Page 1

INSTALLATION AND OPERATING INSTRUCTIONS

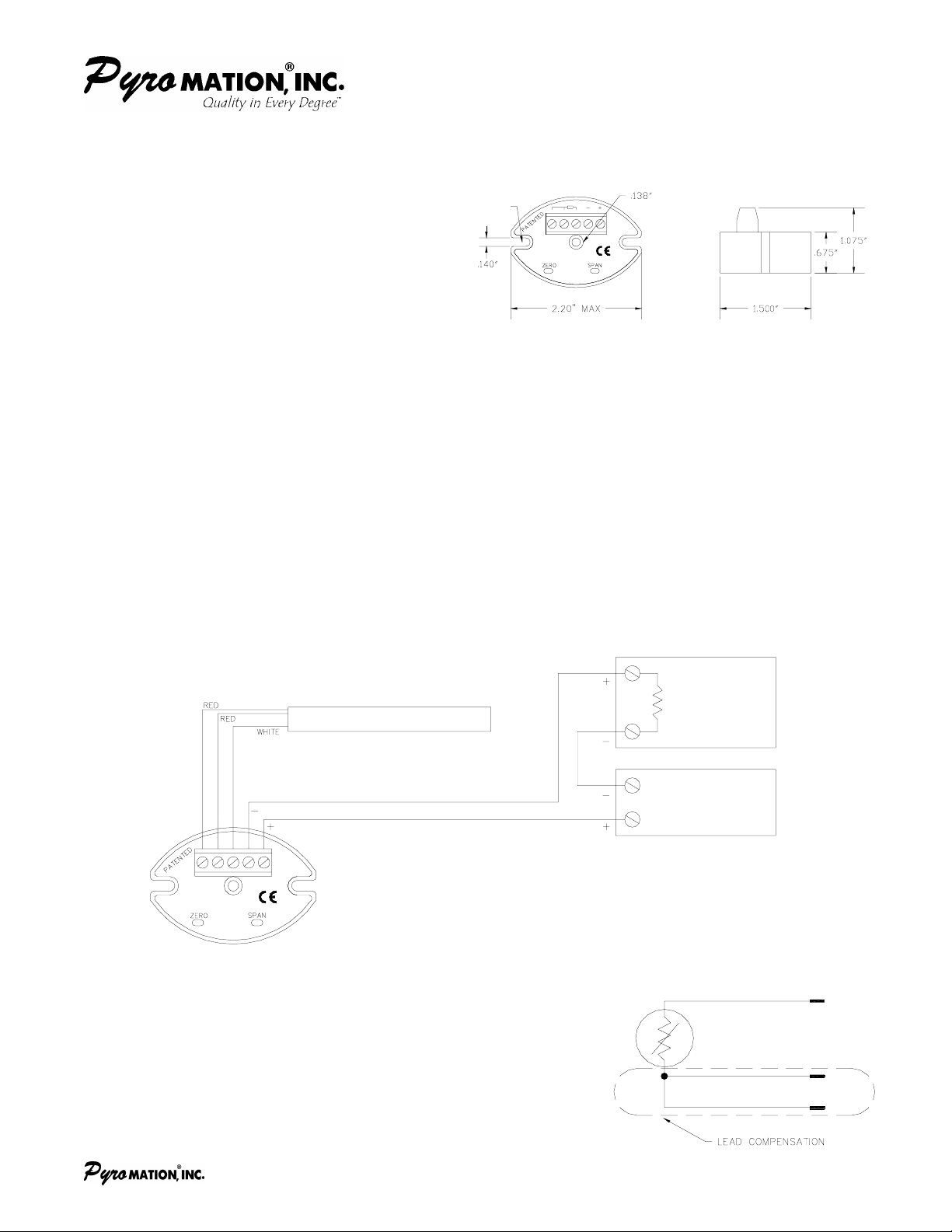

SERIES 401 RTD TEMPERATURE TRANSMITTER

General Information

The Pyromation Series 401 RTD temperature transmitter is a “two wire” loop powered resistance to current

transducer. This transmitter will produce a linearized (4 to 20) mA dc output current proportional to the

temperature of the RTD temperature sensor.

The transmitter’s small size allows universal mounting

inside Series 300, 400, and 900 screw cover heads,

Series 800 explosion-proof, therm ostat housings, and

panel surface mounting us ing two 6-32 screws

1

. The

transmitter is designed for an operating ambient

temperature of (-30 to 65)

°C [(-22 to 149) °F].

Power Supply

The transmitter is designed f or a nom inal 24 V dc power supply. The trans m itter will operate over a range of (9 to

36) V dc depending on the resistive load. Use the following for mulas to deter mine the m axim um r esistive loading

(RL) allowed for the power us ed, or to determine minimum supply voltage (V) required for fixed resistive loads.

The formulas assume a maximum current of 20 mA.

VMIN = 20 mA × RLOAD + 9 V dc RMAXLOAD = (VSUPPLY – 9 V dc ) / 20 mA

One power supply can be used for several transmitter loops. Each loop must have only one transmitter in it and all

loops must be wired in parallel. Do not forget to observe the maximum current rating for your power supply.

Note: If used in a manner not specified by the manufacture, the protection provided by the equipment may be impaired.

Wiring

The terminal block on the trans mitter c an accept wire from 14 to 24 gauge. Shielded or c onduit encased (twisted

pair) cable is required from the transmitter to the controller, including the sensing element and lead wire. Note that

low voltage lines should be run in separate conduit isolated from high voltage or high current carrying lines.

Note 1

RTD ELEMENT

COPPER LEADS

Open Sensor Indication

When an RTD has failed due to an open sensor, the transmitter will

indicate an error. The way the error is produced is by either driving the

current low, under 4 m A (downscale burnout) or by driving the current

high, above 20 mA (upscale burnout). Upscale burnout is standard for

all Pyromation transmitters.

However, the burnout indication does not apply to a break in the lead

compensation loop. In this case, the burnout signal will drive the

transmitter either high or low depending upon which lead has broken.

CONTROLLER

POWER

SUPPLY

5211 Industrial Road • Fort Wayne, IN 46825 USA • (260) 484-2580 FAX: (260) 482-6805 • http://www.pyromation.com 3/02

Copyright 2002 Pyromation, Inc. All rights reserved. Form 401f

Page 2

INSTALLATION AND OPERATING INSTRUCTIONS

SERIES 401 RTD TEMPERATURE TRANSMITTER

Troubleshooting

Problem Possible Causes

No Current Flow in Signal Loop

Current Over 20 mA

Erratic Readings

Destructive Errors

Non-Destructive Errors

Calibration

Pyromation RTD transmitters are factory calibrated. If recalibration is necessary, a zero and span adjustment can

be made from the top of the unit.

Note: adjustment to calibration will void warranty

1. Remove the RTD sensor wires and attach a RTD simulator.

2. Apply a simulated ‘zero’ resistance input and adjust the zero potentiometer for 4.00 mA output.

3. Apply a simulated ‘span’ resistance input and adjust the span potentiometer for 20.00 mA output.

4. The zero and span adjustments are interactive. Repeat steps 2 and 3 as necessary.

Application Hints

The calibrated output of the Pyromation transm itter is (4 to 20) mA. However, the lower and upper limits of output

current are approximately (2.2 and 30) mA respectively. This means that for a system using a 250 ohm resistor

( 1 to 5) V, the maximum voltage could be as high as 7.5 volts ( 30 mA x 250

Some computer bas ed systems will not tolerate input voltages greater than approximately 5.5 volts. Instead of

selecting a different scaling resister (167

with the scaling resist or will c lam p the voltage ac ross the sc aling resis tor to 5.1 V while still allowing the calibrated

range to remain (1 to 5) V.

Limited Warranty

THE SERIES 401 RTD TEMPERATURE TRANSMITTER SOLD BY OR PURCHASED FROM PYROMATION, INC. OR FROM AN AUTHORIZED

PYROMATION, INC. DISTRIBUTOR, OR AGENT IS SUBJECT TO THE FOLLOWING LIMITED WARRANTY.

This product is warranted to be free from functional defects in materials and workmanship at the time the product leaves the Pyromation, Inc. factory, and to conform at that same time to the

specifications set forth in the relevant Pyromation, Inc. installation, wiring, operati on manual for this product for a period of one year after shipment from the Pyromation, Inc. factory.

Pyromation’s exclusive and sole obligati on, and Buyer’s exclusive and sole remedy under the above Limited Warranty is limited to either repair or replacement of such product, at

Pyromation’s option, free of charge to Buyer. Pyromation shall have no obligation to repair or repl ace unless the claimed defect in material or workmanship is reported in writing to

Pyromation at 5211 Industrial Road, Fort Wayne, Indiana 46825 within ten (10) days after delivery to the Buyer from Pyromation or an authorized Pyromation distributor, representative or

reseller. If so requested by Pyromation, the product shall be returned to a designated facility during normal business hours, transportation prepaid.

Any action for breach of this warranty or other action arising out of this contract must be commenced within one year after delivery.

Pyromation shall not be liable for any warranty, express or implied, other than the warranty stated above, and in the event of a breach of the above stated warranty, Pyromation shall not be

liable for any incidental, consequential , special, or other damages, costs, or expenses other than repair or replacement as described above. Pyromation excludes any and all warranties of

merchantability or fitness for a particular purpose. The above stated warranty extends only to the original Buyer from Pyromation, Inc. or from an authorized Pyromation distributor or agent,

and may not be transferred or assigned.

• Current loop may be open at some point

• No Voltage out at power supply

• Reverse polarity on loop connection

• RTD is open

• Current loop connections shorted

• Loose connection in RTD or signal loop

• Damaged RTD

• AC noise on loop connections

• Exceeds loop resistance RL

• Do not connect power to the RTD input; this could destroy the unit

• Do not connect power to the RTD sensor

• Do not use AC line power

• Reverse polarity on loop connection

• Do not connect multiple transmitter in series

Ω ) in the case of an open RTD.

Ω for example gives 5 V for an open RTD), a 5.1 V zener diode in parallel

5211 Industrial Road • Fort Wayne, IN 46825 USA • (260) 484-2580 FAX: (260) 482-6805 • http://www.pyromation.com 3/02

Copyright 2002 Pyromation, Inc. All rights reserved. Form 401f

Loading...

Loading...