange 1-800-654-3545

3. Informations générales sur les produits www.marleymep.com

Remarque : Lorsque vous demandez une intervention, ayez toujours en

main les informations suivantes :

1. Numéro de modèle du produit

2. Date de fabrication

3. Numéro de pièce ou description

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

Part No. 5200-2367-006

ECR 39219

09/11

12

Loading...

Loading...