Page 1

900 Series

Cabinet Unit Heaters

Model B

Installation & Maintenance Instructions

Dear Owner,

Congratulations! Thank you for purchasing this new heater manufactured by Marley Engineered Products.

You have made a wise investment selecting the highest quality product in the heating industry. Please carefully read and follow the installation and maintenance directions shown in this manual. You should enjoy

years of efficient heating comfort with this product from Marley Engineered Products... the industry’s leader

in design, manufacturing, quality and service.

... The Employees of

Marley Engineered Products

!

Read carefully - These instructions are written to help

you prevent difficulties that might arise during installation

of heaters. Studying the instructions first may save you

considerable time and money later. Observe the

following procedures and cut your installation time to a

minimum.

TO REDUCE RISK OF FIRE AND ELECTRIC SHOCK:

1. Disconnect all power coming to the heater at main

service panel before wiring or servicing.

Note: More than one disconnect may be required.

2. All wiring must be in accordance with national and

local electric codes and the heater must be

grounded.

3. Verify the power supply voltage coming to heater

matches the ratings printed on the heater nameplate

before energizing.

4. This heater is hot when in use. To avoid burns, do

not let bare skin touch hot surfaces.

5. Do not insert or allow foreign objects to enter any

ventilation or exhaust opening as this may cause

WARNING

electric shock, fire, or damage to heater.

6. Do not block air intakes or exhaust in any manner.

Keep combustible materials at least 24” (610 mm)

away from heater. Keep drapes at least 6” (153 mm)

above top of front discharge grille. Do not use

drapes above top discharge units. Do not install

behind doors, furniture, towel rack, or boxes.

7. A heater has hot and arcing (sparking) parts inside.

Do not use in areas where gasoline, paint, or

flammable liquids are used or stored.

8. Use this heater only as described in this manual. Any

other use not recommended by the manufacturer

may cause fire, electric shock, or injury.

9. This heater is not approved for use in corrosive

atmospheres such as marine, green house, or

chemical storage areas.

10. FOR DUCT CONNECTED HEATERS, Do not

exceed 0.2” wg. external static pressure and do not

mount heater on end panels.

11. Do not use OPTIONAL 0-100% OUTSIDE AIR

DAMPER with bottom air inlet.

SAVE THESE INSTRUCTION SHEETS

1

Page 2

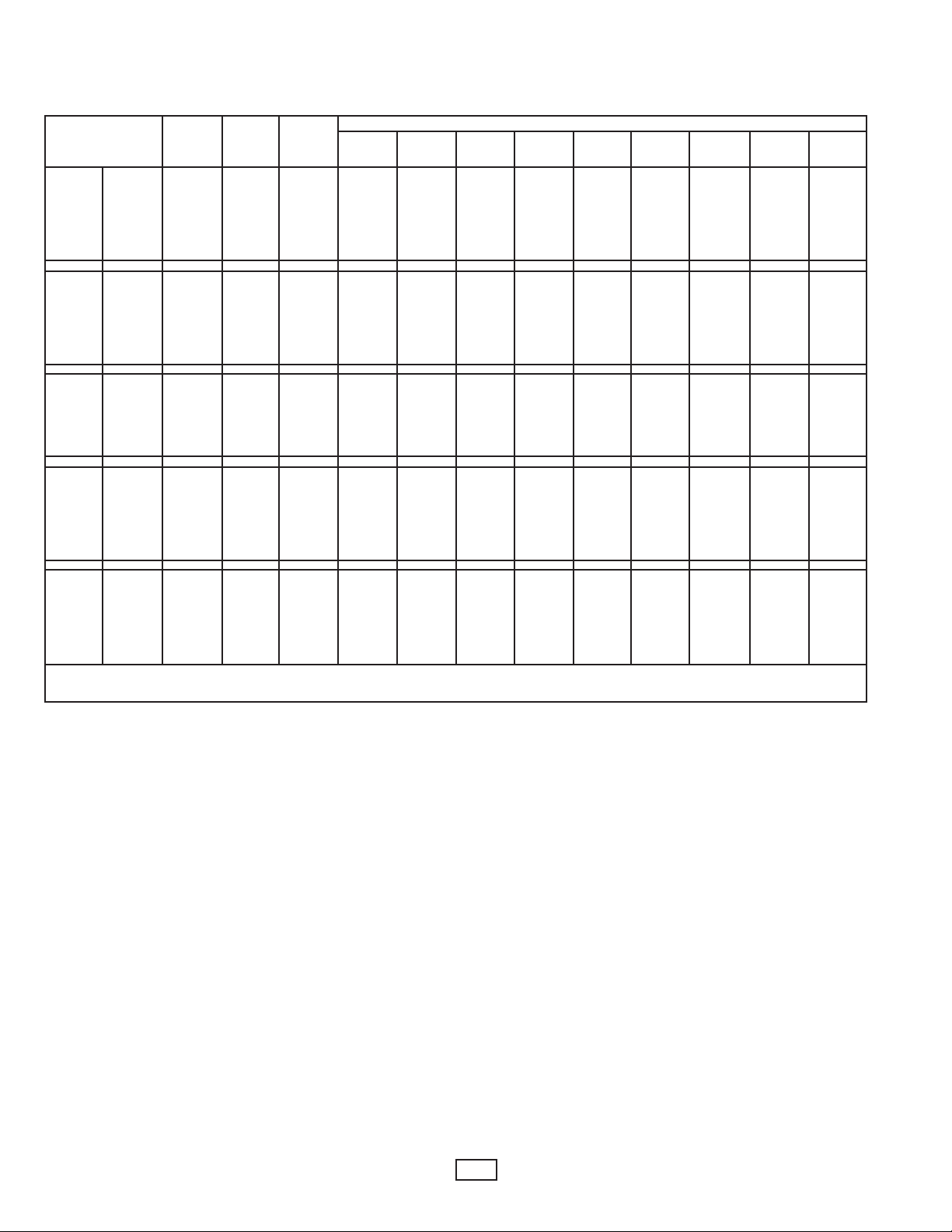

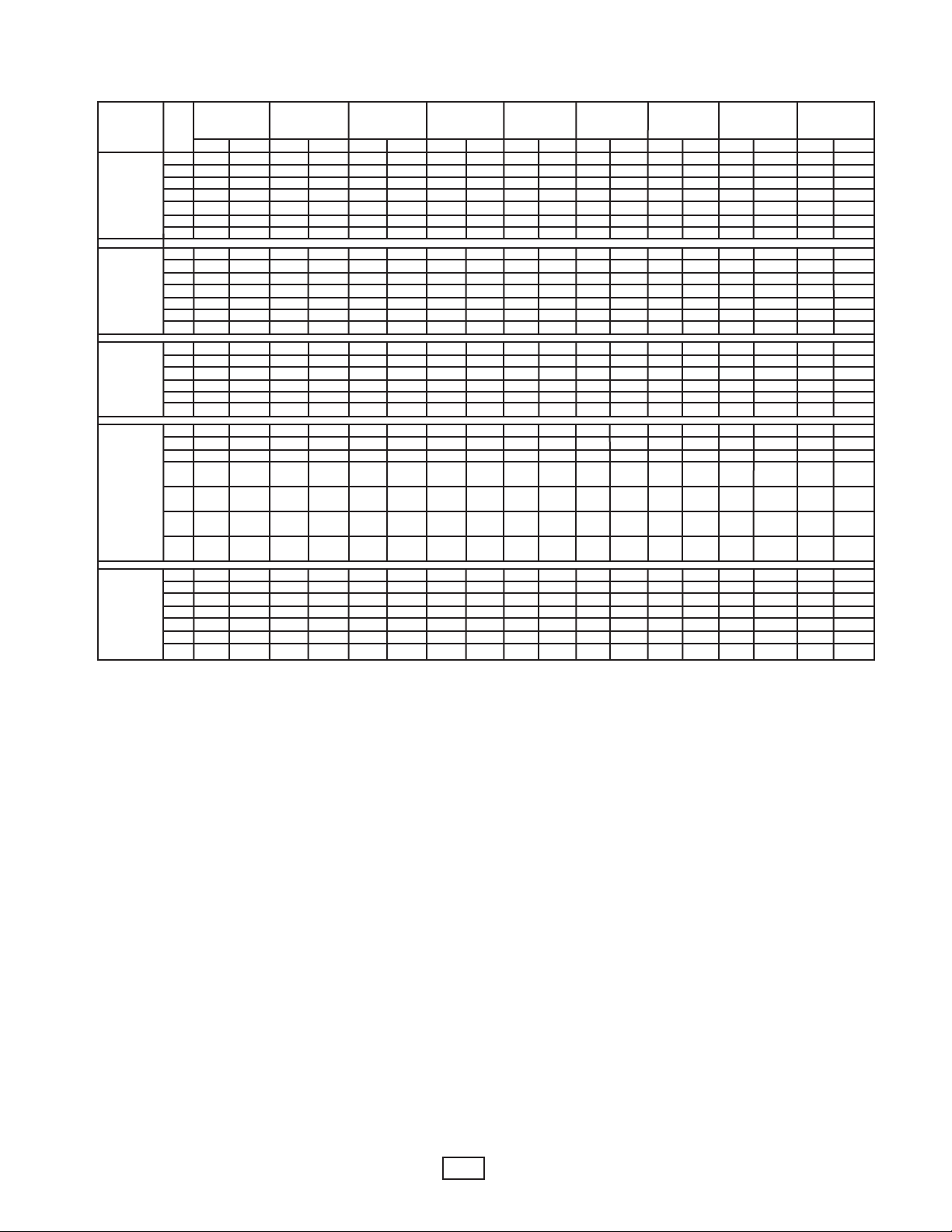

Specifications

HEATING

CAPACITY

eries

K

2

3

4

5

6

7

8

4

6

8

1

12

14

16

6

8

10

1

14

1

6

9

1

15

1

21

24

8

12

16

20

24

28

32

6,826

10,239

13,652

7,065

1

20,478

23,891

27,304

13,652

20,478

27,304

4,130

3

0

40,956

47,785

54,608

20,478

27,304

34,103

0,956

4

2

47,782

4,608

5

6

20,478

30,717

0,956

4

2

51,195

1,434

6

8

71,673

81,912

27,304

40,956

54,608

68,260

81,912

95,564

109,216

TU/hr

B

W

† - CIRCUIT BREAKERS or FUSED DISCONNECT required

* - Value shown for HIGH SPEED on two speed units

S

9

945

9

968

978

Cabinet

ength

L

in)

(

35

58

5

3

45

8

5

68

78

FM*

C

50

2

500

50

7

750

1,000

1

6

208

ph

0 Hz

10

15

20

5

2

30

34

39

20

30

40

8

4

59†

68†

78†

30

40

48

9†

5

68†

8†

7

31

45

0

6

74

8

8

n/a

n/a

41

60†

79†

n/a

n/a

n/a

n/a

208

3

0 Hz

6

5

60†

69†

58†

69†

80†

91†

ph

12

1

17

20

23

12

18

23

2

34

40

46

18

23

29

3

40

4

19

27

3

44

24

36

47

Total Line Amperage (includes motor amps)

6

240

ph

3

0 Hz

6

8

10

1

15

18

20

11

16

20

2

30

35

40

16

20

25

3

35

4

16

24

3

38

4

52†

60†

21

31

41

50†

60†

70†

79†

3

5

0

0

1

5

240

ph

1

0 Hz

6

6

9

5

9

4

6

5

2†

13

17

2

26

30

34

18

26

34

4

51†

59†

68†

26

34

43

5

59†

6

27

39

5

64†

7

89†

n/a

36

52†

69†

86†

n/a

n/a

n/a

9

2

3

1†

8†

2†

7†

1

6

277

ph

0 Hz

8

12

15

9

1

22

26

30

16

23

30

7

3

44

52†

59†

23

30

37

4

4

52†

9†

5

24

34

5

4

56†

7†

6

78†

n/a

31

46

60†

74†

n/a

n/a

n/a

1

6

347

ph

0 Hz

7

9

12

5

1

18

21

24

13

18

24

0

3

36

41

47

18

24

30

6

3

41

7

4

19

28

6

3

45

/a

n

n/a

n/a

25

37

48

n/a

n/a

n/a

n/a

3

6

380

ph

0 Hz

4

5

7

8

10

11

13

7

10

13

6

1

19

22

25

10

13

16

9

1

22

5

2

11

16

0

2

25

9

2

34

38

14

20

27

33

39

45

n/a

3

6

480

ph

0 Hz

3

4

6

7

8

9

10

6

8

11

3

1

16

18

20

8

11

13

6

1

18

0

2

9

13

6

1

20

4

2

27

31

12

17

21

26

31

36

41

3

6

600

ph

0 Hz

3

4

5

6

7

7

8

5

7

9

1

1

13

15

17

7

9

11

3

1

15

7

1

8

11

3

1

16

9

1

22

25

10

14

18

21

15

29

33

2

Page 3

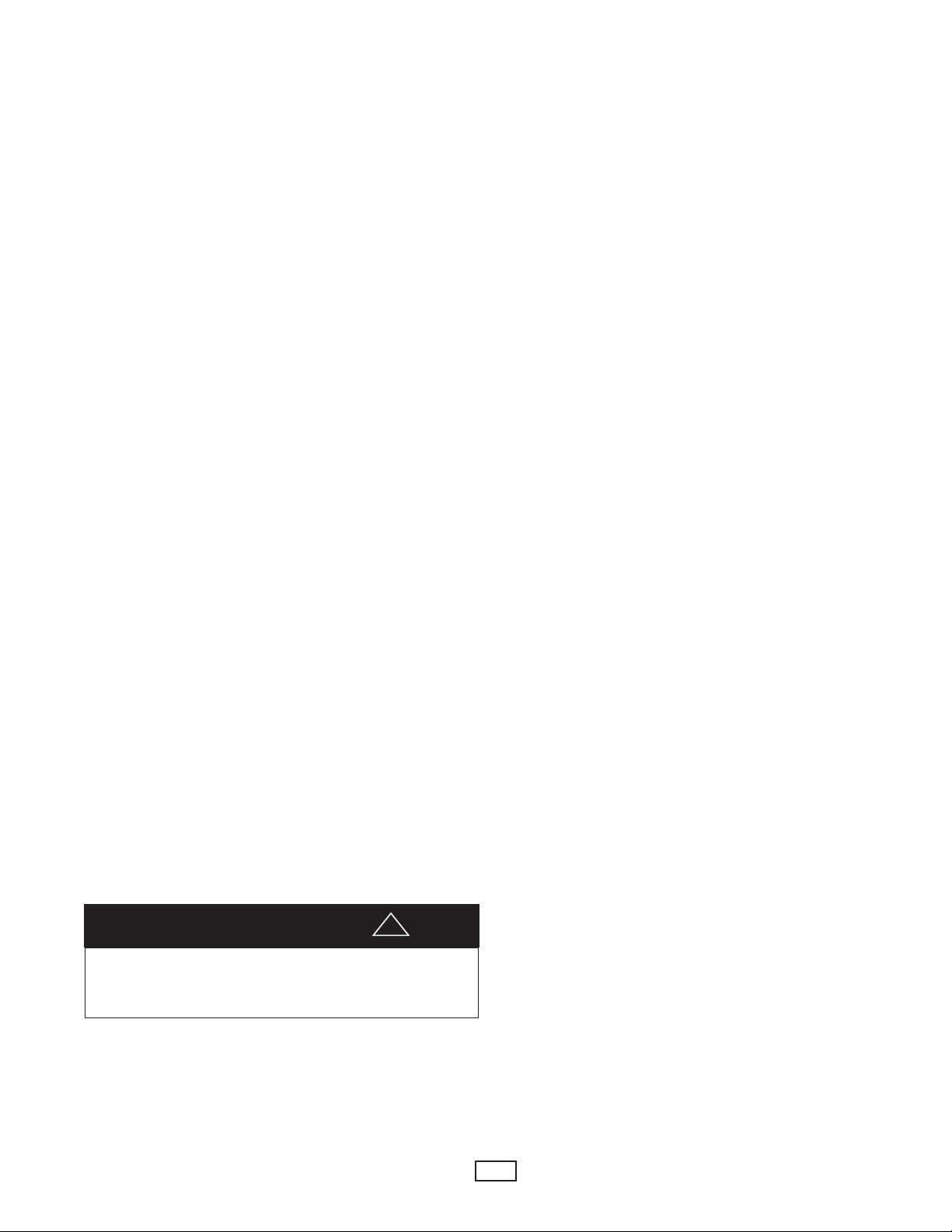

General Information

900 Series Cabinet Unit Heaters are designed and UL & cUL

Listed to be applied as Standard Free Air heaters with both

louvered intake and louvered discharge panels for recess or

surface installation: a) on the floor, with front inlet and up flow

air movement in the up flow, down flow, left or right direction or

b) on the ceiling, or Ducted (0.2” wg external static pressure)

flange for direct connection of field supplied ductwork to the

inlet, discharge, or both inlet and discharge. Ducted heaters

can be installed for recess or surface installation: a) on the

floor, with front inlet and up flow air movement, b) on the wall,

with air movement in the up flow or down flow direction or c)

on the ceiling.

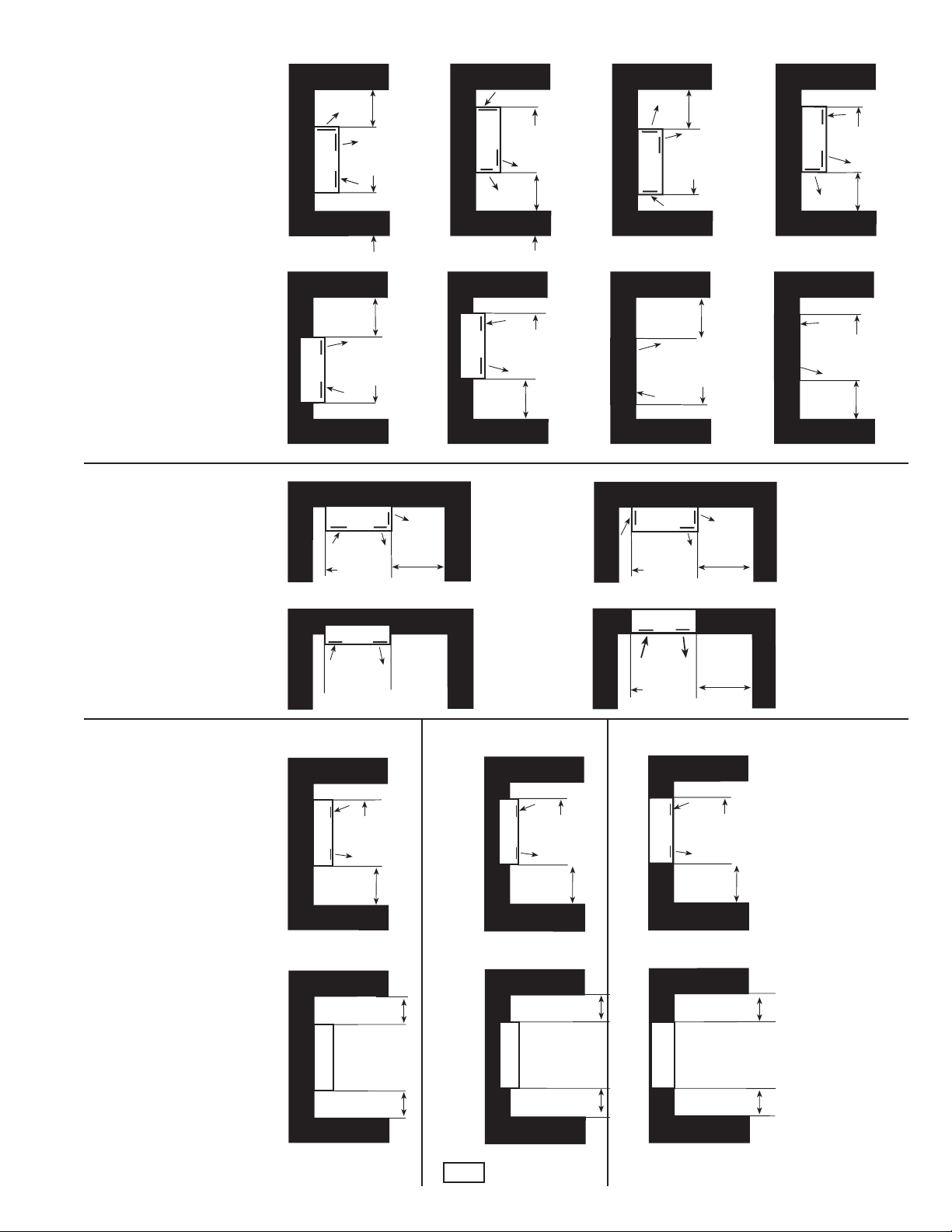

See Figure 1 for Mounting Clearances.

Note: Keep all furniture or any other blocking material at least

24” (610mm) away from front of heater.

When draperies are used, hang them so that when in use they

are at least 6” (153mm) above the top of front discharge

heater.

Do not use draperies with top discharge heaters.

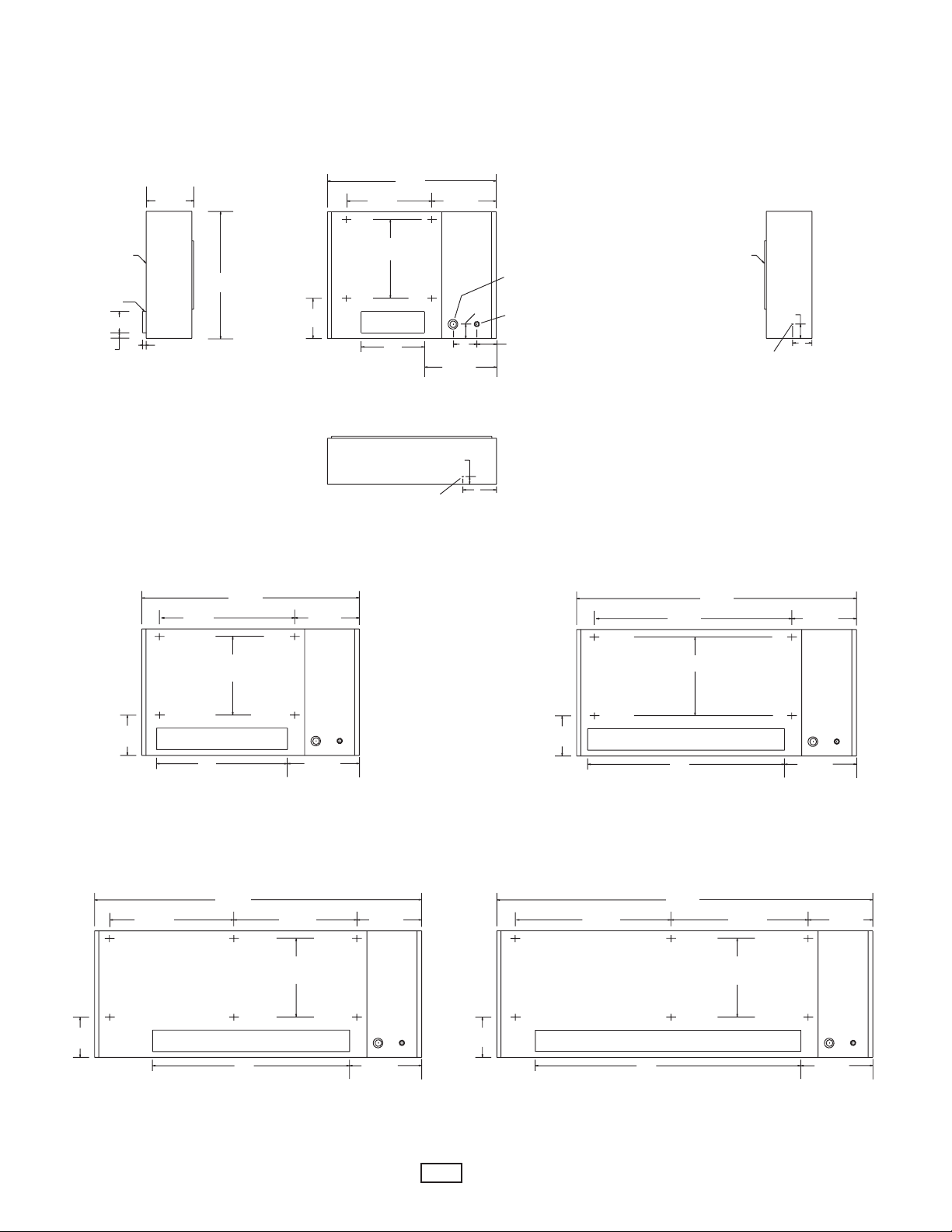

See Figure 2 for Mounting Dimensions

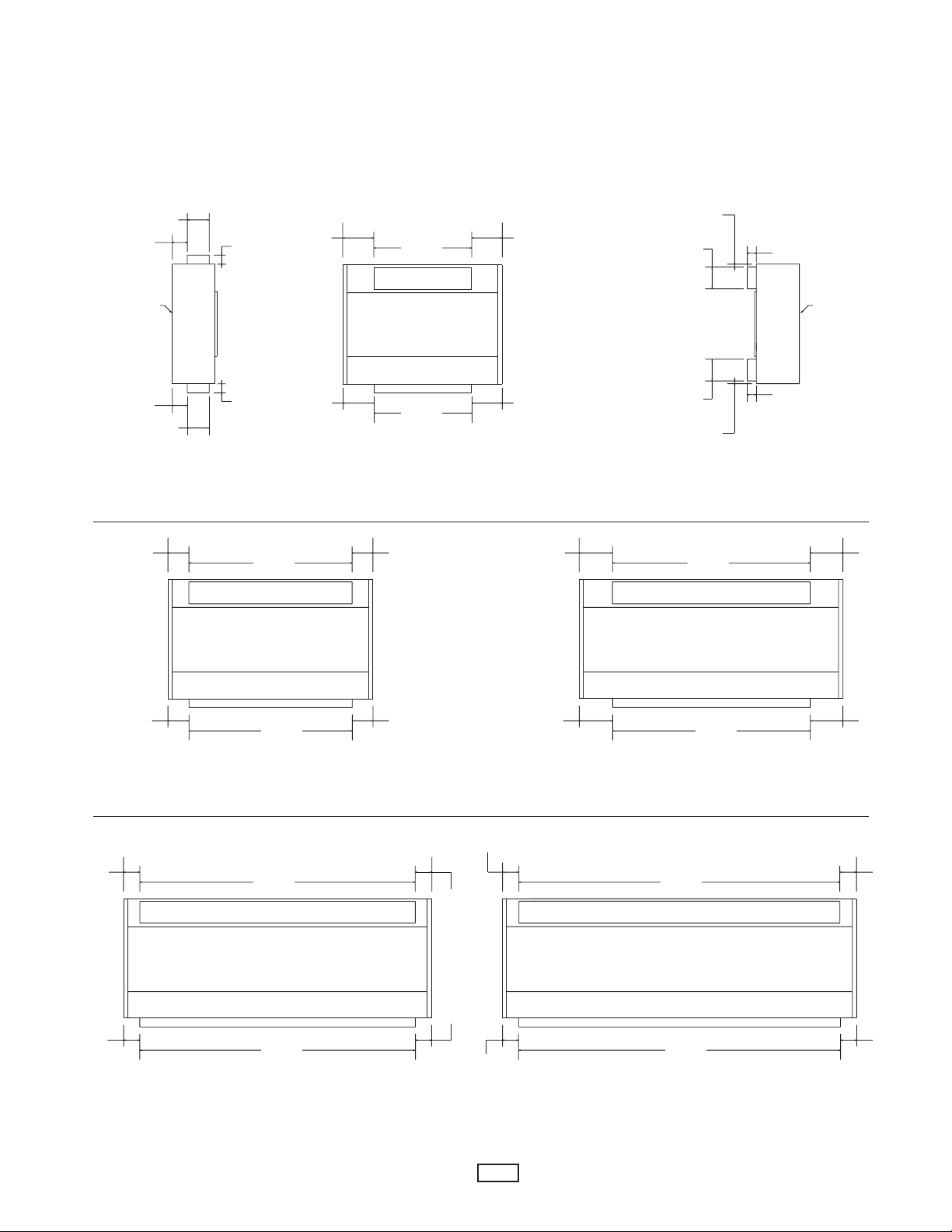

See Figure 3 for Duct Collar Dimensions and Installation

Details.

FLOOR MOUNTING

Heaters with front inlet and up flow air movement

1.

may be mounted directly on any floor surface

including carpeting. Where wall to wall carpeting is

installed after heater installation the carpeting can be

run up to the front and around the heater body. See

Figure 1 for mounting clearances.

2. Heaters can be mounted on either end with air movement

left or right directly on any floor surface including carpeting.

See Figure 1 for mounting clearances.

3. If optional kick plate is not used, proceed to “HEATER

INSTALLATION” section.

INSTALLATION OF OPTIONAL 900 SERIES

BASE KIT

1. If desired, the heaters may be mounted off the floor with

optional kick plate panel.

2. Align panel on bottom of heater (Inlet side only.)

3. There should be a 1” (25mm) space from the panel to the

front and sides of the heater.

4. Match drill .140” (3.55 mm) diameter holes in the bottom of

the heater and secure with screws provided.

5. Proceed to “HEATER INSTALLATION” section.

CAUTION

TO PREVENT HEATER FROM FALLING AND CAUSING

PERSONAL INJURY, EACH FASTENER, AS APPLIED,

SHOULD HAVE THE HOLDING POWER OF AT LEAST 100

POUNDS (45 kg).

!

WALL OR CEILING RECESS MOUNTING

1. Create on opening in the wall 26-5/8” (676mm) high by the

width of the heater plus 1/4” (6.4mm). Example: If the heater

was 68 inches long, the opening should measure

26-5/8” high x 68-1/4” long).

2. The depth of the recess will vary with the desired amount

of heater recess.

3. Proceed to “HEATER INSTALLATION” section.

INSTALLATION OF OPTIONAL

900 SERIES RECESS TRIM KIT

1. Determine depth of heater recess.

2. Align recess trim frame so that the trim frame front edge

will touch wall when heater is installed.

3. Match drill .140” (3.55mm) diameter holes in all four sides of

the heater and secure trim frame with screws provided.

4. Proceed to “HEATER INSTALLATION” section.

HEATER INSTALLATION

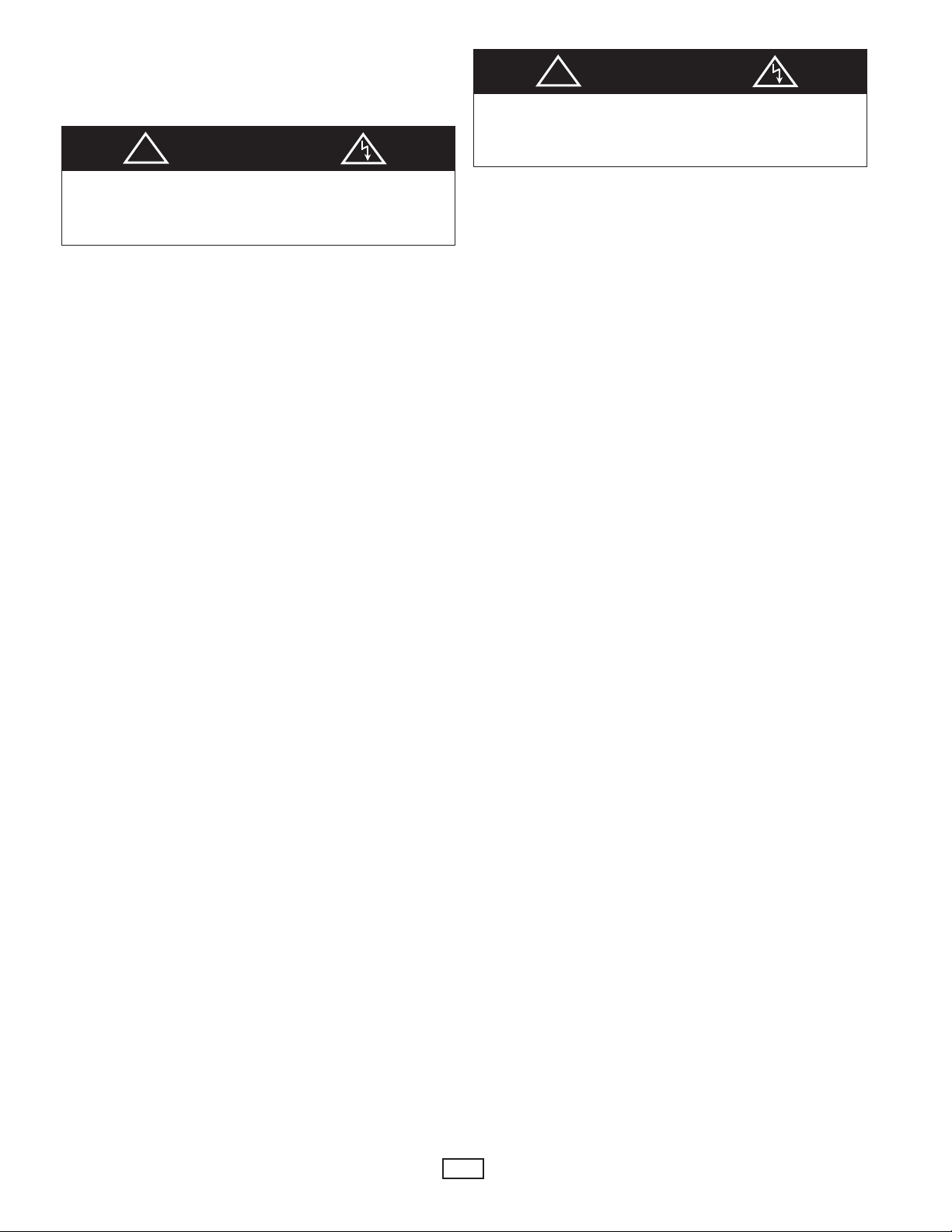

1. Rough-in electrical wiring. See Figure 2 for knockout locations.

2. Remove the proper knockout in the heater or punch the

proper size hole in the bottom or right side of the heater as

shown in Figure 2.

3. Remove the front cover by rotating the lock(s)

counter-clockwise (ccw).

4. Remove Top (Discharge) Louver Panel by removing 2

screws (one on each end) that attach the louver panel to

the end panels.

5. Refer to Figure 3 for location of mounting holes.

6. Mark and drill holes for heater attachment in wall or ceiling.

7. Install heater in opening and tighten screws (field supplied)

to insecure tight fit of the heater against the mounting

surface.

NOTE: Tightening the heater against an irregular wall

will cause distortion of the back panel of the heater. If

this is the case, shims should be used behind the back

panel to keep it straight.

8. Reinstall the Top (Discharge) Louver Panel by sliding the

panel into the heater. Position the panel tabs of the louver

panel to rest on the top of the lip of the heater back.

Position the louver panel top even with the top of the end

panels. Tap the louver panel at the top front (both sides) to

seat the panel. Reinstall 2 screws (one on each side) that

attach louver panel to the end panels.

9. WIRING - See wiring section.

10.After wiring is complete, insure that the control box cover is

closed and fastened and that the filter is installed.

11.Adjust the thermostat to the desired set point.

12.Adjust the heat selector to the heat and fan speed desired.

13.Replace front cover and secure by turning the locks

clockwise (cw) until tight. Replace plug buttons provided.

14.Leave the heater running a few hours before making any

further change in thermostat setting.

3

Page 4

DUCTED APPLICATIONS

1. See Figure 3 for duct flange size and location.

2. Duct collars have been factory located (Bottom inlet, Front

inlet, Top discharge, Front discharge) as ordered.

!

WARNING

TO REDUCE RISK OF FIRE AND ELECTRICAL

SHOCK: DO NOT EXCEED 0.2” WG EXTERNAL STATIC

PRESSURE. DO NOT MOUNT HEATER ON END PANEL

(LEFT OR RIGHT AIR FLOW).

3. To change duct collar location:

A. Heater duct panels are supplied with a duct collar attached

to one surface and a blank-off plate attached to the other

surface. The location of the duct collar and the blank-off

plate can reversed.

B. Remove screws holding blank-off plate and remove

blank-off plate.

C. Remove screws holding duct collar and remove duct collar.

D. Position duct collar to location desired, align screws holes,

insert and tighten screws to secure duct collar to duct

panel.

E. Position blank-off plate to location desired, align screw

holes, insert and tighten screws blank-off plate to duct

panel.

4. Position field ductwork to outside of heater duct flange.

5. Mark and drill starting holes in duct and flange.

6. Install and tighten screws (field supplied) to provide a

secure seal.

!

WARNING

TO REDUCE RISK OF FIRE AND ELECTRICAL

SHOCK: DO NOT USE 100% OUTSIDE AIR DAMPER

OPTION WITH BOTTOM AIR INLET. USE ONLY FRONT AIR

INLET WITH 100% OUTSIDE AIR DAMPER OPTION.

OPTIONAL

100% OUTSIDE AIR DAMPER

1. Flange brackets for the rear mounted duct collar are

packaged unassembled in the heater carton.

2. See Figure 2 for location of damper opening.

3. Position the top flange bracket with the flange at the top of

the damper opening and holes in the flange align with

holes in the cabinet back.

4. Attach flange to cabinet with screws provided.

5. Position and attach remaining three (3) flange brackets

around damper opening.

6. Position field ductwork to outside of flange brackets.

7. Mark and drill starting holes in duct and flange.

8. Install and tighten screws (field supplied) to provide a

secure seal.

OPERATION OF OPTIONAL

100% OUTSIDE AIR DAMPER

1. Controls, consisting of an “OPEN-CLOSED” switch and

100% positioning potentiometer, are located on the

control panel door.

2. Place switch in OPEN position.

3. The damper will remain open until; the “OPEN-CLOSED”

switch is moved to the closed position.

4

Page 5

Zero or greater

Upflow

C

eiling

24" min.

(610 mm)

Downflow

Ceiling

24" min.

(

610 mm)

5

" min.

(127 mm)

24" min.

(

610 mm)

U

pflow

5" min.

(127 mm)

Z

ero or greater

2

4" min.

(610 mm)

Zero or greater

24" min.

(610 mm)

Z

ero or greater

24" min.

(610 mm)

Z

ero or greater

24" min.

(

610 mm)

Zero or greater

2

4" min.

(

610 mm)

Floor

Wall

Floor

Wall

Ceiling

Wall

Wall

Zero or

greater

24" min.

(610 mm)

5" min

(127mm)

24" min.

(610 mm)

Ceiling mounted

Zero or

greater

24" min.

(610 mm)

Ceiling mounted (semi-recess)

24" min.

(610 mm)

Zero or greater

Ceiling

Wall

Wall

Wall

Wall

End mounting

24" min.

(610 mm)

Zero or greater

End mounting

semi-recess

24" min.

(610 mm)

Zero or greater

End mounting

full recess

Zero or greater

Ceiling

Floor

End mounting

Zero or greater

End mounting

semi-recess

End mounting

full recess

Wall

Wall

Wall

Wall

Wall

Wall

Wall

Ceiling

Floor

Wall

Ceiling

Floor

Wall

Zero or greater

Zero or greater

Zero or greater

Zero or greater

Downflow

Upflow

(

semi-recessed)

Upflow

(

full recessed)

Downflow

(semi-recessed)

Downflow

(full recessed)

Ceiling mounted

Ceiling mounted

(full recess)

Figure 1

HEATER:

Wall Mounted

AIR FLOW:

Up or Down

HEATER:

Ceiling Mounted

Minimum 2” (52mm)

to side wall

HEATER:

Wall Mounted on

End Panel

AIR FLOW:

Left or Right

5

Page 6

MOUNTING DIMENSIONS

MOUNTING DIMENSIONS

35

CONTROL

COMPARTMENT

TOP

1

6-1/4

13-1/2

18

5

3

4

-3/8

2

6-3/8

13

14-1/2

O

PTIONAL

9

-7/8

4-1/2(114 mm)

1-3/8

3

/4 (19 mm)

O

UTSIDE AIR

8-7/16

FRONT VIEW

CONTROL

COMPARTMENT

27

OPTIONAL

14-3/8

28

45

TOP

COMPARTMENT

CONTROL

FRONT VIEW

OPTIONAL

41

41

58

TOP

FRONT VIEW

41

OPTIONAL

68

CONTROL

COMPARTMENT

TOP

25-1/2

OPTIONAL

FRONT VIEW

55

32-5/8

78

TOP

CONTROL

28-1/2

COMPARTMENT

Collar

O

PTIONAL

Heater Back

O

UTSIDE AIR

FRONT VIEW

LEFT SIDE VIEW

C

oncentric Knockouts

1-23/32", 1-23/64", 1-31/32"

7

/8", 1-3/32"

Concentric Knockouts

Typical All Heaters

Knockout Size & Location

NOTE:

8-7/16

OUTSIDE AIR

13-1/2

16-1/4

8-7/16

OUTSIDE AIR

14-3/8

13-1/2

16-1/4

13-1/2

8-7/16

16-1/4

14-3/8

OUTSIDE AIR

25-1/2

13-1/2

14-3/8

OUTSIDE AIR

8-7/16

16-1/4

RIGHT SIDE VIEW

Front Cover

3

4

Drill location for conduit hole

BOTTOM VIEW

1-5/8

7

Drill location for conduit hole

(670 mm)

(251 mm)

(214 mm)

(

889 mm)

(

457 mm)

(

343 mm)

(

413 mm)

(35 mm)

(330 mm)

(368 mm)

(

111 mm)

(7

6

m

m

)

(127 mm)

(76 mm)

(102 mm)

(41 mm)

(178 mm)

(1143 mm)

(343 mm)

(711 mm)

(413 mm)

(365 mm)

(686 mm)

(214 mm)

(343 mm)

(1041 mm)

(1473 mm)

(365 mm)

(1041 mm)

(214 mm)

(413 mm)

(343 mm)

(648 mm)

(648 mm)

(1727 mm)

(413 mm)

(214 mm)

(1041 mm)

(365 mm)

(343 mm)

(724 mm)

(829 mm)

(1981 mm)

(214 mm)

(413 mm)

(1397 mm)

(365 mm)

Figure 2Figure 2

Air Flow --->

Air Flow --->

Air Flow --->

Air Flow --->

I

ncluding Front Cover

(Typ. all lengths)

(Typ. all lengths)

(Typ. all lengths)

35" (889 mm) CABINET

45" (1143 mm) CABINET

58" (1473 mm) CABINET

68" (1727 mm) CABINET

78" (1981 mm) CABINET

Figure 2

6

Page 7

DIMENSIONS and INSTALLATION DETAILS

DIMENSIONS and INSTALLATION DETAILS

DUCT COLLARSDUCT COLLARS

RIGHT SIDE VIEW

Air Flow --->

Air Flow --->

Air Flow --->

Figure 3Figure 3

LEFT SIDE VIEW

Heater Back

Air Flow --->

FRONT VIEW

2 (51mm)

4

-7/8

(124 mm)

4-1/16

(103 mm)

2 (51mm)

4-7/8

(124 mm)

(103 mm)

4-1/16

BOTTOM INLET /

2

(51mm)

(14 mm)

9/16

4-7/8

(

124 mm)

(Typ. all lengths)

(

14 mm)

9/16

(

124 mm)

4-7/8

2 (51mm)

Air Flow --->

Heater Back

(Typ. all lengths)

TOP DISCHARGE

FRONT INLET /

FRONT DISCHARGE

(543 mm)

21-3/8

6

-13/16

(

173 mm)

(

173 mm)

6

-13/16

35" (889 mm) CABINET

21-3/8

(173 mm)

6-13/16

(543 mm)

6-13/16

(173 mm)

4-5/8

(118 mm)

35-3/4

(

908 mm)

(118 mm)

4-5/8

35-3/4

4-5/8

(

908 mm)

4-5/8

(118 mm)(118 mm)

FRONT VIEW

45" (1143 mm) CABINET

43-3/8

(

1102 mm)

7-5/16

(186 mm)

(186 mm)

7-5/16

7-5/16

(186 mm)

45-3/8

(

1102 mm)

(186 mm)

7-5/16

58" (1473 mm) CABINET

FRONT VIEW

68" (1727 mm) CABINET

FRONT VIEW

3-5/8

(92 mm)

60-3/4

(1543 mm)

(92 mm)

3-5/8

60-3/4

(1543 mm)

3-5/8

(92 mm)

(92 mm)

3-5/8

(92 mm)

3-5/8

70-3/4

(1797 mm)

(1797 mm)

70-3/4

(92 mm)

3-5/8

(92 mm)

3-5/8

Air Flow --->

3-5/8

(92 mm)

FRONT VIEW

78" (1981 mm) CABINET

7

Page 8

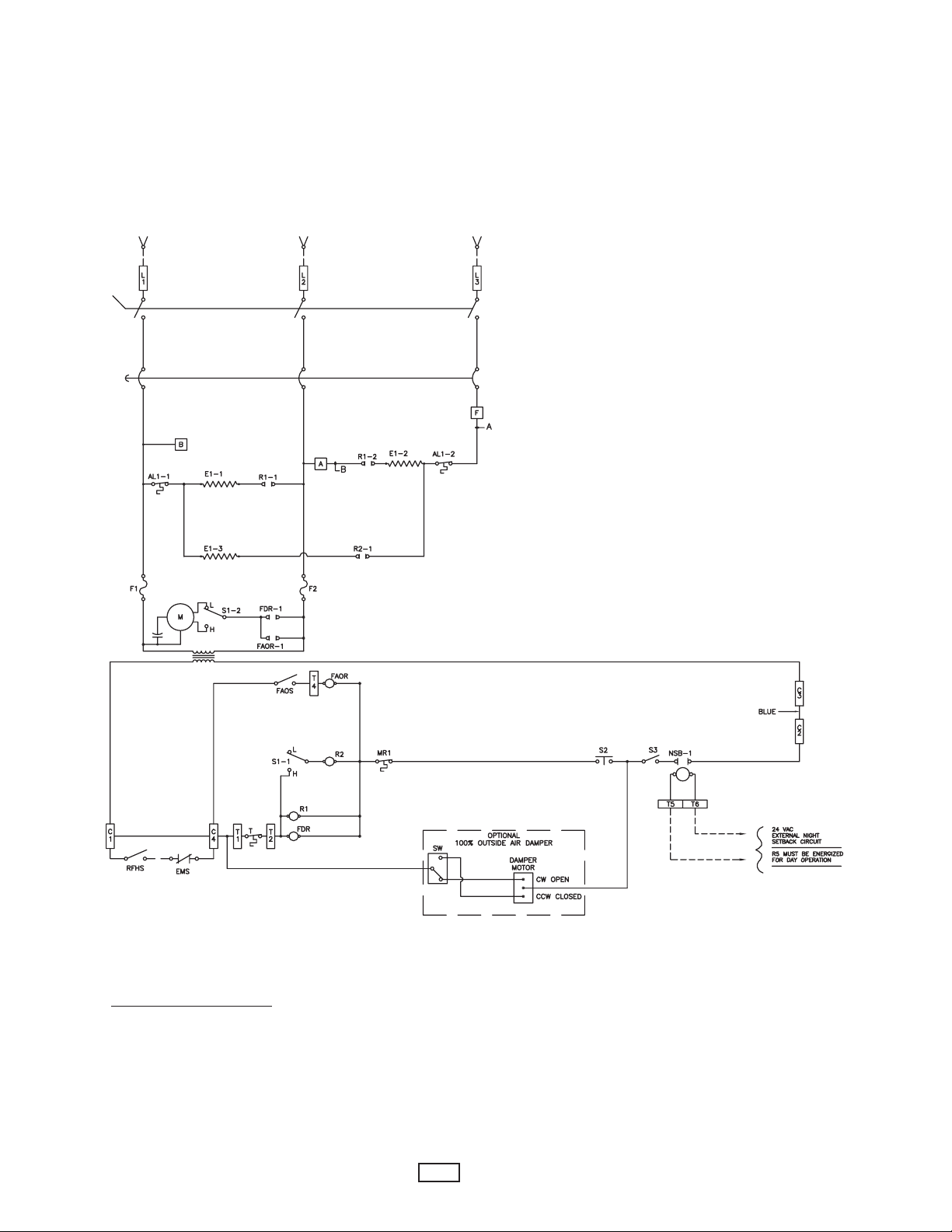

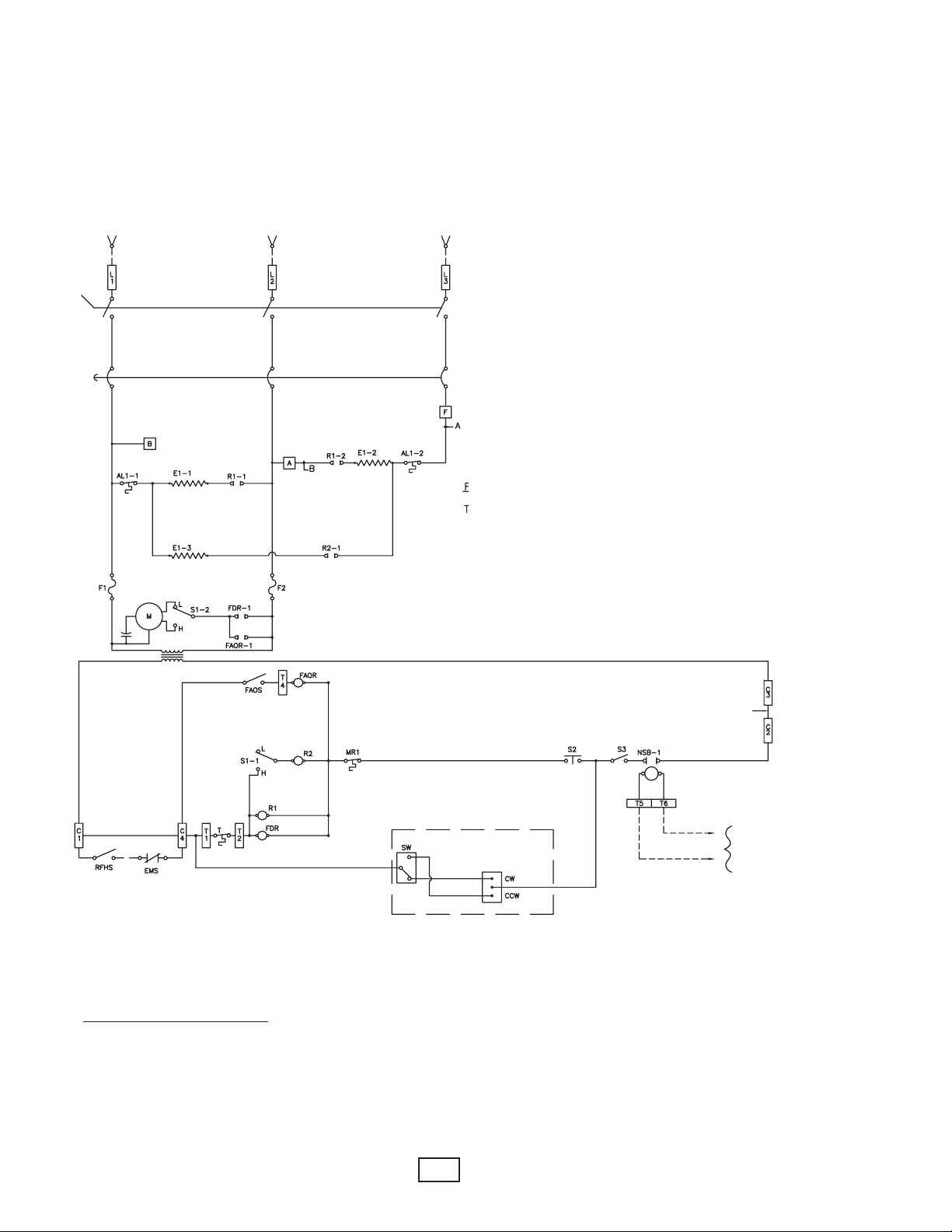

WIRING

SEE WARNING STEPS 1, 2 & 3 ON PAGE 1 OF THIS

INSTRUCTION SHEET.

1. Figure 4 shows a typical wiring diagram.

2. For actual wiring, see the diagram located on the inside of the

front cover.

3. All field wiring must be 75˚ C min.

SUPPLY

OPTIONAL DISCONNECT SWITCH

OPTIONAL CIRCUIT BREAKER

POWER

TO CONVERT 208, 240, 480 & 600 VOLT

STOCK 5 & 10 KW HEATERS

From Three Phase To Single Phase

1. Remove front cover.

2. Refer to wiring diagram located located inside

front cover.

NOTE: Terminal block and wires that need to be

changed are located in wire way above right

hand (RH) blower housing.

3. Remove two screws holding wireway cover to fan

panel.

4. Rotate wireway cover up and out to remove.

5. Terminal block is located within wireway.

6. Relocate wires per wiring diagram located inside

front cover.

7. Reinstall wireway cover and reinstall screws.

8. Reinstall front cover.

Typical Wiring Diagram

See wiring diagram on the inside of heater front cover.

ORANGE

EMS=ENERGY MANAGEMENT SYSTEM TIE-IN (CONTACTS MUST BE CLOSED FOR DAY OPERATION)

RFHS=REMOTE MOUNTED FAN/HEAT ON-OFF SWITCH (FIELD SUPPLIED)

FOR EXTERNAL CONTROL SUPPLY:

S1 = FAN/HEAT HIGH-LOW SELECTOR SWITCH

S2 = DOOR INTERLOCK SWITCH

S3 = FAN/HEAT ON-OFF SWITCH (FACTORY INSTALLED OPTION)

NSB = NIGHT SETBACK RELAY (FACTORY INSTALLED OPTION)

NOTE: IF EMS AND/OR RFHS ARE INSTALLED REMOVE ORANGE WIRE BETWEEN C1 AND C4.

1. REMOVE BLUE JUMPER BETWEEN C2 AND C3.

2. CONNECT EXTERNAL CONTROL (24 VAC STANDARD, 120 VAC OPTIONAL) TO C1 AND C2.

AL = AUTO RESET LIMIT

MR = MANUAL RESET LIMIT (FACTORY INSTALLED OPTION)

T = BUILT-IN OR REMOTE MOUNTED SINGLE POLE THERMOSTAT

FAOS = FAN AUTO-ON SWITCH (BUILT-IN = FACTORY INSTALLED OPTION)

FDR = FAN DELAY RELAY

FAOR = FAN AUTO-ON RELAY (FACTORY INSTALLED OPTION)

8

(REMOTE MOUNTED = FIELD INSTALLED OPTION)

1609-2081-020

Page 9

CIRCUIT BREAKERS ORDER PART NO. 410086+VAR NOTED BELOW

ABINET 1 PH 3PH 1PH 3PH 1PH 1PH 3PH 3PH 3PH

C

ENGTH KW 60HZ 60HZ 60HZ 60HZ 60HZ 60HZ 60HZ 60HZ 60HZ

L

35 in. 51045 1 051 1 044 1 051 1 026 1 018 1 010 1 010 1 059

8 in. 10 1 049 1 055 1 048 1 054 1 007 1 022 1 012 1 011 1 059

4

5

68 in. 18 3 046 1 056 3 045 1 058 1 028 N/A N/A 1 014 1 013 1 061

78 in. 20 N/A N/A 2 055 2 049 2 054 1 068 N/A N/A 1 015 1 014 1 062

1

14 2 046 1 057 2 045 1 056 1 021 1 068 1 013 1 012 1 060

16 2 048 1 058 2 047 1 057 1 022 1 068 1 014 1 013 1 061

8 in. 10 1 049 1 055 1 048 1 054 1 027 1 021 1 011 1 010 1 059

12 2 046 1 056 2 045 1 055 1 007 1 023 1 012 1 011 1 060

14 2 046 1 057 2 045 1 056 1 021 1 068 1 013 1 012 1 060

16 2 048 1 058 2 047 1 057 1 022 1 068 1 014 1 013 1 061

12 2 046 1 056 2 045 1 055 1 007 1 008 1 013 1 012 1 060

1

21 N/A N/A 1 057 3 046 1 056 1 015 N/A N/A 1 015 1 014 1 062

24 N/A N/A 1 058 N/A N/A 1 057 N/A N/A N/A N/A 1 009 1 014 1 063

12 2 046 1 056 2 045 1 055 1 007 1 008 1 013 1 012 1 060

16 2 048 1 058 2 047 1 058 1 022 1 068 1 014 1 013 1 061

24 N/A N/A 2 055 N/A N/A 2 054 N/A N/A N/A N/A 1 009 1 014 1 063

28 N/A N/A 2 057 N/A N/A 2 056 N/A N/A N/A N/A 1 016 1 015 1 064

32 N/A N/A 2 058 N/A N/A 2 057 N/A N/A N/A N/A N/A N/A 1 016 1 065

208 208 240 240 277 347 380 480 600

TY VAR QYT VAR QTY VAR QTY VAR QTY VAR QTY VAR QTY VAR QTY VAR QTY VAR

Q

21041 1 050 1 041 1 050 1 024 1 017 1 010 1 010 1 059

31042 1 050 1 042 1 050 1 024 1 017 1 010 1 010 1 059

41043 1 050 1 043 1 050 1 025 1 018 1 010 1 010 1 059

1 046 1 052 1 045 1 051 1 026 1 019 1 010 1 010 1 059

6

1 047 1 053 1 046 1 052 1 027 1 020 1 010 1 010 1 059

7

1 048 1 053 1 047 1 052 1 027 1 020 1 010 1 010 1 059

8

41044 1 051 1 043 1 050 1 025 1 018 1 010 1 010 1 059

61046 1 052 1 045 1 051 1 026 1 019 1 010 1 010 1 059

1 048 1 053 1 047 1 053 1 027 1 021 1 011 1 010 1 059

8

2 2 046 1 056 2 045 1 055 1 007 1 023 1 012 1 011 1 060

1 046 1 052 1 045 1 051 1 026 1 019 1 010 1 010 1 059

6

1 048 1 053 1 047 1 053 1 027 1 021 1 011 1 010 1 059

8

1 046 1 052 1 045 1 052 1 026 1 019 1 010 1 010 1 059

6

91049 1 054 1 048 1 053 1 028 1 021 1 011 1 011 1 059

5 1 048 1 058 1 048 1 057 1 007 1 068 1 014 1 012 1 061

81049 1 054 1 047 1 054 1 027 1 021 1 011 1 010 1 059

045 1 044 1 026

1

1 052 1 026

1 053 1 052

1 053 1 053

9

Page 10

LEMENTS ORDER PART NO. 1802-2083+VAR NOTED BELOW

E

08 208 240 240 277 347 380 480 600

CABINET 1 PH 3PH 1PH 3PH 1PH 1PH 3PH 3PH 3PH

LENGTH KW 60HZ 60HZ 60HZ 60HZ 60HZ 60HZ 60HZ 60HZ 60HZ

35 in. 51110 1 110 1 111 1 111 1 112 1 113 1 110 1 112 1 113

8 in. 10 2 110 2 110 2 111 2 111 2 112 2 113 2 110 2 112 2 113

4

58 in. 10 2 110 2 110 2 111 2 111 2 112 2 113 2 110 2 112 2 113

68 in. 18 6 107 6 107 6 108 6 108 6 104 N/A N/A 6 107 6 104 6 105

78 in. 20 N/A N/A 4 110 4 111 4 111 4 112 N/A N/A 4 110 4 112 4 113

1

14 2 107 2 107 2 108 2 108 2 104 2 105 2 107 2 104 2 105

16 2 107 2 107 2 108 2 108 2 104 2 105 2 107 2 104 2 105

12 4 107 4 107 4 108 4 108 4 104 4 105 4 107 4 104 4 105

1

16 2 107 2 107 2 108 2 108 2 104 2 105 2 107 2 104 2 105

12 3 106 3 106 3 107 3 107 3 108 3 109 3 106 3 108 3 109

15 3 110 3 110 3 111 3 111 3 112 3 113 3 110 3 112 3 113

21 N/A N/A 3 107 3 108 3 108 3 104 N/A N/A 3 107 3 104 3 105

24 N/A N/A 3 107 N/A N/A 3 108 N/A N/A N/A N/A 3 107 3 104 3 105

12 4 107 4 107 4 108 4 108 4 104 4 105 4 107 4 104 4 105

16 4 106 4 106 4 107 4 107 4 108 4 109 4 106 4 108 4 109

24 N/A N/A 8 107 N/A N/A 8 108 N/A N/A N/A N/A 8 107 8 104 8 105

28 N/A N/A 4 107 N/A N/A 4 108 N/A N/A N/A N/A 4 107 4 104 4 105

32 N/A N/A 4 107 N/A N/A 4 108 N/A N/A N/A N/A N/A N/A 4 104 4 105

2

QTY VAR QTY VAR QTY VAR QTY VAR QTY VAR QTY VAR QTY VAR QTY VAR QTY VAR

1 100 1 100 1 101 1 101 1 102 1 103 1 100 1 102 1 103

2

1 107 1 107 1 114 1 114 1 104 1 105 1 107 1 104 1 105

3

41106 1 106 1 107 1 107 1 108 1 109 1 106 1 108 1 109

62107 2 107 2 108 2 108 2 104 2 105 2 107 2 104 2 105

71107 1 107 1 108 1 108 1 104 1 105 1 107 1 104 1 105

8

42100 2 100 2 101 2 101 2 102 2 103 2 100 2 102 2 103

62107 2 107 2 108 2 108 2 104 2 105 2 107 2 104 2 105

8

2 4 107 4 107 4 108 4 108 4 104 4 105 4 107 4 104 4 105

6

82106 2 106 2 107 2 107 2 108 2 109 2 106 2 108 2 109

4 2 107 2 107 2 108 2 108 2 104 2 105 2 107 2 104 2 105

63100 3 100 3 101 3 101 3 102 3 103 3 100 3 102 3 103

93107 3 107 3 108 3 108 3 104 3 105 3 107 3 104 3 105

84100 4 100 4 101 4 101 4 102 4 103 4 100 4 102 4 103

106 1 106 1 107 1 107 1 108 1 109 1 106 1 108 1 109

1

1 107 1 107 1 108 1 108 1 112 1 113 1 110 1 112 1 113

110 1 110 1 111 1 111 1 112 1 113 1 110 1 112 1 113

1

2 106 2 106 2 107 2 107 2 108 2 109 2 106 2 108 2 109

2 106 2 106 2 107 2 107 2 108 2 109 2 106 2 108 2 109

2 110 2 110 2 111 2 111 2 112 2 113 2 110 2 112 2 113

2 107 2 107 2 108 2 108 2 104 2 105 2 107 2 104 2 105

2 106 2 106 2 107 2 107 2 108 2 109 2 106 2 108 2 109

2 110 2 110 2 111 2 111 2 112 2 113 2 110 2 112 2 113

3 106 3 107 3 108 3 108 3 106 3 108 3 109

3 110 3 111 3 110 3 112 3 113

4 106 4 107 4 106 4 108 4 109

4 110 4 111 4 112 2 113

10

Page 11

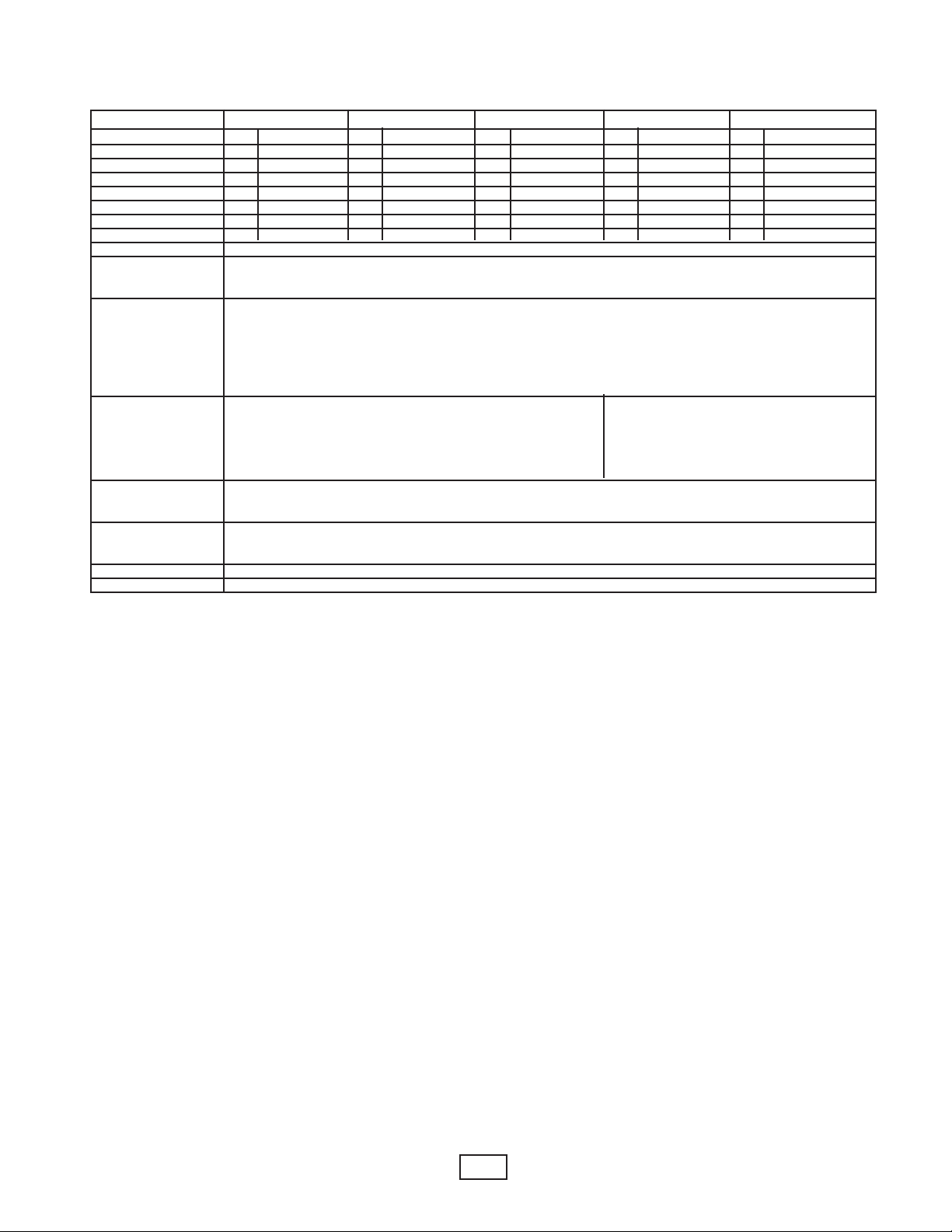

REPLACEMENT PARTS LIST (cont.)

Basic Model Series

Description 935 945 958 968 978

Filter (Permanent) 1 2010-7008-006 1 2010-7008-007 1 2010-7008-008 1 2010-7008-006 2 2010-7008-007

Filter (Throw-Away) 1 2010-7009-006 1 2010-7009-007 1 2010-7009-008 1 2010-7009-006 2 2010-7009-007

Motor 1 3900-2032-000 1 3900-2033-000 1 3900-2033-000 1 3900-2033-000 2 3900-2033-000

Manual Reset Limit 1 4520-2017-000 1 4520-2017-000 1 4520-2017-000 1 4520-2017-001 1 4520-17-002

Auto Reset Limit 4520-2048-000

Power Relay

(24V Control) 410101001

(120V Control) 410101003

Fan Delay Relay

Single Stage Heater

(24V Control) 410171001

(120V Control) 410171002

Two Stage Heater

(24V Control) 410101001

(120V Control) 410101003

Transformer (Power)

277V Heater 490015025 490015024

347V Heater 490015026 490015027

380V Heater 490015011 490015023

480V Heater 490015025 490015024

600V Heater 490015026 490015027

Transformer (Control)

(24V Control) 490026007

(120V Control) 49002604

Thermostat (Built-in)

Single Stage Heater 410127001

Two Stage Heater 5813-2008-000

High-Low Heat Switch 5216-2029-000

Heat On-Off Switch 5216-2029-001

QTY P/N QTY P/N QTY P/N QTY P/N QTY P/N

1 2010-7008-007

1 2010-7009-007

1 3900-2032-000

11

Page 12

LIMITED WARRANTY

All products manufactured by Marley Engineered Products are warranted against defects in workmanship and materials for one

year from date of installation, except heating elements which are warranted against defects in workmanship and materials for five

years from date of installation. This warranty does not apply to damage from accident, misuse, or alteration; nor where the connected voltage is more than 5% above the nameplate voltage; nor to equipment improperly installed or wired or maintained in

violation of the product’s installation instructions. All claims for warranty work must be accompanied by proof of the date of installation.

The customer shall be responsible for all costs incurred in the removal or reinstallation of products, including labor costs, and

shipping costs incurred to return products to Marley Engineered Products Service Center. Within the limitations of this warranty,

inoperative units should be returned to the nearest Marley authorized service center or the Marley Engineered Products Center,

and we will repair or replace, at our option, at no charge to you with return freight paid by Marley. It is agreed that such repair or

replacement is the exclusive remedy available from Marley Engineered Products.

THE ABOVE WARRANTIES ARE IN LIEU OF ALL OTHER WARRANTIES EXPRESSED OR IMPLIED, AND ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE WHICH EXCEED THE AFORESAID

EXPRESSED WARRANTIES ARE HEREBY DISCLAIMED AND EXCLUDED FROM THIS AGREEMENT. MARLEY

ENGINEERED PRODUCTS SHALL NOT BE LIABLE FOR CONSEQUENTIAL DAMAGES ARISING WITH RESPECT TO THE

PRODUCT, WHETHER BASED UPON NEGLIGENCE, TORT, STRICT LIABILITY, OR CONTRACT.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above exclusion or

limitation may not apply to you. This warranty gives you specific legal rights, and you may also have other rights which vary from

state to state.

For the address of your nearest authorized service center, contact Marley Engineered Products in Bennettsville, SC, at

1-800-642-4328. Merchandise returned to the factory must be accompanied by a return authorization and service identification

tag, both available from Marley Engineered Products. When requesting return authorization, include all catalog numbers shown

on the products.

HOW TO OBTAIN WARRANTY SERVICE AND

WARRANTY PARTS PLUS GENERAL INFORMATION

1. Warranty Service or Parts 1-800-642-4328

2. Purchase Replacement Parts 1-800-654-3545

3. General Product Information www.marleymep.com

Note: When obtaining service always have the following:

1. Model number of the product

2. Date of manufacture

3. Part number or description

5200-2386-002

ECR 37677

5/08

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

Page 13

Gabinetes calefactores

Serie 900

Modelo B

Instrucciones de instalación y mantenimiento

Estimado propietario:,

Felicitaciones! Gracias por comprar este nuevo calentador fabricado por Marley Engineered Products. Usted ha efectuado una

sabia decisión al seleccionar el producto de la más alta calidad en la industria de la calefacción. Por favor lea cuidadosamente

las instrucciones de instalación y mantenimiento indicadas en este manual. Ud. debe gozar años de comodidad de calefacción

eficiente con este producto de Marley Engineered Products....el líder de la industria en diseño, fabricación, calidad y servicio.

... Los empleados de

Marley Engineered Products

ADVERTENCIA

!

Lea cuidadosamente -Antes de cablear o efectuar servicios téc-

nicos, desconecte toda alimentación eléctrica que llegue al panel

principal de servicio del calefactor.

PARA REDUCIR LOS RIESGOS DE INCENDIO Y

CHOQUE ELECTRICO:

1. Antes de cablear o efectuar servicios técnicos, desconecte

toda alimentación eléctrica que llegue al panel principal de

servicio del calefactor.

NOTA: Pueden ser necesarias más de una desconexión.

2. Todo el cableado debe ser en concordancia con los códigos

eléctricos nacionales y locales y el calefactor debe tener

toma de tierra.

3. Antes de conectar la alimentación eléctrica, verifique que el

voltaje de la fuente de alimentación que llega al calefactor

sea igual al valor nominal impreso en la placa de identificación del calefactor.

4. Este calefactor se calienta cuando está en uso. Para evitar

quemaduras, no deje que la piel desnuda toque las superficies calientes.

5. No inserte objetos extraños ni deje que entren a ninguna

abertura de ventilación o escape, dado que ello puede

causar choque eléctrico, incendio o daños al calefactor.

CONSERVE ESTAS HOJAS DE INSTRUCCIONES

6. No bloquee de ninguna manera las entradas de aire o el

escape. Mantenga los materiales combustibles separados

61 cm (24 pulg.), como mínimo. Mantenga las cortinas 15,3

cm (6 pulg.) como mínimo, por sobre las unidades con

descarga superior. No lo instale detrás de puertas, muebles,

toalleros o divisores de ambientes.

7. Los calefactores tienen piezas interiores calientes y que

emiten chispas. No los utilice en zonas en las que se utilicen

o almacenen combustibles, pinturas u otros líquidos inflamables.

8. Utilice este calefactor sólo como se describe en este manual. Cualquier otro uso no recomendado por el fabricante

puede causar incendio, choque eléctrico o lesiones.

9. El calefactor no está autorizado para ser utilizado en atmósferas corrosivas tales como las náuticas, los viveros o las

zonas de almacenamiento de productos químicos.

10. PARA LOS CALEFACTORES CONECTADOS A CONDUC-

TOS: No exceda los 50,8 mm (2 pulgadas) de columna de

agua de presión extática externa y no monte el calefactor

sobre los paneles del extremo.

11. Con entrada de aire por la parte inferior, no utilice el AMOR-

TIGUADOR DE AIRE EXTERIOR DE 0 A 100% OPCIONAL.

13

Page 14

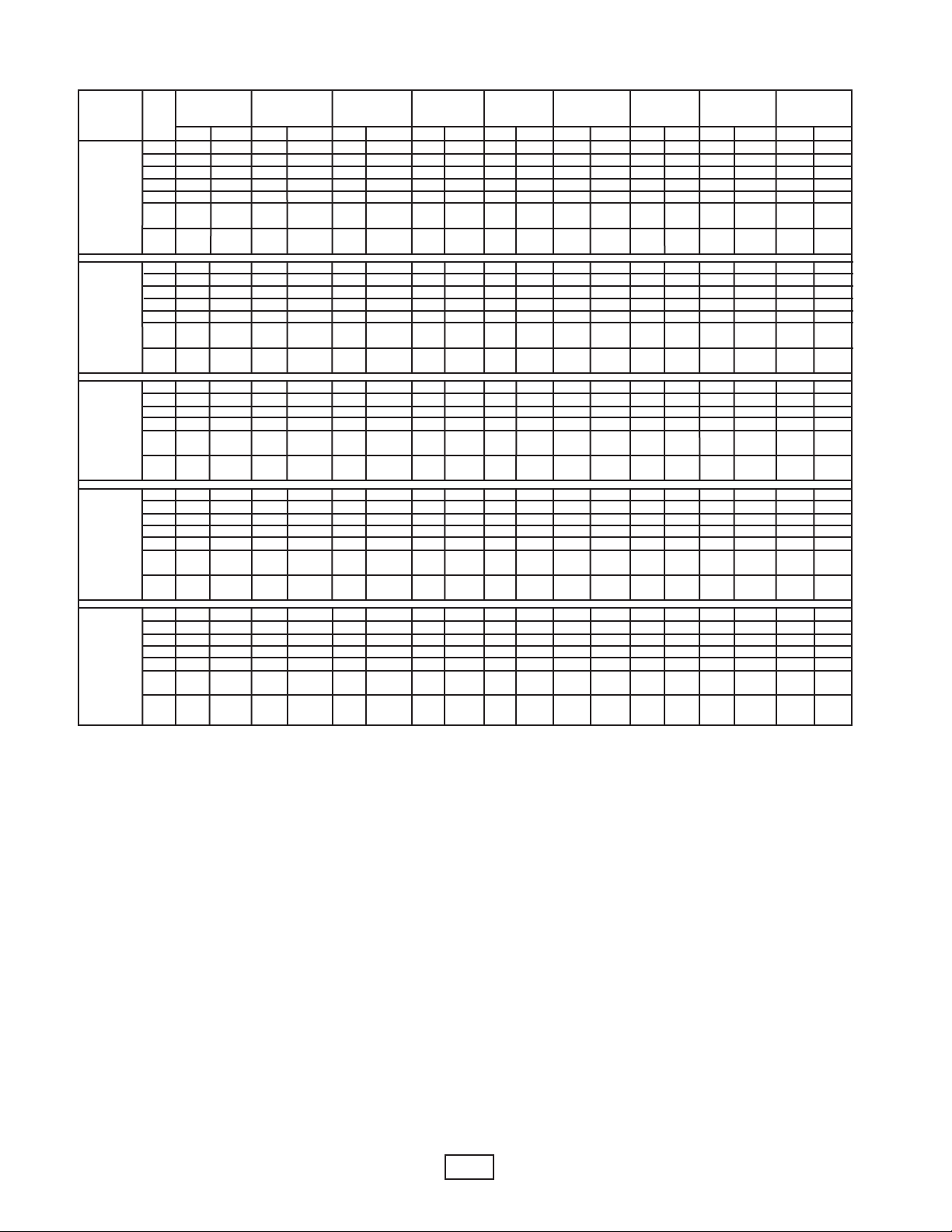

Especificaciones

mperaje total en la línea (incluye el consumo del motor)

CAPACIDAD

CALEFACTORA

TU/hr

B

W

K

2

3

4

5

6

7

8

4

6

8

1

12

14

16

6

8

10

1

14

1

6

9

1

15

1

21

24

8

12

16

20

24

28

32

6,826

10,239

13,652

7,065

1

20,478

23,891

27,304

13,652

20,478

27,304

4,130

3

0

40,956

47,785

54,608

20,478

27,304

34,103

0,956

4

2

47,782

4,608

5

6

20,478

30,717

0,956

4

2

51,195

1,434

6

8

71,673

81,912

27,304

40,956

54,608

68,260

81,912

95,564

109,216

S

erie

9

945

9

968

978

Largo del

abinete

g

in)

(

35

58

5

3

45

8

5

68

78

ies

P

in.*

m

2

500

7

750

1,000

50

50

208

3

/

ph

1

0 Hz

6

10

15

20

5

2

30

34

39

20

30

40

8

4

59†

68†

78†

30

40

48

9†

5

68†

8†

7

31

45

0

6

74

8

8

n/a

n/a

41

60†

79†

n/a

n/a

n/a

n/a

3

6

† - SE REQUIERE LA DESCONEXION DE LOS INTERRUPTORES AUTOMATICOS O FUSIBLES

* - En las unidades de dos velocidades el valor mostrado es para ALTA VELOCIDAD

208

ph

0 Hz

6

9

12

5

1

17

20

23

12

18

23

9

2

34

40

46

18

23

29

4

3

40

6

4

19

27

5

3

44

2†

5

60†

69†

24

36

47

58†

69†

80†

91†

A

240

ph

1

0 Hz

6

9

13

17

2

2

26

30

34

18

26

34

3

4

51†

59†

68†

26

34

43

1†

5

59†

8†

6

27

39

2†

5

64†

7†

7

89†

n/a

36

52†

69†

86†

n/a

n/a

n/a

6

240

ph

3

0 Hz

6

8

10

1

15

18

20

11

16

20

2

30

35

40

16

20

25

3

35

4

16

24

3

38

4

52†

60†

21

31

41

50†

60†

70†

79†

3

5

0

0

1

5

1

6

277

ph

0 Hz

8

12

15

9

1

22

26

30

16

23

30

7

3

44

52†

59†

23

30

37

4

4

52†

9†

5

24

34

5

4

56†

7†

6

78†

n/a

31

46

60†

74†

n/a

n/a

n/a

1

6

347

ph

0 Hz

7

9

12

5

1

18

21

24

13

18

24

0

3

36

41

47

18

24

30

6

3

41

7

4

19

28

6

3

45

/a

n

n/a

n/a

25

37

48

n/a

n/a

n/a

n/a

3

6

380

ph

0 Hz

4

5

7

8

10

11

13

7

10

13

6

1

19

22

25

10

13

16

9

1

22

5

2

11

16

0

2

25

9

2

34

38

14

20

27

33

39

45

n/a

3

6

480

ph

0 Hz

3

4

6

7

8

9

10

6

8

11

3

1

16

18

20

8

11

13

6

1

18

0

2

9

13

6

1

20

4

2

27

31

12

17

21

26

31

36

41

3

6

600

ph

0 Hz

3

4

5

6

7

7

8

5

7

9

1

1

13

15

17

7

9

11

3

1

15

7

1

8

11

3

1

16

9

1

22

25

10

14

18

21

15

29

33

14

Page 15

Información General

Los Gabinetes calefactores de la Serie 900 están incluidos en los

listados UL y cUL y están diseñados para ser aplicados como

calefactores estándar de aire libre, con paneles de entrada y

descarga con grilla, tanto para instalaciones empotradas como

para instalaciones a nivel: a) Sobre el piso, con entrada frontal y

movimiento de aire en flujo ascendente con flujo de salida ascendente, descendente, a la izquierda o a la derecha o b) Sobre el

techo o con brida para conductos (Con 5,1 mm [0,2 pulg.] de

columna de agua de presión estática externa, para conexión directa en conductos instalados localmente, en la entrada, en la

descarga o en ambas. Los calefactores para conductos se pueden

montar en instalaciones empotradas o en la superficie a) Sobre el

piso, con entrada frontal y movimiento de flujo de aire ascendente

o descendente, o b) En el techo.

Vea los huelgos de montaje en la Figura 1.

Nota: Todos los muebles y cualquier otro material que bloquee la

circulación de aire deben mantenerse separados del frente del

calefactor 610 mm (24 pulg.) como mínimo.

Cuando se utilizan cortinas, cuélguelas de manera que al estar en

uso ellas queden a 152 mm (6 pulg.) como mínimo sobre la parte

superior de los calefactores con descarga frontal.

No utilice cortinas con calefactores de descarga por la parte

superior.

Ve las dimensiones de montaje en la Figura 2.

MONTAJE SOBRE EL PISO

1.

Los calefactores con entrada frontal y movimiento de

flujo de aire ascendente, se pueden montar directamente sobre cualquier superficie de piso, incluso sobre

alfombrados. Cuando se coloque alfombrado pared a

pared después de la instalación del calefactor, el alfombrado se puede tender hasta el frente y alrededor del

cuerpo del calefactor. Vea los huelgos de instalación en

la Figura 1.

2. Los calefactores se pueden montar sobre cualquiera de

los extremos, con movimiento de aire hacia la izquierda

o hacia la derecha, también directamente sobre

cualquier superficie de piso, incluso el alfombrado. Vea

los huelgos de montaje en la Figura 1.

3. Si no se instalan paneles protectoras de puntapiés

opcionales, prosiga hasta la sección "INSTALACION

DEL CALEFACTOR"

.

INSTALACION DEL KIT DE BASE

OPCIONAL PARA LA SERIE 900

1. Si se desea, los calefactores se pueden montar sobre el piso

con un panel protector de puntapiés.

2. Alinee el panel sobre la parte inferior del calefactor (sólo en el

lado de la entrada).

3. Debe haber como mínimo 25 mm (1 pulgada) de espacio

desde el panel al frente y costados del calefactor.

4. Perfore orificios coincidentes de 3,55 mm (0,140 pulg.) de

diámetro en la parte inferior del calefactor y fije el panel protector con los tornillos provistos.

5. Prosiga hasta la sección "INSTALACION DEL CALEFACTOR".

PRECAUCION

PARA EVITAR QUE EL CALEFACTOR CAIGA Y CAUSE

LESIONES, CADA ELEMENTO DE FIJACION APLICADO

DEBE TENER UNA FUERZA DE RETENCION DE 45 KG (100

LBS) COMO MINIMO.

!

1. Haga una abertura en la pared que tenga 676 mm (26 5/8

pulg.) de alto por el ancho del calefactor más 6,4 mm (1/4

pulg.). Ejemplo: Si el calefactor tiene 1727 mm de frente (68

pulg.) la abertura debe medir. 676 mm (26 5/8 pulg.) de alto por

1734 mm (68 1/4 pulg.) de ancho.

2. La profundidad del hueco variará según cuanto se desea empotrar el calefactor.

3. Siga hasta la sección "INSTALACION DEL CALEFACTOR".

INSTALACION DEL KIT DE CONTRAMARCO DECORA-

TIVO PARA HUECO, OPCIONAL DE LA SERIE 900

1. Determine la profundidad del hueco del calefactor.

2. Alinee el contramarco decorativo de manera que el borde

frontal del contramarco decorativo toque la pared cuando el

calefactor esté instalado.

3. Perfore orificios coincidentes de 3,55 mm (0,140 pulg.) sobre

los cuatro costados del calefactor y fije el contramarco decorativo con los tornillos provistos.

4. Siga hasta la sección "INSTALACION DEL CALEFACTOR".

INSTALACION DEL CALEFACTOR

1. Tienda el cableado eléctrico en forma aproximada. Vea la ubicación de los orificios ciegos en la Figura 2.

2. Saque las tapas del orificio ciego que corresponda en el calefactor

o perfore el orificio de tamaño apropiado en la parte inferior o en el

costado derecho del mismo, como se muestra en la Figura 2.

3. Saque la cubierta frontal girando la(s) traba(s) hacia la derecha.

4. Saque el panel con grilla superior (descarga) quitando los dos

tornillos (uno en cada extremo) que unen el panel con grilla a los

paneles de los extremos.

5. Refiérase a la Figura 3 para obtener la ubicación de los orificios de

montaje.

6. Marque y perfore en la pared o el techo los orificios para fijación

del calefactor.

7. Instale el calefactor en la abertura y apriete los tornillos (suministrados localmente) para ajustar el calefactor apretado contra la

superficie de montaje en forma segura.

NOTA: Si se aprieta el calefactor contra una pared irregular, se distorsionará el panel posterior del calefactor. Si

este es el caso, se deben utilizar suplementos detrás del

panel posterior para mantenerlo derecho.

8. Reinstale el panel con grilla superior (descarga) deslizando el

panel en el calefactor. Coloque en posición las aletas del

panel con grilla para que asienten en la parte superior del

labio en la parte posterior del calefactor. Coloque en posición

la parte superior del panel con grilla, a ras con la parte superior de los paneles de los extremos. Golpee ligeramente el

panel con grilla en la parte superior delantera (en ambos

lados) para que el panel asiente. Reinstale los dos tornillos

(uno en cada lado) que fijan el panel con grilla a los paneles

de los extremos.

9. CABLEADO - Vea la sección Cableado.

10. Después de completar el cableado, asegúrese de que la

cubierta de la caja de control esté cerrada y asegurada y que

el filtro esté instalado.

11. Ajuste el termostato al punto de referencia deseado.

12. Ajuste el selector del calefactor a la temperatura y velocidad

del ventilador deseadas.

13. Reinstale la cubierta frontal y fíjela girando las trabas hacia la

derecha, hasta que aprieten. Reinstale los tapones con botón

provistos.

14. Deje al calefactor funcionando unas pocas horas antes de

hacer cualquier cambio en la configuración del termostato.

MONTAJE EMPOTRADO EN LA PARED O EL TECHO

15

Page 16

APLICACIONES CON CONDUCTOS

1. Vea el tamaño y ubicación de la brida para conducto en la

Figura 3.

2. Los collares para conductos vienen con la ubicación colocada

en la fábrica (entrada inferior, entrada frontal, descarga superior, descarga frontal) según se haya pedido.

ADVERTENCIA

!

PARA REDUCIR EL RIESGO DE INCENDIO O CHOQUE ELECTRICO,

NO EXCEDA 5,1 mm (0,2 PULG.) DE COLUMNA DE AGUA DE PRESION ESTATICA EXTERNA. NO MONTE EL CALEFACTOR SOBRE EL

PANEL DEL EXTREMO (FLUJO DE AIRE A LA IZQUIERDA O LA

DERECHA).

3. Para cambiar la ubicación del collar para conducto:

A. Los paneles para conductos del calefactor se proveen con el

collar unido a una superficie y una placa ciega unida a la otra

superficie. Se pueden invertir las posiciones del collar para

conducto y de la placa ciega.

B. Saque los tornillos que sostienen la placa ciega y quítela.

C. Saque los tornillos que sostienen el collar para conducto y

quítelo.

D. Coloque en posición el collar de conducto en la ubicación

deseada, alinee los orificios para los tornillos, inserte y apriete

los tornillos para fijar el collar para conducto al panel del conducto.

E. Coloque en posición la tapa ciega en la ubicación deseada, ali-

nee los orificios para los tornillos, inserte y apriete los tornillos

para fijar la placa ciega al panel del conducto.

4. Coloque en posición el conducto instalado localmente en la

parte exterior de la brida para conducto.

5. Marque y perfore los orificios iniciales en el conducto y en la

brida.

6. Instale y apriete los tornillos (provistos localmente) para

proveer un cierre segurol.

ADVERTENCIA

!

PARA REDUCIR EL RIESGO DE INCENDIO O CHOQUE ELECTRICO,

NO UTILICE EL AMORTIGUADOR DE AIRE EXTERIOR OPCIONAL

DE 100% EN CALEFACTORES CON ENTRADA DE AIRE INFERIOR.

UTILICELO SOLAMENTE EN LOS DE ENTRADA DE AIRE FRONTAL.

AMORTIGUADOR DE AIRE EXTERIOR

OPCIONAL DE 100%

1. Los soportes con brida del collar para conducto montado en la

parte posterior, están embaladas desarmadas en la caja del

calefactor.

2. Vea la ubicación de la abertura para el amortiguador en la

Figura 2.

3. Coloque en posición la parte superior de un soporte con brida,

con ésta en la parte superior de la abertura para el amortiguador y los orificios del soporte alineados con los orificios en

la parte posterior del gabinete.

4. Una la brida al gabinete con los tornillos provistos.

5. Coloque en posición alrededor de la abertura para el amortiguador y fije los tres (3) soportes con brida remanentes.

6. Coloque en posición el conducto instalado localmente en la

parte exterior de los soportes con brida.

7. Marque y perfore los orificios iniciales en el conducto y la brida.

8. Instale y apriete los tornillos (provistos localmente) para

proveer un cierre seguro.

OPERACION DEL AMORTIGUADOR DE AIRE

EXTERIOR OPCIONAL DE 100%

1. Los controles, que consisten en un conmutador "OPEN CLOSED" (abierto - cerrado), están ubicados en la puerta del

panel de control.

2. Coloque el conmutador en la posición "OPEN".

3. El amortiguador permanecerá abierto en la posición seleccionada hasta que se mueva el conmutador "OPEN CLOSED" a la posición de cerrado

16

Page 17

Z

ero or greater

U

pflow

C

eiling

2

4" min.

(610 mm)

Downflow

C

eiling

2

4" min.

(610 mm)

5

" min.

(

127 mm)

2

4" min.

(610 mm)

Upflow

5" min.

(

127 mm)

Zero or greater

24" mi

(

610 m

Z

ero or greater

24" min

(610 m

Zero or greater

24" min.

(

610 mm)

Zero or greater

24" min.

(610 mm)

Z

ero or greater

24" min.

(610 mm)

F

loor

Wall

Floor

Wall

Ceiling

Wall

Wall

Zero or

greater

24" min.

(610 mm)

5" min

(127mm)

24" min.

(610 mm)

Ceiling mounted

Zero or

greater

24" min.

(610 mm)

Ceiling mounted (semi-recess)

24" min.

(610 mm)

Zero or greater

Ceiling

Wall

Wall

Wall

Wall

End mounting

24" min.

(610 mm)

Zero or greater

End mounting

semi-recess

24" min.

(610 mm)

Zero or greater

End mounting

full recess

Zero or greater

Ceiling

Floor

End mounting

Zero or greater

End mounting

semi-recess

End mounting

full recess

Wall

Wall

Wall

Wall

Wall

Wall

Wall

Ceiling

Floor

Wall

Ceiling

Floor

Wall

Zero or greater

Zero or greater

Zero or greater

Zero or greater

Downflow

U

pflow

(semi-recessed)

U

pflow

(full recessed)

D

ownflow

(semi-recessed)

D

ownflow

(full recessed

Ceiling mounted

Ceiling mounted

(full recess)

Figura 1

Flugo ascendente

Techo

Flujo descendente

Flujo ascendente

lujo descendente

F

CALEFACTOR:

Montado sobre la

pared

FLUJO DE AIRE:

Ascendente o abajo

CALEFACTOR:

Montado en el

techo

CALEFACTOR:

Montado en la pared

sobre el panel del

extremo

24” min.

(610 mm)

semiempotrado)

(

24”min.

610 mm)

(

Cero o mayor

24” min.

(610 mm)

5” min.

127 mm)

(

Montado en el techo

ared

P

lujo

F

scendente

a

Cero o mayor

5” min.

(127 mm)

Cero o

mayor

Montado en el extremo

(todo empotrado)

ed

ar

P

24” min.

(610 mm)

ared

P

Cero o mayor

Flujo

ascendente

Pared

Montado en el techo

Pared

Montado en el techo (semiempotrado) Montado en el techo (todo empotrado)

Pared

Montado en el extremo

(semiampotrado)

24” min.

(

Cero o mayor

Cero o

mayor

Cero o mayor

Pared

24” min.

(610 mm)

iso

P

Techo

610 mm)

Piso

24” min.

(610 mm)

ared

P

lujo

F

escendente

d

Techo

Cero o mayor

Pared

Techo

Montado en el extremo

(semiempotrado)

ed

ar

P

re

Pa

Montado en el extremo

d

Techo

Pared

Montado en el extremo

(semiempotrado)

Techo

Pared

Montado en el extremo

(todo empotrado)

24” min.

610 mm)

(

” min.

5

(127 mm)

(todo empotrado)

4” min.

2

(610 mm)

24” min.

(610 mm)

24” min.

(610 mm)

Cero o mayor

24” min.

(610 mm)

Techo

P

Techo

ared

Cero o mayor

lujo

F

descendente

Cero o mayor

Minimo 2” (52 mm)

de la pared lateral

4” min.

2

(610 mm)

(todo empotrado)

24” min.

(610 mm)

FLUJO DE AIRE:

Derecha o izquierda

d

Pare

Piso

Cero o mayor

Cero o mayor

17

ed

ar

P

Piso

Cero o mayor

Cero o mayor

ed

ar

P

Cero o mayor

Cero o mayor

Piso

Page 18

MOUNTING DIMENSIONS

MOUNTING DIMENSIONS

35

CONTROL

COMPARTMENT

TOP

16-1/4

1

3-1/2

18

5

3

4

-3/8

26-3/8

13

14-1/2

OPTIONAL

9-7/8

4-1/2(114 mm)

1

-3/8

3/4 (19 mm)

OUTSIDE AIR

8

-7/16

FRONT VIEW

CONTROL

COMPARTMENT

27

OPTIONAL

14-3/8

28

45

TOP

COMPARTMENT

CONTROL

FRONT VIEW

OPTIONAL

41

41

58

TOP

FRONT VIEW

41

OPTIONAL

68

CONTROL

COMPARTMENT

TOP

25-1/2

OPTIONAL

FRONT VIEW

55

32-5/8

78

TOP

CONTROL

28-1/2

COMPARTMENT

C

ollar

OPTIONAL

Heater Back

OUTSIDE AIR

FRONT VIEW

LEFT SIDE VIEW

Concentric Knockouts

1-23/32", 1-23/64", 1-31/32"

7/8", 1-3/32"

Concentric Knockouts

Typical All Heaters

Knockout Size & Location

N

OTE:

8-7/16

OUTSIDE AIR

13-1/2

16-1/4

8-7/16

OUTSIDE AIR

14-3/8

13-1/2

16-1/4

13-1/2

8-7/16

16-1/4

14-3/8

OUTSIDE AIR

25-1/2

13-1/2

14-3/8

OUTSIDE AIR

8-7/16

16-1/4

RIGHT SIDE VIEW

Front Cover

3

4

Drill location for conduit hole

BOTTOM VIEW

1-5/8

7

Drill location for conduit hole

(670 mm)

(

251 mm)

(

214 mm)

(889 mm)

(457 mm)

(343 mm)

(413 mm)

(35 mm)

(330 mm)

(368 mm)

(111 mm)

(

7

6

m

m

)

(127 mm)

(76 mm)

(

102 mm)

(41 mm)

(178 mm)

(1143 mm)

(343 mm)

(711 mm)

(413 mm)

(365 mm)

(686 mm)

(214 mm)

(343 mm)

(1041 mm)

(1473 mm)

(365 mm)

(1041 mm)

(214 mm)

(413 mm)

(343 mm)

(648 mm)

(648 mm)

(1727 mm)

(413 mm)

(214 mm)

(1041 mm)

(365 mm)

(343 mm)

(724 mm)

(829 mm)

(1981 mm)

(214 mm)

(413 mm)

(1397 mm)

(365 mm)

Figure 2Figure 2

Air Flow --->

Air Flow --->

Air Flow --->

Air Flow --->

I

ncluding Front Cover

(Typ. all lengths)

(Typ. all lengths)

(Typ. all lengths)

35" (889 mm) CABINET

45" (1143 mm) CABINET

58" (1473 mm) CABINET

68" (1727 mm) CABINET

78" (1981 mm) CABINET

Figura 2

DIMENSIONES DE MONTAJE

Parte posterior

del calefactor

AIRE EXTERIOR

VISTA LATERAL IZQUIERDA

Cubierta frontal inclusive

Collar de

OPCIONAL

(Típica, todos los largos)

PARTE

SUPERIOR

PARTE

SUPERIOR

Flujo de aire

VISTA FRONTAL GABINETE

DE

Ubicación para perforar los orifi-

cios para conducto

VISTA INFERIOR

(Típica, todos los largos)

AIRE EXTERIOR

OPCIONAL

89 mm (35 PULG.)

8

COMPARTIMIENTO

DE CONTROL

43,7 - 38,1 - 50mm

(1 23/32 - 1 23/64 - 1 31/32)

Orificios ciegos concéntricos

22,2 - 27,8mm

(7/8 - 1 3/32)

Orificios ciegos concéntricos

NOTA:

Tamaño y ubicación de orificios ciegos, tipico para

todos los modelos

Ubicación para perforar los

orificios para conducto

VISTA LATERAL DERECHA

Cubierta frontal

Típica, todos los largos)

(

PARTE

SUPERIOR

Flujo de aire

VISTA FRONTAL GABINETE

AIRE EXTERIOR

OPCIONAL

1143 mm (45 PULG.)

DE

Flujo de aire

VISTA FRONTAL GABINETE

DE

AIRE EXTERIOR

OPCIONAL

1727 mm (68 PULG.)

COMPARTIMIENTO

DE CONTROL

Flujo de aire

AIRE EXTERIOR

OPCIONAL

VISTA FRONTAL GAVINETE

1473 mm (58 PULG.)

DE

COMPARTIMIENTO

DE CONTROL

PARTE

SUPERIOR

COMPARTIMIENTO

DE CONTROL

18

AIRE EXTERIOR

VISTA FRONTAL GABINETE

1981 mm (78 PULG.)

DE

OPCIONAL

PARTE

SUPERIOR

COMPARTIMIENTO

Page 19

DIMENSIONS and INSTALLATION DETAILS

DIMENSIONS and INSTALLATION DETAILS

DUCT COLLARSDUCT COLLARS

RIGHT SIDE VIEW

Air Flow --->

Air Flow --->

Air Flow --->

Figure 3Figure 3

LEFT SIDE VIEW

H

eater Back

Air Flow --->

FRONT VIEW

2 (51mm)

4-7/8

(124 mm)

4-1/16

(

103 mm)

2

(51mm)

4

-7/8

(

124 mm)

(103 mm)

4

-1/16

BOTTOM INLET /

2 (51mm)

(14 mm)

9/16

4-7/8

(

124 mm)

(Typ. all lengths)

(14 mm)

9/16

(

124 mm)

4-7/8

2 (51mm)

Air Flow --->

H

eater Back

(Typ. all lengths)

TOP DISCHARGE

FRONT INLET /

FRONT DISCHARGE

(543 mm)

21-3/8

6-13/16

(173 mm) (173 mm)

6-13/16

35" (889 mm) CABINET

21-3/8

(

173 mm)

6-13/16

(

543 mm)

6-13/16

(

173 mm)

4-5/8

(118 mm)

35-3/4

(908 mm)

(118 mm)

4-5/8

35-3/4

4-5/8

(908 mm)

4-5/8

(118 mm)(118 mm)

FRONT VIEW

45" (1143 mm) CABINET

43-3/8

(1102 mm)

7-5/16

(186 mm)

(186 mm)

7-5/16

7-5/16

(186 mm)

45-3/8

(1102 mm)

(186 mm)

7-5/16

58" (1473 mm) CABINET

FRONT VIEW

68" (1727 mm) CABINET

FRONT VIEW

3-5/8

(92 mm)

60-3/4

(1543 mm)

(92 mm)

3-5/8

60-3/4

(1543 mm)

3-5/8

(92 mm)

(92 mm)

3-5/8

(92 mm

3-5/8

70-3/4

(1797 mm)

(1797 mm)

70-3/4

(92 mm)

3-5/8

(92 mm

3-5/8

Air Flow --->

3-5/8

(92 mm)

FRONT VIEW

78" (1981 mm) CABINET

Figura 3

COLLARES PARA CONDUCTOS

DETALLES DE DIMENSIONES E INSTALACION

Parte posterior

del ccalefactor

VISTA LATERAL IZQUIERDA

ENTRADA INFERIOR

DESCARGA SUPERIOR

Flujo de aire

(Típica, todos los largos)

e

Flujo de air

VISTA FRONTAL GABINETE

889 mm (35 PULG.)

DE

e

r

o de ai

uj

Fl

Parte posterior

del calefactro

VISTA LATERAL DERECHA

ENTRADA FRONTAL

DESCARGA FRONTAL

(Típica, todos los largos)

e

r

o de ai

uj

Fl

VISTA FRONTAL GABINETE

1143 mm (45 PULG.)

DE

Flujo de aire

VISTA FRONTAL GABINETE

DE 1727 mm (68 PULG.)

19

VISTA FRONTAL GABINETE

DE 1473 mm (58 PULG.)

e

r

o de ai

uj

Fl

VISTA FRONTAL GABINETE

DE 1981 mm (78 PULG.)

Page 20

CABLEADO

VEA LOS PASOS 1, 2 Y 3 DE "ADVERTENCIAS" EN LA

PAGINA 1 DE ESTAS HOJAS DE INSTRUCCIONES.

1. En la Figura 4 se muestra un diagrama de cableado típico.

2. Para ver el cableado real de su equipo, consulte el diagrama ubicado en el interior de la cubierta frontal del mismo.

3. Todo el cableado local debe ser para 75 °C como mínimo.

ALIMENTACION DE ENERGIA ELECTRICA

INTERRUPTOR DE

ESCONEXION

D

OPCIONAL

NTERRUPTOR AUTO-

I

MATICO DE CIRCUITO

PCIONAL

O

PARA CONVERTIR LOS CALEFACTORES

DE 208, 240, 480 Y 600 V

Y DE 5 Y 10 Kw EN EXISTENCIA

de trifásicos a monofásicos

1. Saque la cubierta frontal.

2. Refiérase al diagrama de cableado ubicado dentro de

la cubierta frontal.

NOTA: El bloque de terminales y los cables que se

deben cambiar están ubicados en un conducto para

cables, sobre el alojamiento del ventilador, a mano

derecha.

3. Saque los dos tornillos que sostienen la cubierta del

conducto para cables sobre el panel del ventilador.

4. Para sacar la tapa del conducto para cables, gírela

hacia arriba y afuera.

5. El bloque de terminales está ubicado dentro del conducto para cables.

6. Coloque los cables según el diagrama de cableado

dentro del panel frontal.

7. Reinstale la tapa del conducto para cables y vuelva a

colocar los tornillos.

8. Reinstale la cubierta frontal.

DIAGRAMA DE CABLEADO TIPICO

Vea el diagrama de cableado en el interior de la cubierta

frontal del calefactor.

AZUL

NARANJA

EMS = CONEXIÓN DEL SISTEMA DE ADMINISTRACION DE ENERGIA (LOS CONTACTOS DEBEN ESTAR CERRADOS PARA LA OPERACION DIURNA)

RFHS = INTERRUPTOR DE VENTILADOR/TEMPERATURA ON - OFF MONTADO A DISTANCIA (SUMINISTRADO LOCALMENTE)

PARA EL CONTROL DE SUMINISTRO EXTERNO:

S1 = CONMUTADOR SELECTOR DE VENTILADOR/TEMPERATURA ALTO - BAJO AL = LIMITE DE RECONFIGURACION AUTOMÁTICA

S2 = INTERRUPTOR DE INTERBLOQUEO DE LA PUERTA MR = LIMITE DE RECONFIGURACION MANUAL (OPCION INSTALADA EN LA FABRICA)

S3 = VENTILADOR/CALOR INTERUPTOR DE ENCENDIDO-APAGADO T = TERMOSTATO DE UN SOLO POLO INCORPORADO O MONTADO A DISTANCIA

NSB = RELE DE APAGADO NOCTURNO (OPCION INSTALADA EN LA FABRICA)

NOTA: SI ESTA INSTALADO EL SISTEMA EMS Y/O EL INTERRUPTOR RFHS SAQUE EL CABLE NARANJA ENTRE C1 Y C4.

1. SAQUE EL PUENTE AZUL ENTRE C2 Y C3

2. CONECTE EL CONTROL EXTERNO (ALIMENTACION ESTANDAR 24 VCA, OPCIONAL 120 VCA) ENTRE C1 Y C4

(OPCION INSTALADA EN LA FABRICA)

OPCIONAL AMORTIGUADOR

DE AIRE EXTERIOR DE 100%

FDR = RELE DE RETARDO DEL VENTILADOR

MOTOR AMOR-

TIGUADOR

FAOS = INTERRUPTOR DE CONEXIÓN AUTOMATICA DEL VENTILADOR

FAOR = RELE DE CONEXIÓN AUTOMATICA DEL VENTILADOR

ABIERTO

CERRADO

(INCORPORADO = OPCION INSTALADA EN LA FABRICA)

(MONTADO A DISTANCIA = OPCION INSTALADA LOCALMENTE)

(OPCION INSTALADA EN LA FABRICA)

20

CIRCUITO EXTERNO

DE APAGADO NOCTURNO

EL RELE DEBE

ESTAR ENERGIZADO

PARA LA OPERACION

DIURNA

1609-2081-020

Page 21

INTERRUPTORES AUTOMATICOS DE CIRCUITO PIDA PIEZA N°410086 + LA VAR. LISTADA A CONTINUACION

208 208 240 240 277 347 380 480 600

LARGO DEL

GABINETE

35 in. 51045 1 051 1 044 1 051 1 026 1 018 1 010 1 010 1 059

8 in. 10 1 049 1 055 1 048 1 054 1 007 1 022 1 012 1 011 1 059

4

8 in. 10 1 049 1 055 1 048 1 054 1 027 1 021 1 011 1 010 1 059

5

68 in. 18 3 046 1 056 3 045 1 058 1 028 N/A N/A 1 014 1 013 1 061

78 in. 20 N/A N/A 2 055 2 049 2 054 1 068 N/A N/A 1 015 1 014 1 062

W 60HZ 60HZ 60HZ 60HZ 60HZ 60HZ 60HZ 60HZ 60HZ

K

21041 1 050 1 041 1 050 1 024 1 017 1 010 1 010 1 059

31042 1 050 1 042 1 050 1 024 1 017 1 010 1 010 1 059

41043 1 050 1 043 1 050 1 025 1 018 1 010 1 010 1 059

6

7

8

41044 1 051 1 043 1 050 1 025 1 018 1 010 1 010 1 059

61046 1 052 1 045 1 051 1 026 1 019 1 010 1 010 1 059

8

1

14 2 046 1 057 2 045 1 056 1 021 1 068 1 013 1 012 1 060

16 2 048 1 058 2 047 1 057 1 022 1 068 1 014 1 013 1 061

6

8

12 2 046 1 056 2 045 1 055 1 007 1 023 1 012 1 011 1 060

14 2 046 1 057 2 045 1 056 1 021 1 068 1 013 1 012 1 060

16 2 048 1 058 2 047 1 057 1 022 1 068 1 014 1 013 1 061

6

91049 1 054 1 048 1 053 1 028 1 021 1 011 1 011 1 059

12 2 046 1 056 2 045 1 055 1 007 1 008 1 013 1 012 1 060

1

21 N/A N/A 1 057 3 046 1 056 1 015 N/A N/A 1 015 1 014 1 062

24 N/A N/A 1 058 N/A N/A 1 057 N/A N/A N/A N/A 1 009 1 014 1 063

81049 1 054 1 047 1 054 1 027 1 021 1 011 1 010 1 059

12 2 046 1 056 2 045 1 055 1 007 1 008 1 013 1 012 1 060

16 2 048 1 058 2 047 1 058 1 022 1 068 1 014 1 013 1 061

24 N/A N/A 2 055 N/A N/A 2 054 N/A N/A N/A N/A 1 009 1 014 1 063

28 N/A N/A 2 057 N/A N/A 2 056 N/A N/A N/A N/A 1 016 1 015 1 064

32 N/A N/A 2 058 N/A N/A 2 057 N/A N/A N/A N/A N/A N/A 1 016 1 065

PH 3PH 1PH 3PH 1PH 1PH 3PH 3PH 3PH

1

AR

CANT V

1 046 1 052 1 045 1 051 1 026 1 019 1 010 1 010 1 059

1 047 1 053 1 046 1 052 1 027 1 020 1 010 1 010 1 059

1 048 1 053 1 047 1 052 1 027 1 020 1 010 1 010 1 059

1 048 1 053 1 047 1 053 1 027 1 021 1 011 1 010 1 059

2 2 046 1 056 2 045 1 055 1 007 1 023 1 012 1 011 1 060

1 046 1 052 1 045 1 051 1 026 1 019 1 010 1 010 1 059

1 048 1 053 1 047 1 053 1 027 1 021 1 011 1 010 1 059

1 046 1 052 1 045 1 052 1 026 1 019 1 010 1 010 1 059

5 1 048 1 058 1 048 1 057 1 007 1 068 1 014 1 012 1 061

045 1 044 1 026

1

AR

CANT V

1 052 1 026

1 053 1 052

1 053 1 053

CANT V

AR

CANT VARCANT VARCANT VARCANT VARCANT V

AR

CANT V

AR

21

Page 22

ELEMENTOS PIDA PIEZA N° 1801-2083 + LA VAR. LISTADA A CONTINUACION

08 208 240 240 277 347 380 480 600

LARGO DEL

GABINETE

35 in. 51110 1 110 1 111 1 111 1 112 1 113 1 110 1 112 1 113

4

58 in. 10 2 110 2 110 2 111 2 111 2 112 2 113 2 110 2 112 2 113

68 in. 18 6 107 6 107 6 108 6 108 6 104 N/A N/A 6 107 6 104 6 105

78 in. 20 N/A N/A 4 110 4 111 4 111 4 112 N/A N/A 4 110 4 112 4 113

KW 60HZ 60HZ 60HZ 60HZ 60HZ 60HZ 60HZ 60HZ 60HZ

8 in. 10 2 110 2 110 2 111 2 111 2 112 2 113 2 110 2 112 2 113

1

14 2 107 2 107 2 108 2 108 2 104 2 105 2 107 2 104 2 105

16 2 107 2 107 2 108 2 108 2 104 2 105 2 107 2 104 2 105

12 4 107 4 107 4 108 4 108 4 104 4 105 4 107 4 104 4 105

1

16 2 107 2 107 2 108 2 108 2 104 2 105 2 107 2 104 2 105

12 3 106 3 106 3 107 3 107 3 108 3 109 3 106 3 108 3 109

15 3 110 3 110 3 111 3 111 3 112 3 113 3 110 3 112 3 113

21 N/A N/A 3 107 3 108 3 108 3 104 N/A N/A 3 107 3 104 3 105

24 N/A N/A 3 107 N/A N/A 3 108 N/A N/A N/A N/A 3 107 3 104 3 105

12 4 107 4 107 4 108 4 108 4 104 4 105 4 107 4 104 4 105

16 4 106 4 106 4 107 4 107 4 108 4 109 4 106 4 108 4 109

24 N/A N/A 8 107 N/A N/A 8 108 N/A N/A N/A N/A 8 107 8 104 8 105

28 N/A N/A 4 107 N/A N/A 4 108 N/A N/A N/A N/A 4 107 4 104 4 105

32 N/A N/A 4 107 N/A N/A 4 108 N/A N/A N/A N/A N/A N/A 4 104 4 105

2

1 PH 3PH 1PH 3PH 1PH 1PH 3PH 3PH 3PH

ANT

C

VAR C

1 100 1 100 1 101 1 101 1 102 1 103 1 100 1 102 1 103

2

1 107 1 107 1 114 1 114 1 104 1 105 1 107 1 104 1 105

3

41106 1 106 1 107 1 107 1 108 1 109 1 106 1 108 1 109

ANT

VAR C

ANT

VAR C

ANT

VAR C

ANT

VAR C

ANT

VAR C

ANT

VAR C

ANT

VAR C

ANT

62107 2 107 2 108 2 108 2 104 2 105 2 107 2 104 2 105

71107 1 107 1 108 1 108 1 104 1 105 1 107 1 104 1 105

8

106 1 106 1 107 1 107 1 108 1 109 1 106 1 108 1 109

1

1 107 1 107 1 108 1 108 1 112 1 113 1 110 1 112 1 113

110 1 110 1 111 1 111 1 112 1 113 1 110 1 112 1 113

1

42100 2 100 2 101 2 101 2 102 2 103 2 100 2 102 2 103

62107 2 107 2 108 2 108 2 104 2 105 2 107 2 104 2 105

2 106 2 106 2 107 2 107 2 108 2 109 2 106 2 108 2 109

8

2 4 107 4 107 4 108 4 108 4 104 4 105 4 107 4 104 4 105

2 106 2 106 2 107 2 107 2 108 2 109 2 106 2 108 2 109

2 110 2 110 2 111 2 111 2 112 2 113 2 110 2 112 2 113

2 107 2 107 2 108 2 108 2 104 2 105 2 107 2 104 2 105

6

82106 2 106 2 107 2 107 2 108 2 109 2 106 2 108 2 109

4 2 107 2 107 2 108 2 108 2 104 2 105 2 107 2 104 2 105

2 106 2 106 2 107 2 107 2 108 2 109 2 106 2 108 2 109

2 110 2 110 2 111 2 111 2 112 2 113 2 110 2 112 2 113

63100 3 100 3 101 3 101 3 102 3 103 3 100 3 102 3 103

93107 3 107 3 108 3 108 3 104 3 105 3 107 3 104 3 105

3 106 3 107 3 108 3 108 3 106 3 108 3 109

3 110 3 111 3 110 3 112 3 113

84100 4 100 4 101 4 101 4 102 4 103 4 100 4 102 4 103

4 106 4 107 4 106 4 108 4 109

4 110 4 111 4 112 2 113

VAR

22

Page 23

LISTA DE PIEZAS DE REPUESTO (cont.)

Series de los modelos básicos

Descripción 935 945 958 968 978

CANT

. Nº PIEZA

Filtro (permanente) 1 2010-7008-006 1 2010-7008-007 1 2010-7008-008 1 2010-7008-006 2 2010-7008-007

Filtro (descartable) 1 2010-7009-006 1 2010-7009-007 1 2010-7009-008 1 2010-7009-006 2 2010-7009-007

Motor 1 3900-2032-000 1 3900-2033-000 1 3900-2033-000 1 3900-2033-000 2 3900-2033-000

Límite de reconfig. manual

1 4520-2017-000 1 4520-2017-000 1 4520-2017-000 1 4520-2017-001 1 4520-17-002

Límite de reconfig. autom.

Relé de alimentación

(control 24 V) 410101001

(control 120 V) 410101003

elé retardo del ventilador

R

Calefactor una etapa

(control 24 V) 410171001

(control 120 V) 410171002

Calefactor dos etapas

(control 24 V) 410101001

(control 120 V) 410101003

Transformador

(alimentación)

Calefactor 277 V 490015025 490015024

Calefactor 347 V 490015026 490015027

Calefactor 380 V 490015011 490015023

Calefactor 480 V 490015025 490015024

Calefactor 600 V 490015026 490015027

Transformador (de control)

(control 24 V) 490026007

(control 120 V) 49002604

Termostato (incorporado)

Calefactor una etapa 410127001

Calefactor dos etapas 5813-2008-000

Interruptor temp. alta-baja

Interruptor temp: On-Of

f 5216-2029-001

CANT

Nº PIEZA

CANT

4520-2048-000

Nº PIEZA

5216-2029-000

CANT

Nº PIEZA

1 2010-7008-007

1 2010-7009-007

1 3900-2032-000

CANT

Nº PIEZA

23

Page 24

GARANTIA LIMITADA

Todos los productos fabricados por Marley Engineered Products se garantizan contra defectos en mano de obra y materiales por

un año a partir de la fecha de instalación, excepto los elementos térmicos que están garantizados contra defectos en mano de

obra y materiales por cinco años a partir de la fecha de instalación. Esta garantía no se aplica a daños causados por accidente,

mal uso o alteración; ni tampoco donde el voltaje conectado es mayor de 5% del voltaje de la placa de nombre; ni al equipo instalado o cableado o mantenido impropiamente en violación de las instrucciones de instalación del producto. Todos los reclamos

por trabajo de garantía deben estar acompañados por prueba de la fecha de instalación.

El cliente será responsable por todos los costos incurridos en la extracción o reinstalación de los productos, incluyendo costos

de mano de obra y costos de transporte incu-rridos en devolver los productos al Centro de Servicio de Marley Engineered

Products, y repararemos o reemplazaremos, a nuestra opción, sin cargo para Ud., con el flete de retorno pagado por Marley. Se

acuerda en que tal reparación o reemplazo es el remedio exclusivo disponible de Marley Engineered Products.

LAS GARANTIAS DE ARRIBA SON A CAMBIO DE TODAS LAS OTRAS GARANTIAS EXPRESAS O IMPLICITAS Y TODAS

LAS GARANTIAS EXPRESAS DE COMERCIALIZACION Y APTITUD PARA UN PROPOSITO PARTICULAR QUE EXCEDAN

LAS GARANTIAS EXPRESAS MENCIONADAS PREVIAMENTE SON RECHAZADAS Y EXCLUIDAS DEL PRESENTE ACUERDO. MARLEY ENGINEERED PRODUCTS NO SERA RESPONSABLE POR PERJUICIOS CONSECUENTES ORIGINADOS

CON RESPECTO AL PRODUCTO, YA SEA BASADO EN NEGLIGENCIA, LEY, RESPONSABILIDAD ESTRICTA O CONTRATO.

Algunos Estados no permiten la exclusión o limitación de perjuicios incidentales o consecuentes, de manera que la exclusión o