Page 1

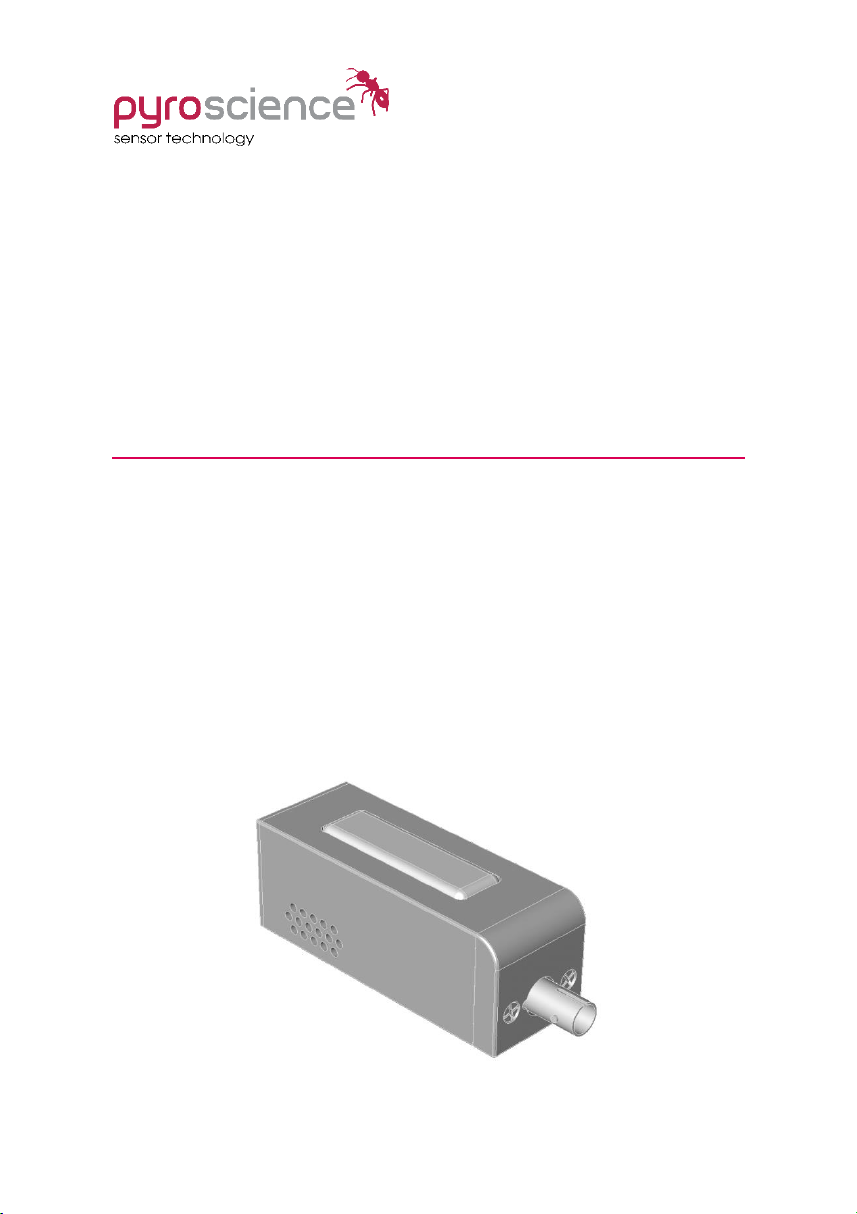

FireStingO2-Mini-ST

OPT I C AL OXY G EN OEM-M O D ULE

WI T H UART - IN T ERFA C E & ANAL O G OUTPU T

FOR F I BE R-OPT IC S E NS O RS

MAN U AL

Page 2

Document Version 1.04

The FireStingO2-Mini-ST is manufactured by

PyroScience GmbH

Hubertusstr. 35

52064 Aachen

Germany

Phone +49 (0)241 5183 2210

Fax +49 (0)241 5183 2299

Email info@pyroscience.com

Internet www.pyroscience.com

Registered: Aachen HRB 17329, Germany

ii

Page 3

TAB L E OF CO N T ENT

1 INTRODUCTION ...................................................................... 1

2 SAFETY GUIDELINES ............................................................... 2

3 OVERVIEW ..............................................................................4

3.1 OPTICAL PORT FOR OXYGEN SENSORS .......................................... 4

3.2 SUPPLEMENTARY INTERNAL SENSORS ........................................... 6

3.3 EXTERNAL TEMPERATURE SENSOR ............................................... 7

4 ELECTRICAL CONNECTORS .................................................... 9

4.1 CONNECTOR X1: POWER + DIGITAL INTERFACE ............................. 10

4.2 CONNECTOR X2: ANALOG OUTPUT ............................................ 11

5 OPERATION VIA THE UART-INTERFACE ................................ 12

5.1 FULL-CONTROL MODE ............................................................. 12

5.2 AUTO-MODE ........................................................................... 13

6 OPERATION VIA THE USB-INTERFACE CABLE ........................ 15

6.1 SOFTWARE INSTALLATION ......................................................... 15

6.2 USING THE PYRO OXYGEN LOGGER SOFTWARE ............................. 16

7 SPECIFICATIONS ................................................................... 18

iii

Page 4

1 Introduction

The FireStingO2-Mini-ST is a high precision optical oxygen meter

for liquid or gas samples, which is based on the opto-electronics of

the successful USB-device FireStingO2 from PyroScience. Most

features of the FireStingO2-Mini-ST are identical to the

FireStingO2. Therefore, for a general introduction it is highly

recommended to consult additionally the detailed manual of the

FireStingO2. Here we will cover mostly the differences of the

FireStingO2-Mini-ST compared to the FireStingO2.

The FSO2-Mini-ST is compatible to most oxygen sensors types

available from PyroScience.

Further, it includes also internal high-precision sensors for

(i) ambient atmospheric pressure, (ii) relative humidity of the

ambient air, and (iii) the temperature of the ambient air.

Additionally, an external temperature probe (PT100) used for

automatic temperature compensation of the oxygen measurement

can be soldered directly to the module (e.g. item TSUB21-NC).

This manual provides only specific information needed for the

FireStingO2-Mini-ST. It is highly recommended to study carefully

the manual of the USB-device FireStingO2 in order to get a

general introduction in optical oxygen measurements and the

related sensor types.

1

Page 5

2 Safety Guidelines

In order to guarantee an optimal performance of the FireStingO2-

Mini-ST please follow these operation instructions and safety

guidelines. If any problems or damage evolve, please disconnect

the instrument immediately, mark it to prevent any further use and

consult PyroScience for repair or maintenance service. The

FireStingO2-Mini-ST should not be manipulated or opened by

unauthorized persons (except for the needed steps in order to

solder the external PT100 to the internal PCB-board), only by

PyroScience or persons advised directly from PyroScience.

Please note that opening the housing (except removing the front

cap for accessing the solder pads for the external temperature

sensor) will void the warranty. There are no serviceable parts inside

the device.

The FireStingO2-Mini-ST and the sensors should be kept and

stored outside the reach of children in a secure place under dry and

clean conditions at room temperature, avoiding moisture, dust,

corrosive conditions and heating of the instrument. This device is

not intended for medical, military or other safety relevant areas. It

should be used in the laboratory by qualified personal only

following the operation instructions and safety guidelines of this

manual.

Please follow the appropriate laws and guidelines for safety like

EEC directives for protective labor legislation, national protective

labor legislation, safety regulations for accident prevention and

safety data-sheets from manufacturer of chemicals used during

measurements.

When used in the field, the environmental conditions (like high

humidity, dust, exposure to direct solar radiation) may cause

damage or interference of the FireStingO2-Mini-ST, which is on

the user's authority.

2

Page 6

Before using the FireStingO2-Mini-ST and its sensors, read

carefully the instructions and user manuals.

In case of problems or damage, disconnect the instrument and

mark it to prevent any further use! Consult PyroScience for

advice! There are no serviceable parts inside the device. Please

note that opening the housing will void the warranty!

The FireStingO2-Mini-ST is not watertight, is sensitive to

corrosive conditions and to changes in temperature causing

condensation. Avoid any condition (e.g. direct sun light) causing

a heating of the device above 50°C (122°F).

Calibration and application of the sensors is on the user’s

authority, as well as data acquisition, treatment and

publication!

The sensors and the oxygen meter FireStingO2-Mini-ST are not

intended for medical, diagnostic, therapeutic, or military

purposes or any other safety-critical applications. The sensors

must not be used for applications in humans and must not be

brought in direct contact with foods intended for consumption

by humans.

The FireStingO2-Mini-ST and sensors should be used in the

laboratory by qualified personnel only, following the user

instructions and the safety guidelines of the manuals, as well as

the appropriate laws and guidelines for safety in the laboratory!

Keep the sensors and the oxygen meter FireStingO2-Mini-ST out

of reach of children!

3

Page 7

3 Overview

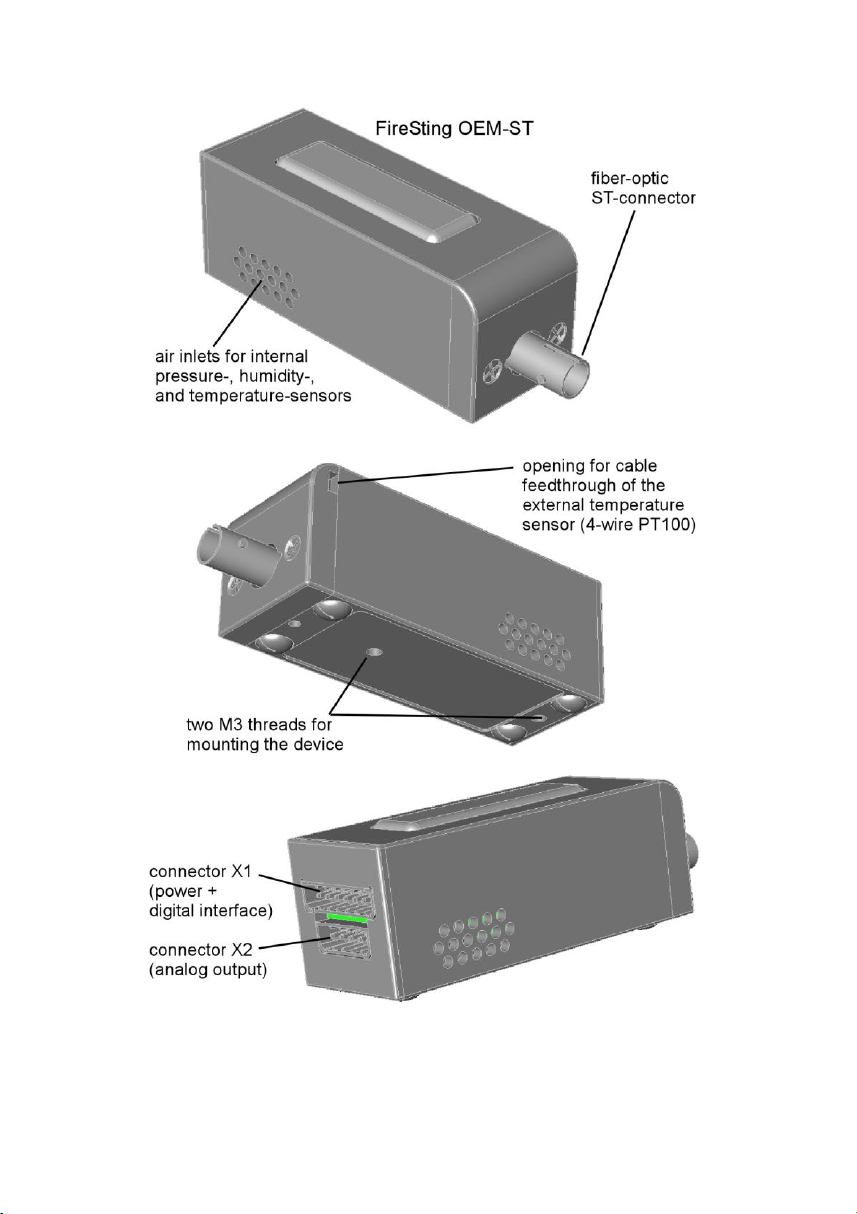

Fig. 1 provides an overview of the FSO2-MINI-ST. The overall

dimension of the module is 67 x 25 x 25 mm (without the optical

port). Two M3 threads can be found at the bottom for mounting

the module in customized setups. Please note, that one of the M3

threads is hidden below the type label. The position of that M3

thread is roughly indicated on the type label. Just penetrate the

type label at this position with e.g. a needle or nail in order to

access the M3 thread.

3.1 Optical Port for Oxygen Sensors

The FSO2-MINI-ST provides an ST-connector as known from the

USB-device FireStingO2. Thus, all optical oxygen sensors available

for the FireStingO2 (e.g. needle-type sensors, robust probes, fibers

for read-out of sensor spots, flow through cells, respiration vials)

can be directly connected to the FSO2-MINI-ST. Please refer to the

manual of the FireStingO2 for further details.

4

Page 8

Fig. 1 Drawing of the FSO2-MINI-ST

5

Page 9

3.2 Supplementary Internal Sensors

Besides the very oxygen sensor, the FireStingO2-Mini-ST provides

three other built-in high precision sensors:

(1) An internal atmospheric pressure sensor for measuring

the ambient air pressure,

(2) an internal sensor for measuring the relative humidity of

the ambient air, and

(3) an internal temperature sensor measuring the

temperature of the ambient air.

These three internal sensors are positioned within the module

close to the air inlets on both sides of the housing. In order to get

reliable data about the ambient air from these internal sensors, it is

important to ensure free air access around the air inlets. The

pressure and the humidity sensors will give in most situations

reliable data about the ambient air. However, the readings of the

internal temperature sensor should be interpreted more carefully.

First, the internal heating by the electronics typically increases the

internal temperature by about 1ºC. This offset can get much

worse, if the module is additionally exposed to e.g. strong

illumination. It is on the user’s authority to interpret the internal

temperature sensor with care.

The internal humidity sensor can be useful if a simple air calibration

of the oxygen sensor shall be performed in ambient air. For this

calibration type the relative humidity of the ambient air has to be

known, because the humidity changes the actual volume fraction

of oxygen in the ambient air.

Similarly, the internal pressure sensor is generally useful for any air

calibration performed under ambient air pressure, because the

actual air pressure has to be known during the calibration. But the

pressure sensor can be also used during the oxygen measurements

6

Page 10

for automatic pressure compensation (useful for the following

oxygen units: %air sat, %O2, µmol/L, mg/L).

3.3 External Temperature Sensor

The oxygen measurement is generally temperature dependent.

Therefore, the FireStingO2-Mini-ST provides a built-in

temperature compensation, which should be activated if the

temperature changes during measurements more than ca. 1ºC.

Although under certain circumstances the internal temperature

sensor can be also utilized for such a compensation, the first choice

should be always an external 4-wire PT10o temperature sensor

placed directly within the sample where the oxygen concentration

is measured. The FireStingO2-Mini-ST provides a high-precision

sensor interface which can be directly connected to any standard

4-wire PT100.

Fig. 2 Connecting a 4-wire PT100 temperature sensor to the OEM module

The PT100 has to be soldered directly to the electronics board

within the module. In order to access the solder pads, the front cap

of the housing has to be removed by unscrewing the two screws

besides the optical port. Please refer to Fig. 2 how to connect the

7

Page 11

4-wire PT100. The front cap provides a small cable feedthrough

where the cable of the external PT100 can penetrate the housing.

When closing the housing again, ensure that the solder points do

not get into contact to the aluminum housing.

NOTE: In order to minimize potential electrical noise coupling into

the external temperature sensor, the 4-wire cable should be

twisted and as short as possible. Cable lengths above 2m are not

recommended. For minimizing any noise further, the 4-wire cable

can be provided with an additional coaxial shield, which has to be

connected to ground.

8

Page 12

4 Electrical Connectors

The electrical interface of the FireStingO2-Mini-ST consists of the

two connectors X1 and X2 (Fig. 1). The package includes for both

connectors the connector plugs S1 and S2, also available from

"Phoenix Contact" item no. 1778887 and 1778861 (Fig. 3). Stripped

cable ends can be connected to S1 and S2 without any soldering or

crimping. When inserting or removing a stripped cable end

(stripping length 6 mm, max. core diameter 0.5 mm²) into one of

the connector holes of the connectors S1 or S2, an internal spring

mechanism has to be unlocked by pushing relatively strong with a

small screw-driver (flat-bladed 2mm in width) into the adjacent

rectangular hole (Fig. 3). Please note that pin 1 of the connectors is

positioned always at the right side of the connector (Fig. 3).

Fig. 3 Electrical connectors of the FireStingO2-Mini-ST

9

Page 13

4.1 Connector X1: Power + Digital Interface

Pin

Name

Function

Description

1

GND

Power

Ground

2

VCC

Power

Power supply

min. 3.5V max. 5.0V DC

max. 50 mA (typical 30 mA)

3

GND

Power

Ground

4

TXD

Digital Output

(0V or 3.3V)

Data transmission pin of the

UART interface

5

RXD

Digital Input

(0V or 3.3V)

(5V tolerant)

Data receive pin of the UART

interface

6

/AUTO

Digital Input

(0V or 3.3V,

internally pulledup to 3.3V)

Leave auto-mode pin

unconnected for normal

operation. Connect to GND

for auto-mode operation.

7

/TRIG

Digital Input

(0V or 3.3V,

internally pulledup to 3.3V)

Trigger input for triggering a

measurement in "triggered

auto-mode". The trigger is

activated at the moment,

when the unconnected pin is

tied to GND.

The pin configuration of the connector X1 is given in Tab. 1. Pins 13 are for power supply of the module. The transmit and receive

pins of the UART-interface are given at pins 4+5. The additional

pins 6+7 are only needed if the module should be operated in automode (see following chapter). In standard operation mode both

pins 6+7 should be left unconnected.

Tab. 1 Pin configuration of the connector X1

10

Page 14

4.2 Connector X2: Analog Output

Pin

Name

Function

Description

1

GND

Ground

2

AO_A

Analog Output

(0 – 2.5 V DC)

(14 bit resolution)

Analog Output Port A

(alternatively digital

alarm output)

3

AO_B

Analog Output

(0 – 2.5 V DC)

(14 bit resolution)

Analog Output Port B

(alternatively digital

alarm output)

4

AO_C

Analog Output

(0 – 2.5 V DC)

(14 bit resolution)

Analog Output Port C

(alternatively digital

alarm output)

5

AO_D

Analog Output

(0 – 2.5 V DC)

(14 bit resolution)

Analog Output Port D

(alternatively digital

alarm output)

The connector X2 provides 4 independent analog outputs with a

range of 0-2.5V DC at a resolution of 14 bits (Tab. 2). The 4 analog

outputs can be configured by the UART communication protocol

very flexible. The parameter given at each analog output can be

chosen (e.g. oxygen concentration in different units, signal

intensity of the oxygen sensor, ambient pressure, ambient

humidity, internal temperature, external temperature from

PT100), the scaling can be adjusted freely, and even an alarm

function can be configured. If an analog output is configured as an

alarm output, it will give 2.5V if a specific parameter is out of a

defined range (and 0V if it is within this range).

For further details please refer to the separately available

communication protocol.

Tab. 2 Pin configuration of the connector X2

11

Page 15

5 Operation via the UART-Interface

The FireStingO2-Mini-ST is operated via a standard UART

interface at 3.3V levels (5V tolerant) consisting merely of a receive

and a transmit line (connector X1, pins 4+5, see Tab. 1). The

configuration of the UART-interface is as follows:

19200 baud, 8 data bit, 1 stop bit, no parity, no handshake

The baud rate can be changed by a special command of the

communication protocol (refer to the communication protocol for

further information). However, after power cycling the module

always reverts to the standard baud rate of 19200.

There are two principal operation modes possible: (1) the fullcontrol mode and the (2) auto-mode. Please note that adjusting

the settings and performing any calibration can only be done in the

full-control mode.

5.1 Full-Control Mode

The standard operation mode of the module is the full-control

mode. The necessary electrical connections are shown in Fig. 4.

Fig. 4 Pin assignment in full-control mode

The full-control mode allows exploiting the full functionality of the

module. Each action of the module is triggered by transmitting a

12

Page 16

text-command via the UART interface. The measurement results

can be either read out via the same UART interface. Alternatively,

measurement results can be also read from the analog output.

For further details please refer to the separately available

communication protocol.

5.2 Auto-Mode

In the full-control mode each single measurement has to be

triggered by a specific command sent via the UART interface (e.g.

the MSR- or TMP-commands for measuring oxygen or

temperature, respectively). Alternatively, an auto-mode can be

activated by connecting pin 6 of connector X1 to ground (Fig. 5).

Fig. 5 Pin assignment in auto-mode

The auto-mode offers the possibility, (i) that the measurements

are automatically triggered periodically by an internal timer

(interval auto-mode) or (ii) that the measurements are triggered

13

Page 17

each time when pin 7 of connector X1 is tied to ground (triggered

auto-mode). The results of the measurements can be either read

from the transmit pin of the UART interface, or from the analog

outputs at connector X2.

NOTE: When the auto-mode is activated, the receive pin of the

UART interface has no function. The module will not respond to

any command sent to it.

The basic idea behind the auto-mode is that a fully configured and

calibrated module can be operated without the need of complex

communication protocols. However, the configuration (including

the configuration of the auto-mode!) and the calibration data have

to be adjusted in the full-control mode (or by using the USBinterface cable in combination with the comfortable windows

software Pyro Oxygen Logger; please refer to the next chapter).

The communication protocol offers a special command for storing

the current configuration and calibration data permanently in the

internal flash memory. Thus, a fully configured module can be

operated in auto-mode even if the power supply is intermediately

interrupted.

A typical application scenario would be the following: the

FireStingO2-Mini-ST could be configured and calibrated in a

"calibration lab" using the full-control mode (or the windows

software Pyro Oxygen Logger). The configuration and the

calibration data are stored in the internal flash memory. Then the

sensor is brought to the "field application" which can be a remote

place. By connecting pin 6 of the connector X1 to ground the

module starts measuring without the need of any UART

communication. The measurement results can be read out from

the analog output (or from a text-string sent via the UART transmit

line).

14

Page 18

For further details please refer to the separately available

communication protocol.

6 Operation via the USB-Interface Cable

For the operation of the FireStingO2-Mini-ST with a usual

Windows PC, the USB-interface cable FSO2-MINI-USB is available

from PyroScience. It includes a license for the comfortable oxygen

logger software Pyro Oxygen Logger. Especially for initial testing

purposes this logger software can speed up OEM-developments

significantly. All special features (including the analog output and

the configuration of the auto-mode) of the FireStingO2-Mini-ST

can be configured in an intuitive user interface. Additionally, the

USB-interface cable FSO2-MINI-USB provides also a virtual COMport. Custom Windows-software can use this virtual COM-port for

communicating directly with the module based on the

communication protocol corresponding to the full-control mode

described in the previous chapter.

6.1 Software Installation

System requirements: PC with Windows 7/8/10 and min. 700 MB

free disk space.

IMPORTANT: Do not connect the USB-interface cable FSO2-

MINI-USB to your PC before the Pyro Oxygen Logger software has

been installed. The software will install automatically the

appropriate USB-drivers.

Installation steps:

• download the installer package and the manual for the

newest version of the Pyro Oxygen Logger software from

the PyroScience homepage:

www.pyroscience.com/downloads.html

• unzip and start the installer and follow the instructions

15

Page 19

• after the successful installation a new program group "Pyro

Oxygen Logger" is added to the start menu, and a shortcut named "Oxygen Logger" can be found on the desktop

• connect one end of the USB-interface cable FSO2-MINI-

USB to the connector X1 of the FireStingO2-Mini-ST

• connect the other end to an USB-port of the PC. The

optical port of the FireStingO2-Mini-ST should flash

shortly, indicating the correct startup of the FireStingO2-

Mini-ST

• start the Pyro Oxygen Logger software.

6.2 Using the Pyro Oxygen Logger software

IMPORTANT: The following instructions are only valid for the

versions ≥3.200 of the Pyro Oxygen Logger software. If you have

an older version, please download and install the newest version.

Please refer to the manual provided with the software for general

operation instructions.

In combination with OEM-applications it is important to know, that

the actual logger settings and the calibration data are

automatically saved in the internal flash memory of the FireSting

device, each time the logger software is closed. A typical scenario

for OEM-applications would be, that the USB-interface cable

FSO2-MINI-USB in combination with the Pyro Oxygen Logger

software is used for configuring all settings and to calibrate the

connected oxygen sensor. This is done in the settings and the

calibration window, respectively.

If also the auto-mode should be configured, press within the

settings window the button Prepare Auto-Mode… (simple

settings, only for "interval auto-mode") or Advanced Auto-

16

Page 20

Mode… (advanced settings, allowing also "triggered auto-mode")

and configure the auto-mode in the respective dialog windows.

Such a configured module can be now used in several ways. The

simplest way would be to operate the module in the auto-mode

(see previous chapter). But even for using it in an OEM-application

under the full-control mode can make sense, because the

communication protocol for simply triggering the measurements

and for reading the results is much more straightforward to

implement, compared to implementing the configuration of all

settings and calibration data.

17

Page 21

7 Specifications

General Specifications

Dimensions

67 x 25 x 25 mm

(without the optical port)

Weight

70 g

Interface

UART (3.3V level, 5V tolerant)

Power Supply

min. 3.5 V max.5.0V DC

max. 50 mA (typical 30 mA)

Operating temperature

0 to 50ºC

Storage temperature

-20 to 70ºC

Max. relative humidity

Non-condensing conditions

Oxygen Sensor

Oxygen measuring principle

lifetime detection of REDFLASH

indicator luminescence

Oxygen channel connector

fiber-optic ST-plug of

FireStingO2-Mini-ST

Excitation wavelength

620 nm (orange-red)

Detection wavelength

760 nm (near infrared)

Max. sample rate

ca. 20 samples per second

(ext. temperature sensor not activated)

ca. 4 samples per second

(ext. temperature sensor activated)

For further specifications of the

oxygen sensors refer to the

separately available

specifications for the

connected oxygen sensor

External Temperature Sensor

PT100 (not included)

18

Page 22

Connection

Twisted 4-wire cable, max. 2m in

length (optional with coaxial shielding

connected to ground)

Resolution

0.02°C

Accuracy

±0.2°C

Range

-30 to 150°C

Internal Temperature Sensor

Resolution

0.01°C

Accuracy

±0.3°C

Range

-40 to 125°C

Response Time

ca. 1 minute

Internal Humidity Sensor

Resolution

0.04% rel. humidity

Accuracy

typ. ±0.2% rel. humidity

Range

0 to 100% rel. humidity

Response Time (t63%)

ca. 10 s

Internal Pressure Sensor

Resolution

0.06 mbar (hPa)

Accuracy

typ. ±3 mbar (hPa)

Range

300 to 1100 mbar (hPa)

Response Time

Instant

Analog Outputs

Resolution

0.15 mV

Accuracy

typ. ±0.3 mV

Range

0 to 2500 mV

19

Loading...

Loading...