Technical Support Line: (952) 985-5675 Email: Info@QA1.net

21730 Hanover Ave.

Lakeville, MN 55044

INSTALL INSTRUCTIONS

QA1 P/N MU1RCA, MU2RCA, MU3RCA ’79-’04 MUSTANG RACE SERIES CONTROL ARMS

QA1 P/N MU1ESA, MU2ESA, MU3ESA ’79-’04 MUSTANG STREET SERIES CONTROL ARMS

READ ALL INSTRUCTIONS CAREFULLY AND THOROUGHLY PRIOR TO STARTING INSTALLATION. PRODUCTS THAT HAVE BEEN INSTALLED ARE NOT ELIGIBLE FOR

RETURN. USE THE PROPER JACKING LOCATIONS. DEATH OR SERIOUS INJURY CAN RESULT IF INSTRUCTIONS ARE NOT CORRECTLY FOLLOWED. A GOOD CHASSIS

MANUAL, AVAILABLE AT YOUR LOCAL PARTS STORE, MAY ALSO AID IN YOUR INSTALLATION.

• DISCLAIMER / WARRANTY •

QA1 WARRANTS THAT THE PRODUCTS WILL BE FREE FROM DEFECTS IN MATERIAL AND WORKMANSHIP FOR ONE YEAR FROM DATE OF SALE TO THE ORIGINAL

PURCHASER. QA1 MAKES NO OTHER WARRANTY OF ANY KIND, EXPRESS OR IMPLIED. QA1 SHALL HAVE NO OBLIGATION UNDER THE FOREGOING WARRANTY

WHERE THE DEFECT IS THE RESULT OF IMPROPER OR ABNORMAL USE, YOUR NEGLIGENCE, VEHICLE ACCIDENT, IMPROPER OR INCORRECT INSTALLATION OR

MAINTENANCE, NOR WHEN THE PRODUCT HAS BEEN REPAIRED OR ALTERED IN ANY WAY. QA1’S LIABILITY IN THE CASE OF DEFECTIVE PRODUCTS SUBJECT

TO THE FOREGOING WARRANTY SHALL BE LIMITED TO THE REPAIR OR REPLACEMENT, AT QA1’S OPTION, OF THE DEFECTIVE PRODUCTS.

THE USER UNDERSTANDS AND RECOGNIZES THAT RACING PARTS, SPECIALIZED STREET ROD EQUIPMENT, AND ALL PARTS AND SERVICES SOLD BY QA1 ARE

EXPOSED TO MANY AND VARIED CONDITIONS DUE TO THE MANNER IN WHICH THEY ARE INSTALLED AND USED. QA1 SHALL BEAR NO LIABILITY FOR ANY

LOSS, DAMAGE OR INJURY, EITHER TO A PERSON OR TO PROPERTY, RESULTING FROM THE INSTALLATION, DIRECT OR INDIRECT USE OF ANY QA1 PRODUCTS

OR INABILITY BY THE BUYER TO DETERMINE PROPER USE OR APPLICATION OF QA1 PRODUCTS. WITH THE EXCEPTION OF THE LIMITED LIABILITY WARRANTY

SET FORTH ABOVE, QA1 SHALL NOT BE LIABLE FOR ANY CLAIMS, DEMANDS, INJURIES, DAMAGES, ACTIONS, OR CAUSES OF ACTION WHATSOEVER TO BUYER

ARISING OUT OF OR CONNECTED WITH THE USE OF ANY QA1 PRODUCTS. MOTORSPORTS ARE DANGEROUS; AS SUCH, NO WARRANTY OR REPRESENTATION

IS MADE AS TO THE PRODUCT’S ABILITY TO PROTECT THE USER FROM INJURY OR DEATH. THE USER ASSUMES THAT RISK.

TOOLS AND SUPPLIES REQUIRED

• Floor Jack • Jack Stands • Tire Chocks • Coil-over Struts

• Tape Measure • Drill & 3/8” bit •Torque Wrench • Common Hand Tools

REMOVAL:

1. Before starting the installation of your QA1 control arms read the instructions carefully and thoroughly. A good service

manual, available at your local parts store may aid in the installation. Check to make sure all of the parts and tools

needed to complete this installation are on hand.

2. Jack up the car so that jack stands can be placed under the frame. Let the jack down so that the frame sets securely on

the stands.

3. Remove the wheels and then unbolt the brake calipers. Secure the brake calipers out of the way of the control arms

(do not let the caliper hang from the brake line. This can cause damage to the brake line). For vehicles equipped with

ABS, refer to your Ford manual for safe removal.

4. Remove the sway bar end links from the vehicle. (Inspect for bushing wear and replace as needed)

5. Use the floor jack to support one of the A-arm assemblies. Jack the A-arm up just enough to take the load off of the

strut and spindle. Use of a spring compressor to contain the spring energy is highly recommended. (Fox body cars will

require the removal of the rotor backing plate before continuing.) Remove the cotter pin from the castle nut on the

ball joint. Loosen the castle nut enough to separate the ball joint. Once the ball joint has been loosened from the

spindle the castle nut should be removed. Slowly, CAREFULLY, let the A-arm assembly down until the spring is free and

can be removed.

6. Repeat this procedure for the opposite side.

www.QA1.net

9919-161 Rev 04112018

1

CONTROL ARM PART NUMBER

END OF ROD END TO

CENTER OF BALL JOINT

MU1RCA

13.687”

MU2RCA

14.875”

MU3RCA

14.687”

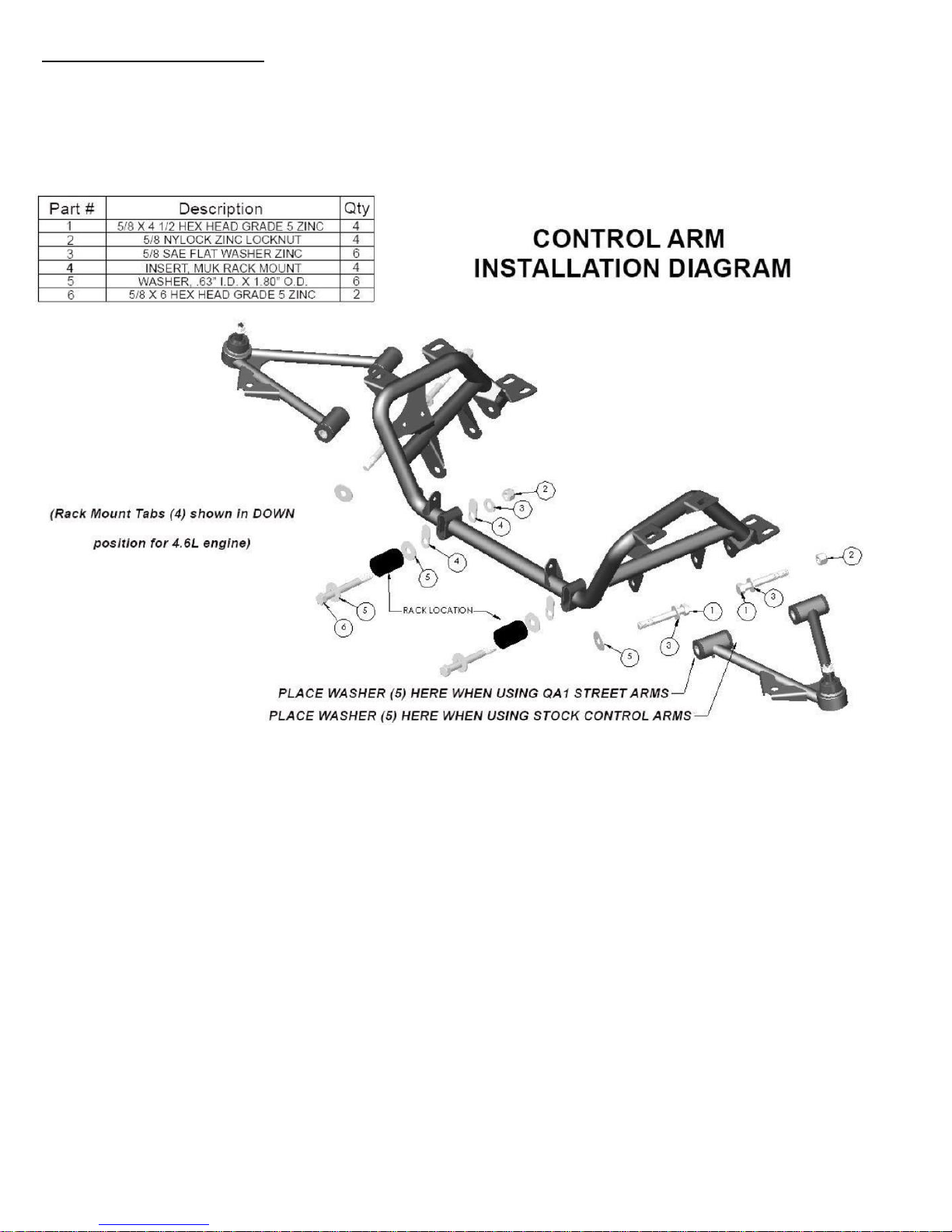

Figure 1

Figure 2

7. Loosen and remove the two bolts and nuts holding each A-arm into the K-member.

8. Inspect the bolts for any defects or wear. Replace hardware if needed. (QA1 p/n 52395)

NOTE: Installation of control arms to QA1 K member will slightly vary as the front bolt will thread into the K member.

PRE-INSTALLATION INSTRUCTIONS: *RACE SERIES CONTROL ARMS*

1. Identify the left and right side A-arms. The tube with the sway bar

attachment will point toward the front of the car.

2. Install 3/4”-16 jam nuts onto 3/4”-16 threaded rod ends and

thread into control arm.

3. Place control arm pivot points against a flat surface and measure

to the center of the ball joint to the following length.

(See Figure 2)

INSTALLATION INSTRUCTIONS: *RACE SERIES CONTROL ARMS*

1. Install the control arm into the K-member on each side of the car using the included spacers. Identify the different

sized spacers and install as shown in Figure 1.

Note: The age and condition of your stock K-member may require resizing of QA1 Race Series control arm spacers for correct fitment.

2. Tighten control arm hardware to 130 lb.-ft.

2

9919-161 Rev 04112018

INSTALLATION INSTRUCTIONS: *STREET SERIES CONTROL ARMS*

1. Identify the left and right side control arms. The tube with the sway bar attachment will point toward the front of

the car.

2. Install the control arm into the K-member on each side of the car. If installing control arms into QA1 k-member, see

Figure 3 or refer to your k-member instructions for correct washer placement.

Figure 3

3. Hand tighten control arm hardware, keeping in mind the final torque should be done with car at ride height as to

not bind the bushings.

4. Grease both ball joints using general automotive grease or synthetic grease.

NOTE: IF THE VEHICLE WAS NOT PREVIOUSLY USING COIL-OVER STRUTS, REFER TO THE NEW COIL-OVER INSTRUCTIONS

BEFORE CONTINUING.

5. Reinstall the brake rotor, caliper, and backing plates.

6. Reinstall the ABS sensor.

7. Reinstall both front wheels.

8. Set ride height by adjusting the spring seat adjuster on the body of the strut.

9. Lock the spring seat adjuster once desired ride height is achieved.

10. Double check all bolts and make sure that they are torqued to manufacture specifications.

11. Torque control arms to 130 lb.-ft. with car at ride height.

12. Bring the vehicle to a reputable shop for a quality frontend alignment to factory specs.

3

9919-161 Rev 04112018

Maintenance of QA1 Ultimate Ball Joints

Grease using high quality NLGI #2 GC-LB Lithium based grease and check preload on a regular basis. Check and

set ball joint preload at least annually or every 3,000 miles, whichever comes first. NOTE: Preload on the ball

stud can be set with the ball joint attached to the control arm if the spring is unloaded and the ball joint taper is

free from the spindle.

1. Using the QA1 spanner socket from Ball Joint Tool Kit (p/n 1891-106) loosen the lock nut by turning counter

clockwise.

2. Using the QA1 hex key, torque the torque nut to 25-30 in. lbs. and then back off 90°.

3. Using the QA1 hex key, a ½’’ open-ended wrench or socket, and the QA1 spanner wrench, tighten the lock

nut while holding the torque nut, locking them together to 25 ft. lbs.

4. Re-check the lash on the ball stud and adjust as needed. The ball stud should not have any axial lash.

9919-161 Rev 04112018

4

Loading...

Loading...