Page 1

1

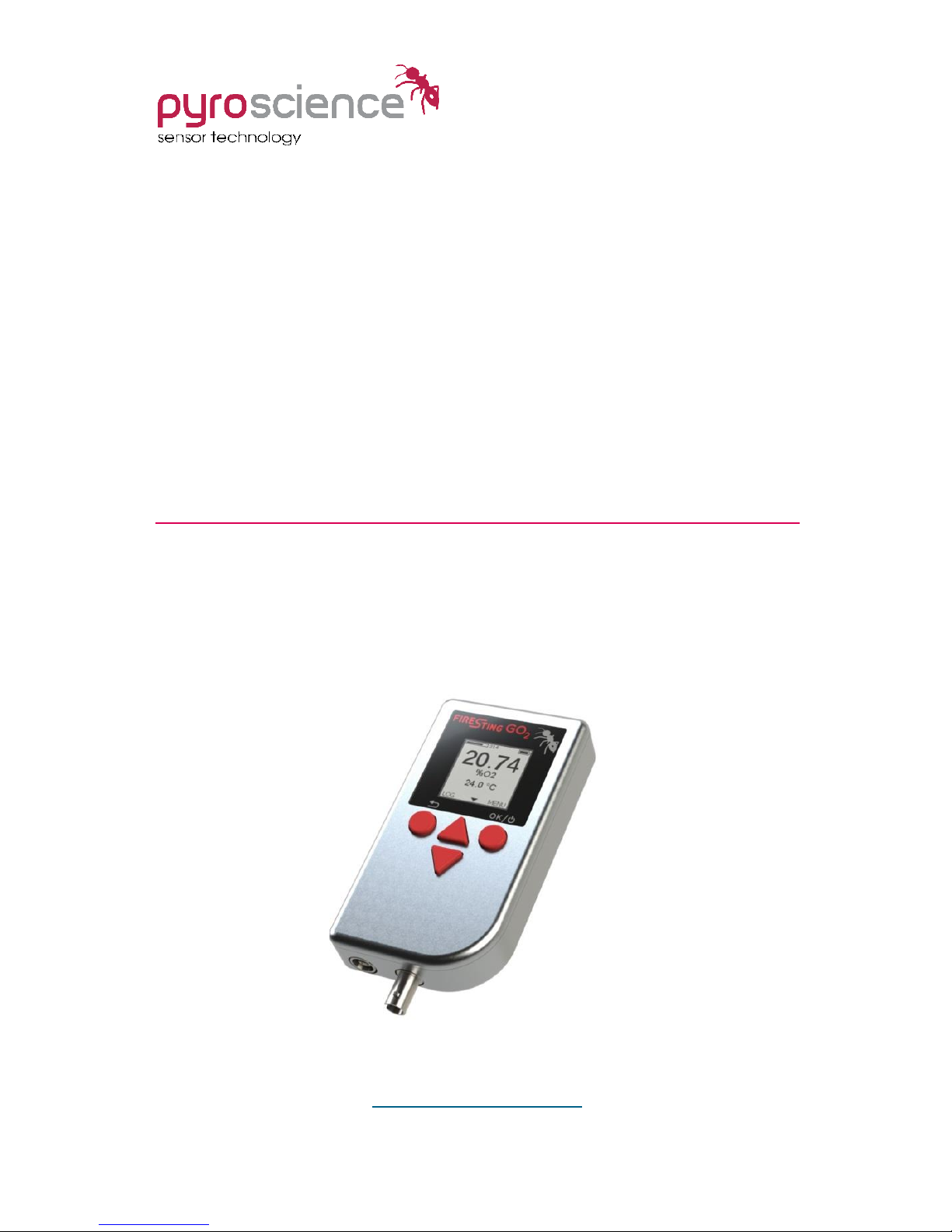

Pocket Oxygen Meter

FireStingGO2

MANUAL

www.pyroscience.com

Page 2

2

Document Version 1.21

Refers to FireStingGO2 Manager software version >1.0

The FireStingGO2 is manufactured by

PyroScience GmbH

Hubertusstr. 35

52064 Aachen

Germany

Phone +49 (0)241 518322-10

Fax +49 (0)241 518322-99

Email info@pyroscience.com

Internet www.pyroscience.com

Registered: Aachen HRB 17329, Germany

Page 3

3

TABLE OF CONTENT

1 INTRODUCTION ..................................................................... 6

2 SAFETY GUIDELINES .............................................................. 8

3 OVERVIEW FIRESTINGGO2 .................................................... 11

3.1 PORTS AND INTEGRATED SENSORS ............................................. 11

3.1.1 Micro USB Port .................................................................. 12

3.1.2 Oxygen Port ...................................................................... 12

3.1.3 Temperature Port .............................................................. 12

3.1.4 Internal Air Sensor ............................................................. 12

3.1.5 Power Button and Recharging the Battery .......................... 13

3.2 STAND CLAMP ......................................................................... 13

3.3 USER INTERFACE ...................................................................... 14

3.4 OPERATION MODES ................................................................. 15

3.4.1 Live Mode .......................................................................... 15

3.4.2 Menu Mode ....................................................................... 15

3.4.3 Logging Mode .................................................................... 15

3.4.4 Standby Mode ................................................................... 16

3.4.5 PC Mode ........................................................................... 16

3.5 STATUS LINE ........................................................................... 16

4 QUICK START ........................................................................ 18

4.1 GETTING STARTED ................................................................... 18

4.2 SETTINGS AND OPTIONS ADJUSTMENTS ...................................... 18

4.3 SENSOR CALIBRATION .............................................................. 18

4.4 LIVE MEASUREMENTS ............................................................... 19

4.5 DATA LOGGING ........................................................................ 19

4.6 DATA MANAGEMENT AND INSPECTION ......................................... 19

5 LIVE MODE ............................................................................ 20

5.1 TOP SCREEN ........................................................................... 20

5.2 SUB-SCREEN 1 ......................................................................... 20

5.3 SUB-SCREEN 2 ......................................................................... 20

5.4 SUB-SCREEN 3 ......................................................................... 20

Page 4

4

6 MENU MODE ......................................................................... 21

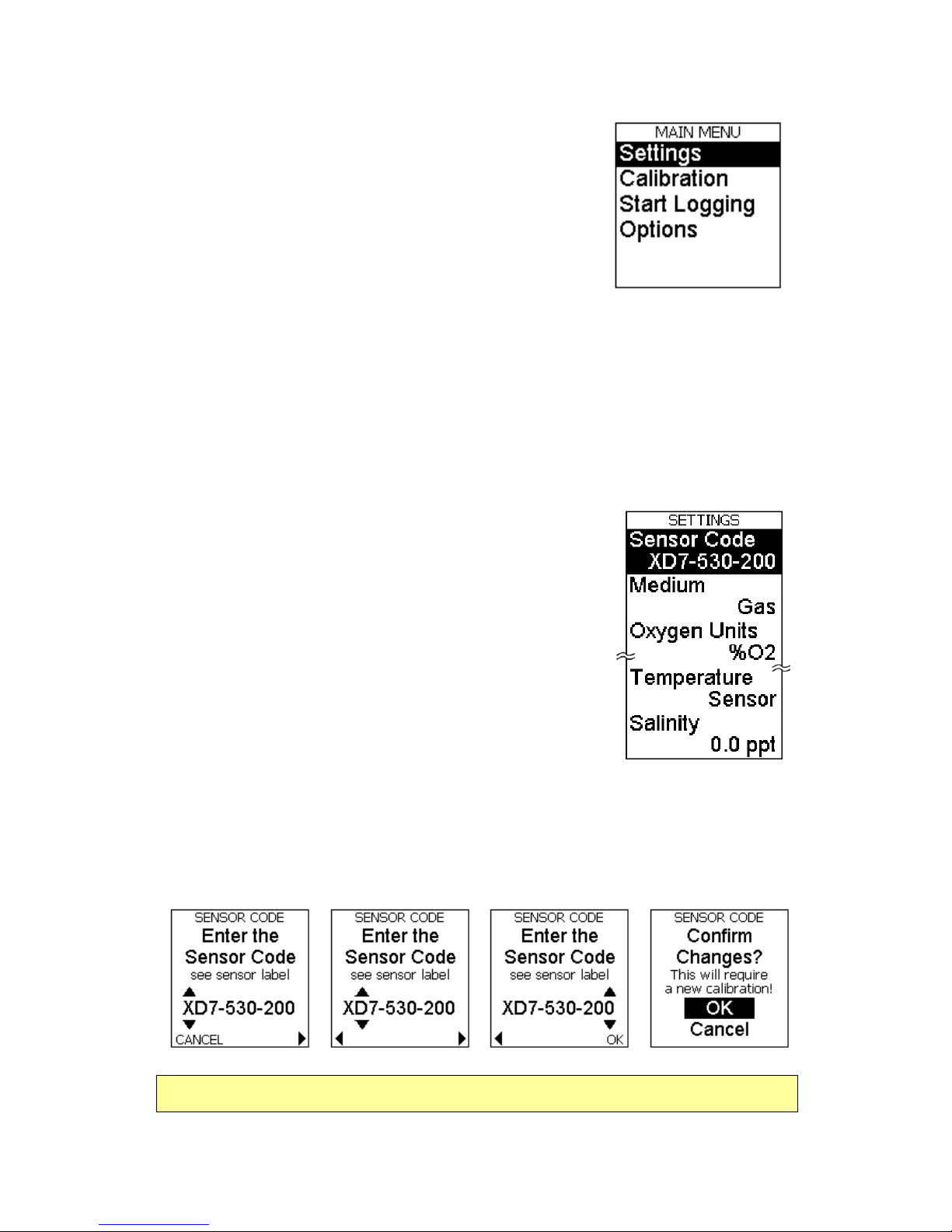

6.1 MAIN MENU ............................................................................ 21

6.2 SETTINGS MENU ...................................................................... 21

6.2.1 Sensor Code ...................................................................... 21

6.2.2 Medium ............................................................................. 22

6.2.3 Oxygen Units ..................................................................... 22

6.2.4 Temperature ...................................................................... 22

6.2.5 Salinity.............................................................................. 23

6.3 CALIBRATION MENU ................................................................. 23

6.3.1 Sensor Code ...................................................................... 24

6.3.2 Air Calibration ................................................................... 24

6.3.3 0% Calibration ................................................................... 27

6.4 OPTIONS MENU ....................................................................... 28

6.4.1 Adjust Time and Date ........................................................ 28

6.4.2 Temperature Offset ........................................................... 29

6.4.3 Device Info and Reset Device .............................................. 29

6.5 ADVANCED MENU .................................................................... 30

7 DATA LOGGING ..................................................................... 31

7.1 START LOGGING ...................................................................... 31

7.1.1 Manual Logging................................................................. 31

7.1.2 Continuous Logging ........................................................... 32

7.2 LOGGING MODE ...................................................................... 33

8 STANDBY MODE ................................................................... 35

9 PC MODE ............................................................................... 35

10 FIRESTINGGO2 MANAGER ..................................................... 36

10.1 SOFTWARE INSTALLATION ......................................................... 36

10.2 OPERATION WITHOUT CONNECTED DEVICE .................................. 36

10.3 OPERATION WITH CONNECTED DEVICE ........................................ 36

10.3.1 Live Graph Window ........................................................ 37

10.3.2 Settings ........................................................................ 40

10.3.3 Calibration .................................................................... 42

10.3.4 Air Calibration ............................................................... 43

10.3.5 0% Calibration .............................................................. 45

10.3.6 Data Logging ................................................................ 47

Page 5

5

10.3.7 Options ......................................................................... 50

10.4 LOG INSPECTOR AND FILE MANAGEMENT .................................... 52

10.4.1 File Management........................................................... 52

10.4.2 Log Inspector Window ................................................... 53

11 WARNINGS ........................................................................... 56

11.1 OXYGEN SENSOR WARNINGS ..................................................... 56

11.2 TEMPERATURE SENSOR WARNING .............................................. 57

12 CALIBRATION STANDARDS ................................................... 59

12.1 THE AIR CALIBRATION STANDARD .............................................. 59

12.1.1 Ambient Air ................................................................... 61

12.1.2 Water-Vapor Saturated Air ............................................ 61

12.1.3 Air Saturated Water ...................................................... 61

12.2 THE 0% STANDARD .................................................................. 62

12.2.1 Water Mixed with a Strong Reductant ............................ 62

12.2.2 Nitrogen Gas ................................................................. 63

13 APPENDIX ............................................................................. 64

13.1 SPECIFICATIONS OF THE FIRESTINGGO2 ...................................... 64

13.2 MEASURING PRINCIPLE ............................................................. 65

13.3 DEFINITION OF OXYGEN UNITS ................................................... 66

13.4 EXPLANATION OF THE SENSOR CODE .......................................... 68

Page 6

6

1 Introduction

The FireStingGO2 is a hand-held fiber-optic oxygen meter based

on the established FireSting technology featuring:

broad oxygen sensor portfolio (micro- and minisensors, robust

probes, sensor spots, flow-through cells, respiration vials)

sensors for the full and the trace oxygen range

measurements in water as well as in the gas phase

automatic temperature and pressure compensation

proven REDFLASH technology

with New Features:

integrated high contrast LCD display

integrated rechargeable battery and memory

extremely low power consumption for long-term logging

and Operation Modes:

stand-alone via intuitive LCD user interface

with Windows PC via USB

Page 7

7

The new pocket meter FireStingGO2 completes the portfolio of

different fiber-optic oxygen meters from PyroScience, comprising

PC-operated 1-, 2- or 4-channel FireStingO2 meters with a broad

oxygen sensor portfolio and the 1-channel

Piccolo2 meter for advanced applications

of contactless sensors, e.g. in microfluidics.

The FireStingGO2 has integrated memory

and battery and combines the established

FireStingO2 technology with stand-alone

operation and the ability of long-term

logging for >1 year. With this flexibility,

oxygen measurements can be performed

independent of a PC at different locations

using the broad range of fiber-optic

oxygen sensors from PyroScience.

The FireStingGO2 impresses by its compactness, functionality and

extremely low power consumption allowing for long-term logging

without the need of recharging. The handling of the FireStingGO2

is intuitive and all information concerning the connected and

internal sensors, measurement and logging parameters are

displayed on a high contrast LCD display.

More information concerning our product portfolio can be found

on our website at www.pyroscience.com or contact us under

info@pyroscience.com.

Your PyroScience Team

Page 8

8

2 Safety Guidelines

The FireStingGO2 is a laboratory instrument to be used with fiberoptic oxygen sensors (optodes) from PyroScience. In order to

guarantee an optimal performance of the FireStingGO2, please

follow these operation instructions and safety guidelines.

If any problems or damage evolve, please turn the instrument off

and disconnect it immediately. Mark this FireStingGO2 to prevent

any further use and consult PyroScience for repair or maintenance

service. The FireStingGO2 should not be manipulated or opened by

unauthorized persons, only by PyroScience or persons advised

directly from PyroScience.

Please note that opening the housing will void the warranty. There

are no serviceable parts inside the device.

The FireStingGO2 meter and the sensors should be kept and

stored outside the reach of children in a secure place under dry and

clean conditions at room temperature, avoiding moisture, dust,

corrosive conditions and heating of the instrument. This device

and the sensors are not intended for medical, military or other

safety relevant areas. They must not be used for applications in

humans; not for in vivo examination on humans, not for humandiagnostic or therapeutic purposes. The sensors must not be

brought in direct contact with foods intended for consumption by

humans.

The FireStingGO2 has an integrated lithium-ion battery, so please

follow the general safety instructions for their use. The

FireStingGO2 is not water-proof and should be used by qualified

personal only, following the operation instructions and safety

guidelines of this manual. Please follow the appropriate laws and

guidelines for safety like EEC directives for protective labor

legislation, national protective labor legislation, safety regulations

Page 9

9

for accident prevention and safety data-sheets from

manufacturers of chemicals used during measurements.

Calibration and application of the sensors, data acquisition, data

processing and data publication is on the user's authority.

When used in the field, the environmental conditions (like high

humidity, dust, exposure to direct solar radiation) may cause

damage or interference of the FireStingGO2, which is on the user's

authority.

Before using the oxygen meter FireStingGO2 and its sensors, read

carefully the available instructions and user manuals.

Page 10

10

In case of problems or damage, turn the instrument off,

disconnect and mark it to prevent any further use! Consult

PyroScience for advice! There are no serviceable parts inside the

device. Opening the housing will void the warranty!

The FireStingGO2 is not water-proof, is sensitive to corrosive

conditions and to changes in temperature causing

condensation. Avoid any condition (e.g. direct sun light) causing

a heating of the device above 50°C (122°F) or below 0°C (32°F).

Avoid elevated humidity causing condensing conditions. Please

follow the safety instructions for integrated lithium-ion

batteries.

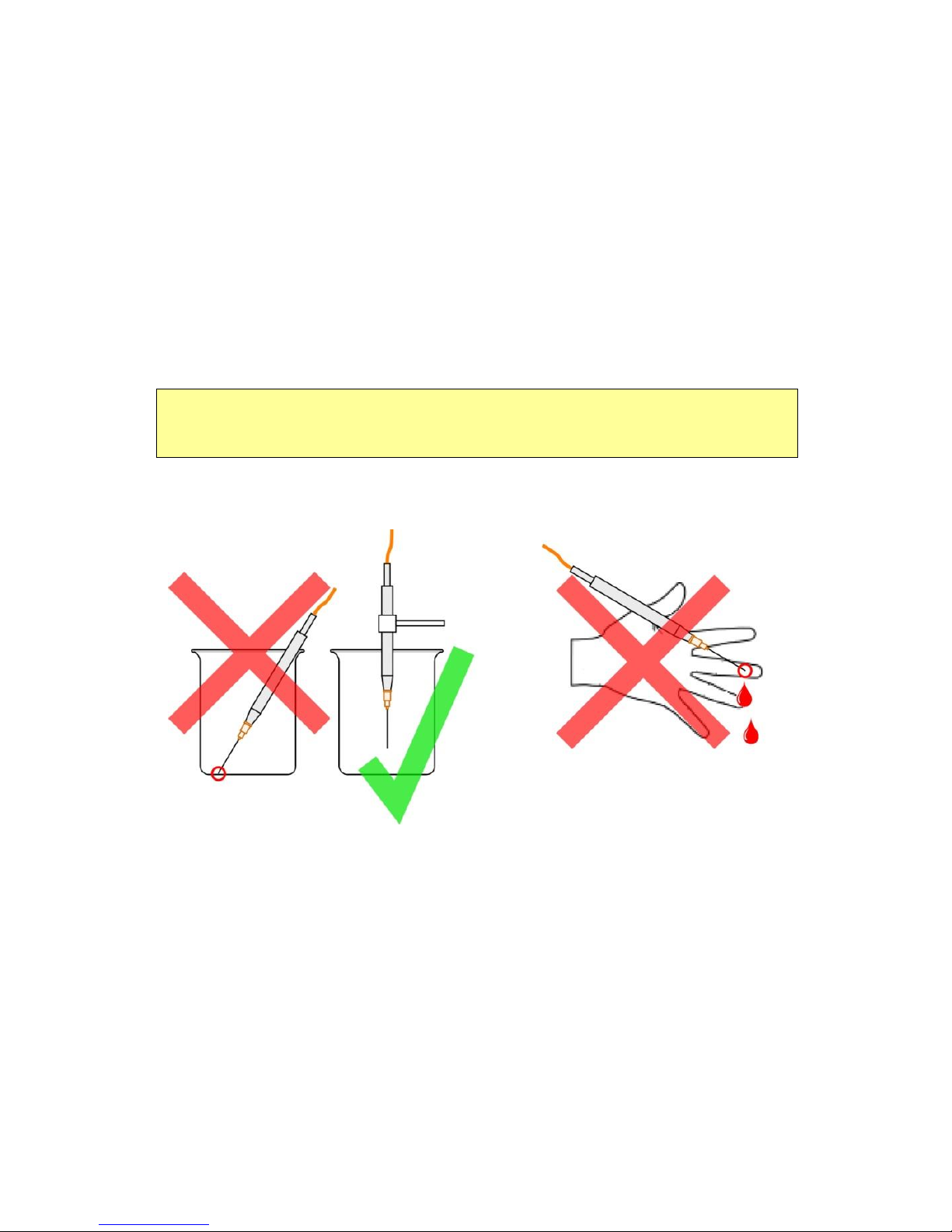

Handle the sensors with care especially after removal of the

protective cap! Prevent mechanical stress to the fragile sensing

tip and injuries with needle-type sensors! Avoid strong bending

of the fiber cable!

Calibration and application of the sensors, data acquisition,

treatment and publication is on the user’s authority!

The sensors and the oxygen meter FireStingGO2 are not

intended for medical, diagnostic, therapeutic, or military

purposes or any other safety-critical applications. The sensors

must not be used for applications in humans and must not be

brought in direct contact with foods intended for consumption

by humans.

The FireStingGO2 and sensors should be used in the laboratory

by qualified personnel only, following the user instructions and

the safety guidelines of the manual, as well as the appropriate

laws and guidelines for safety in the laboratory!

Keep the sensors and the oxygen meter FireStingGO2 out of

reach of children!

Page 11

11

3 Overview FireStingGO2

This chapter provides an overview about the principle components

and general operation procedures of the pocket oxygen meter

FireStingGO2.

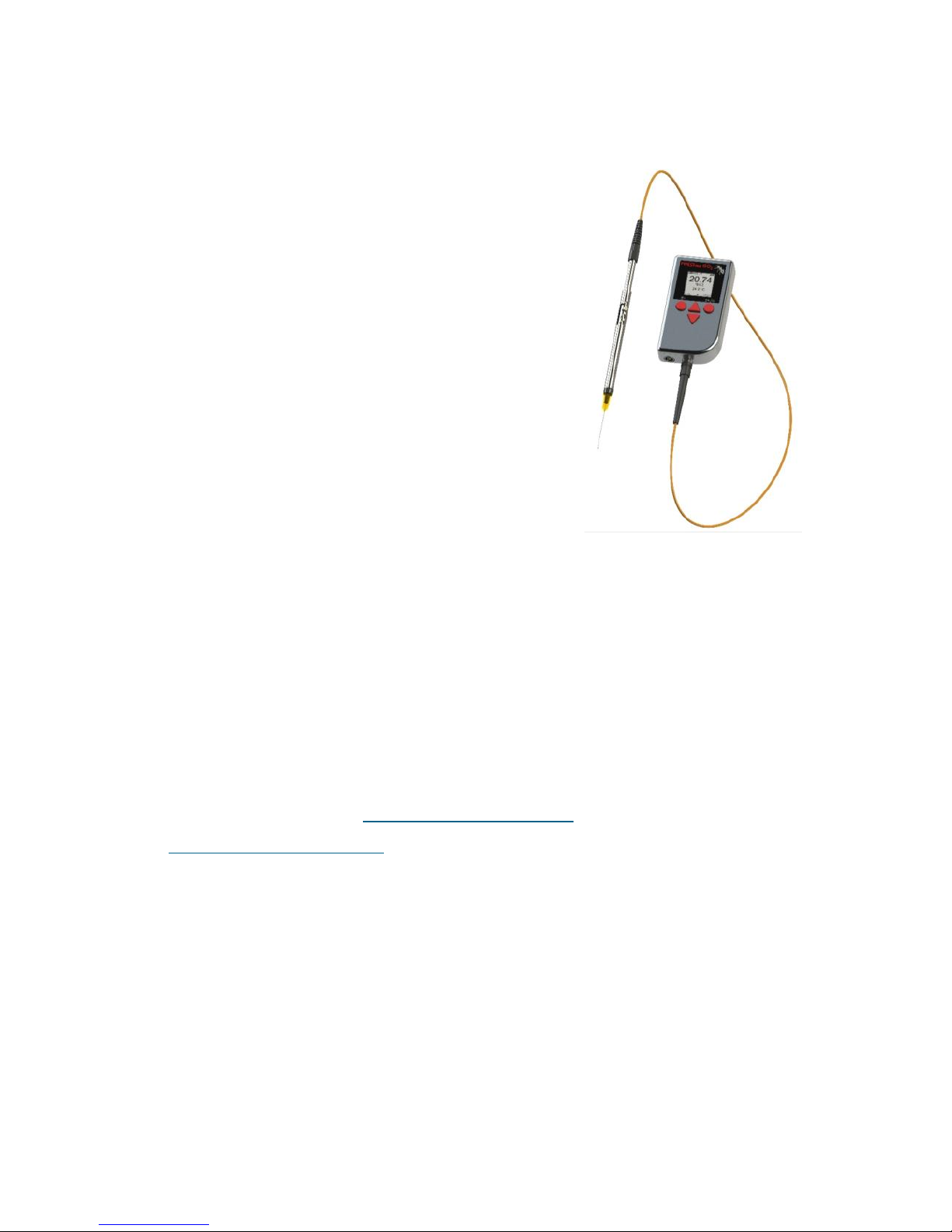

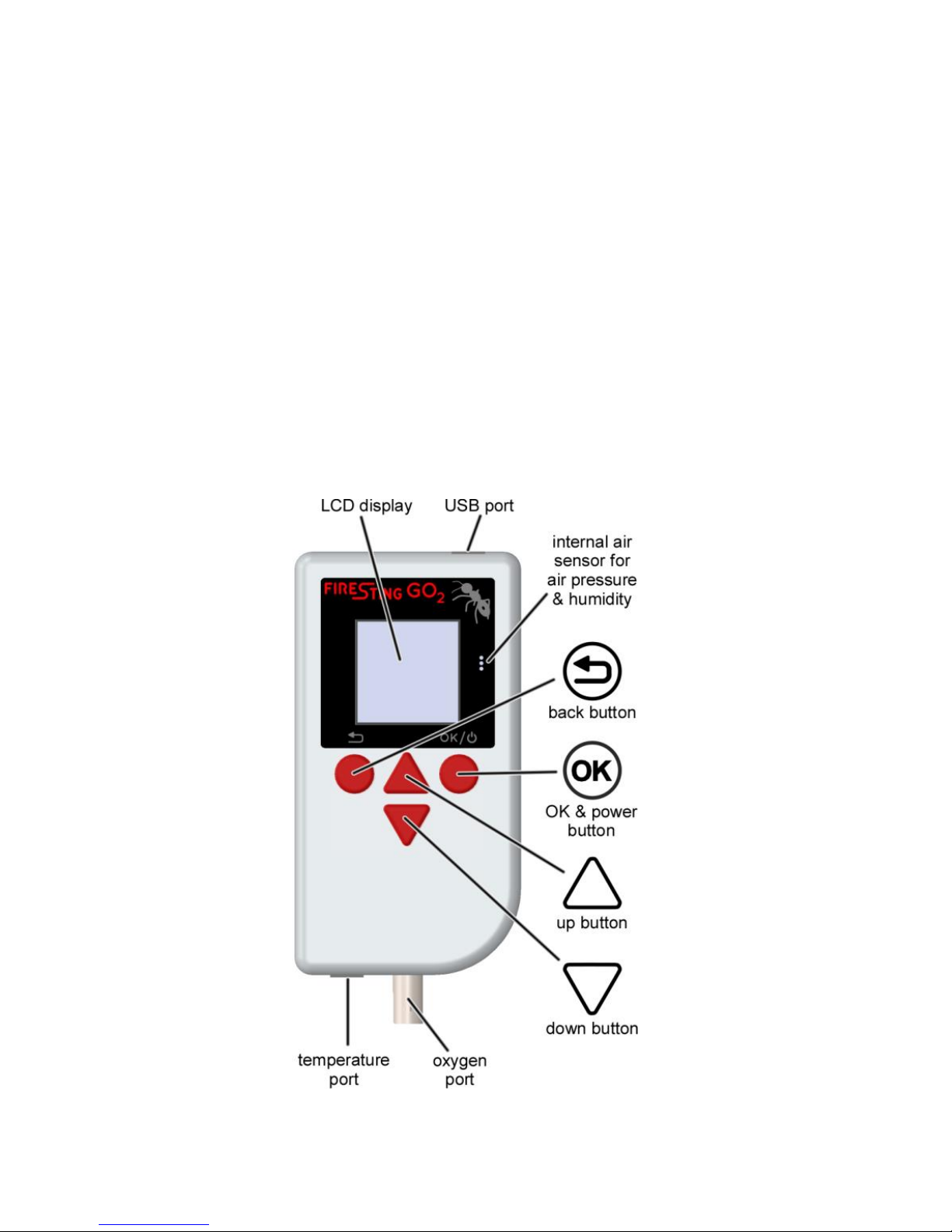

3.1 Ports and Integrated Sensors

The FireStingGO2 has three ports and one integrated sensor:

micro USB port for charging and communication

oxygen port for connecting a fiber-optic oxygen sensor

temperature port for connecting a temperature sensor

internal air sensor for pressure and relative humidity

Page 12

12

3.1.1 Micro USB Port

The micro USB port is used for recharging the integrated battery of

the FireStingGO2 (see below), as well as for data communication

with a PC in combination with the software "FireStingGO2

Manager". This software is especially needed for downloading and

inspecting logged data files from the FireStingGO2 device.

3.1.2 Oxygen Port

Fiber-optic oxygen sensors from PyroScience with ST-connectors

are connected to the oxygen port. Please refer to the website of

PyroScience concerning the broad range of available oxygen

sensor types. Remove the protective caps from the oxygen port as

well as from the ST-connector of the oxygen sensor. Then, insert

the ST-connector into the oxygen port and turn the bayonet

coupling gently clockwise until the plug is locked firmly.

3.1.3 Temperature Port

Temperature sensors (4-wire PT100-sensors with LEMO

connectors) are connected to the temperature port by simply

pushing the connector into the port. Please refer to the website of

PyroScience concerning available temperature sensors.

The temperature sensor can be used for automatic temperature

compensation of the oxygen measurement.

3.1.4 Internal Air Sensor

The internal air sensor measures the pressure and the relative

humidity of the ambient air. It is located behind the three little air

inlets located next to the right side of the display. These sensors

are needed for a precise determination of the actual oxygen level,

if the oxygen sensor is calibrated in ambient air. The pressure

sensor is additionally used for automatic pressure compensation of

the oxygen measurement.

Page 13

13

Keep the three little air inlets of the air sensor clean and dry in

order to assure a proper operation of this sensor. Do not cover

these air holes during the measurements.

3.1.5 Power Button and Recharging the Battery

The FireStingGO2 is switched on and off by pressing the right

button for ca. 1 second (OK button). Note, that the device cannot

be switched off, while the device is logging data or while it is in the

PC mode (see below).

If the device does not switch on by pressing the OK button, the

integrated battery needs to be recharged. For this, connect the

USB port of the FireStingGO2 to any standard micro USB charger

or to any available computer USB port (with the included USB

cable). Typically the battery is fully recharged within ca. 2 hours.

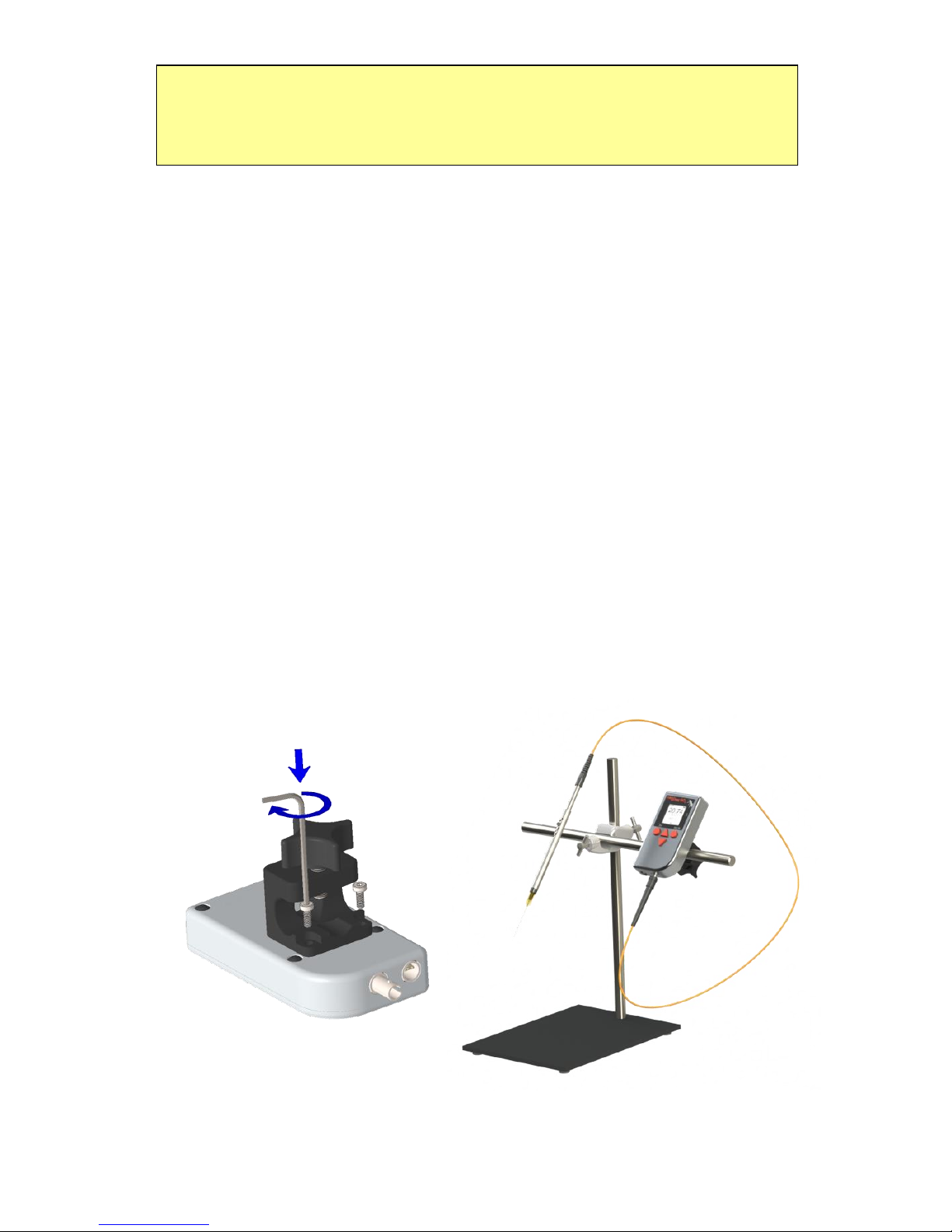

3.2 Stand Clamp

The FireStingGO2 can be optionally mounted on common lab

stands with the included stand clamp. For this, remove the red

silicone shell from the device and mount the stand clamp as shown

in the image.

Page 14

14

3.3 User Interface

The user interface of the FireStingGO2 consists of the display and

four buttons. The high-contrast display features ultra-low power

consumption. Therefore it is permanently activated without

significantly reducing the run-time of the rechargeable battery.

The four buttons allow for an intuitive stand-alone operation of the

FireStingGO2.

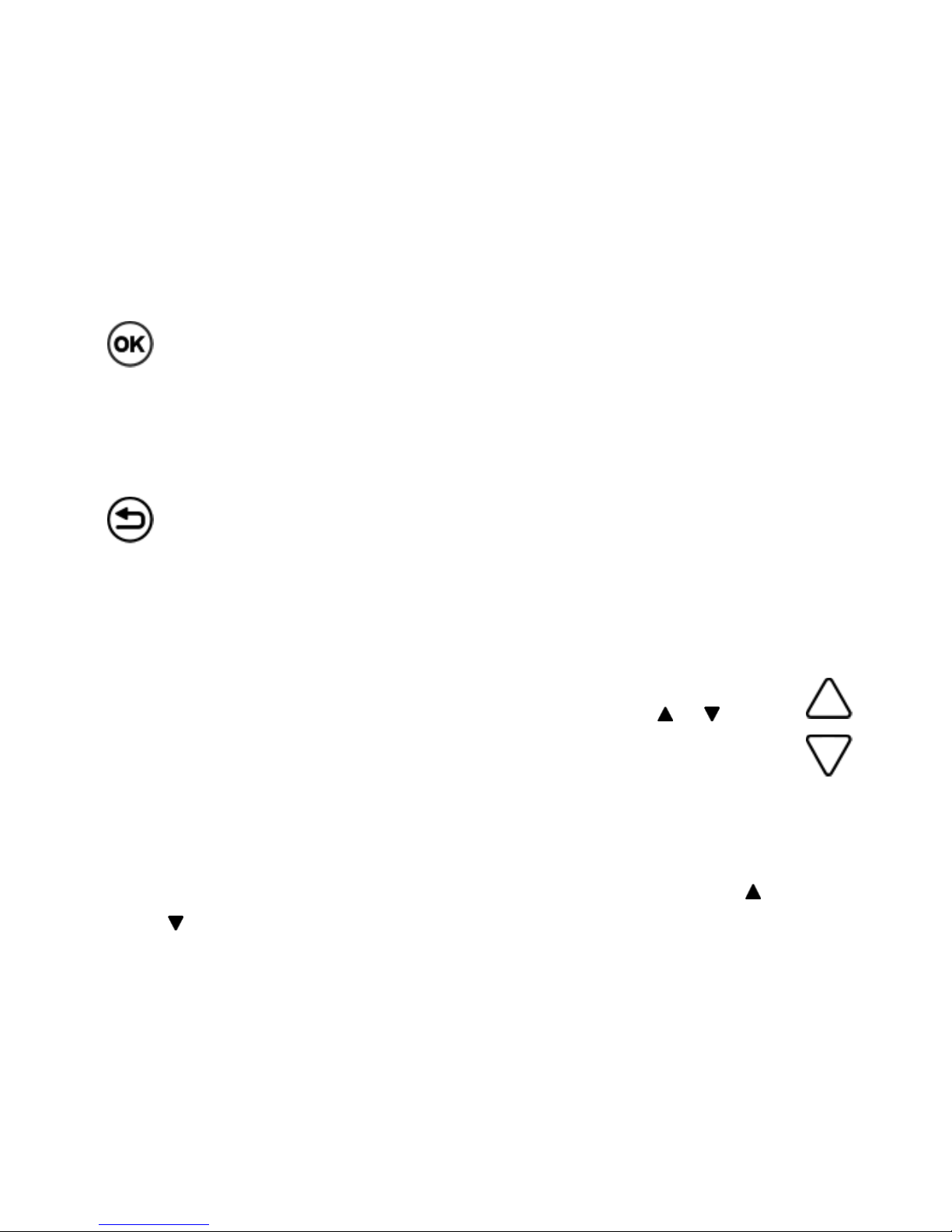

OK Button: If pressed for 1 second, the device is switched on or

off. If pressed shortly, then this button is generally used for

selecting an item or for confirming a setting. Alternatively, the

lower right corner of the display might show a context specific

function, e.g. MENU, START, NEXT, or SAMPLE.

Back Button: This button is generally used for "going back" e.g. in

menus, or for cancelling an operation. Alternatively, the lower left

corner of the display might show a context specific function, e.g.

CANCEL, BACK, or STOP. If pressed for 10 seconds, a hardware

reset of the device can be performed.

Up and Down Buttons: The context specific functionality of these

buttons is always indicated by small black triangles ( or ) in the

display. They are generally used for selecting items from menus or

dialog screens, but also for adjusting numerical values e.g. when

adjusting the sensor code or a temperature value in the settings.

Depending on the operation mode, there might be several „subscreens” available, which is indicated by small black triangles ( or

) appearing in the upper or lower line of the display. By pressing

the up or down buttons, the screen content will scroll up or down,

revealing the other sub-screens.

Page 15

15

3.4 Operation Modes

The user interface of the FireStingGO2 meter comprises five

different operation modes: Live Mode, Menu Mode, Logging

Mode, Standby Mode, and PC Mode.

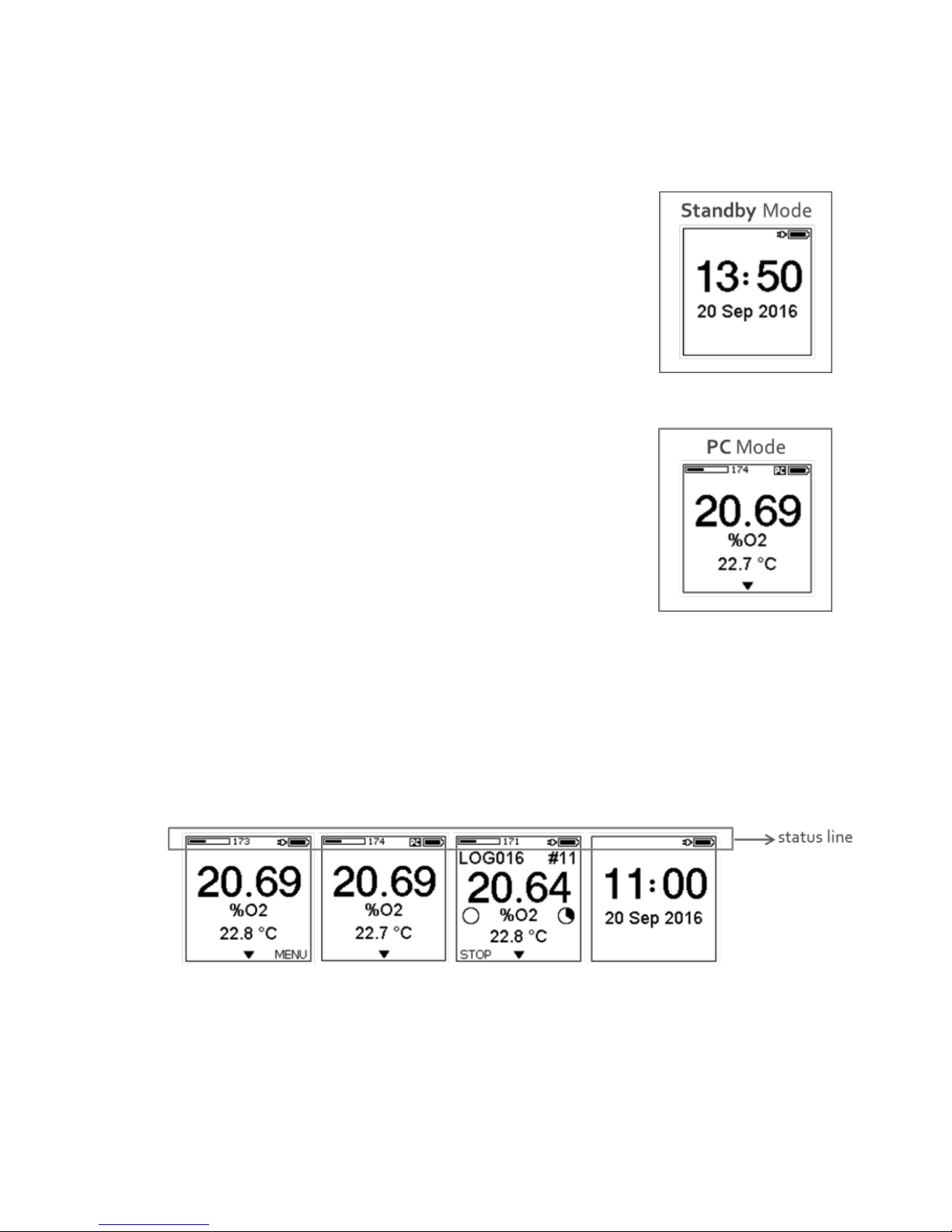

3.4.1 Live Mode

After switching on the FireStingGO2, the device

starts in the Live Mode. Here the device performs a

measurement every 2 seconds and shows the

results in altogether four sub-screens. The data are

not logged in this mode. For more details on the

Live mode refer to chapter 5.

3.4.2 Menu Mode

The Menu Mode can be opened in the Live Mode

by pressing the OK button. The menu is used for:

adjusting the settings

performing sensor calibration

starting data logging

accessing diverse options

After exiting the menu mode with the BACK button, the device

reverts to the Live Mode. For details on the menu mode refer to

chapter 6.

3.4.3 Logging Mode

The Logging Mode is started by selecting "Start

Logging" in the main menu and pressing the OK

button. In the logging mode the measured data

points (sensor readings) are saved in a log file

within the internal data memory of the device.

Altogether six sub-screens provide the user with

detailed information about the progress of the

data logging. If the Logging Mode is terminated, the device will

Page 16

16

revert to the Live Mode. For more details on the logging mode

refer to chapter 7.

3.4.4 Standby Mode

The device automatically enters the Standby

Mode, if the user did not press any button within 5

minutes in the Live Mode. Here the measurements

are stopped to prolong the lifetime of the

connected oxygen sensor. For details on the

Standby Mode refer to chapter 8.

3.4.5 PC Mode

If the device is connected to a PC with the included

USB cable and the software FireStingGO2

Manager is started, the device enters the PC

Mode. This is indicated by the "PC" symbol in the

upper right corner of the display. Here the Menu

Mode is not accessible, only the sub-screens are

accessible with the UP and DOWN buttons. For more details on the

PC mode refer to chapter 9.

3.5 Status Line

In all modes except for the Menu Mode, the status line is shown in

the upper line of the display.

The battery symbol indicates the actual charge level of the internal

battery. The plug symbol indicates that an external power supply is

connected to the USB port. An arrow symbol between the plug and

the battery symbol indicates that charging is in progress. And the

PC symbol indicates that the device is in the PC Mode after the

Page 17

17

FireStingGO2 Manager software has been started on an external

computer (connected via the USB port).

In the Live, PC or Logging Mode, an additional bar graph and a

numerical value show the so-called "signal intensity". It provides

important information on the actual condition and remaining

lifetime of the connected oxygen sensor.

Potential warnings (Low Signal, No Signal, Too High, Bad Ref)

regarding problems with the oxygen sensor signal are displayed at

the position of the bar graph. For more details about trouble

shooting these warnings refer to chapter 11.

Do not continue with measurements if a warning is shown!

Page 18

18

4 Quick Start

4.1 Getting Started

Connect the oxygen sensor and optionally the temperature sensor

to the corresponding ports of the FireStingGO2 (chapter 3.1). Start

the FireStingGO2 meter by pressing the OK button for about 1 sec.

Check the battery charge level of the device in the status line

(chapter 3.5) and recharge the battery if necessary (chapter 3.1.5).

Select MENU with the OK button and first Adjust the local Time

and Date in the Options Menu (chapter 6.4.1)

4.2 Settings and Options Adjustments

For details refer to chapter 6.2.

Open the Settings Menu, enter the Sensor Code of the connected

oxygen sensor, select the sample Medium and choose your

preferred Oxygen Units. Adjust the sample Temperature used for

the temperature compensation of the oxygen measurements

(Sensor or Fixed). If applicable, adjust the sample Salinity.

4.3 Sensor Calibration

For details refer to chapter 6.3.

Open the Calibration Menu in the main menu and review if the

correct Sensor Code was adjusted. Prepare appropriate air and 0%

calibration standards. Open Calibrate Air and select the type of

temperature compensation used during the calibration: Sensor for

automatic temperature compensation with the connected

temperature sensor or Fixed with a defined and constant

calibration temperature (needs to be measured and controlled).

Then select the appropriate calibration medium equivalent to the

sample under investigation: Ambient Air for gas measurements

and Air Saturated Water for measurements in aqueous samples.

Insert the oxygen and temperature sensor into the air calibration

standard, wait for steady state and press SET AIR.

Page 19

19

After a successful air calibration, open Calibrate 0%, select the

type of temperature compensation used during the calibration

(Sensor or Fixed, see above), insert the oxygen and temperature

sensor into the 0% calibration standard, wait for steady state and

press SET 0%.

4.4 Live Measurements

Exit the menu by pressing the BACK button. Measurements are

performed now in the Live Mode every 2 seconds. Access the

different sub-screens with the UP and DOWN buttons, showing

the measurement results. Note, that the data are NOT logged in

the Live Mode.

4.5 Data logging

For details refer to chapter 7.

Open Start Logging in the Main Menu. Choose the appropriate

mode: Manual for manual logging, i.e. data points are logged each

time the OK button (SAMPLE) is pressed; Continuous for

automatized logging with adjustable Logging Interval and

Logging Duration. The logged data are displayed numerically and

graphically on several sub-screens. If the data logging is finished,

EXIT the Logging Mode with the BACK button.

4.6 Data management and inspection

For details refer to chapter 10.

Download and install the FireStingGO2 Manager software from

the PyroScience website to a Windows PC. Connect the

FireStingGO2 device with the included USB cable, and start the

software. Go to the File tab, select a log file and click on Download

& Inspect. This will download the log file from the device to the

PC, and show the logged data in the Log Inspector window.

Page 20

20

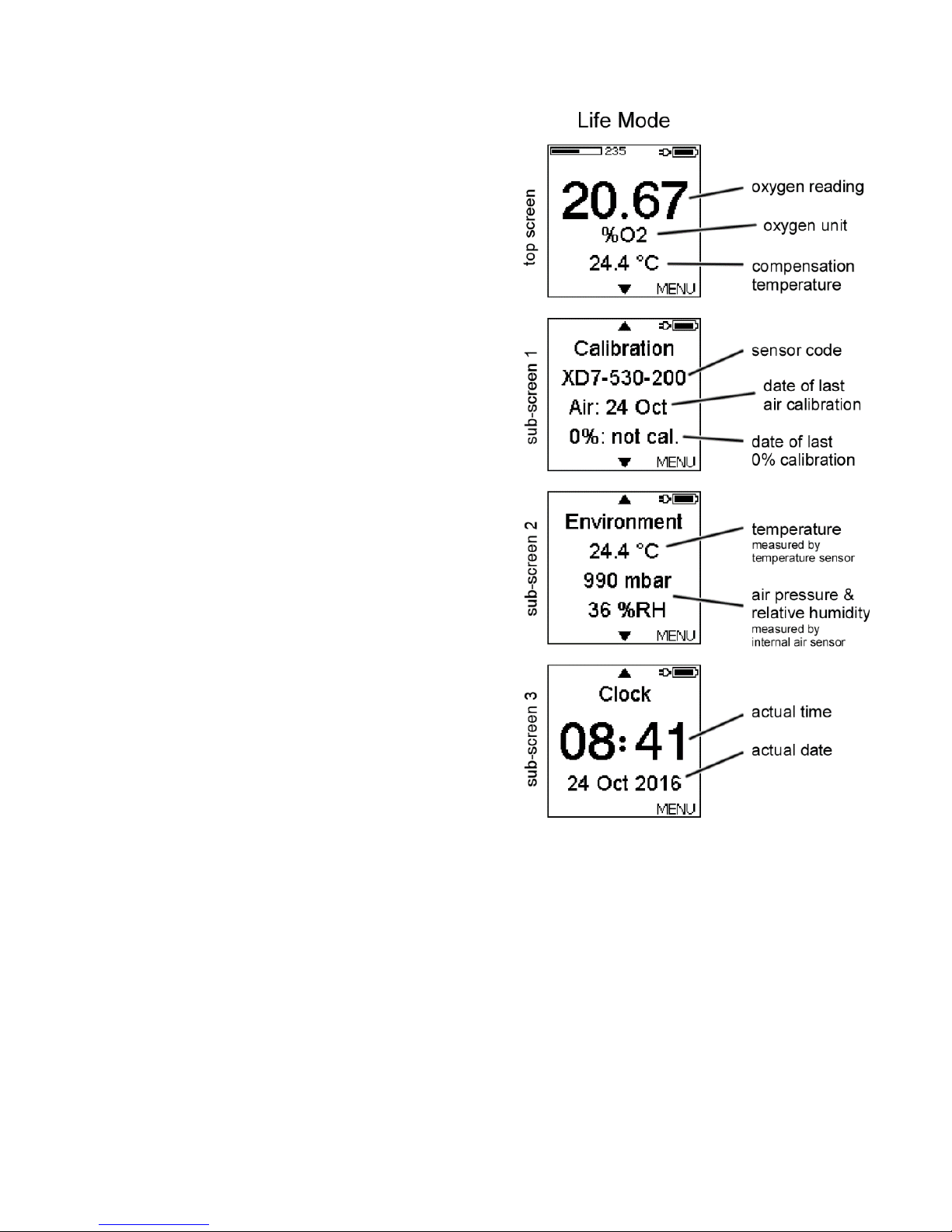

5 Live Mode

After power-up or after activation

from standby the FireStingGO2 is in

the Live Mode. Measurements are

performed every 2 seconds. The

different sub-screens can be

accessed with the UP and DOWN

buttons. Note, that the data are

NOT logged in the Live Mode.

5.1 Top Screen

Here, the current reading of the

connected oxygen sensor and the

selected oxygen unit (see chapter

6.2.3) is shown, as well as the

compensation temperature (sensor

or fixed, see chapter 6.2.4).

5.2 Sub-screen 1

Here the sensor code and the dates

of the last Calibrations are shown

(see chapter 6.3).

5.3 Sub-screen 2

This sub-screen shows details on the Environment, including the

readings of the temperature sensor (if connected) and of the

internal air sensor, including the air pressure (mbar) and relative

humidity (%RH) (see chapter 3.1.4).

5.4 Sub-screen 3

This sub-screen shows the Clock with the actual time and date.

Refer to chapter 6.4.1 how to set the clock.

Page 21

21

6 Menu Mode

The menu is entered by pressing the OK

button in the Live Mode, opening the main

menu.

6.1 Main Menu

The main menu has four entries:

Settings: opens the Settings Menu (chapter 6.2)

Calibration: opens the Calibration Menu (chapter 6.3)

Start Logging: starts data logging (chapter 7)

Options: opens the Options Menu (chapter 6.4)

6.2 Settings Menu

The following settings have to be adjusted in

the Settings Menu.

6.2.1 Sensor Code

The Sensor Code written on the label

attached to the sensor or on the stickers/bags

of contactless sensors must be entered every

time a new oxygen sensor is connected. Enter

this sensor code by moving the cursor with the

BACK and OK buttons, and by adjusting each letter/number with

the UP and DOWN buttons. Press OK after the last number of the

sensor code has been adjusted. Confirm the changes by pressing

OK once more.

Changing the Sensor Code will discard the last calibration!

Page 22

22

6.2.2 Medium

Adjust here the medium Gas or Water of your sample.

6.2.3 Oxygen Units

Select here your preferred oxygen unit. Note, that the available

oxygen units depend on the chosen medium.

6.2.4 Temperature

Here the temperature of the sample has to be

adjusted. This is important in order to assure a

correct temperature compensation of the oxygen

measurement.

Select Sensor for enabling automatic temperature compensation

based on temperature measurements of the connected PT100

temperature sensor (chapter 3.1.3).

In order to ensure proper automatic temperature compensation,

position the temperature sensor in the sample, so that it measures

the same temperature as given around the oxygen sensor tip.

Page 23

23

If your sample is kept at a constant temperature,

then the automatic temperature compensation

can be deactivated by selecting Fixed. Now you

must enter the fixed temperature of your sample

used for the temperature compensation of the

oxygen measurement.

6.2.5 Salinity

The salinity of the sample only has to be

adjusted for measurements in saline samples

(e.g. seawater) using an oxygen concentration

unit, like µmol/L or mg/L.

6.3 Calibration Menu

After adjusting the sensor Settings (see chapter

6.2) and the local date and time in the Options

menu (see Adjust Time and Date in chapter

6.4.1), the connected oxygen sensor needs to be

calibrated before the measurements. Note, that

the top screen of the Live Mode shows the warning Not Calibrated

after a new Sensor Code has been entered. The calibration is

performed in the Calibration menu.

The oxygen sensor can be calibrated at two

calibration points:

(1) at ambient air or in air saturated water

(Calibrate Air), and

(2) at 0%O2, i.e. anoxic conditions (Calibrate

o%). For highest precision it is recommended to calibrate both

calibration points. However, if the expected measuring range is

close to one of the calibration points, then a 1-point calibration

might be sufficient. For example if the expected measuring range

in a liquid sample is 90-100% air sat., then a 1-point calibration at

air saturated water is for many applications sufficient. In this case

Page 24

24

the 0% calibration is taken from the factory calibration encoded in

the Sensor Code.

It is recommended to perform the calibration at conditions close to

the environmental conditions during the measurements, especially

regarding the temperature.

6.3.1 Sensor Code

For security the Calibration menu repeats the Sensor Code entry,

which is in fact identical to the Sensor Code entry given in the

Settings menu (chapter 6.2.1).

Before starting the calibration, double check that the correct

Sensor Code has been entered, as written on the label attached to

the sensor cable or on the bag/stickers of the sensor.

6.3.2 Air Calibration

Select Calibrate Air for starting an air calibration.

Then choose the type of temperature

compensation during the calibration:

a) For automatic temperature compensation of

the Calibration Temperature with the

temperature sensor connected to the

FireStingGO2 meter, select Sensor and confirm

with Ok.

b) A Fixed Calibration Temperature can be

entered with the UP and DOWN buttons after the

temperature of the calibration standard was

measured e.g. with a third-party temperature

meter.

NOTE: Ensure constant calibration conditions! If the calibration is

performed with a Fixed temperature, the temperature in the

calibration standard must be measured and kept constant!

Page 25

25

Now the Calibration Medium of the air calibration

standard needs to be defined as Ambient Air or

Water, depending on the environmental sample

under investigation.

It is recommended to perform the calibration in the same medium

as the one in the sample.

6.3.2.1 Calibration in Ambient Air

Calibration in ambient air is recommended, if the measurements

on the sample are done in the gas phase. During the calibration,

the atmospheric pressure and the relative humidity of the ambient

air will be read automatically from the internal air sensor (chapter

3.1.4). These readings are needed in order to calculate the actual

oxygen partial pressure in the ambient air.

Therefore, it is important that both the FireStingGO2 device and

the connected oxygen sensor are exposed to identical

environmental conditions.

Position the oxygen and the temperature sensor (if selected) close

to the air inlets on the right side of the FireStingGO2 display.

Ensure that the oxygen and temperature sensor are completely

dry; otherwise the relative humidity around the sensor will differ

from the measured humidity inside the FireStingGO2.

It is strongly recommended that the device and the sensors are

placed for >30 min. under constant environmental conditions

before the calibration is performed.

Page 26

26

Now Wait for Steady State until the sensor

readings are stable. Then press SET AIR and the

current oxygen sensor reading is taken for the air

calibration. After the completion of the air

calibration, the system returns to the Calibration

menu, showing now the date of the air calibration.

Note: SET AIR is only active if the oxygen sensor readings are

within the expected range for the connected sensor type. If SET

AIR is replaced by "out of range", check or replace the calibration

standard and the entered Sensor Code. Repeat the calibration.

6.3.2.2 Calibration is Air Saturated Water

Calibration in air saturated water is recommended, if the

measurements are done in aqueous samples. Refer to chapter 12.1

concerning preparation of appropriate calibration standards. This

calibration mode will automatically read the atmospheric pressure

from the internal air sensor inside the FireStingGO2. This reading is

needed to calculate the actual oxygen partial pressure in the

ambient air.

It is important that the sensor in the calibration standard is

exposed to the same atmospheric pressure as the FireStingGO2.

Now insert the oxygen sensor into the calibration

standard. If Sensor was selected for the

calibration temperature (see above), then insert

also the connected temperature sensor into the

calibration standard. Now Wait for Steady State

until the sensor readings are stable.

Note: If using retractable needle-type sensors (e.g. OXR50,

OXR230, OXR430), it is important that the sensor tip is extended!

Page 27

27

Then press SET AIR and the current oxygen sensor reading are

taken for the air calibration. After the completion of the air

calibration, the system returns to the Calibration menu, showing

now the date of the air calibration.

Note: SET AIR is only active if the oxygen sensor readings are

within the expected range for the connected sensor type. If SET

AIR is replaced by "out of range", check or replace the calibration

standard and the entered Sensor Code. Repeat the calibration.

6.3.3 0% Calibration

Refer to chapter 12.2 concerning preparation of appropriate 0%

calibration standards. Select Calibrate 0% for performing a 0%

calibration. Now choose the type of temperature compensation

during the 0% calibration:

a) For automatic temperature compensation of the Calibration

Temperature with the temperature sensor connected to the

FireStingGO2 meter, select Sensor and confirm with OK.

b) A Fixed Calibration Temperature can be

entered with the UP and DOWN buttons after the

temperature of the calibration standard was

measured e.g. with a third-party temperature

meter.

NOTE: Ensure constant calibration conditions! If the calibration is

performed with a Fixed temperature, the temperature in the

calibration standard must be measured and kept constant!

Now insert the oxygen sensor into the 0%

calibration standard. If Sensor was selected for

the calibration temperature, then insert also the

connected temperature sensor into the calibration

standard. Now Wait for Steady State until the

Page 28

28

sensor readings are stable.

Note: If using retractable needle-type sensors (e.g. OXR50,

OXR230, OXR430), it is important that the sensor tip is extended!

Then press SET 0% and the actual oxygen sensor

reading is taken for the 0% calibration. After the

completion of the 0% calibration, the system

returns to the Calibration Menu, showing now the

date of the 0% calibration.

Note: SET 0% is only active if the oxygen readings are within the

expected range for the connected sensor type. If SET 0% is

replaced by "out of range", check or replace the calibration

standard and repeat the calibration.

6.4 Options Menu

In the Options Menu several device and sensor

parameters can be adjusted. Furthermore, device

information can be retrieved and a reset of the

device can be performed.

6.4.1 Adjust Time and Date

Please note that it is recommended to Adjust the local Time and

Date before the calibration of the connected sensor (see chapter

6.3) and before logging is started (see chapter 7.1). Adjust them by

moving the cursor with the BACK and OK buttons, and by

adjusting each item with the UP and DOWN buttons.

Page 29

29

6.4.2 Temperature Offset

It is recommended to check the reading of the

PT100 temperature sensor periodically in a water

bath of known temperature. This is especially

important if a concentration unit (like µmol/L or

mg/L) was selected for the oxygen readings (see

chapter 6.2.3). A manual Temp. Offset can be entered for a 1-point

calibration of the temperature sensor (default: 0).

It is also possible to prepare a water-ice-mixture

giving 0°C, where at least 50 mm of the

temperature sensor tip is submerged. Wait for

steady state, read the measured temperature in

the top screen of the Live Mode, and enter it as a

negative Temperature Offset. After this, a new calibration of the

connected oxygen sensor must be performed (see chapter 6.3).

Changing the temperature offset will lead to a loss of the oxygen

sensor calibration.

6.4.3 Device Info and Reset Device

Information concerning the unique ID number of

the device, the number of saved log files, the used

space of the internal device memory (MB) and the

firmware version can be obtained by selecting

Device Info.

Reset Device can be used in order to reset all settings and

calibrations. Additionally it can be selected, whether to delete also

all log files on the internal device memory (Delete All) or to keep

them (Keep Data).

Page 30

30

Selecting Delete All will irrevocably delete all logged data on the

internal device memory!

6.5 Advanced Menu

The sub-menu Advanced includes advanced

features only for advanced users with special

instructions from PyroScience.

It is not recommended to change these advanced parameters

without the advice of PyroScience!

Page 31

31

7 Data Logging

Before starting data logging on the internal device memory,

ensure that the following steps have been performed:

Adjustment of Time and Date (see chapter 6.4.1)

Adjustment of the sensor Settings (see chapter 6.2)

Calibration of the connected oxygen sensor (see chapter 6.3)

7.1 Start Logging

In order to start the logging, select Start Logging

in the main menu (see chapter 6.1) and confirm

with OK. Here, a Manual (see chapter 7.1.1) and a

Continuous (see chapter 7.1.2) logging mode can

be selected.

7.1.1 Manual Logging

Select the logging mode Manual and press the OK

button. Now data points are logged each time the

OK button (SAMPLE) is pressed. However, the top

screen of the logging mode shows additionally live

readings with 2s sample period. These live

readings are NOT logged.

Please refer to chapter 7.2 for a description of the

information shown on the display during the

logging.

To exit the manual logging mode, press STOP. A

confirmation screen will appear. Press again STOP

for about 1 second, thereby returning to the Live

Mode.

Page 32

32

7.1.2 Continuous Logging

Select the logging mode Continuous and press

the OK button. In this mode data points are

periodically logged with adjustable sample

intervals and total logging duration.

Select the Logging Interval (1 s, 2 s, 5 s, 10 s, 30

s, 1 min, 2 min, 5 min, 10 min, 30 min, 1 hour, 2

hours or 4 hours) and press NEXT.

Select the Logging Duration (1 min, 2 min, 5

min, 10 min, 30 min, 1 hour, 2 hours, 6 hours, 12

hours, 1 day, 2 days, 4 days, 1 week, 2 weeks, 1

month, 3 months, 6 months, 1 year or Non-Stop)

and press NEXT.

Now the logging is started. Please refer to

chapter 7.2 for a description of the information

shown on the display during the logging.

In case of selecting a finite logging duration, the

logging is automatically finished at the end of the

logging duration. Now press EXIT for returning to

the Live Mode.

In case Non-Stop was selected for the Logging

Duration, the logging needs to be actively

stopped by pressing STOP. Also if a finite

Logging Duration was entered, the logging can be terminated at

any time by pressing STOP. A confirmation screen will appear.

Press then again STOP for about 1 second, thereby returning to

the Live Mode.

Page 33

33

7.2 Logging Mode

Each time a new logging is started, a new log file (LOGxxx) is

generated and numbered sequentially upwards (e.g. LOG001,

LOG002, LOG003 etc.). In this log

file, each recorded data point is

numbered sequentially upwards

(#xxx). The log file and the last

logged data point number are

underneath the status line in the

top screen of the Logging Mode.

The top screen shows further the

last logged readings from the

oxygen and the temperature

sensor. Please note, if Manual

Logging was selected, then

additionally live readings with 2s

sample period are shown here. But

data points are only logged each

time the OK button (SAMPLE) is

pressed.

Progress circles next to the oxygen

unit provide feedback when the

next data point will be logged (left

progress circle) and about the

remaining total logging time (right

progress circle).

In sub-screen 1 the last 100 logged

data points of the oxygen sensor

readings are displayed in a graph.

The last logged value is shown

additionally as a numerical value.

Page 34

34

In sub-screen 2 the last 100 data points of the compensation

temperature are displayed in a graph. The last logged

compensation temperature is shown additionally as numerical

value.

Sub-screen 3 shows information concerning the Environment,

including the readings of the temperature sensor (if connected), as

well as the air pressure (mbar) and relative humidity (%RH)

measured by the internal air sensor.

Sub-screen 4 includes all details of the actual log file, like the start

of the logging (Log Start with time and date), the actual log File

Size and Free device memory available. For the Continuous

logging mode, additional information concerning the adjusted

Logging Interval and Duration are shown, as well as the Time Left

for the remaining logging duration.

The last sub-screen 5 shows the clock with the actual device time

and date.

Page 35

35

8 Standby Mode

If no buttons are pressed in the Live Mode

within 5 min, the device enters the Standby

Mode. Here the device clock is shown in the

display. In the Standby Mode the

measurements are stopped in order to safe

lifetime of the connected oxygen sensor.

To return to the Live Mode, any button can

be pressed, opening the top screen of the Live Mode with the

actual readings of the connected sensors.

Note, that in the Logging Mode or in the PC Mode, the system will

not switch into the Standby Mode.

9 PC Mode

For managing the logged data saved on

the internal device memory, the

FireStingGO2 meter needs to be

connected to a Windows PC with the

included USB cable, on which the software

FireStingGO2 Manager was installed (see chapter 10.1).

After start of the software FireStingGO2 Manager on the PC, the

connected FireStingGO2 meter is in the PC Mode. This is indicated

in the status line of the device display.

In the PC Mode, only the UP and DOWN buttons are active for

scrolling between top and sub-screens of the Live Mode. Access to

the menu is blocked. However, now the FireStingGO2 meter can

be controlled completely by the FireStingGO2 Manager software

on the PC. It offers an extended functionality compared to the LCD

user interface, including log file download, log file deletion, and log

file inspection.

Page 36

36

10 FireStingGO2 Manager

The log files saved in the internal device memory of the

FireStingGO2 can be downloaded and inspected on a Windows PC

using the software FireStingGO2 Manager. Additionally, the

FireStingGO2 Manager software offers most features similar to the

ones given in the LCD user interface (adjusting settings,

performing calibrations, options).

10.1 Software Installation

IMPORTANT: Do not connect the FireStingGO2 to your PC before

the FireStingGO2 Manager software has been installed. The

software will install automatically the appropriate USB-drivers.

1. System requirements: PC with Windows 7 / 8 / 10 and min.

700 MB free disk space

2. Download the installer package of the FireStingGO2

Manager software from the PyroScience homepage:

www.pyroscience.com/downloads.html

3. Unzip and start the installer and follow the instructions.

10.2 Operation without Connected Device

The FireStingGO2 Manager software can be also used if no

FireStingGO2 device is connected to the PC. In this case only the

Log Inspector window can be opened, offering access onto the

already downloaded log files. Please refer to chapter 10.4 for more

details.

10.3 Operation with Connected Device

First connect the FireStingGO2 meter to the PC with the included

micro-USB cable, now start the software FireStingGO2 Manager.

The FireStingGO2 will switch into the PC mode, indicated by the

"PC" symbol in the upper right corner of the LCD display.

Page 37

37

The main window of the FireStingGO2 Manager offers 5 different

tabs (Settings, Calibration, Logging, File and Options) for

controlling the FireStingGO2 (more details below).

The battery symbol in the

top line indicates the battery

charging status of the

connected FireStingGO2

device. An animated battery

symbol indicates that the

charging is in progress. As

soon as the animation stops,

the charging is completed.

The buttons in the bottom

line open the Log Inspector

and the Live Graph window

(more details below).

The FireStingGO2 Manager allows full control on the device,

offering most features similar to the LCD user interface of the

FireStingGO2. Before starting live measurements or data logging,

following steps need to be done:

Get accustomed to the Live Graph window (chapter 10.3.1)

Adjust the sensor Settings (chapter 10.3.2)

Perform an oxygen sensor Calibration (chapter 10.3.3)

Perform live measurements or start Logging (chapter 10.3.6)

10.3.1 Live Graph Window

The Live Graph window is opened by clicking on the Live Graph

button in the main window. In the Live graph window, all current

sensor readings are displayed numerically in the Live Display.

Furthermore, different parameters can be displayed in the graph of

the Live Graph window.

Page 38

38

The Live Display shows numerical live readings of all sensors

comprising oxygen, compensation temperature, temperature (if a

temperature sensor is connected), and the readings of the internal

air sensor (air pressure, relative humidity). For

more details refer to chapter 5.

Above the oxygen value, an additional bar

graph and a numerical value show the socalled "signal intensity". It provides important

information on the actual condition and

remaining lifetime of the connected oxygen

sensor. Potential warnings (see chapter 11)

are displayed above the bar graph.

If data logging is not active, the warning "Data are NOT logged!"

is shown above the graph. Data displayed in the Live Graph are

then NOT saved to a log file!

Page 39

39

If data logging is active, the Log Name, the Start time of the

logging and the Comment entered before the start of the logging,

are displayed above the graph.

As default shown in the Live Graph are the

current readings for oxygen and for the

compensation temperature (Comp. Temp.).

To show or hide other parameters in the Live

Graph, click on the small rectangular buttons

next to the respective parameters.

The color and appearance of each graph can be changed by

clicking on the color-control next to the respective parameter,

opening a pop-up menu. With Common Plots, Color, Line Style,

Line Width, Interpolation, and Point Style the chart appearance

can be changed.

The visible time frame of the live graph can be moved with the

scroll bar below the graph. With the button Move, the user has the

possibility to click onto the chart and move the whole area while

keeping the mouse button pressed. To zoom into a certain part of

the graph, click on the button Zoom and select a rectangular area

with the pressed mouse button.

To select the unit of the x-axis Time, click on the button Seconds

(s) (default) and select the appropriate unit as Seconds (s),

Minutes (min), Hours (h), Relative Time (HH:MM:SS), Absolute

Time (HH:MM:SS) or Absolute Time & Date. The activated

Autoscroll button ensures that the latest data points are always

within the visible range of the live graph. Switching off the

Page 40

40

Autoscroll button allows inspection of older data with the scroll

bar.

Smart Autoscale Y will trigger an autoscale of the y axes with

"smart" ranges for better readability. Autoscale X & Y performs a

classical autoscale of all x and y axes. Click on Adjust Scale in order

to adjust all scales manually by entering the maximum, minimum,

and the increment (tag spacing) for all x and y axes.

The graph can be cleared with the button Clear Graph. This will

not affect the saved data in the log file.

10.3.2 Settings

Open the Settings tab to

adjust the sensor settings.

Here, the Sensor Code, the

Medium of the sample, the

Oxygen Units of the

measurements and the

environmental conditions,

including the Temperature

Compensation and, if

applicable, the Salinity

(psu) of the sample under

investigation have to be

adjusted.

The Settings can only be adjusted if data logging is not active.

Enter the Sensor Code written on

the label attached to the sensor

cable or on the bag/stickers of the

oxygen sensor by clicking on the field

Sensor Code, therewith opening the

Sensor Code window. Adjust each

Page 41

41

position of the respective sensor code and click on OK.

Changing the Sensor Code, e.g. in case of connecting a new

sensor, requires a new calibration of the oxygen sensor!

Then define the medium of your sample by clicking in the field

Medium and selecting Gas or Water, depending on the

environmental sample under investigation. Then select the

appropriate Oxygen Units for the measurements. Please note that

different oxygen units can be selected for the Medium Gas (%O2,

hPa, Torr, dphi) and Water (%air saturation, mL/L, µmol/L, mg/L,

µg/L, hPa, Torr, dphi).

Now the Environmental Conditions in the sample need to be

defined. The possible modes of Temperature Compensation

during the oxygen measurements include temperature

measurements in the sample with the connected PT100

temperature Sensor. Alternatively, the measurements can be

performed with a fixed

sample temperature. In

this case the

temperature needs to be

measured in the sample

and entered as Fixed

Temperature (°C).

IMPORTANT: For measurements with a Fixed temperature, the

temperature in the sample must be measured and kept constant

during the entire measurement!

For measurements in saline samples (e.g. seawater) using an

oxygen concentration unit like µmol/L or mg/L, the salinity of the

sample must be measured and entered in the field Salinity (psu).

Page 42

42

For measurements in gas samples this value has no relevance (and

is not shown).

10.3.3 Calibration

The oxygen sensor is calibrated in the Calibration

tab. If a sensor is not yet calibrated, a warning

Not Calibrated replaces the oxygen unit in the

live graph.

The oxygen sensor can be calibrated at two

calibration points:

(1) in ambient air or in air saturated water (Calibrate Air), and/or

(2) at 0%O2, i.e. in an anoxic calibration standard (Calibrate o%).

For highest precision it is

recommended to calibrate

both calibration points.

However, if the expected

measuring range is close to

one of the calibration

points, then a 1-point

calibration might be

sufficient. For example if

the expected measuring

range in a liquid sample is

95-100% air sat., then a 1point calibration at air

saturated water is typically

sufficient. In this case the 0% calibration is taken from the factory

calibration encoded in the Sensor Code.

It is recommended to perform the calibration at conditions close to

the environmental conditions during the measurements.

For security the Calibration tab repeats the Sensor Code entry,

which is in fact identical to the Sensor Code entry given in the

Page 43

43

Settings tab (chapter 10.3.2). Double check the entered Sensor

Code is identical to the one written on the label attached to the

sensor cable or on the bag/stickers of the sensor.

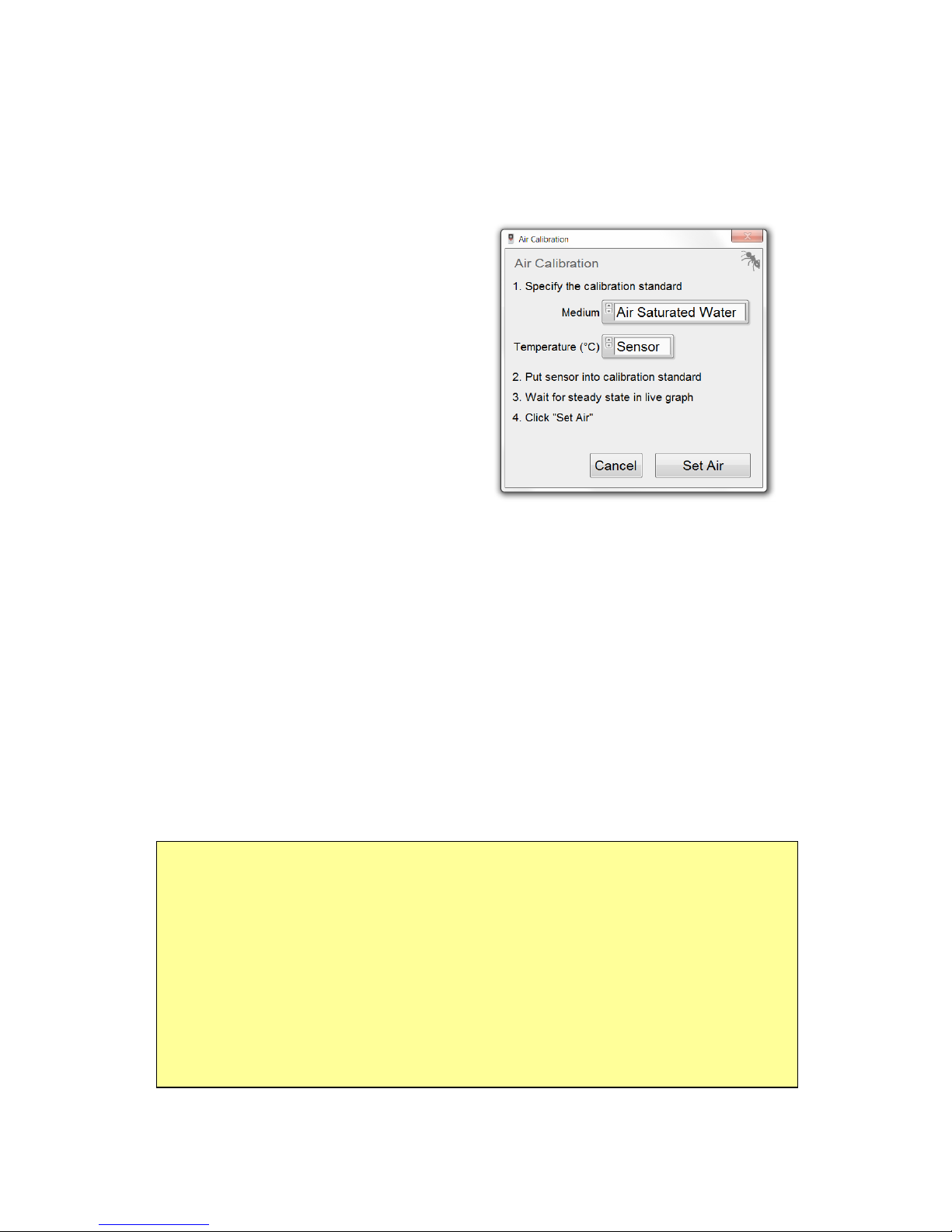

10.3.4 Air Calibration

Click on the button Calibrate Air

to open the Air Calibration

window. This will also

automatically open the Live

Graph window (see 10.3.1).

(1) Choose Calibration Medium.

Specify the Medium of the

calibration standard. If the

measurements will be done in

the gas phase, it is advised to choose Ambient Air and to continue

with step (2A). If the measurements will be done in aqueous

samples, it is advised to choose Air Saturated Water and to

continue with step (2B).

(2A) Calibration in Ambient Air. Ambient air serves as a simple

standard (ca. 20.95%O2 in dry air). In order to determine the

precise oxygen partial pressure in ambient air, the atmospheric

pressure and the relative humidity will be read automatically from

the internal air sensor (chapter 3.1.4).

Ensure that both the FireStingGO2 device and the connected

sensors are exposed to identical environmental conditions.

Position the sensor tips in close proximity to the FireStingGO2

device.

Ensure that the oxygen and the temperature sensor are completely

dry; otherwise the relative humidity around the sensors will differ

from the measured humidity inside the FireStingGO2.

Page 44

44

It is strongly recommended that the device and the sensors are

placed for >30 min. under constant environmental conditions

before the calibration is performed.

(2B) Calibration in Air Saturated Water. Please refer to chapter

12.1 concerning preparation of an appropriate calibration standard.

Note that this calibration mode will automatically read the

atmospheric pressure from the internal air sensor inside the

FireStingGO2, which is needed for calibration. Therefore, the

calibration standard must be exposed to the same atmospheric

pressure as the FireStingGO2 device.

Insert the sensors for oxygen and temperature (if selected for

automatic temperature compensation) into the calibration

standard. It is important that the sensor in the calibration standard

is exposed to the same atmospheric pressure as the FireStingGO2.

Note: If using retractable needle-type oxygen sensors (e.g. OXR50,

OXR230, OXR430), it is important that the sensor tip is extended

when the calibration value is taken.

(3) Temperature Compensation. Select now the mode of

temperature compensation used during air calibration by clicking

on Temperature (°C). For automatic temperature compensation

with the temperature sensor connected to the FireStingGO2

device, select Sensor.

Alternatively, a Fixed calibration temperature can be entered after

the temperature of the calibration standard was measured e.g.

with a third-party temperature meter.

NOTE: Ensure constant calibration conditions! If the calibration is

performed with a Fixed temperature, the temperature in the

calibration standard must be measured and kept constant!

Page 45

45

(4) Wait for Steady State until the oxygen and temperature

readings are stable by observing the Live Graph window (see

10.3.1).

(5) Calibrate by clicking on Set Air. The current oxygen sensor

reading is taken for the air calibration and the date of the last

calibration is updated in the

Calibration tab.

Note: A calibration is only possible if the oxygen sensor readings

are within the expected range for the connected sensor type. If the

warning "Calibration out of expected range" is shown, the

calibration is discarded. Check or replace the calibration standard

and perform a new calibration.

10.3.5 0% Calibration

Refer to chapter 12.2 how to

prepare an appropriate 0%

calibration standard. Click on

Calibrate 0% in the Calibration

tab. This will open the 0%

Calibration window and the

Live Graph window (see

10.3.1).

(1) Temperature Compensation. Select now the mode of

temperature compensation used during 0% calibration by clicking

on Temperature (°C). For automatic temperature compensation

with the PT100 temperature sensor connected to the FireStingGO2

device, select Sensor.

Alternatively, a Fixed calibration temperature can be entered after

the temperature of the calibration standard was measured with a

third-party temperature meter.

Page 46

46

NOTE: Ensure constant calibration conditions! If the calibration is

performed with Fixed temperature, the temperature in the

calibration standard must be measured and kept constant!

(2) Put Sensors into Calibration Standard. Now insert the oxygen

sensor into the calibration standard. If Sensor was selected for the

calibration temperature (see above), then insert also the

connected temperature sensor into the calibration standard.

Note: If using retractable needle-type sensors (e.g. OXR50,

OXR230, OXR430), it is important that the sensor tip is extended

when the calibration value is taken.

(3) Wait for Steady State until the oxygen and the temperature

readings are stable by observing the Live Graph window (see

10.3.1).

(4) Calibrate by clicking on Set 0%. The current oxygen sensor

reading is taken for the 0% calibration and the date of the last

calibration is updated in the Calibration tab.

Note: A calibration is only possible if the oxygen sensor readings

are within the expected range for the connected sensor type. If the

warning "Calibration out of expected range" is shown, the

calibration is discarded. Check or replace the calibration standard

and perform a new calibration.

Page 47

47

10.3.6 Data Logging

Before starting data Logging, adjust the sensor Settings and

complete a sensor Calibration. To deploy the device after logging

has been started, please ensure that the FireStingGO2 Manager

software is closed before the device is disconnected.

Even if the FireStingGO2 is

operated with the FireStingGO2

Manager software, the logged

data are always saved within

the device memory of the

FireStingGO2. After finalization

of the logging, the log file can

be downloaded from the device

to the PC. This feature ensures

that the device can be

disconnected without problems

from the PC, even when logging

is active. A typical scenario is

that the device is configured and calibrated with the FireStingGO2

Manager, then logging is started and the device is disconnected

and deployed at the measurement location. Later when the

measurements are completed, the device is again connected to the

PC, and the logged data are downloaded and inspected. The

following steps must be done for data logging:

(1) Device Time. Data logging is

managed in the Logging tab of the

main window. First check the current

device time (i.e. the time of the internal

clock in the FireStingGO2) shown in this

tab. The time and date information for

the logged data are always related to

this device time (and not the PC time).

Page 48

48

If it is incorrect, click on Set

Device Time. This opens a

window for adjusting the device

time. Clicking on Synchronize

will set it to the PC Time.

Alternatively the time and date

can be adjusted manually. For

this, edit the time and date

below "Set Manually", and click

on Set.

(2) Logging Mode. Select the

Logging Mode as Manual or

Continuous. In the Manual logging mode the user has to trigger

the logging for each single data point. Go on with step (5). In the

Continuous logging mode the device will automatically log data

points in defined time intervals.

(3) Logging Interval (only for continuous mode). Select the

sampling Interval used during the logging as 1 s, 2 s, 5 s, 10 s, 30 s,

1 min, 2 min, 5 min, 10 min, 30 min, 1 h, 2 h or 4 h. It is advised to

choose this interval not unnecessarily too small, in order to

increase the battery run time, and to avoid too large log files.

(4) Logging Duration (only for continuous mode). The logging

Duration can be set to 1 min, 2 min, 5 min, 10 min, 30 min, 1 h, 2 h,

6 h, 12 h, 1 d, 2 d, 4 d, 1 week, 2 weeks, 1 month, 3 months, 6

months, 1 year or to Non-Stop.

(5) Comment. Enter optionally a Comment, which will be saved in

the header of the log file as soon the logging is started.

(6) Start Logging. Click now on Start which opens a separate

window Name Logging File. This window displays the log files

saved in the device memory, including Date and Time, the Log

Name, the Size (in kB), as well as the total number of Log Files and

Page 49

49

the used Device Memory (MB).

The software automatically

generates a new log file with the

default name „LOGxxx”

numbered sequentially upwards

(e.g. LOG001, LOG002, LOG003,

etc.). If wished, this default file

name can be changed by the user

in the field Please name your log

file (8 characters possible).

After clicking on Start Logging,

the Live Graph window opens

(see chapter 10.3.1) and the tabs Settings, Calibration and Options

in the main window are de-activated and cannot be changed

during the logging. The Log Name, the Start time of the logging

and the optional Comment are now displayed in the bottom line of

the Logging tab.

(6a) Manual Logging Mode. Logging of a single data point is now

done manually by clicking on the button Sample. A single data

point is then saved to the log file

and added to the graph in the

Live Graph window. The

FireStingGO2 performs in this

logging mode additional

intermediate measurements with

2 seconds interval which are

displayed only in the Live Display

(see 10.3.1) but NOT in the Live

Graph. These intermediate

measurements are NOT saved to

the log file.

Page 50

50

(6b) Continuous Logging Mode. Data logging is now done

automatically with the chosen logging Interval and logging

Duration. The logged data are displayed in the Live Graph

window.

(7) Finish Logging. Data

logging can be always stopped

by pressing the button Stop.

Additionally the logging is

automatically finished in the

continuous Logging Mode, as

soon the total logging Duration

has elapsed. After data logging

is finished, the respective log file

is automatically downloaded. As

soon the download is finished,

the logged data will be shown in

the Log Inspector (see chapter

10.4.1).

10.3.7 Options

The Options tab contains

information concerning the

FireStingGO2 Manager (soft-

ware version) and the

connected FireStingGO2 device

(Device ID, firmware version).

The Device ID is a unique

identification number specific

for each single device. The

header of each log file contains

this Device ID. This way each

log file can be unequivocally assigned to a specific FireStingGO2

device. The following subsections describe the other feature within

the Options tab.

Page 51

51

10.3.7.1 Temperature Sensor Offset

It is recommended to check the reading of the temperature sensor

periodically in a water bath of known temperature at steady state.

This is especially important if a concentration unit (like µmol/L or

mg/L) was selected for the oxygen readings (see chapter 6.2.3).

A manual Temp. Offset can be entered for a 1-point calibration of

the temperature sensor (default: 0).

Changing the temperature offset requires new calibration of the

connected oxygen sensor afterwards.

For a detailed description how to determine the temperature

offset of the sensor, please refer to chapter 6.4.2.

10.3.7.2 Flash Logo

The button Flash Logo causes a short flashing (ca. 1 sec) of the

PyroScience logo on the display of the FireStingGO2 meter. The

flashing of the logo can help to assign a specific FireStingGO2

Manager software window to the corresponding FireStingGO2

meter, if more than one device is connected.

10.3.7.3 Advanced Mode

The Advanced Mode comprises advanced features only for

advanced users with special instructions from PyroScience. It is

NOT recommended to change these advanced parameters

without the advice of PyroScience!

By activating the Advanced Mode, a new small tab is displayed in

the main window, which enables direct access to low level

parameters only relevant for advanced applications. Furthermore

the Advanced Mode enables to monitor the fundamental raw data

of the oxygen measurement, which comprises the phase shift dphi

(see chapter 13.3) and the signal intensity in the Live Graph and the

Log Inspector.

Page 52

52

10.4 Log Inspector and File Management

The actual data logging is always done on the internal device

memory of the FireStingGO2. The File tab in the main window

provides a list of all log files currently saved in the device memory.

First after a log file has been downloaded, it can be inspected

within a separate window called Log Inspector, which contains a

list of all downloaded log files currently saved on the PC hard disk.

For opening this window manually click on the Log Inspector

button in the main window.

10.4.1 File Management

For the management of the log

files saved in the device

memory, click on the tab File in

the main window. Here, the

Log Files in the Device

Memory of the connected

FireStingGO2 meter are shown

in a file list with details about

the Date and Time, the Log

Name, the Size (kB) and the

Download status (%) of the log

files. Clicking on the header of a

column will sort the list alphabetically for this respective column.

Repeated clicking on the same column header will reverse the

sorting order.

10.4.1.1 Downloading Log Files from the Device to the PC

To download one or several log files from the device to the PC, the

respective log files must be selected by clicking on them in the File

tab. Multiple log files can be selected by pressing additionally the

CTRL or SHIFT buttons on the PC keypad. With the button

Download, the selected log files are then downloaded to an

automatically generated folder PyroScience Log Files/

Page 53

53

FireStingGO2 Device ID xxx within the default user

document folder on the Windows PC. It is

recommended to keep this default folder unchanged.

During downloading, the progress of the download is

indicated and can be stopped by clicking on the red

stop button.

Note, that when an actual data logging is finished while the device

is operated with the FireStingGO2 Manager, then the download of

this actual log file is automatically triggered.

The downloaded data files can be now inspected in the Log

Inspector window (see chapter 10.4.2).

The button Download & Inspect has essentially the same

functionality as the Download button. The only difference is, that

only a single data file can be downloaded, and that the Log

Inspector automatically opens, as soon the download is finished.

10.4.1.2 Deleting Log Files from the Device Memory

In order to delete log files from the

device memory, select one or multiple

log files in the File tab list and click on

Delete from Device. Multiple log files

can be selected by pressing additionally

the CTRL or SHIFT buttons on the PC keypad. Please note that the

selected files are permanently deleted from the internal memory

of the device and cannot be retrieved anymore.

NOTE: Deleted log files are not saved in a recycle bin! Do not

forget to download the log files to the PC before deleting them

from the device memory.

10.4.2 Log Inspector Window

The Log Inspector window is opened manually by clicking on the

Log Inspector button in the main window. Here only the log files

Page 54

54

are listed, which have been downloaded from the device to the

Download Folder on the PC. The left section of the Log Inspector

window lists the downloaded log files in a table with relevant

details (Date and Time, the Log Name and the file Size (kB)).

Above this list, the file path of the default download folder on the

PC is indicated.

Note: The default location of the download folder contains the

Device ID (see chapter 10.3.7), which ensures that the downloaded

files can be unequivocally assigned to a specific FireStingGO2

device. It is advised not to change this download location,

especially if several devices are operated in parallel. Advanced

users might choose a custom download folder by clicking on

Change.

The button Explore opens the current download folder within the

Windows operation system. This feature is not needed for

standard procedures. But it allows for advanced users direct access

to the log files (tab separated text files).

Page 55

55

IMPORTANT if using the button Explore: It is strongly

recommended not to change the log file names or their content

within this download folder, in order to assure a smooth operation

with the FireStingGO2 Manager. It is recommended first to copy

log files from this folder to another location, before processing

them.

Alternatively to the Explore button, the Save as… button can be

used to choose a custom file name and location (e.g. on the

desktop). This will save a copy of the respective log file (tab

separated text file).

In order to delete log files within the download folder on the PC,

select one or multiple log files in the file list and click on Delete

from PC. Multiple log files can be selected by pressing additionally

the CTRL or SHIFT buttons on the PC keypad. Please note that the

selected files are permanently deleted from the PC and cannot be

retrieved anymore.

By selecting a log file in the Download Folder list, the logged data

for this specific log file are automatically shown in the graph visible

in the right section of the Log Inspector window. The header of

the graph includes the Log Name, the Start time of the logging

and the Comment, if entered before the start of the logging.

Please refer to chapter 10.3.1 for the diverse features available for

manipulating the graph appearance.

The actual log file content can be optionally displayed in a text

table by clicking on Data Table. Or it can be directly exported to

Microsoft Excel by clicking on Open in Excel (only possible if

Microsoft Excel is installed on the PC).

To copy a screenshot of the current graph to the Windows

clipboard, click on Copy Graph to Clipboard. Now this screenshot

can be pasted (CTRL+V) to many other Windows programs (e.g.

Microsoft Word or Excel).

Page 56

56

11 Warnings

The following warnings are potentially displayed in the status line

of the LCD screen of the FireStingGO2 (see chapter 3.5). If the

FireStingGO2 is operated with the FireStingGO2 Manager

software, the warnings are also shown in the Live Graph window

(chapter 10.3.1).

11.1 Oxygen Sensor Warnings

A reasonable oxygen sensor shows signal intensities well above 50

(typically 50-500)1. If the signal intensity drops below 50, the

warning Low Signal is shown, indicating that the sensor might get

degraded soon. But for contactless sensors it might indicate that

the distance between the optical fiber and the sensor spot is too

large. In order to increase the signal intensity, advanced users

might increase the intensity of the excitation light (red light flashes

coming out of the oxygen port) by changing the second letter of

the Sensor Code (details in 13.4).

Low Signal: Measurements are still possible with potentially

decreased performance.

If no oxygen sensor is connected or if the sensor is broken or

damaged, the warning No Signal will be shown in the status line /

Live Display.

No Signal: Please check whether the sensor cable is connected or

replace the sensor, the tip might be broken / bleached.

The Warning Too High indicates that there might be too much

ambient light on the sensor tip or on the sensor spot. Or there

1

Note: Exceptions are trace oxygen sensors. During the air calibration at 21% O2, these sensors show a

very low signal intensity (as low as 10). But the signal intensity will strongly increase when a trace oxygen

sensor is applied within its specified range of 0-10% O2.

Page 57

57

might be an incorrect Sensor Code entered in the device or

software.

Too High: Avoid direct sun light exposure or strong direct