Page 1

CSH and DSH

Commercial Sill Height Convection Heaters

(Type CSH)

Convectors

Decorative Sill Height Convection Heaters

(Type DSH)

Installation, Operation & Maintenance Instructions

IMPORTANT INSTRUCTIONS

GENERAL

This heater is designed to provide years of efficient, trouble free operation as a primary or supplementary heat source for comfort

heating in residential and commercial applications. CSH and DSH convector heaters must be thermostatically controlled for efficient,

safe operation. A thermostat is not provided with this heater. However, a single or double pole thermostat accessory is available

for installation into this heater at your place of purchase, or the heater may be connected to any suitable wall mounted thermostat

that will meet the electrical load requirements. Installation or use of this product in any manner not described herein will void the

warranty and could result in injury, damage to property, or permanent damage to heater.

WARNING

WHEN USING ELECTRICAL APPLIANCES, BASIC PRECAUTIONS SHOULD ALWAYS BE FOLLOWED TO REDUCE

THE RISK OF FIRE, ELECTRIC SHOCK, AND INJURY TO

PERSONS, INCLUDING THE FOLLOWING:

1. Read all instructions before installing or using the heater.

2. A heater has hot and arcing or sparking parts inside. Do not

use in areas where gasoline or flammable liquids are used

or stored. Do not use in corrosive environment or any area

where explosive materials are used or stored.

3. This heater is hot when in use. To avoid burns, do not let

bare skin touch hot surfaces. Keep combustible materials,

such as furniture, pillows, bedding, papers, clothes, and curtains away from heater.

RECEIVING

Material when shipped was in good order and Marley

Engineered Products holds clear bill of lading, therefore any

concealed damage must be reported at once to the carrier for

inspection and settlement.

SAVE THESE INSTRUCTIONS

!

4. To prevent a possible fire, do not block air intakes or

exhaust in any manner.

5. Do not insert or allow foreign objects to enter any ventilation

or exhaust opening as this may cause an electric shock or

fire, or damage the heater.

6. Serious injury or death could result from electric shock.

Make sure electrical power supply circuit coming to heater

is disconnected at main disconnect or service panel before

installing or servicing this heater.

This heater is not for residential or household use.

7.

Note:

It is advisable to store cartons in a central area to be

drawn upon as needed per room requirements. If called for on

order, the cartons will have been tagged with proper room

number.

Page 2

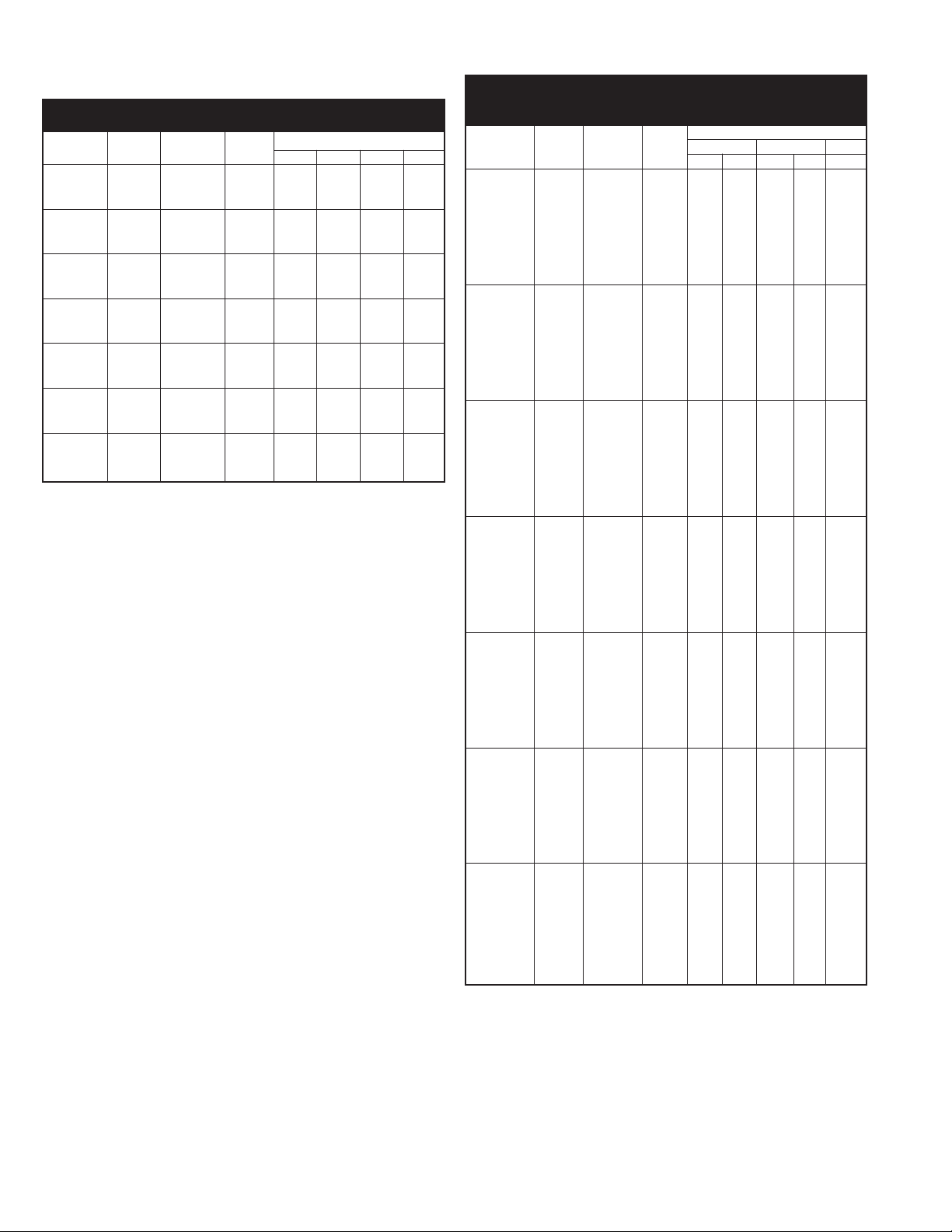

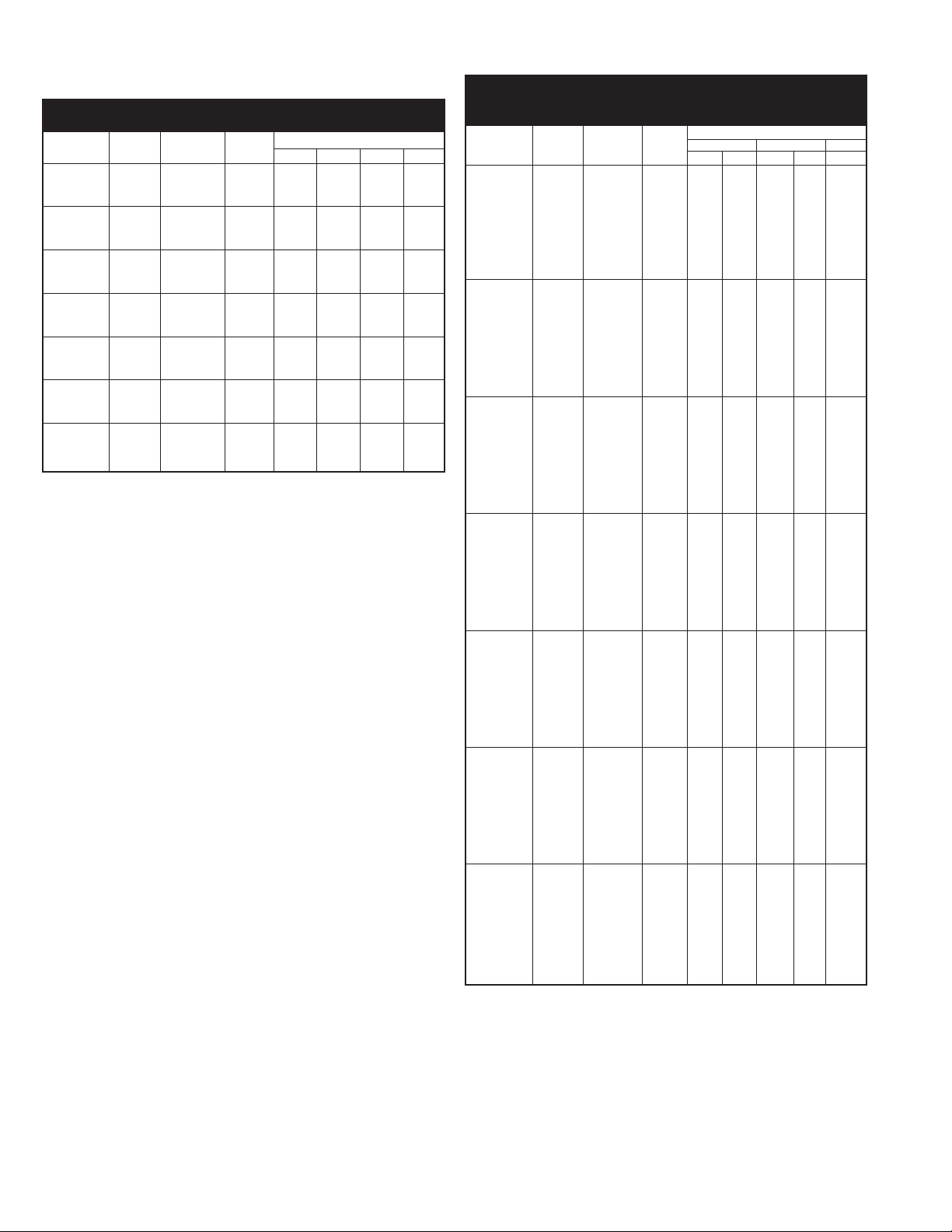

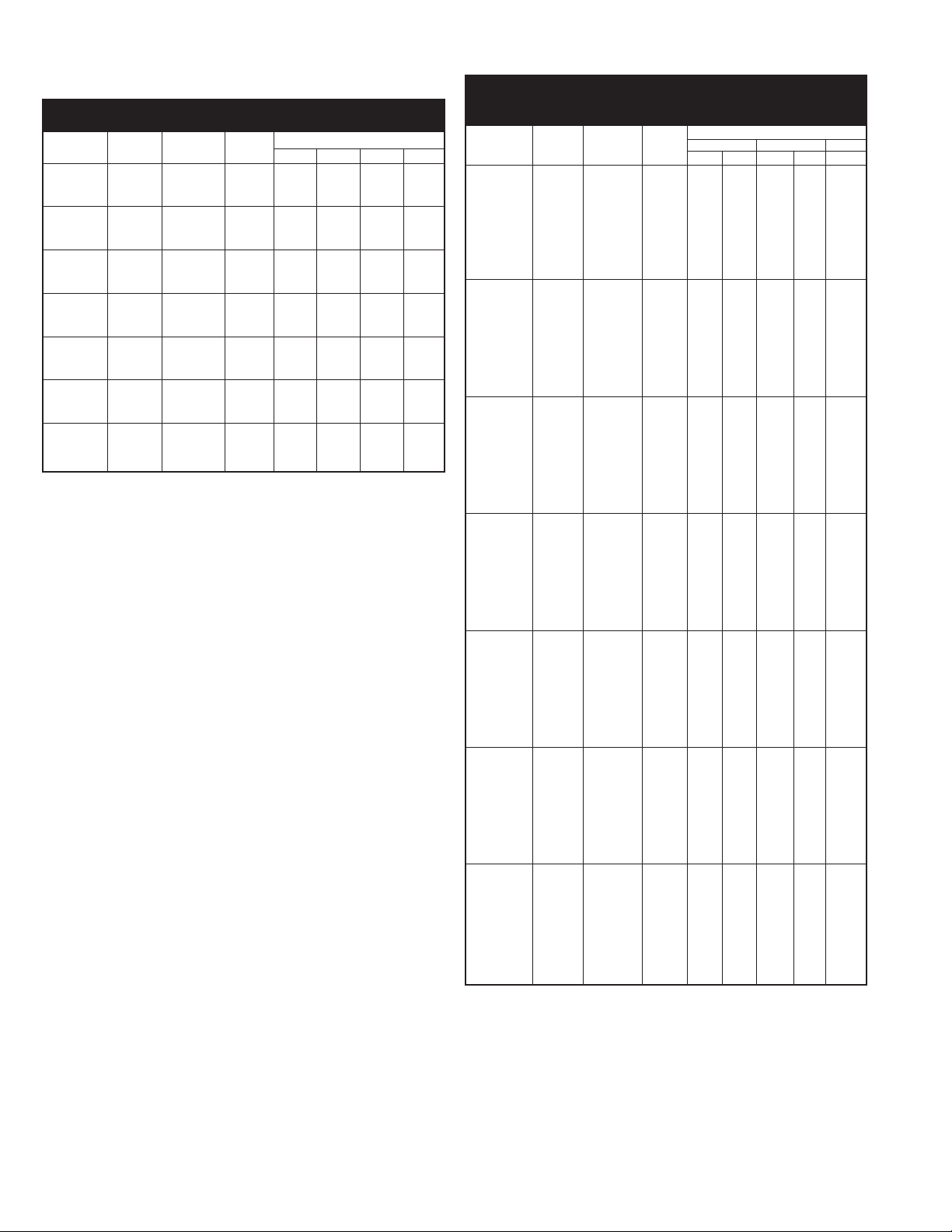

SPECIFICATIONS

Table A

Model CSH05A, DSH05A (H=5 1/2”; D=3”)

Catalog Length Total Amperage

Number* “L” Watts/Ft. Watts 120V 208V 240V 277V

-2125 125 250 2.4 1.2 1.0 0.9

-2188 28” 188 375 3.1 1.8 1.6 1.4

-2250 250 500 4.2 2.4 2.1 1.8

-3125 125 375 3.1 1.8 1.6 1.4

-3188 3’ 188 564 4.7 2.7 2.4 2.0

-3250 250 750 6.2 3.6 3.1 2.7

-4125 125 500 4.2 2.4 2.1 1.8

-4188 4 188 750 6.2 3.6 3.1 2.7

-4250 250 1000 8.3 4.8 4.2 3.6

-5125 125 625 5.2 3.0 2.6 2.2

-5188 5 188 940 7.8 4.5 3.9 3.4

-5250 250 1250 10.4 6.0 5.2 4.5

-6125 125 750 6.2 3.6 3.1 2.7

-6188 6 188 1125 9.4 5.4 4.7 4.1

-6250 250 1500 12.5 7.2 6.2 5.4

-8125 125 1000 - 4.8 4.2 3.6

-8188 8’ 188 1500 - 7.2 6.2 5.4

-8250 250 2000 - 9.6 8.3 7.2

-10125 125 1250 - 6.0 5.2 4.5

-10188 10’ 188 1875 - 9.0 7.8 6.7

-10250 250 2500 - 12.0 10.4 9.0

1

* Prefix with: CSH05A (5

DSH05A (5 1/2” height heaters)

CLEARANCE CHART

For safe and efficient operation, maintain at least the following

minimum clearances at all times:

Bottom of Heater to Finished Floor:

Front Inlet Models:

•

- May be installed on floor. However, for best performance,

install bottom of heater approximately 3 inches (76 mm) off

floor.

Bottom Inlet Models:

•

- 100-250 watts per foot – 1-3/4 inch (44 mm)

- 375-750 watts per foot – 3 inches (76 mm)

NOTE:

linoleum, etc. may be installed around and under the heater

without adversely affecting the performance of the heaters.

Top of Heater to Ceiling (all models):

- Minimum 36 inches (914 mm)

Top of Heater to Bottom of Drapes Above Heater:

- Minimum 12 inches (305 mm)

IMPORTANT NOTE:

as vinyl blinds) may become damaged by the heated air from

the heater and should not be installed above the heater.

Front of Heater to Full Length Drapes in Front of Heater:

- Minimum between bottom of drapes and floor – 2-1/2 inches

(64 mm)

- Minimum between top of drapes and ceiling – 1/2 inch (13

mm)

- Minimum between front of heater and nearest fold of drape –

2 inches (51 mm)

Top of Heater to Bottom of Window Sill:

- Minimum 12 inches (305 mm)

Up to ¾” thick floor covering, such as carpet, tiles,

/2” height heaters)

Certain fabrics and vinyl materials (such

Table A (continued)

Model CSH07A, DSH07A (H=7”; D=5”)

Model CSH14A, DSH14A (H=14”; D=5”)

Amperage

Catalog Length Total 208V 240V 277V

Number** “L” Watts/Ft Watts 1Ø 3Ø 1Ø 3Ø 1Ø

-2125 125 250 1.2 - 1.0 - 0.9

-2188 188 375 1.8 - 1.6 - 1.4

-2250 250 500 2.4 - 2.1 - 1.8

-2375 28” 375 750 3.6 - 3.1 - 2.7

-2500 500 1000 4.8 - 4.2 - 3.6

-2564 564 1125 5.4 3.1 4.7 2.7 4.0

-2625 625 1250 6.0 3.5 5.2 3.0 4.5

-2750 750 1500 7.2 4.2 6.2 3.6 5.4

-3125 125 375 1.8 - 1.6 - 1.4

-3188 188 564 2.7 - 2.4 - 2.0

-3250 250 750 3.6 - 3.1 - 2.7

-3375 3’ 375 1125 5.4 - 4.7 - 4.0

-3500 500 1500 7.2 - 6.2 - 5.4

-3564 564 1690 8.1 4.7 7.4 4.3 6.1

-3625 625 1875 9.0 5.2 7.8 4.5 6.7

-3750 750 2250 11.0 6.5 9.4 5.4 8.1

-4125 125 500 2.4 - 2.1 - 1.8

-4188 188 750 3.6 - 3.1 - 2.7

-4250 250 1000 4.8 - 4.2 - 3.6

-4375 4’ 375 1500 7.2 - 6.2 - 5.4

-4500 500 2000 9.6 - 8.3 - 7.2

-4564 564 2250 10.8 6.2 9.4 5.4 8.0

-4625 625 2500 12.0 6.9 10.4 6.0 9.0

-4750 750 3000 14.4 8.3 12.5 7.2 10.8

-5125 125 625 3.0 - 2.6 - 2.2

-5188 188 940 4.5 - 3.9 - 3.4

-5250 250 1250 6.0 - 5.2 - 4.5

-5375 5’ 375 1875 9.0 - 7.8 - 6.7

-5500 500 2500 12.0 - 10.4 - 9.0

-5564 564 2820 13.5 7.8 11.8 6.8 10.2

-5625 625 3125 15.0 8.7 13.0 7.5 11.3

-5750 750 3750 18.0 10.4 15.6 9.0 13.5

-6125 125 750 3.6 - 3.1 - 2.7

-6188 188 1125 5.4 - 4.7 - 4.0

-6250 250 1500 7.2 - 6.2 - 5.4

-6375 6’ 375 2250 10.8 - 9.4 - 8.1

-6500 500 3000 14.4 - 12.5 - 10.8

-6564 564 3380 16.2 9.4 14.1 8.1 12.2

-6625 625 3750 18.0 10.4 15.6 9.0 13.5

-6750 750 4500 21.6 12.5 18.7 10.8 16.2

-8125 125 1000 4.8 - 4.2 - 3.6

-8188 188 1500 7.2 - 6.2 - 5.4

-8250 250 2000 9.6 - 8.3 - 7.2

-8375 8’ 375 3000 14.4 - 12.5 - 10.8

-8500 500 4000 19.2 - 16.7 - 14.4

-8564 564 4500 21.6 12.5 18.7 10.8 16.2

-8625 625 5000 24.0 13.9 20.8 12.0 18.0

-8750 750 6000 28.6 16.5 15.0 14.4 21.6

-10125 125 1250 6.0 - 5.2 - 4.5

-10188 188 1875 9.0 - 7.8 - 6.7

-10250 250 2500 12.0 - 10.4 - 9.0

-10375 10’ 375 3750 18.0 - 15.6 - 13.5

-10500 500 5000 24.0 - 20.8 - 18.0

-10564 564 5640 27.2 15.7 23.5 13.6 20.4

-10625 625 6250 30.0 17.3 26.0 15.0 22.6

-10750 750 7500 36.0 20.8 31.3 18.1 27.0

** Prefix with: CSH07A (7” height heaters)

DSH07A (7” height heaters)

CSH14A (14” height heaters)

DSH14A (14” height heaters)

2

Page 3

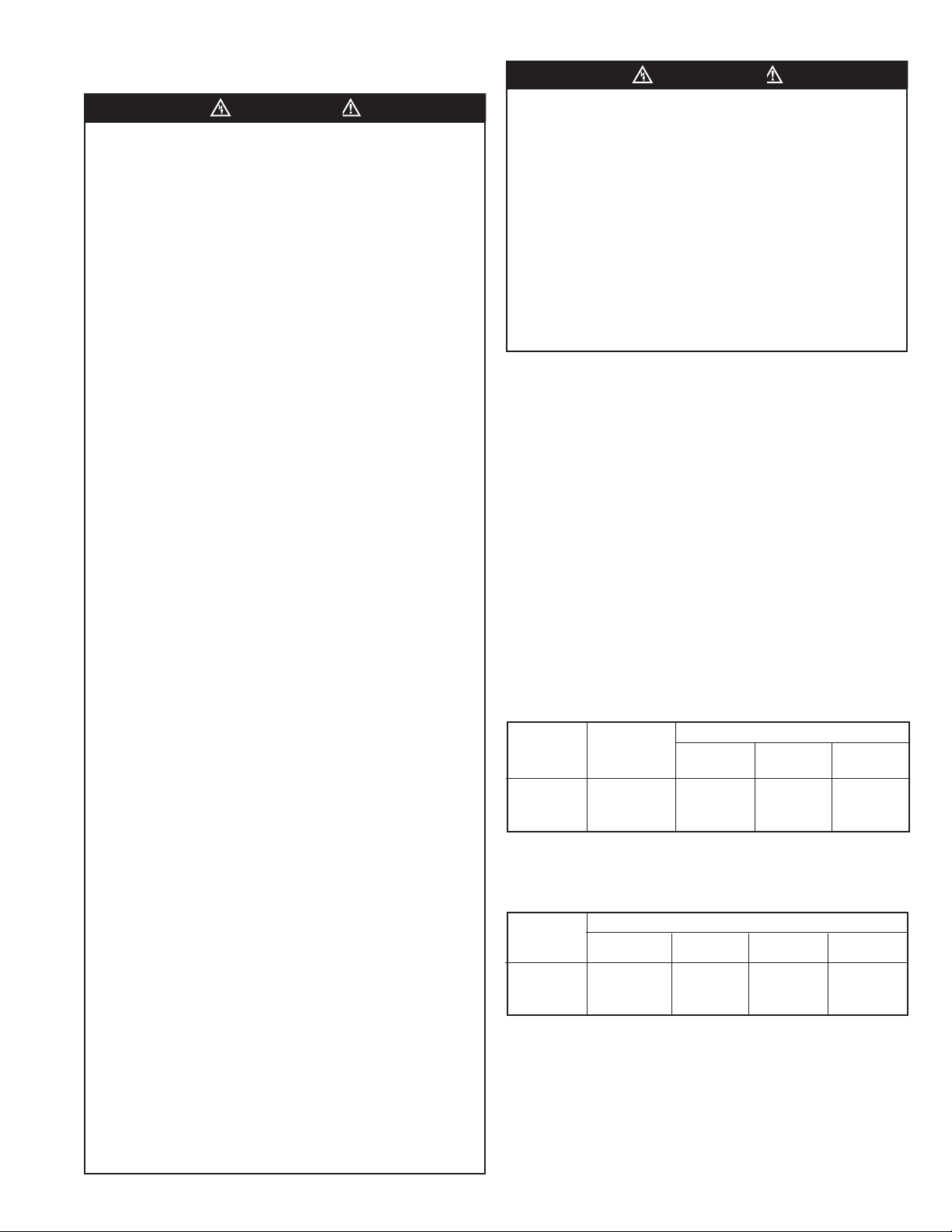

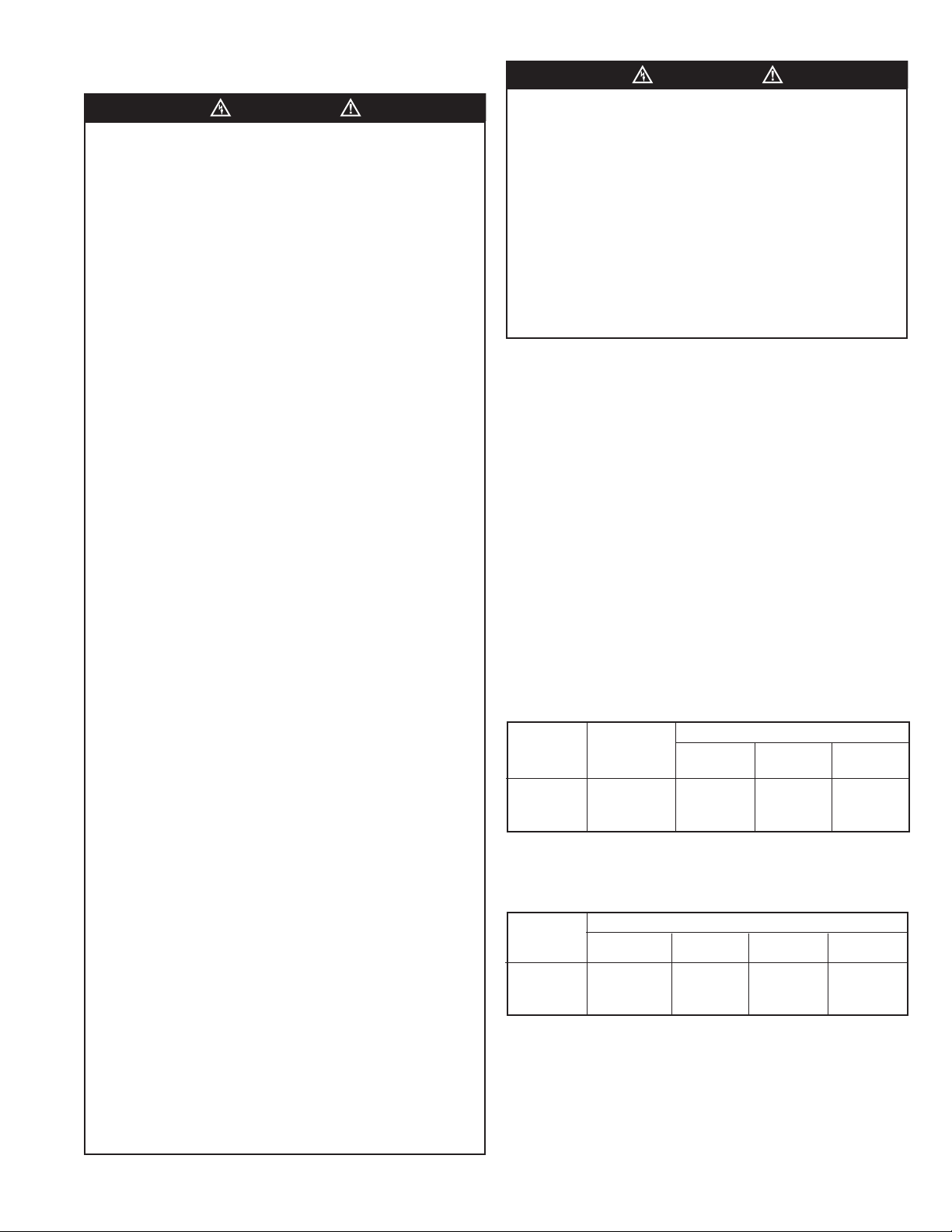

INSTALLATION INSTRUCTIONS

TO REDUCE THE RISK OF FIRE AND ELECTRIC SHOCK

OR INJURY TO PERSONS, OBSERVE THE FOLLOWING:

1. Serious injury or death could result from electric shock.

Make sure electrical power supply circuit coming to heater

is disconnected at main disconnect or service panel before

installing this heater.

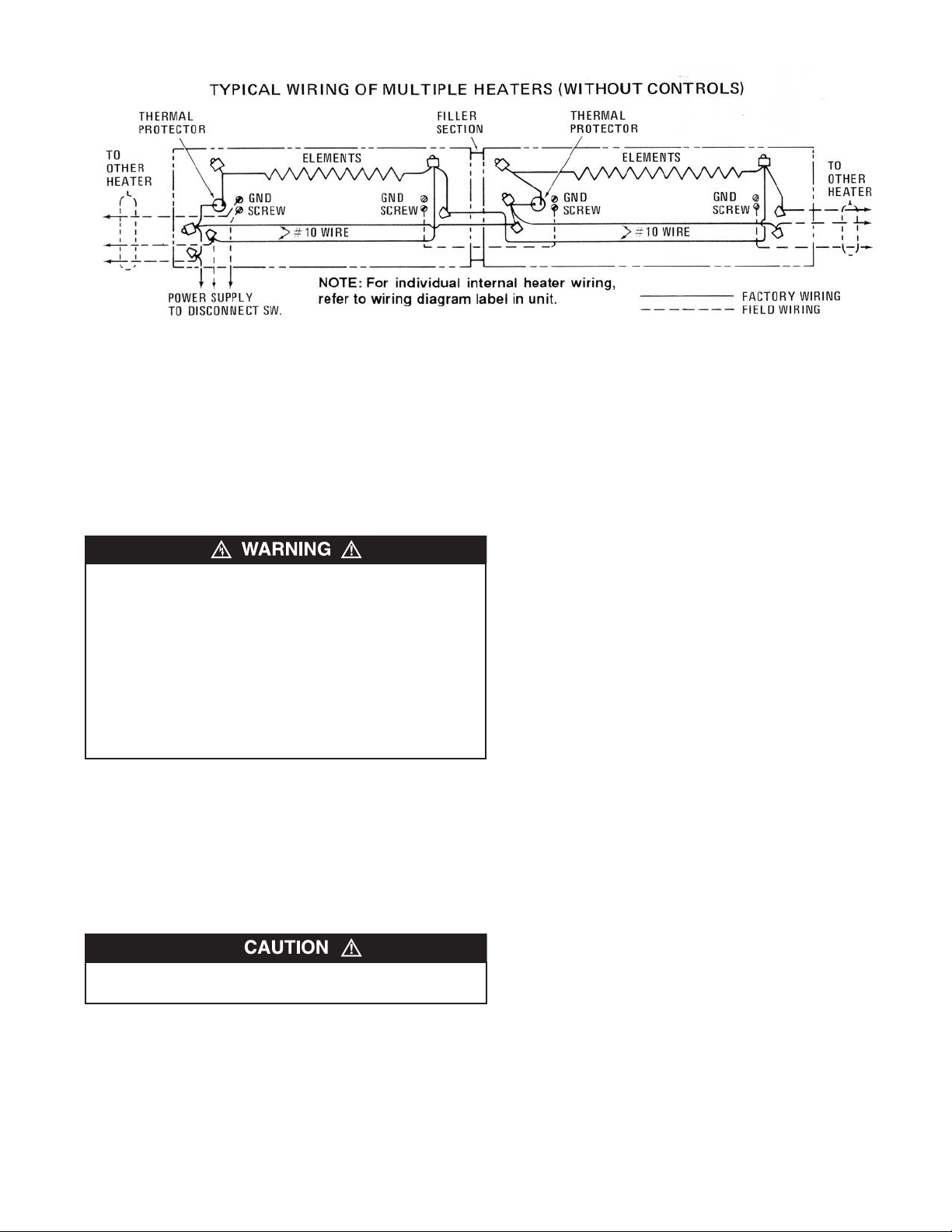

2. Wiring procedures and connections must be in accordance

with the National Electrical Code (NEC) and local codes.

Refer to Wiring Diagram on heater and Figure 8 as well as

Tables B and C. Make sure all electrical connections are

tight to prevent possible overheating. Use Copper Supply

Wire Only.

3. Verify the electrical power supply voltage matches the voltage rating as printed on the heater nameplate.

CAUTION - Never connect a heater to a voltage greater than

the nameplate voltage as this will damage the heater and

could cause a fire.

4. Remove and discard foam packing material inside heater

before installing or energizing the heater.

5. Do not install the heater against combustible low-density

cellulose fiberboard surfaces, against or below vinyl wall

coverings, or below any materials that may be damaged by

heat such as vinyl or plastic blinds, curtains, etc. If heater

must be installed against vinyl surfaces or surfaces that

may be damaged by heat, Standoff Kits Cat. No. S01 or

S02 must be used. Refer to installations instructions

provided with these kits when installing.

6. Do not install heater below an electrical convenience receptacle (outlet).

CAUTION

7.

Electrical Cords (including telephone and computer cables),

Drapes, and Other Furnishings Away From Heater. For efficient and safe operation, we recommend maintaining a minimum of 6 inches (152 mm) clearance above and in front of

the heater at all times. See Clearances Chart for minimum

clearance requirements.

8. To reduce the risk of fire, do not store or use gasoline or

other flammable vapors or liquids in the vicinity of the

heater.

9. Do not install heater upside down or in any position other

than as shown in this manual.

10. Do not recess heater in wall or install heater inside any type

enclosure (unless specifically approved by the manufacturer) as this will cause heater to overheat and could create a

hazard.

11. When mounting heater, use care when drilling mounting

holes and mounting heater to building structure to avoid

damaging internal heater components. Be sure to loosen

mounting screws 1/4 to 3/4 turn to allow for expansion and

contraction.

12. Do not remove or bypass the safety limit control(s) as this

could allow heater to become a fire hazard – see heater

wiring diagram supplied with heater.

13. The factory installed wires inside wireway are used to connect the built-in controls. Limit the maximum current to no

more than 35 amps for CSH05 and DSH05 units and 45

amps for CSH07, DSH07, CSH14 and DSH14 units. Refer

to instructions and current capacity rating as provided with

the accessory.

– Heater Operates at High Temperatures. Keep

14. Heaters that are not installed end to end must have end

caps installed to cover exposed ends of heater. Heaters

joined together must have appropriate filler sections or

other approved assemblies (see Accessories Data listing

on Page 8) installed to cover exposed openings between

heaters.

15. All field wiring brought into the heater or any attached

accessories must be rated at least 75 °C.

16. Do not allow objects to be placed on top of heater as they

may be damaged or create a fire hazard.

17. Before energizing, make sure front cover is properly

installed onto the back housing along the entire length of

the heater – See Fig. 4. Do not operate heater without front

cover installed.

Rough-in Wiring

1. Run branch circuit of proper voltage and wire size to location

of left or right junction box as indicated on heater wiring diagram. Basic heaters are prewired and can be connected to

branch circuit at either end. Heaters with controls are

prewired for connection to branch circuit at one end only

(refer to heater wiring diagram), however, heater can be

wired from opposite end by running wire through heater wireway.

2. If it is necessary to run wires through the heater wireway,

use Table B to size the field installed wiring.

3. The factory installed wires in the heater wireway can be

loaded up to 35 amps in CSH05 and DSH05 units, and up to

45 amps in, CSH05, CSH14, DSH07 and DSH14 units.

Refer to Table C and D for maximum length of heater run

when the heaters are connected in parallel.

Table B. Sizing Field Installed Wiring

Copper Maximum no.

wire size of wires Up to 3 4 to 6 7 thru 9

75º C in wireway Conductors Conductors Conductors

No. 12 AWG 9 11.5 amps 9.3 amps 8.1 amps

No. 10 AWG 8 17.4 amps 14.0 amps 12.1 amps

No. 8 AWG 4 24.0 amps 21.0 amps –

Table C. Maximum Length of Heater Run

(CSH05-1Ø; DSH05-1Ø)

Watts/Ft. of Maximum allowable length of heater run (feet)

the heaters 120 Volts 208 Volts 240 Volts 277 Volts

125 33 58 67 77

188 22 38 44 51

250 16 29 33 38

Note:

For mix of watt densities, calculate amp draw. Do not

exceed values indicated in step 3 above.

Maximum allowable current

3

Page 4

Thermostat

HEATER

HEATERS

BUTTED

TOGETHER

HEATER

FILLER

SECTION

HEATER

INSIDE

CORNER

HEATER

OUTSIDE

CORNER

HEATER

END

CAP

TYPICAL INSTALLATION

SPLICE PLATE

KIT

SPLICE PLATE

KIT

24 amps @ 120-240 VAC

22 amps @ 277 VAC

Pilot duty– 125 VAC (all voltages)

Transformer relay

05A units: 22 amps @ 120-240 VAC

19 amps @ 277 VAC

07A-14A Units: 25 AMPS @ 120-240 VAC

22 AMPS @ 277 VAC

Power relay

25 amps @ 120-277 VAC- see wiring diagram on heater

Disconnect switch

20 amps @ 120-277 VAC

4. Standard 75ºC wiring must be used in junction boxes, wireways, blank sections, filler sections, and corner sections.

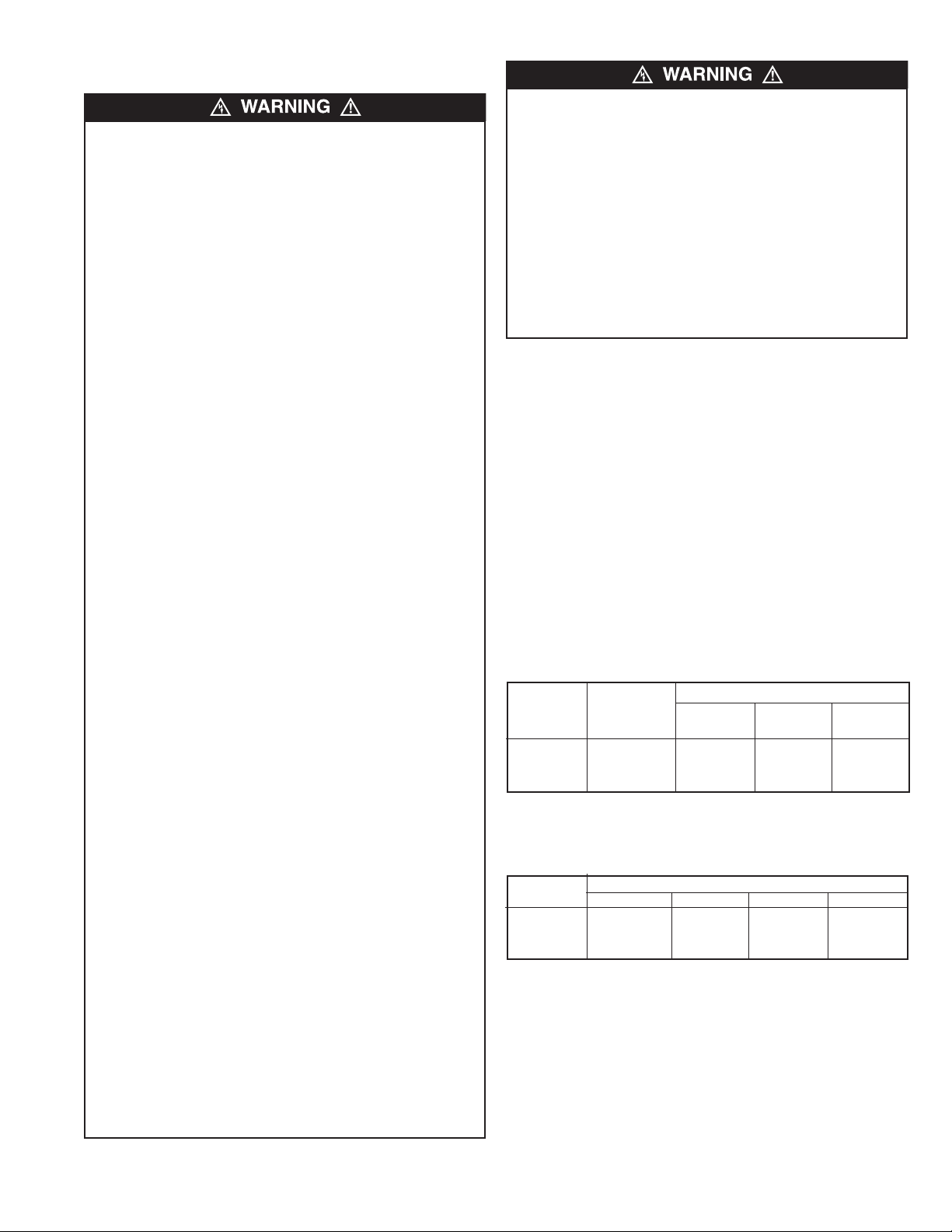

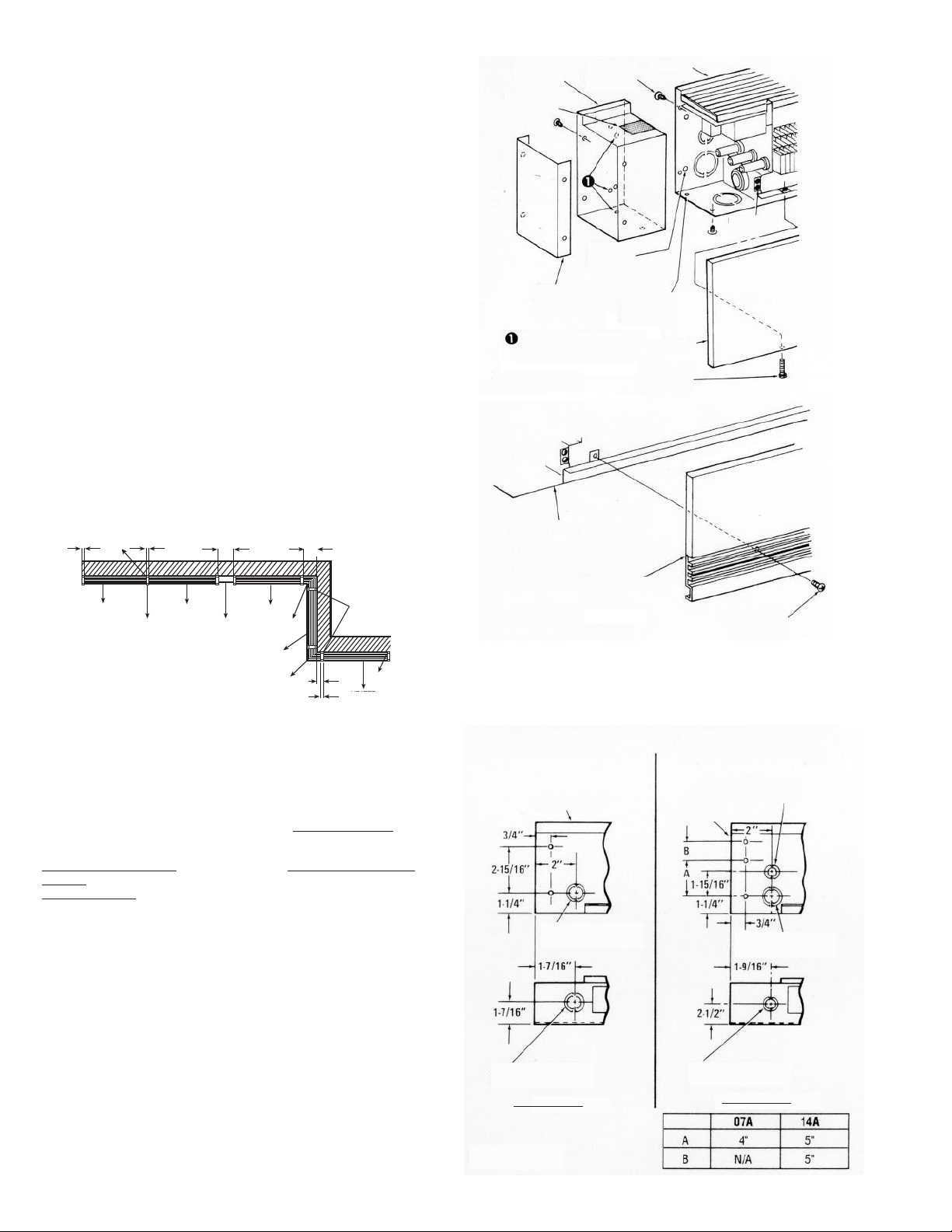

Room Layout

Refer to heating plans for exact room arrangements of heaters

(with or without thermostat and/or relays and/or switches and

accessories.)

Check the heater section dimensions and the additional wall

length required for telescoping accessories (Figure 1) before

starting wall-to-wall type installation. Be certain all heaters and

accessories needed are at hand and are of correct finish.

10

N

7

N

3

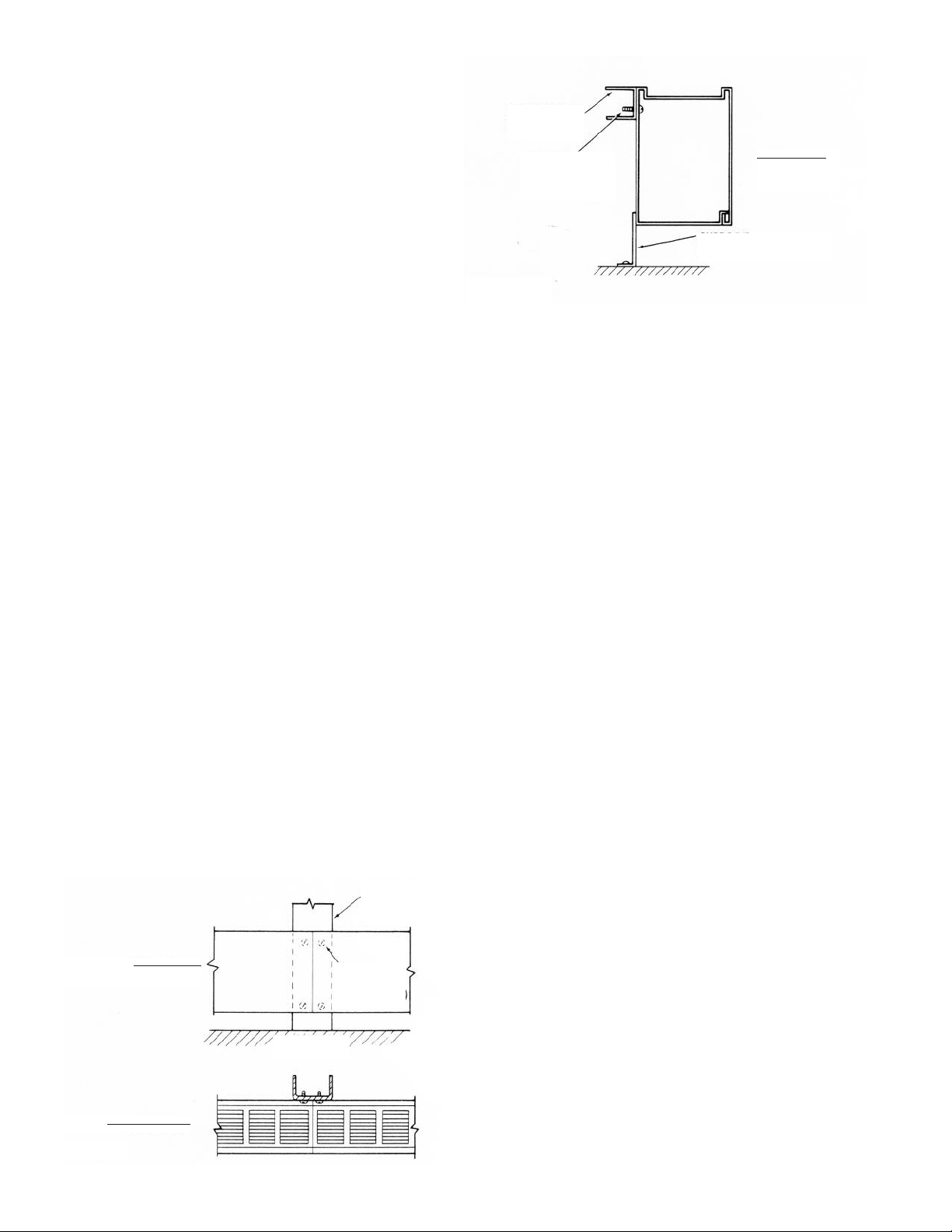

Figure 1

Typical Installation

See page 9 for N dimensions

N

2

4

1

N

10

8

N

5

6

N

9

Figure 2

Mounting Height

At correct height, draw a pencil line on the wall, level and/or parallel with the window sill. Minimum mounting heights above the

floor shall be as follows:

Minimum Mounting Height Above Floor

Watts/Ft. Heater Length Bottom Inlet/Front Inlet

125, 188 and 250 Watts/Ft. 1-3/4” 0”

376, 500, 625, and 750 3” 0”

Watts/Ft.

Note:

Up to 3/4” thick floor covering, such as carpet, tiles,

linoleum, etc., may be installed around and under the heater

without adversely affecting the performance of the heaters.

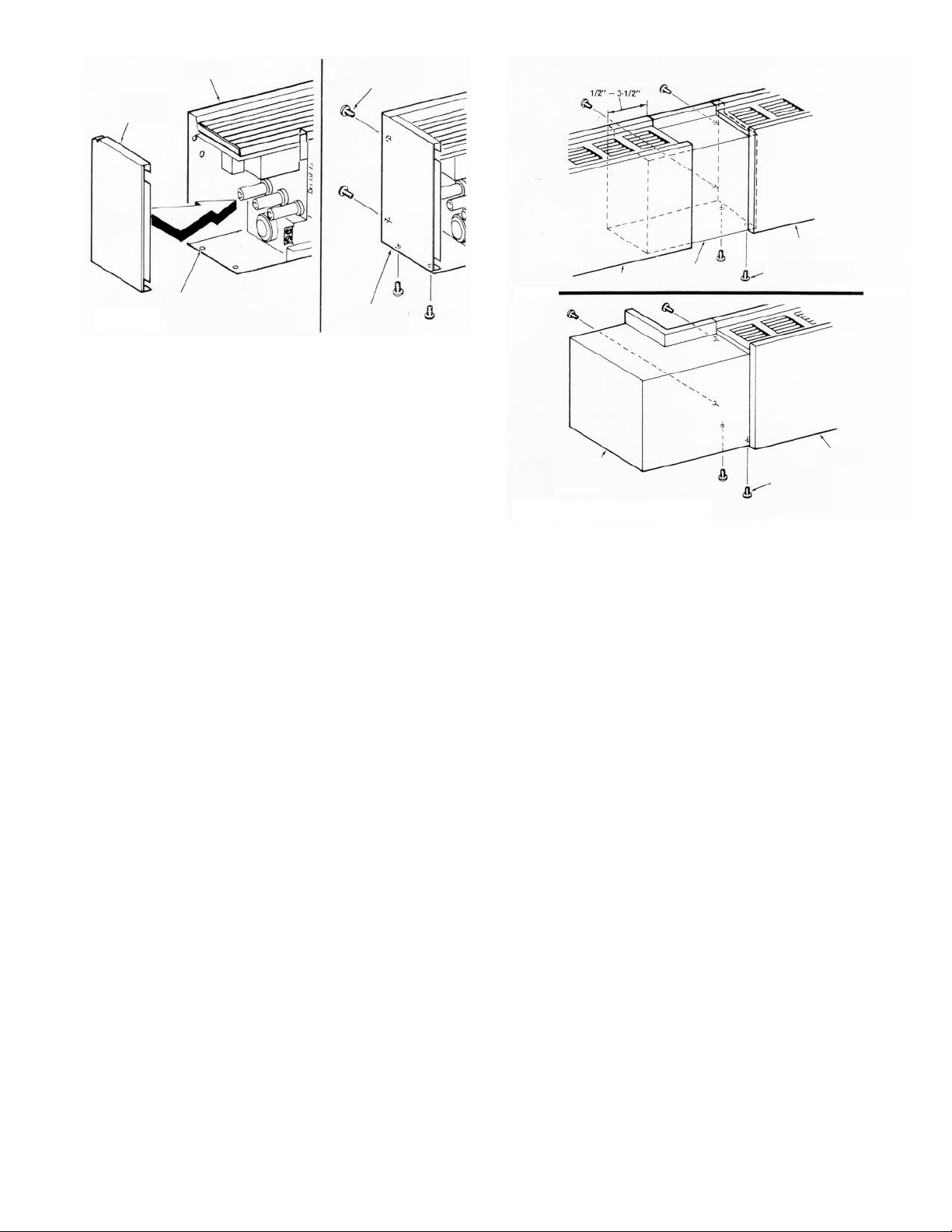

Installation of Single Unit

Note:

For ease of installation, it is important that the sequence

of operations indicated below be followed in order.

1. Remove front cover by removing mounting screws (Figure

2).

2. Remove appropriate electrical knockout from either junction

box. See Figure 3 for location of knockouts.

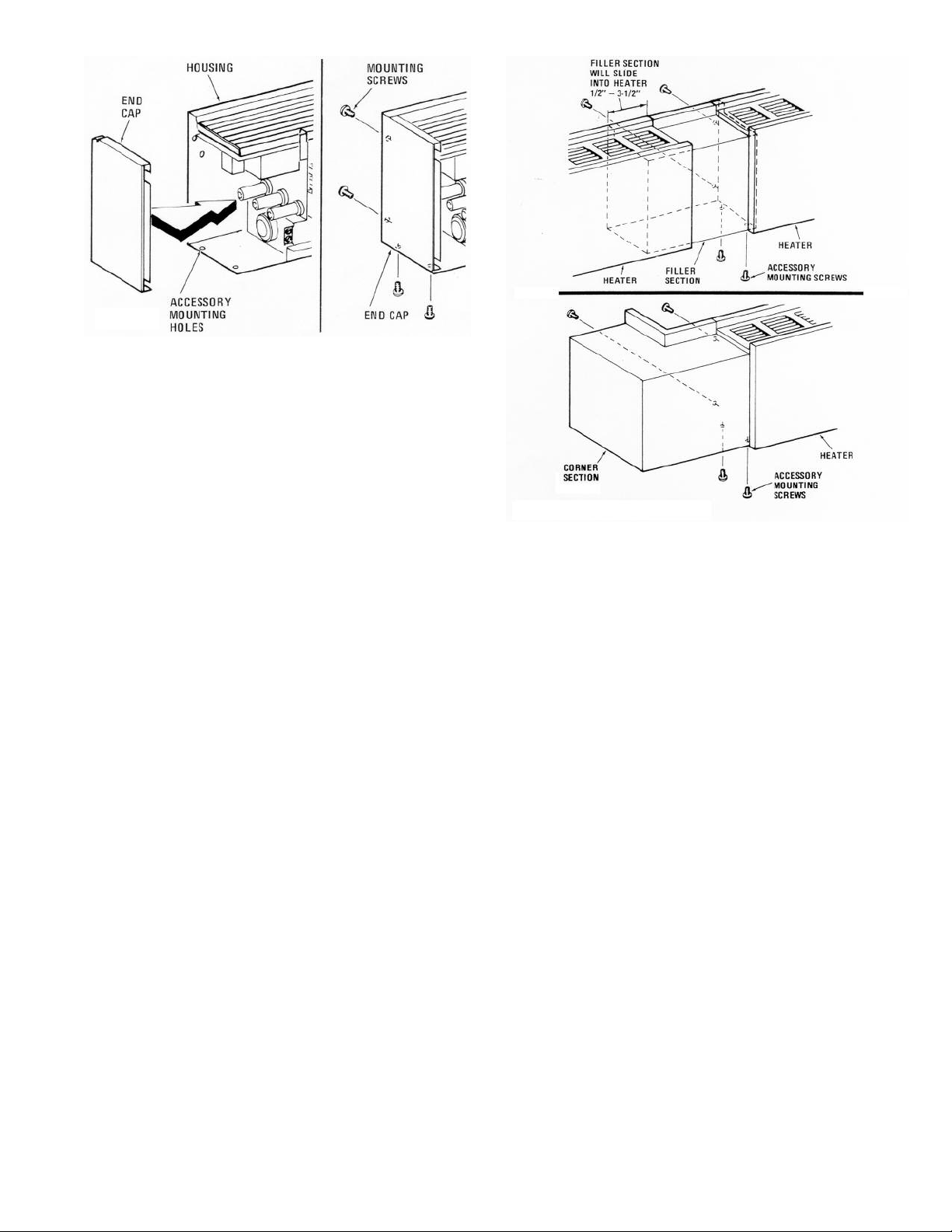

3. Install end caps (must be purchased separately) on both

ends of the heater housing. Refer to Figure 4 for details of

end cap installation.

Figure 3

4

Page 5

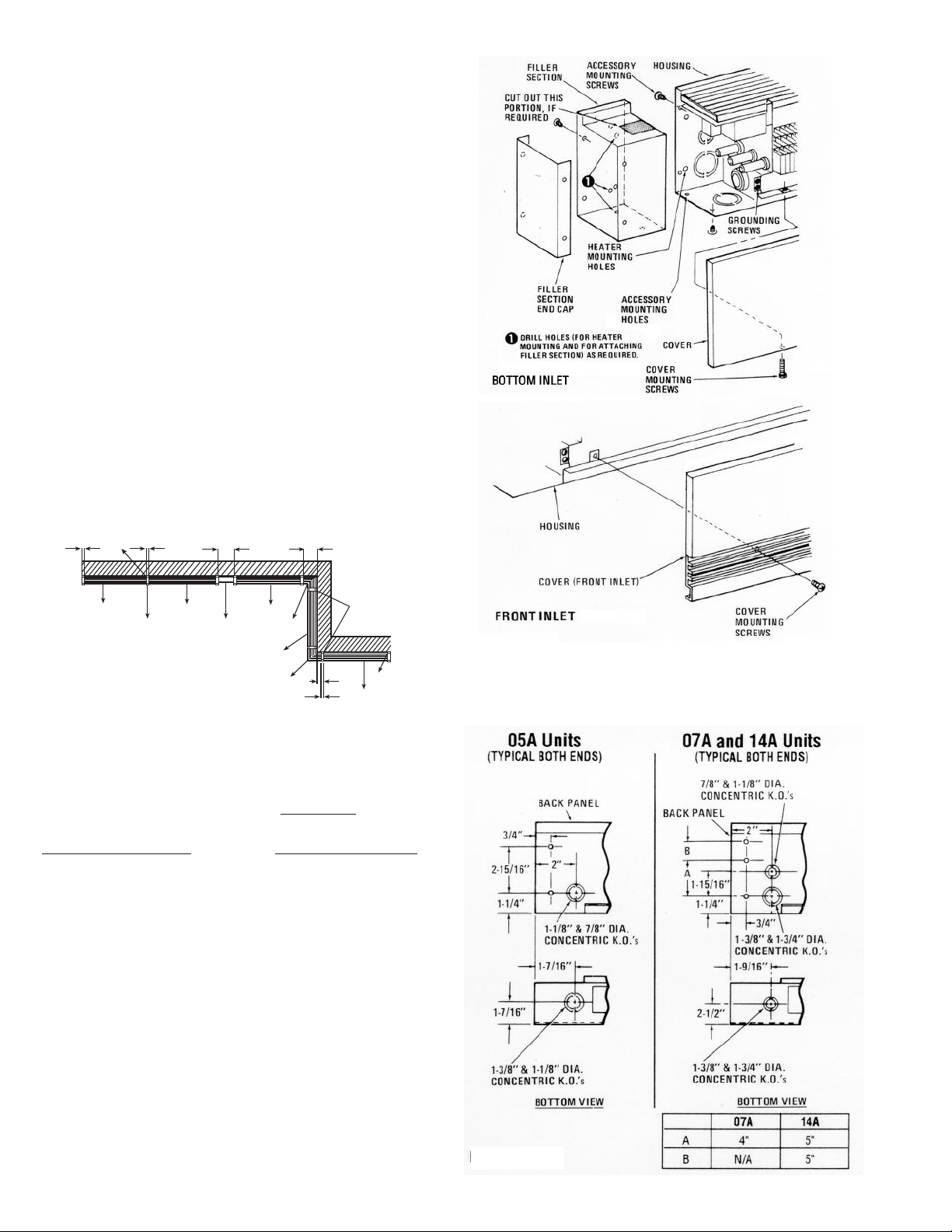

Figure 4

4. If filler section is desired to terminate the heater, install the

filler section in the end of the heater and extend to desired

length. Mark the mounting hole locations, remove the filler

section and drill the required mounting holes. Install the filler

section in the heater and the end cap on the filler section as

shown in Figure 2.

Note:

If a thermostat and/or disconnect switch are installed in

the heater left junction box, it may be necessary to cut away a

portion of the filler section to allow access to these controls

(Figure 2).

5 Position heater housing on wall to check for evenness of

wall. do not draw the heater against an uneven wall surface.

If an uneven wall is encountered, use shims to keep the

heater housing straight.

6. Run proper size branch circuit to the junction box through the

selected knockout.

7. Drill the required size mounting holes in the back of the

heater housing and install the housing on the wall using

screws, bolts or anchors (by installer) to suit the wall construction.

Note:

Predrilled 1/4” diameter mounting holes are provided in

each junction box. Additional mounting holes will have to be

drilled in the housing to support the weight of long length

heaters (6’ and longer). Do not drill any additional holes in the

junction boxes.

8. Tighten mounting screws and back off 1/4 to 3/4 turn to

allow for expansion and contraction of the heater.

9. Following the wiring diagram secured to the heater, make

electrical connections. Ground the heater using the ground

screws provided (Figure 2).

10. Replace front cover and secure with mounting screws. (See

Figure 2).

Figure 5

Installation of Multiple Wall to Wall Units

Note:

For ease of installation, it is important that the sequence

of operations indicated below be followed in order.

1. Remove all the front covers from the heaters by removing

mounting screws (Figure 2).

2. Refer to wiring diagram for power supply entry and remove

appropriate electrical knockout (Figure 3) from the heater in

which power supply connections are to be made. The power

supply may be brought in to the end of only one heater and

the remaining heaters may be connected in parallel using the

wireway. Use Table B to size the field installed wiring in the

wireway.

3. If conduit cover (must be purchased separately) is desired,

cut off the appropriate length and install to the wall.

4. If required by plan, install filler section (1, Figure 1) to either

heater (2) or (3) by means of four #6 screws supplied with

filler section. (Refer to Figure 5.) Discard filler section end

cap in this application.

Note:

Heaters may butt against each other, thus eliminating the

filler piece, if so desired.

Note:

If a heater has a disconnect switch and / or thermostat

and is to have a filler section or a corner section at the left end,

the section must be mounted to the heater since the thermostat

or disconnect switch will prevent the section from telescoping

into the heater.

5 If the wall run has inside or outside corners, install corner (4

and 5) to the heater (2 and 9) by means of four #6 screws

supplied with corner section. (Refer to Figure 5).

6. Install end caps (6) on the outer end of the last heater(7) and

(9) using four #6 screws supplied with end caps. (Refer to

Figure 4 for details of end cap installation.)

7. Drill the required size mounting holes in all the heater hous-

ings.

5

Page 6

Note:

Predrilled 1/4” diameter mounting holes are provided in

each junction box. These holes may be used only when no slipin accessory is to be installed in that end of the heater ( such as

when heater(3 and 7) are butted together as shown in Figure 1).

Additional mounting holes will have to be drilled in the housing

to support the weight of long-length heaters (6’ and longer). Do

not drill any additional holes in junction boxes.

8. Check for evenness of wall. Do not draw the heaters

against an uneven wall surface. If an uneven wall is

encountered, use shims to keep the heater housing

straight.

9. Run proper size branch circuit to the junction box through

the selected knockout.

10. Mount the heater (2, Figure 1) on the wall using screws,

bolts or anchors (by installer) to suit the wall construction.

11. Telescope the heater housing (3) over the filler section (1)

by the desire amount and mount the housing to the wall.

12. Telescope the heater housing (8) over the corner section

(4) by the desired amount and mount the housing to the

wall.

13. Mount the remaining heaters as described above, making

sure that the heaters with end caps are installed at the end

of the run.

14. Blank sections, if any are installed in the same manner as

the heaters.

Note:

75ºC field wiring may be run through the blank sections,

filler sections and corner sections.

15. Control sections, if any, are installed in the same manner

as heaters. Refer to wiring diagram on control sections for

connecting the wiring to the heaters

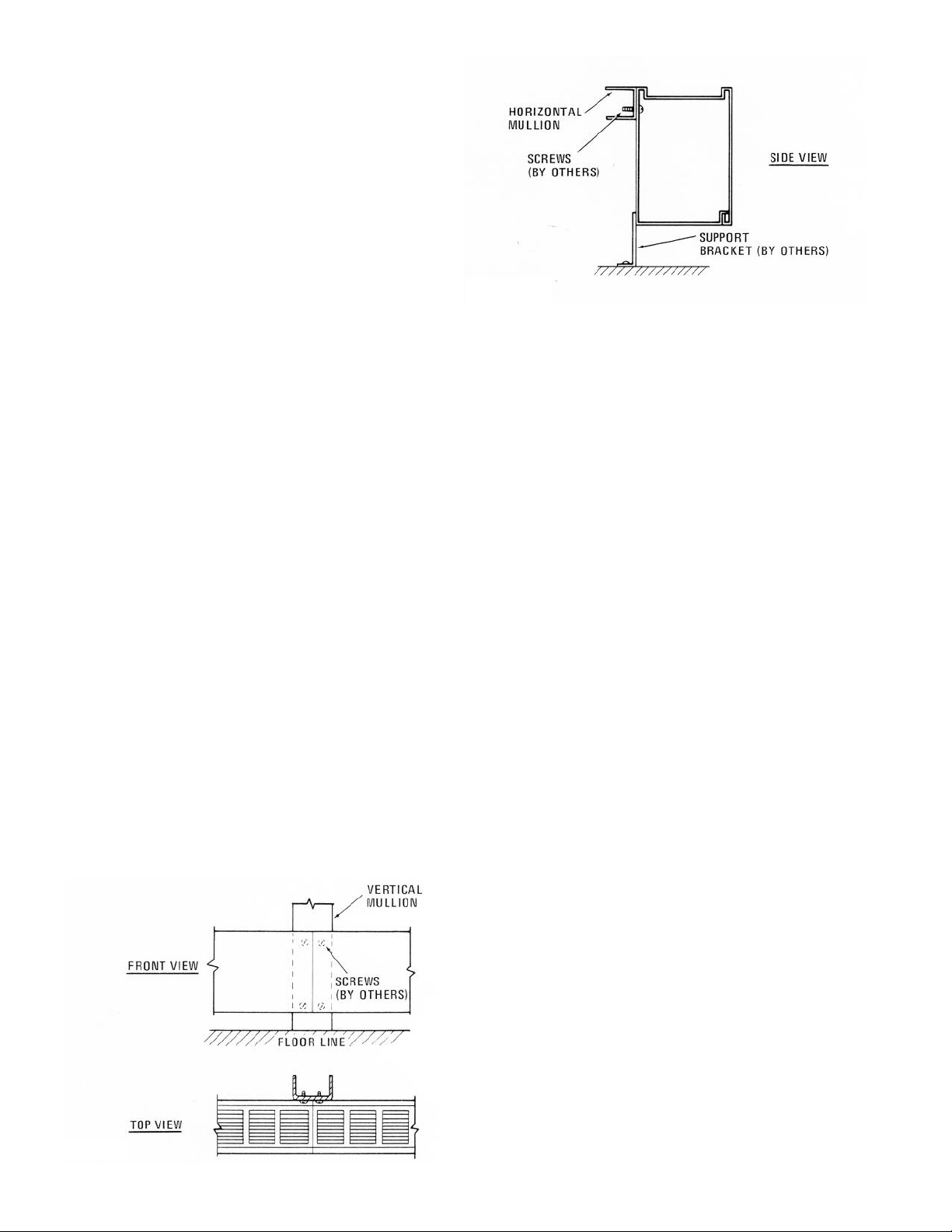

Installation of Mullion to Mullion Units

The back of the heater housing contains no mounting holes

(other than those at the ends) and therefore is ideal for installation in front of glass curtain walls. The housing back presents

an attractive appearance when viewed from the outside through

the glass wall.

Installation procedures are similar to those for wall-to-wall installation (Step Six) except for the following differences.

1. Attach the housing to the mullion using the mounting holes

provided in the junction boxes as shown in Figure 6.

2. On horizontal mullion installation, install support brackets as

shown in Figure 7.

Figure 7

OPERATION INSTRUCTIONS

1. After heaters are completely assembled and installed, set

thermostat or operating controls for NO HEAT and energize

heater circuit (s). Verify the heaters are not producing heat.

2. Adjust thermostat or operating control to call for heat. Allow

heater(s) to operate for a few minutes and verify the heaters

are producing heat.

3. The thermostat or operating controls may be adjusted to

cycle the heater(s) on and off to maintain the desired room

temperature.

Note:

If built-in thermostat is provided, rotation in the clockwise

direction will allow heater to remain on MORE and will maintain a higher room ambient. Likewise, rotation in the counterclockwise direction will result in the heater remaining on

LESS and the room ambient will be lower. If remote thermostat or other types of controls are provided, refer to the

instructions provided with these controls for proper operation.

Figure 6

6

Page 7

Figure 8 - Wiring Diagram

MAINTENANCE INSTRUCTIONS

For efficient and safe operation and to extend the life of the

heaters, they should be cleaned and inspected for damage at

least annually (preferably at the beginning of the heat season)

or more often in dirty environments. Other than cleaning, your

heaters require no other preventative maintenance. The user

and / or cleaning personnel can perform routine cleaning of the

heater that may be done without disassembly of the heater.

However, any cleaning or servicing that requires disassembly of

the heater must be done by qualified service personnel.

SERIOUS INJURY OR DEATH COULD RESULT FROM

ELECTRIC SHOCK. MAKE SURE ELECTRICAL POWER

SUPPLY CIRCUIT(S) COMING TO HEATER IS/ARE DISCONNECTED AT MAIN DISCONNECT OR SERVICE PANEL

BEFORE CLEANING OR SERVICING THIS HEATER.

ALLOW HEATER TO COOL BEFORE CLEANING TO PREVENT A POSSIBLE BURN.

NOTE:

HEATER. BE SURE ALL POWER IS DISCONNECTED TO

HEATER BEFORE CLEANING OR SERVICING.

1. Heater cabinet may be cleaned using a damp cloth to

2. A vacuum cleaner and /or compressed air may be used to

FINS ARE SHARP AND MAY CAUSE CUTS SO AVOID

CONTACT.

3. After cleaning and servicing, always reassemble replacing

MORE THAN ONE POWER SOURCE MAY ENTER

remove dust that may have accumulated on surfaces. Do

not use harsh cleaners and waxes on surfaces since these

could damage the finish or discolor in use.

remove dust and lint that may have accumulated inside

heater around element fins. If heater must be disassembled

for cleaning, use care when cleaning element fins to avoiding

damaging fins.

any hardware removed and check units to make sure they

are operating properly.

789

Page 8

Page 9

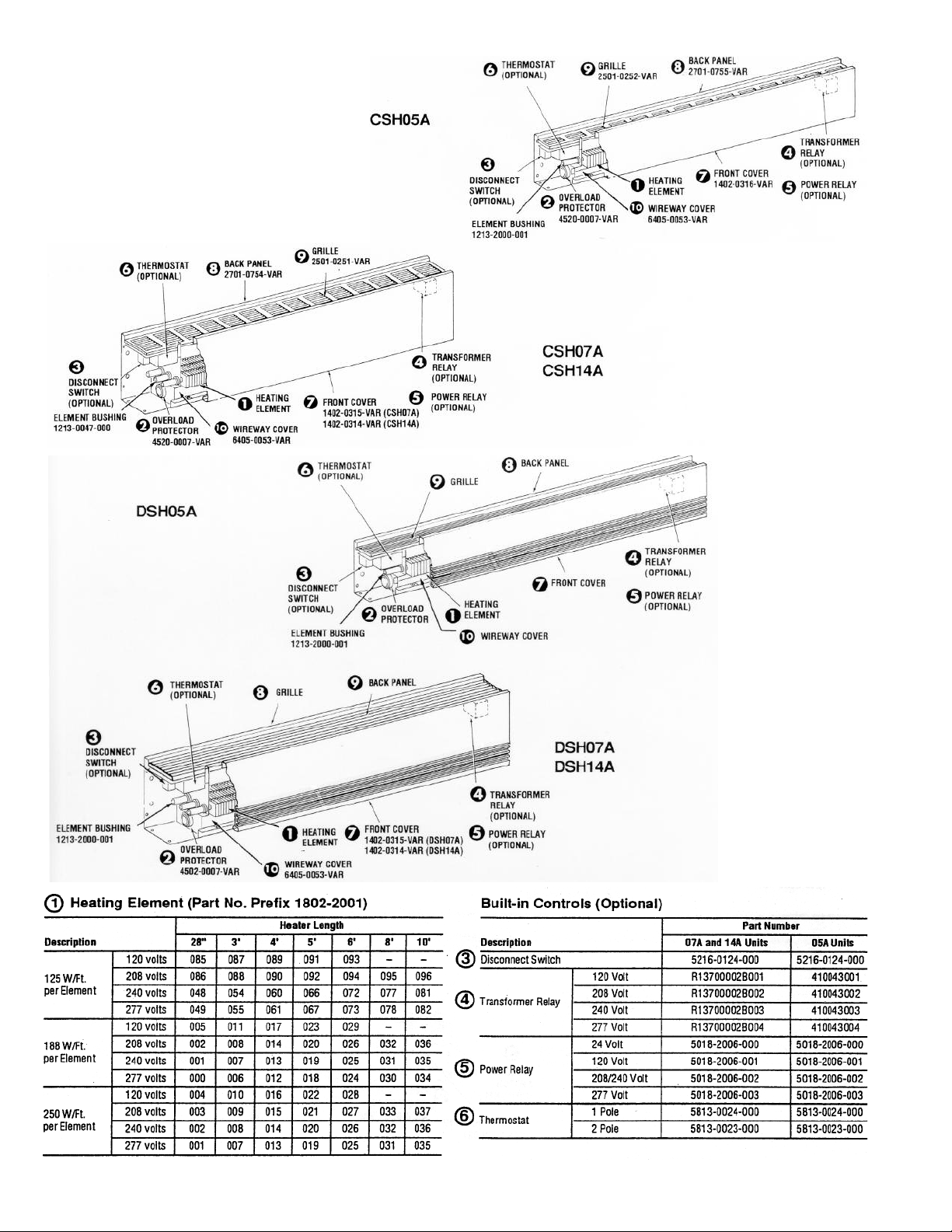

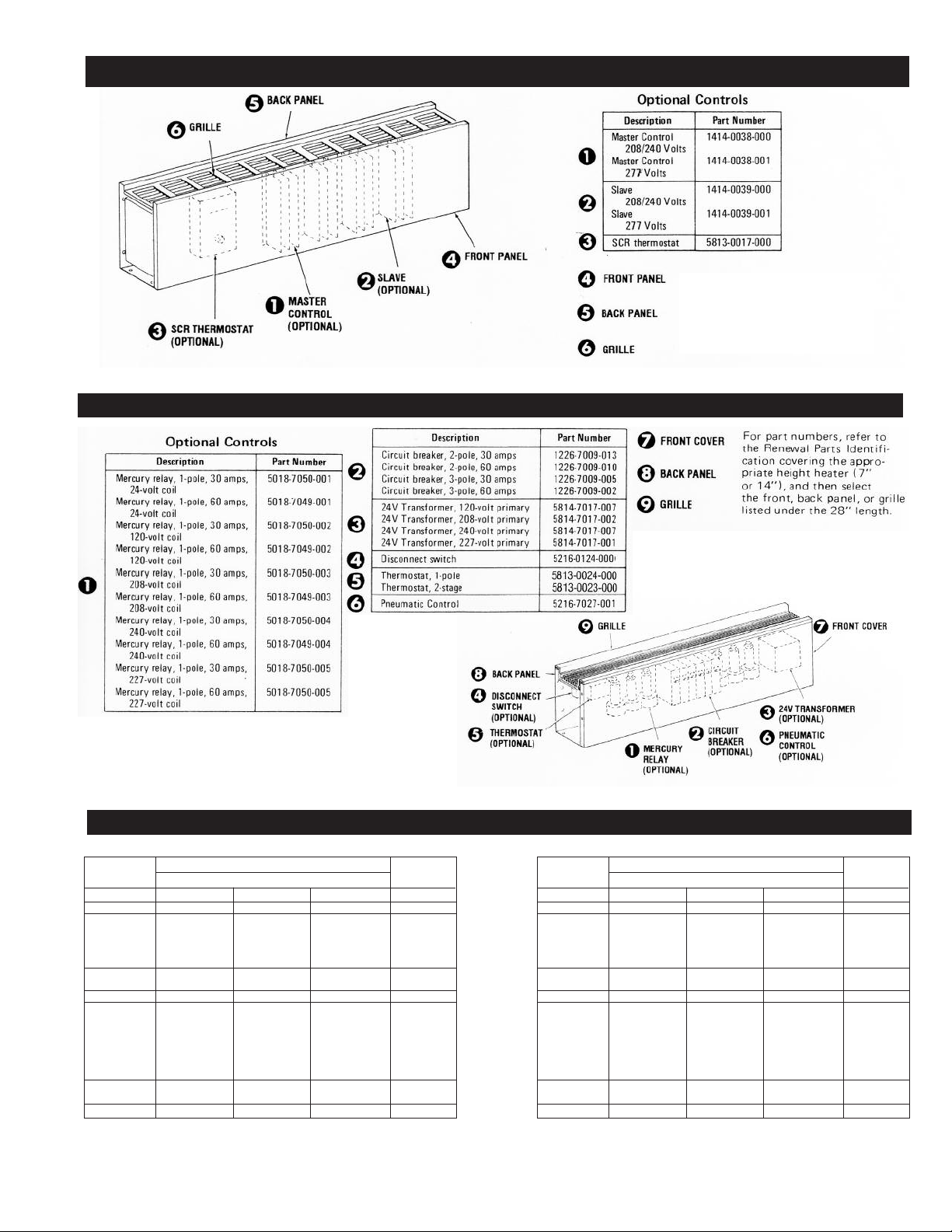

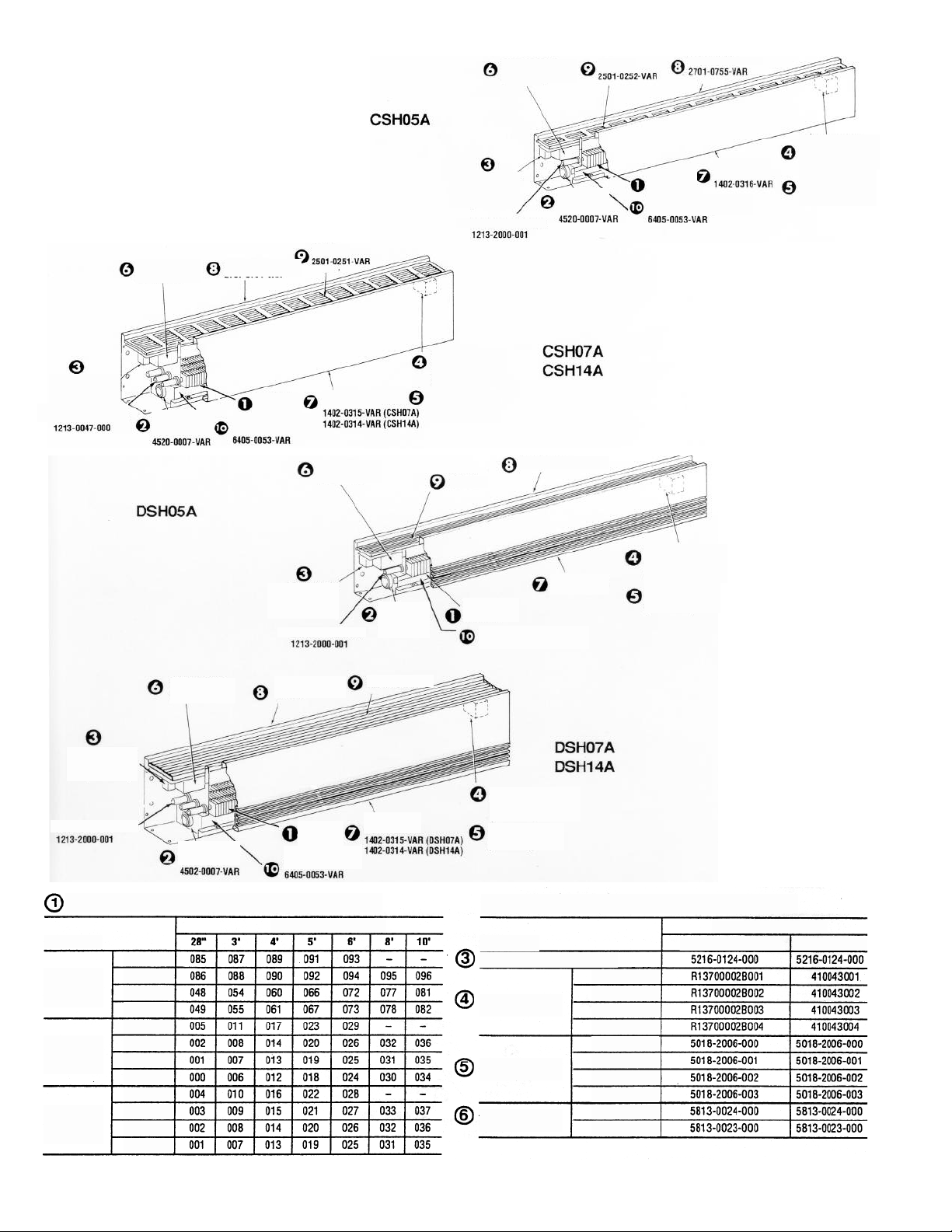

RENEWAL PARTS IDENTIFICATION CSHCSA, DSHCSA

For part numbers, refer to the Renewal

arts Identification covering the appro-

P

priate height heater (7” or 14”), and

then select the front, back panel, or

grille listed under the 28” length.

RENEWAL PARTS IDENTIFICATION CSHCRA, DSHCRA

CSH05A, CSH07A and CSH14A

—

—

Catalog Number

CSH07-ECL(R)

CSH07-ECR(R)

CSH07-FL3(R)

CSH07-FL6(R)

CSH07-FL9(R)

CSH07-FL12(R)

CSH07-FL18(R)

—

CSH07-IC1

CSH07-OC-1

CSH07-BL2-1

CSH07-BL3-1

CSH07-BL4-1

CSH07-BL5-1

CSH07-BL6-1

CSH07-BL8-1

CSH07-BL10-1

CSH07-BCS-1

†

SHCC-07-14

CSH14-ECL(R)

CSH14-ECR(R)

CSH14-FL3(R)

CSH14-FL6(R)

CSH14-FL9(R)

CSH14-FL12(R)

CSH14-FL18(R)

—

CSH14-IC-1

CSH14-OC-1

CSH14-BL2-*

CSH14-BL3-*

CSH14-BL4-*

CSH14-BL5-*

CSH14-BL6-*

CSH14-BL8-*

CSH14-BL10-*

CSH14-BCS-*

†

SHCC-07-14

Description

End Cap-Left

End Cap-Right

Filler

Section

Inside Corner

Outside Corner

Blank Section

Blank Control

Section

Conduit Cover

* Add suffix “1” for bottom inlet top outlet.

Add suffix “3” for bottom inlet front outlet.

† Intended for the installation of components.

(R) Suffix on catalog number refers to accessories with 120 VAC receptacle.

CSH05A CSH07A CSH14A

CSH05-ECL(R)

CSH05-ECR(R)

CSH05-FL3(R)

CSH05-FL6(R)

CSH05-FL9(R)

CSH05-FL12(R)

CSH05-FL18(R)

CSH05-IC1

CSH05-OC-1

CSH05-BL2-1

CSH05-BL3-1

CSH05-BL4-1

CSH05-BL5-1

CSH05-BL6-1

CSH05-BL8-1

CSH05-BL10-1

SHCC-05

ACCESSORIES DATA

Length

Addition “N”

1/8"

1/8"

0" 3"

3" 6"

6" 9"

9" 12"

15" 18"

3-12''

5-1/2''

1/2''

28''

3'

4'

5'

6'

8'

10'

28''

—

Description

End Cap-Left

End Cap-Right

Filler

Section

Inside Corner

Outside Corner

Blank Section

Blank Control

Section

Conduit Cover

* Add suffix “1” for bottom inlet, top outlet, add suffix “2” for front inlet, top outlet.

† Intended for the installation of components.

(R) Suffix on catalog number refers to accessories with 120 VAC receptacle.

DSH05A, DSH07A and DSH14A

Catalog Number

DSH05A DSH07A DSH14A

DSH05-ECL(R)

DSH05-ECR(R)

DSH05-FL3(R)

DSH05-FL6(R)

DSH05-FL9(R)

DSH05-FL12(R)

DSH05-FL18(R)

DSH05-IC1

DSH05-OC-1

DSH05-BL2-1

DSH05-BL3-1

DSH05-BL4-1

DSH05-BL5-1

DSH05-BL6-1

DSH05-BL8-1

DSH05-BL10-1

SHCC-05

—

—

DSH07-ECL(R)

DSH07-ECR(R)

DSH07-FL3(R)

DSH07-FL6(R)

DSH07-FL9(R)

DSH07-FL12(R)

DSH07-FL18(R)

—

DSH07-IC1

DSH07-OC-1

DSH07-BL2-1

DSH07-BL3-1

DSH07-BL4-1

DSH07-BL5-1

DSH07-BL6-1

DSH07-BL8-1

DSH07-BL10-1

DSH07-BCS-1

†

SHCC-07-14

DSH14-ECL(R)

DSH14-ECR(R)

DSH14-FL3(R)

DSH14-FL6(R)

DSH14-FL9(R)

DSH14-FL12(R)

DSH14-FL18(R)

DSH14-IC1

DSH14-OC-1

DSH14-BL2-1

DSH14-BL3-1

DSH14-BL4-1

DSH14-BL5-1

DSH14-BL6-1

DSH14-BL8-1

DSH14-BL10-1

DSH14-BCS-1

SHCC-07-14

Length

Addition “N”

1/8"

1/8"

0" 3"

3" 6"

6" 9"

9" 12"

15" 18"

—

†

3-12''

5-1/2''

1/2''

28''

3'

4'

5'

6'

8'

10'

28''

—

Page 10

All products manufactured by Marley Engineered Products are warranted against defects in workmanship and materials for one year from date of installation, except

LIMITED WARRANTY

heating elements which are warranted against defects in workmanship and materials for five years from date of installation. This warranty does not apply to damage from

accident, misuse, or alteration; nor where the connected voltage is more than 5% above the nameplate voltage; nor to equipment improperly installed or wired or

maintained in violation of the product’s installation instructions. All claims for warranty work must be accompanied by proof of the date of installation.

The customer shall be responsible for all costs incurred in the removal or reinstallation of products, including labor costs, and shipping costs incurred to return products

to Marley Engineered Products Service Center. Within the limitations of this warranty, inoperative units should be returned to the nearest Marley authorized service center or the Marley Engineered Products Service Center, and we will repair or replace, at our option, at no charge to you with return freight paid by Marley. It is agreed that

such repair or replacement is the exclusive remedy available from Marley Engineered Products.

THE ABOVE WARRANTIES ARE IN LIEU OF ALL OTHER WARRANTIES EXPRESSED OR IMPLIED, AND ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE WHICH EXCEED THE AFORESAID EXPRESSED WARRANTIES ARE HEREBY DISCLAIMED AND EXCLUDED FROM

THIS AGREEMENT. MARLEY ENGINEERED PRODUCTS SHALL NOT BE LIABLE FOR CONSEQUENTIAL DAMAGES ARISING WITH RESPECT TO THE

PRODUCT, WHETHER BASED UPON NEGLIGENCE, TORT, STRICT LIABILITY, OR CONTRACT.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above exclusion or limitation may not apply to you. This warranty gives

you specific legal rights, and you may also have other rights which vary from state to state.

For the address of your nearest authorized service center, contact Marley Engineered Products in Bennettsville, SC, at 1-800-642-4328. Merchandise returned to the factory must be accompanied by a return authorization and service identification tag, both available from Marley Engineered Products. When requesting return authorization,

include all catalog numbers shown on the products.

HOW TO OBTAIN WARRANTY SERVICE AND

WARRANTY PARTS PLUS GENERAL INFORMATION

1. Warranty Service or Parts

2. Purchase Replacement Parts

3. General Product Information

Note:

When obtaining service always have the following:

1. Model number of the product

2. Date of manufacture

3. Part number or description

Part No. 5200-2674-001

1-800-642-4328

1-800-654-3545

www.marleymep.com

ECR 38636

11/10

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

Page 11

Calefactores de convección

CSH y DSH

Calefactores de convección comerciales a altura

de antepechos de ventanas

(Tipo CSH)

Calefactores de convección decorativos a altura

de antepechos de ventanas

(Tipo DSH)

Instrucciones de instalación, operación y mantenimiento

INSTRUCCIONES IMPORTANTES

GENERALIDADES

Este calefactor está diseñado para proporcionar años de funcionamiento eficiente sin problemas como fuente de calor principal o complementaria

para calefacción en aplicaciones residenciales y comerciales. Los calefactores de convección CSH y DSH deben controlarse termostáticamente

para lograr un funcionamiento eficiente y seguro. No se suministra termostato con este calefactor. Sin embargo, en su sitio de compra se pueden

conseguir termostatos de uno o dos polos para instalación en este calefactor, o el calefactor puede conectarse a cualquier termostato montado en

pared apropiado que cumpla los requisitos de carga eléctrica. La instalación o uso de este producto de una manera diferente a la descrita en este

documento anulará la garantía y podría resultar en lesiones, daño a la propiedad, o daño permanente al calefactor.

ADVERTENCIA

AL UTILIZAR APARATOS ELÉCTRICOS, SIEMPRE DEBEN

SEGUIRSE PRECAUCIONES BÁSICAS PARA REDUCIR EL

RIESGO DE INCENDIO, DESCARGA ELÉCTRICA Y

LESIONES A PERSONAS, INCLUYENDO LO SIGUIENTE:

1. Lea todas las instrucciones antes de instalar o utilizar el calefactor.

2. Un calefactor tiene en su interior piezas calientes, piezas que

forman arcos eléctricos o paiezas que producen chispa. No

utilice en áreas donde se utilice o almacene gasolina o líquidos inflamables. No utilice en ambientes corrosivos o en

áreas donde se utilicen o almacenen materiales explosivos.

3. Este calefactor está caliente cuando está en uso. Para evitar

quemaduras, no permita que la piel desnuda haga contacto

con las superficies calientes. Mantenga alejados del calefactor los materiales combustibles tales como muebles, almo-

RECEPCIÓN

En el momento de enviar el material, éste estaba en buenas condiciones; y Marley Engineered Products guarda el conocimiento de

embarque autorizado, por lo tanto, cualquier daño oculto debe reportarse inmediatamente a la empresa de transporte para inspección y resolución.

GUARDE ESTAS INSTRUCCIONES

!

hadas, ropa de cama, papeles, ropa y cortinas.

4. Para evitar un posible incendio, no obstruya de ninguna manera las entradas o escape de aire.

5. No inserte ni permita que objetos extraños ingresen a las

aberturas de ventilación o de escape, ya que esto podría

causar una descarga eléctrica, incendio, o podría dañar el

calefactor.

6. Podrían producirse lesiones graves o la muerte por descarga

eléctrica. Antes de instalar o suministrar servicio de mantenimiento a este calefactor, verifique que el circuito de suministro de energía eléctrica que alimenta el calefactor está

desconectado en el interruptor de desconexión principal o

panel de servicio.

Este calefactor no es para uso residencial ni hogareño.

7.

Nota:

Se recomienda guardar las cajas de cartón en una área central

para ser utilizadas según se necesite, según los requisitos del salón. Si

se requiere en orden, la cajas de cartón tendrán que ser etiquetadas

con el número de salón apropiado.

Page 12

ESPECIFICACIONES

Tabla A

Modelo CSH05A, DSH05A (Alt.=5 1/2”; Prof.=3”)

Número de Longitud Watts Amperaje

catálogo* “L” Watts/Pie total 120V 208V 240V 277V

-2125 125 250 2.4 1.2 1.0 0.9

-2188 28” 188 375 3.1 1.8 1.6 1.4

2250 250 500 4.2 2.4 2.1 1.8

-

-3125 125 375 3.1 1.8 1.6 1.4

-3188 3’ 188 564 4.7 2.7 2.4 2.0

3250 250 750 6.2 3.6 3.1 2.7

4125 125 500 4.2 2.4 2.1 1.8

-

-4188 4 188 750 6.2 3.6 3.1 2.7

4250 250 1000 8.3 4.8 4.2 3.6

5125 125 625 5.2 3.0 2.6 2.2

-

-5188 5 188 940 7.8 4.5 3.9 3.4

-5250 250 1250 10.4 6.0 5.2 4.5

-6125 125 750 6.2 3.6 3.1 2.7

-6188 6 188 1125 9.4 5.4 4.7 4.1

-6250 250 1500 12.5 7.2 6.2 5.4

-8125 125 1000 - 4.8 4.2 3.6

-8188 8’ 188 1500 - 7.2 6.2 5.4

-8250 250 2000 - 9.6 8.3 7.2

-10125 125 1250 - 6.0 5.2 4.5

-10188 10’ 188 1875 - 9.0 7.8 6.7

-10250 250 2500 - 12.0 10.4 9.0

* * Prefijo con: CSH05A (calefactores con altura de 5 1/2”)

SH05A (calefactores con altura de 5

D

TABLA DE ESPACIOS LIBRES

Para un funcionamiento seguro y eficiente, siempre mantenga los siguientes espacios libres mínimos:

Entre la parte inferior del calefactor y el piso con acabado:

Modelos con entrada de aire delantera:

•

- Pueden instalarse en el piso. Sin embargo, para lograr el mejor

desempeño, instale la parte inferior del calefactor a aproximadamente 3 pulgadas (76 mm) del piso.

Modelos con entrada de aire inferior (por abajo):

•

- 100-250 watts por pie – 1-3/4 pulgada (44 mm)

- 375-750 watts por pie – 3 pulgada (76 mm)

NOTA:

Puede instalarse cubierta de piso de hasta ¾” de espesor, tal

como alfombra, baldosas, linóleo, etc. alrededor y debajo del calefactor

sin afectar adversamente el desempeño de los calefactores.

Entre la parte superior del calefactor y el techo/cielo raso (todos los

modelos):

- 36 pulgadas (914 mm) mínimo

Entre la parte superior del calefactor y la parte inferior de cortinas sobre

el calefactor:

- 12 pulgadas (305 mm) mínimo

NOTA IMPORTANTE:

mezclas de vinilo) podrían dañarse por el aire caliente procedente del

calefactor y no deben instalarse encima del calefactor.

Entre la parte delantera del calefactor y cortinas de longitud completa al

frente del calefactor:

- Distancia mínima entre la parte inferior de cortinas y el piso – 21/2

pulgadas (64 mm)

- Distancia mínima entre la parte superior de cortinas y el techo/cielo

raso – 1/2 pulgada (13 mm)

- Distancia mínima entre la parte delantera del calefactor y el pliegue

más cercano de cortina – 2 pulgadas (51 mm)

Entre la parte superior del calefactor y la parte inferior del antepecho de

ventana:

- 12 pulgadas (305 mm) mínimo

Ciertas telas y materiales de vinilo (tales como

1

)

/2”

Tabla A (continuación)

Modelo CSH07A, DSH07A (Alt.=7”; Prof.=5”)

Modelo CSH14A, DSH14A (Alt.=14”; Prof.=5”)

Número de Longitud Watts 208V 240V 277V

catálogo** “L” Watts/Pie total 1Ø 3Ø 1Ø 3Ø 1Ø

-2125 125 250 1.2 - 1.0 - 0.9

2188 188 375 1.8 - 1.6 - 1.4

-

-2250 250 500 2.4 - 2.1 - 1.8

-2375 28” 375 750 3.6 - 3.1 - 2.7

2500 500 1000 4.8 - 4.2 - 3.6

-

-2564 564 1125 5.4 3.1 4.7 2.7 4.0

2625 625 1250 6.0 3.5 5.2 3.0 4.5

2750 750 1500 7.2 4.2 6.2 3.6 5.4

-

-3125 125 375 1.8 - 1.6 - 1.4

3188 188 564 2.7 - 2.4 - 2.0

-

-3250 250 750 3.6 - 3.1 - 2.7

-3375 3’ 375 1125 5.4 - 4.7 - 4.0

3500 500 1500 7.2 - 6.2 - 5.4

-

-3564 564 1690 8.1 4.7 7.4 4.3 6.1

-3625 625 1875 9.0 5.2 7.8 4.5 6.7

-3750 750 2250 11.0 6.5 9.4 5.4 8.1

-4125 125 500 2.4 - 2.1 - 1.8

4188 188 750 3.6 - 3.1 - 2.7

-

-4250 250 1000 4.8 - 4.2 - 3.6

-4375 4’ 375 1500 7.2 - 6.2 - 5.4

4500 500 2000 9.6 - 8.3 - 7.2

-

-4564 564 2250 10.8 6.2 9.4 5.4 8.0

-4625 625 2500 12.0 6.9 10.4 6.0 9.0

-4750 750 3000 14.4 8.3 12.5 7.2 10.8

-5125 125 625 3.0 - 2.6 - 2.2

-5188 188 940 4.5 - 3.9 - 3.4

-5250 250 1250 6.0 - 5.2 - 4.5

-5375 5’ 375 1875 9.0 - 7.8 - 6.7

-5500 500 2500 12.0 - 10.4 - 9.0

-5564 564 2820 13.5 7.8 11.8 6.8 10.2

-5625 625 3125 15.0 8.7 13.0 7.5 11.3

-5750 750 3750 18.0 10.4 15.6 9.0 13.5

-6125 125 750 3.6 - 3.1 - 2.7

-6188 188 1125 5.4 - 4.7 - 4.0

-6250 250 1500 7.2 - 6.2 - 5.4

-6375 6’ 375 2250 10.8 - 9.4 - 8.1

-6500 500 3000 14.4 - 12.5 - 10.8

-6564 564 3380 16.2 9.4 14.1 8.1 12.2

-6625 625 3750 18.0 10.4 15.6 9.0 13.5

-6750 750 4500 21.6 12.5 18.7 10.8 16.2

-8125 125 1000 4.8 - 4.2 - 3.6

-8188 188 1500 7.2 - 6.2 - 5.4

-8250 250 2000 9.6 - 8.3 - 7.2

-8375 8’ 375 3000 14.4 - 12.5 - 10.8

-8500 500 4000 19.2 - 16.7 - 14.4

-8564 564 4500 21.6 12.5 18.7 10.8 16.2

-8625 625 5000 24.0 13.9 20.8 12.0 18.0

-8750 750 6000 28.6 16.5 15.0 14.4 21.6

-10125 125 1250 6.0 - 5.2 - 4.5

-10188 188 1875 9.0 - 7.8 - 6.7

-10250 250 2500 12.0 - 10.4 - 9.0

-10375 10’ 375 3750 18.0 - 15.6 - 13.5

-10500 500 5000 24.0 - 20.8 - 18.0

-10564 564 5640 27.2 15.7 23.5 13.6 20.4

-10625 625 6250 30.0 17.3 26.0 15.0 22.6

-10750 750 7500 36.0 20.8 31.3 18.1 27.0

** Prefijo con: CSH07A (calefactores con altura de 7”)

DSH07A (calefactores con altura de 7”)

CSH14A (calefactores con altura de 14”)

DSH14A (calefactores con altura de 14”)

Amperaje

12

Page 13

INSTRUCCIONES DE INSTALACIÓ

ADVERTENCIA

PARA REDUCIR EL RIESGO DE INCENDIO Y DESCARGA ELÉCTRICA O LESIONES A PERSONAS, CUMPLA LO SIGUIENTE:

1. Podrían producirse lesiones graves o la muerte por descarga eléctrica. Antes de instalar este calefactor, verifique que el circuito de

suministro de energía eléctrica que alimenta el calefactor está

desconectado en el interruptor de desconexión principal o panel de

servicio.

2. Las conexiones y procedimientos de cableado deben realizarse de

acuerdo con el Código Eléctrico Nacional (NEC) y los códigos

locales. Consulte el Diagrama de Cableado ubicado en el calefactor

y la Figura 8, y también las Tablas B y C. Verifique que todas las

conexiones eléctricas están apretadas para evitar posible sobrecalentamiento. Sólo utilice alambre de cobre para el alambre de suministro de energía eléctrica.

3. Verifique que el voltaje de suministro de energía eléctrica coincide

con la capacidad nominal de voltaje impresa en la placa de datos del

calefactor.

PRECAUCIÓN voltaje indicado en la placa de datos ya que esto dañará el calefactor y podría causar un incendio.

4. Antes de instalar o energizar el calefactor, remueva y deseche el

material de empaque de espuma colocado dentro del calefactor.

5. No instale el calefactor contra superficies combustibles de tabla de

fibra de celulosa de baja densidad, contra o debajo de cubiertas de

vinilo de pared, o debajo de materiales que pudieran dañarse por el

calor tales como persianas, cortinas de vinilo o plástico, etc. Si el

calefactor debe instalarse contra superficies de vinilo o superficies

que pudieran dañarse por el calor, deben utilizarse los Kits de

Separadores Cat. No. S01 ó S02. Al instalar, consulte las instrucciones de instalación suministradas con estos kits.

6. No instale el calefactor debajo de un tomacorriente eléctrico.

PRECAUCIÓN

7.

Mantenga alejados del calefactor, los cables eléctricos (incluyendo

los cables de teléfonos y computadoras), cortinas y otros muebles.

Para un funcionamiento eficiente y seguro, recomendamos mantener siempre un espacio libre mínimo de 6 pulgadas (152 mm) encima

y al frente del calefactor. Vea la Tabla de Espacios Libres para ver

los requisitos de espacio libre mínimo.

8. Para reducir el riesgo de incendio, no almacene ni utilice gasolina ni

otros vapores o líquidos inflamables cerca del calefactor.

9. No instale el calefactor de manera invertida o en cualquier posición

diferente a la mostrada en este manual.

10. No instale el calefactor de manera empotrada en la pared ni instale

el calefactor dentro de ningún tipo de encerramiento (a menos que

sea aprobado específicamente por el fabricante) ya que esto

causará que el calefactor se sobrecaliente y podría crear un peligro

de seguridad.

11. Al montar el calefactor, tenga cuidado al taladrar los orificios de

montaje y al montar el calefactor en la estructura de la edificación

para evitar dañar los componentes internos del calefactor.

Asegúrese de aflojar los tornillos de montaje 1/4 a 3/4 de vuelta para

permitir la expansión y contracción.

12. No remueva ni puentee el control de límite de seguridad ya que esto

podría permitir que el calefactor se vuelva un peligro de incendio –

vea el diagrama de cableado del calefactor suministrado con el calefactor.

13. Los alambres instalados en fábrica dentro del conducto superficial

de alambres se utilizan para conectar los controles incorporados.

Limite la corriente máxima a no más de 35 amperios para las

unidades CSH05 y DSH05, y 45 amperios para las unidades

CSH07, DSH07, CSH14 y DSH14. Consulte las instrucciones

y la capacidad nominal de corriente según se suministran con

el accesorio.

Nunca conecte el calefactor a un voltaje superior al

– El calefactor funciona a altas temperaturas.

ADVERTENCIA

14. Los calefactores que no están instalados extremo con extremo

deben tener tapas de extremo instaladas para cubrir los extremos

expuestos del calefactor. Los calefactores unidos entre sí deben

tener secciones de relleno apropiadas u otros conjuntos aprobados

(vea la lista de Datos de Accesorios en la Página 8) instalados para

cubrir las aberturas expuestas entre los calefactores.

15. Todo el cableado de campo instalado en el calefactor o cualquier

accesorio conectado debe tener una capacidad nominal mínima

para 75°C.

16. No permita que se coloquen objetos encima de calefactor ya que

éstos podrían dañarse o crear un peligro de incendio.

17. Antes de energizar, asegúrese que la cubierta delantera está instalada apropiadamente sobre la carcasa trasera a lo largo de todo el

calefactor – vea la Fig. 4. No opere el calefactor sin la cubierta

delantera instalada.

Preparación preliminar del cableado

1. Tienda un circuito de derivación de voltaje y tamaño de alambre

apropiados hasta el sitio de la caja de conexiones izquierda o

derecha según se indica en el diagrama de cableado del calefactor.

Los calefactores básicos están precableados y pueden conectarse

al circuito de derivación en cualquier extremo. Los calefactores con

controles están precableados para conexión con el circuito de

derivación en un (1) extremo únicamente (consulte el diagrama de

cableado del calefactor), sin embargo, el calefactor puede cablearse

desde el extremo opuesto tendiendo el alambre a través del conducto superficial de alambres del calefactor.

2. Si es necesario tender alambres a través del conducto superficial de

alambres del calefactor, utilice la Tabla B para dimensionar los

alambres instalables en campo.

3. Los alambres instalados en fábrica en el conducto superficial de

alambres del calefactor pueden cargarse hasta 35 amperios en las

unidades CSH05 y DSH05, y hasta 45 amperios en las unidades

CSH05, CSH14, DSH07 y DSH14. Consulte la Tabla C y D para

obtener la longitud máxima del cableado (tendido) del calefactor

cuando los calefactores se conectan en paralelo.

Tabla B. Dimensionado de los alambres de instalación en campo

Tamaño de de alambres

alambre de en el conducto Hasta 3 4 a 6 7 a 9

cobre 75º C de alambres alambres alambres alambres

No. 12 AWG 9 11.5 amperios 9.3 amperios 8.1 amperios

No. 10 AWG 8 17.4 amperios 14.0 amperios 12.1 amperios

No. 8 AWG 4 24.0 amperios 21.0 amperios –

Tabla C. Longitud máxima del cableado del calefactor

(CSH05-1Ø; DSH05-1Ø)

Watts/Pie. Longitud máxima permisible del cableado del calefactor (pies)

de los

calefactores 120 Voltios 208 Voltios 240 Voltios 277 Voltios

125 33 58 67 77

188 22 38 44 51

250 16 29 33 38

Nota:

Para mezcla de densidades de watts, calcule el consumo de

amperios. No exceda los valores indicados en el paso 3 anterior.

Cant. máxima Corriente máxima permisible

13

Page 14

Termostato

HEATER

HEATERS

BUTTED

TOGETHER

HEATER

FILLER

SECTION

HEATER

INSIDE

CORNER

HEATER

OUTSIDE

CORNER

HEATER

END

CAP

TYPICAL INSTALLATION

SPLICE PLATE

KIT

SPLICE PLATE

KIT

24 amps @ 120-240 VAC

22 amps @ 277 VAC

Servicio piloto – 125 VAC (todos los voltajes)

Relé del transformador

Unidades 05A: 22 amps @ 120-240 VAC

19 amps @ 277 VAC

Unidades 07A-14A: 25 amps @ 120-240 VAC

22 amps @ 277 VAC

Relé de potencia

25 amps @ 120-277 VAC - vea el diagrama

de cableado en el calefactor

Interruptor de desconexión

20 amps @ 120-277 VAC

4. Deben utilizarse alambres estándar para 75ºC en las cajas de

conexiones, los conductos superficiales de alambres, las secciones de

espacios libres, las secciones de relleno, las secciones de esquina.

Disposición en salón

Disposición en salón

Consulte los planos de calefacción para obtener la disposición exacta en

salón de los calefactores (con o sin termostato y/o relés y/o interruptores y

accesorios).

Antes de iniciar la instalación del tipo pared a pared, estudie las dimensiones de las secciones de calefactor y la longitud de pared adicional

requerida para los accesorios telescópicos (de extensión) (Figura 1).

Verifique que todos los calefactores y accesorios necesarios están

disponibles y tienen el acabado correcto.

10

KIT DE PLACAS DE

EMPALME

N

N

N

N

SECCIÓN DE

RELLENO

CORTE ESTA

PORCIÓN, SI SE

REQUIERE

SECCIÓN DE

RELLENO

TAPA DE

EXTREMO

TALADRE ORIFICIOS (PARA MONTAJE

DEL CALEFACTOR Y PARA SUJECIÓN

DE SECCIÓN DE RELLENO) SEGÚN S E

REQUIERA

ENTRADA INFERIOR

(POR ABAJO)

CARCASA

TORNILLOS DE

MONTAJE DE

ACCESORIOS

ORIFICIOS PARA

MONTAJE DEL

CALEFACTOR

ORIFICIOS DE

MONTAJE DE

ORIFICIOS

CARCASA

CARCASA

TORNILLOS

DE MONTAJE

DE CUBIERTA

TORNILLOS

DE CONEXIÓN

A TIERRA

10

KIT DE PLACAS

CALEFACTOR

7

UNIDOS EXTREMO

CALEFACTOR

CALEFACTORES

CON EXTREMO

Figura 1

Instalación típica

Vea la página 9 para las

dimensiones N

SECCIÓN DE

RELLENO

1

2

ESQUINA

INTERIOR

4

CALEFACTOR

8

ESQUINA

EXTERIOR

5

N

3

CALEFACTOR

DE EMPALME

N

CALEFACTOR

9

Altura de Montaje

En la altura correcta, dibuje una línea con lápiz en la pared, a nivel y/o en

paralelo con el antepecho de ventana. Las alturas de montaje mínimas

sobre el piso deberán ser las siguientes:

Altura de montaje mínima sobre el piso

Watts/Pie de longitud de calefactor Entrada inferior/Entrada delantera

125, 188 y 250 Watts/Pie 1-3/4” 0”

376, 500, 625, y 750 Watts/Pie 3” 0”

Nota:

Puede instalarse cubierta de piso de hasta ¾” de espesor, tal como

alfombra, baldosas, linóleo, etc. alrededor y debajo del calefactor sin

afectar adversamente el desempeño de los calefactores.

Instalación de unidad sola

Nota:

Para facilidad de instalación, es importante seguir en orden la

secuencia de operaciones indicada abajo.

1. Remueva la cubierta delantera removiendo los tornillos de montaje

(Figura 2).

2. Remueva la tapa precortada removible apropiada de cualquier caja de

conexiones. Vea la Figura 3 para ver la ubicación de las tapas precortadas removibles.

3. Instale las tapas de extremo (deben comprarse por separado) en

ambos extremos de la carcasa/alojamiento/caja del calefactor. Consulte

la Figura 4 para obtener detalles de la instalación de las tapas de

extremo.

TAPA DE

EXTREMO

CUBIERTA (ENTRADA DELANTERA)

ENTRADA

DELANTERA

TORNILLOS DE

MONTAJE DE

CUBIERTA

Figura 2

6

Unidades 05A

(TÍPICO, AMBOS EXTREMOS)

PANEL TRASERO

TAPAS PRECORTADAS

CONCÉNTRICAS DE 1-1/8” Y

7/8” DE DIÁM.

TAPAS PRECORTADAS

CONCÉNTRICAS DE 1-3/8” Y

1-1/8” DE DIÁM.

VISTA INFERIOR

Unidades 07A y 14A

(TÍPICO, AMBOS EXTREMOS)

TAPAS PRECORTADAS

CONCÉNTRICAS DE 1-1/8” Y

7/8” DE DIÁM.

PANEL TRASERO

TAPAS PRECORTADAS

CONCÉNTRICAS DE 1-1/8” Y

7/8” DE DIÁM.

TAPAS PRECORTADAS

CONCÉNTRICAS DE 1-3/8” Y

1-1/8” DE DIÁM.

VISTA INFERIOR

Figura 3

14

Page 15

TORNILLOS DE

MONTAJE

TAPA DE

EXTREMO

TAPA DE

EXTREMO

Figura 4

CARCASA

ORIFICIOS DE

MONTAJE DE

ACCESORIOS

4. Si se desea que una sección de relleno termine el calefactor, instale

la sección de relleno en el extremo del calefactor y extienda hasta la

longitud deseada. Marque las ubicaciones de los orificios de montaje, remueva la sección de relleno y taladre los orificios de montaje

requeridos. Instale la sección de relleno en el calefactor y la tapa de

extremo en la sección de relleno según se muestra en la Figura 2.

Nota:

Si un termostato y/o interruptor de desconexión están instalados

en la caja de conexiones izquierda del calefactor, podría ser necesario

cortar una porción de la sección de relleno para permitir acceso a estos

controles (Figura 2).

5 Coloque la carcasa del calefactor en la pared para verificar la uni-

formidad de la pared. No instale el calefactor contra una superficie

de pared irregular. Si se encuentra una pared irregular, utilice cuñas

para mantener recta la carcasa del calefactor.

6. Tienda el circuito de derivación de tamaño apropiado hasta la caja

de conexiones a través de la tapa precortada removible seleccionada.

7. Taladre los orificios de montaje de tamaño requerido en la parte

trasera de la carcasa del calefactor e instale la carcasa en la pared

utilizando tornillos, pernos o anclajes (suministrados por el instalador) según la construcción de la pared.

Nota:

Se suministran orificios de montaje pretaladrados de 1/4” de

diámetro en cada caja de conexiones. Deberán taladrarse orificios de

montaje adicionales en la carcasa para soportar el peso de calefactores

largos (6’ y longitudes superiores). No taladre orificios adicionales en las

cajas de conexiones.

8. 8. Apriete los tornillos de montaje y retroceda 1/4 a 3/4 de vuelta

para permitir la expansión y contracción del calefactor.

9. Siguiendo el diagrama de cableado fijado al calefactor, realice las

conexiones eléctricas. Conecte a tierra el calefactor utilizando los

tornillos de conexión a tierra suministrados (Figura 2).

10. Coloque nuevamente la tapa delantera y asegure con los tornillos

de montaje. (Vea la Figura 2).

LA SECCIÓN DE RELLENO

SE DESLIZARÁ DENTRO

DEL CALEFACTOR

CALEFACTOR

TORNILLOS DE MONTAJE

DE ACCESORIOS

CALEFACTOR

TORNILLOS DE

MONTAJE DE

ACCESORIOS

SECCIÓN DE

ESQUINA

CALEFACTOR

SECCIÓN DE

RELLENO

Figura 5

Instalación de unidades múltiples de pared a pared

Nota:

Para facilidad de instalación, es importante seguir en orden la

secuencia de operaciones indicada abajo.

1. 1. Remueva todas las cubiertas delanteras de los calefactores

removiendo los tornillos de montaje (Figura 2).

2. Consulte el diagrama de cableado para la entrada del alambre(s) de

alimentación de energía y remueva la tapa precortada removible

apropiada (Figura 3) del calefactor en que deben realizarse las

conexiones de alimentación de energía. El alambre(s) de alimentación de energía puede introducirse hasta el extremo de sólo

un (1) calefactor y los calefactores restantes pueden conectarse en

paralelo utilizando el conducto superficial de alambres. Utilice la

Tabla B para dimensionar los alambres instalables en campo en el

conducto superficial de alambres.

3. Si se desea tapa del conducto (debe comprarse por separado),

corte la longitud apropiada e instale hasta la pared.

4. Si se requiere por plan, instale la sección de relleno (1, Figura 1) a

cualquier calefactor (2) ó (3) mediante cuatro tornillos #6 suministrados con la sección de relleno. (Consulte la Figura 5). Deseche la

tapa de extremo de la sección de relleno, en esta aplicación.

Nota:

Los calefactores pueden unirse extremo con extremo, eliminando

por lo tanto la pieza de relleno, si así se desea.

Nota:

Si el calefactor tiene un interruptor de desconexión y/o termostato

y debe tener una sección de relleno o una sección de esquina en el

extremo izquierdo, la sección debe montarse en el calefactor ya que el

termostato o el interruptor de desconexión evitarán que la sección se

introduzca telescópicamente dentro del calefactor.

5 Si el tramo de pared tiene esquinas interiores o exteriores, instale la

esquina (4 y 5) en el calefactor (2 y 9) mediante cuatro tornillos #6

suministrados con la sección de esquina. (Consulte la Figura 5).

6. Instale las tapas de extremo (6) en el extremo exterior del último

calefactor (7) y (9) utilizando cuatro tornillos #6 suministrados con

las tapas de extremo. (Consulte la Figura 4 para ver detalles de la

instalación de las tapas de extremo).

7. Taladre orificios de montaje de tamaño requerido en todas las car-

casas de calefactor.

15

Page 16

Nota:

Se suministran orificios de montaje pretaladrados de 1/4” de

diámetro en cada caja de conexiones. Estos orificios pueden utilizarse

únicamente cuando no debe instalarse accesorio de inserción por

deslizamiento en ese extremo al calefactor (tal como cuando los calefactores (3 y 7) se unen extremo con extremo según se muestra en la

Figura 1). Deberán taladrarse orificios de montaje adicionales en la carcasa para soportar el peso de calefactores largos (6’ y longitudes superiores). No taladre orificios adicionales en las cajas de conexiones.

8. 8. Revise la pared en cuanto a uniformidad. No instale los calefac-

tores contra una superficie de pared irregular. Si se encuentra una

pared irregular, utilice cuñas para mantener recta la carcasa del

calefactor.

9. Tienda un circuito de derivación de tamaño apropiado hasta la caja

de conexiones a través de la tapa precortada removible seleccionada.

10. Monte el calefactor (2, Figura 1) en la pared utilizando tornillos,

pernos o anclajes (suministrados por el instalador) según la

construcción de la pared.

11. Deslice telescópicamente la carcasa (3) del calefactor sobre la

sección de relleno (1) en la cantidad deseada y monte la carcasa

en la pared.

12. Deslice telescópicamente la carcasa (8) del calefactor sobre la

sección de esquina (4) en la cantidad deseada y monte la carcasa

en la pared.

13. Monte los calefactores restantes según se describió anteriormente,

asegurándose que los calefactores con tapas de extremo se instalen en el extremo del tramo.

14. Las secciones de espacios libres, si hay alguna, se instalan de la

misma manera como se instalan los calefactores.

Nota:

Los alambres de instalación en campo para 75ºC pueden tenderse a través de las secciones de espacios libres, las secciones de relleno

y las secciones de esquina.

15. Las secciones de control, si hay alguna, se instalan de la misma

manera como se instalan los calefactores. Consulte el diagrama de

cableado en las secciones de control para conectar los alambres a

los calefactores.

Instalación de unidades de entreventana a entreventana

(miembro vertical intermedio en el marco de una ventana)

La parte trasera de la carcasa del calefactor no contiene orificios de

montaje (diferentes a aquellos en los extremos) y por lo tanto es ideal

para instalación en frente de paredes de vidrio. La parte trasera de la

carcasa presenta una apariencia atractiva cuando se mira desde el lado

exterior a través de la pared de vidrio.

Los procedimientos de instalación son similares a aquellos de la instalación pared a pared (paso 6) excepto por las siguientes diferencias.

1. Sujete la carcasa a la entreventana/parteluz utilizando los orificios

de montaje suministrados en las cajas de conexiones según se

muestra en la Figura 6.

ENTREVENTANA

ORIZONTAL

H

TORNILLOS

SUMINISTRA-

(

OS POR

D

TROS)

O

SOPORTE (SUMINISTRADO

POR OTROS)

VISTA LATERAL

Figura 7

2. En la instalación en entreventana horizontal, instale los soportes

según se muestra en la Figura 7.

INSTRUCCIONES DE OPERACIÓN

1. Después que los calefactores están ensamblados e instalados completamente, ajuste el termostato o los controles de operación en NO

HEAT (NO CALOR) y energice el circuito(s) del calefactor. Verifique

que los calefactores no están produciendo calor.

2. Ajuste el termostato o el control de operación para pedir calor.

Permita que el calefactor(es) funcione durante unos pocos minutos y

verifique que los calefactores están produciendo calor.

3. El termostato o los controles de operación pueden ajustarse para

encender y apagar el calefactor(es) para mantener la temperatura

deseada en el salón.

Nota:

Si se suministra termostato incorporado, la rotación en sentido

horario permitirá que el calefactor permanezca en MORE (MÁS) y mantendrá una mayor temperatura del salón. Igualmente, la rotación en sentido antihorario hará que el calefactor permanezca en LESS (MENOS) y

la temperatura en el salón será inferior. Si se suministran termostato

remoto u otros tipos de controles, consulte las instrucciones suministradas con esos controles para un funcionamiento apropiado.

Figura 6

VISTA DELANTERA

VISTA SUPERIOR

TORNILLO

(SUMINISTRADOS POR

OTROS)

LÍNEA DE PISO

ENTREVENTANA

VERTICAL

16

Page 17

Figura 8 - Diagrama de cableado

CABLEADO TÍPICO DE MÚLTIPLES CALEFACTORES (SIN CONTROLES)

PROTECTOR

TÉRMICO

ECCIÓN DE

S

ELLENO

R

ROTECTOR

P

ÉRMICO

T

ACIA OTRO

H

CALEFACTOR

ELEMENTOS CALEFACTORES

TORNILLO

E TIERRA

D

ALAMBRE #10

TORNILLO

DE TIERRA

NOTA: Para el cableado interno e individual del cale-

SUMINISTRO DE ENERGÍA

HACIA INTERRUPTOR DE

DESCONEXIÓN

factor, consulte la etiqueta de diagrama de cableado

en la unidad.

INSTRUCCIONES DE MANTENIMIENTO

Para un funcionamiento eficiente y seguro, y para extender la vida de

los calefactores, éstos deben limpiarse e inspeccionarse en busca de

daño, una vez al año como mínimo (preferiblemente al comienzo de la

temporada de calor) o más frecuentemente en ambientes sucios.

Excepto la limpieza, sus calefactores no requieren otro mantenimiento

preventivo. El usuario y/o el personal de limpieza pueden realizar la

limpieza habitual del calefactor que puede realizarse sin desensamblaje

del calefactor. Sin embargo, cualquier limpieza o servicio de mantenimiento que requiera el desensamblaje del calefactor debe ser realizado

por personal de servicio calificado.

ADVERTENCIA

PODRÍAN PRODUCIRSE LESIONES GRAVES O LA MUERTE POR

DESCARGA ELÉCTRICA. ANTES DE LIMPIAR O SUMINISTRAR

SERVICIO DE MANTENIMIENTO A ESTE CALEFACTOR, VERIFIQUE QUE EL CIRCUITO(S) DE SUMINISTRO DE ENERGÍA ELÉCTRICA QUE ALIMENTA EL CALEFACTOR ESTÁ/ESTÁN

DESCONECTADO(S) EN EL INTERRUPTOR DE DESCONEXIÓN

PRINCIPAL O EL PANEL DE SERVICIO. ANTES DE LIMPIAR, PERMITA QUE EL CALEFACTOR SE ENFRÍE PARA EVITAR UNA POSIBLE QUEMADURA.

LEMENTOS CALEFACTORES

E

ORNILLO

T

DE TIERRA

LAMBRE #10

A

HACIA OTRO

CALEFACTOR

ABLEADO DE FÁBRICA

C

CABLEADO EN CAMPO

NOTA:

MÁS DE UNA (1) FUENTE DE ENERGÍA PODRÍA INGRESAR

AL CALEFACTOR. ANTES DE LIMPIAR O SUMINISTRAR SERVICIO

DE MANTENIMIENTO, ASEGÚRESE QUE TODA ENERGÍA QUE

ALIMENTA EL CALEFACTOR ESTÁ DESCONECTADA.

1. El armario/caja/carcasa del calefactor puede limpiarse utilizando un

trapo húmedo para remover el polvo que pudiera haberse acumulado sobre las superficies. No utilice limpiadores fuertes ni ceras sobre

las superficies ya que éstos podrían dañar el acabado o producir

decoloración.

2. Puede utilizarse una aspiradora y/o aire comprimido para remover el

polvo e hilachas que pudieran haberse acumulado dentro del calefactor alrededor de las aletas del elemento calefactor. Si el calefactor debe desensamblarse para limpieza, tenga cuidado al limpiar las

aletas del elemento calefactor para evitar dañar las aletas.

PRECAUCIÓN

LAS ALETAS SON FILOSAS Y PODRÍAN CAUSAR CORTADURAS,

DE MODO QUE EVITE HACER CONTACTO CON ÉSTAS.

3. Después de limpiar y suministrar servicio de mantenimiento, siempre

reensamble colocando nuevamente cualquier herraje removido y

revise las unidades para verificar que están funcionando apropiadamente.

17

Page 18

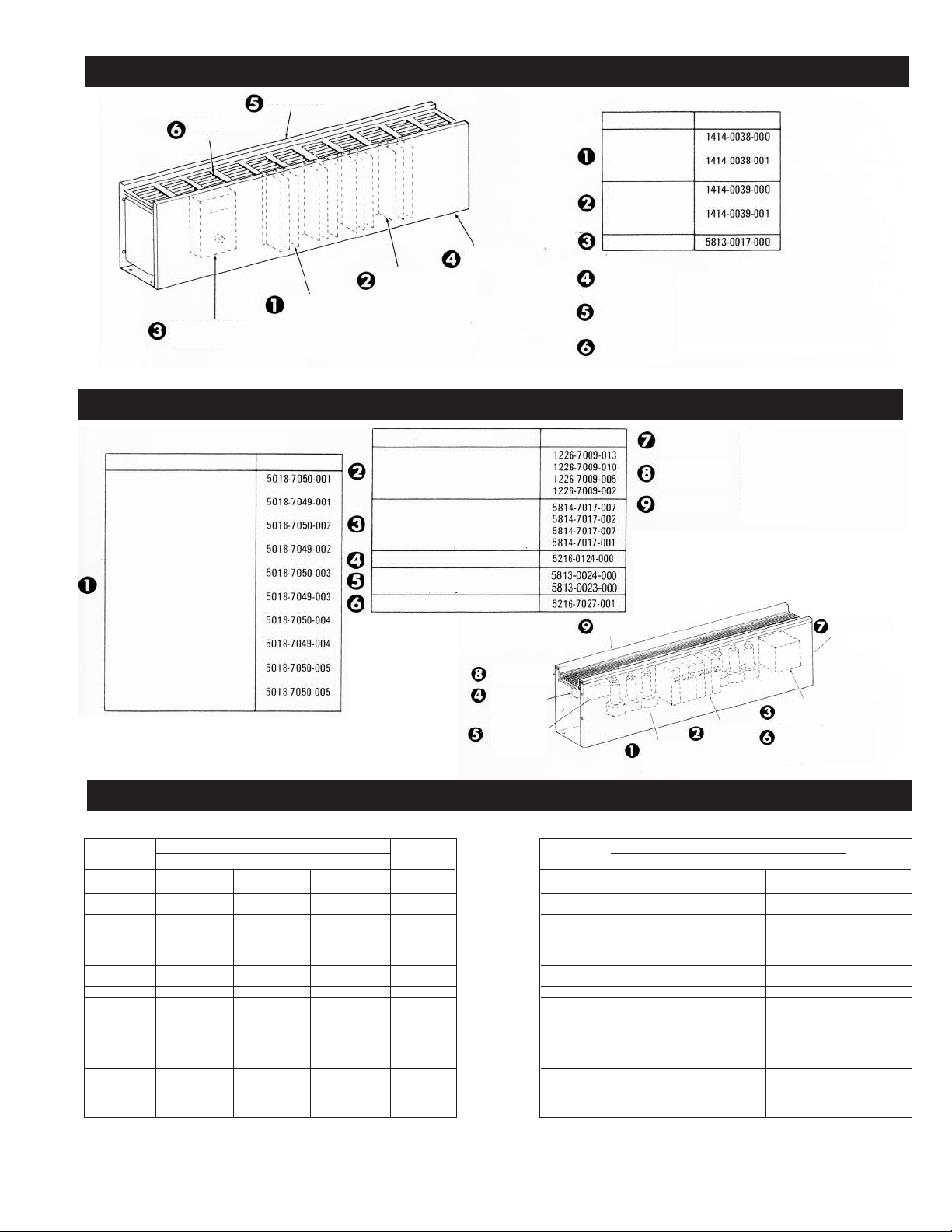

INTERRUPTOR DE

DESCONEXIÓN

(OPCIONAL)

BUJES DEL ELEMENTO

CALEFACTOR

TERMOSTATO

(OPCIONAL)

PROTECTOR DE

SOBRECARGA

PANEL TRASERO

ELEMENTO

CALEFACTOR

CUBIERTA DEL CONDUCTO DE ALAMBRES

REJILLA

CUBIERTA

DELANTERA

INTERRUPTOR DE

DESCONEXIÓN

(OPCIONAL)

BUJES DEL ELEMENTO

CALEFACTOR

RELÉ DEL TRANSFORMADOR

(OPCIONAL)

RELÉ DE

POTENCIA

(OPCIONAL)

TERMOSTATO

(OPCIONAL)

REJILLA

PROTECTOR DE

SOBRECARGA

PANEL TRASERO

CUBIERTA

ELEMENTO

CALEFACTOR

CUBIERTA DEL CONDUCTO

DE ALAMBRES

DELANTERA

RELÉ DEL TRANSFORMADOR

(OPCIONAL)

RELÉ DE

POTENCIA

(OPCIONAL)

INTERRUPTOR DE

DESCONEXIÓN

(OPCIONAL)

BUJES DEL ELEMENTO CALEFACTOR

INTERRUPTOR DE

DESCONEXIÓN

(OPCIONAL)

BUJES DEL ELEMEN-

TO CALEFACTOR

TERMOSTATO

(OPCIONAL)

PROTECTOR DE

SOBRECARGA

REJILLA

CUBIERTA DEL CONDUCTO DE ALAMBRES

Elemento calefactor (Parte No. Prefijo 1802-2001)

Longitud del calefactor

Descripción

120 Voltios

125 W/Pie por

elemento

calefactor

188 W/Pie por

elemento

calefactor

250 W/Pie por

elemento

calefactor

208 Voltios

240 Voltios

277 Voltios

120 Voltios

208 Voltios

240 Voltios

277 Voltios

120 Voltios

208 Voltios

240 Voltios

277 Voltios

TERMOSTATO

(OPCIONAL)

ELEMENTO

CALEFACTOR

PROTECTOR

DE SOBRECARGA

PANEL TRASERO

CUBIERTA

DELANTERA

PANEL TRASERO

REJILLA

CUBIERTA

DELANTERA

ELEMENTO

CALEFACTOR

CUBIERTA DEL CONDUCTO

DE ALAMBRES

RELÉ DEL TRANSFORMADOR

(OPCIONAL)

RELÉ DE

POTENCIA

(OPCIONAL)

Controles incorporados (Opcional)

Descripción

Interruptor de desconexión

120 Voltios

Relé del

transformador

Relé de potencia

Termostato

208 Voltios

240 Voltios

277 Voltios

24 Voltios

120 Voltios

208/240 Voltios

277 Voltios

1 Polo

2 Polos

RELÉ DEL TRANSFORMADOR

(OPCIONAL)

RELÉ DE

POTENCIA

(OPCIONAL)

Número de pieza

Unidades 07A y 14A Unidades 05A

18

Page 19

IDENTIFICACIÓN DE PIEZAS DE RENOVACIÓN CSDCSA, DSHCSA

REJILLA

TERMOSTATO SCR

(OPCIONAL

IDENTIFICACIÓN DE PIEZAS DE RENOVACIÓN CSHCRA, DSHCRA

Controles opcionales

Descripción

Relé de mercurio, 1 polo,

30 amperios, bobina de 24 voltios

Relé de mercurio, 1 polo,

0 amperios, bobina de 24 voltios

6

Relé de mercurio, 1 polo,

0 amperios, bobina de 120 voltios

3

Relé de mercurio, 1 polo,

60 amperios, bobina de 120 voltios

elé de mercurio, 1 polo,

R

30 amperios, bobina de 208 voltios

Relé de mercurio, 1 polo,

60 amperios, bobina de 208 voltios

Relé de mercurio, 1 polo,

30 amperios, bobina de 240 voltios

Relé de mercurio, 1 polo,

60 amperios, bobina de 240 voltios

Relé de mercurio, 1 polo,

30 amperios, bobina de 227 voltios

Relé de mercurio, 1 polo,

60 amperios, bobina de 227 voltios

PANEL TRASERO

CONTROL

PRINCIPAL

(OPCIONAL)

Número de pieza

PANEL

DELANTERO

ESCLAVO

(OPCIONAL)

Descripción Número de pieza

Interruptor automático de circuito, 2 polos, 30 amps

Interruptor automático de circuito, 2 polos, 60 amps

Interruptor automático de circuito, 3 polos, 30 amps

Interruptor automático de circuito, 3 polos, 60 amps

Transformador de 24V, primario de 120 voltios

Transformador de 24V, primario de 208 voltios

Transformador de 24V, primario de 240 voltios

Transformador de 24V, primario de 227 voltios

Interruptor de desconexión

Termostato, 1 polo

Termostato, 2 etapas

Control neumático

PANEL

TRASERO

INTERRUPTOR

DE DESCONEXIÓN (OPCIONAL)

TERMOSTATO

(OPCIONAL)

Controles opcionales

Descripción Número de pieza

Control principal

08/240 Voltios

2

Control principal

277 Voltios

Esclavo

08/240 Voltios

2

Esclavo

277 Voltios

Termostato SCR

PANEL

DELANTERO

PANEL

TRASERO

REJILLA

REJILLA

For part numbers, refer to the Renewal

Para números de piezas, consulte la

dentificación de Piezas de Renovación que

I

arts Identification covering the appro-

P

ubre el calefactor de altura apropiada

c

priate height heater (7” or 14”), and

(7” ó 14”), y luego seleccione el panel

then select the front, back panel, or

elantero, trasero, o la rejilla enumerada bajo

d

grille listed under the 28” length.

a longitud de 28”.

l

PANEL

DELANTERO

PANEL

TRASERO

REJILLA

RELÉ DE

MERCURIO

(OPCIONAL)

ara números de piezas, consulte la

P

Identificación de Piezas de Renovación

que cubre el calefactor de altura apropiada

(7” ó 14”), y luego seleccione el panel

delantero, trasero, o la rejilla enumerada

ajo la longitud de 28”.

b

TRANSFORMADOR DE

24V (OPCIONAL)

INTERRUPTOR

AUTOMÁTICO

DE CIRCUITO

(OPCIONAL)

CONTROL NEUMÁTICO (OPCIONAL)

CUBIERTA

DELANTERA

DATOS DE ACCESORIOS

CSH05A, CSH07A y CSH14A

Descripción

Tapa de

extremo-Izquierda

Tapa de

extremo-Derecha

Sección

de relleno

Esquina interior

Esquina exterior

Sección para

espacios libres

Sección de

control, para

espacios libres

Cubierta de

conducto

* Agregue el sufijo “1” para entrada inferior (por abajo), salida superior (por arriba).

Agregue el sufijo “3” para entrada inferior (por abajo), salida delantera (por delante).

† Diseñado para la instalación de componentes.

(R) Sufijo en número de catálogo se refiere a accesorios con tomacorriente de 120 VAC.

CSH05A CSH07A CSH14A

CSH05-ECL(R)

CSH05-ECR(R)

CSH05-FL3(R)

CSH05-FL6(R)

CSH05-FL9(R)

CSH05-FL12(R)

CSH05-FL18(R)

CSH05-IC1

—

CSH05-OC-1

CSH05-BL2-1

CSH05-BL3-1

CSH05-BL4-1

CSH05-BL5-1

CSH05-BL6-1

CSH05-BL8-1

CSH05-BL10-1

—

SHCC-05

CSH07-ECL(R)

CSH07-ECR(R)

CSH07-FL3(R)

CSH07-FL6(R)

CSH07-FL9(R)

CSH07-FL12(R)

CSH07-FL18(R)

—

CSH07-IC1

CSH07-OC-1

CSH07-BL2-1

CSH07-BL3-1

CSH07-BL4-1

CSH07-BL5-1

CSH07-BL6-1

CSH07-BL8-1

CSH07-BL10-1

CSH07-BCS-1

†

SHCC-07-14

CSH14-ECL(R)

CSH14-ECR(R)

CSH14-FL3(R)

CSH14-FL6(R)

CSH14-FL9(R)

CSH14-FL12(R)

CSH14-FL18(R)

—

CSH14-IC-1

CSH14-OC-1

CSH14-BL2-*

CSH14-BL3-*

CSH14-BL4-*

CSH14-BL5-*

CSH14-BL6-*

CSH14-BL8-*

CSH14-BL10-*

CSH14-BCS-*

†

SHCC-07-14

Número de catálogo

Adición de

longitud “N”

1/8"

1/8"

0" 3"

3" 6"

6" 9"

9" 12"

15" 18"

3-12''

5-1/2''

1/2''

28''

3'

4'

5'

6'

8'

10'

28''

—

19

CSH05A, CSH07A y CSH14A

Descripción

Tapa de

extremo-Izquierda

Tapa de

extremo-Derecha

Sección

de relleno

Esquina interior

Esquina exterior

Sección para

espacios libres

Sección de

control, para

espacios libres

Cubierta de

conducto

* Agregue el sufijo “1” para entrada inferior (por abajo), salida superior (por arriba).

Agregue el sufijo “3” para entrada inferior (por abajo), salida delantera (por delante).

† Diseñado para la instalación de componentes.

(R) Sufijo en número de catálogo se refiere a accesorios con tomacorriente de 120 VAC.

CSH05A CSH07A CSH14A

DSH05-ECL(R)

DSH05-ECR(R)

DSH05-FL3(R)

DSH05-FL6(R)

DSH05-FL9(R)

DSH05-FL12(R)

DSH05-FL18(R)

DSH05-IC1

—

DSH05-OC-1

DSH05-BL2-1

DSH05-BL3-1

DSH05-BL4-1

DSH05-BL5-1

DSH05-BL6-1

DSH05-BL8-1

DSH05-BL10-1

—

SHCC-05

DSH07-ECL(R)

DSH07-ECR(R)

DSH07-FL3(R)

DSH07-FL6(R)

DSH07-FL9(R)

DSH07-FL12(R)

DSH07-FL18(R)

—

CSH07-IC1

DSH07-OC-1

DSH07-BL2-1

DSH07-BL3-1

CSH07-BL4-1

CSH07-BL5-1

CSH07-BL6-1

DSH07-BL8-1

DSH07-BL10-1

DSH07-BCS-1

†

SHCC-07-14

DSH14-ECL(R)

DSH14-ECR(R)

DSH14-FL3(R)

DSH14-FL6(R)

DSH14-FL9(R)

DSH14-FL12(R)

DSH14-FL18(R)

—

DSH14-IC-1

DSH14-OC-1

DSH14-BL2-1*

DSH14-BL3-1*

DSH14-BL4-1*

DSH14-BL5-1*

DSH14-BL6-1*

DSH14-BL8-1*

DSH14-BL10-1*

DSH14-BCS-*

†

SHCC-07-14

Número de catálogo

Adición de

longitud “N”

1/8"

1/8"

0" 3"

3" 6"

6" 9"

9" 12"

15" 18"

3-12''

5-1/2''

1/2''

28''

3'

4'

5'

6'

8'

10'

28''

—

Page 20

Todos los productos fabricados por Marley Engineered Products están garantizados contra defectos en manufactura y materiales durante un (1) año a partir de la fecha

GARANTÍA LIMITADA

instalación, excepto los elementos calefactores los cuales están garantizados contra defectos en manufactura y materiales durante cinco años a partir de la fecha de

instalación. Esta garantía no aplica a daño por accidente, uso incorrecto, o alteración; ni donde el voltaje conectado sea superior en 5% al voltaje indicado en la placa

de datos; ni se aplica a equipo instalado o cableado o mantenido de manera inapropiada en violación de las instrucciones de instalación del producto. Todas las reclamaciones de trabajo de garantía deben incluir un documento que compruebe la fecha de instalación.

El cliente será responsable de todos los costos incurridos en la remoción o reinstalación de productos, incluyendo los costos de mano de obra, y los costos de envío

incurridos para devolver los productos al Centro de Servicio de Marley Engineered Products. Dentro de las limitantes de esta garantía, las unidades inoperantes deben

devolverse al centro de servicio autorizado Marley más cercano o al Centro de Servicio de Marley Engineered Products, y nosotros repararemos o reemplazaremos,

según nuestra elección, sin costo para usted, con el costo de envío de regreso pagado por Marley. Se acuerda que dicha reparación o reemplazo es el remedio exclusivo disponible de parte de Marley Engineered Products.

LAS ANTERIORES GARANTÍAS REEMPLAZAN CUALQUIER OTRA GARANTÍA EXPRESA O IMPLÍCITA, Y TODAS LAS GARANTÍAS IMPLÍCITAS DE MERCADEABILIDAD Y ADECUADIBILIDAD PARA UN PROPÓSITO EN PARTICULAR QUE EXCEDEN LAS GARANTÍAS EXPRESAS MENCIONADAS SON DENEGADAS MEDIANTE ESTE DOCUMENTO Y EXCLUIDAS DE ESTE ACUERDO. MARLEY ENGINEERED PRODUCTS NO SERÁ RESPONSABLE POR DAÑOS CONSECUENCIALES QUE SURJAN CON RESPECTO AL PRODUCTO, ESTÉN O NO BASADOS EN NEGLIGENCIA, INFRACCIÓN, RESPONSABILIDAD ESTRICTA, O CONTRATO.

Algunos estados no permiten la exclusión o la limitación de los daños resultantes o adicionales, de modo que la anterior exclusión o limitación podría no aplicarse a usted.