Page 1

is product yourself.

Do not connect cables in ways other than those mentioned

in this manual. Different connections may cause equipment

PP5600 SERIES

POS PRINTER

USER’S MANUAL

Rev.: A

damage and burning.

Never attempt to repair th

Improper repair work can be dangerous.

Page 2

Federal Communications Commission Radio Frequency

Interference Statement

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with

the instruction manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

For compliance with Federal Noise Interference Standard, this equipment requires a shielded cable.

This statement will be applied only for the printers marketed in U.S.A.

CE manufacturer’s Declaration of Conformity

(EC Council Directive 89/336/EEC of 3 May 1989)

This product has been designed and manufactured in accordance with the International Standards

EN50081-1/01.92 and EN50082-1/01.92 following the provisions of the Electro Magnetic

Compatibility Directive of the European Communities as of May 1989

Warranty Limits

Warranty will terminate automatically when the machine is opened by any person other than

the authorized technicians. The user should consult his/her dealer for the problem happened. Warranty

voids if the user does not follow the instructions in application of this merchandise. The manufacturer is

by no means responsible for any damage or hazard caused by improper application.

About This Manual

This manual is aimed to assist the user to utilize the PP5600 series which is a series of POS

printers delicately designed to work with either serial or parallel interface connection. This manual

covers both operational and technical aspects.

The manufacturer of the PP5600 series heartily apologizes to the user for reserving the right to

change or to modify this manual without notice due to the rapid and constant progress and improvement

on science and technology. The user may always obtain the most up to date information through our

web site: http://www.posiflex.com.tw, http://www.posiflextw.com,

http://www.posiflexuk.com or http://www.posiflexusa.com

© Copyright Mustek Corp. 2004

All rights are strictly reserved. No part of this documentation may be reproduced, stored in a

retrieval system, or transmitted in any form or by any means, electronic, mechanical, photocopying, or

otherwise, without the prior written consent of Mustek Corp. the publisher of this documentation.

P/N: 19380900020

Page 3

Table Of Contents

BEFORE STARTED . . . . . . . . . . . . . . . . . . . . . . . 1 -- 1

CONGRATULATION . . . . . . . . . . . . . . . . . . . . . . 1 -- 1

PRODUCT BRIEFING . . . . . . . . . . . . . . . . . . . . . 1 -- 1

Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . 1 -- 1

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 -- 2

MODELS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 -- 3

UNPACKING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 -- 3

OPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 -- 4

IMPORTANT TIPS . . . . . . . . . . . . . . . . . . . . . . . . 1 -- 5

MAIN PARTS ON THE EXTERIOR . . . . . . . . . 1 -- 6

INDICATORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 -- 7

QUICK START-UP . . . . . . . . . . . . . . . . . . . . . . . . 2 -- 1

CONNECTING CABLES . . . . . . . . . . . . . . . . . . . 2 -- 1

Serial connection . . . . . . . . . . . . . . . . . . . . . . 2 -- 1

Parallel connection . . . . . . . . . . . . . . . . . . . . 2 -- 1

Peripheral connection . . . . . . . . . . . . . . . . . . 2 -- 1

Power connection . . . . . . . . . . . . . . . . . . . . . 2 -- 2

LOADING / REPLACING RIBBON CASSETTE . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 -- 2

LOADING PAPER . . . . . . . . . . . . . . . . . . . . . . . . .2 -- 4

SELF TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 -- 5

SPECIAL ADJUSTMENTS . . . . . . . . . . . . . . . . . 2 -- 6

Paper near end sensor . . . . . . . . . . . . . . . . . .2 -- 6

DIP switch setting . . . . . . . . . . . . . . . . . . . . .2 -- 6

MAINTENANCE GUIDES . . . . . . . . . . . . . . . . . . . . 3 -- 1

MAINTENANCE GUIDE LINES . . . . . . . . . . . . 3 -- 1

GENERAL CLEANING . . . . . . . . . . . . . . . . . . . .3 -- 1

TROUBLE SHOOTING . . . . . . . . . . . . . . . . . . . .3 -- 1

General problems . . . . . . . . . . . . . . . . . . . . . 3 -- 1

i

Page 4

Printing problems . . . . . . . . . . . . . . . . . . . . .3 -- 2

Paper jam problems . . . . . . . . . . . . . . . . . . . 3 -- 3

Auto cutter problems . . . . . . . . . . . . . . . . . . 3 -- 3

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 -- 1

PRINTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 -- 1

PAPER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 -- 1

RIBBON CASSETTE . . . . . . . . . . . . . . . . . . . . . . 4 -- 2

POWER ADAPTOR . . . . . . . . . . . . . . . . . . . . . . . 4 -- 2

ii

Page 5

I. BEFORE STARTED

A. CONGRATULATION

You have made a very wise decision by purchasing the easy

loading; high performance; high reliability 9 pin dot matrix

impact printer Aura PP5600 series of Posiflex products. This

series of printers has been elegantly designed for a Point-Of-Sale,

kitchen & kiosk application. The manufacturer of this printer not

only wishes to take this opportunity to congratulate your smart

investment on buying this printer but also likes to express the

wishes for your prosperous future by using it.

B. PRODUCT BRIEFING

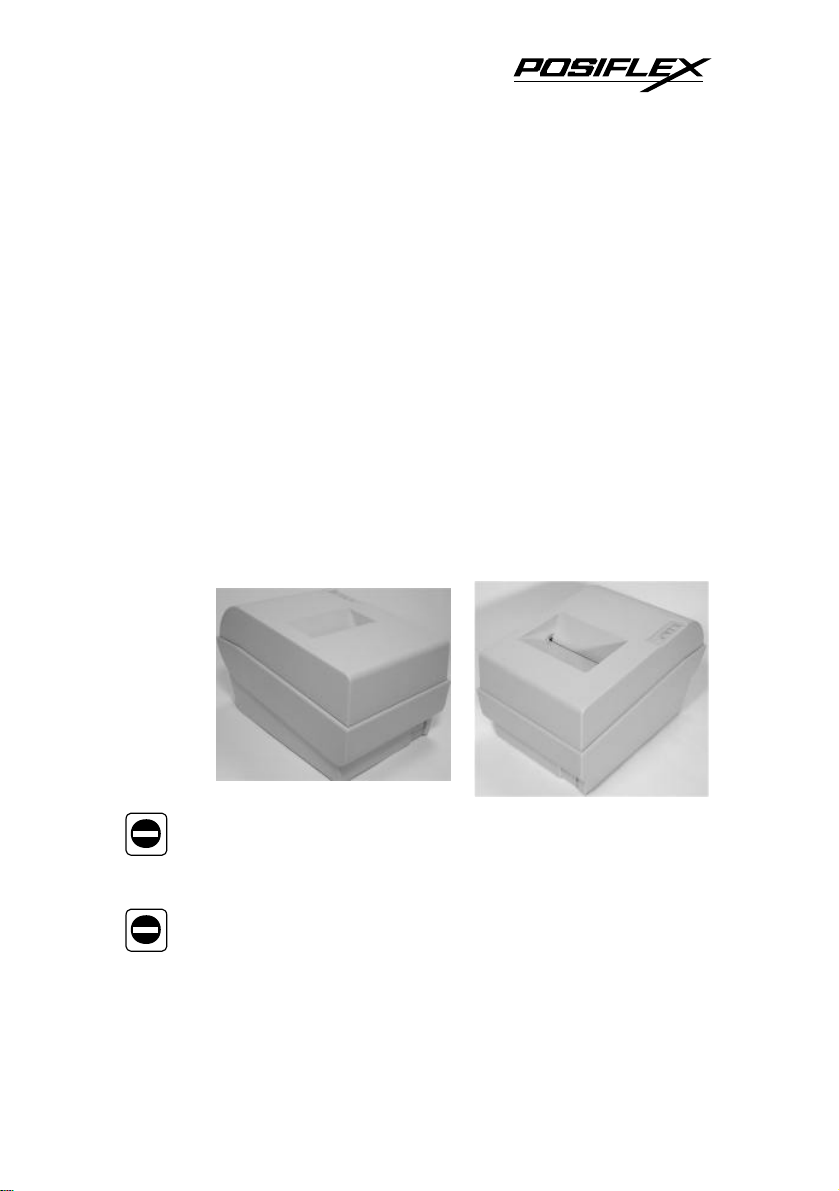

1. DESCRIPTIONS

The Aura PP5600 series printer is a stream-lined low profile

40 column 9 pin dot matrix easy loading impact printer designed

to fit the Posiflex POS system perfectly well and also for other

POS printing applications. The Aura PP5600 series printer serves

the stand-alone desktop application. The print mechanism applied

in this printer series is remarkably reliable. as well as the wall

mount application

The Aura PP5600 series utilizes friction type paper feed

mechanism and supports two types of interface input in one

machine through semi-automatic detection on which type of cable

connected. The interfaces are RS232 for serial interface and

Centronics mode for parallel interface. Cabinet color is selectable

between beige and charcoal.

The Aura PP5600 supports an optional guillotine type auto

cutter for paper partial cut and a standard manual cut mechanism.

1 - 1

Page 6

2

It even supports some enhancement capability for reminder

function to persons around. It can be used to drive a separately

purchased kitchen bell for such reminder function in noisy

environment. This printer also supports application in different

countries of various kinds of power systems by changing the

power cord to the power adaptor. The Aura PP 5600 series also

supports an optional journal paper roll rewinder when non-carbon

copy paper roll is used.

2. Features

• Dot matrix 9 pin printer head

• Bi-directional printing with logic seeking

• Friction type paper feed

• 40 columns for 16.9 CPI

• Print on ordinary paper or up to 3-fold non-carbon copy paper

• DC 24V powered

• Selectable parallel or serial (RS232C) interface by detection

on cable change and DIP switch settings

• 5 character code pages for code range 80h to FFh supported:

USA & Europe PC437, PC850, PC860, PC863, PC865

• 15 international character sets of a dozen characters each

within code range 20h to 7Fh supported: USA, France,

Germany, England, Denmark, Sweden, Italy, Spain, Japan,

Norway, Denmark II, Spain II, Latin America, Korea, Croatia

• Versatile print function as emphasized printing and

underlining set by software print commands

• About 20KB input buffer available enabling simultaneous

printing and data receiving

1 -

Page 7

• Supports Posiflex kitchen bell drive when used as kitchen

printer

• Hardware hand shaking in serial interface through DIP switch

selection

• Manual paper cut mechanism for PP5600D or guillotine type

auto cutter plus manual cut mechanism for PP5600B

• Supports ESC command

• Dimension: 228 mm (l) x 158 mm (w) x 140 mm (h)

C. MODELS

PP5600D – with manual cutter

PP5600B – with auto cutter

PP5600A – with take up rewinder and auto cutter

D. UNPACKING

Followings are items you may find when you carefully

unpack the carton that delivers Aura PP5600 series printer. If

there is any discrepancy or problem, contact your dealer

immediately. Be sure to save the packing materials in case the

printer needs to be shipped at some point in the future.

• The printer itself.

‚ Test paper roll 76 mm in width.

ƒ Ribbon cartridge

„ One of the interface cables:

a Serial cable with 9 pin D sub Female to 9 pin D sub Male

connectors

b Parallel cable with 25 pin D sub Male to 25 pin D sub

Female connectors

1 - 3

Page 8

4

Length of the interface cable depends on whether the order

includes the power adaptor. When power adaptor is included, the

interface cable is 6 ft long for stand alone application. When the

power adaptor is not included in the order, the interface cable is a

shorter one for integrated application in Posiflex POS system.

… One of the power sources:

a Power adaptor + power cord (depend on country type

ordered).

b Power supply cable (when no power adaptor ordered)

This printer power supply cable is used to supply power to

the printer from the PB or PST series of Posiflex POS system.

† This User’s Manual

E. OPTIONS

The underlined items below must be well defined in order, they

can not be field added or changed.

• Paper near end sensor

• Special language selection

• Case color option

• Inked ribbon cartridge

• Kitchen bell

• Guillotine type auto paper cutter

• Journal paper roll rewinder

• Wall mount kit

• Paper roll

1 -

Page 9

Do not set any liquid or drinks such as coffee on the

Choose a place that is well ventilated and free from direct

Use a grounded AC power outlet. Use only the power cord

Do not touch any connector contacts to avoid

Do not use a power outlet of a circuit shared with any

equipment that uses a lot of power, such as a copier or a

coffee maker.

with any

equipment that causes great electrical noise, such as

motors.

Ideal room temperature is from 5ºC to 40ºC. Ideal humidity

Otherwise, both printer and telephone line may be

damaged.

F. IMPORTANT TIPS

Place the printer on a sturdy, level surface.

sunshine and excessive heat, dust, smoke or fume.

Never attempt to disassemble or modify this product.

Unauthorized interior access voids product warranty.

Do not connect a telephone line to the peripheral port.

Do not touch the print head after printing.

It can become very hot.

and power adaptor furnished with the printer.

Do not use a power outlet of a circuit shared

printer case.

possible electrostatic damage.

is from 20% to 85% RH (no condensation).

1 - 5

Page 10

6

Pa

rallel Connector

Manual

Paper Out

LED

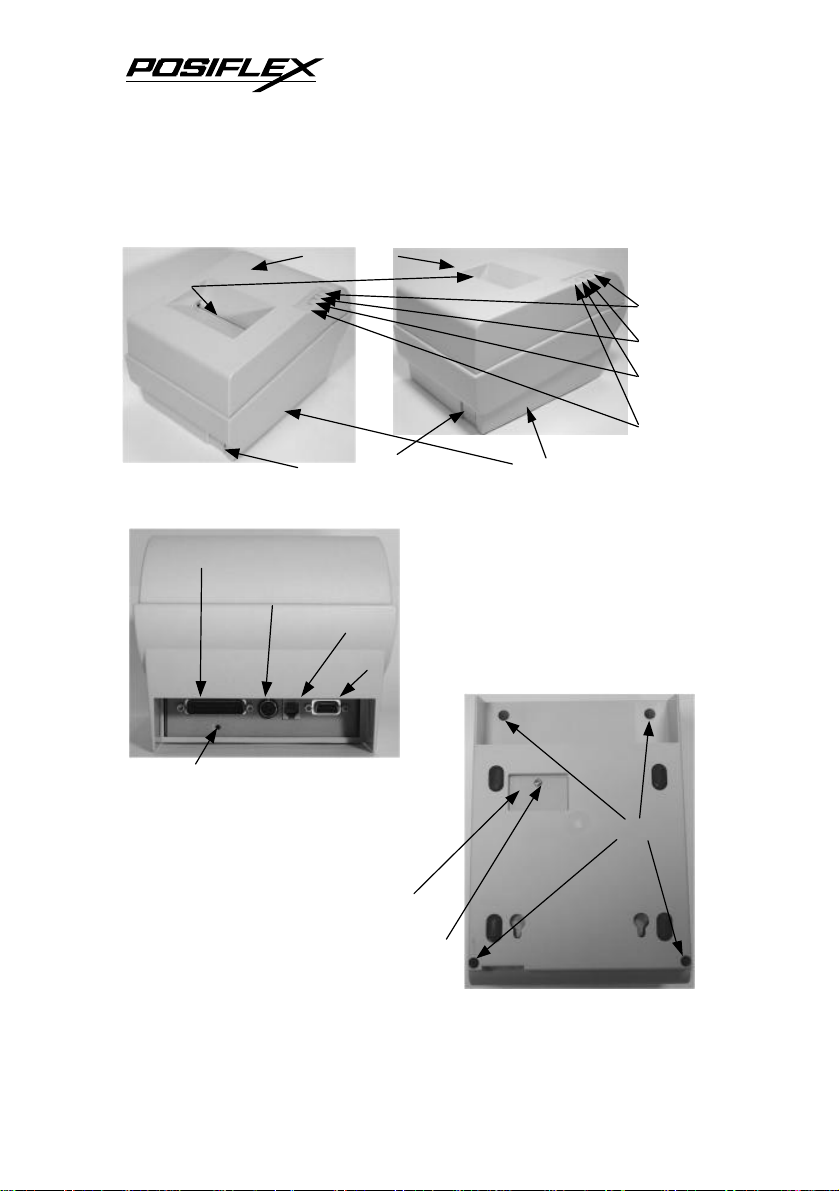

G. MAIN PARTS ON THE EXTERIOR

Top Cover

Cutter

PP5600B

PP5600D

Power LED

Error LED

FEED Button

Frame Ground

Power Switch

Power Connector

Peripheral Connector

Bottom View

Setup Window

Window Plate Screw

Rear View

Serial Connector

Bottom Cover

Screws

1 -

Page 11

Interior View

Lift Tab

Indicators

• Power LED: green

• Error LED: red

• Paper Out LED: red

Auto Cutter

Ribbon Cassette Area

Paper Guide Roller

Paper Roll Area

1 - 7

Page 12

Page 13

II. QUICK START-UP

A. CONNECTING CABLES

1. Serial connection

All the external connectors are in the recessed area at the

rear bottom. The serial connector is a 9 pin D sub Female

connector at the right in the picture above. Apply the male

connector of RS232 cable to this port for serial application. Please

note that when serial connection is used, there must be no cable

connection at the parallel port on the printer. The default protocol

used in serial connection is 9600 bps, none parity check, 8 data

bits, 1 stop bit.

2. Parallel connection

The parallel connector is a 25 pin D sub Male connector at

the leftmost location in the connector area. Apply the female end

of the parallel cable at this port for parallel application. Please

note that when parallel connection is used, there must be no cable

connection at the serial port on the printer. Please also check the

DIP switch settings inside the service window at bottom side of

the printer following instructions later in this chapter.

3. Peripheral connection

The peripheral controller is a RJ11 jack near the serial

connector. With use of Posiflex cash drawer cable 20863018001

(CCBLA-180-1), this port can control a Posiflex cash drawer

CR3100 or CR3200 or CR4000 or CR4210. If a Posiflex special

2 - 1

Page 14

2

split cable 20867023800 (CCBLA-238) is used instead, this port

can control two cash drawers of above models.

When the printer is used as a kitchen printer, please use this

port for kitchen bell connection instead.

4. Power connection

The power connector is a 3 pin jack between the peripheral

connector and the parallel connector. Either a Posiflex supplied

power adaptor or a printer power cable from a Posiflex POS

system can be connected to this connector to supply power for

this printer. During insertion of the power plug, be sure to hear

the click to obtain a firm contact.

CAUTION: Before doing the insertion or extraction of the

power plug, be sure to pull the outer sleeve of the

plug backward to release the internal latch.

Failure to do this could damage the power plug.

Such damage is considered as an artificial

destruction and is not covered by the warranty.

When all the above cable connections are made correctly,

you may connect your power adaptor to the wall outlet. Make

sure that the type of power cord and the voltage requirement of

the power adaptor meet the local power conditions. Do not turn

the power on for the moment.

2 -

Page 15

Ribbon feed knob

Lift

Fastening

Knob

B. LOADING / REPLACING RIBBON

CASSETTE

• Turn off the power to the printer.

• Lift the front end of the top cover

to remove it.

• Open the auto cutter by pulling the

tab up if it is installed in the printer.

(PP5600B)

• Remove slack in the ribbon by

turning the ribbon feed knob of the

ribbon cartridge counterclockwise. The

ribbon must be properly tightened to be

able to set in position in installation.

Never turn the knob the other way

round or the ribbon may mess up inside

the cassette and ruin the whole

cassette.

• If in process of replacing the

ribbon cassette, the cassette shall

be removed in the manner that the

side of the knob is pulled up first

with the end of the holding tab

remain held down.

• Place the ribbon cartridge in

position as shown in the picture.

Seat the side with the holding tab

first then press down the whole

cassette. Rotate the ribbon feed

knob counterclockwise during the

action pressing down the ribbon

cartridge into position to help the

installation operation if necessary.

Pull up this end to remove

Pressing this end

Seat this end first

Tab

2 - 3

Page 16

4

Seat lug outside

š

Î

• Turn the knob counterclockwise to remove slack in ribbon for

use.

• Apply even force

to close the auto

cutter (PP5600B)

so that the small

lug of auto cutter

can seat in right

position on the

bracket of the

print mechanism

as in the picture.

• Close the top cover by fitting its rear end lug first for ribbon

replacement only or go on loading paper as in next paragraph.

bracket below

C. LOADING PAPER

1. Drop the paper roll inside the paper compartment in the

orientation as shown in left picture below.

2. Cut the leading edge of paper roll perpendicular to paper

direction and now please turn on the

power to the printer by pressing the

power button in front side of the

printer. Insert the leading end of the

paper roll into the paper intake slot on

print mechanism. Insert the paper till

you feel the front end caught by the

2 -

Page 17

paper feed roller inside the print mechanism then the paper

will automatically advance to proper position (paper exit of

print mechanism). In case there was a slip at the insertion of

the leading end of paper roll and you want to keep same

heading clearance, you may press the FEED button to

advance the paper to position.

3. Close the top cover back. Should the front end of paper roll

tend to curl as when it comes near end of the paper roll, it is

advisable to press the FEED button to check if the paper

comes out of the slot in top cover. Engage manual support to

make sure it comes out if it fails.

D. SELF TEST

Press and hold down the

feed button while turning on

the power. The printer will then

perform a self test and print out

some major settings detected as

in picture at right. You may

turn off the power and turn it

on again to resume normal use

of the printer at this stage. You

may also press the feed button

at this moment to have the

printer further print out some

basic font used and a special

pattern to have the self test

proceedings completed as in

the picture on next page. Please

note in the first part that both serial and parallel interfaces are

indicated. That means the printer is working on an auto-sensing

and auto-select algorithm. The pattern of long vertical lines at

2 - 5

Page 18

6

Sensor Head

bottom of the slip is an

indicator for adjustment on socalled bi-directional printing

offset.

E. SPECIAL ADJUSTMENTS

1. Paper near end sensor

If the paper near end sensor is

installed in the printer and enabled, a

fine tuning on the position of the

paper near end sensor may be

required for different outer diameter

of the paper roll bobbin. Please refer

to the picture at right from inside the

paper roll compartment that there are

a fixing screw and a sensor head in the wall. Slightly release the

fixing screw using a blade screw driver or suitable coin to adjust

the position of sensor head. For smaller roll diameter, the sensor

head should go lower.

Fixing Screw

2. DIP switch setting

In setup window on bottom plate of

the printer there are 2 DIP switches. The 4

position switch at the right is coded S1 and

controls bi-directional print offset. The 8

2 -

Page 19

position switch at the left is coded S2 for general printer settings.

a.Bi-directional printing offset - S1

Pos. 1

Pos. 2

Pos. 3

Pos. 4

Off On Off On Off On Off On Off On Off On Off On Off On

Off Off On On Off Off On On Off Off On On Off Off On On

Off Off Off Off On On On On Off Off Off Off On On On On

Off Off Off Off Off Off Off Off On On On On On On On On

Value 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

The offset values in above table are in unit of half dot.

The bi-directional printing offset actually is well adjusted

and requires no further action when a new printer is received.

However, after long period of usage some internal mechanical

clearance will vary. This clearance can be observed from the

offset pattern printed in bottom of self test.

Whenever the lower part of the long vertical lines is shifted

horizontally away from the upper part by about one dot width, the

offset value should be adjusted to move it back for decent print if

bi-directional print is engaged. Increasing the offset value by

changing the S1 setting can move the lower part to right and

decreasing the value moves the lower part to left.

b.Printer general setting – S2

Switch

2-1 Hand shaking mode X-ON/X-OFF

Function ON OFF

DTR/DSR

2-2 Data bit 7-bit data 8-bit data

2-3 Parity check Parity check

2-4 Parity selection Even parity

No parity check

Odd parity

2-5 Baud rate (bps) 4800 9600

2-6 Busy on Buffer full Off line or Buffer full

2-7

Column spacing

(columns per line)

2-8 Print direction Uni-direction

2 half dots

(42 / 35)

2 - 7

3 half dots

(40 / 33)

Bi-direction

Page 20

8

Positions 1 to 6 of the S2 switch define the communication

protocol and handshaking criteria in RS232 interface. They shall

always be set to positions 1 to 4 OFF with position 5 set to ON for

parallel interface application.

Position 7 of S2 alters the horizontal spacing between

characters to get different print density on same font format.

Position 8 of S2 determines whether to print only in one

direction of print head operation or in both directions.

All positions of S2 default to OFF when printer delivered.

3. Wall mount application

In wall mount application, the paper near end sensor will

not have proper operation and it is suggested not to install it.

2 -

Page 21

thinner, trichloroethylene

alcohol, or ketone based solvents on the printer’s plastic and

Please pay attention not to be hurt by any sharp edge of the

III. MAINTENANCE GUIDES

A. MAINTENANCE GUIDE LINES

Always turn off and disconnect power before start.

metal parts when handling the interior of the printer.

any dust or paper scraps accumulation inside the printer. Check

also the area of the auto-cutter regularly.

Do not touch the print head and motor after printing.

It can become very hot.

Never use benzene, benzine,

rubber components.

B. GENERAL CLEANING

Please use a soft hair brush or compressed air to clear away

C. TROUBLE SHOOTING

This section gives solutions to some printer problems you

may have.

1. General Problems

No LED lights up on control panel when switched on –

Make sure that the power supply cables are correctly plugged into

the printer, the power adaptor and to the power outlet. Make sure

that power is supplied to the power outlet. If the power outlet is

controlled by a switch or timer, try use another outlet.

3 - 1

Page 22

2

2. Printing Problems

Nothing can be printed with ERROR LED ON – Check

the Paper Out LED. If it is ON, most probably the paper roll is not

installed or is at or near the end. Install a new paper roll. If the

Paper Out LED is OFF, please check for paper jam described in

next item.

If there is no paper jam and the printer has been printing for

quite a period of time, the print head may be overheated. It will

usually cool back in few minutes and the printing will resume.

If there is no paper jam and the print head is not overheated,

turn off the printer and wait for half a minute then turn it back on.

If the problem still remains, contact a qualified service person.

Nothing can be printed with ERROR LED OFF – Try to

run self test according to previous chapter to check if the printer

itself works properly. If the self test passes, check the following:

a. Check the connection of the interface cable at both the

printer and computer ends. Also make sure that this cable

meets the specification required for both the printer and

the computer and also the settings by software.

b. Check the printer data communication settings against the

computer. The printer settings can be found easily on the

self test print out.

If the problem remains or the self test fails, contact your

dealer or a qualified service person.

Poor printing quality – Contaminants like paper scraps and

dusts on the print head or near worn out inked ribbon can lower

the print quality drastically. Clean the print head replace the

ribbon cassette as required.

3 -

Page 23

3. Paper Jam Problems

Paper is jammed inside the printer – Please follow

procedures below.

• Turn off the printer.

• Open the top cover after the print head cools down.

• Cut the paper roll from the paper intake slot with a pair of

scissors.

• Open the auto cutter by pulling the tab up if it is installed in the

printer. (PP5600B)

• Turn the printer power back to on.

• Press the FEED switch to forward the paper out of the paper

guide. Engage mechanical help like tweezers or manual pull if

necessary.

• Clean the paper path when necessary.

• Reload the paper as instructed in “LOADING PAPER”.

opening the auto cutter. Please first resolve the auto cutter

problems per description in next item and then come back to deal

with the paper jam. Please also clear away any contaminants

accumulated in the cutter track.

scraps fall into the auto cutter unit, the auto cutter could get stuck.

In such case, please open the top cover and find adjustment

window in the auto cutter as shown in the picture on top of

following page. Please apply a small cross head screw driver to

turn the plastic screw in the window and to move the cutter blade

along the track and reset it to home position.

Do not touch the print head and motor after printing.

It can become very hot.

If the auto cutter is jammed, you may have difficulty

4. Auto Cutter Problems

If any materials like a staple or paper clip or excessive paper

3 - 3

Page 24

4

spindle

down

šÎš

Î

To check for home position of the auto cutter, please open

the auto cutter and look into the blade slot and the spindle hole as

in pictures below. Use proper tool to cut away the paper around

auto cutter if it presents obstacle to the actions. Clear away any

paper scraps from the auto cutter once it is reset to position.

Blade Slot

Auto Cutter Adjustment Window

Retract blade from the slot

Move

Spindle Hole

In case it is the auto cutter that fails to respond to the paper

cut command, please contact your dealer or a qualified service

person. However, please use manual cutter as a temporary

alternative measure before this problem is remedied.

3 -

Page 25

IV. SPECIFICATIONS

A. PRINTER

ITEM SPECIFICATION

Printing method Dot matrix impact method

Print head configuration 9 pins

Printing direction Bi-directional; logic seeking

Effective printing width 59.85 mm

Printing speed (max.) 4.0 lines / sec @ 42 columns

Paper feed method Friction auto-feed

Paper load method Drop and auto paper feed

Manual cutter Saw tooth blade

Auto-cutter capability Partial cut (1 point at center left)

Dot Pitch 0.30 (H) x 0.353 (V) mm

Paper feed pitch (min.) 0.176 mm (1/144 inches)

Paper feed holding force Min. 8 N (816 gf)

Paper feed speed (max.) 140 mm / sec

Input power type DC

Input voltage 24 V + / - 5 %

Power consumption 43 W @ printing

Dimension (mm)

Weight 1.6 Kg net (1.9 Kg w/ auto cutter)

228 (D) x 158 (W) x 140 (H)

B. PAPER

Paper type

Paper width 76 + 0 / - 0.5 mm

Paper roll outer diameter 82 mm max.

Paper roll inner diameter 12 + 1 / - 0 mm

Paper thickness

1 ply regular roll paper up to 3 ply

non-carbon copy roll paper

70 ~ 100 um for 1 ply, 60 ~ 80 um for

3 plies

4 - 1

Page 26

2

C. RIBBON CASSETTE

ITEM REQUIREMENT

RECOMMENDED TYPE RC200P

COLOR Purple

RIBBON MATERIAL Nylon 66

RIBBON WIDTH 13 mm

CASSETTE DIMENSION 144.4 (W) x 65 (D) x 26.7 (H) mm

EXPECTED LIFE 3 million characters

D. POWER ADAPTOR

ITEM REQUIREMENT

INPUT VOLTAGE 100 V AC ~ 250 V AC

INPUT FREQUENCY 50 ~ 60 HZ

INPUT CURRENT 1.5 A MAX. @ 115 V AC

OUTPUT VOLTAGE + 24 V DC

OUTPUT POWER 52 W MAX.

STATIC LOAD 0 A ~ 2.2 A

OUTPUT REGULATION + / - 5 %

VPP RIPPLE & NOISE 240 mV

MTBF 30,000 HRS

EMI STANDARDS VDE – B, FCC – B, VCCI – B

4 -

Loading...

Loading...