QHT Boiler User Manual

Riva

HEAT ONLY & COMBI BOILER

Please Read This Guide Carefully

and

Save for Future Reference

- This guide is intended to provide

detailed information regarding venting

components and installation.

- This guide must be used in conjunction

with the boiler installation manual.

Non-Condensing Vent

Component & Installation Guide

Prepared by:

QHT, Inc.

Portsmouth, NH

603-334-6400 phone

www.qhtinc.com

Rev. B 04.08.08

2

Table of Contents:

Restrictor Sizing Chart …………………...…………………………………. 4

External Vent Warnings ………………………………………………………. 4

External Vent Clearances ……………………………………………………. 5

Concentric Riser Kit - RI VC RIS 9990322 …………………………………. 6

Concentric Riser Kit Installation Instructions ………………………………. 7-9

Standard Concentric Kit - RI VC 9990148 …………………………………. 10

Standard Concentric Kit Installation Instructions ………………………….. 11-12

Concentric Vent Accessories ………………………………………………... 13

RI VC EXT - 9990149

RI VC 90 - 9990152

RI VC 45 - 9990153

Separate Kit - RI VS 8990016 ……………………………………………….. 14

Separate Kit Installation Instructions ……………………………………….. 15-16

Separate Vent Accessories ………………………………………………….. 17

RI VS EXT 9990159

RI VS 90F 9990160

RI VS 45 9990162

RI VS 90M 9990178

Vertical Roof Vent Kit - RI RV 9990251 …………………………………… 18

Vertical Roof Vent Kit Installation Instructions …………………………… 18-20

Vertical Roof Vent Accessories ……………………………………………. 21

RI RV EXT 9990242

RI RV 90 9990256

RI RV 45 9990255

RI RV CC 9990275

Vertical Roof Vent Accessories Cont. …………………………………….. 22

RI RV CS 9990276

RI RV FF 9990280

RI RV PF 9990252

3

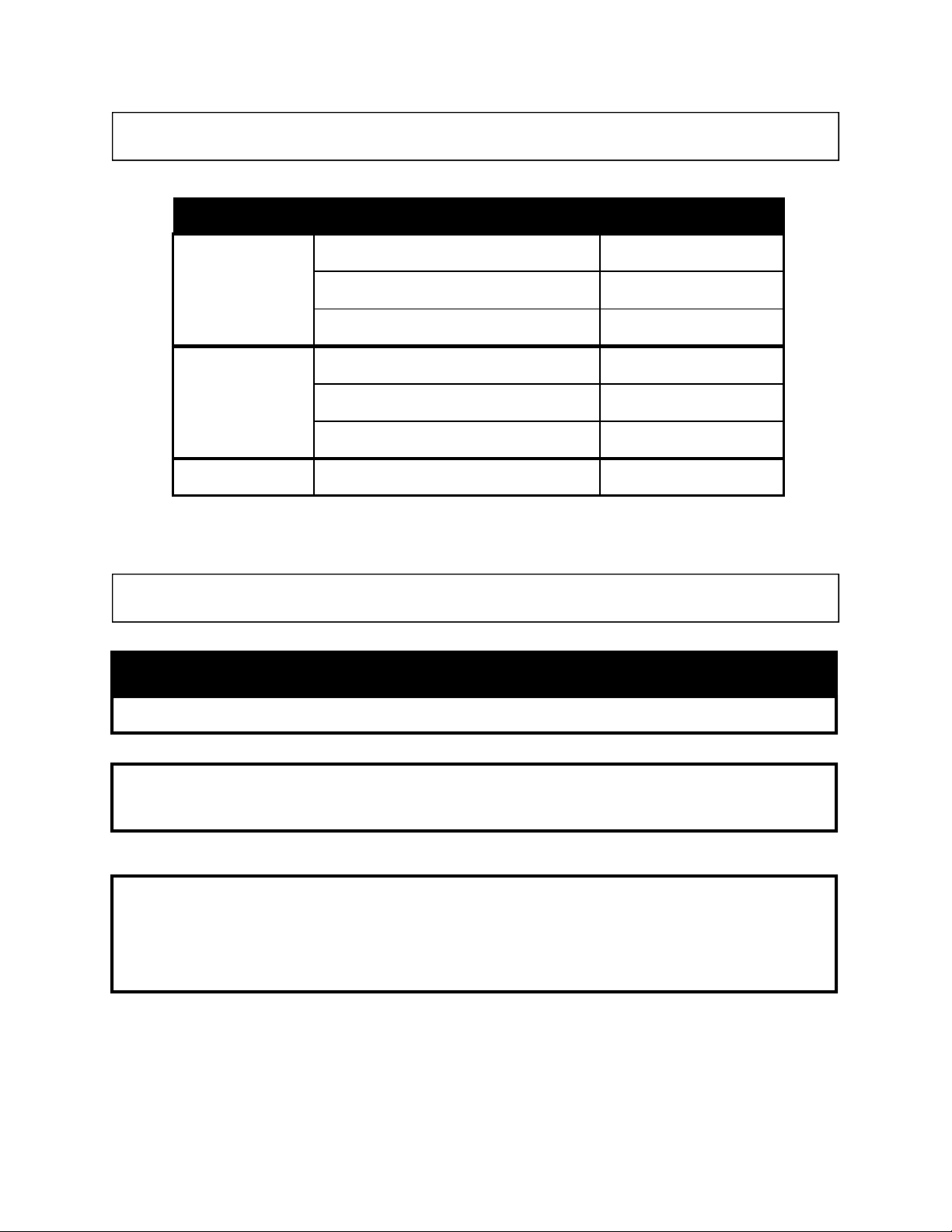

Restrictor Sizing Chart

Vent Type Length (ft ) R estrict or Size

1.65 to 3.3 41

Concentric

1.65 (in) and 1.65 (out) 38

Separate

3.3 to 39.40 ( tot. in + out) 41

39.40 to 131 (t ot. i n + out) N o ne

Vertical 3.3 to 27.8 None

Exterior Vent Warnings

EXTERNAL VENT SURFACES ARE HOT.

3.3 to 8.8 44

8.8 to 32.8 None

CAUTION

IT IS THE RESPONSIBILITY OF THE HOMEOWNER TO KEEP THE VENT

TERMINAL CLEAR OF SNOW AND ICE.

NOTE: USE ONLY LISTED COMPONENTS SUPPLIED WITH THE BOILER.

SURFACE DISCOLORATION OF THE BUILDING MAY OCCUR DUE TO

IMPROPER INSTALLATION. QHT, INC. WILL NOT ACCEPT RESPONSIBILITY

OF LIABILITY FOR SUCH DISCOLORATION.

4

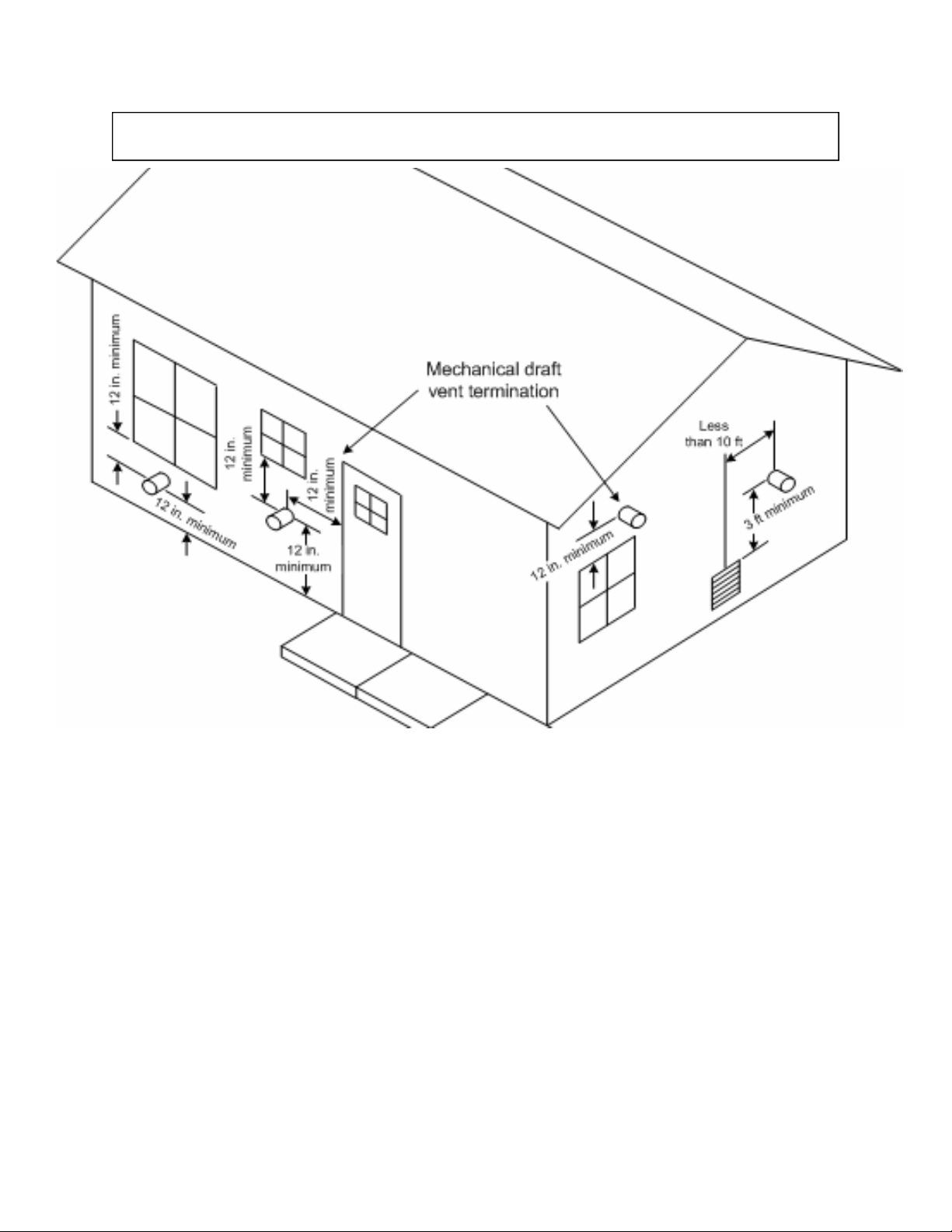

Exterior Vent Clearances

The Exhaust Hood should be installed on the leeward side of the house and conform to the

following guidelines:

1. The vent hood shall not be less than 3 feet above any forced air inlet to the house.

2. The vent hood shall not be less than 1 foot below, 1 foot horizontally, or 1 foot above any door,

window or gravity inlet into any building.

3. The vent hood shall not be less than 2 feet from an adjacent building.

4. The vent hood shall be not less than 7 feet above grade when located adjacent to a public

walkway.

5. The vent hood shall be located so that flue gasses are not directed to jeopardize people,

overheat combustible structures, materials or enter buildings.

6. Minimum of 4’ horizontal clearance from electric meters, gas meters, regulators and relief

equipment.

7. Care should be taken to ensure the rubber gaskets in ALL vent joints are properly

assembled to prevent leakage of products of combustion in the building.

8. Avoid installing exhaust the hood on the North, West, or the side of the house receiving the

prevailing winds.

5

Concentric Riser Vent Kit - RI VC RIS - 9990322

Components included in kit:

A. EXHAUST GASKET (4)

B. UNION CLAMP (3)

C. RISE EXHAUST PIPE (18”)

D. RISE INTAKE PIPE (20”)

E. UNION GASKET (3)

F. FLANGE GASKET (1)

G. FLANGE SCREWS (4)

H. BOILER COLLAR (1)

I. UNION CLAMP SCREWS (6)

J. 90 DEG ELBOW (1)

K. INTAKE TERMINATION (38”)

L. EXHAUST TERMINATION (40”)

M. WALL GASKET (2)

Notes:

Length 1’ to 32.8’ equivalent length

90 Elbow = 5.4’ equivalent length

45 Elbow = 3’ equivalent length

6

Concentric Riser Vent Kit Installation

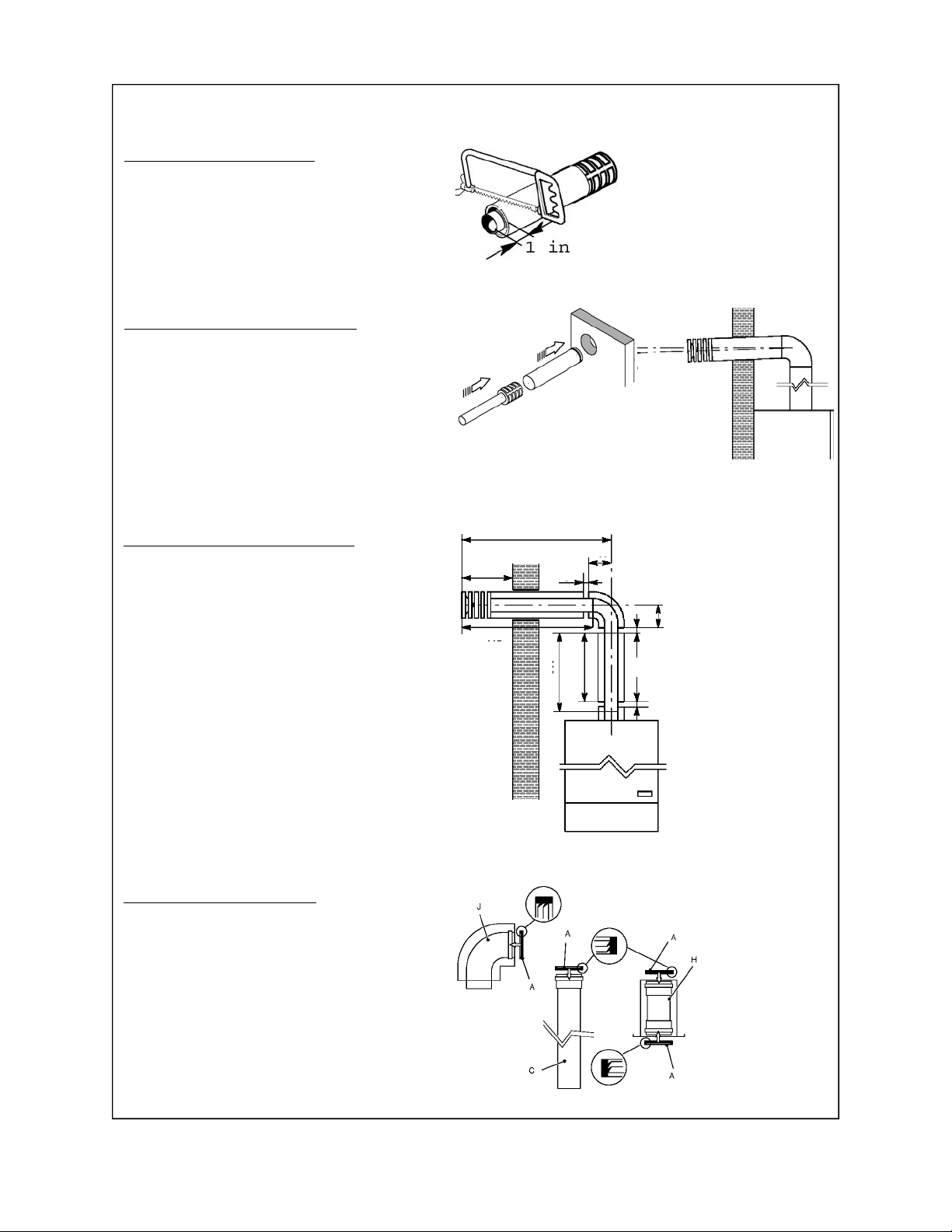

Pipe connections (Figure 1):

Whenever joining concentric pipe cut the inner

exhaust pipe so it is 1 inch long than the outer

intake pipe.

Figure 1

Termination Location / Installation

:

The concentric termination piece is installed

by sliding the outer intake pipe through the

wall from inside the building (shown in figure

2). The inner exhaust pipe is then slid into the

intake pipe until the termination cap bottoms

out on the end of the intake pipe.

Note: The termination should be pitched 3°

downward (2” down per 39” length) away from

the boiler. As shown in Figure 3.

Concentric Riser Kit components

:

Figure 4 depicts the concentric riser kit

components and dimensions. The vertical

and horizontal sections can be cut to length

(from the male end) during installation.

Additional pipe or elbows can be purchased

separately. Refer to page 6 for the relevant

part numbers.

Figure 2

6”

39”

42”

19 3/4”

1/8”

3 3/4”

18”

3° Downward pitch

(2” per 39” length).

Away from boiler

Figure 3

3 3/4”

1/4”

1/4”

Exhaust Gasket Installation

:

Install the red exhaust o-ring gaskets (A) into

each of the vent components female ends as

shown in Figure 5. Be sure to install the

gaskets so the beveled rings are oriented as

shown in Figure 5.

Figure 4

Figure 5

7

Concentric Riser Vent Kit Installation Cont.

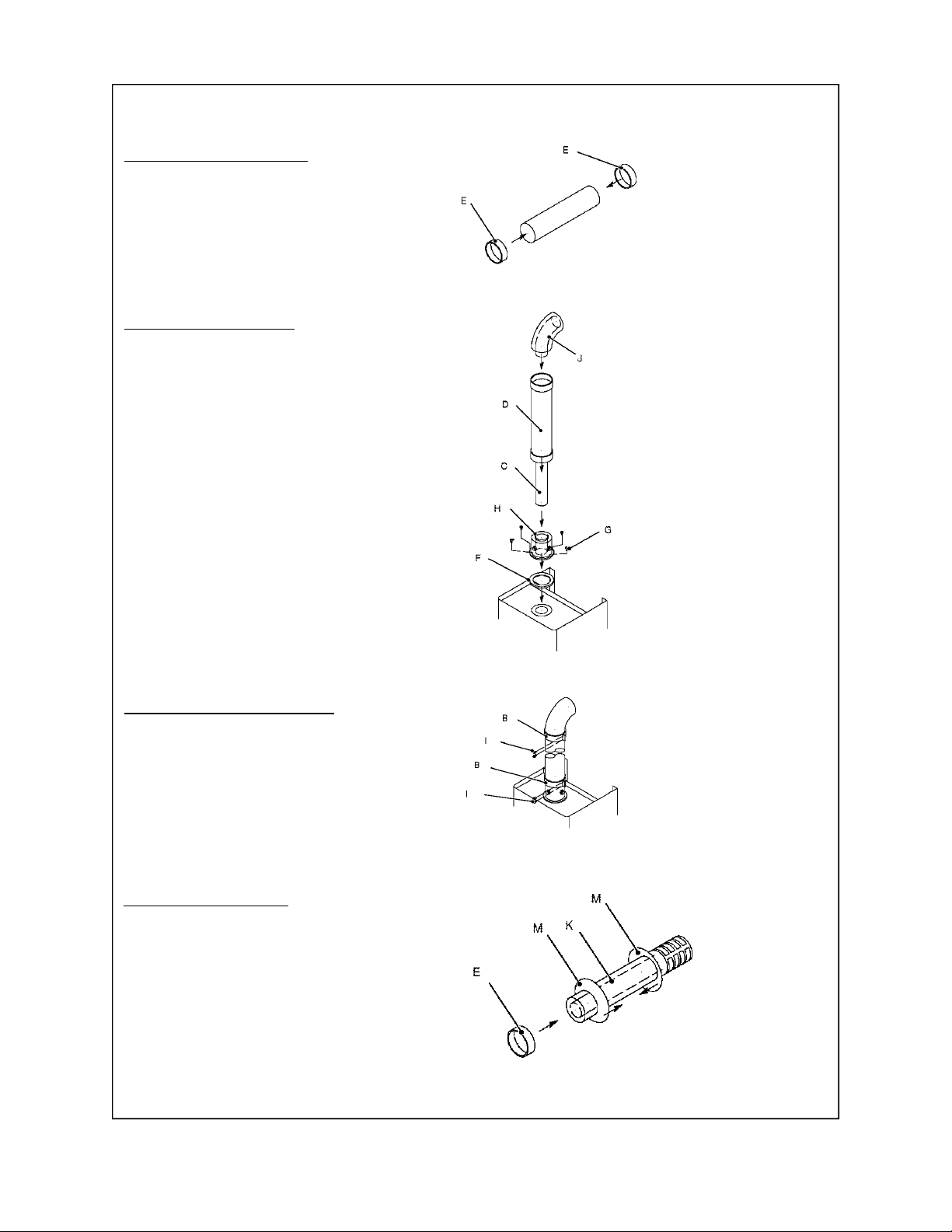

Intake Gasket Installation :

Install the intake gaskets (E) on the intake

pipes as shown in Figure 6.

Figure 6

Vertical Rise Installation

• Install the flange gasket (F) onto the boiler

outlet as shown in Figure 7.

• Attach the boiler collar (H) to the outlet of

the boiler using the 4 screws (G).

• Insert the vertical exhaust pipe (C) into

the boiler collar. (Be careful not to

damage the red exhaust gasket)

• Slide the air intake pipe (D) onto the boiler

collar so that the intake gasket (E) fits

over the intake collar (H).

• Install the elbow (J) onto the vertical rise

pipe.

Intake Pipe Clamp Installation

Install the intake pipe clamps (B) on the intake

gaskets (E) as shown in Figure 8, using

attachment screws (I)

:

:

Figure 7

Termination Installation

• Install the wall gaskets (M) on the

termination pipe (K). One gasket from the

inside of the wall and one from the

outside.

• Install the intake gasket (E) on the

termination pipe (K)

:

Figure 8

Figure 9

8

Loading...

Loading...