Page 1

!

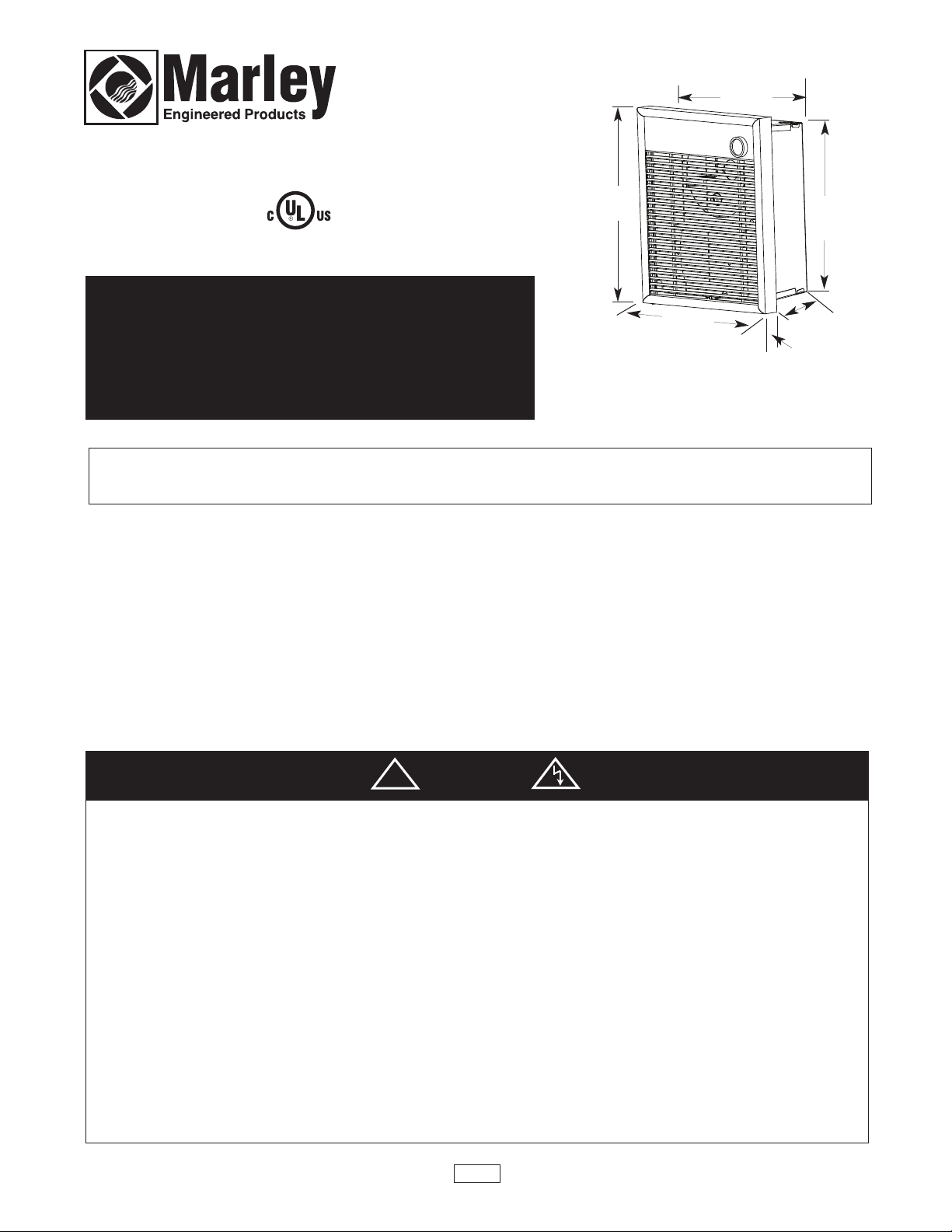

91/4”

(235 mm)

FILE #E21609

SWH ARCHITECTURAL

SERIES

121/8”

(308 mm)

1011/16”

(271 mm)

11/4”

(32 mm)

11”

(279 mm)

4”

(102 mm)

Fan Forced Wall Heaters

Installation & Maintenance Instructions

Dear Owner,

Congratulations! Thank you for purchasing this new heater manufactured by Marley Engineered

Products. You have made a wise investment selecting the highest quality product in the heating industry. Please carefully read the installation and maintenance directions shown in this manual. You should

enjoy years of efficient heating comfort with this product from Marley Engineered Products... the industry’s leader in design, manufacturing, quality and service.

WARNING

Read Carefully - These instructions are written to help

you prevent difficulties that might arise during installation

of heaters. Studying the instructions first may save you

considerable time and money later. Observe the following

procedures, and cut your installation time to a minimum.

To reduce risk of fire or electric shock:

1. Disconnect all power coming to heater at main service panel

before wiring or servicing.

2. All wiring must be in accordance with the National and Local

Electrical Codes and the heater must be grounded as a precaution against possible electric shock.

3. Verify the power supply voltage coming to heater matches the

ratings printed on the heater nameplate before energizing.

4. This heater is hot when in use. To avoid burns, do not let bare

skin touch hot surfaces.

SAVE THESE INSTRUCTIONS

... The Employees of

Marley Engineered Products

5. Do not insert or allow foreign objects to enter any ventilation

or exhaust opening as this may cause an electric shock,

fire,or damage to the heater.

6. Do not block air intakes or exhaust in any manner. Keep combustible materials, such as crates, drapes, etc., away from

heater. Do not install behind doors, furniture, towels,

boxes, or in ceilings.

7. A heater has hot and arcing or sparking parts inside. Do not

use it in areas where gasoline, paint or flammable liquids are

used or stored.

8. Use this heater only as described in this manual. Any other

use not recommended by the manufacturer may cause fire,

electric shock, or injury to persons.

9. This heater is not approved for use in corrosive atmospheres

such as marine, green house or chemical storage areas.

1

Page 2

IMPORTANT

!

!

!

!

!

WARNING

TO PREVENT HAZARD OF FIRE OR ELECTRICAL SHOCK, DO NOT

INSTALLWITHOUT BACK BOX.

CAUTION

TO PROVIDE FOR SAFE OPERATION, THE FOLLOWING CLEARANCES MUST BE MAINTAINED.

WALL MOUNTING: • MINIMUM FOUR (4) INCHES (102MM) TO

FLOUR • MINIMUM TWELVE (12) INCHES (305MM) TO ADJACENT

WALLS • MINIMUM THIRTY SIX (36) INCHES (915MM) TO CEILING

CEILING MOUNTING: • MINIMUM TWELVE (12) INCHES (305MM TO

ANY WALL

CAUTION

THE HEATER IS HOT WHEN IN USE. DO NOT INSTALL THE

HEATER BEHIND DOOR, BEHIND TOWEL RACK, IN CLOSET,

WHERE CURTAINS OR DRAPES COULD TOUCH OR BECOME

SCORCHED BY HEATER, OR WHERE AIRFLOW TO HEATER MAY

BE OBSTRUCTED. KEEP ELECTRICAL CORDS, BEDDING, FURNITURE AND OTHER COMBUSTIBLES AWAY FROM HEATER.

GENERAL

The heater is designed for recessed installation in 2” X 4” (50 mm X 101

mm) stud or larger wall sections using the wall box provided. The heater

may also be surface mounted by using the Surface Mounting Frame,

Model SWHSM or semi-recess mounted by using a SWHS1 (for 1” (25

mm) recess frame) or a SWHS2 (for 2” (50 mm) recess frame). All three

accessories are ordered separately. The heater may be wired with standard building wire (60°C). Refer to specification chart (see pg. 4) for correct supply voltage and wire size.

NOTE: The optimum mounting height for this heater is 18" to 24" (450 to

600 mm) from floor to bottom of back box. Do not install closer than

4”(101 mm) from the floor.

For surface or semi-recess mounting, consult Installation Instructions

packed with SWHSM, SWHS1, SWHS2.

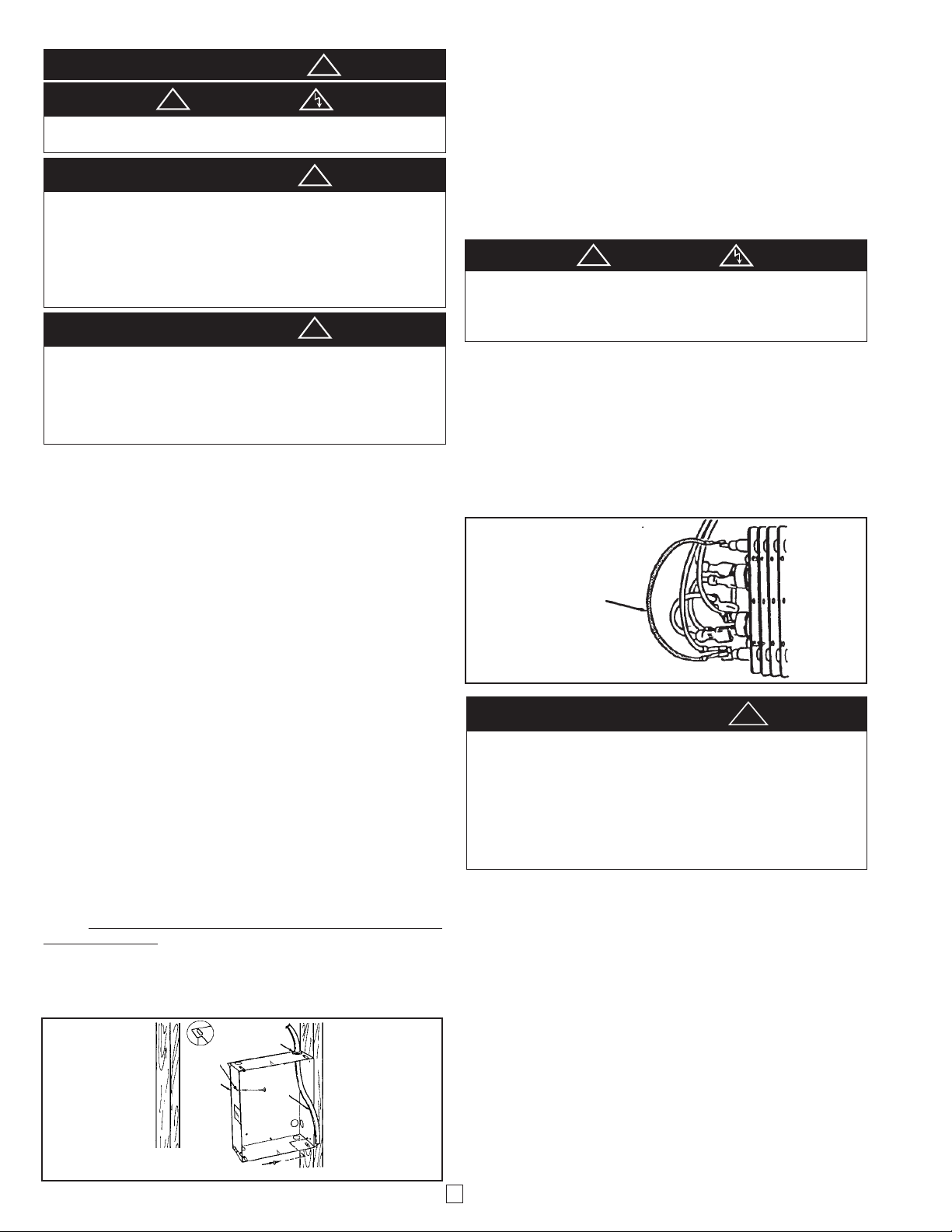

INSTALLATION OF BACK BOX IN NEW CONSTRUCTION

NOTE: If the finished wall surface is already up, follow instructions for

“INSTALLATION OF BACK BOX IN EXISTING CONSTRUCTION”.

1. Determine which side of the back box is to be mounted against a

stud and bend the tabs at the rear corners out 90 degrees so that

the back box will be square with the stud after installation. (See

Figure 1).

2. Remove one of the knockouts on socket side of the back box and

install a cable or conduit connector.

3. Positionback box against sideof studsandsecureusing nailsorscrews

as shown in Figure 1.

NOTE: The back box must be installed with the front edge flush with

the finished surface.

4. Run power supply cable through the connector, leaving about 8” of

wire inside the box.

5. Connect thesupply cableground wiretogreen ground screwprovided.

BEND

OUT

TAB

CABLE CLAMP

LEAD

HOLES

BACK BOX

SUPPLY

WIRING

CABLE

NOTE: Lead holes for a #8 sheet metal screw have been provided in the

sides of the back box.. After the finished wall or ceiling has been put up,

drive a # 8 sheet metal screw (recommended 1” long) through the side of

the box not mounted to the stud. This will prevent the back box from

pulling out when installing the heater assembly. (See Figure 1)

INSTALLATION OF BACK BOX IN

EXISTING CONSTRUCTION

1. Carefully mark and cut a holemeasuring 9-3/8" (235mm) wide by 111/8" (283mm) long. One edge of the hole must be cut along the

edge of a stud.

CAUTION

AN ELECTRICAL SHOCK, FIRE OR WATER DAMAGE COULD

RESULT IF WIRING OR PIPING IS DAMAGED DURING CUTTING.

MAKE SURE ALL WIRING AND PIPING ARE CLEAR OF AREA

BEFORE CUTTING.

2. Proceed to No. 1 through 5 (Installation of Back Box in New

Construction).

FIELD CONVERSION FOR LOWER WATTAGE RATING

NOTE: Refer to specification chart for lower wattage ratings which are

available.

To convert heater to lower wattage rating, completely remove red jumper

wire from both heating elements (See Figure 2). Discard this jumper. Be

sure remaining wires are securely connected.

Remove red

jumper for

lower wattage

rating

Figure 2

a

CAUTION

DO NOT USE A REMOTE THERMOSTAT WITH THIS HEATER.

BUILT IN THERMOSTAT CYCLES THE HEATING ELEMENT ONLY.

FAN DELAY CONTROL AUTOMATICALLY TURNS FAN ON AND

OFF, AND PROVIDES A FAN DELAY OFF FEATURE TO REMOVE

RESIDUAL HEATAFTER THERMOSTAT HAS TURNED HEATING

ELEMENTS OFF. WIRING OF HEATER IN ANY MANNER WHICH

DEFEATS THE FAN DELAY OFF FEATURE CAN RESULT IN

OVERHEATINGAND PERMANENT DAMAGE TO HEATER,AND

WILL VOID THE WARRANTY.

INSTALLATION AND WIRING OF HEATER / FAN ASSEMBLY

1. Following wiring diagram (Figure 3) connect supply wiring to heater

lead wires in back box.

NOTE: For 120 and 277 volt heaters connect the white neutral supply

lead to the heaters white pigtail lead, and connect the black supply lead

to the heater black pigtail lead. For 208 and 240 volt heaters change the

color of the heaters white pigtail lead to black by wrapping with black

electrical tape. (Most electrical codes require the supply leads to be connected to black leads). Then connect the two black supply leads to the

two black receptacle leads.

2. Secure supply ground wire under green ground screw in back box.

!

Figure 1

NAILS OR

SCREWS (2)

2

Page 3

L1

L2(N)

*WHITE FOR 120 AND 277 VOLT

GR

BLK

*BLK

B

ACK BOX

W

IRING

BLUE

BLUE

BLACK

BLACK

D

ISCONNECT

S

WITCH

INDICATOR

LIGHT

HIGH

LIMIT

F

AN

D

ELAY

B

OTTOM ELEMENT

TOP ELEMENT

T

HERMOSTAT

F

AN MOTOR

HEATER ASSEMBLY

*

!

Figure 3

3. Insert wiring plug from heater/fan assembly into socket in back box.

a

CAUTION

BE SURE ALL WIRING IS SECURELY ROUTED AWAY FROM FAN

AND ELEMENT.

4. Fit heater/fan assembly into back box and secure in place with (2)

screws providedthroughthe center slots in the fan assembly.

NOTE: Use the screws provided by the factory to install fan deck to the

back box.

!

7. It may be necessary to readjust thermostat a time or so until

exact comfort level is attained. Rotation in the clockwise

direction will increase the amount of time the heater will produce heat. Rotation in the counterclockwise direction will

reduce the amount of time the heater is on.

NOTE: For best results, the heater should be left “ON” constantly during

the heating season as the thermostat, whenproperly set, will maintain the

desired temperature. In the full counter-clockwise position the heater will

remain off until the room temperature drops well below freezing.

AINTENANCE AND CLEANING

M

Your heateris designed for years of trouble-freeoperation and requires no

specialmaintenance other than occasionalcleaning. The motor is permanently lubricated.

Once each year, the heater should be cleaned to remove dust and other

foreignmaterial which has collectedduringthe heatingseason, as follows:

1. Turn power off at main switch.

2. Remove thermostat knob and grille.

3. Use vacuum cleaner with brush attachment to remove dust and dirt

that has accumulated in heater (especially around element and fan

blade). Do not use water or any cleaners to clean heater components.

4. Replace grille and thermostat knob.

5. Wipe grille clean with a damp cloth. DO NOT use waxes or any

cleaners that leave a residue since these may discolor during heater

operation.

6. Turn the main line switch on at the switch panel to restore power to

heater. The heater is now ready for another season of operation.

OPERATIONAL NOTICE

Your heater is equipped with an automatic reset high limit control that

will automatically turn the heater off to prevent a fire if the heater overheats. Should this occur, the indicator light will illuminate and will continue to shine until the limit resets.

INSTALLATION OF FRONT COVER (GRILLE) AND

THERMOSTAT KNOB

1. Attach grille bracket with screw provided in the top part of

the back box as shown in Figure 4.

2. Mount top portion of the grille over the grille bracket and

push down until grille is secure.

3. Insert screw through bottom of grille louver to mounting hole

and tighten screw.

4. Fit the thermostat knob on to the thermostat shaft and push

into place.

HEATER CHECKOUT AND OPERATION

1. After heater is completely assembled, push the disconnect

switch to the “on” position and rotate thermostat knob counterclockwise until control stops. This is the minimum heat

setting.

2. Turn power supply to heater “ON” at main switch panel.

3. Heater should not operate. If it operates, disconnect power

and re-check wiring.

4. Rotate thermostat clockwise until it stops (maximum heat

setting) and wait at least 2 minutes. Fan control will delay

fan coming on until element is warm.

5. If heater and fan do not come on, disconnect power and

6. Allow heater to continue to operate until room temperature

IF FAN SHUTS OFF IMMEDIATELY, THERMOSTAT WIRING IS

INCORRECT AND MUST BE CHANGED. FAN MUST DELAY SHUTTING OFF TO EXPEL RESIDUAL HEAT TO PREVENT PREMATURE AGING OF INTERNAL HEATER COMPONENTS THAT

COULD LEAD TO A HAZARD OR PREMATURE FAILURE.

check wiring.

reaches desired comfort level. Then rotate thermostat knob

counterclockwise slowly until thermostat clicks off. Fan will

continue to operate for a minute or so until element cools.

a

CAUTION

!

CAUTION

THE ILLUMINATED INDICATOR LIGHT SIGNIFIES THE HEATER

HAS BEEN SUBJECTED TO SOME ABNORMAL CONDITION.

CHECK HEATERTO INSURE THATIT HAS NOT BEEN BLOCKED IN

ANY MANNER (IF SO, REMOVE BLOCKAGE). IF THERE IS NO

INDICATION OF BLOCKAGE, IT IS RECOMMENDED THE HEATER

BE CHECKED BY A REPUTABLE ELECTRICIAN OR REPAIR SERVICE TO INSURE THE HEATER HAS NOT BEEN DAMAGED.

BACK BOX

SCREW

SCREW

Figure 4

3

GRILLE BRACKET

GRILLE

Page 4

Specifications

IMPORTANT INFORMATION

MODEL

NO.

SWH1012AG

SWH1512AG

SWH1812AG

SWH2024AG

SWH2027AG

SWH1527AG

SWH2020AG

SWHSM

SWHS1

SWHS2

VOLTS

AMPS

WATTS

BTU/HR

WIRE

SIZE

120

120

8.40

4.20

12.50

6.25

120

240

15.0

8.40

4.20

208

7.30

3.61

277

240

7.30

3.61

6.25

3.20

277

240

5.50

2.75

4.70

2.35

208

Surface Mounting Frame (Accessory) Order Separately

12-1/2” (318mm)H X 10-3/8” (264mm)W X 4” (102mm)D

1” (25mm) Recess Mounting Frame (Accessory) Order Separately

2” (50mm) Recess Mounting Frame (Accessory) Order Separately

9.6

4.8

1000

500

1500

750

1800

2000

1000

1500

750

2000

1000

1500

750

1500

750

1125

562

2000

1000

3413

1706

5120

2560

6143

6826

3413

5120

2560

6826

3413

5120

2560

5120

2560

3840

1920

6826

3413

14AWG

12AWG

12 AWG

14AWG

14AWG

14AWG

14AWG

NAMEPLATE

MODEL NO.

SMALL ROOM FAN FORCED HEATERS

1000/500W @ 120VAC 60HZ

MUST BE USED WITH BACK BOX.

DO NOT OPERATE WITHOUT FRONT

COVER IN PLACE.

MARLEY ENGINEERED PRODUCTS

BENNETTSVILLE, SC 29512

SWH1012AG DATE CODE 0606

774G LISTED

ROOM HEATER

All products manufactured by Marley Engineered Products are warranted against defects in workmanship and materials for one year from date of

LIMITED WARRANTY

installation, except heating elements which are warranted against defects in workmanship and materials for five years from date of installation. This

warranty does not apply to damage from accident, misuse, or alteration; nor where the connected voltage is more than 5% above the nameplate

voltage; nor to equipment improperly installed or wired or maintained in violation of the product’s installation instructions. All claims for warranty work

must be accompanied by proof of the date of installation.

The customer shall be responsible for all costs incurred in the removal or reinstallation of products, including labor costs, and shipping costs incurred

to return products to Marley Engineered Products Service Center.Within the limitations of this warranty, inoperative units should be returned to the

nearest Marley authorized service center or the Marley Engineered Products Service Center, and we will repair or replace, at our option, at no charge

to you with return freight paid by Marley. It is agreed that such repair or replacement is the exclusive remedy available from Marley Engineered

Products.

THEABOVE WARRANTIESARE IN LIEU OFALLOTHER WARRANTIES EXPRESSED OR IMPLIED. AND ALL IMPLIED WARRANTIES OF MERCHANTABILITYAND FITNESS FOR A PARTICULAR PURPOSE WHICH EXCEED THE AFORESAID EXPRESSED WARRANTIESARE HEREBY

DISCLAIMED AND EXCLUDED FROM THIS AGREEMENT. MARLEY ENGINEERED PRODUCTS SHALL NOT BE LIABLE FOR CONSEQUENTIAL DAMAGES ARISING WITH RESPECT TO THE PRODUCT, WHETHER BASED UPON NEGLIGENCE, TORT, STRICT LIABILITY, OR CONTRACT.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above exclusion or limitation may not apply to

you. This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

For the address of your nearest authorized service center, contact Marley Engineered Products in Bennettsville, SC, at 1-800-642-4328.

Merchandise returned to the factory must be accompanied by a return authorization and service identification tag, both available from Marley

Engineered Products. When requesting return authorization, include all catalog numbers shown on the products.

HOW TO OBTAIN WARRANTY SERVICE AND

WARRANTY PARTS PLUS GENERAL INFORMATION

1. Warranty Service or Parts 1-800-642-4328

2. Purchase Replacement Parts 1-800-654-3545

3. General Product Information www.marleymep.com

Note: When obtaining service always have the following:

1. Model number of the product

2. Date of manufacture

3. Part number or description

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

Part No. 5200-2792-001

ECR 37927

08-08

4

Loading...

Loading...