Page 1

1

Piccolo2

FIBER-OPTIC OXYGEN METER

USER MANUAL

Page 2

2

Document Version 2.04

Refers to Pyro Oxygen Logger Software version >3.2

The Piccolo2 is manufactured by

Pyro Science GmbH

Hubertusstr. 35

52064 Aachen

Germany

Phone +49 (0)241 5183 2210

Fax +49 (0)241 5183 2299

Email info@pyro-science.com

Internet www.pyro-science.com

Registered: Aachen HRB 17329, Germany

Page 3

3

TABLE OF CONTENT

1 OVERVIEW .............................................................................. 5

2 SAFETY GUIDELINES .............................................................. 6

3 INTRODUCTION TO THE PICCOLO2 ......................................... 8

4 SOFTWARE INSTALLATION .................................................... 9

5 OXYGEN SENSOR TYPES....................................................... 10

5.1 ROBUST PROBE ....................................................................... 10

5.2 DIPPING PROBE ....................................................................... 11

5.3 SENSOR SPOTS ........................................................................ 11

5.4 FLOW-THROUGH CELLS ............................................................ 13

5.5 RESPIRATION VIALS .................................................................. 14

5.6 NANOPROBES ......................................................................... 16

5.7 CONNECTING THE SENSORS AND OPTICAL FIBERS ......................... 18

5.8 CLEANING AND MAINTENANCE OF THE SENSORS........................... 20

6 THE SOFTWARE "PYRO OXYGEN LOGGER" ........................... 22

6.1 MAIN WINDOW ........................................................................ 22

6.2 SETTINGS................................................................................ 30

6.2.1 Basic Settings .................................................................... 31

6.2.2 Advanced Settings ............................................................. 32

6.2.3 Conditions in the Sample ................................................... 33

6.2.4 Options ............................................................................. 34

6.3 RAW DATA WINDOW ................................................................ 36

7 CALIBRATION OF OXYGEN SENSORS .................................... 38

7.1 CALIBRATION .......................................................................... 38

7.1.1 Calibration Mode: Factory .................................................. 39

7.1.2 Calibration Mode: 1-Point .................................................. 40

7.1.3 Calibration Mode: 2-Point .................................................. 42

7.1.4 Calibration Mode: Custom .................................................. 44

7.2 ADVANCED ADJUSTMENTS ......................................................... 45

8 CALIBRATION STANDARDS ................................................... 47

8.1 THE AIR CALIBRATION STANDARD .............................................. 47

Page 4

4

8.1.1 Ambient Air ....................................................................... 49

8.1.2 Water-Vapor Saturated Air ................................................ 49

8.1.3 Air Saturated Water ........................................................... 50

8.2 THE 0% STANDARD .................................................................. 51

8.2.1 Water Mixed with a Strong Reductant ................................ 51

8.2.2 Water Flushed with Nitrogen Gas ....................................... 51

8.2.3 Nitrogen Gas ..................................................................... 52

9 CALIBRATION OF CONTACTLESS SENSORS .......................... 53

9.1 CALIBRATION PROCEDURE ......................................................... 53

9.2 MANUAL BACKGROUND COMPENSATION .................................... 54

10 APPENDIX ............................................................................. 56

10.1 SPECIFICATIONS OF THE PICCOLO2 .............................................. 56

10.2 TROUBLESHOOTING ................................................................. 57

10.3 MEASURING PRINCIPLE ............................................................. 58

10.4 OPERATING SEVERAL PICCOLO2 IN PARALLEL ................................ 60

10.5 DEFINITION OF OXYGEN UNITS ................................................... 61

10.6 TABLE OF OXYGEN SOLUBILITY .................................................. 63

10.7 EXPLANATION OF THE SENSOR CODE .......................................... 65

Page 5

5

1 Overview

The ultra-compact Piccolo2 is a fiber-optic oxygen meter

integrated in a small USB stick housing. Despite its small size, it

features the proven REDFLASH technology from Pyro Science (see

Appendix 10.3 for more details). The Piccolo2 can be used in

combination with a variety of optical oxygen sensors, like robust

probes, dipping probes or contactless sensors (sensor spots,

respiration vials, flow-through cells, nanoprobes). The optimized

optics of the Piccolo2 enable contactless oxygen measurements up

to a window thickness of 20 mm. The sensors can be used in water

samples (dissolved oxygen, DO), as well as in the gas phase

(gaseous oxygen, O2). Simply plug the Piccolo2 into a USB port of

your Windows PC or Windows tablet, connect the oxygen sensor of

your choice and start measuring with the comfortable logging

software "Pyro Oxygen Logger".

More information concerning our products can be found at

www.pyro-science.com

or contact us under info@pyro-science.com

Your Pyro Science Team

Page 6

6

2 Safety Guidelines

The Piccolo2 is a laboratory instrument to be used at constant

experimental temperatures with optical oxygen sensors (optodes)

from Pyro Science. In order to guarantee an optimal performance

of the Piccolo2, please follow these operation instructions and

safety guidelines.

Please note that opening the housing will void the warranty. There

are no serviceable parts inside the device.

The Piccolo2 and the sensors should be used in the laboratory by

qualified personnel only, following the operation instructions and

safety guidelines of this manual. They should be kept and stored

out of reach of children in a secure place under dry and clean

conditions at room temperature, avoiding moisture, dust,

corrosive conditions and heating of the instrument.

The Piccolo2 and the sensors are not intended for medical, military

or other safety-relevant areas. They must not be used for

applications in humans; not for in vivo examination on humans, not

for human-diagnostic or therapeutic purposes. The sensors must

not be brought in direct contact with foods intended for

consumption by humans.

Please follow the appropriate laws and guidelines for safety like

EEC directives for protective labor legislation, national protective

labor legislation, safety regulations for accident prevention and

safety data-sheets from manufacturers of chemicals used during

the measurements.

When used in the field, extreme environmental conditions (like

high humidity, dust, and exposure to (salt) water or intense solar

radiation) can cause damage to the Piccolo2.

Page 7

7

Before using the Piccolo2 and the sensors, carefully read the

instructions and user manuals.

In case of problems or damage, disconnect the instrument and

mark it to prevent any further use! Consult Pyro Science for

advice! There are no serviceable parts inside the device. Please

note that opening the housing will void the warranty!

The Piccolo2 is not watertight, is sensitive to corrosive

conditions and to changes in temperature causing

condensation. Avoid temperatures above 50°C (122°F) or below

0°C (32°F). Avoid any elevated humidity causing condensing

conditions.

Handle the sensors with care, especially after removal of the

protective cap! Prevent mechanical stress to the fragile sensing

tip! Avoid strong bending of the fiber cable!

Calibration and application of the sensors are on the user’s

authority, as well as data acquisition, treatment and

publication!

The sensors and the oxygen meter Piccolo2 are not intended for

medical, diagnostic, therapeutic, or military purposes or any

other safety-critical applications. The sensors must not be used

for applications in humans and must not be brought in direct

contact with foods intended for consumption by humans.

The sensors should be used in the laboratory by qualified

personnel only, following the user instructions and the safety

guidelines of the manual, as well as the appropriate laws and

guidelines for safety in the laboratory!

Keep the sensors and the oxygen meter Piccolo2 out of reach of

children!

Page 8

8

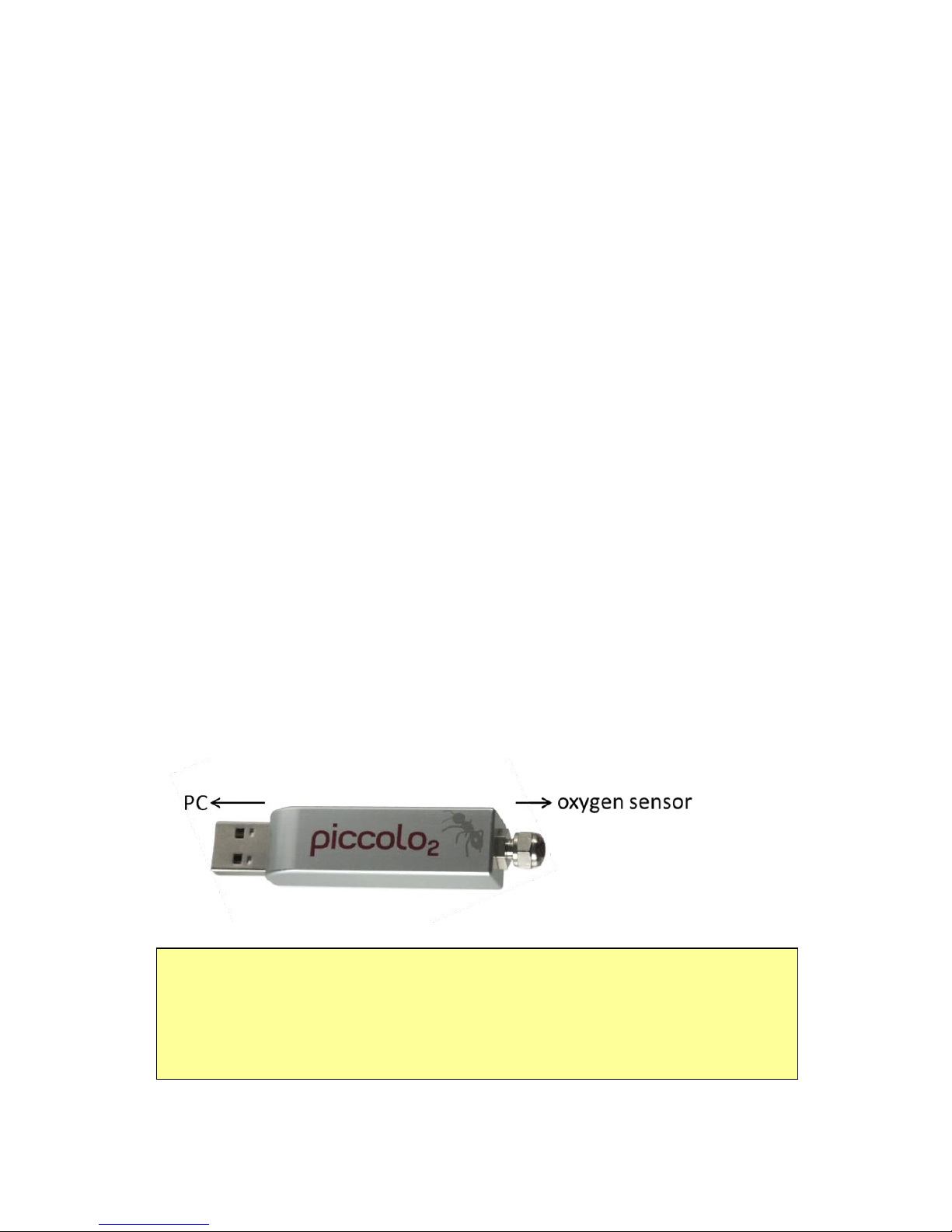

3 Introduction to the Piccolo2

The Piccolo2 is a miniature USB-driven fiber-optic oxygen meter

for usage in the laboratory. It is compatible to a variety of oxygen

sensors from Pyro Science, like robust probes, dipping probes and

contactless sensors, including sensor spots, respiration vials, flowthrough cells and nanoprobes.

These sensors are available in versions for the full range (050% O2, max. range 0-100% O2), and selected sensor types are

additionally available for the trace range (0-10% O2). The Piccolo2

utilizes a measuring principle based on red light excitation and

lifetime detection in the near infrared using the proven REDFLASH

indicators (REDFLASH technology, see Appendix 10.3 for more

details).

The Piccolo2 can be connected directly to a Windows PC with the

USB plug, providing energy supply and data exchange with the PC.

If a greater distance between the PC and the Piccolo2 is needed,

the delivered USB extension cable can be used.

Comfortable calibration and logging functions are provided by the

logging software Pyro Oxygen Logger, available as free download.

IMPORTANT: The Piccolo2 is intended for oxygen measurements

at constant and defined temperatures! Do not submerse the

housing of the Piccolo2 into liquid samples! This destroys the

device. Protect the Piccolo2 against water spray!

Page 9

9

4 Software Installation

IMPORTANT: Do not connect the Piccolo2 to your PC before the

Pyro Oxygen Logger software has been installed. The software will

install the appropriate USB-drivers automatically.

System requirements:

PC or tablet with Windows XP / Vista / 7 / 8 / 10 (but not

Windows RT) and min. 200 MB free disk space

Installation steps:

• download the installer package for the newest version of the Pyro

Oxygen Logger software from the Pyro Science homepage:

www.pyro-science.com/downloads.html

• unzip, then start the installer and follow the instructions

• connect the Piccolo2 to a free USB port of the computer

After successful installation, a new program group "Pyro Oxygen

Logger" is added to the start menu, and a shortcut named "Oxygen

Logger" can be found on the desktop.

Page 10

10

5 Oxygen Sensor Types

For the Piccolo2 meter, Pyro Science offers a range of optical

oxygen probes and contactless oxygen sensors, comprising sensor

spots, flow-through cells, respiration vials and nanoprobes. For an

overview of all available oxygen sensor types, please visit the Pyro

Science website.

5.1 Robust Probe

Characteristics: robust probe for Piccolo2 (item no. OPROB3) with

stainless steel tubing 3 mm in diameter and

30 mm in length

oxygen sensor with optical isolation located

in the 3 mm disc at the tip of the tubing

(sensor end, see chapter 5.7)

fiber cable 3 mm in diameter and 1 m in

length

Note: The fiber cable needs to be handled with care, as strong

bending can lead to breakage and damage of the robust probe.

Applications:

standard laboratory applications in gases and liquids

for aqueous liquids: permanent stirring is recommended, as

diffusion limitation of oxygen towards the 3 mm tip has a

measurable effect on the response time in liquid samples (this

diffusion limitation is negligible in gas samples)

Page 11

11

5.2 Dipping Probe

Characteristics: dipping probe for Piccolo2 (item no. OPDIP20)

with

stainless steel tubing 3 mm in diameter and

200 mm in length

oxygen sensor with optical isolation located

in the 3 mm disc at the tip of the tubing

(sensor end, see chapter 5.7)

Applications:

standard laboratory applications in gases and liquids

full probe length can be dipped into the sample

in aqueous liquids: permanent stirring is recommended, as

diffusion limitation of oxygen towards the 3 mm tip has a

measurable effect on the response time in liquid samples (this

diffusion limitation is negligible in gas samples)

Important: No part of the Piccolo2 device itself must be

submersed into liquid samples!

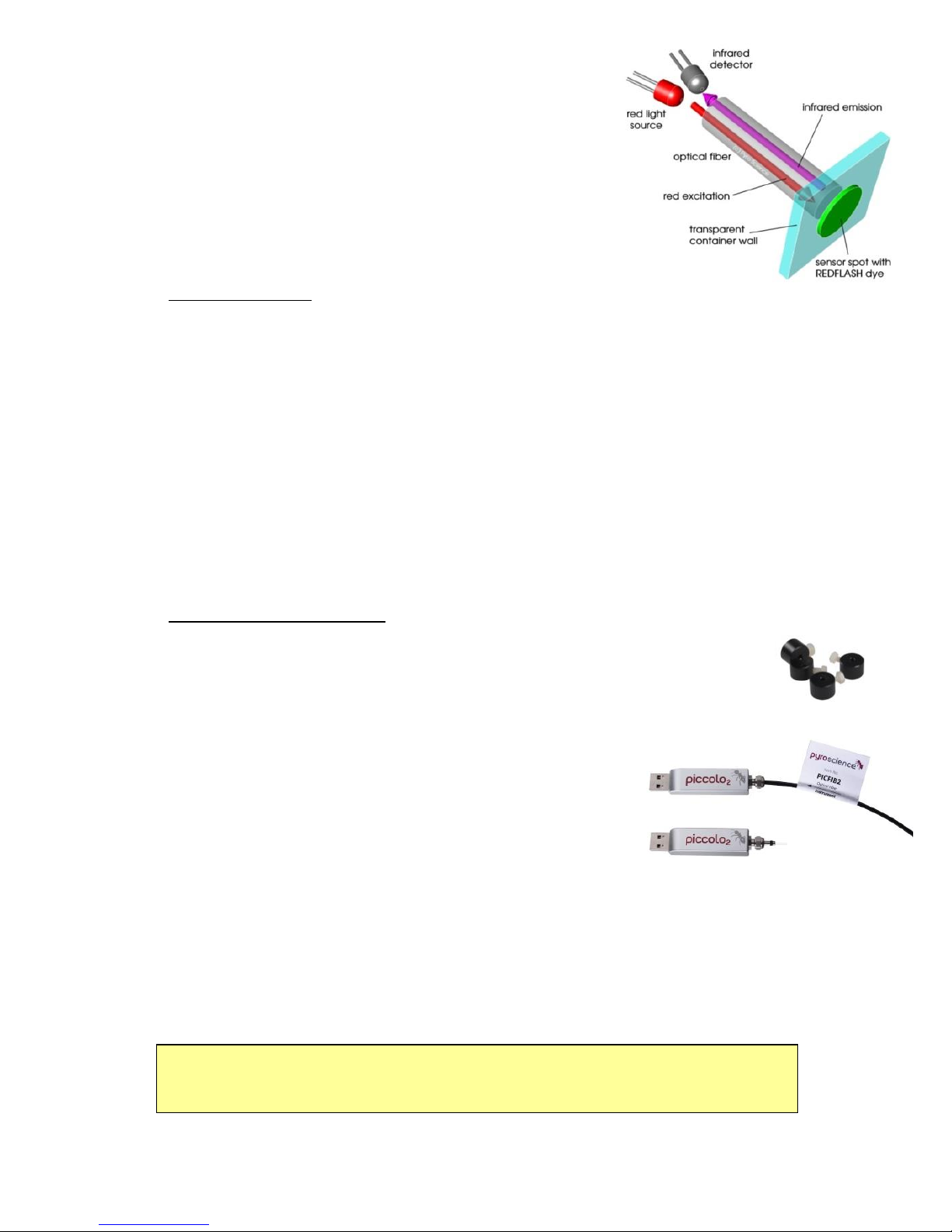

5.3 Sensor Spots

Measuring principle: oxygen sensor spots (item no. OXSP5)

oxygen measurements with contactless read-out

through transparent container walls

Page 12

12

sensor spot with REDFLASH indicator needs to

be glued to the inner container wall

excitation and detection of oxygen indicator

luminescence emission through the

transparent container wall with an optical fiber

fixed at the outer container wall

Characteristics:

PET foil coated with REDFLASH indicator and optical isolation

standard diameter of 5 mm

to be glued with the green back side on transparent, clean and dry

inner container walls (e.g. glass or acrylic glass)

black sensing surface has to be covered completely by the gaseous

or aqueous sample

can be autoclaved few cycles at 121°C for 15 min (requires

calibration afterwards)

Accessories for readout: 0-10 mm thick transparent windows

basic spot adapter SPADBAS: 12 mm in diameter, needs to be

fixed tightly or glued to the outer container wall at the spot

position

optical fiber PICFIB2: black fiber cable, 3 mm in

diameter, 1 m in length, connecting the basic

spot adapter SPADBAS with the Piccolo2 meter

(see also chapter 5.7) or, alternatively,

optical fiber rod PICROD2: stainless steel tubing, 3 mm diameter,

40 mm length, connecting the basic spot adapter SPADBAS with

the Piccolo2 meter (see also chapter 5.7)

transparent silicone glue SPGLUE: based on acetic acid, for gluing

sensor spots and basic spot adapters to the container wall

The PICFIB2 and PICROD2 are also compatible with the flowthrough cells and respiration vials from Pyro Science.

Page 13

13

Note: A change of position of the spot adapter after calibration of

the sensor spot might require a new calibration.

Accessories for readout: 10-20 mm thick transparent windows

optical fiber rod PICROD3: ca. 50 mm in length, needs a

customized fixation on the outer container wall (not compatible

with the spot adapter SPADBAS)

The optical fiber rod PICROD3 is not compatible with the basic

spot adapter SPADBAS. The user has to build a custom fixation at

the wall of the sample container.

Applications:

multi-sampling measurements

measurements of oxygen at greater scales

measurements in closed sample containers,

e.g. in respiration chambers, bioreactors, cell

biological approaches and industrial process water-monitoring

CAUTION: Oxygen measurements in air-tight containers or setups

require special precautions, like constant conditions during

measurements. More details on request.

Options:

trace range version (item no. TROXSP5): for measurements close

to 0% O2 (range: 0-10% O2)

5.4 Flow-Through Cells

Characteristics: flow-through cells (item no. OXFTC, OXFTC2)

flow-through cells with integrated oxygen sensor

available as small version OXFTC and as large version OXFTC2

Page 14

14

equipped with Luer lock connectors on both tubing ends

included Luer lock adapters allow connection of gas-

tight tubings (e.g. stainless steel, ISO-VERSINIC®) with

about 1.0-2.0 mm inner diameter to the OXFTC and

about 3.0-4.0 mm to the OXFTC2

Accessories for readout:

optical fiber PICFIB2: black fiber cable, 3 mm in diameter, 1 m in

length, connecting the flow-through cell with the Piccolo2 meter

(see also chapter 5.7)

Applications:

contactless measurement of oxygen in a

gaseous or liquid sample pumped through

the cell

CAUTION: For liquids, a flow rate of ca. 10-100 mL/min for the

OXFTC and of 20-500 mL/min for the OXFTC2 is recommended!

Lower flow rates are in principle possible; however the user has to

ensure sufficient gas tightness of the connecting tubing.

Options:

trace range version (item no. TROXFTC): for measurements close

to 0% O2 (range: 0-10% O2)

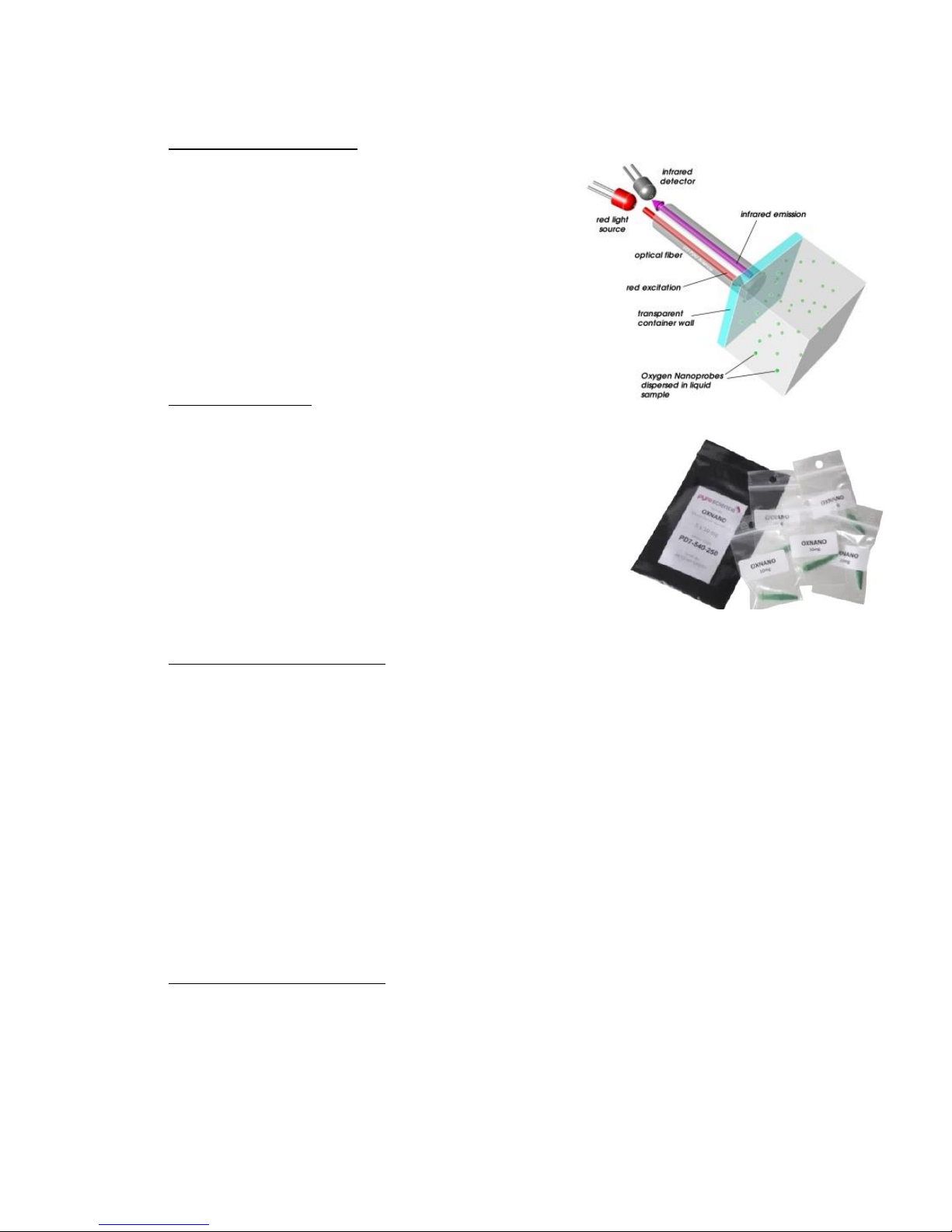

5.5 Respiration Vials

Characteristics: respiration vials (item no. OXVIAL4, OXVIAL20)

ready assembled respiration vials with integrated stripe of the

oxygen sensitive REDFLASH indicator with optical isolation

available with a (uncalibrated) volume of ca. 4 mL (OXVIAL4)

or ca. 20 mL (OXVIAL20)

Page 15

15

elongated shape of the integrated sensor allows

oxygen measurements at different heights within the vial

Note: A change of position of the adapter ring after sensor

calibration might require new calibration.

Accessories for readout:

adapter rings ADVIAL4 / ADVIAL20: for easy fixation of the optical

fiber PICFIB2 to OXVIAL4 / OXVIAL20

optical fiber PICFIB2: black fiber cable, 3 mm in diameter, 1 m in

length, can be fixed in the adapter ring with the clamping screw,

connecting the respiration vial with the Piccolo2 meter (see also

chapter 5.7)

Applications:

for oxygen measurements in e.g. stirred aqueous liquids or

gaseous sample

small-scale respirometry and metabolic rate measurements of e.g.

cell cultures, eggs, larvae, small crustaceans, small fish, water-,

plant-, algal-samples etc.

CAUTION: Oxygen measurements in air-tight vials require special

precautions, like e.g. constant temperature. More details on

request.

Page 16

16

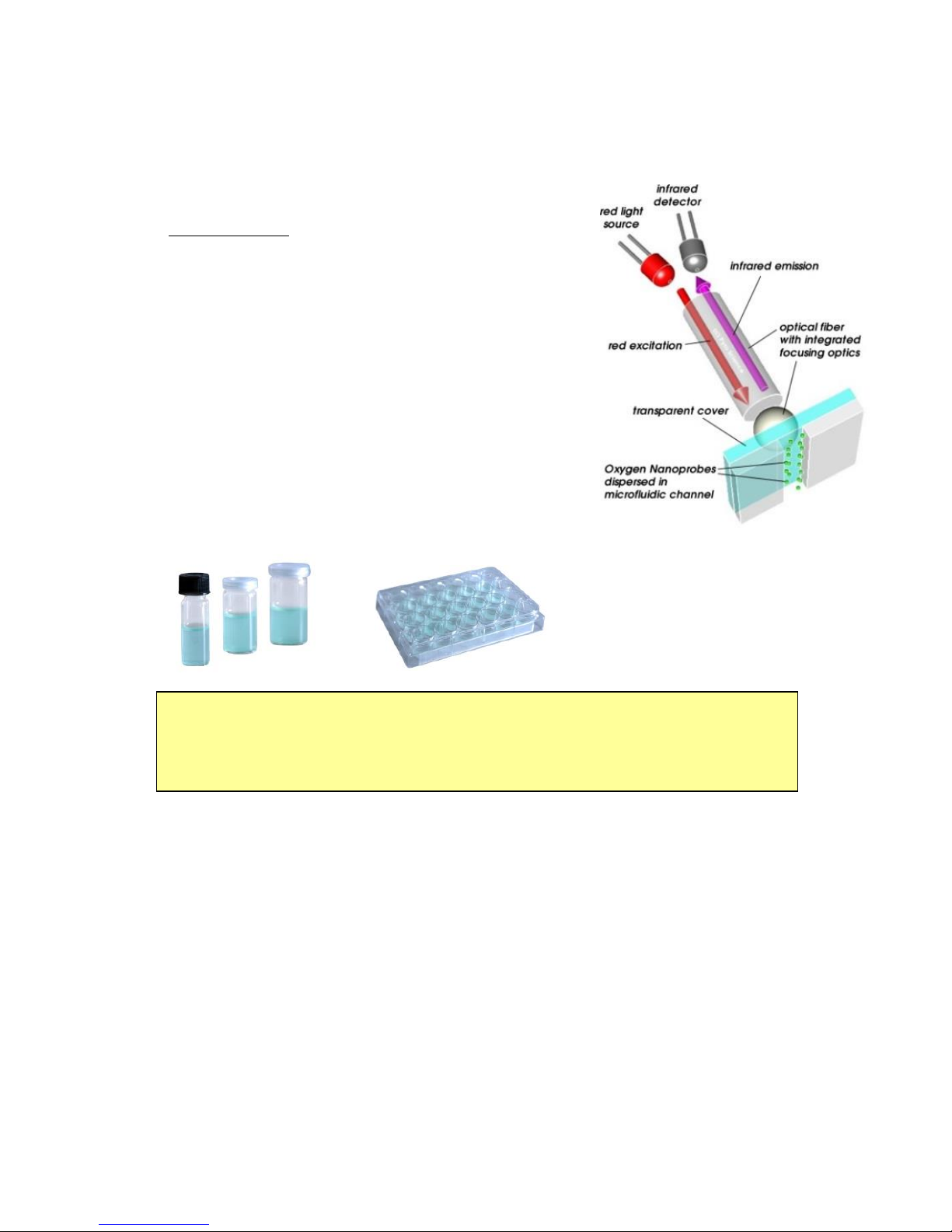

5.6 Nanoprobes

Measuring principle: oxygen nanoprobes (item no. OXNANO)

nanoparticles coated with oxygen-

sensitive REDFLASH indicator

dispersible in aqueous solutions, like e.g.

water, culture media

contactless readout from outside through

transparent windows

Characteristics:

oxygen nanoprobes OXNANO in 5 x 10 mg units

dispersible in aqueous solutions

ultra-fast response times

simple batch calibration

measurements at different positions or in

different vials containing the same dispersion

Accessories for readout: vials, microwell plates

basic spot adapter SPADBAS: 12 mm in diameter, needs to be

fixed tightly or glued to the outer container wall

optical fiber PICFIB2: black fiber cable, 3 mm in diameter, 1 m in

length, connecting the basic spot adapter with the Piccolo2 meter

(see also chapter 5.7) or, alternatively,

optical fiber rod PICROD2: stainless steel tubing, 3 mm in

diameter, 40 mm in length, connecting the basic spot adapter with

the Piccolo2 meter (see also chapter 5.7)

Accessories for readout: microfluidic applications

optical fiber with integrated focusing lens PICFIB2-LNS: black fiber

cable, 1 m in length, stainless steel tip 3 mm in diameter,

connecting the basic spot adapter or custom fixation with the

Piccolo2 meter (see also chapter 5.7) or, alternatively,

Page 17

17

optical fiber rod with integrated focusing lens PICROD2-LNS:

stainless steel tubing, 3 mm in diameter, 40 mm in length,

connecting the basic spot adapter or custom fixation with the

Piccolo2 meter (see also chapter 5.7)

Applications:

real-time monitoring

high through-put screening in e.g. microwell

plates

contactless measurements of fast processes,

like enzymatic reactions

in microfluidic devices (microfluidic chip,

lab-on-a-chip device)

more details on request

CAUTION: Oxygen measurements in closed vials require special

precautions, like constant conditions during measurements. More

details on request.

Page 18

18

5.7 Connecting the Sensors and Optical Fibers

The robust probe OPROB3, the dipping probe OPDIP20, and the

optical fibers PICFIB2 / PICFIB2-LNS or the optical fiber rods

PICROD2 / PICROD3 / PICROD2-LNS must be connected to the

sensor port of the Piccolo2 with their instrument end. At the

instrument end IE, the core of the optical fiber protrudes ca. 1 mm

from the fiber jacket. For OPROB3, OPDIP20 and PICFIB2 the

instrument end IE is marked with "Instrument" on the attached

label.

First, remove the protective caps from both ends of the optical

probe / fiber / rod. Then slightly unscrew and loosen the nut at the

sensor port of the Piccolo2. The nut must not be removed from the

sensor port. Typically, unscrewing the nut with a single half turn

(180°) is sufficient. Insert now the instrument end IE carefully into

the sensor port of the Piccolo2, the insertion length is about 24

mm (see pictures with insertion of a) a dipping probe and b) an

optical fiber rod).

Page 19

19

Insert the optical probe / fiber / rod carefully as deep as possible

(ca. 24 mm) into the sensor port of the Piccolo2!

Fix the optical probe / fiber / rod by screwing down the nut tightly

onto the sensor port of the Piccolo2.

a)

b)

Then, insert the adapter end (AE) of the optical fibers PICFIB2 /

PICFIB2-LNS or optical fiber rods PICROD2 / PICROD2-LNS into

the basic spot adapter, adapter ring or flow-through cell, and fix it

with the clamping screw.

For OPROB3 and OPDIP20, insert the sensor end (SE) into the gas

or (stirred) aqueous liquid sample.

Page 20

20

5.8 Cleaning and Maintenance of the Sensors

Oxygen sensors for the Piccolo2 can be sterilized with ethylene

oxide (EtO) and can be cleaned with ethanol, peroxide (3% H2O2)

or soap solution. They can be applied in gas phases, in aqueous

solutions, as well as in ethanol, methanol or isopropanol (robust /

dipping probe: only short-term application in diluted ethanol,

methanol or isopropanol). Other organic solvents and gaseous

chlorine (Cl2) interfere with the oxygen sensor reading. No crosssensitivity is found for pH 1-14, CO2, CH4, H2S and any ionic

species.

A signal drift of the sensor can indicate photo-bleaching of the

oxygen-sensitive REDFLASH indicator, depending on the ambient

light intensity, as well as the intensity of the excitation light and

the sample interval. This can necessitate new calibration of the

sensor and eventually also readjustment of the Sensor Settings

(LED intensity; see also chapter 6.2.2). In case of sensor spots, repositioning of the spot fiber on the sensor spot and subsequent

new calibration might be necessary. If the signal intensity is getting

too low (typically after several millions of data points), as indicated

by the horizontal indicator bar in the main window of the Pyro

Oxygen Logger software and by the respective warning (see

chapter 6), the sensor needs to be replaced.

After finalization of the measurements, the sensor tip of the robust

and dipping probe should be rinsed carefully with demineralized

water. Especially after application in seawater, it is recommended

to clean the sensor thoroughly with demineralized water. After

drying, put on carefully the protective caps onto both ends of the

probe.

For sensor spots and respiration vials, wet cotton swabs can be

used for carefully wiping the sensing surface. Rinse the sensing

Page 21

21

surface sufficiently with demineralized water afterwards to remove

small particles and let it dry before storage.

After drying, put the respiration vials into the corresponding black

bag and store them in a secure, dry and dark place at room

temperature!

Store sensors in a dry, dark and secure place at room temperature.

Page 22

22

6 The Software "Pyro Oxygen Logger"

This chapter describes all functions of the Pyro Oxygen Logger

software excluding sensor calibration, which is described in detail

in chapter 7 and 9.

6.1 Main Window

After start of the Pyro Oxygen Logger software the following main

window is shown:

As default, uncalibrated oxygen sensor readings (raw value) are

shown, which give only a qualitative information of the actual

oxygen level.

Note that placing the cursor on many elements in the window will

show a short description ("tool tip"). By clicking on the right mouse

button and selecting "Description and Tip" a more detailed

description might be available additionally.

Page 23

23

The sensor readings are displayed in a numeric display (D) and in a

chart recorder (C) in the chosen oxygen unit (UD). The color and

appearance of each graph can be changed by clicking on the colorcontrol (CC), opening a pop-up menu. With Common Plots, Color,

Line Style, Line Width, Interpolation, and Point Style the chart

appearance can be changed. Clicking on the small rectangular

button (to the left of CC) allows hiding / showing the respective

graph.

The visible time frame of the chart recorder (C) can be changed by

moving the bar along the scroll bar (SCB). Switching off the

Autoscroll button will allow inspection of older data which are not

visible anymore in the time frame, e.g. during long-time

measurements.

The description of the sensor, as defined in the Settings by the

Sensor Code, is shown in the description display (DD). The Signal

Page 24

24

Intensity (SI) of the oxygen sensor is shown as a horizontal

indicator bar just underneath the numeric display (D).

A reasonable oxygen sensor shows signal intensities well above 50

(typically 50-500)1. If the signal intensity drops below 50, the

indicator bar (SI) turns gradually from grey to red, indicating that

the sensor gets degraded soon.

At signal intensities <10, the warning Low signal will

appear in the warning display (WD). At a signal intensity <5, the

display changes to NaN (Not a Number),

indicating that the signal is too low and

the sensor needs to be replaced (or moved to another position on

the sensor spot).

Besides the warning Not calibrated for an uncalibrated oxygen

sensor, the warning display (WD) can show the following warnings:

Low signal The sensor is either not connected or needs to be

replaced by a new one. In case of contactless sensors it might

indicate that the distance between the optical fiber and the sensor

spot is too large. (For advanced users: increase the LED intensity

and / or the amplification in the Advanced Settings).

Signal too high There might be too much ambient light on the

sensor tip or sensor spot. Avoid direct sun light exposure or strong

direct illumination with a lamp. (For advanced users: decrease the

LED intensity and / or the amplification in the Advanced Settings)

Bad reference This indicates internal problems of the Piccolo2.

Please contact Pyro Science for support.

1

Note: Exceptions are trace oxygen sensors. During the air calibration at 21% O2, these sensors naturally

show a very low signal intensity (as low as 10). But the signal intensity will strongly increase when a trace

oxygen sensor is applied within its specified range of 0-10% O2.

Page 25

25

Refer to the Troubleshooting in chapter 10.2.

The actual Compensation Temperature (i.e. the temperature used

for calculating the oxygen values) is shown in the temperature

display (TD) in units of degree Celsius (°C).

If a sensor is not yet calibrated, the

warning Not Calibrated is shown on

the right-hand side of the Calibrate button. As long as the sensors

are not calibrated, the data are shown in units of "raw value"

reflecting the measured oxygen levels only qualitatively. In order

to switch to quantitative oxygen units, the sensor settings need to

be adjusted in the Settings and calibration has to be performed by

clicking on the button Calibrate. The calibration procedure is

explained in detail in chapter 7.

The adjustment of the Settings using the button Settings is

described in detail in chapter 6.2.

The button Save Setup can be used to save the current settings

and calibration data of the Piccolo2. They can be reloaded anytime

by pressing the button Load Setup. This allows e.g. to switch

between different laboratory setups with a single Piccolo2. This

function might be useful also if different computers are used for

calibration and for actual measurements. You might calibrate the

sensors with the first computer, save the configuration with Save

Setup. By transferring this file and also the oxygen meter Piccolo2

to a second computer, you can load this configuration again with

Load Setup, giving you calibrated sensors ready for measurement.

Note, that for this procedure identical software versions of the

Pyro Oxygen Logger must be installed on both computers.

Page 26

26

Save Setup and Load Setup might be useful also if e.g. a Piccolo2

should be used repeatedly with several oxygen sensors. Initially,

each sensor needs to be calibrated only once and the configuration

of each sensor is saved with Save Setup. If later on a measurement

should be performed with a specific sensor, it is only necessary to

load the configuration for this sensor with Load Setup (but it must

be checked if the calibration is still valid).

All current settings and calibration data are automatically saved

when closing the Pyro Oxygen Logger software and are

automatically loaded again at the next startup. The Last Setup

loaded is shown underneath the Settings button.

The button Flash Logo causes a short flashing (ca. 1-2 sec) of the

status LED of the Piccolo2. Several Piccolo2 meters can be

connected to the PC in parallel and multiple measurements can be

performed by opening the Pyro Oxygen Logger software a number

of times corresponding to the number of connected Piccolo2

meters. The different windows operate completely independent of

each other and are assigned to exactly one Piccolo2. This allows

measurements in different setups at the same time. The flashing of

the status LEDs can help to assign a specific logger window to the

corresponding Piccolo2 (more details in chapter 10.4).

Clicking on Raw Data opens a pop-up window Oxygen Sensor

Raw Data which is described in chapter 6.3.

Clicking on the button Bar Graph will

open the Bar Graph Window. Here,

different parameters can be chosen to

be displayed in the bar graph by clicking

next to "Select data type", e.g. the

Signal Intensity (mV) of the connected

oxygen sensor.

Page 27

27

A Measurement is started by clicking on the

measurement start button (MSB). The arrow

in the button turns from dark green to light

green indicating that a measurement is in

progress. Clicking on it again will stop the

measurement.

The mode of Measurement can be chosen as

single data point acquisition, continuous

sampling (default setting) or as continuous

sampling limited to a defined time interval.

The duration of this time interval can be

adjusted in the duration display (DUD) shown

as hour (HH): minutes (MM): seconds (SS).

The Sample Interval (s) for continuous sampling can be defined in

the field designed with set. Setting the sample interval to 0.25 will

give the maximal possible scan rate. The exact maximal rate

depends on the settings. The actual sample interval is shown in the

display actual and is displayed in red if the actual ≠ the set sample

interval.

Acquired data can be smoothed by a Data Smoothing (range

1…10, default: 3, a value of 1 means no data smoothing). For

continuous or duration measurements with a sample interval

<10 s, data smoothing is done by a simple running average (e.g.

with Data Smoothing=5 always the last 5 sampled data points are

averaged). However, for single data point measurements and for

continuous or duration measurements with sample intervals

>10 s, the data smoothing is done by averaging repetitive

measurements (e.g. with Data Smoothing=3 for each data point 3

oxygen measurements are performed as fast as possible

sequentially, and the average of these 3 measurements is

displayed as the new data point).

Page 28

28

IMPORTANT: By default the displayed data are not automatically

saved to a data file.

To activate data logging, click on the red start button (SB) of Log

to File. Select a file name in the appearing file dialog. The saved

data files are simple text-files with the file extension ".txt", which

can be imported easily into common spreadsheet programs.

Thereafter, the indicators Comment and File Path are shown in

the main window additionally. In the field Comment, the measurements can be commented and this comment is then saved

together with the next data point into the data file.

During data logging, the data file can be displayed and opened by

clicking on the button Show File. The data logging is indicated by

the light green arrow in the grey Log to File button and can be

stopped by clicking this button again.

NOTE: During data logging, the buttons Settings and Calibrate

are not active and cannot be used before Log to File is stopped.

Page 29

29

The display of the data in the charts can be changed by different

chart tools arranged underneath the chart recorder.

The button with the magnifying glass offers different zoom

options. After clicking the button with the hand, the user can click

on the chart and move the whole area while keeping the mouse

button pressed.

The button Clear Graph offers the option to clear the graph and to

zero the time scale. Note, that this will not affect the saved data in

the data file.

The unit of the x-axis can be changed with the selector Time Scale.

The time scale can be displayed in Seconds (s), Minutes (min),

Hours (h), Relative Time (HH:MM:SS), Absolute Time (HH:MM:SS),

Absolute Time and Date, and numbered Data Points.

The scales of the y- and x-axis can be adjusted by clicking on

Adjust Scales, opening a pop-up window:

The upper (Maximum) and lower

limits (Minimum) and the Increment

of the Y Scale (Oxygen) and of the X

Scale (Time) can be changed by

clicking on the respective selectors or

by double-clicking directly onto the

field and entering the values

manually (changing these parameters

will automatically deactivate the

autoscaling). Autoscaling for all axes

can be activated with the Autoscale button. The arrow in the

button turns from dark green to light green indicating that

Autoscale is activated. By default only the y-axis Oxygen is in

Autoscale mode.

Page 30

30

6.2 Settings

To open the dialog window Piccolo2 Settings click on the Settings

button in the Main Window:

The Settings can be adjusted only when data logging is not active.

In the Settings the user has to enter the Sensor Code of the

connected oxygen sensor and to define (1) the Sensor Settings, (2)

the Conditions in the Sample under investigation and (3) the

oxygen Units for the measurements.

In the Channel 1 tab, the oxygen sensor can be activated /

deactivated by clicking on the button Activate. Activation is

indicated by a change from dark to light green of the arrow in the

button. A text describing the connected sensor type appears on

the right-hand side of this button after the Sensor Code (see label

on sensor) has been entered. This description will be shown in the

description display (DD) of the main window and in the data file as

well.

Page 31

31

Please take care that the sensor code of the sensor connected to

the Piccolo2 is entered into the field Sensor Code in the Channel 1

tab of the window Piccolo2 Settings. It includes information for

optimal sensor settings and for calibration data needed for the

(rough) factory calibration and for the 1-point calibration. The first

letter of the sensor code defines the sensor type. A detailed

explanation of the sensor code is given in chapter 10.7.

The oxygen units can be selected by the selector Units. The

selectable units include raw value (default), % air saturation, % O2,

mL/L, µmol/L, mg/L (ppm), hPa (mbar), mmHg (Torr), dphi and

µg/L (ppb). For measurements in a Gas Phase only the units raw

value, % O2, hPa (mbar), mmHg (Torr) and dphi can be selected,

whereas for measurements of dissolved oxygen in a Water sample

(DO) all units except % O2 can be selected. For details please refer

to chapter 10.5.

NOTE: The chart in the main window is automatically cleared after

the Settings have been modified. Readjustments in the Settings

might require also new calibration of the sensor.

If changes of the Settings require new sensor

calibration, a warning Not Calibrated appears on the

right-hand side of the Calibrate button in the main window.

6.2.1 Basic Settings

The Sensor Settings can be adjusted in a Basic or

an Advanced mode. The first-time user is advised to

work with the Basic Settings. Please ensure that the

correct sensor code (see label on the connected

sensor) has been entered in the field Sensor Code.

The Measuring Mode can be adjusted gradually

between low drift (1) and low noise (128) of the

sensor signal by moving the arrow with the cursor along the scale,

Page 32

32

thereby changing the oxygen measuring time. For standard

applications, an intermediate mode (8 or 16) is advisable.

The Fiber Length (m) of the connected robust probe (OPROB3) or

of the connected optical fiber (PICFIB2) for contactless sensors

must be entered, which is typically 1 m (refer to chapter 9.2 for

more details). For the dipping probe OPDIP20 and for the optical

fiber rods PICROD2 and PICROD3, please enter a Fiber Length of

0 m (zero m).

NOTE: Ensure that the correct sensor code has been entered. If the

sensor is not yet calibrated, a warning Not Calibrated is displayed

in the main window.

6.2.2 Advanced Settings

If Advanced Sensor Settings are chosen, more complex setting

controls will be shown. Please ensure that the correct sensor code

(see label on sensor) has been entered in the field Sensor Code.

The Advanced Measuring Parameters comprise

the LED Intensity for excitation of the REDFLASH

indicator (in %) and Amplification of the sensor

signal. As a rule of thumb, the LED Intensity

should be 10-30% for robust / dipping probes, but

can be increased up to 100% for contactless

sensors (sensor spots, flow-through cells,

respiration vials). The Amplification should be typically chosen as

80x, 200x or 400x. Note that varying the LED Intensity and the

Amplification has direct influence on the signal intensity and

therefore on the signal-to-noise-ratio.

The Oxygen Measuring Time defines the integration time for

acquisition of a single data point. Shorter measuring times provide

low long-term drift, whereby longer measuring times assure less

noise. The maximal possible value is 128 ms.

Page 33

33

NOTE: If using the Advanced Sensor Settings, it is recommended

to perform a 2-Point calibration of the oxygen sensor. Later

readjustments in the Advanced Settings might require also new

calibration of the sensor.

The Fiber Length (m) of the connected robust

probe (OPROB3) or of the connected optical fiber

(PICFIB2) for contactless sensors must be

entered, which is typically 1 m (refer to chapter

9.2 for more details). For the dipping probe

OPDIP20 and for the optical fiber rods PICROD2

and PICROD3, please enter a Fiber Length of 0 m.

Alternatively, it is possible to select Manual Background

Compensation, which is described in detail in chapter 9.2. Finally,

the background compensation can be completely deactivated by

selecting No Background Compensation.

NOTE: Generally, it is advised to select Fiber Length (m) and to

enter the fiber length there. The alternative options Manual

Background Compensation or No Background Compensation

are only intended for advanced users (see also chapter 9.2).

6.2.3 Conditions in the Sample

The next step is determination of the Conditions in

the Sample, which can be Water for dissolved

oxygen (DO) or a Gas Phase.

The temperature of the environmental sample has

to be measured with a thermometer, kept constant

and entered manually as Fixed Temperature (°C).

This "Compensation Temperature" will be

displayed in the main window (TD).

Page 34

34

IMPORTANT: The measurements must be performed at constant

temperature and constant environmental conditions!

It is important to keep the temperature constant during calibration

and measurements, as

the luminescence of the REDFLASH indicator is temperature

dependent and

the conversion of some oxygen units is dependent on

temperature.

The atmospheric pressure (e.g. read from a separate barometer)

must be entered manually as Fixed Pressure (mbar). Common

conditions refer to 1013 mbar (default).

If the actual atmospheric pressure cannot be determined on site, it

is also possible to enter the Elevation (m) above sea level. For this

click on Elevation and enter the actual elevation in meters. This

procedure will calculate only the average atmospheric pressure for

this elevation; therefore, this option is less precise than measuring

the actual atmospheric pressure.

The Salinity (g/L) of the environmental sample needs to be

measured and entered, e.g. in case of saline water. For

measurements in gas samples this value has no relevance (and is

not active). For measurements in liquid samples, the salinity is only

relevant if a concentration unit was selected (e.g. mg/L or µmol/L).

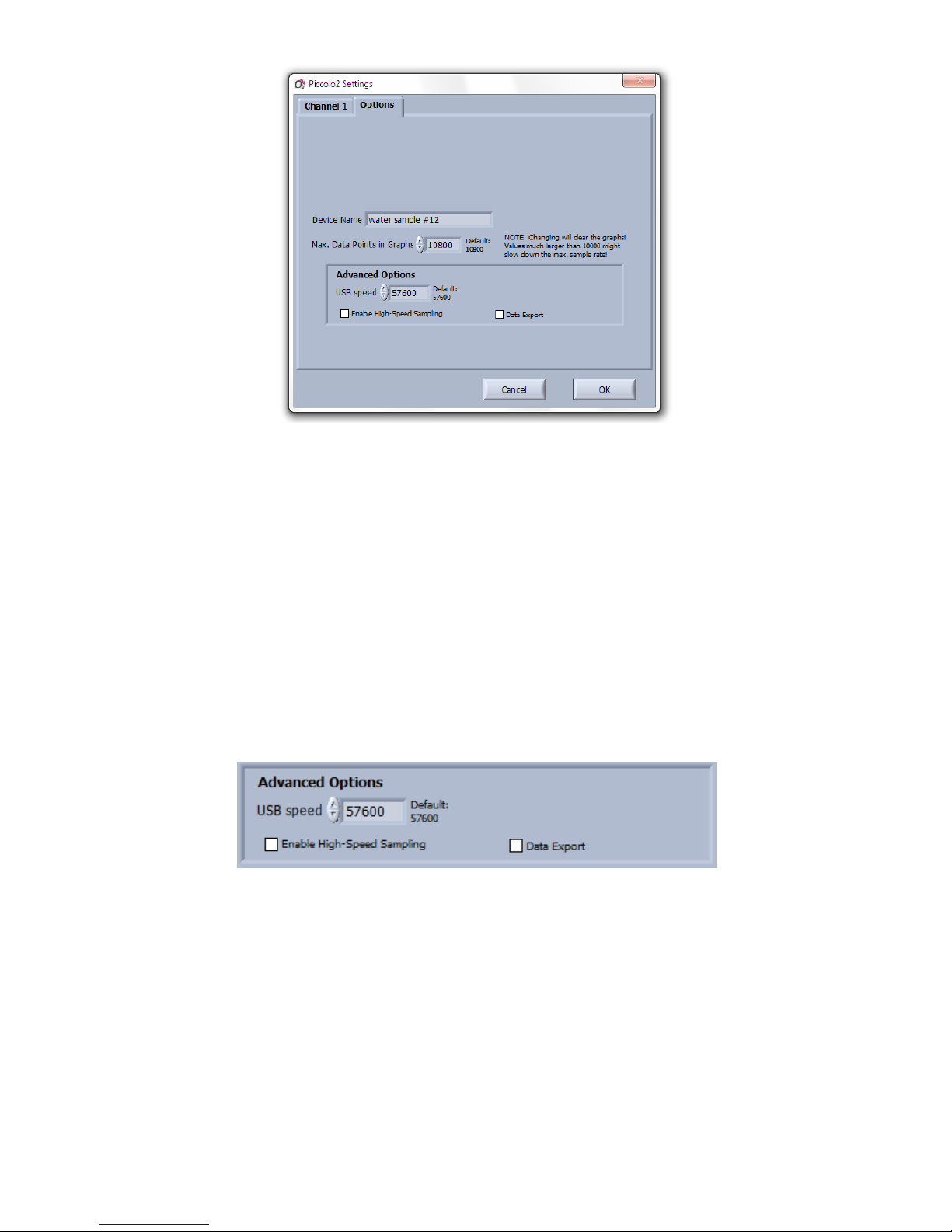

6.2.4 Options

In the panel Options, it is possible to designate a specific name to

the connected Piccolo2 by typing a name in the field Device Name

e.g. "water sample #12". This device name is then displayed in the

top line of the main window. This option is useful especially if

several Piccolo2 devices are operated in parallel in order to

distinguish the opened logger windows.

Page 35

35

The maximum number of data points kept in the graphs can be

changed by the selector Max. Data Points in Graphs (default:

10800). A change of the number of data points will clear the

graphs, and high values (>>10000) might decrease the maximum

sample rate (increase the actual sample interval).

Advanced Options (only for advanced users):

The USB communication speed can be adjusted e.g. for improving

the maximum sampling rate (default: 57600).

Activation of the button Enable High-Speed Sampling will enable

adjustment of a Sample Interval <0.25 s in the main window (and

disable Max. Data Points in Graphs).

The Data Export is relevant only for OEM modules or third-party

software.

Page 36

36

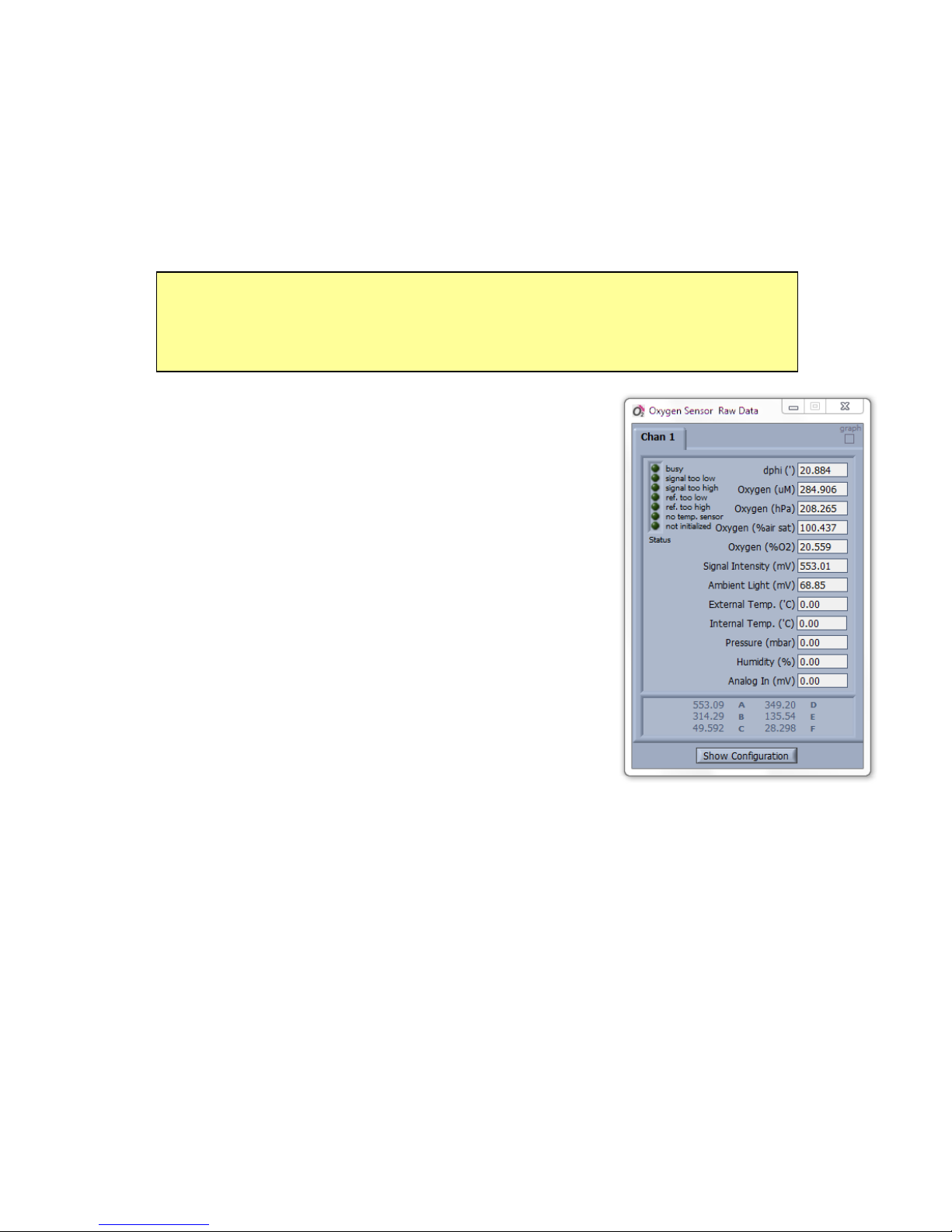

6.3 Raw Data Window

The Raw Data Window is mostly intended for trouble shooting and

advanced users. During standard measurements it is not needed in

general. After clicking on the Raw Data button in the main window

the Oxygen Sensor Raw Data window will open.

NOTE: While the Oxygen Sensor Raw Data window is opened, all

raw values are saved also in the data file in additional columns

behind the standard data columns.

The panel of the oxygen channel (Chan 1)

shows the phase shift as "delta phi" (dphi, in °).

dphi is the actual measured raw value which is

used for internal calculation of oxygen

concentration Oxygen (µM), Oxygen partial

pressure (hPa), Oxygen in % air saturation (%

air sat) and Oxygen (% O2) (see also chapter

10.3).

The Signal Intensity (in mV) gives a measure

of quality of the oxygen measurement and is

also displayed in the horizontal bar indicator in

the main window.

Ambient Light (in mV) gives a measure of the ambient light

entering the sensor from outside. At too high ambient light levels,

the detector of the Piccolo2 might get saturated, indicated by the

warning Signal too high in this window and in the warning display

of the main window.

On the left side, the Status and different warnings related to the

signal and reference intensity (too low, too high) can be indicated.

Page 37

37

On the right side of the channel tab, a graph can be activated,

showing the dphi (°) and Signal Intensity (mV) in the graph (default

setting). Plotting of additional parameters can be activated by

clicking on the small rectangular button next to the color control of

the respective parameter.

Page 38

38

7 Calibration of Oxygen Sensors

This chapter describes the possible calibration modes for oxygen

sensors connected to the Piccolo2 meter using the logger software

Pyro Oxygen Logger.

For sensor calibration, the temperature in the calibration standard,

the atmospheric pressure and the relative humidity of the ambient

air are important parameters ensuring high precision of calibration.

It is on the user´s authority to measure and adjust these

parameters manually.

This chapter covers only the necessary steps during the calibration

procedure. For details regarding preparation of calibration

standards refer to chapter 8.

Please note that during oxygen sensor calibration, the Sample

Interval is automatically set to 0.5 s and the Data Smoothing to 5,

ensuring fast determination of a precise mean value during sensor

calibration. After completion of the calibration, the program

returns to the former settings automatically.

7.1 Calibration

To calibrate a sensor, click on the button Calibrate in the main

window. Note that during data logging this button cannot be used

until Log to File is stopped.

A dialog window Oxygen Sensor Calibration will open in which

the calibration mode can be selected:

Page 39

39

Factory calibration (for a quick, rough calibration): taking the 0%

and the air calibration values from the sensor code; advised only

for rough measurements or testing purposes.

1-Point: taking the 0% value from the sensor code and the air

calibration value from a manual calibration for precise

measurements around 21% O2.

2-Point: taking the 0% and the air calibration value from a manual

calibration for precise measurements over the full range (0-21% O2

or 0-100% dissolved O2 (DO)).

NOTE: It is recommended to determine the air calibration value in

air saturated water if measurements will be performed in water

samples (aqueous liquids).

For advanced users and applications, a Custom Mode can be

selected, allowing the user to combine freely the possible

calibration types for the air and the 0% calibration.

7.1.1 Calibration Mode: Factory

NOTE: Factory Calibration is intended only for rough

measurements and testing purposes. It is only possible if the

correct Sensor Code has been entered in the Settings (see chapter

6.2).

Page 40

40

If the calibration mode Factory Calibration is chosen, ensure that

the correct sensor code has been entered in the Settings (as

displayed in 2. Adjust Calibration Conditions of the Oxygen

Sensor Calibration window). If the sensor code displayed is not

correct, click on Finish, open Settings, enter the correct Sensor

Code and repeat Factory Calibration.

After clicking on Finish factory calibration is completed, and the

program returns to the main window.

7.1.2 Calibration Mode: 1-Point

NOTE: The calibration mode 1-Point is only possible if the correct

Sensor Code has been entered in the Settings (see chapter 6.2).

The calibration mode 1-point is selected by clicking on the button

1-Point. This mode uses a manual calibration in an air calibration

standard for adjusting the air calibration value. The 0% calibration

value is taken from the Sensor Code. The preparation of

appropriate air calibration standards is described in chapter 8.1.

Depending on the air calibration standard used, select Water (DO)

for dissolved oxygen or Gas Phase.

The air calibration standard (see also chapter 8.1) can be:

ambient air of known humidity,

water-vapor saturated air or

air saturated water (100% air saturation).

The oxygen level in the calibration standard (unit: %O2) can be

freely chosen in Oxygen (%O2). If the air calibration standard is

based on ambient air or air saturated water, then this value should

be kept at 20.95% O2 (default), representing the standard oxygen

volume fraction in ambient air. However, other values can be

adjusted if custom calibration gases are used, of e.g. 5% O2, which

might be useful when using trace oxygen sensors.

Page 41

41

The temperature of the calibration standard needs to be

measured, kept constant and entered manually in Fixed

Temperature.

In addition, the actual atmospheric pressure in the calibration

standard can be entered manually in Pressure (mbar). Normal

conditions refer to 1013 mbar (default setting).

If the actual atmospheric pressure cannot be determined on site,

alternatively it is possible to enter the actual Elevation (m) in

meters above sea level. For this click on Elevation and enter the

actual elevation. Please note, that this option takes only the

elevation-dependent pressure change into account, but not the

variations due to actual weather conditions. Therefore,

determining the actual atmospheric pressure with a barometer

gives more precise results.

The relative Humidity (%RH) of the gas phase (e.g. air) needs to

be adjusted. If a calibration standard with water-vapor saturated

air is used (see chapter 8.1.2), it must be adjusted to 100% RH.

Otherwise, the humidity must be determined with a hygrometer

and must be entered.

Now place the oxygen sensor into the air calibration standard.

NOTE: Ensure constant calibration conditions and a constant

temperature in the calibration standard!

Page 42

42

Wait for steady-state until the sensor reading is stable by

observing the graph. Also ensure stable temperature during

calibration.

Note that the button Set Air will be highlighted as soon as the

oxygen reading is within the expected range for the connected

sensor type (the latter does not apply for custom air calibration

with ≠20.95% O2).

If the oxygen readings have reached their steady-state, click on

Set Air, and the current oxygen sensor reading is taken for the

air calibration. If the oxygen reading seems to be out of the

expected range, a warning will be shown offering the option to

repeat calibration (it is not recommended to continue without

checking the calibration standard and the sensor!).

A completed air calibration is indicated by the green indicator

Calibrated at Air.

For Factory 0% Calibration, no further steps are necessary (refer

to chapter 7.1.3). Ensure that the correct sensor code has been

entered in the Settings.

7.1.3 Calibration Mode: 2-Point

The calibration mode 2-point is selected by clicking on the button

2-Point. In this mode both the air calibration value and the 0%

calibration value are determined in specially prepared calibration

standards. Preparation of appropriate 0% and air calibration

standards is explained in chapter 8.

The air calibration standard and the calibration conditions need to

be defined and entered as described for the 1-Point calibration

(see chapter 7.1.2).

Now place the oxygen sensor into the air calibration standard.

Page 43

43

NOTE: Ensure constant calibration conditions and a constant

temperature in the calibration standard!

Wait for steady-state until the sensor reading is stable by

observing the graph. Ensure also stable temperature conditions in

the standard during calibration.

Note that the button Set Air will be highlighted as soon as the

oxygen readings are within the expected range for the connected

sensor type (the latter does not apply for custom air calibration

with ≠20.95% O2).

If the oxygen sensor readings have reached their steady-state, click

on Set Air, and the current oxygen sensor reading is taken for air

calibration. If the oxygen reading seems to be out of the expected

range, a warning will be shown offering the option to repeat

calibration (it is not recommended to continue without checking

the calibration standard and the sensor!).

A completed air calibration is indicated by the green indicator

Calibrated at Air.

Subsequently, insert the oxygen sensor into the 0% calibration

standard. Wait for steady-state until the sensor reading is stable by

observing the graph. Ensure stable temperature conditions during

calibration.

Page 44

44

Note that the button Set 0% will be highlighted as soon as the

oxygen readings are within the expected range for the

connected sensor type.

If the oxygen sensor readings have reached their steady-state,

click on Set 0%, and the current oxygen sensor reading is

taken for 0% calibration. If the oxygen reading is out of the

expected range, a warning will be shown offering the option to

repeat calibration (it is not recommended to continue without

checking the calibration standard and the sensor!).

A completed 0% calibration is indicated by the green indicator

Calibrated at 0%.

Finally, click on Finish for returning to the main window.

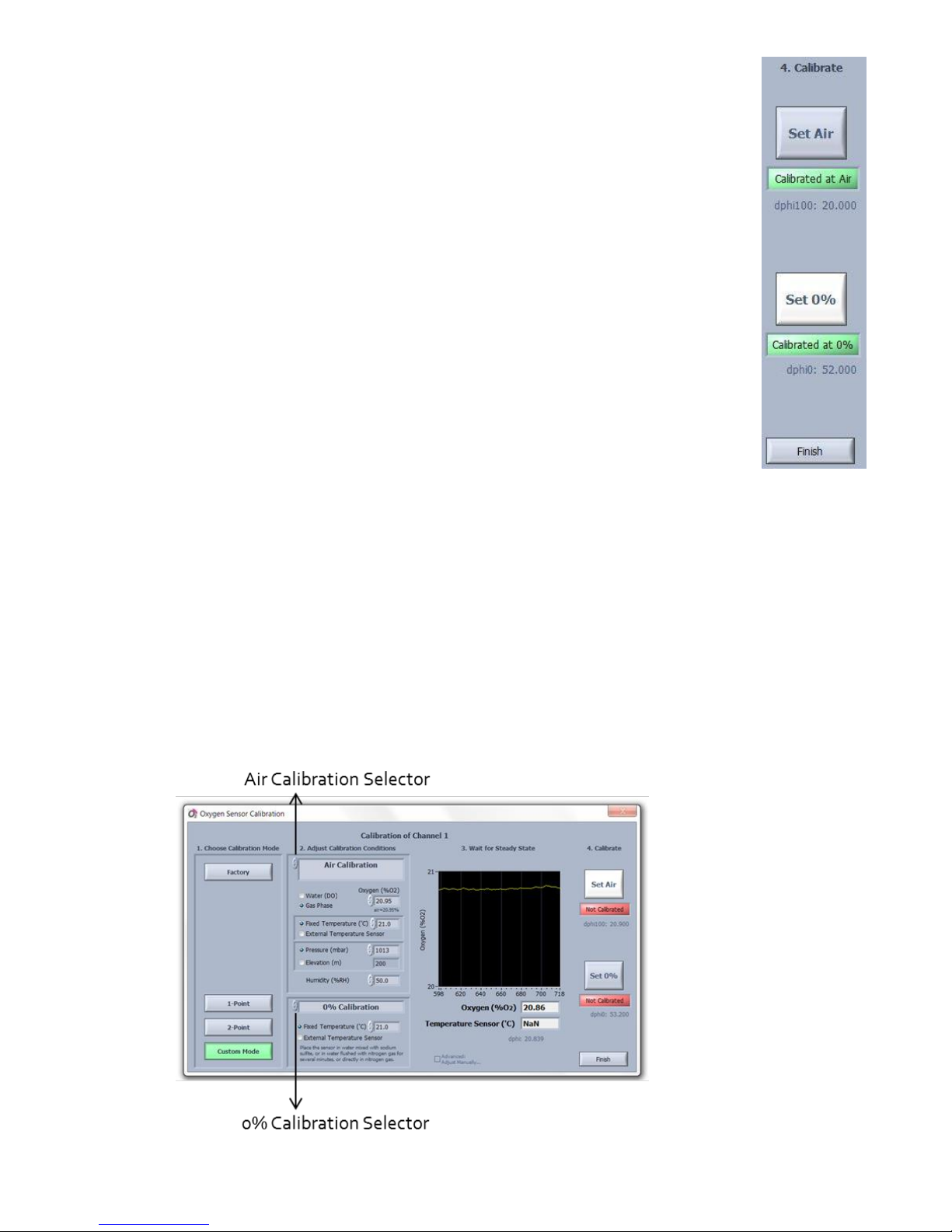

7.1.4 Calibration Mode: Custom

The custom calibration mode is selected by clicking on the button

Custom Mode. This mode allows to freely combine all possible

calibration types for the air calibration and the 0% calibration. The

air calibration type can be selected by clicking on the "Air

Calibration Selector". The 0% calibration type can be selected by

clicking on the "0% Calibration Selector".

Page 45

45

The following air calibration types can be selected:

Factory Air Calibration (refer to chapter 7.1.1)

Air Calibration (refer to chapter 7.1.2)

For the 0% calibration the following types can be selected:

Factory 0% Calibration (refer to chapter 7.1.1)

0% Calibration (refer to chapter 7.1.3)

7.2 Advanced adjustments

This section is for advanced users only!

For very advanced applications, it is possible to manipulate all

internal calibration parameters of the Piccolo2 manually. This

option is accessible by selecting Custom Mode and subsequently

clicking on Advanced: Adjust Manually, which opens a separate

window showing all internal calibration parameters.

Here, the Upper Calibration Point (default: Partial Volume of

Oxygen 20.95% O2) can be defined. The calibration conditions

(Temperature, Air Pressure, Humidity) need to be measured and

entered, as well as the Temperature (°C) at 0% for the 0%

Calibration Point.

Page 46

46

Further, the phase shift "dphi" (dphi, see chapter 10.3) for the 0%

calibration standard (dphi 0% in °) and for the air calibration

standard (dphi 100% in °) can be adjusted manually.

The Background Amplitude (in mV) and the Background dphi

(phase shift in °) can be adjusted (refer to chapter 9.2 for more

details). These two values are relevant only if background

compensation for measurements with contactless sensors has

been activated in the Advanced Settings.

The parameters f, m, F, kt, mt, Tofs, and tt are needed for internal

calculation of the oxygen concentration data. These parameters

are specific constants for the REDFLASH indicators, and are

automatically adjusted for the selected Sensor Type in the

Settings. Unless otherwise communicated by Pyro Science, it is

strongly advised to leave these parameters at their default

values.

Page 47

47

8 Calibration Standards

8.1 The Air Calibration Standard

The Air Calibration standard can be

ambient air

water-vapor saturated air

air saturated water (100% air saturation)

Always use a proper lab stand for mounting the oxygen sensor!

All air calibration standards described in the following rely on the

virtually constant oxygen content in the earth’s atmosphere of

about 20.95% O2 in dry air. Slight deviations might be given in

closed rooms occupied by many people (or e.g. candles,

combustion engines) consuming the oxygen. So if in doubt, ensure

good ventilation of the room with fresh air e.g. by opening a

window for some minutes.

Furthermore, the relative humidity of the air causes deviations

from the ideal value of 20.95% O2. Simply speaking, the water

vapor in humid air replaces a fraction of the oxygen, resulting in a

diminished oxygen level of e.g. 20.7% O2. For temperatures

around and below 20°C, this effect fortunately causes a maximum

deviation of about 0.5% O2 only. However, for higher

temperatures at 30°C or even 40-50°C, the humidity of the air has

a significant influence on the actual oxygen level. For example,

ambient air at body temperature (37°C) with 100% relative

humidity contains only 19.6% O2 compared to dry air with 20.95%

O2.

During calibration of oxygen sensors, there are two possibilities to

take the humidity into account:

Page 48

48

(1) The relative humidity and the temperature of the ambient air must

be determined during calibration and entered into the software.

Then, the Pyro Oxygen Logger software will automatically

calculate the real oxygen level under these conditions.

(2) The calibration standard is prepared in a closed vessel either filled

with water or partly filled with e.g. wet cotton wool or a wet

sponge. This ensures a constant humidity of 100% RH and there is

no need to measure the humidity.

Option (2) is utilized for the calibration standards "Water-Vapor

Saturated Air" (see section 8.1.2) and "Air Saturated Water" (see

section 8.1.3).

Another parameter even more important for the air calibration

standard is the atmospheric pressure. The principle parameter

measured by the oxygen sensors is not the partial volume (i.e. "%

O2"), but the partial oxygen pressure (i.e. "mbar") (see also chapter

10.5). So, an oxygen level of e.g. 20.7% O2 (determined as

described above by a given humidity and temperature) is

converted internally by the Pyro Oxygen Logger software into a

partial pressure of oxygen essentially by multiplying the relative

oxygen level with the atmospheric pressure of e.g. 990 mbar (see

chapter 10.5):

0.207 x 990 mbar = 205 mbar

giving a partial oxygen pressure of e.g. 205 mbar. This is the

essential calibration value used internally by the Pyro Oxygen

Logger software. The atmospheric pressure can be influenced 1) by

weather changes (e.g. varying between ca. 990 mbar and 1030

mbar at sea level) and 2) by the elevation above sea level (e.g. at

1000 m elevation the typical atmospheric pressure is about 900

mbar compared to 1013 mbar at sea level).

Page 49

49

Thus, in summary, there are three important parameters to be

known for the air calibration standard:

Temperature (°C)

Relative Humidity (% RH)

Atmospheric Pressure (mbar)

8.1.1 Ambient Air

If ambient air is used as the air calibration standard, the following

parameters must be independently determined in parallel

- air temperature (thermometer),

- air humidity (hygrometer),

- atmospheric pressure (barometer),

and entered into 2. Adjust Calibration Conditions of the Oxygen

Sensor Calibration window. Ensure that these three parameters

are kept constant during the calibration procedure.

Then, the dry oxygen sensor connected to the Piccolo2 is exposed

to the ambient air. Otherwise, follow the calibration procedures

given in chapter 7.

For precise calibrations in ambient air, it is important that the

measuring tip / surface of the oxygen sensor is completely dry.

Wet sensor tips will cause undefined humidity levels around the

sensor tips. And even worse, the evaporation of water drops would

cool down the sensor tips causing undefined temperatures.

8.1.2 Water-Vapor Saturated Air

Enclose wet cotton wool into a flask (e.g. DURAN flask) with a lid

prepared with one hole for the oxygen sensor connected to the

Piccolo2 and another hole for a temperature sensor. Typically,

about 1/3 to 1/2 of the flask volume is filled with wet cotton wool,

while the other volume fraction is left free for inserting the tip of

Page 50

50

the oxygen sensor and a temperature sensor. Otherwise, follow

the calibration procedures given in chapter 7.

8.1.3 Air Saturated Water

Fill an appropriate amount of water into a flask (e.g. Duran flask)

with a lid prepared with holes for inserting the oxygen sensor and a

temperature sensor. For about 10 minutes, stream air through the

water with an air stone connected to an air pump (available as

commercial equipment for fish aquaria). Alternatively, if no air

pump is available, fill water into the flask leaving >50% air in the

headspace, close it with a lid and shake the flask strongly for about

1 minute. Open the lid shortly for ventilating the headspace with

fresh air. Close it again and shake the flask for 1 more minute.

Insert the oxygen sensor and temperature sensor into the flask.

Ensure that the tips of the sensors are immersed in the water.

Otherwise, follow the calibration procedures given in chapter 7.

Please consider that streaming air through water may cause

cooling of the water. Ensure correct temperature determination!

Page 51

51

8.2 The 0% Standard

The 0% calibration standard can be

water mixed with a strong reductant

water flushed with nitrogen gas (N2)

nitrogen gas (N2)

8.2.1 Water Mixed with a Strong Reductant

Fill an appropriate amount of water into a glass flask (e.g. Duran

flask) with a lid prepared with holes for inserting the oxygen sensor

and a temperature sensor. Add a strong reductant, like sodium

dithionite (Na2S2O4) or sodium sulfite (Na2SO3) at a

concentration of 30 g/L, creating oxygen-free water by chemical

reaction. It is not recommended to use saline water (e.g. seawater)

for this, because the high salinity of the water might prevent a

proper dissolution of the reductant. Stir the solution until the salt is

completely dissolved and let the solution stand for about 15

minutes. Insert the oxygen sensor and temperature sensor into the

flask, and ensure that the sensor tips are completely immersed into

the water. Otherwise, follow the calibration procedures given in

chapter 7.

Do not store the sensors in this solution and rinse them sufficiently

with demineralized water after calibration.

8.2.2 Water Flushed with Nitrogen Gas

Fill water into a glass flask (e.g. Duran flask) with a lid prepared

with holes for inserting the oxygen sensor and a temperature

sensor. Close it and stream nitrogen gas through the water for

about 10 minutes. You might speed up this process by first boiling

the water (and thereby removing all dissolved gases) and then

stream the nitrogen gas through it during cooling. Insert the

oxygen and temperature sensor into the flask, let it equilibrate and

perform calibration as described in chapter 7.

Page 52

52

Please consider that streaming N2 gas through water may cause

cooling of the water. Ensure correct temperature determination of

the 0% calibration standard!

8.2.3 Nitrogen Gas

Flush 100% nitrogen gas through a glass flask (e.g. Duran flask)

with a lid prepared with holes for inserting the oxygen sensor and a

temperature sensor. Ensure that all air has been replaced by the

nitrogen gas before performing calibration. Insert the oxygen and

temperature sensor into the flask, let it equilibrate and perform

calibration as described in chapter 7.

Ensure that no ambient air enters the flask again during the

calibration process. Convectional gas transport is a very fast

process! It is therefore advised to keep flushing the flask with

nitrogen gas during the complete calibration process!

Please consider that nitrogen gas from gas bottles might be

significantly cooled down by the decompression process. Ensure

correct temperature determination of the calibration standard!

Page 53

53

9 Calibration of Contactless Sensors

For preparing a setup with contactless oxygen sensors, please refer

to the chapters 5.3-5.7. More details on oxygen nanoprobes in

microfluidic applications are available on request.

9.1 Calibration Procedure

In general, the calibration procedure for contactless sensors (e.g.

sensor spots, flow-through cells, respiration vials) is the same as

for the robust and dipping probe described in chapters 7 and 8.

However, if a 1-point or a 2-point calibration should be performed,

the calibration standards have to be filled directly into the vessel

containing the sensor spot, into the tubing of the flow-through cell

or into the respiration vial.

If "Ambient Air" is used for the air calibration standard (see chapter

8.1.1), a good air circulation of the ambient air into the dry setup is

important. For precision applications without the possibility to

ensure a dry setup for the calibration procedure, the alternative air

calibration standards "Water-Vapor Saturated Air" (see also

chapter 8.1.2) or "Air Saturated Water" (see also chapter 8.1.3)

should be preferred. In the first case, some part of the inner

volume of the setup can be filled with e.g. wet cotton wool

ensuring 100% RH around the oxygen sensor position. In the latter

case, the inner volume of the setup is simply filled with air

saturated water prepared as described in chapter 8.1.3. Ensure that

the oxygen sensor is completely covered with air saturated water!

Page 54

54

9.2 Manual Background Compensation

The calibration of contactless sensors (e.g. sensor spots, flowthrough cells, respiration vials, nanoprobes) includes a

compensation of potential background fluorescence from the

fiber-optic cable connecting the Piccolo2 with the contactless

oxygen sensor. Based on the Fiber Length (m) entered in the

Settings (see chapters 6.2.1 and 6.2.2), a background signal for

compensation is estimated automatically by the Pyro Oxygen

Logger software. So the user usually does not notice the

background compensation at all. For standard applications this

should be the preferred procedure.

But for precision applications and especially for low signal

intensities (e.g. <50 mV), a manual background compensation can

be performed by the user alternatively. For this, Manual

Background Compensation must be selected in the Advanced

Settings (see chapter 6.2.2). After opening the calibration window

by clicking on Calibrate, a separate Background Compensation

window will open automatically:

Here, the background fluorescence of the connected optical fiber

can be compensated. For this it is important that

Page 55

55

the instrument end of the Optical Fiber is connected to the

Piccolo2 (see 5.7) and

the adapter end of the Optical Fiber is not attached to the

sensor (i.e. disconnect the adapter end from the spot

adapter, adapter ring or from the flow-through cell)

Then, wait for steady-state and press the button Take Actual

Values.

Alternatively, the button Keep Last Values can be used if the

sensor spots are calibrated again with the same optical fiber, which

was background compensated before. Then, the last values for

background compensation are kept.

It is also possible to manually enter values for the Background and

dphi (°) into the field Manual and subsequently, clicking on Take

Manual Values. If you manually enter zero for Background, no

background compensation is performed.

After background compensation is finished, the window closes and

the program proceeds with the main oxygen sensor calibration

window (see chapter 7). It is important that, for the subsequent

calibration process, the Optical Fiber is attached to the sensor spot

position again, e.g. by connecting the adapter end again to the

spot adapter, adapter ring or flow-through cell.

Please ensure that during background compensation the Optical

Fiber is not connected to the contactless sensor.

Please ensure that during the subsequent calibration process the

Optical Fiber is attached again to the contactless sensor.

Keep in mind that the position of the spot adapter or adapter ring

should not be changed after calibration of the sensor spot;

otherwise it has to be calibrated again.

Page 56

56

10 Appendix

10.1 Specifications of the Piccolo2

Dimensions

15.5 x 15.5 x 54 mm

Weight

ca. 20 g

Interface

USB 2.0

Power Supply

5VDC from USB-port, ca. 3-5mA

average current consumption with

max. 40mA peaks (of about 10200ms duration) during an oxygen

measurement

Supported operating systems

Windows 2000, XP, VISTA, 7,8, 10

(but not Windows RT)

Operating temperature

0 to 50ºC

Max. relative humidity

Non-condensing conditions

Oxygen channels

1

Oxygen measuring principle

lifetime detection of REDFLASH

indicator luminescence

Excitation wavelength

620 nm (orange-red)

Detection wavelength

760 nm (NIR)

Max. sample rate

4 samples per second

Max. sample rate with enabled “high

speed sampling” in Settings->Options

ca. 10-20 samples per second

*Please note, that the oxygen sensors have different temperature ranges (typ. 050°C specified, -20°C to 70°C not specified).

Page 57

57

10.2 Troubleshooting

How to respond to the warnings shown in the Pyro Oxygen Logger

software:

Signal Too High

Too much ambient light exposed to the sensor, or amplification is

too high, or LED intensity is too high:

→ darken the surrounding

→ and / or decrease the Amplification in the Advanced settings

→ and / or decrease the LED Intensity in the Advanced settings

Low Signal

Sensor signal is too low:

→ check whether the sensor cable is connected

→ increase the Amplification in the Advanced settings

→ and / or increase the LED Intensity in the Advanced settings

→ replace the sensor, the tip might be broken / bleached

Bad Reference

Internal problem of the electronics

→ contact Pyro Science

Page 58

58

10.3 Measuring Principle

The REDFLASH technology is based on the unique oxygensensitive REDFLASH indicator showing excellent brightness. The

measuring principle is based on the quenching of the REDFLASH

indicator luminescence caused by collision between oxygen

molecules and the REDFLASH indicator immobilized on the sensor

tip or surface. The REDFLASH indicators are excitable with red

light (more precisely: orange-red at a wavelength of 610-630 nm)

and show an oxygen-dependent luminescence in the near infrared

(NIR, 760-790 nm).

The REDFLASH technology impresses by its fast response times,

high precision, high reliability, low power consumption, and low

cross-sensitivity. The red light excitation significantly reduces

Page 59

59

interferences caused by autofluorescence and reduces stress in

biological systems. The REDFLASH indicators show much higher

luminescence brightness than competing products working with

blue light excitation. Therefore, the duration of the red flash for a

single oxygen measurement could be decreased from typically 100

ms to now typically 10 ms, significantly decreasing the light dose

exposed to the measuring setup. Further, due to the excellent

luminescence brightness of the REDFLASH indicator, the actual

sensor matrix can be prepared much thinner now, leading to fast

response times of the Pyro Science oxygen sensors.

The measuring principle is based on a sinusoidally modulated red

excitation light. This results in a phase-shifted sinusoidally

modulated emission in the NIR. The Piccolo2 measures this phase

shift (termed "dphi" in the software). The phase shift is then

converted into oxygen units based on the Stern-Vollmer-Theory.

Page 60

60

10.4 Operating several Piccolo2 in parallel

The fiber-optic oxygen meter Piccolo2 offers one oxygen channel.

In order to realize extendable multichannel systems with higher

channel numbers, several Piccolo2 can be operated at a single PC

as described in the following:

Connect each Piccolo2 to a free

USB port of your PC. If the PC

does not provide a sufficient

number of USB ports, you can

use an external USB-hub.

The Pyro Oxygen Logger

software now has to be started

separately for each connected

Piccolo2. So, if you want to operate e.g. 4 different Piccolo2, you

have to start the Pyro Oxygen Logger software 4 times, which will

open 4 Pyro Oxygen Logger windows on your desktop. The

different windows operate completely independent from each

other, and each of them will be associated to exactly one Piccolo2.

In order to check which window is associated to a specific Piccolo2,

simply press the Flash Logo button in the main window of the Pyro

Oxygen Logger software, which causes a short flashing (1-2 sec.) of

the red status LED at the associated Piccolo2.

When closing the Pyro Oxygen Logger software, all settings and all

current calibration data are saved in a "setup file", which is

automatically loaded at the next startup. This setup file is saved

specifically for each Piccolo2 serial number, i.e. each Piccolo2 in

the setup described above keeps its own settings and calibration

data.

Page 61

61

10.5 Definition of Oxygen Units

phase shift dphi

The phase shift dphi is the fundamental unit measured by the

optoelectronics in the Piccolo2 (see chapter 10.3). Please note, that

dphi is not at all linearly dependent on the oxygen units, and

increasing oxygen levels correspond to decreasing dphi values,