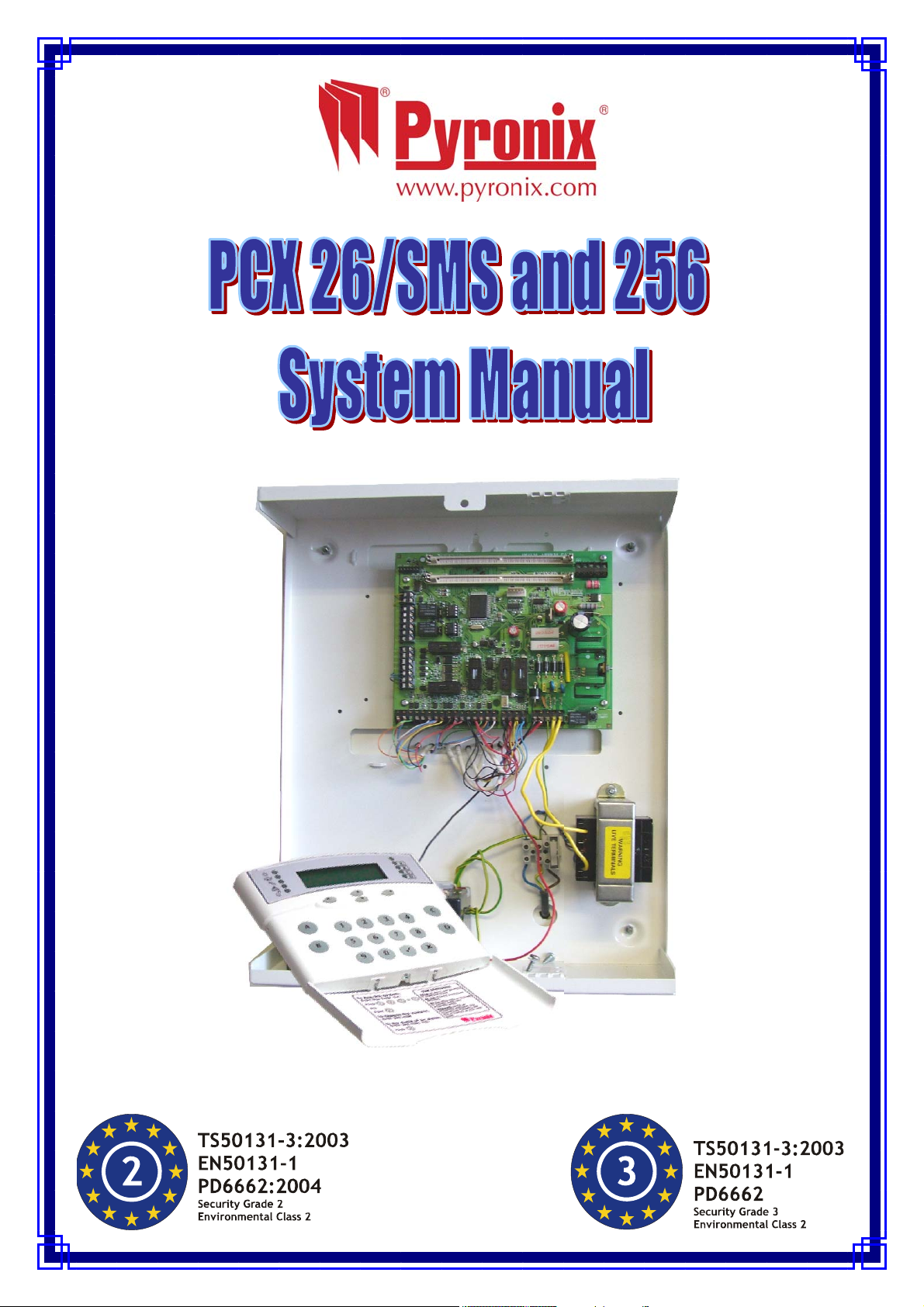

Page 1

RINS871-3

Customer Support line:

0870 122 3360 (national rate)

Page 2

Page 3

Pyronix Installers Club (PI Club)

Installer Support

The PI Club has been developed with the focus on what you the installer would like to see from one of the

world’s leading manufactures of security equipment.

The philosophy behind the association is that you will receive tangible benefits, which are applicable to both

the work and home environment.

Dedicated Website

You will have access to a dedicated PI Club section of the Pyronix website which is packed full of features

that will keep you updated on Pyronix and industry news.

Product Training

Product training days are run monthly at Pyronix Head Office, and on-site training can also be provided to

meet your individual needs.

To Join the PI Club please register at www.pyronix.com

marketing department at marketing@pyronix.com

, or for further information please contact our

.

As a new member of the PI Club a technical help free phone number will be issued to you.

Page 4

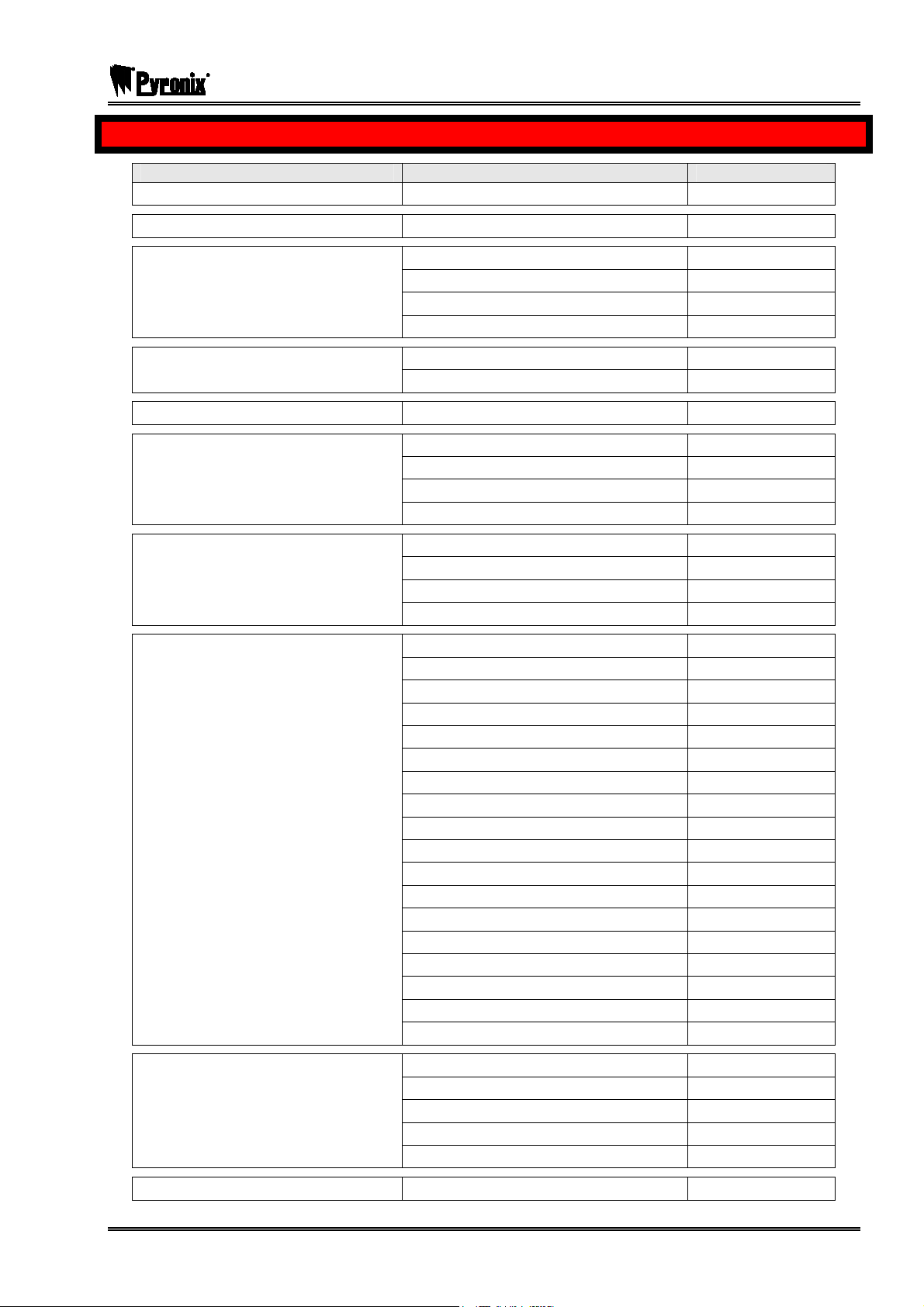

CONTENTS

CHAPTER 1: ENGINEER MENU STRUCTURE ................................................................ 9

CHAPTER 2: QUICK FIND GUIDE .................................................................................. 12

2.1 COMMUNICATION ................................................................................................................12

2.2 ENGINEER TEST FUNCTIONS .............................................................................................12

2.3 ADDRESSING / CONNECTING DEVICES ............................................................................12

2.4 PROGRAMMING OPTIONS ..................................................................................................12

2.5 TABLES .................................................................................................................................12

CHAPTER 3: THE ENGINEERS MENU........................................................................... 13

3.1 ENTERING THE ENGINEERS MENU ............................................................................................13

3.2 EXITING THE ENGINEER MENU..................................................................................................13

CHAPTER 4: SYSTEM OVERVIEW................................................................................. 14

4.1 PCX 26/SMS INPUT INFORMATION ...........................................................................................14

4.2 PCX 256 INPUT INFORMATION.................................................................................................. 14

4.3 SYSTEM OVERVIEW..................................................................................................................15

4.3.1 Inputs ...............................................................................................................................15

4.3.2 Programmable Outputs (PGM) ........................................................................................15

4.3.3 Keypads (PCX-LCD/UK) ..................................................................................................16

4.3.4 Tag Readers (PCX-PROX/INT & PCX-PROX/EXT) ........................................................16

4.3.5 Arm Points........................................................................................................................16

4.3.6 Partitions ..........................................................................................................................16

4.3.7 User Codes ......................................................................................................................16

4.3.8 Central Monitoring Options ..............................................................................................16

4.3.9 Other ................................................................................................................................17

4.4 DEFAULTS ............................................................................................................................18

CHAPTER 5: TECHNICAL SPECIFICATION .................................................................. 22

5.1 INTRODUCTION.........................................................................................................................22

5.2 WARRANTY..............................................................................................................................22

5.3 PCX SYSTEM SPECIFICATIONS.................................................................................................23

5.4 DEVICES TECHNICAL SPECIFICATION ........................................................................................24

5.4.1 Lightning Protection .........................................................................................................24

5.4.2 Code Guessing ................................................................................................................24

CHAPTER 6: SAFETY ..................................................................................................... 25

CHAPTER 7: INSTALLATION ......................................................................................... 26

7.1 ELECTROMAGNETIC COMPATIBILITY (EMC) ..............................................................................26

7.2 MOUNTING PROCEDURE FOR THE PCX SYSTEM ........................................................................26

7.3 RESISTORS ..............................................................................................................................26

7.4 THE PCX PANEL LAYOUT ........................................................................................................27

7.5 BATTERY INSTALLATION PROCEDURE.......................................................................................27

7.6 MOUNTING PROCEDURE FOR DEVICES......................................................................................27

7.7 TAMPER SWITCH......................................................................................................................28

7.8 MAINS CONNECTION ................................................................................................................28

7.9 SYSTEM CONNECTIONS ............................................................................................................28

7.10 DIGI MODEM CARD.................................................................................................................28

7.11 EXPANDER CARD ...................................................................................................................28

7.12 ACCESS CONTROL AND GUARD TOUR EQUIPMENT .................................................................28

7.13 CABLING INFORMATION .......................................................................................................... 29

7.13.1 Planning the Cable Routes ............................................................................................29

7.13.2 Screened Cable .............................................................................................................29

7.13.3 Wiring Specifications......................................................................................................29

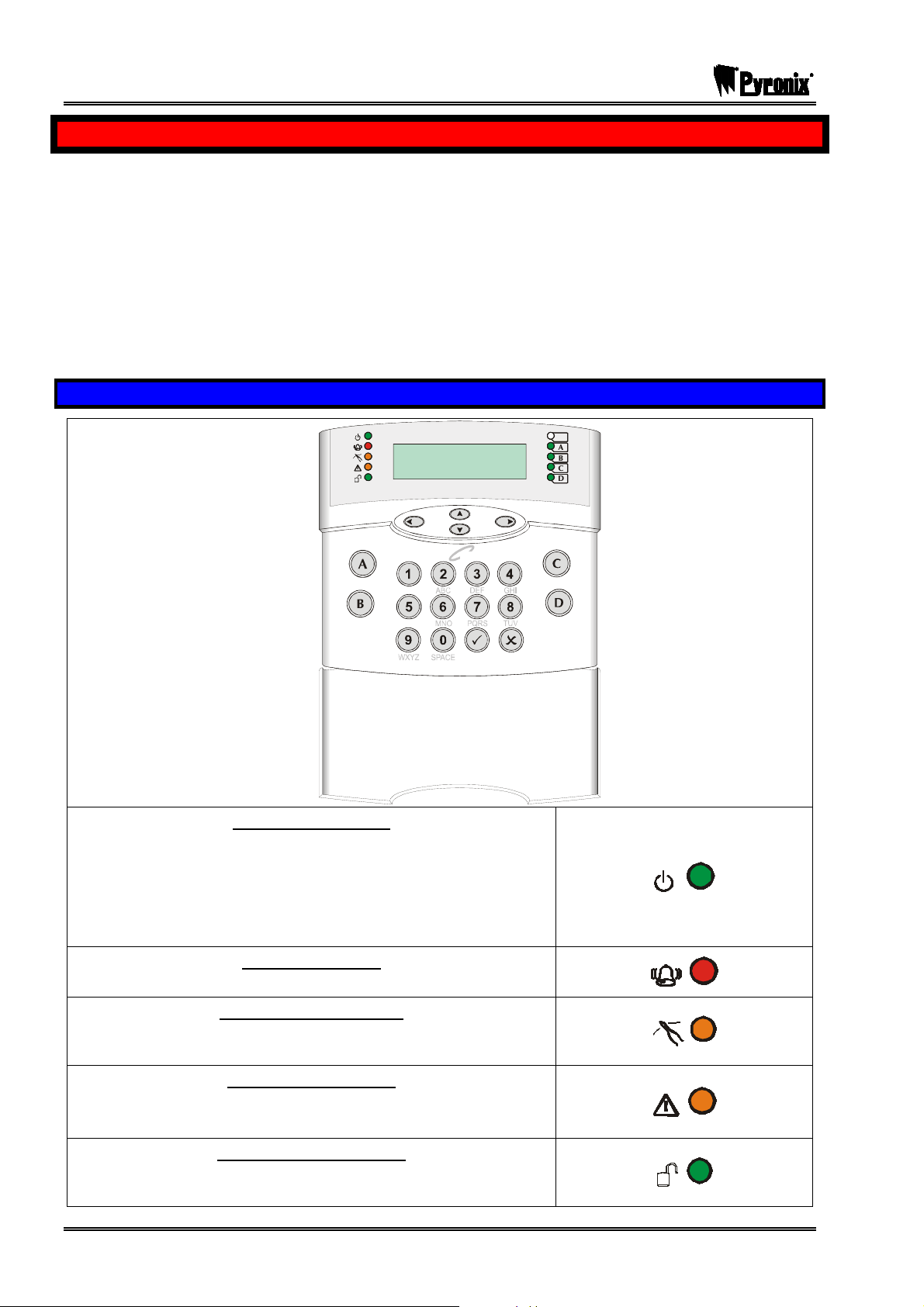

CHAPTER 8: KEYPAD AND READER INDICATIONS.................................................... 30

8.1 THE PCX LCD KEYPAD (PCX-LCD/UK) ..................................................................................30

8.2 THE INTERNAL READER (PCX-PROX/INT)...............................................................................32

Page 5

8.3 THE EXTERNAL READER (PCX-PROX/EXT) ............................................................................ 33

CHAPTER 9: THE PCX DEVICES.................................................................................... 34

CHAPTER 10: NOTES ON THE PCX SYSTEM ............................................................... 36

10.1 PARTITION / LEVEL ARM SYSTEM ........................................................................................... 36

10.1.1 PCX 26/SMS Level Arming............................................................................................ 36

10.1.2 PCX 256 Partition / Level Arming .................................................................................. 36

10.2 ARMING / DISARMING THE SYSTEM ........................................................................................ 36

10.2.1 Flexi Arm........................................................................................................................ 36

10.2.2 Intelligent Arming ...........................................................................................................36

10.2.3 Force Arming The System ............................................................................................. 36

10.3 EMERGENCY ALARMS............................................................................................................ 36

10.4 SHUNT INPUTS ....................................................................................................................... 36

10.5 THE MSX CARD AND THE DIGI MODEM CARD......................................................................... 37

10.6 GRADE 3 MASK DETECTORS .................................................................................................. 37

10.7 REMOTE SIGNALLING............................................................................................................. 37

10.7.1 ARC Signalling Using The Digi-Modem Card ................................................................ 37

10.7.2 Using A Communication Loom ...................................................................................... 37

10.7.3 Partition Signalling ......................................................................................................... 37

10.7.4 Functionality................................................................................................................... 37

10.7.5 Sequential Confirmation Signalling................................................................................ 38

10.8 TERMINOLOGY ....................................................................................................................... 39

CHAPTER 11: THE MASTER MANAGER MENU............................................................ 40

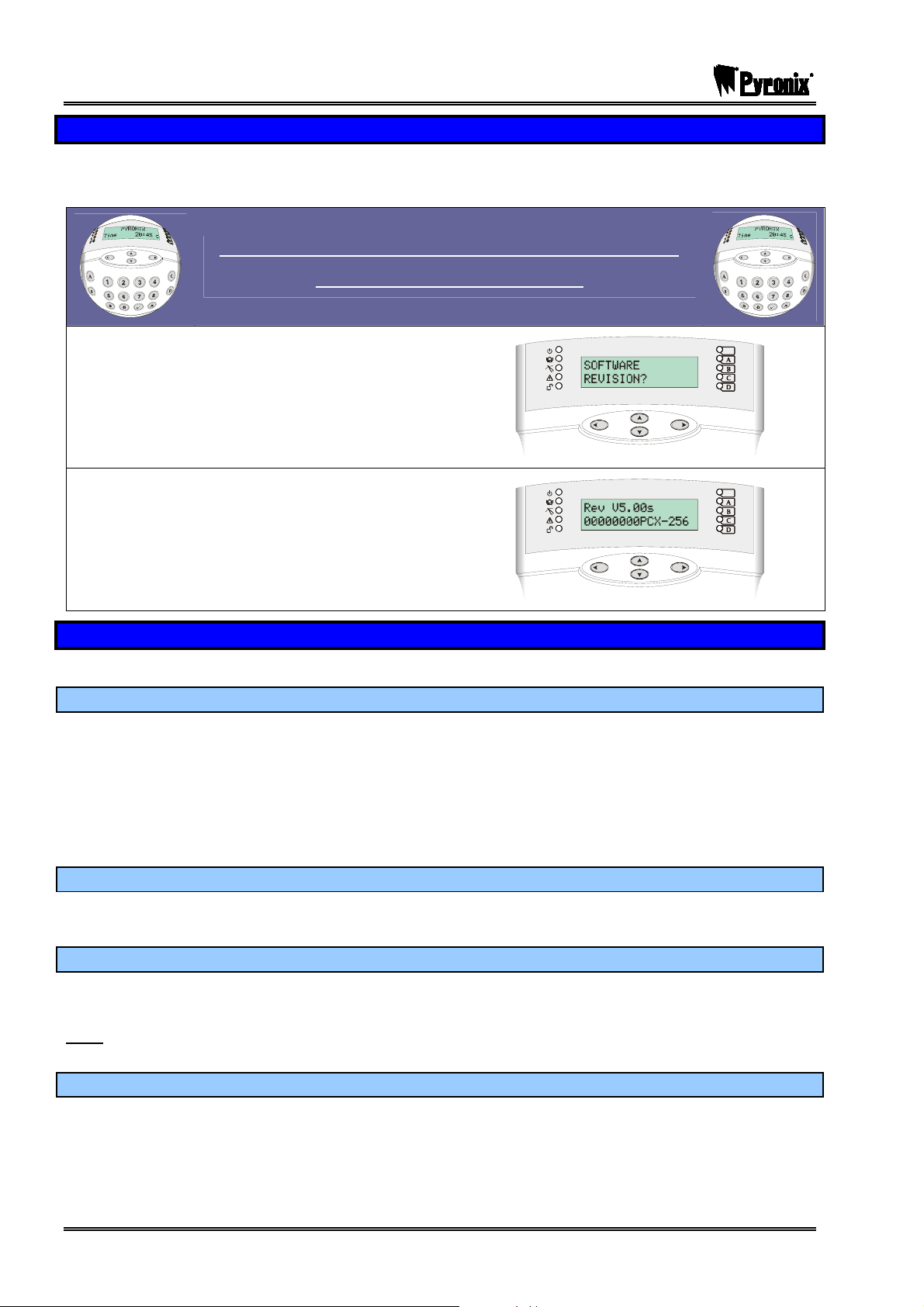

CHAPTER 12: POWERING UP & KEYPAD OPERATIONS ............................................ 41

12.1 INITIAL POWER UP ................................................................................................................. 41

12.2 NOTES ON ADDRESSING KEYPADS ......................................................................................... 41

12.3 TESTING THE KEYPAD ........................................................................................................... 41

12.4 TEXT PROGRAMMING ............................................................................................................. 42

12.5 ARM / DISARM SYSTEM .......................................................................................................... 42

12.6 FORCED ARM ON INPUTS ....................................................................................................... 43

CHAPTER 13: THE ENGINEER FUNCTIONS .................................................................44

13.1 NVM RESET ..........................................................................................................................44

13.2 INHIBIT FIRE/HU ....................................................................................................................45

13.3 SOFTWARE REVISION............................................................................................................. 46

13.4 CHOOSE MODE...................................................................................................................... 46

13.4.1 The End of Line Range.................................................................................................. 46

13.4.2 SEOL or DEOL .............................................................................................................. 46

13.4.3 Input Response Time..................................................................................................... 46

13.4.4 Input XDF....................................................................................................................... 46

13.5 INSTALL RIX.......................................................................................................................... 48

13.6 CHANGE INPUTS .................................................................................................................... 49

13.6.1 Input Types .................................................................................................................... 49

13.6.2 Entry Shock Input Type (21) .......................................................................................... 50

13.6.3 Creating a Common Partition ........................................................................................ 51

13.6.4 Input Attributes............................................................................................................... 51

13.6.5 Shunt Inputs................................................................................................................... 55

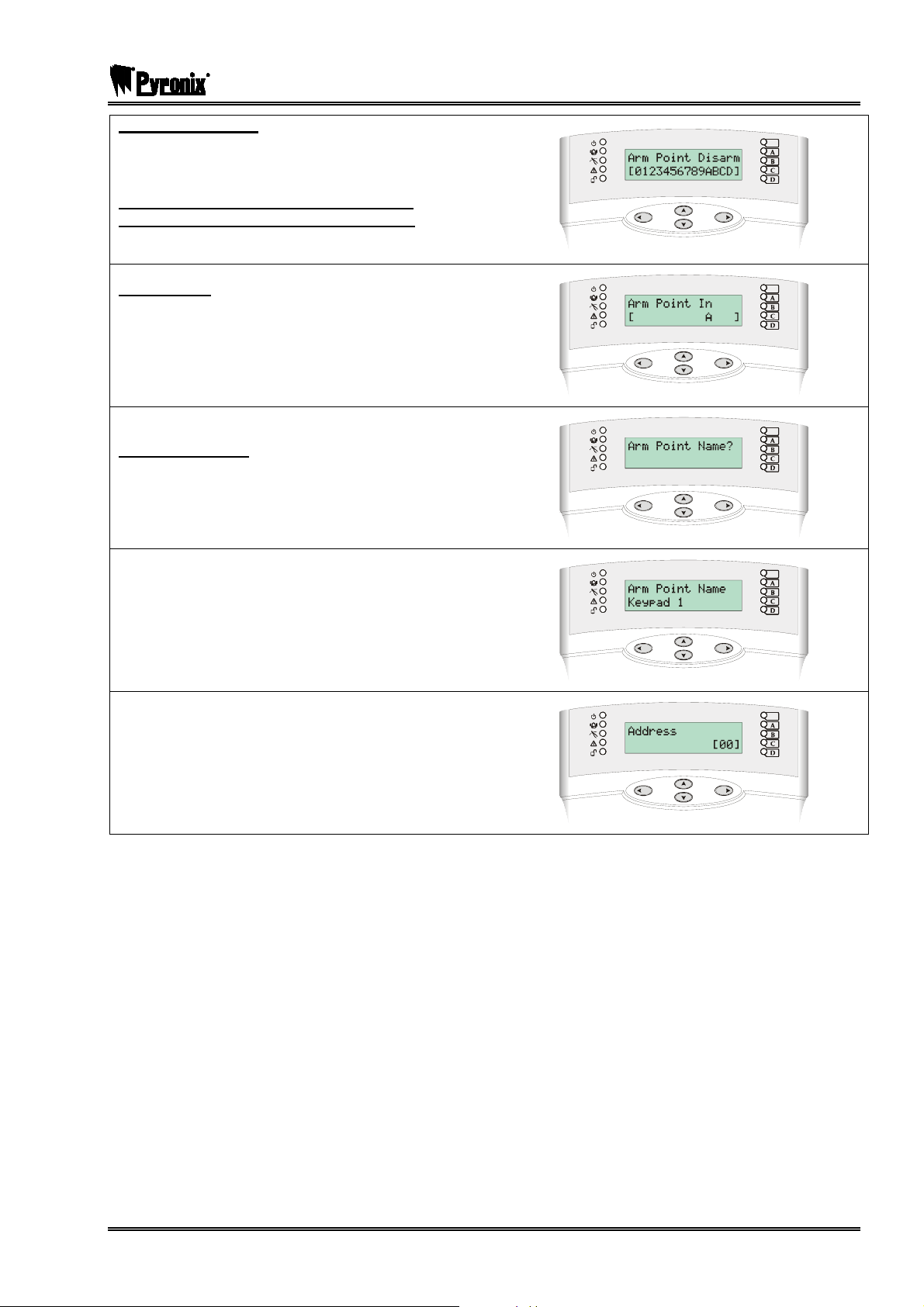

13.7 ASSIGN KEYPADS/READERS .................................................................................................. 59

13.7.1 Reader Is: ...................................................................................................................... 59

13.7.2 Arm Point Arms.............................................................................................................. 59

13.7.3 Arm Point Disarms......................................................................................................... 59

13.7.4 Arm Point In ................................................................................................................... 59

13.7.5 Access Control............................................................................................................... 62

13.8 SYSTEM DISPLAYS................................................................................................................. 64

13.8.1 Partition Texts................................................................................................................ 64

13.8.2 Sign On Message ..........................................................................................................64

13.8.3 Site Name ......................................................................................................................64

13.8.4 Display When Arm .........................................................................................................64

13.9 CHANGE TIMERS.................................................................................................................... 65

Page 6

13.10 SET TIME AND DATE.............................................................................................................66

13.11 EXIT MODES ........................................................................................................................67

13.11.1 Timed ...........................................................................................................................67

13.11.2 Final Door.....................................................................................................................67

13.11.3 Timed/Final ..................................................................................................................67

13.11.4 PTS (Push To Set).......................................................................................................67

13.12 CHANGE CODES (DURESS/GUARD ONLY).............................................................................68

13.12.1 Code Types and Numbers. ..........................................................................................68

13.12.2 User Types...................................................................................................................68

13.12.3 User Arm Options.........................................................................................................68

13.12.4 Flexi Arm......................................................................................................................69

13.13 VOLUME CONTROL...............................................................................................................72

13.13.1 Code Stops Sound.......................................................................................................72

13.13.2 E / E Keypads Only......................................................................................................72

13.13.3 Alert Kps Only ..............................................................................................................72

13.14 ALARM RESPONSE...............................................................................................................73

13.14.1 Silent 1st Alarm.............................................................................................................73

13.14.2 Disable Confirm On Entry ............................................................................................73

13.14.3 Inputs to Confirm After Entry........................................................................................73

13.14.4 Alarm Starts / Stops (Alarm Responses) .....................................................................73

13.15 CHANGE OUTPUTS............................................................................................................... 75

13.15.1 PGM Output Types ......................................................................................................75

13.15.2 STU / ATE Pin Outputs (Defaults)................................................................................78

13.15.3 Digi Channel Outputs...................................................................................................78

13.15.4 PCX-PROX/EXT PGM Output .....................................................................................78

13.15.5 The ‘Follow Input’ PGM................................................................................................81

13.16 INTELLIGENT ARM ................................................................................................................82

13.16.1 Intelligent Arm for User Level Arming ..........................................................................82

13.16.2 Intelligent Arm for Partition systems.............................................................................82

13.17 SITE OPTIONS ......................................................................................................................83

13.17.1 Site Option Types.........................................................................................................83

13.18 ENGINEER RESET OPTIONS ..................................................................................................85

13.19 REVIEW LOGS ......................................................................................................................86

13.19.1 Log Entries...................................................................................................................86

13.19.2 Code Identification .......................................................................................................86

13.19.3 Fault Codes (Device Fail).............................................................................................86

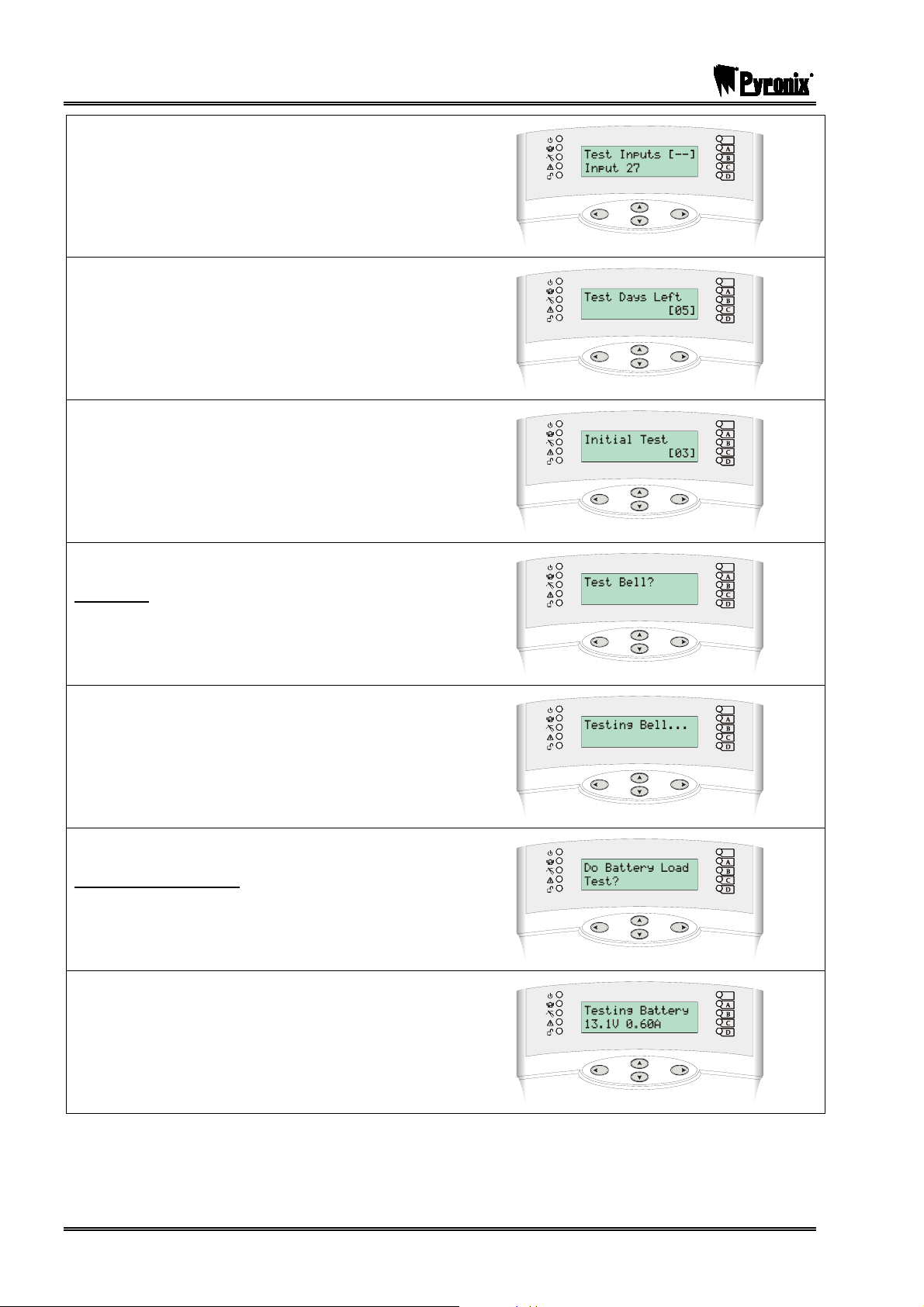

13.20 ENGINEER TESTS .................................................................................................................87

13.20.1 Sounds To Play............................................................................................................87

13.20.2 Walk Test .....................................................................................................................87

13.20.3 Test Control..................................................................................................................88

13.20.4 Test Bell .......................................................................................................................88

13.20.5 Do Battery Load Test ...................................................................................................88

13.20.6 Test PGMs ...................................................................................................................88

13.20.7 Test PHC Communications..........................................................................................88

13.21 DIAGNOSTICS.......................................................................................................................92

13.22 SET UP DOWNLOADING........................................................................................................94

13.22.1 Download By................................................................................................................94

13.22.2 Security Mode ..............................................................................................................94

13.22.3 Telephone Line ............................................................................................................94

13.22.4 ARM / Modem Telephone Number ..............................................................................94

13.23 PROGRAMME DIGI / SMS? ..................................................................................................97

13.23.1 Programming Fast Format ...........................................................................................97

13.23.2 Programming Contact ID............................................................................................101

13.23.3 Programming SMS Texts...........................................................................................105

13.24 PABX TELEPHONE SYSTEMS .............................................................................................106

13.25 DIAL OUT MENU.................................................................................................................109

13.25.1 Dial Out Menu on the PCX 26/SMS ........................................................................... 109

CHAPTER 14: THE DIGI MODEM CARD ...................................................................... 110

14.1 FITTING THE DIGI-MODEM CARD TO THE END STATION..........................................................110

Page 7

14.2 PSTN WIRING ..................................................................................................................... 111

14.3 PROGRAMMING THE UNIT ..................................................................................................... 111

14.4 INITIALISATION..................................................................................................................... 111

CHAPTER 15: SYSTEM EXPANSION AND ENHANCEMENT...................................... 112

15.1 INSERTING THE MSX CARD ..................................................................................................112

15.2 ADDITIONAL FACILITIES WITH MSX CARDS........................................................................... 112

15.2.1 RS-232 Connection ..................................................................................................... 112

15.2.2 Outputs (PGMs)........................................................................................................... 112

15.2.3 Output (PGM) Types.................................................................................................... 112

CHAPTER 16: THE RADIO EXPANDER........................................................................ 113

16.1 THE RADIO EXPANDER......................................................................................................... 113

16.2 THE RADIO PIR DETECTOR .................................................................................................. 113

16.3 THE RADIO DOOR CONTACT ................................................................................................ 113

16.4 ADDRESSING THE RADIO EXPANDER .................................................................................... 114

16.5 ASSIGNING RADIO DETECTORS ............................................................................................ 114

16.6 DELETING RADIO DETECTORS.............................................................................................. 114

16.7 DISPLAY THE SIGNAL STRENGTH.......................................................................................... 114

16.8 ASSIGNING REPEATERS TO THE RADIO EXPANDER ............................................................... 115

16.9 SUPERVISION TIME .............................................................................................................. 115

16.10 PROBLEM SOLVING............................................................................................................ 115

16.11 TECHNICAL SPECIFICATION................................................................................................ 115

CHAPTER 17: WIRING DIAGRAMS .............................................................................. 116

17.1 PCX 26/SMS AND PCX 256 PRINTED CIRCUIT BOARD LAYOUT ........................................... 116

17.1.1 Relay Terminals:..........................................................................................................116

17.2 IMPORTANT NOTES ON CONNECTIONS ....................................................................... 117

17.2.1 Terminals .....................................................................................................................117

17.2.2 470 ohm resistor .......................................................................................................... 117

17.2.3 Notes on wiring extra devices...................................................................................... 117

17.2.4 Resistor Values............................................................................................................ 117

17.3 POWER SUPPLY WIRING ...................................................................................................... 118

17.4 TELEPHONE LINE WIRING..................................................................................................... 118

17.5 STU/ATE AND RS232 CONNECTIONS .................................................................................. 119

17.5.1 RS232 Connector ........................................................................................................ 119

17.5.2 Connecting the Communication Loom......................................................................... 119

17.5.3 STU/ATE Output Pins.................................................................................................. 120

17.5.4 STU/ATE Plug-On Loom Diagram............................................................................... 120

17.5.5 STU/ATE 14 Pin Connector Diagram .......................................................................... 120

17.6 KEYPADS WIRING (PCX-LCD/UK)....................................................................................... 121

17.6.1 Connecting the PCX-LCD/UK...................................................................................... 121

17.6.2 Addressing the PCX-LCD/UK ...................................................................................... 121

17.7 TAG READER WIRING (PCX-PROX/INT).............................................................................. 122

17.7.1 Connecting the PCX-PROX/INT .................................................................................. 122

17.7.2 Addressing the PCX-PROX/INT .................................................................................. 122

17.8 EXTERNAL TAG READER (PCX-PROX/EXT) ........................................................................ 123

17.8.1 Connecting the PCX-PROX/EXT................................................................................. 123

17.8.2 Programming the RED LED to follow a PGM ..............................................................123

17.8.3 Addressing a PCX-PROX/EXT .................................................................................... 124

17.9 REMOTE INPUT EXPANDER (PCX-RIX8) ............................................................................... 125

17.9.1 Connecting the PCX-RIX8 ........................................................................................... 125

17.9.2 PCX-RIX8 Terminals ...................................................................................................125

17.9.3 Addressing the PCX-RIX8 ........................................................................................... 126

17.10 REMOTE INPUT EXPANDER (PCX-RIX8+/PSU)................................................................... 127

17.10.1 Connecting the PCX-RIX8+/PSU............................................................................... 127

17.10.2 Addressing a PCX-RIX8+/PSU.................................................................................. 128

17.11 CONNECTING THE RADIO EXPANDER .................................................................................. 129

17.11.1 Addressing the Radio Expander ................................................................................ 129

17.12 REMOTE OUTPUT EXPANDER (PCX-ROX16R & PCX-ROX16R/PSU) ............................... 130

17.12.1 Connecting a PCX-ROX16R...................................................................................... 130

Page 8

17.12.2 Connecting a PCX-ROX16R/PSU..............................................................................131

17.12.3 Terminals of the PCX-ROX16R .................................................................................132

17.12.4 Addressing the PCX-ROX16R ...................................................................................132

17.13 INPUT CONFIGURATION ......................................................................................................133

17.13.1 Single End of Line (SEOL) Wiring..............................................................................133

17.13.2 Double End of Line (DEOL) Wiring ............................................................................134

17.13.3 Connecting Series Door Contacts to One Input .........................................................135

17.13.4 Grade 3 Configuration Using An Anti Mask Detector To A Single Input ....................136

17.13.5 Configuration of Shunt Inputs.....................................................................................137

17.14 ACCESS CONTROL (PCX-ACCESS) ..................................................................................138

17.14.1 Connecting the PCX-ACCESS System......................................................................140

17.14.2 Addressing the PCX-ACCESS................................................................................... 140

17.15 PROGRAMMABLE OUTPUTS WIRING....................................................................................141

17.15.1 Belle Connection........................................................................................................141

17.15.2 Decibell Connection ...................................................................................................141

17.15.3 Twin Alert Internal Sounder Connection ....................................................................142

17.15.4 Internal Speaker Connection......................................................................................142

APPENDIX A: FAULTS ............................................................................................... 143

Device Fail.................................................................................................................................................. 143

Fault Indications ......................................................................................................................................... 143

APPENDIX B: INPUT TYPES...................................................................................... 146

Input Types................................................................................................................................................. 148

Input Attributes ........................................................................................................................................... 149

APPENDIX C: OUTPUT TYPES.................................................................................. 150

APPENDIX D: USER / ENGINEER OPERATIONS ..................................................... 153

Anti Code / Engineer Reset........................................................................................................................ 153

Chime Function .......................................................................................................................................... 154

Omitting Inputs ........................................................................................................................................... 154

Hold up Alarm............................................................................................................................................. 155

APPENDIX E: MASTER MANAGER MENU ............................................................... 156

Set Date & Time ......................................................................................................................................... 156

Omit Inputs ................................................................................................................................................. 156

Change Codes ........................................................................................................................................... 156

Deleting a User Code................................................................................................................................. 157

Review Logs............................................................................................................................................... 158

Phonebook ................................................................................................................................................. 159

Walk Test ................................................................................................................................................... 159

Bell Test ..................................................................................................................................................... 159

Test PHC Communications........................................................................................................................ 160

Dial Out Menu ............................................................................................................................................ 160

Allow Engineer Menu ................................................................................................................................. 161

Block Remote Arm ..................................................................................................................................... 161

Block UDL .................................................................................................................................................. 161

Enter Anti-Code.......................................................................................................................................... 161

Exit Manager Mode .................................................................................................................................... 161

APPENDIX F: CONTACT DETAILS............................................................................ 162

APPENDIX G: INDEX .................................................................................................. 163

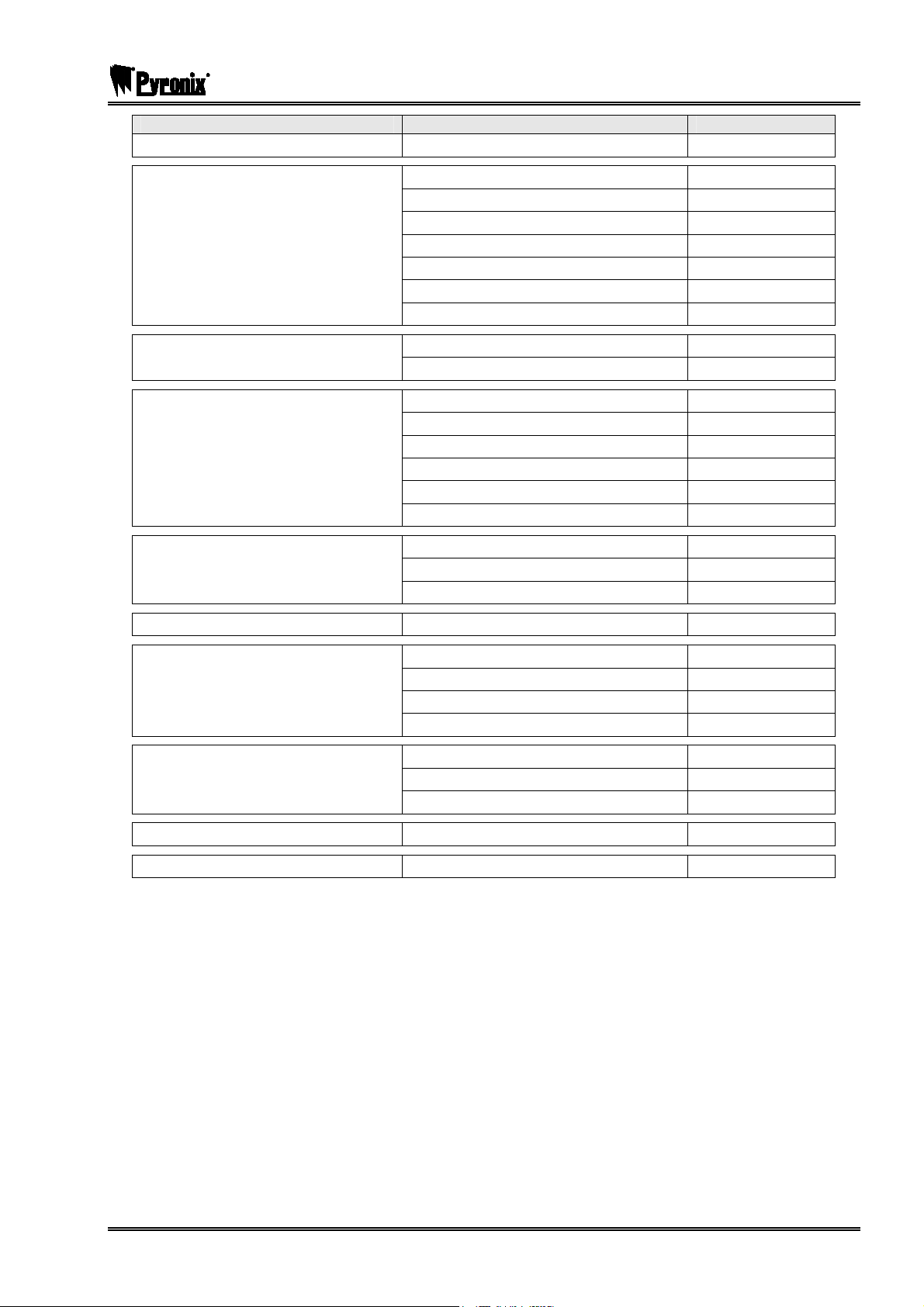

Page 9

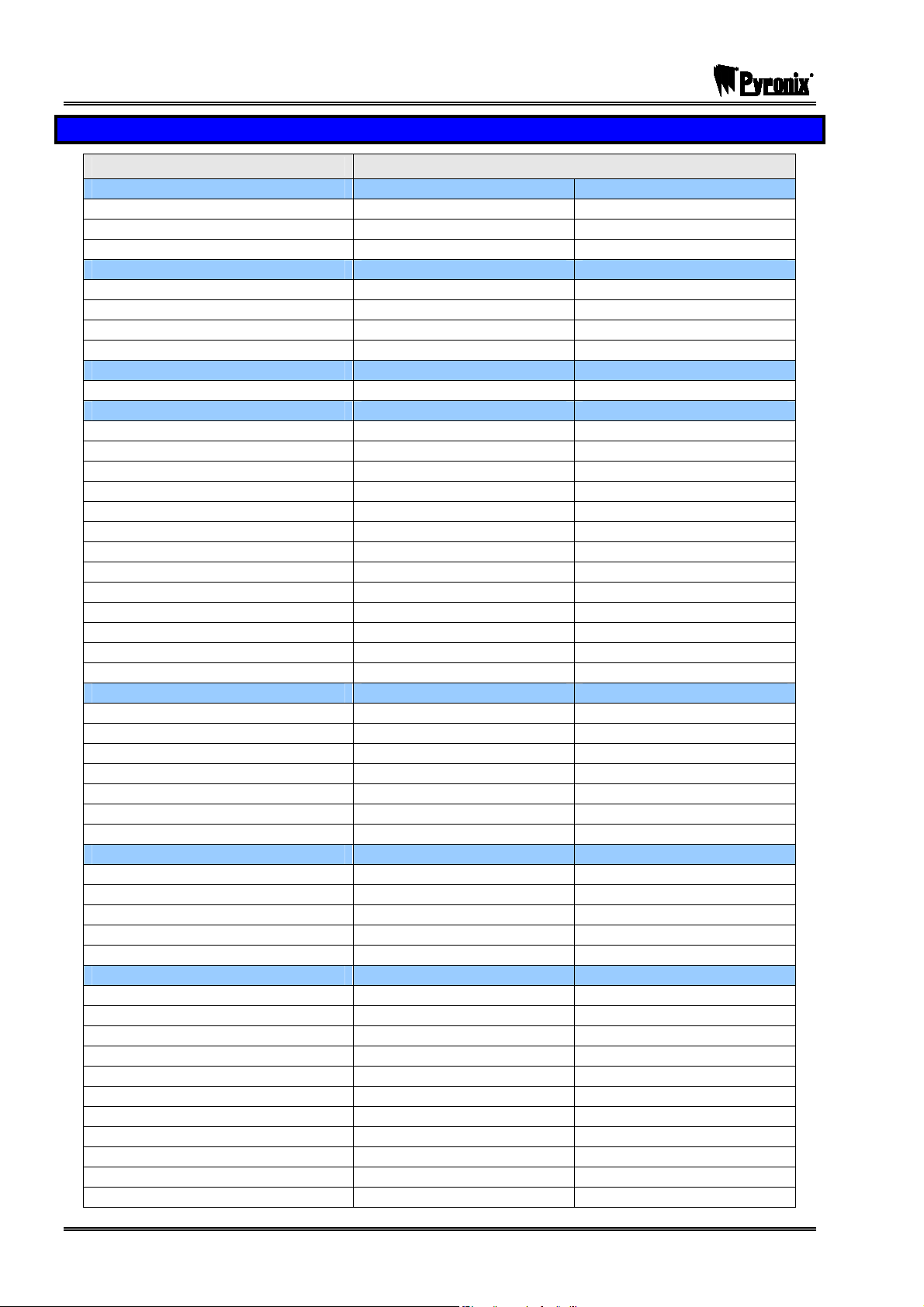

PCX SMS AND PCX 256 SYSTEM MANUAL

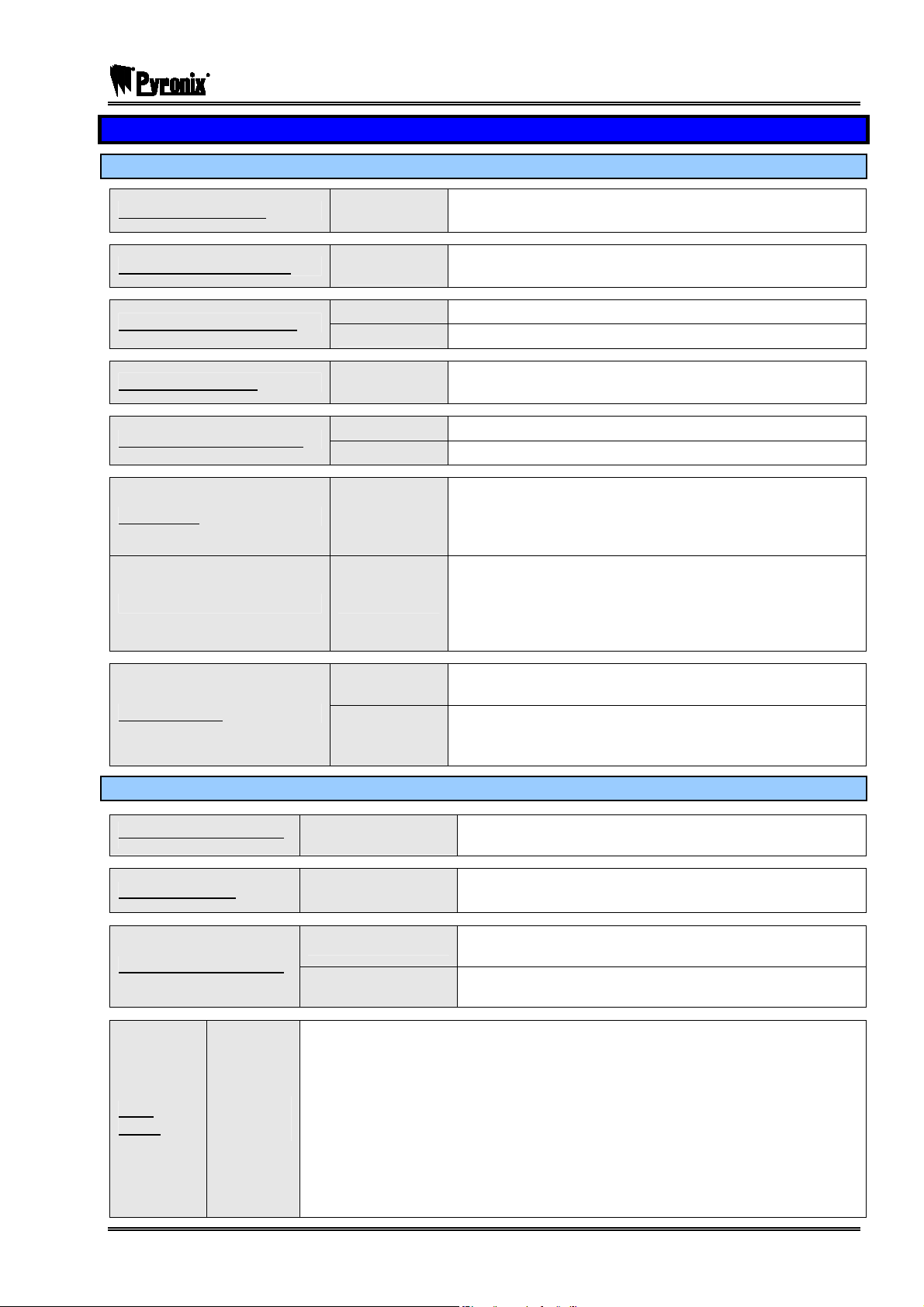

CHAPTER 1: ENGINEER MENU STRUCTURE

MENU

INHIBIT FIRE/HU?

SOFTWARE REVISION?

CHOOSE MODE?

INSTALL RIX?

CHANGE INPUTS?

ASSIGN KEYPADS/READERS?

SYSTEM DISPLAYS?

CHANGE TIMERS?

SET DATE & TIME?

EXIT MODES?

Sub-Menu Page:

Inhibit Fire/HU Page: 45

Page: 46

EOL Range* Page: 47

EOL Mode Page: 47

Input Response Page: 47

Input XDF Page: 47

RIX Address Page: 48

RIX Installed Page: 48

Input Page: 52

Address Page: 60

Type Page: 60

Default Level / Arming Points Page: 60

Arm Point Name Page: 60

Partition Text Page: 64

Sign On Message Page: 64

Site Name Page: 64

Display When Armed* Page: 64

Partition Entry Time Page: 66

Partition Exit Time Page: 66

Partition Bell Time Page: 66

Confirm Time Page: 66

Bell Delay Page: 66

Strobe Time Page: 66

Re-Arm No. Page: 66

AC Signal Delay Page: 66

Speaker Page: 66

Final Exit Delay Page: 66

Double Knock Page: 66

Pre-Alarm Page: 66

Line Fault Page: 66

Arm Fail Page: 66

Guard Code Alarm Page: 66

Fire Bell Time Page: 66

Input NAT Days* Page: 66

Input NAT Hours* Page: 66

Year (00-99) Page: 66

Month (1-12) Page: 66

Day (1-31) Page: 67

Hours (0-23) Page: 67

Minutes (0-59) Page: 67

Partition Exit Mode Page: 67

RINS871-3 Page: 9

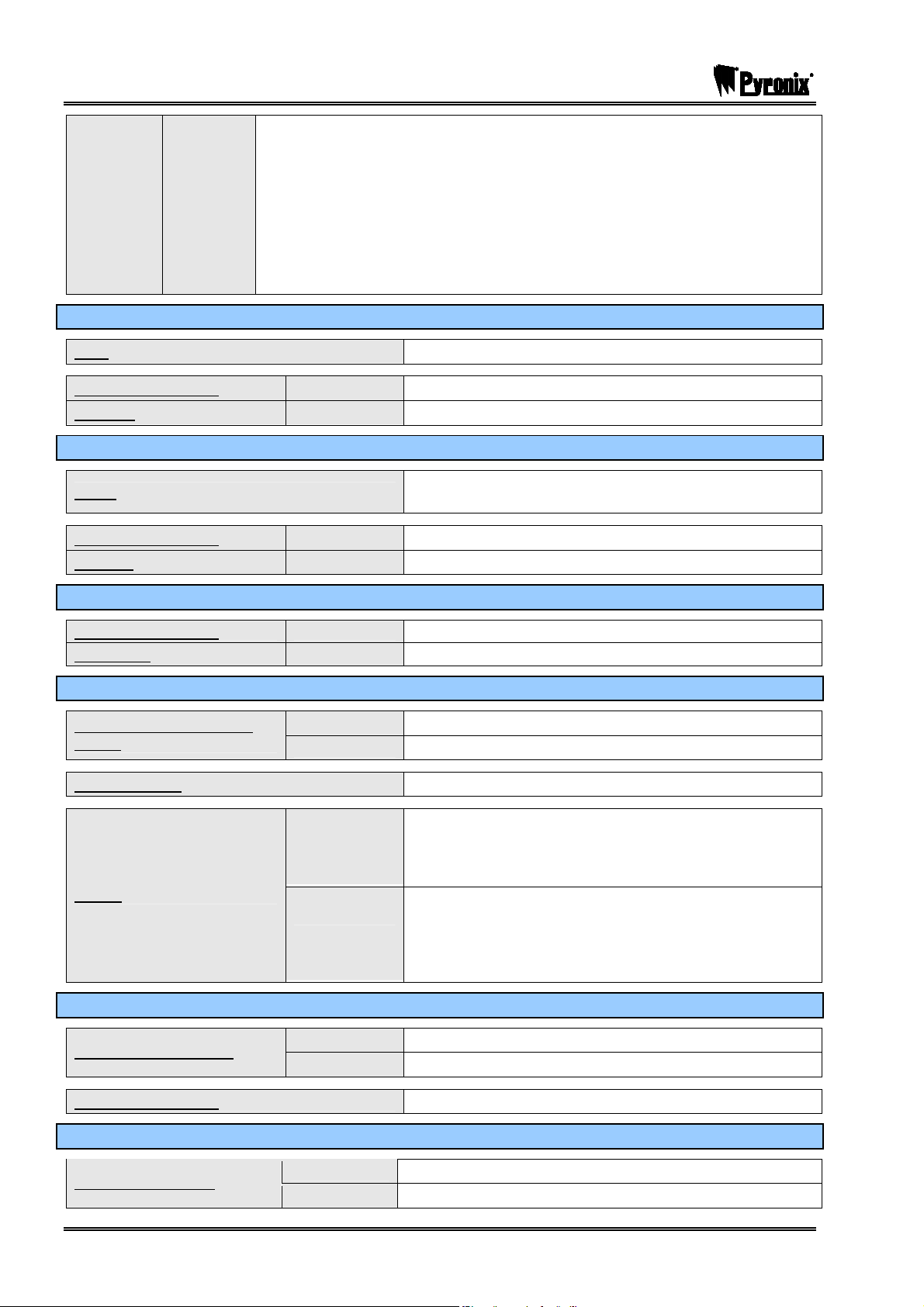

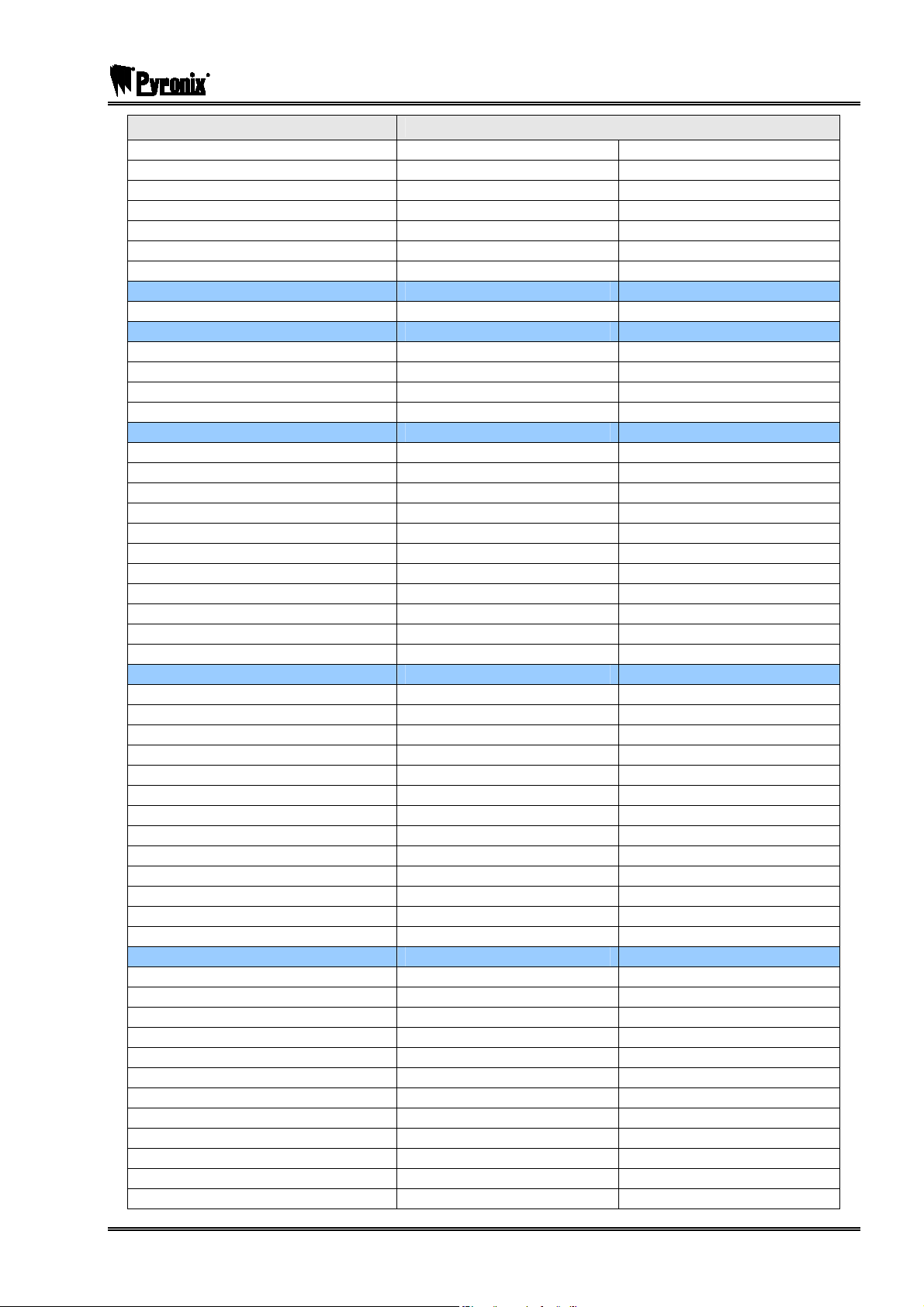

Page 10

PCX SMS AND PCX 256 SYSTEM MANUAL

MENU

CHANGE CODES?

VOLUME CONTROL?

ALARM RESPONSE?

CHANGE OUTPUTS?

INTELLIGENT ARM?

SITE OPTIONS?

Sub-Menu Page:

5 Digit Pins?* Page: 69

Change Duress Codes? Page: 69

Change Master Manager Code? Page: 70

Change Engineer Code? Page: 71

Partition Entry Page: 72

Partition Exit Page: 72

Alarm Page: 72

Code Stops Sound Page: 72

E/E Keypads Only Page: 73

Alert KPs Only Page: 73

Silent 1

st

Alarm Page: 74

Disable Confirm Page: 74

Inputs to Confrm Page: 74

Part’n Starts Page: 74

Part’n Stops Page: 75

Fire Starts At Page: 75

Fire Stops At Page: 75

Gas Starts At Page: 75

Gas Stops At Page: 75

HU Starts At Page: 75

HU Stops At Page: 75

Disarm Starts Page: 75

Disarm Stops Page: 75

Endstation PGMs? Page: 79

RIX PGMs? Page: 79

ROX Module PGMs? Page: 80

Keypad PGMs? Page: 80

Reader PGMs? Page: 80

Intelligent Page: 83

Arm With Fault Page: 84

Arm With Tamper+ Page: 84

Arm With ATS Fault Page: 84

Arm Part TFault* Page: 84

Arm Fail = Alarm Page: 84

Do Bat Load Test Page: 84

Part Misoperate* Page: 84

Strobe Confirm Page: 84

Re-Arm Omits Page: 84

Confirmed When Page: 84

Set Force Arm* Page: 84

Restrict PIN Use Page: 84

Invert ATE O/Ps Page: 84

Common Exit Mode* Page: 84

Flexi Unset Page: 84

2 Key HU Page: 84

Page: 10 RINS871-3

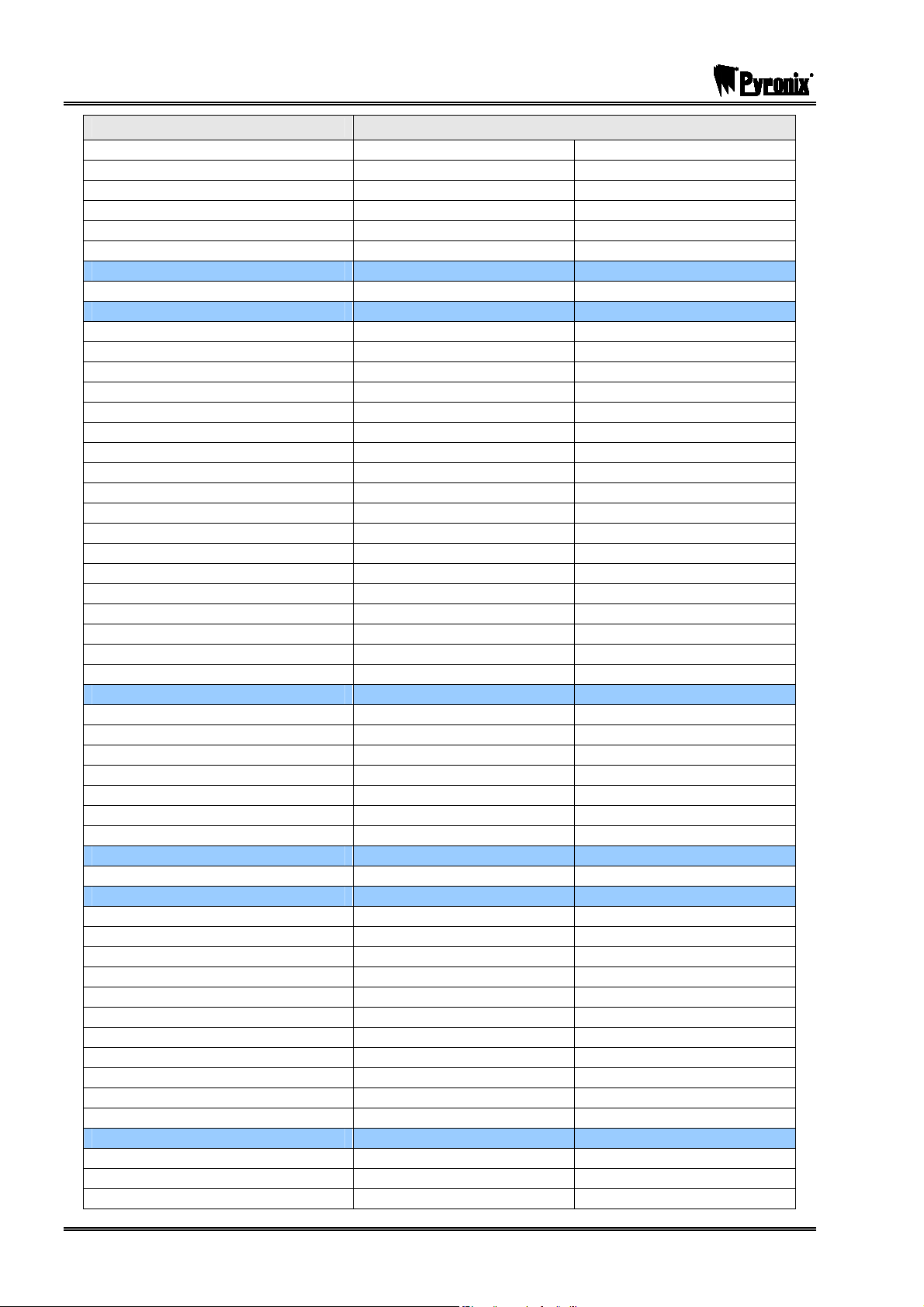

Page 11

PCX SMS AND PCX 256 SYSTEM MANUAL

MENU

ENGINEER RESTORE OPTIONS?

REVIEW LOGS?

ENGINEER TESTS?

DIAGNOSTICS?

SET UP DOWNLOADING?

PROGRAM DIGI/SMS?

DIAL OUT MENU?

NVM RESET?

EXIT ENGINEER MODE?

Sub-Menu Page:

ATE Inputs Page: 84

Eng Restore Int Page: 85

Eng Restore HU Page: 85

Eng Restore Tamp Page: 85

Eng Restore Soak Page: 85

Eng Restore Conf Page: 85

Eng Restore Faults Page: 85

Anti-code Restore Page: 85

Panel Log? Page: 87

Access Log?* Page: 87

Walk Test? Page: 89

Test Control? Page: 89

Test Bell? Page: 90

Do Battery Load Test? Page: 90

Test PGMs? Page: 91

Test PHC Communications? Page: 91

View PSU? Page: 92

View Inputs? Page: 93

Calibration? Page: 94

Download By Page: 95

Program Digi/SMS Calls? Page: 98

Program Digi Channels? Page: 98

Program SMS details? Page: 100

3 Way Calling Page: 100

Select PC To dial* Page: 109

Calling Remote PC* Page: 109

Select Operation* Page: 109

[ ] Page: 44

Page: 13

*These functions are not available on the PCX 26/SMS

RINS871-3 Page: 11

Page 12

PCX SMS AND PCX 256 SYSTEM MANUAL

CHAPTER 2: QUICK FIND GUIDE

2.1 COMMUNICATION

Function Description Pages

PROGRAM DIGI/SMS?

ENGINEER RESTORE

OPTIONS?

SET UP DOWNLOADING?

DIAL OUT MENU?

ALARM RESPONSE?

SITE OPTIONS?

Programming of telephone numbers, Digi channels and SMS

details.

Anti code and Engineer resets after alarms Page: 85

Makes the system available for upload/download via a

modem or RS232 lead.

Makes the system dial to a PC. Page: 109

Disable Confirm on Entry, Inputs to Confirm Page: 73

ATE Inputs Page: 83

2.2 ENGINEER TEST FUNCTIONS

Function Description Pages

ENGINEER TESTS?

DIAGNOSTICS?

Walk Test, PGM test, PHC Communications Test Page: 87

Readings of the PSU, Input Resistances, etc. Page: 92

Page: 97

Page: 94

2.3 ADDRESSING / CONNECTING DEVICES

Function Description Pages

ASSIGN

KEYPADS/READERS?

INSTALL RIX?

CHANGE OUTPUTS?

WIRING DIAGRAMS

Address Keypads, Readers, Access Control Page: 59

Address Remote Input Expanders Page: 48

Address Remote Output Expanders Page: 75

Wiring diagrams of all PCX components Page: 113

2.4 PROGRAMMING OPTIONS

Function Description Pages

CHANGE INPUTS?

CHANGE OUTPUTS?

CHANGE TIMERS?

CHANGE CODES?

THE RADIO EXPANDER

Programs input types, attributes etc Page: 49

Programs output types Page: 75

Programs bell time, confirm time, entry/exit time, bell delay

etc.

Programs Duress, Manager & Engineer codes. For user

please see page: 40

Addressing up the radio expander, Assigning and deleting

detectors

Page: 65

Page: 68

Page: 113

2.5 TABLES

Function Description Pages

FAULTS / DEVICE FAIL

INPUT TYPES

OUTPUT TYPES

USER / ENGINEER

OPERATIONS

MASTER MANAGER MENU

Page: 12 RINS871-3

Fault descriptions Page: 143

Table of all the input types available Page: 148

Table of all the output types available Page: 150

Details of user / engineer operations in day mode. Page: 153

Details of the master manager functions Page: 156

Page 13

PCX SMS AND PCX 256 SYSTEM MANUAL

CHAPTER 3: THE ENGINEERS MENU

In order to program system configurations from the keypad, you must be in the Engineer Menu. The panel

will enter the Engineering Menu after entering a valid engineer code when the panel is in a disarmed state.

Whilst in Engineer Mode all tamper alarms (including case tamper), will be disabled.

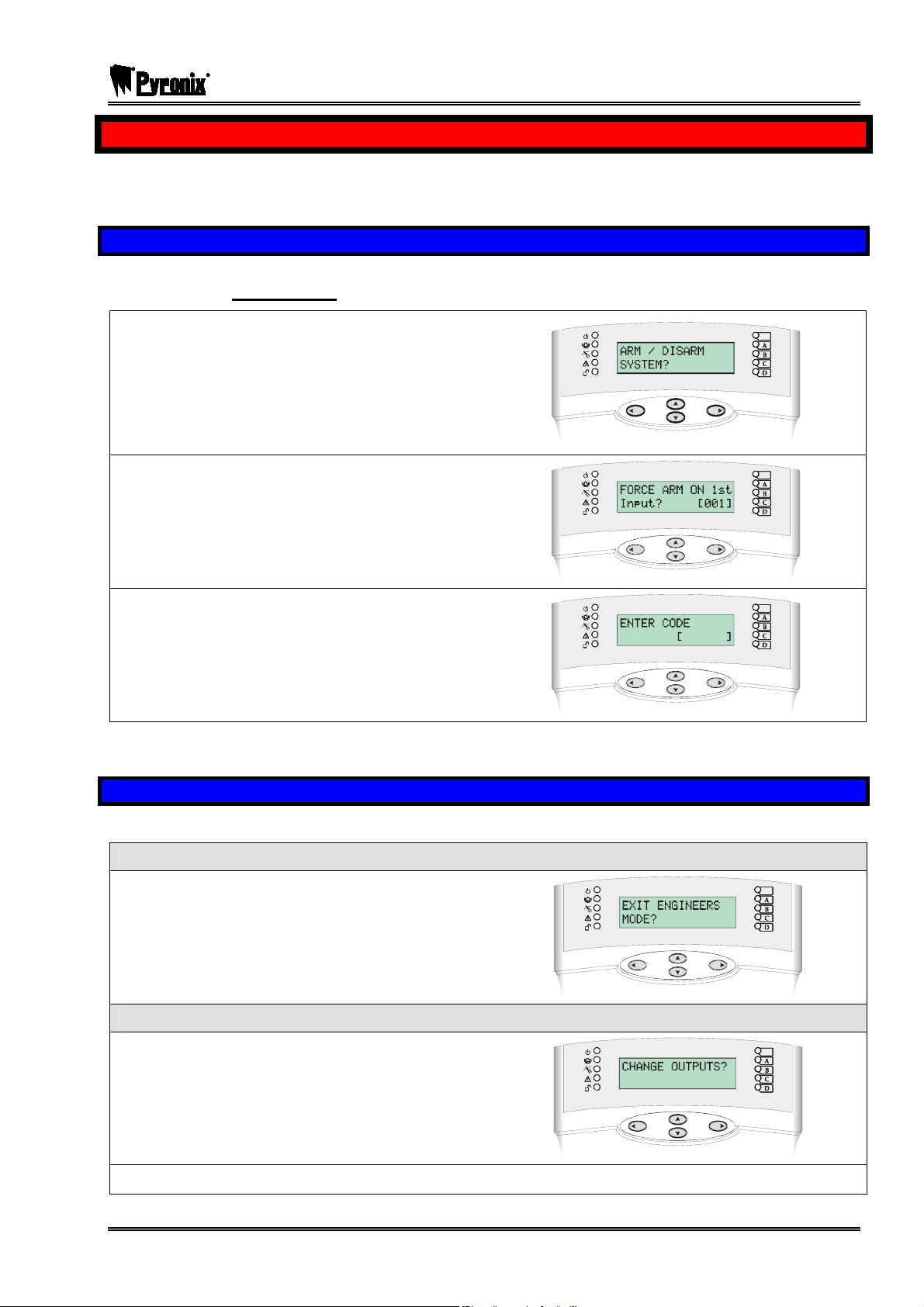

3.1 Entering The Engineers Menu

NOTE: You will not be able to access Engineers Mode if partitions or arm levels are armed. The

system must be fully disarmed

¾ Enter the Engineer Code (default 9999).

¾ Any active faults will be shown. Press

thePkey.

¾ “ARM / DISARM SYSTEM?” will be displayed

in order to gain access to the Engineer Menu.

¾ Press thePkey

¾ “FORCE ARM ON 1st INPUT[01]” will be

displayed

¾ Press thePkey

¾ “ENTER CODE” will be displayed

¾ Enter the Engineers code (default 9999)

¾ “INHIBIT FIRE/HU?” will be displayed indicating

that Engineers Mode has been entered.

Once you are in the Engineer Menu, a high pitch tone will be generated regularly to remind you that you are

still in the Engineer Menu.

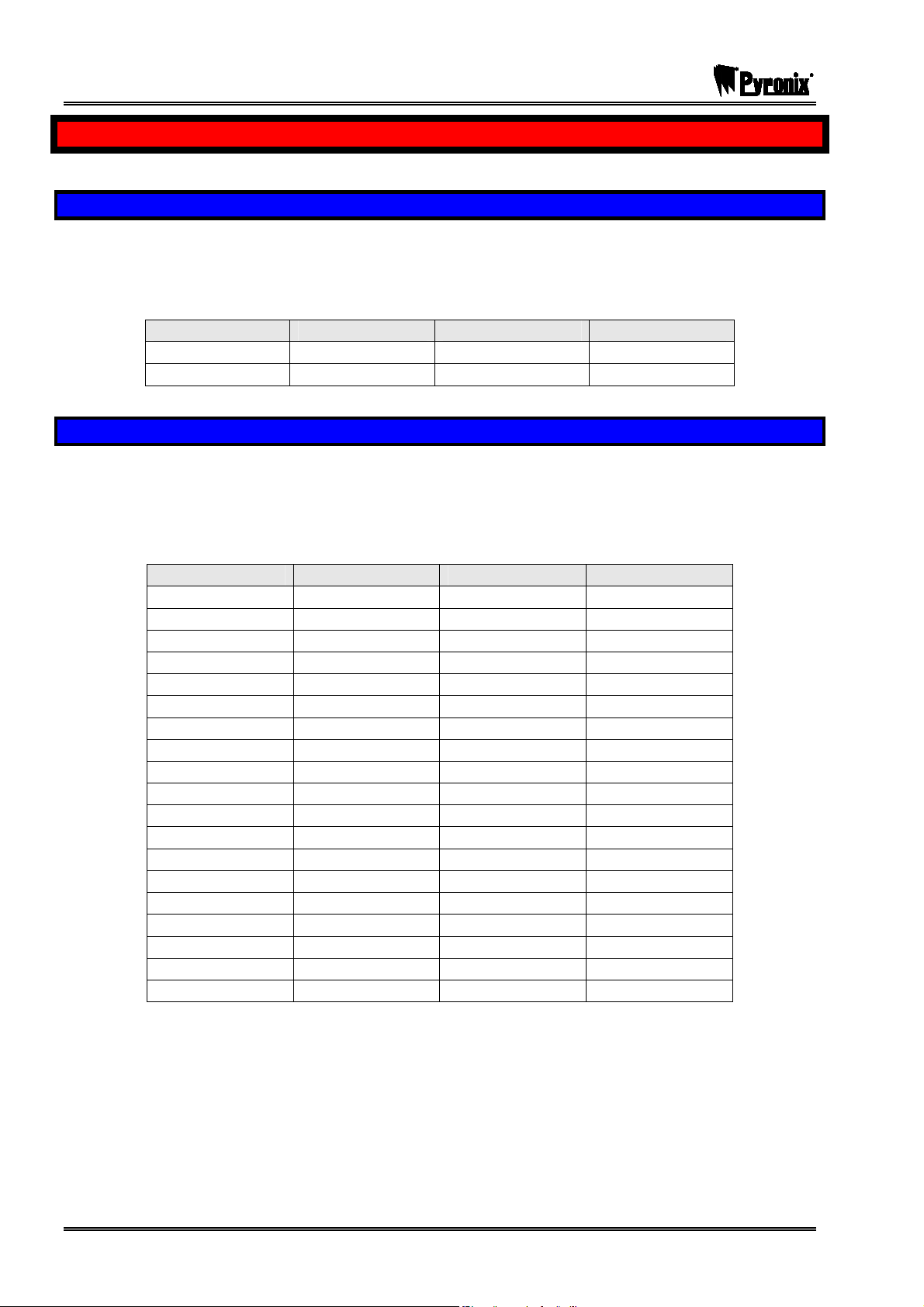

3.2 Exiting The Engineer Menu

On completion of programming, the system can be returned back to normal mode by:

METHOD ONE

¾ Use the scroll keys: ^and ! to scroll to

“EXIT ENGINEERS MODE”

¾ Press the Okey

¾ You will be returned to day mode

METHOD TWO

¾ When the display shows any main menu item (i.e.

an item shown in capitals) press the k key, you

will be returned to day mode.

Please see page: 143, for all fault codes that may appear when exiting the Engineers menu.

RINS871-3 Page: 13

Page 14

PCX SMS AND PCX 256 SYSTEM MANUAL

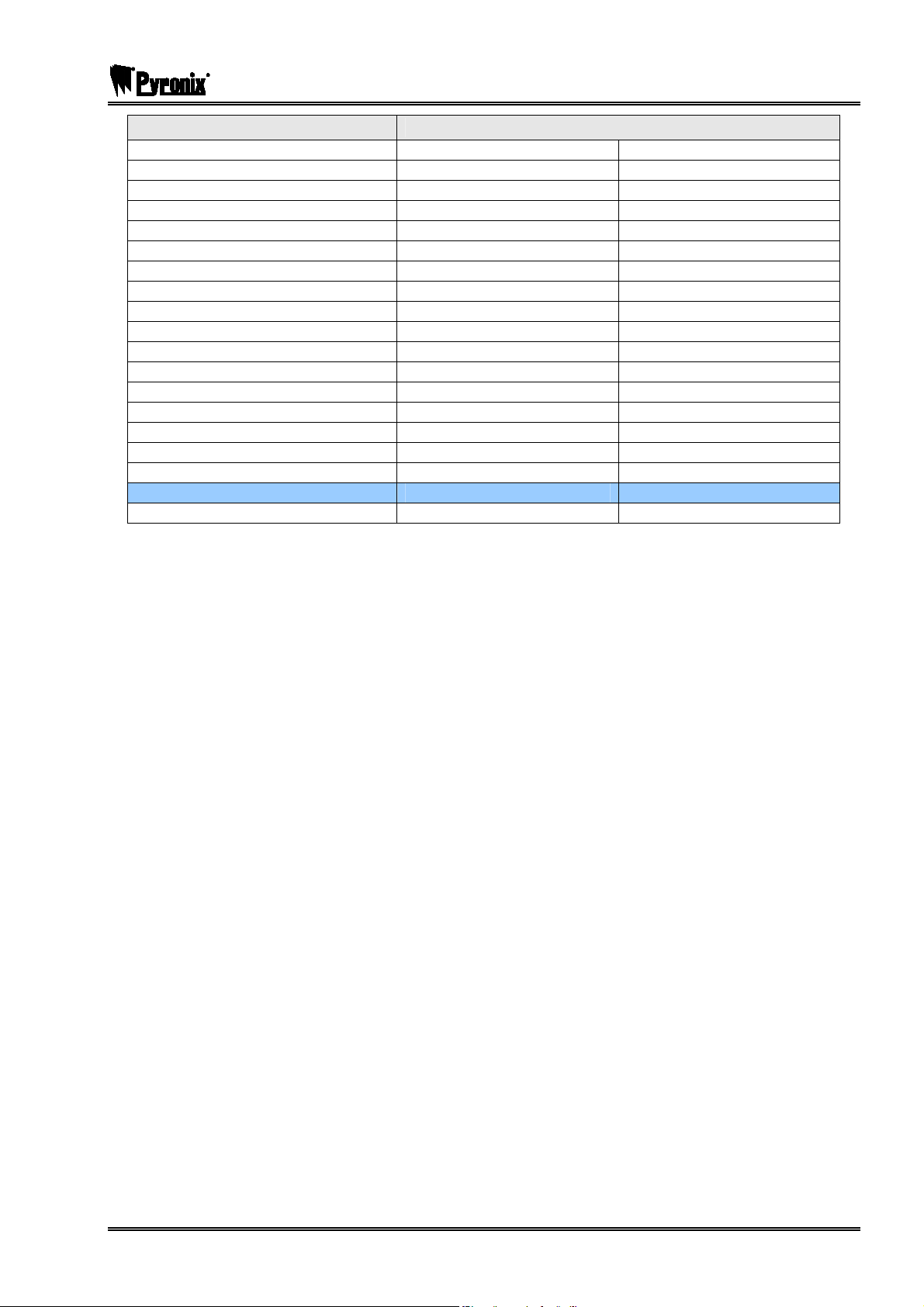

CHAPTER 4: SYSTEM OVERVIEW

This manual supports the following panels: PCX 26/SMS and the PCX 256.

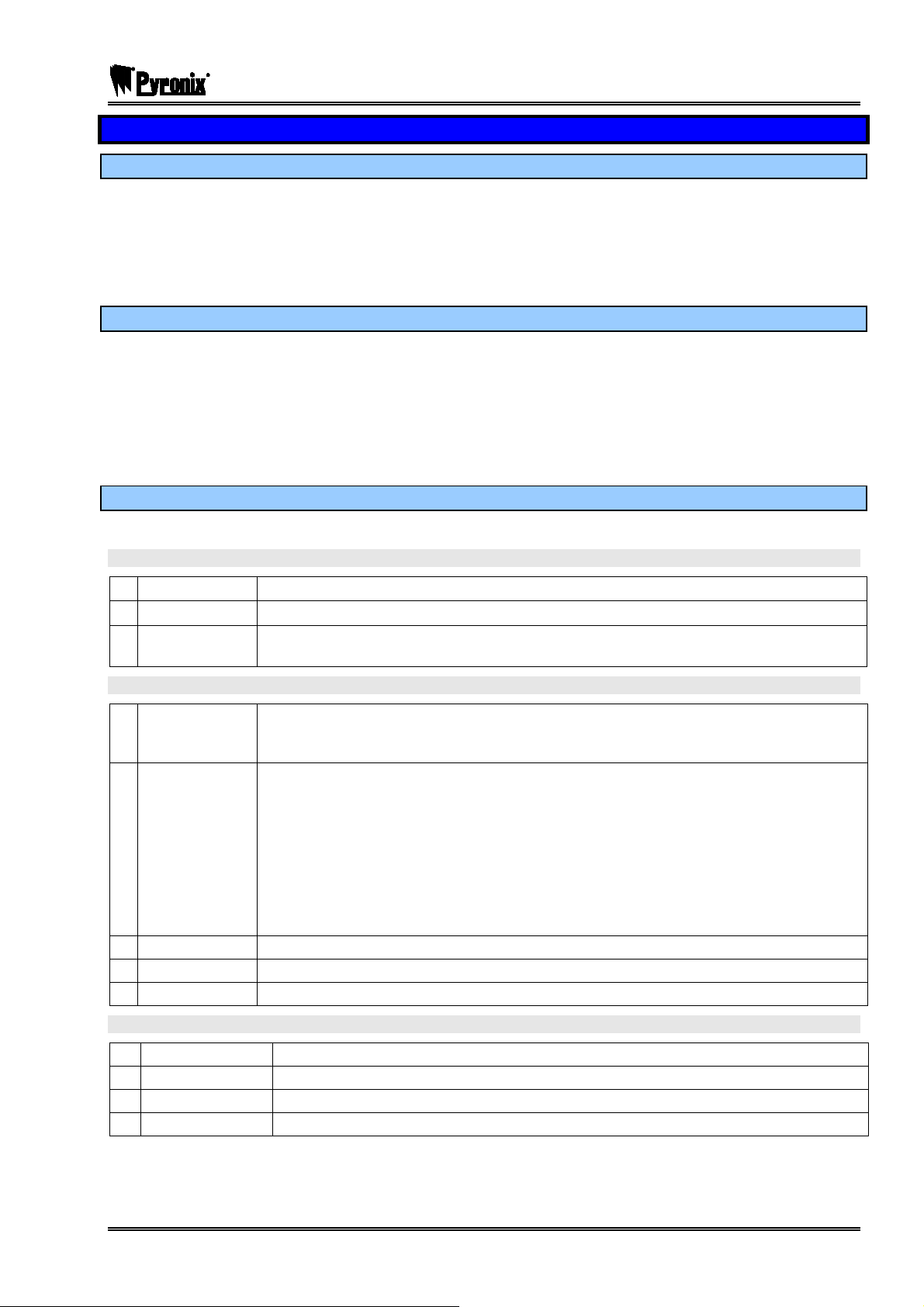

4.1 PCX 26/SMS Input Information

The PCX 26/SMS consists of the following components:

¾ PCX 8 Input Expander

¾ PCX LCD Keypad

Location Inputs Location Inputs

Control Panel

RIX 00

1 – 8

9 – 16

4.2 PCX 256 Input Information

The PCX 256 consists of the following components:

¾ MSX Card

¾ PCX 8 Input Expander

RIX 01

Keypad/Reader 00

17 – 24

25 – 26

¾ PCX LCD Keypad

Location Inputs Location Inputs

Control Panel

RIX 00

RIX 01

RIX 02

RIX 03

RIX 04

RIX 05

RIX 06

RIX 07

RIX 08

RIX 09

RIX 10

RIX 11

RIX 12

RIX 13

RIX 14

RIX 15

RIX 16

RIX 17

1 – 8

9 – 16

17 – 24

25 – 32

33 – 40

41 – 48

49 – 56

57 – 64

65 – 72

73 – 80

81 – 88

89 – 96

97 – 104

105 – 112

113 – 120

121 – 128

129 – 136

137 – 144

145 – 152

RIX 18

RIX 19

RIX 20

RIX 21

RIX 22

RIX 23

RIX 24

RIX 25

RIX 26

RIX 27

RIX 28

Keypad/Reader 00

Keypad/Reader 01

Keypad/Reader 02

Keypad/Reader 03

Keypad/Reader 04

Keypad/Reader 05

Keypad/Reader 06

Keypad/Reader 07

153 – 160

161 – 168

169 – 176

177 – 184

185 – 192

193 – 200

201 – 208

209 – 216

217 – 224

225 – 232

233 – 240

241 – 242

243 – 244

245 – 246

247 – 248

249 – 250

250 – 252

253 – 254

255 – 256

Page: 14 RINS871-3

Page 15

PCX SMS AND PCX 256 SYSTEM MANUAL

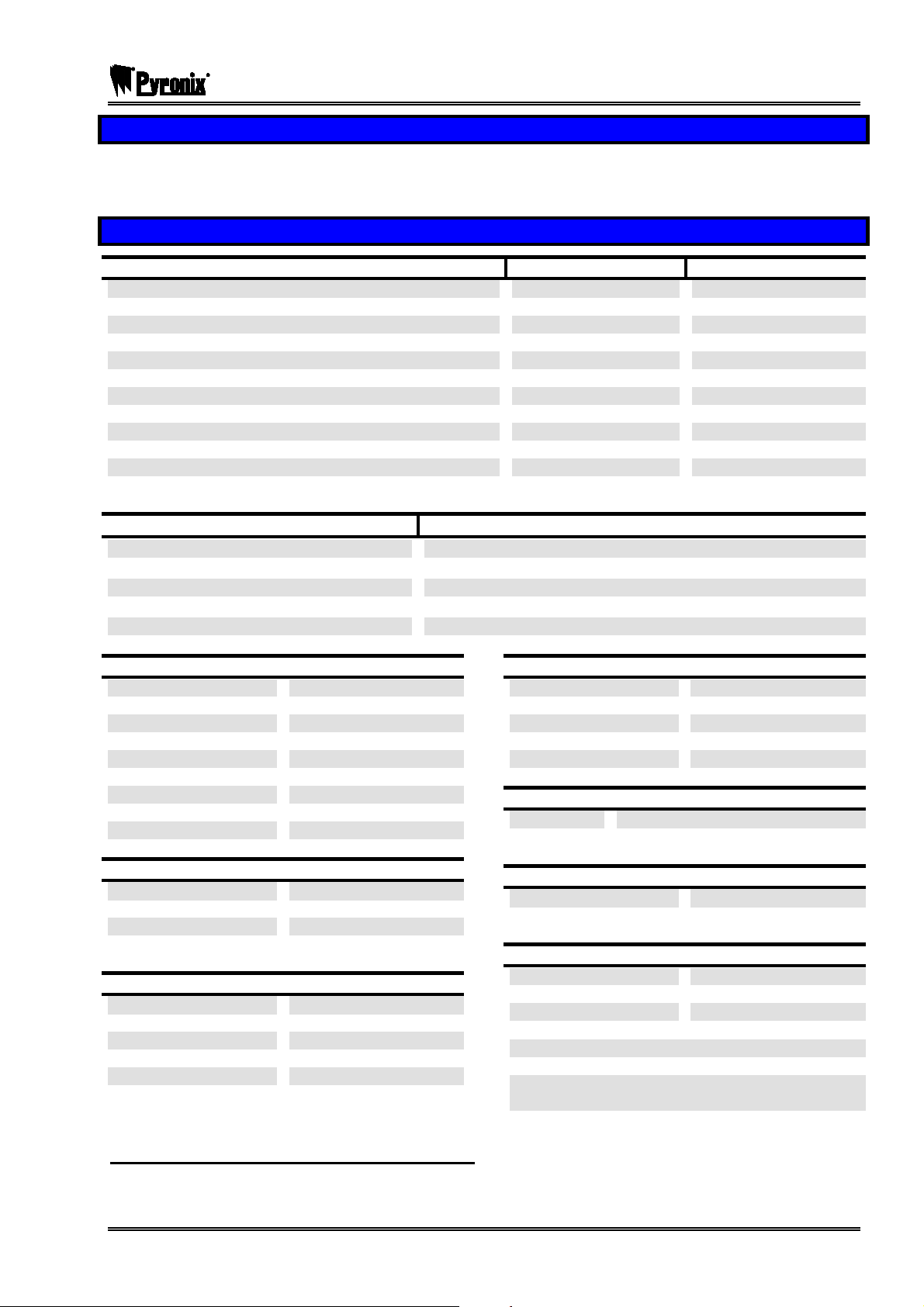

4.3 System Overview

4.3.1 Inputs

Inputs on Main Board

Input Expander PCX-RIX

Maximum Inputs Capacity

PCX 26/SMS /

PCX 256

PCX 26/SMS /

PCX 256

8 fully programmable inputs

8 fully programmable inputs

PCX 26/SMS 26 inputs using 2 x PCX RIXs & 1 PCX Keypad

PCX 256 256 inputs using 29 x PCX RIXs & 8 PCX Keypads

Input Configurations

Panel Additions/Expansion

PCX 26/SMS /

PCX 256

DEOL, SEOL

PCX 26/SMS Digi Modem Card

PCX 256 Digi Modem Card, Expansion Card

Unused, Fire, Gas, HU, Silent HU, Tamper, Immediate,

Input Types PCX 26/SMS

Entry/Exit, Access, A (Part EE), EE (Part A), PTS,

Switcher, 24 Hour, Fault, Closure Supervision, Keyswitch

Latched, Entry Shock Input, Keyswitch Pulsed

Unused, Fire, Gas, HU, Silent HU, Tamper, Immediate,

Entry/Exit, Access, A (Part EE), EE (Part A), PTS,

PCX 256

Switcher, 24 Hour, Sub Part Control, Fault, Closure

Supervision, Shunt Input, Disarm Input, Keyswitch

Latched, Entry Shock Input, Keyswitch Pulsed

PCX 26/SMS

Input Attributes

PCX 256

Chime, Omittable, Double Knock, Dual Trip, Normally

Open, Confirm Group.

Chime, Omittable, Double Knock, Dual Trip, Normally

Open, Monitor Activity, Special Logged, Paired Input,

Confirm Group.

4.3.2 Programmable Outputs (PGM)

PGM Outputs On-Board PCX 26/SMS / 256

Output Expander PCX 26/SMS / 256

PCX 26/SMS

Maximum PGM Outputs

PCX 256

Not Used, Fire, Hold Up Any, Intruder Any, Misoperation Any (Abort), Confirmed

Any, Tamper Any, Duress, HU Device Any, Gas, Arm Fail, Entry Deviation,

Secure Intruder Any, Bell Any, Strobe Any, Omit Rearm Any, Unconfirmed Any,

PGM

Types

PCX

26/SMS

Exit Starts Any, Final Arm Any, Strobe Set Fail, Keyswitch Unset, Entry/Exit,

Lights, Reset 1 (Viper Reset), Reset 2 (Viper Arm/Disarm), PIR Latch 1, PIR

Latch 2, Mains Good, Follow Test, Off During Test, Telephone Line Fault, AC

Fail, Battery Faults, Low Volts, Global Fault 1, Global Fault 2, Guard Code

Used, Engineer Access, Initialise Digi, Test ATS.

PGM1, PGM2: Relay (NC,C, NO), Speaker Output,

PGM4, PGM5: Transistor (Active High, Low)

PCX Remote Output Expander 16 Way Relay Outputs.

(PCXROX16R or PCXROX16R/PSU)

20 (4 on board + 1 ROX)

Note: PGMs also on RKPs, RIXs and Readers.

132 (4 on board + 8 ROXs)

Note: PGMs also on RKPs, RIXs and Readers.

RINS871-3 Page: 15

Page 16

PCX SMS AND PCX 256 SYSTEM MANUAL

Fire, Hold Up Any, Intruder Any, Final Arm Any, Misoperation Any (Abort),

Confirmed Any, Tamper Any, Duress, HU Device Any, Gas, Arm Fail, Entry

Deviation, Secure Intruder Any, Bell Any, Strobe Any, Omit Rearm Any,

Unconfirmed Any, Can All Arm, Exit Starts All, Exit Starts Any, Final Arm Any,

PCX 256

Strobe Set Fail, Keyswitch Disarm, Entry, Exit, Entry/Exit, Lights, Follow Input,

Shunt Fault, Reset 1 (Viper Reset), Reset 2 (Viper Arm/Disarm), PIR Latch 1,

PIR Latch 2, Mains Good, Detr Indn Enable, Follow Test, Off During Test,

Telephone Line Fault, AC Fail, Battery Faults, Low Volts, Global Fault 1, Global

Fault 2, German Relay, Guard Code Used, Engineer Access, Initialise Digi, Test

ATE/GSM, Test ATS, Timer, Calendar, Follow Input.

4.3.3 Keypads (PCX-LCD/UK)

Type LCD with integral tag reader. 32 character

Maximum Number of PCX 26/SMS 4 keypads

Keypads PCX 256 16 Keypads

4.3.4 Tag Readers (PCX-PROX/INT & PCX-PROX/EXT)

Types

Internal Tag Reader with 2 inputs & 2 outputs

External Prox Reader with 1 input

Maximum Number of PCX 26/SMS 3 Tag Readers

Readers PCX 256 15 Internal Readers / 7 External Readers

4.3.5 Arm Points

Maximum Number of PCX 26/SMS 4 Arm Points

Arm Points PCX 256 30 Arm Points

4.3.6 Partitions

Number of Partitions/ Arm

Modes

Arming Options Timed Exit, Final Exit, Timed/Final, Push to set,

Timers

PCX 26/SMS 4 Arm Modes

PCX 256 14 Partitions or 14 Arm Modes

Entry Time, Exit Time, Bell Time, Confirm Time, Bell

PCX 26/SMS

Delay, Strobe Time, Re-Arm No, AC Signal Delay,

Speaker, Final Exit delay, Double Knock, Pre-Alarm, Line

Fault, Arm Fail, Guard Code Alarm, Fire Bell Time.

Entry Time, Exit Time, Bell Time, Confirm Time, Bell

Delay, Strobe Time, Re-Arm No, AC Signal Delay,

PCX 256

Speaker, Final Exit delay, Double Knock, Pre-Alarm, Line

Fault, Arm Fail, Guard Code Alarm, Fire Bell Time, Input

NAT days, Input NAT Hours.

4.3.7 User Codes

Number of User Codes

User Code Attributes User Type, Partitions, Arm Options, Flexi Arm

PCX 26/SMS 20 User Codes, 10 Duress Codes.

PCX 256 500 User Codes, 20 Duress Codes.

4.3.8 Central Monitoring Options

Telephone Numbers

Page: 16 RINS871-3

PCX 26/SMS 4 numbers

PCX 256 4 primary numbers and 4 auxillary

Page 17

PCX SMS AND PCX 256 SYSTEM MANUAL

Communication Protocols Fast Format, SIA Level 1, SIA DK, Contact ID, SMS

Group Reporting to CMS

Redials, Time Out, Stop on Success, Test Calls, Low

Battery Report.

Arm, Disarm, Special Disarm, Arm Fail, Alarm, First alarm,

Alarm Silenced, Confirmed, LoTechFault, HiTechFault,

Tech Info, Manager Info, Engineer Info, AccessC Alarm,

Content Types for Contact ID & SMS

AccessC Info, Accessc Ref, SL SwitchON, SL SwitchOFF,

SL OtherOn, SLOtherOff, Sub-partitions Set, Sub-partitions

Unset, Sub-partitions Alarm, Input omitted, Input restore,

Test Call, Mains fail, Emergency input, Emergency restore,

Tamper input, First tamper input, Tamp Input Restore

Telephone Line Monitoring Yes

Digital Communicator Analogue Line and Digi Modem Card.

4.3.9 Other

UDL Programming software. Equipment needed:

Software Support

Memory Event Log

PCX 26/SMS 300

PCX 256 3000

Direct Dial: PCX RS232 lead

Remotely: Modem

RINS871-3 Page: 17

Page 18

PCX SMS AND PCX 256 SYSTEM MANUAL

4.4 DEFAULTS

Functions/Parameters Default Setting

CODES

Engineer Code 9999 9999

User Code 1234 1234

Manager Code 5678 5678

CHOOSE MODE

EOL Range - 4k7 Range

EOL Mode DEOL DEOL

Input Response 400 400

Input XDF Normal Normal

INSTALL RIX

RIX Installed All addresses disabled All addresses disabled

CHANGE INPUTS

All Input Types Unused Unused

Input Partitions A A

Input Partition Any Any

Chime No No

Omittable No No

Double Knock No No

Dual Trip No No

Normally Open No No

Monitor Activity - No

Special Log - No

Paired Input - No

Confirm Group 00 00

Input Name Input ### (Text String) Input ### (Text String)

ASSIGN KEYPADS/READERS

Address 00 Keypad Keypad

All other addresses Not Used Not Used

Arm Point Arms - 0123456789ABCD

Arm Point Disarms - 0123456789ABCD

Arm Point In - A

Default Level A Arm Point Name Device ## (Text String) Device ## (Text String)

SYSTEM DISPLAYS

Partition Text Partition # (Text String) Partition # (Text String)

Full Partition Text - Full (Text String)

Sign On Message PCX 26.V5.e (Text String) PCX 256.V5.e (Text String)

Site Name _ (Text String) _ (Text String)

Display When Arm - No

CHANGE TIMERS

Entry Time 30 seconds (All partitions) 30 seconds (All partitions)

Exit Time 30 seconds (All partitions) 30 seconds (All partitions)

Bell Time 15 minutes 15 minutes

Confirm Time 30 minutes 30 minutes

Bell Delay Zero minutes Zero minutes

Strobe Time Zero minutes Zero minutes

Re-Arm No. 3 3

AC Signal Delay 40 minutes 60 minutes

Speaker Zero seconds Zero seconds

Final Exit Delay 5 seconds 5 seconds

Double Knock 10 seconds 10 seconds

PCX 26/SMS PCX 256

PCX 26/SMS PCX 256

PCX 26/SMS PCX 256

PCX 26/SMS PCX 256

PCX 26/SMS PCX 256

PCX 26/SMS PCX 256

PCX 26/SMS PCX 256

Page: 18 RINS871-3

Page 19

PCX SMS AND PCX 256 SYSTEM MANUAL

Functions/Parameters Default Setting

Pre-Alarm 30 seconds 30 seconds

Line Fault 20 seconds 20 seconds

Arm Fail 40 seconds 40 seconds

Guard Code Alarm 3 minutes 3 minutes

Fire Bell Time 99 minutes 99 minutes

Input NAT days - 14

Input NAT hours - Zero

EXIT MODES

PCX 26/SMS PCX 256

All Partition Exit Modes Timed Timed

CHANGE CODES

PCX 26/SMS PCX 256

5 Digit Pins - Yes

Change Duress Codes None None

Change Master Manager Code 5678 5678

Change Engineer Code 9999 9999

VOLUME CONTROL

PCX 26/SMS PCX 256

Partition Entry 4 4

Partition Exit 4 4

Alarm 7 7

Fire 7 7

Tamper 6 6

Disarmed 6 6

Chime 3 3

Intelligent Arm 3 3

Code Stops Sound Yes Yes

E/E Keypads Only No No

Alert Kps Only Yes Yes

ALARM RESPONSE

PCX 26/SMS PCX 256

Silent 1st Alarm Never Never

Disable Confirm On Entry No No

Inputs to Confirm After Entry 2 2

Partitions Starts Digi Digi

Partitions Stops Confirm Confirm

Fire/Gas/HU Starts at Digi Digi

Fire/Gas/HU Stops at Digi Digi

Disarm Starts Bells Only Bells Only

Disarm Stops Bells Only Bells Only

Start At - Digi

If Partition set - None

Start At - Digi

If Partition set - None

CHANGE OUTPUTS

PCX 26/SMS PCX 256

Endstation Outputs PGM 1 PIR Latch 1 PIR Latch 1

Endstation Outputs PGM 2 Not Used Not Used

Endstation Outputs PGM 4 Strobe Any Strobe Any

Endstation Outputs PGM 5 Bells Any Bells Any

ATE Pin 1 Fire Fire

ATE Pin 2 HU Device Any HU Device Any

ATE Pin 3 Unconfirmed Any Unconfirmed Any

ATE Pin 4 Final Arm Any Final Arm Any

ATE Pin 5 Tamper Any Omit Re-arm Any

ATE Pin 6 Confirmed Any Tamper Any

ATE Pin 7 Omit Rearm Any Confirmed Any

ATE Pin 8 Global Fault 2 AC Fail

RINS871-3 Page: 19

Page 20

PCX SMS AND PCX 256 SYSTEM MANUAL

Functions/Parameters Default Setting

ATE Pin 9 Global Fault 1 Global Fault 2

ATE Pin 10 Test ATS Test ATS

RIX PGMs All Not Used All Not Used

ROX Module PGMs All Not Used All Not Used

Keypad PGMs All Not Used All Not Used

Reader PGMs All Not Used All Not Used

INTELLIGENT ARM

PCX 26/SMS PCX 256

Intelligent No No

SITE OPTIONS

PCX 26/SMS PCX 256

Arm With Fault No Yes

Arm With Tamper+ No No

Arm With ATS Flt Yes Yes

Arm Part TFault - Yes

Arm Fail = Alarm No No

Do Battery Load Test No No

Part Misoperate No No

Strobe Confirm No No

Re-Arm Omits No No

Use Level Arm - No

Confirmed When Final Arm Final Arm

Autoset Force - No

Restrict PIN Use No Yes

Invert ATE O/Ps Yes Yes

Common Exit Mode - Yes

Flexi Unset No No

2 Key HU None None

ATE Inputs None None

ENGINEER RESTORE OPTIONS?

PCX 26/SMS PCX 256

Engineer Restore Intruder No No

Engineer Restore HU No No

Engineer Restore Tamper No Yes

Engineer Restore Soak No No

Engineer Restore Confirmed No Yes

Engineer Restore Faults No Yes

Anti-code Restore No Yes

ENGINEER TESTS?

PCX 26/SMS PCX 256

Sound To play - No Sound

SET UP DOWNLOADING?

PCX 26/SMS PCX 256

Download by None None

(modem) Security Mode Auto-Answer Auto-Answer

Telephone Line Dedicated Dedicated

Number of Rings to Prime - 03

Modem Speed High High

Arm Tel No Blank Blank

Modem Tel No Blank Blank

Signal Alarms - No

Signal Faults - No

Signal Open/Close - No

Signal Access C - No

PROGRAMME DIGI/SMS?

PCX 26/SMS PCX 256

Disable Digi/SMS Yes Yes

Active No No

Choose Format Fast 4.8.1 Fast 4.8.1

Page: 20 RINS871-3

Page 21

PCX SMS AND PCX 256 SYSTEM MANUAL

Functions/Parameters Default Setting

Stop On Sucess Yes Yes

Redials 3 3

Time Out 15 15

Low Batt Report No No

Test Calls No No

Digi Channel 1 Fire Fire

Digi Channel 2 HU Device Any HU Device Any

Digi Channel 3 Unconfirmed Any Unconfirmed Any

Digi Channel 4 Final Arm Any Final Arm Any

Digi Channel 5 Tamper Any Omit Rearm Any

Digi Channel 6 Confirmed Any Unused

Digi Channel 7 Omit rearm any Confirmed Any

Digi Channel 8 AC Fail AC Fail

Digi Channel 9 Global Fault 1 Global Fault 2

Digi Channel 10 Test ATS Test ATS

Digi Channels 11-16 Not Used Not Used

3 Way Calling No No

DIAL OUT MENU

PCX 26/SMS PCX 256

Select Operation Are You Sure? Connect to PC

RINS871-3 Page: 21

Page 22

PCX SMS AND PCX 256 SYSTEM MANUAL

CHAPTER 5: TECHNICAL SPECIFICATION

This chapter outlines the essential specifications for the PCX range.

Pyronix Ltd. reserves the right to change these specifications at any time, without notice, in the interests of

product improvement.

Please ensure that this information is used in designing the system, so that it can be installed and

programmed as intended, and will continue to function reliably. In particular, system outputs and power

supplies must be used within their rated specifications.

5.1 Introduction

The PCX range has been designed to offer a choice of options to suit most European security applications.

All systems can be controlled using PIN code and/or proximity cards.

All products are compatible with the Digi Modem for remote signalling, downloading and/or SMS text

messaging.

Training courses are available on application to the sales office.

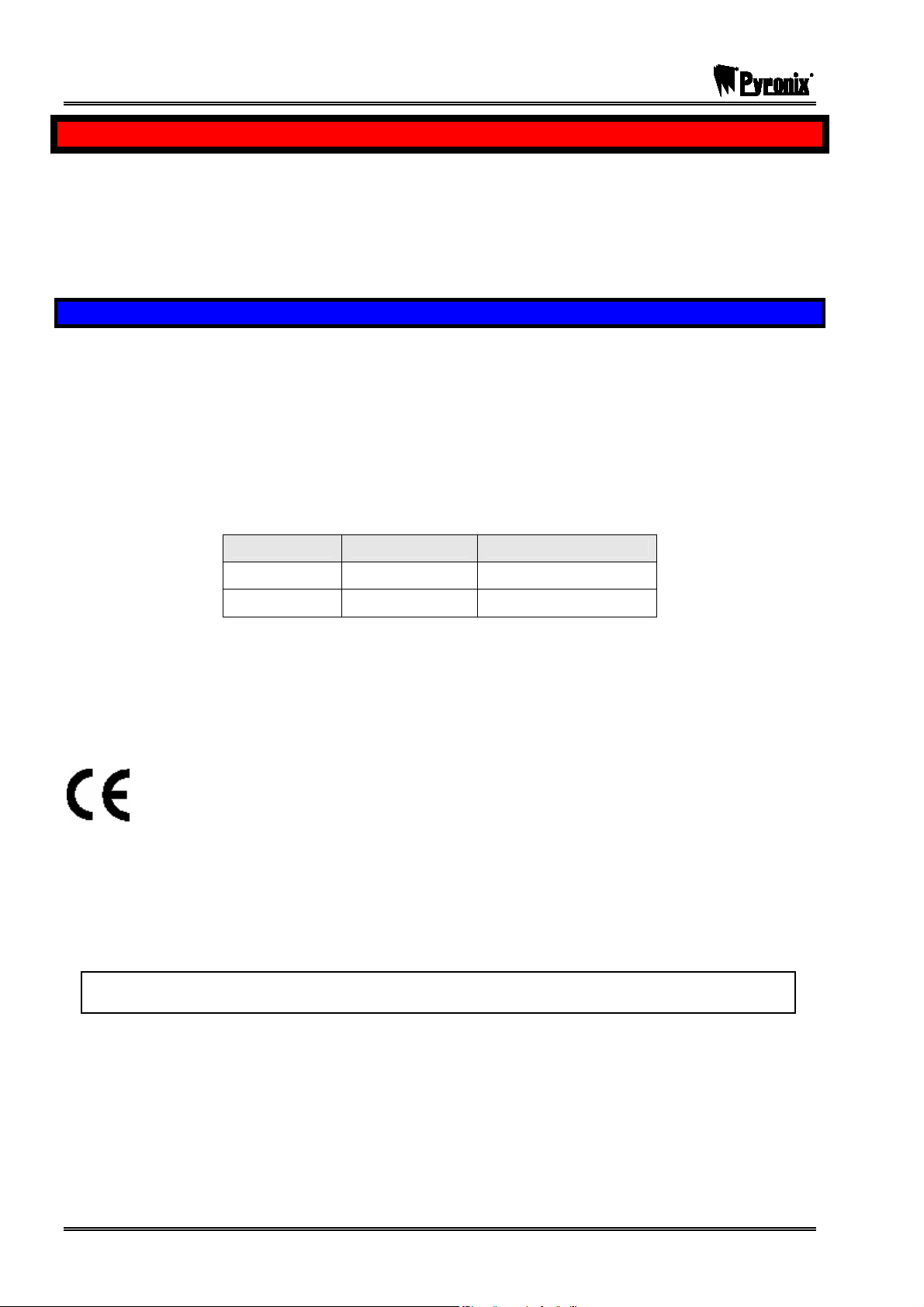

EN-50131

The PCX range is suitable for installation in systems specified below:

Product Security Grade Environmental Class

PCX 26/SMS 1 and 2 1 and 2

PCX 256 1 to 3 1 and 2

Power supplies conform to EN-501346

BS-4737

The PCX range has the facilities required to be able to control a system installed to BS-4737 requirements.

Compliance Statement

The PCX range complies with the requirements of the European EMC Directive (89/336/EC) and

the Low Voltage Directive (72/23/EC and 93/68/EC).

It is essential that the recommendations in this manual are followed, and that equipment and wiring be

installed so as to avoid the effects of potential sources of interference.

The PCX range fully complies with the requirements of DD243:2002. This has been verified using the BSIA

“Manufacturer’s Check List for Compliance with the Requirements of DD243:2002”.

All appropriate facilities and options are available for systems using sequential confirmation signalling

except: Zeroing of ‘Confirm Timer’ if first input to alarm retriggers.

When all parts are working normally, this equipment in combination with the PSTN and suitable

ARC equipment will meet the requirements of ATS2.

PCX 26/SMS/26: This product complies with TS50131-3:2003 and is suitable for use in EN50131-

6:1998 systems at security grade 2, environmental class 2.

UK = Suitable for use with systems installed to PD6662:2004 (AMD)

EXPORT = Suitable for use with systems installed to EN50131-1

PCX 256: This product complies with TS50131-3:2003 and is suitable for use in EN50131-6:1998

systems at security grade 3, environmental class 2.

UK = Suitable for use with systems installed to PD6662:2004 (AMD)

EXPORT = Suitable for use with systems installed to EN50131-1

Page: 22 RINS871-3

Page 23

PCX SMS AND PCX 256 SYSTEM MANUAL

5.2 Warranty

This product is sold subject to our standard warranty conditions and is warranted against defects in

workmanship for a period of 2 years. In the interest of continuing improvement of quality, customer care and

design, Pyronix reserves the right to amend specifications without giving prior notice.

5.3 PCX System Specifications

SYSTEM ANALYSIS PCX 26/SMS PCX 256

Power Supply 1.5A 1.5A

Inputs (max) 26 256

Arm Points (max) 4 30

Full Partitions - 14

Part-Sets 4 14

Sub-Parts (max) - 16

User / Manager Codes* 20 500

Duress/Guard Codes* 10 20

Logs 750 3000

Access Control (max) - 15

RIX Modules 2 25

ROX Modules 1 8

FUSES VALUES

F1 (PGMs) 800mA fast blow RFSE016 = F800mAL glass body

F2 (BELL) 800mA fast blow RFSE016 = F800mAL glass body

F3 (AUX) 800mA fast blow RFSE016 = F800mAL glass body

F4 (BUS) 800mA fast blow RFSE016 = F800mAL glass body

F5 (BATTERY) 3.15A slow blow RFSE027 = T3.15AL Glass body

POWER SUPPLY

Power Input 17V AC

Transformer Rating 27VA

Input Voltage 230V AC

Output Voltage 12V DC nominal

EN50131-6 Type A

Voltage Range 13.60 – 14.9V DC

Ripple 5mV @ 1.5A

Panel Current Req. End Station: 75-90mA

Total Current Output 1.5A

BATTERY

Battery Type 12V Lead Acid

Recharge Time PCX 26/SMS: 72 hours

Recharge Time PCX 256: 24 hours

Battery Capacity 22Ahr Max

INPUTS (ACTIVATION RESISTANCE)

Normal 3K7 to 8K3

Intruder 8K4 to 10K2

Fault 10K3 to 14K9

Masking 15K to 23K

Tamper <3K7 or >23K

Standard to which component claims compliance

CIE: DD/CLC TS50131-1:2003, as reconciled with PD6662:2004 by BSIA Form 179

PSU: EN50131-6:1998, as clarified by BSIA Form 180

PROGRAMMABLE OUTPUTS (PGMS)

PGM 1 (relay) 30V @ 3A

PGM 2 (relay) 30V @ 3A

Speaker 16 ohms

PGM 4 (transistor) 500mA

PGM 5 (transistor) 500mA

TEMPERATURES

Operational -10°C to +40°C. (14°F to 104°F)

Storage -20°C to +60°C. (-4°F to 140°F)

DIMENSIONS

Casing 390 x 305 x 100mm

Printed Circuit Board 150 x 175 x 30mm

VARIATIONS LOGICAL / PHYSICAL KEYS

4-digit codes 10,000

5-digit codes 100,000

Disallowed codes None

Other logical keys 16

12

Method

According to TS50131-3:2003 Annex B

According to spec of manufacturer of RFiD

components used

RINS871-3 Page: 23

Page 24

PCX SMS AND PCX 256 SYSTEM MANUAL

5.4 Devices Technical Specification

LCD KEYPAD (PCX-LCD/UK)

Supply Voltage 13.8V (9-16V range)

Supply Current

Min brightness setting 80mA

Max brightness setting 150mA

Operating Temperature 0 to 50°C

Dimension 139 x 127 x 29mm

Output (PGM) Current 100mA

EXTERNAL TAG READER (PCX-PROX/EXT)

Supply Voltage 13.8V (9-16V range)

Supply Current Max. 90mA @ 13.8V

Operating Temperature -10 to +50°C

Dimensions 85 x 85 x 21mm

INTERNAL TAG READER (PCX-PROX/INT)

Supply Voltage 10.5 to 15V

Supply Current 60mA

Operating Temperature -10°C to +40°C

Dimension 100 x 70 x 30mm

Output (PGM) Current 100mA

Supply Voltage 10.5 to 15V

REMOTE INPUT EXPANDER (PCX-RIX2)

Supply Voltage 10.5 to 15V

Supply Current 40mA

Operating Temperature -10°C to +40°C

Dimension 100 x 70 x 30mm

Output (PGM) Current 500mA

REMOTE INPUT EXPANDER (PCX-RIX8)

Supply Voltage 10.5V to 15V

Quiescent Current 30mA

Dimensions 210 x 130 x 50 mm

REMOTE INPUT EXPANDER (PCX-RIX8+)

Supply Voltage 10.5 to 15V

Supply Current 40mA

Operating Temperature -10°C to +40°C

Dimension 100 x 70 x 30mm

Output (PGM) Current 500mA

Supply Voltage 10.5 to 15V

REMOTE OUTPUT EXPANDER (PCX-ROX16R)

Supply Voltage 10.5V to 15V

Supply Current 30mA (no relays active)

Supply Current 340mA (all relays active)

Max Switching Voltage 24A

Max Switching Current 3A

POWER SUPPLIES FOR RIXs and ROXs

Power Supply 2.5A

Mains (220-240V AC) 50Hz 150mA

Mains Fuse Slow Blow (T) 250mA

Output 13.75V 1.0A continuous

Battery Fuse 3.15A Quick Blow

Output Fuse 1.25A Quick Blow

5.4.1 Lightning Protection

The inbuilt lightning protection is provided by fast acting gas discharge tubes.

The quality of the protection is protected upon the low impedance telecoms earth being connected.

5.4.2 Code Guessing

When the PCX is armed, an intruder may try to ‘guess’ the user code to disarm the system, the PCX

incorporates a feature that stops this; If 30 or more invalid key presses are input, or 6 invalid tags are

presented at the keypad, the keypad will disable or ‘freeze’ for 90 seconds. It will then subsequently ‘freeze’

after 7 further invalid key presses or another invalid tag is presented.

After the lock up time has timed out, a valid user code/tag may be presented and the system will disarm.

‘Code Guessing’ will be visible on the keypad. To clear this press P.

Page: 24 RINS871-3

Page 25

PCX SMS AND PCX 256 SYSTEM MANUAL

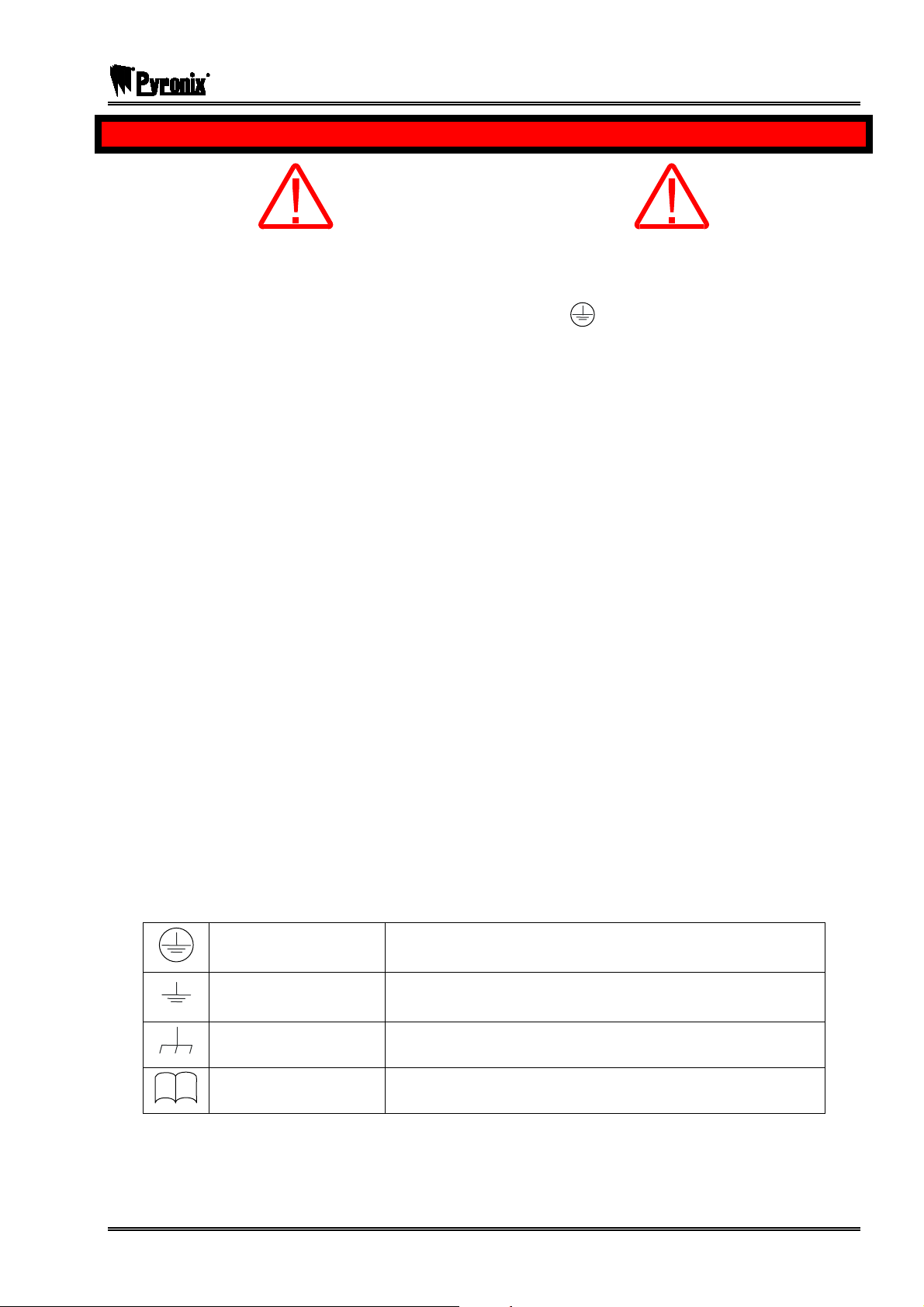

CHAPTER 6: SAFETY

SAFETY

1. A technically competent person must carry out the mains installation in accordance with the national and

local electrical installation regulations

2. Protective Earth: This equipment must be earthed/grounded.

3. Functional Earth: Must be connected to earth terminal to allow the equipment to operate correctly. Has

no safety implications.

2

4. Connect the unit to a single pole, unswitched, 3 Amp fused spur, using 0.75mm

cannot be positively identified use a double pole disconnect version.

5. Always remove / isolate the mains supply before carrying out any servicing of the panel.

6. Fuses: For continued protection against the risk of fire, replace only with the same type and rating of

fuse.

7. There are no user serviceable parts inside the equipment.

cable. If the Neutral

8. This unit should be mounted so that there will be no outside access to the electrical cable entry point.

9. Ventilation: To ensure the correct airflow, always mount the unit vertically with the unit having a clear

space on all sides. It must not be covered by clothes, furnishings, boxes, etc. It must not be mounted

close to, or above, heat radiating sources.

10. On completion of wiring, use tie-wraps to prevent any loose wires causing a safety hazard.

11. The mechanical mounting of the unit must be secure enough to carry the full weight of the unit including

all batteries.

12. Batteries: Ensure that the battery terminal connections will not create an electrical short-circuit on the

case metalwork when the unit is closed. Use insulated battery lead connectors.

13. Dispose of old batteries as required by environmental legislation / recommendations.

14. The battery case must have a flame-retardant rating of UL94-V2/V1/V0 – IEC60950:2000

15. Water: The equipment must be kept free from dampness, water and any other liquids. It is only suitable

for installation indoors.

Protective Earth

Protective Bonding

Must be connected to the electrical installation earth / ground

Must be connected to the equipment protective earth terminal

Functional Earth

Read

RINS871-3 Page: 25

Must be connected to earth terminal to allow the equipment to

operate correctly. Has no safety implications.

Read equipment instructions

Page 26

PCX SMS AND PCX 256 SYSTEM MANUAL

CHAPTER 7: INSTALLATION

This chapter describes the recommended procedure for installing PCX systems

7.1 Electromagnetic Compatibility (EMC)

The PCX system has been designed to meet or exceed all relevant EMC requirements. This alone does not

guarantee that no problems will be experienced, especially in relation to older equipment not designed to the

same standards, or to equipment for which the same provisions of the EMC Directive do not apply.

To maintain full EMC performance for the system, it is essential that the following points be followed:

a. All other equipment used must carry the CE mark for electromagnetic compatibility.

b. Do not locate the PCX system, or any other component, close to equipment switching high frequencies,

or using radio frequencies in its operation.

c. Avoid using mains supplies contaminated by interference generated by switching, arcing, etc.

d. The system must be connected to a good, clean earth. The earth connection of housing lids is a

mandatory safety requirement.

e. The correct cable type should be used for each application as specified.

f. Cables should be routed to avoid the possibility of interference being picked up from other nearby cabling

or equipment. Be alert to the possibility of other cables being installed after the alarm system has been

commissioned.

For further information refer to BSIA “EMC Guidelines for Alarm Installers”.

7.2 Mounting Procedure for the PCX system

The following steps illustrate basic mounting procedure for the PCX metal case.

Step 1 – Remove the case lid from the PCX panel and check all parts and components are in place.

Step 2 – Decide where the PCX panel will be situated. The PCX panel may be housed in the loft or different

rooms in the premises. A discrete and concealed place is advisable, as only the PCX keypads need to be

seen.

Step 3 – Secure the PCX panel to a sturdy and stable surface, using the mounting screws provided. First

mark the wall where the panel is to be situated (using the mounting holes), drill holes in the wall, and fasten

the panel base to the wall using the screws provided.

Step 4 – Before the panel base is completely secured to the wall feed cables for keypads / AC power supply

/ and accessories through the cable entry holes as illustrated.

7.3 Resistors

The resistor values are recognised as follows:

4k7 resistor = Yellow/Violet/Red

6k8 resistor = Blue/Grey/Red

470Ω resistor = Yellow/Violet/Brown

The PCX System recognises the following:

4k7: Alarm

4k7: Tamper

6k8: Mask/Fault (Not applicable on PCX 26/SMS)

Page: 26 RINS871-3

Page 27

PCX SMS AND PCX 256 SYSTEM MANUAL

h

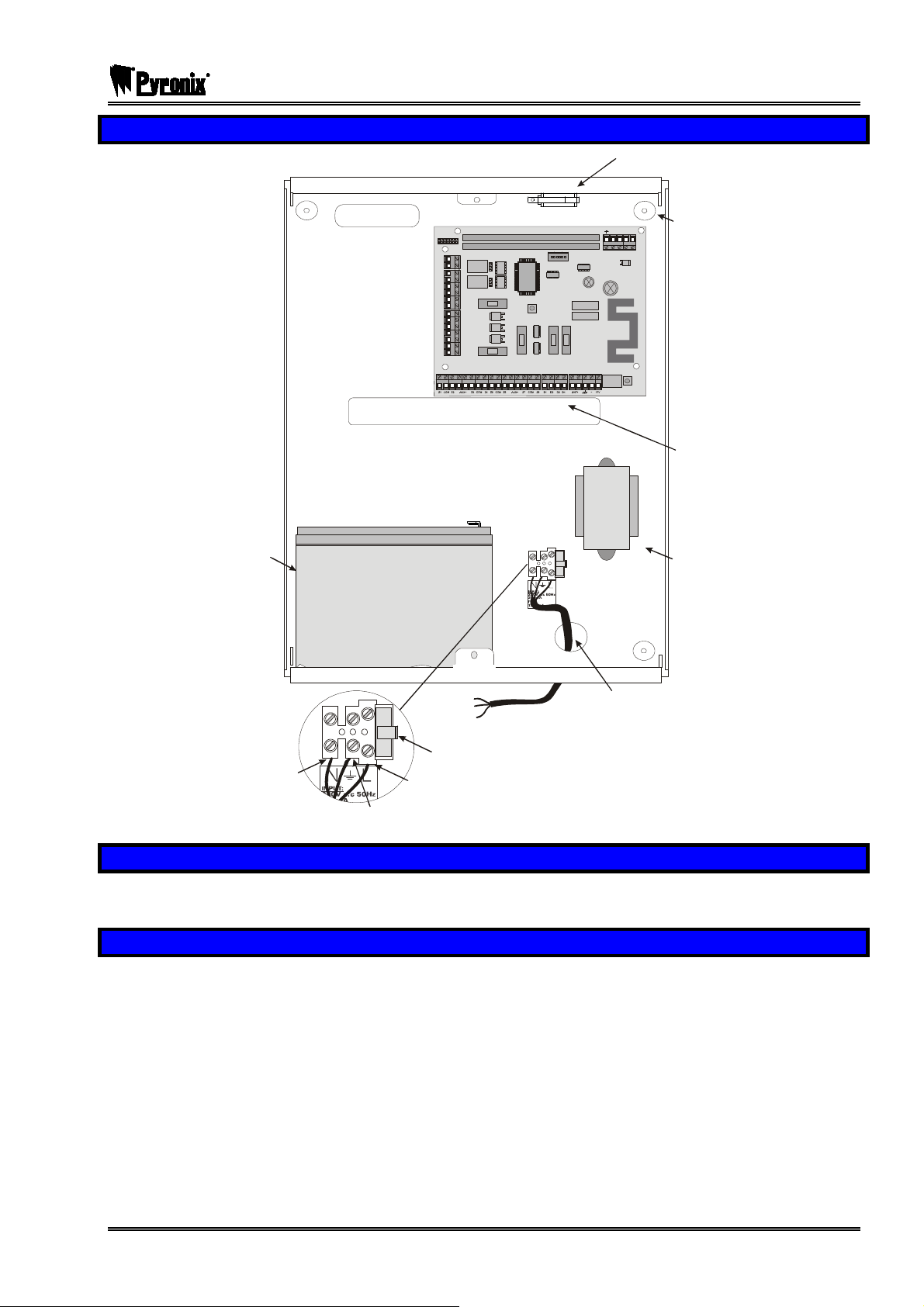

7.4 The PCX Panel Layout

Tam per Sw itc

Battery

17Ah

17Ah

DIGI MODEM CARD SLOT

EXPANSION CARD SLOT

T

A

M

P

E

R

NO1

C1

NC1

NO2

C2

NC2

F1

AUX+

PGM3

PGM4

PGM5

BT

B-

B+

F3 F4 F5

F2

T-1 R-1 TIP RING

Wall Fixing

Holes

Cable

Entry Holes

Mains

Tran sforme r

Neutral

Earth

To M ai ns Su pp ly

Fuse carrier handle

(fuse nominal - 250m A)

Live

Main Cable

Entry Hole

7.5 Battery Installation Procedure

Place two foam pads on the bottom of the battery and two on the upper rear. Place the battery in the case

and secure with two tie wraps.

7.6 Mounting Procedure for Devices

Mount the equipment carefully in suitable locations, noting particularly the following:

a. Input expander units (RIXs or RIX2s) should be located to suit the wiring to appropriate detectors.

Mounting more than two together is not recommended.

b. Where input expanders, output modules or access controllers are mounted on power supplies, all

connections are automatically made to draw all current from the power supply, and to use the system

diagnostic capabilities to control the power supply.

c. Intelligent power supplies cannot be used in isolation from the PCX system plug-on PCBs.

d. Keypads and tag readers should NOT be mounted on or near a metal surface, or within a metre of each

other, or tag response could be affected.

e. Where provided, metal housings must have the earth strap connected to the lid to meet electrical safety

regulations.

RINS871-3 Page: 27

Page 28

PCX SMS AND PCX 256 SYSTEM MANUAL

A

7.7 Tamper Switch

The Tamper switch that is already fitted onto the metal case connects via a plug-on connector to the tamper

pins on the PCX control panel as shown below:

Tam p er S w it c h

COMMUNICATION C ARD

COMMS PGMS

NC1

C1

NO1

NC2

C2

NO2

AUX+

SPK

---------- ------SA B---- --------- ---

TR

B-

B+

TAMPER

EXPANSIO N CAR D SLO T

PGMS

F1

BELL

F2

RESET

BUS

AUX

F3 F4 F5

ENGINEER

KEYPAD

RS232

BATTERY

-1 B-1 A B

BATTERY

CONNEC T

7.8 Mains Connection

MAINS ELECTRICITY IS DANGEROUS!

Mains connection must be performed by a qualified electrician, in accordance with electrical wiring

regulations (BS.7671).

The earth connection must be correctly made to the centre terminal of the mains block, and to terminal G1 of

the End Station, and of any intelligent power supplies.

Metal lids must be correctly connected to mains earth by the wiring loom provided, before securing in

position.

Note:

The PCB ground connection is NOT a safety earth connection, but is for EMC filtering

purposes.

Warning:

Always disconnect the mains supply before removing the cover and working on the

equipment.

7.9 System Connections

Note: Never add equipment to the system with power applied, or damage can result.

Please refer to the following diagrams to identify the functions of all the terminals on PCX components. Note

that all components use the same identification for equivalent applications – e.g. D1, D2, D3 and D4 will

always be the RS-485 terminations, etc.

7.10 Digi Modem Card

Information for installing the Digi Modem Card is shown separately on page 110.

7.11 Expander Card

Information for installing the Expander card is shown separately on page 112. Please note that this is not

available on the PCX 26/SMS.

7.12 Access Control and Guard Tour Equipment