Page 1

ENVIRONMENTAL SERIES

®

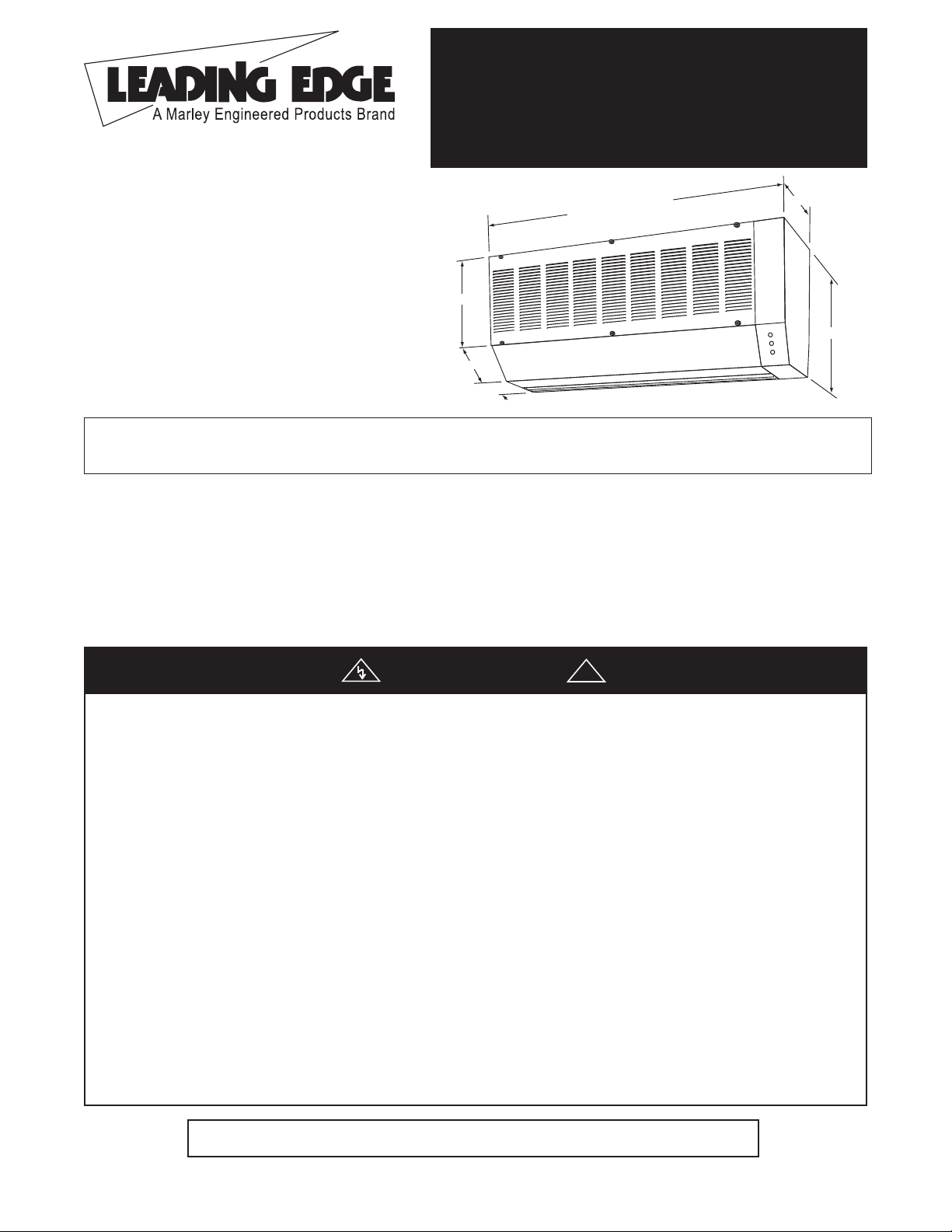

15 3/4”

1

3”

Refer to individual model numbers

f

or unit width

8

1/4”

4 7/8”

11 7/8”

ELECTRICALLY HEATED AIR CURTAINS

8 KW THROUGH 48 KW

36” THROUGH 144”

Installation & Maintenance Instructions

Dear Owner,

Congratulations! Thank you for purchasing this new air curtain manufactured by M arley Engineered Products. You have made

a wise investment selecting the highest quality product in the industry. Please carefully read the installation and

maintenance instructions shown in this m anual. You should enjoy years of efficient serv ice with this product from Marley

Engineered Products... the industry’s leader in design, m anufacturing, quality and service.

... The Employees of Marley Engineered Products

WARNING

Read Carefully - These instructions are written to help you

prevent difficulties that might arise during installation of the

unit. Studying the instructions first may save you considerable time and money later. Observe the following procedures, and cut your installation time to a minimum.

CAUTION - TO REDUCE RISK OF FIRE AND ELECTRIC

SHOCK OBSERVE THE FOLLOWING:

1. Disconnect all power coming to the unit at main service panel

before wiring or servicing. Lock service panel to prevent power

from being switched on accidentally.

NOTE: Do not depend upon a thermostat or other switch as the sole

means of disconnecting power when installing or servicing the unit.

Always disconnect power at the main service panel as described

above.

2. All wiring should be done by a qualified electrician, using copper

wire only and in accordance with the National Electrical Code

(NEC), all applicable code and ordinances, including fire rated

construction, and all sections of this manual. Any variance voids

the warranty and may create unsafe conditions.

3. To prevent the risk of electric shock, the unit must be properly

grounded. This should be accomplished by connecting a bonding conductor between the disconnecting means and the

grounding lug provided in the Main Control Box of the unit. Each

cabinet wiring compartment is provided with grounding lugs for

connecting bonding conductors between each cabinet and the

Main Control Box. To ensure a proper ground, the grounding

means must be tested by a qualified electrician.

4. Verify the power supply voltage coming to unit matches the ratings printed on the heater nameplate before energizing.

5. This unit can be hot when in use. To avoid burns, do not let bare

skin touch hot surfaces.

6. Do not insert or allow foreign objects to enter any ventilation or

exhaust opening as this may cause an electric shock, fire or

damage to the unit.

7. Do not block air intakes or exhaust in any manner. Keep combustible materials, such as crates, drapes, etc., away from air

curtain.

8. This unit has hot and arcing or sparking parts inside. Do not use

it in areas where gasoline, paint or flammable liquids are used

or stored.

9. Use this unit only as described in this manual. Any other use

not recommended by the manufacturer may cause fire, electric

shock, or injury to persons. If you have questions contact the

manufacturer.

10. This unit is not approved for use in corrosive atmospheres such

as marine, green house or chemical storage areas.

!

READ AND SAVE THESE INSTRUCTIONS

1

Page 2

Environmental Series Specifications and Performance

MODEL NOZZLE Volts Heater # MOTORS @ OF CONTROL MAX VEL AVG VEL AIRFLOW SHIPPING

NUMBER WIDTH (IN) AC Watts BTU/HR HP CABINETS VOLTAGE (FPM) (FPM) (CFM) WEIGHT (LBS)

1/2 HP Models

E36081#50HE 36 # 8000 27,320 1 @ 1/2 1 24 3800 3040 2460 93

E42081#50HE 42 # 8000 27,320 1 @ 1/2 1 24 3800 2890 2730 98

E48081#50HE 48 # 8000 27,320 1 @ 1/2 1 24 3800 2815 3040 105

E60081#50HE 60 # 8000 27,320 1 @ 1/2 1 24 3800 2740 3350 117

E72162#50HE 72 # 16000 54,640 2 @ 1/2 2 24 3800 3040 4920 177

E84162#50HE 84 # 16000 54,640 2 @ 1/2 2 24 3800 2910 5460 181

E96162#50HE 96 # 16000 54,640 2 @ 1/2 2 24 3800 2815 6080 189

E108243#50HE 108 # 24000 81,960 3 @ 1/2 3 24 3800 3040 7380 261

E120243#50HE 120 # 24000 81,960 3 @ 1/2 3 24 3800 2950 7920 273

E132243#50HE 132 # 24000 81,960 3 @ 1/2 3 24 3800 2875 8540 285

E144243#50HE 144 # 24000 81,960 3 @ 1/2 3 24 3800 2815 9120 297

E36121#50HE 36 # 12000 40,980 1 @ 1/2 1 24 3800 3040 2460 93

E42121#50HE 42 # 12000 40,980 1 @ 1/2 1 24 3800 2890 2730 98

E48121#50HE 48 # 12000 40,980 1 @ 1/2 1 24 3800 2815 3040 105

E60121#50HE 60 # 12000 40,980 1 @ 1/2 1 24 3800 2740 3350 117

E72242#50HE 72 # 24000 81,960 2 @ 1/2 2 24 3800 3040 4920 177

E84242#50HE 84 # 24000 81,960 2 @ 1/2 2 24 3800 2910 5460 181

E96242#50HE 96 # 24000 81,960 2 @ 1/2 2 24 3800 2815 6080 189

E108363#50HE 108 # 36000 122,940 3 @ 1/2 3 24 3800 3040 7380 261

E120363#50HE 120 # 36000 122,940 3 @ 1/2 3 24 3800 2950 7920 273

E132363#50HE 132 # 36000 122,940 3 @ 1/2 3 24 3800 2875 8540 285

E144363#50HE 144 # 36000 122,940 3 @ 1/2 3 24 3800 2815 9120 297

E36161#50HE 36 # 16000 54,640 1 @ 1/2 1 24 3800 3040 2460 93

E42161#50HE 42 # 16000 54,640 1 @ 1/2 1 24 3800 2890 2730 98

E48161#50HE 48 # 16000 54,640 1 @ 1/2 1 24 3800 2815 3040 105

E60161#50HE 60 # 16000 54,640 1 @ 1/2 1 24 3800 2740 3350 117

E72322#50HE 72 # 32000 109,280 2 @ 1/2 2 24 3800 3040 4920 177

E84322#50HE 84 # 32000 109,280 2 @ 1/2 2 24 3800 2910 5460 181

E96322#50HE 96 # 32000 109,280 2 @ 1/2 2 24 3800 2815 6080 189

E108483#50HE 108 # 48000 163,920 3 @ 1/2 3 24 3800 3040 7380 261

E120483#50HE 120 # 48000 163,920 3 @ 1/2 3 24 3800 2950 7920 273

E132483#50HE 132 # 48000 163,920 3 @ 1/2 3 24 3800 2875 8540 285

E144483#50HE 144 # 48000 163,920 3 @ 1/2 3 24 3800 2815 9120 297

# - INDICATE VOLTAGE: 3 = 208V 3-PH, 4 = 240V/208V 3-PH, 5 = 480V 3-PH.

Note: Multiply listed wattage by .75 for actual 208V rating. Maximum 15 kilowatts per cabinet at 240V.

NUMBER AIR DELIVERY @ NOZZLE OUTLET APPROX.

3/4 HP Models

E42081#75HE 42 # 8000 27,320 1 @ 3/4 1 24 4850 3685 3480 108

E48081#75HE 48 # 8000 27,320 1 @ 3/4 1 24 4850 3595 3880 115

E60081#75HE 60 # 8000 27,320 1 @ 3/4 1 24 4850 3395 4580 131

E72162#75HE 72 # 16000 54,640 2 @ 3/4 2 24 4850 3880 6280 195

E84162#75HE 84 # 16000 54,640 2 @ 3/4 2 24 4850 3715 6960 208

E96162#75HE 96 # 16000 54,640 2 @ 3/4 2 24 4850 3595 7760 221

E108243#75HE 108 # 24000 81,960 3 @ 3/4 3 24 4850 3880 9420 288

E120243#75HE 120 # 24000 81,960 3 @ 3/4 3 24 4850 3765 10100 301

E132243#75HE 132 # 24000 81,960 3 @ 3/4 3 24 4850 3670 10900 314

E144243#75HE 144 # 24000 81,960 3 @ 3/4 3 24 4850 3595 11640 327

E42121#75HE 42 # 12000 40,980 1 @ 3/4 1 24 4850 3685 3480 108

E48121#75HE 48 # 12000 40,980 1 @ 3/4 1 24 4850 3595 3880 115

E60121#75HE 60 # 12000 40,980 1 @ 3/4 1 24 4850 3395 4580 131

E72242#75HE 72 # 24000 40,980 2 @ 3/4 2 24 4850 3880 6280 195

E84242#75HE 84 # 24000 81,960 2 @ 3/4 2 24 4850 3715 6960 208

E96242#75HE 96 # 24000 81,960 2 @ 3/4 2 24 4850 3595 7760 221

E108363#75HE 108 # 36000 81,960 3 @ 3/4 3 24 4850 3880 9420 288

E120363#75HE 120 # 36000 122,940 3 @ 3/4 3 24 4850 3765 10100 301

E132363#75HE 132 # 36000 122,940 3 @ 3/4 3 24 4850 3670 10900 314

E144363#75HE 144 # 36000 122,940 3 @ 3/4 3 24 4850 3595 11640 327

E42161#75HE 42 # 16000 122,940 1 @ 3/4 1 24 4850 3685 3480 108

E48161#75HE 48 # 16000 54,640 1 @ 3/4 1 24 4850 3595 3880 115

E60161#75HE 60 # 16000 54,640 1 @ 3/4 1 24 4850 3395 4580 131

E72322#75HE 72 # 32000 54,640 2 @ 3/4 2 24 4850 3880 6280 195

E84322#75HE 84 # 32000 54,640 2 @ 3/4 2 24 4850 3715 6960 208

E96322#75HE 96 # 32000 109,280 2 @ 3/4 2 24 4850 3595 7760 221

E108483#75HE 108 # 48000 109,280 3 @ 3/4 3 24 4850 3880 9420 288

E120483#75HE 120 # 48000 109,280 3 @ 3/4 3 24 4850 3765 10100 301

E132483#75HE 132 # 48000 163,920 3 @ 3/4 3 24 4850 3670 10900 314

E144483#75HE 144 # 48000 163,920 3 @ 3/4 3 24 4850 3595 11640 327

# - INDICATE VOLTAGE: 3 = 208V 3-PH, 4 = 240V/208V 3-PH, 5 = 480V 3-PH.

Note: Multiply listed wattage by .75 for actual 208V rating. Maximum 15 kilowatts per cabinet at 240V.

2

Page 3

CAUTION

THIS HEATED AIR CURTAIN AND ITS SUB-ASSEMBLIES AND

CONTROLS SHOULD BE INSTALLED BY QUALIFIED PERSONNEL, USING COPPER WIRES AND IN ACCORDANCE

WITH THE NATIONAL ELECTRICAL CODE (NEC) AND ALL

APPLICABLE LOCAL CODES AND ORDINANCES.

NOTE: A MAIN DISCONNECT OR CIRCUIT BREAKER IS

REQUIRED AHEAD OF THE MAIN PANEL OF THIS HEATED

AIR CURTAIN.

!

WARNING

ALWAYS DISCONNECT POWER AT THE MAIN DISCONNECT

OR CIRCUIT BREAKER BEFORE INSTALLING OR SERVICING THIS HEATED AIR CURTAIN. IF THE POWER DISCONNECT IS OUT OF SIGHT OR IS LOCATED GREATER THAN

50 FEET FROM THE MAIN PANEL OF THIS HEATED AIR

CURTAIN, LOCK THE MAIN DISCONNECT IN THE OPEN

POSITION AND TAG IT TO PREVENT UNEXPECTED APPLICATION OF POWER. FAILURE TO DO SO COULD RESULT

IN FATAL ELECTRICAL SHOCK.

!

When facing the inlet grille of the unit, the main control box is

attached on the right side of the combination. A maximum of three

supplementary 60 amp rated circuit breakers (or 60A load fuses)

will be provided for units with full load rating greater than 48 amps.

Field control terminal blocks are also provided with the Main

Control box. A class 2 certified, 24V secondary, 75 VA control

transformer is provided. Class 2 wiring may be used for controls

but it is recommended to use Class 1 wiring for controls since

these are usually located in a commercial-industrial environment.

The load on the thermostat will always be one small relay (4VA) for

heat and another relay for the fan circuit whether the unit is a single, a double or a triple cabinet installation. Any standard low voltage (24V) heating thermostat may be used.

On the Main Control Panel are three indicator lights. These lights

serve the following functions:

Top Light - Power is on to the unit.

Middle Light - The heating elements are on in the unit.

Bottom Light - The fan is on in the unit.

If the “HEAT ON” light is lit at the Main Control Box, the indicator

light at each cabinet control compartment should also be lit. The

cabinet with an unlit light in this instance will need investigation.

Either the bulb is burned out or the automatic reset protective

device in this cabinet has functioned and taken the heating contactor out of circuit. The airflow should also be checked on this

cabinet. The air passageways may be blocked or the blower

wheel is loose or turning in the wrong direction.

!

WARNING

TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK, DO

NOT USE THIS AIR CURTAIN WITH ANY SOLID STATE

SPEED CONTROL DEVICE.

GENERAL INFORMATION

Air curtains produce a wall of continuously flowing air that acts as

a thermal barrier against outside air and provides protection

against insects, dust, odor, fumes and other contaminants. Air curtains maintain interior conditioned temperature by preventing heated or cooled air from escaping through open doorways. Heated air

curtains are engineered to treat incoming cold air at customers’

entrance areas. Used over front door entrances, heated air curtains supplement existing heat to prevent infiltration of colder outside air. Heated units are not recommended for areas subject to

high winds.

The heated air curtains covered by this Installation & Maintenance

Instructions are permanently installed units intended for permanent

connection to a single electrical supply source and are intended to

be located over doorways at least 7 ft. above the floor. The units

may be installed with zero minimum clearances from combustibles

on three sides of the unit and the minimum clearance from the

adjacent wall to the hinged door of the main control box is 16 inches.

Each cabinet employs a dual shaft motor, driving two blower type

air circulators causing air flow over a heater assembly. The heater

assembly consists of two sections, one section per blower. The

heater assembly is controlled by contactors with 24 volt AC low

voltage coils. A replaceable thermal cut-off or one shot protective

device is provided on each leg of each assembly. Each section is

provided with an automatic reset overheat protective device. In

case of overheating, the automatic resets will shut off only the heat

contactor for the heater assembly in the cabinet associated with it

and not the fan contactor and thus airflow should continue. Each

cabinet in a multiple cabinet installation are independent of each

other as far as the operation of the auto resets are concerned.

Each cabinet will have its own control compartment with a heating

contactor with an indicator light and a fan contactor and the

required control terminals for interconnection.

!

WARNING

DURING INITIAL POWER UP OF HEATED AIR CURTAINS,

HINGED CONTROL DOOR MUST BE IN CLOSED POSITION

FOR CORRECT OPERATINO OF THE PRESSURE

DIFFERENTIAL SWITCH. ENERGIZING UNIT WITH DOOR

OPEN MAY CAUSE PERMANENT DAMAGE TO HEATING

ELEMENTS. SEE DETAILS BELOW.

Initial Start Up - Checking For Correct Fan Motor Rotation:

On all three phase units, it is essential for the units to be checked

for correct fan rotatino since it is always possible the motor could

be rotating backwards. Before energizing the units, make sure

units are fully assembled, all wiring is correct and cabinet doors

are closed. Energize units and observe air flow from exhaust. If

correct, the discharge airflow will be strond and the heater elements will come on in a short time to provide heaterd air. All three

indicator lights will be on when the heater and fan are on.

If motor rotation is backwards, interchange any two wires to the

motor and check to see that the motor rotation is correct.

When Removing Blower Assembly From Cabinet(s):

If it becomes necessary to remove the blower assembly from the

cabinets, care must be given to assure the sensing tube for the

pressure differential switch is reassembled correctly and in the

poper locations.

CAUTION

INCORRECT INSTALLATION OF THESE TUBES WILL RESULT

IN THE UNITS NOT OPERATING PROPERLY AND COULD

CAUSE PERMANENT DAMAGE TO UNITS

The sensing tube is provided with an in-line quick connector

located near the blower assembly so the tube can be easily disconnected and reconnected. This is the only portion of the tube

that should be disturbed during this process. To separate, hold

the body of the connector and push the release ring towards the

center of the connector body and then pull the tube from the connector. To reconnect, push the tube into the connector unitil it is

secured in place.

!

3

Page 4

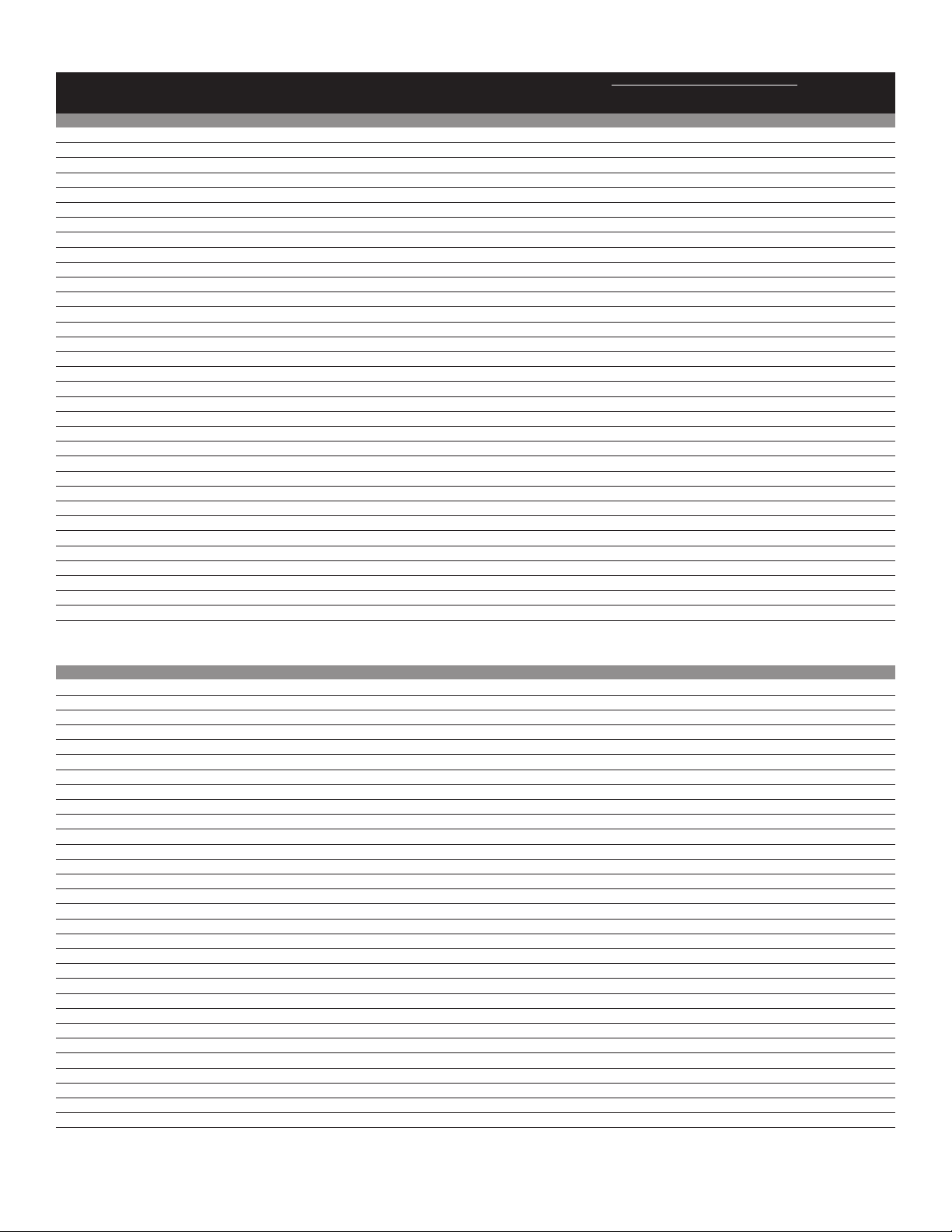

Important Note: The portion of the sensing tube that attaches to

the blower has an opening that must face the blower and be positioned near the center of the blower inlet. This should not be

removed or disturbed during the romoval and reinstallation of the

blower assembly into the cabinet. After reasembly, check to make

sure this sensing tube has not been damaged or dislodged. In the

control compartment, the sensing tube attaches to the “LOW” port

on the pressure differential switch.

Sensing tube location

Quick connector

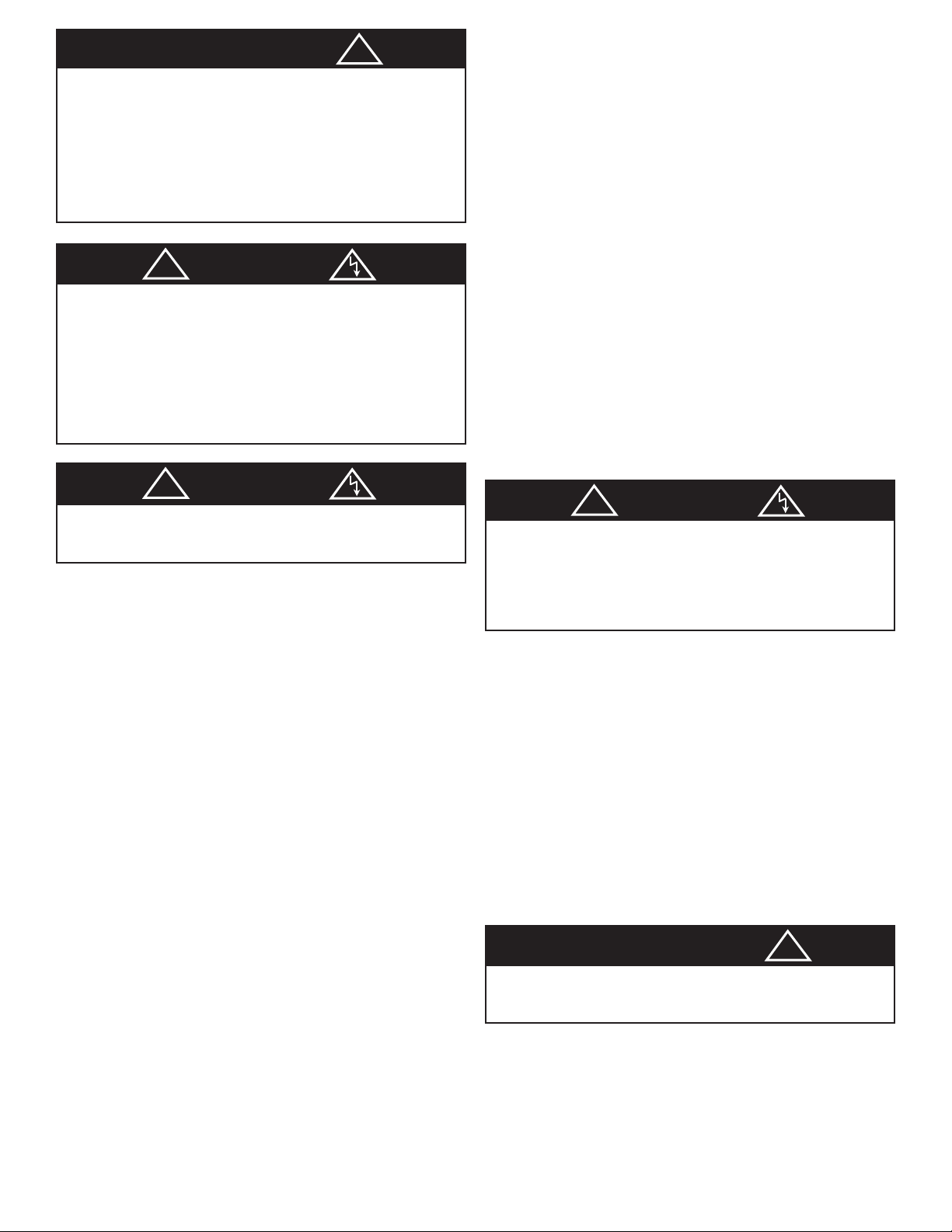

4. Unscrew six (6) knurled nuts and remove air intake grille. (See

Figure 3)

5. Carefully disconnect motor electric cord from socket and plug

assembly and remove two wing nuts on blower base. (See

Figure 4)

6. Carefully disconnect pressure switch hose quick connector at

blower by holding body of connector and pushing the release

ring towards the center of connector while pulling the hose to

disconnect.

7. To remove motor blower assembly, lift from rear of motor housing to prevent damage and misalignment to shaft and blower

wheels. Once the motor/blower assembly is removed, the heater

assembly will be accessed.

NOTE: After unpacking unit, inspect carefully for any damage that

may have occurred during transit. Check for loose, missing or damaged parts. The hinged cabinet wiring compartment cover should

also be opened to inspect the components and wiring inside.

8. Make sure the open coil elements do not touch any metal part

and all the porcelains holding the elements are not broken and

are in their proper place.

Figure 3: Sensing Tube Location

When powering the unit for the first time, always check the wiring

for correctness and tightness, make sure the power supply

matches the nameplate rating of the unit, make sure the sensing

tubes of each PD switch are in the proper position and location

and all the cabinet compartment covers are closed. It is also recommended that the front grille covers should be in place. This will

make sure the pressure switch will sense enough vacuum and

turn on heater.

Figure 3

UNPACKING

For Single Cabinet Units: 36”, 42”, 48” and 60”

1. With packaged unit on the floor, carton arrows should point

upward.

2. Carefully remove staples from top of carton and fold back sides.

3. Carefully remove cabinet from carton by lifting out unit using finger holes in styrofoam side inset and place on work surface.

CAUTION: Do not attempt to lift this air curtain by its louver or

damage may result.

!

WARNING

MAKE SURE NO COMBUSTIBLE MATERIAL NOR ANY

OTHER FOREIGN MATERIAL FALLS ON THIS HEATING

ELEMENT CAVITY WHILE IT IS EXPOSED WITH THE

MOTOR/ BLOWER ASSEMBLY OUT OF THE CABINET

For 2 Cabinet Units: 72”, 84” and 96” See Figure 5, Page 5

1. With packaged units on the floor, carton arrows should point

upward. Cartons are marked A & B.

2.

Follow Steps 2 through 8 for Single Cabinet Units.

NOTE: Cabinet A (left), Cabinet B (right). Carton labeled

Cabinet B will contain the Main Control Box and all harness

wires and parts bag to interconnect the two cabinets.

For 3 Cabinet Units: 108”, 120”, 132” and 144”

See Figure 6, Page 6

1. With packaged units on the floor, carton arrows should point

upward. Cartons are marked A, B and C.

2.

Follow Steps 2 through 8 for Single Cabinet Units.

NOTE: CabinetA (left), Cabinet B (center), Cabinet C (right).

Carton labeled Cabinet C will contain the Main Control Box

and harness wires and parts bag to interconnect the three

cabinets. Cabinet B may also have harness wires to interconnect to Cabinet A.

INSTALLATION

For Single Cabinet Units:

CAUTION

THE HARDWAREAND THE SUPPORTING STRUCTURE MUST

BE CAPABLE OF SUPPORTING A MINIMUM 150 LB LOAD.

!

4

Figure 4

NOTE:All installation should be done to meet local building codes.

1. Using template provided, determine mounting location.

2. Drill holes and attach mounting hardware (not included).

3. Mount cabinet on wall and securely tighten hardware.

4. Replace motor/blower assembly in cabinet. Pass pres-

sure switch hose through proper hole on blower base.

Reconnect motor electric cord plug assembly.

5. Attach pressure switch hose to quick connector at right

blower housing.

6. Secure two wing nuts on blower base.

Page 5

7. Replace intake grille with louvers facing down and fasten

knurled nuts.

Field Power Wiring: Refer to Wiring Diagram and

Nameplate.

!

WARNING

ALL HEATED AIR CURTAINS SHOULD BE INSTALLED BY

QUALIFIED PERSONNEL.

1. Before wiring be sure that available power supply, voltage,

phase and frequency corresponds to that specified on unit rating plate. In addition, make certain that service capacity is sufficient to handle load imposed by the heated air curtain.

2. Install all wiring, protection and grounding in accordance with

the National Electrical Code (NEC) and all local requirements.

3. Run proper size copper power supply conductors from the field

power supply disconnecting means (supplied by others) with

insulation rated 75 degrees C minimum (167º F) to the power

supply blocks provided at the Main Control Box of the air curtain. This field supplied disconnecting means shall be provided

to disconnect the heater, motor controller(s) and any supplementary overcurrent protective devices from all ungrounded

conductors. This disconnecting means shall be within sight of

the heater, motor controller(s) or supplementary protective

devices. If it is not within sight or is located greater than 50

feet, disconnecting means shall be capable of being locked in

the open position.

4. The heater control box must have an unbroken electrical

ground from its Main Control Box to its field supplied disconnecting means to minimize personal injury in case an electrical

fault should occur.

5. Always refer to nameplate data and wiring diagram located on

the inside of the hinged cover of the main control box for

important information and other data before proceeding with

wiring of the unit.

!

WARNING

THE MOTORS OF THIS HEATED AIR CURTAIN HAVE AN

INTERNAL SELF RESETTING THERMAL OVERLOAD PROTECTOR. ALWAYS DISCONNECT FROM POWER SUPPLY

BEFORE SERVICING.

NOTE: This heated air curtain is equipped with a step-down

transformer 24V control circuit. Any standard 24V heating thermostat with or without fan control may be used. Door switches

may be used to control the operation of the unit. A door switch

may be connected to control the operation of the fan only or it

can be connected in parallel with the heating thermostat to call

for fan and heat every time the door is opened. The thermostat

may call for fan and heat even when door is closed. The step

down transformer is a 75 VA approved Class 2 transformer and a

control knockout is provided with the control terminal blocks

spaced away from power wire to allow Class 2 wiring for controls

but it is recommended to use Class 1 wiring, especially to door

switches to protect it from physical damage in an industrial or

commercial environment.

6. Replace hinged cover of the main control box.

7. Unit is ready for operation.

8. Restore power to the unit. Call for heat through the thermostat

or through the door switch if supplied. Unit should run. Check

for correct air flow.

9. Inspect unit for excessive vibration during operation. If exces-

sive vibration is noticeable, disconnect power supply. Inspect

mounting installation and refer to “Trouble Shooting Chart”,

page 7 for probable cause.

Field Control Wiring: Refer to Wiring Diagram, pages

8-10.

FOR INSTALLATION OF MULTIPLE CABINET AIR

CURTAINS

For 2 Cabinet Units: 72”, 84” and 96” See Figure 5

CAUTION

THE HARDWAREAND THE SUPPORTING STRUCTURE MUST

BE CAPABLE OF SUPPORTING A MINIMUM 300 LB LOAD.

NOTE: All installation should be done to meet local building codes.

1. Using template provided, determine mounting location

for Cabinet A (left side), left of centerline.

2. Drill holes and attach mounting hardware (not included)

for Cabinet A.

3. Mount Cabinet A on wall and securely tighten hardware.

4. Repeat steps 1,2 and 3 for mounting Cabinet B (right

side), right of centerline.

5. Secure Cabinet A to Cabinet B using parts provided in

installation kit. After alignment of cabinets is completed, carefully secure all assembly mounting hardware.

6. Install motor/blower assembly in Cabinet A. Pass pressure switch hose through proper hole on blower base.

Attach hose to right blower. Secure two wing nuts on

blower base. Reconnect motor (A) electric cord plug

assembly.

7. Install motor/blower assembly (B) in Cabinet B.

pressure switch hose through proper hole on blower base.

Attach hose to right blower. Secure two wing nuts on blower

base. Reconnect motor (B) electric cord plug assembly.

8. Replace intake grilles with louvers facing down and refasten

knurled nuts.

9. Refer to “Field Power Wiring” and “Field Control Wiring” sections for single cabinet installation in this manual. All

instructions and safety warnings and notes also apply to

electrical connections of multiple cabinets. Additional steps

are necessary only for harness connections of Cabinet A to

Cabinet B and/or to the Main Control Box.

10. Refer to wiring diagram on the inside of the hinged cover of

the Main Control Box and to applicable wiring diagrams in this

manual. Harness wires are provided with the right ends of

the harness wires already connected to the unit and the

installer has to connect the left ends of the harness wires to

the correct terminal points as shown in the diagram. The

Cabinet wiring compartment covers will have to be opened.

These covers are also hinged to the cabinets. Route and

locate wiring and wire strap the wires as shown in Figure 9,

page 7 and allow for the movement of the wires as the covers

are opened and closed.

11. Replace all hinged covers.

12. Unit is ready for operation.

13. Restore power to the unit. Call for heat through the thermostat or through the door switch if supplied. Unit should run.

Check for correct air flow.

14. Inspect unit for excessive vibration during operation. If

excessive vibration is noticeable, disconnect power supply.

Inspect mounting installation and refer to “Trouble Shooting

Chart”, page 7 for probable cause.

Cabinet A

Figure 5

Cabinet B

!

Pass

5

Page 6

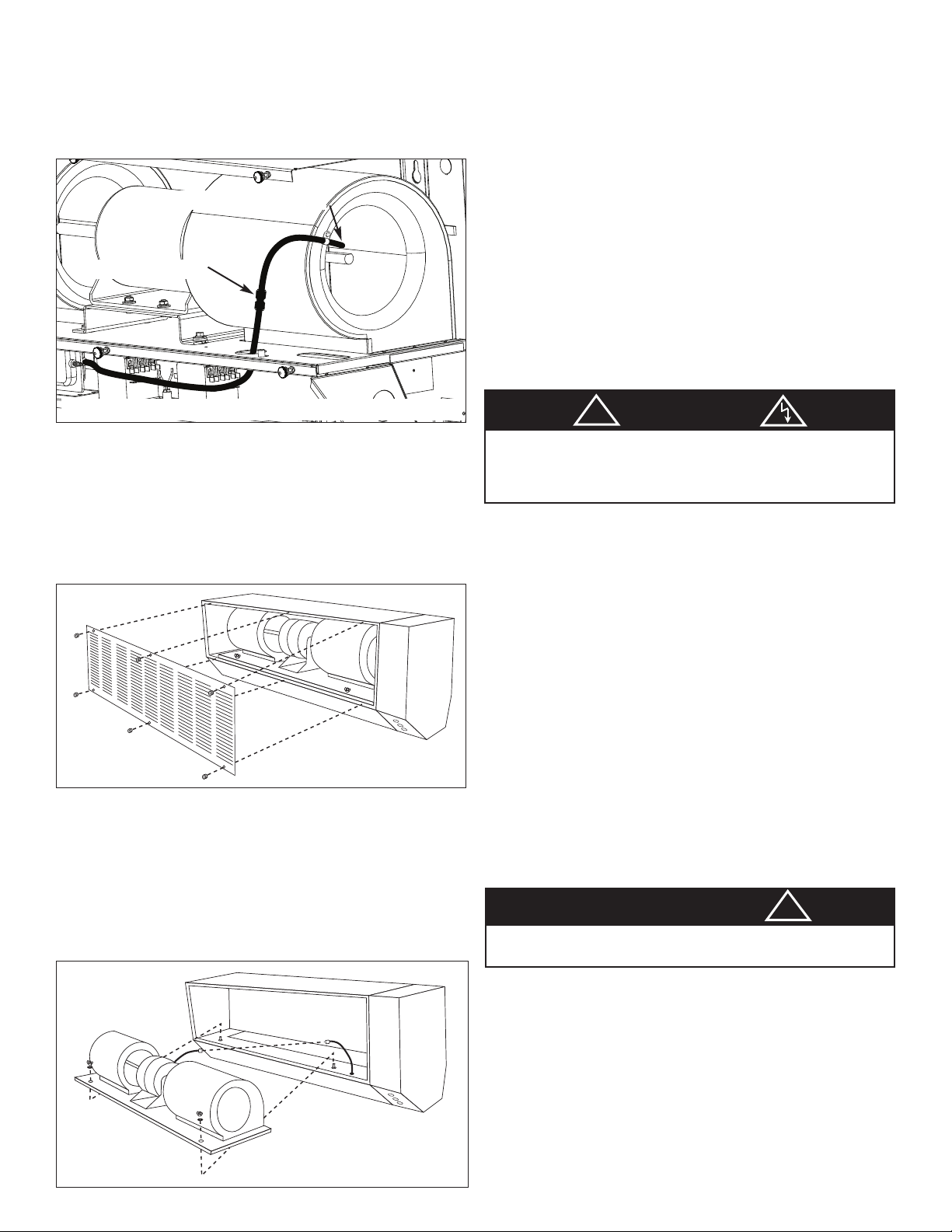

For 3 Cabinet Units: 108”, 120”, 132” and 144” See Figure 6

CAUTION

THE HARDWAREAND THE SUPPORTING STRUCTURE MUST

BE CAPABLE OF SUPPORTING A MINIMUM 500 LB LOAD.

NOTE: All installation should be done to meet local building codes.

1. Determine mounting location of center cabinet (See Figure 6).

2. Using template provided, determine mounting location for

Cabinet A (left side), left of center cabinet.

3. Drill holes and attach mounting hardware (not included) for

Cabinet A.

4. Mount Cabinet A on wall and securely tighten hardware.

5. Repeat steps 1, 2, 3 and 4 for mounting Cabinet B (center).

6. Repeat steps 1, 2, 3 and 4 for mounting Cabinet C (right),

right of center cabinet.

7. Secure Cabinet A to Cabinet B to Cabinet C using parts provided in installation kit. After alignment of cabinets is completed, carefully secure all assembly mounting hardware.

8. Install motor/blower assembly (A) in Cabinet A. Pass pressure switch hose through proper hole on blower base.

Attach hose to right blower. Secure two wing nuts on blower

base. Reconnect motor (A) electric cord plug assembly.

9. Install motor/blower assembly (B) in Cabinet B. Pass pressure switch hose through proper hole on blower base.

Attach hose to right blower. Secure two wing nuts on blower

base. Reconnect motor (B) electric cord plug assembly.

10. Install motor/blower assembly (C) in Cabinet C. Pass pressure switch hose through proper hole on blower base.

Attach hose to right blower. Secure two wing nuts on blower

base. Reconnect motor (C) electric cord plug assembly.

11. Replace intake grilles with louvers facing down and fasten

knurled nuts.

12. Refer to “Field Power Wiring” and “Field Control Wiring”

sections, page 5 for single cabinet installation in this manual.

All instruction and safety warning and notes also apply to

electrical connections of multiple cabinets. Additional steps

are necessary only for harness connection of Cabinet A to

Cabinet B and Cabinet B to Cabinet C and/or to the Main

control Box.

13. Refer to wiring diagram on the inside of the hinged cover of

the Main control Box and to applicable wiring diagrams in

this manual. Harness wires are provided with the right ends

of the harness wires already connected to the unit and the

installer has to connect the left ends of the harness wires to

the correct terminal points as shown in the diagram. The

cabinet wiring compartment covers will have to be opened.

These covers are also hinged to the cabinets. Route and

locate wiring and wire strap the wires as shown in

Figure 9 and allow for the movement of the wires as the

hinged covers are opened and closed.

14. Replace all hinged covers.

15. Unit is ready for operation.

16. Restore power to the unit. Call for heat through the thermostat or through the door switch if supplied. Unit should run.

Check for correct air flow.

17. Inspect unit for excessive vibration during operation. If

excessive vibration is noticeable, disconnect power supply.

Inspect mounting installation and refer to “Trouble Shooting

Chart” page 7 for probable cause.

!

OPERATION

1. After power has been connected to unit, unit is ready to

respond to its control devices such as the thermostat or door

switches.

2. Air direction at outlet can be controlled by adjustable vanes

at the nozzle which compensates for possible draft conditions.

NOTE: Air direction settings shown in Figures 7 & 8.

NOTE: Cold air will try to escape near top of doorway. Air flow

can be controlled by direction of nozzle louvers.

NOTE: Each unit is supplied with an air flow probing switch which

is located in each cabinet compartment and this is supplied with a

hose located in the suction side of the blower. A blower turning in

the wrong direction may be prevented from turning the heat on by

this switch.

Figure 7 - Desired air flow

adjustment for temperature

and humidity control.

Figure 8 - Desired air flow

adjustment for insect and

dust control.

MAINTENANCE

!

WARNING

ALL ELECTRICAL POWER MUST BE DISCONNECTED

WHEN INSTALLING OR SERVICING THIS EQUIPMENT.

MORE THAN ONE DISCONNECT SWITCH MAY BE

REQUIRED TO REMOVE POWER FROM THE UNIT.

NOTE: Ball bearings are permanently lubricated and require no

further lubrication.

Cleaning:

1. The air curtain cabinet(s) may be wiped off with a damp

cloth. Do not allow motor to get wet. Do not use solvents or

harsh detergents.

NOTE: Keep air intake louvers clear of dirt and dust accumulation which could affect performance.

2. Check blower wheels for accumulated dirt twice a year and

clean. If disassembly is required, see “General Servicing”

section.

6

Cabinet A

Figure 6

Cabinet B

Cabinet C

Page 7

GENERAL SERVICING

!

WARNING

IF SERVICE IS REQUIRED, IT SHOULD BE DONE BY

QUALIFIED PERSONS ONLY.

ALWAYS DISCONNECT POWER SUPPLY BEFORE SERVICING

1. To remove motor/blower assembly, repeat steps 4, 5, 6 and 7

in “Unpacking” section.

2. Place motor/blower assembly on workbench.

3. To replace blower wheel, remove the three slotted hex head

screws on outer blower ring assembly (See Figure 10,

Replacement Parts Illustration). The wheel is held onto shaft

by two hex head screws.

4. To remove motor:

a. Remove blower wheels. (See Step 3 above).

b. Remove blower scroll (six hex head screws).

c. Unscrew and remove motor mounts.

6. To replace heater assembly: Do the reverse of Step 5 above.

NOTE: To re-assemble, repeat steps 4, 5 and 6 in installation

section for single cabinet units.

7. Replace motor/blower assembly.

IMPORTANT

NOTE POSITION OF WHEELS TO PREVENT RUBBING WHEN

REPLACED.

5. To remove heater assembly:

a. Remove blower wheels. (See Step 3 above).

b. Remove heater assembly (two screws). Disconnect two

yellow wires and blue, black and red wires from heating contactor. Pass wires through bushing as you pull out the

heater assembly.

!

Figure 9 - Main control box cover & cabinet

compartment cover shown open and with air

intake grille removed.

TROUBLE SHOOTING CHART

Symptom Possible Cause Corrective Action

Fan inoperative 1. Blown fuse or open circuit breaker. 1. Replace fuse or reset circuit breaker

2. Electricity turned off. 2. Contact local power company.

3. Loose motor cord connection. 3. Re-check all connections.

4. Thermostat off/defective 4. Call for fan/Replace.

5. Defective fan relay/contactor. 5. Replace.

6. Defective fan relay/contactor. 6. Replace.

7. Defective capacitor (1 phase unit only) 7. Replace.

8. Defective motor. 8. Replace.

9. Wrong wiring. 9. Correct wiring.

Excessive noise 1. Wheel rubbing on housing. 1. Center wheel.

2. Motor base/blower loose. 2. Tighten mounting bolts.

3. Defective motor bearings. 3. Replace motor.

Insufficient air flow 1. Improper voltage. 1. Reconnect proper voltage or exchange unit

with proper voltage rating.

2. Outlet louvers closed. 2. Open louvers

3. Intakes obstructed. 3. Remove any obstruction.

4. Dirty blower wheels. 4. Clean.

5. Motor in reverse rotation. 5. Interchange red & black power leads.

Fan cuts out on thermal 1. Low voltage. 1. Check voltage/Use correct wire size.

overload (self-resets) 2. Obstruction to blower wheel. 2. Remove obstruction.

No heat 1. Fuse link open. 1. Replace w/ G5AM0400117C

2. Heater element broken. 2. Replace w/ proper Ga and watts.

3. Control transformer open 3. Check wiring /Reset control breaker

4. Auto reset functioned* 4. Wait to reset/check for insufficient airflow.

*Heat indicator light On (Main Panel)

BUT heat indicator light OFF (Cabinet)

4a. Auto reset functioned possibly due 4a. Remove cause of overheat/wait to reset.

to overheating.

4b. Air flow switch not closing its 4b. Check hose/switch/wiring & check for

normally open contact. insufficient air flow.

5. Heat Indicator light OFF (Main Panel) 5. Adjust/check thermostat.

thermostat not calling for heat.

7

Page 8

*

SEE

CHART

PLUG/SOCKET

CONNECTOR

K

W LOAD PER UNIT:

480

16 16

12 12

88

208

11.25 11.25

99

66

240

15 15

12 12

88

VOLTS

1/2 HP 3/4 HP

5

075

M

OTOR CODE

R

L

1L2L3

G

32

1

PLPLPL

R1 R1 R2

FU

T

G

MAIN PANEL

G

H H F F C C

FROM MOTOR

YEL

YEL

A1

A2

NO

C

FROM HEATER

B

LK

YEL

BLU

FR1 HR1

T

1

FR1

HR1

4

PL

T

2

PDS1

PWB1

CABINET COMPONENTS PANEL

G

WH F C

PWB1

LEGEND

A1, A2..............AUTOMATIC RESET PROTECTION

R1....................HEATINGRELAY

R

2....................FAN RELAY

HR1 .................HEATINGCONTACTOR

FR1..................FAN CONTACTOR

T

......................CONTROL TRANSFORMER

FU....................CONTROL FUSE

PL1, PL4..........PILOT LIGHT, HEATON

PL2..................PILOT LIGHT, POWER ON

PL3..................PILOT LIGHT, FAN ON

G......................GROUND LUG

L1L2L3 ............POWER TERMINAL BLOCKS

RGWHFC ........CONTROL TERMINAL BLOCKS

HHFFCC..........CONTROL TERMINAL BLOCKS

PWB1 ..............POWER WIRE BUNDLE (MAIN TO UNIT 1)

CWB1..............CONTROL WIRE BUNDLE (MAIN TO UNIT 1)

PDS1...............PRESSURE DIFFERENTIAL SWITCH

R

G

W

THERMOSTAT

(FIELD INSTALLED)

C

WB1

DOOR SWITCH

(FIELD

INSTALLED)

FIELD WIRING

*

CONNECTION CHART FOR PRIMARY OF

M

ULTIPLE TAP TRANSFORMER:

V

OLTAGE: CONNECTION:

2

08 V BLACK AND RED

2

40 V BLACK AND ORANGE

4

80 V BLACK AND BLK/RED

T

3

R

2

R1

L1

L2

L3

* SEE

CHART

PLUG/SOCKET

CONNECTOR

(NO. OF UNITS) X KW LOAD PER UNIT:

480

(2) X 16

(2) X 16

(2) X 12

(2) X 12

(2) X 8

(2) X 8

208

(2) X 6 (2) X 6

240

(2) X 8

VOLTS

1/2 HP

3/4 HP

50

75

MOTOR CODE

R

L1 L2 L3

G

R2 R1 R1 R2

FU

T

G

MAIN PANEL

G

H H F F C C

FROM MOTOR

YEL

YEL

A1

A2

NO

C

G

H H F F C C

FROM MOTOR

YEL

YEL

A1

A2

NO

C

FROM HEATER FROM HEATER

BLK

YEL

BLU

FR2 HR2

T1

FR2

HR2

T2 T3

FR1 HR1

T1

FR1

HR1

T2 T3

PDS2 PDS1

PWB1

CWB2

CABINET COMPONENTS PANEL1

CWB1

FWB1

CABINET COMPONENTS PANEL2

CWB2

FWB1

GWHFC

PWB1

LEGEND

A1,A2....................AUTOMATIC RESET PROTECTION

R1.........................HEATING RELAY

R2.........................FAN RELAY

HR1, HR2 .............HEATING CONTACTORS

FR1, FR2..............FAN CONTACTORS

T...........................CONTROL TRANSFORMER

FU.........................CONTROL FUSE

PL1, PL4, PL5 ......PILOT LIGHT, HEAT ON

PL2.......................PILOT LIGHT, POWER ON

PL3.......................PILOT LIGHT, FAN ON

G...........................GROUND LUG

L1L2L3 .................POWER TERMINAL BLOCKS

RGWHFC .............CONTROL TERMINAL BLOCKS

HHFFCC...............CONTROL TERMINAL BLOCKS

PWB1 ...................POWER WIRE BUNDLE (MAIN TO UNIT 1)

FWB1....................FAN CONTACTOR WIRE BUNDLE (FR1 TO UNIT 2

CWB1...................CONTROL WIRE BUNDLE (MAIN TO UNIT 1)

CWB2...................CONTROL WIRE BUNDLE (UNIT 1 TO UNIT 2)

PDS1, PDS2.........PRESSURE DIFFERENTIAL SWITCH

*CONNECTION CHART FOR PRIMARY OF

MULTIPLE TAP TRANSFORMER:

VOLTAGE: CONNECTION:

208 V BLACK AND RED

240 V BLACK AND ORANGE

480 V BLACK AND BLK/RED

R

G

W

THERMOSTAT

(FIELD INSTALLED)

CWB1

DOOR SWITCH

(FIELD INSTALLED)

FIELD WIRING

R1

BLU

L1

L2

L3

L1

L2

L3

32

1

PLPLPL

4

PL

5

PL

(2) X 8

WIRING DIAGRAM: 240V, 208V, 480V - Single cabinet,

8KW, 12KW and 16KW

WIRING DIAGRAM: 240V, 208V, 480V - Two cabinets,

8KW, 12KW and 16KW

8

Page 9

*

SEE

C

HART

PLUG/SOCKET

CONNECTOR

(

NO. OF UNITS) X KW LOAD PER UNIT:

480 (3) X 12 (3) X 12

(3) X 8(3) X 8

VOLTS 1/2 HP 3/4 HP

50 75

M

OTOR CODE

R

L1 L2 L3

G

321

PLPLPL

R2 R1 R1 R2

F

U

T

G

MAIN PANEL

G

H H F F C C

F

ROM MOTOR

Y

EL

YEL

A

1

A

2

N

O

C

G

H H F F C C

F

ROM MOTOR

Y

EL

Y

EL

A

1

A

2

NO

C

G

FR3

H

R3

T

1

F

R3

HR3

6

PL

H H F F C C

F

ROM MOTOR

YEL

YEL

A

1

A

2

P

DS3

NO

C

F

ROM HEATER FROM HEATER FROM HEATER

BLK

YEL

BLU

T

2T3

F

R2

H

R2

T1

F

R2

HR2

5

PL

T2 T3

FR1

HR1

T

1

F

R1

HR1

4

PL

T

2T3

P

DS2 PDS1

PWB1

CWB2

CABINET COMPONENTS PANEL 1

CWB1

FWB1

CWB3

CABINET COMPONENTS PANEL2

C

WB2

FWB2

CABINET COMPONENTS PANEL 3

CWB3

FWB2

F

WB1

G

WH F C

PWB1

LEGEND

A1,A2...................AUTOMATICRESET PROTECTION

R

1......................HEATING RELAY

R2......................FAN RELAY

H

R1, HR2, HR3...........HEATING CONTACTORS

FR1, FR2, FR3...........FAN CONTACTORS

T

.. .....................CONTROL TRANSFORMER

F

U......................CONTROL FUSE

PL1, PL4, PL6...........PILOT LIGHT, HEAT ON

P

L2.....................PILOT LIGHT, POWERON

PL3.....................PILOT LIGHT, FAN ON

G.......................GROUND LUG

L1L2L3..................POWER TERMINAL BLOCKS

RGWHFC..................CONTROL TERMINAL BLOCKS

HHFFCC..................CONTROL TERMINAL BLOCKS

PWB1....................POWER WIRE BUNDLE (MAIN TO UNIT 1)

FWB1....................FAN CONTACTOR WIRE BUNDLE (FR1 TO UNIT 2)

FWB2....................FAN CONTACTOR WIRE BUNDLE (FR2 TO UNIT 3)

CWB1....................CONTROL WIRE BUNDLE (MAIN TO UNIT 1)

CWB2....................CONTROL WIRE BUNDLE (UNIT 1 TO UNIT 2)

CWB3....................CONTROL WIRE BUNDLE (UNIT 2 TO UNIT 3)

PDS1, PDS2, PPDS3.......PRESSURE DIFFERENTIAL SWITCH

*CONNECTION CHART FOR PRIMARY OF

MULTIPLE TAP TRANSFORMER:

V

OLTAGE: CONNECTION:

480 V BLACK AND BLK/RED

R

G

W

THERMOSTAT

(FIELD INSTALLED)

CWB1

DOOR SWITCH

(FIELD INSTALLED)

FIELD WIRING

R1

BLU

L

1

L2

L3

L

1

L

2

L

3

L

1

L

2

L

3

* SEE

CHART

PLUG/SOCKET

CONNECTOR

(NO. OF UNITS) X KW LOAD PER UNIT:

208

(2) X 11.25 (2) X 11.25

(2) X 9 (2) X 9

240

(2) X 15 (2) X 15

(2) X 12 (2) X 12

VOLTS 1/2 HP 3/4 HP

50 75

MOTOR CODE

R

L1 L2 L3

G

321

PLPLPL

R2 R1 R1 R2

FU

T

G

MAIN PANEL

G

H H F F C C

FROM MOTOR

YEL

YEL

A1

A2

NO

C

G

H H F F C C

FROM MOTOR

YEL

YEL

A1

A2

NO

C

FROM HEATER FROM HEATER

BLK

YEL

BLU

FR2 HR2

T1

FR2

HR2

5

PL

T2

T3

FR1 HR1

T1

FR1

HR1

4

PL

T2 T3

PDS2 PDS1

BWB1

CWB2

CABINET COMPONENTS PANEL 1

CWB1

BWB2

CABINET COMPONENTS PANEL2

CWB2

GWHFC

BWB1

LEGEND

A1,A2...............AUTOMATIC RESET PROTECTION

R1....................HEATING RELAY

R2....................FAN RELAY

CB1, CB2.........CIRCUIT BREAKERS

HR1, HR2 ........HEATING CONTACTORS

FR1, FR2.........FAN CONTACTORS

T......................CONTROL TRANSFORMER

FU....................CONTROL FUSE

PL1, PL4, PL5.PILOT LIGHT, HEAT ON

PL2..................PILOT LIGHT,POWER ON

PL3..................PILOT LIGHT,FAN ON

G......................GROUND LUG

L1L2L3 ............POWER TERMINAL BLOCKS

RGWHFC ........CONTROL TERMINAL BLOCKS

HHFFCC..........CONTROL TERMINAL BLOCKS

BWB1 ..............C-BREAKER WIRE BUNDLE (BRKR 1 TO UNIT 1)

BWB2 ..............C-BREAKER WIRE BUNDLE (BRKR 2 TO UNIT 2)

CWB1..............CONTROL WIRE BUNDLE (MAIN TO UNIT 1)

CWB2..............CONTROL WIRE BUNDLE (UNIT 1 TO UNIT 2)

PDS1, PDS2....PRESSURE DIFFERENTIAL SWITCH

*CONNECTION CHART FOR PRIMARY OF

MULTIPLE TAP TRANSFORMER:

VOLTAGE: CONNECTION:

208 V BLACK AND RED

240 V BLACK AND ORANGE

R

G

W

THERMOSTAT

(

FIELD INSTALLED)

CWB1

DOOR SWITCH

(FIELD INSTALLED)

F

IELD WIRING

CB1 CB2

BWB2

R1

BLU

L1

L2

L3

L1

L2

L3

WIRING DIAGRAM: 480V - Three cabinets,

8KW and 12KW

WIRING DIAGRAM: 240V, 208V - Two cabinets,

8KW, 12KW and 15KW

9

Page 10

* SEE

CHART

PLUG/SOCKET

C

ONNECTOR

(

NO. OF UNITS) X KW LOAD PER UNIT:

208

(3) X 11.25 (3) X 11.25

(3) X 9 (3) X 9

(3) X 6 (3) X 6

2

40

(

3) X 15 (3) X 15

(

3) X 12 (3) X 12

(3) X 8 (3) X 8

V

OLTS

1/2 HP 3/4 HP

50 75

M

OTOR CODE

R

L1 L2 L3

G

PLPLPL

R

1

R1 R2

FU

T

G

MAIN PANEL

G

H H F F C C

FROM MOTOR

YEL

YEL

A1

A2

NO

C

G

H H F F C C

FROM MOTOR

YEL

YEL

A1

A2

NO

C

G

FR3

H

R3

T

1

FR3

HR3

H H F F C C

FROM MOTOR

YEL

YEL

A1

A2

PDS3

NO

C

FROM HEATER FROM HEATER FROM HEATER

B

LK

YEL

BLU

T

2 T3

F

R2

HR2

T

1

FR2

HR2

5

PL

T

2 T3

F

R1

HR1

T1

FR1

HR1

4

PL

T2 T3

P

DS2

PDS1

BWB1

CWB2

CABINET COMPONENTS PANEL 1

CWB1

BWB2

CWB3

CABINET COMPONENTS PANEL 2

CWB2

B

WB3

CABINET COMPONENTS PANEL 3

CWB3

G

W H F C

BWB1

*CONNECTION CHART FOR PRIMARYOF

MULTIPLE TAP TRANSFORMER:

VOLTAGE: CONNECTION:

208 V BLACK AND RED

240 V BLACK AND ORANGE

R

G

W

T

HERMOSTAT

(FIELD INSTALLED)

CWB1

DOOR SWITCH

(FIELD INSTALLED)

FIELD WIRING

CB1 CB2 CB3

BWB2 BWB3

R

2

R1

BLU

L1

L

2

L3

L

1

L2

L3

L

1

L2

L3

1

2 3

L

EGEND

A

1, A2...................AUTOMATIC RESET PROTECTION

R

1.........................HEATING RELAY

R

2.........................FAN RELAY

C

B1, CB2, CB3.....CIRCUIT BREAKERS

H

R1, HR2, HR3....HEATING CONTACTORS

F

R1, FR2, FR3.....FAN CONTACTORS

T

...........................CONTROL TRANSFORMER

F

U.........................CONTROL FUSE

PL1, PL4, PL6 ......PILOT LIGHT, HEAT ON

PL2.......................PILOT LIGHT, POWER ON

PL3.......................PILOT LIGHT, FANON

G...........................GROUND LUG

L1L2L3 .................POWER TERMINAL BLOCKS

RGWHFC .............CONTROL TERMINAL BLOCKS

HHFFCC...............CONTROL TERMINAL BLOCKS

BWB1 ...................FUSEBLOCK WIRE BUNDLE (FB1 TO UNIT 1)

BWB2 ...................FUSEBLOCK WIRE BUNDLE (FB2 TO UNIT 2)

CWB1...................CONTROL WIRE BUNDLE (MAIN TO UNIT 1)

CWB2...................CONTROL WIRE BUNDLE (UNIT 1 TO UNIT 2)

CWB3...................CONTROL WIRE BUNDLE (UNIT 2 TO UNIT 3)

PDS1, PDS2, PPDS3 PRESSURE DIFFERENTIAL SWITCH

6

PL

WIRING DIAGRAM: 240V, 208V - Three cabinets,

8KW, 12KW and 15KW

WIRING DIAGRAM: 480V - Three cabinets,

16KW

10

Page 11

5

E

4808-1550

HE

C

FID: XXXXXXXXXX

MODEL NO.

D

ATECODE

0105

48” 480V HEATEDAIR CURTAIN

WARNING- RISK OF FIRE. DO NOT USE AS A

RESIDENTIAL OR HOUSEHOLD HEATER.

480-3

480-3

8

MOTOR VOLTS-PH

HEATER VOLTS-PH

HEATER

KW

60 HZ, .5 AMPS

60 HZ

10.12

16

15

TOTAL

AMPS

MIN. CIR.

AMPACITY

MAX CURRENT

PROTECTION

AUTOMATICALLY OPERATED

DEVICE. TO REDUCE THE

RISK OF INJURY,

DISCONNECT FROM POWER

BEFORE SERVICING.

M

ARLEY ENGINEERED PRODUCTS

BENNETTSVILLE, SC 29512 USA

4104-2221-048

LISTED AIR HEATER

9900268

4

3

2

1

Figure 10

Replacement Parts List for Air Curtain Cabinets

Ref.

No. Description

1 Cabinet Intake Grille

2 Electric Box Cover

3 Front Control Panel

4 Motor Assembly

5 Heater Element Set

6 Cabinet Box Assembly

7 Main Control Panel

6

7

Nameplate

SAMPLE

For Replacement Parts please call for assistance 1-800-642-4328.

Please have the Configuration ID number for the specific unit. The

Configuration ID (example- CFID: XXXXXXXXXX) is a ten digit

number found on the nameplate in the upper right just below the

date code . (Refer to sample nameplate at right)

11

Page 12

All products manufactured by Marley Engineered Products are warranted against defects in workmanship and materials for eighteen months from date of installation. This

LIMITED WARRANTY

warranty does not apply to damage from accident, misuse, or alteration; nor where the connected voltage is more than 5% above the nameplate voltage; nor to equipment

improperly installed or wired or maintained in violation of the product’s installation instructions. All claims for warranty work must be accompanied by proof of the date of

installation.

The customer shall be responsible for all costs incurred in the removal or reinstallation of products, including labor costs, and shipping costs incurred to return products to

Marley Engineered Products Service Center.Within the limitations of this warranty, inoperative units should be returned to the nearest Marley authorized service center or

the Marley Engineered Products Service Center, and we will repair or replace, at our option, at no charge to you with return freight paid by Marley. It is agreed that such

repair or replacement is the exclusive remedy available from Marley Engineered Products.

THE ABOVE WARRANTIES ARE IN LIEU OF ALL OTHER WARRANTIES EXPRESSED OR IMPLIED, AND ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE WHICH EXCEED THE AFORESAID EXPRESSED WARRANTIES ARE HEREBY DISCLAIMED AND EXCLUDED FROM THIS

AGREEMENT. MARLEY ENGINEERED PRODUCTS SHALL NOT BE LIABLE FOR CONSEQUENTIAL DAMAGES ARISING WITH RESPECT TO THE PRODUCT,

WHETHER BASED UPON NEGLIGENCE, TORT, STRICT LIABILITY, OR CONTRACT.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above exclusion or limitation may not apply to you. This warranty gives

you specific legal rights, and you may also have other rights which vary from state to state.

For the address of your nearest authorized service center, contact Marley Engineered Products in Bennettsville, SC, at 1-800-642-4328. Merchandise returned to the factory must be accompanied by a return authorization and service identification tag, both available from Marley Engineered Products. When requesting return authorization,

include all catalog numbers shown on the products.

HOW TO OBTAIN WARRANTY SERVICE AND

WARRANTY PARTS PLUS GENERAL INFORMATION

1. Warranty Service or Parts 1-800-642-4328

2. Purchase Replacement Parts 1-800-654-3545

3. General Product Information www.marleymep.com

Note: When obtaining service always have the following:

1. Model number of the product

2. Date of manufacture

3. Part number or description

Part No. 5200-2644-002

ECR 38002

2/09

12

Loading...

Loading...