Page 1

Electric Counterflow

Wall Furnace

Model # Voltage Watts Amps BTU/Hr.

CFWF920 240V 9.2kW 38 31,395

Installation & Maintenance Instructions

Dear Owner,

Congratulations! Thank you for purchasing this new heater manufactured by Marley Engineered

Products. You have made a wise investment selecting the highest quality product in the heating industry. Please carefully read the installation and maintenance directions shown in this manual. You should

enjoy years of efficient heating comfort with this product from Marley Engineered Products... the industry’s leader in design, manufacturing, quality, and service.

... The Employees of

Marley Engineered Products

!

WARNING

Read Carefully - These instructions are written to help

you prevent difficulties that might arise during installation

of your heaters. Studying the instructions first may save

you considerable time and money later. Observe the following procedures, and cut your installation time to a minimum.

TO REDUCE RISK OF FIRE OR ELECTRICAL SHOCK:

1. Disconnect all power coming to heater at main service

panel before wiring or servicing.

2. All wiring must be in accordance with the National and

Local Electrical Codes and the heater must be grounded.

3. Verify the power supply voltage coming to heater

matches the ratings printed on the heater nameplate

before energizing.

4. This heater is hot when in use. To avoid burns, do not

let bare skin touch hot surfaces.

5. Do not insert or allow foreign objects to enter any ven-

tilation or exhaust opening as this may cause an electric shock, fire,or damage to the heater.

6. Do not block air intakes or exhaust in any manner.

Keep combustible materials, such as crates, drapes,

etc., away from heater. Do not install behind doors,

furniture, towels, or boxes.

7. A heater has hot and arcing or sparking parts inside.

Do not use it in areas where gasoline, paint, or flammable liquids are used or stored.

8. Use this heater only as described in this manual. Any

other use not recommended by the manufacturer may

cause fire, electric shock, or injury to persons.

9. This heater is not approved for use in corrosive atmospheres such as marine, green house, or chemical storage areas.

10. Do not install this heater in an alcove.

11. Do not install this heater in a travel trailer or recreational vehicle.

SAVE THESE INSTRUCTIONS

Page 2

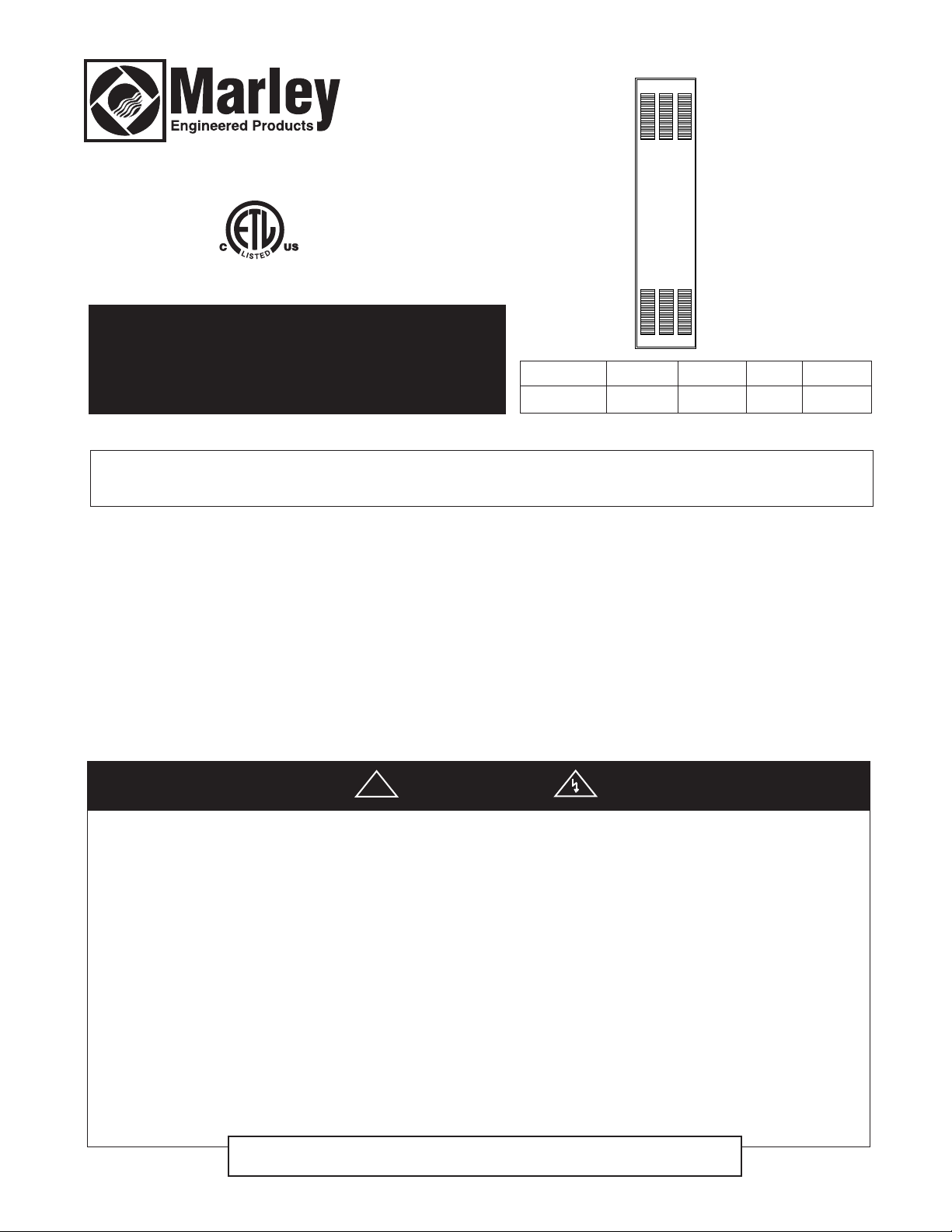

CFWF920 Description

Your Counterflow Wall Furnace is shipped assembled for

nstallation on any wall. It may be recessed up to 5-3/8

i

inches (137 mm) with studs spaced 16 inches (406 mm)

n center, or it may be mounted directly on the wall sur-

o

face.

This heater works by drawing cool air in at the top grille

inlet and pushing it with a fan downward over the heating

element. Warm air is discharged into the room through

the bottom grille outlet near the floor. The warm air at the

floor creates a gentle convective process in the room,

preventing stratification of warm air near the ceiling and

ensuring comfort for the occupants.

This heater runs on single-phase 240V line voltage and

produces 9.2 kW of heat or 31,395 BTU/Hr.

The Counterflow Wall Furnace is controlled by a low voltage wall-mounted thermostat (provided). The unit is

made of heavy gauge steel with a durable baked powder

coat finish.

Removing your Furnace

from the Carton

The shipping carton contains the heater and the parts

needed for installation.

1. While the heater is still in the carton, lift straight up on

the top of the furnace. Remove the top trim cover with

its packing materials and the hardware kit (thermostat,

wire, and screws). Put this hardware kit aside where it

will not be lost or damaged.

2. Finish removing heater from the carton and lay on its

back. Carefully remove the remaining packing supports from around the furnace and set aside.

3. Remove the screws from the top front panel. Gently

pull panel toward the top of the cabinet about 1/2 inch

(13 mm). Panel will loosen. Remove panel from cabinet and set top front panel and screws aside where

they will not be lost or damaged.

4. Give fan blade a small push counterclockwise to

ensure that it spins freely.

5. Remove the four screws holding the junction box cover

above the fan. Place cover and screws aside where

they cannot be lost or damaged. The electrical junction

box and transformer should now be accessible. Refer

to the section "ELECTRICAL WIRING" before attempting to wire your heater.

6. Remove the four mounting screws from the bottom

front panel. Remove panel from cabinet. Set panel

and screws aside where they will not be lost or damaged.

7. Before discarding packing material, examine it carefully for any loose furnace parts. Dispose of packing

material properly (recycle).

Figure 1

Optional Accessories

Rear Outlet Kit CFWFRO

This accessory allows you to divert some heated air to a

second room behind the furnace. The finished wall of this

room must be within 10 inches (254 mm) of the furnace.

The built-in damper allows you to close the rear outlet, rediverting all the air to the front outlet grill. If this accessory is to be used, the opening must be cut in the rear of the

cabinet, at this time. See “Optional Rear Outlet

Installation” section of this manual.

2

Page 3

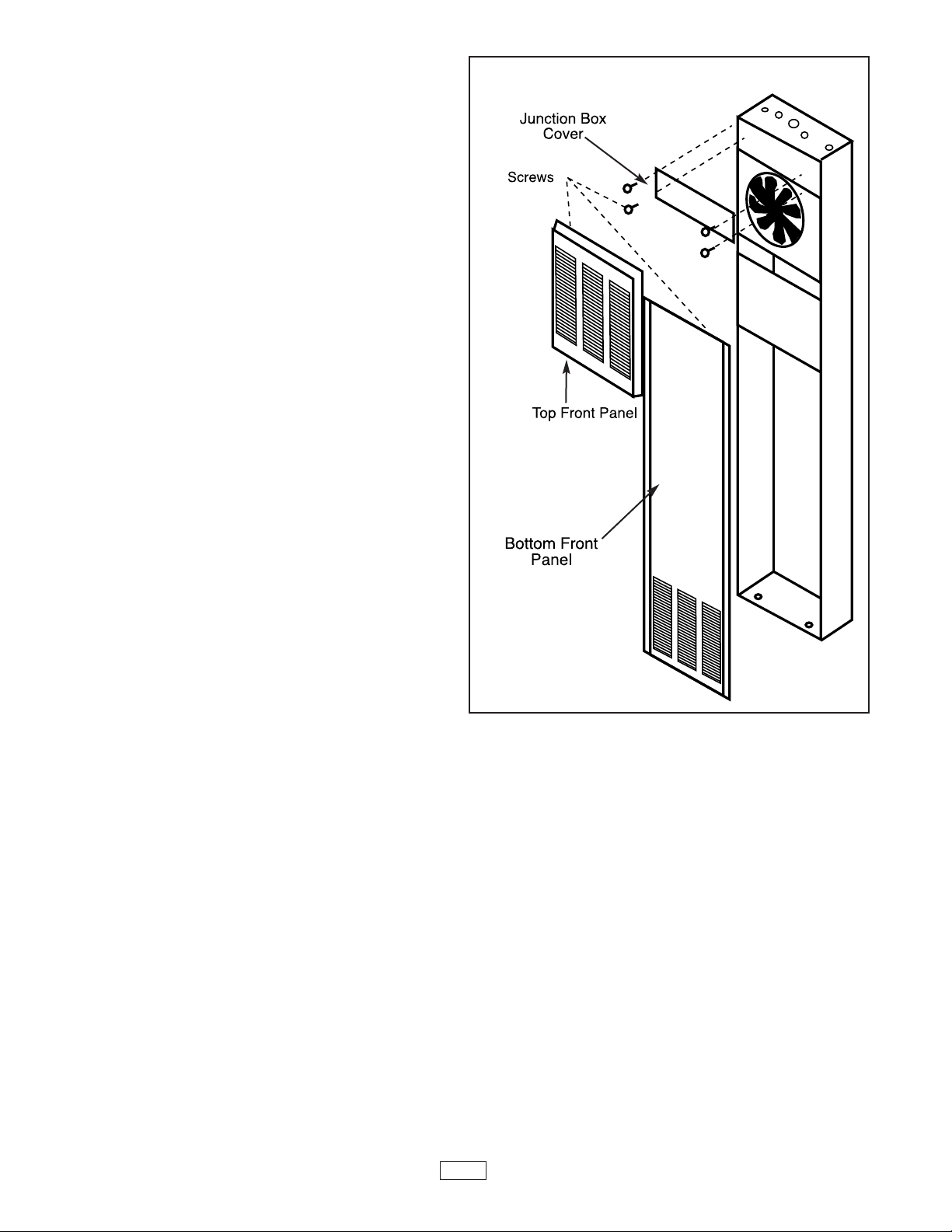

How to Install Your Wall Furnace

Follow the directions carefully to ensure proper installation and safe operation of your Counterflow Wall Furnace.

All wiring must be in accordance with the National and

ocal Electrical Codes and the heater must be grounded

L

as a precaution against possible electric shock. If you are

not sure what the requirements are, check with your local

authorities for local and state codes affecting installation.

Always get professional help when needed.

Figure 2

W

ALL

Locating the Counterflow

Wall Furnace & Thermostat

1. Furnace can be surface mounted or recessed in any

interior or exterior wall.

Note: The optional rear outlet (CFWFRO) may only be

used on an interior wall.

2. This heater may be recessed a maximum of 5-3/8 inches (137 mm).

Note: Check all clearances. The side of the furnace must

be at least 6 inches (152 mm) from a corner or from a

wall divider.

Note: Your wall furnace works best when it is placed as

near to the center of the space to be heated as possible.

3. Ensure that electrical service is available at your

desired installation location,

4. To ensure that there are adequate clearances and

service access, the front of the heater must face the

open room. Do not place furniture directly in front of

the Counterflow Wall Furnace.

5. Locate the thermostat approximately 5 feet (152 cm)

above the floor on an inside wall. Since you want the

thermostat to sense average room temperatures,

avoid cold and drafty locations and warm or sunny

locations which could mislead the sensing device in

the thermostat. You have been supplied with approximately 20 feet (610 cm) of thermostat wire. This

should allow you to locate the thermostat approximately 16 feet (489 cm) from the furnace if the wire is

run through the attic, 12 feet (366 cm) if under the

floor.

6. After selecting a location for your Counterflow Wall

Furnace, ensure that there are no pipes, wiring, etc.

that would interfere with the heater or thermostat location. If so, select another location.

6”

(152 mm)

Recessed Mount Installation

!

To avoid electrical shock, turn off electrical circuits that run through the wall where you are

installing the furnace.

If you are using the optional rear outlet (CFWFRO), refer

to Optional Rear Outlet Installation on page 7 before proceeding.

Locate Wall Studs

Use a stud locator or small finishing nails. Drive and

remove a small finishing nail through the wall surface until

you find a stud. Then locate the side of the stud using the

same technique. Leaving that locating nail there, locate

the other side of the stud. Once you have done this, you

should be able to easily locate the next stud. The inside

edge of the next stud should be approximately 14-1/2

inches (369 mm) from the one you just found.

CAUTION

3

Page 4

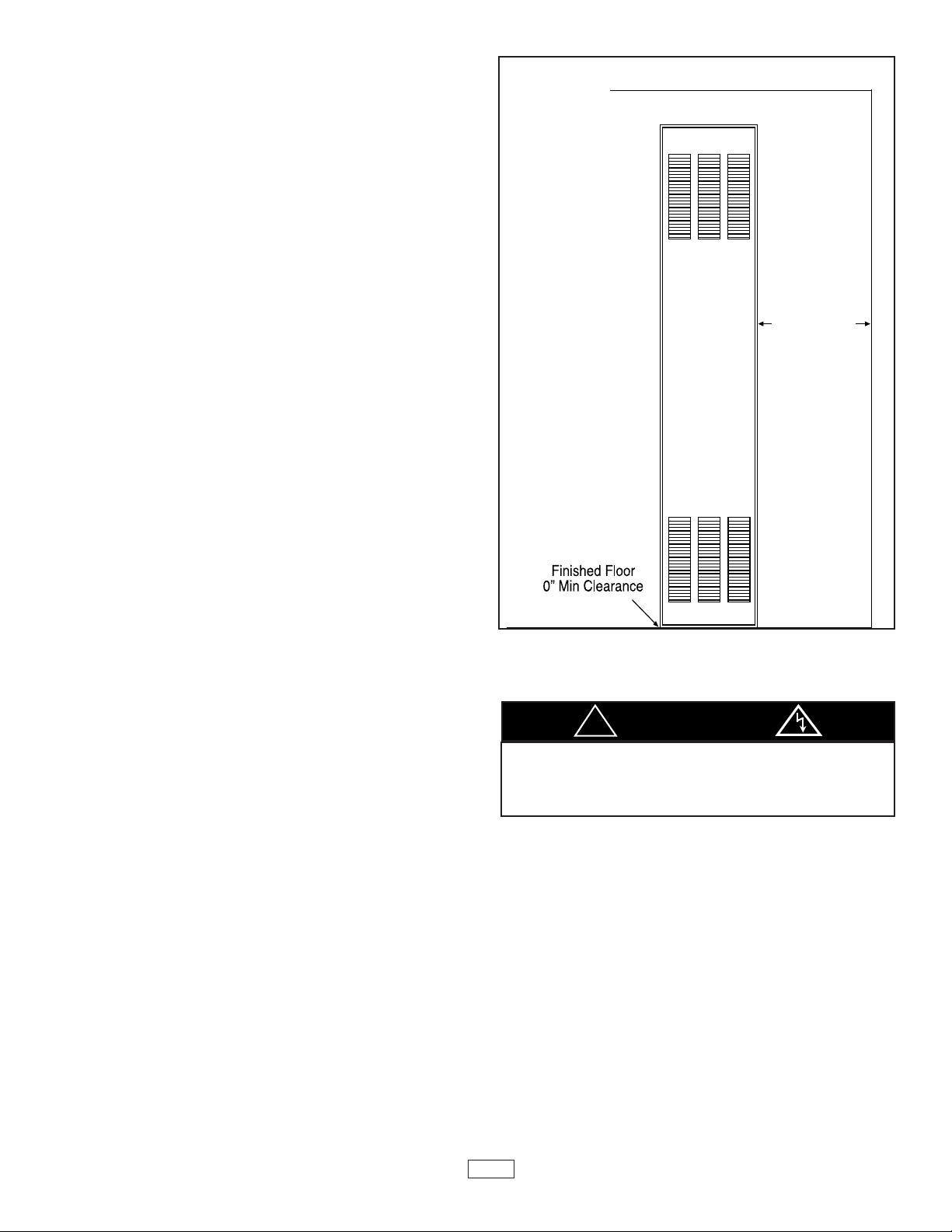

Note: IF STUDS ARE NOT ON 16-INCH (406 mm) CEN-

C

L

TERS, SEE CLOSE OFF STUD SPACE ON PAGE 4 AND

5.

Cut Wall Openings

Refer to Figure 3. Lay out and cut the required opening

n wall.

i

he vertical height given includes an allowance of 3 inch-

T

es (76 mm) extra to allow room for wiring after the furnace

is installed.

Electrical Supply Rough-In

1. Make entry holes in the ceiling wall plate above the furnace to route the conduit, electrical power supply

wires, and the thermostat wiring to the furnace.

2. If this is impractical, entry holes 1 inch (25 mm) for

electrical conduit and 1/2 inch (13 mm) for thermostat

wire may be drilled through either wall stud above the

furnace and the wiring may be routed from an adjoining stud space. You may also route the wiring from the

crawl space or basement to a point above the furnace

to match the openings in Fig. 4.

3. Install conduit so that it extends 4 inches (102 mm)

below the top of the furnace wall opening. One (1)

inch (25 mm) of conduit should extend inside the furnace cabinet (See Fig. 3).

1/2”

13mm)

(

24V THERMOSTAT WIRE ENTRY

3/4” (19 mm) CONDUIT ENTRY

7”

18-3/8”

(467mm)

FRONT

SIDE

2-1/4” (57mm)

179mm)

(

6-1/8”(156mm)

2-1/2”

7

(184cm)

8”

(203mm)

4-1/8”

1

359mm)

(

BACK

OPTIONAL REAR

OUTLET CUTOUT

MARKS

FRONT

6-1/8”

156 mm)

(

2”

50 mm)

(

Note: Flexible conduit may be used only if it meets local

codes and ordinances.

1. The electrical supply wires, ground wire, and the thermostat wires may now be routed to the furnace locations. See THERMOSTAT INSTALLATION, pages 6,

and ELECTRICAL WIRING page 8.

2. Ensure that there is enough wire at the furnace to

make the connections inside the furnace junction box.

4”

FLEXIBLE

CONDUIT

WALL CUTOUT

FOR OPTIONAL

REAR OUTLET

CENTERED

BETWEEN STUDS

6”

(152mm)

(102mm)

14-3/8”

(365mm)

71-1/2”

(1816mm)

75-1/2”

(1905mm)

8”

(203mm)

4-7/8”

124 mm)

(

Figure 4

6-5/8”

168 mm

12”

(305 mm)

INISHED FLOOR

F

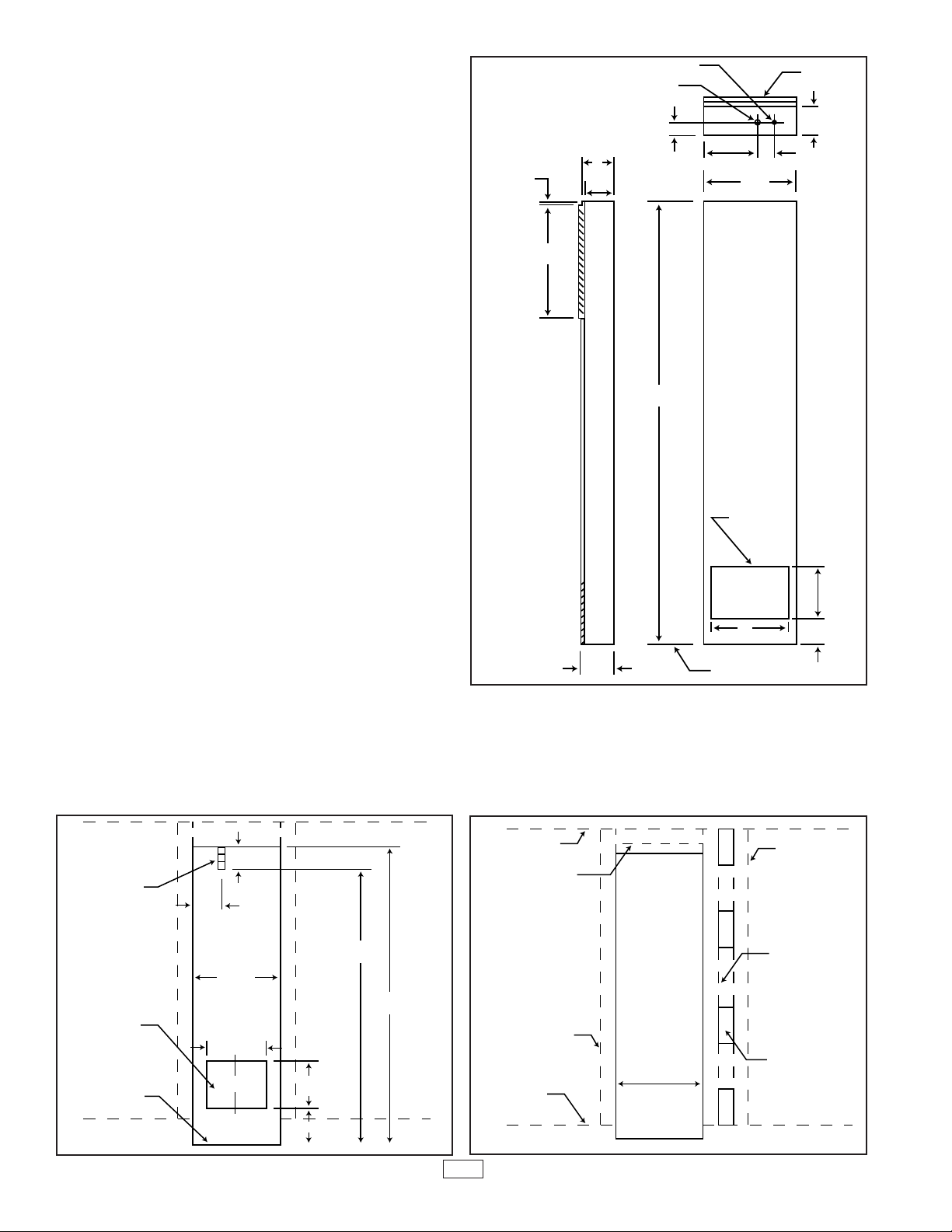

Close Off Stud Space (If Necessary)

If studs are not on 16 inch (406 mm) centers, cut the hole

for the Counterflow Wall Furnace next to an existing stud

and frame in the other side using a 2x4 (or other lumber

as required) and spacer blocks or shims. See Fig. 5.

CEILING

PLATE

2X4 BACKING

IF MORE THAN

18” BETWEEN

TOP OF

CUTOUT &

CEILING LATE

EXISTING STUD

NEW STUD

FINISHED

FLOOR

Figure 3

12-1/4”

(311mm)

8-1/4”

(210mm)

3-3/4”(95mm)

EXISTING STUD

FLOOR PLATE

14-3/8”

(365mm)

SPACER

BLOCK AS

REQUIRED

Figure 5

4

Page 5

In some high ceilings the distance from the top of the

cutout to the ceiling wall plate may be more than 18 inches (457 mm). If so, we recommend that you close off this

pace. Nail a 2x4 horizontally between the studs to close

s

off this space. Drill entry holes in this as required.

!

CAUTION

To avoid electrical shock, turn off electrical

circuits that run through the wall where you

are installing the furnace.

Surface Mount Installation

If you are using the optional rear outlet (CFWFRO), refer

to Optional Rear Outlet Installation on page 7 before proceeding.

Locate Wall Studs

Use a stud locator or small finishing nails. Drive and

remove a small finishing nail through the wall surface until

you find a stud. Then locate the side of the stud using the

same technique. Leaving that locating nail there, locate

the other side of the stud. Once you have done this, you

should be able to easily locate the next stud. The inside

edge of the next stud should be approximately 14-1/2

inches (368 mm) from the one you just found.

6. You may now route the electrical supply wires, ground

wire, and the thermostat wires to the furnace locations.

See THERMOSTAT INSTALLATION, pages 6, and

LECTRICAL WIRING page 9.

E

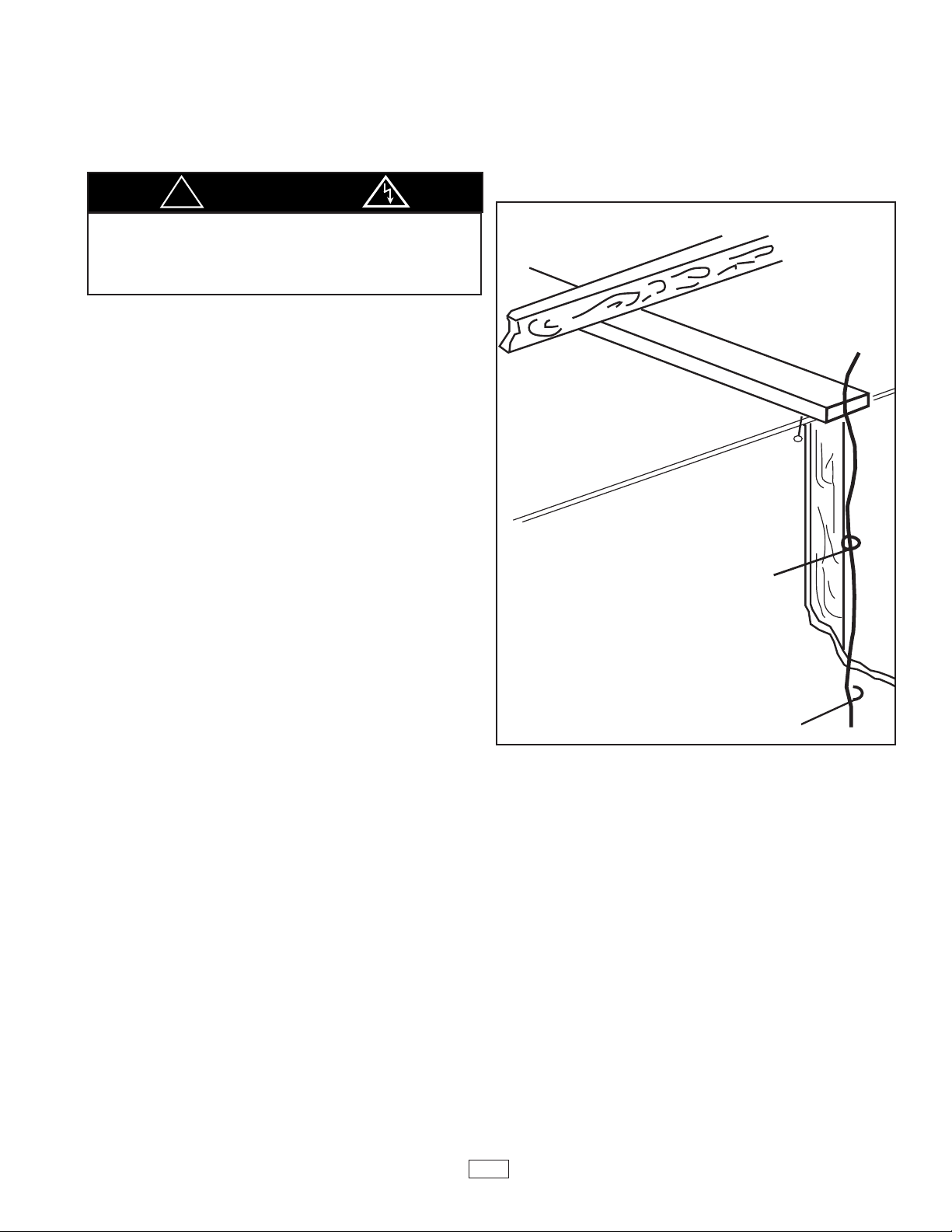

Route Thermostat Cable

SMALL

FINISH

NAIL TO

LOCATE

EADER

H

THERMOSTAT

CABLE

Cut Wall Opening

If you are using the optional rear outlet (CFWFRO), cut

the 8-1/4 (210 mm) inch by 12-1/4 inch (311 mm) opening

ONLY as shown in Fig. 3, page 4. Refer to Optional Rear

Outlet Installation on page 7 before proceeding.

1. If impractical to route the wiring to the furnace from the

attic, entry holes 1 inch (25 mm) for electrical conduit

and 1/2 inch (13 mm) for thermostat wire may be

drilled through either wall stud above the furnace and

the wiring may be routed from an adjoining stud space.

You may also route the wiring from the crawl space or

basement to a point above the furnace to match the

openings in Fig. 4.

2. To route the conduit, electrical power supply wires, and

thermostat wires to the furnace top, entry holes must

be made in the wallboard above the furnace location.

3. Electrical supply opening must be located at 2 inches

(51 mm)above the furnace top to match opening

shown in Fig. 4., page 6.

4. Drill a 1-inch (25 mm) hole for the electrical supply

wiring and a 1/2 inch (13 mm) hole for the thermostat

wires at the selected locations.

5. Route the flexible conduit to the 1 inch (25 mm) hole in

the wallboard and allow 1 inch (25 mm) to extend

below the furnace top (71-1/2 inches [1816 mm] from

the finished floor). See Fig. 3, page 4.

Figure 6

STIFF WIRE TO

SNAG CABLE

Thermostat Installation

1. Thermostat cable must be run to the location selected.

All wiring must agree with the local codes and ordinances. These instructions describe how to wire the

thermostat from the attic but it can also come from the

basement or crawl space.

2. Locate the thermostat and then drive a small nail hole

through the ceiling in the corner of the wall and ceiling

above the thermostat location. Pull out the nail and

push a small stiff wire through the hole to locate the

wire in the attic. Drill a 1/2 inch (13 mm) hole through

the ceiling wall plate.

3. Using the stiff wire, probe for obstructions in the wall.

Then drill 1/2 inch (13 mm) hole through the wall at the

selected location for the thermostat.

4. Feed the thermostat cable from the ceiling into the

wall. Snag the thermostat cable through the hole and

pull through so that 6 inches (152 mm) of cable pro-

trudes.

5. Route cable to Counterflow Wall Furnace.

5

Page 6

Mounting the Thermostat

Figure 7

RECESSED MOUNT

TOP FASTENING

METALANCHORS

1. Read instructions for thermostat. Grasp thermostat

over and pull gently outward at top to remove.

c

2. Connect the thermostat wires to terminal screws

marked R and W on the base.

3. Push excess wire back through the hole in the wall

and plug hole with insulation to prevent drafts from

affecting thermostat operation.

4. Fasten the thermostat base to the wall through the

mounting holes with the screws provided.

5. Set dip switches to 1-ON, 2-OFF, and 3-OFF.

6. Replace the thermostat cover.

Mounting Your Furnace

Note: If you are installing the CFWFRO optional rear out-

let refer to Optional Rear Outlet Installation on page 7

before proceeding.

1. If you have elected to recess your heater, clear the

recess of all construction debris.

2. Move furnace upright into position. Drop the flex conduit through the hole provided in the top of the furnace.

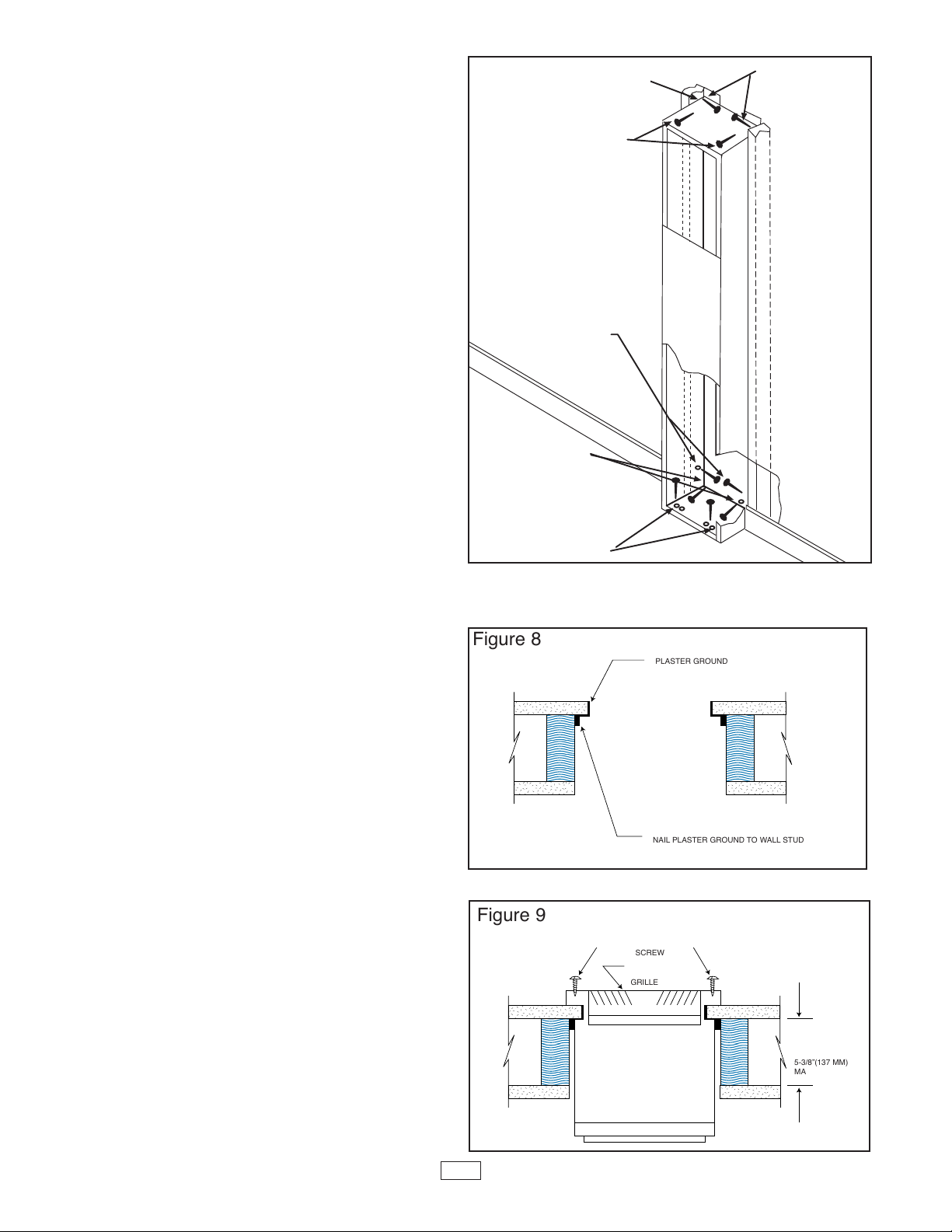

3. Fasten Furnace Top (Recessed Mounting) to the

studs through holes provided into top flanges using

(2) long screws provided (Fig. 8).

SURFACE MOUNT

OP FASTENING

T

NOTE: INTERNAL COMPONENTS

NOT SHOWN FOR CLARITY

ECESSED

R

MOUNT BOTTOM

FASTENING IF

CONCRETED

FLOOR

SURFACE MOUNT

BOTTOM FASTENING

IF CONCRETE FLOOR

BOTTOM FASTENING

OOD FLOOR

W

NOTE: DO NOT USE BOTTOM DOOR HOLES FOR

MOUNTING FURNACE

Fasten Furnace Top

(Surface Mounting)

Fasten furnace top to wall using (2) metal anchors

(packed in hardware kit) by placing them over the back

flange of furnace top and screwing to wall with (2) long

screws provided. See Fig. 8.

Note: Some fasteners are not provided and some

holes are not pre-drilled due to the many various construction situations that may be encountered.

Suitable fasteners for your application may be purchased at your local hardware store

Fasten Furnace Bottom

(Surface and Recessed Mount)

Drill (2) holes in the bottom of the furnace cabinet near

each side. Fasten the furnace through these holes to the

floor. If your floor is made of concrete, use the alternate

fastening location as shown in Fig. 7.

Figure 8

Figure 9

PLASTER GROUND

NAIL PLASTER GROUND TO WALL STUD

RECESSED MOUNTING

(10 INCH MOUNTING BOOT REQUIRED)

SCREW

GRILLE

5-3/8”(137 MM)

MAX RECESS

6

Page 7

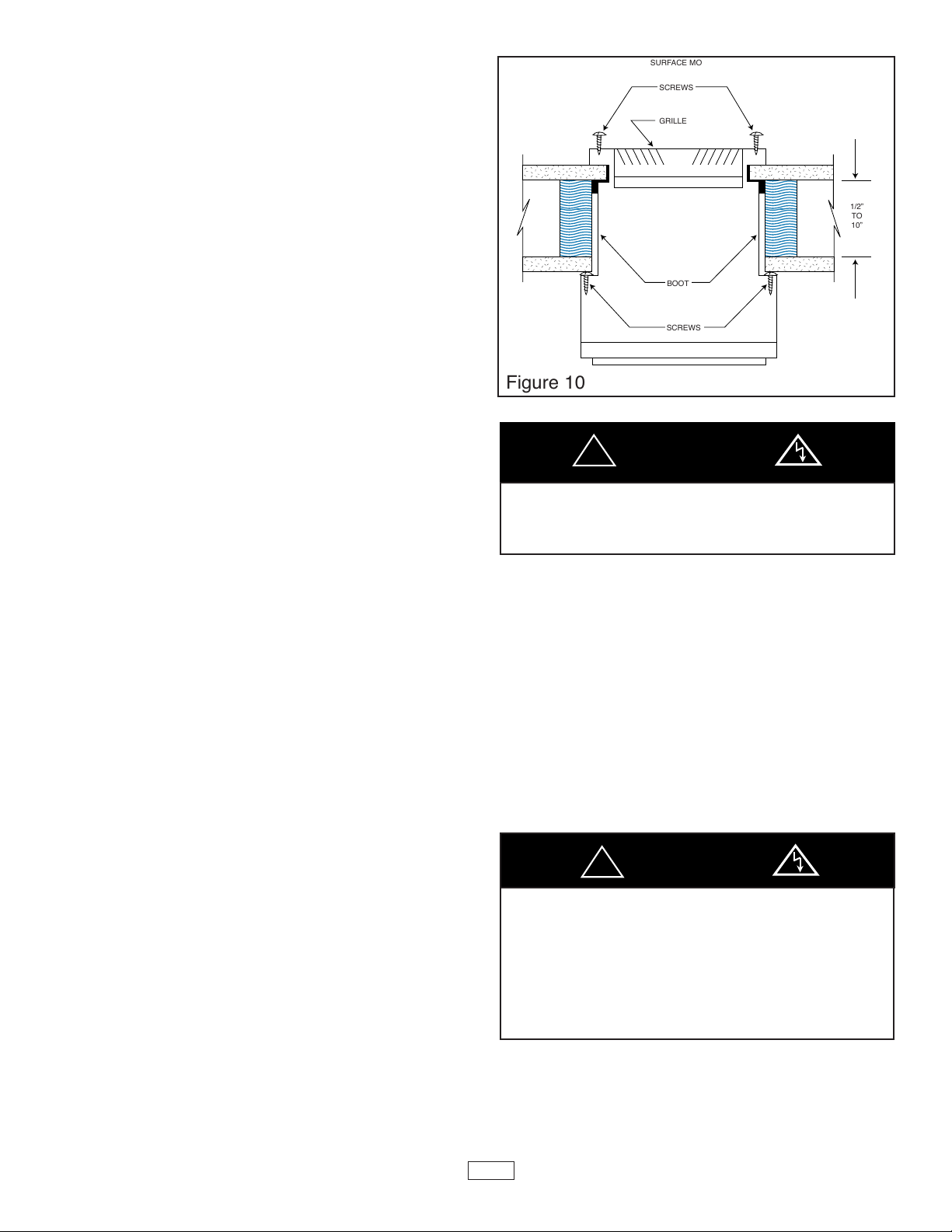

Optional Rear Outlet Installation

URFACE MOUNTING

S

(BOOT TRIMMED FLUSH WITH WALL)

SCREWS

Recessed Mount Furnace

. Cut 8-1/4 inch (210 mm) x 12-1/4 (311 mm) inch hole

1

in wall as shown in Fig. 3, page 4.

2. There are four diamond-shaped holes at the bottom of

the cabinet on the rear panel. Using these diamondshaped holes, draw straight lines to mark your outline

for the CFWFRO and cut out your opening.

3. Mount furnace in the recess. (See Mounting Your

Furnace, Page 3).

4. Place plaster ground in opening and nail into studs.

(Fig. 8)

Note: In new construction, install plaster ground before

wall finish is applied. In drywall construction the plaster ground may be omitted.

5. Center grille over hole in rear wall and mark location

of holes in grille on wall.

6. With a 1/8 inch drill bit, drill (2) holes through plaster

or drywall and the cabinet for attaching grille.

7. Attach the grille with screws provided (Fig.10). The 10

inch boot is not required for recessed installation.

GRILLE

BOOT

SCREWS

Figure 10

!

WARNING

Danger of Property Damage,

Bodily Injury, or Death

1/2”

TO

10”

Surface Mount Furnace

1. Cut 8-1/4 inch (210 mm) x 12-1/4 inch (311 mm) hole

in wall as shown in Fig. 3, page 4.

2. There are four diamond-shaped holes at the bottom

of the cabinet on the rear panel. Using these diamond-shaped holes, draw straight lines to mark your

outline for the CFWFRO and cut out your opening.

3. Place the boot against cabinet with inner side of boot

exactly on the edges of the hole.

4. Mark screw locations, remove boot and drill holes for

sheet metal screws.

5. Attach boot to back of furnace with screws provided.

6. Place plaster ground in opening and nail into studs

(Fig. 8).

Note: In new construction, install plaster ground before

wall finish is applied.

7. Place furnace with boot attached through hole in wall

and mark end of the boot so it can be cut off flush with

the outer wall.

8. Remove furnace from wall and cut boot where

marked.

9. Place furnace with trimmed boot attached, through

holes in wall and mount the furnace. (See Mounting

Your Furnace, page 6).

10. Center grille over hole in rear wall and mark location

of holes in grille on wall.

11. With a 1/8 inch drill bit, drill (2) holes through plaster

ground and plaster (or drywall).

12. Attach grille with screws provided (Fig. 10).

TURN OFF ELECTRIC POWER AT

FUSE BOX OR SERVICE PANEL

BEFORE MAKING ANY ELECTRICAL

CONNECTIONS.

INSULATE WHERE NECESSARY...

ALL LINE VOLTAGE AND GROUND CON-

NECTIONS MUST BE COMPLETED BEFORE

ELECTRICAL POWER IS RESTORED.

!

CAUTION

Label all wires prior to disconnection

when servicing. Wiring errors can

cause improper and dangerous

operation. Verify proper operation

after servicing.

All electrical work must conform to your

local codes and ordinances and with the

National Electrical Codes.

7

Page 8

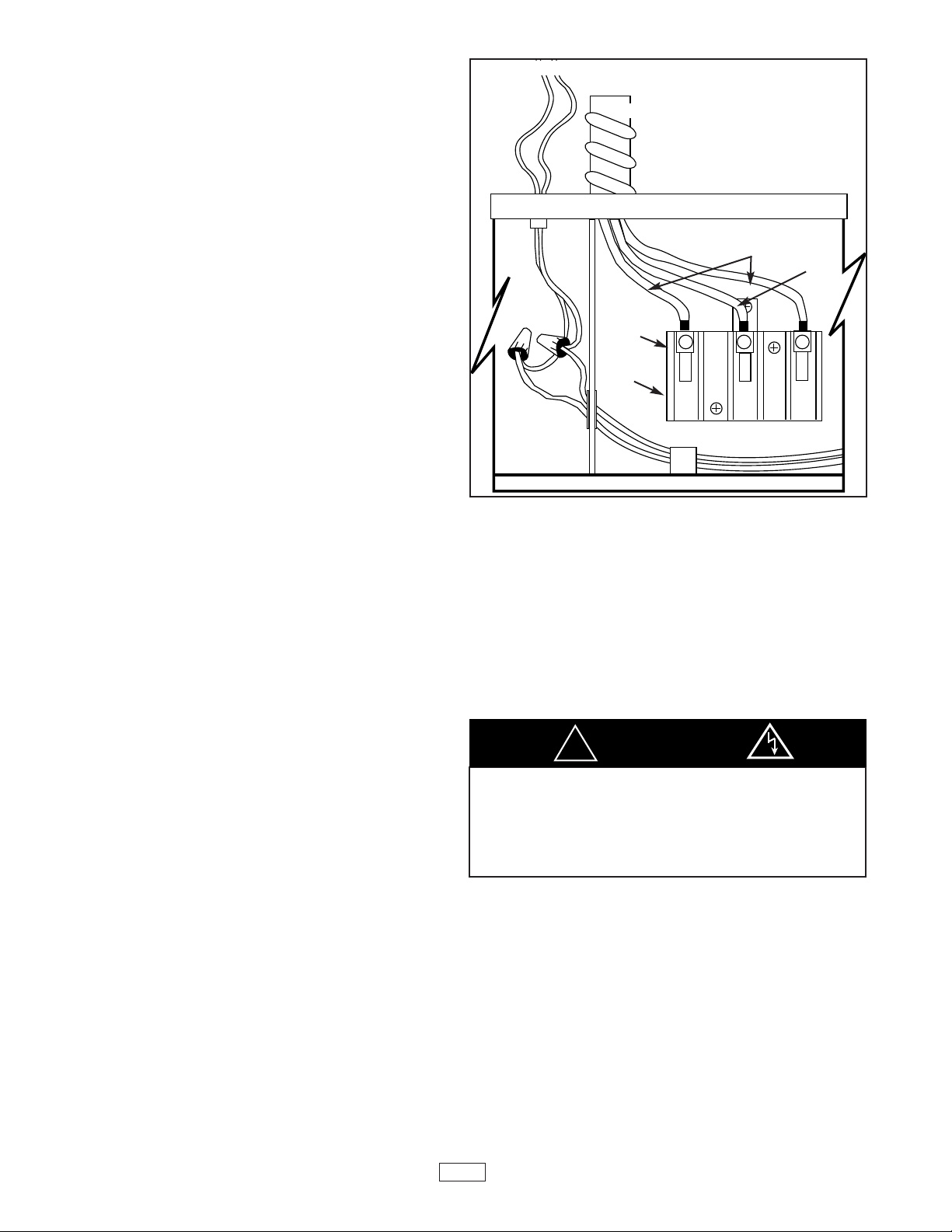

Electric Power Supply

TO THERMOSTAT

Your Counterflow Wall Furnace requires a 240-volt, 60

cycle, 40-ampere circuit from a separate circuit breaker or

fuse in your service panel. Do not run supply wires inside

he furnace cabinet, except from the top of the cabinet

t

down to the junction box.

Junction Box

Power supply connections are made inside the junction

box located in the upper end of the cabinet. See Fig. 11

and Fig. 1, page 2.

Electrical Connection

Connect 240V conduit to top of furnace as shown in Fig.

11. Pull supply wires through conduit and into junction

box. Attach 240V supply wires to "LINE" connection at

terminal board. Refer to wiring diagram on junction box

cover plate. If you do not feel comfortable doing this, or

have any doubts

how to comply with code, consult your electrical inspector

or a licensed electrician.

Grounding

Provide ground connection from the unitʼs terminal board

to a grounded connection in the electrical service panel or

a properly driven and electrically grounded ground rod.

Low Voltage Connections

Run thermostat wire to the furnace. See THERMOSTAT

INSTALLATION, page 6.

Connect the thermostat wires to the two (thermostat)

wires extending inside the junction box. Refer to wiring

diagram on junction box cover plate and Fig. 11.

When furnace mounting has been completed, see steps

1, 2, and 3 below.

Refer to Fig. 1, page 2.

1. Replace junction box cover plate. Tighten screws

securely.

2. Replace bottom front panel

3. Replace top front panel.

CONDUIT

ELECTRICAL SUPPLY

UNCTION

J

OX

B

SEE WIRE

CONNECTION

DIAGRAM

BOVE

A

ERMINAL

T

BOARD

WIRES-240V

LINE 1 GND. LINE 2

TO APPROVED

GROUND

Figure 11NOTE: ALL WIRING NOT SHOWN

This heater is equipped with an automatic reset over-temperature device. This device cuts the heater off if it should

operate at an abnormal temperature. Also, a pilot light

located on the top right of the fan panel (visible through

the grille) will come on. When the heater cools back down

to a normal level, the automatic reset will restore operation and the pilot light will turn off.

Additionally, your heater is equipped with micro temp heat

limits ("one-shots") to protect against excessive and pro-

!

WARNING

If this light comes on this means your

heater has operated abnormally. Check for

air blockages and remove. If this does not

solve your problem, call a qualified

Service Technician.

longed current surges. If these device(s) open(s) the

heating circuit, the limit(s) must be replaced by a qualified

Service Technician, who will also determine and correct

the cause of failure.

Note: For supply connections use 6 AWG or larger wires

suitable for at least 60 C (140 F). Use copper wire only.

Operating Your Furnace

This heater is controlled by a 24-volt wall thermostat that

is included. Set the thermostat to a higher temperature

than you think will be comfortable. Let the heater run and

when the room reaches a comfortable temperature, adjust

the dial counter-clockwise slowly until the heater cuts off.

The thermostat will maintain this temperature.

Air volume may be adjusted if you have installed the

CFWFRO rear grille. Do not attempt to reduce the flow

of air from the front grille. Doing so will cause the limit

devices to shut down the heater. Do not obstruct the front

grille (or rear grille, if so equipped).

8

Page 9

How to Take Care of Your Furnace

Annual Upkeep

1. Heating Element and Optional Rear

Outlet

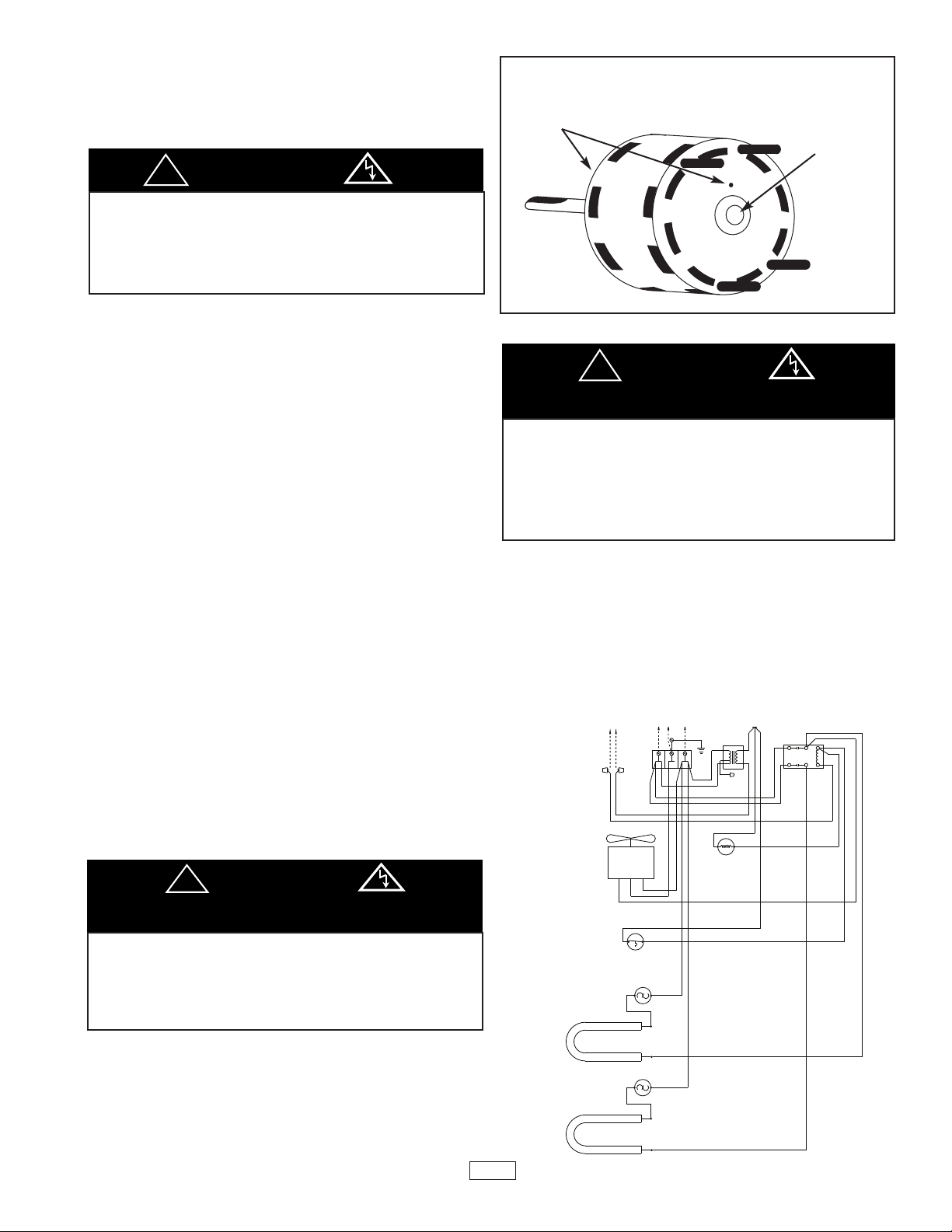

Figure 12

OIL PORTS

AN

F

MOTOR

!

WARNING

Turn off electric power supply at disconnect switch, fuse box, or service panel

before removing any doors or access or

service panels from unit.

Keep clean at all times. Use a soft brush or vacuum

cleaner to clean all foreign materials from inlet and outlet

grille (and rear outlet grille if installed). To access the

heating element, remove (2) screws (Fig. 1, page 2) and

grasp face panel near bottom. Pull up and out. After

cleaning heating elements and Optional Rear Outlet,

replace the panel.

2. Motor and Fan

In order to get the maximum life out of your fan your

should clean any dust (by vacuuming or blowing) from the

ventilation holes. You should also add a few drops of #20

non-detergent oil to the bearing cavity (See Fig. 12).

To access the motor:

A. Remove the four screws holding the fan shroud to

side flanges of cabinet and remove the shroud (Fig.

1, page 2).

B. Caution: Be sure to mark the position of the fan blade

in relation to the motor shaft before removing.

Examine the blade nut and the amount of shaft that is

visible. Mark the motor shaft with a scratch or in

another fashion in order to reinstall the fan to its original position.

C. Loosen the 5/32-inch "allen head" set screw holding

the fan blade to the motor shaft and remove the fan

blade. A wrench is provided for this purpose.

D. Reverse steps 1-3 to replace the fan blade.

!

WARNING

2. Cabinet Finish

!

CAUTION

Source of Possible Ignition

High temperature. Keep combustible

material away from front of the heater.

The appliance must be kept clear and free

from combustible material, gasoline, and

other flammable vapor and liquids.

Clean the cabinet with a damp rag. Do not use abrasive

cleaners, as this may permanently damage the surface.

This heater is finished with a heat resistant polyester

powder baked finish. Do not refinish with wall paint.

WIRING DIAGRAM FOR MODEL CFWF920

To External

Low Voltage

Thermostat

Power Supply

Red

Yellow

Fan

Motor

Former

Red

Pilot

Light

Yellow

0

4

2

6

8

1

Yel

Control X-

L1

G

L2

Blk

Wht

Terminal Block

Danger of Bodily Injury

Turn off electric power supply at disconnect switch, fuse box, or service panel

before removing any doors or access or

service panels from unit.

1. Appliance Area

To more effectively heat your room and improve air circulation, do not place furniture closer than 4 feet to the front

of the cabinet or 2 feet to the side of the cabinet.

Auto Reset

Limit

Thermal Fuse

Element

Thermal Fuse

Element

9

Page 10

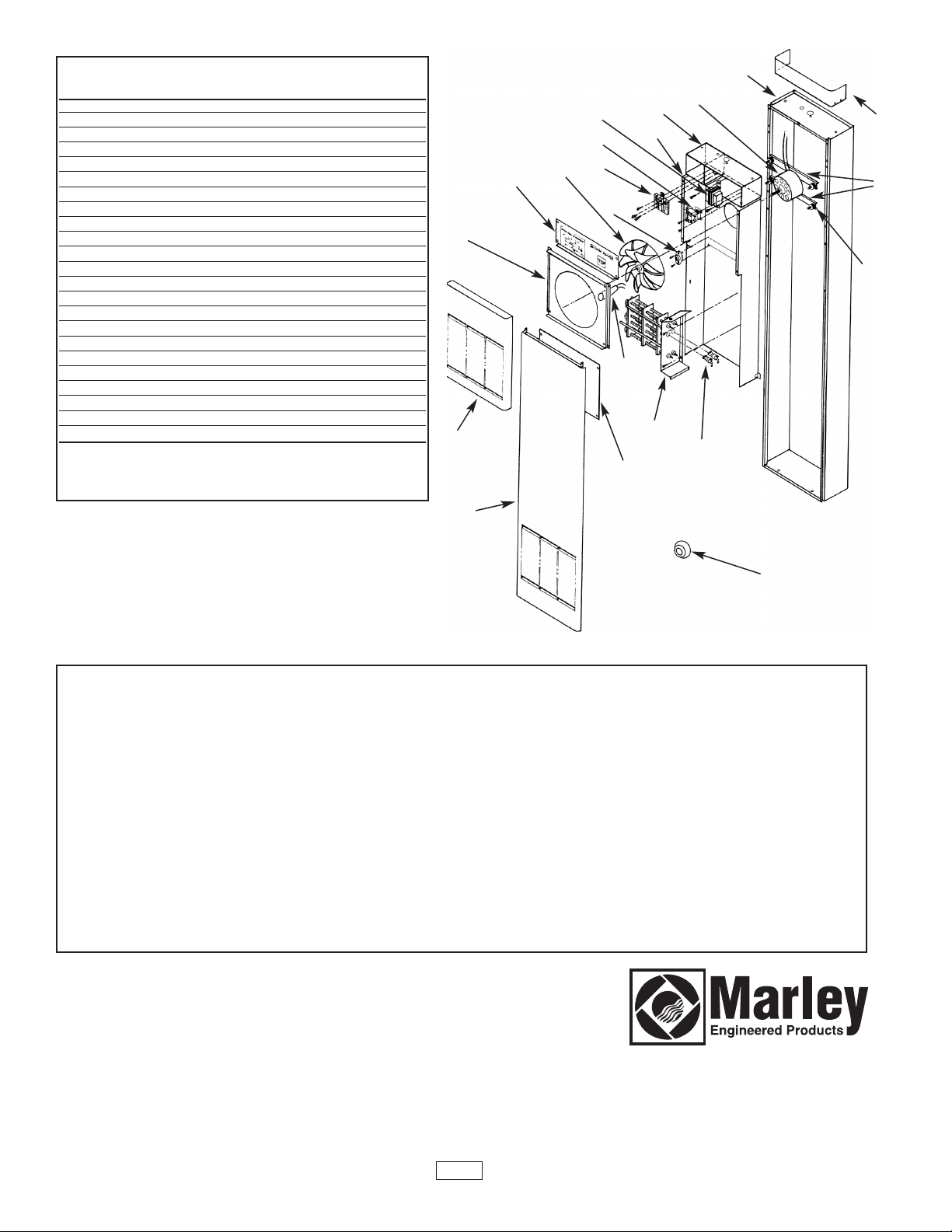

PARTS LIST FOR CFWF920

1

ITEM DESCRIPTION PART NUMBER

1 OUTER CASING 2701-2033-000

2 TOP FRONT PANEL 1402-2312-000

3 BOTTOM FRONT PANEL 1402-2313-000

4 TOP TRIM COVER 5806-2004-000

5 COVER, ELEMENT 1402-2282-000

6 WIRING BOX ASSY. 1217-2057-000

7 FAN PANEL 4513-2151-000

8 MOTOR 3900-2036-000

9 RELAY 5018-2017-001

10 TRANSFORMER 5814-0003-000

11 HIGH LIMIT 4520-2053-000

12 HEATING ELEMENT ASSY 1802-2117-000

13 FUSE LIMITER (2) + 4520-2052-000

14 POWER BLOCK 5823-0004-007

15 MOTOR BRACKET(2) 1215-2173-000

16 FAN BLADE ++ 1210-2009-000

17 PILOT LIGHT 3510-2001-000

18 MOTOR MOUNT (4) 3902-2004-000

19 WIRING BOX COVER 1402-2281-000

20 VENTURI PLATE 4503-2075-000

21 WALL THERMOSTAT T8775A1009

INSTRUCTIONS 5200-2484-VAR

+ The Fuse Limiter is not field replaceable and servicing

should be referred to a qualified service technician.

++ Fan blade appearance not as shown.

20

2

8

6

7

4

5

1

19

16

10

9

14

11

18

17

12

13

5

3

21

LIMITED WARRANTY

All products manufactured by Marley Engineered Products are warranted against defects in workmanship and materials for one year from date of installation, except

heating elements which are warranted against defects in workmanship and materials for five years from date of installation. This warranty does not apply to damage

from accident, misuse, or alteration; nor where the connected voltage is more than 5% above the nameplate voltage; nor to equipment improperly installed or wired or

maintained in violation of the productʼs installation instructions. All claims for warranty work must be accompanied by proof of the date of installation.

The customer shall be responsible for all costs incurred in the removal or reinstallation of products, including labor costs, and shipping costs incurred to return products to Marley Engineered Products Service Center. Within the limitations of this warranty, inoperative units should be returned to the nearest Marley authorized service center or the Marley Engineered Products Service Center, and we will repair or replace, at our option, at no charge to you with return freight paid by Marley. It is

agreed that such repair or replacement is the exclusive remedy available from Marley Engineered Products.

THE ABOVE WARRANTIES ARE IN LIEU OF ALL OTHER WARRANTIES EXPRESSED OR IMPLIED, AND ALL IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE WHICH EXCEED THE AFORESAID EXPRESSED WARRANTIES ARE HEREBY DISCLAIMED AND EXCLUDED

FROM THIS AGREEMENT. MARLEY ENGINEERED PRODUCTS SHALL NOT BE LIABLE FOR CONSEQUENTIAL DAMAGES ARISING WITH RESPECT TO THE

PRODUCT, WHETHER BASED UPON NEGLIGENCE, TORT, STRICT LIABILITY, OR CONTRACT.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above exclusion or limitation may not apply to you. This warranty

gives you specific legal rights, and you may also have other rights which vary from state to state.

For the address of your nearest authorized service center, contact Marley Engineered Products in Bennettsville, SC, at 1-800-642-4328. Merchandise returned to the

factory must be accompanied by a return authorization and service identification tag, both available from Marley Engineered Products. When requesting return authorization, include all catalog numbers shown on the products.

HOW TO OBTAIN WARRANTY SERVICE AND

WARRANTY PARTS PLUS GENERAL

INFORMATION

1. Warranty Service or Parts 1-800-642-4328

2. Purchase Replacement Parts 1-800-654-3545

3. General Product Information www.marleymep.com

Note: When obtaining service always have the following:

1. Model number of the product

2. Date of manufacture

3. Part number or description

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

Part No. 5200-2484-006

38748

05/10

10

Page 11

Generador eléctrico de aire

caliente de retrocirculación,

de pared.

Modelo No. Voltaje Vatios Amp. BTU/Hr.

CFWF920 240V 9.2KV 38 31,395

Instrucciones de instalación y mantenimiento

Estimado propietario:,

Felicitaciones! Gracias por comprar este nuevo calentador fabricado por de Marley Engineered

Products. Usted ha efectuado una sabia decisión al seleccionar el producto de la más alta calidad en la

industria de la calefacción. Por favor lea cuidadosamente las instrucciones de instalación y mantenimiento indicadas en este manual. Ud. debe gozar años de comodidad de calefacción eficiente con este

producto de Marley Engineered Products....el líder de la industria en diseño, fabricación, calidad y ser-

vicio.

... Los empleados de

Marley Engineered Products

!

ADVERTENCIA

Lea cuidadosamente -Antes de cablear o efectuar servicios técnicos,

desconecte toda alimentación eléctrica que llegue al panel principal de servicio del calefactor

PARA REDUCIR LOS RIESGOS DE INCENDIO Y CHOQUE ELECTRICO:

1. Antes de cablear o efectuar servicios técnicos, desconecte toda alimentación eléctrica que llegue al panel principal de servicio del calefactor.

NOTA: Pueden ser necesarias más de una desconexión.

2. Todo el cableado debe ser en concordancia con los códigos eléctricos

nacionales y locales y el calefactor debe tener toma de tierra.

3. Antes de conectar la alimentación eléctrica, verifique que el voltaje de

la fuente de alimentación que llega al calefactor sea igual al valor nominal impreso en la placa de identificación del calefactor.

4. Este calefactor se calienta cuando está en uso. Para evitar quemaduras, no deje que la piel desnuda toque las superficies calientes.

5. No inserte objetos extraños ni deje que entren a ninguna abertura

de ventilación o escape, dado que ello puede causar choque eléctrico, incendio o daños al calefactor.

6. No bloquee de ninguna manera las entradas de aire o el escape.

Mantenga los materiales combustibles separados. Mantenga materiales combustibles tales como cajones, cortinas, etc., alejados del

calentador. No instale detrás de puertas, muebles, toallas o cajas.No

lo instale detrás de puertas, muebles, toalleros o divisores de ambientes.

7. El calentador tiene piezas calientes o causantes de arco eléctrico

adentro. No lo use donde se usan o almacenan gasolina, pintura o

líquidos inflamables.

8. Use este calentador como se describe en este manual solamente.

Cualquier otro uso no recomendado por el fabricante puede causar

incendio, choque eléctrico o lesiones a las personas.

9. El calefactor no está autorizado para ser utilizado en atmósferas corrosivas tales como las náuticas, los viveros o las zonas de almacenamiento de productos químicos.

10. No instale este calentador en una alcoba.

11. No instale este calentador en un remolque de viaje o vehículo recreativo.

CONSERVE ESTAS HOJAS DE INSTRUCCIONES

Page 12

Descripción del CFWF920

Su generador eléctrico de aire caliente de retrocirculación, de

pared, se envía ensamblado para instalar en cualquier pared.

Puede empotrarse hasta 5-3/8 pulgadas (137mm) con los pernos

prisioneros separados a 16 pulgadas (406 mm) en el centro, o

puede montarse directamente sobre la superficie de la pared.

Este calentador funciona absorbiendo aire frío en la rejilla

superior de entrada e impulsándolo con un ventilador hacia abajo

sobre el elemento térmico. El aire caliente se descarga dentro del

cuarto a través de la rejilla inferior de salida, cerca del piso. El aire

caliente al nivel del piso crea un proceso convectivo suave en el

cuarto, evitando la estratificación del aire caliente cerca del cieloraso y asegurando el bienestar de los ocupantes.

Este calentador funciona con un voltaje de línea monofásica de

240V y produce 9.2KV de calor ó 31,395 BTU/Hr.

ubierta de la

C

caja de

empalme

Tornillos

El generador eléctrico de aire caliente de retrocirculación, de

pared, está controlado por un termostato de bajo voltaje montado

en la pared (provisto). La unidad está fabricada de acero de

grueso calibre con un acabado duradero de recubrimiento granu-

lar recocido.

Extracción del generador de la caja

La caja de transporte contiene el generador y las piezas requeridas para la instalación.

1. Mientras el calentador está todavía en la caja, levante directamente por el tope del mismo. Extraiga la cubierta de la

moldura superior con sus materiales de empaque y el juego

de ferretería (termostato, cable, y tornillos). Coloque este

juego de ferretería a un lado donde no pueda perderse o

dañarse.

2. Termine de extraer el calentador de la caja y coloque sobre

su parte posterior. Extraiga cuidadosamente los soportes

restantes de empaque alrededor del generador y coloque a

un lado.

3. Extraiga los tornillos del panel delantero superior. Tire

suavemente del panel hacia el tope del gabinete 1/2 pulgada

(13 mm) aprox. El panel se afloja. Extraiga el panel del gabinete y coloque el panel delantero superior y los tornillos a un

lado donde no se pierdan o dañen.

4. Impulse un poco la hélice del ventilador en sentido contrario

a las agujas del reloj para asegurarse que gira libremente.

5. Extraiga los cuatro tornillos que fijan la cubierta de la caja de

empalmes sobre el ventilador. Coloque la cubierta y los

tornillos a un lado donde no puedan perderse ni dañarse. La

caja de empalmes eléctricos y el transformador deben ser

accesibles ahora. Antes de intentar cablear su calentador

refiérase a la sección de "Cableado Eléctrico".

6. Extraiga los cuatro tornillos de montaje del panel delantero

inferior. Extraiga el panel del gabinete. Coloque el panel y

los tornillos a un lado donde no se pierdan ni dañen.

7. Antes de descartar el material de empaque, revíselo cuidadosamente por partes sueltas del generador. Descarte

apropiadamente el material de empaque (recicle).

Panel delantero

superior

Panel delantero

inferior

Figura 1

Accesorios opcionales

Juego de salida posterior CFWFRO

Este accesorio le permite derivar algo del aire calentado a un

segundo cuarto detrás del generador. La pared terminada de este

cuarto debe estar dentro de 10 pulgadas (254 mm) del generador.

El regulador integrado de tiro le permite cerrar la salida posterior,

rederivando todo el aire a la rejilla delantera de salida. Si se usa

este accesorio, debe cortarse la abertura en la parte posterior del

gabinete. Vea la sección de "Instalación opcional de la salida posterior".

12

Page 13

Cómo instalar su generador de pared

Para asegurar una instalación apropiada y una operación segura

de su Generador de Contracirculación, de Pared, siga cuidadosamente las instrucciones. Todo el cableado debe estar de acuerdo

con los códigos eléctricos nacionales y locales y el calentador

debe estar conectado a tierra como precaución contra un posible

choque eléctrico. Si usted no está seguro cuáles son los requer-

mientos, consulte con sus autoridades locales por los códigos

i

locales y estatales que afectan la instalación. Siempre obtenga

ayuda profesional cuando la necesite.

Figura 2

Pared

Ubicación del Generador de

Contracirculación de Pared y del Termostato

1. El generador puede montarse en la superficie o empotrado en

cualquier pared interior o exterior.

Nota: La salida opcional posterior (CFWFRO) puede usarse en

una pared interior solamente.

2. Este calentador puede empotrarse un máximo de 5-3/8 pulgadas (137 mm).

Nota: Inspeccione todas las distancias. El lado del generador

debe estar a 6 pulgadas (152 mm) de una esquina o de un divisor de pared.

Nota: Su generador de pared funciona mejor cuando está coloca-

do tan cerca del centro del espacio a calentar, como sea posible.

3. Asegúrese que el servicio eléctrico esté disponible en su ubicación deseada de instalación.

4. Para asegurar que hay distancias y accesos de servicio adecuados, el frente del calentador debe estar orientado hacia el

cuarto abierto. No coloque muebles directamente enfrente del

Generador de Contracirculación de Pared.

5. Ubique el termostato a 5 pies (152 cm) aproximadamente,

sobre el piso en una pared interior. Dado que usted desea que

el termostato detecte las temperaturas promedio del cuarto,

evite ubicaciones frías y ventosas y calurosas o soleadas, que

pueden confundir al mecanismo de detección en el termostato. Se le ha proporcionado 20 pies (610 cm) aproximadamente

de cable de termostato. Esto le debe permitir ubicar el termostato a 16 pies (489 cm) aproximadamente del generador si

el cable se tiende a través del altillo, 12 pies (366 cm) si se

tiende por debajo del piso.

6. Después de seleccionar una ubicación para su Generador de

Contracirculación, de Pared, asegúrese que no haya caños,

cables, etc. que interfieran con la ubicación del generador o del

termostato. De haberlos, seleccione otra ubicación.

6”

(152 mm)

Piso terminado

Distancia mínima

de 0"

Instalación de montaje empotrado

!

PRECAUCION

Para evitar un choque eléctrico, apague los circuitos eléctricos que pasan a través de la pared

donde usted está instalando el generador.

Si usted está usando la salida posterior opcional (CWWFRO),

referirse a la instalación de la salida posterior opcional en la página 7 antes de proceder.

Localización de los montantes verticales

de la pared

Use un localizador de montante vertical o clavos pequeños de

acabado. Introduzca y extraiga un clavo pequeño de acabado a

través de la superficie de la pared hasta que encuentre un montante vertical. A continuación localice el lado del montante vertical

usando la misma técnica. Dejando el clavo localizador en esa

posición, localice el otro lado del montante vertical. Una vez hecho

esto, usted tiene que poder localizar fácilmente el próximo montante vertical. El borde interior del próximo montante vertical debe

estar a 14-1/2 pulgadas (369 mm) aproximadamente, del montante vertical recién localizado.

13

Page 14

ota: SI LOS CENTROS DE LOS MONTANTES VERTICALES

C

L

N

NO ESTAN SEPARADOS POR 16 PULGADAS (406 mm), VEA

EL CIERRE DE LA DISTANCIA ENTRE MONTANTES VERTICALES EN LAS PAGINAS 4 Y 5.

Corte de aberturas en la pared

Refiérase a la Figura 3. Marque la abertura requerida en la pared.

La altura vertical dada incluye una tolerancia de 3 pulgadas (76

mm) adicionales para permitir espacio para cablear después de

haber instalado el generador.

Preliminares de la alimentación eléctrica

ENTRADA DEL CABLE DEL

NTRADA DEL CONDUCTO DE 3/4" (19 mm)

E

1/2”

13mm)

(

18-3/8”

(467mm)

TERMOSTATO DE 24V

179mm)

(

7”

6-1/8”(156mm)

2-1/4” (57mm)

(203mm)

4-1/8”

1

359mm)

(

RENTE

F

6-1/8”

156 mm)

(

8”

50 mm)

(

2”

1. Perfore orificios de entrada en la placa de la pared del cieloraso sobre el generador para encaminar los cables de alimentación eléctrica y el cableado del termostato al generador.

2. Si esto no es práctico, perfore orificios de entrada de 1 pulgada (25 mm) para el conducto eléctrico y 1/2 pulgada (13 mm)

para el cable del termostato, a través de cada pared del montante vertical sobre el generador y el cableado puede encaminarse desde un espacio adyacente del montante vertical.

Usted puede también encaminar el cableado desde el espacio

de gateo o sótano a un punto sobre el generador para corresponder con las aberturas en la Fig. 4.

3. Instale el conducto de manera que se extienda a 4 pulgadas

(102 mm) por debajo del tope de la abertura de la pared del

generador. Una (1) pulgada de conducto debe extenderse dentro del gabinete del generador (Vea la Fig.3).

NOTA: Puede usarse un conducto flexible sólo si cumple con los

códigos y ordenanzas locales.

1. Los cables de alimentación eléctrica, el cable de conexión a

tierra y los cables del termostato pueden encaminarse ahora

a las ubicaciones del generador. Vea INSTALACION DEL

TERMOSTATO, página 6, y CABLEADO ELECTRICO,

página 8.

2. Asegúrese que haya suficiente cable en el generador para

efectuar las conexiones dentro de la caja de empalmes del

generador.

PARTE `POSTERIOR

Figura 4

FRENTE

LADO

6-5/8”

168 mm

2-1/2”

7

(184cm)

ARCAS PARAEL

M

CORTE DE LA

SALIDA OPCIONAL

POSTERIOR

12”

(305 mm)

ISO TERMINADO

P

4-7/8”

124 mm)

(

8”

(203mm)

Cierre del espacio del montante vertical (si necesario)

Si los centros de los montantes verticales no están separados por

16 pulgadas (406 mm), corte el orificio para el Generador de

Contracirculación, de Pared, cerca de un montante vertical y

marco existentes, del otro lado, usando un 2x4 (u otro trozo de

madera según requerido) y bloques separadores o cuñas. Vea la

CONDUCTO

FLEXIBLE

CORTE DE PARED

PARA UNA SALIDA

OPCIONAL

POSTERIOR

CENTRADA ENTRE

LOS MONTANTES

VERTICALES

PISO

ACABADO

Figura 3

PLACA DEL

4”

(102mm)

6”

(152mm)

71-1/2”

(1816mm)

14-3/8”

(365mm)

75-1/2”

(1905mm)

12-1/4”

(311mm)

8-1/4”

(210mm)

3-3/4”(95mm)

CIELORASO

RESPALDO DE

2X4 SI HAY MAS

DE 16 ENTRE EL

TOPE DEL CORTE

Y LA PLACA DEL

CIELORASO

MONTANTE

VERTICAL

EXISTENTE

PLACA DEL

PISO

Figura 5

14-3/8”

(365mm)

MONTANTE

VERTICAL

EXISTENTE

NUEVO

MONTANTE

VERTICAL

BLOQUE

SEPARADOR

SEGUN

REQUERIDO

14

Page 15

ig. 5. En algunos cielorasos altos la distancia desde el tope del

F

corte a la placa de pared del cieloraso puede ser mayor de 18 pulgadas (457 mm). De ser el caso recomendamos que usted cierre

este espacio. Clave un 2x4 horizontalmente entre los montantes

erticales próximos para cerrar este espacio. Taladre orificios de

v

entrada en esto según sea requerido.

!

PRECAUCION

Para evitar un choque eléctrico, desconecte los circuitos eléctricos que pasan a través de la pared

donde usted está instalando el generador.

Instalación de montaje de superficie

Si usted usa la salida opcional posterior (CFWFRO), refiérase a la

Instalación de la Salida Opcional Posterior en la página 7 antes de

proceder.

Localización de los montantes verticales de

pared

Use un localizador de montante vertical o clavos pequeños de

acabado. Introduzca y extraiga un clavo pequeño de acabado a

través de la superficie de la pared hasta que encuentre un montante vertical. A continuación localice el lado del montante vertical

usando la misma técnica. Dejando el clavo localizador en esa

posición, localice el otro lado del montante vertical. Una vez hecho

esto, usted tiene que poder localizar fácilmente el próximo montante vertical. El borde interior del próximo montante vertical debe

estar a 14-1/2 pulgadas (369 mm) aproximadamente, del montante vertical recién localizado.

n la plancha de pared y permita que 1 pulgada (25 mm( se

e

extienda por debajo del tope del generador (71-1/2 pulgadas

(1816 mm) desde el piso terminado). Ver la Fig.3, página 4.

6. Usted puede ahora encaminar los cables de alimentación eléctria, el cable de conexión a tierra y los cables del termostato a las

c

ubicaciones del generador. Vea INSTALACION DEL TERMOSTATO, página 6, y CABLEADO ELECTRICO, página 9.

Instalación del Termostato

Encaminado del cable del termostato

CLAVO

PEQUEÑO DE

CABADO PARA

A

LOCALIZAR EL

CABEZAL

CABLE DEL

TERMOSTATO

Corte de la abertura de pared

Si usted usa la salida posterior opcional (CFWFRO), corte la abertura de 8-1/4 pulgadas (210 mm) por 12-1/4 pulgadas (311 mm)

SOLO según se muestra en la Fig.3, página 4. Refiérase a instalación de la salida posterior opcional en la página 7 antes de proceder.

1. Si no es práctico encaminar el cableado al generador desde el

altillo, pueden perforarse orificios de entrada de 1 pulgada (25

mm) para el conducto eléctrico y 1/2 pulgada (13 mm) para el

cable del termostato, a través de cualquier montante vertical de

pared sobre el generador y el cableado puede encaminarse

desde un espacio adyacente de montante vertical. Usted puede

también encaminar el cableado desde el espacio de gateo o

sótano a un punto arriba del generador para corresponder con

las aberturas en la Fig.4.

2. Para encaminar el conducto, los cables de alimentación eléctrica

y los cables del termostato, en la plancha de pared sobre la ubicación del generador.

3. La abertura de alimentación eléctrica debe estar ubicada a 2 pulgadas (51 mm) sobre el tope del generador para corresponder

con la abertura mostrada en la Fig. 4, página 6.

4. Taladrar un orificio de 1 pulgada (25 mm) para el cableado de alimentación eléctrica y un orificio de 1/2 pulgada (13 mm) para los

cables del termostato en las ubicaciones seleccionadas.

5. Encaminar el conducto flexible al orificio de 1 pulgada (25 mm)

CABLE RIGIDO

PARA ENGAN-

Figura 6

CHAR EL CABLE

1. El cable del termostato debe tenderse a la ubicación seleccionada. Todo el cableado debe cumplir con los códigos y ordenanzas locales. Esas instrucciones describen como cablear el

termostato desde el altillo pero puede provenir también del

sótano o del espacio de gateo.

2. Localizar el termostato y a continuación clave un clavo pequeño

a travésdel cieloraso en la esquina de la pared y cieloraso sobre

la ubicación del termostato. Saque el clavo y empuje un cable

rígido pequeñoa través del orificio paraubicar el cable en el altillo. A continuación taladre un orificio de 1/2 pulgada (13 mm) a

través de la pared en la ubicación seleccionada para el termostato.

3. Usando un alambre rígido, sondee para obstrucciones en la

pared. Luego perfore un hueco de 13 mm (1/2 pulgada) a través

de la pared en la locación seleccionada para el termostato.

4. Alimente el cable del termostato desde el cieloraso dentro de la

pared. Enganche el cable del termostato a través de la pared y

tire de manera que sobresalgan 6 pulgadas (152 mm).

5. Encamine el cable al Generadorde Contracirculación, de pared.

15

Page 16

Montaje del Termostato

. Lea las instrucciones para el termostato. Sujete la cubierta del

1

termostato y tire suavemente de ella hacia afuera por su parte

superior para desmontarla.

2. Conecte los conductores para el termostato en las terminales

e tornillo identificadas como R y W en la base.

d

3. Empuje todo el excedente de conductor hacia afuera a través

del agujero en la pared y tape el agujero con material aislante

para impedir que las corrientes de aire afecten el funcionamiento del termostato.

4. Sujete la base del termostato en la pared a través de los agu-

jeros de montaje con los tornillos suministrados.

5. Disponga los conmutadores DIP a: 1-ON, 2-OFF y 3-OFF.

6. Reinstale la cubierta del termostato.

Montaje de su generador

NOTA: Si está instalando la salida posterior opcional CFWFRO,

refiérase a la Instalación de la Salida Posterior Opcional en la

página 7 antes de proceder.

1. Si ha seleccionado empotrar su calentador, limpie el recinto

de todos los desechos de construcción.

2. Mueva el generador vertical a su posición. Introduzca el conducto flexible a través del orificio provisto al tope del generador.

3. Fije el tope del generador (montaje empotrado) a los montantes verticales a través de los orificios provistos, dentro de

las bridas del tope usando dos (2) tornillos largos provistos.

Ver la Fig.8.

Figura 7

NOTA: NO SE MUESTRAN LOS

COMPONENTES INTERNOS POR

CLARIDAD

FIJACION DEL FONDO EN

MONTAJE DE SUPERFICIE

EN CASO DE PISO DE

CONCRETO

FIJACION DEL FONDO

A

FIJACION DEL

TOPE EN EL MONTAJE EMPOTRADO

FIJACION DEL TOPE

N MONTAJE DE

E

SUPERFICIE

IJACION DEL FONDO

F

EN MONTAJE EMPOTRADO EN CASO DE

PISO DE CONCRETO.

L PISO DE MADERA

ANCLAS DE METAL

NOTA: NO USE LOS ORIFICIOS DEL FONDO DE LA

PUERTA PARA MONTAR EL GENERADOR

Fijación del tope del generador

(Montaje de superficie)

Fije el tope del generador a la pared usando dos (2) anclas de

metal (envasadas en el juego de ferretería) colocándolas sobre la

brida posterior del tope del generador y atornillándolas a la pAred

con dos (2) tornillos largos provistos. Vea la Fig.8.

Nota: Algunos sujetadores (pernos) no se proveen y algunos

huecos no se han hecho previamente ya que se pueden presentar muchas situaciones diferentes de construcción.

Sujetadores apropiados para usar pueden ser comprados en

su ferreteria local.

Fijación del fondo del generador

(Montaje de superficie y empotrado)

Taladre dos (2) orificios en el fondo del gabinete del generador,

cerca de cada lado. Fije el generador a través de esos orificios, al

piso. Si su piso es de concreto, use la ubicación alternativa de

fijación según se muestra en la Fig.7.

Figura 8

Figura 9

PLANCHA DE YESO

CLAVE LA PLANCHA DE YESO AL

MONTANTE VERTICAL DE PARED

(SE REQUIERE UNA BOTA DE MONTAJE DE 10 PULGADAS)

MONTAJE EMPOTRADO

TORNILLOS

REJILLA

EMPOTRAMIENTO

MAX.

5-3/8" (137 MM)

16

Page 17

Instalación de la salida posterior opcional

Generador de montaje empotrado

1. Corte un orificio de 8-1/4 de pulgada (210 mm) x 12-1/4 puladas (311 mm) en la pared según se muestra en la Fig. 3,

g

página 4.

2. Hay cuatro orificios de forma de diamante al fondo del gabi-

nete en el panel posterior. Usando esos orificios de forma de

iamante, trace líneas rectas para marcar su contorno para el

d

CFWFRO y corte su abertura.

3. Monte el generador en el recinto. (Vea Montaje de su

Generador, Página 3)

. Coloque su plancha de yeso en la abertura y clave a los mon-

4

tantes verticales. (Fig. 8)

Nota: En construcción nueva, instale la plancha de yeso

antes de aplicar el acabado de la pared. En construcción de

tabique de yeso y cartón, puede omitirse la plancha de yeso.

5. Centre la parrilla sobre el orificio en la pared posterior y mar-

que la ubicación de los orificios de la rejilla en la pared.

6. Con una broca de taladro de 1/8 de pulgada, taladre dos (2)

orificios a través del yeso o del tabique de cartón y yeso y del

gabinete, para fijar la rejilla.

7. Fije la rejilla con los tornillos provistos (Fig.10). No se requiere

la bota de 10 pulgadas, para una instalación empotrada.

MONTAJE DE SUPERFICIE

BOTA CORTADAAL RAS CON LA PARED)

(

TORNILLOS

REJILLA

BOTA

TORNILLOS

Figura 10

12. Fije la rejilla con los tornillos provistos (Fig.10).

!

ADVERTENCIA

Peligro de daño a la propiedad,

lesiones corporales o muerte

1/2”

TO

10”

Generador de Montaje de Superficie

1. Corte un orificio de 8-1/4 de pulgada (210 mm) x 12-1/4 pul-

gadas (311 mm) en la pared según se muestra en la Fig. 3,

página 4.

2. Hay cuatro orificios de forma de diamante al fondo del gabi-

nete en el panel posterior. Usando esos orificios de forma de

diamante, trace líneas rectas para marcar su contorno para el

CFWFRO y corte su abertura.

3. Coloque la bota contra el gabinete con el lado interno de la

bota exactamente en los bordes del orificio.

4. Marque las ubicaciones del tornillo, extraiga la bota y taladre

orificios para los tornillos de láminas de metal.

5. Fije la bota a la parte posterior del generador con los tornillos

provistos.

6. Coloque la plancha de yeso en la abertura y clave a los mon-

tantes verticales (Fig.8)

Nota: En construcción nueva, instale la plancha de yeso antes de

aplicar el acabado de la pared.

7. Coloque el generador con la bota fijada a través del orificio de

la pared y marque el extremo de la bota para que se pueda

cortar al ras con la pared externa.

8. Extraiga el generador de la pared y corte la bota donde está

marcado.

9. Coloque el generador con la bota cortada fijada, a través de

los orificios en la pared y monte el generador. (Vea Montaje

de su Generador, página 6).

10. Centre la rejilla sobre el orificio en la pared posterior y mar-

que la ubicación de los orificios de la rejilla en la pared.

11. Con un broca de taladro de 1/8 de pulgada, taladre dos (2)

orificios a través de la plancha de yeso y yeso (o tabique de

cartón y yeso).

ANTES DE EFECTUAR CONEXIONES ELEC-

TRICAS DESCONECTE LA ELECTRICIDAD

EN LA CAJA DE FUSIBLES O EN EL PANEL

DE SERVICIO.

AISLE CUANDO SEA NECESARIO...

DEBE COMPLETARSE TODO EL VOLTAJE DE

LINEA Y LAS CONEXIONES

A

TIERRA ANTES DE CONECTAR LA ELECTRICIDAD

!

PRECAUCION

Rotule todos los cables previo a desconectar

al prestar servicio. Los errores de cableado

pueden causar una operación inapropiada y

peligrosa. Verifique que opere a propiadamente después de prestar servicio.

Toda la instalación eléctrica debe conformar

con sus códigos y ordenanzas locales y con

los Códigos Eléctricos Nacionales.

17

Page 18

Alimentación de corriente eléctrica

AL TERMOSTATO

Su Generador de Contracirculación, de Pared, requiere un circuito

de 240 voltios, 60 ciclos, 40 amperios de un interruptor separado

de circuito o fusible en su panel de servicio. No tienda cables de

alimentación dentro del gabinete del generador, excepto desde el

ope del gabinete hacia abajo a la caja de empalmes.

t

Caja de empalmes

as conexiones de alimentación de electricidad se efectúan den-

L

tro de la caja de empalmes ubicada en el extremo superior del

gabinete. Vea la Fig.11 y la Fig.1, página 2.

Conexión eléctrica

Conecte el conducto de 240V al tope del generador según se

muestra en la Fig. 11. Estirar los alambres de alimentacion a

través del conducto y dentro de la caja de empalmes. Fije los

cables de alimentación de 240V a la conexión de "LINE" ("LINEA")

en el tablero terminal. Si no se siente cómodo haciendo esto,

refiérase al diagrama de cableado en la placa de la cubierta de la

caja de empalme, o, si tiene dudas con respecto al cumplimiento

con el código, consulte con su inspector eléctrico o con un electricista licenciado.

Conexión a tierra

Proporcione una conexión a tierra desde el panel terminal de la

unidad a una conexión conectada a tierra en el panel eléctrico de

servicio o a una varilla conectada a tierra bien clavada y eléctricamente conectada a tierra.

Conexiones de bajo voltaje

Tienda el cable del termostato al generador. Vea INSTALACION

DEL TERMOSTATO, página 6.

CONDUCTO

CABLES DE

LIMENTACION

A

AJA DE

C

MPALME

E

VEA ARRIBA EL

DIAGRAMA DE

CONEXION DEL

CABLE

ABLERO

T

TERMINAL

ELECTRICA-240V

LINEA 1

CONEXION

A TIERRA

UNA CONEXION

A

A TIERRA

APROBADA

LINEA 2

Figura 11NOTA: NO SE MUESTRA TODO EL CABLEADO

mayor que usted considere que es cómoda. Permita que el calentador funcione y cuando el cuarto alcance una temperatura cómoda, ajuste lentamente el dial en sentido contrario a las agujas del

reloj hasta que el calentador se pare. El termostato mantiene esta

temperatura.

Este calentador está equipado con un mecanismo de regraduación automática de temperatura excesiva. Este mecanismo

para el calentador si funciona a una temperatura anormal.

También, se enciende una luz piloto ubicada en el tope derecho

del panel del ventilador (visible a través de la rejilla). Cuando el

Conecte los cables del termostato a los dos cables (termostato)

que se extienden dentro de la caja de empalmes. Refiérase al diagrama de cableado en la placa de la cubierta de la caja de

empalmes y la Fig.11.

Vea los pasos 1, 2 y 3 debajo, cuando se ha completado el montaje del generador.

Refiérase a la Fig. 1, página 2.

1. Vuelva a colocar la placa de la cubierta de la caja de

empalmes. Ajuste seguramente los tornillos.

2. Vuelva a colocar el panel delantero del fondo.

3. Vuelva a colocar el panel delantero del tope.

Nota: Para las conexiones de alimentación, use cables de 6 AWG

o mayores usables para 60C(140F) por lo menos. Use cable de

cobre solamente..

Operación de su generador

Este generador está controlado por un termostato de pared de

24V, que está incluido. Gradúe el termostato a una temperatura

!

ADVERTENCIA

Si se enciende esta luz, significa que su calentador

está operando anormalmente. Inspeccione por

obstrucciones del aire y destape. Consulte con un técnico calificado de servicio, si esto no resuelve su

problema.

calentador se enfría a un nivel normal, el regraduador automático

restaura la operación y se apaga la luz piloto.

Además, su calentador está equipado con microlímites térmicos

de temperatura (de un tiro) para proteger contra incrementos

excesivos y prolongados de corriente. Si ese(os) mecanismo(s)

abre(en) el circuito térmico, el (los) límite(s) deben volverse a colocar por un técnico calificado de servicio, que determinará y corregirá también, la causa de la falla.

Puede ajustarse el volumen de aire si usted ha instalado la rejilla

posterior CFWFRO. No intente reducir el flujo de aire desde la

rejilla delantera. El hacerlo causa que los mecanismos de límite

apaguen el calentador. No obstruya la rejilla delantera o posterior,

si así equipado.

18

Page 19

Como cuidar su generador

Cuidado anual

!

ADVERTENCIA

Antes de extraer puertas o paneles de acceso o servicio de la unidad, desconecte la alimentación de electricidad en el conmutador desconectador, caja de

fusibles o del panel de servicio.

1.Elemento térmico y salida posterior opcional

Mantenga limpio en todo momento. Use un cepillo suave o aspiradora de todos los materiales extraños desde las rejillas de entrada y salida (y de la rejilla posterior de salida, si instalada). Para

ganar acceso al elemento térmico extraiga dos (2) tornillos (Fig. 1,

página 2) y sujete el fondo del panel posterior. Tire hacia arriba y

afuera. Vuelva a colocar el panel, después de limpiar los elementos térmicos y la salida posterior opcional.

2. Motor y Ventilador

Para obtener la duración máxima de su ventilador usted debe

limpiar el polvo (aspirando o soplando) de los orificios de ventilación. Debe agregar también unas pocas gotas de aceite no

detergente No. 20 a la cavidad del cojinete (Vea la Fig.12).

Figura 12

AVIDADES DEL

C

COJINETE

!

PRECAUCION

OTOR DEL

M

VENTI-

ADOR

L

Fuente posible de ignición

Alta temperatura. Mantenga el material combustible alejado del frente del calentador. El

artefacto debe mantenerse limpio y libre de

material combustible, gasolina y otros

vapores y líquidos inflamables.

2. Acabado del gabinete

Para ganar acceso al motor

A. Extraiga los cuatro tornillos que fijan la cubierta del ventilador a

las bridas laterales del gabinete o extraiga la cubierta (Fig. 1,

página 2).

B. Precaución: Antes de extraer , asegúrese de marcar la posición

de la hélice del ventilador en relación con el eje del motor.

Revise la tuerca de la hélice y el tramo de eje visible. Marque el

eje del motor con una rayadura o de otra manera para volver a

instalar el ventilador en su posición original.

C. Afloje el tornillo de posición de "cabeza allen" de 5/32 pulgadas,

que fija la hélice del ventilador al eje del motor y extraiga la

hélice del ventilador. Se provee una llave para este fin.

D. Invierta los pasos 1-3 para reemplazar la hélice del ventilador.

!

ADVERTENCIA

Peligro de lesión corporal

Antes de extraer puertas o paneles de acceso o servicio de la unidad, desconecte la alimentación eléctrica en el conmutador desconectador, caja de fusibles o

panel de servicio.

Limpie el gabinete con un trapo húmedo. No use limpiadores abrasivos, ya que pueden dañar permanentemente la superficie. Este

calentador se acaba con un acabado recocido de polvo de

poliéster térmicamente resistente. No reacabe con pintura de

pared.

DIAGRAMA DE CABLEADO PARA EL MODELO CFW920

Al termostato

externo de

bajo voltaje

Límite de reposición

Fusible térmico

Suministro eléctrico

Rojo

Bloque de terminales

Amarillo

Motor del

ventilador

automática

Elemento

de control

Luz

piloto

Rojo

Amarillo

0

4

2

6

8

1

Amarillo

ransformador

T

L1

L2

G

Negro

Blanco

1. Area del artefacto

Para calentar más efectivamente su cuarto y mejorar la circulación

de aire, no coloque los muebles cerca de 4 pies del frente del gabinete o 2 pies del lado del gabinete.

Fusible térmico

Elemento

19

Page 20

20

Page 21

LISTA DE PIEZAS PARA EL CFWF920

ART. DESCRIPCION NO. DE PIEZA

1 BASTIDOR EXTERNO 2701-2033-000

2 PANEL DELANTERO SUPERIOR 1402-2312-000

3 PANEL DELANTERO INFERIOR 1402-2313-000

CUBIERTA DE LA MOLDURA SUPERIOR 5806-2004-000

4

5 CUBIERTA DEL ELEMENTO 1402-2282-000

6 CAJA DE CABLEADO 1217-2057-000

PANEL DEL VENTILADOR 4513-2151-000

7

MOTOR 3900-2036-000

8

RELE 5018-2017-001

9

10 TRANSFORMADOR 5814-0003-000

1 LIMITE ALTO 4520-2053-000

1

2 ELEMENTO TERMICO 1802-2117-001

1

3 LIMITADOR DE FUSIBLE (2) + 4520-2052-000

1

14 BLOQUE DE POTENCIA 5823-0004-007

15 SOPORTE DEL MOTOR (2) 1215-2173-000

6 HELICE DEL VENTILADOR ++ 1210-2009-000

1

7 LUZ PILOTO 3510-2001-000

1

18 MONTURA DEL MOTOR (4) 3902-2004-000

9 CUBIERTA DE CAJA DE CABLEADO 1402-2281-000

1

0 PLACA DE VENTURI 4503-2075-000

2

1 TERMOSTATO DE PARED T8775A1009

2

+ El limitador de fusibles no se reemplaza en el campo y

el servicio debe referirse a un técnico calificado de servicio.

++ La apariencia de la hélice del ventilador no es como

ilustrada.

INSTRUCCIONES 5200-2484-VAR

20

2

19

16

9

14

10

11

17

5

7

12

1

8

6

4

5

1

18

13

3

21

GARANTIA LIMITADA

Todos los productos fabricados por Marley Engineered Products se garantizan contra defectos en mano de obra y materiales por un año a partir de la fecha de instalación,

excepto los elementos térmicos que están garantizados contra defectos en mano de obra y materiales por cinco años a partir de la fecha de instalación. Esta garantía no

se aplica a daños causados por accidente, mal uso o alteración; ni tampoco donde el voltaje conectado es mayor de 5% del voltaje de la placa de nombre; ni al equipo

instalado o cableado o mantenido impropiamente en violación de las instrucciones de instalación del producto. Todos los reclamos por trabajo de garantía deben estar acompañados por prueba de la fecha de instalación.

El cliente será responsable por todos los costos incurridos en la extracción o reinstalación de los productos, incluyendo costos de mano de obra y costos de transporte incurridos en devolver los productos al Centro de Servicio de Marley Electric Heating, y repararemos o reemplazaremos, a nuestra opción, sin cargo para Ud., con el flete de

retorno pagado por Marley. Se acuerda en que tal reparación o reemplazo es el remedio exclusivo disponible de Marley Electric Heating.

LAS GARANTIAS DE ARRIBA SON A CAMBIO DE TODAS LAS OTRAS GARANTIAS EXPRESAS O IMPLICITAS Y TODAS LAS GARANTIAS EXPRESAS DE COMERCIALIZACION Y APTITUD PARA UN PROPOSITO PARTICULAR QUE EXCEDAN LAS GARANTIAS EXPRESAS MENCIONADAS PREVIAMENTE SON RECHAZADAS

Y EXCLUIDAS DEL PRESENTE ACUERDO. MARLEY ELECTRIC HEATING NO SERA RESPONSABLE POR PERJUICIOS CONSECUENTES ORIGINADOS CON

RESPECTO AL PRODUCTO, YA SEA BASADO EN NEGLIGENCIA, LEY, RESPONSABILIDAD ESTRICTA O CONTRATO.

Algunos Estados no permiten la exclusión o limitación de perjuicios incidentales o consecuentes, de manera que la exclusión o limitación de arriba puede no aplicarse a

Ud. Esta garantía le otorga derechos legales específicos, y Ud. también puede tener otros derechos que varían de Estado a Estado.

Consulte con Marley Engineered Products en Bennettsville, SC, al 1-800-642-4328, para la dirección de su centro autorizado de servicio más cercano. La mercadería

devuelta a la fábrica debe estar acompañada por una autorización de devolución y una etiqueta de identificación de servicio, ambos disponibles de Marley Electric Heating.

Incluya todos los números de catálogo mostrados en los productos, al requerir autorización de devolución.

CÓMO OBTENER SERVICIO EN GARANTÍA, PIEZAS DE

REPUESTO E INFORMACIÓN GENERAL

1. Servicio o repuestos, en garantía: 1-800-642-4328

2. Compra de piezas de repuesto: 1-800-654-3545

3. Información general sobre productos: www.marleymep.com

Nota: cuando solicite servicio, siempre dé la información que sigue:

1. Número de modelo del producto

2. Fecha de fabricación

3. Número de parte o descripción

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

Part No. 5200-2484-006

38748

05/10

20

Page 22

Radiateur mural à

contrecourant

N° de modèle Tension Watts A BTU/h

CFWF920 240V 9,2kW 38 31,395

Notice dʼinstallation et dʼentretien

Cher utilisateur,

Félicitations ! Nous vous remercions d'avoir fait l'acquisition de ce nouveau radiateur fabriqué par de

Marley Electric Heating. Vous avez fait un bon investissement en choisissant un appareil de qualité imbattable. Veuillez lire attentivement et suivre scrupuleusement les consignes de ce manuel concernant l'installation et l'entretien. Nous sommes sûrs que vous bénéficierez de nombreuses années de confort grâce

à cet appareil de chauffage efficace de Marley Electric Heating... le numéro 1 du secteur du chauffage en

matière de conception, fabrication, qualité et service.

...Les employés de

Marley Electric Heating

!

! AVERTISSEMENT !

Lire attentivement -Ces instructions ont été écrites pour vous

aider à éviter toute difficulté durant l'installation des radiateurs. Si

vous étudiez ces instructions, vous pourrez plus tard gagner du

temps et économiser des frais. En suivant les conseils ci-après,

vous réduirez vos délais d'installation au minimum.

POUR RÉDUIRE LES RISQUES D'INCENDIE ET

D'ÉLECTROCUTION :

1. Sur le tableau de jonction principal, déconnectez toutes les arrivées

électriques au radiateur avant de commencer le câblage ou une réparation.

2. Tous les fils électriques doivent respecter la réglementation gouvernementale en vigueur et le radiateur doit être mis à la terre.

3. Avant de mettre sous tension, assurez-vous que l'alimentation électrique arrivant au radiateur correspond aux capacités nominales

imprimées sur la plaque signalétique de l'appareil.

4. Ce radiateur devient chaud lorsqu'il est utilisé. Pour éviter les

brûlures, ne touchez à aucune surface chaude sans vous protéger al

peau.

5. Il ne faut jamais insérer ou ni laisser des corps étrangers pénétrer

dans une ouverture dʼévacuation ou dʼaération, ce qui risquerait de

provoquer une électrocution, un incendie ou divers dommages au

radiateur.

6. Il ne faut jamais obstruer les ouvertures d'admission ou d'évacuation

d'air. Garder les matériaux combustibles (palettes de bois, rideaux,

etc.) à bonne distance du radiateur. Il ne faut jamais lʼinstaller derrière

une porte, un meuble, des serviettes ou des boîtes.

7. Ce radiateur possède des composants internes pouvant chauffer ou

produire des étincelles. Il ne faut donc pas lʼutiliser dans un endroit où

quelquʼun conserve ou utilise de lʼessence, de la peinture ou dʼautres

liquides inflammables.

8. Ce radiateur ne doit être utilisé que pour les utilisations prévues dans

ce manuel. Toute autre utilisation non recommandée par le fabricant

risque de causer un incendie, une électrocution et des blessures.

9. Ce radiateur n'est pas homologué pour une utilisation dans une atmosphère très corrosive comme celle d'un bateau, d'une serre ou d'un

site d'entreposage de produits chimiques.

10. Il ne faut pas installer ce radiateur dans une alcôve.

11. Il ne faut pas installer ce radiateur dans une roulotte ou dans un

véhicule de camping.

CONSERVEZ CES FEUILLES D'INSTRUCTIONS

Page 23

Description du radiateur CFWF920

Votre radiateur mural à contre-courant est expédié entièrement

assemblé, prêt à être installé contre un mur. Il peut être encastré

sur une profondeur atteignant 5 3/8 po (137 mm) avec des pièces

de colombage espacées de 16 po (406 mm) entre leurs centres,

mais il peut également être installé directement sur le mur.

Ce radiateur fonctionne en aspirant de lʼair frais par la grille dʼadmission supérieure, puis en poussant cet air vers le bas à lʼaide

dʼun ventilateur, jusquʼà lʼélément chauffant. Lʼair chauffé est alors

envoyé dans la pièce par la grille dʼévacuation inférieure, près du

sol. Lʼair chaud qui se trouve près du sol crée ensuite un mouve-

ent de convexion agréable, qui empêche toute accumulation

m

dʼair chaud à proximité du plafond, afin que les occupants aient un

confort maximum.

Le radiateur fonctionne avec une tension monophasée sous 240 V

et produit une chaleur de 9,2 kW (ou 31 395 BTU/heure).

Il est commandé par un thermostat mural à tension basse (fourni).

Votre radiateur est fabriqué en acier épais, recouvert dʼun revêtement pulvérisé durable, cuit après application.

Procédure de déballage du radiateur

La boîte dʼexpédition contient le radiateur, ainsi que les pièces

nécessaires à son installation.

Couvercle de la

boîte de jonction

Vis

Panneau

supérieur avant

Panneau

inférieur avant

1. Alors que le radiateur se trouve toujours dans la boîte, saisissez le dessus du radiateur et soulevez en tirant droit vers le

haut. Enlevez la moulure supérieure, ainsi que les matériaux

dʼemballage et le kit dʼaccessoires (thermostat, fil et vis).

Placez ce kit dʼaccessoires dans un endroit sûr, où il ne sera

pas endommagé.

2. Finissez de sortir le radiateur et déposez-le sur son panneau

arrière. Enlevez délicatement les autres supports dʼemballage

qui restent autour du radiateur et mettez-les de côté.

3. Enlevez les vis sur le panneau supérieur avant. Tirez délicatement ce panneau vers le haut du radiateur sur environ 1/2 po

(13 mm). Le panneau devrait se libérer. Enlevez complètement

le panneau et mettez-le de côté, avec les vis, dans un endroit

sûr, à lʼabri de tout dommage.

4. Donnez une petite poussée sur une pale du ventilateur (dans le

sens anti-horaire) pour vous assurer quʼelle tourne librement.