Page 1

!

FILE #E21069

Electric Radiant

Ceiling Heat

Panels

Installation & Maintenance Instructions

a

Dear Owner,

Congratulations! Thank you for purchasing this new heater manufactured by Marley Engineered

Products. You have made a wise investment selecting the highest quality product in the heating industry.

Please carefully read the installation and maintenance directions shown in this manual. You should enjoy

years of efficient heating comfort with this product from Marley Engineered Products . . . the industry’s

leader in design, manufacturing, quality, and service.

. . . The Employees of

Marley Engineered Products

a

WARNING

Read Carefully - These instructions are written to help you prevent

difficulties that might arise during installation of heaters. Studying the

instructions first may save you considerable time and money later.

Observe the following procedures and cut your installation time to a

minimum.

1. To prevent possible electrical shock, disconnect ALL power coming to heater at main service panel before wiring or servicing.

2. All wiring must be in accordance with the National and Local

Electrical Codes and the heater must be grounded as a precaution against possible electrical shock.

3. Verify the power supply voltage coming to the heater matches the

ratings printed on the heater nameplate before energizing.

4. This heater is NOT suitable for use in hazardous locations as

described by the National Fire Protection Association (NFPA).

DO NOT use in areas where gasoline, paint or other flammable

liquids are used or stored. DO NOT use in wet areas or areas

where corrosive agents are present, such as marine, green

house, chemical storage, swimming pool, or areas of high

humidity, unless special custom panels are used. Special custom

panels may be available for certain environments. Contact manufacturer for details.

5. To prevent a possible injury or fire from falling panels, panels

MUST be securely fastened to the building structure.

When T-bar Mounted: The T-bar grid work frame must be

secured to the building to provide adequate support for the panels. Holes are provided in the sides of each panel for attachment

of steel support wires for additional support of the panels where

the T-bar grid work frame strength is questionable. Support wire

must be steel and at least 18 gage (0.047 in. dia. / 0.119 cm. dia).

When Surface or Recess Mounted: The surface or recess mounting frame accessory kits (Models ASF . . . or ARF . . . ) must be

used. Kits must be sized to match heaters being used. Do not

drill holes, drive nails, screws, etc., into or through panels. To do

so may result in fire, electric shock, or permanent damage to

heater. Surface or recess kits must be securely fastened to building structure using a minimum of four (4) 1/4 inch (.635 cm) diameter screws or bolts.

6. To prevent possible fire due to the overheating of wiring, all field

wiring coming to heating panels must be rated at least 90° C

when junction box is allowed to lie on top of heating panel or is

enclosed between heater and ceiling above. When thermal insulation is used on top of heater, the junction box must be above

the insulation.

7. Panels are intended for ceiling installation only. Do not install on

walls, floor, etc. Painted (bottom) surface of panel is hot. Panels

must be installed at least seven (7) feet off floor and should not

be installed where panels can be easily contacted during use.

Keep combustibles at least 3 feet (0.9m) from face of heater.

GENERAL

Marley Engineered Products Radiant Heating Panels are

designed to provide comfort by warming the surfaces

below the heaters just as the sun warms surfaces through

radiant energy. This heating process heats objects in a

Although the heater contains thermal insulation, it will

operate more efficiently in well insulated rooms. Four or

more inches of insulation above an exposed ceiling will

increase both comfort and economy.

room without having to bring the room air temperature up

to the same level. These panels are ideal for spot heating

in high heat loss areas. Panels may be installed side by

side or individually above areas requiring additional heat. If

used as a sole source of heat, more heat will be felt while

The heaters are intended to be controlled by a remote wall

mounted thermostat. The thermostat should be located in

the same room on a side wall. It should also be above

five feet above the floor, but not directly under the heater.

standing directly under the panel.

SAVE THESE INSTRUCTIONS

Page 2

NOTE: For a period of time after the panels are put into

!

BLACK

BLACK G

208 OR 240 VOLT

HEATER

LINE VOLTAGE

THERMOSTAT

OR SWITCH

(NOT INCLUDED)

SEE NAMEPLATE FOR

LINE VOLTAGE SUPPLY

WIRING

DIAGRAM

HEATERS MUST BE

PROPERLY GROUNDED

BLACK WHITE

G

120, 277 OR 347 VOLT

HEATER

SEE NAMEPLATE FOR

LINE VOLTAGE SUPPLY

operation the owner may notice a “new smell” coming

from the heaters. This is expected on new installations

nd will dissipate after approximately 24 hours of opera-

a

tion.

PAINTING

1. Heaters may be repainted. Do not remove paint from

heaters. The surface must be first free of grease or

oil. Use only a thin brush-on coat of high quality pure

acrylic water base flat latex. An off-white will give better

coverage.

Do not paint with aluminum, oil base, vinyl-latex or

rubber-base latex paint.

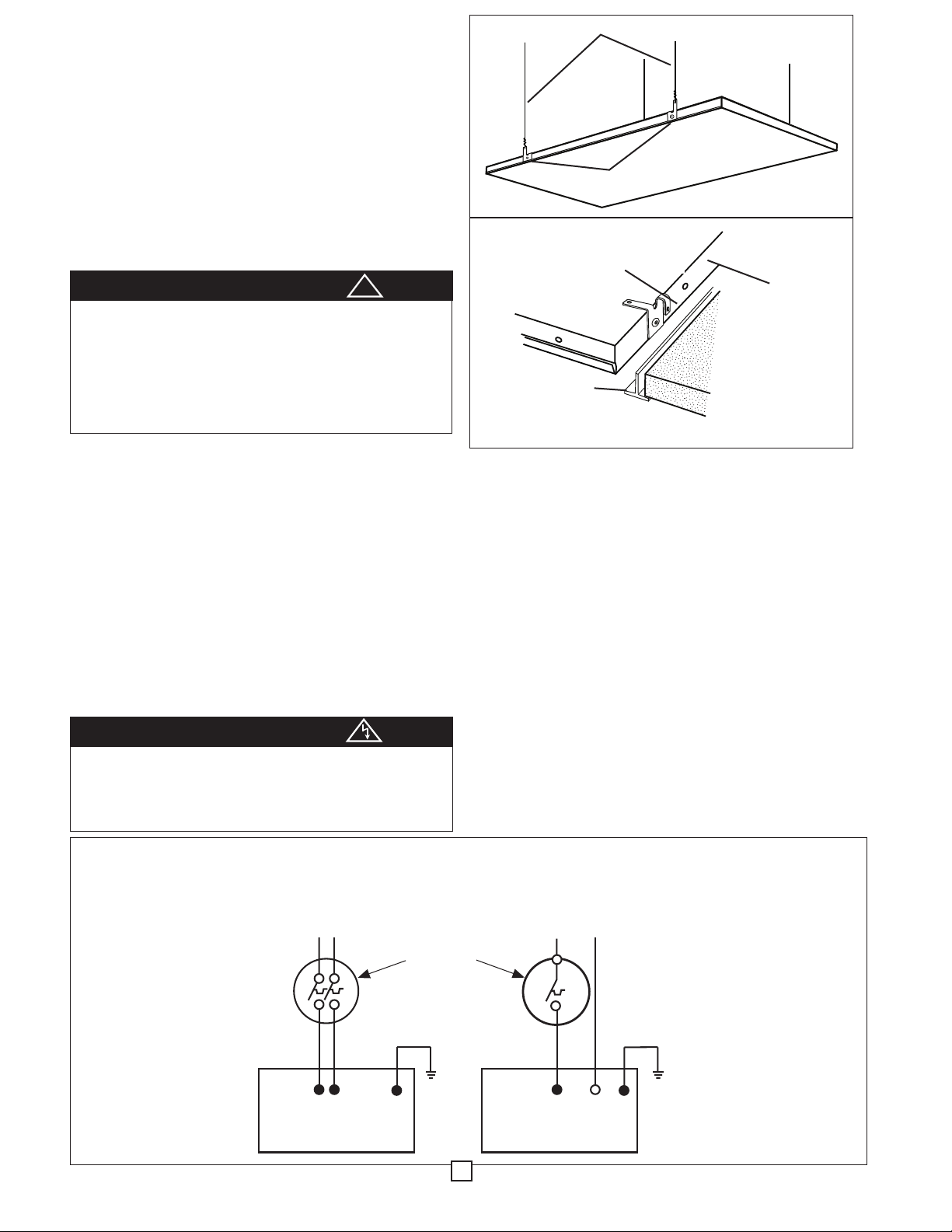

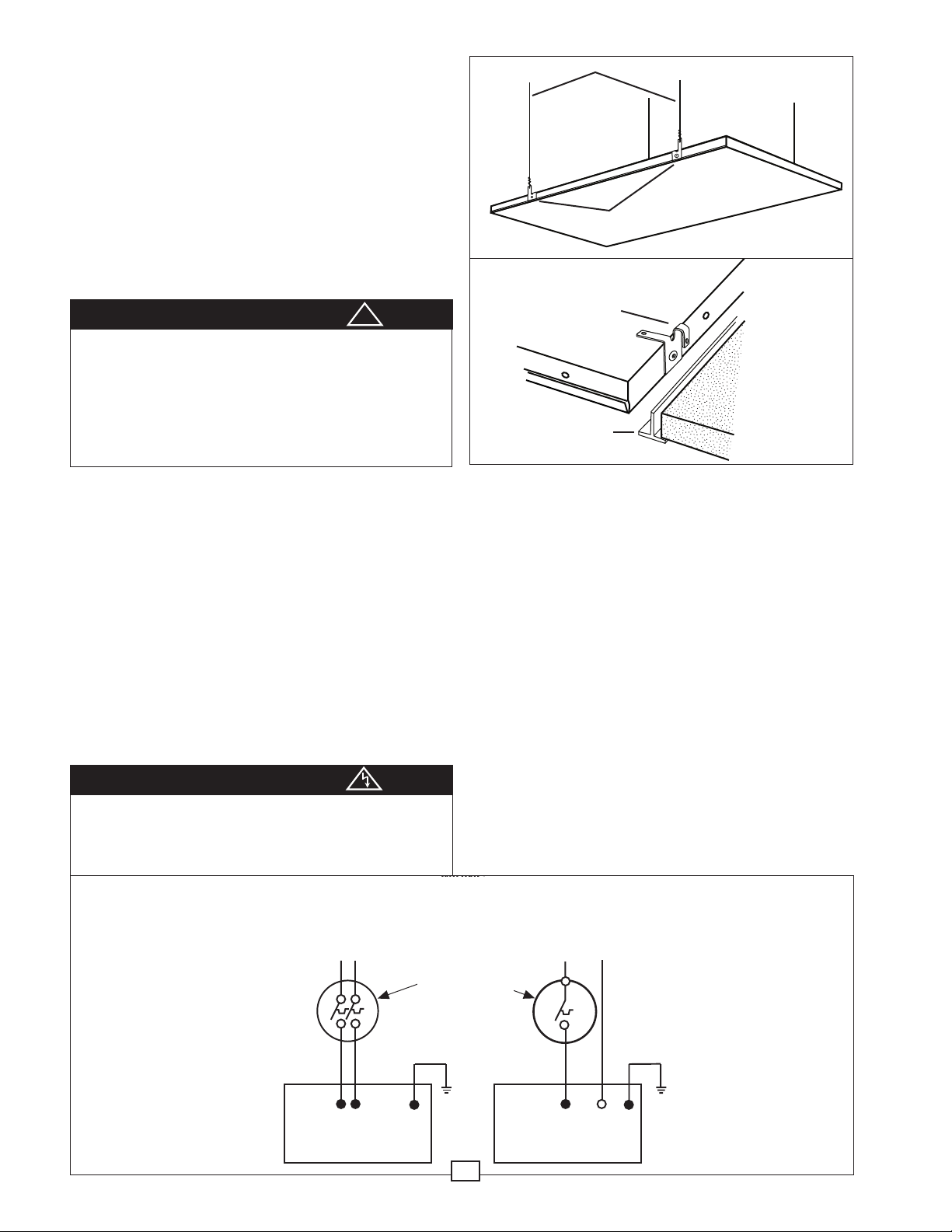

T-BAR MOUNTING

1. The heater panels are designed for installation in T-Bar

ceilings.

CAUTION

To prevent possible injury from falling panels, the T-Bar

must be securely fastened to the building structure and

capable of supporting the weight of the panel (30

pounds). Extra holes are provided for suspending the

heater panel (see Fig. 1) on steel wires no smaller than

No. 18 ga. (0.047 in. diameter / 0.119 cm diameter).

These extra support wires must be used where T-Bar

strength is inadequate or where vibration is anticipated.

2. Three (3) inch (7.67cm) minimum distance must be provided between the front painted surface and the ceiling

above. However, installation may be difficult and six (6)

inches (15.2 cm) or more clearance will improve installation of heaters and inspection or wiring. It may be necessary to remove a cross tee for installation when T-Bars

are at close distances to the ceiling.

3. Locate T-Bar hanger wires at the corners where the

cross tees intersect the main tees so that they do not

interfere with installation or removal of panels.

4. The heater panels are supplied with four built in hanging/hold-down clips which are located on each long side of

the heater panel. The clips can be used either to hang the

heater with support wires (see Figure 1) or bent as hold

down clips to the T-Bar frame (see Figure 2). Carefully lift

heater panel into place, making sure hold down clips hook

securely over T-bar (see Figure 2).

CAUTION

To prevent possible injury from electric shock, make

sure that electricity is turned off at the main switch. All

wiring must be done in accordance with national and

local codes and the unit must be properly grounded as

a precaution against electrical shock.

UPPORT WIRES

Fig. 1

S

HOLD DOWN CLIPS

Fig. 2

HOLD DOWN CLIP

T-BAR

WIRING

1. Maximum number of heaters per circuit is limited to circuit wiring and thermostat or switch capacity. See catalog for available thermostats and Warning No. 2.

2. Make wiring connections in accordance with Fig. 3 (on

following page) and wiring instructions. The heater must

be properly grounded as a precaution against electrical

shock. Use a properly grounded junction box for connecting the heater to the power supply.

3. Always use a properly grounded junction box when

splicing. See wiring diagrams for proper connections.

Install only in a location where the power supply con-

nections will be accessible. Install junction box as far

above panel as possible and above building insulation,

where present. Use field wiring suitable for 90 ºC if

junction box is allowed to lie on heater or is enclosed

between heater and ceiling above. When installed in a

drop ceiling, the wiring terminals should be accessible

through removable ceiling sections with adequate clearance to permit access to the top of the heater.

HEATER

PANEL

Fig. 3

2

Page 3

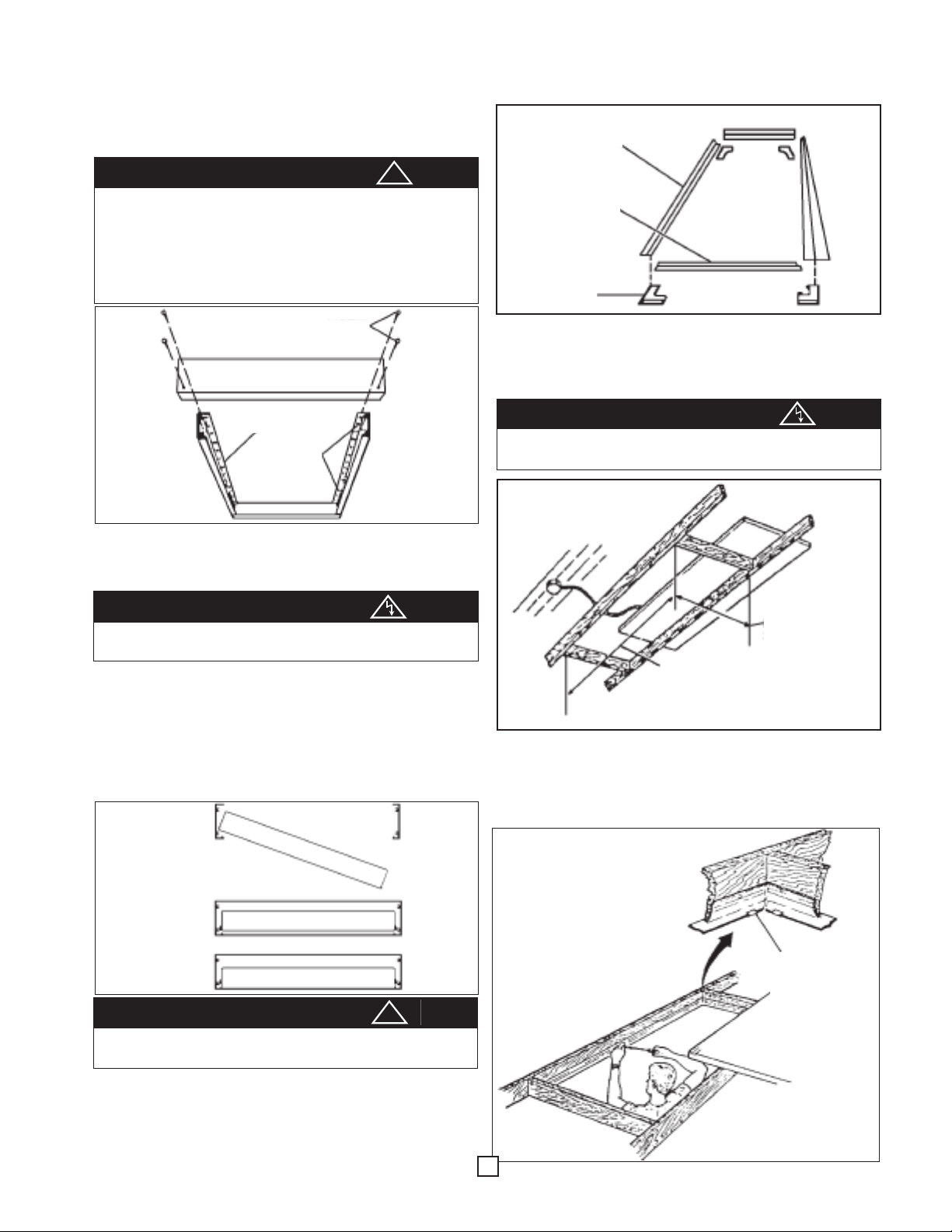

1. The Surface Mounting Kit comes a in separate carton which

!

!

contain two side frames, two end frames, and eight assembly screws.

2. Assemble the end frames to the side frames using the

screws provided (see Fig. 4) before installing on the ceiling.

CAUTION

To prevent possible injury from falling panels, use at

least four screws (1/4" or 0.635 minimum diameter) to

secure each side frame. Screws must thread securely

into a sturdy structural member of the ceiling, such as a

eiling joist. It may be necessary to frame-in an extra

c

support member. Do not finish from dry-wall, plater or

other finish ceiling materials.

CREWS

SURFACE MOUNTING

ND FRAME

E

SIDE FRAME

M

H

OUNTING

OLES

S

smaller than 2"x 4" (5cm x 10cm) for support. Use screws

no smaller than number 10 in each hole provided in side and

end frames.

Fig. 6

SIDE FRAME

ND FRAME

E

CORNER

3. Insert the heater panel through the opening (see Fig. 7) and

make wiring connections (see Fig. 3 and WIRING instructions). The heater must be properly grounded as a precaution against electrical shock. Use a properly grounded junction box for connecting the heater to the power supply.

CAUTION

Be sure electricity is turned off at main switch before

wiring to prevent possible injury from electric shock.

A

Fig. 4

3. Mounting the frame assembly to the ceiling.

4. Remove one end frame and install heater panel in side

frames as shown in Fig. 5.

CAUTION

Be sure electricity is turned off at main switch before

wiring to prevent possible injury from electric shock.

5. Connect the heater panel leads to the power supply leads

(see Fig. 3 and WIRING instructions). The heater must be

properly grounded as a precaution against electrical shock.

Use a properly grounded junction box for connecting the

heater to the power supply. The heater may be moved along

side frames to facilitate wiring.

6. Re-assemble the end frame to the side frames to lock the

heater panel securely in place.

Fig. 5

Step A

Step B

Fig. 7

Panel width plus

3/8” (9.5 mm)

Panel

length

plus 3/8”

(9.5 mm)

(ALL DIMENSIONS

ARE INSIDE)

4. Loosely screw side and end frames to ceiling opening, then

attach corners in place (see Fig. 8).

5. After attaching corners, tighten screws securely.

6. Carefully lower heater panel in place on frames.

Fig. 8

PLACE CORNER

Step C

IN POSITION AND

SECURE BY

BENDING TABS UP

CAUTION

Failure to mount this kit securely may result in serious

personal injury from falling heat panels.

RECESS MOUNTING

1. The Recess Mounting Kit comes in a separate carton which

contain four frame sections and four corners (See Fig. 6).

2. Recessed heater panels require a cutaway in ceiling and a

secure method of support (see Fig. 7). Use boards no

3

Page 4

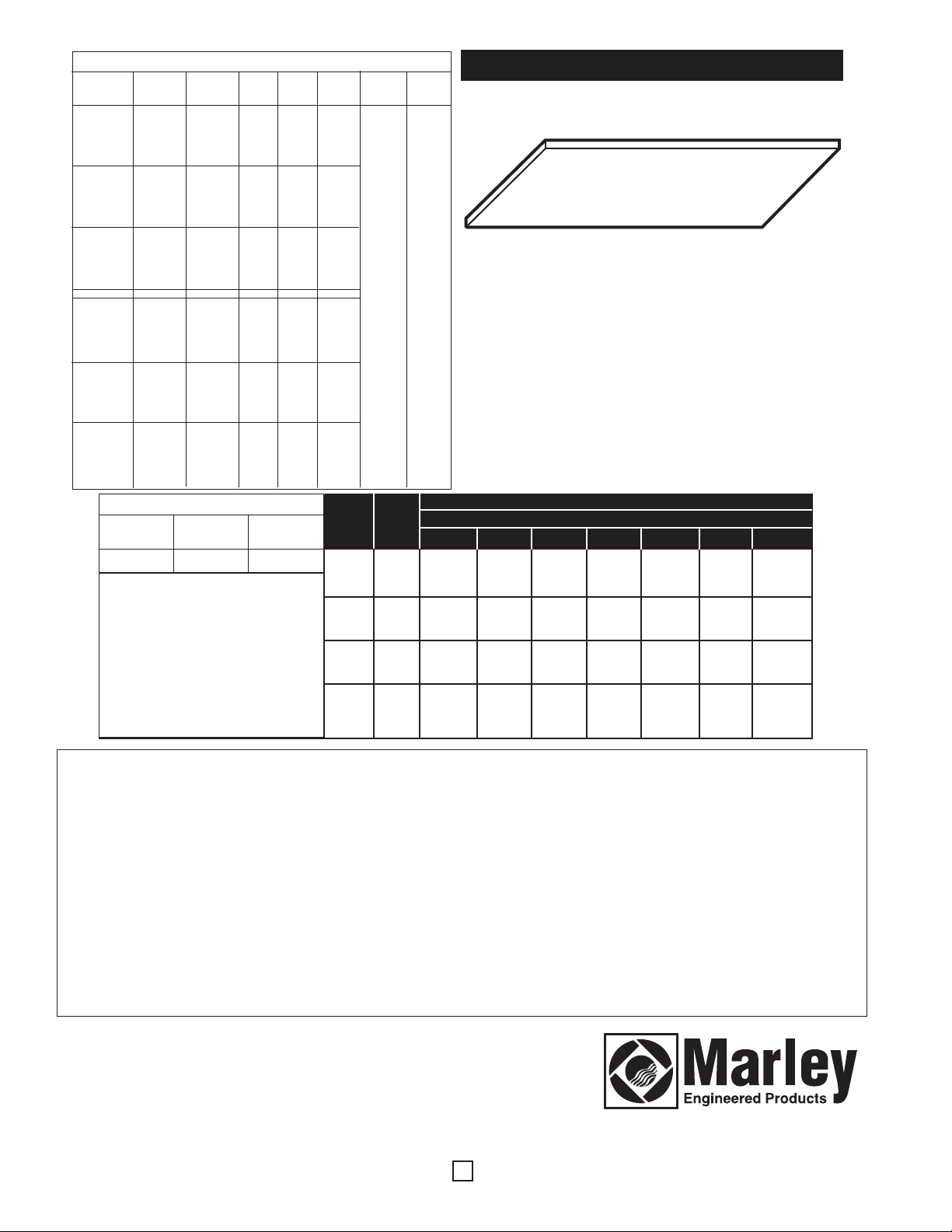

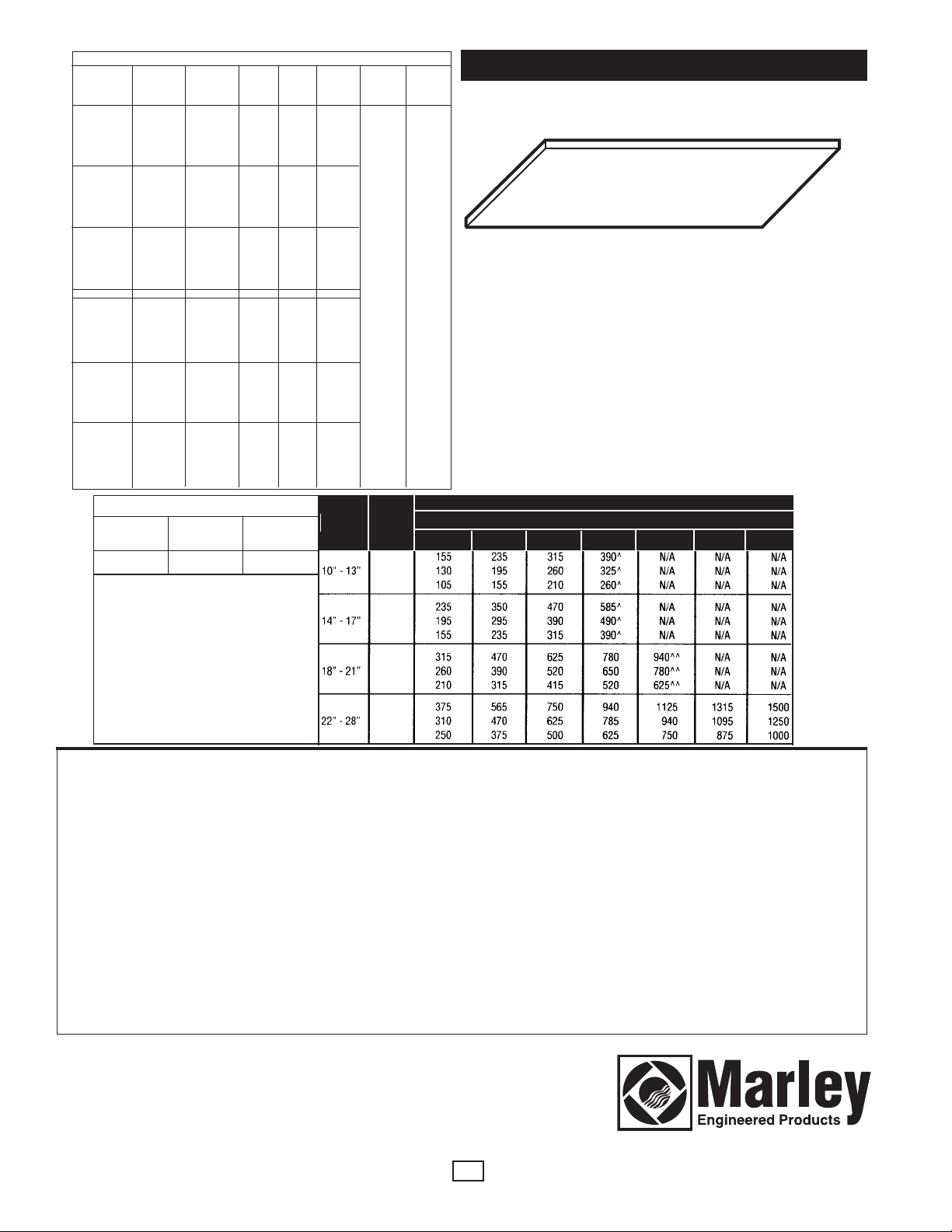

SPECIFICATIONS: STANDARD SIZE

Model

Number

ATL24241A

ATL24242A

ATL24248A

ATL24247A

ATL24243A

ATM24241A

ATM24242A

ATM24248A

ATM24247A

ATM24243A

ATH24241A

ATH24242A

ATM24248A

ATM24247A

ATM24243A

ATL24481A

ATL24482A

ATL24488A

ATL24487A

ATL24483A

ATM24481A

ATM24482A

ATM24488A

ATM24487A

ATM24483A

ATH24481A

ATH24482A

ATH24488A

ATH24487A

ATH24483A

Catalog

Number

CP2501

CP2502

CP2508

CP2507

CP2503

CP3101

CP3102

CP3108

CP3107

CP2103

CP3751

CP3752

CP3758

CP3757

CP3753

CP5001

CP5002

CP5008

CP5007

CP5003

CP6251

CP6252

CP6258

CP6267

CP6253

CP7501

CP7502

CP7508

CP7507

CP7503

Catalog

Number

CP251

CP252

CP258

CP257

CP253

CP311

CP312

CP318

CP317

CP313

CP371

CP372

CP378

CP377

CP373

CP501

CP502

CP508

CP507

CP503

CP621

CP622

CP628

CP627

CP623

CP751

CP752

CP758

CP757

CP753

Volts Watts

SPECIFICATIONS: CUSTOM SIZE

Model

Number

AT+**@@#A BT+**@@# QT+**@@#

Catalog

Number

+ = Watt Density

(H=High; M=Medium; L=Low)

** = Width of heater

@@ = Length of panel

# = AC Voltage designation

(1=120; 2=240; 3=347; 7=277; 8=208)

^ = Max. Panel Length = 60 inches

^^ = Max. Panel Length = 72 inches

a

120

240

208

277

347

120

240

208

277

347

120

240

208

277

347

120

240

208

277

347

120

240

208

277

347

120

240

208

277

347

250

250

250

250

250

310

310

310

310

310

375

375

375

375

375

500

500

500

500

500

625

625

625

625

625

750

750

750

750

750

Catalog

Number

BUT/HRDIM

(IN.)

853

853

853

853

853

1058

1058

1058

1058

1058

1280

1280

1280

1280

1280

1706

1706

1706

1706

1706

2133

2133

2133

2133

2133

2560

2560

2560

2560

2560

a

DIM

(CM.)

24

24

24

48

61

X

X

1

X

X

1

X

122

X

2.5

61

X

122

X

2.5

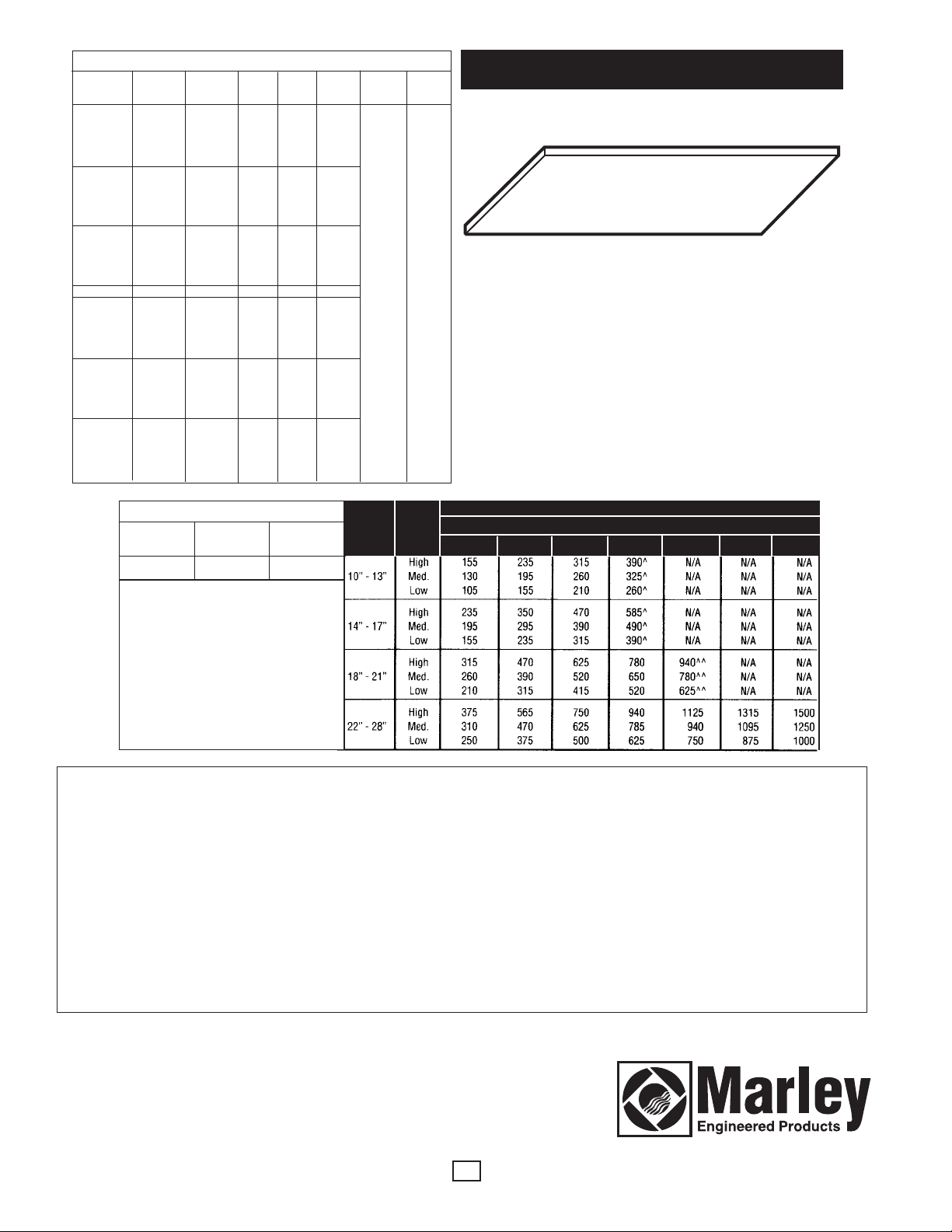

Panel Watt Normal Panel Length

Width Density 24”-35” 36”-47” 48”-59” 60”-71” 72”-83 84”-95” 96”

High 155 235 315 390^ N/A N/A N/A

10”-13” Med. 130 195 260 325^ N/A N/A N/A

Low 105 155 210 260^ N/A N/A N/A

High 235 350 470 585^ N/A N/A N/A

14”-17” Med. 195 295 390 490^ N/A N/A N/A

Low 155 235 315 390^ N/A N/A N/A

High 315 470 625 780 940^^ N/A N/A

18”-21” Med. 260 390 520 650 780^^ N/A N/A

Low 210 315 415 520 625^^ N/A N/A

High 375 565 750 940 1125 1315 1500

22”-28” Med. 310 470 625 785 940 1095 1250

Low 250 375 500 625 750 875 1000

ELECTRIC RADIANT HEATING PANELS

Watts Per Panel

LIMITED WARRANTY

All products manufactured by Marley Engineered Products are warranted against defects in workmanship and materials for one year from date of installation,

except heating elements which are warranted against defects in workmanship and materials for five years from date of installation. This warranty does not

apply to damage from accident, misuse, or alteration; nor where the connected voltage is more than 5% above the nameplate voltage; nor to equipment

improperly installed or wired or maintained in violation of the product’s installation instructions. All claims for warranty work must be accompanied by proof of

the date of installation.

The customer shall be responsible for all costs incurred in the removal or reinstallation of products, including labor costs, and shipping costs incurred

products to Marley Engineered Products Service Center. Within the limitations of this warranty, inoperative units should be returned to the nearest Marley

to return

authorized service center or the Marley Engineered Products Center, and we will repair or replace, at our option, at no charge to you with return freight paid

by Marley. It is agreed that such repair or replacement is the exclusive remedy available from Marley Engineered Products.

THE ABOVE WARRANTIES ARE IN LIEU OF ALL OTHER WARRANTIES EXPRESSED OR IMPLIED AND ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE WHICH EXCEED THE AFORESAID EXPRESSED WARRANTIES ARE HEREBY DISCLAIMED AND EXCLUDED FROM THISAGREEMENT. MARLEY ENGINEERED PRODUCTS SHALL NOT BE LIABLE FOR CONSEQUENTIAL DAMAGES

ARISING WITH RESPECT TO THE PRODUCT, WHETHER BASED UPON NEGLIGENCE, TORT, STRICT LIABILITY, OR CONTRACT.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above exclusion or limitation may not apply to you. This

warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

For the address of your nearest authorized service center, contact Marley Engineered Products in Bennettsville, SC, at 1-800-642-4328. Merchandise

returned to the factory must be accompanied by a return authorization and service identification tag, both available from Marley Engineered Products. When

requesting return authorization, include all catalog numbers shown on the products.

HOW TO OBTAIN WARRANTY SERVICE AND

WARRANTY PARTS PLUS GENERAL INFORMATION

1. Warranty Service or Parts 1-800-642-4328

2. Purchase Replacement Parts 1-800-654-3545

3. General Product Information www.marleymep.com

Note: When obtaining service always have the following:

1. Model number of the product

2. Date of manufacture

3. Part number or description

5200-2235-006

ECR 38134

03/09

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

4

Page 5

Paneles calefactores

!

radiantes eléctricos

de techo

FILE #E21069

Instrucciones de Instalación y Mantenimiento

a

Estimado Propietario,

¡Felicitaciones! Gracias por comprar este nuevo calentador fabricado por Marley Engineered Products.

Usted ha efectuado una sabia inversión al seleccionar el producto de la más alta calidad en la industria de

calefacción. Por favor lea cuidadosamente las instrucciones de instalación y mantenimiento indicadas en

este manual. Usted debería gozar de años de calefacción eficiente con este producto de Marley Engineered

Products......el líder de la industria en diseño, fabricación, calidad y servicio.

......Los empleados de

Marley Engineered Products

a

ADVERTENCIA

Lea cuidadosamente - Estas instrucciones están escritas paraayudarloa prevenir

dificultades que pudieranocurrir durante la instalación decalentadores. Elestudiar

primero lasinstrucciones puede ahorrarlemucho tiempo y dinero después. Para cortar

a un mínimo su tiempo de instalación, observe losprocedimientos siguientes.

1. Antes de cablearo prestarservicio, para prevenir un posiblechoque eléctrico,

desconecte TODA lapotencia entrante al calentador en el panel maestro de servicio.

2. Todo el cableado debe conformarcon losCódigos EléctricosNacionales y Locales

y el calentador debe estar conectado a tierracomo precaución contra un posible

choque eléctrico.

3. Antes de activar, verifique elvoltaje del suministroeléctrico entrante alcalentador

corresponda conlas clasificaciones nominales impresas enla placa de nombre.

4. Este calentador NO es apropiado parausar enubicacionesriesgosas según

descritopor laAsociación Nacionalde Protección Contra Incendios (NFPA). NO

use en áreasdonde se usa o almacenagasolina, pintura u otros líquidos inflamables. NO useenáreas mojadas o áreas donde están presentes agentes corrosivos, tales como marinas,invernaderos, almacenamientoquímico, piscinas, o

áreas de alta humedad,a menosque se usenpaneles especiales. Paneles especiales pueden estardisponibles para ciertos medio ambientes. Consulte con el fabricantepara los detalles.

5. Para prevenir una posible lesión o incendiodepaneles caídos, losmismos

DEBEN sujetarse bien a la estructura deledificio.

Cuando montadoen unabarra en T:

T debe estar aseguradoal edificioparaproveer un soporte adecuado para los pa-

Los paneles de Calor Radiante Marley Engineered Products

están diseñados para proveer bienestar calentando las superficies debajo de los calentadores de la misma manera que el

sol calienta las superficies mediante la energía radiante. Este

proceso de calefacción calienta objetos en un cuarto sin elevar la temperatura del aire del cuarto al mismo nivel. Esos

paneles son ideales para calefacción de sectores en áreas de

pérdidas térmicas elevadas. Los paneles pueden instalarse

lado por lado o individualmente sobre áreas que requieren

calor adicional. Si se usan como fuente exclusiva de calor, se

siente más calor mientras la persona está parada directamente debajo del panel.

Elarmazón de trabajodelarejilla de barra en

GENERAL

GUARDE ESTAS INSTRUCCIONES

neles. Seproveen orificios a los lados de cada panelparafijar loscablesde

soporte de acero para un soporte adicional de los panelesdonde es dudosa la

resistencia delarmazón detrabajo de la rejillade la barra en T.Elalambre de

soporte debe serdeacero y deuncalibre 18 porlomenos (0.047 pulg. de

diám./0.119 cm de diám.).

Cuando está montadoen la superficie o empotrado:

accesorios de armazón de montajedesuperficieo empotrado (ModelosASF.....o

ARF). Debe determinarse el tamaño de los juegos para correspondercon los

calentadores que se usan. No taladreorificios,clave clavos,tornillos, etc.,en o a

través delos paneles.Elhacerlo puede resultar en incendio, choque eléctricoo

dañopermanente al calentador. Los juegos de superficie o empotrados deben

estar bien aseguradosa la estructura del edificio usando un mínimo de cuatro (4)

tornillos o pernos de 1/4 de pulg. (.635 cm)dediámetro.

6. Para prevenir un posibleincendio debido al sobrecalentamiento del cableado, todo

elcableado decampo entrante a los panelesdecalefacción deben tener una

clasificación nominal de 90˚C cuando se permiteque una caja deempalmes se

apoye sobre el topedel panel delcalentadoro está colocado entre el calentador y

elcieloraso arriba.Cuandoseusa aislación térmica en el topedel calentador,la

cajadeempalme debe estar arriba de la aislación.

7. Los paneles tienen el finde instalación en el cieloraso. No instale enlas paredes,

pisos, etc. La superficie pintada (fondo)del panelestácaliente. Lospaneles deben

instalarse a siete (7) pies por lo menos del pisoy no deben instalarse cuandolos

paneles se pueden tocar fácilmente durante el uso.Se DEBE mantener un

espacio libre de al menos 0.9 m (3 pies) entre la frontal del calentador y

los materiales combustibles.

Deben usarse los juegos de

A pesar que el calentador contiene aislación térmica, operará

más eficientemente en cuartos bien aislados. Cuatro o más

pulgadas de aislación sobre un cieloraso expuesto incrementarán el bienestar y la economía.

Los calentadores están diseñados para ser controlados por

un termostato remoto montado en la pared. El termostato

debe estar ubicado en el mismo cuarto en una pared lateral.

Debe estar también a cinco pies sobre el piso, pero no directamente debajo del calentador.

Page 6

NOTA: Por un período después que los paneles se ponen

!

BLACK

BLACK G

208 OR 240 VOLT

HEATER

LINE VOLTAGE

THERMOSTAT

OR SWITCH

(NOT INCLUDED)

SEE NAMEPLATE FOR

LINE VOLTAGE SUPPLY

WIRING

DIAGRAM

HEATERS MUST BE

PROPERLY GROUNDED

BLACK WHITE

G

120, 277 OR 347 VOLT

HEATER

SEE NAMEPLATE FOR

LINE VOLTAGE SUPPLY

en operación, el propietario puede notar un “olor a

uevo” proveniente de los calentadores. Esto se espera

n

en nuevas instalaciones y se disipará después de 24

horas aproximadamente de operación.

PINTURA

1. Los calentadores pueden repintarse. No elimine la pintura

de los calentadores. La superficie debe estar primero libre

de grasa o aceite. Use sólo un recubrimiento fino de pincel

de látex incoloro de base de acrílico puro y agua de alta

calidad. Un color blancuzco proveerá una mejor cobertura.

No pinte con pintura de aluminio, base de aceite, vinilolátex o de látex de base de goma.

PRECAUCION

Para prevenir una posible lesión de paneles caídos, la

barra en T debe estar bien asegurada a la estructura del

edificio y capaz de soportar el peso del panel (30 libras).

Se proveen orificios adicionales para suspender el

panel del calentador (vea la Fig.2) de alambres de acero

no menores de calibre 18 (0.047 pulg. de diám./0.119 cm

de diám.). Esos cables de soporte adicional deben

usarse donde la resistencia de la barra en T no es adecuada o donde se prevee vibración.

MONTAJE DE BARRA EN T

1. Los paneles del calentador están diseñados para instalar

en cielorasos de barra en T.

2. Debe proveerse una distancia mínima de tres (3) pulgadas

(7.67 cm) entre la superficie delantera pintada y el cieloraso arriba. Sin embargo, la instalación puede ser difícil y

seis (6) pulgadas (15.2cm) o más de separación mejorarán

la instalación e inspección o cableado de los calentadores.

Puede ser necesario extraer una t transversal para instalar, cuando las barras en T están cerca del cieloraso.

3. Ubique los alambres suspensores de la barra en T en las

esquinas donde las Tés transversales cortan transversalmente las Tés principales de manera que no interfieran

con la instalación o extracción de los paneles.

4. Los paneles del calentador se proveen de cuatro construi-

dos en broches de sujeción situados en cada lado largo del

panel del calentador. Los broches de sujeción se pueden

utilizar para colgar el calentador con los alambres (vea la

Fig. 1) o los broches de sujeceón se puede doblar como

clips de la ayuda para el marco apropiado de la barra en T

PRECAUCION

Para evitar una posible lesión del choque eléctrico,

asegúrese que la electricidad esté desconectada en el

interruptor maestro. Todo el cableado debe efectuarse

de acuerdo con los códigos nacionales y locales y la

unidad debe conectarse adecuadamente a tierra como

precaución contra el choque eléctrico.

(vea la Fig.2). Levante cuidadosamente el panel del calentador a su lugar, asegurándose que los broches de sujeción

enganchan seguramente sobre la barra en T (vea la Fig.2).

Fig. 1

Fig. 2

LAMBRES DE SOPORTE

A

BROCHES DE SUJECION

BROCHE DE

UJECION

S

ARRA EN T

B

PANEL DEL

CALENTADOR

CABLEADO

1. La cantidad máximade calentadorespor circuito está limi

tado por el cableado del circuito y por la capacidad del termostato

o conmutador. Para los termostatos disponibles y la Advertencia

No.2 vea el catálogo.

2. Efectúe las conexionesde cableado de acuerdo conla

Fig.3 (en la página siguiente) y las instrucciones de cableado. El

calentador debe estar adecuadamente conectado a tierra como

precaución contrael choqueeléctrico.Use unacaja deempalmes

adecuadamente conectada a tierra para conectar el calentador al

suministro de potencia.

3. Use siempre unacajade empalme adecuadamente conectada a tierra al empalmar. Para las conexiones adecuadas vea el

diagrama de cableado. Instale sólo en una ubicación donde las

conexiones del suministrode potencia sean accesibles. Instale la

caja de empalme a tanta distancia sobre el panel como sea posible y sobre la aislación del edificio, donde esté presente. Use

cableadodecampoadecuadopara 90 gradossisepermiteque la

caja de empalme se apoye sobre el calentador o está colocado

entre el calentador y el cieloraso arriba. Cuando está instalado en

uncieloraso colgante, los terminalesdel cableadodebenser accesibles a través de secciones móviles del cieloraso con una separación adecuada para permitir acceso altopedel calentador.

Fig. 3

DIAGRAMA DE

CABLEADO

LOS CALENTADORES DEBEN

CONECTARSE

ADECUADAMENTE A TIERRA

VEA LA PLACA DE NOMBRE

PARA EL SUMINISTRO DE

VOLTAJE DE LINEA

NEGRO NEGRO G

CALENTADOR DE

208 O 240 VOLTIOS

TERMOSTATO O

DE VOLTAJE DE

CONMUTADOR

LINEA (NO

INCLUIDO)

VEA EL

CATALOGO

6

VEA LA PLACA DE NOMBRE

PARA EL SUMINISTRO DEL

VOLTAJE DE LINEA

NEGRO BLANCO G

CALENTADOR DE

120, 277 O 347

Page 7

ONTAJE DE SUPERFICIE

!

!

M

. Los Juegos de Montaje de Superficie se entregan en dife--

1

rentes cajas que contienen dos armazones laterales, dos

armazones de extremo y ocho tornillos de ensamblado.

2. Ensamble los armazones de extremo a los armazones la-terales usando los tornillos provistos (vea la Fig.4) antes de

instalar en el cieloraso.

3. Montaje del conjunto del armazón al cieloraso.

PRECAUCION

Para prevenir lesiones posibles de paneles caídos, use

por lo menos cuatro tornillos (de 1/4” ó 0.635 de

diámetro mínimo) para asegurar a cada armazón lateral.

Los tornillos deben enroscarse seguramente a un miembro estructural resistente del cieloraso, tal como una

viga de cieloraso. Puede ser necesario encuadrar con

n armazón un miembro adicional de soporte. No ter-

u

mine la instalación desde materiales de terminación de

cielorasos tales como yeso, plateador u otros.

ARMAZON DEL

EXTREMO

RMAZON

A

LATERAL

ORIFICIOS DE

Fig. 4

4. Extraiga un armazón del extremo e instale el panel del

calentador en los armazones laterales según se muestra

en la Fig.5.

5. Conecte las guías del panel del calentador a las guías de

TORNILLOS

MONTAJE

cuatro esquinas (Vea la Fig.6).

Fig. 6

RMAZON DEL EXTREMO

A

RMAZON LATERAL

A

SQUINA

E

2 Los paneles empotrados del calentador requieren un corte

en el cieloraso y un método seguro de soporte (vea la

Fig.7). Use tablas no menores de 2” x 4” (5cm x 10cm) para

soporte. Use tornillos no menores que el número 10 en

ada orificio provisto en los armazones laterales y del

c

extremo.

3. Inserte el panel del calentador a través de la abertura (vea

la Fig.7) y efectúe las conexiones del cableado (vea la

Fig.3 y las instrucciones de CABLEADO). Como precaución contra el choque eléctrico, el calentador debe estar

adecuadamente conectado a tierra. Para conectar el calentador al suministro de potencia, use una caja de empalme

adecuadamente conectada a tierra.

PRECAUCION

Antes de cablear asegúrese que la electricidad está

desconectada en el conmutador principal, para prevenir

posibles lesiones por el choque eléctrico.

A

Fig. 7

PRECAUCION

Antes de cablear asegúrese que la electricidad está

desconectada en el conmutador principal, para prevenir

posibles lesiones por el choque eléctrico.

suministro de potencia (vea la Fig.3 y las instrucciones de

CABLEADO). El calentador debe conectarse adecuadamente a tierra como precaución contra el choque eléctrico.

Para conectar el calentador al suministro de potencia, use

una caja de empalme adecuadamente conectada a tierra.

Para facilitar el cableado, el calentador puede moverse a lo

largo de los armazones laterales.

6. Reensamble el armazón del extremo a los armazones la-

Fig. 5

Paso A

Paso B

Paso C

PRECAUCION

La falla en montar seguramente este juego puede resultar en lesiones personales graves de paneles caídos del

calentador.

terales para calzar el panel del calentador seguramente en

su lugar.

1. Los Juegos de Montaje de Superficie vienen en diferentes

cajas que contienen cuatro secciones de armazón y

MONTAJE EMPOTRADO

Ancho del panel más

3/8” (0.95cm)

Largo del

panel más

3/8” (0.95cm)

(TODAS LAS

DIMENSIONES ESTAN

ADENTRO)

4. Atornille flojamente los armazones laterales y del extremo

a la abertura del cieloraso y a continuación fije las esquinas

en su lugar (vea la Fig.8).

5. Después de fijar las esquinas, ajuste bien los tornillos.

6. Baje cuidadosamente el panel del calentador en su lugar

en los armazones.

Fig. 8

COLOQUE LA

ESQUINA EN

POSICION Y

ASEGURE

DOBLANDO LAS

ALETAS HACIA

ARRIBA

7

Page 8

Número

de

Modelo

ATL24241A

ATL24242A

ATL24248A

ATL24247A

ATL24243A

ATM24241A

ATM24242A

ATM24248A

ATM24247A

ATM24243A

ATH24241A

ATH24242A

ATM24248A

ATM24247A

ATM24243A

ATL24481A

ATL24482A

ATL24488A

ATL24487A

ATL24483A

ATM24481A

ATM24482A

ATM24488A

ATM24487A

ATM24483A

ATH24481A

ATH24482A

ATH24488A

ATH24487A

ATH24483A

Número

Catálogo

CP2501

CP2502

CP2508

CP2507

CP2503

CP3101

CP3102

CP3108

CP3107

CP2103

CP3751

CP3752

CP3758

CP3757

CP3753

CP5001

CP5002

CP5008

CP5007

CP5003

CP6251

CP6252

CP6258

CP6267

CP6253

CP7501

CP7502

CP7508

CP7507

CP7503

de

Número

de

Catálogo

CP251

CP252

CP258

CP257

CP253

CP311

CP312

CP318

CP317

CP313

CP371

CP372

CP378

CP377

CP373

CP501

CP502

CP508

CP507

CP503

CP621

CP622

CP628

CP627

CP623

CP751

CP752

CP758

CP757

CP753

Voltios Vatios

120

240

208

277

347

120

240

208

277

347

120

240

208

277

347

120

240

208

277

347

120

240

208

277

347

120

240

208

277

347

ESPECIFICACIONES: TAMAÑO ESPECIAL

ESPECIFICACIONES: TAMAÑO ESTANDAR

Número de

Modelo

Número de

Catálogo

Número de

AT+**@@#A BT+**@@# QT+**@@#

+ = Densidad de Vatios

(H = Alto; M = Medio; L = Bajo)

** = Ancho del calentador

@@ = Largo del panel

# = Designación del voltaje de CA

(1=120, 2=240; 3=347; 7=277; 8=208)

^ =

Long. Máx. del panel = 60 pulgadas

^^ =

Long. Máx. del panel = 72 pulgadas

a

250

250

250

250

250

310

310

310

310

310

375

375

375

375

375

500

500

500

500

500

625

625

625

625

625

750

750

750

750

750

Catálogo

BUT/HRDIAM

(PULG.)

853

853

853

853

853

1058

1058

1058

1058

1058

1280

1280

1280

1280

1280

1706

1706

1706

1706

1706

2133

2133

2133

2133

2133

2560

2560

2560

2560

2560

a

DIAM

(CM.)

24

24

24

48

61

X

X

1

X

X

1

X

122

X

2.5

61

X

122

X

2.5

Ancho Densidad

del de Largo Normal del Panel

Panel Vatios 24”-35” 36”-47” 48”-59” 60”-71” 72”-83 84”-95” 96”

Alto

Med.

Bajo

Alto

Med.

Bajo

Alto

Med.

Bajo

Alto

Med.

Bajo

PANELES RADIANTES DEL CALENTADOR ELECTRICO AZTEC

Vatios por Panel

GARANTIA LIMITADA

Todos los productos fabricados por Marley Engineered Products están garantizados contra defectos de mano de obra y materiales durante un año a partir de la fecha

de instalación. Esta garantía no se aplica por daños ocurridos por accidente, mal uso, o alteración, ni cuando el voltaje conectado sea 5% mayor que el indicado en la

placa de nombre; ni al equipo instalado o cableado indebidamente, o mantenido en violación de las instrucciones de instalación del producto. Todos los reclamos de

trabajo de garantía deben estar acompañados por prueba de la fecha de instalación.

El cliente será responsable por todos los costos incurridos en la extracción o reinstalación de los productos, incluyendo costos de mano de obra, y costos de transporte

incurridos al retornar los productos a Marley Engineered Products Service Center y nosotros las repararemos o reemplazaremos, a nuestra opción, sin cargo para usted,

con transporte de regreso pagado por Marley. Se acuerda mutuamente que tal reparación o reemplazo es el remedio exclusivo disponible de Marley Engineered

Products.

LAS GARANTIAS INDICADAS ARRIBA SON A CAMBIO DE CUALQUIER OTRA GARANTIA EXPRESA O IMPLICITA Y SE DESCONOCEN Y EXCLUYEN DE ESTE

ACUERDO TODAS LAS GARANTIAS IMPLICITAS DE COMERCIALIZACION Y APTITUD PARA UN FIN PARTICULAR QUE EXCEDAN LAS GARANTIAS PREVIAMENTE EXPRESADAS. MARLEY ELECTRICAL NO SERA RESPONSABLE POR DAÑOS CONSECUENTES ORIGINADOS POR EL PRODUCTO, YA SEAN QUE

ESTEN BASADOS EN NEGLIGENCIA, LITIGACION, RESPONSABILIDAD ESTRICTA O CONTRATO.

Algunos estados no permiten la exclusión o limitación de los daños incidentales o consecuentes, de manera que la exclusión o limitación indicada arriba puede no aplicarse a usted. Esta garantía le otorga derechos legales específicos, y usted puede tener también otros derechos que varían de estado a estado.

Llame a Marley Engineered Products, Bennettsville, SC 29512 EE.UU., al 1-800-642-4328, para la dirección de su centro autorizado de servicio más cercano. La mercadería retornada a la fábrica debe estar acompañada por una autorización de retorno y una etiqueta de identificación de servicio, ambas disponibles de Marley

Engineered Products. Incluya todos los números de catálogo mostrados en el producto, al requerir autorización de retorno.

COMO OBTENER SERVICIO EN GARANTIA,

PIEZAS DE REPUESTO E INFORMACION GENERAL

1. Servicio o repuestos, en garantía: 1-800-642-4328

2. Compra de piezas de repuesto: 1-800-654-3545

3. Información general sobre productos: www.marleymep.com

Nota: Cuando solicite servicio, siempre dé la información que sigue:

1. Número de modelo del producto

2. Fecha de fabricación

3. Número de parte o descripción

5200-2235-006

ECR 38134

03/09

8

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

Page 9

Panneaux électriques

!

de chaleur radiante

de plafond

FICHIER #E21069

Instructions d’installation et d’entretien

a

Cher propriétaire,

Félicitations! Nous vous remercions d’avoir acheté ce nouveau radiateur fabriqué par Marley Engineered

Products. Vous avez fait un bon investissement en sélectionnant le produit de la plus haute qualité de l’industrie du chauffage. Veuillez lire attentivement les instructions d’installation et d’entretien de ce manuel. Vous

apprécierez des années de chauffage efficace et confortable avec ce produit de Marley Engineered

Products... le leader de l’industrie pour la conception, la fabrication, la qualité et l’entretien.

. . . Les employés de

Marley Engineered Products

a

AVERTISSEMENT

Lire attentivement - Ces instructions ont été écrites pour vous aider à éviter

des difficultés qui peuvent se produire pendant l’installation des radiateurs.

Étudier les instructions avant de procéder à l’installation peut faire gagner du

temps et éviter des dépenses considérables plus tard. Observer les procédures

suivantes pour réduire le temps d’installation au minimum.

1. Pour éviter des risques d’électrocution, débrancher TOUTES les sources

d’alimentation du radiateurdepuis le panneau d’alimentation principal avant

de câbler ou d’effectuer un entretien,

2. Tout le câblage doit être conforme avec les codes locaux et nationaux et le

radiateurdoit être misà la terrecomme précaution contre les risques d’électrocution.

3. Vérifier que la tension d’alimentation arrivant au radiateur corresponde à la

tension nominale imprimée sur la plaque signalétique du radiateur avant de

le mettre sous tension.

4. Ce radiateur ne convient PAS à une utilisation dans les emplacements dangereux décrits par l’association nationale de protection contre les incendies

(NFPA). NE PAS l’utiliser dans les endroits où de l’essence, de la peinture

ou d’autres liquides inflammables sont utilisés ou stockés. NE PAS utiliser

dans les lieux humides ou dans les lieux où des agents corrosifs sont présents, tels queles marinas,les serres, les lieuxde remisage de produits chimiques, les piscines, ou les lieux à forte humidité, à moins que des panneaux spéciaux faits surmesures ne soient utilisés. Despanneaux spéciaux

sur mesures sont disponibles pour certains environnements. Contacter le

fabricant pour plus de détails.

5. Pour éviter des blessures ou des incendies causées par la chute de panneaux, ceux-ci doivent être fermement fixés à la charpente du bâtiment.

GÉNÉRALITÉS

Les panneaux de chaleur radiante Marley Engineered Products

sont conçus pour fournir une chaleur confortable en réchauffant

la surface en dessous d’eux de la même manière que le soleil

réchauffe les surfaces par l’énergie irradiée. Ce processus de

chauffage réchauffe les objets dans une pièce sans avoir besoin

d’amener la température de la pièce à la même température.

Ces panneaux sont idéaux pour le chauffage localisé dans les

zones à forte perte de chaleur. Ils peuvent être installés côte à

côte ou individuellement au-dessus des zones nécessitant un

chauffage supplémentaire. S’ils sont utilisés comme seule

source de chaleur, une plus grande chaleur sera ressentie en

CONSERVER CES INSTRUCTIONS

Lors de fixation sur fer en T : la grille de fers en T doit être fixée à la charpente pour fournir un support approprié aux panneaux. Des trous sont

prévus dans les côtés de chaque panneau pour fixer des fils d’acier de support pour un support supplémentaire des panneaux là où la résistance de la

grille de fers en T est insuffisante. Le fil de support doit être en acier et au

moins de jauge 18 (1,19 mm de diamètre).

Pour une fixation en surface ou encastrée : les kits d’accessoires de châssis encastré ou en surface (modèles ASF ... ou ARF ... )doivent être utilisés.

Les dimensions des kits doivent correspondre aux radiateurs utilisés. Ne

pas percer de trous ni enfoncer de clous, vis, etc., dans les panneaux. Ceci

pourrait résulter en incendie, électrocution, ou dégâts permanents du radiateur. Les kits de fixation encastrée ou en surface doivent être fermement

fixés à la charpente avec au moins quatre (4) vis ou boulons de

6,3 mm de diamètre.

6. Pour éviter unrisque d’incendie causé par la surchauffe des fils,tous les fils

reliés aux panneauxde chauffage doivent être prévus pour une température

minimum de 90˚C lorsque la boîte de jonction est posée sur le panneau de

chauffageou est contenue entre le radiateur et le plafond au-dessusdu radiateur. Lorsqu’une isolation thermique est utilisée au-dessus du radiateur, la

boîte de jonction doit être au-dessus de l’isolation.

7. Les panneaux sontconçus uniquement pour une installation au plafond. Ne

pas installer sur des murs, sur le sol, etc. La surface peinte (inférieure) du

panneau est chaude. Les panneaux doivent être installés à au moins

2,14 mètres au-dessus du sol, et ne doivent pas être installés là où lespanneaux peuvent facilement être touchés pendant leur emploi. Un dégage-

ment minimal de 0,9 m (3 pi) DOIT être maintenu entre la partie

avant du radiateur et les produits combustibles.

étant directement en dessous du panneau.

Bien que le radiateur contienne une isolation thermique, il fonc-

tionne plus efficacement dans une pièce bien isolée. Dix centimètres ou plus d’isolation au-dessus d’un plafond exposé augmentent le confort et l’économie.

Les radiateurs sont prévus pour être contrôlés par un thermostat mural monté à distance. Le thermostat doit être placé

dans la même pièce sur une paroi murale. Il doit également

être au moins 1,50 mètres au-dessus du sol, mais pas directement en dessous du radiateur.

Page 10

REMARQUE : Pendant une certaine période après la

!

BLACK

BLACK G

208 OR 240 VOLT

HEATER

LINE VOLTAGE

THERMOSTAT

OR SWITCH

(NOT INCLUDED)

SEE NAMEPLATE FOR

LINE VOLTAGE SUPPLY

WIRING

DIAGRAM

HEATERS MUST BE

PROPERLY GROUNDED

BLACK WHITE

G

120, 277 OR 347 VOLT

HEATER

SEE NAMEPLATE FOR

LINE VOLTAGE SUPPLY

mise en service des radiateurs, l’utilisateur peut remarquer une “odeur de neuf” émanant des radiateurs. Ceci

st attendu sur les nouvelles installations et se dissipe au

e

bout d’environ 24 heures de fonctionnement.

PEINTURE

1. Les radiateurs peuvent être repeints. Ne pas retirer la pein-

ture des radiateurs. La surface doit tout d’abord être débarrassée des graisses et de l’huile. Appliquer uniquement une

ine couche au pinceau de peinture latex acrylique mate à

f

base aqueuse de haute qualité. Un ton écru assure une

meilleure couverture.

FIXATION SUR FER EN T

1. Les panneaux de radiateur sont conçus pour installation

dans les plafonds à fers en T.

ATTENTION

Pour éviter le risque de blessures provoquées par la

chute de panneaux, les fers en T doivent être fermement

fixés à la charpente et capables de supporter le poids

du panneau (13,6 kg). Des trous supplémentaires sont

prévus pour suspendre le panneau de radiateur (voir la

figure 2) sur des fils d’acier d’un diamètre minimum de

1.19 mm (jauge 18). Ces fils de support supplémentaire

doivent être utilisés lorsque la résistance du fer en T

n’est pas appropriée ou s’il y a risque de vibrations.

2. Une distance minimum de 76,7 mm doit être prévue entre

la surface peinte avant et le plafond au-dessus. Cependant,

l’installation peut être difficile et un jeu de 152 mm ou plus

facilitera l’installation des radiateurs et l’inspection du

câblage. Il peut être nécessaire de déposer une traverse en

T pour permettre l’installation lorsque les fers en T sont

proches du plafond.

3. Placer les fils de suspension des fers en T aux coins où les

traverses en T croisent les fers en T principaux pour qu’ils

ne gênent par l’installation et la dépose des panneaux.

4. Lespanneaux de réchauffeur sontfournis avec quatre pincesde

retenuesituées de chaque longcôtédu panneauderéchauffeur.

Les pinces de retenue peuvent être utilisées pour accrocher le

réchauffeur avec des fils de support (voir la figure 1) ou être

pliées comme maintiennent des agrafes à l'armature de fer en T

(voir la figure 2). Soulever soigneusement le panneau de radiateur en place, en s’assurant que les pinces de retenue s’accrochent fermement sur les fers en T (voir la figure 2).

ATTENTION

Pour éviter les risques d’électrocution, s’assurer que l’alimentation soit coupée au disjoncteur principal. Tout le

câblage doit être effectué conformément aux codes applicables et leradiateurdoit être correctement mis à la terre à titre

de précaution contre les risques d’électrocution.

Fig. 1

FILS DE SUPPORT

PINCE DE

RETENUE

Fig. 2

PINCE DE

RETENUE

PANNEAU DE

ADIATEUR

R

FER EN T.

1. Le nombre maximum de radiateurs par circuit est limité par

la capacité du câblage du circuit et du thermostat ou du

commutateur. Consulter le catalogue pour les thermostats

disponibles et l’avertissement nº 2.

2. Effectuer les connexions électriques conformément à la figure 3 (sur la page suivante) et aux instructions de câblage.

Le radiateur doit être mis correctement à la terre comme

précaution contre les risques d’électrocution. Utiliser une

boîte de jonction correctement mise à la terre pour brancher

le radiateur sur la source d’alimentation.

3.Toujours utiliser une boîte de jonction correctement mise à

la terre lors des raccords. Voir le schéma de câblage pour

les connexions correctes. Installer les radiateurs uniquement dans les emplacements où les connexions d’alimentation sont accessibles. Installer la boîte de jonction aussi loin

que possible au-dessus du panneau, et au-dessus de l’isolation du bâtiment, s’il y a lieu. Utiliser des fils prévus pour

une températures de 90 degrés si la boîte de jonction est

posée sur le panneau de chauffage ou est contenue entre le

radiateur et le plafond au-dessus du radiateur. Lors de l’installation dans un plafond suspendu, le bornier doit être accessible au travers de sections de plafond amovibles avec

suffisamment de place pour permettre l’accès au dessus du

radiateur.

CÂBLAGE

Fig. 3

VOIR LA PLAQUE SIGNALÉTIQUE

POUR LA TENSION D’ALIMENTATION

SCHÉMA DE

CÂBLAGE

LES RADIATEURS DOIVENT ÊTRE

CORRECTEMENT MIS À LA TERRE

208 OU 240 VOLTS

NOIR NOIR

RADIATEURS

THERMOSTAT OU

COMMUTATEUR DE

TENSION D’ALIMEN-

TATION (NON

INCLUS, VOIR LE

CATALOGUE)

10

VOIR LA PLAQUE SIGNALÉTIQUE

POUR LA TENSION D’ALIMENTATION

BLANC

NOIR

RADIATEURS

120, 277 OU 347 VOLTS

Page 11

e kit de fixation en surface est fourni dans des emballages

!

!

FIXATION EN SURFACE

1. L

éparés qui contiennent deux cadres latéraux, deux cadres

s

’extrémité et huit vis d’assemblage.

d

. Assembler les cadres d’extrémité aux cadres latéraux en

2

tilisant les vis fournies (voir la figure 4), avant l’installation

u

u plafond.

a

. Le kit de fixation encastrée est fourni dans des emballages

FIXATION ENCASTRÉE

1

éparés qui contiennent quatre morceaux de cadre et qua-

s

re coins (voir la figure 6).

t

Fig. 6

ADRE

C

ATÉRAL

L

ATTENTION

Pour éviter le risque de blessures causées par la chute

de panneaux, utiliser au moins quatre vis (de 6,35 mm

de diamètre) pour fixer chaque cadre latéral. Les vis

doivent être fermement vissées dans une structure

robuste du plafond, telle qu’une poutre du plafond. Il

peut être nécessaire d’installer une poutre supplémentaire. Ne pas fixer sur du placo-plâtre, du plâtre ou autre

matériaux de finition.

ADRE D’EXTRÉMITÉ

C

CADRE LATÉRAL

TROUS DE

FIXATION

VIS

Fig. 4

3. Fixer le cadre au plafond.

4. Déposer un cadre d’extrémité et installer le panneau de radiateur dans les cadres latéraux comme illustré dans la figure 5.

ATTENTION

Pour éviter les risques d’électrocution, s’assurer que

l’alimentation soit coupée au disjoncteur principal avant

d’effectuer le câblage.

3. Fixer le cadre au plafond.

4. Déposer un cadre d’extrémité et installer le panneau de radiateur dans les cadres latéraux comme illustré dans la figure 5.

Fig. 5

Étape A

Étape B

ADRE

C

’EXTRÉMITÉ

D

OIN

C

. Les panneaux de radiateur encastrés nécessitent une dé-

2

oupe dans le plafond et une méthode de support sûre (voir

c

la figure 7). Utiliser pour le support des planches d’au moins

5 cm x 10 cm. Utiliser des vis au moins numéro 10 dans

chaque trou prévu dans les cadres d’extrémité et latéraux.

ATTENTION

Pour éviter les risques d’électrocution, s’assurer que

l’alimentation soit coupée au disjoncteur principal avant

d’effectuer le câblage.

A

Fig. 7

Largeur du panneau

plus 9,5 mm

Longueur du

panneau plus

9,5 mm

3. Insérer le panneau de radiateur dans l’ouverture (voir la figure 7) et effectuer les connexions électriques (voir la figure

3 et les instructions de CÂBLAGE). Le radiateur doit être

correctement mis à la terre pour éviter les risques d’électrocution. Utiliser une boîte de jonction correctement mise à la

terre pour relier le radiateur à l’alimentation.

4. Visser légèrement les cadres d’extrémité et latéraux dans

l’ouverture du plafond, puis fixer les coins en place (voir la

figure 8).

5. Après avoir fixé les coins, serrer fermement les vis.

6. Abaisser prudemment le panneau de radiateur en place sur

les cadres.

(TOUTES LES DIMENSIONS SONT INTERNES)

Étape C

Fig. 8

ATTENTION

Ne pas fermement fixer ce kit peut résulter en blessures

graves causées par la chute de panneaux de radiateur.

5. Connecter les fils de panneau de radiateur aux fils d’alimen-

tation (voir la figure 3 et les instructions de CÂBLAGE). Le

radiateur doit être correctement mis à la terre pour éviter les

risques d’électrocution. Utiliser une boîte de jonction correctement mise à la terre pour relier le radiateur à l’alimentation. Le radiateur peut être déplacé le long des cadres

latéraux pour faciliter le câblage.

6. Re-monter le cadre d’extrémité sur les cadres latéraux pour

bloquer le radiateur fermement en place.

11

PLACER LES COINS

EN PLACE ET LES

BLOQUER EN PLIANT LES

LANGUETTES VERS

LE HAUT

Page 12

CARACTÉRISTIQUE : DIMENSION STANDARD

Nº de

modèle

ATL24241A

ATL24242A

ATL24248A

ATL24247A

ATL24243A

ATM24241A

ATM24242A

ATM24248A

ATM24247A

ATM24243A

ATH24241A

ATH24242A

ATM24248A

ATM24247A

ATM24243A

ATL24481A

ATL24482A

ATL24488A

ATL24487A

ATL24483A

ATM24481A

ATM24482A

ATM24488A

ATM24487A

ATM24483A

ATH24481A

ATH24482A

ATH24488A

ATH24487A

ATH24483A

Nº de

catalogue

CP2501

CP2502

CP2508

CP2507

CP2503

CP3101

CP3102

CP3108

CP3107

CP2103

CP3751

CP3752

CP3758

CP3757

CP3753

CP5001

CP5002

CP5008

CP5007

CP5003

CP6251

CP6252

CP6258

CP6267

CP6253

CP7501

CP7502

CP7508

CP7507

CP7503

Nº de

catalogue

CP251

CP252

CP258

CP257

CP253

CP311

CP312

CP318

CP317

CP313

CP371

CP372

CP378

CP377

CP373

CP501

CP502

CP508

CP507

CP503

CP621

CP622

CP628

CP627

CP623

CP751

CP752

CP758

CP757

CP753

Volts Watts BUT/H

250

120

250

240

250

208

250

277

250

347

310

120

310

240

310

208

310

277

310

347

375

120

375

240

375

208

375

277

375

347

500

120

500

240

500

208

500

277

500

347

625

120

625

240

625

208

625

277

625

347

750

120

750

240

750

208

750

277

750

347

853

853

853

853

853

1058

1058

1058

1058

1058

1280

1280

1280

1280

1280

1706

1706

1706

1706

1706

2133

2133

2133

2133

2133

2560

2560

2560

2560

2560

DIM

(PO.)

24

X

24

X

1

24

X

48

X

1

a

DIM

(CM.)

61

X

122

X

2.5

61

X

122

X

2.5

PANNEAUX DE CHALEUR RADIANTE

ÉLECTRIQUES AZTEC

CARACTÉRISTIQUE

Nº de

modèle

Nº de

modèle

Nº de

modèle

Panel Watt LONGUEUR DU PANNE

Width Density 24”-35” 36”-47” 48”-59” 60”-71” 72”-83 84”-95” 96”

LA PUISSANCE EN WATTS

AT+**@@#A BT+**@@# QT+**@@#

+ = Watt Density

(H=High; M=Medium; L=Low)

** = Width of heater

@@ = Length of panel

# = AC Voltage designation

(1=120; 2=240; 3=347; 7=277; 8=208)

^ = Max. Panel Length = 60 inches

^^ = Max. Panel Length = 72 inches

a

Tous les produits fabriqués par Marley Engineered Products sont garantis contre les défauts de main d’œuvre et de matériaux pendant un an à compter de la date d’installation, à l’exception des éléments chauffants qui sont garantis contre les défauts de main d’œuvre et de matériaux pendant cinq ans à compter de la date d’installation. Cette

garantie ne s’applique pas aux dégâts causés par un accident, une mauvaise utilisation ou une modification; ou si la tension d’alimentation est supérieure de plus de 5% à la

tension de la plaque signalétique; ou si l’équipement n’est pas installé ou câblé correctement ou s’il n’est pas entretenu conformément aux instructions d’installation du produit. Toutes les demandes de travail sous garantie doivent être accompagnées d’une preuve de la date d’installation.

Le client est responsable de tous les frais encourus pour la dépose et la ré-installation des produits, y compris la main d’œuvre et les frais d’expédition encourus pour renvoyer

les produits au centre de service après-vente Marley Engineered Products. Dans les limites de cette garantie, les appareils défectueux doivent être retournés au centre de service après-vente agrée Marley le plus proche ou au centre de service après-vente Marley Engineered Products, et nous les réparerons ou remplacerons, à notre choix, sans

frais pour vous, avec les frais de retour payés par Marley. Il est convenu que cette réparation ou ce remplacement constituent le seul recours offert par Marley Engineered

Products.

LES GARANTIES CI-DESSUS REMPLACENT TOUTES LES AUTRES GARANTIES EXPRESSES OU IMPLICITES. ET TOUTES LES GARANTIES IMPLICITES DE

COMMERCIABILITÉ ET D’ADAPTATION À UN USAGE PARTICULIER EN EXCÈS DES GARANTIES EXPRESSES DÉJÀ CITÉES SONT PAR LA PRÉSENTE REJETÉES

ET EXCLUES DE CET ACCORD. MARLEY ENGINEERED PRODUCTS NE SERA PAS RESPONSABLE DES DOMMAGES INDIRECTS CAUSÉS PAR LE PRODUIT,

QU’ILS SOIENT LE FRUIT DE NÉGLIGENCE, TORT, RESPONSABILITÉ STRICTE, OU CONTRAT.

Certaines provinces ne permettent pas l’exclusion ou les limitations des dommages indirects et fortuits, les exclusions et limitations ci-dessus peuvent donc ne pas vous concerner. Cette garantie vous donne des droits légaux spécifiques, et vous pouvez avoir d’autres droits qui varient d’une province à l’autre.

Pour obtenir l’adresse du centre de service après-vente agréé le plus proche, contacter Marley Engineered Products à Bennettsville, SC, au 1-800-642-4328. Les marchandises renvoyées à l’usinedoiventêtre accompagnées d’une autorisation de retour et d’une étiquette d’identification de service, qui peuvent toutes deux être obtenues de Marley

Engineered Products. Lors de la demande d’autorisation de retour, inclure tous les numéros catalogue indiqués sur les produits.

GARANTIE LIMITÉE

COMMENT OBTENIR DES INFORMATIONS GÉNÉRALES ET

DEMANDER UNE RÉPARATION OU DES PICES SOUS GARANTIE

1. Réparations et pices sous garantie 1-800-642-4328

2. Achat de pices de rechange 1-800-654-3545

3. Informations générales sur les produits www.marleymep.com

Remarque : Lorsque vous demandez de l'assistance, ayez toujours en main

1. Le numéro de modle du produit

2. La date de fabrication

3. Numéro ou description de la pice

5200-2235-006

ECR 38134

03/09

12

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

Loading...

Loading...