Page 1

Q Series

Commercial

Fan Forced

Wall Heaters

Read Carefully - These instructions are written to help you prevent

difficulties that might arise during installation of heaters. Studying

the instructions first may save you considerable time and money

later. Observe the following procedures and cut your installation

time to a minimum.

TO REDUCE RISK OF FIRE AND ELECTRIC SHOCK:

1. To prevent electrical shock, disconnect all power coming to

heater at main service panel before wiring or servicing.

2. All wiring must be in accordance with the National and Local

Electrical Codes and the heater must be grounded as a precaution against possible electric shock.

3. Verify the power supply voltage coming to heater matches the

ratings printed on the heater nameplate before energizing.

4. This heater is hot when in use. To avoid burns, do not let bare

skin touch hot surfaces.

5. Do not insert or allow foreign objects to enter any ventilation or

exhaust opening as this may cause an electric shock, fire, or

damage to the heater.

6. To prevent a possible fire, do not block air intakes or exhaust in

any manner. Keep combustible materials, such as crates,

drapes, etc., away from heater. Do not install behind doors, furniture, towels, or boxes. Do not install in ceiling.

7. A heater has hot and arcing (sparking) parts inside. Do not use it

in areas where gasoline, paint, or flammable liquids are used or

stored.

8. Use this heater only as described in this manual. Any other use

not recommended by the manufacturer may cause fire, electric

shock, or injury to persons.

9. This heater is not approved for use in hazardous or corrosive

atmospheres, such as marine, green house, or chemical storage

areas.

WARNING

SA VE THESE INSTRUCTIONS

Installation & Maintenance Instructions

Dear Owner,

Congratulations! Thank you for purchasing this new heater manufactured by Marley Engineered

Products. You have made a wise investment selecting the highest quality product in the heating industry.

Please carefully read the installation and maintenance instructions shown in this manual. You should

enjoy years of efficient heating comfort with this product from Marley Engineered Products... the industry’s leader in design, manufacturing, quality and service.

... The Employees of

Marley Engineered Products

1

!

31-3/4 (806mm)

Back box dimensions 30-3/8 (771mm) wide x 21-1/4 (540mm)

high x 3-3/4 (95mm) deep.

22-19/32

(565mm)

Page 2

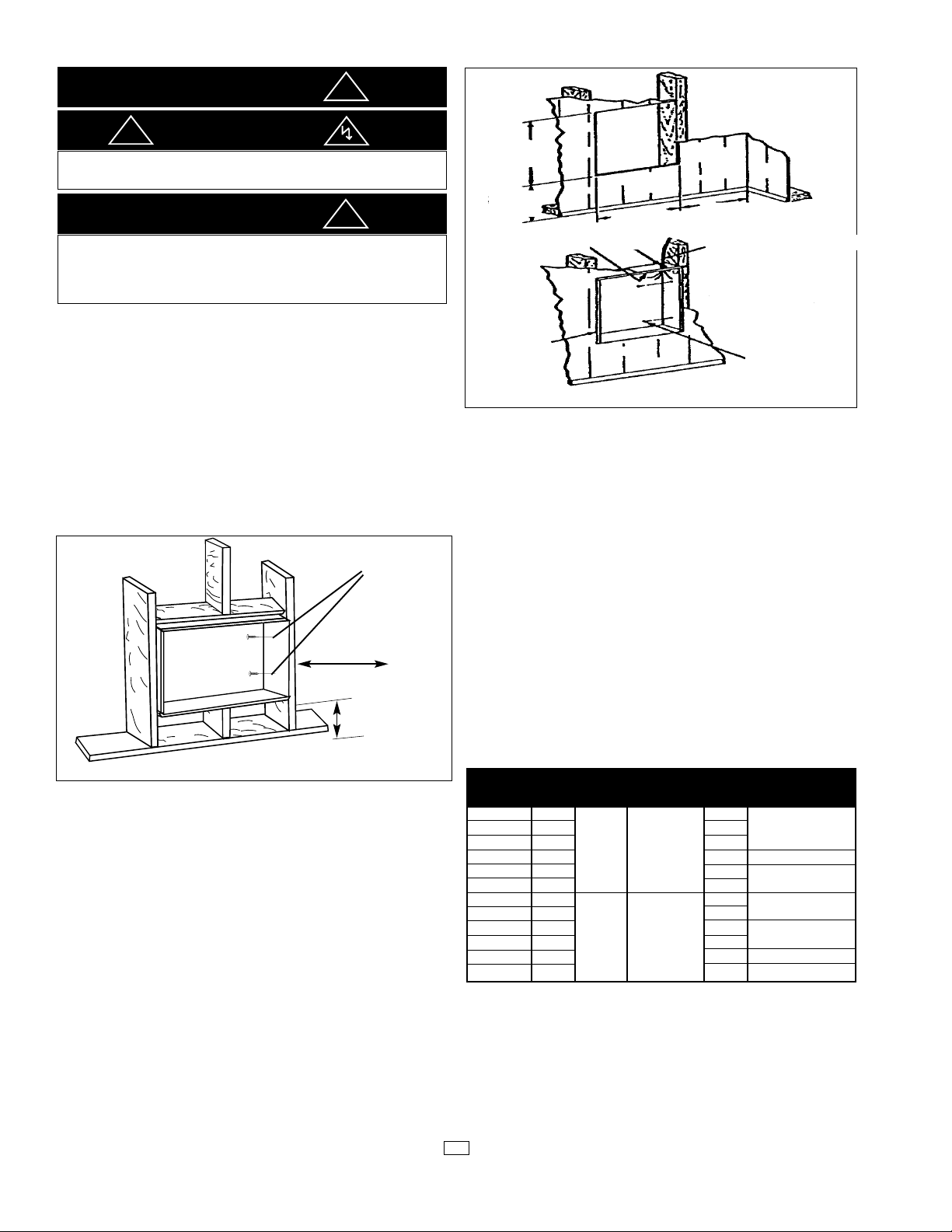

Installation of Recessed Back Box

in New Construction

1. Mounting Back Box (See Figure 1).

NOTE: Heater fan panels are installed into back box at

factory. These must be removed during the installation of

back box.

a. Place the back box between two 32" (812 mm)

center-to-center wall studs at the desired mounting

height but no closer than 8" (203 mm) to adjacent wall

or floor.

b. Align back box such that the bottom and sides will be

flush with finished wall surface.

c. Secure the back box in position with wood screws or

nails as shown in Figure 1.

2. Power Supply Wiring (See Figure 2)

NOTE: Wire compartment volume - 260in3 (4260cm3).

a. Run a power supply cable into the knockout area in the

upper right hand corner of the back box. All wiring must

be in accordance with National and Local Electrical

Codes. Refer to Table 1 for correct wire size.

b. Remove disconnect switch bracket by removing two

screws on the left side of the disconnect switch cover.

c. Install a cable clamp in the “knockout” in the upper right

corner of the back box.

d. Insert power supply cable through cable clamp, allowing

at least 6" (152mm) of leads to extend inside the back

box. Connect the blue lead wires of disconnect switch to

the supply wire leads using wire connectors (see wiring

diagram, pg. 3.)

e. Ground the back box by connecting the supply ground lead

wire to the marked ground lug located in the upper right

corner of the back box.

f. Secure disconnect switch cover in place.

Installation of Recessed

Back box in Existing Construction

1. Provide a wall opening 30-1/2" (774mm) wide by 21-1/8"

(536mm) high at the desired mounting height, but no closer

than 8" (203mm) to floor or adjacent wall. (See Figure 2.)

2. Power Supply Wiring

NOTE: Wiring Compartment Volume - 260in3 (4260cm3).

a. Run a power supply cable into the area above the top

of the wall opening. All wiring must be in accordance

with National and Local Electrical Codes. Refer to Table 1

for correct wire size.

b. Remove disconnect switch bracket by removing the

two screws on the left side of disconnect switch cover.

c. Install a cable clamp in the “knockout” in the top right

corner of back box.

d. Insert power supply cable through cable clamp, allowing

approximately 6" (152mm) of cable length to remain inside

the back box to facilitate connections.

3. Mounting Back Box

a. Place the back box into wall opening flush with finished

wall surface on bottom and sides of box.

b. Secure the back box in place with wood screws or nails.

(see Fig. 2)

4. Wiring Disconnect Switch

a. Connect the power supply wires to the blue wires of the dis-

connect switch using wire connectors (see wiring diagram, pg. 3)

b. Ground the back box connecting the supply ground lead

wire to the marked ground lug located in the upper right

corner of the back box.

c. Secure disconnect switch cover in place.

Installation of Back box with

Surface-Mounting Frame

(See Figure 3)

1. Secure back box to wall with knockouts in upper right hand

corner using screws and anchors.

NOTE: If heater is located in a high traffic area, where it may

be subjected to vandalism or abuse, take extreme care to see

that the box is firmly attached to the wall.

2. Power Supply Wiring

Notes:

•

Wiring compartment volume: 260in3(4226cm3).

CAUTION

WARNING

DO NOT INSTALL HEA TER UPSIDE DOWN OR SIDEWA YS.

DO NOT USE HEATER WITHOUT GRILLE.

FOR WALL MOUNTING ONLY. DO NOT INSTALL HEATER

CLOSER THAN 8" (203 mm) TO THE FLOOR OR ANY ADJACENT WALLSURFACE.

DO NOT INSTALL CLOSER THAN 36"

(915 mm) TO THE CEILING.

IMPORTANT

2

Fig. 1: Locating Recessed Back Box in New Construction

Fig. 2: Locating Recessed Back Box in Existing Construction

!

!

!

Table 1 Minimum Supply

Q6008 208 28.8

Q6004 240 25.0 10 AWG

Q6007 277 21.7

Q6003 347 1 6,000 17.3 12 AWG

Q60048 480 12.5

Q6006 600 10.0 14 AWG

Q8008 208 38.5

Q8004 240 33.3

8 AWG

Q8007 277 1 8,000 28.9

Q8003 347 23.1

10 AWG

Q80048 480 16.7 12 AWG

Q8006 600 13.3 12 AWG

8” minimum from

adjacent wall

nail or screw

(2 each side)

8” minimum from

floor

Back Box

Power supply cable

8” min (203mm)

30-1/2” (774mm)

Nail or screw

(2 each side)

Cable Clamp

Ground

Screw

Back

Box

21-1/8”

(536mm)

8”

(203mm)

Catalog # Volts Phase Watts Amps Wire Size

Page 3

• Supply may enter heater back box from wall through back

knockout or through top knockout when surface type conduit is provided. When surface conduit system is used, the

“U” shaped knockout in the surface frame must be removed

to allow clearance over conduit.

a. Remove the disconnect switch bracket from back box by

removing the two screws.

b. Remove desired knockout in rear or top of back box and run

supply cable to heater location and into upper right corner of

back box, leaving at least 6” of wire inside box for connection.

Cable arrangement must be in accordance with the National

and Local Electric Codes and cable must be properly protected by use of appropriate cable clamp or conduit fittings.

c. Referring to the appropriate wiring diagram make the follow-

ing connections:

1. Connect the supply ground conductor to the back box by

attaching to the grounding lug marked “Ground.”

2. Connect each supply power lead wire to one of the blue

lead wires from the disconnect switch using wire nuts or

approved wire connectors.

3. If black leads from disconnect switch are not already

attached to terminal block attach as shown in the wiring

diagram. Check to make sure connections are tight.

4. Secure disconnect switch and bracket to back box with the

screws removed earlier.

3. Carefully fit surface frame over back box making sure back

edges of frame are flush with finished wall. See fig. 3. Secure

frame in place with two screws as shown.

Installation of Heater Assembly and Grille

After back box is completely installed and no further construction

dirt is expected, clean debris from back box. Heater fan panels

were shipped mounted to back box and were removed to mount

back box.

1. Insert the heater assemblies (fan panels) into back box, placing the four mounting holes (with key-hole slots) over the

screws in the back box. Tighten all screws securely.

2. If surface-mounting frame is used, ensure that the

frame is even with all four heater assembly tabs before

tightening screws.

3. Connect the two disconnected black switch wires to the

heater terminal block (see wiring diagram). Connect red, blue

and black wires from both fan panels to heater terminal

block (see wiring diagram). Check that all wiring connections are tight.

4. Turn thermostat(s) to the extreme counterclockwise position.

5. Turn disconnect switch “ON”.

6. Mount the grille using the six (6) long screws provided.

The screws thread into holes located in the flanges of the

back box.

Operation

NOTE: The operation instructions apply to 208, 240 and 277V

heaters with one thermostat. Units operating at 347V, 480V and

600V have

two thermostats.

3-13/16" (97mm)

HANG FRAME

ON BACK BOX

MOUNT BACK

BOX TO W ALL

USING REAR

MOUNTING

BRACKETS

23-7/64" (585mm)

32-7/32" (818mm)

Fig. 3: Surface Mounting Installation

3

L2F

L1

L2E

BLACK

RED

BLUE

BLACK

RED

BLUE

BLACK L2F

RED L2

BLUE L2E/B

BLACK L2F

RED L1

BLUE L2E/A

L2F

L1

L2E

Left fan panel

assembly

Right fan panel

assembly

Right fan panel

assembly

To

Disconnect

Switch

Assembly

L2F

L1

L2E/A

L2E/B

L2F

L1

L2E

BLACK

RED

BLUE

BLACK

RED

BLUE

L2F

BLACK

L2

RED

L2E/B

BLUE

BLACK L2F

RED L1

BLUE L2E/A

L2F

L1

L2E

Left fan panel

assembly

To

Disconnect

Switch

Assembly

L2F

L1

L2E/A

L2E/B

Thermostat

Wiring diagram for

fan panels used on

208V, 240V, 277V

Q Series

Q6008

Q6004

Q6007

Q8008

Q8004

Q6007

Wiring diagram

for fan panels

used on 347V,

480V, 600V

Q Series

Q6003

Q60048

Q6006

Q8003

Q80048

Q8006

Typical Fan Panel Assembly

Typical Fan

Panel Assembly

Terminal Block

Terminal Block

Page 4

1. Rotate the thermostat(s) fully clockwise. This should energize

the heating elements and, after a short delay, engage the

fan causing warm air to flow from the hot air discharge at the

openings in the bottom of the grille.

2. After the operation check, rotate the thermostat(s) by inserting

a small screw driver through the grille to the desired position

to obtain room comfort. For units with two thermostats, it is

recommended that both should be set at approximately the

same setting.

NOTE: For best results, the heater should be left “ON” constantly

during the heating season because the thermostat, when properly

set, will maintain the desired temperature.

TO RESET MANUAL RESET LIMITS

Y our heater is equipped with two manual reset safety thermal limit

controls that will automatically turn the heater off to prevent a fire if

the heater overheats. These controls are located on the fan panel

assemblies between the elements and fan blades and marked

“reset”. The red reset buttons can be seen through the front grille

when the heater is installed. T o reset, allow the heater to cool, then

push the red buttons that are visible through the hole in the fan

panels. The heater should immediately return to normal operation.

Determine why manual reset tripped! (See Caution note)

Maintenance

Once each year the heater should be cleaned to remove dust

and other foreign material which has collected during the heating

season. This is a simple operation when performed as follows:

1. Turn off the electric power at main line switch (or remove all

fuses) to disconnect electric power from the heater. THIS IS

IMPORTANT.

2. Remove the grille and turn the disconnect switch to the OFF

position.

3. With a vacuum cleaner nozzle or dust cloth, remove dust

and other foreign material.

4. After cleaning, turn disconnect switch to ON position and

reinstall the grille.

5. Turn on the main line switch (or replace fuses) to restore

power to the heater. The heater is now ready for another

season of operation.

OPERATION OF THE MANUALRESET SAFETY THERMALLIMIT CONTROL IS AN INDICATION THAT THE HEATER HAS BEEN SUBJECTED

TO SOME ABNORMALCONDITION. IT IS RECOMMENDED THATTHE

HEATER BE CHECKED BY A REPUTABLE ELECTRICIAN OR REPAIR

SERVICE TO ENSURE THE HEATER HAS NOT BEEN DAMAGED.

DO NOT USE WATER OR DAMP CLOTH FOR CLEANING AND DO

NOT DISTURB THE HEATING ELEMENT.

LIMITED W ARRANTY

All products manufactured by Marley Engineered Products are warranted against defects in workmanship and materials for one year from date of installation, except heating elements which are warranted against defects in workmanship and materials for five years from date of installation. This warranty does not apply to damage from accident, misuse, or alteration; nor where the connected voltage is more than 5% above the nameplate voltage; nor to equipment improperly installed or wired or maintained

in violation of the product’s installation instructions. All claims for warranty work must be accompanied by proof of the date of installation.

The customer shall be responsible for all costs incurred in the removal or reinstallation of products, including labor costs, and shipping costs incurred to return products

to Marley Engineered Products Service Center. Within the limitations of this warranty, inoperative units should be returned to the nearest Marley authorized service center or the Marley Engineered Products Center, and we will repair or replace, at our option, at no charge to you with return freight paid by Marley. It is agreed that such

repair or replacement is the exclusive remedy available from Marley Engineered Products.

THE ABOVE WARRANTIES ARE IN LIEU OF ALL OTHER WARRANTIES EXPRESSED OR IMPLIED. AND ALL IMPLIED WARRANTIES OF MERCHANTABILITYAND

FITNESS FOR A PARTICULAR PURPOSE WHICH EXCEED THE AFORESAID EXPRESSED WARRANTIES ARE HEREBY DISCLAIMED AND EXCLUDED FROM

THIS AGREEMENT. MARLEY ENGINEERED PRODUCTS SHALL NOT BE LIABLE FOR CONSEQUENTIAL DAMAGES ARISING WITH RESPECT TO THE PRODUCT, WHETHER BASED UPON NEGLIGENCE, TORT, STRICT LIABILITY, OR CONTRACT.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above exclusion or limitation may not apply to you. This warranty gives

you specific legal rights, and you may also have other rights which vary from state to state.

For the address of your nearest authorized service center, contact Marley Engineered Products in Bennettsville, SC, at 1-800-642-4328. Merchandise returned to the factory must be accompanied by a return authorization and service identification tag, both available from Marley Engineered Products. When requesting return authorization, include all catalog numbers shown on the products.

MODEL NO. Q6004 DATE CODE: 0996

FAN FORCED WALL HEATER

APPAREILDE CHAUFFAGE MURAL À AIR PULSÉ

240 6000 1

VOLTS AC 60HZ WATTS PHASE

USE ONLY WITH TWO FAN PANELS

MODEL

FP3004

A N’UTILISER QU’AVEC LE TABLEAU À

DEUX VENTILA TEURS MODÈLE FP3004

DO NOT OPERA TE WITHOUT FRONT COVER IN PLACE

NE PAS UTILISER SI LE COUVERCLE AVANT

N’EST PAS EN PLACE

MARLEY ENGINEERED PRODUCTS

BENNETTSVILLE, SC 29512 4104-2171-001

774G LISTED

ROOM HEATER

IMPORTANT

CAUTION

CAUTION

HOW TO ORDER REPAIR PARTS

In order to obtain any needed repair or replacement parts,

warranty service or technical information, please contact Marley

Engineered Products Service Center toll-free by calling

1-800-642-HEAT.

When ordering repair parts, always give the information listed as

follows:

8/97

Part No. 5200-2288-001

ECR 33603

NAMEPLATE

!

!

!

MORE THAN ONE DISCONNECT MAY BE NECESSARY IF RELAY

ACCESSORY IS USED.

1. The Part Number

2. The Model Number

3. The Part Description

4. Date of Manufacture

4

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

Loading...

Loading...