Page 1

Instruction Manual

Manuel d’utilisation

Manual de Instrucciones

371

2 1/2" x 14" Compact Belt Sander

Ponceuse à Courroie Compacte

64 mm x 355 mm (2 1/2 po x 14 po)

Lijadora de banda compacta de

64 mm x 355 mm (2 1/2" x 14")

®

ADVERTENCIA: Lease este instructivo antes de usarel producto.

DEFINITIONS - SAFETY GUIDELINES

avoided, will result in death or serious injury.

avoided, could result in death or serious injury.

avoided, may result in minor or mod er ate injury.

hazardous situation which, if not avoided, may result in property damage.

indicates an imminently hazardous situation which, if not

indicates a potentially hazardous situation which, if not

indicates a potentially haz ard ous situation which, if not

used without the safety alert symbol indicates potentially

General Safety Rules

shock, fi re and/or serious injury. The term “power tool” in all of the warnings listed below refers to

your mains-operated (corded) power tool or battery-operated (cordless) power tool.

Read all instructions. Failure to follow all instructions listed below may result in electric

SAVE THESE INSTRUCTIONS

1) Work area safety

a) Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive atmospheres, such as in the presence of

fl ammable liquids, gases or dust. Power tools create sparks which may ignite the dust

or fumes.

c) Keep children and bystanders away while operating a power tool. Distractions can

2) Electrical safety

3) Personal safety

cause you to lose control.

a) Power tool plugs must match the outlet. Never modify the plug in any way. Do not

use any adapter plugs with earthed (grounded) power tools. Unmodifi ed plugs and

matching outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces such as pipes, radiators,

ranges and refrigerators. There is an increased risk of electric shock if your body is

earthed or grounded.

c) Do not expose power tools to rain or wet conditions. Water entering a power tool will

increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the

power tool. Keep cord away from heat, oil, sharp edges or moving parts. Damaged or

entangled cords increase the risk of electric shock. Use only 3-wire extension cords that

have 3-prong grounding-type plugs and 3-pole receptacles that accept the tool’s plug.

e) When operating a power tool outdoors, use an extension cord suitable for outdoor

use. If an extension cord is to be used outdoors, it must be marked with the suffi x W-A or

W following the cord type designation. Use of a cord suitable for outdoor use reduces the

risk of electric shock. When using an extension cord, be sure to use one heavy enough to

carry the current your product will draw. An undersized cord will cause a drop in line voltage resulting in loss of power and overheating. The following table shows the correct size

to use depending on cord length and nameplate ampere rating. If in doubt, use the next

heavier gauge. The smaller the gauge number, the heavier the cord.

Minimum Gauge for Cord Sets

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

Ampere Rating Gauge of wire in AWG units

From 0 to 6 amps 18 16 16 14

a) Stay alert, watch what you are doing and use common sense when operating a pow-

er tool. Do not use a power tool while you are tired or under the infl uence of drugs,

alcohol or medication. A moment of inattention while operating power tools may result in

serious personal injury.

b) Use safety equipment. Always wear eye protection. Safety equipment such as dust

mask, non-skid safety shoes, hard hat, or hearing protection used for appropriate conditions will reduce personal injuries.

c) Avoid accidental starting. Be sure the switch is in the off-position before plugging in.

Carrying power tools with your fi nger on the switch or plugging in power tools that have

the switch on invites accidents.

d) Remove any adjusting key or wrench before turning the power tool on. A wrench or a

key left attached to a rotating part of the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance at all times. This enables better

control of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing and

gloves away from moving parts. Loose clothes, jewelry or long hair can be caught in

moving parts.

www.porter-cable.com

Copyright © 2006 Porter-Cable

Part No. A17064 - 07-12-06 - Rev. A

Instructivo de operacion,

centros de servicio y poliza de garantia.

g) If devices are provided for the connection of dust extraction and collection facilities,

ensure these are connected and properly used. Use of these devices can reduce dust-

related hazards.

4) Power tool use and care

a) Do not force the power tool. Use the correct power tool for your application. The cor-

rect power tool will do the job better and safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it on and off. Any power tool that

cannot be controlled with the switch is dangerous and must be repaired.

c) Disconnect the plug from the power source before making any adjustments, chang-

ing accessories, or storing power tools. Such preventive safety measures reduce the

risk of starting the power tool accidentally.

d) Store idle power tools out of the reach of children and do not allow persons unfamil-

iar with the power tool or these instructions to operate the power tool. Power tools are

dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding of moving parts, breakage

of parts and any other condition that may affect the power tools operation. If damaged, have the power tool repaired before use. Many accidents are caused by poorly

maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits etc., in accordance with these instruc-

tions and in the manner intended for the particular type of power tool, taking into

account the working conditions and the work to be performed. Use of the power tool

5)

for operations different from those intended could result in a hazardous situation.

Service

a) Have your power tool serviced by a qualifi ed repair person using only identical re-

placement parts. This will ensure that the safety of the power tool is maintained.

ADDITIONAL SPECIFIC SAFETY RULES

• Hold tool by insulated gripping surfaces when performing an operation where the cutting

tool may contact hidden wiring or its own cord. Contact with a “live” wire will make exposed

metal parts of the tool “live” and shock the operator.

• Do not sand metal of any kind with your belt sander. Sparks may be generated by sanding

screws, nails or other metals which may ignite dust particles.

• Do not wet sand with this sander. Liquids may enter the motor housing and cause electric

shock.

• Do not operate this tool for long periods of time. Vibration caused by the operating action of

this tool may cause permanent injury to fingers, hands, and arms. Use gloves to provide extra

cushion, take frequent rest periods, and limit daily time of use.

• Clean out your tool often, especially after heavy use. Dust and grit containing metal

particles often accumulate on interior surfaces and could create a risk of serious injury,

electric shock or electrocution. ALWAYS WEAR SAFETY GLASSES.

•

Ventilate your work area adequately when performing sanding operations.

•

Make sure the sanding belt is not contacting the workpiece before the switch is turned on.

•

Be sure to clamp or secure sander if it is inverted and bench mounted for use as a table sander.

When using any accessory that converts a belt sander in this manner, be sure to read and follow all

instructions included with the accessory. Always use the included safety features with the accessory,

such as the edge stop or guide, when sanding short or small workpieces. Fingers or clothing can be

dragged into pulley and housing area if guards are not in place. Also, be aware of the switch location

and know how to shut off the tool in emergency situations.

struction activities contains chemicals known to cause cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber (CCA).

Your risk from these exposures varies, depending on how often you do this type of work. To reduce

your exposure to these chemicals: work in a well ventilated area, and work with approved safety

equipment, such as those dust masks that are specially designed to fi lter out microscopic particles.

other construction activities. Wear protective clothing and wash exposed ar eas with soap and water.

Allowing dust to get into your mouth, eyes, or lay on the skin may promote absorption of harmful

chemicals.

permanent respiratory or other injury . Always use NIOSH/OSHA appr oved r espiratory protection appropriate for the dust exposure. Direct particles away from face and body.

conditions and duration of use, noise from this product may contribute to hearing loss.

SYMBOLS

The label on your tool may include the following symbols. The symbols and their definitions are as

follows:

V.......................volts A...........................amperes

Hz ....................hertz W .........................watts

min ..................minutes

(grounded) ........................safety alert symbol

.....................Class II Construction …/min .................revolutions or reciprocations

(double insulated) per minute

BPM ..............beats per minute

To reduce the risk of injury:

Some dust created by power sanding, sawing, grinding, drilling, and other con-

Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling, and

Use of this tool can generate and/or disburse dust, which may cause serious and

Wear appr opriate hearing protection during use. (ANSI S12.6 (S3.19)) Under some

.......................alternating current

................direct current

....................Class I Construction .........................earthing terminal

n

o .........................no load speed

ADDITIONAL SAFETY RULES FOR P AINT REMOV AL

vapors of paint may contain lead, which is poisonous. Exposure to even low levels of lead can cause

irreversible brain and nervous system damage. Young and unborn children are particularly vulnerable.

Before beginning any paint removal process you should determine whether the paint you are r emoving

contains lead. This can be done by your local health department or by a professional who uses a paint

analyzer to check for lead.

Lead-based paint should only be removed by a professional.

Persons removing paint should follow these guidelines:

1. Keep the work area well ventilated. Open the windows and put an exhaust fan in one of them.

Be sure the fan is moving air from inside to outside.

2. Remove or cover any carpets, rugs, furniture, clothing, cooking utensils, and air ducts.

Such preventive safety measures reduce the risk of exposure.

3. Place drop cloths in the work area to catch any paint chips or peelings. Wear protective

clothing such as extra work shirts, overalls and hats.

the risk of exposure.

4. Work in one room at a time. Furnishings should be removed or placed in the center of the room

and covered. Work areas should be sealed off from the rest of the dwelling by sealing doorways

with drop cloths.

5. Children, pregnant (or potentially pregnant) women and nursing mothers should not be

present in the work area until the work is done and all cleanup is complete. Such preventive

safety measures reduce the risk of injury.

6. Wear a dust respirator or a dual filter (dust and fume) respirator mask which has been

approved by the Occupational Safety and Health Administration (OSHA), the National

Institute of Safety and Health (NIOSH), or the United States Bureau of Mines. These

masks and replaceable filters are readily available at major hardware stores. Be sure the mask

fits. Beards and facial hair may keep the masks from sealing properly. Change filters often.

DISPOSABLE PAPER MASKS ARE NOT ADEQUATE.

7. Keep food and drink out of the work area. Wash hands, arms, and face and rinse mouth before

eating or drinking. Do not smoke or chew gum or tobacco in the work area.

8. Clean up all removed paint and dust by wet mopping the floors. Use a wet cloth to clean all

walls, sills and any other surfaces where paint or dust is clinging. DO NOT SWEEP, DRY DUST

OR VACUUM. Use a high phosphate detergent or trisodium (TSP) to wash and mop ar eas.

9. At the end of each work session, put the paint chips and debris in a double plastic bag,

close it with tape or twist ties and dispose properly.

the risk of exposure.

10. Remove protective clothing and work shoes in the work area to avoid carrying dust into

the rest of the dwelling. Wash work clothes separately. Wipe shoes off with a wet rag, then

wash that rag with the work clothes. Wash hair and body thoroughly with soap and water.

Extreme care should be taken when removing paint. The peelings, residue, and

Such preventive safety measures reduce

Such preventive safety measures reduce

Page 2

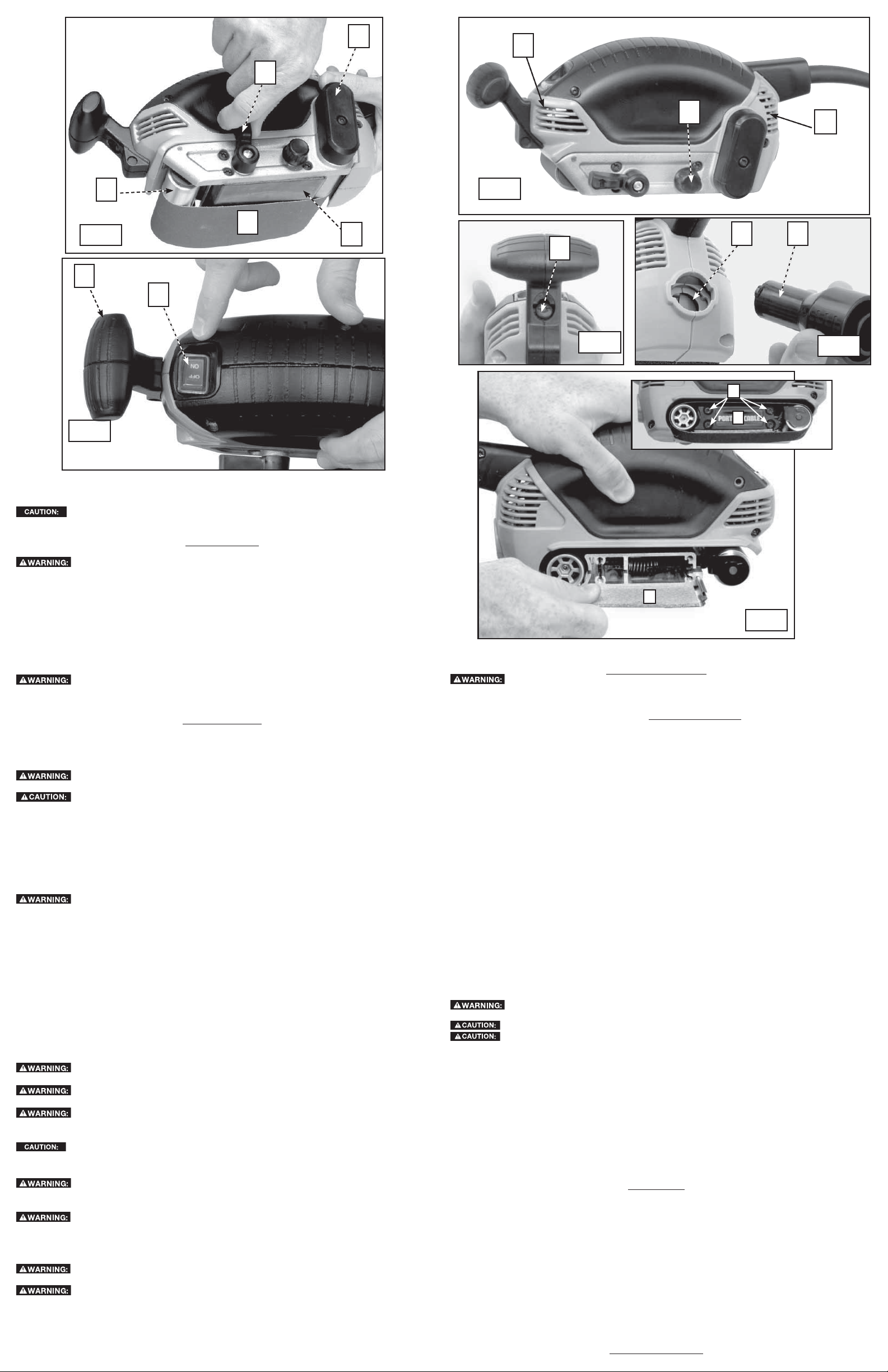

T

L

A

Fig. 1

E

Fig. 2

G

M

B

Fig. 3

C

H

JK

S

D

Fig. 4

Fig. 5

O

N

SAVE THESE INSTRUCTIONS!

MOTOR

not operate tools rated A.C. only on D.C. current. To do so may seriously damage the tool.

Do not operate your tool on a current on which the voltage is not within correct limits. Do

ASSEMBLY

REPLACING THE SANDING BELT

supply when changing the sanding belt. Before reconnecting the tool, make sure the switch (D) Fig. 2 is

in the off position.

To replace the belt:

1. Rotate the belt release lever (A) Fig. 1 up until front wheel of the sander (B) Fig. 1 retracts and

releases the tension on the abrasive belt (C).

2. Remove the wor n out belt.

3. Slip a new belt around the wheels. Sanding belts without arrows can go either direction. If the

belt is unidirectional and has arrows printed on its inside, make sure to point these arrows in the

direction of wheel rotation.

the sander)

properly and may overhang the housing, possibly causing severe lacerations.

4. Rotate the belt release lever (A) Fig. 1 down into position to reapply tension to the belt.

To reduce the risk of injury, be sure sander is turned off and disconnected from the power

(Wheel rotation would be clockwise when looking into the open side of

.

Severe laceration hazard. If installed backwards, unidirectional sanding belts may not track

OPERATION

SWITCH OPERATION

To turn unit on, depress the side of the dust-protected switch (D) Fig. 2 that reads “ON” and corresponds to the symbol “I.” To turn the unit off, depress the side of the switch that reads “OFF” and

corresponds with the symbol “O.”

the switch is turned on.

secured, and working correctly.

FRONT HANDLE

The front auxilliary handle is removeable to allow the sander into tight spaces. The unit comes with

the handle (E) Fig. 2 installed as shown. To remove the handle, loosen the screw (S) Fig. 4 in the

center of the handle using a flat head screwdriver and then remove handle and screw.

NOTE: The handle must be properly seated over the mounting surface before tightening the

screw.

TRACKING THE BELT

the housing. A running belt overhanging the housing can cause severe lacerations.

Make sure the sanding belt is tracking properly on your unit. To do this:

1. Grasp unit in your hand and hold with the belt facing you.

2. Turn on switch (D) Fig. 2 to start the belt.

3. Turn the tracking knob (G) Fig. 3 counterclockwise (turning towards the front of the sander) to

move the belt toward the housing. Turn the knob clockwise (towards the power cord) to move

it away from the housing.

NOTE: The belt should be aligned with the flush edge of the platen (H) Fig. 1 while the sander

is in operation.

4. Turn switch off and make sure the belt has come to a complete stop before setting unit down.

PROPER HAND POSITION

This can be a one-handed tool. Proper hand position would be to have one hand on the rubber

portion of the body, as shown in Fig. 6. If needed, the other hand can grip the auxilliary handle (E)

Fig. 2.

do so could result in the sanding of the hands or fingers possibly causing serious injury.

do so could result in fingers getting pinched, causing possible serious injury.

If the sanding belt were to run off, or if it were not properly adjusted, your fingers could come in contact

with the moving sanding belt resulting in possible serious injury.

OPERATING THE SANDER

Before sanding a workpiece, make sure it is secured or clamped down.

towards the user.

VACUUM ADAPTER

faces such as polyurethane, varnish, shellac, etc. Dispose of coated dust particles according to

the fi nish manufacturer’s guidelines, or place in a metal can with a tight fi tting metal lid. Remove

coated dust particles from the premises daily . The accumulation of fi ne sanding dust particles may

self ignite and cause fi re.

may generate static electricity that could result in startling static discharge.

which may cause serious personal injury and/or damage to the tool.

Your belt sander is equipped with a dual hose adpater. The adapter can be attached to both 1"

(inside diameter) and 35 mm (outside diameter) shop vacuum hoses for dust collection. Insert the

adpater (J) Fig. 5 into the dust port (K) and turn it 1/8 turn clockwise to secure the adapter to the

sander. Then, attach the appropriate vacuum hose to the adapter.

To reduce the risk of injury, make sure the sander is not resting on the workpiece when

To reduce the risk of injury, check to see that the belt guard (T) Fig. 1 is in place,

Severe laceration hazard. Properly adjust the tracking of the belt to avoid it overhanging

Severe abrasion hazard. Keep hands and fingers clear of moving sanding belt. Failure to

Severe pinching hazard. Keep hands and fingers clear of front roller at all times. Failure to

Severe abrasion hazard. Do not let the fingers rest over the front or right edge of the sander.

Make sure all air vents on the sander (L) and (M) Fig. 3 are not covered during use.

To reduce the risk of injury, always secure work to prevent it from being thrown back

Empty dust collection system frequently, especially when sanding resin-coated sur-

Shock hazard. The use of a vacuum hose and vacuum adapter with the belt sander

Do not use a dust collection device when sanding metal. Doing so creates a fire hazard,

P

Fig. 6

MAINTENANCE

or removing or installing accessories.

REPAIRS

For assistance with your tool, visit our website at www.porter-cable.com for a list of service centers, or

call the Porter-Cable Customer Care Center at (888) 848-5175.

TO REPLACE THE PLATEN/CORK

The cork under the platen on your belt sander may require replacement at some point during the life

of the tool. A new platen/cork is available through your PORTER-CABLE service center.

1. Remove the sanding belt as described in ASSEMBLY.

2. Rotate the belt release lever (A) Fig. 1 down.

3. Remove the plastic cover (N) Fig. 6 (inset) from right side of platen by removing four screws

(O).

4. Slide old platen/cork (P) Fig. 6 out.

5. Slide the new platen/cork into the sander and discard the old one.

6. Reinstall the plastic cover and make sure the tracking spring is installed correctly.

7. Install a sanding belt as described in ASSEMBLY.

BRUSH INSPECTION

For your continued safety and electrical protection, brush inspection and replacement on this tool

should ONLY be performed by a PORTER-CABLE FACTORY SERVICE CENTER OR PORTER-CABLE

AUTHORIZED WARRANTY SERVICE CENTER.

At approximately 100 hours of use, take or send your tool to your nearest Porter-Cable Factory

Service center or Porter-Cable Authorized Warranty Service Center to be thoroughly cleaned and

inspected. Have worn parts replaced and lubricated with fresh lubricant. Have new brushes installed,

and test the tool for performance.

Any loss of power before the above maintenance check may indicate the need for immediate servicing

of your tool. DO NOT CONTINUE TO OPERATE TOOL UNDER THIS CONDITION. If proper operating

voltage is present, return your tool to the service station for immediate service.

CLEANING

Periodically blow out all air passages with dry compressed air.

Use only mild soap and a damp cloth to clean the tool.

LUBRICATION

This tool has been lubricated with a sufficient amount of high grade lubricant for the life of the unit

under normal operating conditions. No further lubrication is necessary. However, it is recommended

that, once a year, you take or send the tool to a PORTER-CABLE service center for a thorough

cleaning and inspection.

Any loss of power before the above maintenance check may indicate the need for immediate servicing

of your tool. DO NOT CONTINUE TO OPERATE TOOL UNDER THIS CONDITION. If proper operating

voltage is present, return your tool to the service station for immediate service.

FAILURE TO START

Should your tool fail to start, check to make sure the prongs on the cord plug are making good contact

in the outlet. Also, check for blown fuses or open circuit breakers in the line.

To reduce the risk of injury, turn off and unplug sander before making any adjustments

Wear ANSI Z87.1 safety glasses while using compressed air.

Never let any liquid get inside the tool; never immerse any part of the tool into a liquid.

Never use solvents or other harsh chemicals for cleaning the non-metallic parts of the tool.

SERVICE

REPLACEMENT PAR TS

Use only identical replacement parts. For a parts list or to order parts, please visit our website at

servicenet.porter-cable.com. You can also order parts from your nearest Porter-Cable Factory Service

Center or Porter-Cable Authorized W arranty Service Center. Or , you can call our Customer Car e Center

at (888) 848-5175.

SERVICE AND REPAIRS

All quality tools will eventually require servicing and/or replacement of parts. For information about

Porter-Cable, its factory service centers or authorized warranty service centers, visit our website at

www.porter-cable.com or call our Customer Care Center at (888) 848-5175. All repairs made by our

service centers are fully guaranteed against defective material and workmanship. We cannot guarantee

repairs made or attempted by others.

You can also write to us for information at PORTER-CABLE, 4825 Highway 45 North, Jackson,

Tennessee 38305 - Attention: Product Service. Be sure to include all of the information shown on the

nameplate of your tool (model number , type, serial number, etc.).

ACCESSORIES

Page 3

A complete line of accessories is available from your Porter-Cable Factory Service Center or a Porter-

RRÈGLES DE SÉCURITÉ SUPPLÉMENTAIRES POUR L’ÉLIMINATION

DE LA PEINTURE

Cable Authorized Warranty Service Center. Please visit our Web Site www.porter-cable.com for a catalog or for the name of your nearest supplier.

Since accessories other than those offered by Porter -Cable have not been tested with this

product, use of such accessories could be hazardous. For safest operation, only Porter-Cable recommended accessories should be used with this product.

WARRANTY

T o r egister your tool for warranty service visit our website at

PORTER-CABLE LIMITED ONE YEAR WARRANTY: Porter-Cable warrants its Pr ofessional Power Tools for a

period of one year from the date of original purchase. W e will repair or r eplace at our option, any part or parts

of the product and accessories covered under this warranty which, after examination, proves to be defective

in workmanship or material during the warranty period. For repair or replacement return the complete tool

or accessory, transportation prepaid, to your nearest Porter-Cable Factory Service Center or Porter-Cable

Authorized Warranty Service Center . Proof of purchase may be r equired. This warranty does not apply to repair

or replacement required due to misuse, abuse, normal wear and tear or repairs attempted or made by other

than our servicecCenters or authorized warranty service centers.

ANY IMPLIED WARRANTY, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE, WILL LAST ONLY FOR ONE (1) YEAR FROM THE DATE OF

PURCHASE. To obtain information on warranty performance please write to: PORTER-CABLE, 4825

Highway 45 North, Jackson, Tennessee 38305; Attention: Product Service. THE FOREGOING OBLIGATION

IS PORTER-CABLE’S SOLE LIABILITY UNDER THIS OR ANY IMPLIED WARRANTY AND UNDER NO

CIRCUMSTANCES SHALL PORTER-CABLE BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL

DAMAGES. Some states do not allow limitations on how long an implied warranty lasts or the exclusion or

limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you.

This warranty gives you specifi c legal rights and you may also have other legal rights which vary from state to

state.

www.porter -cable.com

.

WARNING LABEL REPLACEMENT

If your warning labels become illegible or are missing, call (888) 848-5175 for a free replacement.

AVERTISSEMENT

L’UTILISATEUR DOIT TOUJOURS LIRE ET COMPRENDRE LE GUIDE

D’UTILISATION. IL FAUT TOUJOURS PORTER DE L’ÉQUIPEMENT DE

PROTECTION OCULAIRE ET RESPIRATOIRE APPROPRIÉ.

ADVERTENCIA

DEBERÁ LEER Y COMPRENDER EL MANUAL DE INSTRUCCIONES.

SIEMPRE SE DEBERÁ LLEVAR LA PROTECCIÓN APROPIADA PARA LA

VISTA Y PARA LAS VÍAS RESPIRATORIAS.

AFIN DE MINIMISER LES

RISQUES DE BLESSURES,

PARA DISMINUIR EL RIESGO

DE LESIONES, EL USUARIO

READ TOOL INSTRUCTION MANUAL BEFORE OPERATING

PRODUCT.

EYE PROTECTION.

L’UTILISATEUR DOIT TOUJOURS LIRE ET COMPRENDRE LE GUIDE

D’UTILISATION. IL FAUT TOUJOURS PORTER DE L’ÉQUIPEMENT DE

PROTECTION OCULAIRE ET RESPIRATOIRE APPROPRIÉ.

DEBERÁ LEER Y COMPRENDER EL MANUAL DE INSTRUCCIONES.

SIEMPRE SE DEBERÁ LLEVAR LA PROTECCIÓN APROPIADA PARA LA

VISTA Y PARA LAS VÍAS RESPIRATORIAS.

TO REDUCE THE RISK

OF INJURY, USER MUST

ALWAYS WEAR RESPIRATORY AND ANSI

A14540

AVERTISSEMENT

ADVERTENCIA

Z87.1

AFIN DE MINIMISER LES

RISQUES DE BLESSURES,

PARA DISMINUIR EL RIESGO

DE LESIONES, EL USUARIO

MESURES DE SÉCURITÉ - DÉFINITIONS

Indique une situation dangereuse imminente qui, si elle n’est pas évitée,

causera la mort ou des blessures graves.

Indique une situation potentiellement dangereuse qui, si elle n’est

pas évitée, pourrait se solder par un décès ou des blessures graves.

Indique une situation potentiellement dangereuse qui, si elle n’est pas

évitée pourrait se solder par des blessures mineures ou modérées.

Utilisé sans le symbole d’alerte à la sécurité, indique une situation

potentiellement dangereuse qui, si elle n'est pas évitée pourrait se solder par des

dommages à la propriété.

Règles Générales Sur la Sécurité

risques de choc électrique, d’incendie et/ou de blessure grave. Le terme « outil électrique » dans tous

les avertissements ci-après se rapporte à votre outil électrique à alimentation sur secteur (avec fi l) ou

par piles (sans fi l).

CONSERVER CES DIRECTIVES

1) Sécurité du lieu de travail

a) Tenir la zone de travail propre et bien éclairée. Les lieux encombrés ou sombres sont

propices aux accidents.

b) Ne pas faire fonctionner d’outils électriques dans un milieu défl agrant, soit en pré-

sence de liquides, de gaz ou de poussières infl ammables. Les outils électriques produisent des étincelles qui peuvent enfl ammer la poussière ou les vapeurs.

c) Éloigner les enfants et les personnes à proximité pendant l’utilisation d’un outil élec-

trique. Une distraction pourrait vous en faire perdre la maîtrise.

2) Sécurité en matière d’électricité

a) La fi che de l’outil électrique doit être compatible avec la prise de courant. Ne modi-

fi ez jamais la fi che de quelque façon que ce soit. N’utilisez jamais d’adaptateurs de

fi ches avec des outils électriques mis à la terre. Le risque de choc électrique sera réduit

par l’utilisation de fi ches non modifi ées et de prises de courant compatibles.

b) Éviter tout contact physique avec des surfaces mises à la terre comme des tuyaux,

des radiateurs, des cuisinières et des réfrigérateurs. Le risque de choc électrique est

plus élevé si votre corps est mis à la terre.

c) Ne pas exposer les outils électriques à la pluie ou à l’humidité. La pénétration de l’eau

dans un outil électrique augmente le risque de choc électrique.

d) Ne pas utiliser le cordon de façon abusive. Ne jamais utiliser le cordon pour trans-

porter, tirer ou débrancher un outil électrique. Tenir le cordon éloigné de la chaleur,

de l’huile, des bords tranchants ou des pièces mobiles. Les cordons endommagés ou

enchevêtrés augmentent les risques de choc électrique. Utiliser uniquement une rallonge à

3 fi ls pourvue d’une fi che de mise à la terre à 3 lames et une prise à 3 fentes correspondant

à la fi che.

e) Pour l’utilisation d’un outil électrique à l’extérieur, se servir d’une rallonge convenant

à une telle utilisation. Si la rallonge sera utilisée à l’extérieur , elle doit être estampillée d’un

W-A ou d’un W suivi de la classifi cation de la rallonge. L’utilisation d’une rallonge conçue

pour l’extérieur réduit les risques de choc électrique. Lorsque qu’une rallonge électrique

est utilisée, s’assurer d’en utiliser une de calibre suffi samment élevé pour assurer le transport du courant nécessaire au fonctionnement de l’appareil. Un cordon de calibre inférieur

causera une chute de tension de ligne et donc une perte de puissance et une surchauffe.

Le tableau suivant indique le calibre approprié à utiliser selon la longueur du cordon et

l’intensité nominale de la plaque signalétique. En cas de doute, utiliser le calibre suivant le

plus gros. Plus le numéro de calibre est petit, plus le cordon est lourd.

Volts Longueur totale de la rallonge

120V 0-25 pi 26-50 pi 51-100 pi 101-150 pi

0-7,6 m 7,6 m - 15,2 m 15,2 m - 30,5 m 30,5 m - 45,7 m

Amperes Calibre de fil dans des unités d’A.W.G.

De 0 à 6 ampères 18 16 16 14

3) Sécurité personnelle

a) Être vigilant, surveiller le travail effectué et faire preuve de jugement lorsqu’un outil

électrique est utilisé. Ne pas utiliser d’outil électrique en cas de fatigue ou sous l’infl uence de drogues, d’alcool ou de médicaments. Un moment d’inattention, durant

l’utilisation d’un outil électrique, peut se solder par des blessures graves.

b) Utiliser un équipement de sécurité. Toujours porter une protection oculaire. L’utili-

sation d’un équipement de sécurité comme un masque anti-poussières, des chaussures

antidérapantes, un casque de sécurité ou des protecteurs auditifs lorsque la situation le

requiert réduira les risques de blessures corporelles.

c) Éviter un démarrage accidentel. S’assurer que l’interrupteur se trouve à la position

d’arrêt avant de brancher l’outil. T ransporter un outil électrique alors que le doigt repose

sur l’interrupteur ou brancher un outil électrique dont l’interrupteur est à la position de

marche risque de provoquer un accident.

d) Retirer toute clé de réglage ou clé standard avant de démarrer l’outil. Une clé stan-

dard ou une clé de réglage attachée à une partie pivotante de l’outil peut provoquer des

blessures corporelles.

e) Ne pas trop tendre les bras. Conserver son équilibre en tout temps. Cela permet de

mieux maîtriser l’outil électrique dans les situations imprévues.

f) S’habiller de manière appropriée. Ne pas porter de vêtements amples ni de bijoux.

Garder les cheveux, les vêtements et les gants à l’écart des pièces mobiles. Les vête-

Lire toutes les directives. Tout manquement aux directives suivantes pose des

Calibre de fil minimum recommandé pour les rallonges

ments amples, bijoux ou cheveux longs pourraient s’enchevêtrer dans les pièces mobiles.

g) Si des composants sont fournis pour le raccordement de dispositifs de dépoussiéra-

ge et de ramassage, s’assurer que ceux-ci sont bien raccordés et utilisés. L’utilisation

de ces dispositifs peut réduire les risques engendrés par les poussières.

4) Utilisation et entretien d’un outil électrique

a) Ne pas forcer un outil électrique. Utiliser l’outil électrique approprié à l’application.

L’outil électrique approprié effectuera un meilleur travail, de façon plus sûre et à la vitesse

pour laquelle il a été conçu.

b) Ne pas utiliser un outil électrique dont l’interrupteur est défectueux. Tout outil électri-

que dont l’interrupteur est défectueux est dangereux et doit être réparé.

c) Débrancher la fi che du bloc d’alimentation avant de faire quelque ajustement que ce

soit, de changer d’accessoire ou de ranger les outils électriques. Ces mesures préventives réduisent les risques de démarrage accidentel de l’outil électrique.

d) Ranger les outils électriques inutilisés hors de la portée des enfants, et ne permettre

à aucune personne n’étant pas familière avec l’outil électrique ou son mode d’emploi

d’utiliser ce dernier. Les outils électriques deviennent danger eux entre les mains d’utilisa-

teurs inexpérimentés.

e) Entretenir les outils électriques. Vérifi er si les pièces mobiles sont mal alignées ou

coincées, si des pièces sont brisées ou présentent toute autre condition susceptible

de nuire au bon fonctionnement de l’outil électrique. En cas de dommage, faire réparer l’outil électrique avant toute nouvelle utilisation. Beaucoup d’accidents sont causés

par des outils électriques mal entretenus.

f) S’assurer que les outils de coupe sont aiguisés et propres. Les outils de coupe bien en-

tretenus et affûtés sont moins susceptibles de se coincer et sont plus faciles à contrôler.

g) Utiliser un outil électrique, ses accessoires, mèches, etc., conformément aux pré-

sentes directives et suivant la manière prévue pour ce type particulier d’outil électrique, en tenant compte des conditions de travail et du travail à effectuer. L’utilisation

d’un outil électrique pour toute opération autre que celle pour laquelle il a été conçu est

dangereuse.

5) Réparation

a) Faire réparer l’outil électrique par un réparateur professionnel en n’utilisant que des

pièces de rechange identiques. Cela permettra de maintenir une utilisation sécuritaire de

l’outil électrique.

RÈGLES DE SÉCURITÉ SPÉCIFIQUE

• Tenir l’outil par sa surface de prise isolée dans une situation où l’outil de coupe peut entrer

en contact avec un câblage dissimulé ou avec son propre cordon d’alimentation. En effet,

tout contact avec un fil « sous tension » mettra « sous tension » les pièces métalliques exposées

de l’outil et électrocutera l’opérateur.

• Ne pas poncer de surfaces métalliques, de tout type, avec la ponceuse à courroie. Le ponçage de vis, clous ou autres pièces métalliques produit des étincelles qui pourraient enflammer

des particules de poussière.

• Ne pas poncer à l’eau avec la présente ponceuse. Du liquide risque de pénétrer le boîtier du

moteur et ainsi provoquer un choc électrique.

• Ne pas faire fonctionner cet outil durant de longues périodes. Les vibrations causées par

le fonctionnement de cet outil peuvent provoquer des blessures permanentes aux doigts, aux

mains et aux bras. Utiliser des gants pour amortir davantage les vibrations, faire des pauses

fréquentes et limiter la durée d’utilisation quotidienne.

• Nettoyer l’outil régulièrement, particulièrement après une utilisation intensive. La poussière

et le grain abrasif, qui contient des particules métalliques, s’accumulent souvent sur les surfaces

internes et pourraient représenter un risque grave de blessure, de choc électrique ou d’électrocution. TOUJOURS PORTER DES LUNETTES DE SÉCURITÉ.

•

Bien aérer la zone de travail lors d’activités de ponçage.

• S’

assurer que la bande abrasive ne touche pas à la pièce avant de démarrer l’appareil.

• Cette ponceuse n’est pas conçue pour une utilisation fi xe, montée à un banc en position inversée, pour une utilisation sur une table de montage pour perceuse. Une telle utilisation pourrait

accroître le risque de blessures.

perçage et autres activités de construction peuvent contenir des produits chimiques pouvant causer

le cancer, des anomalies congénitales ou d’autres problèmes liés aux fonctions reproductrices.

Voici quelques exemples de ces produits chimiques :

• le plomb contenu dans les peintures à base de plomb;

• la silice cristalline de la brique, du ciment et d’autres produits de maçonnerie; et

• l’arsenic et le chrome provenant du bois traité chimiquement.

Les risques reliés à l’exposition à ces poussières varient selon la fréquence à laquelle l’utilisateur

travaille avec ce type de matériaux. Pour réduire votre exposition à ces produits chimiques : travailler

dans un endroit bien ventilé et porter un équipement de sécurité approuvé comme un masque antipoussières conçu spécialement pour fi ltrer les particules microscopiques.

ponçage, sciage, meulage, perçage et autres activités de construction. Porter des vêtements de protection et laver les parties du corps exposées avec une solution d’eau et de savon. Le fait de laisser

la poussière pénétrer dans la bouche et les yeux ou de la laisser reposer sur la peau, peut promouvoir

l’absorption de produits chimiques nocifs.

raient causer des problèmes respiratoires graves et permanents, ou d’autres problèmes médicaux.

Toujours porter un appareil respiratoire approuvé par la NIOSH/OSHA pour se protéger de la poussière. Diriger les particules loin du visage et du corps.

S12.6 (S3.19)) Dans certaines conditions et selon la durée d’utilisation, le bruit émis par ce produit

peut contribuer à une perte auditive.

SYMBOLES

L'étiquette apposée sur votre outil peut comprendre les symboles suivants. Les symboles et leurs

définitions sont indiqués ci-après :

V ....................volts A ......................ampères

Hz .................hertz W .....................watts

min ................minutes

..............courant continu

..................Construction de classe I .....................borne de terre

(mis à la terre) ....................symbole d'alerte à la sécurité

...................Construction de classe II …/min.............. rotations ou alternance

(à double isolation) par minute

BPM ..............coups par minute

ÈGLES DE SÉCURITÉ SUPPLÉMENTAIRES POUR L’ÉLIMINATION

Les éclats, les résidus et les vapeurs de peinture peuvent contenir du plomb qui est toxique.

L’exposition fût-ce à de bas niveaux de plomb peut causer des lésions irréversibles au cerveau et

au système nerveux ; les jeunes enfants et les foetus sont particulièrement vulnérables.

Avant de commencer à éliminer la peinture, vous devez déterminer si la peinture en question contient

du plomb. Cette détermination peut être faite par votre département de santé local ou par un

professionnel qui utilise un analyseur de peinture pour vérifier la teneur en plomb.

La peinture au plomb ne doit etre eliminee que par un professionnel.

Les personnes éliminant la peinture doivent suivre ces directives :

1. Gardez l’aire de travail bein ventilee. Ouvrez les fenêtres et placez un ventilateur aspirant dans

l’une d’elles. Assurez-vous que le ventilateur déplace l’air depuis l’intérieur vers l’extérieur.

2. Enlevez ou couvrez les tapis, les moquettes, les meubles, les vêtements, les ustensiles de

cuisson et les prises d’air . Telles mesur es préventives de sûreté réduisent le risque d'exposition.

3. Placez des jetees dans l’aire de travail pour ramasser tout éclat de peinture. Portez

des vêtements protecteurs tels que des chemises de travail, des bleus de travail et des

chapeaux. Telles mesures préventives de sûreté réduisent le risque d'exposition.

4. Travaillez dans une piece a la fois. L’ameublement doit être enlevé ou placé au centre de la

pièce et couvert. Les aires de travail doivent être isolées du reste de l’habitation en scellant

les portes à l’aide de jetées.

5. Les enfants, les femmes enceintes ou potentiellement enceintes et les mères qui

allaitent ne doivent pas être présentes dans l’aire de travail tant que le travail n’est

pas achevé et que le nettoyage n’est pas terminé. Telles mesures préventives de sûreté

réduisent le risque blessure.

6. Portez un respirateur antipoussiere ou un masque respirateur à double filtre (poussière

et gaz) qui a été approuvé par l’Occupational Safety and Health Administration (OSHA),

le National Institute of Safety and Health (NIOSH), ou le Bureau of Mines des États-Unis.

On peut se procurer facilement ces masques et filtres remplaçables auprès des grandes

quincailleries. Assurez-vous que le masque fait. Les barbes et le poil facial peuvent empêcher

les masques de bien faire. Changez les filtres souvent. LES MASQUES EN PAPIER À USAGE

UNIQUE NE SONT PAS ADÉQUATS.

7. Gardez les aliments et les boissons hors de l’aire de travail. Lavez-vous les mains, les

Pour réduire le risque de blessures :

Certaines poussières produites par les activités de ponçage, sciage, meulage,

Éviter le contact prolongé avec les poussières produites par les activités de

L’utilisation de cet outil peut produire et/ou propulser des poussières qui pour-

Porter une protection auditive appropriée pour utiliser l’appareil. (ANSI

...................courant alternatif

n

o ....................vitesse à vide

DE LA PEINTURE

On doit procéder extrêmement soigneusement en éliminant la peinture.

Page 4

bras et le visage, et rincez-vous la bouche avant de manger ou de boire. Ne fumez pas et ne

mâchez pas de gomme ou de tabac dans l’aire de travail.

8. Ramassez toute la peinture enlevee et la poussière en passant un balai-éponge mouillé

sur les planchers. Utilisez un chiffon mouillé pour nettoyer tous les murs, les seuils et toute

autre surface où adhère la peinture ou la poussière. NE BALAYEZ PAS, N’ÉPOUSSETEZ PAS

À SEC ET NE PASSEZ PAS L’ASPIRATEUR. Utilisez un détersif à haute teneur en phosphate

ou de l’irisodium (TSP) pour laver les aires de travail.

9. À la fin de chaque session de travail, mettez les éclats de peinture et les débris dans un

double sac en plastique, fermez-le avec du ruban ou des attaches, et mettez au rebut

adéquatement. Telles mesures préventives de sûreté réduisent le risque d'exposition.

10. Enlevez les vetements protecteurs et les chaussures de travail dans l’aire de travail

pour éviter de transporter de la poussière dans le reste de l’habitation. Lavez les

vêtements de travail séparément. Essuyez les chaussures avec un chiffon mouillé qui est

alors lavé avec les vêtements de travail. Lavez les cheveux et le corps soigneusement à l’eau

savonneuse.

CONSERVER CES DIRECTIVES!

MOTEUR

les limites correctes. Ne pas faire fonctionner des outils à courant alternatif (c.a.) sur un courant

continu (c.c.). Un tel branchement pourrait endommager gravement l’outil.

Ne pas utiliser l’outil relié à un courant pour lequel la tension n’est pas dans

ASSEMBLAGE

REMPLACEMENT DE LA BANDE ABRASIVE

Pour réduire le risque de blessures, s’assurer que la ponceuse soit hors tension et

débranchée lors du changement de la bande abrasive. Avant de rebrancher l’outil, s’assurer que l’interrupteur (D) Fig. 2 soit en position d’arrêt.

Remplacement de la bande abrasive :

1. Pivoter le levier de dégagement de la bande (A) fig. 1 vers le haut jusqu’à ce que la roue avant

de la ponceuse (B) fig. 1 se relève et relâche la tension sur la bande abrasive (C).

2. Retirer la bande abrasive usée.

3. Insérer une nouvelle bande autour des roues. Si des flèches sont présentes à l’intérieur de la

bande, orientez la bande dans la direction de rotation des roues. Pour celles sans flèches, la

direction n’est pas importante.

dégagé de la ponceuse)

.

Risque de lacération grave. Si les bandes abrasives unidirectionnelles sont inver-

(La roue tourne en sens horaire lorsque vous regardez du côté

sées lors de l’installation, il est possible qu’elles ne demeurent pas centrées et qu’elles pendent du

boîtier. Une telle situation risque de provoquer des lacérations graves.

4. Pivoter le levier de dégagement de la bande (A) fig. 1 vers le bas de sorte à tendre de nou-

veau la bande abrasive.

FONCTIONNMENT

FONCTIONNEMENT DE L’INTERRUPTEUR

Pour mettre la ponceuse en marche, enfoncer la section de l’interrupteur étanche (D) fig. 2 qui affiche

« ON » et qui correspond au symbole « I ». Pour l’arrêter, enfoncer l’autre section qui affiche « OFF » et

qui correspond au symbole « O ».

Pour réduire le risque de blessure, s’assurer que la ponceuse ne repose pas

contre la pièce lors de la mise sous tension de l’outil.

Pour réduire le risque de blessures, vérifier si le protège-courroie (T) Fig. 1 est en

position, fixé et qu’il fonctionne correctement.

POIGNÉE AVANT

La poignée auxiliaire avant est amovible pour le ponçage dans les endroits restreints. L’outil est livré

avec la poignée (E) fig. 2 en position comme illustré. Pour retirer la poignée, desserrer la vis (S) fig.

4 au centre de la poignée avec un tournevis plat puis retirer la vis et la poignée.

REMARQUE: la poignée doit être bien au-dessus de la surface de montage avant de resserrer la vis.

ALIGNEMENT DE LA BANDE ABRASIVE

Risque de lacération grave. Régler correctement la bande abrasive pour éviter

qu’elle ne pende du boîtier. Un tel cas risque de provoquer de graves lacérations.

S’assurer que la bande abrasive soit correctement centrée. Pour ce faire, procéder comme suit :

1. Saisir l’outil dans une main, bande abrasive vous faisant face.

2. Enfoncer l’interrupteur (D) fig. 2 pour démarrer la bande.

3. Tourner le bouton d’alignement (G) fig. 3 en sens antihoraire (en tournant vers l’avant de la pon-

ceuse) pour éloigner la bande abrasive du boîtier du moteur. Tourner le bouton en sens horaire

(en direction du cordon d’alimentation) pour éloigner la bande abrasive du boîtier.

REMARQUE : la bande abrasive doit être alignée à ras avec le bord du porte-pièce (H) fig. 1

lorsque la ponceuse fonctionne.

4. Éteindre l’appareil et s’assurer que la courroie soit complètement immobile avant de déposer

l’appareil.

POSITIONNEMENT ADÉQUAT DES MAINS

Il est possible d’utiliser le présent outil à une seule main. Saisir la section caoutchoutée du corps de

l’outil pour un positionnement adéquat de la main, comme indiqué à la figure 6. Au besoin, saisir la

poignée auxiliaire avec l’autre main (E) fig. 2.

Risque d’abrasion grave. Éloigner les doigts et les mains de la bande abrasive en

mouvement. Le non-respect de cette directive pourrait se solder par le ponçage des mains ou des doigts

et provoquer ainsi de graves blessures.

Risque de pincement grave. Éloigner en tout temps les mains et les doigts du rouleau avant. Le non-respect de cette directive pourrait se solder par un pincement des doigts et provoquer

ainsi des blessures graves.

Risque d’abrasion grave. Ne pas laisser les doigts pendre au-dessus des bords avant

et droit de la ponceuse. Si la bande abrasive se détache soudainement ou si elle est mal ajustée, les doigts

risquent de toucher la bande en mouvement. Un tel cas risque de provoquer des blessures graves.

S’assurer que les orifices de ventilation de la ponceuse, (L) et (M) fig. 3 ne sont

pas couverts lors de l’utilisation.

FONCTIONNEMENT DE L' PONCEUSE

Avant de poncer une pièce, s’assurer qu’elle soit fixée solidement.

Pour réduire le risque de blessures, toujours fixer la pièce pour éviter qu’elle ne soit

projetée vers l’arrière en direction de l’opérateur.

ADAPTATEUR POUR L’ASPIRATEUR

Vider souvent le dépoussiéreur, particulièrement lors du ponçage de surfaces

enduites de matières à base de résine comme du polyuréthanne, du vernis, du vernis à la gomme

laque, etc. Éliminer les particules de poussière enduites de produit selon les recommandations du

fabricant du fini ou les amasser dans une boîte de métal avec un couvercle bien ajusté. Les retirer

des lieux quotidiennement. L’accumulation de particules fines de poussière r isque de s’enflammer

spontanément et provoquer un incendie.

Risque de choc électrique. L’utilisation d’un tuyau et d’un adaptateur d’aspirateur avec la ponceuse à courroie risque de produire de l’électricité statique qui pourrait donner

une décharge électrique surprenante.

Risque d’incendie. Ne pas utiliser un dépoussiéreur lors du ponçage de métaux.

Un telle pratique risque de provoquer un incendie qui se solderait par des blessures corporelles graves

ou endommagerait l’outil.

La ponceuse à courroie est dotée d’un adaptateur double pour tuyau.

L’adaptateur se raccorde aux tuyaux d’aspirateur industriel de 25,4 mm (1 po) (diamètre interne) et

de 35 mm (diamètre externe) pour l’aspiration de la poussière. Insérer l’adaptateur (J) fig. 5 dans la

goulotte à poussière (K) et tourner 1/8 tour en sens horaire pour fixer solidement l’adaptateur à la

ponceuse. Puis raccorder le bon tuyau d’aspirateur industriel à l’adaptateur.

ENTRETIEN

d’effectuer tout réglage ou d’enlever ou installer tout accessoire.

RÉPARATIONS

Pour obtenir de l’aide au sujet de l’outil, consulter notre site Web www.porter-cable.com pour obtenir

une liste des centres de réparation ou composer le (888) 848-5175 pour le service à la clientèle de

Porter-Cable.

REMPLACEMENT DU PORTE-PIÈCE/LIÈGE

Le liège sous le porte-pièce de la ponceuse à courroie pourrait exiger un remplacement à un certain

moment au cours de la vie utile de l’outil. Un nouveau porte-pièce/liège est offert à votre Centre de

réparation PORTER-CABLE.

1. Retirer la bande abrasive comme décrit sous la rubrique ASSEMBLAGE.

2. Pivoter le levier de dégagement de la bande (A) fig. 1 vers le bas.

3. Retirer le couvercle de plastique (N) fig. 6 (encart) du côté droit du porte-pièce en dévissant les

quatre vis (O).

4. Coulisser et retirer le porte-pièce/liège (P) fig. 6.

5. Insérer le nouveau porte-pièce/liège dans la ponceuse et jeter la pièce usée.

6. Réinstaller le couvercle en plastique et s’assurer que le ressort d’alignement soit correctement installé.

Pour réduire le risque de blessures, eteindre et débrancher la ponceuse avant

7. Insérer une bande abrasive comme décrit sous la rubrique ASSEMBLAGE.

INSPECTION DE LA BROSSE

Pour votre propre sécurité et une bonne protection électrique, l’inspection et le remplacement de la

brosse de l’outil doivent être exécutés UNIQUEMENT à un CENTRE DE RÉPARATION AUTORISÉ ou

un CENTRE DE RÉPARATION DE L’USINE de PORTER-CABLE•DELT A.

Après 100 heures environ d’utilisation, apporter ou envoyer l’outil au centre de réparation autorisé

Porter-Cable le plus proche pour un nettoyage et une inspection approfondis. Faire remplacer

les pièces usées et lubrifier avec un lubrifiant neuf. Faire installer de nouvelles brosses et tester le

rendement de l’outil.

Toute perte de puissance avant ce point d’entretien pourrait indiquer la nécessité d’un entretien

immédiat de l’outil. NE PAS FAIRE FONCTIONNER L’OUTIL DANS CET ÉTAT. Si le problème persiste

en présence d’une tension normale, retourner l’outil à un centre de réparation pour un entretien

immédiat.

NETTOYAGE

Dégager régulièrement toutes les conduites d’air avec de l’air comprimé sec.

Porter des lunettes de sécurité conformes à la norme ANSI Z87.1 pour l’utilisation

d’air comprimé.

Utiliser uniquement un savon doux et un chiffon humide pour nettoyer l’outil.

Ne jamais laisser de liquide pénétrer dans l’outil et n’immerger aucune partie de l’outil

dans un liquide.

Ne jamais utiliser de solvants ni d’autres produits chimiques puissants pour nettoyer

les pièces non métalliques de l’outil.

LUBRICATION

L’outil a été lubrifi é avec une quantité suffi sante de lubrifi ant de haute qualité pour la durée de vie de

celui-ci sous des conditions d’utilisation normale. Aucune lubrifi cation supplémentaire n’est nécessaire.

Toutefois, il est conseillé de ramener ou d’envoyer l’outil, une fois par année, à un Centre de réparation PORTER-CABLE pour un nettoyage complet et une inspection approfondie.

Toute perte de puissance avant ce point d’entretien pourrait indiquer la nécessité d’un entretien immédiat de l’outil. NE PAS F AIRE FONCTIONNER L’OUTIL DANS CET ÉT AT. Si le problème persiste en présence d’une tension normale, retourner l’outil à un centre de réparation pour un entretien immédiat.

DÉMARRAGE IMPOSSIBLE

Si l’outil ne démarre pas, s’assurer que les lames de la fi che du cordon d’alimentation sont bien enfoncées

dans la prise de courant. Vérifi er également s’il y a des fusibles grillés ou un disjoncteur déclenché

SERVICE

PIÈCES DE RECHANGE

Utiliser seulement des pièces de rechange identiques. Pour obtenir une liste des pièces de rechange ou

pour en commander, consulter notre site Web au servicenet.porter-cable.com. Commander aussi des

pièces auprès d’une succursale d’usine, ou composer le (888) 848-5175 pour le service à la clientèle.

ENTRETIEN ET RÉPARATION

T ous les outils de qualité fi nissent par demander un entretien ou un changement de pièce. Pour de plus

amples renseignements à propos de Porter -Cable, ses succursales d’usine ou un centr e de réparation

sous garantie autorisé, consulter notre site Web au www.porter-cable.com ou composer le (888) 8485175 pour le service à la clientèle. Toutes les réparations effectuées dans nos centres de réparation

sont entièrement garanties contre les défauts de matériaux et de main-d’œuvre. Nous ne pouvons

garantir les réparations effectuées en partie ou totalement par d’autres.

Pour de plus amples renseignements par courrier, écrire à PORTER-CABLE, 4825 Highway 45 North,

Jackson, Tennessee 38305, É.-U. – à l’attention de : Product Service. S’assurer d’indiquer toutes les

informations fi gurant sur la plaque signalétique de l’outil (numéro du modèle, type, numéro de série,

etc.).

ACCESSOIRES

Une gamme complète d’accessoires est disponible auprès de votre fournisseur Porter-Cable centr es de réparation de l’usine Porter-Cable•Delta et centres de réparation agréés Porter-Cable. Veuillez consulter le site

Web www .porter -cable.com pour un catalogue ou le nom du fournisseur le plus près de chez vous.

Puisque les accessoires autres que ceux offerts par Porter-Cable n’ont pas été

testés avec ce produit, l’utilisation de ceux-ci pourrait s’avérer dangereux. Pour un fonctionnement en

toute sécurité, utiliser seulement les accessoires recommandés Porter -Cable avec le pr oduit.

GARANTIE

Pour enregistrer l’outil en vue d’obtenir un service de garantie, consulter notre site W eb au

GARANTIE LIMITÉE D’UN AN DE PORTER-CABLE : Porter -Cable garantit les outils électriques pr ofession-

nels pour une période de un (1) an à partir de la date d’achat d’origine. Après analyse, nous réparerons ou

remplacerons, à notre discrétion, toute(s) pièce(s) du produit et accessoir es couverts en vertu de la présente

garantie présentant un défaut de fabrication ou de matériel au cours de la période de garantie. Pour toute

réparation ou remplacement, retourner l’outil ou l’accessoire complet au centre de réparation Porter-Cable

ou un centre de réparation agréé, port prépayé. Une preuve d’achat peut être requise. La présente garantie

ne s’applique pas aux réparations ou remplacements suite à la mauvaise utilisation, l’abus, l’usure normale,

aux tentatives de réparations ou réparations effectuées par d’autre qu’un de nos centres de réparation ou

centres de réparations agréés.

TOUTE GARANTIE IMPLICITE Y COMPRIS TOUTE GARANTIE DE QUALITÉ MARCHANDE ET D’ADÉQUA TION À UN USAGE P ARTICULIER DURERA SEULEMENT UN (1) AN À PAR TIR DE LA DA TE D’ACHA T.

Pour des renseignements à propos du rendement de la garantie, veuillez écrire à : PORTER-CABLE, 4825

Highway 45 North, Jackson, T ennessee, É.-U. 38305 – à l’attention de : Product Service. LES DISPOSITIONS

PRÉCÉDENTES, DE LA PRÉSENTE GARANTIE OU DE TOUTE GARANTIE IMPLICITE, REPRÉSENTENT

LA SEULE RESPONSABILITÉ DE PORTER-CABLE ET EN AUCUNE CIRCONSTANCE, PORTER-CABLE

NE POURRAIT ÊTRE TENU RESPONSABLE DES DOMMAGES ACCESSOIRES OU INDIRECTES. Certains

états n’autorisent pas les restrictions sur la durée d’une garantie implicite ni l’exclusion ou la restriction des

dommages accessoires ou indirects, auquel cas les exclusions et restrictions du présent document pourraient ne pas être applicables.

Cette garantie vous accorde des droits légaux spécifi ques et vous pourriez avoir d’autres droits légaux qui

varient d’un état ou d’une province à l’autre.

www.porter -cable.com.

REMPLACEMENT GRATUIT DE L'ETIQUIETTE

Si les étiquettes d’avertissement deviennent illisibles ou sont manquantes, composer le (888)

848-5175 pour en obtenir le remplacement gratuit.

AVERTISSEMENT

L’UTILISATEUR DOIT TOUJOURS LIRE ET COMPRENDRE LE GUIDE

D’UTILISATION. IL FAUT TOUJOURS PORTER DE L’ÉQUIPEMENT DE

PROTECTION OCULAIRE ET RESPIRATOIRE APPROPRIÉ.

ADVERTENCIA

DEBERÁ LEER Y COMPRENDER EL MANUAL DE INSTRUCCIONES.

SIEMPRE SE DEBERÁ LLEVAR LA PROTECCIÓN APROPIADA PARA LA

VISTA Y PARA LAS VÍAS RESPIRATORIAS.

AFIN DE MINIMISER LES

RISQUES DE BLESSURES,

PARA DISMINUIR EL RIESGO

DE LESIONES, EL USUARIO

READ TOOL INSTRUCTION MANUAL BEFORE OPERATING

PRODUCT.

EYE PROTECTION.

L’UTILISATEUR DOIT TOUJOURS LIRE ET COMPRENDRE LE GUIDE

D’UTILISATION. IL FAUT TOUJOURS PORTER DE L’ÉQUIPEMENT DE

PROTECTION OCULAIRE ET RESPIRATOIRE APPROPRIÉ.

DEBERÁ LEER Y COMPRENDER EL MANUAL DE INSTRUCCIONES.

SIEMPRE SE DEBERÁ LLEVAR LA PROTECCIÓN APROPIADA PARA LA

VISTA Y PARA LAS VÍAS RESPIRATORIAS.

TO REDUCE THE RISK

OF INJURY, USER MUST

ALWAYS WEAR RESPIRATORY AND ANSI

A14540

AVERTISSEMENT

ADVERTENCIA

Z87.1

AFIN DE MINIMISER LES

RISQUES DE BLESSURES,

PARA DISMINUIR EL RIESGO

DE LESIONES, EL USUARIO

PAUTAS DE SEGURIDAD/DEFINICIONES

Indica una situación de peligro inminente que, si no se evita,

provocará

la

muerte o lesiones graves.

provocar la

provocar

muerte o lesiones graves.

Indica una situación de peligro potencial que, si no se evita,

lesiones leves o moderadas.

Utilizado sin el símbolo de alerta de seguridad indica una situación de

peligro potencial que, si no se evita,

Indica una situación de peligro potencial que, si no se evita,

puede provocar

daños en la

propiedad

podría

puede

.

Normas Generales de Seguridad

ciones enumeradas a continuación puede provocar una descarga eléctrica, un incendio y/o lesiones

graves. El término “herramienta eléctrica” incluido en todas las advertencias enumeradas a continuación hace referencia a su herramienta eléctrica operada con corriente (con cable) o a su herramienta

eléctrica operada con baterías (inalámbrica).

¡CONSERVE ESTAS INSTRUCCIONES!

1) Seguridad en el área de trabajo

a) Mantenga el área de trabajo limpia y bien iluminada. Las áreas abarrotadas y oscuras

Lea todas las instrucciones. El incumplimiento de todas y cada una de las instruc-

propician accidentes.

Page 5

b) No opere las herramientas eléctricas en atmósferas explosivas, como ambientes

donde haya polvo, gases o líquidos infl amables. Las herramientas eléctricas originan

chispas que pueden encender el polvo o los vapores.

c) Mantenga alejados a los niños y a los espectadores de la herramienta eléctrica en

funcionamiento. Las distracciones pueden provocar la pérdida de control.

2) Seguridad eléctrica

a) Los enchufes de las herramientas mecánicas deben coincidir con el tomacorriente.

No modifi que nunca el enchufe de ningún modo. No use enchufes adaptadores con

herramientas mecánicas conectadas a tierra (puestas a tierra). Los enchufes no mo-

difi cados y los tomacorrientes coincidentes reducirán el riesgo de sacudidas eléctricas.

b) Evite el contacto corporal con superfi cies con descarga a tierra tales como tuberías,

radiadores, estufas y refrigeradores. Existe mayor riesgo de descarga eléctrica si su

cuerpo está puesto a tierra.

c) No exponga las herramientas eléctricas a la lluvia o a condiciones de humedad. Si

entra agua a una herramienta eléctrica, aumentará el riesgo de descarga eléctrica.

d) No use el cable indebidamente. Nunca utilice el cable para transportar, tirar o des-

enchufar la herramienta eléctrica. Mantenga el cable alejado del calor, el aceite, los

bordes fi losos o las piezas móviles. Los cables dañados o enredados aumentan el ries-

go de descarga eléctrica. Utilice solamente cables prolongadores de 3 conductores que

tengan enchufes a tierra de 3 patas y receptáculos tripolares que se adapten al enchufe de

la herramienta.

e) Al operar una herramienta eléctrica en el exterior, utilice un cable prolongador ad-

ecuado para tal uso. Si el cable prolongador se va a utilizar en el exterior, debe tener la

marca W-A o W de acuerdo con la designación del tipo del cable. Utilice un cable adecuado para uso en exteriores a fi n de reducir el riesgo de descarga eléctrica. Cuando utilice

un cable prolongador , asegúrese de que tenga la capacidad para conducir la corriente que

su producto exige. Un cable de menor capacidad provocará una disminución en el voltaje

de la línea, lo cual producirá una pérdida de potencia y sobrecalentamiento. La siguiente

tabla muestra la medida correcta que debe utilizar según la longitud del cable y la capacidad nominal en amperes indicada en la placa. En caso de duda, utilice el calibre inmediatamente superior. Cuanto menor sea el número de calibre, más grueso será el cable.

Tamaño mínimo recomendado del conductor

para los cables de extensión

Volts Longitud total del cable

120V 0-25 pi 26-50 pi 51-100 pi 101-150 pi

0-7,6 m 7,6 m - 15,2 m 15,2 m - 30,5 m 30,5 m - 45,7 m

Amperes T amaño AWG del conductor

A partir 0 a 6 amperes 18 16 16 14

3) Seguridad personal

a) Permanezca alerta, controle lo que está haciendo y utilice el sentido común cuando

emplee una herramienta eléctrica. No utilice una herramienta eléctrica si está cansado o bajo el efecto de drogas, alcohol o medicamentos. Un momento de descuido

mientras se opera una herramienta eléctrica podría provocar lesiones personales graves.

b) Use equipo de seguridad. Siempre utilice protección para los ojos. El uso del equipo

de seguridad, como las máscaras para polvo, el calzado de seguridad antideslizante, los

cascos o la protección auditiva, en las condiciones adecuadas reducirá las lesiones personales.

c) Evite el encendido accidental. Asegúrese de que el interruptor esté en la posición de

apagado antes de enchufar la herramienta. Transportar herramientas eléctricas con su

dedo apoyado sobre el interruptor o enchufar herramientas eléctricas con el interruptor en

la posición de encendido puede propiciar accidentes.

d) Retire la clavija de ajuste o la llave de tuercas antes de encender la herramienta

eléctrica. Una llave de tuercas o una clavija de ajuste que quede conectada a una pieza

giratoria de la herramienta eléctrica puede provocar lesiones personales.

e) No se estire. Conserve el equilibrio y párese adecuadamente en todo momento. Esto

permite un mejor control de la herramienta eléctrica en situaciones inesperadas.

f) Use vestimenta adecuada. No use ropas holgadas o joyas. Mantenga el cabello, la

ropa y los guantes alejados de las piezas en movimiento. Las ropas holgadas, las joyas

o el cabello largo pueden quedar atrapados en las piezas móviles.

g) Si se suministran dispositivos para la conexión de accesorios con fi nes de recolec-

ción y extracción de polvo, asegúrese de que estén conectados y que se utilicen

correctamente. El uso de estos dispositivos puede reducir los peligros relacionados

con el polvo. Los accesorios que pueden ser aptos para una herramienta, pueden con-

vertirse en un factor de riesgo cuando se utilizan en otra herramienta.

4) Uso y mantenimiento de la herramienta eléctrica

a) No fuerce la herramienta eléctrica. Utilice la herramienta eléctrica correcta para el

trabajo que realizará. Si se la utiliza a la velocidad para la que fue diseñada, la herra-

mienta eléctrica correcta permite trabajar mejor y de manera más segura.

b) No utilice la herramienta eléctrica si no puede encenderla o apagarla con el inter-

ruptor. T oda herramienta eléctrica que no pueda ser contr olada mediante el interruptor es

peligrosa y debe repararse.

c) Desconecte el enchufe de la fuente de energía antes de realizar ajustes, cambiar

accesorios o guardar las herramientas eléctricas. Estas medidas de seguridad preventivas reducen el riesgo de encender la herramienta eléctrica en forma accidental.

d) Guarde las herramientas eléctricas que no están en uso fuera del alcance de los

niños y no permita que otras personas no familiarizadas con ella o con estas instrucciones operen la herramienta. Las herramientas eléctricas son peligrosas si son opera-

das por usuarios no capacitados.

e) Realice el mantenimiento de las herramientas eléctricas. Revise que no haya piezas

en movimiento mal alineadas o trabadas, piezas rotas o cualquier otra situación que

pueda afectar el funcionamiento de las herramientas eléctricas. Si encuentra daños,

haga reparar la herramienta eléctrica antes de utilizarla. Se producen muchos ac-

cidentes a causa de las herramientas eléctricas que carecen de un mantenimiento adecuado.

f) Mantenga las herramientas de corte afi ladas y limpias. Las herramientas de corte con

mantenimiento adecuado y con los bordes de corte afi lados son menos propensas a trabarse y son más fáciles de controlar.

g) Utilice la herramienta eléctrica, los accesorios y las brocas de la herramienta, etc. de

acuerdo con estas instrucciones y de la forma prevista para el tipo de herramienta

eléctrica en particular , teniendo en cuenta las condiciones de trabajo y el trabajo que

debe realizarse. El uso de la herramienta eléctrica para operaciones diferentes de aquél-

las para las que fue diseñada podría originar una situación peligrosa.

5) Mantenimiento

a) Solicite a una persona califi cada en reparaciones que realice el mantenimiento de su

herramienta eléctrica y que sólo utilice piezas de repuesto idénticas. Esto garantizará

la seguridad de la herramienta eléctrica.

NORMAS DE SEGURIDAD ESPECÍFICAS ADICIONALES

Para reducir el riesgo de lesiones:

• Sostenga la herramienta por las superficies de agarre aisladas cuando realice una oper-

ación en la que la herramienta de corte pueda tocar cables eléctricos escondidos o su

propio cable. El contacto con un cable con corriente eléctrica hará que las partes expuestas de

la herramienta tengan corriente y que el operador reciba una descarga eléctrica.

• No use su lijadora de banda para lijar ningún tipo de metal. Lijar tornillos, clavos u otros

metales que pueden encender partículas de polvo puede producir chispas.

• No utilice esta lijadora para lijar superficies húmedas. Los líquidos pueden entrar en la caja

del motor y pueden provocar descargas eléctricas

• No haga funcionar esta herramienta durante períodos prolongados. La vibración que pro-

duce el funcionamiento de esta herramienta puede provocar lesiones permanentes en dedos,

manos y brazos. Use guantes para proveer amortiguación adicional, tome descansos frecuentes

y limite el tiempo diario de uso.

• Limpie su herramienta con frecuencia, especialmente después de un uso intensivo. El

polvo y la suciedad que contienen partículas del metal a menudo se depositan en las superficies interiores y crean un riesgo de lesión grave, descarga eléctrica o electrocución. UTILICE

SIEMPRE ANTEOJOS DE SEGURIDAD.

• Ventile el área de trabajo en forma adecuada cuando realice operaciones de lijado.

• Asegúrese de que la banda no esté en contacto con la pieza de trabajo antes de encender el interruptor .

• Esta lijadora no está diseñada para colocarla en posición invertida y montarla sobre un banco para

usarla como una lijadora de mesa. Utilizarla de esta forma podría aumentar el riesgo de lesiones.

Algunas partículas originadas al lijar , aserrar, amolar, taladrar y realizar otras

actividades de construcción contienen productos químicos que producen cáncer, defectos

de nacimiento y otros problemas reproductivos.

Algunos ejemplos de estas sustancias químicas son:

• el plomo de las pinturas de base plomo,

• la sílice cristalina de ladrillos, cemento y otros productos de mampostería, y

• el arsénico y el cromo de la madera con tratamiento químico (CCA).

El riesgo derivado de estas exposiciones varía según la frecuencia con la que se realice este tipo de

trabajo. Para reducir la exposición a estos productos químicos, se recomienda trabajar en áreas bien

ventiladas y usar equipos de seguridad aprobados, como las máscaras para polvo especialmente

diseñadas para fi ltrar las partículas microscópicas.

al lijar , aserrar , esmerilar, taladrar y otras actividades de la construcción. Use indumentaria protectora

y lave las áreas expuestas con agua y jabón. Evite que el polvo entre en la boca y en los ojos o se

deposite en la piel, para impedir la absorción de productos químicos nocivos.

eden causar lesiones respiratorias permanentes y graves u otras lesiones. Use siempre protección

respiratoria apropiada para la exposición al polvo aprobada por el Instituto Nacional de Salud y Seguridad Ocupacional de EE.UU. y la Administración de Salud y Seguridad Ocupacional de EE.UU.

(NIOSH y OSHA respectivamente, por sus siglas en inglés). Aleje la cara y el cuerpo del contacto

con las partículas.

S12.6 (S3.19)) Bajo ciertas circunstancias y según el período de uso, el ruido producido por este

producto puede contribuir a la pérdida de audición.

SÍMBOLOS

La etiqueta de su herramienta puede incluir los siguientes símbolos. Los símbolos y sus definiciones

son los siguientes:

V ....................voltios A ....................amperios

Hz .................hertz W ...................vatios

min ................minutos

..............corriente directa

..................Construcción Clase I ................... terminal a tierra

(con conexión a tierra) ..................símbolo de alerta de seguridad

...................Construcción Clase II …/min ............ revoluciones o reciprocidad

(con aislamiento doble) por minuto

BPM ..............golpes por minuto

Evite el contacto durante tiempo prolongado con las partículas de polvo originadas

El uso de esta herramienta puede generar o dispersar partículas de polvo, que pu-

Mientras use la herramienta, utilice la protección auditiva adecuada. (ANSI

.................corriente alterna

n

o ...................velocidad sin carga

La SEGURIDAD ADICIONAL GOBIERNA P ARA la ELIMINACION de PINTURA

uo, y los vapores de pintura pueden contener plomo que es venenoso. Hasta un nivel bajo puede

afectar el cerebro y el sistema nervioso. Afecta aún más a los niños chicos y a los prenatales.

Antes de empezar cualquier trabajo de quitar pintura se debe determinar si la pintura contiene

plomo. Para hacer esta determinación, se puede llamar al representante del departamento de

salud local o a un profesional con un analizador de pintura.

Sólo los profesionales deben quitar la pintura que contiene plomo.

Las personas que quitan pintura deben seguir estas instrucciones:

1. Mantenga bien ventilada el área de trabajo. Abra las ventanas y ponga un ventilador aspirante

en una de ellas. Asegúrese de que el ventilador haga circular el aire del interior al exterior.

2. Quite o cubra todas las alfombras, alfombrillas, muebles, ropa, utensilios de cocina

y conductos de aire. Tales medidas impeditivas de la seguridad reducen el riesgo de la

exposición.

3. Coloque telas colgantes en el área de trabajo para atrapar todos los desconchones o

descascarillados de pintura. Use ropa protectora, tal como camisas de trabajo adicionales,

guardapolvo y casco. Tales medidas impeditivas de la seguridad reducen el riesgo de la

exposición.

4. Trabaje en un cuarto por vez. Los muebles deben sacarse del cuarto o colocarse en el

centro del mismo y cubrirse. Las áreas de trabajo deben aislarse del resto de la vivienda

tapando los vanos de las puertas con telas colgantes.

5. Los ninos, las mujeres embarazadas o potencialmente embarazadas y las madres

lactantes no deben estar presentes en el área de trabajo hasta que se haya hecho el

trabajo y se haya completado toda la limpieza. Tales medidas impeditivas de la seguridad

reducen el riesgo de la herida.

6. Use un respirador antipolvo o una máscara respiradora con filtro doble (para polvo y para

vapores) que haya sido aprobada por la Administración de Salud y Seguridad Ocupacional

(OSHA) de los EE.UU., el Instituto Nacional de Seguridad y Salud (NIOSH) de los EE.UU. o

al Departamento de Minas de los Estados Unidos. Estas máscaras y filtros recambiables se

pueden obtener fácilmente en todas las ferreterías principales. Asegúrese de que la máscara

quede bien ajustada. La barba y el vello facial pueden impedir que la máscara se ajuste

apropiadamente. Cambie los filtros a menudo. LAS MÁSCARAS DE PAPEL DESECHABLES NO

SON ADECUADAS.

7. Mantenga la comida y la bebida fuera del área de trabajo. Lávese las manos, los brazos y

la cara y enjuáguese la boca antes de comer o beber. No fume ni masque chicle ni tabaco en

el área de trabajo.

8. Limpie toda la pintura que se haya quitado y el polvo que estén en el piso usando un

trapeador mojado. Utilice un paño mojado para limpiar todas las paredes, los rebordes y

cualquier otra superficie donde la pintura o el polvo esté adherido. NO BARRA, NI QUITE EL

POLVO EN SECO, NI LIMPIE CON ASPIRADORA. Utilice un detergente con alto contenido

de fosfatos o use fosfato trisódico (FTS) para lavar y limpiar con trapeador las áreas de

trabajo.

9. Al final de cada sesion de trabajo, ponga los desconchones y residuos de pintura en

una bolsa de plástico doble, ciérrela con cinta adhesiva o con ataduras de torsión y

tírela adecuadamente. Tales medidas impeditivas de la seguridad reducen el riesgo de la

exposición.

10. Quitese la ropa protectora y los zapatos de trabajo en el área de trabajo para evitar llevar

polvo al resto de la vivienda. Lave la ropa de trabajo separadamente. Limpie los zapatos con

un trapo mojado y luego lave el trapo con la ropa de trabajo. Lávese el pelo y el cuerpo muy

bien con agua y jabón.

Se debe usar extrema precaución al quitar la pintura. El descascarillado, el resid-

¡CONSERVE ESTAS INSTRUCCIONES!

MOTOR