Leaders in Environmental Compliance Products

OPERATIONS

Au

to

Pump

+

MANUAL

ATEX Version

602418-02 (doc # 602418 ) (Rev 12/10/12)

DURABLE,

DEPENDABLE,

& DELIVERS

AutoPump Controllerless System

(For 4 inch wells or larger)

1-800-624-2026 (North America Only) (734) 995-2547 - Tele (734) 995-1170 - Fax info@qedenv.com - E-mail www.qedenv.com

QED Environmental Systems - P.O. Box 3726 / 2355 Bishop Circle W. Dexter, Michigan 48130-3726

QED Environmental Systems (West) - 1565 Alvarado Street San Leandro, California 94577-2640

1-800-537-1767 (North America Only) (510) 346-0400 - Tele (510) 346-0414 - Fax

Copyright QED Environmental Systems, Dec. 2012

Patents/Trademarks

The equipment in this manual is protected under U.S. and foreign patents issued and pending:

U.S. Patents:

AutoPump (AP)

"AP" is a Registered Trademark of "QED Environmental Systems"

"AutoPump" is a Registered Trademark of "QED Environmental Systems"

The QED Environmental Systems logo is a Registered Trademark of "QED Environmental Systems"

QED Environmental Systems is a Registered Trademark of "QED Environmental Systems"

5,004,405

Table of Contents

Introduction

Chapter 1: Safety

_________________________________________________

_______________________________

Safety

How to Contact QED

_______________________________

____________________________________________

A Partial List of Safety Procedures

Fire and Explosion Protection

_______________________________

Chapter 2: ATEX Certification Information

ATEX Certifications, Label Detail and Explanation

Chapter 3: Overview

Chapter 4: Equipment

Chapter 5: Installation

Chapter 6: Maintenance

Chapter 7: Troubleshooting & Repairs

_________________________________________

General Specifications

This is How it Works

_______________________________

_______________________________

________________________________________

Unpacking

Equipment List

Single Stage Filter/Regulator

_______________________________

_______________________________

_______________________________

_____________________________

Installation

Hose Bundling

_______________________________

_______________________________

______________________________________

Cleaning Pump Interior

Iron Build-up Cleaning Procedure

_______________________________

__________________________

Troubleshooting

Returning Equipment for Service

Equipment Cleaning Requirements

_______________________________

_______________________________

____________________________________________

_______________________________

_______________________________

_______________________________

_______________________________

1

1

1

2

2

2

3

3

5

5

5

8

8

8

8

9

9

10

13

13

13

20

20

22

22

Pump Specifications

_______

AP4+ Bottom Inlet Long

AP4+ Bottom Inlet Short

AP4+ Bottom Inlet Low Drawdown

AP4+ Top Inlet Long

AP4+ Top Inlet Short

AP4+ Top Inlet Low Drawdown

Terms, Conditions and Warranty

Figures:

Figure 1 -

Figure 2 -

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure 12 -

Figure 13 -

ATEX Label Detail and Explanation

ATEX Label Location and Appearance

- 3

- 4

- 5

- 6

Examples of Well Caps

- 7

Hose Bundling

- 8

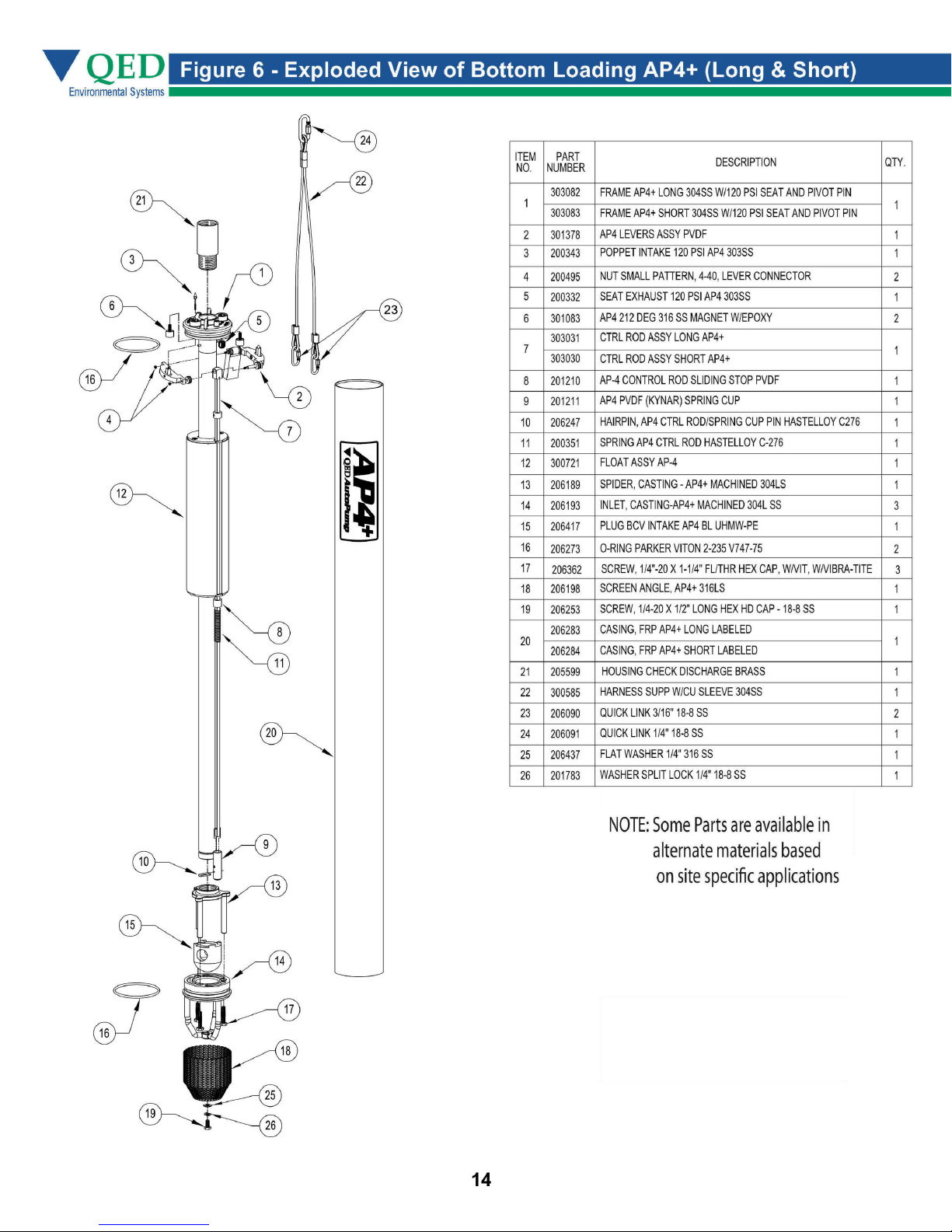

Exploded View of a Bottom-Loading AutoPump AP-4+ (Long & Short)

- 9

Exploded View of a Bottom-Loading AutoPump AP-4+ (Low Drawdown)

Exploded View of a Top-Loading AutoPump AP-4+ (Long & Short)

- 01

- 11

Exploded View of a Top-Loading AutoPump AP-4+ (Low Drawdown)

Exploded View of AP-4+ Lever Assembly

Exploded View of 1-Inch Brass Check Valve

_______________________________

_______________________________

_______________________________

_______________________________

_______________________________

_______________________________

_______________________________

_______________________________

_______________________________

_______________________________

skroW ti woH

_______________________________

metsyS pmuPotuA eht fo weivrevO

_______________________________

_______________________________

_______________________________

_______________________________

_______________________________

stcennoC-kciuQ htiw 06 rotalugeR/retliF egatS elgniS

_______________________________

_______________________________

_______________________________

_______________________________

23

23 - 26

27 - 29

31 - 34

35 - 38

39 - 42

43 - 46

47

3

4

6

7

8

11

12

14

15

16

17

18

19

Introduction

Welcome to QED Environmental Systems’ AutoPump® (AP4+) manual.

To ensure the best operator safety and system performance, it is strongly recommended that the operators read this

entire manual before using the system.

This manual reflects our many years of experience and includes comments and suggestions from our sales and

service personnel and most importantly from our customers. The chapters, their contents and sequence were designed

with you, the user and installer, in mind. We wrote this manual so it can be easily understood by users who may not be

familiar with systems of this type or are using a QED system for the first time.

Safety

Safety has been a cornerstone of our design which has been proven out in building and shipping systems throughout

the world. Our high level of performance is achieved by using quality components, building in redundancies or backup

systems, and not compromising our commitment to quality manufacturing. The net result is the highest quality and

safest pneumatic pump recovery system on the market. We feel so strongly about safety, based on years of working

with the hydrocarbon industry, that it is the first section of all our manuals

How to Contact QED

If for any reason you are unable to find what you need in this manual feel free to contact the QED Service Department

at any time. We encourage you to use following communication methods to reach us at any time:

San Leandro Service Center

1565 Alvarado Street

San Leandro, California 94577-2640

(

(510) 346-0400 — Tele.

(510) 346-0414 — Fax

QED can be reached 24 hours a day

Service Department

QED Environmental Systems

www.qedenv.com

ylnO aciremA htroN — 7671-735 )008

Ann Arbor Service Center

PO Box 3726

Ann Arbor, Michigan 48106-3726

2355 Bishop Circle W.

Dexter, Michigan 48130

(800) 624-2026 — North America Only

(734) 995-2547 — Tele.

(734) 995-1170 — Fax

info@qeden

v.com — E-mail

We welcome your comments and encourage your feedback regarding anything in this manual and the equipment you

have on-site.

Thank you again for specifying QED equipment.

1

Chapter 1: Safety

Safety has been a prime consideration when designing the AutoPump System. Safety guidelines are provided in this

manual, and the AutoPump System safety features are listed below. Please do not attempt to circumvent the safety

features of this system.

We have also listed some possible hazards involved when applying this system to site remediation. Nothing will protect

you as much as understanding the system, the site at which it is being used, and the careful handling of all equipment

and fluids. If you have any questions, please contact the QED Service Department for guidance.

As you read through this manual, you will encounter three kinds of warnings. The following examples indicate how they

appear and lists their respective purposes.

Highlights information of interest.

Note:

Caution:

Warning:

Highlights ways to avoid damaging equipment.

Highlights personal safety issues.

A Partial List of Safety Procedures

WARNING:The air compressor and any other electrical equipment used with this pneumatic system must be

positioned outside of any area considered hazardous because of possible combustible materials.

These safety procedures should be followed at all times when operating QED equipment on or off site, and should

be considered as warnings:

Wear safety goggles when working with the AutoPump System to protect eyes from any splashing or pressure

•

release.

•

Wear chemically resistant rubber gloves, boots, and coveralls when handling the AutoPump and fluid discharge

hose to avoid skin contact with the fluid being removed

•

Point tubing/hoses away from personnel and equipment when connecting or disconnecting.

•

Always ensure that the fluid discharge line is connected before the air line to prevent accidental discharge.

The AutoPump System minimizes the potential for accidents with the following safeguards:

Fire and Explosion Protection

Almost all of QED underground fluid extraction systems are pneumatic. This offers many inherent fire and explosion

protection features.

2

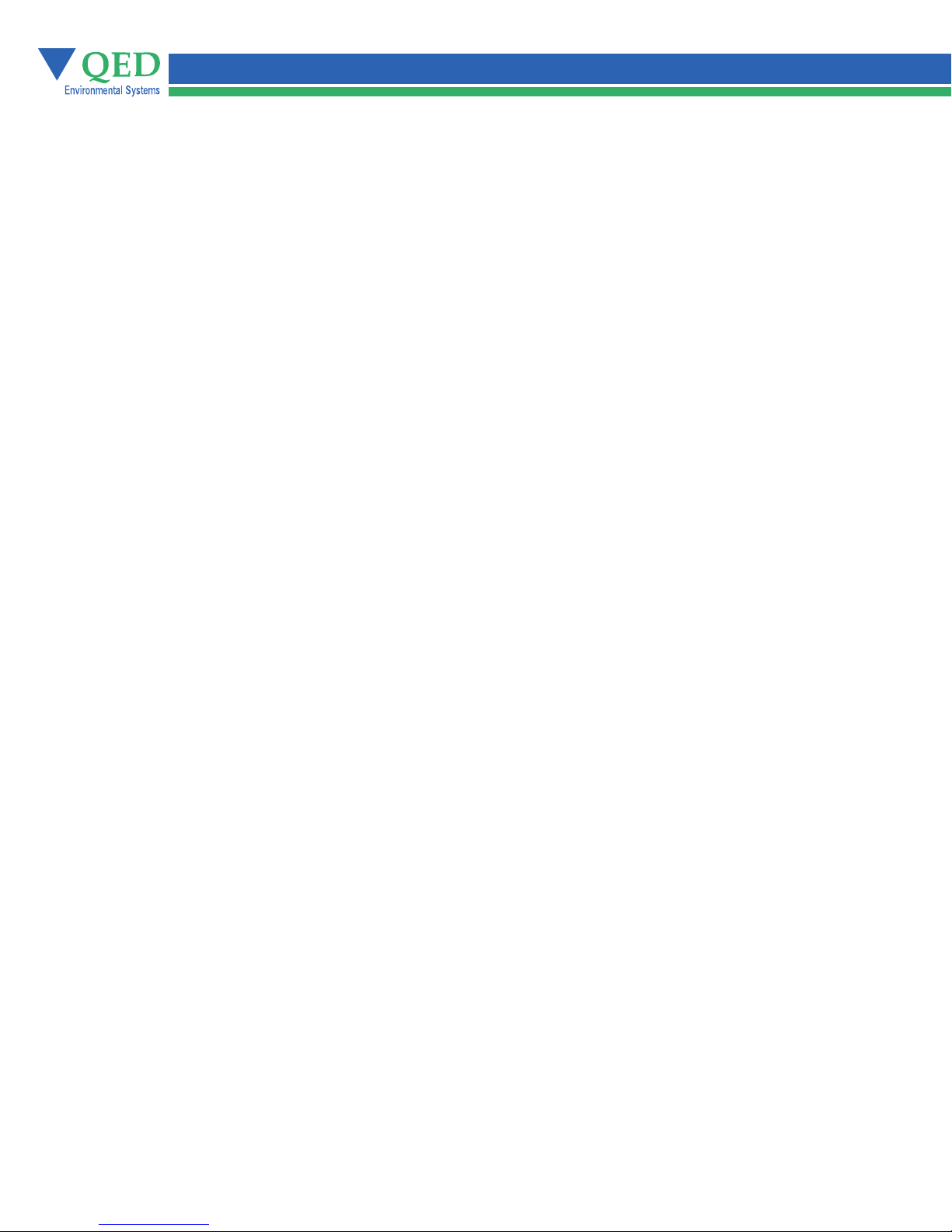

Chapter 2 ATEX Certifications, Label Detail and Explanation

Equipment with an ATEX label similar to the example in Figure 1, is ATEX certified.

Equipment without the label is not ATEX certified.

Figure 1 explains the ATEX label, Figure 2, (following Page) shows the label location and

appearance.

Figure 1

This equipment has been certified to Hazardous Area Classification:

1725

CE

Symbol

Code No. of Notified

Body Certifying

Quality Management

System

of Manufacturer

Equipment Model:

= 2-inch AutoPump

AP2

= 3-inch AutoPump

AP3

= 4-inch AutoPump

AP4

= 4-inch AutoPump

AP4+

= Genie Pump

GNE

= Bladder Pump

BP

= 2-inch Specific

SPG2

Gravity Skimmer

= 4-inch Specific

SPG4

Gravity Skimmer

= 2-inch Selective

SOS2

Oil Skimmer

= 4-inch Selective

SOS4

Oil Skimmer

X

3

Indicates That

the Equipment

May Be Used in

a Hazardous Area

Group

Catagory

Atmosphere*

*G=Gas D=Dust

II

1

G D G D G D

Manufacturer, Zip Code, Country

1

G

II

2

TL EX DIS IN

AP4+

FM

APPROVED

Approving Entity

II

c

B

Protection Method

is by Construction

The Equipment

May be Located

Where Flammable

Gases and Vapors

3

MAXIMUM PRESSURE

of Group IIB May

QED, 94577-2640, USA

1725

YEAR

PAT. 5004405,

5641272, 5495890, 5358038

6T

be Present

X

3

II

c 1 65

1

G

Maximum Operating Pressure

as Appropriate and as Noted

T

a

Certificate Number

FM08ATEX0028

B

II

*Serial Number May be

LocatedOutside the Label

II

T

T

a

6

9.0 BAR (130 PSI)

13.8 BAR (200 PSI)

Year of Manufacture

Patent Number(s)

Serial Number*

o

II

c c

1 6

Allowable Ambient

Temperature Range

for Equipment

Minimum Auto

Ignition Temperature

of Surrounding

Substance by Class

o

o

C C

t

o

S/N:AP4+C-XXXXX

t

T1

T2

T3

T4

T5

T6

o

o

5

450° C

300° C

200° C

135° C

100° C

85° C

X

3

Figure 2 ATEX Label Location and Appearance

Figure 2

Bottom Loading

A

M

P

P

AutoPump

Top Loading

Pump Serial Numbers

Located on the Pump’s Head

I

2

,

9

4

7

,

O

6

4

577

ED

Q

4

P

+

E

A

R

Y

A

U

A

X

E

R

T

A

A

8

B

.

MMU

I

SSS

.

R

3

A

R

U

3

E

8

1

.

B

R

,

,

5

4

9

5

7

OOO

4

5

1

1

,

4

8

9 9

3

5555

O O

8

3

5

8

Obverse View

I

2

,

9

4

7

,

O

6

4

577

ED

Q

4

P

A

+

E

A

R

Y

A

I

2

9

7

,

4

R

E

4

4

55

8

577

E

A

R

Y

8

.

3

3

1

,

9

5

OOO

5

,

3

O O

5

8

.

7

ED

Q

4

P

A

+

A

U

A

M

MMU

X

I

P

E

SSS

R

P

U

.

T

5

A

4

9 9

,

4

O

6

A

B

R

A

B

R

,

5

1

1

8

5

3

8

U

A

M

X

I

P

E

SSS

R

.

T

A

P

A

8

B

.

MMU

R

3

A

R

U

3

E

8

1

.

B

R

,

,

5

4

9

5

7

OOO

4

5

1

1

,

4

8

9 9

O O

3

5555

8

3

5

8

Reverse View

X

1

a

T

T

6

F

APPROVED

7

M

MF

3

5

2

t

C

O

1

=

E

O

T

8

A

AutoPump

C

G

1

I

I

OO

1

1 1

O

X

O

B

II

C

2

8

2

2

5

T

C

4

T

C

4

T

8

4

Chapter 3: Overview

The AutoPump® fills and empties automatically, and is very easy to install, use, and maintain.

The AutoPump is a pneumatic fluid extraction pump that pumps in pulses. It handles any liquid which flows freely

into the pump and is compatible with the component materials and with the connecting hoses. The AP4+ is intended

for vertical operation in well casings with a 3.75-inch or greater internal diameter. It can pump particles up to

1/8-inch in diameter.

The AutoPump is very versatile and available in a wide range of lengths, valve arrangements, and materials of

construction to meet particular site specifications.

Equipment will vary by application and site specifications. (See Chapter 3)

General Specifications

Pump Diameter:

Pressure Range:

High Pressure Option:

Flow Ranges:

3.6 inch (91 mm)

5 - 120 psi (0.4 - 8.5 Kg/cm²)

5 - 200 psi (0.4 - 14.1 Kg/cm²)

0-14 gallons per minute (0-53 liters per minute)

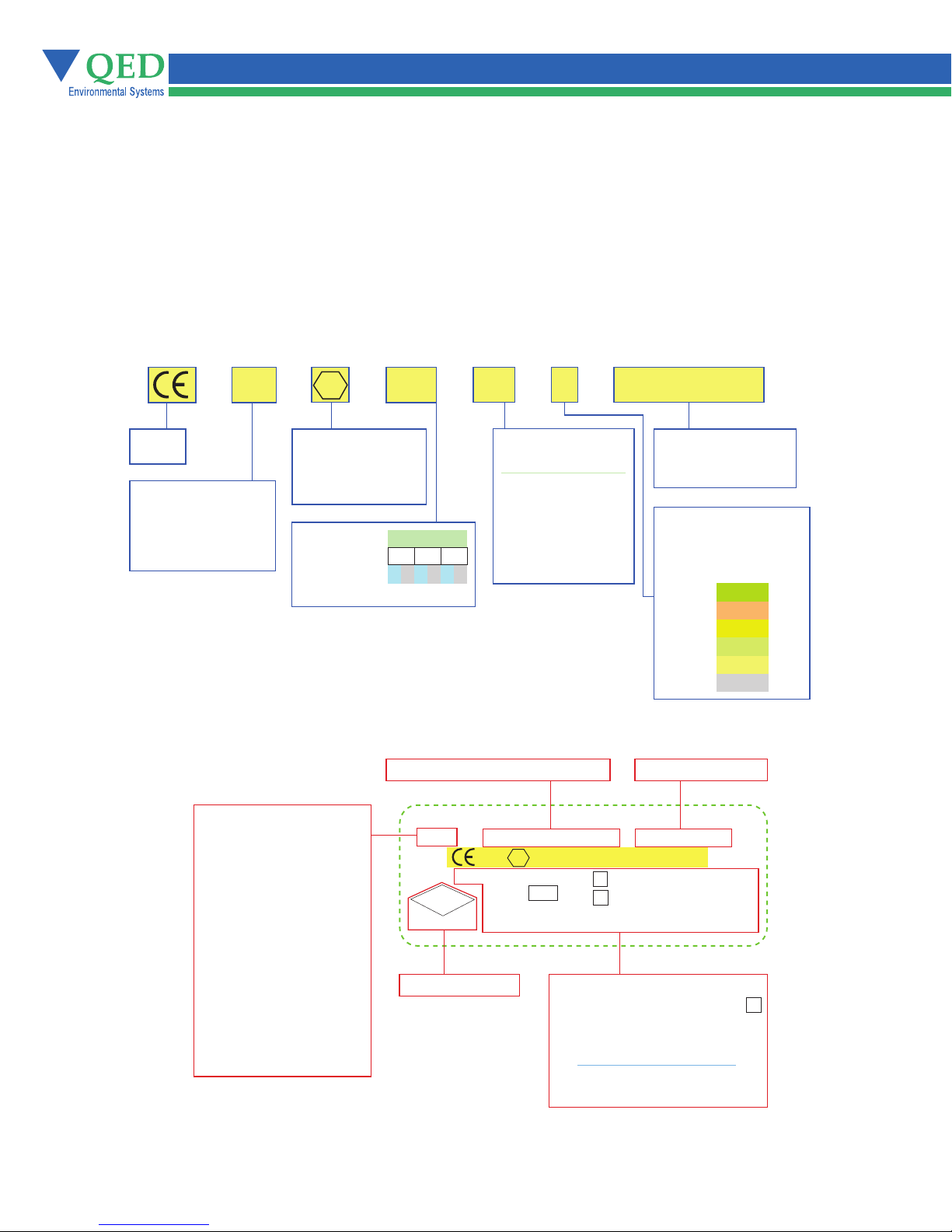

This is How it Works

The AutoPump is a submersible compressed air-driven pump which fills and empties automatically. It also controls

the fluid level in a well automatically. The pump fills (See Figure 1) when fluids enter either the top or bottom check

valve. Air in the pump chamber exits through the exhaust valve as the fluid fills the pump. The float inside the pump

is carried upwards by the fluids rising in the casing until it pushes against a stop on the control rod, forcing the valve

mechanism to switch to the discharge mode.

The switching of the valve causes the exhaust valve to close and the air inlet valve to open. This causes the pump

to empty (see Figure 1) by allowing compressed air to enter the pump. This pressure on the fluid closes the inlet

check valve and forces the fluids up the discharge line and out of the pump through the outlet check valve. As the

fluid level falls in the pump, the float moves downward until it pushes against the lower stop on the control rod, forcing

the valve mechanism to switch to the fill mode. The outlet check valve closes and prevents discharged fluids from

re-entering the pump. The filling and discharging of the pump continues automatically.

NOTE: The figures shown here are simplified schematics.

5

Figure 3 - How it Works

Pump FillingPump Emptying

Pivoting Lever

Tipped Upward

By Rising Float

Compressed Air

Flowing Into

Pump

As Pump Empties,

Float Descends

Air Exhausting

From Pump

Upper

Float Stop

Pivoting Lever

Tipped Downward

By Descending

Float

Lower

Float Stop

Check Valve Seated

Sealing Inlet

As Pump Fills,

Float Rises

Lower

Float Stop

Check Valve

Unseated

Allowing

Liquid into

Pump

6

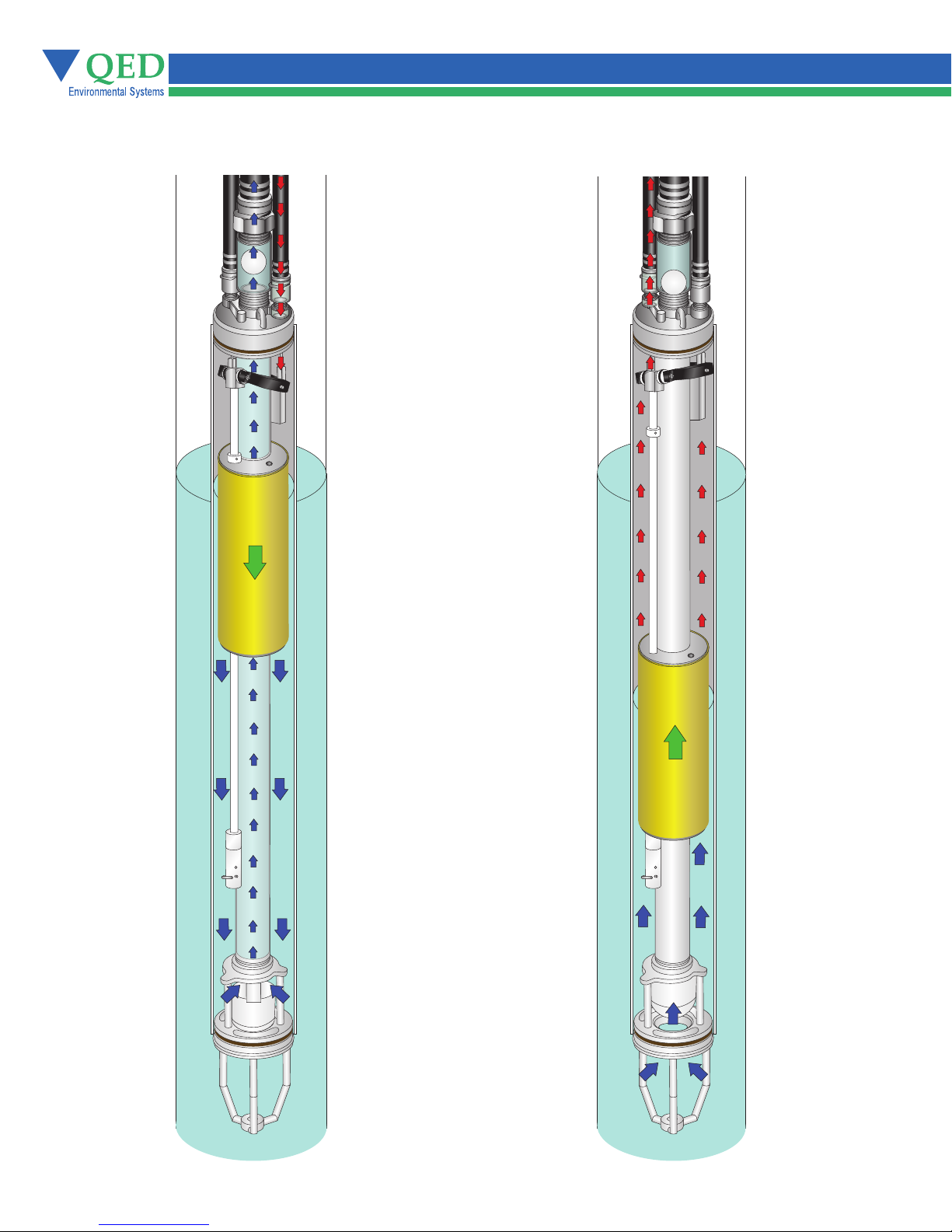

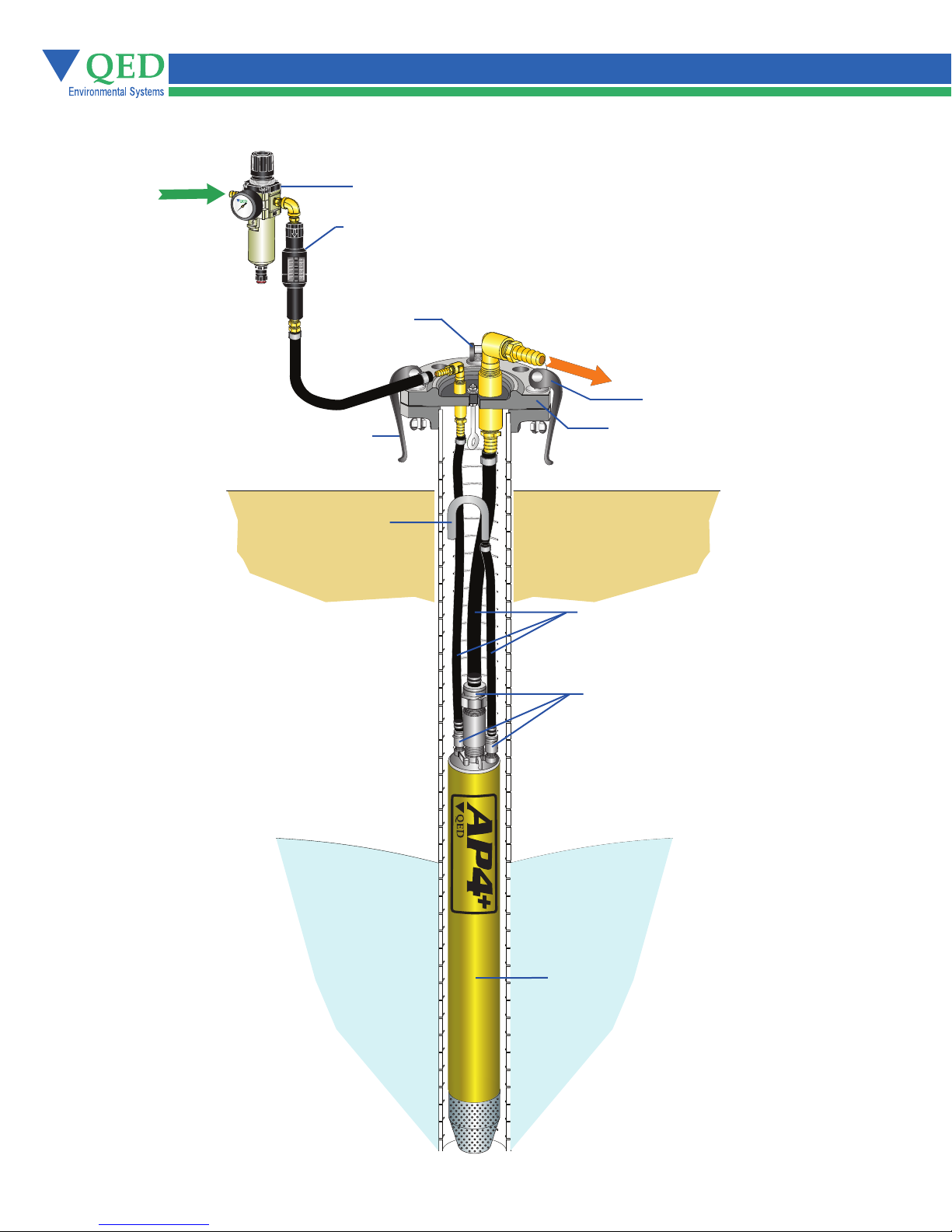

Figure 4 - Overview of the AP4+ System

AP4+ System provides everything required for pumping fluid from a well.

Air

Supply

From

Compressor

8

0

0

6

1

0

0

4

0

1

2

0

2

0

www.qedenv.com

1

4

0

0

1

6

0

Filter/Regulator

Cycle Counter

999999

111111

000000

Easy Bolt

Fluid

Discharge

Easy Bolt

Easy Bolt

Note: Support Harness, Rope, and

Tubing Sheath Omitted for Clarity

Wellhead

Air Exhaust

Tubing

Easy Fittings

pmuPotuA

Pump

7

Chapter 4: Equipment

Unpacking

During the unpacking procedure, check for the following:

• All parts on the packing list have been included in the box

• All fitting openings are unobstructed

• The equipment has not been damaged in shipment

Equipment List

The equipment list will vary depending on site specifications, but the following list is a typical configuration

1. Top-Loading or Bottom-Loading AP-4 with support harness

2. Single stage filter/regulator with:

•

5 Micron filter with auto drain tap

•

Pressure regulator with gauge

•

Maximum operating pressure 120 P.S.I. (8.4 Kg/cm²)

3. Pump Cycle Counter (PCC)

4. Pump support system:

• pac lleW

• epor eriw SS ro ylbmessa knil-kciuq htiw epor troppus enelyporpyloP

(Alternate materials as required)

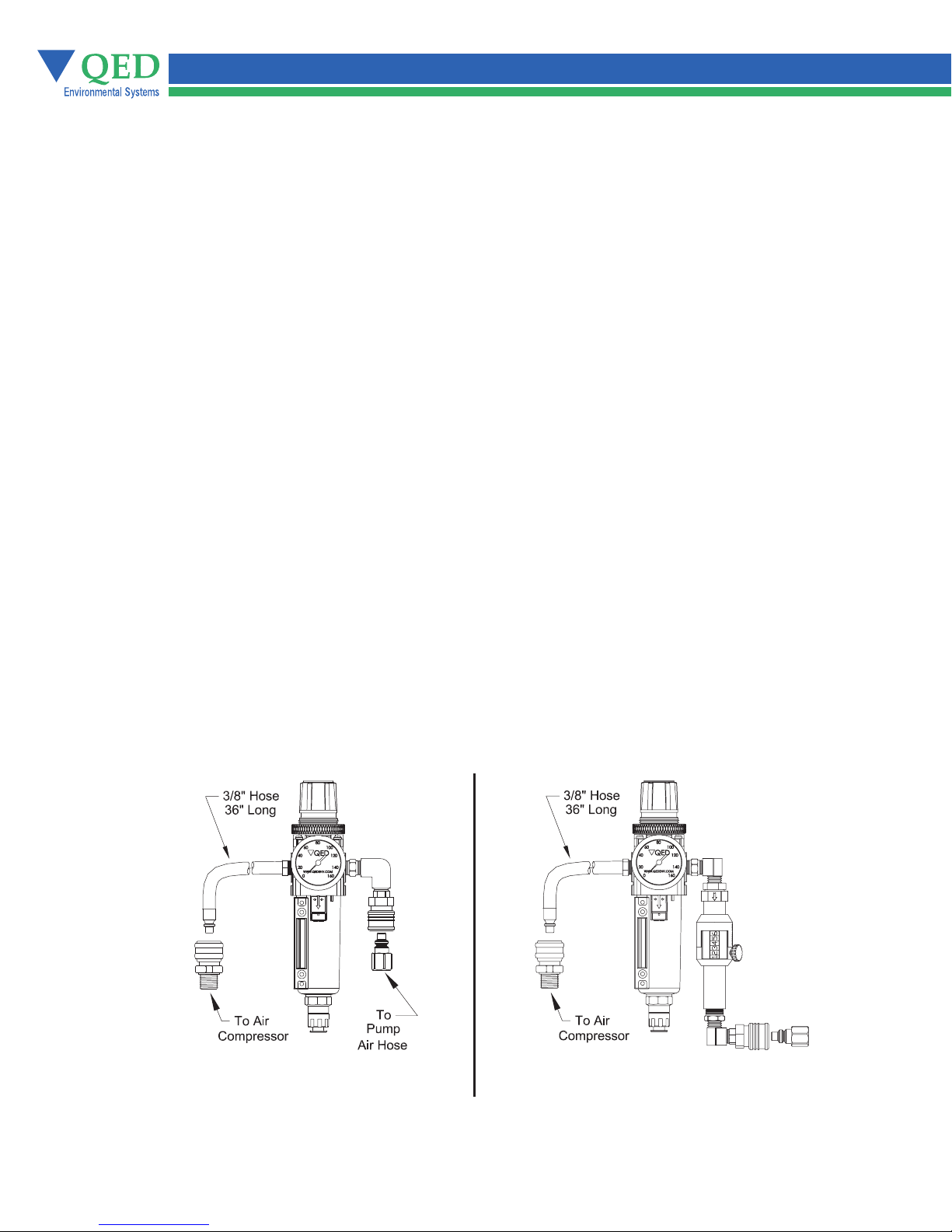

Single Stage Filter/Regulator

A single stage 5 Micron particulate air filter/regulator has a manual or an optional automatic drain and is installed

on the system air supply line. The filter/regulator removes particles and water droplets from the

air passing to the AP4+.

NOTE: Too much air pressure can result in low pump efficiency

Figure 5 - Single Stage Filter/Regulator with Quick-Connects

Part # 302468

For Standard Systems

Maximum operating pressure 120 P.S.I. (8.4 Kg/cm²)

Part # 302470

For Systems with Pump Cycle Counter

8

Chapter 5: Installation

1. Cover the pump tubing/hose ends with tape if they are to be pulled through trenches or laid on the

ground. This is to prevent debris from entering the lines.

2. Blow out all water and particles from compressed air conduits (including downwell pump air supply lines)

and fluid lines for at least 10 seconds after the water and particles exit before connecting them to the

system.

3. Slip clamps over appropriate tubing/hose prior to connecting the tubing/hose to the pump barbs.

4. Push tubing/hose down flush with the fitting's nut if possible; cover at least three barbs if three or more

are present (Note: when installing tubing in freezing weather, tubing can be dipped in warm water for a

few seconds to soften the nylon).

5. Attach pump support rope/cable to the pump.

6. Attach pump air supply and liquid discharge lines to the well cap. Attach the air exhaust line to the well

cap if the pump air is to exhaust outside the well (Note: the liquid discharge line is always the largest

diameter of the three lines, and the air supply line is always the smallest diameter).

7. Connect the pump air supply and liquid discharge lines to the appropriate surface lines/headers.

8. Turn on the air pressure to the pump (minimum of 0.5 psi per foot of vertical static head).

Caution: Submerging the pump before supplying it with air will result in fluid entering the exhaust tubing/hose.

Those fluids will be discharged from the exhaust tubing/hose during the first few cycles of the pump. If this

discharge will not be confined to the well; i.e., if the air exhaust line is routed outside the well*, it is important

to make sure that the air exhaust line is not directed such that equipment/ personnel could be splashed by the

discharged fluid when air is turned on to the pump.

Note: Submerging the pump before supplying it with air can also result in fluid entering the air supply line.This

fluid from the well can contain particles, which could interfere with operation of the pump's air valve.

9. Lower the pump to the desired depth in the well.

10. Secure the pump by tying off the pump support line or by placing the well cap (or flange) on the well.

11. Increase the air pressure to the pump until the pump is pushing the fluid out at the desired rate. With

sufficient air pressure (at least 10 to 15 psi higher than the vertical static head), the pump will gradually

draw down the fluid level in the well to the level of the pump. The time required for this draw down varies

with the yield of the well as compared to the flow rate of the pump. The maximum recommended pump

operating pressure is 120 psi.

Note: If the well environment is such that deposition occurs on stainless steel parts, the operator

may wish to raise the pump above the water level during a shutdown of the system.

* Routing the air exhaust in vacuum wells:

QED controllerless pumps automatically control the liquid level in the well. Under normal conditions,

the liquid level will be maintained at a point approximately one foot below the top of a bottom load

pump (this is the pump's actuation point). The pump will automatically start and stop as needed to

maintain the level at this actuation point.

When QED controllerless pumps are used in wells that are under vacuum, and the exhaust air is

routed into the well, the well level will be maintained at this normal actuation point. If, however, the

well is under vacuum and the exhaust air is routed outside of the well (to atmospheric pressure),

the actuation point of the pump will be higher than the normal actuation point by a distance equal

to the amount of vacuum applied to the well (expressed in "inches of water column"). Please note

that the pump will still function normally and maintain the liquid level, albeit a higher level.

9

Chapter 5: Installation

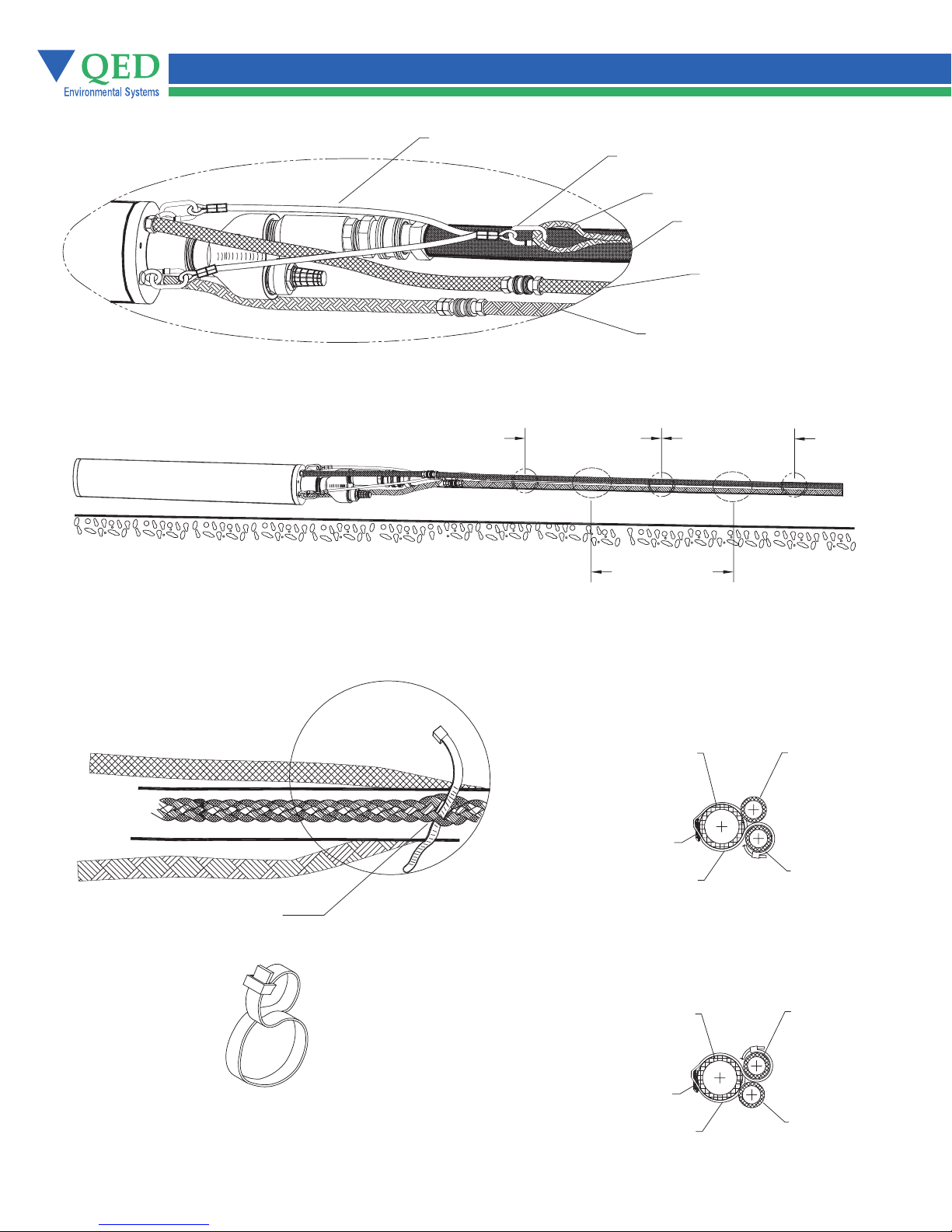

Hose Bundles

Hose bundling or the use of jacketed tubing reduces equipment entanglement at the well surface, and

aids the removal of the pump from the well. Bundling also assists in positioning the pump and

down-well hose assembly against one side of the well casing. Maximum space is created for other

items, such as probes, to be periodically placed inside the well.

Follow these instructions to create a hose bundle:

1. Lay the equipment on the ground and make all of the necessary hose connections. (See Figure 5).

2. If a well cap is supplied, install it on the hoses. (See Figure 4).

3. Connect the quick-link assembly on the support rope to the eyebolt on the AP4+ and lay the

support rope out along with the hoses. Make sure that none of the hoses or support ropes are

crossing over each other (See Figure 5).

Note: To make the next step easier, pull the support rope and the hoses taut.

4. Starting at the AutoPump end of the hose, put a tie-wrap through the center of the braided support

rope just above the uppermost quick-connect or barb on the AutoPump (See Figure 5).

5. Pulling the rope taut, put the tie-wrap around the fluid discharge hose with the rough surface

outwards. Cross the ends and complete the connect the tie-wrap make sure it is straight and is not

kinking the hoses (See Figure 5).

Note: After completing this step, the fluid discharge hose will be attached to the support rope and

the exhaust hose. At this point the air supply hose is still lying free.

6. Place the next tie-wrap two feet towards the well cap from the first. Secure the air supply hose

rather than the exhaust hose.

Note: It is important to put the tie-wraps approximately two feet apart to keep a proper discharge

hose/support rope bundle. Experience has shown that spreading the tie-wraps further apart than

two feet increases the probability for hose kinking.

7. Continue to alternate the air exhaust and the air supply tie-wraps every two feet, stopping about

five feet from the wellhead.

8. Being careful not to leave any sharp edges, cut the excess from the tie-wraps.

You now have a down-well bundled hose assembly that supports both the hoses and the down-well

equipment.

10

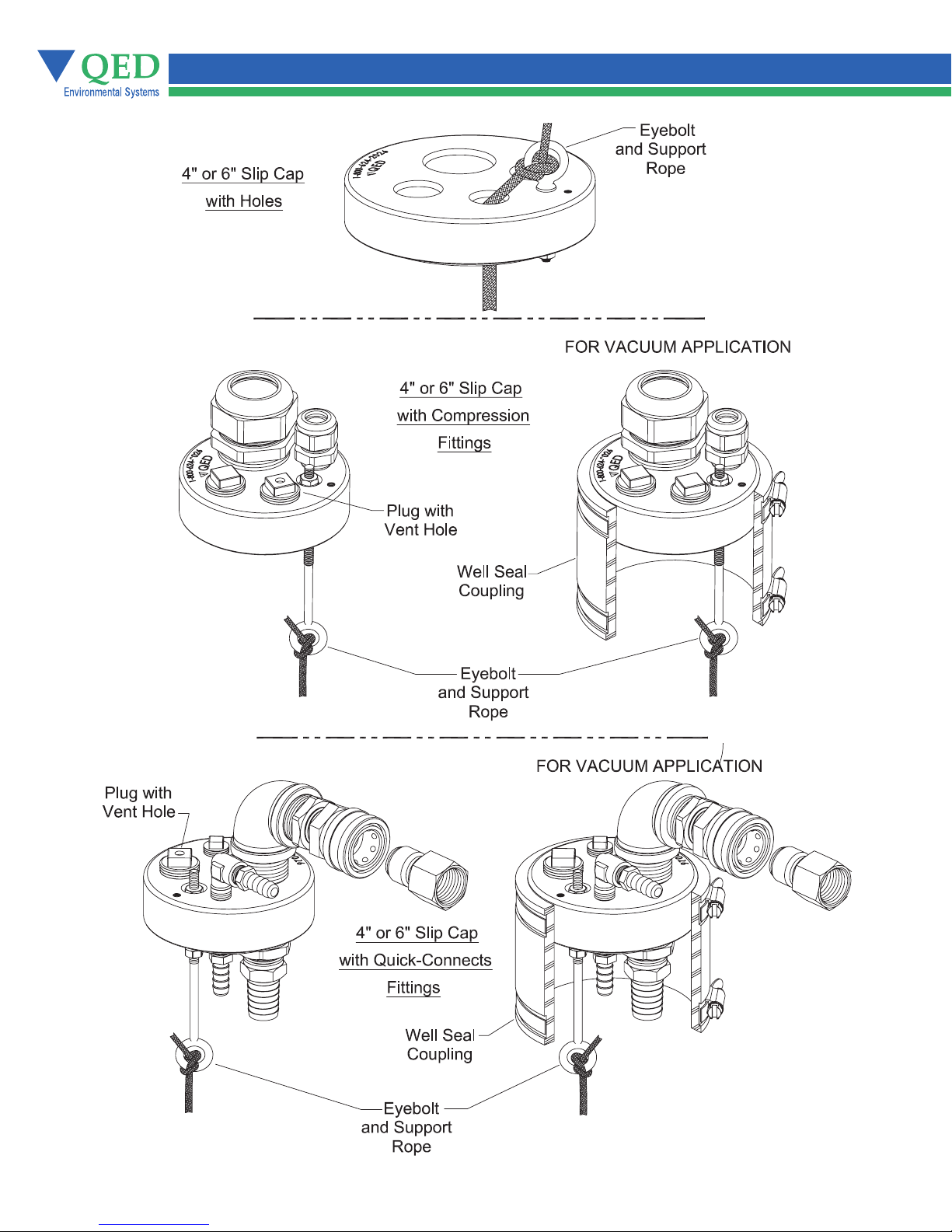

Figure 6 - Examples of Well Caps

11

Figure 7 - Hose Bundling

Air Exhaust Tie-Wraps in Between Air Exhaust Tie-Wraps Every 4 Ft. (122 Cm)

Support Harness

Quick Link Assembly

Support Rope

Fluid Discharge

Hose (Black)

Air Exhaust

Hose (Blue)

AutoPump® Air

Hose (Green)

Tie-Wrap Detail

Thread Tie-Wraps

Through Support Line

Air Exhaust Tie-Wraps in Between Air Hose Tie-Wraps Every 4 Ft. (122 Cm)

Air Exhaust Tie-Wrap

Fluid Discharge

Hose (Black)

Support Rope

Air Exhaust

Tie-Wrap

Air Hose Tie-Wrap

Fluid Discharge

Hose (Black)

AutoPump Air

Hose (Green)

Air Exhaust

Hose (Blue)

AutoPump Air

Hose (Green)

Figure 8 Tie-Wrap Layout

12

Support Rope

Air Hose

Tie-Wrap

Air Exhaust

Hose (Blue)

Chapter 6: Maintenance

Removing the Pump’s Casing

1. Remove the bolt at the bottom of the pump which holds the inlet screen in place (bottom loading pumps only).

2. Remove the three bolts at the bottom of the pump which hold the inlet in place. (See Figures 6,7,8,and 9)

3. Remove. the inlet from the pump’s casing by pulling it out.

4. Twist and slide the casing down off the pump’s frame.

Cleaning Pump Interior

The inner workings of the pump should now be exposed for inspection and cleaning. (See Figures 6 Through 11)

Note: A Scotch Brite® abrasive pad is useful for cleaning debris from the pump components.

.1 Gently brush off built-up solids from the float, the discharge line, the pump casing and the control rod guide.

2. The pump can be steam cleaned without damage.

3. Remove thick deposits of hardened scale on the discharge tube by using a handbrush or by lightly tapping the

discharge tube with a small hammer. Be careful not to strike any pins or other components, since they may be

damaged.

Iron Build-up Cleaning Procedure

After the casing has been removed from the AutoPump please follow the procedure below:

1. The bottom “spider” should be removed by unthreading it from the pump’s discharge pipe. (See Figures 6,7,8,and 9)

2. Visually inspect the 1 inch stainless steel fluid discharge pipe for scale build-up or debris. Also, do the same with the float

that rides up and down on the SS discharge pipe.

3. Should there be scale deposits on either or both the discharge pipe or float, then remove the float from the SS fluid discharge

pipe as follows . (See Figures 6,7,8,and 9)

Remove the small SS hairpin from the bottom spring cup. Removing the hairpin and spring cup will allow you to

remove the spring, sliding stop and float from the SS discharge pipe.

4. The 1 inch stainless steel fluid discharge pipe can now be cleaned using either a ScotchBrite pad, a wire brush or

a wire wheel on either a drill or a grinding machine. After removing the scale/debris, it is recommended the pipe

be water rinsed.

Both the internal and external surfaces of the float will generally require cleaning. The cleaning material choices

include a Scotch Brite pad, and a light grade 150 sandpaper.

The plates are removed to ease cleaning, they should be replaced on the same float end from which they came.

That is, the plates should maintain their original top and bottom positions.

5. The white plastic square Control Rod is the next component to be cleaned. The control rod is the item that fits

through the smaller hole in the float and is adjacent to the SS discharge pipe in the assembled pump. To Clean

use the Scotch Brite pad or a razor or Exacto knife (not sandpaper).

6. The final component to be cleaned is the outer AP4+ casing. The fastest and most effective way to clean out

the inside surface of the pump casing is to use a three-stone honing tool. The technique is to move the hone in and-out, a half dozen times or so through, each end of the casing. The time for the casing cleaning should take no

longer than 5 minutes.

The AutoPump is now ready for re-assembly by following the steps above in reverse order.

Note: Before threading the bottom “spider” onto the pump’s discharge pipe, be sure to wrap the discharge pipe’s

threads completely with Teflon tape.

13

Figure 10 - Exploded View of Top Loading AP4+ (Long & Short)

NOTE: Some Parts are available in

alternate materials based

16

Figure 11 - Exploded View of Top Loading AP4+ Low Drawdown

NOTE: Some Parts are available in

alternate materials based

17

Figure 12 - Exploded View of AP4+ Lever Assembly

Parts Assembled

18

ITEM NO. PART NUMBER DESCRIPTION

200359

1

200359

1

200665

1

200337

2

200337

2

200336

2

201465

3

200497

4

301654

5

200328

6

200495

7

200330

8

201053

9

200327

10

200327

10

206008

10

200496

11

201052

12

201458

13

120 P.SI INTAKE POPPET CONNECTOR-LONG

120 P.SI INTAKE POPPET CONNECTOR-SHORT

120 P.SI INTAKE POPPET CONNECTOR-LDD

303 SS 120 P.SI EXHAUST POPPET-LONG

303 SS 120 P.SI EXHAUST POPPET-SHORT

303 SS 120 P.SI EXHAUST POPPET-LDD

316 SS POPPET PIN

PH 15-17 MO POPPET PIN RETAINING E-CLIP

PVDF LEVER /BUSHING ASSEMBLY

303 SS LEVER CONNECTING PIN

4-40 SS SMALL PATTERN NUT LEVER CONNECTING

17-7 COUNTERWEIGHT ROLLER

316 SS COUNTERWEIGHT BUSHING

303 SS COUNTERWEIGHT-LONG

303 SS COUNTERWEIGHT-SHORT

303 SS COUNTERWEIGHT-LDD

VITON BUMPER O-RING

316 SS CONTROL ROD ADAPTER BUSHING

PVDF CONTROL ROD ROLLER

QTY.

1

1

1

1

1

1

2

2

2

1

2

4

1

1

1

1

4

1

2

Figure 13 - Exploded View of 1 Inch Check Valve

Adapter

OR

Barbed

Fitting

Check

Ball

Check

Valve

Housing

19

Chapter 7: Troubleshooting & Repairs

Problems may occur and usually can be easily resolved by following these instructions. If, after careful reading and

service, you cannot resolve the problem, please contact the QED Environmental Systems (QED) Service Department

at (800) 537-1767.

Caution: Wear goggles, gloves, and coveralls when servicing this system.After troubleshooting is completed and

before assembling the pump, slowly move the float through its range to ensure that the lever will trip even if the

pump fills and empties slowly.

Note: Maintenance for disassembly and cleaning instructions.

Possible Causes

Detailed Instructions

Follow This Chart

Air Supply

Fluid Level

Air Exhaust Restricted

Fluid Inlet Clogged

5. Debris, Scale or Very

Viscous Fluid

6. Lever Pivot Wear X

7. Debris in Air Inlet

Valve

8. Fluid Check Valve

9. Valve Timing

Pump Not Cycling

X1. X

X2.

X3. X

X4.

X

X

X

X

Symptoms

Pump Not Cycling,

Volume is Reduced or

There is No Discharge

X

X

Air in Fluid or

Discharge

X

Troubleshooting

1. Air Supply

If the air pressure is too low, or if the flow is severely restricted, the pump will not cycle. The minimum air

•

pressure requirement for pump operation is 0.5 psi per foot of vertical static head.

•

If the air pressure exceeds the design limitations of the pump, the pump may fail to cycle, or the exhaust

may have locked up and caused air to enter the fluid discharge.

2. Fluid Level

The fluid level must be above the fluid inlet on a Top-Loading pump. On a Bottom-Loading pump, the fluid must

•

be no lower than 9 inches below the head of the pump

:detcirtseR tsuahxE riA.3

• .retemaid ni llams oot ro ,deggulp ,deknik eb ton tsum enil tsuahxe ehT

The air exhaust outlet must be above the fluid level

•

• .enil yrevocer ropav gninoitcnuf a ro erehpsomta eht ot detnev eb tsum llew eht ,llew eht ni stsuahxe ria eht fI

20

Chapter 7: Troubleshooting & Repairs

• If the air exhausts to the atmosphere (outside the well) and a vacuum is drawn on the well, the pump may fail

to fill. In order for the pump to fill under these conditions, the pump must be submerged to make up for the

pressure difference between the atmosphere and the partial vacuum in the well.

The pressure difference, expressed as feet of water column (FT. W. C.), is the distance the fluid must be above

the pump before it can fill.

4. Fluid Inlet Clogged

•

If the fluid inlet screen is clogged with debris water cannot enter the pump.

5.Debris, Scale, or very Viscous Fluid

If debris, scale or a very viscous fluid has accumulated inside the pump, the float may not move freely up and

•

down, or the control rod may not slide easily through the float.

Clean the float, control rod, and the casing. (See Chapter 5 for cleaning instructions).

•

6. Lever Pivot Wear

• Grasp the center of the lever with thumb and forefinger. Rotate the lever to horizontal.

• Push up and down, toward and away from the head. Confirm that there is less than 1/32 inch of movement.

•

Replace the levers if the pivot hole is worn

7. Debris in Air Inlet Valve (First check #6-Lever Pivot Wear)

•

Open the pump. Connect the air supply. Pull the control rod down. Listen to determine if air leaks through. If

air still leaks through the valve with the control rod down, the air tubing must be removed to access the valve

inlet to check for debris in the valve. Clean the valve by blowing air or water through it from both ends.

Push the rod upwards. If little or no air passes through, remove the tubing to access the valve inlet. Blow air

•

through the valve from the poppet side to clear debris from the ball and seat.

8. Fluid Check Valves

• Open the pump. Hold the pump vertically and pour water into the discharge check valve. If water flows through,

clean the valve.

•

Remove the valve and use emery cloth or a very fine sand paper to polish the surface where the ball seats.

• If the pump is a Bottom-Loading design, inspect the seat of the bottom check valve for debris and wear. Clean

or replace if necessary.

If the pump is a Top-Loading design, remove the fluid inlet check valve and inspect the seating surface and the

•

ball for debris and wear.

9. Air Inlet Valve Timing

•

(First check lever pivot wear per #6 above)

• Call the QED Service Department for correct air valve timing for your pump.

21

Chapter 7: Troubleshooting & Repairs

Returning Equipment for Service

If the equipment needs to be returned to QED for servicing, please follow these steps:

1. Call the QED Service Department and obtain a Return Material Authorization (RMA) number. Please have

available the contact person’s name, company name and address, phone number, fax number, reason for the

return, and the names of the chemicals to which the equipment has been exposed.

2. Clean all equipment before shipping. (See Equipment Cleaning Requirements at the end of this section). If the

equipment must be cleaned after it arrives at QED, the customer will be charged for the cleaning and disposal of

material, if necessary. (Cost can be $500.00 per piece of equipment cleaned.) It is also important to note that

shipping equipment with a known hazardous waste is a violation of federal law. Drain and dry all equipment after

cleaning.

3. Package the equipment so that it will not be damaged in shipment. Use bubble pack rather than styrofoam flakes

as packing material.

4. Ship the equipment via a carrier and service level (i.e., one-day, two-day shipping) in consideration of probable

service time and return shipment time.

5. It is recommended that such shipments be insured so, if the shipment is badly damaged or lost, the customer can

replace the equipment at little or no cost.

6. Include the contact’s name, company, phone number and RMA number given by QED.

7. Write the RMA number on the outside of the packaging so it will be directed immediately to the QED Service

Department.

Equipment Cleaning Requirements

If the equipment is to be shipped to another site or to the factory for service, it needs to be thoroughly cleaned before

leaving the site. Cleaning the equipment protects the user (sender), the shipper, and the receiver from dirt and/or

contaminants. If the equipment is not cleaned prior to shipping for servicing, it may be severely delayed, refused or

the shipper may be charged a cleaning fee. Before packing and shipping, ensure that the equipment is dry inside and

out.

To Clean the AP4+:

1. Pump clean water or water with a gentle soap solution (e.g. Dove Dish Soap) through the pump to remove free

product and particles.

2. Rinse all soap off of the equipment.

3. Soak and rinse the outside of the unit with water to remove loose debris and dirt.

4. Steam clean inside and out to remove difficult dirt and contaminants.

Caution: Use low pressure (less than 40 psi) when steam cleaning.

22

Specifications - Bottom Inlet, Long

AP4

Max. Flow

Length

Advantages

1. The original automatic air-

powered well pump, proven

worldwide over 23 years

2. The highest ow rates and

deepest pumping capabilities in

the industry

+

14 gpm (53 lpm)

O.D.

51.4 in. (131cm)

B

Description

The AP4+ Bottom Inlet Long AutoPump provides maximum

)mm 19( ni 6.3

4PA

+

pmuPotuA

capabilities and ow in a bottom inlet pump for 4” (100 mm)

diameter and larger wells with shorter water columns and/or

the need to pump down to lower water levels, compared to

full-length pumps. It is oered in optional versions to handle

even the most severe remediation and landll pumping

applications, and delivers ow rates up to 14 gpm (49 lpm)*.

The AP4+ Long Bottom Inlet AutoPump is complemented by

the most comprehensive selection of accessories to provide

a complete system to meet site specic requirements. Call

QED for prompt, no-obligation assistance on your pumping

project needs.

The AutoPump Heritage

The AP4+ Bottom Inlet Long AutoPump is part of the

famous AutoPump family of original automatic air-powered

pumps, developed in the mid 1980s specically to handle

unique pumping needs at remediation and landll sites.

Over the years they’ve proven their durability at thousands

of sites worldwide. AutoPumps are designed to handle

dicult pumping challenges that other pumps can’t, such

as hydrocarbons, solvents, suspended solids, corrosives,

temperature extremes, viscous uids and frequent start/stop

cycles. Beyond just the pump, AutoPump systems oer the

most complete range of tubing, hose, connectors, wellhead

caps and accessories to help your installation go smoothly.

This superior pumping heritage, application experience and

support back up every AutoPump you put to work on your

project.

3. Patented, proven design for

superior reliability and

durability, even in severe

applications

4. Handles solids, solvents,

hydrocarbons corrosive

conditions, viscous uids and

high temperatures beyond the

limits of electric pumps

5. Five-year warranty

23

Specifications - Bottom Inlet, Long

AP4

+

B

AP4

AutoPum

+

p

Liquid Discharge

Air Supply

Exhaust

Specifications & Operating RequirementsPump Dimensions

Model

Liquid Inlet Location

Overall Length With Extended Screen

Weight

Maximum Flow Rate

Pump Volume/Cycle

Minimum Accuation Level

Standard Pump

Maximum Depth

Air Pressure

Air Usage

High Pressure Pump

Maximum Depth

Air Pressure

Minimum Liquid Density

Standard Construction Materials¹

Pump Body

Pump Ends

Internal Components

Tube & Hose Fittings

Fitting Type

4" - Long AP4+ Bottom Inlet

Bottom

O.D.

3.6 in. (91 mm)

51.4 in. (131 cm)

16.7 lbs. (7.6 kg)

14 gpm (53 lpm)* - See Flow Rate Chart

0.58 - 0.78 gal (2.2 - 3L )

38.4 in. (98 cm)

250 ft. (76 m)

5 - 120 psi (0.4 - 8.4 kg/cm2)

0.4 - 1.1 scf / gal. (3.0 - 8.5 liter of air /

fluid liter) - See air usage chart

425 ft. (130 m)

5 - 200 psi (0.4 - 14.1 kg/cm2)

0.7 SpG (0.7 g/cm3)

Fiberglass or Stainless Steel

Stainless Steel

Stainless Steel, Viton, PVDF

Brass or Stainless Steel

Barbs, Quick Connects or Easy Fittings

³,

Hastelloy-C

Length with Extended Screen Attached 51.4" (131 cm)

Actuation Level 38.4" (98 cm)

Inlet

O.D. 3.6" (91 mm)

Application Limits (Base model)

AP4+ AutoPumps are designed to handle

the application ranges described below.

For applications outside these ranges,

consult QED about AP4+ upgrades.

Maximum Temperature: 180°F (82°C)

pH Range: 4-9

Solvents and Fuels: diesel, gasoline,

JP1-JP6,#2 heating oils, BTEX, MTBE,

landfill liquids

Tube & Hose Options

Tubing Materials²

Sizes - Liquid Discharge

Pump Air Supply

Air Exhaust

Sizes - Liquid Discharge

1

Material upgrades available

2

Applies to QED supplied tubing;

other tubing sources may not

conform to QED fittings.

Hose Material

Pump Air Supply

Air Exhaust

Nylon

1 in. (25 mm) or 1-1/4 in. (32 mm) OD

1/2 in. (13 mm) OD

5/8 in. (16 mm) OD

Nitrile

3/4 in. (19 mm) or 1 in. (25 mm) ID

3/8 in. (9.5 mm) ID

1/2 in. (13 mm) ID

Long and short AP4+ AutoPumps are warranted for

five(5) years: Low-Drawdown AP4+ AutoPumps are

warranted for one (1) year.

*Consult QED for higher flow requirements

24

Specifications - Bottom Inlet, Long

AP4

+

B

3/4 inch (19 mm)

Inside Diameter Discharge Hose

(Equivalent to 1-Inch O.D. Tubing)

6-INCH (15 cm) SUBMERGENCE OF PUMP HEAD

18

16

GALLONS

PER

MINUTE

WITH

3/4-INCH

I.D. HOSE

GALLONS

PER

MINUTE

WITH

3/4-INCH

I.D. HOSE

GALLONS

PER

MINUTE

WITH

3/4-INCH

I.D. HOSE

14

12

AIR INLET PRESSURES

10

8

6

4

40 PSI

2

0

0

2 FT. (60 cm) SUBMERGENCE OF PUMP HEAD

6.1

20

3 Kg/cm

40

12.26018.3

2

80

24.4

18

16

14

12

AIR INLET PRESSURES

10

8

6

4

40 PSI

2

0

0

10 FT. (300 cm) SUBMERGENCE OF PUMP HEAD

20

6.1

3 Kg/cm

40

12.2

2

60

18.3

80

24.4

18

16

14

12

AIR INLET PRESSURES

10

8

6

4

2

0

40 PSI

2

3 Kg/cm

80

40

60

20

0

12.2

18.3

6.1

24.4

100

30.5

100

30.5

100

30.5

120

36.6

120

36.6

120

36.6

140

42.7

140

42.7

140

42.7

100 PSI

7 Kg/cm

70 PSI

5 Kg/cm

160

48.8

100 PSI

7 Kg/cm

70 PSI

5 Kg/cm

160

48.8

100 PSI

7 Kg/cm

70 PSI

5 Kg/cm

160

48.8

180

54.9

180

54.9

180

54.9

Flow Rates

1

1 inch (25.4 mm)

Inside Diameter Discharge Hose

(Equivalent to 1.25-Inch O.D. Tubing)

68.1

60.6

53

APPROXIMATE

LITERS

45.4

37.9

30.3

22.7

2

15.1

PER

MINUTE

WITH

19 mm

I.D. HOSE

7.6

2

200

0

FT.

Meters

61

DEPTH

IN WELL

68.1

60.6

53

APPROXIMATE

LITERS

45.4

37.9

30.3

22.7

2

15.1

PER

MINUTE

WITH

19 mm

I.D. HOSE

7.6

2

200

0

FT.

Meters

61

DEPTH

IN WELL

68.1

60.6

53

APPROXIMATE

LITERS

45.4

37.9

30.3

22.7

2

15.1

PER

MINUTE

WITH

19 mm

I.D. HOSE

7.6

2

200

0

FT.

Meters

61

DEPTH

IN WELL

6-INCH (15 cm) SUBMERGENCE OF PUMP HEAD

18

16

GALLONS

PER

MINUTE

WITH

1-INCH

I.D. HOSE

GALLONS

GALLONS

PER

MINUTE

WITH

1-INCH

I.D. HOSE

GALLONS

PER

MINUTE

WITH

1-INCH

I.D. HOSE

14

12

10

8

6

4

2

0

20

0

6.1

2 FT. (60 cm) SUBMERGENCE OF PUMP HEAD

18

16

14

12

10

8

6

2

0

20

0

6.1

10 FT. (300 cm) SUBMERGENCE OF PUMP HEAD

18

16

14

12

10

8

6

4

2

0

20

0

6.1

AIR INLET PRESSURES

40 PSI

2

3 Kg/cm

40

60

12.2

18.3

AIR INLET PRESSURES

40 PSI

2

3 Kg/cm

40

60

12.2

18.3

40 PSI

2

3 Kg/cm

40

60

12.2

18.3

80

24.4

80

24.4

80

24.4

7 Kg/cm

70 PSI

5 Kg/cm

100

30.5

100

30.5

AIR INLET PRESSURES

100

30.5

120

36.6

120

36.6

120

36.6

140

42.7

140

42.7

140

42.7

160

5 Kg/cm

160

48.8

5 Kg/cm

160

48.8

100 PSI

180

8.84 9.45 16

100 PSI

7 Kg/cm

70 PSI

180

100 PSI

7 Kg/cm

70 PSI

180

54.9

2

2

9.45 16

2

68.1

60.6

53

APPROXIMATE

45.4

LITERS

FT.

Meters

APPROXIMATE

FT.

Meters

APPROXIMATE

FT.

Meters

PER

MINUTE

WITH

25.4 mm

I.D. HOSE

DEPTH

IN WELL

LITERS

PER

MINUTE

WITH

25.4 mm

I.D. HOSE

DEPTH

IN WELL

LITERS

PER

MINUTE

WITH

25.4 mm

I.D. HOSE

DEPTH

IN WELL

37.9

30.3

22.7

2

15.1

7.6

0

200

68.1

60.6

53

45.4

37.9

30.3

22.7

2

15.14

7.6

0

200

68.1

60.6

53

45.4

37.9

30.3

2

22.7

15.1

7.6

0

200

61

1FLOW RATES MAY VARY WITH SITE CONDITIONS. CALL QED FOR TECHNICAL ASSISTANCE.

25

Specifications - Bottom Inlet, Long

AP4 B

uA

t

4PA

Po

mu

+

p

+

STANDARD

CUBIC FEET OF AIR

PER

GALLON PUMPED

(SCF/GAL)

Air Consumption

1.6

1.5

1.4

1.3

1.2

1.1

1.0

.9

.8

.7

.6

.5

.4

.3

40 PSI

3 Kg/cm

100 PSI

2

7 Kg/cm

70 PSI

2

5 Kg/cm

2

12

3/4 inch (19 mm)

11.2

Inside Diameter Discharge Hose

(Equivalent to 1-Inch O.D. Tubing)

10.5

9.7

9.0

8.2

APPROXIMATE

STANDARD

7.5

LITER OF AIR

PER

LITER PUMPED

6.7

(STD L/LITER)

6.0

5.2

4.5

3.7

3.0

2.2

STANDARD

CUBIC FEET OF AIR

PER

GALLON PUMPED

(SCF/GAL)

.2

20 40 60 80 100 120 140 160 180 200

1.6

1.5

1.4

1.3

1.2

1.1

1.0

.9

.8

.7

.6

.5

.4

.3

. .

40 PSI

3 Kg/cm

2

48.87.246.635.034.4218.312.26.1

70 PSI

5 Kg/cm

54.9 61

100 PSI

7 Kg/cm

2

2

1.5

FT.

Meters

12

11.2

10.5

9.7

9.0

8.2

7.5

6.7

6.0

5.2

4.5

3.7

3.0

2.2

DEPTH

IN WELL

1 i

nch (25.4 mm)

Inside Diameter Discharge Hose

(Equivalent to 1.25-Inch O.D. Tubing)

APPROXIMATE

STANDARD

LITER OF AIR

PER

LITER PUMPED

(STD L/LITER)

.2

20 40 60 80 100 120 140 160 180 200

48.87.246.635.034.4218.312.26.1

54.9 61

26

1.5

FT.

Meters

DEPTH

IN WELL

Specifications - Bottom Inlet, Short

AP4 B

Max. Flow

Length

+

13 gpm (49 lpm)

O.D.

39.3 in. (100 cm)

Advantages

1. The original automatic air-

powered well pump, proven

worldwide over 23 years

2. The highest ow rates and

deepest pumping capabilities in

the industry

3. Patented, proven design for

superior reliability and

durability, even in severe

applications

Description

The AP4+ Bottom Inlet Short AutoPump provides maximum

)mm 19( ni 6.3

4PA

+

pmuPotuA

capabilities and ow in a bottom inlet pump for 4” (100 mm)

diameter and larger wells with shorter water columns and/or

the need to pump down to lower water levels, compared to

full-length pumps. It is oered in optional versions to handle

even the most severe remediation and landll pumping

applications, and delivers ow rates up to 13 gpm (49 lpm)*.

The AP4+ Short Bottom Inlet AutoPump is complemented by

the most comprehensive selection of accessories to provide

a complete system to meet site specic requirements. Call

QED for prompt, no-obligation assistance on your pumping

project needs.

The AutoPump Heritage

The AP4+ Bottom Inlet Short AutoPump is part of the

famous AutoPump family of original automatic air-powered

pumps, developed in the mid 1980s specically to handle

unique pumping needs at remediation and landll sites.

Over the years they’ve proven their durability at thousands

of sites worldwide. AutoPumps are designed to handle

dicult pum

as hydrocarbons, solvents, suspended solids, corrosives,

temperature extremes, viscous uids and frequent start/

stop cycles. Beyond just the pump, AutoPump systems

oer the most complete range of tubing, hose, connectors,

wellhead caps and accessories to help your installation go

smoothly. This superior pumping heritage, application

experience and support back up every AutoPump you put

to work on your project.

ping challenges that other pumps can’t, such

4. Handles solids, solvents,

hydrocarbons corrosive

conditions, viscous uids and

high temperatures beyond the

limits of electric pumps

5. Five-year warranty

27

Specifications - Bottom Inlet, Short

AP4 B

+

AP4

A

ut

oPum

+

p

Liquid Discharge

Air Supply

Exhaust

Specifications & Operating RequirementsPump Dimensions

Model

Liquid Inlet Location

Overall Length With Extended Screen

Weight

Maximum Flow Rate

Pump Volume/Cycle

Minimum Accuation Level

Standard Pump

Maximum Depth

Air Pressure

Air Usage

High Pressure Pump

Maximum Depth

Air Pressure

Minimum Liquid Density

Standard Construction Materials¹

Pump Body

Pump Ends

Internal Components

Tube & Hose Fittings

Fitting Type

4" - Short AP4+ Bottom Inlet

Bottom

O.D.

3.6 in. (91 mm)

39.3 in. (100 cm)

13.7 lbs. (6.2 kg)

13 gpm (49 lpm)* - See Flow Rate Chart

0.22 - 0.36 gal (.83 - 1.36 L )

26.7 in. (68 cm)

250 ft. (76 m)

5 - 120 psi (0.4 - 8.4 kg/cm2)

0.4 - 1.1 scf / gal. (3.0 - 8.5 liter of air /

fluid liter) - See air usage chart

425 ft. (130 m)

5 - 200 psi (0.4 - 14.1 kg/cm2)

0.7 SpG (0.7 g/cm3)

Fiberglass or Stainless Steel

Stainless Steel

Stainless Steel, Viton, PVDF

Brass or Stainless Steel

Barbs, Quick Connects or Easy Fittings

³,

Hastelloy-C

Actuation Level 26.7" (68 cm)

Length with Extended Screen Attached 39.3" (100 cm)

Inlet

O.D. 3.6" (91 mm)

Application Limits (Base model)

AP4+ AutoPumps are designed to handle

the application ranges described below.

For applications outside these ranges,

consult QED about AP4+ upgrades.

Maximum Temperature: 180°F (82°C)

pH Range: 4-9

Solvents and Fuels: diesel, gasoline,

JP1-JP6,#2 heating oils, BTEX, MTBE,

landfill liquids

Tube & Hose Options

Tubing Materials²

Sizes - Liquid Discharge

Pump Air Supply

Air Exhaust

Sizes - Liquid Discharge

1

Material upgrades available

2

Applies to QED supplied tubing;

other tubing sources may not

conform to QED fittings.

Hose Material

Pump Air Supply

Air Exhaust

Nylon

1 in. (

25 mm) or 1-1/4 in. (32 mm) OD

1/2 in. (13 mm) OD

5/8 in. (16 mm) OD

Nitrile

3/4 in. (19 mm) or 1 in. (25 mm) ID

3/8 in. (9.5 mm) ID

1/2 in. (13 mm) ID

Long and short AP4+ AutoPumps are warranted for

five(5) years: Low-Drawdown AP4+ AutoPumps are

warranted for one (1) year.

*Consult QED for higher flow requirements

28

Specifications - Bottom Inlet, Short

AP4 B

+

3/4 inch (19 mm)

Inside Diameter Discharge Hose

(Equivalent to 1-Inch O.D.Tubing)

6-INCH (15 cm) SUBMERGENCE OF PUMP HEAD

18

16

GALLONS

PER

MINUTE

WITH

3/4-INCH

I.D. HOSE

GALLONS

PER

MINUTE

WITH

3/4-INCH

I.D. HOSE

GALLONS

PER

MINUTE

WITH

3/4-INCH

I.D. HOSE

14

10

8

6

2

0

0

2 FT. (60 cm) SUBMERGENCE OF PUMP HEAD

18

16

14

12

10

8

6

2

0

0

10 FT. (300 cm) SUBMERGENCE OF PUMP HEAD

18

16

14

12

10

8

6

4

2

0

0

AIR INLET PRESSURES

40 PSI

2

3 Kg/cm

40

60

20

12.2

18.3

6.1

AIR INLET PRESSURES

40 PSI

2

3 Kg/cm

40

60

20

18.3

12.2

6.1

40 PSI

2

3 Kg/cm

40

60

20

18.3

12.2

6.1

80

24.4

80

24.4

80

24.4

70 PSI

2

5 Kg/cm

100

30.5

70 PSI

5 Kg/cm

100

30.5

AIR INLET PRESSURES

70 PSI

5 Kg/cm

100

30.5

120

36.6

120

36.6

120

36.6

160

140

42.7

100 PSI

7 Kg/cm

2

160

140

42.7

48.8

2

160

140

42.7

48.8

100 PSI

7 Kg/cm

180

8.84 9.45 16

180

100 PSI

7 Kg/cm

180

54.9

2

2

9.45 16

2

200

200

200

61

68.1

60.6

53

45.412

37.9

30.3

22.7

7.6

0

68.1

60.6

53

45.4

37.9

30.3

22.7

15.14

7.6

0

68.1

60.6

53

45.4

37.9

30.3

22.7

15.1

7.6

0

1.5 14

FT.

Meters

FT.

Meters

FT.

Meters

APPROXIMATE

I.D. HOSE

APPROXIMATE

I.D. HOSE

APPROXIMATE

I.D. HOSE

Flow Rates

LITERS

PER

MINUTE

WITH

19 mm

DEPTH

IN WELL

LITERS

PER

MINUTE

WITH

19 mm

DEPTH

IN WELL

LITERS

PER

MINUTE

WITH

19 mm

DEPTH

IN WELL

1

1 inch (25.4 mm)

Inside Diameter Discharge Hose

(Equivalent to 1.25-Inch O.D.Tubing)

6-INCH (15 cm) SUBMERGENCE OF PUMP HEAD

18

16

GALLONS

PER

MINUTE

WITH

1-INCH

I.D. HOSE

GALLONS

PER

MINUTE

WITH

1-INCH

I.D. HOSE

GALLONS

PER

MINUTE

WITH

1-INCH

I.D. HOSE

14

12

10

8

6

4

2

0

20

0

6.1

2 FT. (60 cm) SUBMERGENCE OF PUMP HEAD

18

16

14

12

10

8

6

2

0

20

0

6.1

10 FT. (300 cm) SUBMERGENCE OF PUMP HEAD

18

16

14

12

10

8

6

4

2

0

20

0

6.1

AIR INLET PRESSURES

40 PSI

2

3 Kg/cm

40

60

18.3

12.2

AIR INLET PRESSURES

40 PSI

2

3 Kg/cm

40

60

18.3

12.2

40 PSI

2

3 Kg/cm

40

60

12.2

18.3

80

24.4

80

24.4

80

24.4

70 PSI

120

36.6

120

36.6

140

42.7

140

42.7

5 Kg/cm

160

100 PSI

7 Kg/cm

5 Kg/cm

160

48.8

100

30.5

100

30.5

AIR INLET PRESSURES

70 PSI

5 Kg/cm

100

30.5

120

36.6

140

42.7

160

48.8

100 PSI

7 Kg/cm

180

8.84 9.45 16

70 PSI

180

100 PSI

7 Kg/cm

2

180

54.9

2

2

2

9.45 16

68.1

60.6

53

APPROXIMATE

15.1

7.6

0

FT.

Meters

15.14

7.6

0

FT.

Meters

15.1

7.6

0

FT.

Meters

LITERS

PER

MINUTE

WITH

25.4 mm

I.D. HOSE

DEPTH

IN WELL

APPROXIMATE

LITERS

PER

MINUTE

WITH

25.4 mm

I.D. HOSE

DEPTH

IN WELL

APPROXIMATE

LITERS

PER

MINUTE

WITH

25.4 mm

I.D. HOSE

DEPTH

IN WELL

45.4

37.9

30.3

22.7

2

200

68.1

60.6

53

45.4

37.9

30.3

22.7

200

68.1

60.6

53

45.4

37.9

30.3

22.7

2

200

61

1FLOW RATES MAY VARY WITH SITE CONDITIONS. CALL QED FOR TECHNICAL ASSISTANCE.

29

Specifications - Bottom Inlet, Short

AP4 B

A

u

t

4PA

uPo

m

+

p

+

STANDARD

CUBIC FEET OF AIR

PER

GALLON PUMPED

(SCF/GAL)

Air Consumption

1.6

1.5

1.4

1.3

1.2

1.1

1.0

.9

.8

.7

.6

.5

.4

.3

40 PSI

3 Kg/cm

2

100 PSI

7 Kg/cm

70 PSI

5 Kg/cm

2

12

2

Inside Diameter Discharge Hose

(Equivalent to 1-Inch O.D. Tubing)

10.5

9.7

9.0

8.2

APPROXIMATE

STANDARD

7.5

LITER OF AIR

PER

LITER PUMPED

6.7

(STD L/LITER)

6.0

5.2

4.5

3.7

3.0

2.2

3/4 inch (19 mm)

11.2

STANDARD

CUBIC FEET OF AIR

PER

GALLON PUMPED

(SCF/GAL)

.2

20 40 60 80 100 120 140 160 180 200

1.6

1.5

1.4

1.3

1.2

1.1

1.0

.9

.8

40 PSI

2

.7

.6

.5

.4

.3

3 Kg/cm

48.87.246.635.034.4218.312.26.1

100 PSI

7 Kg/cm

70 PSI

5 Kg/cm

54.9 61

2

2

1.5

FT.

Meters

12

11.2

10.5

9.7

9.0

8.2

7.5

6.7

6.0

5.2

4.5

3.7

3.0

2.2

DEPTH

IN WELL

1 i

nch (25.4 mm)

Inside Diameter Discharge Hose

(Equivalent to 1.25-Inch O.D. Tubing)

APPROXIMATE

STANDARD

LITER OF AIR

PER

LITER PUMPED

(STD L/LITER)

.2

20 40 60 80 100 120 140 160 180 200

48.87.246.635.034.4218.312.26.1

54.9 61

30

1.5

FT.

Meters

DEPTH

IN WELL

Specifications - Low-Drawdown Bottom Inlet

LDAP4 B

Max. Flow

Length

7.0 gpm (26.5 lpm)

O.D.

3.6 in (91 mm)

27.5 in. (70 cm)

+

Advantages

1. The original automatic air-

powered well pump, proven

worldwide over 23 years

2. The highest

deepest pumping capabilities in

the industry in a low drawdown

bottom-

3. Patented, proven design for

superior reliability and

durability, even in severe

applications

rates and

ll pump

Description

The AP4+ Low-Drawdown Bottom Inlet AutoPump provides

maximum capabilities an

4” (100 mm) diameter and larger wells with very short

water columns and/or the need to pump down to as low

as 15.3 inches (39 cm) above the bottom. It is o

optional versions to handle even the most severe remediation

and l

A

u

t

4PA

uPo

m

+

p

to 7 gpm (26.5 lpm). The AP4+ Low Drawdown Bottom Inlet

AutoPump is complemented by the most comprehensive

selection of accessories to provide a complete system to

meet site speci

no-obligation assistance on your pumping project needs.

The AutoPump Heritage

The AP4+ Low-Drawdown Bottom Inlet AutoPump is part of

the famous AutoPump family of original automatic airpowered pumps, developed in the mid 1980s speci

to handle unique pumping needs at remediation and lan ll

sites. Over the years they’ve proven their durability at

thousands of sites worldwide. AutoPumps are designed t

handle

such as hydrocarbons, solvents, suspended solids,

corrosives, temperature extremes, viscou

frequent start/stop cycles. Beyond just the pump,

AutoPump systems o

tubing, hose, connectors, wellhead caps and accessories

to help your installation go smoothly. This superior

pumping heritage, application experience and support back

up every AutoPump you put to work on your project.

l pumping applications, and delivers ow rates up

c requirements. Call QED for prompt,

pumping challenges that other pumps can’t,

ow in a bottom inlet pump for

ered in

cally

o

uids and

er the most complete range of

4. Handles solids, solvents,

hydrocarbons corrosive

conditions, viscous

high temperatures beyond the

limits of electric pumps

5. One-year warranty

ds and

31

Specifications - Low-Drawdown Bottom Inlet

LDAP4 B

Length with Extended Screen Attached 27.5" (70 cm)

+

A

u

t

4PA

uPo

m

+

p

Actuation Level 15.3" (39 cm)

Liquid Discharge

Air Supply

Exhaust

Inlet

Specications & Operating RequirementsPump Dimensions

Model

Liquid Inlet Location

O.D.

Overall Length With Extended Screen

Weight

Maximum Flow Rate

Pump Volume/Cycle

Minimum Accuation Level

Maximum Depth

Air Pressure

Air Usage

Minimum Liquid Density

Standard Construction Materials¹

Pump Body

Pump Ends

Internal Components

Tube & Hose Fittings

Fitting Type

Tube & Hose Options

Tubing Materials²

Sizes - Liquid Discharge

Pump Air Supply

Air Exhaust

Hose Material

Sizes - Liquid Discharge

Pump Air Supply

Air Exhaust

4" - Low Drawdown AP4+ Bottom Inlet

Bottom

3.6 in. (91 mm)

27.5 in. (70 cm)

11.7 lbs. (5.3 kg)

7 gpm (26.5 lpm)* - See Flow Rate Chart

0.11 - 0.16 gal (.42 - .61 L )

15.3 in. (39 cm)

250 ft. (76 m)

5 - 120 psi (0.4 - 8.4 kg/cm2)

.32 - 2.86 scf/gal. (2.2 - 21.5 liter of air /

uid liter) - See air usage chart

0.7 SpG (0.7 g/cm3)

Fiberglass or Stainless Steel

less Steel

Stain

³,

Stainless Steel, Viton, PVDF

Brass or Stainless Steel

Barbs, Quick Connects or Easy Fittings

Nylon

1 in. (25 mm) or 1-1/4 in. (32 mm) OD

1/2 in. (13 mm) OD

5/8 in. (16 mm) OD

Nitrile

3/4 in. (19 mm) or 1 in. (25 mm) ID

3/8 in. (9.5 mm) ID

1/2 in. (13 mm) ID

Hastelloy-C

O.D. 3.6" (91 mm)

Application Limits (Base model)

AP4+ AutoPumps are designed to handle

the application ranges described below.

For applications outside these ranges,

consult QED about AP4+ upgrades.

Maximum Temperature: 180 °F (82 °C)

pH Range: 4-9

Solvents and Fuels: diesel, gasoline,

JP1-JP6,#2 heating oils, BTEX, MTBE,

landll liquids

* Consult QED for higher ow requirements

1

Material upgrades available

2

Applies to QED supplied tubing;

other tubing sources may not

conform to QED ttings.

Low-Drawdown AP4+ AutoPumps are warranted for

one (1) year.

32

Specifications - Low-Drawdown Bottom Inlet

LDAP4 B

+

3/4 inch (19 mm)

Inside Diameter Discharge Hose

(Equivalent to 1-Inch O.D.Tubing)

6-INCH (15 cm) SUBMERGENCE OF PUMP HEAD

9

8

GALLONS

MINUTE

WITH

3/4-INCH

I.D. HOSE

GALLONS

MINUTE

WITH

3/4-INCH

I.D. HOSE

GALLONS

MINUTE

WITH

3/4-INCH

I.D. HOSE

7

PER

6

5

4

3

2

1

0

0

2 FT. (60 cm) SUBMERGENCE OF PUMP HEAD

9

8

7

6

PER

5

4

3

2

1

0

0

10 FT. (300 cm) SUBMERGENCE OF PUMP HEAD

9

8

7

PER

6

5

4

3

2

1

0

0

40 PSI

2

3 Kg/cm

40

60

20

12.2

18.3

6.1

40 PSI

2

3 Kg/cm

40

60

20

18.3

12.2

6.1

40 PSI

2

3 Kg/cm

40

60

20

18.3

12.2

6.1

AIR INLET PRESSURES

70 PSI

5 Kg/cm

100

80

24.4

30.5

AIR INLET PRESSURES

70 PSI

5 Kg/cm

100

80

24.4

30.5

AIR INLET PRESSURES

70 PSI

5 Kg/cm

100

80

24.4

30.5

120

36.6

120

36.6

120

36.6

100 PSI

7 Kg/cm

2

140

42.7

100 PSI

7 Kg/cm

2

140

42.7

100 PSI

7 Kg/cm

2

140

42.7

160

48.8

160

48.8

160

48.8

Flow Rates

1

1 inch (25.4 mm)

Inside Diameter Discharge Hose

(Equivalent to 1.25-Inch O.D.Tubing)

34.1

30.3

26.5

APPROXIMATE

22.7

18.9

180

54.9

200

15.1

11.4

7.6

3.8

61

2

0

FT.

Meters

LITERS

PER

MINUTE

WITH

19 mm

I.D. HOSE

DEPTH

IN WELL

6-INCH (15 cm) SUBMERGENCE OF PUMP HEAD

9

GALLONS

PER

MINUTE

WITH

1-INCH

I.D. HOSE

8

7

6

5

4

3

2

1

0

20

0

6.1

40 PSI

3 Kg/cm

40

12.2

60

18.3

2

AIR INLET PRESSURES

24.4

100 PSI

2

7 Kg/cm

70 PSI

2

5 Kg/cm

100

80

30.5

120

36.6

140

42.7

160

48.8

2 FT. (60 cm) SUBMERGENCE OF PUMP HEAD

34.1

30.3

26.5

APPROXIMATE

22.7

18.9

180

54.9

2

180

9.45 16

200

200

15.1

11.4

7.6

3.8

61

34.1

30.3

26.5

22.7

18.9

15.1

11.4

2

0

FT.

Meters

7.6

3.8

0

FT.

Meters

LITERS

PER

MINUTE

WITH

19 mm

I.D. HOSE

DEPTH

IN WELL

APPROXIMATE

LITERS

PER

MINUTE

WITH

19 mm

I.D. HOSE

DEPTH

IN WELL

GALLONS

GALLONS

PER

MINUTE

WITH

1-INCH

I.D. HOSE

GALLONS

PER

MINUTE

WITH

1-INCH

I.D. HOSE

9

8

7

6

4

3

2

1

0

20

0

6.1

40 PSI

3 Kg/cm

40

12.2

18.3

2

60

AIR INLET PRESSURES

100 PSI

7 Kg/cm

70 PSI

2

5 Kg/cm

100

80

24.4

30.5

120

36.6

140

42.7

160

48.8

10 FT. (300 cm) SUBMERGENCE OF PUMP HEAD

9

8

40 PSI

3 Kg/cm

40

12.2

60

18.3

AIR INLET PRESSURES

100 PSI

7 Kg/cm

2

70 PSI

2

5 Kg/cm

100

80

24.4

30.5

120

36.6

140

42.7

160

48.8

7

6

5

4

3

2

1

0

20

0

6.1

34.1

30.3

26.5

APPROXIMATE

22.7

200

180

9.45 16

34.1

26.5

22.7

2

200

180

9.45 16

34.1

26.5

22.7

2

200

180

9.45 16

18.9

15.1

11.4

7.6

3.8

0

30.3

18.95

15.1

11.4

7.6

3.8

0

30.3

18.9

15.1

11.4

7.6

3.8

0

FT.

Meters

FT.

Meters

FT.

Meters

LITERS

PER

MINUTE

WITH

25.4 mm

I.D. HOSE

DEPTH

IN WELL

APPROXIMATE

LITERS

PER

MINUTE

WITH

25.4 mm

I.D. HOSE

DEPTH

IN WELL

APPROXIMATE

LITERS

PER

MINUTE

WITH

25.4 mm

I.D. HOSE

DEPTH

IN WELL

1FLOW RATES MAY VARY WITH SITE CONDITIONS. CALL QED FOR TECHNICAL ASSISTANCE.

33

Specifications - Low-Drawdown Bottom Inlet

LDAP4 B

A

u

t

4PA

uPo

m

+

p

+

STANDARD

CUBIC FEET OF AIR

PER

GALLON PUMPED

(SCF/GAL)

Air Consumption

2.9 21.7

2.8

2.7

2.6

2.5

2.4

2.3

2.2

2.1

2.0

1.9

1.8

1.7

1.6

1.5

1.4

1.3

1.2

1.1

1.0

.9

.8

.7

.6

.5

.4

.3

.2 1.5

20 40 60 80 100 120 140 160 180 200

40 PSI

3 Kg/cm

70 PSI

5 Kg/cm

2

100 PSI

7 Kg/cm

2

2

48.87.246.635.034.4218.312.26.1

20.9

20.2

19.4

18.7

18.0

17.2

16.5

15.7

15

14.2

13.5

12.7

12

11.2

10.5

9.7

9.0

8.2

7.5

6.7

6.0

5.2

4.5

3.7

3.0

2.2

54.9 61

3/4 inch (19 mm)

Inside Diameter Discharge Hose

(Equivalent to 1-Inch O.D. Tubing)

APPROXIMATE

STANDARD

LITER OF AIR

PER

LITER PUMPED

(STD L/LITER)

FT.

Meters

DEPTH

IN WELL

STANDARD

CUBIC FEET OF AIR

PER

GALLON PUMPED

(SCF/GAL)

2.9 21.7

2.8

2.7

2.6

2.5

2.4

2.3

2.2

2.1

2.0

1.9

1.8

1.7

1.6

1.5

1.4

1.3

1.2

1.1

1.0

.9

.8

.7

.6

.5

.4

.3

.2 1.5

20 40 60 80 100 120 140 160 180 200

40 PSI

3 Kg/cm

70 PSI

5 Kg/cm

2

100 PSI

7 Kg/cm

2

2

48.87.246.635.034.4218.312.26.1

20.9

20.2

19.4

18.7

18.0

17.2

16.5

15.7

15

14.2

13.5

12.7

12

11.2

10.5

9.7

9.0

8.2

7.5

6.7

6.0

5.2

4.5

3.7

3.0

2.2

54.9 61

1 i

nch (25.4 mm)

Inside Diameter Discharge Hose

(Equivalent to 1.25-Inch O.D. Tubing)

APPROXIMATE

STANDARD

LITER OF AIR

PER

LITER PUMPED

(STD L/LITER)

FT.

Meters

DEPTH

IN WELL

34

AP4

Max. Flow

O.D.

Length

Specifications - Top Inlet, Long

+

T

xxxxxxxxxxxxxxxxx

xxxxxxxxxxxxxxxxx

xxxxxxxxxxxxxxxxx

10 gpm (38 lpm)

3.6 in (91 mm)

56.7 in. (144 cm)

xxxxxxxxxxxxxxxxx

4PA

+

pmuPotuA

Description

The AP4+ Top Inlet Long AutoPump provides maximum

capabilities and ow in a top inlet pump for 4” diameter

and larger wells needing an elevated inlet, such as pumping