Page 1

D Series

Commercial

FILE #E37116

Baseboard Heater

Installation, Operation & Maintenance Instructions

IMPORTANT INSTRUCTIONS

GENERAL

This heater is designed to provide years of efficient, trouble free operation as a primary or supplementary heat source for comfort

heating in residential and commercial applications. Baseboard heaters must be thermostatically controlled for efficient, safe operation. A thermostat is not provided with this heater. However, a single or double pole thermostat accessory is available for installation into this heater at your place of purchase, or the heater may be connected to any suitable wall mounted thermostat that will

meet the electrical load requirements. Installation or use of this product in any manner not described herein will void the warranty

and could result in injury, damage to property, or permanent damage to heater.

WARNING

WHEN USING ELECTRICAL APPLIANCES, BASIC PRECAUTIONS SHOULD ALWAYS BE FOLLOWED TO REDUCE

THE RISK OF FIRE, ELECTRIC SHOCK, AND INJURY TO

PERSONS, INCLUDING THE FOLLOWING:

1. Read all instructions before installing or using the heater.

2. A heater has hot and arcing or sparking parts inside. Do not

use in areas where gasoline or flammable liquids are used

or stored.

3. This heater is hot when in use. To avoid burns, do not let

bare skin touch hot surfaces. Keep combustible materials,

such as furniture, pillows, bedding, papers, clothes, and curtains away from heater.

SAVE THESE INSTRUCTIONS

!

4. To prevent a possible fire, do not block air intakes or

exhaust in any manner.

5. Do not insert or allow foreign objects to enter any ventilation

or exhaust opening as this may cause an electric shock or

fire, or damage the heater.

6. Serious injury or death could result from electric shock.

Make sure electrical power supply circuit coming to heater

is disconnected at main disconnect or service panel before

installing or servicing this heater.

Page 2

INSTALLATION INSTRUCTIONS

2

" (51mm) CLEARANCE

(MIN)

1" (25mm) CLEARANCE

(

MIN)

BASEBOARD HEATER

E

XAMPLE 1

WALL

F

LOOR

C

EILING

1" (25mm) CLEARANCE

(MIN)

DRAPERY

6" (152mm) CLEARANCE

(

MIN)

BASEBOARD HEATER

E

XAMPLE 2

WALL

F

LOOR

C

EILING

DRAPERY

1

" (25mm) CLEARANCE

(MIN)

TO REDUCE THE RISK OF FIRE AND ELECTRIC SHOCK

OR INJURY TO PERSONS, OBSERVE THE FOLLOWING:

1. Serious injury or death could result from electric shock.

Make sure electrical power supply circuit coming to heater

is disconnected at main disconnect or service panel before

installing this heater.

2. Wiring procedures and connections must be in accordance

with the National Electrical Code (NEC) and local codes.

Refer to Wiring Diagram Figures 6 and 10 as well as Tables

1 and 2. Make sure all electrical connections are tight to

prevent possible overheating. Use Copper Supply Wire

Only.

3. Verify the electrical power supply voltage matches the voltage rating as printed on the heater nameplate.

CAUTION - Never connect a heater to a voltage greater than

the nameplate voltage as this will damage the heater and

could cause a fire.

4. Check to see that all packing pads and materials are

removed from heater before installing.

5. Do not install the heater against combustible low-density

cellulose fiberboard surfaces, against or below vinyl wall

coverings, or below any materials that may be damaged by

heat such as vinyl or plastic blinds, curtains, etc.

6. Do not install heater below an electrical convenience receptacle (outlet).

CAUTION

7.

Electrical Cords (including telephone and computer cables),

Drapes, and Other Furnishings Away From Heater. For efficient and safe operation, we recommend maintaining a minimum of 6 inches (152 mm) clearance above and in front of

the heater at all times. See Clearances section and Figure

1 for minimum clearance requirements.

8. To reduce the risk of fire, do not store or use gasoline or

other flammable vapors or liquids in the vicinity of the

heater.

9. Do not install heater upside down or in any position other

than as shown in this manual.

10. Do not recess heater in wall or install heater inside any type

enclosure (unless specifically approved by the manufacturer) as this will cause heater to overheat and could create a

hazard.

11. When mounting heater, use care when drilling mounting

holes and mounting heater to building structure to avoid

damaging internal heater components. Be sure to loosen

mounting screws ½ turn to allow for expansion and contraction.

12. Do not remove or bypass the safety limit control(s) as this

could allow heater to become a fire hazard – see heater

wiring diagrams Figures 6 and 10.

13. All field wiring brought into the heater must be rated at least

90 °C.

14. Do not allow objects to be placed on top of heater as they

may be damaged or create a fire hazard.

15. Heater may be mounted on finished floor or may be mounted above finished floor (such as above baseboard).

However, if installed above floor, power supply must enter

heater through knockout in the back of the heater.

– Heater Operates at High Temperatures. Keep

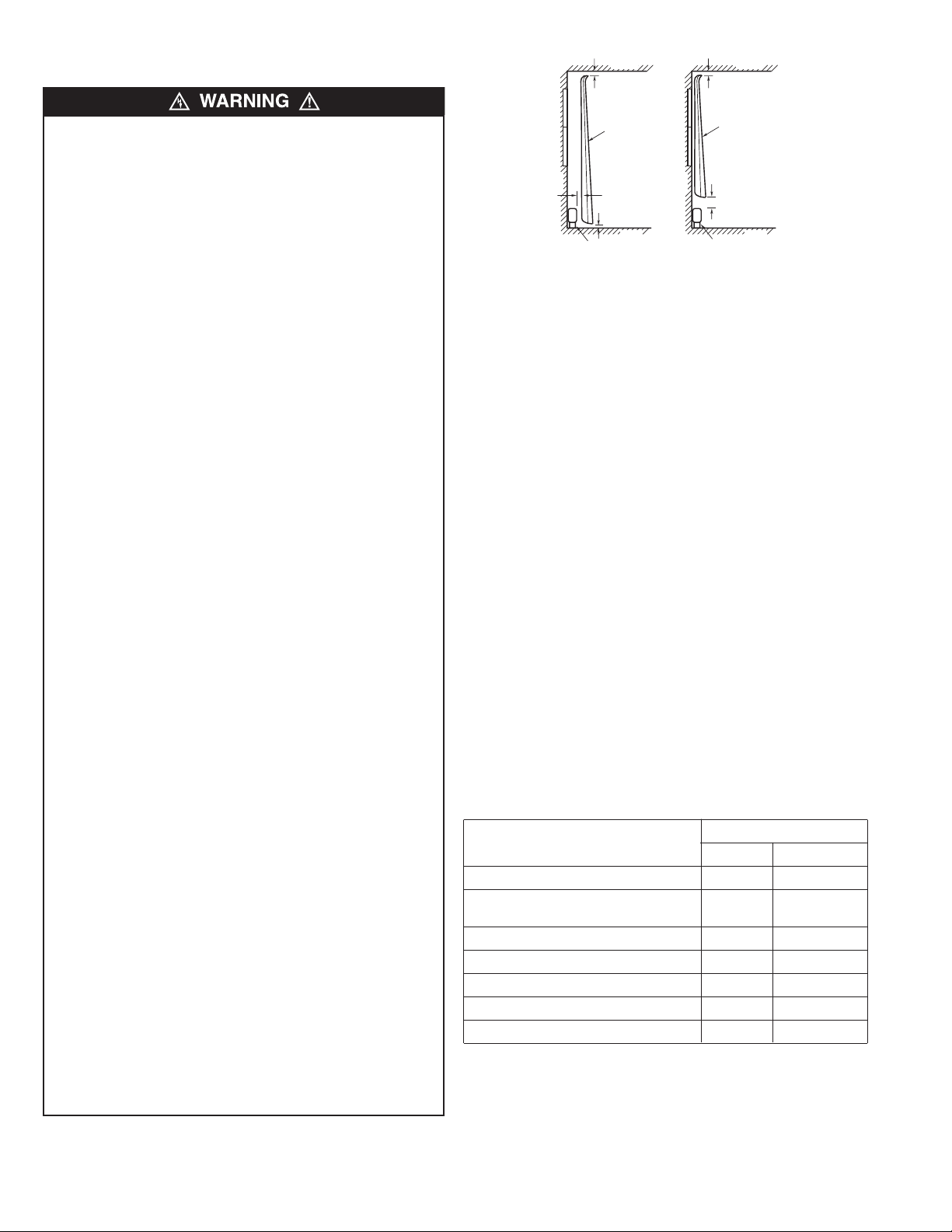

Figure 1. Positioning Drapery Near Heater

Clearances

loors & Carpeting:

F

Heaters may be mounted directly on any

floor surface, including carpeting. Where wall-to-wall carpets are

installed after the baseboard installation, the carpeting can be

run up to the front and around the heater body.

Full Length Drapes

The following clearances must be

maintained:

1. Hang drapes so that, in use, they extend below the center

line of the heater, but with at least 1” (25mm) clearance from

the top of the finished floor covering, such as carpet, tile, etc.

2. Hang drapes so there is at least 2” (51mm) between the

extreme front of the heater and the nearest fold of drapes, in

the folded back position (open drape position).

3. Hang drapes so there is at least 1” (25mm) between the top

of the drapes and the ceiling.

Short Drapes:

Hang drapes so there is at least 6” (152mm)

clearance above the top of the heater.

Furniture:

Do not place furniture against heater. It is recommended all items be kept a minimum of 6” (152mm) inches from

heater.

Installation of Single Unit

Commercial baseboard heaters are designed for installation in

new or existing construction. In existing construction, baseboard

molding should be removed and the heaters mounted flush

against the wall surface. When replacing molding allow 1/16”

(1 mm) clearance between molding and ends of heaters.

NOTE: This heater can be wired in either the right or left hand

junction box. See Table 1 for wiring compartment volumes.

Table 1. Field Wiring Compartment Volumes

Est. Net Total Volume

Description CM

3

Heater Wiring Compartment (One End) 200 13.25

Heater Wiring Compartment with

T1 or T2 Thermostat Accessory 175 11.25

Accessory Blank Section (No Controls) 2400 145

AC Accessory Section 2300 140

DR Accessory Section 2300 140

CDS2 Accessory Section 2300 140

LVR Accessory Section 2100 130

1. Position the heater at the desired location on the wall as

shown in Figure 2. For maximum heating comfort, position

the heater under a window.

2. Mark the location on the wall or floor for the power supply

entry into the heater. Remove the heater from the wall and

drill appropriate hole in the wall or floor.

2

3

In

Page 3

N

OTE: ALLOW 1/8" (3mm) MINIMUM

CLEARANCE AT ENDS OF HEATER FOR

E

XPANSION AND CONTRACTION

N

AIL POINTS

F

LOOR

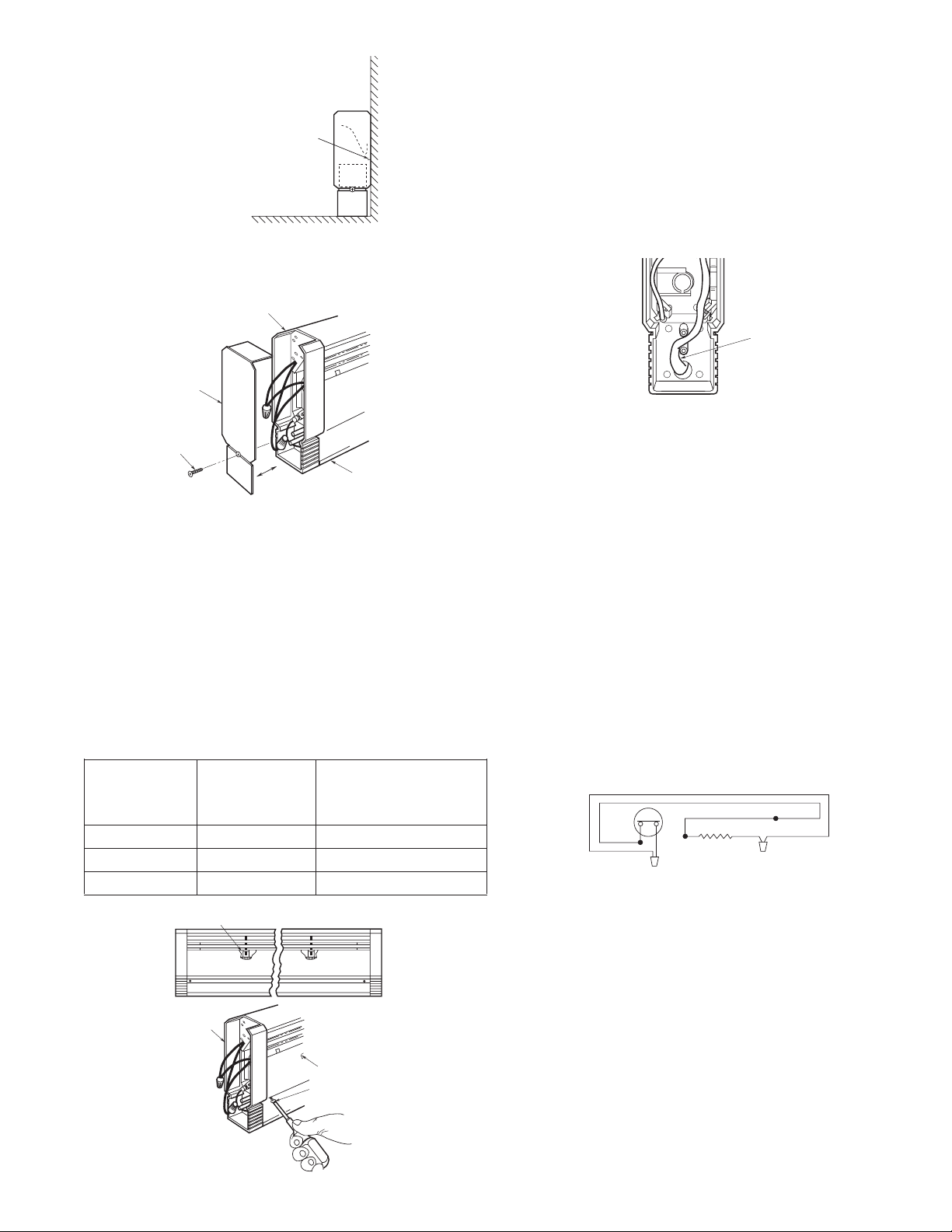

Figure 2. Installation of Heater

J

UNCTION BOX

JUNCTION

B

OX END

CAP

SCREW

HEATER

SNAP TOP OF COVER OFF THE CENTER BRACKET/

INTERMEDIATE SUPPORTS

JUNCTION BOX

HEATER COVER

SCREW

POWER

SUPPLY

C

ABLE

LIMIT

ELEMENT

WIRENUT

WIRENUT

CONNECT POWER SUPPLY TO EITHER END OF HEATER BY REMOVING

WIRENUT AND CONNECTING HEATER LEADS INDIVIDUALLY TO SUPPLY

LEADS.

3. Remove the left or right junction box end cap by removing

the screw in the end of the heater and sliding the cap outward from the heater (Figure 3).

Figure 3. Removal of End Cap

4. Remove the front cover of the heater by removing the

screws in the lower corners. Pull the bottom of the cover outward and lift the top of the cover off the junction box. Repeat

for the opposite end. Snap the top of the cover off the center

bracket and off the intermediate supports. See Figure 4.

5. If wires are to enter or pass through raceway, remove raceway cover and remove the appropriate electrical knockout

from the back of the heater or raceway as necessary.

6. If one or more heaters are connected to a single branch circuit, determine the total amperage load (see Specifications

Table on page 4), then determine the power supply wire size

and the circuit breaker or fuse size required (See Table 2).

Table 2.

Minimum Circuit

AWG Wire Breaker

Total Size or Fuse

Amps (Copper) Size

0 thru 12 #14 15 Amp

12.1 thru 16 #12 20 Amp

16.1 thru 24 #10 30 Amp

7. Bring power supply wire to the heater and thermostat locations as determined by the thermostat option selected.

IF POWER SUPPLY IS TO ENTER HEATER THROUGH

KNOCKOUT IN BACK OF HEATER, install wire using cable

clamp leaving 6 to 8-inches (152 to 203mm) of wire inside

heater for connections.

IF POWER SUPPLY ENTERS HEATER THROUGH RACEWAY, install wire using cable clamp at the knockout in the

raceway, and feed the wire into the junction box leaving 6 to

8-inches (152 to 203mm) of wire inside junction box for connections. DO NOT make connections in raceway.

Figure 5. Routing of Power Supply Cable

NOTE:

No clamp is required where the cable passes through

the hole in the plastic junction box.

8. Position the heater on the wall and locate wall studs. Drill or

punch holes through the enclosure back (above the element)

at stud locations.

NOTE:

The heater enclosure is provided with nail point marks

showing correct locations for mounting holes.

The following methods of mounting the heaters to common

types of wall surfaces are suggested:

a. Plaster Walls:

b. Wall Studs:

Use toggle or molly screw anchors.

Use #12 round head screws penetrating at

least 3/4" (19mm) into stud.

c. Masonry Walls:

Use #12 round head screws into lead, plas-

tic, or fiber expansion anchor.

Tighten all screws snugly, then back off 1/2-turn to allow the

back panel to expand and contract.

9. Connect supply wiring to heater as described in Figure 6, or

as shown in the wiring diagrams supplied with the accessory

kits intended for use with this heater.

WIRING DIAGRAM

Figure 4. Removal of Front Cover

Figure 6. Heater Wiring Connections

10.Secure the desired accessories to baseboard as shown in

the accessory instruction sheet, and use the wiring diagram

supplied with the accessory.

NOTE: Baseboard heaters must be thermostatically controlled.

11.Replace the front cover by fitting the top lip of the cover onto

the tabs on each junction box and top edge of the element

support bracket(s). Rotate the cover downward, pushing the

bottom corners inward. Install two screws (removed in Step

4) through the cover into the junction boxes. See that the

bottom of the cover is engaged onto the bottom of each element support bracket. See Figure 7.

12.Replace the end cap(s) by installing screw(s) (removed in

Step 3).

3

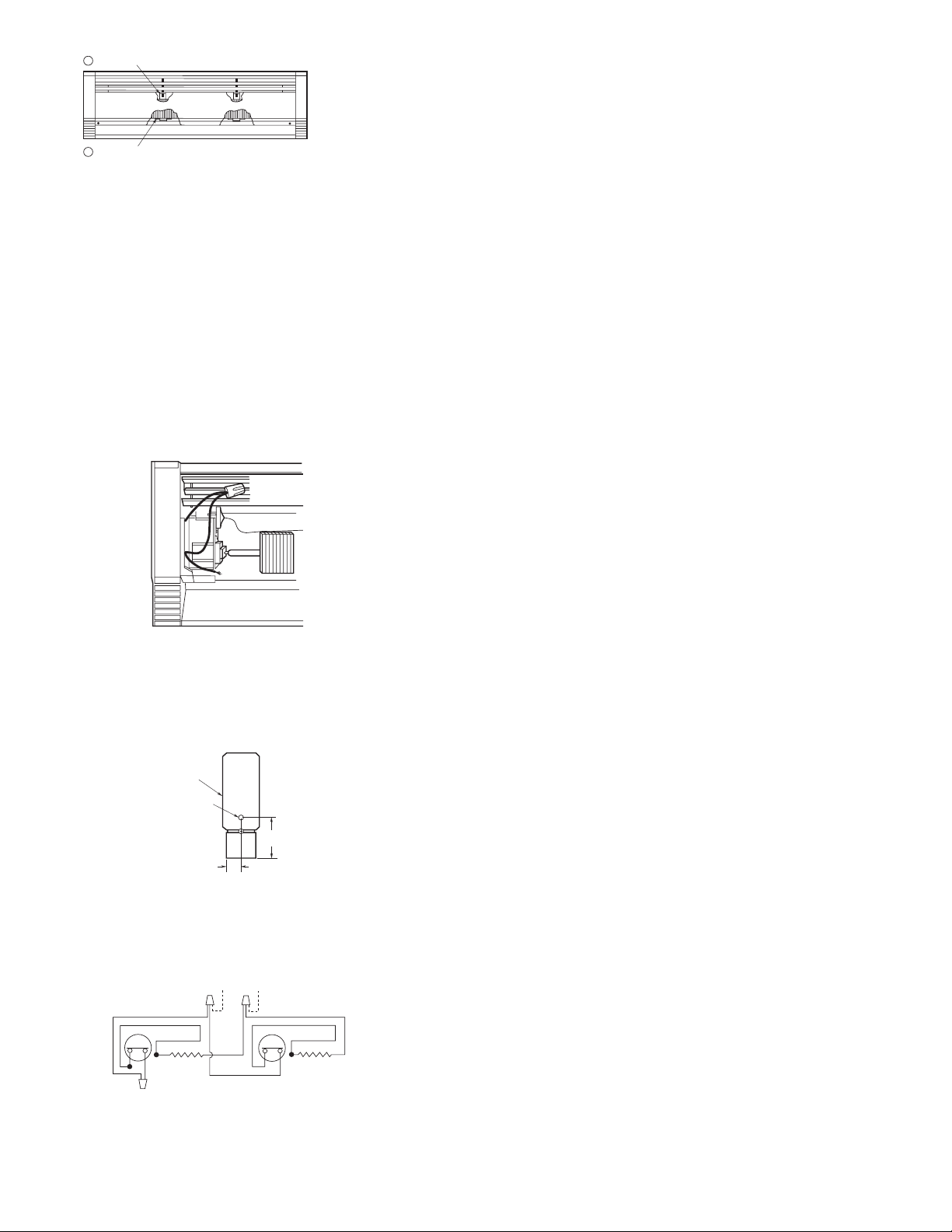

Page 4

A

FTER CONNECTING POWER

SUPPLY CABLE TUCK WIRING

BACK INTO THE JUNCTION BOX

FRONT OF

HEATER

115/32"

(37mm)

1

/2" DIA.

(13mm)

3"

(76mm)

LIMIT

ELEMENT

LIMIT

ELEMENT

TWO HEATERS ON ONE SUPPLY

POWER SUPPLY

S

NAP COVER ONTO TOP OF ELEMENT SUPPORT BRACKET.

SNAP COVER ONTO BOTTOM OF ELEMENT BRACKET.

1

2

Figure 7. Cover Attachment

Installation of Multiple Units

1. With heaters mounted end-to-end, allow 1/32-inch (1mm) of

expansion space per heater between each heater.

2. For each heater to be installed, refer to and follow

“Installation of Single Unit”, Steps 1 through 7.

3. If the power supply is to enter through the end of the heater

series so that the end cap can be installed after the heaters

are installed, continue “Installation of Single Unit”, Steps 8

through 11.

4. If the power supply is to feed heaters at the junction box that

is adjacent to another heater, it is easier for the power supply

connections to be made prior to the installation of the

heater(s) to the wall. If this is not possible, connections may

be made through the opening in the junction boxes when the

front cover(s) is removed. See Figure 8.

Figure 8. Wiring Through Junction Box Opening

5. Connecting power supply cables may be routed from heater

to heater by drilling a 1/2-inch (13mm) diameter hole in the

end caps for the heaters that fit together. See Figure 9.

To prevent possible damage to internal heater wiring, all

drilling of end caps must be done with end caps removed

from heater.

OPERATING INSTRUCTIONS

1. This heater must be properly installed before it is used.

2. An integral or remote wall thermostat is recommended for

each room. In very large rooms it is recommended that a low

voltage thermostat with double or multiple circuit relays be

used to provide the most comfortable results.

DO LOCATE DO NOT

THERMOSTAT LOCATE THERMOSTAT

• A minimum of two feet • Near televisions or

(61cm) from any appliances that emit heat.

outside wall. • Near drafts from an

• Approximately five feet open doorway.

(1,5m) from the floor, • Where it would be struck

preferably on an inside by direct rays of sunlight.

wall location.

3. After the baseboard system has been completely installed,

all thermostats should be turned to LOW or NO HEAT setting. Then turn on breakers or install fuses. Wait 3 to 5 minutes and check to see that none of the heaters are operating.

If operating, disconnect power and check wiring. If none are

operating then turn the thermostats to highest setting and

wait 3 to 5 minutes. Check to see that all heaters are operating. Should any not be operating, disconnect power and

check wiring.

4. Allow entire system to operate steadily for 1/2-hour. For a

period of time after the heaters are put into operation, the

owner may notice a “new smell” coming from the heaters.

This is expected on new installations. Bringing heaters to full

operation will eliminate this condition in a short period of

time.

5. Select the setting for comfort on all thermostats.

6. There are safety over-temperature limiting devices inside this

heater. These safety devices are there to turn off the heater

automatically in the event of an over-temperature condition.

These devices are not to be tampered with or disconnected

from the electrical system. If the heater is installed correctly

and wired to the correct voltage, these devices should never

operate to turn off the heater. If this device is cycling the

heater off and on, turn off power to the heater and have the

heater serviced by qualified service personnel.

Figure 9. End Cap Drill Pattern

6. Wire heaters as shown in Wiring Diagram, Figure 10.

7. Replace the front covers and end caps according to

“Installation of Single Unit”, Steps 11 and 12.

WIRING DIAGRAM

Figure 10. Dual Heater Wiring Connections

4

Page 5

MAINTENANCE INSTRUCTIONS

For efficient and safe operation and to extend the life of the

heaters, they should be cleaned and inspected for damage at

least annually (preferably at the beginning of the heat season)

or more often in dirty environments. Other than cleaning, your

heaters require no other preventative maintenance. The user

can perform some basic cleaning of the heater. All other servicing is to be done by qualified service personnel.

SERIOUS INJURY OR DEATH COULD RESULT FROM

ELECTRIC SHOCK. MAKE SURE ELECTRICAL POWER

SUPPLY CIRCUIT COMING TO HEATER IS DISCONNECTED AT MAIN DISCONNECT OR SERVICE PANEL BEFORE

CLEANING OR SERVICING THIS HEATER. ALLOW HEATER

TO COOL BEFORE CLEANING TO PREVENT A POSSIBLE

BURN.

1. Heater cabinet may be cleaned using a damp cloth to

remove dust that may have accumulated on surfaces. Do

not use harsh cleaners and waxes on surfaces since these

could damage the finish or discolor in use.

2. A vacuum cleaner and /or compressed air may be used to

remove dust and lint that may have accumulated inside

heater around element fins. If heater must be dissembled for

cleaning, removed the two screws securing front cover and

remove front cover to allow for access to inside. Use care

when cleaning element fins to avoiding damaging fins.

Repainting of Heater Enclosure

The heater is designed with both metal and plastic components.

Repainting of the heater is not recommended as certain paints

may not adhere or work well on both type materials. In addition,

repainting of the heater grille with standard enamel paints (versus high temperature paints) may result in the grill finish being

damaged by the heated air flowing over these surfaces. If

repainting of the heater must be done, use care to paint only the

exterior cabinet - do not paint the interior, heating element, or

copper limit capillary tube. Follow directions provided by paint

manufacturer for surface preparation and application.

FINS ARE SHARP AND MAY CAUSE CUTS, DO NOT

TOUCH.

3. After cleaning and servicing, replace front cover and screws

removed making sure cover is properly secured into each

element support bracket at top and bottom – see Figure 7.

4. Energize heater and check for correct operation.

5

Page 6

SPECIFICATIONS

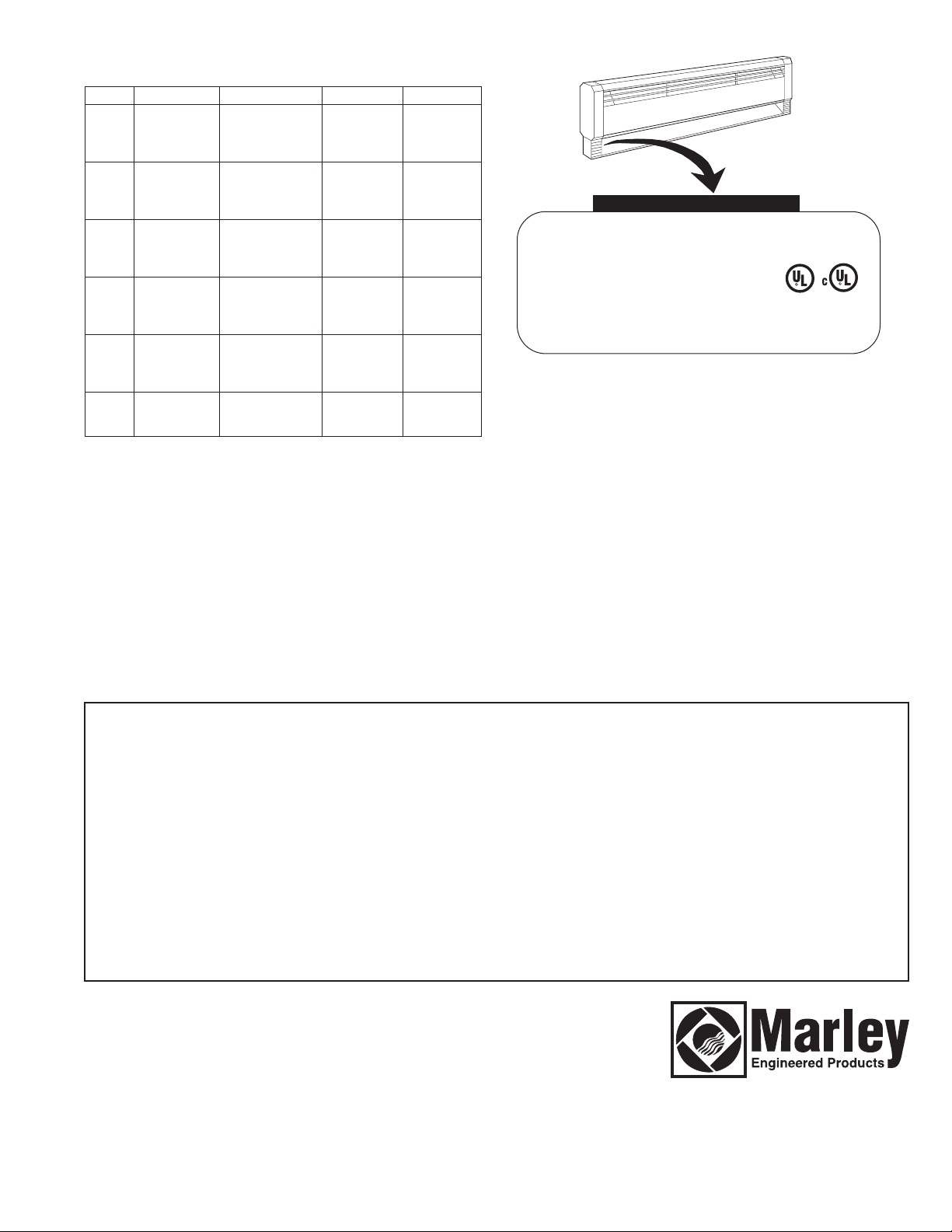

Model Volts Watts Amps Length

D500

D508

D504

D507

D750

D758

D754

D757

D1000

D1008

D1004

D1007

D1250

D1258

D1254

D1257

D1500

D1508

D1504

D1507

D2008

D2004

D2007

120 500 4.2

208 500 2.4 28”

240/208 500/375 2.1/1.8 (71.1cm)

277/240/208 500/375/282 1.8/1.6/1.4

120 750 6.3

208 750 3.6 34”

240/208 750/562 3.1/2.7 (86.4cm)

277/240/208 750/562/422 2.7/2.3/2.0

120 1000 8.3

208 1000 4.8 46”

240/208 1000/750 4.2/3.6 (1.17m)

277/240/208 1000/750/562 3.6/3.1/2.7

120 1250 10.4

208 1250 6.0 58”

240/208 1250/938 5.2/4.5 (1.47m)

277/240/208 1250/938/704 4.5/3.9/3.4

120 1500 12.5

208 1500 7.2 70”

240/208 1500/1125 6.3/5.4 (1.78m)

277/240/208 1500/1125/844 5.4/4.7/4.1

208 2000 9.6

240/208 2000/1500 8.3/7.2

277/240/208 2000/1500/1125 7.2/6.3/5.4

(2.39m)

94”

NAMEPLATE

ODEL NO.

M

D1007

ELECTRIC BASEBOARD HEATER

PLINTHE CHAUFFANTE ELECTRIQUE

VOLTS AC WATTS AMPS 60HZ

277/240/208 1000/750/565 3.6/3.2/2.8

MARLEY ENGINEERED PRODUCTS

BENNETTSVILLE, SC 29512

ATE CODE

D

0310

54E1 LISTED

ELECTRIC

ASEBOARD HEATER

B

4104-2022-275

All products manufactured by Marley Engineered Products are warranted against defects in workmanship and materials for one year from date of installation, except

LIMITED WARRANTY

heating elements which are warranted against defects in workmanship and materials for five years from date of installation. This warranty does not apply to damage from

accident, misuse, or alteration; nor where the connected voltage is more than 5% above the nameplate voltage; nor to equipment improperly installed or wired or

maintained in violation of the product’s installation instructions. All claims for warranty work must be accompanied by proof of the date of installation.

The customer shall be responsible for all costs incurred in the removal or reinstallation of products, including labor costs, and shipping costs incurred to return products

to Marley Engineered Products Service Center. Within the limitations of this warranty, inoperative units should be returned to the nearest Marley authorized service center or the Marley Engineered Products Service Center, and we will repair or replace, at our option, at no charge to you with return freight paid by Marley. It is agreed that

such repair or replacement is the exclusive remedy available from Marley Engineered Products.

THE ABOVE WARRANTIES ARE IN LIEU OF ALL OTHER WARRANTIES EXPRESSED OR IMPLIED, AND ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE WHICH EXCEED THE AFORESAID EXPRESSED WARRANTIES ARE HEREBY DISCLAIMED AND EXCLUDED FROM

THIS AGREEMENT. MARLEY ENGINEERED PRODUCTS SHALL NOT BE LIABLE FOR CONSEQUENTIAL DAMAGES ARISING WITH RESPECT TO THE

PRODUCT, WHETHER BASED UPON NEGLIGENCE, TORT, STRICT LIABILITY, OR CONTRACT.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above exclusion or limitation may not apply to you. This warranty gives

you specific legal rights, and you may also have other rights which vary from state to state.

For the address of your nearest authorized service center, contact Marley Engineered Products in Bennettsville, SC, at 1-800-642-4328. Merchandise returned to the factory must be accompanied by a return authorization and service identification tag, both available from Marley Engineered Products. When requesting return authorization,

include all catalog numbers shown on the products.

HOW TO OBTAIN WARRANTY SERVICE AND

WARRANTY PARTS PLUS GENERAL INFORMATION

1. Warranty Service or Parts

2. Purchase Replacement Parts

3. General Product Information

Note:

When obtaining service always have the following:

1. Model number of the product

2. Date of manufacture

3. Part number or description

1-800-642-4328

1-800-654-3545

www.marleymep.com

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

Part No. 5200-2113-003

ECR 38721

01/11

Page 7

Calefactor a altura

de zócalo, comercial,

ILE #E37116

F

Serie D

Instrucciones de instalación, operación y mantenimiento

INSTRUCCIONES IMPORTANTES

GENERALIDADES

Este calefactor está diseñado para proporcionar años de funcionamiento eficiente sin problemas como fuente de calor principal o complementaria

para calefacción en aplicaciones residenciales y comerciales. Los calefactores a altura de zócalo deben controlarse termostáticamente para un funcionamiento eficiente y seguro. No se suministra termostato con este calefactor. Sin embargo, en su sitio de compra se pueden conseguir termostatos de uno o dos polos para instalación en este calefactor, o el calefactor puede conectarse a cualquier termostato montado en pared apropiado que cumpla los requisitos de carga eléctrica. La instalación o uso de este producto de una manera diferente a la descrita en este documento

anulará la garantía y podría resultar en lesiones, daño a la propiedad, o daño permanente al calefactor.

AL UTILIZAR APARATOS ELÉCTRICOS, SIEMPRE DEBEN

SEGUIRSE PRECAUCIONES BÁSICAS PARA REDUCIR EL RIESGO DE INCENDIO, DESCARGA ELÉCTRICA Y LESIONES A PERSONAS, INCLUYENDO LO SIGUIENTE:

1. Lea todas las instrucciones antes de instalar o utilizar el calefactor.

2. Un calefactor tiene en su interior piezas calientes, piezas que forman arcos eléctricos o piezas que producen chispa. No utilice en

áreas donde se utilice o almacene gasolina o líquidos inflamables.

3. Este calefactor está caliente cuando está en uso. Para evitar quemaduras, no permita que la piel desnuda haga contacto con las

superficies calientes. Mantenga alejados del calefactor los materiales combustibles tales como muebles, almohadas, ropa de cama,

papeles, ropa y cortinas.

GUARDE ESTAS INSTRUCCIONES

4. Para evitar un posible incendio, no obstruya de ninguna manera las

entradas o escape de aire.

5. No inserte ni permita que objetos extraños ingresen a las aberturas

de ventilación o de escape, ya que esto podría causar una descarga eléctrica, incendio, o podría dañar el calefactor.

6. Podrían producirse lesiones graves o la muerte por descarga eléctrica. Antes de instalar o suministrar servicio de mantenimiento a

este calefactor, verifique que el circuito de suministro de energía

eléctrica que alimenta el calefactor está desconectado en el interruptor de desconexión principal o panel de servicio.

Page 8

2" (51mm) CLEARANCE

(MIN)

1

" (25mm) CLEARANCE

(

MIN)

BASEBOARD HEATER

EXAMPLE 1

WALL

FLOOR

C

EILING

1" (25mm) CLEARANCE

(MIN)

DRAPERY

6

" (152mm) CLEARANCE

(

MIN)

BASEBOARD HEATER

EXAMPLE 2

WALL

FLOOR

C

EILING

DRAPERY

1" (25mm) CLEARANCE

(MIN)

INSTRUCCIONES DE INSTALACIÓN

ADVERTENCIA

PARA REDUCIR EL RIESGO DE INCENDIO Y DESCARGA ELÉCTRICA

O LESIONES A PERSONAS, CUMPLA LO SIGUIENTE:

. Podrían producirse lesiones graves o la muerte por descarga eléctrica.

1

Antes de instalar este calefactor, verifique que el circuito de suministro

de energía eléctrica que alimenta el calefactor está desconectado en el

nterruptor de desconexión principal o panel de servicio.

i

2. Las conexiones y procedimientos de cableado deben realizarse de

acuerdo con el Código Eléctrico Nacional (NEC) y los códigos locales.

onsulte las Figuras 6 y 10 de Diagrama de Cableado y también las

C

Tablas 1 y 2. Verifique que todas las conexiones eléctricas están apretadas para evitar posible sobrecalentamiento. Sólo utilice alambre de

obre para el alambre de suministro de energía eléctrica.

c

3. Verifique que el voltaje de suministro de energía eléctrica coincide con

a capacidad nominal de voltaje impresa en la placa de datos del cale-

l

factor.

PRECAUCIÓN - Nunca conecte el calefactor a un voltaje superior al voltaje indicado en la placa de datos ya que esto dañará el calefactor y podría

causar un incendio.

. Antes de instalar, verifique que todos los materiales y almohadillas de

4

empaque/embalaje fueron removidos del calefactor.

. No instale el calefactor contra superficies combustibles de tabla de fibra

5

de celulosa de baja densidad, contra o debajo de cubiertas de vinilo de

pared, o debajo de materiales que pudieran dañarse por el calor tales

como persianas, cortinas de vinilo o plástico, etc.

6. No instale el calefactor debajo de un tomacorriente eléctrico.

PRECAUCIÓN

7.

alejados del calefactor, los cables eléctricos (incluyendo los cables de

teléfonos y computadoras), las cortinas y otros muebles. Para un funcionamiento eficiente y seguro, recomendamos mantener siempre un

espacio libre mínimo de 6 pulgadas (152 mm) encima y al frente del

calefactor. Vea la sección Espacios libres y la Figura 1 para averiguar

los requisitos de espacios libres mínimos.

8. Para reducir el riesgo de incendio, no almacene ni utilice gasolina ni

otros vapores o líquidos inflamables cerca del calefactor.

9. No instale el calefactor de manera invertida o en cualquier posición

diferente a la mostrada en este manual.

10. No instale el calefactor de manera empotrada en la pared ni instale el

calefactor dentro de ningún tipo de encerramiento (a menos que sea

aprobado específicamente por el fabricante) ya que esto causará que

el calefactor se sobrecaliente y podría crear un peligro de seguridad.

11. Al montar el calefactor, tenga cuidado al taladrar los orificios de montaje y al montar el calefactor en la estructura de la edificación para evitar dañar los componentes internos del calefactor. Asegúrese de aflojar _ vuelta los tornillos de montaje para permitir la expansión y contracción.

12. No remueva ni puentee el control de límite de seguridad ya que esto

podría permitir que el calefactor se convierta en un peligro de incendio

– vea los diagramas de cableado del calefactor en las Figuras 6 y 10.

13. Todo el cableado de campo conectado con el calefactor debe tener una

capacidad nominal mínima para 90°C.

14. No permita que se coloquen objetos encima de calefactor ya que éstos

podrían dañarse o crear un peligro de incendio.

15. El calefactor puede montarse en pisos con acabado o puede montarse

por encima de pisos con acabado (tal como encima de zócalos). Sin

embargo, si se instala por encima de pisos, el suministro de energía

eléctrica debe ingresar al calefactor a través del orificio precortado en

la parte trasera del calefactor.

– El calefactor funciona a altas temperaturas. Mantenga

IELO RASO

C

" (25 mm) ESPACIO

1

LIBRE (MÍN)

CORTINAS

EJEMPLO 1

2" (51 mm) ESPACIO

IBRE (MÍN)

L

PARED

" (25 mm) ESPACIO

1

LIBRE (MÍN)

ISO

ALEFACTOR A ALTURA DE ZÓCALO

C

P

IELO RASO

C

1" (25 mm) ESPACIO

IBRE (MÍN)

L

ORTINAS

C

EJEMPLO 2

6" (152 mm) ESPACIO

IBRE (MÍN)

L

PARED

ALEFACTOR A ALTURA DE ZÓCALO

C

PISO

Figura 1. Colocación de cortinas cerca del calefactor

Espacios libres

Pisos y alfombras:

cualquier superficie de piso, incluyendo alfombras. En los lugares donde se

instalen alfombras de pared a pared después de la instalación de los zócalos,

las alfombras pueden colocarse hasta la parte delantera y alrededor del cuerpo del calefactor.

Cortinas de longitud completa:

ibres:

l

1. Cuelgue las cortinas de modo que, cuando estén en uso, éstas se extiendan por debajo de la línea central del calefactor, pero con un espacio libre

ínimo de 1” (25 mm) desde la parte superior de la cubierta del piso

m

cabado, tal como alfombra, baldosa, etc.

a

2. Cuelgue las cortinas de modo que haya 2” (51 mm) como mínimo entre la

parte delantera extrema del calefactor y el pliegue más cercano de las

cortinas, en la posición trasera plegada (posición de cortina abierta).

3. Cuelgue las cortinas de modo que haya 1” (25 mm) como mínimo entre la

parte superior de las cortinas y el cielo raso/techo.

Cortinas cortas:

mo de 6” (152 mm) por encima de la parte superior del calefactor.

Muebles:

No coloque los muebles contra el calefactor. Se recomienda que

todos los elementos mantengan un espacio mínimo de 6” (152 mm) del calefactor.

Los calefactores pueden montarse directamente en

eben mantenerse los siguientes espacios

D

Cuelgue las cortinas de modo que haya un espacio libre míni-

Instalación de unidad sola

Los calefactores a altura de zócalo, comerciales, están diseñados para instalación en construcciones nuevas o existentes. En construcciones existentes,

debe removerse la moldura del zócalo/rodapié y los calefactores deben montarse montarse a ras contra la superficie de la pared. Al volver a colocar las

molduras, deje un espacio libre de 1/16” (1 mm) entre las molduras y los

extremos de los calefactores.

NOTA: Este calefactor puede cablearse en la caja de conexiones derecha o

izquierda. Vea la Tabla 1 para averiguar los volúmenes de los compartimientos de cableado.

Tabla 1. Volúmenes de los compartimientos de cableado

en campo

Volumen total neto est.

Descripción CM

3

Compartimiento de cableado del calefactor

(un extremo) 200 13.25

Compartimiento de cableado del calefactor

con Accesorio de termostato T1 ó T2 175 11.25

Sección ciega para accesorios (Sin Controles) 2 400 145

Sección de accesorios AC 2 300 140

Sección de accesorios DR 2 300 140

Sección de accesorios CDS2 2 300 140

Sección de accesorios LVR 2 100 130

1. Coloque el calefactor en la ubicación deseada en la pared según se

muestra en la Figura 2. Para lograr la máxima comodidad de calefacción, coloque el calefactor bajo una ventana.

2. Marque la ubicación en la pared o el piso para el ingreso del suministro

de energía en el calefactor. Retire el calefactor de la pared y taladre el

orificio apropiado en la pared o piso.

8

Pulg

3

Page 9

NOTE: ALLOW 1/8" (3mm) MINIMUM

CLEARANCE AT ENDS OF HEATER FOR

EXPANSION AND CONTRACTION

NAIL POINTS

FLOOR

JUNCTION BOX

JUNCTION

BOX END

C

AP

SCREW

HEATER

SNAP TOP OF COVER OFF THE CENTER BRACKET/

INTERMEDIATE SUPPORTS

JUNCTION BOX

HEATER COVER

SCREW

P

OWER

SUPPLY

CABLE

LIMIT

ELEMENT

WIRENUT

WIRENUT

CONNECT POWER SUPPLY TO EITHER END OF HEATER BY REMOVING

WIRENUT AND CONNECTING HEATER LEADS INDIVIDUALLY TO SUPPLY

LEADS.

NOTA: DEJE UN ESPACIO LIBRE MÍNIMO DE

1/8” (3 mm) EN LOS EXTREMOS DEL CALEFAC-

OR PARA EXPANSIÓN Y CONTRACCIÓN

T

igura 2. Instalación del calefactor

F

3. Remueva la tapa de extremo de la caja de conexiones izquierda o

erecha removiendo el tornillo en el extremo del calefactor y deslizando

d

la tapa hacia afuera del calefactor (Figura 3).

TAPA DE EXTREMO

DE LA CAJA DE

ONEXIONES

C

TORNILLO

Figura 3. Remoción de tapa de extremo

4. Remueva la cubierta delantera del calefactor removiendo los tornillos en

las esquinas inferiores. Hale hacia afuera la parte inferior de la cubierta y

levante la parte superior de la cubierta fuera de la caja de conexiones.

Repita para el extremo opuesto. Remueva a presión la parte superior de

la cubierta fuera del soporte central y fuera de los soportes intermedios.

Vea la Figura 4.

5. Si los alambres deben ingresar o pasar a través del canal, remueva la

cubierta del canal y remueva la tapa precortada removible eléctrica

apropiada de la parte trasera del calefactor o canal según sea necesario.

6. Si uno o más calefactores están conectados a un único circuito de

derivación, determine la carga de amperaje total (vea la Tabla de

Especificaciones en la página 4), luego determine el tamaño del alambre

de suministro de energía y el tamaño requerido del interruptor automático (breaker) o fusible (vea la Tabla 2).

Tabla 2

Amperaje alambre AWG interruptor automático

total mínimo (cobre) o fusible

0 a 12 #14 15 Amp

12,1 a 16 #12 20 Amp

16,1 a 24 #10 30 Amp

REMUEVA A PRESIÓN LA PARTE SUPERIOR DE LA CUBIERTA

FUERA DEL SOPORTE CENTRAL/ SOPORTES INTERMEDIOS

CAJA DE CONEXIONES

Figura 4. Remoción de la cubierta

delantera

PUNTOS DE CLAVO

PISO

CONEXIONES

CALEFACTOR

Tamaño de Tamaño del

CUBIERTA DEL CALEFACTOR

TORNILLO

7. Conecte el alambre de suministro de energía con el calefactor y las ubiaciones de termostato según lo determinado por la opción de termosta-

c

to seleccionada.

I EL SUMINISTRO DE ENERGÍA DEBE INGRESAR AL CALEFACTOR

S

A TRAVÉS DEL ORIFICIO PRECORTADO EN LA PARTE TRASERA

DEL CALEFACTOR, instale el alambre utilizando abrazadera de cable

ejando 6 a 8 pulgadas (152 a 203 mm) de alambre dentro del calefactor

d

para conexiones.

I EL SUMINISTRO DE ENERGÍA INGRESA AL CALEFACTOR A

S

TRAVÉS DEL CANAL, instale el alambre utilizando la abrazadera de

able en la tapa precortada removible en el canal, e introduzca el alam-

c

bre dentro de la caja de conexiones dejando 6 a 8 pulgadas (152 a 203

mm) de alambre dentro de la caja de conexiones para conexiones. NO

ealice conexiones en el canal.

r

ABLE DE SUMINISTRO DE

C

NERGÍA

E

Figura 5. Enrutamiento del cable de suministro de energía

NOTA:

o se requiere abrazadera cuando el cable pasa a través del orificio

N

en la caja de conexiones plástica.

8. Coloque el calefactor en la pared y localice las columnas de pared.

Taladre o perfore orificios a través de la parte trasera de la carcasa/gabi-

ete (encima del elemento calefactor) en las ubicaciones de columna.

n

NOTA:

La carcasa del calefactor se suministra con marcas de puntos de

clavo mostrando las ubicaciones correctas para los orificios de montaje.

Se sugieren los siguientes métodos de montaje de los calefactores en

tipos comunes de superficies de pared:

a. Paredes de yeso/estuco:

Utilice anclajes tipo codillo o anclajes de

tornillo molly.

b. Columnas de pared:

Utilice tornillos de cabeza redonda #12 que pene-

tren al menos 3/4" (19 mm) dentro de la columna.

c. Paredes de mampostería/ladrillo:

Utilice tornillos de cabeza redonda

#12 dentro de anclajes de expansión plásticos, de plomo o fibra.

Apriete de manera ceñida todos los tornillos, luego regrese _ vuelta para

permitir que el panel trasero se expanda y contraiga.

9. Conecte los alambres de suministro de energía con el calefactor según

se describe en la Figura 6, o según se muestra en los diagramas de

cableado suministrados con los kits de accesorios diseñados para uso

con este calefactor.

DIAGRAMA DE CABLEADO

LÍMITE

ELEMENTO

CONECTE EL SUMINISTRO DE ENERGÍA CON CUALQUIER EXTREMO DEL CALEFACTOR REMOVIENDO EL

CONECTOR DE ALAMBRES (CAPUCHÓN) Y CONECTANDO LOS ALAMBRES DEL CALEFACTOR DE MANERA

INDIVIDUAL CON LOS ALAMBRES DE SUMINISTRO DE ENERGÍA ELÉCTRICA.

CONECTOR DE ALAMBRES (CAPUCHÓN)

CALEFACTOR

CONECTOR DE ALAM-

BRES (CAPUCHÓN)

Figura 6. Conexiones de alambres del calefactor

10. Sujete los accesorios deseados al zócalo según se muestra en la hoja

de instrucciones de los accesorios, y utilice el diagrama de cableado

suministrado con el accesorio.

NOTA: Los calefactores a altura de zócalo deben controlarse termostáticamente.

11. Coloque nuevamente la cubierta delantera encajando el reborde superior

de la cubierta sobre las pestañas salientes en cada caja de conexiones y

el borde superior del soporte(s) del elemento calefactor. Gire hacia abajo

la cubierta, empujando hacia adentro las esquinas inferiores. Instale los

dos tornillos (removidos en el Paso 4) a través de la cubierta dentro de

las cajas de conexiones. Observe que la parte inferior de la cubierta está

enganchada sobre la parte inferior de cada soporte del elemento calefactor. Vea la Figura 7.

12. Coloque nuevamente la tapa(s) de extremo instalando el tornillo(s)

(removido en el Paso 3).

9

Page 10

AFTER CONNECTING POWER

SUPPLY CABLE TUCK WIRING

BACK INTO THE JUNCTION BOX

FRONT OF

HEATER

115/32"

(37mm)

1

/2" DIA.

(13mm)

3"

(76mm)

LIMIT

ELEMENT

LIMIT

ELEMENT

TWO HEATERS ON ONE SUPPLY

POWER SUPPLY

SNAP COVER ONTO TOP OF ELEMENT SUPPORT BRACKET.

SNAP COVER ONTO BOTTOM OF ELEMENT BRACKET.

1

2

SUJETE A PRESIÓN LA CUBIERTA SOBRE LA PARTE SUPERIOR DEL SOPORTE DEL

ELEMENTO CALEFACTOR.

SUJETE A PRESIÓN LA CUBIERTA SOBRE LA PARTE INFERIOR DEL SOPORTE DEL

ELEMENTO CALEFACTOR.

Figura 7. Sujeción de la cubierta

Instalación de múltiples unidades

1. Con los calefactores montados extremo con extremo, deje 1/32 pulgada (1 mm) de espacio para expansión por calefactor, entre cada

calefactor.

2. Para cada calefactor a instalar, consulte y siga la “Instalación de

unidad sola”, Pasos 1 al 7.

3. Si el suministro de energía debe ingresar a través del extremo de la

serie de calefactores de modo que la tapa de extremo pueda instalarse después que se instalen los calefactores, continúe la

“Instalación de unidad sola”, Pasos 8 al 11.

4. Si el suministro de energía debe alimentar los calefactores en la

caja de conexiones que está adyacente a otro calefactor, es más

fácil que las conexiones de suministro de energía se realicen antes

de la instalación del calefactor(s) en la pared. Si esto no es posible,

las conexiones pueden realizarse a través de la abertura en las

cajas de conexiones cuando la cubierta(s) delantera está removida.

Vea la Figura 8.

DESPUÉS DE CONECTAR EL CABLE DE SUMINISTRO DE ENERGÍA, META LOS ALAMBRES DE

REGRESO DENTRO DE LA CAJA DE CONEXIONES

Figura 8. Cableado a través de la abertura de la caja de conexiones

5. Los cables de suministro de energía pueden enrutarse de calefactor

a calefactor taladrando un orificio de _ pulgada (13 mm) de diámetro

en las tapas de extremo para los calefactores que encajan entre sí.

Vea la Figura 9. Para evitar posible daño a los cables interiores del

calefactor, todo taladrado/perforación de las tapas de extremo debe

realizarse con las tapas de extremo estando removidas fuera del

calefactor.

INSTRUCCIONES DE OPERACIÓN

1. Este calefactor debe instalarse apropiadamente antes de su uso.

2. Se recomienda un termostato de pared integral o remoto para cada

habitación/salón. En salones muy grandes, se recomienda utilizar un

termostato de bajo voltaje con relés de circuito dobles o múltiples

para proporcionar los resultados más cómodos.

COLOQUE NO COLOQUE

EL TERMOSTATO EL TERMOSTATO

• A una distancia mínima de dos • Cerca de televisores o aparatos

pies (61cm) de cualquier que emitan calor.

pared exterior. • Cerca de flujos de aire

• A aproximadamente cinco pies procedentes de una

(1,5m) del piso, preferiblemente puerta abierta.

en una ubicación de pared interior. • Donde le pudieran llegar los

rayos directos del sol.

3. Después de haberse instalado completamente el sistema a altura de

zócalo, todos los termostatos deben colocarse en el valor de

CALOR BAJO o NO CALOR (LOW ó NO HEAT). Luego coloque los

interruptores automáticos (breakers) en la posición de encendido o

instale los fusibles. Espere 3 a 5 minutos y verifique que ninguno de

los calefactores esté en funcionamiento. Si están en funcionamiento,

desconecte la energía y revise el cableado. Si ninguno está en funcionamiento, entonces coloque los termostatos en el valor más alto

y espere 3 a 5 minutos. Verifique que todos los calefactores están

en funcionamiento. Si ninguno está funcionando, desconecte la

energía y revise el cableado.

4. Permita que todo el sistema funcione continuamente durante _ hora.

Durante un período de tiempo después que se coloquen en funcionamiento los calefactores, el propietario podría notar un “olor a

nuevo” procedente de los calefactores. Esto se espera en las instalaciones nuevas. Llevar los calefactores hasta el funcionamiento

pleno eliminará esta condición en un corto periodo de tiempo.

5. Seleccione el valor de ajuste en todos los termostatos para lograr

una temperatura cómoda.

6. Dentro de este calefactor hay dispositivos de seguridad limitadores

de sobrecalentamiento. Estos dispositivos de seguridad están allí

para apagar automáticamente el calefactor en caso de una condición de sobrecalentamiento. Estos dispositivos no deben alterarse o

desconectarse del sistema eléctrico. Si el calefactor se instala correctamente y se conecta al voltaje correcto, estos dispositivos nunca

deberían operar para apagar el calefactor. Si este dispositivo está

apagando y encendiendo el calefactor, apague el suministro eléctrico hacia el calefactor y solicite a personal de servicio calificado que

suministre servicio de mantenimiento al calefactor.

PARTE DELANTERA

DEL CALEFACTOR

PUNZÓN DE 1/2" DIÁM.

(13 mm)

(76 mm)

(37 mm)

Figura 9. Plantilla de taladrado de tapa de extremo

6. Conecte los alambres de los calefactores según se muestra en el

diagrama de cableado, Figura 10.

7. Coloque nuevamente las cubiertas delanteras y las tapas de extremo

de acuerdo con la “Instalación de unidad sola”, Pasos 11 y 12.

DIAGRAMA DE

SUMINISTRO DE ENERGÍA

CABLEADO

LÍMITE LÍMITE

Figura 10. Conexiones de alambres de calefactor doble

ELEMENTO

CALEFACTOR

DOS CALEFACTORES EN UN (1) SUMINISTRO DE ENERGÍA

ELEMENTO

CALEFACTOR

10

Page 11

INSTRUCCIONES DE MANTENIMIENTO

Para un funcionamiento eficiente y seguro, y para extender la vida de los

alefactores, éstos deben limpiarse e inspeccionarse en busca de daño, una

c

ez al año como mínimo (preferiblemente al comienzo de la temporada de

v

calor) o más frecuentemente en ambientes sucios. Excepto la limpieza, sus

alefactores no requieren otro mantenimiento preventivo. El usuario puede

c

realizar cierta limpieza básica del calefactor. Todos los demás procedimien-

os de servicio de mantenimiento deben ser realizados por personal de servi-

t

io calificado.

c

ADVERTENCIA

PODRÍAN PRODUCIRSE LESIONES GRAVES O LA MUERTE POR

DESCARGA ELÉCTRICA. ANTES DE LIMPIAR O SUMINISTRAR SERVI-

IO DE MANTENIMIENTO A ESTE CALEFACTOR, VERIFIQUE QUE EL

C

CIRCUITO DE SUMINISTRO DE ENERGÍA ELÉCTRICA QUE ALIMENTA

EL CALEFACTOR ESTÁ DESCONECTADO EN EL INTERRUPTOR DE

ESCONEXIÓN PRINCIPAL O EL PANEL DE SERVICIO. ANTES DE

D

LIMPIAR, PERMITA QUE EL CALEFACTOR SE ENFRÍE PARA EVITAR

NA POSIBLE QUEMADURA.

U

1. El armario/caja/carcasa del calefactor puede limpiarse utilizando un trapo

úmedo para remover el polvo que pudiera haberse acumulado sobre las

h

superficies. No utilice limpiadores fuertes ni ceras sobre las superficies

a que éstos podrían dañar el acabado o producir decoloración.

y

2. Puede utilizarse una aspiradora y/o aire comprimido para remover el

olvo e hilachas que pudieran haberse acumulado dentro del calefactor

p

alrededor de las aletas del elemento calefactor. Si el calefactor debe

desensamblarse para limpieza, remueva los dos tornillos que aseguran

la cubierta delantera y remueva la cubierta delantera para permitir acceso al interior. Tenga precaución al limpiar las aletas del elemento calefactor para evitar dañar las aletas.

Repintado de la carcasa del calefactor

l calefactor está diseñado con componentes metálicos y plásticos. No se

E

ecomienda el repintado del calefactor ya que ciertas pinturas podrían no

r

adherirse o no funcionar bien en ambos tipos de materiales. Adicionalmente,

l repintado de la rejilla del calefactor con pinturas de esmalte normales (en

e

lugar de pinturas para alta temperatura) podría resultar en daño del acabado

de la rejilla por el aire caliente que fluye sobre estas superficies. Si debe

ealizarse el repintado del calefactor, tenga cuidado de pintar únicamente el

r

gabinete exterior - no pinte el interior, el elemento calefactor, o el tubo capilar

e límite de cobre. Siga las instrucciones suministradas por el fabricante de

d

la pintura para preparación de la superficie y la aplicación.

PRECAUCIÓN

LAS ALETAS SON FILOSAS Y PODRÍAN CAUSAR CORTADURAS, NO

TOCAR.

3. Después de limpiar y suministrar el servicio de mantenimiento, coloque

nuevamente la cubierta delantera y los tornillos removidos verificando

que la cubierta está asegurada apropiadamente en cada soporte del elemento calefactor en la parte superior e inferior – vea la Figura 7.

4. Energice el calefactor y verifique el funcionamiento correcto.

11

11

Page 12

ESPECIFICACIONES

Modelo

D500

D508

D504

D507

D750

D758

D754

D757

D1000

D1008

D1004

D1007

D1250

D1258

D1254

D1257

D1500

D1508

D1504

D1507

D2008

D2004

D2007

Voltios Watts Amperios Longitud

120 500 4,2

208 500 2,4 28”

240/208 500/375 2,1/1,8 (71,1cm)

77/240/208 500/375/282 1,8/1,6/1,4

2

120 750 6,3

208 750 3,6 34”

240/208 750/562 3,1/2,7 (86,4cm)

277/240/208 750/562/422 2,7/2,3/2,0

20 1000 8,3

1

208 1000 4,8 46”

240/208 1000/750 4,2/3,6 (1,17m)

277/240/208 1000/750/562 3,6/3,1/2,7

20 1250 10,4

1

08 1250 6,0 58”

2

240/208 1250/938 5,2/4,5 (1,47m)

277/240/208 1250/938/704 4,5/3.9/3.4

120 1500 12,5

08 1500 7,2 70”

2

40/208 1500/1125 6,3/5,4 (1,78m)

2

277/240/208 1500/1125/844 5.4/4.7/4.1

208 2000 9,6

240/208 2000/1500 8,3/7,2

77/240/208 2000/1500/1125 7,2/6,3/5,4

2

94”

(2,39m)

PLACA DE DATOS

ODEL NO.

M

D1007

LECTRIC BASEBOARD HEATER

E

LINTHE CHAUFFANTE ELECTRIQUE

P

VOLTS AC WATTS AMPS 60HZ

277/240/208 1000/750/565 3.6/3.2/2.8

MARLEY ENGINEERED PRODUCTS

BENNETTSVILLE, SC 29512

ATE CODE

D

0310

54E1 LISTED

ELECTRIC

ASEBOARD HEATER

B

4104-2022-275

Todos los productos fabricados por Marley Engineered Products están garantizados contra defectos en manufactura y materiales durante un (1) año a partir de la fecha

GARANTÍA LIMITADA

instalación, excepto los elementos calefactores los cuales están garantizados contra defectos en manufactura y materiales durante cinco años a partir de la fecha de instalación. Esta garantía no aplica a daño por accidente, uso incorrecto, o alteración; ni donde el voltaje conectado sea superior en 5% al voltaje indicado en la placa de datos;

ni se aplica a equipo instalado o cableado o mantenido de manera inapropiada en violación de las instrucciones de instalación del producto. Todas las reclamaciones de

trabajo de garantía deben incluir un documento que compruebe la fecha de instalación.

El cliente será responsable de todos los costos incurridos en la remoción o reinstalación de productos, incluyendo los costos de mano de obra, y los costos de envío incurridos para devolver los productos al Centro de Servicio de Marley Engineered Products. Dentro de las limitantes de esta garantía, las unidades inoperantes deben devolverse al centro de servicio autorizado Marley más cercano o al Centro de Servicio de Marley Engineered Products, y nosotros repararemos o reemplazaremos, según nuestra elección, sin costo para usted, con el costo de envío de regreso pagado por Marley. Se acuerda que dicha reparación o reemplazo es el remedio exclusivo disponible

de parte de Marley Engineered Products.

LAS ANTERIORES GARANTÍAS REEMPLAZAN CUALQUIER OTRA GARANTÍA EXPRESA O IMPLÍCITA, Y TODAS LAS GARANTÍAS IMPLÍCITAS DE MERCADEABILIDAD Y ADECUADIBILIDAD PARA UN PROPÓSITO EN PARTICULAR QUE EXCEDEN LAS GARANTÍAS EXPRESAS MENCIONADAS SON DENEGADAS MEDIANTE ESTE DOCUMENTO Y EXCLUIDAS DE ESTE ACUERDO. MARLEY ENGINEERED PRODUCTS NO SERÁ RESPONSABLE POR DAÑOS CONSECUENCIALES

QUE SURJAN CON RESPECTO AL PRODUCTO, ESTÉN O NO BASADOS EN NEGLIGENCIA, INFRACCIÓN, RESPONSABILIDAD ESTRICTA, O CONTRATO.

Algunos estados no permiten la exclusión o la limitación de los daños resultantes o adicionales, de modo que la anterior exclusión o limitación podría no aplicarse a usted.

Esta garantía le otorga derechos legales específicos, y además, usted podría tener otros derechos que varían de un estado a otro.

Para obtener la dirección de su centro de servicio autorizado más cercano, comuníquese con Marley Engineered Products en Bennettsville, SC, en el teléfono: 1-800-642-

4328. La mercancía devuelta a la fábrica debe incluir una autorización de devolución y la etiqueta de identificación de servicio, las cuales pueden conseguirse en Marley

Engineered Products. Al solicitar la autorización de devolución, incluya todos los números de catálogo mostrados en los productos.

CÓMO OBTENER EL SERVICIO DE GARANTÍA Y LAS PIEZAS DE

GARANTÍA, Y ADEMÁS, INFORMACIÓN GENERAL

1. Servicio o Piezas de Garantía

2. Compra de Piezas de Repuesto

3. Información General de Productos

Nota:

Al solicitar servicio, siempre tenga a mano lo siguiente:

1. Número de modelo del producto

2. Fecha de fabricación

3. Número o descripción de la pieza

1-800-642-4328

1-800-654-3545

www.marleymep.com

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

Pieza No. 5200-2113-003

ECR 38721

01/11

Page 13

Série D

Radiateur-plinthe

FILE #E37116

commercial

Instructions d’installation, d’utilisation et d’entretien

INSTRUCTIONS IMPORTANTES

GÉNÉRALITÉS

Ce radiateur est conçu pour fournir des années de fonctionnement sans soucis comme source de chaleur principale ou auxiliaire, pour du chauffage

de confort dans des applications résidentielles et commerciales. Les radiateurs-plinthes doivent être thermostatiquement contrôlés pour un fonctionnement efficace et sûr. Il n’est pas fourni de thermostat avec ce radiateur. Cependant, un thermostat accessoire unipolaire ou bipolaire est

disponible pour être installé dans ce radiateur sur votre lieu d’achat, ou bien le radiateur peut être raccordé sur n’importe quel thermostat à montage

mural convenable qui répondra aux exigences au point de vue d’alimentation électrique. L’installation ou l’utilisation de ce produit d’une manière non

décrite ici annulera la garantie et pourra entraîner des blessures, des dégâts matériels ou des dommages permanents sur le radiateur.

AVERTISSEMENT

LORS DE L’UTILISATION D’APPAREILS ÉLECTRIQUES, DES PRÉCAUTIONS DE BASE DOIVENT TOUJOURS ÊTRE SUIVIES AFIN

DE RÉDUIRE LE RISQUE DE DÉPART D'INCENDIE, DE COMMOTION ÉLECTRIQUE ET DE BLESSURES AUX PERSONNES,

INCLUANT CELLES QUI SUIVENT :

1. Lisez toutes les instructions avant d’installer ou d’utiliser le radiateur.

2. Un radiateur comporte à l’intérieur des parties chaudes, et pouvant

produire un arc ou des étincelles électriques. Ne l’utilisez pas dans

des zones où de l’essence ou des liquides inflammables sont utilisés.

3. Ce radiateur est chaud quand il est en fonctionnement. Pour éviter

des brûlures, ne laissez pas de peau nue toucher ses surfaces

chaudes. Maintenez les matières combustibles, comme les

CONSERVEZ CES INSTRUCTIONS

!

meubles, les oreillers et la literie, les papiers, les habits et les

rideaux, à distance du radiateur.

4. Pour éviter un possible départ d’incendie, n'obstruez en aucune

façon les admissions et les échappements d’air.

5. N’insérez pas d’objets étrangers, et ne permettez pas qu’il en entre,

dans toute ouverture d’admission ou d’évacuation, car cela peut

causer une commotion électrique ou un départ d’incendie, ou

endommager le radiateur.

6. Une blessure sérieuse voire mortelle peut résulter d’une commotion

électrique. Assurez-vous que le circuit du secteur d’alimentation

électrique arrivant au radiateur est bien débranché en amont à l’interrupteur général ou au panneau de service avant d’intervenir pour

installer ou dépanner ce radiateur.

Page 14

INSTRUCTIONS D'INSTALLATION

2" (51mm) CLEARANCE

(MIN)

1

" (25mm) CLEARANCE

(

MIN)

BASEBOARD HEATER

EXAMPLE 1

WALL

FLOOR

C

EILING

1" (25mm) CLEARANCE

(MIN)

DRAPERY

6

" (152mm) CLEARANCE

(

MIN)

BASEBOARD HEATER

EXAMPLE 2

WALL

FLOOR

C

EILING

DRAPERY

1" (25mm) CLEARANCE

(MIN)

PLAFOND

PLAFOND

POUR RÉDUIRE LE RISQUE DE DÉPART D’INCENDIE, DE COMMOTION ÉLECTRIQUE ET DE BLESSURES AUX PERSONNES,

OBSERVEZ LES CONSIGNES SUIVANTES :

1. Une blessure sérieuse voire mortelle peut résulter d’une commotion électrique. Assurez-vous que le circuit du secteur d’alimentation électrique arrivant au radiateur est bien débranché en amont à

l’interrupteur général ou au panneau de service avant d’installer ce

radiateur.

2. Les procédures de câblage et les connexions doivent être en conformité avec la norme électrique américaine (NEC) et les normes

locales. Référez-vous au Schéma de câblage aux Figures 6 et 10,

ainsi qu’aux Tableaux 1 et 2. Assurez-vous que toutes les connexions électriques sont bien serrées pour éviter une possible surchauffe. N’utilisez que des fils d’alimentation en cuivre.

3. Vérifiez que la tension du secteur correspond à la tension nominale

telle qu’imprimée sur la plaque signalétique du radiateur.

ATTENTION – Ne branchez jamais un radiateur sur une source de tension supérieure à celle de sa plaque signalétique, car cela l'endommagerait et pourrait causer un départ d'incendie.

4. Vérifiez bien avant d’installer que toutes les cales et matériaux

d’emballage sont bien enlevés du radiateur.

5. N’installez pas le radiateur contre des surfaces inflammables de

panneaux de fibre en cellulose de faible densité, contre ou sous

des revêtements muraux en vinyle, ou sous tous les matériaux

pouvant être endommagés par la chaleur, comme des stores en

vinyle ou en plastique, des rideaux, etc.

6. N’utilisez pas le radiateur sous une prise d’alimentation secteur.

ATTENTION

7.

– Le radiateur fonctionne à des températures

élevées. Maintenez les cordons électriques (dont les câbles du

téléphone et de l’ordinateur), les tentures et autres parties de

l’ameublement à distance du radiateur. Pour un fonctionnement sûr

et efficace, nous recommandons de garder 6 pouces (152 mm) d’écartement au-dessus et devant le radiateur en permanence.

Consultez la section sur les écartements et la Figure 1 pour les exigences minimales d’écartements.

8. Pour réduire le risque de départ d’incendie, n’entreposez pas et

n’utilisez pas d’essence ou d’autres produits aux vapeurs inflammables à proximité du radiateur.

9. N’installez pas le radiateur à l’envers ou dans toute position qui ne

serait pas montrée dans ce manuel.

10. N’encastrez pas le radiateur dans un mur, ou ne l’installez pas

dans un quelconque type d’enceinte (sauf si c’est spécifiquement

approuvé par le constructeur), car cela provoquerait sa surchauffe

et pourrait créer un danger.

11. Au montage du radiateur, faites attention pour percer les trous de

montage et en fixant le radiateur sur la structure du bâtiment, pour

éviter d’endommager des composants internes. Assurez-vous de

desserrer les vis de fixation d’un demi tour pour permettre l’expansion et la contraction.

12. N’enlevez pas et ne contournez pas le(s) contrôle(s) de limite de

sécurité car cela pourrait faire du radiateur un risque de départ d’incendie – consultez les schémas de câblage du radiateur aux

Figures 6 et 10.

13. Tout le câblage sur site amené dans le radiateur doit pouvoir supporter au moins 90 °C.

14. Ne laissez pas placer d'objets sur le dessus du radiateur, ils pourraient être endommagés et créer un risque de départ d'incendie.

15. Le radiateur peut être monté sur la finition de sol au au-dessus

(comme au-dessus de la plinthe). Cependant si le radiateur est

installé au-dessus du sol, son alimentation électrique doit entrer

dedans par une pastille à enfoncer sur son arrière.

MUR

ÉCARTEMENT MIN. DE

" (25 mm)

1

DRAPERIE

CARTEMENT MIN. DE

É

" (51 mm)

2

CARTEMENT MIN. DE

É

1" (25 mm)

SOL

ÉCARTEMENT MIN. DE

" (25 mm)

1

RAPERIE

D

ÉCARTEMENT MIN. DE

6" (152 mm)

MUR

RADIATEUR-PLINTHERADIATEUR-PLINTHE

SOL

Figure 1. Positionnement de draperie près du radiateur

Écartements

Sols et moquettes :

toute surface sol, y compris moquettée. Quand des moquettes sont

placées de mur à mur après l’installation des radiateurs-plinthes, elles

doivent arriver jusqu’à l’avant et autour du carter de radiateur.

Draperies pleine longueur :

respectés :

1. Suspendez les draperies de façon à ce qu’elles descendent jusqu’en

dessous de la ligne central du radiateur, mais au moins avec un

espace de 1” (25mm) par rapport au dessus du revêtement de finition du sol, comme une moquette, un carrelage, etc.

2. Suspendez les draperies de façon à ce qu’il y ait au moins 2”

(51mm) entre la partie la plus avancée du radiateur et les pans de

draperie les plus proches en position repliée fermée.

3. Suspendez les draperies de façon à ce qu’il y ait au moins

1” (25 mm) entre leur haut et le plafond.

Draperies courtes :

moins un espace de 6” (152 mm) au-dessus du haut du radiateur.

Mobilier :

Ne placez aucun meuble contre le radiateur. Il est

recommandé de maintenir tous les objets à au moins 6” (152 mm)

du radiateur.

Les radiateurs peuvent se monter directement sur

Les écartements suivants doivent être

Suspendez les draperies de façon à ce qu’il y ait au

Installation d’une unité unique

Les radiateurs-plinthes industriels sont conçus pour une installation dans

des constructions neuves ou anciennes. Dans une construction ancienne,

la plinthe de bas de mur doit être enlevée et les radiateurs montés au contact de la surface murale. À l’enlèvement de morceaux de plinthe, laissez

un espace de 1/16” (1 mm) entre les plinthes restantes et les extrémités

du radiateur.

REMARQUE : Ce radiateur peut se câbler par le boîtier de raccordement

de droite ou de gauche. Consultez le Tableau 1 pour les

volumes des compartiments de câblage.

Table 1. Volumes de compartiments de câblage sur site

Volume total net estimé

Description CM

3

Compartiment de câblage de radiateur

(une extrémité) 200 13.25

Compartiment de câblage de radiateur avec

thermostat accessoire T1 ou T2 175 11.25

Section accessoire vide (sans contrôles) 2 400 145

Section accessoire AC 2 300 140

Section accessoire DR 2 300 140

Section accessoire CDS2 2 300 140

Section accessoire LVR 2 100 130

1. Positionnez le radiateur à l’emplacement voulu sur le mur comme

montré en Figure 2. Pour un confort de chauffage maximal, placez le

radiateur sous une fenêtre.

2. Marquez l’endroit sur le mur ou sur le sol pour l’arrivée de l’alimentation électrique dans le radiateur. Enlevez le radiateur du mur et

percez un trou approprié dans le mur ou le sol.

14

Pouce

3

Page 15

NOTE: ALLOW 1/8" (3mm) MINIMUM

CLEARANCE AT ENDS OF HEATER FOR

EXPANSION AND CONTRACTION

NAIL POINTS

FLOOR

JUNCTION BOX

JUNCTION

B

OX END

CAP

SCREW

H

EATER

SNAP TOP OF COVER OFF THE CENTER BRACKET/

INTERMEDIATE SUPPORTS

JUNCTION BOX

HEATER COVER

SCREW

POWER

S

UPPLY

CABLE

LIMIT

ELEMENT

WIRENUT

WIRENUT

CONNECT POWER SUPPLY TO EITHER END OF HEATER BY REMOVING

WIRENUT AND CONNECTING HEATER LEADS INDIVIDUALLY TO SUPPLY

LEADS.

REMARQUE : LAISSEZ AU MOINS UN

ESPACE DE 1/8" (3 MM) AUX EXTRÉMITÉS

U RADIATEUR POUR PERMETTRE SON

D

XPANSION ET SA RÉTRACTION

E

OINTS DE CLOUAGE

P

Figure 2. Installation du radiateur-plinthe

SOL

3. Enlevez le capuchon d’extrémité du boîtier de raccordement de

gauche ou de droite en ôtant la vis en bout du radiateur et en faisant

RACCORDEMENT

7. Installez le câblage d’alimentation dans le radiateur et vers l’emplacement du thermostat, selon l’option de thermostat choisie.

SI L’ALIMENTATION ÉLECTRIQUE DOIT ENTRER DANS LE RADIATEUR PAR UN TROU DE PASTILLE DANS SON ARRIÈRE,

installez un collier serre-câble en laissant 6 à 8 pouces (15 à 20 cm)

de fils à l'intérieur du radiateur pour les connexions.

Si l’alimentation électrique entre dans le radiateur par le chemin de

câble, installez un collier serre-câble par le trou de pastille dans le

chemin, et passez les fils dans le boîtier de raccordement en laissant

6 à 8 pouces (15 à 20 cm) de fils à l'intérieur du boîtier pour les connexions. NE réalisez PAS les connexions dans le chemin de câble.

CÂBLE D’ALIMENTATION SECTEUR

EXTRÉMITÉ DE

BOÎTIER DE

RACCORDEMENT

VIS

Figure 3. Enlèvement du capuchon d’extrémité

glisser ce capuchon vers l’extérieur du radiateur (Figure 3).

4. Enlevez le couvercle frontal du radiateur en ôtant les vis aux angles

inférieurs. Tirez le bas du couvercle vers l’extérieur et soulevez son

haut pour dégager le boîtier de raccordement. Recommencez du

côté opposé. Dégagez le haut du couvercle du l’équerre centrale et

des supports intermédiaires. Voir la Figure 4.

5. Si les fils doivent entrer ou passer par le chemin de câble, enlevez

son couvercle et ouvrez un trou à enfoncer approprié à l’arrière du

radiateur ou du chemin de câble selon le besoin.

6. Si un ou plusieurs radiateurs sont connectés à une même branche

de circuit secteur, déterminez la charge totale en courant (Voir le

Tableau 4), puis déterminez le calibre des fils d’alimentation et du

disjoncteur ou du fusible en amont (Voir le Tableau 2).

Tableau 2

Ampérage des fils disjoncteur

total (Cuivre) ou fusible

0 à 12 #14 15 ampères

12,1 à 16 #12 20 ampères

16,1 à 24 #10 30 ampères

DÉGAGEZ LE HAUT DU COUVERCLE DU L’ÉQUERRE

CENTRALE ET DES SUPPORTS INTERMÉDIAIRES

BOÎTIER DE RACCORDEMENT

Figure 4. Enlèvement du couvercle

frontal

RADIATEUR

Calibre Calibre

AWG min. de

COUVERCLE DE RADIATEUR

VIS

Figure 5. Acheminement du câble d’alimentation secteur

REMARQUE :

Il n’y a pas besoin de collier à l’endroit où le câble passe

au travers du trou dans le boîtier de raccordement en plastique.

8. Positionnez le radiateur sur le mur et repérez les poteaux muraux.

Percez ou perforez des trous au travers du dos du carter (au-dessus

de l’élément) aux emplacements des poteaux muraux.

REMARQUE :

Le carter du radiateur est muni de marquages des

points de clouage montrant les emplacements corrects pour les

trous de montage.

Les méthodes qui suivent pour monter les radiateurs sont suggérées

en fonction des surfaces murales habituelles :

a. Cloisons en plâtre :

Utilisez des chevilles à barrette articulée ou

repliables type Molly.

b. Poteaux muraux :

Utilisez des vis à tête ronde calibre #12

pénétrant d’au moins 3/4" (19 mm) dans le poteau, ou utilisez une

cloueuse.

c. Murs en maçonnerie :

Utilisez des vis à tête ronde calibre #12 dans

des chevilles à expansion en plomb, plastique ou fibre.

Serrez ces vis à fond, puis desserrez-les d’un demi-tour pour permettre au panneau arrière de l’expansion et de la rétraction.

9. Branchez le câblage d’alimentation au radiateur comme décrit en

Figure 6, ou comme montré sur les schémas de câblage fournis

avec les kits d’accessoires devant être utilisés avec ce radiateur.

SCHÉMA DE CÂBLAGE

LIMITE

ÉLÉMENT DE

CHAUFFE

BOUCHON DE

BOUCHON DE RACCORDE-

BRANCHEZ L’ALIMENTATION SECTEUR POUR UNE OU L’AUTRE DES EXTRÉMITÉS DU RADIATEUR, EN ENLEVANT LE BOUCHON DE

RACCORDEMENT COMMUN ET EN RACCORDANT LES FILS DU RADIATEUR INDIVIDUELLEMENT SUR LES FILS D’ARRIVÉE SECTEUR.

RACCORDEMENT

Figure 6. Connexions de câblage du radiateur

10. Fixez les accessoires voulus sur le radiateur-plinthe comme montré

dans leur fiche d’instructions, et utilisez le schéma de câblage fourni

avec.

REMARQUE : Les radiateurs-plinthes doivent être contrôlés thermostatiquement.

11. Remettez en place le couvercle frontal en ajustant la lèvre

supérieure du couvercle sur les pattes de chaque boîtier de raccordement et le bord supérieur d’équerre(s) de support d’élément de

chauffe. Faites pivoter le couvercle vers le bas, en poussant ses

angles inférieurs vers l’intérieur. Mettez deux vis (enlevées

précédemment à l’étape 4) au travers du couvercle dans les boîtiers

de raccordement. Vérifiez que le bas du couvercle est engagé dans

le bas de chaque équerre de support d’élément. Voir la Figure 7.

12. Remettez en place le(s) capuchon(s) d’extrémité en utilisant la/les

vis (enlevée(s) à l’étape 3).

15

Page 16

AFTER CONNECTING POWER

S

UPPLY CABLE TUCK WIRING

BACK INTO THE JUNCTION BOX

FRONT OF

HEATER

115/32"

(37mm)

1

/2" DIA.

(13mm)

3"

(76mm)

LIMIT

ELEMENT

LIMIT

ELEMENT

TWO HEATERS ON ONE SUPPLY

POWER SUPPLY

SNAP COVER ONTO TOP OF ELEMENT SUPPORT BRACKET.

SNAP COVER ONTO BOTTOM OF ELEMENT BRACKET.

1

2

NCLIQUETEZ LE COUVERCLE DANS LE HAUT DE L’ÉQUERRE DE SUPPORT D’ÉLÉMENT.

E

NCLIQUETEZ LE COUVERCLE DANS LE BAS DE L’ÉQUERRE DE SUPPORT D’ÉLÉMENT.

E

Figure 7. Fixation du couvercle

Installation d’unités multiples

1. Avec des radiateurs montés bout à bout, laissez 1/32 pouce (1mm)

d’intervalle pour expansion par radiateur entre deux unités adjacentes.

2. Pour l’installation de chaque radiateur, suivez les consignes d’installation d’une unité unique, étapes 1 à 7.

3. Si l’alimentation électrique doit entrer par la fin de la série de radiateurs, de façon à ce que le capuchon d’extrémité puisse être mis

après l’installation de tous les radiateurs, poursuivez les consignes

d’installation d’une unité unique, étapes 8 à 11.

4. Si l’alimentation électrique doit alimenter les radiateurs au boîtier de

raccordement qui est adjacent à un autre radiateur, il est plus facile

de réaliser les raccordements électriques avant l’installation des

radiateurs sur le mur. Si ce n’est pas possible, les raccordements

doivent se faire par l’ouverture dans les boîtiers de raccordement

avec les couvercles frontaux enlevés. Voir la Figure 8.

APRÈS LE BRANCHEMENT DU CÂBLE D’ALIMENTATION SECTEUR, POUSSEZ LE CÂBLAGE

DANS LE BOÎTIER DE RACCORDEMENT.

Figure 8. Câblage au travers de l’ouverture de boîtier de raccordement

5. Les câbles d’alimentation reliant les radiateurs peuvent être acheminés d’un radiateur à l’autre en perçant un trou de diamètre 1/2

pouce (13 mm) dans les capuchons d’extrémité des radiateurs raccordés ensemble. Pour éviter de possibles dommages au câblage

intérieur du radiateur, tout le perçage des capuchons d’extrémité doit

se faire avec ces capuchons ôtés du radiateur.

INSTRUCTIONS D’UTILISATION

1. Le radiateur doit être correctement installé avant d’être utilisé.

2. Un thermostat intégré ou à distance est recommandé pour chaque

pièce. Dans les très grandes pièces, il est recommandé qu’un thermostat à basse tension avec deux ou plusieurs relais de circuit soit

utilisé afin de fournir les résultats les plus confortables.

BONNE IMPLANTATION MAUVAISE IMPLANTATION

DU THERMOSTAT DU THERMOSTAT

• À au moins deux pieds (61cm) • Près de téléviseurs ou d’appareils

de tout mur sur l’extérieur. émettant de la chaleur.

• À environ cinq pieds (1,5m) • Dans des courants d’air d’une

du sol, de préférence sur une porte d’entrée.

cloison intérieure. • À un endroit directement exposé au

rayonnement solaire.

3. Une fois que le système de radiateurs-plinthes a été complètement

installé, tous les thermostats doivent être passés en position LOW

ou NO HEAT. Puis ouvrez le circuit d’alimentation en enclenchant le

disjoncteur ou en mettant un fusible. Puis attendez 3 à 5 minutes et

vérifiez qu’aucun des radiateurs n’est en fonctionnement. Si un radiateur chauffe déjà, débranchez-le et vérifiez le câblage. Si aucun

radiateur ne chauffe, passez les thermostats sur la position la plus

forte et attendez de nouveau 3 à 5 minutes. Vérifiez que tous les

radiateurs chauffent bien.

Si un radiateur ne chauffait pas, débranchez-le et vérifiez le câblage.

4. Laissez le système complet fonctionner régulièrement pendant 1/2

heure. Pendant un certain temps après la mise en marche des radiateurs, le propriétaire peut déceler une nouvelle odeur qui s’en

dégage. C’est à attendre sur des nouvelles installations. L’activation

à plein régime des radiateurs va éliminer cette situation assez vite.

5. Choisissez un réglage de confort sur tous les thermostats.

6. Il existe des dispositifs de sécurité protégeant d’un dépassement de

température à l’intérieur de ce radiateur. Ces dispositifs de sécurité

ont pour but de couper automatiquement le radiateur en cas de surchauffe. Ces dispositifs ne doivent pas être bricolés ou débranchés

du système électrique. Si le radiateur est installé correctement et

câblé avec la bonne tension, ces dispositifs ne devraient jamais à

avoir à le couper. Si ce dispositif fait que le radiateur suit des cycles

d’activation/désactivation, coupez son alimentation et faites-le réviser par du personnel de service qualifié.

AVANT DU

RADIATEUR

Ø 1/2"

(13 mm)

(76 mm)

(37 mm)

Figure 9. Disposition de perçage du capuchon d’extrémité

6. Câblez les radiateurs comme c’est montré au schéma de câblage de

la Figure 10.

7. Remettez en place les couvercles frontaux et les capuchons d’extrémité en suivant les instructions d’installation d’une unité unique,

étapes 11 et 12.

SCHÉMA DE CÂBLAGE

LIMITE LIMITE

Figure 10. Connexions de câblage de deux radiateurs

ALIMENTATION SECTEUR

ÉLÉMENT DE

CHAUFFE

DEUX RADIATEURS SUR UNE ALIMENTATION

ÉLÉMENT DE

CHAUFFE

16

Page 17

INSTRUCTIONS D’ENTRETIEN

Pour un fonctionnement efficace et sûr et pour prolonger la durée de

service des radiateurs, il faut les nettoyer et les inspecter pour des dommages éventuels au moins une fois par an (de préférence au début de

la saison de chauffage), ou plus souvent dans des environnements

sales. En dehors de ce nettoyage, vos radiateurs ne demandent pas

d’autre entretien préventif. L’utilisateur peut effectuer lui-même un nettoyage élémentaire du radiateur. Toute autre intervention est réservée

au personnel de service qualifié.

UNE BLESSURE SÉRIEUSE VOIRE MORTELLE PEUT RÉSULTER

D’UNE COMMOTION ÉLECTRIQUE. ASSUREZ-VOUS QUE LE CIRCUIT D’ALIMENTATION SECTEUR ARRIVANT AU RADIATEUR EST

DÉBRANCHÉ EN AMONT À L’INTERRUPTEUR GÉNÉRAL OU AU

PANNEAU DE SERVICE AVANT D’INTERVENIR POUR DU NETTOYAGE OU DU SERVICE SUR CE RADIATEUR. LAISSEZ LE RADIATEUR REFROIDIR AVANT DE LE NETTOYER POUR ÉVITER DE

POSSIBLES BRÛLURES.

1. Le carter de radiateur peut être nettoyé en utilisant un chiffon

humide pour enlever la poussière qui peut s’être accumulée sur les

surfaces. N’utilisez pas de nettoyants forts ni de cires sur les surfaces car cela pourrait endommager leur finition ou la décolorer à

l’usage.

2. Un aspirateur et/ou de l’air comprimé peuvent être utilisés pour

enlever la poussière et la peluche qui peuvent s’être accumulées

dans le radiateur autour des ailettes d’élément. Si le radiateur doit

être démonté pour son nettoyage, ôtez les vis retenant le couvercle

de l’avant et sortez-le pour accéder à l’intérieur. Faites attention en

nettoyant les ailettes de l’élément de chauffe pour éviter de les

endommager.

Nouvelle peinture pour le carter de radiateur

Le radiateur est constitué de composants en métal et d’autres en plastique. Repeindre le radiateur n’est pas recommandé car certaines peintures peuvent ne pas adhérer ou bien se comporter sur ces deux types

de matériaux. De plus, le fait de repeindre la grille du radiateur avec des