Page 1

1990

SI

PyroMATION,

INSTRUCTION MANUAL

Series 423 Digital Indicator

®

INC.

Copyright© 1993, Pyromation, Inc.

(01/94)

Page 2

TABLE OF CONTENTS PAGE

NO.

1-1

2-1

2-2

3-1

4-1

5-1

5-2

5-3

5-4

6-1

6-2

6-3

7-1

7-2

7-3

7-4

Notes .....................................................................................................................

General Information..........................................................................................

Limited Warranty...............................................................................................

Specifications......................................................................................................

Thermocouple and RTD Order Code.................................................................

Unpacking..........................................................................................................

Location.............................................................................................................

Mounting..............................................................................................................

Mounting Illustrations............................................................................................

Line Supply Wiring............................................................................................

AC Line Conversion............................................................................................

RTD Input Wiring...............................................................................................

Thermocouple Input Wiring...............................................................................

Relay Wiring.........................................................................................................

Auxillary Power Supply Wiring.........................................................................

4 - 20mA Input with and without Loop Power ..................................................

1

2

2

3

4

5

5

5

5

6

6

6

7

7

7

7

8-1

8-3

9-1

10-1

11-1

12-1

13-1

14-1

14-2

15-1

16-1

17-1

12 - Position Selector Switch Wiring Illustrations............................................

Unit Repairs........................................................................................................

Trouble Shooting.................................................................................................

Main Menu Program...............................................................................................

Relay Menu Program............................................................................................

4 - 20mA Menu Program.....................................................................................

4 - 20mA Calibration Procedures..........................................................................

Password Menu Program......................................................................................

Calibration Menu Program..................................................................................

Calibration Procedures..........................................................................................

RTD Calibration Procedures............................................................................

CJC Calibration Procedures................................................................................

8

8

9

10

11

12

13

14

14

15

16

17

Page 3

2-1 GENERAL INFORMATION

The 423 Series Instruments are a Microprocessor-Based Digital Process Indicator for thermocouples and RTD's. The instrument

has no potentiometers for calibration. All calibration is done from the

front panel and stored in non-volatile memory. The program menu has

been secured at the factory by the use of a password which prevents

unauthorized users from entering the calibration mode.

Thermocouple and RTD inputs can be changed through the

pushbuttons as well. Calibration for these are also prompted through

pushbutton commands. Again, there are no potentiometers for calibration. Fahrenheit and Celsius and decimal point conversions are made

through menu commands.

Menu program lockout is available through pushbutton commands. This lockout is a specified codeword which prevents personnel

from entering the menu if desired. There is a universal codeword which

will over-ride any user specified codeword. This is maintained in case

the user loses or forgets the specified codeword.

2-2 LIMITED WARRANTY

THE MODEL 423 SERIES DIGITAL INDICATOR SOLD BY OR PURCHASED FROM PYROMATION, INC. OR

FROM AN AUTHORIZED PYROMATION DISTRIBUTOR, OR AGENT IS SUBJECT TO THE FOLLOWING

LIMITED WARRANTY.

This product is warranted to be free from functional defects in materials and workmanship at the time the product

leaves the Pyromation, Inc. factory, and to conform at that same time to the specifications set forth in the relevant

Pyromation, Inc. installation, wiring, operation manual for this product for a period of one year after shipment from the

Pyromation, Inc. factory.

Pyromation's exclusive and sole obligation, and Buyer's exclusive and sole remedy under the above Limited Warranty

is limited to either repair or replacement of such product, at Pyromation's option, free of charge to Buyer. Pyromation

shall have no obligation to repair or replace unless the claimed defect in material or workmanship is reported in writing

to Pyromation at 5211 Industrial Road, Fort Wayne, Indiana 46825 within ten (10) days after delivery to the Buyer from

Pyromation or an authorized Pyromation distributor, representative or reseller. If so requested by Pyromation, the

product shall be returned to a designated facility during normal business hours, transportation prepaid.

Any action for breach of this warranty or other action arising out of this contract must be commenced within one year

after delivery.

Pyromation shall not be liable for any warranty, express or implied, other than the warranty stated above, and in the

event of a breach of the above stated warranty, Pyromation shall not be liable for any incidental, consequential, special,

or other damages, costs, or expenses other than repair or replacement as described above. Pyromation excludes

any and all warranties of merchantability or fitness for a particular purpose. The above stated warranty extends only

to the original Buyer from Pyromation, Inc. or from an authorized Pyromation distributor or agent, and may not be

transferred or assigned.

Page 2

Page 4

3-1 SPECIFICATIONS

- STANDARD -

Power Supply:

DC Isolation:

Ambient Temperature:

Overall Accuracy:

Input Impedance:

RTD Excitation Current:

Error Due to Lead Resistance:

Conversion Rate:

Filtering:

Resolution:

120 or 240VAC +10%/-15%

50/60HZ

External Fuse Required - .5A

@ 500 VP

32 to 122°F (0 - 50°C)

RTD or Thermocouple: + 1°F

4 - 20 mA: + .1%

47M Ohm (Millivolt inputs only)

.25mA

0.1uV per Ohm (T/C Inputs Only)

2.5 per Second

Digital: Average of 16 conversions per update

Analog: 2.2K in parallel with 0.1uf

.1 or 1 Degree

(Automatic 1 Deg., Resolution above 999.9)

Display:

Display Readouts:

Physical Dimensions:

Power Supply:

Auxillary Power Supply:

Relays:

.54" High LED, High Intensity Alpha Numeric

UNDR - Underrange

OVER - Overrange

OPEN - Open Input

48 x 96 x 148mm (overall dimensions)

(1.89" x 3.78" x 5.83")

- OPTIONS -

12 or 24 VDC +20/-10%

External Fuse Required - .5A

24 VDC (30 mA Maximum)

250 VAC (8A Maximum)

30 VDC (8A maximum)

Page 3

Page 5

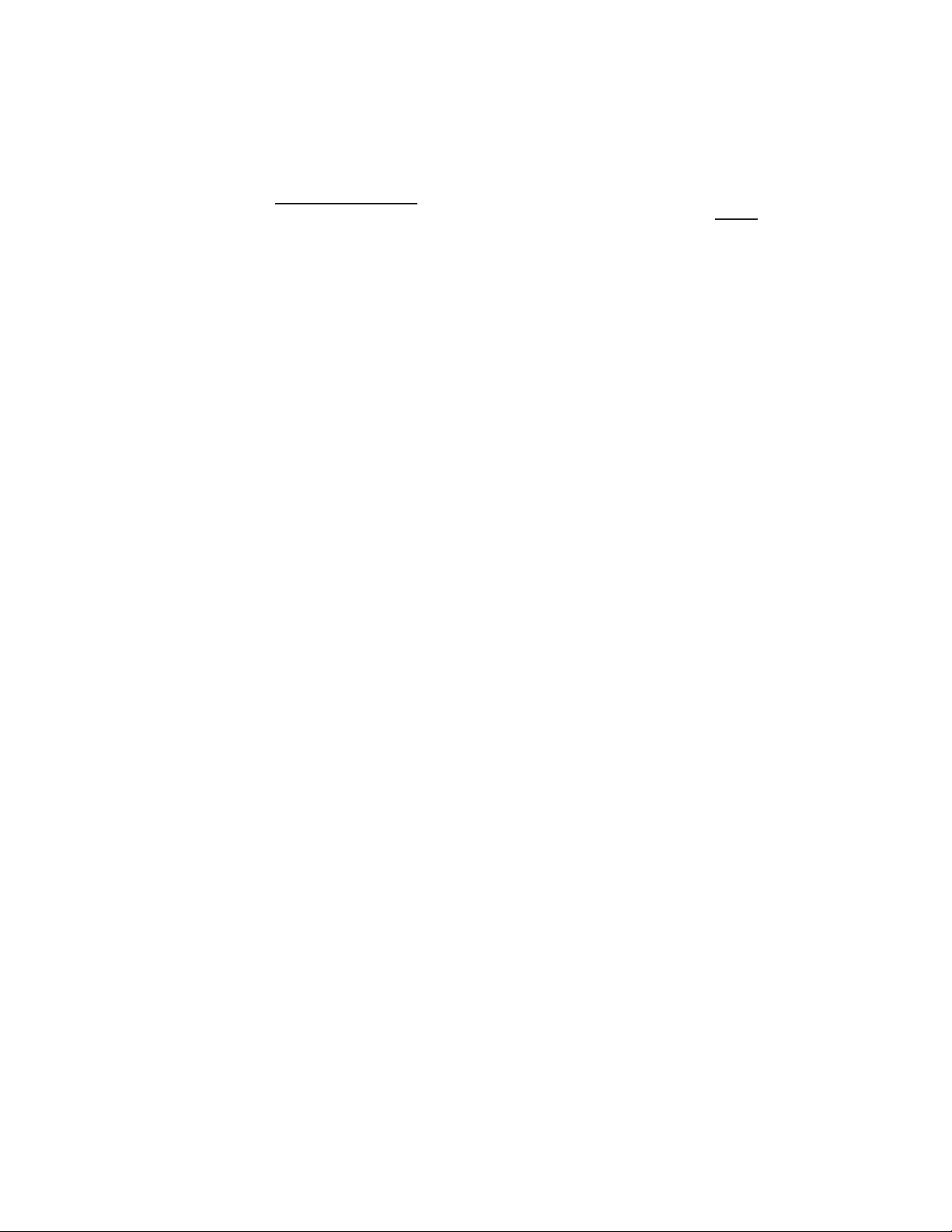

4-1 ORDER CODE

Example Order Number:

- - - -

423 1 1 42 R1 04 S (0-5000)

METER STYLE

ORDER

CODE

1

DESCRIPTION

Input Selectable for T/C or RTD's

with Fixed Range or 4 - 20 mADC

with Scaleable Display

Table 6Table 1

ORDER

CODE

S

* Insert actual scaling desired as per examples below

Table 5Table 2

DISPLAY SCALING

Factory Scaled 4-20 mA Inputs Only

0 - 5000, 50 - 150, -100 to 100, 500-0

POWER SUPPLY OPTIONS

ORDER

CODE

1

2

3

4

Table 3 Table 4

ORDER

CODE

00

85

42

4J

4K

4T

4E

4N

* Meters are shipped calibrated for Type K

thermocouples, degrees F, and 1° resolution

DESCRIPTION

120 VAC

240 VAC

24 VDC

12 VDC

(Field Selectable)

(Field Selectable)

(Factory Installed)

(Factory Installed)

INPUT SELECTION

DESCRIPTION

Customer Configured *

100 Ohm Plat. RTD, .00385 T.C.

4 - 20 mADC

Type

J

Thermocouple

K

Thermocouple

Type

Type T Thermocouple

E

Thermocouple

Type

N

Thermocouple

Type

ORDER

CODE

00

01

02

03

04

05

DESCRIPTION

No Options

Splash Proof Panel Gasket Seal

Meter Mounted 12 Pt. Sel. Switch

One SPDT Process Alarm

SPDT Process Alarms

Two

VDC Power Supply Output

24

ORDER

CODE

00

F1

F2

C1

C2

00

F1

F2

C1

C2

00

R1

R2

R3

R4

DESCRIPTION

AVAIL.

LIMITS

Not w/Opt. 02

DISPLAY RESOLUTION

T/C or RTD INPUTS

DESCRIPTION

Customer Configured

1° F

.1° F

1° C

.1° C

4 to 20 mA INPUTS

Customer Configured

1° F

.1° F

1° C

.1° C

Customer Configured

1

Unit Resolution

.1

Unit Resolution

.01

Unit Resolution

.001

Unit Resolution

*

(9999)

(999.9)

(99.99)

(9.999)

Page 4

Page 6

5-1 UNPACKING

Unpack the instrument immediately upon receipt, and visually

inspect for shipping damages. If the instrument was damaged in

transit, note any damage and file a claim with the carrier.

5-2 LOCATION

Install the instrument in an area where it will not be subjected to

excessive shock, vibration, dirt, oil, and where the temperature will not

exceed 0-50°C (32-122°F). The instrument should not be installed in

an area where rapid temperature changes may occur (e.g. near heating

or cooling ducts).

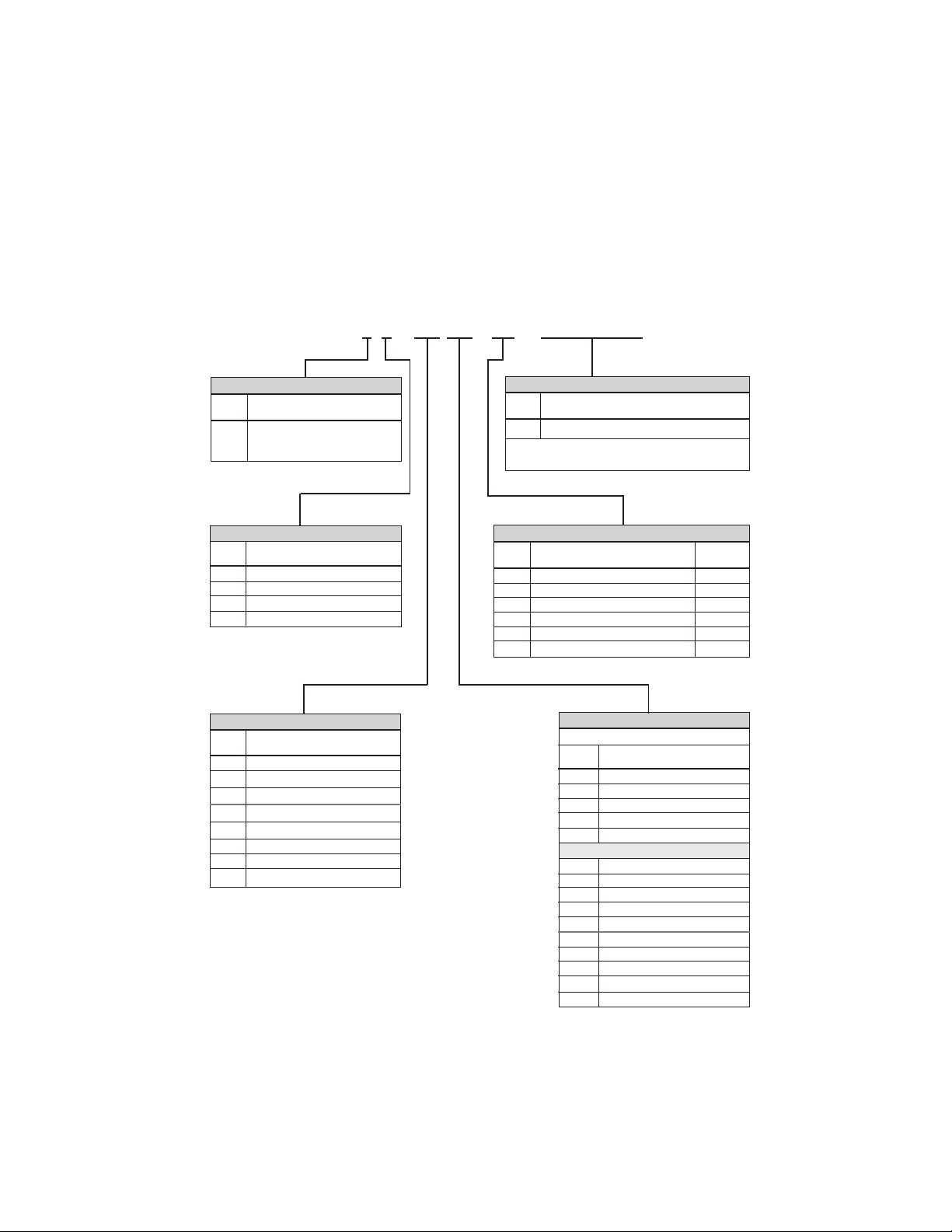

5-3 MOUNTING

Figure 1 thru figure 4 below shows panel cutout dimensions and

case dimensions. (For units with 12 position selector, cutout dimensions are

3.67" high by 3.56" wide).

Remove slide retaining screws and slides.

Insert the instrument through the cutout from the front side of the panel

and re-insert slides and screws. Do not over-tighten screws.

5-4 MOUNTING ILLUSTRATIONS

1.89"

3.78"

Figure 1

s

l

t

PyroMATION, INC.

Figure 3

s

l

t

PyroMATION, INC.

PyroMATION, INC.

3.78"

3.78"

Figure 2

1

2

C

F

.25"

0.0 - .188" THICK

5.58"

Figure 4

3.56" MIN.

1

2

C

F

Page 5

1.77"

MIN.

3.67" MIN.

Page 7

6-1 LINE SUPPLY WIRING

Figure 5 Figure 6

120 or 240 VAC Line Supply

12 or 24 VDC Line Supply

GND

12

.5A FUSE

+

-

D C

SUPPLY

6-2 AC LINE SUPPLY CONVERSION

The 423 Series meter can be field changed from 120 to 240 VAC or back.

This is accomplished by changing the jumper on the PC board. The jumpers are

located in the rear next to the transformer. See figures below. (This change will

not void the limited warranty).

Figure 8Figure 7

Jumpers

Jumper

6-3 RTD INPUT WIRING

Figure 9

3 Wire RTD Hookup

GND

567

Figure 10

2 Wire RTD Hookup

RTD

JUMPER

5

67

NOTE: RTD input extension wire should not be run in the same conduit as line voltage, nor should they be exposed

to excessive electrical noise.

RTD

Figure 11

4 Wire RTD Hookup

NO CONNECTION

RTD

765

Page 6

Page 8

7-1 THERMOCOUPLE INPUT WIRING

Figure 12

GND

Note: Thermocouple input extension wire should not be run in the same conduit as line voltage, nor should they be

exposed to excessive electrical noise. Always use compensated leadwire when wiring for thermocouple inputs.

T/C

-

56

T/C

+

7-2 RELAY WIRING

Figure 13

ALARM 2

8

910 1213 14

GND

ALARM 1

11

* See note on Page 11

7-3 AUXILLARY POWER SUPPLY WIRING

Figure 14

11

+

24 VDC

OUTPUT

-

3

7-4 4 - 20mA INPUT with and without INTERNAL LOOP POWER

Figure 15 -

GND

RTD

RED

RED

with Loop Power

11

+

-

-

43

WHITE

5

JUMPER

+

Page 7

Figure 16 - without Loop Power

GND

4

5

+

RED

RED

RTD

WHITE

-

+

Page 9

8-1 12-POSITION SELECTOR SWITCH WIRING ILLUSTRATIONS

8-2

Figure 17

RTD Selector Switch Connections

65

COPPER

OUTPUT

SWITCH

BOX

WIRE

SWITCH

RTD

7

Figure 19

Figure 18

Thermocouple Selector Switch Connections

6

5

+

-

T/C

WIRE

SWITCH

OUTPUT

SWITCH

BOX

T/C

(RED)

-

T/C

+

.250"

1.06"

Note: Always use compensated leadwire when wiring for thermocouple inputs.

5.58"

8-3 UNIT REPAIRS

If returning instrument, contact the factory or local representa-

tive for a Return Authorization Number. Include the reason for the

return with your shipment.

Page 8

Page 10

9-1 TROUBLE SHOOTING

PROBLEM

' OPEN '

' OVER '

' UNDR '

Erratic Readings

POSSIBLE CAUSES

l

Sensor not connected

l

Damaged sensor

l

Sensor is over temperature range

l

Incorrect sensor

l

Sensor is under temperature range

l

Incorrect sensor

l

Wrong polarity on connection

l

Loose connection on sensor input

l

Damaged sensor

l

AC noise on sensor connections

POSSIBLE WIRING ERRORS

Destructive Errors

l

Do not connect power to the sensor input. This could destroy

the panel meter.

l

Do not connect power to the sensor itself.

l

Incorrect line power on the unit; check options.

Non-Destructive Errors

l

Reversing the polarity on line power input.

l

Reversing the polarity on sensor input.

Page 9

Page 11

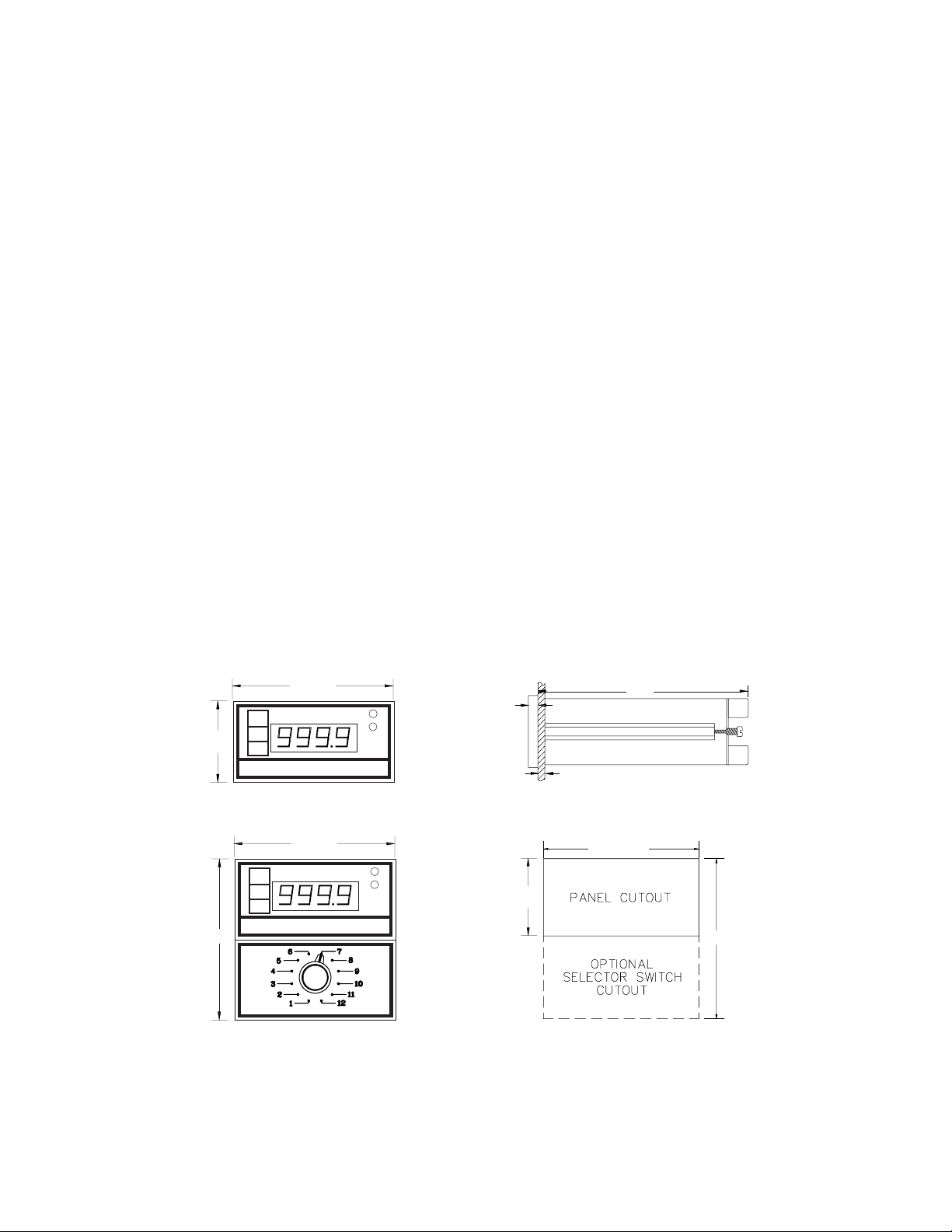

10-1 MAIN MENU

Below is a block diagram showing the basic menu program. Specific menu breakdowns

are described on the following pages. The middle button is used as the enter key.

This will move you through the program. The buttons allow you to view and

change variables to the program. Please note, to eliminate changes made, simply

disconnect power before you come to the

ENTER PSWD

This Portion

Not Applicable

If Password Is Off

DISPLAYED

000

TO PASSWORD

028 PASSWORD

MENU

SNSR

PWRD YES/NO prompt.

Figure 20

(028 is Universal Password)

J K T....PRESENT INPUT TYPE

TO SCROLL THROUGH INPUT

or

RETURN WHEN

AT DESIRED INPUT

DP

UNIT

or

or

TO CHANGE DECIMAL

TO CHANGE F / C

RLY 1

or

YES / NO

RLY 2

or

YES / NO

CAL

IF CALIBRATING, SEE FIGURE 24

PWRD

or

YES / NO

WAIT

.

.

V3.1

.

.

PRESENT

DISPLAY

TYPES

IF YES, SEE FIGURE 21

IF NO

IF YES, SEE FIGURE 21

IF NO

IF YES, SEE FIGURE 23

IF NO

Page 10

Page 12

11-1 RELAY MENU

RLY 1

or

RLY 2

or

YES/NO

YES/NO

Figure 21

IF YES

IF NO

IF YES

IF NO

or

or

LOW/HIGH

LOW/HIGH

SP 1

or

SP 2

or

150

150

RETURN WHEN

AT DESIRED

SETPOINT

RETURN WHEN

AT DESIRED

SETPOINT

HYS 1

or

001

RETURN WHEN

AT DESIRED

HYSTERISIS

HYS 2

or

001

RETURN WHEN

AT DESIRED

HYSTERISIS

CAL

.

.

.

Note 1: Recommend using MOVs on Relay Terminals. Metal-oxide varistors (MOVs) are

variable resistors for protecting electronic circuits against AC (alternating-current) voltage

transients.

Note 2: They must be operated within their ratings or they will be destroyed.

Page 11

Page 13

12-1 4 - 20 mA MENU

SNSR

MAMP

DP

or

UNIT

or

ZERO

k

CONNECT 4mA SOURCE

or

TO CHANGE DECIMAL

TO CHANGE F/C/OFF

RETURN WHEN

000

AT DESIRED

READING

Figure 22

WAIT

SPAN

k

CONNECT 20mA SOURCE

or

WAIT

UNDR

or

OVER

or

RLY 1

.

.

.

RETURN WHEN

000

000

000

AT DESIRED

RETURN WHEN

AT DESIRED

UNDER INDICATION

RETURN WHEN

AT DESIRED

OVER INDICATION

Page 12

READING

Page 14

13-1 4 - 20mA CALIBRATION PROCEDURES (All steps must be completed)

{Step 1}

{Step 2}

{Step 3}

{Step 4}

{Step 5}

{Step 6}

= UP

= ENTER

= DOWN

Power panel meter for at least 30 minutes.

Enter menu program, go to the SNSR menu. Press the ENTER

button. MAMP should appear on the display. If not, press the

down button until MAMP is displayed. Press the ENTER

button.

Select proper resolution for the decimal point by pressing the

down button. When proper resolution has been selected

press the ENTER button.

Select proper scale indication by pressing the down button.

If °F or °C is not desired, select OFF. Press the ENTER button.

(Note: If OFF was selected, scale indication stickers have

been supplied for the front display)

Now that ZERO appears, press the down or up button, then

select the desired display reading.

Once the display reading has been established, connect a

4mA source to the input of the meter. Refer to Figure 16 for

proper connections. Press the ENTER button. Wait until

SPAN appears.

{Step 7}

{Step 8}

{Step 9}

{Step 10}

Now that SPAN appears, press the down or up button, then

select the desired display reading.

Once the display reading has been established, connect a

20mA source to the input of the meter. Refer to Figure 16 for

proper connection. Press the ENTER button, WAIT until UNDR

appears.

Now that UNDR appears, press the down or up button, then

select the desired display reading for the under indication.

Press the ENTER button.

Now that OVER appears, press the down or up button, then

select the desired display reading for the over indication.

Press the ENTER button. Calibration is now complete.

Refer to 4 - 20mA menu on page 12 for the above steps (fig. 22)

Page 13

Page 15

14-1 PASSWORD MENU

Described below is the menu for selecting menu passwords.

PWRD

Figure 23

NEW PWRD

WAIT

.

V3.1

.

READING

or

YES / NO

IF YES

ENTR

PWRD

RETURN WHEN

AT DESIRED

PASSWORD

028

TO PICK

NEW VALUE

14-2 CALIBRATION MENU

The calibration routine is for thermocouples and RTD's only. Described below is

the menu program for calibration. Each calibration can be independently done

using the down arrow to scroll to the next routine. Push the up arrow

anywhere to exit the calibration routine.

CAL

HOLD UNTIL METER INDICATES SHRT (approximately 1.5 seconds)

PUSH TO SKIP SHORT

USING COPPER WIRE JUMPER TERMINALS 5,6,7

WAIT

PUSH TO SKIP 50mV

50mV

DISCONNECT JUMPERS

INPUT 50.040mV THROUGH COPPER WIRE TO TERMINALS 5,6

Figure 24

WAIT

PUSH TO SKIP 100 OHMS

100 OHMS

INPUT 100.0W ACROSS TERMINALS 5,6,7

DISCONNECT 50.040mV

WAIT

PUSH TO SKIP CJC

CJC

DISCONNECT 100W

or

PWRD

.

.

TO VIEW

77.0

or

Page 14

Equipment Needed for Calibration

50.040 mV + .005 Power Source

100.03W

+ .01W Resistor

+ .1°F Thermometer

Note1 : Adjust a potentiometer to achieve

100.03W

TO SET NEW VALUE

AGAINST THERMOMETER

1

Page 16

15-1 THERMOCOUPLE CALIBRATION PROCEDURE

{Step 1}

{Step 2}

{Step 3}

{Step 4}

= UP

= ENTER = DOWN

Power panel meter for at least 30 minutes.

Enter menu program, go to the CAL mode. Press the down

button and hold for approximately 1.5 seconds until the meter

reads SHRT, then release the button. Failure to hold the button

for 1.5 seconds will terminate the calibration process.

Install jumpers between terminals 5, 6, and 7 using copper

wire. Press and release the enter button. Wait until 50mV

appears. Disconnect jumpers.

JUMPER

6

5

7

Figure 25

Now that 50mV appears, connect the leads from the 50mV

source to the meter using terminals 5 and 6, remembering that

terminal 5 is negative. Set the voltage supply for 50.040mV,

then press and release the enter button. This simulates a

thermocouple input. Wait until 100 ohm appears. Disconnect

supply.

{Step 5}

{Step 6}

Press the down button to skip 100 ohm input.

Now that CJC appears, place the thermometer across the

terminal strip and do not remove until the temperature stabilizes. The reading from the thermometer is going to be the new

CJC temperature. Press and release the enter button. Use the

up or down button to set the value, then press the enter button

three times until V3.1 appears. Calibration is now complete.

Figure 26

CJC COMPENSATION

Note: If calibration is off due to the CJC, refer to CJC Calibration on page 17

Page 15

Page 17

16-1 RTD CALIBRATION PROCEDURES

{Step 1}

{Step 2}

{Step 3}

{Step 4}

= UP

= ENTER = DOWN

Power panel meter for at least 30 minutes.

Enter menu program, go to the CAL mode. Press the down

button and hold for approximately 1.5 seconds until the meter

reads SHRT, then release the button. Failure to hold the button

for 1.5 seconds will terminate the calibration process.

Install jumpers between terminals 5, 6, and 7 using copper

wire. Press and release the enter button. Wait until 50mV

appears. Disconnect jumpers.

JUMPER

6

5

7

Figure 27

Press the down button to skip 50mV input.

{Step 5}

{Step 6}

Now that 100 ohm appears, install jumper between terminals

6 and 7, and insert the 100W resistor into terminals 5 and 6.

Then press and release the enter button. This simulates a 3

wire RTD. Wait until CJC appears. Disconnect jumper and

resistor.

RTD

5

67

JUMPER

Figure 28

Press the up button to save and exit calibration, then press the

enter button three times until V3.1 appears. Calibration is now

complete.

Page 16

Page 18

17-1 CJC CALIBRATION PROCEDURES

{Step 1}

{Step 2}

{Step 3}

{Step 4}

= UP

= ENTER = DOWN

Power panel meter for at least 30 minutes.

Enter menu program, go to the CAL mode. Press the down

button and hold for approximately 1.5 seconds until the meter

reads SHRT, then release the button. Failure to hold the button

for 1.5 seconds will terminate the calibration process.

Press the down button until CJC appears.

Now that CJC appears, place the thermometer across the

terminal strip and do not remove until the temperature stabilizes. The reading from the thermometer is going to be the new

CJC temperature. Press and release the enter button. Use the

up or down button to set the value, then press the enter button

three times until V3.1 appears. Calibration is now complete.

Figure 29

CJC COMPENSATION

Page 17

Loading...

Loading...