Page 1

QBD COOLING SYSTEMS INC.

31 Bramsteele Rd, Brampton, Ontario, Canada L6W 3K6

1-800-663-3005 TEL : (905) 459-0709 FAX: (905) 459-1478

QBD.COM info@qbd.com

R-290 COOLERS (HC SERI ES)

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

CAUTION

READ THIS MANUAL BEFORE INSTALLATION, OPERATION AND/OR

SERVICING YOUR COOLER.

V2.5 01-2017

Publication: 47-0480-189 B

Page 2

- Always use QBD supplied OEM parts only. Use of non-OEM

parts will not only void the warranty but may also lead to a fire,

explosion, serious injury or death.

------------------------------------------------------------------------------------------

- Only trained and certified technician, for Hydrocarbon

systems, should service these coolers.

------------------------------------------------------------------------------------------

- Use extreme caution and follow all local/regional codes for

transportation or relocation of Hydrocarbon coolers.

QBD COOLING SYSTEMS INC.

QBD.COM

Contents

1. DISCLAIMER .......................................................................................................................................................................................... 3

2. GENERAL INSTRUCTIONS ............................................................................................................................................................... 5

3. SYMBOLS USED IN THIS MANUAL .............................................................................................................................................. 6

4. INTENDED USE ..................................................................................................................................................................................... 7

5. R290 REFRIGERANT .......................................................................................................................................................................... 7

6. FIRST AID MEASURES FOR R-290 ............................................................................................................................................... 8

7. INSPECTION UPON DELIVERY ...................................................................................................................................................... 8

8. VISUAL CHANGES TO CD 3.0 .......................................................................................................................................................... 9

9. ELECTRICAL SAFETY ....................................................................................................................................................................... 11

10. RECOMMENDED ELECTRICAL PARTS FOR HC COOLERS .............................................................................................. 13

11. INSTALLATION ................................................................................................................................................................................... 14

12. CASTER INSTALLATION ................................................................................................................................................................. 15

13. SHELF INSTALLATION .................................................................................................................................................................... 15

14. COLD CONTROL ................................................................................................................................................................................. 16

15. WIRING DIAGRAM FOR CDxxHC & DCxxHC COOLERS ..................................................................................................... 18

16. LED LIGHTING .................................................................................................................................................................................... 19

17. COOLING DECK REMOVAL, ACCESS AND RE-INSTALL .................................................................................................... 20

18. HC MODEL DOOR REVERSAL AND ADJUSTMENT ............................................................................................................. 21

19. PREVENTIVE MAINTENANCE AND CLEANING INSTRUCTIONS ................................................................................. 23

20. REPLACE VS REPAIR FOR COOLING DECK 3.0 .................................................................................................................... 24

21. SAFETY INSTRUCTIONS FOR SERVICE, MAINTENANCE AND HANDLING OF QBD HC COOLER .................. 24

22. RECOMMENDED SERVICE PROCEDURES FOR HC COOLER .......................................................................................... 26

23. GUIDELINES FOR TROUBLE- SHOOTING ............................................................................................................................... 28

24. FREQUENTLY ASKED QUESTIONS ............................................................................................................................................ 30

25. QBD CONTACT INFORMATION ................................................................................................................................................... 31

2

Page 3

- Always use QBD supplied OEM parts only. Use of non-OEM

parts will not only void the warranty but may also lead to a fire,

explosion, serious injury or death.

------------------------------------------------------------------------------------------

- Only trained and certified technician, for Hydrocarbon

systems, should service these coolers.

------------------------------------------------------------------------------------------

- Use extreme caution and follow all local/regional codes for

transportation or relocation of Hydrocarbon coolers.

QBD COOLING SYSTEMS INC.

QBD.COM

1. DISCLAIMER

Please read this manual carefully before

installing, operating and servicing this QBD

R-290 Hydrocarbon cooler. Improper

installation, operation and maintenance of

cooler can cause damage to the cooler, fire,

explosion, severe injuries or death.

This manual must be kept in an accessible

location for easy reference during

installation, operation, maintenance and

service.

QBD neither assumes nor authorizes any

representative or other person to assume

for it any obligation or liability in connection

with the QBD product, its sale, operation or

use other than such as is expressly set forth

herein.

derivatives sustained in connection with

the Product, its sale, operation or use.

c) glass (Door & Side Window) or light

bulb breakage (Fluorescent Tubes or

Light Bulbs), castors, hinges, magnetic

gasket, sliding door wheels, (Header &

Header Lens),door tracks, decals,

(Power Cord, Starters) and parts of

normal wear and tear.

d) any product that has been subject to

misuse, neglect, alteration, tampering,

accident, or to any damage to any

product caused during transportation,

improper installation (except when the

Product is installed by employees of

QBD), flood, fire, water damage,

burglary, terrorism or acts of God.

Exclusions from Warranty Coverage

QBD warranty does not cover:

a) Spoilage of products, loss of sales,

incidental, indirect, consequential or

special damages, or any injury, loss,

cost or expense directly or indirectly

sustained in connection with the

Product, its sale, operation or use.

b) without limiting the generality of the

foregoing, spoilage of products, loss of

sales, incidental, indirect, consequential

or special damages, or any injury, loss,

cost or expense arising directly or

indirectly from fungi or fungal

Limited Warranty

QBD warrants to the original purchaser at

the location of original installation of the

Product that the Product is free from defects

in material or workmanship under normal

use and service for a period as defined in

warranty terms from the date of shipment.

QBD’s obligation under this warranty shall

be limited to repairing or replacing at QBD’s

option, any part of such product, which

proves thus defective and which upon

examination by QBD and to its satisfaction

to be defective shall be determined to be

defective. Notwithstanding this assumption

3

Page 4

- Always use QBD supplied OEM parts only. Use of non-OEM

parts will not only void the warranty but may also lead to a fire,

explosion, serious injury or death.

------------------------------------------------------------------------------------------

- Only trained and certified technician, for Hydrocarbon

systems, should service these coolers.

------------------------------------------------------------------------------------------

- Use extreme caution and follow all local/regional codes for

transportation or relocation of Hydrocarbon coolers.

! CAUTION

1. The cooler contains flammable

refrigerant R-290 (Propane). To

confirm refrigerant type, please refer

serial label inside cabinet.

2. The cooler requires adequate ventilation

at all times during installation, operation

and servicing.

3. In order to carry out service and repair

on R-290 COOLER the service

personnel must be qualified and

trained to handle flammable

refrigerants. This includes knowledge

on tools, transportation of the

compressor and refrigerant, relevant

regulations and safety precautions.

Also, service must be performed in a

well-ventilated area and in compliance

with the local/ regional /national safety

codes.

4. Conversions from refrigerant R134A

to R-290 is NOT allowed. Using R-290

in a system, which is not approved and

does not have symbols indicating use of

R-290, may cause fire, explosion,

severe injury or death.

5. As per the EPA, R-290 is prohibited for

retrofitting in existing hydrofluorocarbon

(HFC) refrigerant systems.

6. Only a maximum 150 grams (5.3 oz.) of

R-290 charge is allowed in any HC

based beverage cooler refrigeration

system. (Ref: UL#471). However you

are advised to refer serial plate to

check R-290 charge amount in your

cooler. Refrigerant overcharge may

lead to fire, explosion, severe injury

or death.

7. EPA has approved the venting of

Hydrocarbon refrigerant into the

atmosphere. However, it is

recommended that you observe venting

requirements in your jurisdiction. Use

extreme precaution while venting- refer

paragraph 9 on page 26 for more

instructions on safe venting practices.

QBD COOLING SYSTEMS INC.

QBD.COM

of responsibility by QBD, QBD’s

responsibility for the costs and labour

incurred in repairing or replacing the

Product shall not exceed the sale price of

the Product. The labor warranty shall

include standard straight time labor charges

only and reasonable travel time, as

determined by QBD.

For CD Series coolers, QBD reserves the

right to exchange the cooling deck, and the

defective cooling deck must be returned.

Labor charges to remove and install the

cooling deck, is not covered by warranty.

4

Page 5

- Always use QBD supplied OEM parts only. Use of non-OEM

parts will not only void the warranty but may also lead to a fire,

explosion, serious injury or death.

------------------------------------------------------------------------------------------

- Only trained and certified technician, for Hydrocarbon

systems, should service these coolers.

------------------------------------------------------------------------------------------

- Use extreme caution and follow all local/regional codes for

transportation or relocation of Hydrocarbon coolers.

8. R-290 cooling deck must be installed

in R-290 certified cabinet only. Only

cabinets with serial plate indicating

R-290 should be used for R-290

based refrigeration system. R-290

installation on a non-approved cabinet

may result into fire, explosion, severe

injury or death.

9. Check for refrigerant leak before

connecting or disconnecting power to

cooler.

10. Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this cooler.

11. Smoking is strictly prohibited near

coolers with R-290 refrigerant.

12. Ensure the cooler, refrigerant, oil and/or

other component(s) are disposed in

accordance with local and federal

regulations.

13. To maintain average product

temperature at 3.3°C (38°F), follow

temperature setting as indicated on

rating plate inside the cooler. Any

change in setting could result in poor

performance and/or component(s)

failure.

14. QBD will not be responsible for poor

performance, component failure(s),

damages or losses due to improper

installation of the cooling deck, electrical

components, cooler itself, and/or use of

non-OEM parts.

15. Use of NON OEM parts is strictly

prohibited. Use of non OEM parts will

not only void the warranty but may also

lead to a major fire or explosion causing

property damage, severe personal injury

or even death.

All repairs must be performed by a

trained and authorized service

technician and at a safe environment.

QBD COOLING SYSTEMS INC.

QBD.COM

2. GENERAL INSTRUCTIONS

Unsafe use of the cooler other than

intended by QBD can result in death,

serious injury, property damage and /or

cooler failure.

This manual contains important information

about cooler safety and maintenance.

READ and UNDERSTAND this manual

before operating the cooler. If you have any

questions, please call QBD (Contact

number (905)-459-0709) for clarification.

This manual must remain near the cooler

and should be available to all users and

service technicians.

All specifications are subject to change

without notice.

5

Page 6

- Always use QBD supplied OEM parts only. Use of non-OEM

parts will not only void the warranty but may also lead to a fire,

explosion, serious injury or death.

------------------------------------------------------------------------------------------

- Only trained and certified technician, for Hydrocarbon

systems, should service these coolers.

------------------------------------------------------------------------------------------

- Use extreme caution and follow all local/regional codes for

transportation or relocation of Hydrocarbon coolers.

This sign will indicate that

you are handling a

flammable substance that

may be present in the

surrounding environment.

WARNING Indicates

potentially hazardous

situation which, if not

avoided, may result in

injury, property damage

and/or cooler failure.

DANGER Indicates

potentially hazardous

situation which, if ignored,

could result in death or

serious injury, property

damage and/or cooler

failure.

!

CAUTION emphasise

information which may

cause cooler failure or

environmental harm.

This label is used to indicate

that the flammable

refrigerant (R-290) is

present within the

application and service

equipment

Images that indicate

something that should be

strictly avoided

Specific bans!

Instructions for first aid!

Fire protection!

QBD COOLING SYSTEMS INC.

QBD.COM

3. SYMBOLS USED IN THIS

MANUAL

6

Page 7

- Always use QBD supplied OEM parts only. Use of non-OEM

parts will not only void the warranty but may also lead to a fire,

explosion, serious injury or death.

------------------------------------------------------------------------------------------

- Only trained and certified technician, for Hydrocarbon

systems, should service these coolers.

------------------------------------------------------------------------------------------

- Use extreme caution and follow all local/regional codes for

transportation or relocation of Hydrocarbon coolers.

Odor:

Odorless

Chemical formula:

C3H8

Appearance:

Liquefied

compressed gas

Boiling Temp.:

-42°C (460mm/Hg)

Flash point temp:

−104 °C

Self-ignition

temperature :

470°C (Under 760

mm/Hg)

Lower Explosive

Limit (LEL) :

2.30%

Upper Explosive

Limit (UEL) :

9.50%

Density:

580 Kg/m3 (25°C)

QBD COOLING SYSTEMS INC.

QBD.COM

4. INTENDED USE

QBD`s coolers are designed for storage of

beverage products and/or commercial

merchandise.

Storage of pharmaceutical products (unless

it is an RX-series cooler), perishable food,

scientific material or temperature sensitive

product in the cooler is NOT

RECOMMENDED.

QBD warranty does not cover spoilage of

products, loss of sales, incidental, indirect,

consequential or special damages, or any

injury, loss, cost or expense directly or

indirectly sustained in connection with the

Product, its sale, operation or use.

This cooler is NOT intended for

outdoor use or to be subjected to

direct sunlight, dampness, high dust

levels, extreme heat and/or cold

temperature. Ensure adequate

ventilation around the cooler.

5. R290 REFRIGERANT

This cooler contains R-290

refrigerant. It is highly

flammable and is heavier

than air and the

concentration will always

be highest at floor level.

It should not be subjected to

temperature more than 90°F and relative

humidity more than 65%.

7

Page 8

- Always use QBD supplied OEM parts only. Use of non-OEM

parts will not only void the warranty but may also lead to a fire,

explosion, serious injury or death.

------------------------------------------------------------------------------------------

- Only trained and certified technician, for Hydrocarbon

systems, should service these coolers.

------------------------------------------------------------------------------------------

- Use extreme caution and follow all local/regional codes for

transportation or relocation of Hydrocarbon coolers.

Ingestion

DO NOT induce vomiting unless directed to

do so by medical personnel. Never provide

anything by mouth to an unconscious

person. Get medical attention if symptoms

persist.

Skin Contact

In case of contact, immediately flush skin

with plenty of water. Remove contaminated

clothing and shoes. Wash clothing before

reuse. Thoroughly clean shoes before reuse.

Get medical attention.

Eyes

Immediately flush eyes with plenty of water

for at least 15min. Get medical attention.

Frostbite

Try to warm up the frozen tissues and seek

medical attention.

Inhalation

Immediately move to area with fresh air. If

breathing has stopped, give artificial

respiration. If breathing is difficult, qualified

personnel may give oxygen. Get medical

attention.

QBD COOLING SYSTEMS INC.

QBD.COM

6. FIRST AID MEASURES FOR R-

290

Material Safety Data Sheet

(MSDS) of R-290 (Propane)

is required to be available to

all users and employees at

the installed sites. It is

mandatory for users to refer to MSDS for

complete understanding of hazards and

take necessary precautions.

7. INSPECTION UPON DELIVERY

Your cooler contains R-290 refrigerant. For

safety, examine all packaging material for

damage when received. Damage to external

packaging may have resulted in unit

damage.

If you received a damaged cooler, refuse

the shipment and immediately contact the

carrier to report the incident.

Unpack the cooler. Check cooler for all

accessories and components, including

legs, casters (if applicable) and shelves.

All goods are shipped at the customer’s risk.

Return of goods to the factory must have

the authorized approval from QBD.

No returns will be accepted after 10 days.

Any shortage claims must be made within 5

days of receiving the goods.

If the cooler is tilted during

transportation/relocation please allow it to

sit for 2 hours in upright position before

connecting to power source. Ensure the

cooler is not damaged during transportation.

Follow all local/regional codes

for transportation or relocation

of hydrocarbon coolers.

Refer to updated MSDS for more details.

8

Page 9

- Always use QBD supplied OEM parts only. Use of non-OEM

parts will not only void the warranty but may also lead to a fire,

explosion, serious injury or death.

------------------------------------------------------------------------------------------

- Only trained and certified technician, for Hydrocarbon

systems, should service these coolers.

------------------------------------------------------------------------------------------

- Use extreme caution and follow all local/regional codes for

transportation or relocation of Hydrocarbon coolers.

Technicians are responsible to ensure these red sleeves are

always present on access points as per UL#471 requirement.

QBD COOLING SYSTEMS INC.

QBD.COM

8. VISUAL CHANGES TO CD 3.0

9

Page 10

- Always use QBD supplied OEM parts only. Use of non-OEM

parts will not only void the warranty but may also lead to a fire,

explosion, serious injury or death.

------------------------------------------------------------------------------------------

- Only trained and certified technician, for Hydrocarbon

systems, should service these coolers.

------------------------------------------------------------------------------------------

- Use extreme caution and follow all local/regional codes for

transportation or relocation of Hydrocarbon coolers.

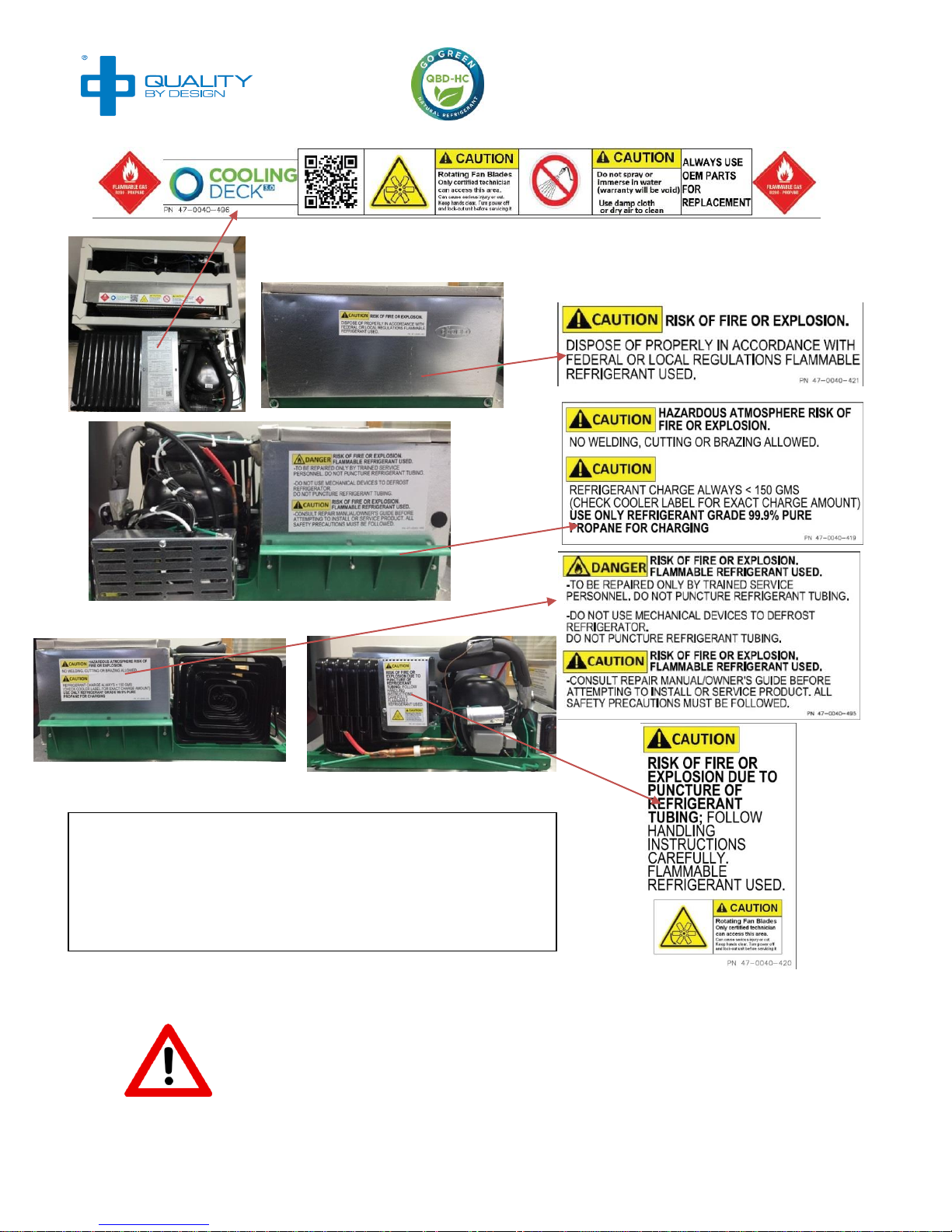

All QBD Hydrocarbon coolers are provided with multiple

identification and hazard labels. These can be located

inside the cabinet and other visible surfaces of the

cooler. Please contact QBD technical support for more

information.

QBD COOLING SYSTEMS INC.

QBD.COM

10

Page 11

- Always use QBD supplied OEM parts only. Use of non-OEM

parts will not only void the warranty but may also lead to a fire,

explosion, serious injury or death.

------------------------------------------------------------------------------------------

- Only trained and certified technician, for Hydrocarbon

systems, should service these coolers.

------------------------------------------------------------------------------------------

- Use extreme caution and follow all local/regional codes for

transportation or relocation of Hydrocarbon coolers.

QBD COOLING SYSTEMS INC.

QBD.COM

outlet is effectively grounded. If only an old

9. ELECTRICAL SAFETY

The cooler must always be plugged into its

own dedicated individual electrical circuit,

which has a voltage rating same as

mentioned on the serial plate, and is in

compliance with the Canadian Electrical

Code, Part I, the National Electrical Code or

the local Electrical Code.

Ensure that a dedicated 3-prong grounded

electrical receptacle is available at the

intended location of the cooler.

Ensure that the electrical branch circuit of

the fixed wiring to the dedicated receptacle

is protected with a fuse or a circuit breaker.

two-prong wall outlet is available, it is the

user’s responsibility and obligation to have it

replaced with an effectively grounded threeprong wall outlet for protection against

potential electrical shock and fire hazard.

DO NOT USE EXTENSION CORDS,

POWER BARS, AND / OR WIRING

DEVICE ADAPTERS TO POWER THE

COOLER.

Inspect the cooler power supply cord for any

damage prior to use. Do not use a cord that

is damaged or have crack signs. If power

cord is damaged, it must be replaced with

QBD supplied OEM part only. Do not alter

impact or apply pressure on power cord.

For personal safety, this appliance must be

effectively grounded at all times. The power

cord of this cooler is equipped with a threeprong (grounding) plug which mates with a

standard three-prong (grounding) wall outlet

(receptacle) to minimize the possibility of

electric shock hazard from this cooler.

Have the wall outlet and circuit checked by

a qualified electrician to make sure the

Don’t access electrical parts & mechanically

moving parts without authorization and this

should be done by a qualified service

technician only.

11

Page 12

- Always use QBD supplied OEM parts only. Use of non-OEM

parts will not only void the warranty but may also lead to a fire,

explosion, serious injury or death.

------------------------------------------------------------------------------------------

- Only trained and certified technician, for Hydrocarbon

systems, should service these coolers.

------------------------------------------------------------------------------------------

- Use extreme caution and follow all local/regional codes for

transportation or relocation of Hydrocarbon coolers.

QBD COOLING SYSTEMS INC.

QBD.COM

CAUTION

Always check for Hydrocarbon leak

(using a certified hydrocarbon leak

detector) before plugging / unplugging/

or switching ON-OFF power supply.

CAUTION

When working on the equipment or

parts thereof, the system has to be deenergized (by master switch, circuit

breaker or separate cut-out) and

unplug power cord, such that it cannot

be restarted accidentally. Do not

reconnect the system to the electric

circuit until all work is completed and all

connections are tested.

CAUTION

All units must be powered at their

nominal operating voltages at all times.

The voltage should be within 10% of the

nameplate voltage rating, as overvoltage

or under voltage could damage the cooler.

QBD is not responsible for the repair or

replacement of failed or damaged

components resulting from electrical

power failure, incorrect supply voltage,

low voltage, or unstable supply voltage.

Ensure that the power quality (i.e. the

voltage and current harmonics) are

within the acceptable industry tolerance.

CAUTION

Please do not spray or immerse any

electrical component with water and/or

chemicals. Doing so may will void all

warranties and may lead to fire,

explosion, severe injury or death.

Always use QBD supplied OEM

components only which are approved and

certified to be used in coolers using R290.

Consult QBD technical service (Contact

number (905)-459-0709) for details on

wiring diagram, or other electrical

components.

12

Page 13

- Always use QBD supplied OEM parts only. Use of non-OEM

parts will not only void the warranty but may also lead to a fire,

explosion, serious injury or death.

------------------------------------------------------------------------------------------

- Only trained and certified technician, for Hydrocarbon

systems, should service these coolers.

------------------------------------------------------------------------------------------

- Use extreme caution and follow all local/regional codes for

transportation or relocation of Hydrocarbon coolers.

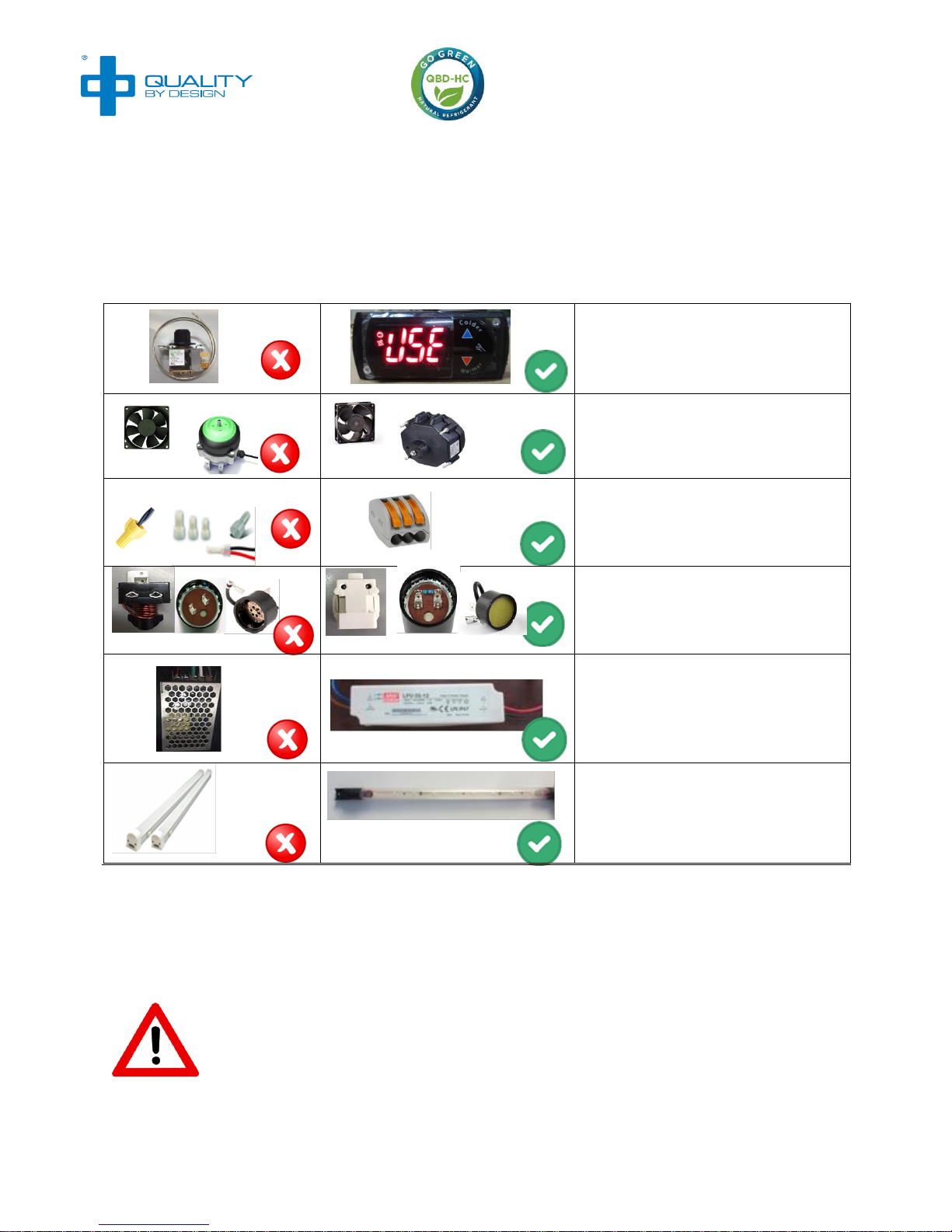

CONTROLLER

Please contact QBD Technical support

for more information on controller for your

particular cooler.

ECM MOTORS

UL Approved / Very High

Efficiency / Brushless / Wider

operating range

ELECTRICAL CONNECTORS

USE OEM PARTS ONLY

COMPRESSOR

RELAY/OVERLOAD/

CAPACITOR

USE OEM PARTS ONLY

LED POWER SUPPLY

Approved for Hydrocarbon / Class

2 Type Power supply: 12V DC /

High Energy Efficiency

LED+ Lighting

up-to 50% more product

illumination

QBD COOLING SYSTEMS INC.

QBD.COM

10. ELECTRICAL PARTS FOR HC COOLERS

Always use QBD supplied OEM parts only. Use of non-OEM parts will not only

void the warranty but may also lead to a fire, explosion, serious injury or death.

Below is just to demonstrate some examples of difference in parts used in non R-290 vs

R-290 systems.

13

Page 14

- Always use QBD supplied OEM parts only. Use of non-OEM

parts will not only void the warranty but may also lead to a fire,

explosion, serious injury or death.

------------------------------------------------------------------------------------------

- Only trained and certified technician, for Hydrocarbon

systems, should service these coolers.

------------------------------------------------------------------------------------------

- Use extreme caution and follow all local/regional codes for

transportation or relocation of Hydrocarbon coolers.

- Clearance

- Inches

- Side wall

- 1/2

- Rear wall

- 1/2

- Front glass

- 1

QBD COOLING SYSTEMS INC.

QBD.COM

- Minimum INTERNAL clearances are

11. INSTALLATION

LOCATION & LEVELING— INDOORS

ONLY!

- Cooler must be leveled front to back and

side to side to ensure optimum

performance. Use leg -adjust for proper

leveling.

- Improper leveling may cause cooler

door(s) to not close properly. This can

cause the evaporator coil to accumulate

frost and/or drain pan to overflow.

required for adequate air circulation

inside the cooler. Maintain internal

clearances between the beverages and

the cooler walls and door(s) as follows :

EXTERNAL AND INTERNAL

CLEARANCES, SHELF POSITION AND

DOOR SUPPORT BRACKETS

- Always maintain the following

EXTERNAL clearances for ease of

installation, door opening and proper air

circulation:

o Top .............….........2”

o Hinge Side............. 1 1/4”

o Non Hinge Side...... 1/2”

o Back...................... 3”

- Maintain a clearance of at least 2 feet in

front of the grill to ensure free air flow

from the refrigeration unit.

- Cooler is designed for freestanding

installation only. It should not be

recessed or built-in.

- Don’t locate cooler in close proximity to

high heat appliances such as fryers,

heating ranges and / or heating ducts.

- MUST remove the door support

bracket(s) before installation.

(applicable for specific models only)

- ALWAYS use the door support

bracket(s) during transport and/or

changing locations.

14

Page 15

- Always use QBD supplied OEM parts only. Use of non-OEM

parts will not only void the warranty but may also lead to a fire,

explosion, serious injury or death.

------------------------------------------------------------------------------------------

- Only trained and certified technician, for Hydrocarbon

systems, should service these coolers.

------------------------------------------------------------------------------------------

- Use extreme caution and follow all local/regional codes for

transportation or relocation of Hydrocarbon coolers.

QBD COOLING SYSTEMS INC.

QBD.COM

12. CASTER INSTALLATION

The cooler has a new design for caster

installation. It does not require a transfer

plate anymore.

Nut insert (to fit casters) is flush with the

bottom surface of base channel. This design

will allow caster top in firm contact with

cooler base channel. Hence, transfer plate

can be avoided.

- DC6/DC7 models have option for

adjustable leg too.

13. SHELF INSTALLATION

- Cooler shelves (flat or gravity) and a

bag containing shelf support clips are

packed at the factory inside the unit.

- In CD HC models (except CD10/12/20

HC), a bottom shelf must be installed on

top of the base step (return air duct).

No Transfer plate required as caster top is

directly in contact with the vase channel

plate. Shim plate may be required for

leveling of cooler.

IMPORTANT NOTE:

- QBD does not offer casters for PC8**

/PC8L** models Do not use any third

party casters kits. For safety and

stability of the cooler, only use the

supplier levelling legs.

- Don’t adjust the levelling legs beyond a

Maximum Height of 1/2`` (1/2 inch) on

PC8xx coolers.

- Improper shelf clip installation may

cause shelf and/or product to fall which

could result in personal injury or

damage to the cooler.

- Do NOT place solid packages on bottom

shelf to avoid poor cooling performance.

15

Page 16

- Always use QBD supplied OEM parts only. Use of non-OEM

parts will not only void the warranty but may also lead to a fire,

explosion, serious injury or death.

------------------------------------------------------------------------------------------

- Only trained and certified technician, for Hydrocarbon

systems, should service these coolers.

------------------------------------------------------------------------------------------

- Use extreme caution and follow all local/regional codes for

transportation or relocation of Hydrocarbon coolers.

QBD COOLING SYSTEMS INC.

QBD.COM

- Don’t overload the shelves. The cooler

is designed to use all the shelves

provided. Install in equally spaced

configuration. If fewer shelves or a

different configuration is required,

contact QBD to ensure that shelf

overloading will not occur.

- Store products as evenly as possible

inside the cabinet to maintain uniform

product temperature.

14. COLD CONTROL

Different cold controls are being used in

different models of HC coolers. All these are

certified for use in an HC unit. Please

contact QBD technical support to know

more about cold control for your unit.

All cooling deck based HC coolers are

equipped with customized CAREL cold

control (QBD Part # 47-0520-255). The

recommended setting is at #5 which will

allow the cooler to operate between 3842°F. Temperature probe should be in the

return air section.

This controller features voltage protection,

automatic defrost and energy saving logics.

DISPLAY INDICATORS

This indicates the Evaporator Motor(s)

is/are running but the Compressor is off. On

initial power up, there is an intelligent delay

for protection of the Compressor. Power to

the Compressor will initiate after one (1)

minute.

This is the typical look of the CAREL

controller while in use. "USE" indicates the

unit is in working order. The symbols to the

left of "USE" indicate that the Compressor

and Evaporator Motor(s) are both running. If

the Compressor Indicator is blinking, the

compressor is under "Time Protection".

DEFROST CYCLE

Indication that unit is in DEFROST cycle.

Evaporator Fan Motor(s) is/are ON for 4

minutes and OFF for 1 minute during this

cycle. To manually initiate the defrost cycle,

push and hold the "WARMER" button for 3

seconds. The controller will automatically

come out of DEFROST after 20 minutes. To

manually end the defrost cycle, push the

"WARMER" button for 3 seconds.

Second picture is the indication that unit is

in DEFROST MODE and Evaporator

16

Page 17

- Always use QBD supplied OEM parts only. Use of non-OEM

parts will not only void the warranty but may also lead to a fire,

explosion, serious injury or death.

------------------------------------------------------------------------------------------

- Only trained and certified technician, for Hydrocarbon

systems, should service these coolers.

------------------------------------------------------------------------------------------

- Use extreme caution and follow all local/regional codes for

transportation or relocation of Hydrocarbon coolers.

QBD COOLING SYSTEMS INC.

QBD.COM

Motor(s) will be running. There is an

automatic defrost cycle of 20 minutes every

6 hours.

This is the indication that the cold control is

"OFF" and power to the Compressor and

condenser fan motor has been disabled.

Power to Evaporator Motor(s) is still live. To

manually turn the controller "OFF", push

and hold the "COLDER" (upper) key for 3

seconds. To turn back "ON", push and hold

the "COLDER" (upper) button for 3 seconds

This is the indication that an ERROR has

occurred with the probe. Either the probe is

faulty or it has been disconnected from the

controller.

CHANGE THE TEMPERATURE SETTING

Check controller temperature setting.

Proper setting should be #5 on CAREL

Controllers. Push the "WRENCH" button for

3 seconds to get to the settings mode. Use

the "COLDER" or "WARMER" buttons to

adjust to the desired setting. To save the

new setting, you MUST push and hold the

"WRENCH" button for 3 seconds or until the

controller returns to "USE".

- QBD doesn't recommend any

temperature setting change without prior

authorization.

- Cold control is set at #5 for beverage

storage. Cooler maintains average

product temperature of 3.3°C (38°F).

- Cold control follows an automatic

defrost cycle every six hours for 20 min.

- Evaporator fan follows a defined logic (4

minutes ON and 1 minute OFF) during

compressor OFF cycle and defrost cycle

for optimum energy conservation.

Other HC coolers have mechanical (QBD

Part # 47-0430-257, 47-0430-258) or

electronic Danfoss cold control (QBD

Part # 47-0430-206).

Please contact QBD technical support

(phone number 905-459-0709) to confirm

the right controller for your cooler.

The temperature control dial has settings

from 1 to 9 plus “OFF” or “O”.

1 is the warmest setting.

9 is the coldest setting.

Initially set the temperature to the

recommended setting shown on the cabinet

serial-name plate, this setting is for ambient

condition of 75º F (±2°F). For every 5

degree rises in ambient temperature the

17

Page 18

- Always use QBD supplied OEM parts only. Use of non-OEM

parts will not only void the warranty but may also lead to a fire,

explosion, serious injury or death.

------------------------------------------------------------------------------------------

- Only trained and certified technician, for Hydrocarbon

systems, should service these coolers.

------------------------------------------------------------------------------------------

- Use extreme caution and follow all local/regional codes for

transportation or relocation of Hydrocarbon coolers.

QBD COOLING SYSTEMS INC.

QBD.COM

control setting should be moved 1 digit warmer (backwards).

After using the cooler for 24 hours, adjust

the temperature control to the setting that is

best suited for your needs.

NOTE : If the cooler is unplugged or turned

off, you must allow 5 minutes before starting

it or plugging it back in. If you attempt to

USE OF NON-QBD REPLACEMENT PARTS WILL VOID THE WARRANTY. PLEASE

CONTACT QBD (Tel: 905-459-0709) TO CONFIRM MOST CURRENT PART NUMBERS

restart it in less than 5 minutes, it may not

restart and it may damage the compressor

and VOID WARRANTY. Turning the

temperature control dial to “OFF” or “O”

stops cooling but does not shut off power to

the cooler.

15. WIRING DIAGRAM FOR CDxxHC & DCxxHC COOLERS

Ref No#47-0040-532

18

Page 19

- Always use QBD supplied OEM parts only. Use of non-OEM

parts will not only void the warranty but may also lead to a fire,

explosion, serious injury or death.

------------------------------------------------------------------------------------------

- Only trained and certified technician, for Hydrocarbon

systems, should service these coolers.

------------------------------------------------------------------------------------------

- Use extreme caution and follow all local/regional codes for

transportation or relocation of Hydrocarbon coolers.

QBD COOLING SYSTEMS INC.

QBD.COM

Please call QBD service for additional information if required. Check for refrigerant leak before

connecting or disconnecting power to unit.

16. LED LIGHTING

- All HC coolers are installed with customized LED+ lighting for maximum product

illumination, high energy efficiency and convenient replacement option.

- Check for HC leak prior to disconnecting power. Do not use lights or light

connectors, which are not UL certified for R-290 coolers. This may also lead to a

major fire, explosion, severe injury or death..

19

Ref No#47-0040-533

Page 20

- Always use QBD supplied OEM parts only. Use of non-OEM

parts will not only void the warranty but may also lead to a fire,

explosion, serious injury or death.

------------------------------------------------------------------------------------------

- Only trained and certified technician, for Hydrocarbon

systems, should service these coolers.

------------------------------------------------------------------------------------------

- Use extreme caution and follow all local/regional codes for

transportation or relocation of Hydrocarbon coolers.

QBD COOLING SYSTEMS INC.

QBD.COM

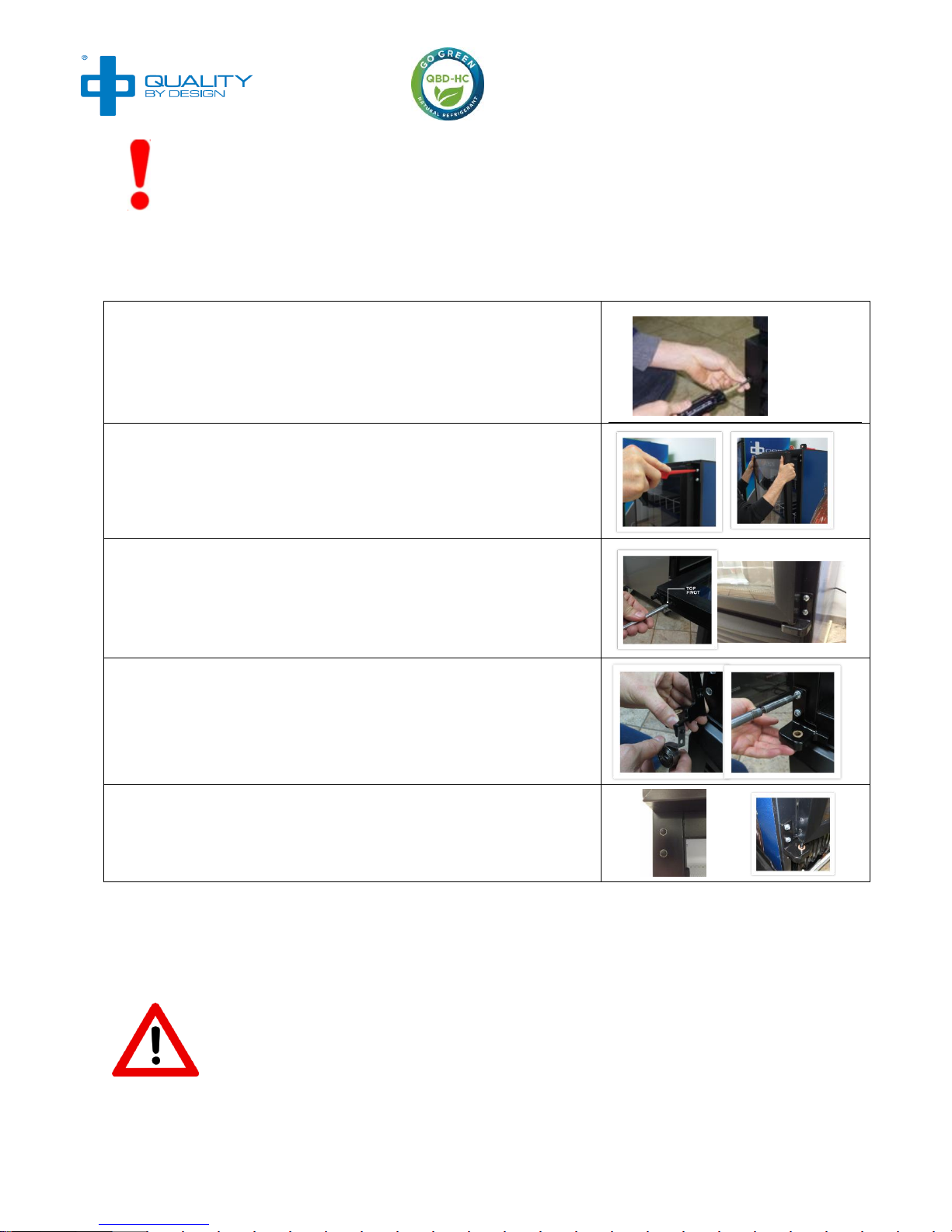

17. COOLING DECK REMOVAL, ACCESS AND RE-INSTALL

FOLLOW STEPS BELOW FOR COOLING DECK REMOVAL & RE-INSTALLATION

20

Page 21

- Always use QBD supplied OEM parts only. Use of non-OEM

parts will not only void the warranty but may also lead to a fire,

explosion, serious injury or death.

------------------------------------------------------------------------------------------

- Only trained and certified technician, for Hydrocarbon

systems, should service these coolers.

------------------------------------------------------------------------------------------

- Use extreme caution and follow all local/regional codes for

transportation or relocation of Hydrocarbon coolers.

Loosen the two hold down screws of the front grill. Remove

front grill by lifting the grill vertically upward approximately ½”

until the grill is lifted free of the two keyhole slots and screws

that hold the grill in place.

Use a Philips type screwdriver to remove the top right bracket

while holding the door. If there is a shim under the bracket,

remove it too. Set the bracket aside but take care to hold the

door.

Open the door slightly and lift it up firmly. The spring would be

released at the bottom.

Place the door on a flat non-scratching surface. Interchange the

door’s top and bottom pivot pins by removing and fixing the two

screws. Do not disturb the door handle.

Remove the bottom right bracket and if there is a shim under the

bracket, remove it too.

Install the new bottom left hinge bracket on the left side (QBD

Part# 47-0090-015), before fully

tightening the two screws, mount the door spring onto the pin

on the back side of the hinge bracket.

Now fully tighten the screws.

Remove and re-insert the plastic plugs for the screw holes on

the cooler’s front face from the left side to the right side

holes.

Set the door on the cabinet through the bronze bushing in the

bottom hinge bracket.

QBD COOLING SYSTEMS INC.

QBD.COM

- Don’t pull or apply pressure on suction line.

- Ensure locking bar is re-positioned after installation.

- Maintain clean coil and clear drain lines

18. HC MODEL DOOR REVERSAL AND ADJUSTMENT

To position the door hinges from the right side (factory set) to the left for CD models:

21

Page 22

- Always use QBD supplied OEM parts only. Use of non-OEM

parts will not only void the warranty but may also lead to a fire,

explosion, serious injury or death.

------------------------------------------------------------------------------------------

- Only trained and certified technician, for Hydrocarbon

systems, should service these coolers.

------------------------------------------------------------------------------------------

- Use extreme caution and follow all local/regional codes for

transportation or relocation of Hydrocarbon coolers.

Install the new left top hinge bracket to its new top left position.

(QBD Part # 47-0090-014)

Fix the door closing spring into the door pivot pin slot located at

the bottom left of the cabinet.

Pre-load the spring by giving one (1) full turn. Swing the door to

test the proper operation.

Remove the brand QBD logo from the bottom of the door and

refit at the right hand top corner of the door.

Install front grill.

QBD COOLING SYSTEMS INC.

QBD.COM

To position the door hinges from the

right side (factory set) of the cooler to

6. Remove the bottom bracket and shims if

applicable.

the left for Counter Top Model:

7. Remove the bronze inserts from the

1. Unplug the cooler and empty it.

bottom bracket and transfer it to the

other opening in the hinge.

2. Don’t remove the leveling legs

3. Use a Philips type screwdriver to

remove the top bracket while holding the

door. If there is a shim under the

8. Relocate the bottom bracket to the left

side. Remove the front block and rest

the cooler in the upright position. Don’t

alter the door handle.

bracket, remove it as well. Set the

bracket aside while continuing to

support the door.

9. Remove the door and place it on a flat

and smooth (none scratching) surface.

Interchange the top and bottom pivot

4. Open the door slightly and lift it firmly.

pins.

The spring will be released at the

bottom.

10. Remove the bronze insert from the top

bracket and transfer it to the other hole

5. Tilt the cooler approximately 6” to the

in the hinge.

back and block the lower front section to

create enough space to proceed to step

6.

USEFUL TIP: Easier to order and install a

new insert.

22

Page 23

- Always use QBD supplied OEM parts only. Use of non-OEM

parts will not only void the warranty but may also lead to a fire,

explosion, serious injury or death.

------------------------------------------------------------------------------------------

- Only trained and certified technician, for Hydrocarbon

systems, should service these coolers.

------------------------------------------------------------------------------------------

- Use extreme caution and follow all local/regional codes for

transportation or relocation of Hydrocarbon coolers.

QBD COOLING SYSTEMS INC.

QBD.COM

11. Remove all the plastic screw plugs

(caps) on the left side and reinsert them

to cover the holes on the right side.

12. Reinstall the door by positioning the

lower pivot pin into the hole of the

bottom bracket with the bronze insert.

Attach the top left hand hinge to the top

pivot pin and screw bracket to the

cabinet.

13. Tilt cooler back (similar to step 5).

Position the spring under the bottom

bracket and turn the spring counter

clockwise for one full turn (for models

DC6/7) and attach the spring to the slot

in the pivot pin. Remove and reposition

any label and graphic if required.

14. Check door gasket for proper sealing

and alignment

19. PREVENTIVE MAINTENANCE

AND CLEANING INSTRUCTIONS

Interior-Exterior Cleaning (Cabinet)

- Check the area for any refrigerant leak

before connecting or disconnecting

power to unit.

- Remove all products and shelves.

- Never use acids, chemical thinner,

gasoline, benzene or the like for

cleaning any part of the cooler. Boiling

water or benzene may deform or

damage plastic parts.

- Avoid using abrasive materials, scouring

powders or aggressive spray cleaners

which may damage the painted surfaces

of the cooler.

- Wipe inside of the cooler with damp

cloth and mild non-abrasive detergent.

Then dry with soft cloth.

- Clean the door gasket (s) and shelves

with mild detergent and dry with soft

cloth.

- To help prevent odors, leave open box

of baking soda inside the cooler and

replace every three months.

- Wipe exterior of the cooler with a soft

cloth dampened with soapy water.

Make sure the cooler is completely dry

before installing shelves.

PLEASE DO NOT SPRAY OR IMMERSE

ANY ELECTRICAL COMPONENT WITH

WATER AND / OR CHEMICALS. DOING

SO WILL VOID ALL WARRANTIES AND

MAY LEAD TO FIRE, EXPLOSION,

SEVERE INJURY OR DEATH.

23

Page 24

- Always use QBD supplied OEM parts only. Use of non-OEM

parts will not only void the warranty but may also lead to a fire,

explosion, serious injury or death.

------------------------------------------------------------------------------------------

- Only trained and certified technician, for Hydrocarbon

systems, should service these coolers.

------------------------------------------------------------------------------------------

- Use extreme caution and follow all local/regional codes for

transportation or relocation of Hydrocarbon coolers.

QBD COOLING SYSTEMS INC.

QBD.COM

“LTC” (Lint Tolerant Condenser)

cleaning procedure:

It is recommended to clean the condenser

once a month or earlier based on

surrounding environment conditions.

- Remove all dust and debris from

condenser coil by using a wand type

duster, soft brush, vacuum cleaner or

compressed air if available.

- Failure to keep condenser coil clean and

unobstructed at all times will result in

inefficient or poor cooling. It may also

cause damage(s) to the cooler and void

the warranty.

Once all necessary servicing and/or

cleaning have been carried out, reverse the

above procedures to reinstall the cooling

deck. Please make sure you connect the

power supply, lift the handles, install the

locking bar and fasten the two screws (CD

coolers only).

Never use any sharp tool for

cleaning the condensing coil.

The cooler contains

flammable refrigerant.

20. REPLACE VS REPAIR FOR

COOLING DECK 3.0

Replace (swap) the cooling deck under the

following circumstances:

a. Compressor failure

b. Refrigerant leak

c. Damaged/broken base (platform)

Repair the cooling deck under the following

conditions:

d. Controller failure

e. Motor (condenser/evaporator)

malfunction

f. Damaged fan blade(s)

NOTE: Use only OEM parts for

replacement.

21. SAFETY INSTRUCTIONS FOR

SERVICE, MAINTENANCE AND

HANDLING OF QBD HC COOLER

This section covers maintenance and safety

aspects related to the handling of R-290

refrigeration systems. Note that the

requirements detailed under this manual are

not exhaustive but are intended as a guide

only. Additional precautions may be

required dependent upon the particular

equipment, application and conditions.

Practical Competence

Any person involved with working on or

breaking into an R-290 refrigerant circuit

24

Page 25

- Always use QBD supplied OEM parts only. Use of non-OEM

parts will not only void the warranty but may also lead to a fire,

explosion, serious injury or death.

------------------------------------------------------------------------------------------

- Only trained and certified technician, for Hydrocarbon

systems, should service these coolers.

------------------------------------------------------------------------------------------

- Use extreme caution and follow all local/regional codes for

transportation or relocation of Hydrocarbon coolers.

QBD COOLING SYSTEMS INC.

QBD.COM

should hold a valid certificate from an

industry accredited authority.

General approach to handling of

Hydrocarbon Refrigerant

All flammable refrigerant gases when mixed

with air form a flammable mixture. The

effect of ignition of such a mixture can be

severe. It is therefore important that

appropriate safety requirements are

observed at all times when working with

flammable refrigerants.

Any equipment and tools (including

measuring equipment) used in the process

of repair must be suitable for use with R-290

refrigerant. Particular attention is to be paid

to the selection of the following:

- Refrigerant recovery units (no external

brushes)

- Refrigerant leak detector (non-sparking,

adequately sealed and intrinsically safe)

- Electric test meter

- Refrigerant recovery cylinder

- Portable lighting

If possible, it is recommended that the

cooler/cooling deck be removed from its

existing position to a controlled

workshop environment suitable to

conduct the repair safely.

minimized. Please comply with the following

precautions:

- Work Procedure:

Work shall be undertaken only under a

controlled procedure so as to minimize the

presence of flammable gas or vapor while

work is being performed. Prior to work

taking place the area surrounding the

equipment is to be surveyed to establish

any flammable hazards or ignition risks.

Display “NO-SMOKING” signs.

- General Work Area

All maintenance staff and personnel working

near the area should be notified as to the

nature of work being carried out. Work in

confined spaces should be avoided. The

area around the workspace is to be

sectioned off. Ensure that the condition

within the work area is safe and free of any

flammable materials.

- Checking for presence of Refrigerant

The area shall be checked with an

appropriate refrigerant detector prior to and

during work to ensure the technician is

aware of any potentially flammable

conditions.

Safety Checks

Prior to conducting maintenance or service

on R-290 coolers, perform all necessary

safety checks to ensure the risk of ignition is

! CAUTION

R-290 is the refrigerant used in this cooler

and it is odourless.

25

Page 26

- Always use QBD supplied OEM parts only. Use of non-OEM

parts will not only void the warranty but may also lead to a fire,

explosion, serious injury or death.

------------------------------------------------------------------------------------------

- Only trained and certified technician, for Hydrocarbon

systems, should service these coolers.

------------------------------------------------------------------------------------------

- Use extreme caution and follow all local/regional codes for

transportation or relocation of Hydrocarbon coolers.

QBD COOLING SYSTEMS INC.

QBD.COM

Ensure that the leak detector equipment

being used is suitable for use with R-290

refrigerant, i.e. non-sparking, adequately

sealed and intrinsically safe.

Presence of a Fire Extinguisher

If any hot work is to be conducted on the

cooler or any associated parts, appropriate

fire extinguishing equipment shall be

available on hand. Make sure a dry powder

or CO2 fire extinguisher is available

adjacent to the charging area.

No Ignition Sources

Any person carrying out work on an R-290

refrigeration system, which involves

exposing any pipe work containing or has

contained flammable refrigerant, shall not

carry any sources of ignition in such a

manner that it may lead to the risk of fire or

explosion.

All possible ignition sources, including

cigarette smoking, should be sufficiently far

away from the site of installation, repairing,

removal and disposal during which R-290

refrigerant can possibly be released to

surrounding space.

If brazing or welding is required, this should

be performed in an area detached from the

cooler. If this is not possible, then the

system should be fully evacuated using

guidelines as outlined in QBD service

documents.

Ventilated Area

Ensure that the area is in the open or that it

is adequately ventilated before breaking into

the system. Ventilation should continue for

the duration of the work process. The

process should safely disperse any

released R-290 refrigerant to the

atmosphere.

Checks to the Refrigeration Equipment

Where electrical components are being

replaced, they are to be “fit for purpose” and

to the correct specifications. At all times the

manufacturer’s maintenance and service

guidelines are to be followed. If in doubt

consult QBD.

22. RECOMMENDED SERVICE

PROCEDURES FOR HC COOLER

If diagnosis indicate failure of any sealed

system component (e.g. compressor,

evaporator or condenser leak, partial

blockage, full/partial loss of refrigerant, etc.),

please follow recommended procedures

below:

Venting or Recovery

R-290 refrigerant recovery is not required

under SNAP but may still be called for

under other authorities, controls or

practices. Always follow local laws and

regulations for recovery or venting of

hydrocarbon refrigerant.

If the HC refrigerant is to be vented to the

atmosphere, either the unit should be

moved to a well ventilated area before the

26

Page 27

- Always use QBD supplied OEM parts only. Use of non-OEM

parts will not only void the warranty but may also lead to a fire,

explosion, serious injury or death.

------------------------------------------------------------------------------------------

- Only trained and certified technician, for Hydrocarbon

systems, should service these coolers.

------------------------------------------------------------------------------------------

- Use extreme caution and follow all local/regional codes for

transportation or relocation of Hydrocarbon coolers.

QBD COOLING SYSTEMS INC.

QBD.COM

venting procedure begins or use hoses

long enough to discharge it safely to

outside environment.

- Attach gauges to both the high and low

sides of the system using an approved

method.

- To avoid accidental release of

refrigerant and lubricant, ensure that

they are recovered/ vented safely from

the system before removing the failed

component of the sealed system.

- Always recover the refrigerant from both

high and low sides of the system to

assure that no refrigerant is trapped in

the system.

- Purge the system with Oxygen Free Dry

Nitrogen (OFDN) several times to

ensure complete removal of refrigerant

from refrigeration system.

- Achieve a 500 micron vacuum in the

refrigeration system using a certified

vacuum pump before replacing failed

sealed system component(s).

- Use a tube cutter rather than a torch to

remove the failed component as shown

below. Using a torch may cause a fire

hazard, especially if the refrigerant has

not been completely discharged/

recovered. If you must use a torch to

remove the failed component of sealed

system, do so while running dry nitrogen

continuously through the system.

Always use OEM parts only. Use of nonOEM parts will not only void the warranty

but may also lead to a major fire,

explosion, severe injury or death.

Pressure Testing and Evacuation

- Pressurise the serviced refrigeration

system with oxygen free dry nitrogen

(OFDN) up to 150 psig.

- Hold the pressure and check for

possible leak.

- Purge OFDN before starting the

evacuation process.

- Never use a compressor to evacuate a

system. Use a certified vacuum pump

with manifold gauges and initiate

evacuation..

- The discharge of the vacuum pump

must be vented to an open-air area.

- Ensure the refrigeration system holds a

vacuum pressure of at least 100 micron

before charging.

- Never attempt to start the compressor

while the system is under vacuum.

- Always break a vacuum with refrigerant

charge before starting the compressor.

Charging refrigerant

- Do not overcharge the refrigeration

system (maximum 150 grams or 5.3

oz.) as per UL#471. Overcharging is a

safety hazard.

- Use only recommended type and

amount of refrigerant as indicated on the

serial label

27

Page 28

- Always use QBD supplied OEM parts only. Use of non-OEM

parts will not only void the warranty but may also lead to a fire,

explosion, serious injury or death.

------------------------------------------------------------------------------------------

- Only trained and certified technician, for Hydrocarbon

systems, should service these coolers.

------------------------------------------------------------------------------------------

- Use extreme caution and follow all local/regional codes for

transportation or relocation of Hydrocarbon coolers.

Symptom

Possible Cause

Solution

Compressor starts and

runs but short cycles

on the overload

protector

- Excess current passing

through overload

- Low / unstable voltage

- Overload failed

- Capacitor fault

- Excessive discharge

- Suction pressure too high

- Compressor overheating

- Compressor electrical fault

- Check wiring diagram for wrong

connections of electrical components

- Check voltage supply

- Replace overload

- Replace capacitor

- Check for over charge or condenser

blockage / condenser fan failure

- Check refrigerant charge

- Replace compressor

Units runs OK but

short cycles

- Overload protection

- Incorrect thermostat setting

- Check the wiring

- Replace the overload

- Change the thermostat setting if

required

Warm temperature

- Too low control setting

- Inadequate air circulation

- Reset the controller to colder setting

- Improve air movement

QBD COOLING SYSTEMS INC.

QBD.COM

- Always use proper charging techniques

e.g.- using only certified and calibrated

weighting scales

Leak test

- Leaks inside or outside of a cooler may

result in a flammable mixture.

- Leak detection must be done using

electronic or ultrasonic leak detectors

calibrated for hydrocarbon refrigerants.

Sealing the process tubes

- Seal the process tube using an

- Improper sealing of the process tube

23. GUIDELINES FOR TROUBLE- SHOOTING

approved method or by pinching the

tubing with the recommended

equipment and then sealing it with

brazing material or silver solder.

may lead to leaks or a sudden

release of flammable refrigerant.

28

Page 29

- Always use QBD supplied OEM parts only. Use of non-OEM

parts will not only void the warranty but may also lead to a fire,

explosion, serious injury or death.

------------------------------------------------------------------------------------------

- Only trained and certified technician, for Hydrocarbon

systems, should service these coolers.

------------------------------------------------------------------------------------------

- Use extreme caution and follow all local/regional codes for

transportation or relocation of Hydrocarbon coolers.

Blowing Fuse

- Power cord is cut and

grounding out

- Defective compressor

- Defective overload

- High Voltage

- Low Voltage

- Replace power cord

- Replace compressor

- Replace overload

- Correct voltage condition

- Ensure cooler plugged into dedicated

supply with properly sized circuit.

(Correct voltage condition)

Suction line frosted

- Evaporator fan not working

- Overcharged system

- Determine reason or replace if

required

- Correct the charge

Leaking water

- Very humid conditions

- Blocked drain

- Door not sealed properly /

top door seal

- Clear blocked drains

- Repair/replace door gaskets,

realign/seal doors

Evaporator freeze up

- Temperature controller set

too cold

- Blocked/restricted air flow

- Defective evap motor/

running at low speed

- Blocked drain

- Low refrigerant charge

- Open door or door not

sealed properly

- Defective or open gasket on

cooling deck

- Deck not in locked position.

- Adjust to higher temperature setting

(lower number)

- Remove source of blockage

- Replace evap motor

- Clear blocked drain

- Repair/recharge system

- Repair/seal air leaks. Replace

defective or damaged gasket

- Lock deck in position and secure

with locking bar

Controller

miscommunication

- Internal controller failure

- Voltage spike

- Replace controller & probe

QBD COOLING SYSTEMS INC.

QBD.COM

29

Page 30

- Always use QBD supplied OEM parts only. Use of non-OEM

parts will not only void the warranty but may also lead to a fire,

explosion, serious injury or death.

------------------------------------------------------------------------------------------

- Only trained and certified technician, for Hydrocarbon

systems, should service these coolers.

------------------------------------------------------------------------------------------

- Use extreme caution and follow all local/regional codes for

transportation or relocation of Hydrocarbon coolers.

QBD COOLING SYSTEMS INC.

QBD.COM

24. FREQUENTLY ASKED

QUESTIONS

1. How do I know if a cooler is using R290 refrigerant?

A number of visual differences have

been made in coolers running on R-290.

Check for R-290 indication on Cooling

Deck and the serial plate of the cooler.

2. Do you need any specialized training

to service R-290?

Although it is not mandatory, we

recommend you to attend specialized

training for this. Contact Refrigeration

Service Engineers Society

www.rses.org for more details.

3. Can I retrofit any cabinet to HC/R-290

refrigerant?

NO. The EPA has ruled that the

retrofitting of any existing equipment is

prohibited. All potential spark producing

parts in the system, including those in

cabinet have to be UL certified. Any

negligence may also lead to a major fire,

explosion, severe injury or death.

4. Can I use/add light switches in R-290

cabinet?

NO. All electrical fittings must comply

with UL # 471 and must be explosion

proof. It is therefore recommended not

to add any electrical switch in the

cabinet. LEDs provided with the cooler

are compliant to UL#471 and must be

replaced with OEM parts only.

5. Can the same tools be used to

service a hydrocarbon cooler and an

R-134a/R-404A system?

Since refrigerant R-290 is highly

flammable, no spark producing tool can

be used with HC cooling system. More

details of recommended tools are

provided in this manual. Please check

with QBD technical support team if you

have any questions.

6. Can the same parts be used in a

hydrocarbon cooler and an R-134a/R404A system?

NO

7. Is there a maximum charge amount

for R-290 refrigeration systems?

YES. You can only have a maximum

charge amount of 150 grams (5.3

ounces) in HC refrigeration system.

8. Do I need to recover the R-290

refrigerant?

NO. It is not mandatory. Always follow

local laws and regulations for

recovery or venting of hydrocarbon

refrigerant.

9. Where can I get R-290 refrigerant?

You can source this refrigerant from an

HVAC supply house or a company that

sells gases and welding supplies.

Always make sure you are purchasing

“refrigerant grade propane R-290”.

30

Page 31

- Always use QBD supplied OEM parts only. Use of non-OEM

parts will not only void the warranty but may also lead to a fire,

explosion, serious injury or death.

------------------------------------------------------------------------------------------

- Only trained and certified technician, for Hydrocarbon

systems, should service these coolers.

------------------------------------------------------------------------------------------

- Use extreme caution and follow all local/regional codes for

transportation or relocation of Hydrocarbon coolers.

QBD COOLING SYSTEMS INC.

QBD.COM

25. QBD CONTACT INFORMATION

31

Loading...

Loading...