Page 1

ARWH Series

Smart Series

Architectural Wall Heater

Installation, Operation & Maintenance Instructions

Table 1. Specifications

MIN. SUPPLY

MODEL VOLTS PHASE WATTS AMPS WIRE GAUGE

ARWH1802 120 1 540-1800 15 12

ARWH4808 208 1 1440-4800 23.1 10

ARWH4804 240 1 1440-4800 20.0 10

ARWH4807 277 1 1440-4800 17.3 12

NOTE: The model numbers shown are Northern White color. Add suffix to the model number for the following colors:

AL = Aluminum, BZ = Bronze, W = Navajo White.

IMPORTANT INSTRUCTIONS

WARNING

WHEN USING ELECTRIC APPLIANCES, BASIC PRECAUTIONS SHOULD ALWAYS BE FOLLOWED TO REDUCE THE

RISK OF FIRE, ELECTRIC SHOCK, AND INJURY TO PERSONS, INCLUDING THE FOLLOWING:

1. Read all instructions before installing or using this heater.

2. This heater is hot when in use. To avoid burns, do not let

bare skin touch hot surfaces. Keep combustible materials,

such as furniture, pillows, bedding, papers, clothes, etc. and

curtains at least 3 feet (0.9 m) from the front of the heater.

3. Extreme caution is necessary when any heater is used by or

near children or invalids and whenever the heater is left

operating and unattended.

4. Do not operate any heater after it malfunctions. Disconnect

power at service panel and have heater inspected by a reputable electrician before using.

5. Do not use outdoors.

6. To disconnect heater, turn controls to OFF, and turn OFF

power to heater circuit at main disconnect panel.

7. Do not insert or allow foreign objects to enter any ventilation

or exhaust opening as this may cause an electric shock, fire,

or damage to the heater.

8. To prevent a possible fire, do not block air intake or exhaust

in any manner.

9. A heater has hot and arcing or sparking parts inside. Do not

use it in areas where gasoline, paint, or flammable liquids

are used or stored.

!

10. Use this heater only as described in this manual. Any other

use not recommended by the manufacturer may cause fire,

electric shock, or injury to persons.

11. This heater is provided with a red alarm light that will illuminate only if the heater has turned off as a result of overheating. Should the sensor register an overheat condition,

the heater will stop generating heat and the fan will turn off.

The red alarm light will turn ON, and ALL BUTTONS WILL

BE DISABLED. Once the heater is safe for resetting, the red

alarm light will blink/flash. DO NOT OPERATE THE

HEATER WITH THE ALARM LIGHT ILLUMINATED. See

TO RESET THERMAL LIMIT CONTROL in OPERATING

INSTRUCTIONS section.

12. This heater is intended for comfort heating applications and

not intended for use in special environments. Do not use in

damp or wet locations such as marine or greenhouse or in

areas where corrosive or chemical agents are present.

13. When installing, see INSTALLATION INSTRUCTIONS for

additional warnings and precautions.

14. For safe and efficient operation, and to extend the life of your

heater, keep your heater clean - See MAINTENANCE

INSTRUCTIONS.

SAVE THESE INSTRUCTIONS

ECR 39603 11/12 5200-11074-001

Page 2

INSTALLATION

INSTRUCTIONS

To prevent a possible fire, injury to persons or damage to the

heater, adhere to the following:

1. Disconnect all power coming to heater at main service

panel before wiring or servicing.

2. All wiring procedures and connections must be in accordance with the National and Local Codes having jurisdiction

and the heater must be grounded.

3. Verify the power supply voltage coming to heater matches

the ratings as shown on the heater nameplate.

CAUTION: ENERGIZING HEATER AT A VOLTAGE GREATER

THAN THE VOLTAGE PRINTED ON THE NAMEPLATE WILL

DAMAGE THE HEATER AND VOID THE WARRANTY AND

COULD CAUSE A FIRE.

4. CAUTION - High temperature, risk of fire, keep electrical

cords, drapery, furnishings, and other combustibles at least

3 feet (0.9 m) from front of heater. Do not install heater

behind doors, below towel racks, or in an area where it is

subject to being blocked by furniture, curtains or storage

materials. Hot air from the heater may damage certain fabrics and plastics.

5. To reduce the risk of fire, do not store or use gasoline or

other flammable vapors and liquids in the vicinity of the

heater.

6. For wall mounting only with air discharge downward. Do

NOT install in floor, ceiling, upside down (air discharge

upward), or sideways.

7. The following minimum clearances must be maintained:

Bottom of heater to floor - 12” (305 mm).

Sides of heater to adjacent wall - 12” (305 mm).

Top of heater to ceiling - 36” (915 mm).

8. Do not operate the heater without the back box.

9. Do not use this heater for dry out purposes as the paint,

plaster, sawdust and drywall sanding dust will permanently

damage the heater and must be kept out of the heater.

10. Remove motor shipping bracket and yellow tag prior to operating this heater.

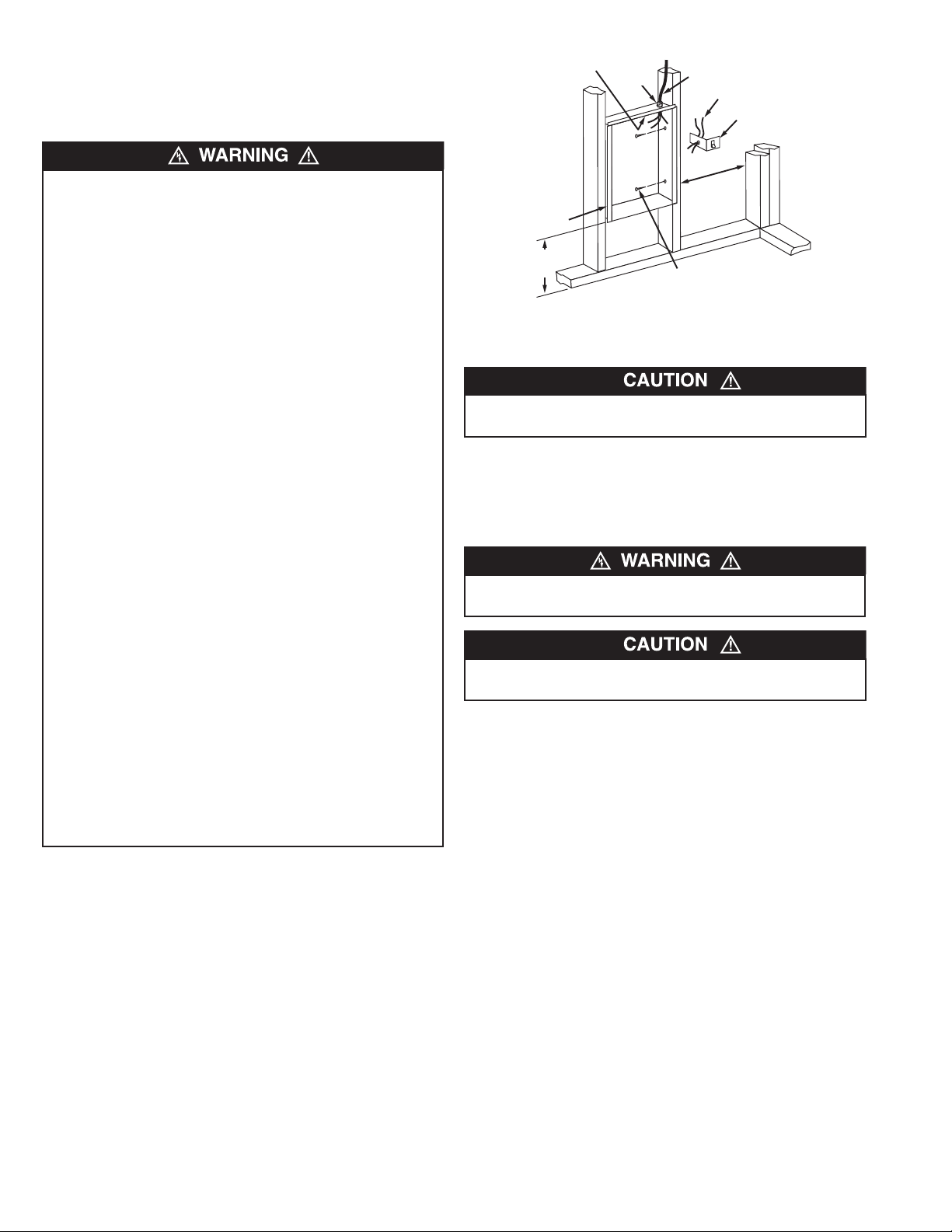

The heater is designed for recessed installation in 2” x 4”

(50 mm x 101 mm) studs or larger wall sections using the back

box provided. The heater may be wired with standard building

wire (60°C). Refer to “Specifications” and heater nameplate for

correct supply voltage and wire size.

NOTE: The optimum mounting height for this heater is 18” to 24”

(450 mm to 600 mm) from floor to bottom of back box. DO NOT

install closer than 12” (305 mm) from the floor.

Ground screw

Back Box

12” Min.

(305 mm)

Figure 1: Locating Back Box in New Construction

Cable

clamp

Power supply cable

Lead wires (Blue)

12” Min.

(305 mm)

Nail or screw

(2 each side)

Disconnect switch

bracket with switch and

leads

(No disconnect

switch on

208V models)

Mounting Clearances

TO PROVIDE FOR SAFE OPERATION, THE FOLLOWING

CLEARANCES MUST BE MAINTAINED.

Wall Mounting Only:

a. Minimum twelve (12) inches (305 mm) to floor;

b. Minimum twelve (12) inches (305 mm) to adjacent walls;

c. Minimum thirty six (36) inches (915 mm) to ceiling.

TO PREVENT HAZARD OF FIRE OR ELECTRICAL SHOCK,

DO NOT INSTALL WITHOUT BACK BOX.

TO PREVENT POSSIBLE DAMAGE TO POWER WIRING,

USE ONLY THE KNOCKOUTS PROVIDED IN BACK BOX.

Installation of Back Box in New Construction

(See Figure 1).

NOTE: If the finished wall surface is already up, follow instruc-

tions for “Installation of Back Box in Existing Construction”.

1. Place the back box between two 16" (406 mm) center-tocenter wall studs at the desired mounting height but no closer than 12" (305 mm) to adjacent wall or floor.

NOTE: If wall studs are spaced greater than 16” (407 mm) on

center, additional framing supports may be necessary.

2. Align back box such that the bottom and sides will be flush

with finished wall surface (top flange of back box should protrude approximately 1/2" (12.7 mm) from finished wall surface

(You must know the thickness of the finished wall when

installing).

3. Secure the back box in position with wood screws or nails as

shown in Figure 1.

4. Run a power supply cable into the knockout area in the upper

right hand corner of the back box (see Figure 1). All wiring

must be in accordance with National and Local Electrical

Codes. Refer to Specifications for correct wire size.

5. Remove disconnect switch bracket by loosening two screws

on the right side.

6. Install a cable clamp in the knockout in the top of the back

box.

2

Page 3

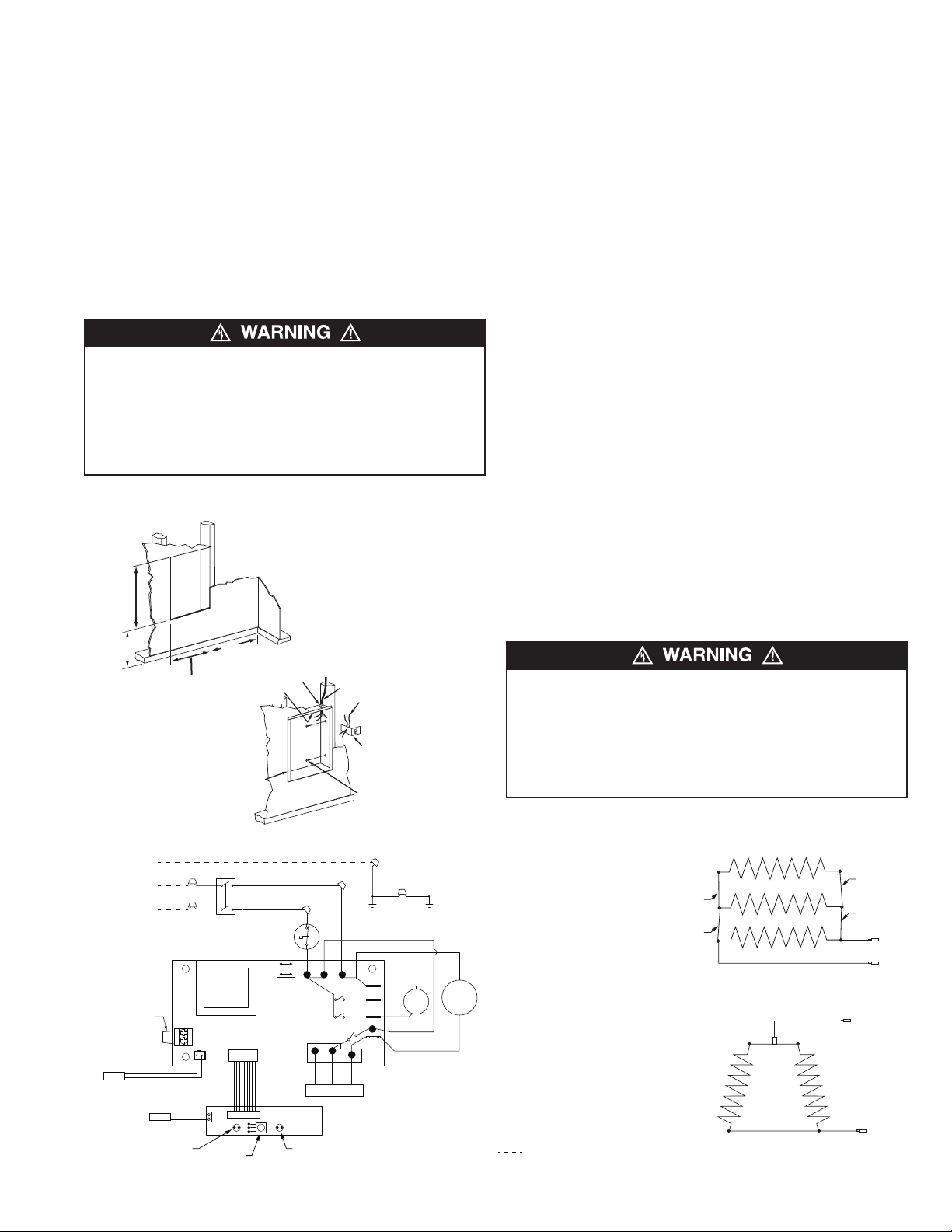

7. Insert power supply cable through cable clamp, allowing at

POWER BOARD

DISCONNECT SWITCH

(PROVIDED ON ALL MODELS

EXCEPT 208V/1P UNITS)

RED JUMPER WIRE FOR

BUILDING MANAGEMENT

SYSTEM CONNECTION

OVERHEAT

THERMISTOR

REGULATING

THERMISTOR

ELEMENT

MOTOR

TRIAC

V1GV2

J-JUMPER

TRIAC-N

EOL

LIMIT

SWITCH

L/N

*BLU

BMS

L1

L/N *BLK

BLK

L1

G

G1 G2

GRN

GRN GRN

E1

R1

C

D

E

(ON GRILL)

13

42

R2

RL-4

FAN-N

HIGH

LOW

YEL

WHT

BLK

TRIAC-LL

ELEMENT

Transformer

B

A

DATA CABLE

POWER

LIGHT

INFRARED

RECEIVER

OVERHEAT

LIGHT (see page 5)

DISPLAY BOARD

LEGEND

EOL END OF LIFE SWITCH

BMS BUILDING MANAGEMENT SYSTEM

G1, G2 GROUND SCREWS

J JUMPER

R1, R2 MANUAL RESET RELAY

FIELD WIRING

NOTES:

1. WIRES “C”, “E” AND JUMPER “J” ARE

SUPPLIED SOLDERED TO THE PC BOARD.

2. *BLK AND *BLU LEAD WIRES ARE IDENTIFIED

WITH WHITE TAPE AT EACH STRIPPED ENDS

TO INDICATE THAT THE NEUTRAL FOR THE

120V AND 277V MODELS ARE TO BE

CONNECTED TO THESE LEADS.

B

A

J3

J1

J2

J4

ELEMENT WIRING FOR 4800W, 208V/1PH

B

A

J5

ELEMENT WIRING FOR 4800W, 240V/1PH, 277V/1PH

& 1800W 120V/1PH

least 6" (152 mm) of leads to extend inside the back box.

Connect the blue lead wires of disconnect switch to the supply wire leads using wire connectors (see Figure 4, Wiring

Diagram).

NOTE: If power supply is provided by standard non-metallic

sheathed cable (Romex) and the supply voltage is 240 or 208

volts (two power wires), the white wire color must be changed

using black electrical tape to comply with the NEC. White is only

allowed for a Neutral conductor.

8. Connect building ground conductor to the back box using the

green screw located in the inside top of the back box.

9. Secure disconnect switch bracket in place by tightening

screws.

POWER SUPPLY VOLTAGE MUST BE THE SAME AS

HEATER VOLTAGE RATING SHOWN ON HEATER NAMEPLATE. CONNECTING TO A VOLTAGE IN EXCESS OF

NAMEPLATE RATING WILL DAMAGE HEATER AND VOID

WARRANTY.

ALL CONNECTIONS MUST BE MADE WITH APPROPRIATELY

SIZED LISTED WIRE CONNECTORS.

Installation of Recessed Back Box in

Existing Construction

1. Provide a wall opening 14-3/4" (375 mm) wide by 18-1/2"

(470 mm) high at the desired mounting height, but no closer

than 12" (305 mm) from floor. (See Figure 2.) Locate so at

least one side of opening is at wall stud.

2. Run a power supply cable into the knockout area in the upper

right hand corner of the wall opening (see Figure 2). All

wiring must be in accordance with National and Local

Electrical Codes. Refer to Specifications for correct wire size.

3. Remove disconnect switch bracket by loosening two screws

on the right side.

4. Install a cable clamp in the knockout in the top of the back

box.

5. Insert power supply cable through cable clamp, allowing at

least 6" (152 mm) of leads to extend inside the back box.

Connect the blue lead wires of disconnect switch to the supply wire leads using wire connectors (see Figure 4, Wiring

Diagram).

NOTE: If power supply is provided by standard non-metallic

sheathed cable (Romex) and the supply voltage is 240 or 208

volts (two power wires), the white wire color must be changed

using black electrical tape to comply with the NEC. White is only

allowed for a Neutral conductor.

6. Connect building ground conductor to the back box using the

green screw located in the inside top of the back box.

7. Secure disconnect switch bracket in place by tightening

screws.

8. Insert back box in wall opening being careful not to damage

the supply wiring. Secure the back box in place with wood

screws or nails.

12” Min.

(305 mm)

14 1/2” Min.

(362 mm)

12” Min.

(305 mm)

Ground

screw

Cable

clamp

Back Box

Figure 2: Locating Back Box in Existing Construction

Figure 3- Wiring Diagram

Power supply cable

Lead wires (Blue)

Disconnect switch

bracket with switch

and leads. (No disconnect switch on 208V

models)

Nail or screw

(2 each side)

POWER SUPPLY VOLTAGE MUST BE THE SAME AS

HEATER VOLTAGE RATING SHOWN ON HEATER NAMEPLATE. CONNECTING TO A VOLTAGE IN EXCESS OF

NAMEPLATE RATING WILL DAMAGE HEATER AND VOID

WARRANTY.

ALL CONNECTIONS MUST BE MADE WITH APPROPRIATELY

SIZED LISTED WIRE CONNECTORS.

3

Page 4

Building Management Systems (BMS)

To utilize the BMS capabilities of this unit, remove the red

jumper wire between terminals A and B on the control terminal

board ( see figure 3, wiring diagram). Connect two wires from a

dry contact (no voltage) in the BMS system to terminals A and B.

NOTE: DO NOT REMOVE THE RED JUMPER UNLESS

THE UNIT IS BEING CONTROLLED BY A BUILDING MANAGEMENT SYSTEM (BMS).

When BMS takes control, heater functions will not work, the

touch screen is locked, BMS light on the heater touchscreen

blinks.

When BMS releases control, heater functions are available,

heater resumes operating at previously programmed settings.

Refer to Operations Manual for programming options and details.

Control

Shelf

Notches

Installation of Grille and Control Wire Connector

1. Push disconnect switch into ON position.

2. Position the grille in front of the heater assembly, insert the

control shelf edges into the notches on either side of the

back box at the same time hooking the tabs on the bottom

corners of the grille assembly over the bottom flange of the

back box (see Figures 4 and 5). With the top of the grille

assembly leaning forward, supported by the first notch in

control shelf, extend the control wires from the back of the

electronic control at the top of the grille and connect to the

wires of the disconnect switch assembly according to Wiring

Diagram Figure 3.

THE HEATER ASSEMBLY MUST BE CAREFULLY POSITIONED TO ENSURE THE CONTROL WIRES ARE NOT

TRAPPED BETWEEN THE HEATER ASSEMBLY AND THE

BACK BOX.

3. Lift and rotate the the grille assembly into the backbox carefully to ensure the control wire is not trapped between the

grille assembly and back box. Insert two screws at the top

edge of grille assembly on either side of the control panel as

shown in Figure 6.

4. Install (2) plastic bezels (left and right) on either side of the

control panel by inserting the wide tab under the flange on

the control panel as shown in Figure 7, rotating the narrow

end down and pressing firmly so the clip snaps into place.

Figure 4- Installation of Heater/Grille Assembly

Back Box

Notch

Tab

Control

Shelf

Figure 5- Grille Assembly Detail, Grille Supported for Wiring

Screw Locations

Flange

OPERATION

INSTRUCTIONS

Initial Setup Instructions (Performed by Installer)

NOTE: After installation, the installer should perform the follow-

ing procedures to ensure proper operation of the heater (see

Figure 8 for Control Panel Layout). Refer to the OPERATIONS

MANUAL for details on programming and activating other features of the heater.

1. Turn ON power to the unit at the main service panel. When

the heating unit is first powered up, it will default to ON. The

green power indicator LED will illuminate as long as there is

power to the heating unit.

NOTE: If the unit does not beep and the display does not light,

turn off power at the main service panel and check that the

Control Wire is connected and the Disconnect Switch is in the

ON position.

Figure 6- Securing Grille Assembly

Plastic Bezel

Clip

Figure 7- Securing Plastic Bezel

2 If the heating unit is OFF, touch the POWER button to turn

the unit ON (The display is a touch screen and does not

respond to pressure). The display should illuminate showing

the current room temperature and default program number,

4

Tab Under Flange

of Control Panel

Page 5

Fan Speed

Indicator

Heat Control

Indicator

Day Indicator

Time

Time

Periods

Temperature

Centigrade / Fahrenheit

Indicator

Mode Button

Up Button

Night Light

Indicator

Lockout

Indicator

Automatic Mode

Indicator

Hold Mode

Indicator

Building Management

System indicator

Figure 8 - Control Panel Layout

AUTO icon and time. If the screen is in the activated state,

and no buttons are touched for 30

seconds the display backlight will turn OFF (standby mode).

NOTE: If heating unit is in the stand by mode (where display

backlight is OFF), touching any button will illuminate the backlight and display operating buttons. Touching the POWER button

when the heater is in stand by mode will illuminate the backlight,

touching the POWER button again will turn the heater OFF.

Please note power is live to heating unit when the unit is OFF.

3. Set Day and Time:

NOTE: For the following setup procedures, the display will auto-

matically save the setting after a 30 second pause and return to

the previous operating setting. If this occurs, start back at

Step a of the Set Day and Time procedure.

a. Simultaneously touch and hold the UP button and DOWN

button for 1.5 seconds. A beep will sound and the Day indicator at the top of the display will flash (the buttons on the

display respond to touch, not pressure).

NOTE: If user touches the POWER button at any point during

setup procedure, the display will automatically save settings and

return to the previous operating setting.

b. Using the UP or DOWN buttons, adjust to appropriate DAY

of week.

c. Touch the MODE button. AM / PM indicator will flash. Use

the UP and DOWN buttons to set appropriate time.

AM / PM will change automatically once you pass 12:00.

d. Touch the MODE button, MINUTES will flash. Use the UP

and DOWN buttons to set MINUTES to the appropriate

time.

e. After the last parameter is set, touch the MODE button to

lock in your settings.

4. Once the installer has performed the initial setup, power

down the unit by touching the POWER button if no other programming will be done at this time.

NOTE: The unit is programmed with default time and temperature settings for the Automatic Mode (see below). If these settings are satisfactory, then no other programming needs to be

done. Refer to the OPERATIONS MANUAL for instructions on

other useful options and features.

Default settings for Automatic Mode:

Period Time Setpoint

1. Wake Up 6:00 AM 70°F (21°C)

2. Daytime 8: 00 AM 62°F (17°C)

3. Evening 6:00 PM 70°F (21°C)

4. Sleep Time 10:00 PM 62°F (17°C)

Power Button

Down Button

Operational Notice

This heater is equipped with a manual reset thermal limit control

that will automatically turn OFF the heater if it overheats to prevent

a fire. A red warning light will illuminate, error code and overheat

temperature will flash on the display, and an audible alarm (beep)

will sound to alert that this control has activated (see

Troubleshooting under Maintenance for a list of error codes). Once

activated the heater will turn OFF and the display will lock. Once

the unit has cooled to a normal operating temperature the display

will unlock and the user will be able to reset the thermal limit control.

THE ACTIVATION OF THE THERMAL LIMIT CONTROL AND

RED WARNING LIGHT OCCURS WHEN THE HEATER OVERHEATS. CHECK HEATER TO MAKE SURE IT IS NOT

BLOCKED – IF SO, REMOVE THE BLOCKAGE. IF THERE IS

NO BLOCKAGE, IT IS RECOMMENDED THAT THE HEATER

BE INSPECTED BY A REPUTABLE ELECTRICIAN OR

REPAIR SERVICE TO ENSURE THE HEATER IS NOT

DAMAGED. DO NOT CONTINUE TO USE HEATER IF IT

REPEATEDLY CYCLES OFF ON THIS THERMAL LIMIT.

TO RESET THERMAL LIMIT CONTROL

After the unit has cooled to a safe operating temperature, the red

warning light will begin to flash, and the display will become

active. The heater is now ready to be reset. In order to reset the

thermal limit control, press the POWER and UP buttons and hold

for 1.5 seconds, the unit will return to normal operation.

DO NOT TAMPER WITH OR BYPASS ANY THERMAL LIMITS

INSIDE HEATER.

CAUTION - DO NOT CONTINUE TO ATTEMPT TO USE THE

HEATER IF THE THERMAL LIMIT CONTROL REPEATEDLY

OPERATES AFTER BEING RESET. TO DO SO COULD PERMANENTLY DAMAGE THE HEATER OR CREATE A FIRE OR

SAFETY HAZARD.

NOTE: The unit is provided with an End of Life “oneshot” protective device. This serves as a back up protector in extreme conditions when the electronic overheat protector fails during an overheat condition. If the protector opens (no light or sound on the

display controller) and the power is connected and the unit does

not come ON, the the heater is no longer functional and has to

be replaced.

5

Page 6

MAINTENANCE

INSTRUCTIONS

It is important to keep this heater clean. Your heater will give you

years of service and comfort with only minimum care. To assure

efficient operation follow the simple instructions below.

ALL SERVICING BEYOND SIMPLE CLEANING THAT

REQUIRES DISASSEMBLY SHOULD BE PERFORMED BY

QUALIFIED SERVICE PERSONNEL.

TO REDUCE RISK OF FIRE AND ELECTRIC SHOCK OR

INJURY, DISCONNECT ALL POWER COMING TO HEATER

AT MAIN SERVICE PANEL AND CHECK THAT THE ELEMENT

IS COOL BEFORE SERVICING OR PERFORMING

MAINTENANCE.

User Cleaning Instructions:

1. After the heater has cooled, a vacuum cleaner with brush

attachment may be used to remove dust and lint from exterior

surfaces of the heater including the grille openings.

2. With a damp cloth, wipe dust and lint from grille and exterior

surfaces.

3. Return power to heater and check to make sure it is operating properly.

Maintenance Cleaning Instructions:

(To be performed only by Qualified Service Personnel)

At least annually, the heater should be cleaned and serviced by

a qualified service person to assure safe and efficient operation.

This should include the removal of the grille/heater assembly as

necessary from the backbox to clean residue from the unit. After

completing the cleaning and servicing, the heater should be fully

reassembled and checked for proper operation.

Error Codes

In the event of overheating or other malfunction the heater will

display one of the error codes below:

E1 E1 is displayed if the regulating thermistor is

OPEN. A red warning light will illuminate, the

alarm will beep 10 times and E1 will continue to

flash on the display. The user should disconnect

power at the main circuit panel and call

Technical Support: 800-642-4328.

E2 E2 will be displayed if the regulating thermistor has

malfunctioned. A red warning light will illuminate,

the alarm will beep 10 times and E2 will continue

to flash on the display. The user should disconnect

power at the main circuit panel and call

Technical Support: 800-642-4328.

ES ES will be displayed if the Thermal Limit Control

has malfunctioned. A red warning light will illuminate, the alarm will beep 10 times and ES will continue to flash on the display. The user should disconnect power at the main circuit panel and call

Technical Support: 800-642-4328.

ES/Temp ES/Temperature will toggle back and forth on the

display if there is an overheat condition. A red

warning light will illuminate, the alarm will beep 10

times and ES/Temperature will continue to flash on

the display. See To Reset Thermal Limit Control on

page 5.

ES (E1/E2) ES will toggle back and forth with E1/E2 on the

display if there is a malfunction with one of the

thermistors. A red warning light will illuminate, the

alarm will beep 10 times and ES and E1/E2 will

continue to flash on the display. The user should

disconnect power at the main circuit panel and call

Technical Support: 800-642-4328.

6

Page 7

REPAIR PARTS

9

5

8

7

6

2

10

16

13

11

3

12

4

1

Repair Parts List

Ref Part Number

No Description ARWH4804 ARWH4808 ARWH4807 ARWH1802

1 Grille 2501-11019-VAR* 2501-11019-VAR* 2501-11019-VAR* 2501-11019-VAR*

2 Motor 3900-11026-000 3900-11026-000 3900-11026-001 3900-11026-002

3 Element 302012810 1802-2075-801 302012811 302012828

4 Fan Blade 490030103 490030103 490030103 490030103

5 Right Bezel 1219-11009-001 1219-11009-001 1219-11009-001 1219-11009-001

6 Left Bezel 1219-11009-000 1219-11009-000 1219-11009-000 1219-11009-000

7 Disconnect Switch 410170001 N/A 410170001 410170001

8 Control Power Board 1414-11033-000 1414-11033-000 1414-11033-001 1414-11033-002

9 Display Bezel 1016-11188-000 1016-11188-000 1016-11188-000 1016-11188-000

10 Thermistor 5262-11007-000 5262-11007-000 5262-11007-000 5262-11007-000

11 Over Heat Sensor 5262-11009-000 5262-11009-000 5262-11009-000 5262-11009-000

12 Grille Bracket Left 1215-11070-000 1215-11070-000 1215-11070-000 1215-11070-000

13 Grille Bracket Right 1215-11070-001 1215-11070-001 1215-11070-001 1215-11070-001

14 Remote (not shown) 1414-11037-000 1414-11037-000 1414-11037-000 1414-11037-000

15 Parts Kit (not shown) 1205-11023-000 1205-11023-000 1205-11023-000 1205-11023-000

16 Element Bracket 1215-11090-000 1215-11090-000 1215-11090-000 1215-11090-000

*NOTE: The standard color is Northern White. Add suffix to the model number for the following colors:

AL = Aluminum, BZ = Bronze, W = Navajo White. Call Factory for part number.

7

Page 8

All products manufactured by Marley Engineered Products are warranted against defects in workmanship and materials for one year from date of installation, except

LIMITED WARRANTY

heating elements which are warranted against defects in workmanship and materials for five years from date of installation. This warranty does not apply to damage from

accident, misuse, or alteration; nor where the connected voltage is more than 5% above the nameplate voltage; nor to equipment improperly installed or wired or

maintained in violation of the product’s installation instructions. All claims for warranty work must be accompanied by proof of the date of installation.

The customer shall be responsible for all costs incurred in the removal or reinstallation of products, including labor costs, and shipping costs incurred to return products to

Marley Engineered Products Service Center. Within the limitations of this warranty, inoperative units should be returned to the nearest Marley authorized service center

or the Marley Engineered Products Service Center, and we will repair or replace, at our option, at no charge to you with return freight paid by Marley. It is agreed that such

repair or replacement is the exclusive remedy available from Marley Engineered Products.

THE ABOVE WARRANTIES ARE IN LIEU OF ALL OTHER WARRANTIES EXPRESSED OR IMPLIED, AND ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE WHICH EXCEED THE AFORESAID EXPRESSED WARRANTIES ARE HEREBY DISCLAIMED AND EXCLUDED FROM THIS

AGREEMENT. MARLEY ENGINEERED PRODUCTS SHALL NOT BE LIABLE FOR CONSEQUENTIAL DAMAGES ARISING WITH RESPECT TO THE

PRODUCT, WHETHER BASED UPON NEGLIGENCE, TORT, STRICT LIABILITY, OR CONTRACT.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above exclusion or limitation may not apply to you. This warranty gives

you specific legal rights, and you may also have other rights which vary from state to state.

For the address of your nearest authorized service center, contact Marley Engineered Products in Bennettsville, SC, at 1-800-642-4328. Merchandise returned to the factory must be accompanied by a return authorization and service identification tag, both available from Marley Engineered Products. When requesting return authorization,

include all catalog numbers shown on the products.

HOW TO OBTAIN WARRANTY SERVICE AND

WARRANTY PARTS PLUS GENERAL INFORMATION

1. Warranty Service or Parts 1-800-642-4328

2. Purchase Replacement Parts 1-800-654-3545

3. General Product Information www.marleymep.com

Note: When obtaining service always have the following:

1. Model number of the product

2. Date of manufacture

3. Part number or description

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

Loading...

Loading...