Page 1

Commercial Pedestal

Convection Heater

(Type CPH)

Decorative Pedestal

Convection Heaters

(Type DPH)

CPH and DPH

Convectors

IMPORTANT INSTRUCTIONS

Dear Owner,

Congratulations! Thank you for purchasing this new heater manufactured by Marley Engineered Products.

You have made a wise investment selecting the highest quality product in the heating industry.

Please carefully read the installation and maintenance instructions shown in this manual. You should enjoy

years of efficient heating comfort with this product from Marley Engineered Products... the industry’s leader in

design, manufacturing, quality and service.

WARNING

Read Carefully –

prevent difficulties that might arise during installation of these

Pedestal Heaters. Studying these instructions first may save

you considerable time and money later. These Pedestal

Heaters are designed for easy and economical installation.

Follow these instructions to keep your installation time to a

minimum.

1. Read all instructions before using the heater.

Hazard of fire or electric shock

2.

cal shock, be sure electricity is turned off at main switch first

before wiring. All wiring must be in accordance with the

National Electrial Code (NEC) applicable local codes and

the entire heater installation must be grounded as a precaution against possible electrical shock.

3. Check the supply voltage to make sure it is the same as

indicated on the heater nameplate before energizing.

4. Do not install heaters against combustible low-density

cellulose fiberboard surfaces.

5. Due to variations in vinyl compositions and their potential to

discolor, the use of stand off brackets (SO1A and SO2A)

and / or specifying a lower watt density unit may be required

when installing on vinyl wall coverings or under vinyl window

dressings.

These instructions are written to help you

– To avoid possible electri-

... The Employees of

Marley Engineered Products

!

6. The ends of the heater must be fully closed by the use of

adjoining heaters, end caps, or other accessories.

7. Do not locate the heater below an electrical convenience

receptacle.

8. A heater has hot and arcing or sparking parts inside. Do not

use it in areas where gasoline, paint, or flammable liquids

are used or stored. Do not install this heater upside down

or where water is present.

9. This heater is hot when in use. To avoid burns, do not let

bare skin touch hot surfaces. Keep combustible materials,

such as furniture, pillows, bedding, papers, clothes, and curtains away from heater.

10. To prevent possible fire, do not block air intakes or exhaust

in any manner.

11. Do not insert or allow foreign objects to enter any ventilation

or exhaust opening as this may cause an electric shock or

fire, or damage the heater.

12. Discard packing pads before heater is used.

See also additional warnings located in this manual

SAVE THESE INSTRUCTIONS

Page 2

RECEIVING

1. Each Pedestal Heater is shipped in two cartons. One carton

contains the heater, the other contains the pedestals.

2. Material when shipped was in good order and Marley

Engineered Products hold clear bill of lading, therefore any

concealed damage must be reported at once to the carrier

for inspection and settlement.

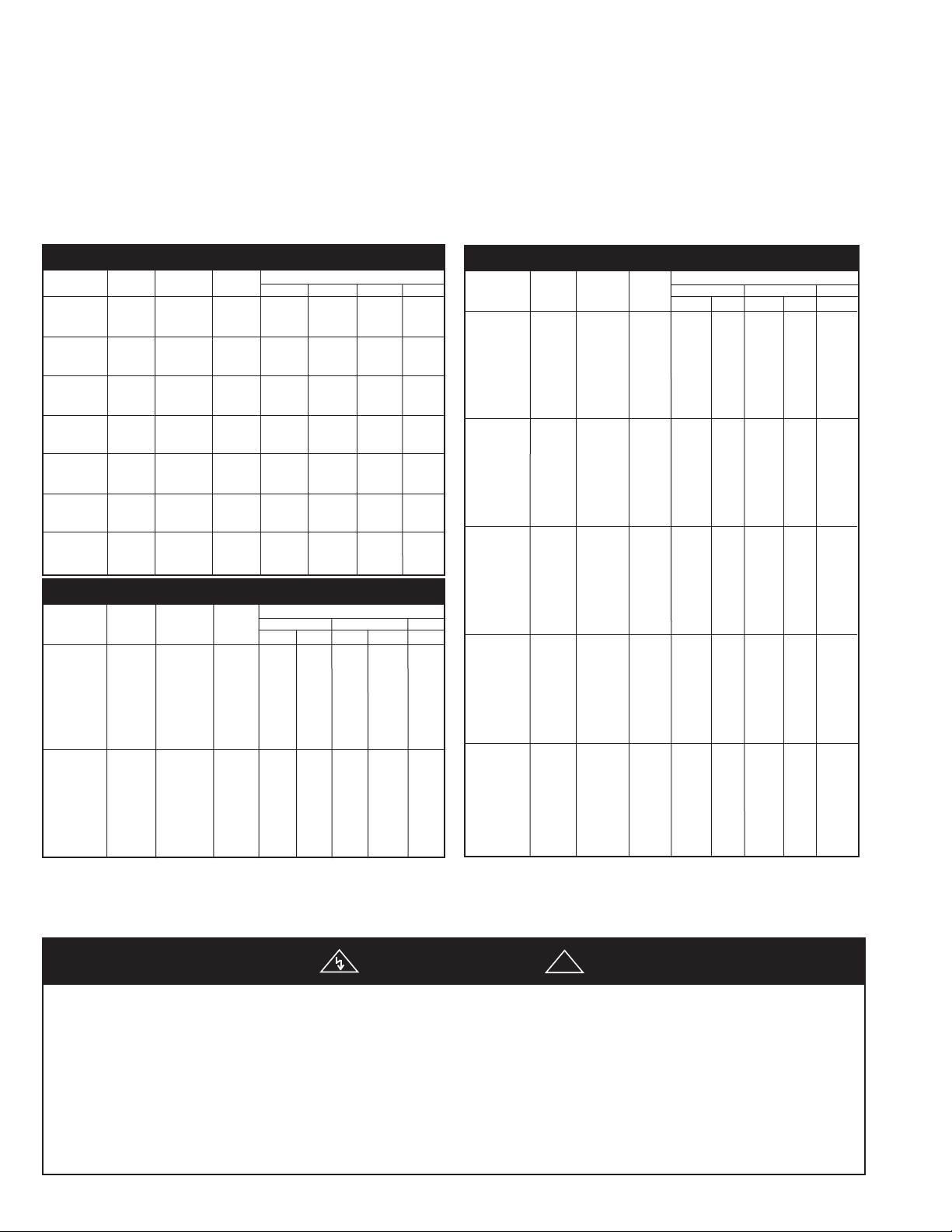

SPECIFICATIONS

Table A

Model CPH05A, DPH05A (H=5-1/2”; D=3”)

Catalog Total Amperage

Number* Length Watts/Ft. Watts 120V 208V 240V 277V

05A-2125 125 250 2.4 1.2 1.0 0.9

05A-2188 28” 188 375 3.1 1.8 1.6 1.4

05A-2250 250 500 4.2 2.4 2.1 1.8

5A-3125 125 375 3.1 1.8 1.6 1.4

0

05A-3188 3’ 188 564 4.7 2.7 2.4 2.0

05A-3250 250 750 6.2 3.6 3.1 2.7

05A-4125 125 500 4.2 2.4 2.1 1.8

05A-4188 4’ 188 750 6.2 3.6 3.1 2.7

5A-4250 250 1000 8.3 4.8 4.2 3.6

0

05A-5125 125 625 5.2 3.0 2.6 2.2

05A-5188 5’ 188 940 7.8 4.5 3.9 3.4

05A-5250 250 1250 10.4 6.0 5.2 4.5

5A-6125 125 750 6.2 3.6 3.1 2.7

0

05A-6188 6’ 188 1125 9.4 5.4 4.7 4.1

05A-6250 250 1500 12.5 7.2 6.2 5.4

5A-8125 125 1000 - 4.8 4.2 3.6

0

5A-8188 8’ 188 1500 - 7.2 6.2 5.4

0

05A-8250 250 2000 - 9.6 8.3 7.2

05A-10125 125 1250 - 6.0 5.2 4.5

05A-10188 10’ 188 1875 - 9.0 7.8 6.7

05A-10250 250 2500 - 12.0 10.4 9.0

Model CPH07A, DPH07A (H=7”; D=5”)

Catalog Total Amperage

Number* Length Watts/Ft. Watts 208V 240V 277V

07A-2125 125 250 1.2 - 1.0 - 0.9

07A-2188 188 375 1.8 - 1.6 - 1.4

07A-2250 250 500 2.4 - 2.1 - 1.8

07A-2375 375 750 3.6 - 3.1 - 2.7

07A-2500 28” 500 1000 4.8 - 4.2 - 3.6

07A-2564 564 1125 5.4 3.1 4.7 2.7 4.0

07A-2625 625 1250 6.0 3.5 5.2 3.0 4.5

07A-2750 750 1500 7.2 4.2 6.2 3.6 5.4

07A-3125 125 375 1.8 - 1.6 - 1.4

07A-3188 188 564 2.7 - 2.4 - 2.0

07A-3250 250 750 3.6 - 3.1 - 2.7

07A-3375 3’ 375 1125 5.4 - 4.7 - 4.0

07A-3500 500 1500 7.2 - 6.2 - 5.4

07A-3564 564 1690 8.1 4.7 7.4 4.3 6.1

07A-3625 625 1875 9.0 5.2 7.8 4.5 6.7

07A-3750 750 2250 11.0 6.5 9.4 5.4 8.1

1Ø 3Ø 1Ø 3Ø 1Ø

Note:

It is advisable to store cartons in a central area to be

drawn upon as needed per room requirements. If called for on

order, the cartons will have been tagged with proper room

number.

Table A (continued)

Model CPH07A, DPH07A (H=7”; D=5”) (Cont.)

Catalog Total Amperage

Number* Length Watts/Ft. Watts 208V 240V 277V

07A-4125 125 500 2.4 - 2.1 - 1.8

07A-4188 188 750 3.6 - 3.1 - 2.7

07A-4250 250 1000 4.8 - 4.2 - 3.6

07A-4375 375 1500 7.2 - 6.2 - 5.4

07A-4500 4’ 500 2000 9.6 - 8.3 - 7.2

07A-4564 564 2250 10.8 6.2 9.4 5.4 8.0

07A-4625 625 2500 12.0 6.9 10.4 6.2 9.0

07A-4750 750 3000 14.4 8.3 12.5 7.2 10.8

07A-5125 125 625 3.0 - 2.6 - 2.2

07A-5188 188 940 4.5 - 3.9 - 3.4

07A-5250 250 1250 6.0 - 5.2 - 4.5

07A-5375 5’ 375 1875 9.0 - 7.8 - 6.7

07A-5500 500 2500 12.0 - 10.4 - 9.0

07A-5564 564 2820 13.5 7.8 11.8 6.8 10.2

07A-5625 625 3125 15.0 8.6 13.0 7.5 11.3

07A-5750 750 3750 18.0 10.4 15.6 9.0 13.5

07A-6125 125 750 3.6 - 3.1 - 2.7

07A-6188 188 1125 5.4 - 4.7 - 4.0

07A-6250 250 1500 7.2 - 6.2 - 5.4

07A-6375 6’ 375 2250 10.8 - 9.4 - 8.1

07A-6500 500 3000 14.4 - 12.5 - 10.8

07A-6564 564 3380 16.2 9.4 14.1 8.1 12.2

07A-6625 625 3750 18.0 10.4 15.6 9.3 13.5

07A-6750 750 4500 21.6 12.5 18.7 10.8 16.2

07A-8125 125 1000 4.8 - 4.2 - 3.6

07A-8188 188 1500 7.2 - 6.2 - 5.4

07A-8250 250 2000 9.6 - 8.3 - 7.2

07A-8375 8’ 375 3000 14.4 - 12.5 - 10.8

07A-8500 500 4000 19.2 - 16.7 - 14.4

07A-8564 564 4500 21.6 12.5 18.7 10.8 16.2

07A-8625 625 5000 24.0 13.9 20.8 12.4 18.0

07A-8750 750 6000 28.6 16.5 25.0 14.4 21.6

07A-10125 125 1250 6.0 - 5.2 - 4.5

07A-10188 188 1875 9.0 - 7.8 - 6.7

07A-10250 250 2500 12.0 - 10.4 - 9.0

07A-10375 10’ 375 3750 18.0 - 15.6 - 13.5

07A-10500 500 45000 24.0 - 20.8 - 18.0

07A-10564 564 5640 27.2 15.7 23.5 13.6 20.4

07A-10625 625 6250 30.0 17.4 26.0 15.0 22.6

07A-10750 750 7500 36.6 20.8 31.3 18.1 27.0

1Ø 3Ø 1Ø 3Ø 1Ø

INSTALLATION

WARNING

Warningto property, read, understand and follow the below special

instructions:

1. All wiring procedures and connections must be in accor-

2. Do not install heaters against combustible low-density cellu-

3. Do not install heaters below electrical convenience recepta-

To reduce the risk of fire, electric shock and damage

dance with the National Electrical Code (NEC) and local

codes.

lose fiberboard surfaces.

cles (outlets).

!

4. To reduce the risk of fire, do not store or use gasoline or

other flammable vapors or liquids in the vicinity of the

heater.

CAUTION

5.

- Heater operates at High Temperatures. Keep

Electrical Cords, Drapes and Other Furnishings Away From

Heater. Maintain a minimum of 4 inches (102 mm) clearance from all exposed heater surfaces (top and front) at all

times.

2

Page 3

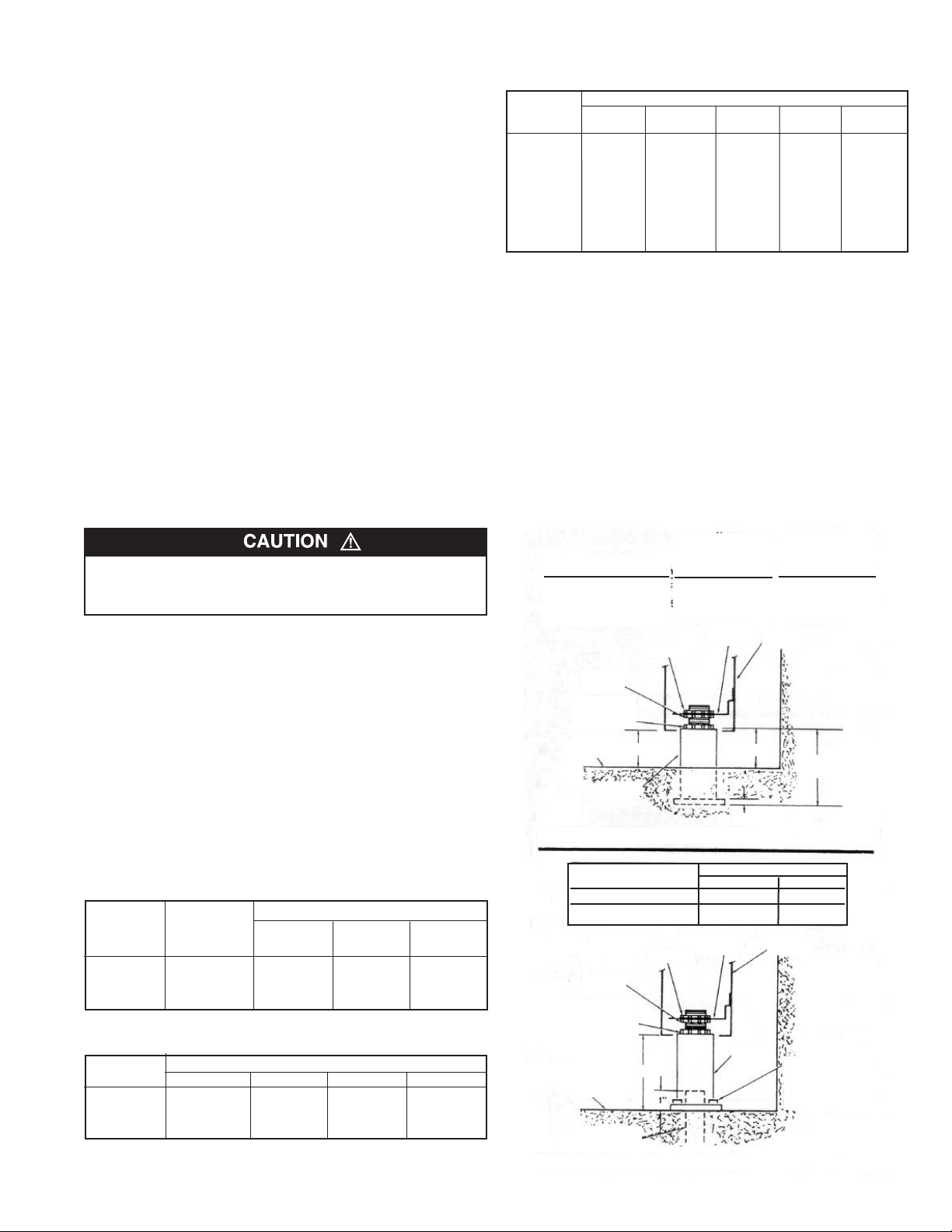

Rough-in Wiring

1. Branch circuits for the heaters shall be enclosed in 1” rigid

conduit for 05A heaters, or 1-1/4” rigid conduit for 07A

heaters.

2. Run branch circuit of proper voltage and wire size, in rigid

conduit, to location of left or right junction box as indicated

on heater wiring diagram. Wire entry to heater is through

either end pedestal.

Note

When pedestal is not used for wire entry, pedestal base

must be covered with cover plate (supplied with pedestal). See

Figure 2.

3. When installing heaters on existing floors, the threaded end

of the rigid conduit must extend 7/8” to 1” above finished

concrete. Conduit must be threaded a minimum of 3/8”.

4. Basic heaters are prewired and can be connected to branch

circuit at either end. Heaters with controls are prewired for

connection to branch circuit at one end only (refer to heater

wiring diagram), however, heater can be wired from opposite

end by running wires through heater wireway.

5. If it is necessary to run wires through the heater wire way,

use Table B to size the field installed wiring.

6. The factory installed wires in the heater wireway can be

loaded up to 35 amps in 05A units and up to 45 amps in 07A

units. Refer to Table C and D for maximum length of heater

run when the heaters are connected in parallel.

TABLE D. Maximum Length of Heater Run

(07A - 1Ø and 3Ø)

Watts/Ft. of Maximum Allowable Length of Heater Run (Feet)

the Heaters 208 Volts 208 Volts 240 Volts 240 Volts 277 Volts

1Ø 3Ø 1Ø` 3Ø 1Ø

125 74 - 86 - 99

188 49 - 57 - 66

250 37 - 43 - 49

376 24 - 28 - 33

500 18 - 21 - 24

564 16 27 19 32 22

625 14 24 17 29 19

750 12 20 14 24 16

7. Standard 75˚C wiring must be used in junction boxes,

wire-

way and blank sections.

Room Layout

Refer to heating plans for exact room arrangements of heaters

(with or without thermostat and/or relays and/or switches and

accessories.)

Mounting Height

Refer to Figure 1a. for typical mounting of heaters and pedestals

imbedded in floor; refer to Figure 1b. for surface-mounted

heaters and pedestals.

Note:

Up to 3/4” thick floor covering, such as carpet, tiles,

linoleum, etc., may be installed around and under the heater.

IF THE FACTORY INSTALLED WIRES IN THE WIREWAY

ARE USED TO CONNECT THE BUILT-IN CONTROLS, LIMIT

THE MAXIMUM CURRENT TO THE VALUES LISTED

Thermostat

24 amps @ 120-240 VAC

22 amps @ 277 VAC

Pilot duty– 125 VAC (all voltages)

Transformer relay

05A units: 22 amps @ 120-240 VAC

19 amps @ 277 VAC

07A Units: 25 AMPS @ 120-240 VAC

22 AMPS @ 277 VAC

Power relay

25 amps @ 120-277 VAC- see wiring diagram on heater

Disconnect switch

20 amps @ 120-277 VAC

Table B. Sizing Field Installed Wiring

Copper Maximum no.

wire size of wires Up to 3 4 to 6 7 thru 9

75º C in wireway Conductors Conductors Conductors

No. 12 AWG 9 11.5 amps 9.3 amps 8.1 amps

No. 10 AWG 8 17.4 amps 14.0 amps 12.1 amps

No. 8 AWG 4 24.0 amps 21.0 amps –

Maximum allowable current

Table C. Maximum Length of Heater Run

(05A-1Ø)

Watts/Ft. of Maximum allowable length of heater run (feet)

the heaters 120 Volts 208 Volts 240 Volts 277 Volts

125 33 58 67 77

188 22 38 44 51

250 16 29 33 38

Note:

For mix of watt densities, calculate amp draw. Do not

exceed values indicated in step 6 above.

Heater Capacity

(Watts.Ft. Heater Length)

125, 188 and 250 Watts/Ft.

376, 500, 564, 625 and 750

Watts/Ft.

Locknut

Leveling

Nut

Locknut (Do

Not Loosen

Or Remove)

Floor

Line

A

Pedestal

Figure 1a. Pedestal Imbedded in Floor

Heater Catalog Number Height Above Floor (Dim. “A)

05A 2-5/8” 3-3/8”

07A 3-7/8” 4-5/8”

Leveling

Nut

Locknut (Do

Not Loosen

Or Remove)

Rigid

Conduit

A

Floor

Line

Figure 1b. Surface-Mounted Pedestal

3

Dimension “A”

(Minimum Mounting

Height Above Floor)

Locknut

Heater

1-3/4”

3”

Welded

Bracket

3/8”

Min. Max.

Welded

Bracket

Pedestal

Heater

B

Heater

Pedestal

Dimension “B”

(Minimum Height

Above Floor)

2”

3-1/4”

2-7/8” (5” Heaters)

4-1/8” (7” Heaters)

Base Mounting

Holes - 1/4” DIa.

(Suitable

Fasteners By

Others)

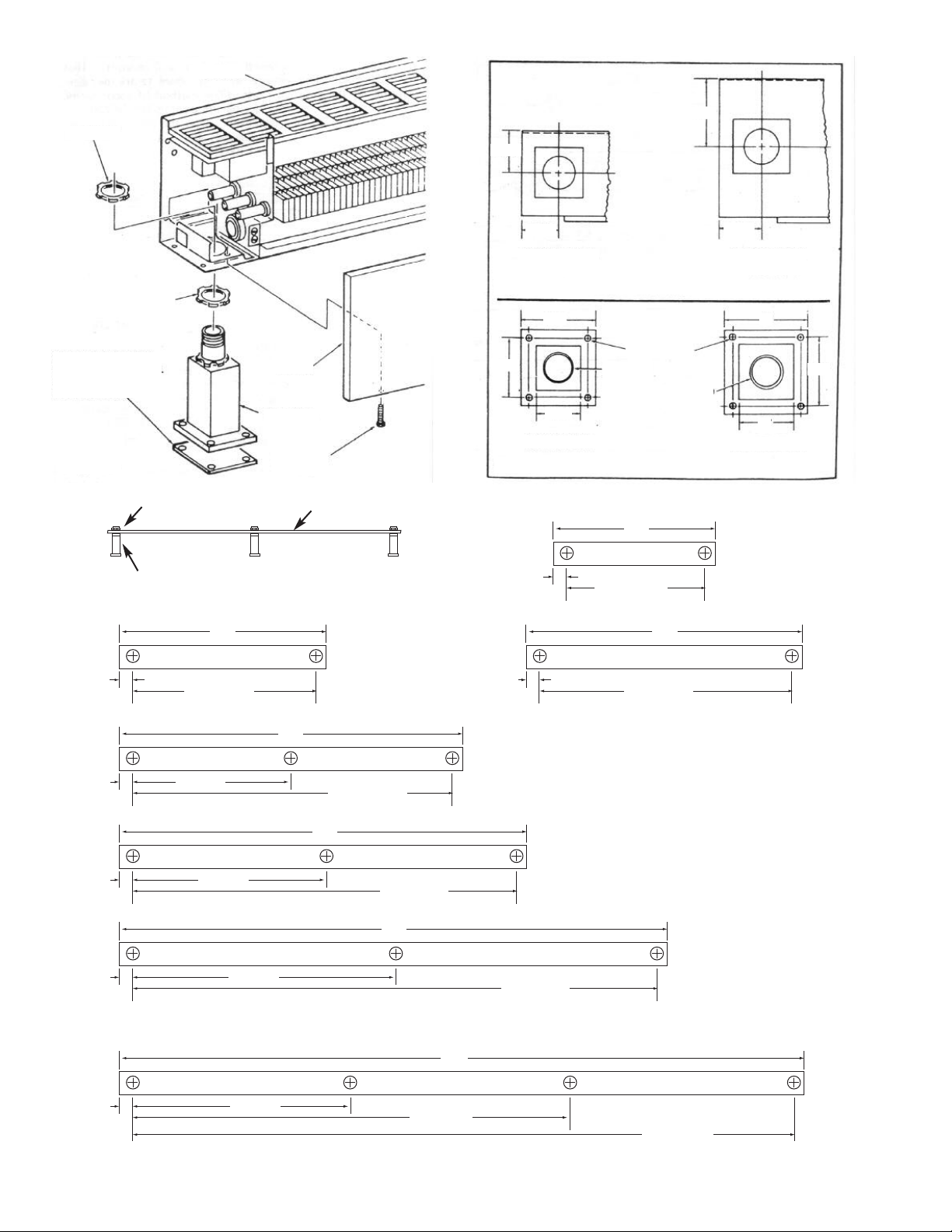

Page 4

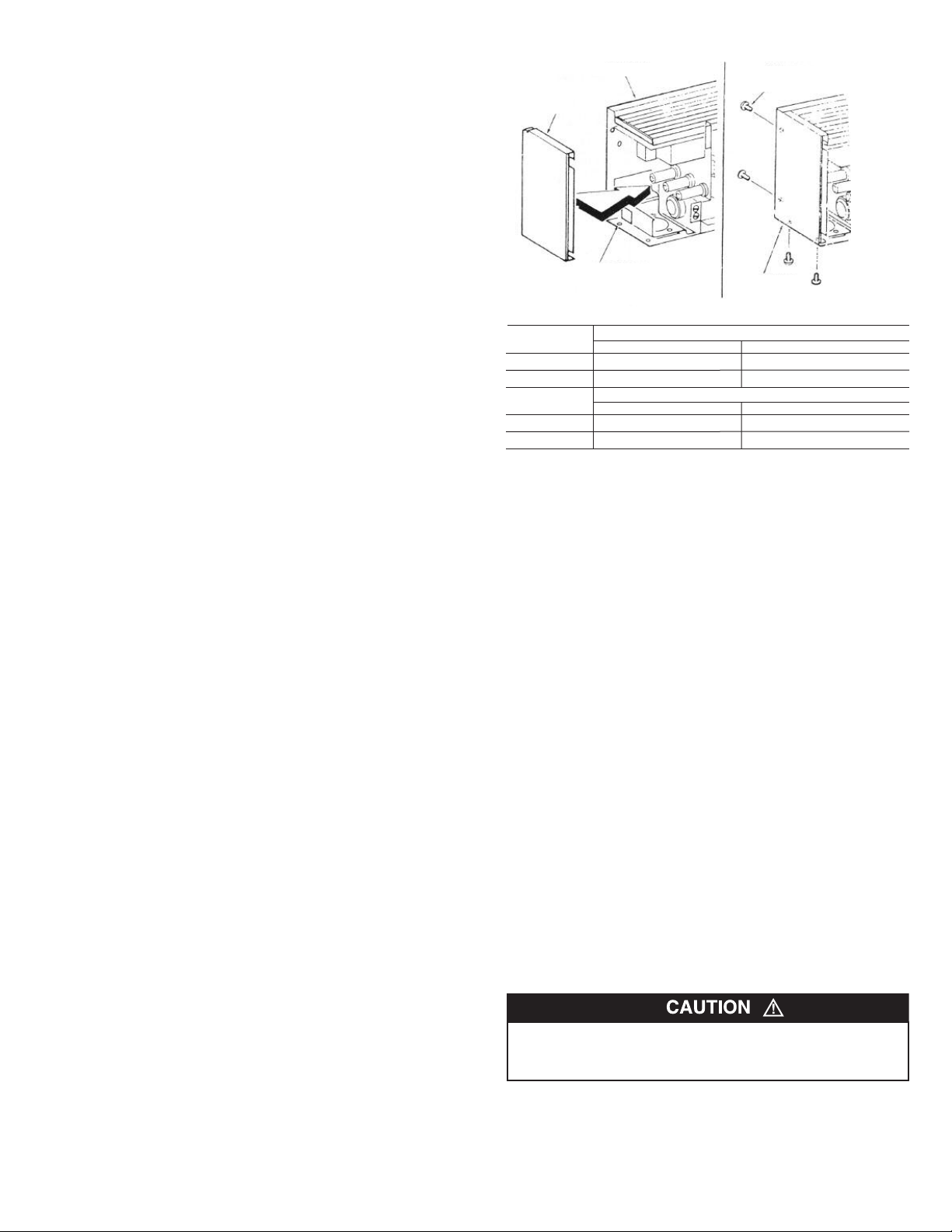

ocknut

L

Housing

-7/16”

1

2

-1/2”

Cover Plate (Used

Only When Pedestal Is

Not Used For Wire

Entry)

Figure 2.

1-7/16” (05A)

1-9/16” (07A)

Leveling

Nut

ocknut

L

Pedestal

Cover

Pedestal

Cover

Mounting

Screws

ypical Set-Up of Heater

T

edestal Using Jigs To

P

Maintain Proper Positioning

During Concrtete Pouring.

36”

33-1/8” (05A)

32-7/8” (07A)

ooden Jig

W

3-Foot Heater

1-7/16”

BOTTOM OF

05A HEATER

Figure 3a. End Pedestal Locations

2.75”

.125”

2

.625”

1

05A PEDESTAL

Figure 3b. Pedestal Details

1-7/16” (05A)

1-9/16” (07A)

1-7/16” (05A)

1-9/16” (07A)

0.250” Dia.

ounting Holes

M

1” Threaded

Pipe

28”

25-1/8” (05A)

24-7/8” (07A)

45-1/8” (05A)

44-7/8” (07A)

1-1/4” Threaded

Pipe

48”

1-9/16”

BOTTOM OF

07A HEATER

3”

”

2

07A PEDESTAL

28-Inch Heater

4-Foot Heater

2.5”

1-7/16” (05A)

1-9/16” (07A)

1-7/16” (05A)

1-9/16” (07A)

1-7/16” (05A)

1-9/16” (07A)

1-7/16” (05A)

1-9/16” (07A)

Figure 4.

28-13/16”

32-13/16”

44-13/16”

36-13/16”

60”

57-1/8” (05A)

56-7/8” (07A)

72”

69-1/8” (05A)

68-7/8” (07A)

94”

76-13/16”

5-Foot Heater

120”

4

6-Foot Heater

93-1/8” (05A)

92-7/8” (07A)

NOTE: HOLES IN JIGS SHOULD BE

1-3/8” FOR 05A HEATERS, OR 1-11/16”

FOR 07A HEATERS.

* WHEN BUTTING HEATERS,

LEAVE A 1/16” GAP BETWEEN

HEATERS TO ALLOW FOR

EXPANSION.

8-Foot Heater

10-Foot Heater

117-1/8” (05A)

116-7/8” (07A)

Page 5

Pedestal Installation

(Surface-Mounted to Existing Floor)

Note:

For ease of installation, it is important that the sequence

of operations indicated below be followed in order.

1. Remove front cover by removing mounting screws (Fig. 2)

2. Remove the top lock nut and the leveling nut from each

pedestal. (Do not loosen or remove the bottom lock nut.)

3. Screw one pedestal onto threaded rigid conduit protruding

from floor.

4. Install remaining pedestal(s) in heater and secure by

installing lock nut finger tight.

5. Install heater onto the pedestal which is screwed on the rigid

conduit. Position heater in desired location and mark

pedestal mounting hole locations on floor. Then remove the

heater and the one pedestal from the rigid conduit.Remove

the remaining pedestal(s) from the heater.

6. Drill holes in floor (Fig. 3b) and install threaded inserts (or

equivalent for 1/4” mounting bolts (inserts and bolts supplied

by installer.)

7. Reinstall the one pedestal on the rigid conduit, then secure

all other pedestals (with cover plates) to the floor with four

1/4” bolts through each pedestal flange.

Pedestal Installation

(Imbedded in New Concrete Floor)

When a heater installation is to be imbedded in a new concrete

floor, the pedestals are first installed in the concrete, then the

heater installed after the concrete has set. It is imperative that

the pedestals be installed in perfect alignment so that the holes

in order to achieve the required alignment, it is recommended

that the pedestals be held in place by the use of jigs during the

concrete pour. The jigs should be constructed of good quality 1”

x 4” lumber as shown in Figure 4. The pedestals are installed in

the jigs and then positioned for the concrete pour. One end

pedestal must be screwed onto rigid wall conduit so that the

mounting height requirements in Figure 1a are met after pouring

of the finished floor. (The method of securing the pedestals and

jigs in place during the pouring of the concrete is at the option of

the installer.) After the concrete has set, remove the jigs from

the pedestals and install the heater as indicated in steps Seven

or Eight.

Installation of Single Unit

Note:

For ease of installation, it is important that the sequence

of operations below be followed in order.

1. Remove front cover by removing mounting screws (Fig. 2)

2. Install end caps (must be purchased separately) on both

ends of the heater housing. Refer to Figure 5 (Type CPH

and DPH) for details of end cap installation.

3. Install leveling nut on each installed pedestal, then position

heater on pedestals. Adjust the leveling nuts until the heater

is level and at the desired mounting height. Then install and

tighten the pedestal lock nuts.

4. Run proper size branch circuit to the junction box through the

appropriate end pedestal.

5. Following the wiring diagram secured to the heater, make

electrical connections.

6. Replace front cover and secure with mounting screws. (See

Figure 2.)

7. If the heater is equipped with a built-in thermostat, adjust the

shaft to the mid-range and let the heater run for a few hours.

ousing

End

Cap

H

Accessory

Mounting

Holes

nd Cap

E

ounting

M

crews

S

End Cap Data

Description CPH05A CPH07A

End Cap Left CPH05-ECL(R) CPH07-ECL(R)

End Cap Right CPH05-ECR(R) CPH07-ECR(R)

End Cap Left DSH05-ECL(R) DSH07-ECL(R)

End Cap Right DSH05-ECR(R) DSH07-ECR(R)

(R) Suffix on catalog number refers to accessories with 120 VAC receptacle.

Heater Catalog Number

Heater Catalog Number

DPH05A DPH07A

Figure 5. (Type CPH and DPH Only)

If the room temperature is too hot,

rotate the shaft counterclockwise; if too cool, rotate the shaft clockwise until

a comfortable temperature is obtained. Let room temperature stabilize after each setting change.

Note:

The thermostat adjustment shaft and the disconnect

switch are accessible through the grille openings at the left end

of the heater.

Installation of Multiple Units

Note:

For ease of installation, it is important that the sequence

of operations indicated below be followed in order.

1. Remove front cover by removing mounting screws (Figure

2.)

2. Install end caps on the outer end of the first and last heater

(or blank section ) in a run using four No. 6 screws supplied

with end caps. (Refer to Figure 5a or 5b for details of end

cap installation.)

3. Run proper size branch circuit to the junction box through

heaters and blank sections (if applicable) on pedestals.

Note (Type CPH and DPH only):

end, be sure to position heaters carefully to insure proper alignment. Leave a 1/16” gap between heaters to allow for expansion.

4. Adjust the leveling nuts until the heaters are level and at the

desired mounting height. Then install and tighten the

pedestal lock nuts.

DO NOT OPERATE THE HEATERS UNLESS THE OUTER

END OF THE LAST HEATERS (OR BLANK SECTIONS) IN

THE RUN ARE CLOSED WITH END CAPS.

Note

: 75˚C field wiring may be run through the blank section

wireway.

5

When butting heaters end to

Page 6

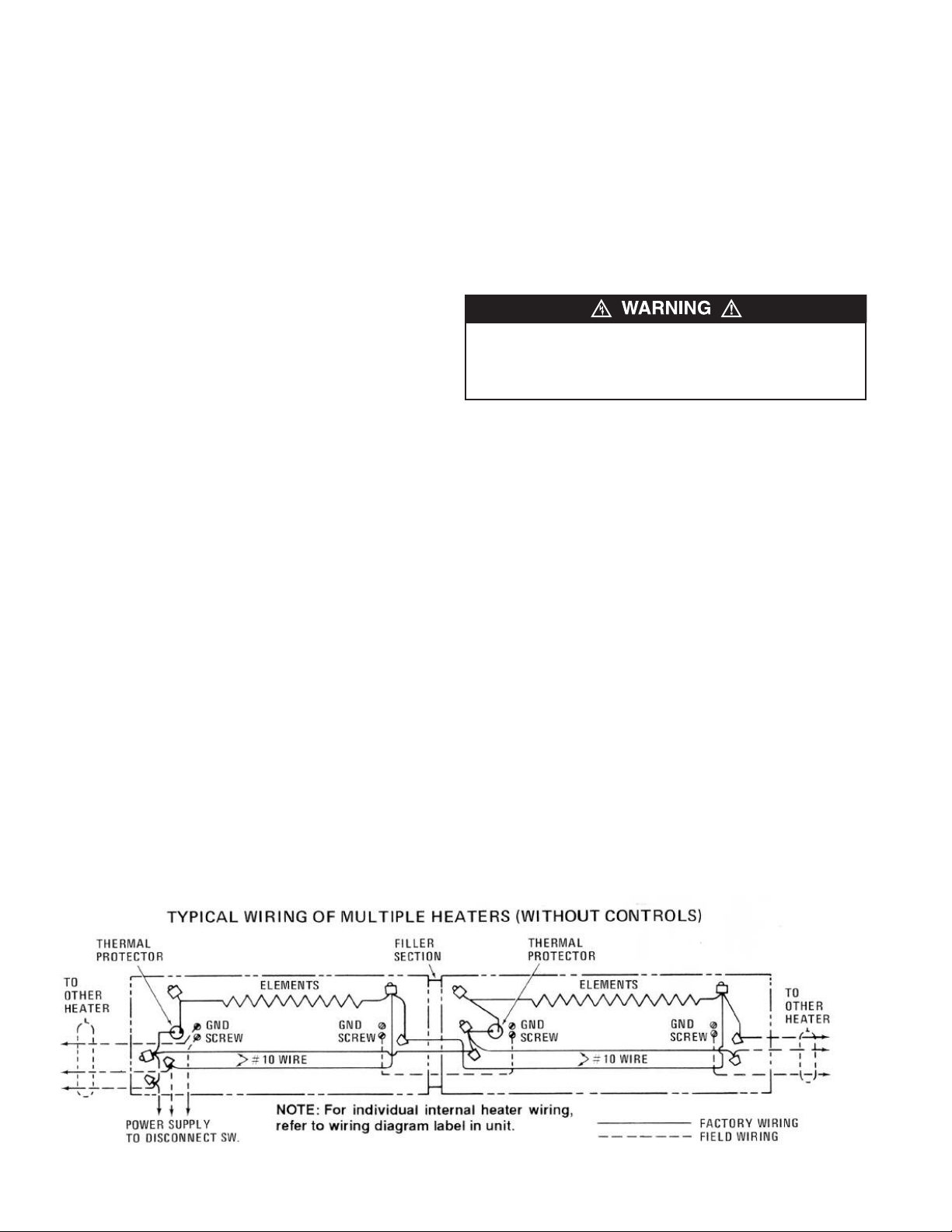

5. Following the wiring diagram secured to the heater, make the

electrical connections. Refer to Figure 7 to connect the other

heaters in parallel. Grounding of the other heaters is accomplished by connecting a jumper wire (not supplied) between

the two adjacent heaters.

6. Replace front covers, and secure with mounting screws.

(Figure 2.)

7. If the heaters are equipped with built-in thermostat, adjust

the shaft to the mid-range and let the heaters run for a few

hours. If the room temperature is too hot, rotate the shaft

counterclockwise; if too cool, rotate the shaft clockwise until

a comfortable temperature is obtained. Let room temperature

stabilize after each setting change.

Note:

The thermostat adjustment shaft and the disconnect

switch are accessible through the grille openings at the left end

of the heater.

OPERATION

1. This heater must be properly installed before it is used.

2. If the heater is equipped with a built-in thermostat, adjust the

shaft to the mid-range and let the heater run for a few hours.

If the room temperature is too hot, rotate the shaft counterclockwise; if too cool, rotate the shaft clockwise until a comfortable temperature is obtained. Let room temperature stabilize after each setting change. The heater will automatically cycle around this set point on the thermostat.

Note:

If a thermostat or disconnect switch is provided in the

heater, these components are accessible through the grille

openings at the left or right end of the heater.

3. There are safety over-temperature limiting devices inside the

heater. These safety devices are there to turn off the heater

automatically in the event of an over-temperature condition.

These devices are not to be tampered with or disconnected

from the electrical system. If the heater is installed correctly

and wired to the correct voltage, these devices should never

operate to turn off the heater. If this device is cycling the

heater off and on, turn off power to the heater and and have

the heater serviced by qualified service personnel.

MAINTENANCE

1. The user can perform periodic cleaning of the outer cabinet.

All other servicing is to be done by qualified service personnel.

2. The finish of the heater may be cleaned with a slightly damp

rag if desired.

3. Because of the convection heating principle which depends

on air circulation through the heater, dust can collect

between the fins. The heater should be cleaned annually for

maximum efficiency.

4. To remove the front cover, remove attachment screws at the

bottom of the front cover.

BEFORE REMOVING THE FRONT COVER FOR SERVICING

OR CLEANING, BE SURE POWER HAS BEEN TURNED OFF

AT THE CIRCUIT BREAKER PANEL AND THE HEATER ELEMENT IS COOL.

5. A vacuum cleaner with a brush attachment may be used for

cleaning of the element fins.

6. Replace front cover, (using the screws provided), restore

power and check heater for proper operation.

Figure 7 - Wiring Diagram

6

Page 7

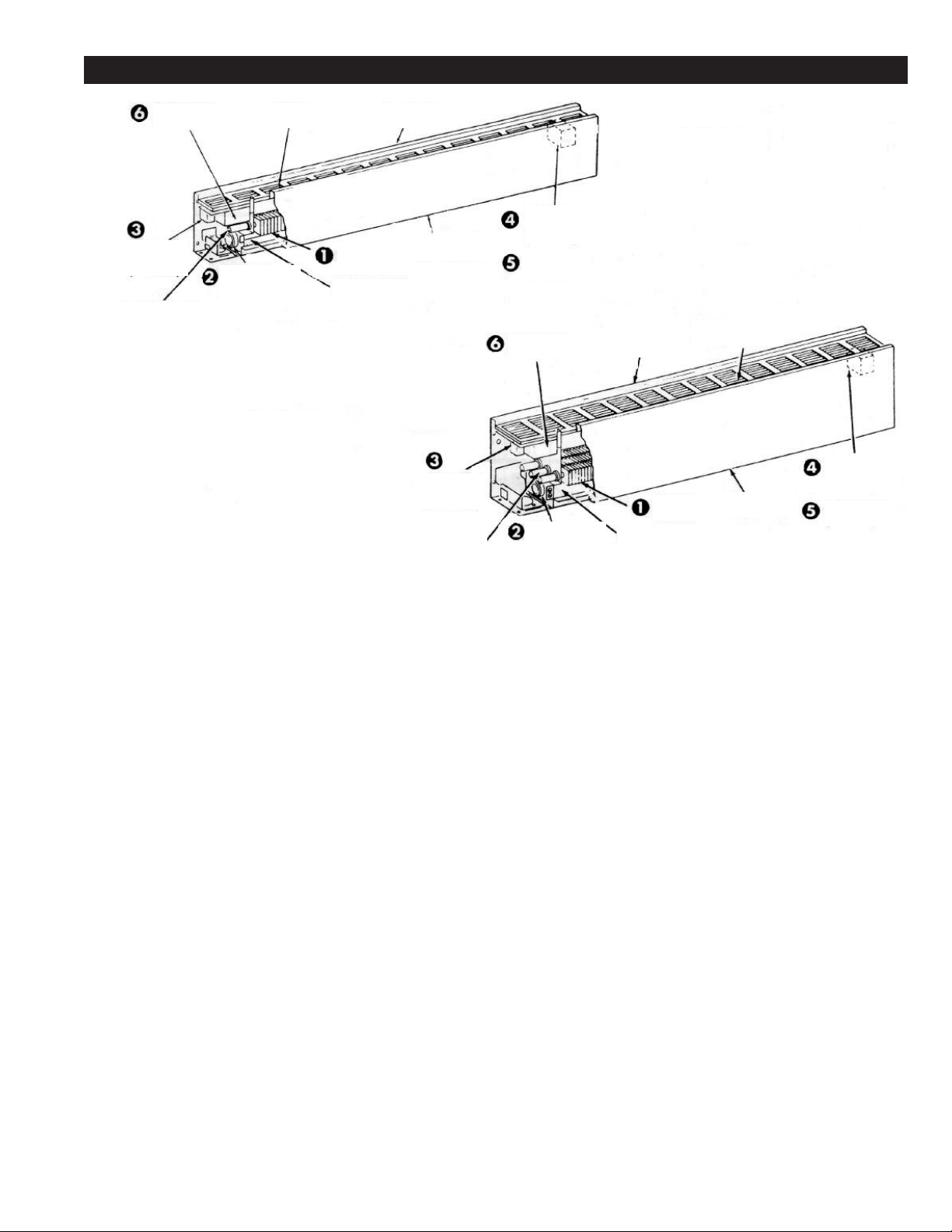

RENEWAL PARTS IDENTIFICATION CPH

Thermostat

(Optional)

Disconnect

witch

S

(Optional)

Element Bushing

1213-2000-001

2501-0257-VAR

Overload

Protector

520-0007-VAR

4

CPH07A

*Grille

*Back Panel

2701-0765-VAR

eating

H

lement

E

Wireway Cover

6405-0053-VAR

Element Bushing

*Front Cover

1402-0316-VAR

Disconnect

Switch

Optional)

(

1213-2000-000

Transformer

Relay

Optional)

(

ower Relay

P

Optional)

(

Thermostat

(Optional)

verload

O

Protector

4520-0007-VAR

*Back Panel

701-0766-VAR

2

Wireway Cover

6405-0053-VAR

CPH05A

eating

H

Element

Grille

*

2501-0251-VAR

Front Cover

*

1402-0315-VAR

Transformer

elay

R

(Optional)

Power Relay

(Optional)

7

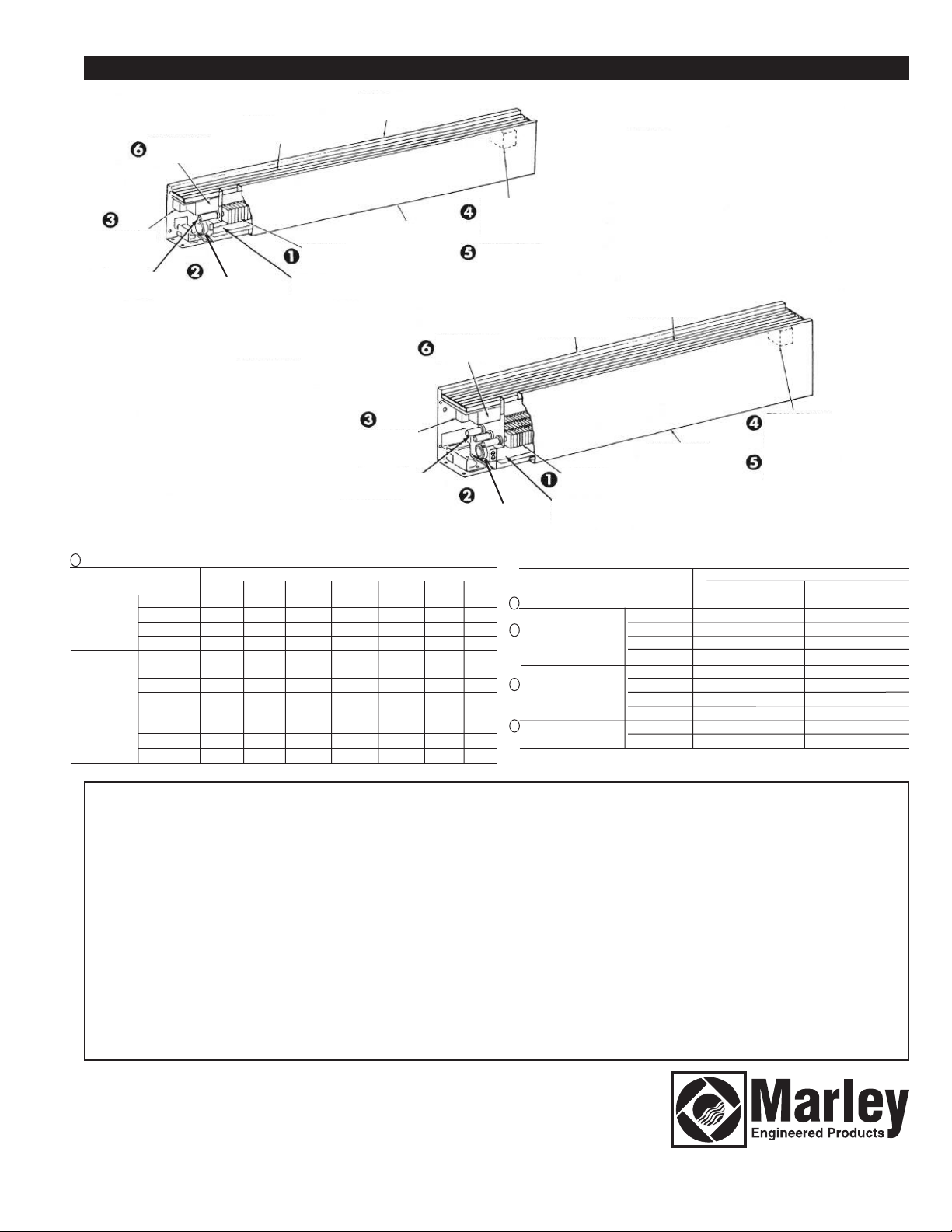

Page 8

isconnect

D

Switch

(Optional)

lement Bushing

E

1213-2000-001

Thermostat

Optional)

(

*Grille

2501-0252-VAR

verload

O

Protector

4520-0007-VAR

DPH07A

RENEWAL PARTS IDENTIFICATION DPH

*Back Panel

2701-0765-VAR

DPH05A

Transformer

Relay

Optional)

(

Power Relay

(Optional)

Optional)

Overload

rotector

P

4520-0007-VAR

*Back Panel

701-0766-VAR

2

eating

H

Element

ireway Cover

W

6405-0053-VAR

2501-0251-VAR

Heating

Element

Wireway Cover

6405-0053-VAR

Disconnect

Optional)

(

Element Bushing

213-2000-000

1

*Front Cover

402-0316-VAR

1

Switch

Thermostat

(

*Grille

*Front Cover

402-0315-VAR

1

Transformer

elay

R

(Optional)

Power Relay

(Optional)

1

Heating Element (Part No. Prefix 1802-2001)

Heater Length

Description 28” 3’ 4’ 5’ 6’ 8’ 10’

120 Volts 085 087 089 091 093 -125 W/Ft. 208 Volts 086 088 090 092 091 095 096

per Element 240 Volts 048 054 060 066 072 077 081

277 Volts 049 055 061 067 073 078 082

120 Volts 005 011 017 023 029 -188 W/Ft. 208 Volts 002 008 014 020 026 032 036

per Element 240 Volts 001 007 013 019 025 031 035

277 Volts 000 006 012 018 024 030 034

120 Volts 004 010 016 022 028 -250 W/Ft. 208 Volts 003 009 015 021 027 033 037

per Element 240 Volts 002 008 014 020 026 032 036

277 Volts 001 007 013 019 025 031 035

Built-In Controls (Optional)

Description 07A and 14A Units 05A Units

Disconnect Switch 5216-0124-000 5216-0124-000

3

4

Transformer Relay 208 Volt R13700002B002 410043002

5

Power Relay 120 Volt 5018-2006-001 5018-2006-001

6

Thermostat 1 Pole 5813-0024-000 5813-0024-000

120 Volt R13700002B001 410043001

240 Volt R13700002B003 410043003

277 Volt R13700002B004 410043004

24 Volt 5018-2006-000 5018-2006-000

208/240 Volt 5018-2006-002 5018-2006-002

277 Volt 5018-2006-003 5018-2006-003

2 Pole 5812-0023-000 5813-0023-000

Part Number

LIMITED WARRANTY

All products manufactured by Marley Engineered Products are warranted against defects in workmanship and materials for one year from date of installation, except

heating elements which are warranted against defects in workmanship and materials for five years from date of installation. This warranty does not apply to damage from

accident, misuse, or alteration; nor where the connected voltage is more than 5% above the nameplate voltage; nor to equipment improperly installed or wired or

maintained in violation of the product’s installation instructions. All claims for warranty work must be accompanied by proof of the date of installation.

The customer shall be responsible for all costs incurred in the removal or reinstallation of products, including labor costs, and shipping costs incurred to return products

to Marley Engineered Products Service Center. Within the limitations of this warranty, inoperative units should be returned to the nearest Marley authorized service center or the Marley Engineered Products Service Center, and we will repair or replace, at our option, at no charge to you with return freight paid by Marley. It is agreed that

such repair or replacement is the exclusive remedy available from Marley Engineered Products.

THE ABOVE WARRANTIES ARE IN LIEU OF ALL OTHER WARRANTIES EXPRESSED OR IMPLIED, AND ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE WHICH EXCEED THE AFORESAID EXPRESSED WARRANTIES ARE HEREBY DISCLAIMED AND EXCLUDED FROM

THIS AGREEMENT. MARLEY ENGINEERED PRODUCTS SHALL NOT BE LIABLE FOR CONSEQUENTIAL DAMAGES ARISING WITH RESPECT TO THE

PRODUCT, WHETHER BASED UPON NEGLIGENCE, TORT, STRICT LIABILITY, OR CONTRACT.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above exclusion or limitation may not apply to you. This warranty gives

you specific legal rights, and you may also have other rights which vary from state to state.

For the address of your nearest authorized service center, contact Marley Engineered Products in Bennettsville, SC, at 1-800-642-4328. Merchandise returned to the factory must be accompanied by a return authorization and service identification tag, both available from Marley Engineered Products. When requesting return authorization,

include all catalog numbers shown on the products.

HOW TO OBTAIN WARRANTY SERVICE AND

WARRANTY PARTS PLUS GENERAL INFORMATION

1. Warranty Service or Parts

2. Purchase Replacement Parts

3. General Product Information

1-800-642-4328

1-800-654-3545

www.marleymep.com

Part No. 5200-2109-002

Note:

When obtaining service always have the

following:

1. Model number of the product

2. Date of manufacture

3. Part number or description

ECR 39036

02/11

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

Page 9

Calefactor de convección

comercial de pedestal (Tipo

CPH)

Calefactores de convección

decorativos de pedestal (Tipo

DPH)

CPH y DPH

Calefactor de convección

INSTRUCCIONES IMPORTANTES

Estimado Propietario,

¡Felicitaciones! Gracias por comprar este nuevo calefactor fabricado por Marley Engineered Products. Usted

ha hecho una sabia inversión al seleccionar el producto de la más alta calidad en la industria de la calefacción. Por favor lea cuidadosamente las instrucciones de instalación y mantenimiento incluidas en este manual. Así podrá disfrutar de años de calefacción confortable y eficiente con este producto de Marley Engineered

Products ... el líder de la industria en diseño, fabricación, calidad y servicio.

ADVERTENCIA

Lea cuidadosamente

darle a solucionar las dificultades que pudieran surgir durante la

instalación de estos Calefactores de Pedestal. El estudio previo de

estas instrucciones le ahorrará considerable tiempo y dinero en el

futuro. Estos Calefactores de Pedestal están diseñados para una

instalación fácil y económica. Siga estas instrucciones para mantener

su tiempo de instalación en un mínimo.

1. Lea todas las instrucciones antes de usar el calefactor.

Peligro de incendio o descarga eléctrica

2.

ble descarga eléctrica, primero verifique que la electricidad está

apagada en el interruptor principal antes de cablear. Todo el

cableado debe realizarse de acuerdo con el Código Eléctrico

Nacional (NEC) y los códigos locales aplicables, y toda la instalación del calefactor debe conectarse a tierra como precaución

contra una posible descarga eléctrica.

3. Antes de energizar, verifique el voltaje de suministro para asegurarse que es igual al indicado en la placa de datos del calefactor.

4. No instale calefactores contra superficies combustibles de tabla

de fibra de celulosa de baja densidad.

5. Debido a las variaciones en las composiciones del vinilo y su

posibilidad de decoloramiento, al instalar sobre cubiertas de

pared de vinilo o debajo de adornos de vinilo de ventanas,

podría requerirse el uso de separadores (SO1A y SO2A) y/o

especificar una unidad con densidad de potencia (watts) inferior.

– Estas instrucciones están escritas para ayu-

– Para evitar una posi-

... Los Empleados de

Marley Engineered Products

!

6. Los extremos del calefactor deben quedar completamente cerrados mediante el uso de calefactores contiguos, tapas de

extremo, u otros accesorios.

7. No coloque el calefactor debajo de un tomacorriente eléctrico.

8. Un calefactor tiene en su interior piezas calientes, piezas que

forman arcos eléctricos o piezas que producen chispa. No utilice

esta unidad en áreas donde se utiliza o almacena gasolina, pintura, o líquidos inflamables. No instale este calefactor en posición invertida (boca abajo) o donde exista agua.

9. Este calefactor está caliente cuando está en uso. Para evitar

quemaduras, no permita que la piel desnuda haga contacto con

las superficies calientes. Mantenga alejados del calefactor los

materiales combustibles tales como muebles, almohadas, ropa

de cama, papeles, ropa y cortinas.

10. Para evitar un posible incendio, no obstruya de ninguna manera

las entradas o escape de aire.

11. No inserte ni permita que objetos extraños ingresen a las aberturas de ventilación o de escape, ya que esto podría causar una

descarga eléctrica, incendio, o podría dañar el calefactor.

12. Ante de utilizar el calefactor, deseche las almohadillas de

empaque.

Además, vea las advertencias adicionales indicadas en este manual.

GUARDE ESTAS INSTRUCCIONES

Page 10

RECEPCIÓN

1. Cada Calefactor tipo Pedestal se envía en dos cajas de cartón. Una

caja contiene el calefactor, la otra caja contiene los pedestales.

2. En el momento de enviar el material, éste estaba en buenas condiciones; y Marley Engineered Products guarda el conocimiento de

embarque autorizado, por lo tanto, cualquier daño oculto debe

reportarse inmediatamente a la empresa de transporte para inspección y resolución.

ESPECIFICACIONES

Tabla A

Modelo CPH05A, DPH05A (Alt.=51/2”; Prof.=3”)

Número de Watts/ Watts Amperaje

catálogo* Longitud Pie total 120 V 208 V 240 V 277 V

05A-2125 125 250 2.4 1.2 1.0 0.9

05A-2188 28” 188 375 3.1 1.8 1.6 1.4

05A-2250 250 500 4.2 2.4 2.1 1.8

5A-3125 125 375 3.1 1.8 1.6 1.4

0

05A-3188 3’ 188 564 4.7 2.7 2.4 2.0

05A-3250 250 750 6.2 3.6 3.1 2.7

05A-4125 125 500 4.2 2.4 2.1 1.8

05A-4188 4’ 188 750 6.2 3.6 3.1 2.7

5A-4250 250 1000 8.3 4.8 4.2 3.6

0

05A-5125 125 625 5.2 3.0 2.6 2.2

05A-5188 5’ 188 940 7.8 4.5 3.9 3.4

05A-5250 250 1250 10.4 6.0 5.2 4.5

5A-6125 125 750 6.2 3.6 3.1 2.7

0

05A-6188 6’ 188 1125 9.4 5.4 4.7 4.1

05A-6250 250 1500 12.5 7.2 6.2 5.4

5A-8125 125 1000 - 4.8 4.2 3.6

0

5A-8188 8’ 188 1500 - 7.2 6.2 5.4

0

05A-8250 250 2000 - 9.6 8.3 7.2

05A-10125 125 1250 - 6.0 5.2 4.5

05A-10188 10’ 188 1875 - 9.0 7.8 6.7

05A-10250 250 2500 - 12.0 10.4 9.0

Modelo CPH07A, DPH07A (Alt.=7”; Prof.=5”)

Número de Watts/ Watts Amperaje

catálogo* Longitud Pie total 120 V 208 V 240 V 277 V

07A-2125 125 250 1.2 - 1.0 - 0.9

07A-2188 188 375 1.8 - 1.6 - 1.4

07A-2250 250 500 2.4 - 2.1 - 1.8

07A-2375 375 750 3.6 - 3.1 - 2.7

07A-2500 28” 500 1000 4.8 - 4.2 - 3.6

07A-2564 564 1125 5.4 3.1 4.7 2.7 4.0

07A-2625 625 1250 6.0 3.5 5.2 3.0 4.5

07A-2750 750 1500 7.2 4.2 6.2 3.6 5.4

07A-3125 125 375 1.8 - 1.6 - 1.4

07A-3188 188 564 2.7 - 2.4 - 2.0

07A-3250 250 750 3.6 - 3.1 - 2.7

07A-3375 3’ 375 1125 5.4 - 4.7 - 4.0

07A-3500 500 1500 7.2 - 6.2 - 5.4

07A-3564 564 1690 8.1 4.7 7.4 4.3 6.1

07A-3625 625 1875 9.0 5.2 7.8 4.5 6.7

07A-3750 750 2250 11.0 6.5 9.4 5.4 8.1

1Ø 3Ø 1Ø 3Ø 1Ø

Nota:

Se recomienda guardar las cajas de cartón en una área central

para ser utilizadas según se necesite, según los requisitos del salón. Si

se requiere en orden, la cajas de cartón tendrán que ser etiquetadas

con el número de salón apropiado.

Tabla A (continuación)

Modelo CPH07A, DPH07A (Alt.=7”; Prof.=5”) (Cont.)

Número de Watts/ Watts Amperaje

catálogo* Longitud Pie total 120 V 208 V 240 V 277 V

07A-4125 125 500 2.4 - 2.1 - 1.8

07A-4188 188 750 3.6 - 3.1 - 2.7

07A-4250 250 1000 4.8 - 4.2 - 3.6

07A-4375 375 1500 7.2 - 6.2 - 5.4

07A-4500 4’ 500 2000 9.6 - 8.3 - 7.2

07A-4564 564 2250 10.8 6.2 9.4 5.4 8.0

07A-4625 625 2500 12.0 6.9 10.4 6.2 9.0

07A-4750 750 3000 14.4 8.3 12.5 7.2 10.8

07A-5125 125 625 3.0 - 2.6 - 2.2

07A-5188 188 940 4.5 - 3.9 - 3.4

07A-5250 250 1250 6.0 - 5.2 - 4.5

07A-5375 5’ 375 1875 9.0 - 7.8 - 6.7

07A-5500 500 2500 12.0 - 10.4 - 9.0

07A-5564 564 2820 13.5 7.8 11.8 6.8 10.2

07A-5625 625 3125 15.0 8.6 13.0 7.5 11.3

07A-5750 750 3750 18.0 10.4 15.6 9.0 13.5

07A-6125 125 750 3.6 - 3.1 - 2.7

07A-6188 188 1125 5.4 - 4.7 - 4.0

07A-6250 250 1500 7.2 - 6.2 - 5.4

07A-6375 6’ 375 2250 10.8 - 9.4 - 8.1

07A-6500 500 3000 14.4 - 12.5 - 10.8

07A-6564 564 3380 16.2 9.4 14.1 8.1 12.2

07A-6625 625 3750 18.0 10.4 15.6 9.3 13.5

07A-6750 750 4500 21.6 12.5 18.7 10.8 16.2

07A-8125 125 1000 4.8 - 4.2 - 3.6

07A-8188 188 1500 7.2 - 6.2 - 5.4

07A-8250 250 2000 9.6 - 8.3 - 7.2

07A-8375 8’ 375 3000 14.4 - 12.5 - 10.8

07A-8500 500 4000 19.2 - 16.7 - 14.4

07A-8564 564 4500 21.6 12.5 18.7 10.8 16.2

07A-8625 625 5000 24.0 13.9 20.8 12.4 18.0

07A-8750 750 6000 28.6 16.5 25.0 14.4 21.6

07A-10125 125 1250 6.0 - 5.2 - 4.5

07A-10188 188 1875 9.0 - 7.8 - 6.7

07A-10250 250 2500 12.0 - 10.4 - 9.0

07A-10375 10’ 375 3750 18.0 - 15.6 - 13.5

07A-10500 500 45000 24.0 - 20.8 - 18.0

07A-10564 564 5640 27.2 15.7 23.5 13.6 20.4

07A-10625 625 6250 30.0 17.4 26.0 15.0 22.6

07A-10750 750 7500 36.6 20.8 31.3 18.1 27.0

1Ø 3Ø 1Ø 3Ø 1Ø

INSTRUCCIONES DE INSTALACIÓN

ADVERTENCIA

Advertenciadaño a la propiedad, lea, entienda y siga las siguientes instrucciones

especiales:

1. Todas las conexiones y procedimientos de cableado deben

realizarse de acuerdo con el Código Eléctrico Nacional (NEC) y los

códigos locales.

2. No instale calefactores contra superficies combustibles de tabla de

fibra de celulosa de baja densidad.

3. No instale los calefactores debajo de tomacorrientes eléctricos.

Para reducir el riesgo de incendio, descarga eléctrica y

!

4. Para reducir el riesgo de incendio, no almacene ni utilice gasolina

ni otros vapores o líquidos inflamables cerca del calefactor.

PRECAUCIÓN-

5.

Mantenga alejados del calefactor los cables eléctricos, cortinas y

muebles. Mantenga a todo momento un espacio libre mínimo de 4

pulgadas (102 mm) en todas las superficies expuestas del calefactor (superiores y delanteras).

10

El calefactor funciona a altas temperaturas.

Page 11

Preparación preliminar del cableado

1. Los circuitos de derivación para los calefactores deberán encerrarse

en conducto/tubo rígido de 1” para los calefactores 05A, ó conducto

rígido de 1-1/4” para los calefactores 07A.

2. Tienda un circuito de derivación de voltaje y tamaño de alambre

apropiados, dentro de conducto rígido, hasta el sitio de la caja de

conexiones izquierda o derecha según se indica en el diagrama de

cableado del calefactor. La entrada de alambres al calefactor es a

través de cualquier pedestal de extremo.

Nota-

Cuando el pedestal no se utiliza para la entrada de alambres, la

base del pedestal debe cubrirse con placa (suministrada con el

pedestal). Vea la Figura 2.

3. Al instalar calefactores sobre pisos existentes, el extremo roscado

del conducto rígido debe extenderse 7/8” a 1” por encima del concreto acabado. El conducto/tubo debe tener rosca de 3/8” como mínimo.

4. Los calefactores básicos están precableados y pueden conectarse

al circuito de derivación en cualquier extremo. Los calefactores con

controles están precableados para conexión con el circuito de

derivación en un (1) extremo únicamente (consulte el diagrama de

cableado del calefactor), sin embargo, el calefactor puede cablearse

desde el extremo opuesto tendiendo los alambres a través del conducto superficial de alambres del calefactor.

5. Si es necesario tender alambres a través del conducto superficial de

alambres del calefactor, utilice la Tabla B para dimensionar los

alambres instalables en campo.

6. Los alambres instalados en fábrica en el conducto superficial de

alambres del calefactor pueden cargarse hasta 35 amperios en las

unidades 05A y hasta 45 amperios en las unidades 07A. Consulte la

Tabla C y D para obtener la longitud máxima del cableado (tendido)

del calefactor cuando los calefactores se conectan en paralelo.

PRECAUCIÓN

SI LOS ALAMBRES INSTALADOS EN FÁBRICA EN EL CONDUCTO SUPERFICIAL DE ALAMBRES SE UTILIZAN PARA CONECTAR LOS CONTROLES INCORPORADOS, LIMITE LA CORRIENTE MÁXIMA A LOS VALORES INDICADOS

Termostato

Relé del transformador

Unidades 05A: 22 amps @ 120-240 VAC

Unidades 07A: 25 amps @ 120-240 VAC

24 amps @ 120-240 VAC

22 amps @ 277 VAC

Servicio piloto – 125 VAC

(todos los voltajes)

19 amps @ 277 VAC

22 amps @ 277 VAC

TABLA D. Longitud máxima del cableado del calefactor

(07A - 1Ø y 3Ø)

Watts/Pie. Longitud máxima permisible del cableado del calefactor (pies)

de los 208 Voltios 208 Voltios 240 Voltios 240 Voltios 277 Voltios

calefactores 1Ø 3Ø 1Ø` 3Ø 1Ø

125 74 - 86 - 99

188 49 - 57 - 66

50 37 - 43 - 49

2

76 24 - 28 - 33

3

00 18 - 21 - 24

5

564 16 27 19 32 22

625 14 24 17 29 19

750 12 20 14 24 16

7. Deben utilizarse alambres estándar para 75°C en las cajas de

conexiones, los conductos superficiales de alambres y las secciones

de espacios libres.

Disposición en salón

Consulte los planos de calefacción para obtener la disposición exacta

en salón de los calefactores (con o sin termostato y/o relés y/o interruptores y accesorios).

Altura de Montaje

Consulte la Figura 1a. para ver el montaje típico de calefactores y

pedestales incrustados en piso; consulte la Figura 1b. para ver

pedestales y calefactores montados en superficie.

Nota:

Puede instalarse cubierta de piso de hasta 3/4” de espesor, tal

como alfombra, baldosas, linóleo, etc. alrededor y debajo del calefactor.

Capacidad del calefactor

(Watts/Pie de

longitud de

calefactor)

25, 188 y 250 Watts/Pie

1

376, 500, 564, 625 y 750

Watts/Pie

Tuerca de

nivelación

Tuerca de fijación

(no aflojar ni

remover)

Línea de

piso

A

Pedestal

Tuerca de

fijación

Calefactor

Dimensión “A” (Altura

de montaje mínima

sobre el piso)

-3/4”

1

3”

Brazo

soldado

B

Pedestal

Dimensión “B”

(Altura mínima

sobre el piso)

2

3-1/4”

Calefactor

2-7/8” (Calefactores de 5”)

4-1/8” (Calefactores de 7”)

”

Relé de potencia

25 amps @ 120-277 VAC - vea el

diagrama de cableado en el calefactor

Interruptor de desconexión

Tabla B. Dimensionado de los alambres de instalación en campo

Tamaño de de alambres en

alambre de el conducto Hasta 3 4 a 6 7 a 9

cobre 75° C de alambres alambres alambres alambres

No. 12 AWG 9 11.5 A 9.3 A 8.1 A

No. 10 AWG 8 17.4 A 14.0 A 12.1 A

No. 8 AWG 4 24.0 A 21.0 A –

Tabla C. Longitud máxima del cableado del calefactor (05A-1Ø)

Watts/Pie. Longitud máxima permisible

de losdel cableado del calefactor (pies)

calefactores 120 Voltios 208 Voltios 240 Voltios 277 Voltios

125 33 58 67 77

188 22 38 44 51

250 16 29 33 38

Nota:

Para la mezcla de densidades de potencia (watts), calcule el consumo

Cant. máxima Corriente máxima permisible

20 amps @ 120-277 VAC

de amperios. No exceda los valores indicados en el paso 6 anterior.

Figura 1a. Pedestal incrustado en piso

Número de catálogo Altura sobre el piso (Dimen. “A”)

del calefactor

05A 2-5/8” 3-3/8”

07A 3-7/8” 4-5/8”

Tuerca de fijación

Tuerca de

nivelación

Tuerca de fijación

(no aflojar ni

remover)

Conducto/

tubo rígido

A

Línea de

piso

Figura 1b. Pedestal montado en superficie

11

3/8”

Min. Max.

Brazo

soldado

Pedestal

Calefactor

Orificios de montaje

de base - 1/4” diám.

(Sujetadores apropi-

ados suministrados

por otros)

Page 12

Tuerca de fijación

Carcasa

-7/16”

1

2

-1/2”

uerca de

T

nivelación

Placa (sólo se utiliza cuando

el pedestal no se utiliza para

la entrada de alambres)

Figura 2.

P

1-7/16” (05A)

1-9/16” (07A)

uerca de fijación

T

Instalación típica de pedestal de cale-

factor utilizando plantillas de guía para

edestal

mantener el posicionamiento apropia-

o durante el vertido del concreto.

d

36”

33-1/8” (05A)

32-7/8” (07A)

Cubierta

Pedestal

ornillos de

T

montaje de

cubierta

Tuerca de fijación

Calefactor de 3 pies

1-7/16”

PARTE INFERIOR DE

CALEFACTOR 05A

Figura 3a. Ubicaciones de pedestales de extremo

.125”

2

PEDESTAL DEL 05A

2.75”

.625”

1

0.250” Diám.

Tubo rosca-

do de 1”

Orificios de

montaje de

Figura 3b. Detalles del pedestal

28”

1-7/16” (05A)

1-9/16” (07A)

1-7/16” (05A)

1-9/16” (07A)

25-1/8” (05A)

24-7/8” (07A)

45-1/8” (05A)

44-7/8” (07A)

Tubo roscado

de 1-1/4”

48”

1-9/16”

PARTE INFERIOR DE

CALEFACTOR 07A

3”

”

2

PEDESTAL DEL 07A

Calefactor de

28 pulgadas

Calefactor de 4 pies

2.5”

1-7/16” (05A)

1-9/16” (07A)

1-7/16” (05A)

1-9/16” (07A)

1-7/16” (05A)

1-9/16” (07A)

1-7/16” (05A)

1-9/16” (07A)

Figura 4.

28-13/16”

32-13/16”

44-13/16”

36-13/16”

60”

Calefactor de 5 pies

57-1/8” (05A)

56-7/8” (07A)

72”

69-1/8” (05A)

68-7/8” (07A)

94”

NOTA: LOS ORIFICIOS EN LAS PLANTILLAS DE GUÍA DEBEN SER DE 1-3/8”

PARA LOS CALEFACTORES 05A, Ó 111/16” PARA LOS CALEFACTORES 07A.

* AL UNIR EXTREMO CON

Calefactor

de 6 pies

EXTREMO LOS CALEFACTORES,

DEJE UN ESPACIO DE 1/16”

ENTRE LOS CALEFACTORES

PARA PERMITIR LA EXPANSIÓN.

Calefactor de 8 pies

93-1/8” (05A)

92-7/8” (07A)

Calefactor de 10 pies

120”

76-13/16”

117-1/8” (05A)

116-7/8” (07A)

12

Page 13

Instalación de pedestal

(Montaje en superficie en piso existente)

Nota:

Para facilidad de instalación, es importante seguir en orden la

secuencia de operaciones indicada abajo.

1. Remueva la cubierta delantera removiendo los tornillos de montaje

(Fig. 2).

2. Remueva la tuerca de fijación superior y la tuerca de nivelación de

cada pedestal. (No afloje ni remueva la tuerca de fijación inferior).

3. Atornille un (1) pedestal sobre el conducto rígido roscado que sobresale del piso.

4. Instale el pedestal(es) restante(s) en el calefactor y asegure instalando y apretando a mano la tuerca de fijación.

5. Instale el calefactor sobre el pedestal que está atornillado sobre el

conducto rígido. Posicione el calefactor en la ubicación deseada y

marque en el piso las ubicaciones de los orificios de montaje del

pedestal. Luego remueva el calefactor y el pedestal fuera del

conducto rígido. Remueva el pedestal(es) restante(s) fuera

del calefactor.

6. Taladre orificios en el piso (Fig. 3b) e instale insertos roscados o

pernos de montaje de 1/4” (insertos y pernos suministrados por el

instalador).

7. Reinstale el pedestal sobre el conducto rígido, luego asegure todos

los otros pedestales (con placas) al piso con cuatro pernos de 1/4” a

través de cada brida de pedestal.

Instalación de pedestal

(Incrustado en piso de concreto nuevo)

Cuando una instalación de calefactor debe incrustarse en un piso de

concreto nuevo, primero se instalan los pedestales en el concreto, luego

se instala el calefactor después que el concreto se haya endurecido. Es

indispensable que los pedestales se instalen en perfecta alineación con

el fin de lograr la alineación requerida, se recomienda que los

pedestales se mantengan en su sitio mediante el uso de plantillas de

guía durante el vertido del concreto. Las plantillas de guía deben construirse a partir de tabla de madera de 1” x 4” de buena calidad, según

se muestra en la Figura 4. Los pedestales se instalan en las plantillas

de guía y luego se posicionan para el vertido del concreto. Debe atornillarse un (1) pedestal de extremo sobre el conducto de pared rígido de

modo que, después del vertido del piso acabado, se cumplan los requisitos de altura de montaje indicados en la Figura 1a. (El método de asegurar los pedestales y plantillas de guía en su sitio durante el vertido del

concreto es elección del instalador). Después que el concreto se ha

endurecido, remueva las plantillas de guía fuera de los pedestales e

instale el calefactor según se indica en los pasos siete u ocho.

Instalación de unidad sola

Nota:

Para facilidad de instalación, es importante seguir en orden la

secuencia de operaciones indicada abajo.

1. Remueva la cubierta delantera removiendo los tornillos de montaje

(Fig. 2).

2. Instale las tapas de extremo (deben comprarse por separado) en

ambos extremos de la carcasa del calefactor. Consulte la Figura 5

(tipo CPH y DPH) para obtener detalles de la instalación de las

tapas de extremo.

3. Instale la tuerca de nivelación en cada pedestal instalado, luego

coloque el calefactor sobre los pedestales. Ajuste las tuercas de

nivelación hasta que el calefactor esté nivelado y a la altura de montaje deseada. Luego instale y apriete las tuerca de fijación del

pedestal.

4. Tienda un circuito de derivación de tamaño apropiado hasta la caja

de conexiones a través del pedestal extremo apropiado.

5. Siguiendo el diagrama de cableado fijado al calefactor, realice las

conexiones eléctricas.

6. Coloque nuevamente la cubierta delantera y asegure con los tornillos de montaje. (Véase la Figura 2).

7. Si el calefactor tiene un termostato incorporado, ajuste el eje del termóstato en un rango intermedio y permita que el calefactor funcione

durante unas pocas horas.

Carcasa

apa de

T

extremo

Orificios de montaje

e accesorios

d

Datos en tapa de extremo

Número de catálogo del calefactor

Descripción CPH05A CPH07A

apa de extremo-Izquierda CPH05-ECL(R) CPH07-ECL(R)

T

Tapa de extremo-Derecha CPH05-ECR(R) CPH07-ECR(R)

Número de catálogo del calefactor

DPH05A DPH07A

Tapa de extremo-Izquierda DSH05-ECL(R) DSH07-ECL(R)

apa de extremo-Derecha DSH05-ECR(R) DSH07-ECR(R)

T

El Sufijo (R) en el número de catálogo se refiere a accesorios con tomacorriente

de 120 VAC.

Figura 5. (Tipo CPH y DPH únicamente)

ornillos de

T

montaje

apa de

T

extremo

Si la temperatura ambiente es demasiado caliente, gire el eje del termostato en sentido antihorario; si es demasiado fría, gire el eje del termostato en sentido horario hasta obtener una temperatura cómoda.

Permita que la temperatura ambiente se estabilice después de cada

cambio de valor.

Nota:

Se puede tener acceso al eje de ajuste del termostato y al interruptor de desconexión a través de las aberturas de rejilla en el extremo

izquierdo del calefactor.

Instalación de múltiples unidades

Nota:

Para facilidad de instalación, es importante seguir en orden la secuencia de

operaciones indicada abajo.

1. Remueva la cubierta delantera removiendo los tornillos de montaje (Figura 2).

2. Instale tapas de extremo en el extremo exterior del primero y último calefactor

(o sección de espacio libre) en un tramo, utilizando cuatro tornillos No. 6 suministrados con las tapas de extremo. (Consulte la Figura 5a ó 5b para ver

detalles de la instalación de las tapas de extremo).

3. Tienda un circuito de derivación de tamaño apropiado hasta la caja de conex-

iones a través de los calefactores y las secciones de espacios libres (si aplica)

sobre los pedestales.

Nota (tipo CPH y DPH únicamente):

asegúrese de posicionar cuidadosamente los calefactores para garantizar una

alineación apropiada. Deje un espacio de 1/16” entre los calefactores para permitir

la expansión.

4. Ajuste las tuercas de nivelación hasta que los calefactores estén nivelados y a

la altura de montaje deseada. Luego instale y apriete las tuercas de fijación

del pedestal.

Al unir extremo con extremo los calefactores,

PRECAUCIÓN

NO PONGA A FUNCIONAR LOS CALEFACTORES A MENOS QUE EL

EXTREMO EXTERIOR DE LOS ÚLTIMOS CALEFACTORES (O SECCIONES

DE ESPACIOS LIBRES) EN EL TRAMO ESTÉN CERRADOS CON TAPAS DE

EXTREMO.

Nota:

El cableado en campo para 75°C puede tenderse a través del

conducto superficial de alambres de la sección de espacio libre.

13

Page 14

5. Siguiendo el diagrama de cableado fijado al calefactor, realice las

conexiones eléctricas. Consulte la Figura 7 para conectar los otros

calefactores en paralelo. La conexión a tierra de los otros calefactores se logra conectando un alambre de puente (no suministrado)

entre los dos calefactores adyacentes.

6. Coloque nuevamente las cubiertas delanteras y asegure con los

tornillos de montaje. (Figura 2).

7. Si los calefactores tienen un termostato incorporado, ajuste el eje

del termostato en un rango intermedio y permita que los calefactores

funcionen durante unas pocas horas. Si la temperatura ambiente es

demasiado caliente, gire el eje en sentido antihorario; si es demasiado fría, gire el eje en sentido horario hasta obtener una temperatura

cómoda. Permita que la temperatura ambiente se estabilice después

de cada cambio de valor.

Nota:

Se puede tener acceso al eje de ajuste del termostato y al interruptor de desconexión a través de las aberturas de rejilla en el extremo

izquierdo del calefactor.

INSTRUCCIONES DE OPERACIÓN

1. Este calefactor debe instalarse apropiadamente antes de su uso.

2. Si el calefactor tiene un termostato incorporado, ajuste el eje del ter-

mostato en un rango intermedio y permita que el calefactor funcione

durante unas pocas horas. Si la temperatura ambiente es demasiado caliente, gire el eje en sentido antihorario; si es demasiado fría,

gire el eje en sentido horario hasta obtener una temperatura cómoda. Permita que la temperatura ambiente se estabilice después de

cada cambio de valor. El calefactor se apagará y encenderá

automáticamente alrededor de su valor deseado (set point) en el termostato.

Nota:

Si el calefactor tiene un termostato o un interruptor de desconexión, se puede tener acceso a estos componentes a través de las aberturas de rejilla en el extremo izquierdo o derecho del calefactor.

3. Dentro del calefactor hay dispositivos de seguridad limitadores de

sobrecalentamiento. Estos dispositivos de seguridad están allí para

apagar automáticamente el calefactor en caso de una condición de

sobrecalentamiento. Estos dispositivos no deben alterarse o

desconectarse del sistema eléctrico. Si el calefactor se instala correctamente y se cablea al voltaje correcto, estos dispositivos nunca

deberían operar para apagar el calefactor. Si este dispositivo está

apagando y encendiendo el calefactor, apague el suministro eléctrico hacia el calefactor y solicite a personal de servicio calificado que

suministre servicio de mantenimiento al calefactor.

INSTRUCCIONES DE MANTENIMIENTO

1. El usuario puede realizar limpieza periódica de la carcasa/gabinete

exterior. Todos los demás procedimientos de servicio de mantenimiento deben ser realizados por personal de servicio calificado.

2. Si se desea, la capa de acabado del calefactor puede limpiarse con

un trapo levemente húmedo.

3. Debido al principio de calefacción por convección que depende de la

circulación del aire a través del calefactor, podría acumularse polvo

entre las aletas. El calefactor debe limpiarse anualmente para lograr

una eficiencia máxima.

4. Para remover la cubierta delantera, remueva los tornillos de sujeción

ubicados en la parte inferior de la cubierta delantera.

ADVERTENCIA

ANTES DE REMOVER LA CUBIERTA DELANTERA PARA SERVICIO DE

ANTENIMIENTO O LIMPIEZA, VERIFIQUE QUE SE HAYA APAGADO

M

EL SUMINISTRO ELÉCTRICO EN EL PANEL DE INTERRUPTORES

UTOMÁTICOS (CIRCUIT BREAKER) Y QUE EL ELEMENTO CALEFAC-

A

TOR ESTÉ FRÍO.

5. Puede utilizarse una aspiradora con accesorio de cepillo para

limpiar las aletas del elemento calefactor.

6. Vuelva a colocar la cubierta frontal (mediante los tornillos provistos),

y restablezca la alimentación eléctrica y verifique que el calefactor

funcione correctamente.

CABLEADO TÍPICO DE MÚLTIPLES CALEFACTORES (SIN CONTROLES)

PROTECCIÓN

TÉRMICA

HACIA OTRO

CALEFACTOR

SUMINISTRO DE ENERGÍA HACIA INTERRUPTOR DE DESCONEXIÓN

Figura 7 - Diagrama de cableado

ELEMENTOS CALEFACTORES

TORNILLO DE

TIERRA

SECCIÓN DE

RELLENO

TORNILLO DE

TIERRA

ALAMBRE #10 ALAMBRE #10

NOTA:

Para el cableado interno e individual del cale-

PROTECCIÓN

TÉRMICA

ELEMENTOS CALEFACTORES

TORNILLO DE

TIERRA

TORNILLO DE

factor, consulte la etiqueta de diagrama de cableado en

la unidad.

14

TIERRA

CABLEADO DE FÁBRICA

CABLEADO EN CAMPO

HACIA OTRO

CALEFACTOR

Page 15

IDENTIFICACIÓN DE PIEZAS DE RENOVACIÓN CPH

Termostato

(Opcional)

Interruptor de

esconexión

d

(Opcional)

Bujes del ele-

mento calefactor

213-2000-001

1

*Rejilla

2501-0257-VAR

Protector contra

sobrecargas

520-0007-VAR

4

CPH07A

*Panel trasero

2701-0765-VAR

lemento

E

alefactor

c

Cubierta del con-

ducto superficial

de alambres

405-0053-VAR

6

Bujes del elemento

1213-2000-000

*Cubierta

delantera

402-0316-VAR

1

Interruptor de

esconexión

d

(Opcional)

calefactor

Relé del

transformador

Opcional)

(

elé de

R

otencia

p

(Opcional)

Termostato

(Opcional)

rotector contra

P

sobrecargas

4520-0007-VAR

*Panel trasero

701-0766-VAR

2

Cubierta del con-

ducto superficial

de alambres

6405-0053-VAR

CPH05A

lemento

E

calefactor

Rejilla

*

2501-0251-VAR

Cubierta

*

delantera

1402-0315-VAR

Relé del

ransformador

t

(Opcional)

Relé de

potencia

(Opcional)

15

Page 16

Termostato

nterruptor de

I

desconexión

(Opcional)

ujes del ele-

B

mento calefactor

1213-2000-001

Opcional)

(

IDENTIFICACIÓN DE PIEZAS DE RENOVACIÓN DPH

*Rejilla

2501-0252-VAR

rotector contra

P

sobrecargas

4520-0007-VAR

DPH07A

*Panel trasero

2701-0765-VAR

Elemento

calefactor

Cubierta del con-

ducto superficial

e alambres

d

6405-0053-VAR

1

Interruptor de

desconexión

Opcional)

(

Bujes del ele-

ento calefactor

m

1213-2000-000

*Cubierta

elantera

d

402-0316-VAR

transformador

Thermostat

optionnel)

(

Protector contra

obrecargas

s

4520-0007-VAR

Relé del

Opcional)

(

elé de

R

potencia

(Opcional)

*Panel trasero

2

701-0766-VAR

lemento

E

calefactor

ubierta del conducto

C

superficial de alambres

6405-0053-VAR

DPH05A

*Rejilla

2501-0251-VAR

*Cubierta delantera

402-0315-VAR

1

Relé del

transformador

Opcional)

(

Relé de

potencia

Opcional)

(

1

Elemento calefactor (Prefijo No. Pieza 1802-2001)

Longitud del calefactor

Descripción 28” 3’ 4’ 5’ 6’ 8’ 10’

120 Voltios 085 087 089 091 093 -125 W/Pie 208 Voltios 086 088 090 092 091 095 096

por Elemento 240 Voltios 048 054 060 066 072 077 081

277 Voltios 049 055 061 067 073 078 082

120 Voltios 005 011 017 023 029 -188 W/Pie 208 Voltios 002 008 014 020 026 032 036

por Elemento 240 Voltios 001 007 013 019 025 031 035

277 Voltios 000 006 012 018 024 030 034

120 Voltios 004 010 016 022 028 -250 W/Pie 208 Voltios 003 009 015 021 027 033 037

por Elemento 240 Voltios 002 008 014 020 026 032 036

277 Voltios 001 007 013 019 025 031 035

Controles incorporados (Opcional)

Descripción Unidades 07A y 14A Unidades 05A

Interruptor de desconexión 5216-0124-000 5216-0124-000

3

4

Relé del 208 Voltios R13700002B002 410043002

transformador 240 Voltios R13700002B003 410043003

5

Relé de potencia 120 Voltios 5018-2006-001 5018-2006-001

6

Termostato Unipolaire 5813-0024-000 5813-0024-000

120 Voltios R13700002B001 410043001

277 Voltios R13700002B004 410043004

24 Voltios 5018-2006-000 5018-2006-000

208/240 Voltios 5018-2006-002 5018-2006-002

277 Voltios 5018-2006-003 5018-2006-003

Bipolaire 5812-0023-000 5813-0023-000

Número de pieza

GARANTÍA LIMITADA

Todos los productos fabricados por Marley Engineered Products están garantizados contra defectos en manufactura y materiales durante un (1) año a partir de la fecha

instalación, excepto los elementos calefactores los cuales están garantizados contra defectos en manufactura y materiales durante cinco años a partir de la fecha de instalación. Esta garantía no aplica a daño por accidente, uso incorrecto, o alteración; ni donde el voltaje conectado sea superior en 5% al voltaje indicado en la placa de datos;

ni se aplica a equipo instalado o cableado o mantenido de manera inapropiada en violación de las instrucciones de instalación del producto. Todas las reclamaciones de

trabajo de garantía deben incluir un documento que compruebe la fecha de instalación.

El cliente será responsable de todos los costos incurridos en la remoción o reinstalación de productos, incluyendo los costos de mano de obra, y los costos de envío incurridos para devolver los productos al Centro de Servicio de Marley Engineered Products. Dentro de las limitantes de esta garantía, las unidades inoperantes deben devolverse al centro de servicio autorizado Marley más cercano o al Centro de Servicio de Marley Engineered Products, y nosotros repararemos o reemplazaremos, según nuestra elección, sin costo para usted, con el costo de envío de regreso pagado por Marley. Se acuerda que dicha reparación o reemplazo es el remedio exclusivo disponible

de parte de Marley Engineered Products.

LAS ANTERIORES GARANTÍAS REEMPLAZAN CUALQUIER OTRA GARANTÍA EXPRESA O IMPLÍCITA, Y TODAS LAS GARANTÍAS IMPLÍCITAS DE MERCADEABILIDAD Y ADECUADIBILIDAD PARA UN PROPÓSITO EN PARTICULAR QUE EXCEDEN LAS GARANTÍAS EXPRESAS MENCIONADAS SON DENEGADAS MEDIANTE ESTE DOCUMENTO Y EXCLUIDAS DE ESTE ACUERDO. MARLEY ENGINEERED PRODUCTS NO SERÁ RESPONSABLE POR DAÑOS CONSECUENCIALES

QUE SURJAN CON RESPECTO AL PRODUCTO, ESTÉN O NO BASADOS EN NEGLIGENCIA, INFRACCIÓN, RESPONSABILIDAD ESTRICTA, O CONTRATO.

Algunos estados no permiten la exclusión o la limitación de los daños resultantes o adicionales, de modo que la anterior exclusión o limitación podría no aplicarse a usted.

Esta garantía le otorga derechos legales específicos, y además, usted podría tener otros derechos que varían de un estado a otro.

Para obtener la dirección de su centro de servicio autorizado más cercano, comuníquese con Marley Engineered Products en Bennettsville, SC, en el teléfono:

1-800-642-4328. La mercancía devuelta a la fábrica debe incluir una autorización de devolución y la etiqueta de identificación de servicio, las cuales pueden conseguirse

en Marley Engineered Products. Al solicitar la autorización de devolución, incluya todos los números de catálogo mostrados en los productos.

CÓMO OBTENER EL SERVICIO DE GARANTÍA Y LAS PIEZAS DE

GARANTÍA, Y ADEMÁS, INFORMACIÓN GENERAL

1. Servicio o piezas de garantía

2. Compra de piezas de repuesto

3. Información general de productos

Part No. 5200-2109-002

1-800-642-4328

1-800-654-3545

www.marleymep.com

Nota:

Al solicitar servicio, siempre tenga a

mano lo siguiente:

1. Número de modelo del producto

2. Fecha de fabricación

3. Número o descripción de la pieza

ECR 39036

02/11

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

Page 17

Radiateur commercial à convection sur pieds

(Type CPH)

Radiateurs décoratifs à convection sur pieds

(Type DPH)

Convecteurs

CPH et DPH

INSTRUCTIONS IMPORTANTES

Cher propriétaire,

Félicitations! Merci d’avoir acheté ce nouveau radiateur fabriqué par Marley Engineered Products.

Vous avez fait un investissement sage en choisissant le produit de la meilleure qualité dans l’industrie du

chauffage. Veuillez lire soigneusement les instructions d’installation et d’entretien développées dans ce

manuel. Vous devriez apprécier des années de confort de chauffe efficace avec ce produit de Marley

Engineered Products... le leader de l’industrie pour la conception, la fabrication, la qualité et le service.

AVERTISSEMENT

À lire attentivement –

monter les difficultés qui peuvent survenir pendant l’installation de ces

radiateurs sur pieds. L’étude de ces instructions peut vous faire gagner

un temps considérable au départ et de l’argent ensuite. Ces radiateurs

sur pieds sont conçus pour une installation facile et économique. Suivez

ces instructions pour réduire votre temps d’installation à un minimum.

1. Lisez toutes les instructions avant d’installer ou d’utiliser le radiateur.

Risque de départ d’incendie ou de commotion électrique

2.

éviter une possible commotion électrique, assurez-vous que l’alimentation secteur est coupée en amont à l’interrupteur principal avant de

câbler. Tout le câblage doit être réalisé en conformité avec la norme

électrique américaine (NEC) et les normes locales applicables, et

toute l’installation du radiateur doit être reliée à la terre comme précaution contre une possible commotion électrique.

3. Vérifiez la tension d’arrivée pour vous assurer qu’elle est la même

que celle indiquée sur la plaque signalétique du radiateur avant de

mettre sous tension.

4. N’installez pas de radiateurs contre des surfaces de panneau de

fibres en cellulose base densité.

5. Du fait des variations des compositions des vinyles, et de leur potentiel à se décolorer, l’utilisation de supports de sécurité (SO1A et

SO2A) et/ou une spécification d’unité à puissance moindre peut être

nécessaire lors de l’installation sur des couvertures murales en

vinyle ou sous des habillages de fenêtres en vinyle.

Ces instructions sont écrites pour vous aider à sur-

– Pour

... Les employés et employées de

Marley Engineered Product

!

6. Les extrémités du radiateur doivent être complètement fermées par

l’utilisation de radiateurs adjacents, de capuchons d’extrémité ou

d’autres accessoires.

7. N’utilisez pas le radiateur sous une prise d’alimentation secteur.

8. Un radiateur comporte à l’intérieur des parties chaudes, et pouvant

produire un arc ou des étincelles électriques. Ne l’utilisez pas dans

des zones où de l’essence ou des liquides inflammables sont utilisés

ou entreposés. N’installez pas ce radiateur à l’envers ou en

présence d’eau.

9. Ce radiateur est chaud quand il est en fonctionnement. Pour éviter

des brûlures, ne laissez pas de peau nue toucher ses surfaces

chaudes. Maintenez les matières combustibles, comme les meubles,

les oreillers et la literie, les papiers, les habits et les rideaux, à distance du radiateur.

10. Pour éviter un possible départ d’incendie, n'obstruez en aucune

façon les admissions et les échappements d’air.

11. N’insérez pas d’objets étrangers, et ne permettez pas qu’il en entre,

dans toute ouverture d’admission ou d’évacuation, car cela peut

causer une commotion électrique ou un départ d’incendie, ou

endommager le radiateur.

12. Mettez au rebut les cales d’emballage avant d’utiliser le radiateur.

Consultez aussi les mises en garde supplémentaires dans ce manuel.

CONSERVEZ CES INSTRUCTIONS

Page 18

RÉCEPTION

1. Chaque radiateur sur pieds est livré en deux cartons. Un carton contient le radiateur, l’autre contient les pieds.

2. Le matériel au moment où il a été expédié était en bon état et

Marley Engineered Products garde un reçu pour l’embarquement

clair, de ce fait tout dommage caché doit être signalé immédiatement au transporteur pour inspection et traitement.

SPÉCIFICATIONS

Tableau A

Modèles CPH05A, DPH05A (H=5-1/2” ; P=3”)

N° au Watts/ Total en Ampérage

catalogue Longueur pied watts 120 V 208 V 240 V 277 V

05A-2125 125 250 2.4 1.2 1.0 0.9

05A-2188 28” 188 375 3.1 1.8 1.6 1.4

05A-2250 250 500 4.2 2.4 2.1 1.8

5A-3125 125 375 3.1 1.8 1.6 1.4

0

05A-3188 3’ 188 564 4.7 2.7 2.4 2.0

05A-3250 250 750 6.2 3.6 3.1 2.7

05A-4125 125 500 4.2 2.4 2.1 1.8

05A-4188 4’ 188 750 6.2 3.6 3.1 2.7

5A-4250 250 1000 8.3 4.8 4.2 3.6

0

05A-5125 125 625 5.2 3.0 2.6 2.2

05A-5188 5’ 188 940 7.8 4.5 3.9 3.4

05A-5250 250 1250 10.4 6.0 5.2 4.5

5A-6125 125 750 6.2 3.6 3.1 2.7

0

05A-6188 6’ 188 1125 9.4 5.4 4.7 4.1

05A-6250 250 1500 12.5 7.2 6.2 5.4

5A-8125 125 1000 - 4.8 4.2 3.6

0

5A-8188 8’ 188 1500 - 7.2 6.2 5.4

0

05A-8250 250 2000 - 9.6 8.3 7.2

05A-10125 125 1250 - 6.0 5.2 4.5

05A-10188 10’ 188 1875 - 9.0 7.8 6.7

05A-10250 250 2500 - 12.0 10.4 9.0

Modèles CPH07A, DPH07A (H=7” ; P=5”)

N° au Watts/ Total en Ampérage

catalogue Longueur pied watts 120 V 208 V 240 V 277 V

07A-2125 125 250 1.2 - 1.0 - 0.9

07A-2188 188 375 1.8 - 1.6 - 1.4

07A-2250 250 500 2.4 - 2.1 - 1.8

07A-2375 375 750 3.6 - 3.1 - 2.7

07A-2500 28” 500 1000 4.8 - 4.2 - 3.6

07A-2564 564 1125 5.4 3.1 4.7 2.7 4.0

07A-2625 625 1250 6.0 3.5 5.2 3.0 4.5

07A-2750 750 1500 7.2 4.2 6.2 3.6 5.4

07A-3125 125 375 1.8 - 1.6 - 1.4

07A-3188 188 564 2.7 - 2.4 - 2.0

07A-3250 250 750 3.6 - 3.1 - 2.7

07A-3375 3’ 375 1125 5.4 - 4.7 - 4.0

07A-3500 500 1500 7.2 - 6.2 - 5.4

07A-3564 564 1690 8.1 4.7 7.4 4.3 6.1

07A-3625 625 1875 9.0 5.2 7.8 4.5 6.7

07A-3750 750 2250 11.0 6.5 9.4 5.4 8.1

1Ø 3Ø 1Ø 3Ø 1Ø

Remarque :

Il est conseillé de garder les cartons dans un endroit central

pour être utilisés selon les besoins. S’ils sont demandés en séquence,

les cartons devront être étiquetés avec le numéro de pièce adéquat.

Tableau A (suite)

Modèles CPH07A, DPH07A (H=7” ; P=5”) (Suite)

N° au Watts/ Total en Ampérage

catalogue Longueur pied watts 120 V 208 V 240 V 277 V

07A-4125 125 500 2.4 - 2.1 - 1.8

07A-4188 188 750 3.6 - 3.1 - 2.7

07A-4250 250 1000 4.8 - 4.2 - 3.6

07A-4375 375 1500 7.2 - 6.2 - 5.4

07A-4500 4’ 500 2000 9.6 - 8.3 - 7.2

07A-4564 564 2250 10.8 6.2 9.4 5.4 8.0

07A-4625 625 2500 12.0 6.9 10.4 6.2 9.0

07A-4750 750 3000 14.4 8.3 12.5 7.2 10.8

07A-5125 125 625 3.0 - 2.6 - 2.2

07A-5188 188 940 4.5 - 3.9 - 3.4

07A-5250 250 1250 6.0 - 5.2 - 4.5

07A-5375 5’ 375 1875 9.0 - 7.8 - 6.7

07A-5500 500 2500 12.0 - 10.4 - 9.0

07A-5564 564 2820 13.5 7.8 11.8 6.8 10.2

07A-5625 625 3125 15.0 8.6 13.0 7.5 11.3

07A-5750 750 3750 18.0 10.4 15.6 9.0 13.5

07A-6125 125 750 3.6 - 3.1 - 2.7

07A-6188 188 1125 5.4 - 4.7 - 4.0

07A-6250 250 1500 7.2 - 6.2 - 5.4

07A-6375 6’ 375 2250 10.8 - 9.4 - 8.1

07A-6500 500 3000 14.4 - 12.5 - 10.8

07A-6564 564 3380 16.2 9.4 14.1 8.1 12.2

07A-6625 625 3750 18.0 10.4 15.6 9.3 13.5

07A-6750 750 4500 21.6 12.5 18.7 10.8 16.2

07A-8125 125 1000 4.8 - 4.2 - 3.6

07A-8188 188 1500 7.2 - 6.2 - 5.4

07A-8250 250 2000 9.6 - 8.3 - 7.2

07A-8375 8’ 375 3000 14.4 - 12.5 - 10.8

07A-8500 500 4000 19.2 - 16.7 - 14.4

07A-8564 564 4500 21.6 12.5 18.7 10.8 16.2

07A-8625 625 5000 24.0 13.9 20.8 12.4 18.0

07A-8750 750 6000 28.6 16.5 25.0 14.4 21.6

07A-10125 125 1250 6.0 - 5.2 - 4.5

07A-10188 188 1875 9.0 - 7.8 - 6.7

07A-10250 250 2500 12.0 - 10.4 - 9.0

07A-10375 10’ 375 3750 18.0 - 15.6 - 13.5

07A-10500 500 45000 24.0 - 20.8 - 18.0

07A-10564 564 5640 27.2 15.7 23.5 13.6 20.4

07A-10625 625 6250 30.0 17.4 26.0 15.0 22.6

07A-10750 750 7500 36.6 20.8 31.3 18.1 27.0

1Ø 3Ø 1Ø 3Ø 1Ø

INSTRUCTIONS D’INSTALLATION

AVERTISSEMENT

Avertissement –

trique et de dégâts matériels, lisez, assimilez et suivez ces instructions

spéciales :

1. Les procédures de câblage et les connexions doivent être en conformité avec la norme électrique américaine (NEC) et les normes

locales.

2. N’installez pas de radiateurs contre des surfaces de panneau de

fibres en cellulose base densité.

3. N’utilisez pas le radiateur sous une prise d’alimentation secteur.

Pour réduire de départ d’incendie, de commotion élec-

!

4. Pour réduire le risque de départ d’incendie, n’entreposez pas et

n’utilisez pas d’essence ou d’autres produits aux vapeurs inflammables à proximité du radiateur.

ATTENTION

5.

Maintenez les cordons électriques, les draperies et autres textiles

domestiques à l’écart du radiateur. Gardez un écartement d’au

moins 4 pouces (102 mm) par rapport à toutes les surfaces

exposées du radiateur (au-dessus et devant) en permanence.

18

– Le radiateur fonctionne à des températures élevées.

Page 19

Câblage de préparation

1. Les branches de circuit pour les radiateurs doivent être incluses

dans un conduit rigide, de 1" pour les modèles 05A, ou de 1-1/4”

pour les 07A.

2. Tirez une branche de circuit secteur, avec la bonne tension et une

taille de fils correcte, jusqu’à l’emplacement du boîtier de raccordement de gauche ou de droite, comme indiqué sur le schéma de

câblage du radiateur. L’entrée des fils dans le chauffage se fait par

le pied de l’une ou l’autre extrémité.

Remarque

– Quand un pied n’est pas utilisé pour entrer les fils, sa base

doit recevoir une plaque de couverture (fournie avec le pied). Voir la

Figure 2.

3. Pour l’installation de radiateurs sur des sols existants, l’extrémité

filetée du conduit rigide doit dépasser de 7/8” à 1” au-dessus du

béton avec finition. Le conduit doit être fileté au minimum sur 3/8”.

4. Les radiateurs de base sont précâblés et peuvent se connecter au

secteur d’un côté ou de l’autre. Les radiateurs avec contrôles sont

précâblés pour un raccordement au secteur d’un côté seulement

(référez-vous au schéma de câblage du radiateur), cependant le

radiateur peut être alimenté par l’autre extrémité en traversant le

radiateur avec le câble secteur dans le chemin de câbles.

5. S’il est nécessaire de faire traverser des fils dans le radiateur,