Page 1

Operating Instructions

Series 642

Field Transmitter HART

®

BA01169O/09/en/01.12

71205730

Device software

01.03

Page 2

Brief overview

For rapid and easy commissioning:

Safety instructions → ä 4

Æ

Installation → ä 7

Æ

Wiring → ä 9

Æ

Display and operating elements → ä 13

Æ

Commissioning → ä 18

Quick SET UP - quick access to device configuration for standard operation

Series 642

2 Pyromation, Inc.

Page 3

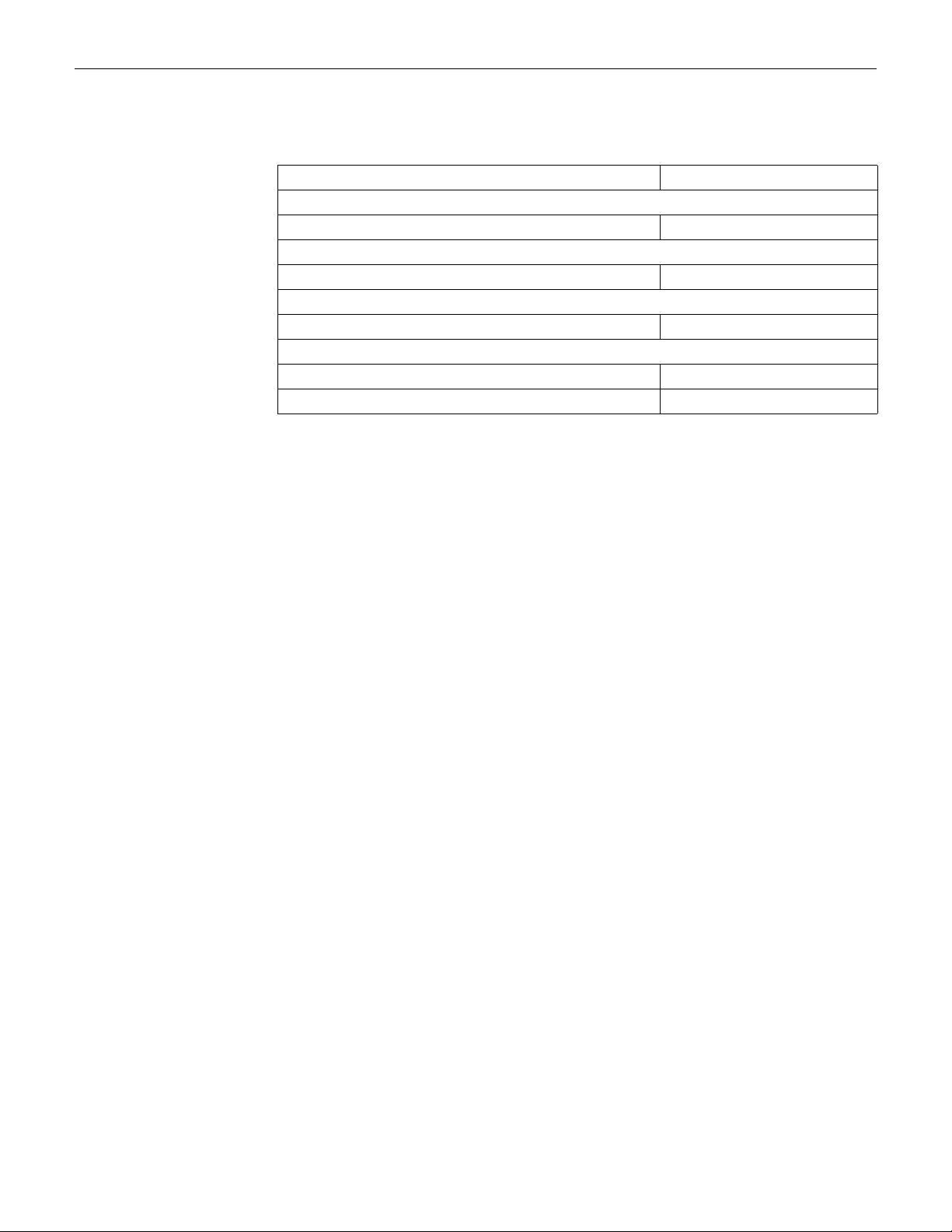

Table of contents Series 642

Table of contents

1 Safety instructions . . . . . . . . . . . . . . . . 4

1.1 Designated use . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Installation, commissioning, operation . . . . . . . . . . 4

1.3 Operational safety . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.5 Notes on safety conventions and icons . . . . . . . . . . 5

2 Identification . . . . . . . . . . . . . . . . . . . . 6

2.1 Device designation . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3 Certificates and approvals . . . . . . . . . . . . . . . . . . . . 6

3 Installation . . . . . . . . . . . . . . . . . . . . . . 7

3.1 Quick installation guide . . . . . . . . . . . . . . . . . . . . . 7

3.2 Installation conditions . . . . . . . . . . . . . . . . . . . . . . 8

3.3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.4 Installation check . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4 Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.1 Quick wiring guide . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.2 Connecting the sensor . . . . . . . . . . . . . . . . . . . . . 10

4.3 Connecting the measuring unit . . . . . . . . . . . . . . . 10

4.4 Screening and potential equalization . . . . . . . . . . . 11

4.5 Degree of protection . . . . . . . . . . . . . . . . . . . . . . . 12

4.6 Connection check . . . . . . . . . . . . . . . . . . . . . . . . 12

9 Technical data . . . . . . . . . . . . . . . . . . 33

10 Appendix . . . . . . . . . . . . . . . . . . . . . . 39

10.1 The Callendar - van Dusen Method . . . . . . . . . . . . 39

10.2 Polynomial RTD . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5 Operation . . . . . . . . . . . . . . . . . . . . . . 13

5.1 Display and operating elements . . . . . . . . . . . . . . 13

5.2 Local operation . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.3 Communication using the HART® protocol . . . . . 15

6 Commissioning. . . . . . . . . . . . . . . . . . 18

6.1 Installation check . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.2 Switch on the device . . . . . . . . . . . . . . . . . . . . . . 18

6.3 Quick Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.4 Device configuration . . . . . . . . . . . . . . . . . . . . . . 19

7 Maintenance. . . . . . . . . . . . . . . . . . . . 28

8 Trouble-shooting . . . . . . . . . . . . . . . . 28

8.1 Trouble-shooting instructions . . . . . . . . . . . . . . . . 28

8.2 Error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

8.3 Application errors without messages . . . . . . . . . 30

8.4 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

8.5 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

8.6 Software history . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Pyromation, Inc. 3

Page 4

Safety instructions Series 642

NOTICE

1 Safety instructions

1.1 Designated use

• The device is a universal and configurable temperature field transmitter for resistance

thermometers (RTD), thermocouples (TC) and resistance and voltage transmitters. The device is

designed for installation in the field.

• The manufacturer does not accept liability for damage caused by improper or non-designated use.

1.2 Installation, commissioning, operation

Please note the following:

• Mounting, electrical installation, commissioning and maintenance of the device must only be

carried out by trained technical personnel authorised to perform such work by the owneroperator. They must have read and understood these Operating Instructions and must follow the

instructions they contain.

• The device may only be operated by staff authorised and instructed by the owner-operator. Strict

adherence to the instructions in these Operating Instructions is mandatory.

• The installer must ensure that the measuring system is correctly connected in accordance with

the electrical wiring diagrams.

• Observe local regulations governing the opening and repair of electrical devices.

1.3 Operational safety

The measuring device meets the general safety requirements of EN 61010 and the EMC

requirements of EN 61326 as well as NAMUR recommendations NE 21, NE 43 and NE 89.

Power supply

► Power must be fed to the device from an 11 to 40 VDC power supply in accordance with NEC

Class 02 (low voltage/current) with short-circuit power limit to 8 A/150 VA.

Hazardous area

Separate Ex documentation is provided for measuring systems used in hazardous areas. This

documentation is an integral part of these Operating Instructions. The installation instructions and

connection data it contains must be observed!

1.4 Return

To reuse later or in case of repair, the device must be packed in protective packaging, preferably the

original packaging. Repairs must only be carried out by your supplier's service organisation or

specially trained personnel.

Enclose a note describing the fault and the application when sending the unit in for repair.

4 Pyromation, Inc.

Page 5

Series 642 Safety instructions

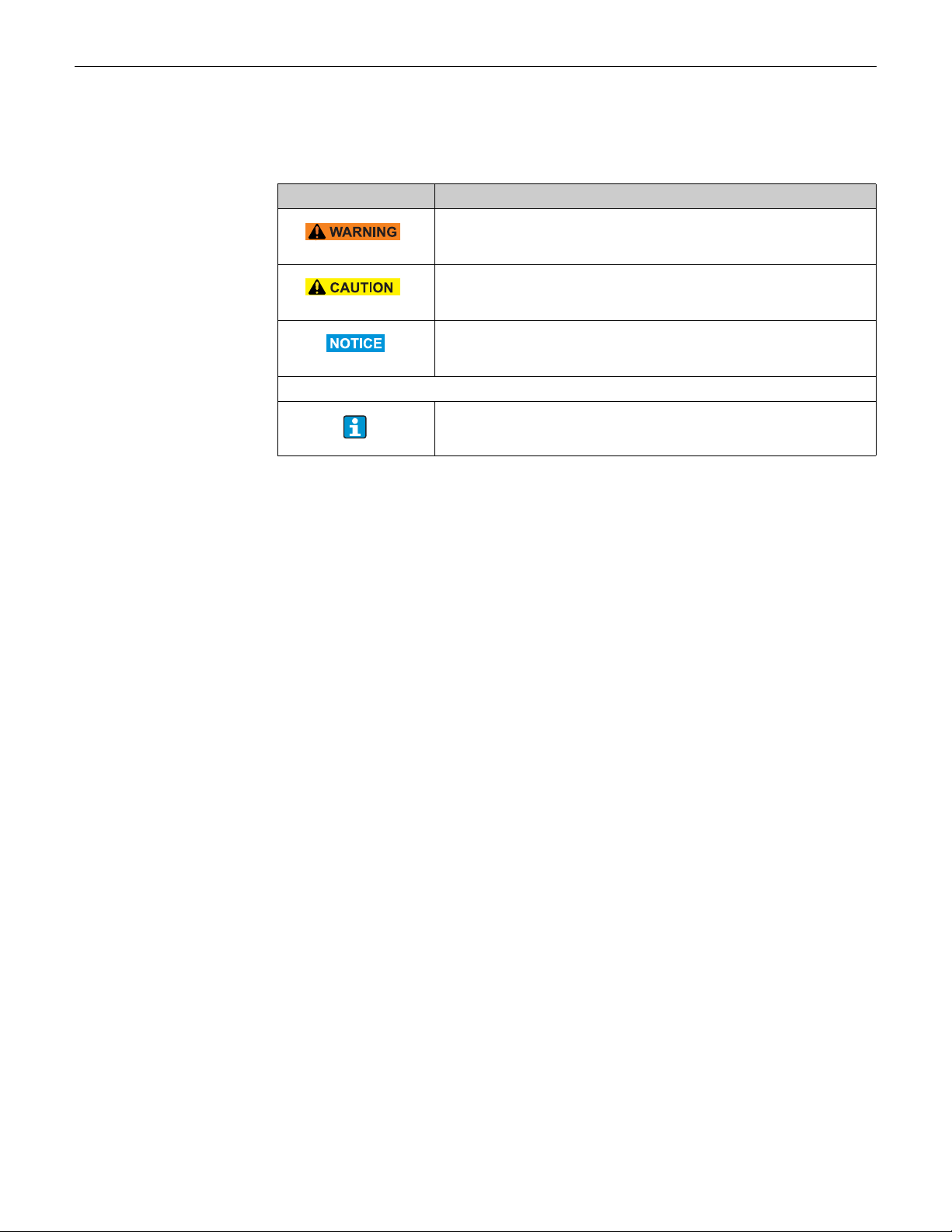

1.5 Notes on safety conventions and icons

The safety instructions in these Operating Instructions are labelled with the following safety icons

and symbols:

Symbol Meaning

WARNING!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result

A0011190-EN

in serious or fatal injury.

CAUTION!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result

A0011191-EN

in minor or medium injury.

NOTICE!

This symbol contains information on procedures and other facts which do not result in

A0011192-EN

personal injury.

Indicates additional information, Tip

A0011193

Pyromation, Inc. 5

Page 6

Identification Series 642

2 Identification

2.1 Device designation

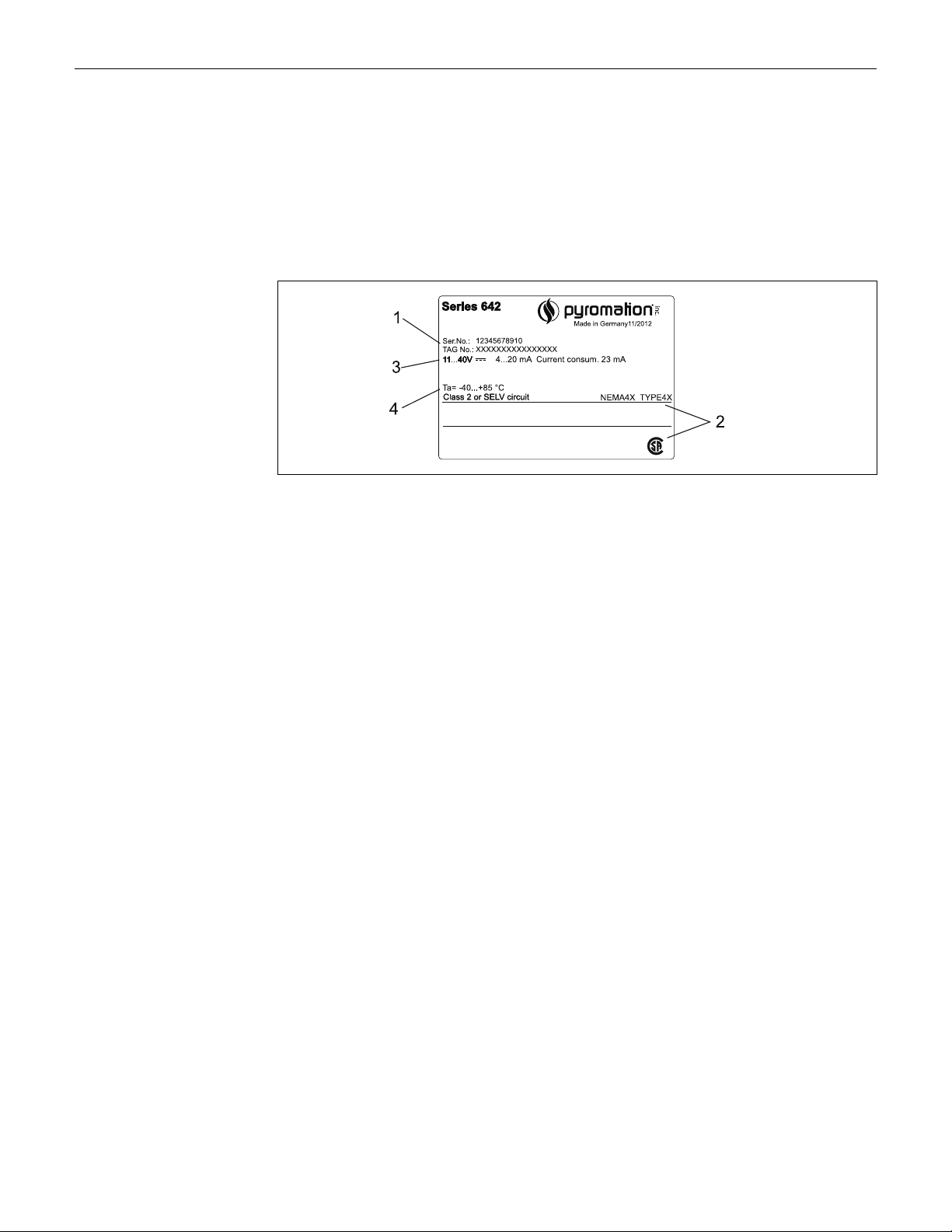

2.1.1 Nameplate

Compare the nameplate on the device with the following diagram:

Fig. 1: Nameplate of the field transmitter (example)

1 Order code and serial number of the device

2 Degree of protection and approvals

3 Power supply and output signal

4 Ambient temperature

2.2 Scope of delivery

The scope of delivery of the field transmitter comprises:

• Temperature field transmitter

• Dummy plug

• Mounting bracket

• Operating Instructions

2.3 Certificates and approvals

CE mark, declaration of conformity

The temperature field transmitter is designed to meet state-of-the-art safety requirements, has been

tested and left the factory in a condition in which it is safe to operate. The device meets the relevant

standards and directives as per IEC 61 010 "Safety requirements for electrical equipment for

measurement, control and laboratory use".

The device described in these Operating Instructions thus meets the legal requirements of the EU

directives. The manufacturer confirms that the device has been tested successfully by affixing the

CE mark.

CSA GP approved

6 Pyromation, Inc.

Page 7

Series 642 Installation

3 Installation

3.1 Quick installation guide

If the sensor is fixed then the unit can be fitted directly to the sensor.

If the sensor is to be mounted at a right angle to the cable gland, swap the dummy plug and cable

gland.

The device can be mounted directly on the wall. A mounting bracket is available for pipe mounting

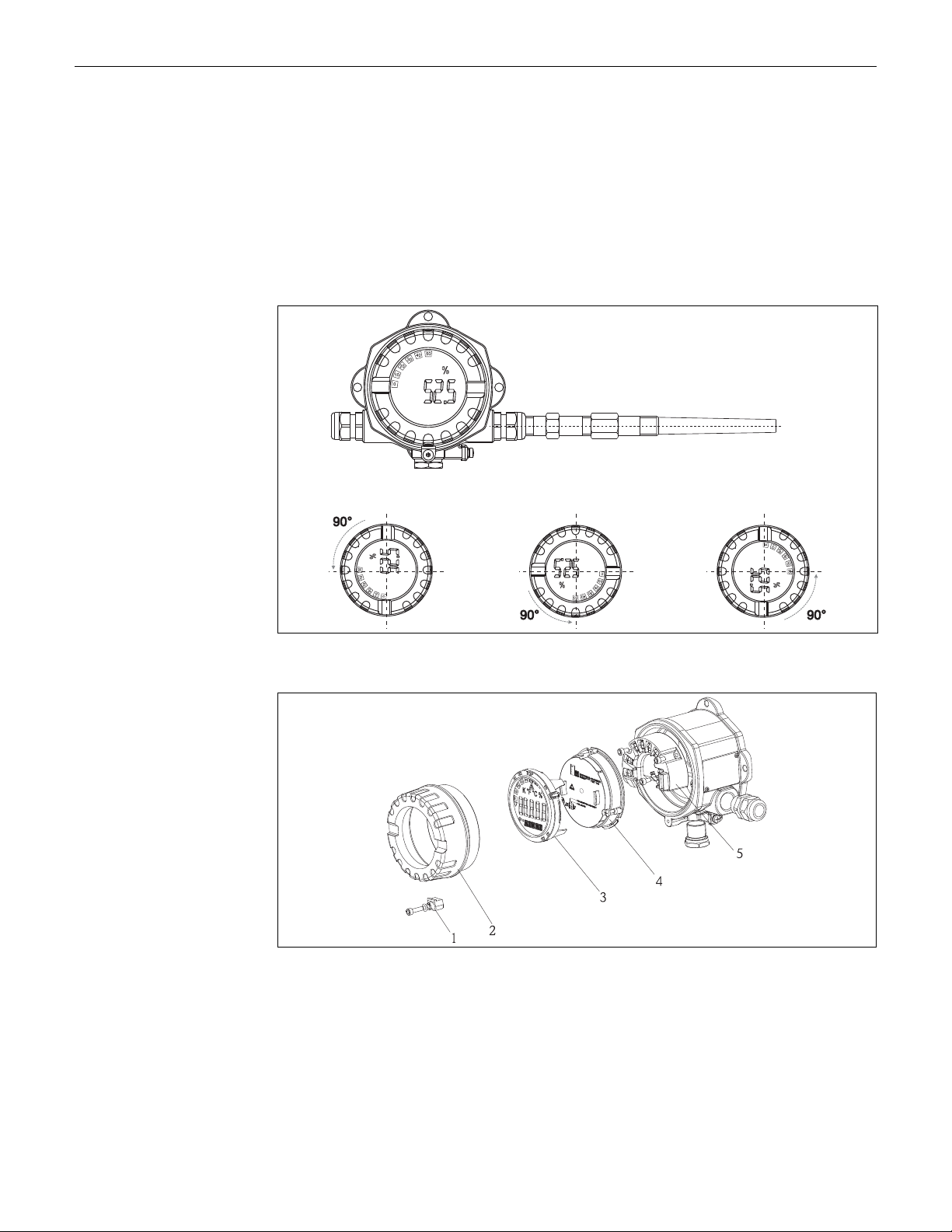

(see Fig. 4). The illuminated display can be mounted in four different positions (→ å 2):

Fig. 2: Temperature field transmitter with sensor, 4 display positions, can be plugged-in in 90° steps

Fig. 3: Turning the display

1. Remove the cover clamp (Pos. 1).

2. Unscrew the housing cover together with the O-ring (Pos. 2).

3. Remove the display with retainer (Pos. 3) from the electronics module (Pos. 4). Adjust the

display with retainer in 90°stages to your desired position and rearrange it on the particular

slot in the electronics module.

4. Then screw on the housing cover together with the O-ring. Mount the cover clamp.

Pyromation, Inc. 7

Page 8

Installation Series 642

3.2 Installation conditions

3.2.1 Dimensions

The dimensions of the device can be found in chapter 10 ''Technical data".

3.2.2 Installation point

Information on installation conditions, such as ambient temperature, protection classification,

climatic class etc., can be found in chapter 10 "Technical data".

3.3 Installation

3.3.1 Direct wall mounting

Proceed as follows to mount the device directly on wall:

• Drill 2 holes

• Attach the device to the wall with 2 screws (M6).

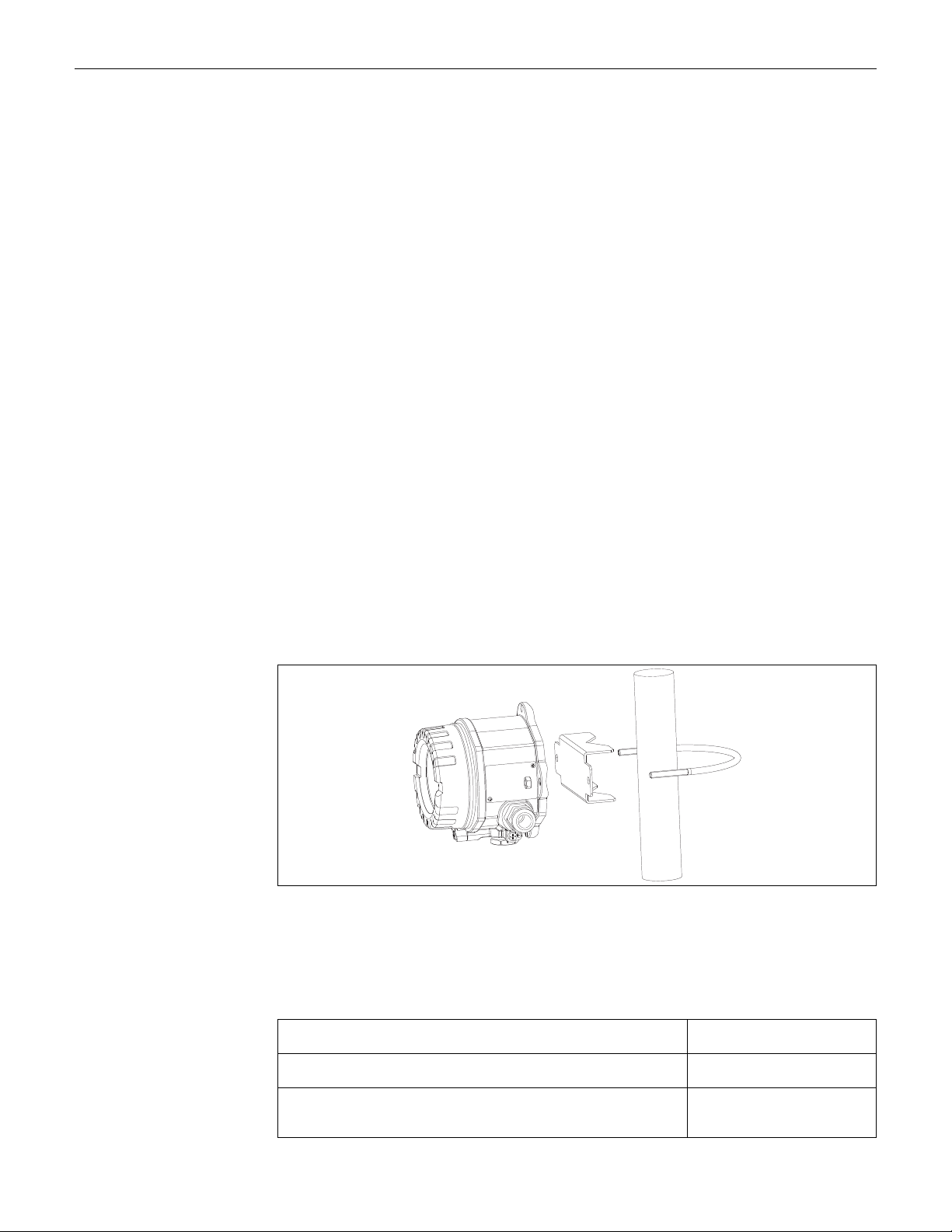

3.3.2 Pipe installation

The mounting bracket is suited for pipes with a diameter between 1.5" - 3.3".

Proceed as follows to mount the device on a pipe:

• Attach the mounting bracket to the pipe

• The additional mounting plate must be used for pipes with a diameter of 1.5" to 2.2".

• Fix the device to the mounting bracket with the two screws supplied. The mounting plate is not

needed for pipes with a diameter of 2.2" - 3.3".

Fig. 4: Mounting the field transmitter with the mounting bracket, see 'Accessories' section

3.4 Installation check

After installing the device, always run the following final checks:

Device condition and specification Hint

Is the device visibly damaged (visual check)? -

Does the device comply to the measurement point specifications, such as

ambient temperature, measurement range etc.?

8 Pyromation, Inc.

See chapter 10 "Technical data"

Page 9

Series 642 Wiring

NOTICE

NOTICE

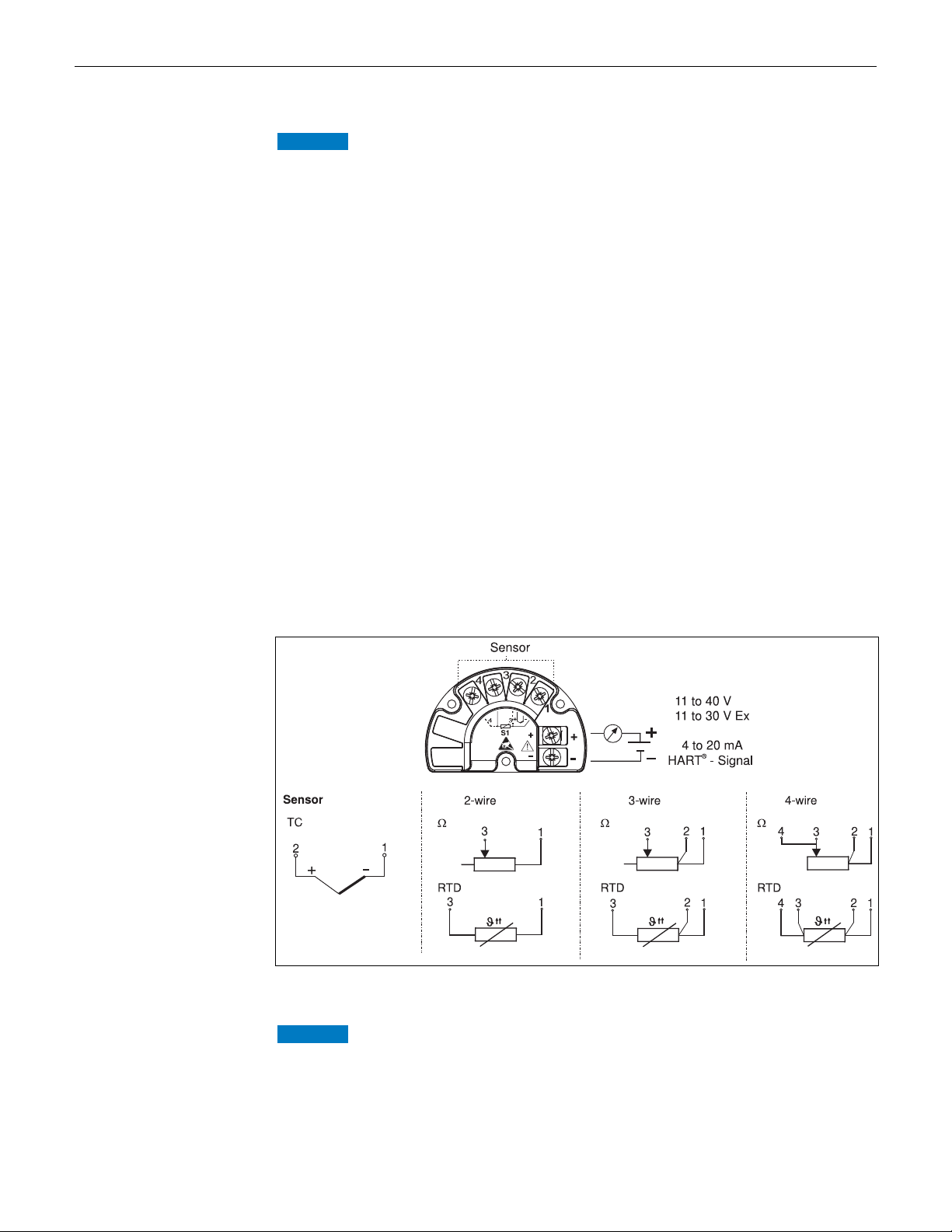

4 Wiring

Installation in hazardous area

► When installing Ex-approved devices in a hazardous area please take special note of the

instructions and connection schematics in the respective Ex documentation added to this

operating manual. The local representative is available for assistance if required.

For wiring the device proceed as follows:

1. Remove the cover clamp (→ å 3, item 1).

2. Remove the device cover (→ å 3, item 2).

3. Remove the display from the electronics module (→ å 3, item 3).

4. Open the 2 screws of the electronics unit and remove the electronics unit (→ å 3, item 4).

5. Open the cable gland at the device (→ å 3, item 5).

6. Feed the cable through the opening in the cable gland.

7. Connect the wires (→ å 5).

8. Make sure that the terminal screws are tight. Re-seal the cable gland by screwing the cover

back on.

9. In order to avoid connection errors always take note of the hints given in the section

connection check!

4.1 Quick wiring guide

Terminal layout

Fig. 5: Wiring the field transmitter

ESD - Electrostatic discharge

► Protect the terminals from electrostatic discharge. Failure to observe this may result in

destruction of parts of the electronics.

Pyromation, Inc. 9

Page 10

Wiring Series 642

NOTICE

4.2 Connecting the sensor

Please refer to Section 4.1 "Quick wiring guide" for the terminal assignment of the sensor

connections.

4.3 Connecting the measuring unit

Electronic parts may be damaged

► Switch off power supply before installing or connecting the device. Failure to observe this may

result in destruction of parts of the electronics.

► If the device has not been grounded as a result of the housing being installed, grounding it via

one of the ground screws is recommended.

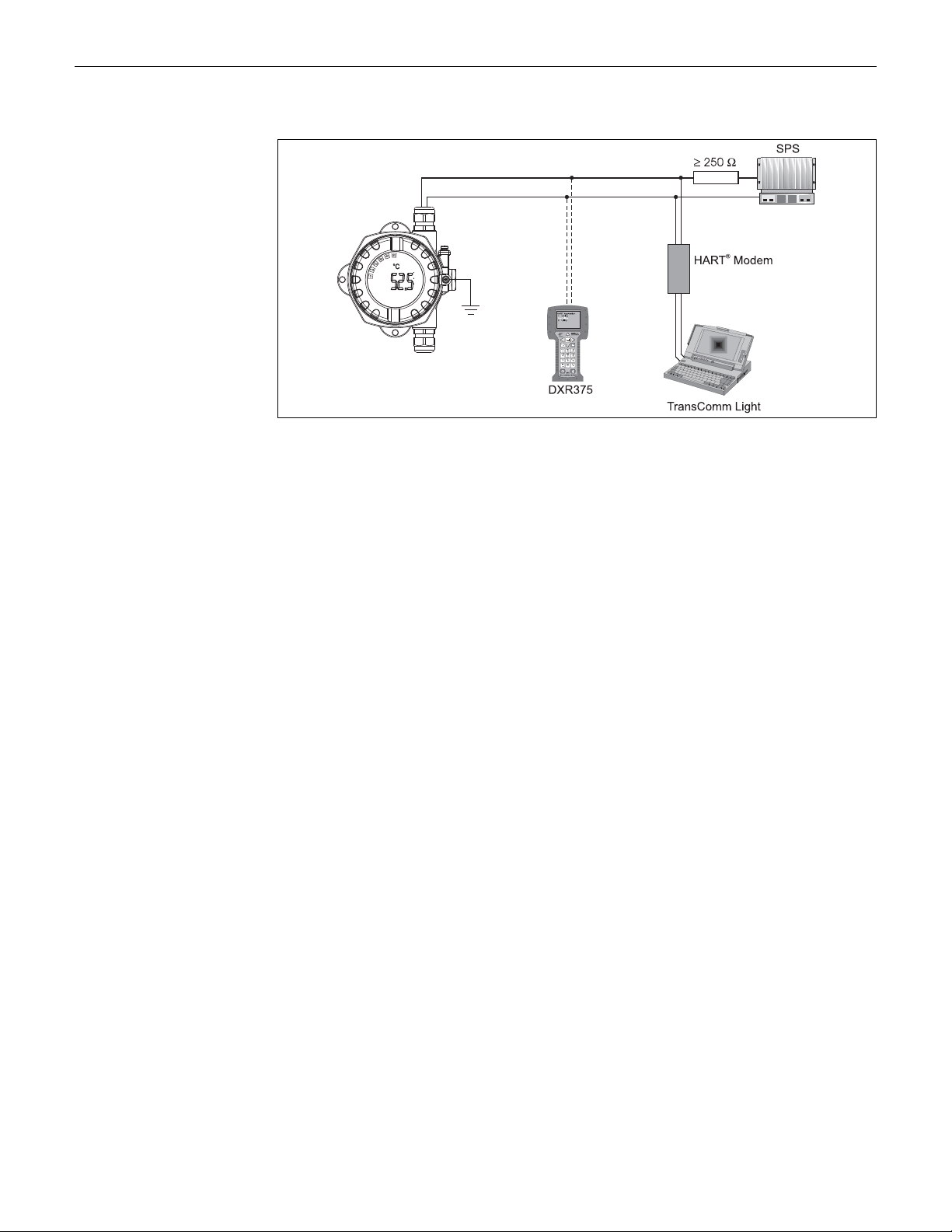

4.3.1 HART® connection

If the HART

communication resistor must be fitted into the 2-wire supply lines.

For connection hints, please take special notice of the documentation supplied by the

HART

overview”.

®

communication resistance is not built into the power supply, a 250 Ω

®

Communication Foundation, specifically HCF LIT 20: “HART, a technical

Connection using a transmitter power supply

HART® connection with a transmitter power supply

10 Pyromation, Inc.

Page 11

Series 642 Wiring

Connection using other power supplies

HART® connection using other power supplies, e. g. a SPS

4.4 Screening and potential equalization

Please take note when installing the device:

If screened (shielded) cables are used then the screen connected to the output (output signal 4 to

20mA) must be at the same potential as the screen at the sensor connection!

When operating in plants with high electromagnetic fields, it is recommended that all cables be

screened using a low ohm ground connection. Due to the possible danger of lightning strikes

screening is also recommended for cables that are run outside buildings!

Pyromation, Inc. 11

Page 12

Wiring Series 642

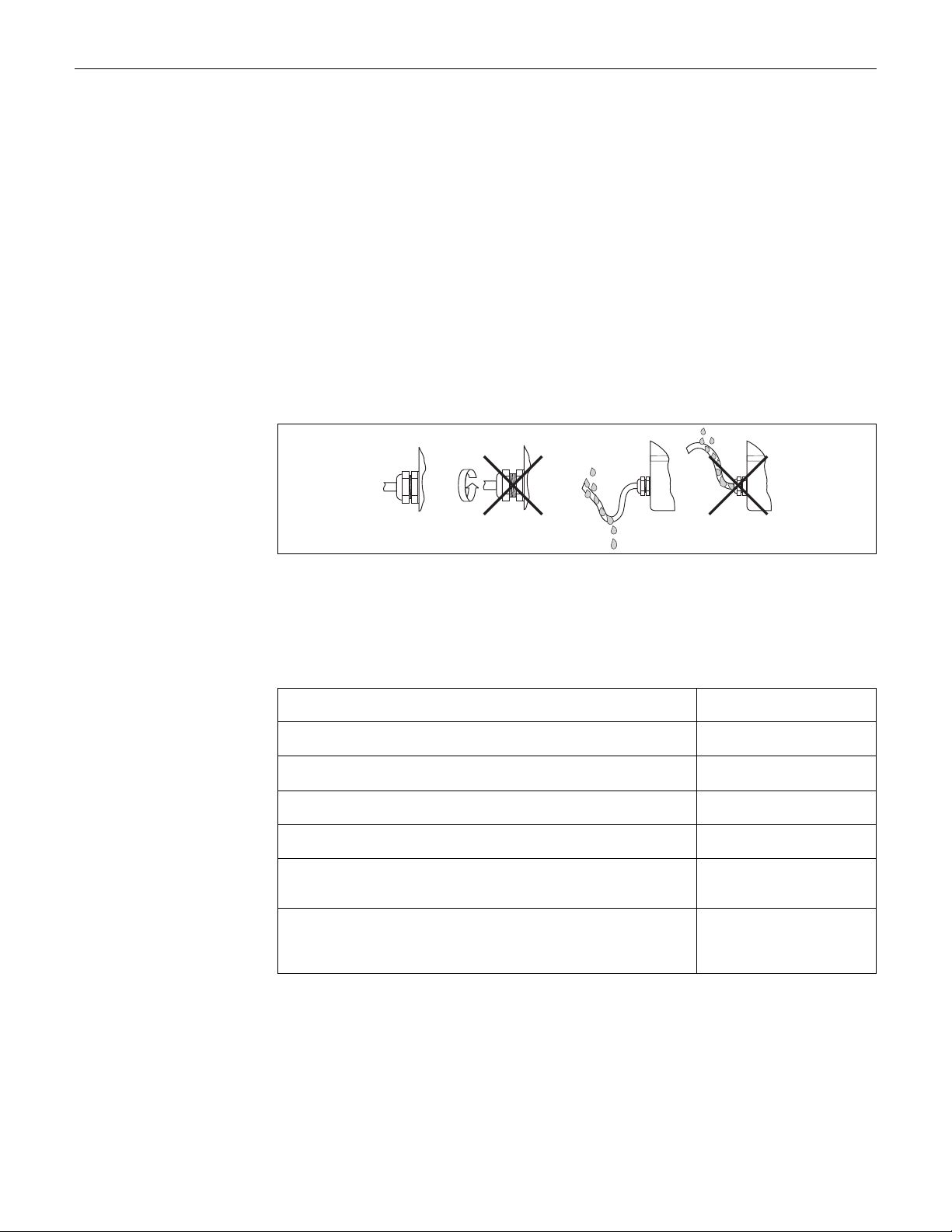

4.5 Degree of protection

The device conforms to the requirements to IP 67 ingress protection. In order to fulfil an IP 67

degree of protection after installation or service, the following points must be taken into

consideration:

• The housing seals must be clean and undamaged before they are replaced into the sealing rebate.

If they are found to be too dry then they should be cleaned or even replaced.

• All housing screws and covers must be pulled tight.

• The cables used for connection must be of the correct specified outside diameter (e.g. M20 x 1.5,

cable diameter from 8 to 12 mm; 0.315 to 0.47 in).

• Tighten cable gland (→ å 6).

• Loop the cable before placing into the cable entry ("Water sack", → å 6). This means that any

moisture that may form cannot enter the gland. Install the device so that the cable entries are not

facing upwards.

• Cable entries not used are to be blanked off using the blanking plates provided.

• The protective olive must not be removed from the cable gland.

Fig. 6: Connection hints to retain IP 67 protection

4.6 Connection check

After the electrical installation of the device, always perform the following final checks:

Device condition and specification Hint

Are the device or the cables undamaged (visual check)? -

Electrical connection Hint

Is the cable installation correctly separated, with no loops or crossovers? -

Are the cables load relieved? -

Have the cables been correctly connected? Compare with the

connection schematic on the terminals or → Fig. 5.

Are all terminal screws tightened?

Is the cable entry sealed?

Is the housing cover screwed tight?

See connection schematic on the

housing

Visual check

12 Pyromation, Inc.

Page 13

Series 642 Operation

°C

°F

%

K

10

0

20

30

40

50

60

70

80

90

100

!

Ê

Ë

Ì

Í

Î

Ï

Ð

5Operation

5.1 Display and operating elements

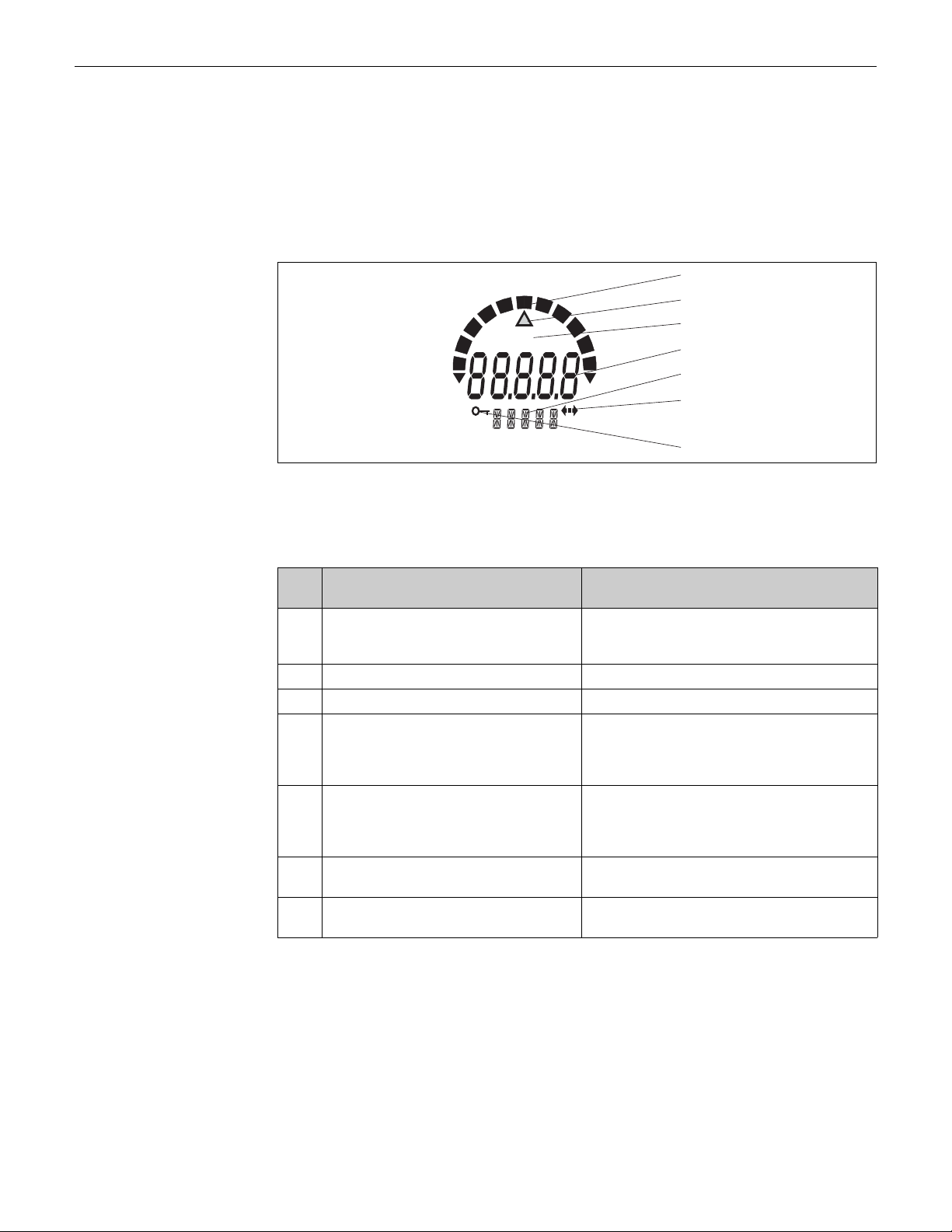

5.1.1 Display

Fig. 7: LC display of the field transmitter (illuminated, can be plugged in 90° stages)

5.1.2 Display symbols

Item

Function Description

No.

1 Bargraph display In 10 % stages with indicators for overranging/

2 'Caution' indicator This appears in the event of an error or warning

3 Unit display K, °F, °C or % Unit display for the measured value displayed

4 Measured value display (digit height 20.5 mm) The measured value is displayed. In the event of a warning,

5 Status and information display Indicates which value is currently shown on the display. A

6 'Communication' display The communication symbol appears for read and write

7 'Configuration blocked' display The 'configuration blocked' symbol appears if configuration

underranging. The bargraph display flashes when an error

occurs.

the display switches between the measured value and the

code of the warning. In the event of an error, the error code

is displayed instead of the measured value.

customer-specific text can be entered for PV. In the event

of a warning, 'WARN' is displayed along with the code for

the warning. In the event of an error, 'ALARM' is displayed.

®

access via the HART

via software or hardware is blocked.

protocol

Pyromation, Inc. 13

Page 14

Operation Series 642

NOTICE

5.2 Local operation

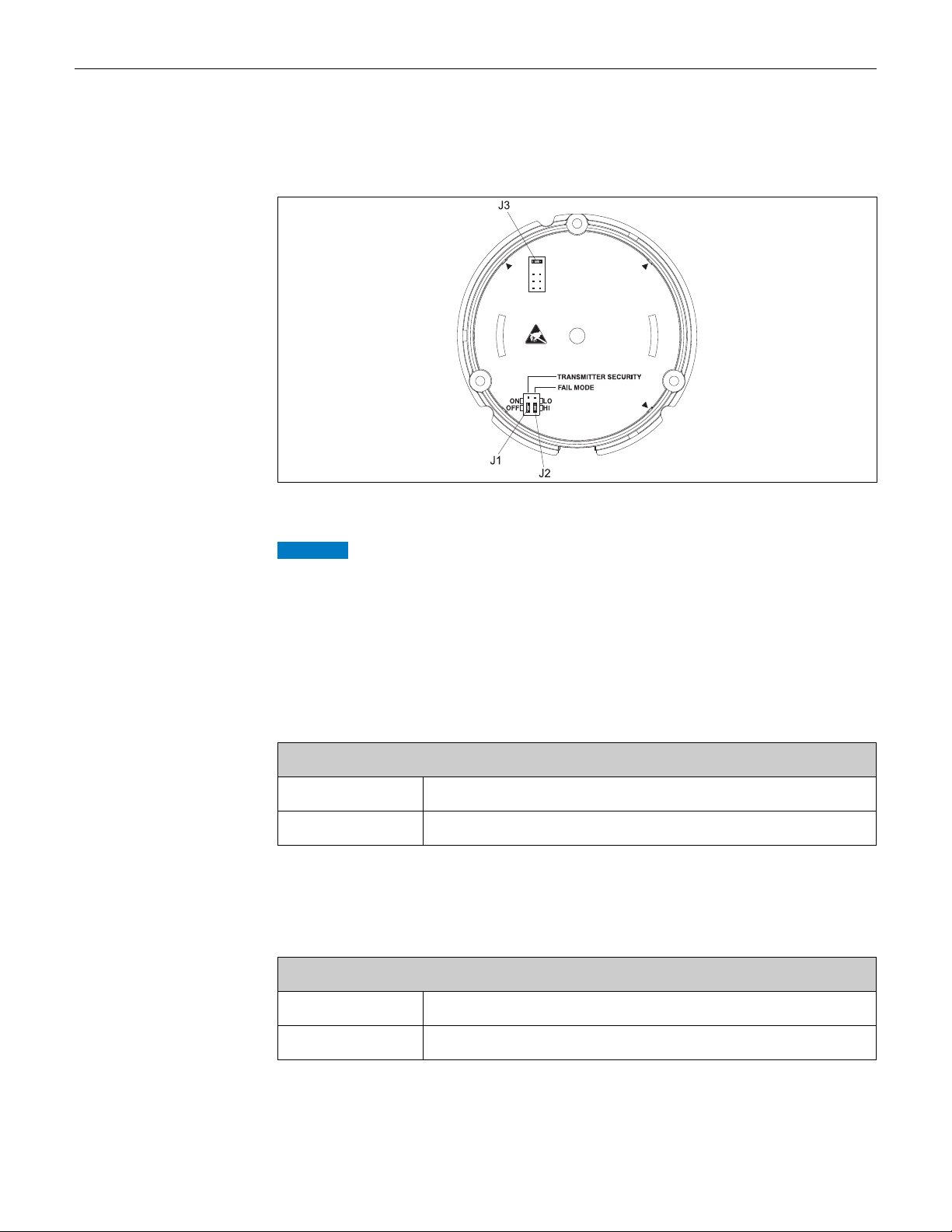

5.2.1 Hardware setting

Fig. 8: Hardware settings via jumpers J1, J2 and J3

ESD - Electrostatic discharge

► Protect the terminals from electrostatic discharge. Failure to observe this may result in

destruction of parts of the electronics.

Jumpers J1, J2 and J3 for the hardware setting are located at the electronics module. To set the

jumper, open the threaded joint of the electronics module (opposite the threaded joint of the

connection compartment) and remove the display if necessary.

Hardware locking the configuration with jumper J1

TRANSMITTER SECURITY

ON Configuration locked

OFF Configuration enabled

The hardware setting for configuration locking has priority over the software setting.

Setting the failsafe mode via the hardware with jumper J2

FAILURE MODE

LO ≤ 3.6 mA

HI ≥ 21.0 mA

The failsafe mode set via the jumpers only takes effect if the microcontroller fails.

14 Pyromation, Inc.

Page 15

Series 642 Operation

Please check that the hardware and software setting for the failsafe mode match.

Hardware setting with jumper J3 (only for devices without a display)

If jumper J3 is set, the minimum operating voltage can be reduced from 11 V to 8 V.

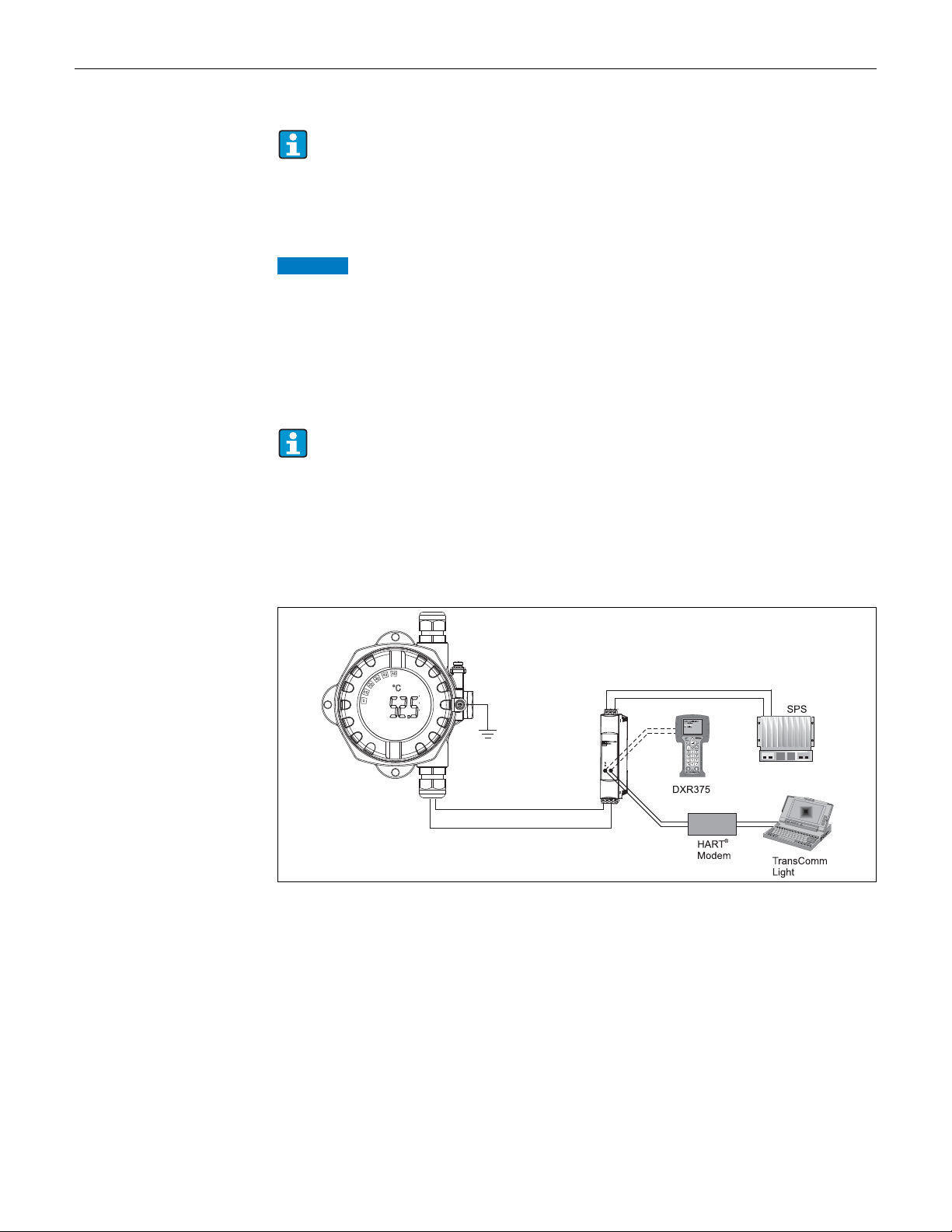

5.3 Communication using the HART® protocol

The set-up and measured value read out of the measuring device is done using the HART® protocol.

®

The digital communication is done using the 4 to 20 mA current output HART

(see Figs. 4 and 5).

There are a number of possible set-up methods available to the user:

®

• Operation using the universal handheld module "HART

Communicator DXR375".

• Operation using a PC combined with an operating software, e.g. 'TransComm Light' as well as a

®

modem.

HART

• Operating programs of other manufacturers ('AMS', Fisher Rosemount; 'SIMATIC PDM',

Siemens).

®

If communication errors occur in the Microsoft

®

Windows

2000 operating systems the following measure is to be taken:

Windows NT ® Version 4.0 and

Switch off setting "FIFO active".

In order to do this follow these steps.

®

1. On Windows NT

Version 4.0:

Select the menu point "COM-Port" using the menu "START" ➠ "SETTINGS" ➠ "CONTROL

PANEL" ➠ "PORTS". Using the menu string "SETTINGS" ➠ "ADVANCED" switch the

command "FIFO active" off. Now restart the PC.

®

2. For Windows

2000 and Windows® XP (classic category view):

Select "Advanced settings for COM1" using the menu "START" ➠ "SETTINGS" ➠ "CONTROL

PANEL" ➠ "SYSTEM" ➠ "HARDWARE" ➠ "DEVICE MANAGER" ➠ "PORTS (COM and

LPT)" ➠ "COMMUNICATIONS PORT (COM1)" ➠ "CONNECTION SETTINGS" ➠

"ADVANCED". Deactivate the "Use FIFO buffer". Now restart the PC.

5.3.1 HART® Communicator DXR375

With the HART

menu levels with the aid of the function matrix (→ ä 16). All the device functions are

explained in chapter 6.4.1 "Description of Device Functions".

Procedure:

1. Switch on the handheld module:

– Measuring device not yet connected. The HART

appears for every HART

Information on off-line configuration can be found in the Operating Instructions of the

“Communicator DXR375” handheld module.

– Measuring device is already connected. The 1st menu level of the device function matrix

appears directly (see Fig. 9). All the functions accessible under HART

arranged in this matrix.

2. Select the function group (e.g. Sensor ) and then the desired function, e.g. “Sensor type”.

3. Enter type or change the setting. Then confirm with the function key F4 “Enter”.

4. “SEND” appears via the function key “F2”. Pressing the F2 key transfers all the values entered

with the handheld module to the device measuring system.

Pyromation, Inc. 15

®

handheld module, all device functions are selected by means of various

®

®

programming, i.e. irrespective of the measuring device type.

main menu appears. This menu level

®

are systematically

Page 16

Operation Series 642

Standard

set-up

!

Note!

are marking the Quick Setup menu.

The black highlighted function fields

Min measurm

range

Max

measurm

range

RTD

connection

PV value

in %

Value

Sensor 1

RJ value

Measured

values

Sensor

Output

Safety

settings

Display

Diagnosis

Identification

Service

functions

PV up

range value

Display

Device status

Measuring

point

Tag

Device

release

Descriptor

Serial no.

Software

rev.

Certificates Manufacturer Model Date

Hardware

rev.

Message

Security

locking

Simulation

mode

Simulation

value

Trim

4mA

Trim

20 mA

PV lo

range value

Fault

condition

Display text

Last

diagnostic

Device infos

Default

values

Analog

output

Alarm

hysteresis

Decimal

places

Status

sensor

Config.

changed

Max. value

sensor

Min. value

sensor

Max.

RJ value

Min.

RJ value

HART

Output mode

Num. resp.

preams

Poll

addr.

Corros.

detection

Over-/Under-

range alarm

Mains filter

Filter time

Ambient

alert

Display

interval

AO

PV unit

PV

Sensor type

Sensor

connect.

Cold

junction

External

temp.

2-wire

comp.

Offset

sensor

Meas. unit

sensor

Value

sensor

Serial no.

sensor

Static

Revision Counter

5. With the "F3" function key HOME, you return to the 1st menu level.

Fig. 9: Configuration at the handheld module, using 'Sensor input' as an example’

HART

®

function matrix

16 Pyromation, Inc.

Page 17

Series 642 Operation

•With the HART

disabled. However, you can enable the HART

®

handheld module, all parameters can be read and programming is

®

function matrix by entering 246 in the

SECURITY LOCKING function. The enable status is retained even after a power failure.

®

Delete the release code 246 to lock the HART

• Detailed information can be found in the HART

function matrix again.

®

instruction manual that can be found

in the handheld module transport pouch.

5.3.2 TransComm Light

This is a universally applicable service and configuration software. Connection is made using a

®

HART

• Set-up device functions

• Measured value visualisation

• Device parameter data storage

• Measuring point documentation

Analog output

► The analog output is undefined when downloading the device function parameters from the PC

Further in-depth information to operation via TransComm Light can be found in the online

documentation of the software. TransComm Light can be downloaded free of charge from the

following address:

modem. The operating software offers the user the following possibilities:

NOTICE

configuration software to the device.

www.pyromation.com

5.3.3 Command classification in the HART® protocol

The HART® protocol makes it possible for configuration and diagnostic purposes to transmit

measured and device data between the HART

®

masters such as the handheld module or PC-based operating programmes require so-called

HART

device description files (DD = device descriptions, DTM), these make it possible to access all

®

information in a HART

device. Transmission of such information is done exclusively using

"commands".

There are three command classifications:

• Universal commands

Universal commands are supported and used by all HART

the following functionalities:

®

–Recognising HART

device

– Read out of digital measured values

• Common practice commands:

These general commands offer functions that are supported or used by some but not all field

devices.

• Device specific commands

These commands enable access to device specific functions that are not HART

Such commands access, amongst other things, individual field device information.

Chapter 6.4.2 contains a list of all HART

®

master and the respective field device.

®

devices. Combined are, for example,

®

commands supported.

®

standardised.

Pyromation, Inc. 17

Page 18

Commissioning Series 642

6Commissioning

6.1 Installation check

Before commissioning the measurement point make sure that all final checks have been carried out:

• Checklist “Installation check”

• Checklist “Connection check”

6.2 Switch on the device

Once the power has been connected, the field transmitter is operational.

6.3 Quick Setup

Using the Quick Setup the operator is led through all the most important unit functions, which must

be set up for standard measurement operation of the unit.

Standard set-up

®

Availability in TransComm Light and HART

(symbol

Function + +

PV mode + +

PV unit + +

Sensor

Sensor type + +

Sensor connection + +

Unit + +

OUTPUT

PV lower range value + +

PV upper range value + +

Safety/maintenance functions

Fault condition + +

)

7

communicator DXR375

TransComm Light

7

Alarm ambient temperature + +

Further set-up for special measurement applications are possible (see Section 6.4.1).

18 Pyromation, Inc.

Page 19

Series 642 Commissioning

6.4 Device configuration

6.4.1 Description of device functions

All parameters that can be read out and set-up for the configuration of the temperature transmitter

Availability in TransComm Light, HART

are listed and described in the following tables. The menu structure in the PC configuration software

TransComm Light and in the HART

Factory default setup is shown in bold text.

Function group STANDARD SETTINGS

®

communicator DXR375 (symbol 7) TransComm Light

®

communicator DXR375 are shown in the following tables.

7

PV unit Enter the unit of the PV (= Primary Value)

Availability in TransComm Light, HART

Sensor type

IEC 60751

JIS

IEC 60751

Edison Copper

Winding No. 15

SAMA

Edison Curve No. 7

GOST

Input: ° C, °F, K, R, mV or Ω

The setting PV unit has priority, the selection list of the sensor type is shown

independently from the PV unit.

Function group SENSOR

®

communicator DXR375 (symbol 7) TransComm Light

Sensor type

Pt100

Pt200

Pt100

Pt500

Pt1000

Ni100

Ni1000

Cu10

Pt100

Ni120

Pt50

Pt100

Cu50

Cu100

Meas. range

start

-200 °C (-328 °F)

-200 °C (-328 °F)

-200 °C (-328 °F)

-200 °C (-328 °F)

-200 °C (-328 °F)

-60 °C (-76 °F)

-60 °C (-76 °F)

-100 °C (-148 °F)

-100 °C (-148 °F)

-70 °C (-94 °F)

-200 °C (-328 °F)

-200 °C (-328 °F)

-200 °C (-328 °F)

-200 °C (-328 °F)

Meas. range

full scale value

850 °C (1562 °F)

850 °C (1562 °F)

649 °C (1200.2 °F)

250 °C (482 °F)

250 °C (482 °F)

250 °C (482 °F)

150 °C (302 °F)

260 °C (500 °F)

700 °C (1292 °F)

270 °C (518 °F)

1100 °C (2012 °F)

850 °C (1562 °F)

200 °C (392 °F)

200 °C (392 °F)

min. range

10 K (18 °F)

10 K (18 °F)

10 K (18 °F)

10 K (18 °F)

10 K (18 °F)

10 K (18 °F)

10 K (18 °F)

10 K (18 °F)

10 K (18 °F)

10 K (18 °F)

10 K (18 °F)

10 K (18 °F)

10 K (18 °F)

10 K (18 °F)

++

7

++

Polynomial RTD

Callendar - van

Dusen (Pt100)

-200 °C (-328 °F)

-200 °C (-328 °F)

850 °C (1562 °F)

850 °C (1562 °F)

10 K (18 °F)

10 K (18 °F)

Pyromation, Inc. 19

Page 20

Commissioning Series 642

Function group SENSOR

Availability in TransComm Light, HART® communicator DXR375 (symbol 7) TransComm Light

Sensor type Sensor type

TC Type B

TC Type C

TC Type D

TC Type E

TC Type J

TC Type K

TC Type L

TC Type N

TC Type R

TC Type S

TC Type T

TC Type U

10 to 400 Ω

10 to 2000 Ω

-20 to 100 mV

Specific linearization and sensor matching

Selecting the sensor types 'Callendar-van-Dusen' or 'Polynomial RTD' improves the accuracy of the system or defines user-specific linearisation of resistance

thermometers. A detailed description of the 'Callendar-van-Dusen' method and 'Polynomial RTD' linearisation is provided in the Appendix to these Operating

Instructions.

The selection list of the sensor type is displayed depending on the PV unit. Example: When

selecting a resistance thermometer the PV unit must first be set to Ω.

Sensor connection Input of RTD connection mode.

Input:

•2-wire

• 3-wire

•4-wire

Function is only active on selection of a resistance thermometers (RTD) in the device

function SENSOR TYPE.

Meas. range

start

0 °C (32 °F)

0 °C (32 °F)

0 °C (32 °F)

-270 °C (-454 °F)

-210 °C (-346 °F)

-270 °C (-454 °F)

-200 °C (-328 °F)

-270 °C (-454 °F)

-50 °C (-58 °F)

-50 °C (-58 °F)

-270 °C (-454 °F)

-200 °C (-328 °F)

10 Ω

10 Ω

-20 mV

Meas. range

full scale value

1820 °C (3308 °F)

2320 °C (4208 °F)

2495 °C (4523 °F)

1000 °C (1832 °F)

1200 °C (2192 °F)

1372 °C (2501.6 °F)

900 °C (1652 °F)

1300 °C (2372 °F)

1768 °C (3214.4 °F)

1768 °C (3214.4 °F)

400 °C (752 °F)

600 °C (1112 °F)

400 Ω

2000 Ω

100 mV

min. range

500 K (900 °F)

500 K (900 °F)

500 K (900 °F)

50 K (90 °F)

50 K (90 °F)

50 K (90 °F)

50 K (90 °F)

50 K (90 °F)

500 K (900 °F)

500 K (900 °F)

50 K (90 °F)

50 K (90 °F)

10 Ω

100 Ω

5 mV

++

++

7

Cold junction Selection of the internal (Pt100) or an external comparison

External

temperature

2-wire

compensation

measurement point.

Input:

• internal

• external

Function is only active on selection of a thermo-couple (TC) in the device function SENSOR

TYPE.

Input of the external comparison point measurement value.

put: -40.00 to 85.00 °C (°C, °F, K)

In

0 °C

Function is only active when "external" has been selected in the device function COLD

JUNCTION.

Input of cable resistance compensation on a 2-wire RTD connection.

Input: 0.00 to 30.00 Ω

Function is only active when a 2-wire connection has been selected in the device function

SENSOR CONNECTION.

++

++

++

20 Pyromation, Inc.

Page 21

Series 642 Commissioning

Function group SENSOR

Availability in TransComm Light, HART® communicator DXR375 (symbol 7) TransComm Light

Offset Input of the zero point correction (offset).

Input: -10.00 to 10.00 °C (-18.00 to 18.00 °F)

0.00 °C

Unit Display of measurement unit.

Sensor unit = PV unit

Serial no. sensor Input of the serial number of the sensor connected to this sensor input. + +

Function group OUTPUT

®

Availability in TransComm Light, HART

PV lower range value Input of 4 mA value.

Input: Limitation values see device function SENSOR TYPE.

0 °C

PV upper range value Input of 20 mA value.

Input: Limitation values see device function SENSOR TYPE.

100 °C

Analog output Input of the standard (4 to 20 mA) or inverse (20 to 4 mA) current output signal.

Input:

• 4 to 20 mA

•20 to 4 mA

communicator DXR375 (symbol 7)TransComm Light

++

++

++

++

++

7

7

Filter Selection of the digital filter 1. order (filter time constant).

HART Output/

Multidrop

Input: 0 to 60 s

Preamble Input: Number of response preambles: 5 to 20

5

Device

address

Input: HART address of the temperature transmitters:

0 to 15

If addresses > 0, the temperature transmitter

is in Multidrop mode and the analogue output is set to 4 mA. Device

address is shown on the display in the Multidrop mode

++

-+

Pyromation, Inc. 21

Page 22

Commissioning Series 642

Function group SAFETY/MAINTENANCE

®

Availability in TransComm Light, HART

communicator DXR375 (symbol 7)TransComm Light

7

Fault condition Input of the output signal on sensor rupture or short circuit.

Error current

specification

Alarm hysteresis Transient alarms are suppressed at the analog output (e.g. caused by electrostatic

Alarm ambient

temperature

Corrosion detection Sensor connection cable corrosion can lead to false measured value readings. Therefore

Input:

• max (≥ 21.0 mA)

•min (≤ 3.6 mA)

Input only possible if fault condition = max

Input: 21.6 to 23 mA

21.7 mA

discharge).

Input:

• 0 s

•2 s

•5 s

In the time entered, the last measured value before the alarm is output. If the error is still

present after this period, an alarm is signalled.

An alarm for overshooting/undershooting of permitted ambient temperature is

deactivated here.

Input:

• on

•off

If the ambient temperature alarm is deactivated then the unit will not go into alarm but

will transmit a warning. Change is the responsibility of the user.

our unit offers the possibility to recognise any corrosion before the measured values are

affected. (see chapter 9.2.1).

There are 2 different steps selectable dependent on the application requirements:

• off (warning output just before reaching the alarm set point. This allows for

preventative maintenance/trouble-shooting to be done.)

• on (no warning, immediate alarm)

++

++

++

++

++

Alarm for

undershooting/

overshooting

Mains filter Selection of mains filter

Availability in TransComm Light, HART

DISPLAY Activating the values to be shown on the device display:

Input:

• OFF

If the measuring range is undershot or overshot, the output signal is temperature-linear

up to 3.8 mA or 20.5 mA and remains at these values (as per NAMUR NE43).

•ON

An error is signalled if the measured temperature corresponds to an output value < 3.8

mA or > 20.5 mA, (see 'Fault condition').

z

• 50 H

•60Hz

Function group DISPLAY

®

communicator DXR375 (symbol 7) TransComm Light

++

++

7

22 Pyromation, Inc.

Page 23

Series 642 Commissioning

Function group DISPLAY

• Display: PV (= Primary Value)

• Display: sensor value

• Display: RJ value

• Display Analogue output value

• Display: Status

• Display: percentage value (on/off)

The primary value (PV) is displayed as a

percentage.

In order to activate the values to be shown in the device display using HART

module DXR375: Add (DXR=x) of the values to be displayed and enter the sum.

• Display: time (2s, 4s, 6s, 8s)

• Display: figures after decimal point (0,1,2)

• Display PV text (customer specific text, 8 characters)

Function group DIAGNOSTICS

®

Availability in TransComm Light, HART

Diagnostics Display of information required for device diagnostics.

• Device status or error code

(See chapter 9.2 "Error messages")

• Last error code (status) or previous error code

(See chapter 9.2 "Error messages")

• Status sensor (0 = no error; 0 ≠ error)

• Configuration changed

communicator DXR375 (symbol 7)TransComm Light

(DXR=1)

(DXR=2)

(DXR=8)

(DXR=16)

(DXR=32)

off (DXR=0)

on (DXR=64)

®

handheld

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

7

+

+

+

+

+

+

+

Diagnostics • Static revision

Availability in TransComm Light, HART

Measuring point

Input and display of the information relating to the measuring point identification

The "Static revision" is increased on every parameter change. This is for compliance to

21 CFR Part 11, showing that no further parameter changes have been made.

• Sensor max. value

•Sensor min. value

• RJ max. value

•RJ min. value

Display of the maximum process value. The process value will be accepted after starting

the measurement.

Display of the minimum process value. The process value will be accepted after starting

the measurement.

Display of the maximum and minimum measured temperatures of the internal Pt100 DIN

B comparison measurement point.

• Maximum process value is changed to the actual process value on write access. On

reset to factory default value the default value is entered -9999.99.

• Minimum process value is changed to the actual process value on write access. On

reset to factory default value the default value is entered +9999.99.

Function group IDENTIFICATION

®

communicator DXR375 (symbol 7)TransComm Light

-

+

+

+

+

-

+

+

+

+

7

Pyromation, Inc. 23

Page 24

Commissioning Series 642

Function group IDENTIFICATION

TAG Input: 8 characters + +

Descriptor Input: 16 characters + +

Message Input: 32 characters - +

Device information

Display of the information relating to the device identification

Device release Display of device release - +

Serial number 11 digit display of the device serial number

Software rev. Display of the software version + +

Hardware rev. Display of the hardware version + +

Certificates Display of device approvals - +

Device

Display of the information relating to the HART

Manufacturer Manufacturer’s identification: Pyromation Inc. - +

Model Device type identification: Series 642 - +

Date Individual use of this parameter - +

Hardware Rev. HART Device Revision - +

(equal to that on the legend plate).

®

device identification

++

24 Pyromation, Inc.

Page 25

Series 642 Commissioning

Function group SERVICE FUNCTIONS

®

Availability in TransComm Light, HART

communicator DXR375 (symbol 7) TransComm Light

7

Security locking Set-up release code.

Reset to default Reset to factory default values.

Output simulation Activate simulation mode.

Simulation value Input of the simulation value (current).

User calibration

(trim) analog output

Availability in TransComm Light, HART

Input:

• Lock = 0

•Release = 246

Input: 642

0

Input:

• OFF

•ON

Input: 3.58 to 23 mA

For changing the 4 or 20 mA value by ± 0.150 mA

• Trimming 4 mA

• Trimming 20 mA

Function group MEASURED VALUES

®

communicator DXR375 (symbol 7)TransComm Light

++

++

++

++

++

7

PV PV value ++

AO PV value in mA - +

PV % PV value in % - +

Sensor Sensor process value - +

Internal temperature Internal temperature of the device - +

Pyromation, Inc. 25

Page 26

Commissioning Series 642

6.4.2 Supported HART® commands

r = read access, w = write access

No. Description Access

Universal Commands

00 Read unique identifier r

01 Read primary variable r

02 Read p.v. current and percent of range r

03 Read dynamic variables and p.v. current r

06 Write polling address w

11 Read unique identifier associated with tag r

12 Read message r

13 Read tag, descriptor, date r

14 Read primary variable sensor information r

15 Read primary variable output information r

16 Read final assembly number r

17 Write message w

18 Write tag, descriptor, date w

19 Write final assembly number w

Common practice

34 Write primary variable damping value w

35 Write primary variable range values w

38 Reset configuration changed flag w

40 Enter/exit fixed primary variable current mode w

42 Perform master reset w

44 Write primary variable units w

48 Read additional device status r

59 Write number of response preambles w

Device specific

144 Read matrix parameter r

145 Write matrix parameter w

231 Check Device Status r

•HART

®

command No. 48 (HART-Cmd #48)

Apart from the response code and the device status byte, the field transmitter calls up a detailed

diagnosis by means of Cmd #48. This diagnosis is 8 bytes long.

26 Pyromation, Inc.

Page 27

Series 642 Commissioning

Byte Contents Meaning

1

2 0 x 01 warning: backup switched on

Overall device status

3 0 x 01 information: device starting

4 0 x 40 global bit for a warning

5

Status channel 1

7

8 Device operating mode Always 0

Extended device status

0 x 01 error: EEPROM

0 x 02 error: ADC

0 x 04 error: channel 1

0 x 10 error: comparison

measurement point

0 x 20 error: HART ASIC

0 x 40 warning: measured value range undershoot

0 x 80 warning: measured value range overshoot

0 x 02 information: maintenance necessary

0 x 04 information: drift too small/large

0 x 08 information: corrosion at terminals

0 x 10 information: ambient temperature too high/low

0 x 20 information: output current at fixed value

0 x 40 information: no LCD connected or LCD error

0 x 80 information: upload/download active

0 x 02 error: supply voltage too low

0 x 80 global bit for an error

0 x 01 warning corrosion

0 x 02 corrosion

0 x 04 sensor rupture

0 x 08 sensor short circuit

0 x 10 range undershoot

0 x 20 range overshoot

0 x 40 channel not operational

0 x 80 error A/D conversion

0 x 01 maintenance necessary

0 x 02 warnings / error present

•HART® command No. 231 (HART-Cmd #231)

The classified diagnosis of the device can be checked by means of this command. Fault classes

according to GMA VDE NAMUR 2650 guidelines:

Byte Contents Meaning

1 Information acc. to GMA VDE

NAMUR 2650

2+3 Device error messages, see

section 9.2

0x01 -F- Fault

0x02 -C- Device in service mode

0x03 -M- Maintenance required

0x04 -S- Out of specification

Fault classification see Section 9.2 Error messages.

Pyromation, Inc. 27

Page 28

Maintenance Series 642

7 Maintenance

No special maintenance work is required on the device.

8 Trouble-shooting

8.1 Trouble-shooting instructions

Always begin trouble-shooting with the following checklists if errors occur after commissioning or

during measuring operation. The questions guide you to the cause of the error and the appropriate

remedial action.

8.2 Error messages

Fault code Cause Action/cure Mode

0 No error, warning - -

10 Hardware error (device defective) Replace device F

13 Reference measuring point defective Replace device F

15 EEprom defective Replace device F

16 A/D converter defective Replace device F

17 Ambient temperature limit overshot Electronics possibly damaged by

overshooting ambient temperature limits,

return electronics to manufacturer for

checking

19 Supply voltage too low Check supply voltage; check connection

50 Sensor cable open circuit Check sensor *

51 Sensor short-circuit Check sensor *

52 Sensor corrosion Check sensor *

53 Outside sensor range Wrong sensor type for application *

81 Alarm: measuring range undershoot Measuring range poss. set too small F

82 Alarm: measuring range overshoot Measuring range poss. set too small F

106 Warning: upload/download active - C

107 Warning:

Output simulation active

201 Warning:

Measured value too low

202 Warning:

measured value too large

203 Warning:

Ambient temperature limit overshot

206 Warning:

Sensor corrosion

208 Reset device to factory default values - 0

wires for corrosion

Deactivate output simulation C

Change PV lower range value M

Change PV upper range value M

Electronics possibly damaged by

overshooting ambient temperature limits,

return electronics to manufacturer for

checking

Check sensor M

0, F

F

0

1)

28 Pyromation, Inc.

Page 29

Series 642 Trouble-shooting

Fault code Cause Action/cure Mode

209 Device initialization - 0

+1000 Additional errors active Eliminate error displayed

1) The modes have the following meaning: F: Fault, C: Device in service mode, M: Maintenanca required, S: Out of

specification, *: depends on mode (F or M). See also section 6.4.2 Supported HART

®

commands.

1)

If several errors are present, the error with the highest priority is output. Once this error is

eliminated, the next error is output! An offset of 1000 indicates that more than one error is

present.

Device behavior in event of sensor error

In the event of a warning or error, the "Caution" symbol appears on the display and the error code

is shown. If an error occurs, the bargraph also flashes on the display and only the error code is

displayed and not the measured value. (See also Section 5.2).

8.2.1 Corrosion detection

Corrosion detection only for RTD 4-wire connection.

Sensor connection cable corrosion can lead to false measured value readings. Therefore our unit

offers the possibility to recognize any corrosion before the measured values are affected.

There are 2 different steps selectable dependent on the application requirements:

• off (warning output just before reaching the alarm set point. This allows for preventative

maintenance/trouble-shooting to be done.)

• on (no warning, immediate alarm)

The following table describes how the device behaves when the resistance changes in a sensor

connection line, depending on whether on or off is selected.

1)

RTD

off --- WARNING ALARM

on --- ALARM ALARM

1) Pt100 = 100 Ω at 0°C / Pt1000 = 1000 Ω at 0°C

TC < ≈ 10 kΩ 10 kΩ ≈ < x< ≈ 15 kΩ > ≈ 15 kΩ

off --- WARNING

on --- ALARM ALARM

1) If the ambient temperature is very high, it is possible to have a measured error 3 times that of the specified value.

< ≈ 2 kΩ 2 kΩ ≈ < x< ≈ 3 kΩ > ≈ 3 kΩ

1)

ALARM

The sensor resistance can have an effect on the resistance data in the table. If all the sensor

connection line resistances are increased simultaneously, the values described in the table are

halved. In corrosion detection, it is assumed this is a slow process with a continuous increase in

resistance.

Pyromation, Inc. 29

Page 30

Trouble-shooting Series 642

8.2.2 Monitoring the supply voltage

If the necessary supply voltage is undershot, the analog output value drops approx. 3 s ≤ 3.6 mA.

Error code 19 appears on the display. Then the device attempts to output the normal analog output

value again. If the supply voltage remains too low, the analog output value drops again to ≤ 3.6 mA.

This prevents the device from constantly outputting an incorrect analog output value.

8.3 Application errors without messages

8.3.1 Application errors in general

Error pattern Cause Action/cure

No communication No power supply via the

2-wire line

250 Ω communication resistance missing See Section 4.3.1 "Connecting HART

Supply voltage too low (<11 V or 8 V

without display with jumper J3)

Interface cable defective Check interface cable

Interface defective Check interface of your PC

Device defective Replace device

Connect connecting cables correctly in

accordance with terminal plan (polarity)

®

Check power supply

"

8.3.2 Application errors for RTD connection

Pt100/Pt500/Pt1000/Ni100

Error pattern Cause Action/cure

Error current

(≤ 3.6 mA or ≥ 21 mA)

Sensor defective Check sensor

Incorrect RTD connection Connect connecting cables correctly

(terminal plan)

Incorrect 2-wire line connection Connect connecting cables correctly in

Faulty device programming (number of

wires)

Programming Incorrect sensor type configured in the

Device defective Replace device

accordance with terminal plan (polarity)

Change SENSOR CONNECTION device

function

SENSOR TYPE device function; change to

correct sensor type

30 Pyromation, Inc.

Page 31

Series 642 Trouble-shooting

Error pattern Cause Action/cure

Measured value is incorrect/

inaccurate

Orientation of the sensor is incorrect Install sensor properly

Heat conducted by sensor Observe face-to-face length of the sensor

Faulty device programming (number of

wires)

Faulty device programming (scaling) Change scaling

Incorrect RTD configured Change SENSOR TYPE device function

Sensor connection (2-wire) Check sensor connection

Line resistance of sensor (2-wire) was not

compensated

Offset incorrectly configured Check offset

Change SENSOR CONNECTION device

function

Compensate line resistance

8.3.3 Application errors for TC connection

Error pattern Cause Action/cure

Error current

(≤ 3.6 mA or ≥ 21 mA)

Sensor connected incorrectly Connect sensor in accordance with

terminal plan (polarity)

Sensor defective Check sensor

Programming Incorrect sensor type configured in the

SENSOR TYPE device function; set correct

thermocouple

Device defective Replace device

Error pattern Cause Action/cure

Measured value is incorrect/

inaccurate

Orientation of the sensor is incorrect Install sensor properly

Heat conducted by sensor Observe face-to-face length of the sensor

Faulty device programming (scaling) Change scaling

Wrong thermocouple type (TC) configured Change SENSOR TYPE device function

Incorrect comparison measurement point

configured

Offset incorrectly configured Check offset

Interference through thermo-wire welded

in thermowell (interference voltage

coupled in)

See Section "Description of device

functions"

Use sensor that does not have a weld-on

thermo-wire

8.4 Return

To reuse later or in case of repair, the device must be packed in protective packaging, preferably the

original packaging. Repairs must only be carried out by your supplier's service organisation or

specially trained personnel.

Enclose a note describing the fault and the application when sending the unit in for repair.

Pyromation, Inc. 31

Page 32

Trouble-shooting Series 642

8.5 Disposal

The device contains electronic components and must, therefore, be disposed of as electronic waste

in the event of disposal. Please observe in particular the local waste disposal regulations of your

country.

8.6 Software history

SW Revision

The software version in the Operating Instructions indicates the device release history: XX.YY.ZZ

(example 01.02.01).

XX Change in the main version.

YY Change in the functionality and operation.

ZZ Debugging and internal modifications.

SW Revision, date Operation, documentation Modifications

01.03.01, 03/2005 Compatible with:

01.03.03, 12/2006 - Internal SW

No longer compatible. Changes to device and Operating Instructions.

Compatible. Changes to Operating Instructions.

No changes to Operating Instructions.

• HART Communicator DXR375 (from OS1.6)

• (TransComm Light as of version 1.0.

MS (as of version 5.0)

• A

• PDM (as of version 5.1)

15.0)

modifications.

32 Pyromation, Inc.

Page 33

Series 642 Technical data

9 Technical data

9.0.1 Input

Measured variable Temperature (temperature linear transmission behaviour), resistance and voltage

Measuring range The transmitter records different measuring ranges depending on the sensor connection and input

signals.

Input Designation Measuring range limits Min. span

Resistance thermometer (RTD)

To IEC 60751

(α = 0.00385)

To JIS C1604-81

(α = 0.003916)

To DIN 43760

(α = 0.006180)

To Edison Copper Winding No.15

(α = 0.004274)

To SAMA

(α = 0.003923)

To Edison Curve

(α = 0.006720)

To GOST

(α = 0.003911)

To GOST

(α = 0.004278)

Pt100

Pt200

Pt500

Pt1000

Pt100

Ni100

Ni1000

Cu10

Pt100

Ni120

Pt50

Pt100

Cu50, Cu100

Polynomial RTD

Pt100 (Callendar - van Dusen)

• Type of connection: 2-wire, 3-wire or 4-wire connection

• With 2-wire circuit, compensation of wire resistance possible (0 to 30 Ω)

• With 3-wire and 4-wire connection, sensor wire resistance to max. 50 Ω per wire

• Sensor current: ≤ 0.3 mA

-200 to 850 °C (-328 to 1562 °F)

-200 to 850 °C (-328 to 1562 °F)

-200 to 250 °C (-328 to 482 °F)

-200 to 250 °C (-238 to 482 °F)

-200 to 649 °C (-328 to 1200 °F)

-60 to 250 °C (-76 to 482 °F)

-60 to 150 °C (-76 to 302 °F)

-100 to 260 °C (-148 to 500 °F)

-100 to 700 °C (-148 to 1292 °F)

-70 to 270 °C (-94 to 518 °F)

-200 to 1100 °C (-328 to 2012 °F)

-200 to 850 °C (-328 to 1562 °F)

-200 to 200 °C (-328 to 392 °F)

-200 to 850 °C (-328 to 1562 °F)

-200 to 850 °C (-328 to 1562 °F)

10 K (18 °F)

10 K (18 °F)

10 K (18 °F)

10 K (18 °F)

10 K (18 °F)

10 K (18 °F)

10 K (18 °F)

10 K (18 °F)

10 K (18 °F)

10 K (18 °F)

10 K (18 °F)

10 K (18 °F)

10 K (18 °F)

10 K (18 °F)

10 K (18 °F)

Resistance transmitter Resistance Ω 10 to 400 Ω

10 to 2000 Ω

Thermocouples (TC)

To NIST monograph 175,

IEC 584

to ASTM E988

to DIN 43710

Type B (PtRh30-PtRh6)

Type E (NiCr-CuNi)

Type J (Fe-CuNi)

Type K (NiCr-Ni)

Type N (NiCrSi-NiSi)

Type R (PtRh13-Pt)

Type S (PtRh10-Pt)

Type T (Cu-CuNi)

Type C (W5Re-W26Re)

Type D (W3Re-W25Re)

Type L (Fe-CuNi)

Type U (Cu-CuNi)

• Internal cold junction (Pt100); accuracy of cold junction: ± 1 K

• Max. sensor resistance 10 kΩ (if sensor resistance is greater than 10 kΩ, error message as per NAMUR NE 89)

1)

0 to +1820 °C (32 to 3308 °F)

-270 to +1000 °C (-454 to 1832 °F)

-210 to +1200 °C (-346 to 2192 °F)

-270 to +1372 °C (-454 to 2501 °F)

-270 to +1300 °C (-454 to 2372 °F)

-50 to +1768 °C (-58 to 3214 °F)

-50 to +1768 °C (-58 to 3214 °F)

-270 to +400 °C (-454 to 752 °F)

0 to +2320 °C (32 to 4208 °F)

0 to +2495 °C (32 to 4523 °F)

-200 to +900 °C (-328 to 1652 °F)

-200 to +600 °C (-328 to 1112 °F)

10 Ω

100 Ω

500 K (900 °F)

50 K (90 °F)

50 K (90 °F)

50 K (90 °F)

50 K (90 °F)

500 K (900 °F)

500 K (900 °F)

50 K (90 °F)

500 K (900 °F)

500 K (900 °F)

50 K (90 °F)

50 K (90 °F)

Pyromation, Inc. 33

Page 34

Technical data Series 642

Input Designation Measuring range limits Min. span

Voltage transmitter (mV) Millivolt transmitter (mV) -20 to 100 mV 5 mV

1) Increasing inaccuracy for temperatures < 300 °C (< 572 °F)

9.0.2 Output

Output signal Analog 4 to 20 mA, 20 to 4 mA

Signal on alarm • Underranging:

Linear drop to 3.8 mA

•Overranging:

Linear rise to 20.5 mA

• Sensor break; sensor short-circuit (not for thermocouples TC):

≤ 3.6 mA or ≥ 21.0 mA (configurable 21.6 mA to 23 mA)

Load Max. (V

Linearisation/transmission

Temperature linear, resistance linear, voltage linear

power supply

- 11 V) / 0.022 A (current output)

behaviour

st

Filter 1

order digital filter: 0 to 60 s

Galvanic isolation U = 2 kV AC (input/output)

Input current required ≤ 3.5 mA

Current limit ≤ 23 mA

Switch-on delay 4 s (during switch-on operation I

= 4 mA)

a

34 Pyromation, Inc.

Page 35

Series 642 Technical data

NOTICE

9.0.3 Power supply

Supply voltage Ub= 11 to 40 V (8 to 40 V without display), reverse polarity protection

Power supply

► Power must be fed to the device from an 11 to 40 VDC power supply in accordance with NEC

Class 02 (low voltage/current) with short-circuit power limit to 8 A/150 VA.

Residual ripple Perm. residual ripple U

9.0.4 Accuracy

Response time 1 s

Reference operating

conditions

Maximum measured error

Calibration temperature: +25 °C, ± 5 K; (+77 °F, ± 9 °F)

Resistance thermometer (RTD)

Thermocouples (TC)

1) % relates to the set span. Accuracy = digital + D/A accuracy

≤ 3 V at Ub ≥ 13.5 V, f

ss

Designation

Cu100, Pt100, Ni100, Ni120

Pt500

Cu50, Pt50, Pt1000, Ni1000

Cu10, Pt200

K, J, T, E, L, U

N, C, D

S, B, R

max.

= 1 kHz

Accuracy

Digital D/A

0.2 K (0.36 °F)

0.6 K (1.08 °F)

0.4 K (0.72 °F)

2 K (3.6 °F)

typ. 0.5 K (0.9 °F)

typ. 1 K (0.18 °F)

typ. 2 K (3.6 °F)

1)

0.02%

0.02%

0.02%

0.02%

0.02%

0.02%

0.02%

Measuring range

Resistance transmitter (Ω)

Voltage transmitter (mV) -20 to 100 mV ± 20 μV 0.02%

1) % relates to the set span. Accuracy = digital + D/A accuracy

Physical input range of the sensors

10 to 400 Ω Cu10, Cu50, Cu100, polynomial RTD, Pt50, Pt100, Ni100, Ni120

10 to 2000 Ω Pt200, Pt500, Pt1000, Ni1000

-20 to 100 mV Thermocouple type: C, D, E, J, K, L, N

-5 to 30 mV Thermocouple type: B, R, S, T, U

10 to 400 Ω

10 to 2000 Ω

Digital D/A

± 0.08 Ω

± 1.6 Ω

Accuracy

1)

0.02%

0.02%

Repeatability 0.03% of the physical input range (15 Bit)

Resolution A/D conversion: 18 Bit

Pyromation, Inc. 35

Page 36

Technical data Series 642

Influence of supply voltage ≤ ±0.005%/V deviation from 24 V, related to the full scale value

Long-term stability ≤ 0.1 K (0.18 °F)/year or ≤ 0.05%/year

Data under reference conditions. % relates to the set span. The larger value applies.

Influence of ambient

temperature (temperature

drift)

Total temperature drift = input temperature drift + output temperature drift

Effect on the accuracy when ambient temperature changes by 1 K (1.8 °F)

Input 10 to 400 Ω 0.002% of measured value

Input 10 to 2000 Ω 0.002% of measured value

Input -20 to 100 mV typ. 0.002% of measured value (maximum value = 1.5 x typ.)

Input -5 to 30 mV typ. 0.002% of measured value (maximum value = 1.5 x typ.)

Output 4 to 20 mA typ. 0.002% of measured value (maximum value = 1.5 x typ.)

Typical sensor resistance change when process temperature changes by 1 K (1.8 °F):

Cu10: 0.04 Ω Pt200: 0.8 Ω Ni120: 0.7 Ω Cu50: 0.2 Ω Pt50: 0.2 Ω

Cu100, Pt100: 0.4 Ω Pt500: 2 Ω Pt1000: 4 Ω Ni100: 0.6 Ω Ni1000: 6 Ω

Typical change in thermoelectric voltage when process temperature changes by 1 K (1.8 °F):

B: 10 μVC: 20 μVD: 20 μVE: 75 μVJ: 55 μVK: 40 μV

L: 55 μVN: 35 μVR: 12 μVS: 12 μV T: 50 μVU: 60 μV

Examples for calculating the accuracy:

• Example 1

Input temperature drift Δϑ = 10 K (18 °F), Pt100, span 0 to 100 °C (32 to 212 °F)

Maximum process value: 100 °C (212 °F)

Measured resistance value: 138.5 Ω (see IEC 60751)

Typ. influence in Ω: (0.002% of 138.5 Ω) * 10 = 0.0277 Ω

Conversion Ω to °C: 0.0277 Ω / 0.4 Ω/K = 0.07 K (0.013 °F)

• Example 2

Input temperature drift Δϑ = 10 K (18 °F), thermocouple type K with span 0 to 600 °C (32 to

1112 °F)

Maximum process value: 600 °C (1112 °F)

Measured thermoelectric voltage: 24905 μV (see IEC584)

Typ. influence in μV: (0.002% of 24905 μV) * 10 = 5 μV

Conversion Ω to °C: 5 μV / 40 μV/K = 0.12 K (0.216 °F)

• Example 3

Output temperature drift Δϑ = 10 K (18 °F), measuring range 0 to 100 °C (32 to 212 °F)

Span: 100 K (180 °F)

Typical influence: (0.002% of 100 K) * 10 = 0.02 K; (0.002% of 180 °F) * 10 = 0.036 °F

Δϑ = deviation of ambient temperature from the reference operating condition

Total measuring point error = max. possible measured error + temperature sensor error

Influence of cold junction Pt100 DIN IEC 60751 Cl. B (internal cold junction with thermocouples TC)

36 Pyromation, Inc.

Page 37

Series 642 Technical data

9.0.5 Environment

Ambient temperature limits • Without display: -40 to +85 °C (-40 °F to +185 °F)

• With display: -40 to +80 °C (-40 °F to +176 °F)

For use in hazardous areas, see Ex certificate

At temperatures < -4 °F (-20 °C) the display may react slowly. Readability of the display

cannot be guaranteed at temperatures < -30 °C (-22 °F).

Storage temperature • Without display: -40 to +100 °C (-40 °F to +212 °F)

• With display: -40 to +85 °C (-40 °F to +185 °F)

Operating height Up to 2000 m above MSL

Climate class As per EN 60 654-1, Class C

Degree of protection IP 67, NEMA 4x

Shock and vibration resistance 3g / 2 to 150 Hz as per IEC 60 068-2-6

Electromagnetic compatibility

(EMC)

Condensation Permitted

Installation category I

Pollution degree 2

Interference immunity and interference emission as per EN 61 326-1 (IEC 1326) and NAMUR NE

21

0.08...2 GHz 10 V/m; 1.4...2 GHz 30 V/m to EN 61000-4-3

Pyromation, Inc. 37

Page 38

Technical data Series 642

9.0.6 Mechanical construction

Design, dimensions

Fig. 10: Dimensions in inches (mm in brackets)

• Display rotatable in 90 stages

Weight Approx. 1.6 kg (3.53 lb) (aluminum housing)

Material • Housing: die-cast aluminum housing AlSi10Mg with powder coating on polyester basis

• Nameplate: 1.4301 (AISI 304)

Terminals Cables / wires up to max. 2.5 mm

2

(AWG 13) plus ferrule

9.0.7 Certificates and approvals

CE mark The device meets the statutory requirements of the EC directives. The manufacturer confirms

successful testing of the device by affixing to it the CE mark.

Hazardous area approval Information about currently available hazardous area versions (FM, CSA, etc.) can be supplied by

your representative office on request. All explosion protection data are given in a separate

documentation which is available upon request.

CSA GP CSA General Purpose

Other standards and

guidelines

• IEC 60529: Degree of protection through housing (IP code)

• IEC 61010: Protection measures for electrical equipment for measurement, control, regulation

and laboratory procedures

• IEC 1326: Electromagnetic compatibility (EMC requirements)

• NAMUR: Association for Standards for Control and Regulation in the Chemical Industry

38 Pyromation, Inc.

Page 39

Series 642 Appendix

R

T

R01 AT BT2CT 100–()T

3

++ +[]=

a

R

100

R0–

100 R

0

·

---------------------

=

R

T

R

0

R0a T·+=

T

R

T

R0–

R

0

a·

--------------------

=

d

T

h

RThR0–

R

0

a·

-----------------------

–

T

h

100

-------- -

1–

èø

æö

T

h

100

-------- -

èø

æö

--------------------------------------

=

RTR0R0a T(d

T

100

-------- -

1–

èø

æö

–

T

100

-------- -

èø

æöøö

++=

10 Appendix

10.1 The Callendar - van Dusen Method

It is a method to match sensor and transmitter to improve the accuracy of the measurement system.

According to IEC 60751, the non-linearity of the platinum thermometer can be expressed as (1):

in which C is only applicable when T < 0 °C.

The coefficients A, B, and C for a standard sensor are stated in IEC 60751. If a standard sensor is

not available or if a greater accuracy is required than can be obtained from the coefficients in the

standard, the coefficients can be measured individually for each sensor. This can be done e.g. by

determining the resistance value at a number of known temperatures and then determining the

coefficients A, B, and C by regression analysis.

However, an alternative method for determination of these coefficients exists. This method is based

on the measuring of 4 known temperatures:

•Measure R

•Measure R

•Measure R

•Measure R

Calculation of α

First the linear parameter α is determined as the normalized slope between 0 and 100 °C (2):

If this rough approximation is enough, the resistance at other temperatures can be calculated as (3):

and the temperature as a function of the resistance value as (4):

Calculation of δ

Callendar has established a better approximation by introducing a term of the second order, δ , into

the function. The calculation of δ is based on the disparity between the actual temperature, T

the temperature calculated in (4) (5):

at T0 = 0 °C (the freezing point of water)

0

at T

100

at Th = a high temperature (e.g. the freezing point of zink, 419.53 °C)

h

at Tl = a low temperature (e.g. the boiling point of oxygen, -182.96 °C)

l

= 100 °C (the boiling point of water)

100

, and

h

Pyromation, Inc. 39

With the introduction of δ into the equation, the resistance value for positive temperatures can be

calculated with great accuracy (6):

Page 40

Appendix Series 642

b

T

l

RTlR0–

R

0

a·

-------------------- -

d

T

l

100

-------- -

è

æ

1 )

T

l

100

-------- -

èø

æö

–+–

T

l

100

-------- -

1–

èø

æö

T

l

100

-------- -

èø

æö

3

--------------------------------------------------------------------------------------

=

R

T

R0R0a T d

T

100

-------- -

1–

èø

æö

T

100

-------- -

èø

æö

– b

T

100

-------- -

1–

èø

æö

T

100

-------- -

èø

æö

3

–+=

R

T

R01 AT BT2100CT

3

– CT

4

++ +()=

A a

ad·

100

------------

èø

æö

+=

B

ad·

100

2

------------

=

ab·

100

4

------------

=

Calculation of β

At negative temperatures (6) will still give a small deviation. Van Dusen therefore introduced a term

of the fourth order, β , which is only applicable for T < 0 °C. The calculation of β is based on the

disparity between the actual temperature, t

only α and δ (7):

With the introduction of both Callendar's and van Dusen's constant, the resistance value can be

calculated correctly for the entire temperature range, as long as one remembers to set β = 0 for

T > 0 °C (8):

Conversion to A, B and C

Equation (8) is the necessary tool for accurate temperature determination. However, seeing that the

IEC 751 coefficients A, B and C are more widely used, it would be natural to convert to these

coefficients.

Equation (1) can be expanded to (9):

, and the temperature that would result from employing

l

and by simple coefficient comparison with equation (8) the following can be determined (10):

(11)

(12)

The device accepts the coefficients to be specified as α, β, δ and A, B, C.

Information on the coefficients can be requested from the sensor manufacturers in question.

40 Pyromation, Inc.

Page 41

Series 642 Appendix

10.2 Polynomial RTD

With "Polynomial RTD", the sensor is defined by a polynomial (X4*x4+X3*x3+X2*x2+X1*x1+X0)

with 5 coefficients. The physical measuring range is 10 to 400 Ω.

The 5 coefficients of the polynomial are calculated using the PC configuration software TransComm

Light. There are two different ways of determining the polynomial:

• The sensor-matching-calibration

The deviation (compared to standard RTD) of the sensor or at the complete measuring point

(transmitter with connected sensor, Measured = ΔT /°C or mA) is measured at different

temperatures (sampling points). By using a "weight factor" it is possible to set special focus either

on the given points (the deviation on the rest of the curve can be quite high) or on the trend

compared to the reference linearization (The sampling points are only reference points of an e.g.

aged sensor). These sampling points lead to a new revised linearization, which is transferred to

the temperature transmitters.

• The customer specific linearization

The linearization is made by measured resistance or current values over the target temperature

range. These sampling points lead also to a new revised linearization, which is transferred to the

temperature transmitters.

10.2.1 How to use with the PC configuration software TransComm

Light:

1. Select POLYNOM RTD in Choice-field "Sensor type".

2. Press button LINEARIZATION to open module SMC32.

3. Default setting is Sensor-matching-calibration which can be recognized by "ΔT/°C" in the

groupbox "Measured". Alternative choice is "Ohm" or "mA" for customer specific linearization.

4. Default reference RTD linearization is Pt100. Check "Type of Sensor" if another RTD is

required. With customer specific linearization it is not possible to select "Type of Sensor".

5. "Weighting" default is 50%. As described above 100% means full focus on the accuracy at the

sampling points, 0% uses the sampling points as trend information for the complete curve.

6. The "sampling points" can be edited in the shown table, default points are the min and max

temperature of the reference element. These values can be modified to a reduced range.

7. To see the results of the new linearization use menu Calculate … Calculate Curve and/or

Calculate … Show Coefficients (Coefficients are shown in an extra form).

8. The red curve in the graph (scale on right) shows the deviation between calculated and

reference curve. This graph easily shows the effect of changing the "weighting".

9. When files exist, data can also be loaded (Data … Load). Files made with older versions (SW

< 2.0) do only supply sampling points, the extra information ("Measured", "Type of Sensor")

has to be edited after loading data.

10. Storing all data in files use Data … Save or Data … Save as....

11. For using this functionality in the transmitter please press OK (data will be taken over in the

PC configuration software TransComm Light) and start to transmit to the device.

Pyromation, Inc. 41

Page 42

Index Series 642

Index

Numerics

250 Ohm communication resistor. . . . . . . . . . . . . . . . . . . 10

C

Callendar - van Dusen Method. . . . . . . . . . . . . . . . . . . . . 39

CE mark (declaration of conformity) . . . . . . . . . . . . . . . . . . 6

Communicator DXR375 . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Connection using a transmitter power supply . . . . . . . . . . 10

Connection using other power supplies. . . . . . . . . . . . . . . 11

Corrosion detection . . . . . . . . . . . . . . . . . . . . . . . . . . 22, 29

D

Declaration of conformity (CE mark). . . . . . . . . . . . . . . . . . 6

Device behaviour in event of sensor error . . . . . . . . . . . . . 29

Device Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

E

Error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

F

Function group

DIAGNOSTICS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

DISPLAY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

IDENTIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

MEASURED VALUES . . . . . . . . . . . . . . . . . . . . . . . . . 25

OUTPUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

SAFETY / MAINTENANCE . . . . . . . . . . . . . . . . . . . . 22

Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

SERVICE FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . 25

Standard set-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

S

Sensor-matching-calibration . . . . . . . . . . . . . . . . . . . . . . . 41

Supported HART® commands . . . . . . . . . . . . . . . . . . . . . 26

T

Terminal layout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

TransComm Light. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

W

Wall mounted installation . . . . . . . . . . . . . . . . . . . . . . . . . . 8

H

Hardware setting

Locking the configuration . . . . . . . . . . . . . . . . . . . . . . 14

Setting the failsafe mode . . . . . . . . . . . . . . . . . . . . . . . 14

Hazardous area. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

I

Internet address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

M

Monitoring the supply voltage. . . . . . . . . . . . . . . . . . . . . . 30

Mounting

Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Wall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8